Page 1

INSTALLATION

IP110 Series

Camclosure

Integrated Camera System

®

C3432M-F (6/08)

Page 2

Contents

Important Safety Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Regulatory Notices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Open Source Software Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

System Models. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Basic System Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Cover and Back Box Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Basic Surface Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4S Electrical Box Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

404 Plaster Ring Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Side Conduit Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Wiring Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Cat5 Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Alarm and 24 VAC Wires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Connecting a Relay Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Connecting Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Camera Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Camera Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Module Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Camera Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Varifocal Lens Zoom and Focus Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

DN/CH Series Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Blemish Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Day/Night Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

DW/CW Series (Wide Dynamic Range) Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Auto Iris Level Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Camera Positioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Install Dome and Trim Ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Service Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Reset Button. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

2 C3432M-F (6/08)

Page 3

List of Illustrations

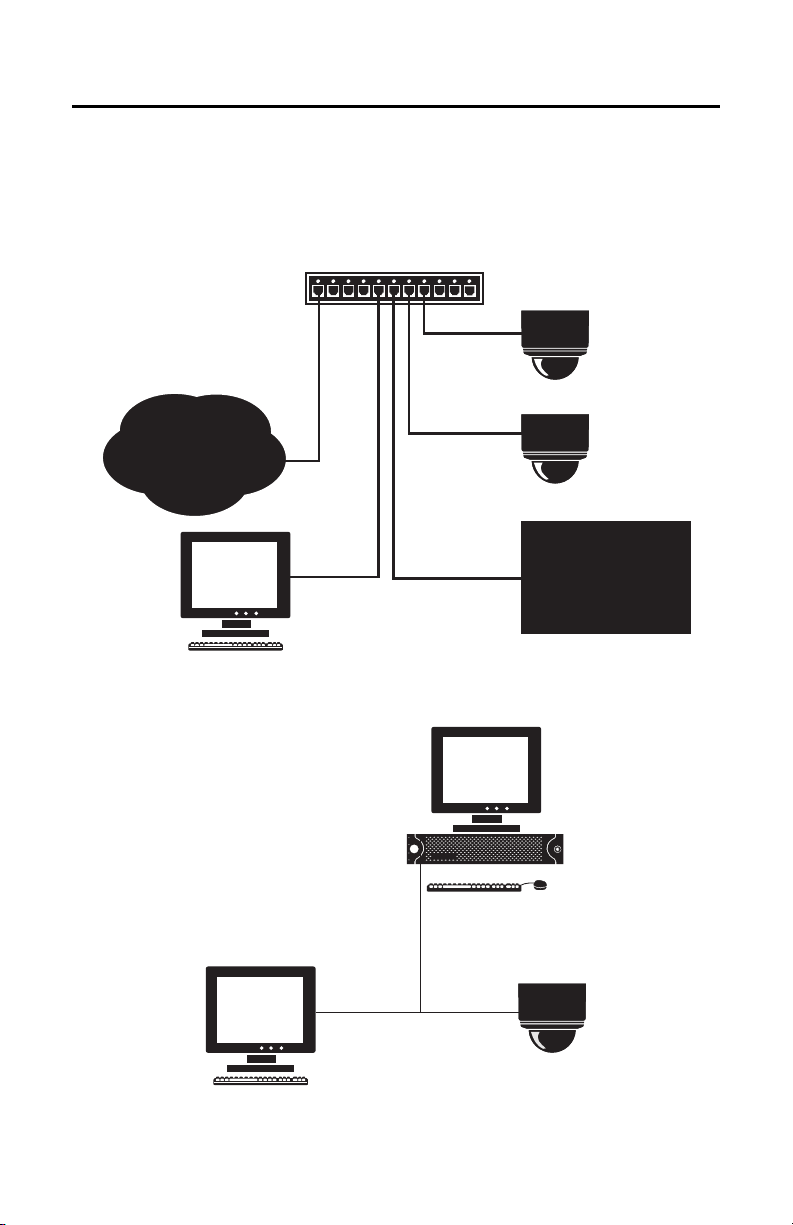

1 DHCP Network Example. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 Endura Network Example. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

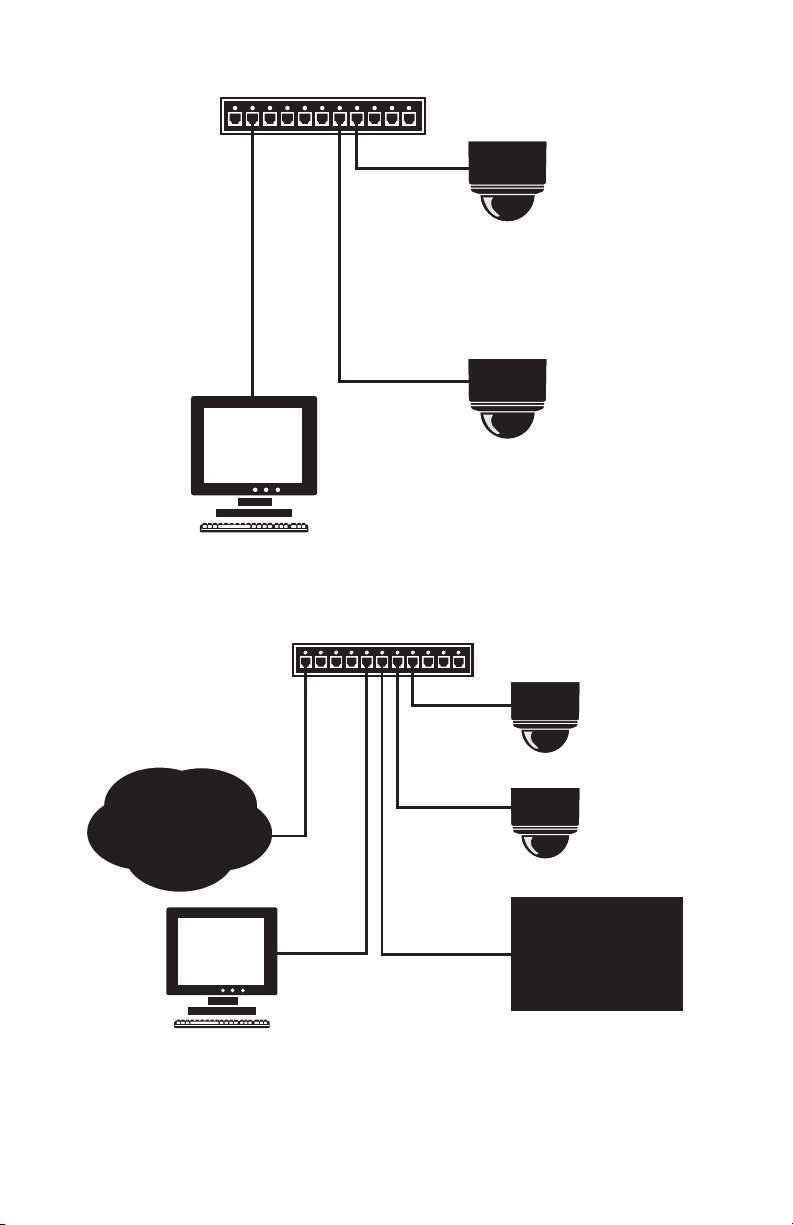

3 Private Network Example. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4 Static Network Example. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5 Basic Surface Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6 4S Electrical Box Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

7 404 Plaster Ring Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

8 Side Conduit Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

9 Relay Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

10 Supervised Alarm Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

11 Supervised Alarm Input Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

12 Unsupervised Alarm Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

13 Unsupervised Alarm Input Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

14 Unsupervised Alarm Input Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

15 Camera Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

16 Back Box Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

17 Camera Module Bracket. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

18 Location of Zoom and Focus Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

19 Adjusting the IP110-DN/CH Series Camclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

20 DN Models Threshold Switching Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

21 Adjusting the IP110-DW/CW Series Camclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

22 DW Models Threshold Switching Levels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

23 Positioning the Camera . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

24 Dome Liner Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

25 Service Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

26 Attaching the 2.5 mm Monaural Headphone Plug. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

27 Location of Reset Button and LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

List of Tables

A Pin Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

B Wire Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

C DN Models Switching Thresholds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

D DW Models Switching Thresholds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

C3432M-F (6/08) 3

Page 4

Important Safety Instructions

1. Read these instructions.

2. Keep these instructions.

3. Heed all warnings.

4. Follow all instructions.

5. Do not use this apparatus near water.

6. Do not block any ventilation openings. Install in accordance with the manufacturer’s instructions.

7. Only use attachments/accessories specified by the manufacturer.

8. Apparatus shall not be exposed to dripping or splashing and that no objects filled with liquids, such

as vases shall be placed on the apparatus.

9. Installation should be done only by qualified personnel and conform to all local codes.

10. Unless the unit is specifically marked as a NEMA Type 3, 3R, 3S, 4, 4X, 6, or 6P enclosure, it is

designed for indoor use only and it must not be installed where exposed to rain and moisture.

11. Use only installation methods and materials capable of supporting four times the maximum

specified load.

12. Use stainless steel hardware to fasten the mount to outdoor surfaces.

13. Only use replacement parts recommended by Pelco.

14. After replacement/repair of this unit’s electrical components, conduct a resistance measurement

between the line and exposed parts to verify the exposed parts have not been connected to the line

circuitry.

4 C3432M-F (6/08)

Page 5

Regulatory Notices

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

RADIO AND TELEVISION INTERFERENCE

This equipment has been tested and found to comply with the limits of a Class B digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may cause harmful interference

to radio communications. However there is no guarantee that the interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or television reception, which can

be determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and the receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

• Consult the dealer or an experienced radio/TV technician for help.

You may also find helpful the following booklet, prepared by the FCC: “How to Identify and Resolve

Radio-TV Interference Problems.” This booklet is available from the U.S. Government Printing Office,

Washington D.C. 20402.

Changes and Modifications not expressly approved by the manufacturer or registrant of this equipment

can void your authority to operate this equipment under Federal Communications Commission’s rules.

This Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

C3432M-F (6/08) 5

Page 6

Open Source Software Notice

This product includes certain open source or other software originated from third parties that is subject to

the GNU General Public License (GPL), GNU Library/Lesser General Public License (LGPL), and different

and/or additional copyright licenses, disclaimers, and notices.

The exact terms of GPL, LGPL, and some other licenses are provided to you with this product. Please refer

to the exact terms of the GPL and LGPL at http://www.fsf.org (Free Software Foundation) or

http://www.opensource.org (Open Source Initiative) regarding your rights under said license. You may

obtain a complete corresponding machine-readable copy of the source code of such software under the

GPL or LGPL by sending your request to digitalsupport@pelco.com; the subject line should read Source

Code Request. You will then receive an e-mail with a link for you to download the source code.

This offer is valid for a period of three (3) years from the date of the distribution of this product by Pelco.

WARNING: This product is sensitive to Electrostatic Discharge (ESD). To avoid ESD damage to this

product, use ESD safe practices during installation. Before touching, adjusting or handling this product,

correctly attach an ESD wrist strap to your wrist and appropriately discharge your body and tools. For more

information about ESD control and safe handling practices of electronics, please refer to ANSI/ESD S20.201999 or contact the Electrostatic Discharge Association (www.esda.org).

The materials used in the manufacture of this document and its components are compliant to the requirements

of Directive 2002/95/EC.

This equipment contains electrical or electronic components that must be recycled properly to comply with

Directive 2002/96/EC of the European Union regarding the disposal of waste electrical and electronic

equipment (WEEE). Contact your local dealer for procedures for recycling this equipment.

6 C3432M-F (6/08)

Page 7

Description

The IP110 Series Camclosure® is an indoor/outdoor, fixed mini dome system with a built-in 100Base-TX

network interface for live streaming to a standard Web browser (Microsoft

®

Firefox

). The network mini dome features open architecture connectivity for third-party software

recording solutions and is also Endura Enabled

streams.

The IP110 Series Camclosure also includes built-in Power over Ethernet (PoE), which supplies power to the

camera through the network. If PoE is not available, the unit is prewired for 24 VAC.

Before installing your new system, thoroughly familiarize yourself with the information in this manual.

The following is supplied with the IP110 Series Camclosure integrated camera system:

Qty Description

1 IP110 Series Camclosure integrated camera system

• Cover and back box (assembled)

• Trim ring with bubble and dome liner

• Camera module

1 1/8-inch hollow screwdriver bit

2 8-32 x 0.375-inch Phillips pan head screws with washers (attached to cover and back box)

3 6-32 x 0.75-inch Phillips pan head screws

2 8-32 x 0.75-inch Phillips flat head screws

2 8-32 x 0.75-inch Phillips pan head screws

™

to record, manage, configure, and view multiple live

®

Internet Explorer® or

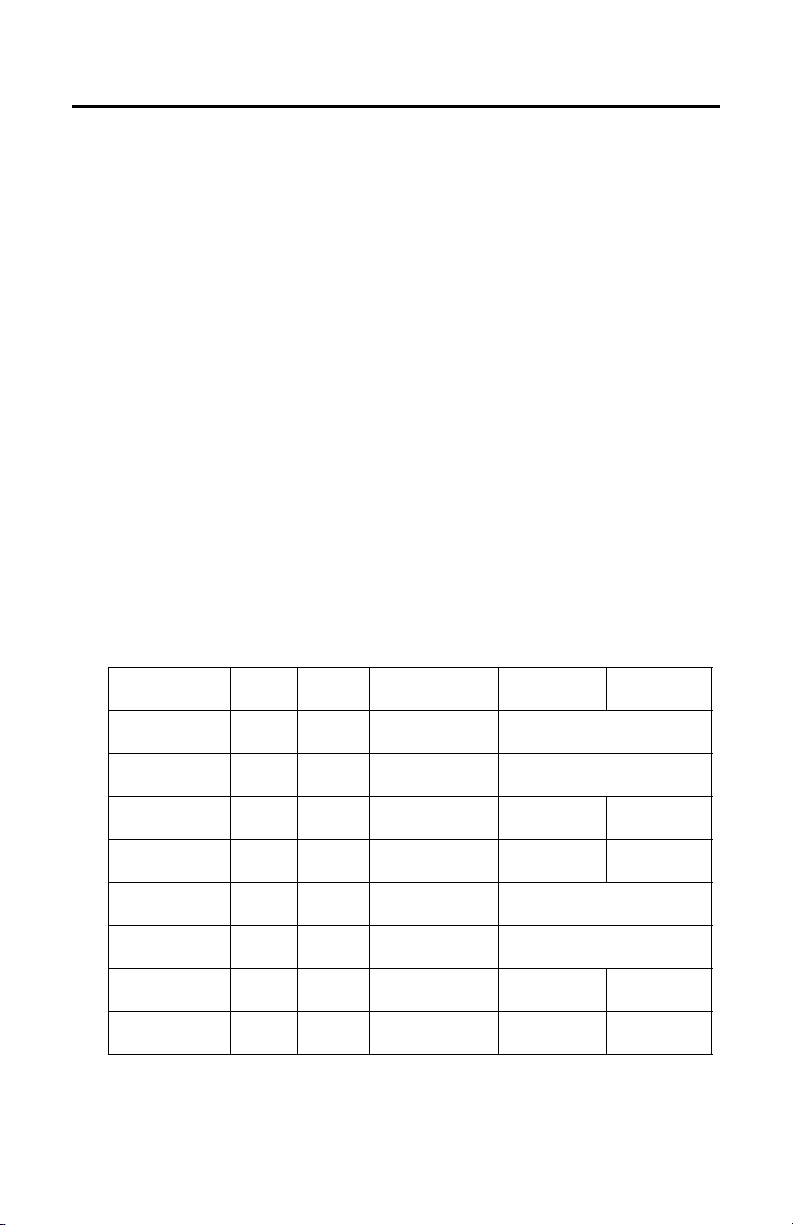

SYSTEM MODELS

Camera Type

Day/Night, Wide

Dynamic Range

Day/Night, Wide

Dynamic Range

Day/Night Smoked 3-9 mm

Day/Night Clear 3-9 mm

Color, Wide

Dynamic Range

Color, Wide

Dynamic Range

Color, High

Resolution

Color, High

Resolution

Lower

Dome Lens Lens Type NTSC PAL

Smoked 3-9 mm

9-22 mm

Clear 3-9 mm

9-22 mm

9-22 mm

9-22 mm

Smoked 3-9 mm

9-22 mm

Clear 3-9 mm

9-22 mm

Smoked 3-9 mm

9-22 mm

Clear 3-9 mm

9-22 mm

Varifocal, Auto Iris IP110-DWV9

IP110-DWV22

Varifocal, Auto Iris IP111-DWV9

IP111-DWV22

Varifocal, Auto Iris IP110-DNV9

IP110-DNV22

Varifocal, Auto Iris IP111-DNV9

IP111-DNV22

Varifocal, Auto Iris IP110-CWV9

IP110-CWV22

Varifocal, Auto Iris IP111-CWV9

IP111-CWV22

Varifocal, Auto Iris IP110-CHV9

IP110-CHV22

Varifocal, Auto Iris IP111-CHV9

IP111-CHV22

IP110-DNV9X

IP110-DNV22X

IP111-DNV9X

IP111-DNV22X

IP110-CHV9X

IP110-CHV22X

IP111-CHV9X

IP111-CHV22X

C3432M-F (6/08) 7

Page 8

Basic System Configurations

TCP / IP / INTERNET

3rd PARTY

RECORDING SOLUTION

IMPORTANT NOTE. PLEASE READ. The network implementations in this document are shown as

general representations only and are not intended to show detailed network topologies. Your actual

network will differ, requiring changes or perhaps additional network equipment to accommodate the

systems as illustrated. Please contact your local Pelco Representative to discuss your specific

requirements.

CABLE MODEM ROUTER / SWITCH

WITH DHCP SERVER

NOTE: FOR A SECURE NETWORK,

PELCO RECOMMENDS THE IP110

CAMERA IS PLACED BEHIND A

FIREWALL.

IP110

TCP / IP / INTERNET

IP110

WEB

BROWSER

DHCP NETWORK

3rd PARTY

RECORDING SOLUTION

Figure 1. DHCP Network Example

ENDURA

WEB

BROWSER

IP110

Figure 2. Endura Network Example

8 C3432M-F (6/08)

Page 9

NETWORK SWITCH

TCP / IP / INTERNET

3rd PARTY

RECORDING SOLUTION

IP110

IF NOT DHCP, CAMERA IS ASSIGNED

DEFAULT IP ADDRESS 192.168.0.20 ON

NETMASK 255.255.0.0

WEB

BROWSER

NOTE: FOR A SECURE NETWORK,

PELCO RECOMMENDS THE IP110

CAMERA IS PLACED BEHIND A

FIREWALL.

TCP / IP / INTERNET

WEB

BROWSER

Figure 3. Private Network Example

CABLE MODEM ROUTER / SWITCH

(DHCP SERVER DISABLED)

IP110

IP110

IP110

RECORDING SOLUTION

CAMERA 1 FIXED BUT

UNIQUE IP ADDRESS,

SAME SUBNET MASK

AS COMPUTER

CAMERA 2 FIXED BUT

UNIQUE IP ADDRESS,

SAME SUBNET MASK

AS COMPUTER

3rd PARTY

STATIC NETWORK

(FIXED BUT UNIQUE IP ADDRESS

SAME SUBNET MASK AS CAMERAS)

Figure 4. Static Network Example

C3432M-F (6/08) 9

Page 10

Cover and Back Box Installation

The IP110 Series Camclosure integrated camera system mounts only to a surface. It can be wired through

the cover into a surface, electrical box, plaster ring, or through a side conduit opening.

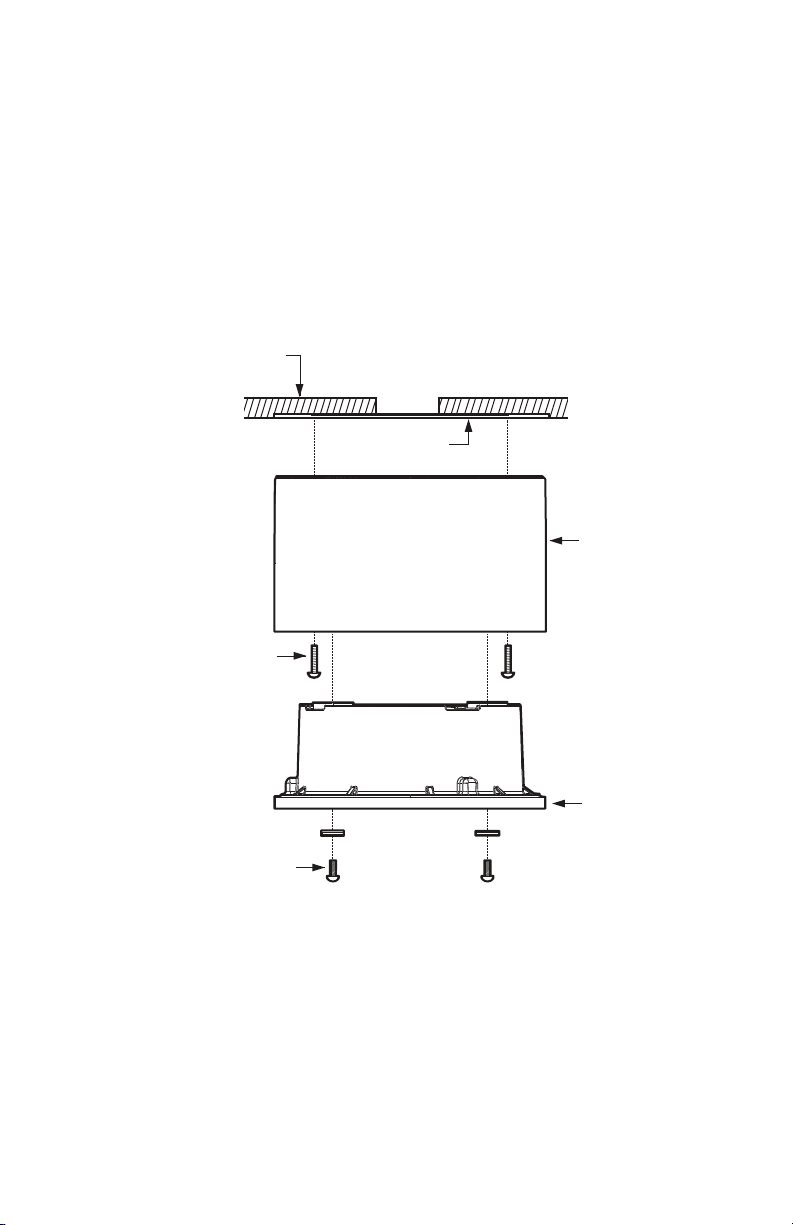

BASIC SURFACE INSTALLATION

1. Remove the two 8-32 x 0.375-inch Phillips pan head screws and washers to separate the cover from

the back box.

2. Cut out the hole for the cable/wiring. Pull the cable/wires through the mounting surface and then

through the hole of the cover.

3. Attach the cover to the mounting surface (hardware not supplied). Use stainless steel hardware

when installing the system outdoors.

4. Install the camera module into the back box before installing the back box into the cover. Rotate the

camera module to access the mounting holes inside the back box. Refer to Camera Module on

page 19 for more information.

5. Connect the cable/wires (refer to Wiring Tables on page 14 for information).

6. Reinstall the back box inside the cover. Use the two 8-32 x 0.375-inch Phillips pan head screws and

washers (removed earlier) to secure the back box to the cover.

COVER

MOUNTING

SCREWS

(NOT SUPPLIED)

8-32 X 0.375-INCH

PHILLIPS PAN HEAD

SCREWS WITH WASHERS

(SUPPLIED)

Figure 5. Basic Surface Installation

10 C3432M-F (6/08)

BACK BOX

Page 11

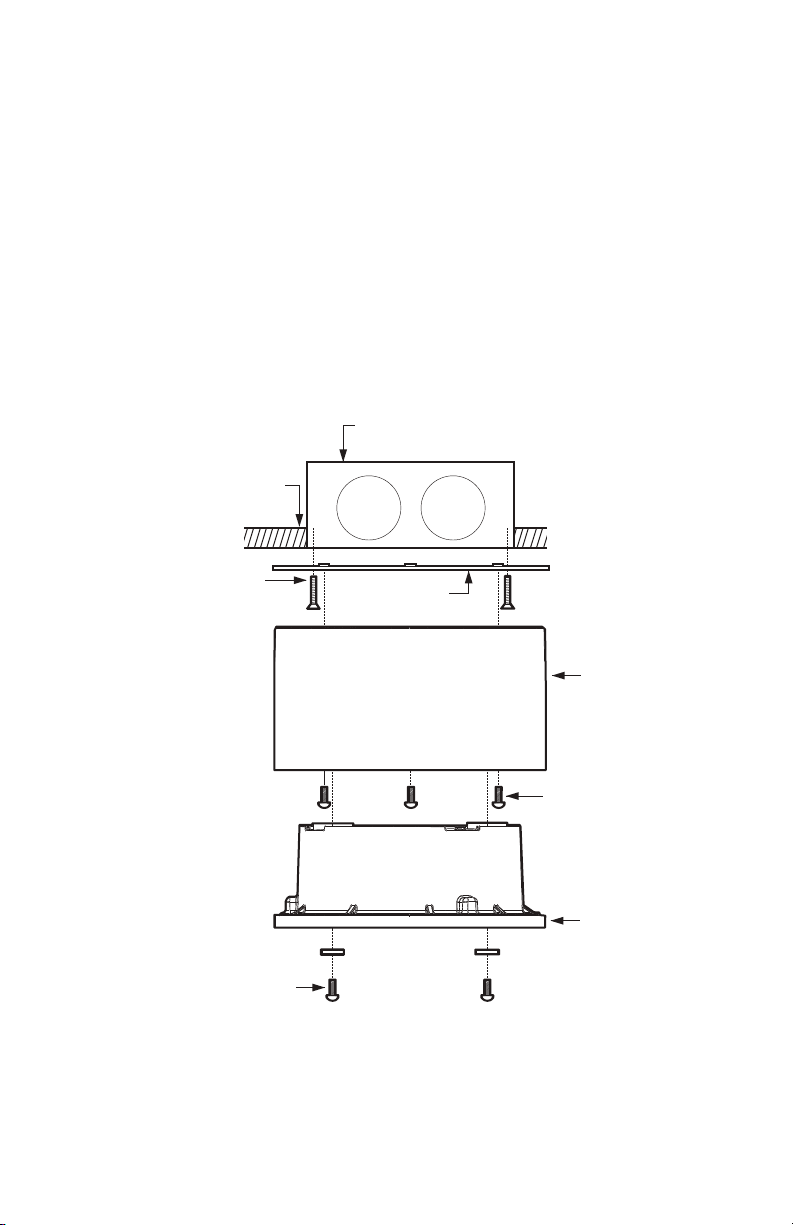

4S ELECTRICAL BOX INSTALLATION

1. Attach an ICS110-AP adapter plate (not supplied) to a 4S electrical box. Use two 8-32 x 0.75-inch

Phillips flat head screws (supplied with both the IP110 and the adapter plate).

2. Remove the two 8-32 x 0.375-inch Phillips pan head screws and washers to separate the cover from

the back box.

3. Pull the cable/wires into the cover.

4. Attach the cover to the adapter plate with four 8-32 x 0.375-inch Phillips pan head screws (supplied

with the adapter plate). Use stainless steel hardware when installing the system outdoors.

5. Install the camera module into the back box before installing the back box into the cover. Rotate the

camera module to access the mounting holes inside the back box. Refer to Camera Module on

page 19 for more information.

6. Connect the cable/wires (refer to Wiring Tables on page 14 for information).

7. Reinstall the back box inside the cover. Use the two 8-32 x 0.375-inch Phillips pan head screws and

washers (removed earlier) to secure the back box to the cover.

4S STANDARD

ELECTRICAL BOX

CEILING/

WALL

8-32 X 0.75-INCH

PHILLIPS FLAT

HEAD SCREWS

(SUPPLIED)

8-32 X 0.375-INCH

PHILLIPS PAN HEAD

SCREWS WITH WASHERS

(SUPPLIED)

ADAPTER PLATE

(ICS110-AP)

COVER

8-32 X 0.375-INCH

PHILLIPS PAN

HEAD SCREWS

(SUPPLIED WITH

ICS110-AP)

BACK BOX

Figure 6. 4S Electrical Box Installation

C3432M-F (6/08) 11

Page 12

404 PLASTER RING INSTALLATION

1. Remove the two 8-32 x 0.375-inch Phillips pan head screws and washers to separate the cover from

the back box.

2. Pull cable/wires into the cover. Use three supplied 6-32 x 0.75-inch Phillips pan head screws or two

supplied 8-32 x 0.75-inch Phillips pan head screws to attach the cover to an installed 404 plaster

ring. Use stainless steel hardware when installing the system outdoors.

3. Install the camera module into the back box before installing the back box into the cover. Rotate the

camera module to access the mounting holes inside the back box. Refer to Camera Module on

page 19 for more information.

4. Connect the cable/wires (refer to Wiring Tables on page 14 for information).

5. Reinstall the back box inside the cover. Use the two 8-32 x 0.375-inch Phillips pan head screws and

washers (removed earlier) to secure the back box to the cover.

CEILING/

WALL

404 PLASTER RING

(NOT SUPPLIED)

COVER

6-32 X 0.75-INCH

OR 8-32 X 0.75-INCH

PHILLIPS PAN

HEAD SCREWS

(SUPPLIED)

BACK BOX

8-32 X 0.375-INCH

PHILLIPS PAN HEAD

SCREWS WITH WASHERS

(SUPPLIED)

Figure 7. 404 Plaster Ring Installation

12 C3432M-F (6/08)

Page 13

SIDE CONDUIT INSTALLATION

1. Remove the two 8-32 x 0.375-inch Phillips pan head screws and washers to separate the cover from

the back box.

2. Remove the conduit plug from the cover. Install a 0.75-inch (1.91 cm) threaded conduit connector

(not supplied) into the conduit hole in the cover.

3. Attach the cover to the mounting surface (hardware not supplied). Use stainless steel hardware

when installing the system outdoors.

4. Install the camera module into the back box before installing the back box into the cover. Rotate the

camera module to access the mounting holes inside the back box. Refer to Camera Module on

page 19 for more information.

5. Connect the cable/wires (refer to Wiring Tables on page 14 for information).

6. Reinstall the back box inside the cover. Use the two 8-32 x 0.375-inch Phillips pan head screws and

washers (removed earlier) to secure the back box to the cover.

0.75-INCH CONDUIT

CONNECTOR

REMOVE

CONDUIT PLUG

COVER

BACK BOX

8-32 X 0.375-INCH

PHILLIPS PAN HEAD

SCREWS WITH WASHERS

(SUPPLIED)

Figure 8. Side Conduit Installation

C3432M-F (6/08) 13

Page 14

Wiring Tables

8

8

1

1

CAT5 CABLE

Connect a Cat5 cable to the RJ-45 network connector. The 8-pin connector includes video and PoE for the

camera. PoE (IEEE 802.3af) injects power over the same cabling that carries the network data, eliminating

the need for a separate power supply, This simplifies the installation and operation of the camera without

any degradation of network performance.

NOTE: The IP110 Camclosure will auto sense and work with either a cross over cable or straight cable.

Refer to the following wiring table for pin descriptions.

Table A. Pin Descriptions

Pin Function

1TX+

2TX-

3RX+

4 PoE 1-2

5 PoE 1-2

6RX-

7 PoE 3-4

8 PoE 3-4

1

2

3

4

5

6

7

8

8

7

6

5

4

3

2

1

14 C3432M-F (6/08)

Page 15

ALARM AND 24 VAC WIRES

+

_

Table B. Wire Descriptions

Wire Color Description

Black 24 VAC (use only if PoE is not connected)

Red 24 VAC (use only if PoE is not connected)

Blue Alarm In

Blue/White Alarm In, Return

Green Relay Out

Green/White Relay Out, Return

CONNECTING A RELAY DEVICE

The IP110 Camclosure has an output for triggering an external device. It supports both momentary and

continuous relay operation.

You can operate the relay interactively, during an active connection, or automatically to coincide with

certain events. Typical applications include activating a door, gate or lock, or switching on lights or other

electrical devices.

WARNING: Do not exceed the maximum rating of 12 VDC, 0.15 A.

Figure 9 shows how to wire the relay with its power source to the Camclosure.

CONNECTING A RELAY DEVICE

(CONNECTION EXAMPLE)

DC

GREEN WIRE

GREEN / WHITE WIRE

Figure 9. Relay Wiring

NOTE: The green/white wire is internally connected to the camclosure chassis. Any connected signalling

device should be left floating with respect to the camclosure chassis, otherwise damage could result.

C3432M-F (6/08) 15

Page 16

CONNECTING ALARMS

The IP110 Camclosure provides an alarm input for external signaling devices, such as door contacts or

motion detectors. Both normally open and normally closed devices are supported.

Supervised Alarms

When an alarm is configured as a supervised alarm, IP110 Camclosure maintains a constant electrical

current through the alarm circuit (3.3 VDC, 1 ohm). If the alarm circuit length changes, due to an electrical

short or a bypass, the voltage fluctuates from its normal state. Therefore, the unit triggers an alarm.

NOTE: Install the 1 kohm resistor as close to the switch as possible.

Figure 10 illustrates the alarm and no alarm conditions of a supervised alarm input. Whether the alarm is

normally closed or normally open, neither a cut nor a bypass can defeat these alarms.

NO ALARMNO ALARM

ALARM

ALARM

ALARM

NORMALLY OPEN

GND

GND

GND

CUT

GND

NORMALLY CLOSED

1K

GND

ALARM

ALARM

ALARM

1K

GND

1K

GND

1K

GND

+V

+V

+V

CUT

+V

BYPASS

Figure 10. Supervised Alarm Conditions

Figure 11 illustrates the wiring configuration for supervised alarm inputs.

NORMALLY CLOSED

1 KΩ

1 K

Ω

NORMALLY OPEN

1K

1K

1K

1K

BYPASS

+V

+V

+V

+V

1 K

Ω

1 K

Ω

UNUSED

1 K

INPUTS

Ω

MUST ALSO

BE WIRED

1 K

UNUSED

INPUTS

Ω

MUST ALSO

BE WIRED

Figure 11. Supervised Alarm Input Wiring

16 C3432M-F (6/08)

Page 17

Unsupervised Alarms

When an alarm is configured as an unsupervised alarm, the Camclosure only triggers an alarm when the

normal alarm state (open or closed) changes.

Figure 12 illustrates the alarm and no alarm conditions of an unsupervised alarm input. A normally closed

alarm input can be defeated with a bypass. A normally open input can be defeated with a cut.

NORMALLY CLOSED

NO ALARM

GND

ALARM

GND

ALARM

GND

NO ALARM

GND

BYPASS

CUT

+V

+V

+V

+V

NORMALLY OPEN

NO ALARM

GND

ALARM

GND

NO ALARM

GND

ALARM

GND

Figure 12. Unsupervised Alarm Conditions

Figure 13 illustrates the wiring configuration for unsupervised alarm inputs.

NORMALLY CLOSED

UNUSED

INPUTS

MAY BE

SHORTED

NORMALLY OPEN

CUT

BYPASS

UNUSED

INPUTS

MUST BE LEFT

UNWIRED

+V

+V

+V

+V

Figure 13. Unsupervised Alarm Input Wiring

C3432M-F (6/08) 17

Page 18

Alarm Connections

Figure 14 shows how to wire the IP110 Camclosure to an alarm (refer to Wiring Tables on page 14).

ALARM RETURN: BLACK / WHITE WIRE

ALARM: BLACK WIRE

Figure 14. Unsupervised Alarm Input Wiring

NOTE: The black wire is internally connected to the Camclosure chassis. Do not connect directly to any

potential except chassis ground.

18 C3432M-F (6/08)

Page 19

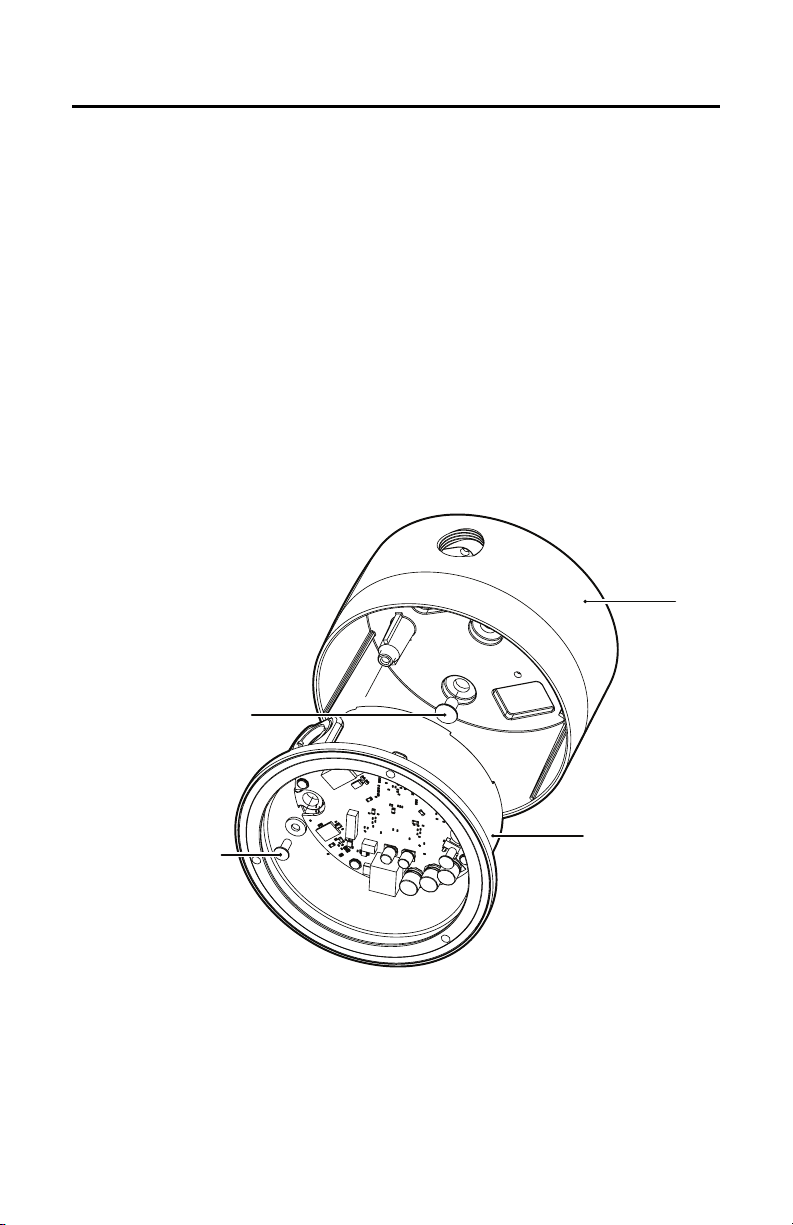

Camera Module

The IP110 Series Camclosure camera module includes the camera, camera bracket, and heater board.

To perform most camera adjustments, you must remove the module from the back box.

Use the following instructions to install/remove the camera module.

WARNING: Heater elements could be hot! When camera power is on, use caution when adjusting

the camera. This applies to all models.

CAMERA ORIENTATION

At the factory, the camera module is configured for ceiling mounting. For wall mounting, you must change

the camera orientation or the video image will be upside down.

To change the camera orientation (refer to Figure 15):

1. Remove the camera module from the back box (if necessary).

2. Remove the tilt adjustment screw and lock washer from each side of the camera.

3. Carefully rotate the camera one half turn. Make sure the wiring harness does not bind.

4. Reinstall the tilt adjustment screw and lock washer on each side of the camera.

5. Verify the camera orientation.

CEILING MOUNT (DEFAULT)

TILT ADJUSTMENT

SCREW AND

LOCK WASHER

BOTTOM

OF CAMERA

TILT ADJUSTMENT

SCREW AND

LOCK WASHER

Figure 15. Camera Orientation

WALL MOUNT

TOP OF

CAMERA

C3432M-F (6/08) 19

Page 20

MODULE INSTALLATION

To install the camera module into the back box:

1. Plug the camera (10-pin), heater board (4-pin), and service (3-pin) connectors into the back box (refer

to Figure 16).

HEATER

CONNECTOR

Figure 16. Back Box Connectors

2. Make sure the tabs on the camera bracket and the service connector are pointing out of the

enclosure, away from the ceiling or wall.

3. Gently squeeze the bracket, place it against the groove inside the back box, and then gently release

(refer to Figure 17).

SERVICE

CONNECTOR

CAMERA

CONNECTOR

BRACKET

Figure 17. Camera Module Bracket

20 C3432M-F (6/08)

Page 21

Camera Adjustments

To perform camera adjustments, complete the following steps:

1. Make sure the camera and service connectors are connected to the board inside the back box.

You may have to remove the camera module from the back box.

2. Connect a monitor to the service connector (refer to Service Connector on page 31). Turn on power to

the monitor.

3. Turn on power to the camera. The camera will start the following configuration process:

• The green LED inside the back box flashes five times per second for approximately two

minutes, or until the PC or server recognizes the mini dome.

• If the dome is not connected to a DHCP PC/server, the green LED will flash for about four

minutes before the camera switches to an automated private IP addressing mode.

NOTE: If the IP110 is connected to a DHCP network, the server will automatically assign an

IP address to the camera. If the IP110 is connected to static network, the IP address

192.168.0.20 on netmask 255.255.0.0 is automatically assigned to the camera. If the camera

has an older software version installed (versions 01.00.0038 and older for IP110 and versions

01.00.0018 for IP3701H), the network will automatically cycle through the IP address range of

169.254.200.0 through 169.254.200.255, on netmask 255.255.0.0. The first available address

located will be assigned to the IP110. If the network cannot find an open address in the default

range, contact your network administrator.

4. To adjust the camera, you will need a miniature trimpot adjustment tool with a 0.05-inch (1.27 mm)

blade. Suggested tools include a miniature flat-tip screwdriver, a Philmore trimpot tool (#63-6808),

and the Philmore 10-piece tool set (#63-910).

5. Refer to the following sections for detailed information on camera adjustments:

• Varifocal Lens Zoom and Focus Adjustments on page 22

• DN/CH Series Adjustments on page 23

• DW/CW Series (Wide Dynamic Range) Adjustments on page 26

6. After you have adjusted the unit, reinstall the camera module into the back box, and then install the

trim ring, bubble, and dome liner (refer to page 30).

C3432M-F (6/08) 21

Page 22

VARIFOCAL LENS ZOOM AND FOCUS ADJUSTMENTS

To adjust the field of view and the focus:

1. Select a field of view by turning the zoom adjustment ring clockwise/counterclockwise (refer to

Figure 18).

2. Tighten the zoom locking screw.

3. Adjust the focus by moving the focus locking screw clockwise/counterclockwise.

4. Tighten the focus locking screw.

FOCUS

ZOOM

Figure 18. Location of Zoom and Focus Adjustments

22 C3432M-F (6/08)

Page 23

DN/CH SERIES ADJUSTMENTS

Refer to Figure 19 to adjust the IP110-DN or IP110-CH model.

Figure 19. Adjusting the IP110-DN/CH Series Camclosure

SWITCH SETTINGS

Locate the DIP switch. Then set the switches for your installation.

SW4-1: Auto Gain Control

The automatic gain control (AGC) adjusts the image automatically to compensate for changes in light

levels.

Set SW4-1 to ON to enable AGC. Set it to OFF to disable AGC. The default setting is ON.

SW4-2: Backlight Compensation

The backlight compensation (BLC) feature compensates for backlit scenes by enhancing objects in the

center of the scene.

Set SW4-2 to ON to enable BLC. Use this setting if a bright backlight is present and the subject in the

center of the picture appears dark or as a silhouette.

Set it to OFF to disable backlight compensation. This is the default setting.

SW4-3: N/A

C3432M-F (6/08) 23

Page 24

SW4-4: Flickerless

In certain lighting conditions, a flicker in the light source may affect camera operation. Flickering can be

caused by a number of conditions, including the quality of the source power and the age and type of

fluorescent bulbs and ballasts.

Set SW4-4 to ON to enable flickerless operation. The camera will remove the effects of flickering when

present. The shutter speed will be set to 1/120 (NTSC) or 1/100 (PAL).

Set it to OFF to disable flickerless operation. This is the default setting.

NOTE: If you enable flickerless operation, you should use AC line lock for best results.

SW4-5: Auto White Balance/Manual White Balance

Auto white balance (AWB) is enabled by default (OFF).

To manually set and lock the white balance:

1. Set SW4-5 to OFF.

2. Hold a white background in front of the lens until the video shows all white.

3. While holding the background in place, set SW4-5 to ON. A blue blinking block appears on the video

image for a few seconds. When the block changes to solid green, the manual white balance (MWB)

process is complete.

SW4-6: Reserved

Do not change SW4-6 from its factory setting. SW4-6 must be set to OFF for Varifocal models; it must be

set to ON for fixed iris lenses.

BLEMISH DETECTION

If small white or color spots appear in the video image, one or more pixels on the camera imager may be

defective. (This condition is common for both CCD and CMOS imagers.)

DN and CH Series cameras with auto iris lenses automatically detect and correct defective pixels during

startup. Video turns on, then off, and then on again. If white or color spots still appear, you can correct the

defective pixels manually.

CH Series cameras with fixed iris lenses do not automatically detect and correct defective pixels. You can

correct the defective pixels manually.

To manually correct defective pixels:

1. Cover the lens completely. Make sure no light can enter the lens.

NOTE: The mechanical iris lens aperture does not completely block the light.

2. Press and hold button SW3 for one second. The camera will find and correct defective pixels.

NOTE: Any defective pixels that cannot be completely corrected may still appear.

3. Release button SW3.

4. Uncover the lens for normal camera operation.

24 C3432M-F (6/08)

Page 25

DAY/NIGHT OPERATION

NOTE: This section only applies to DN model cameras.

DN model cameras regularly check the brightness level of the field of view to determine when to switch

between day (color) and night (black-white) operation.

Actual brightness threshold levels are affected by camera angle, amount of zoom, field of view, lens, and

type of lighting. The switching process lasts from seven to 10 seconds.

Figure 22 and Table C show how the camera switches between color and black-white operation.

MODE

COLOR

MODE

3.0 lux

COLOR

B-W

1.5 lux

MODE

FALLING LIGHT LEVEL

B-W

RISING LIGHT LEVEL

MODE

Figure 20. DN Models Threshold Switching Levels

Table C. DN Models Switching Thresholds

Color to B-W 1.5 lux ±1.0 lux

B-W to Color 3.0 lux ±1.0 lux

NOTE: These switching thresholds are approximate. Use the thresholds in Table C as a guide when

installing the unit.

C3432M-F (6/08) 25

Page 26

DW/CW SERIES (WIDE DYNAMIC RANGE) ADJUSTMENTS

Refer to Figure 21 to adjust the IP110-DW or IP110-CW model.

SW1

DEFAULT SWITCH POSITION

Figure 21. Adjusting the IP110-DW/CW Series Camclosure

R7

SWITCH SETTINGS

Locate the DIP switch. Then set the switches for your installation.

SW1-1: Video Format

Set SW1-1 to ON for NTSC. Set it to OFF for PAL. The default setting is ON.

SW1-2: N/A

SW1-3: Interlaced Scanning/Progressive Scanning

Interlaced scanning is the standard for analog recording installations. Each frame contains one odd and

one even field, each processed separately.

Progressive scanning is better for digital recording installations. Each frame is processed as a whole,

which results in less blurring and cleaner digital conversion. It also saves storage space on digital video

recorders.

Set SW1-3 to ON to select interlaced scanning.

Set it to OFF to select progressive scanning. The default setting is ON.

26 C3432M-F (6/08)

Page 27

SW1-4: Auto White Balance/Manual White Balance

Auto white balance (AWB) is enabled by default (ON).

To manually set and lock the white balance:

1. Set SW1-4 to ON.

2. Hold a white background in front of the lens until the video shows all white.

3. While holding the background in place, set SW1-4 to OFF. A green block and a white block alternate

briefly on the video image until the manual white balance (MWB) process is complete.

SW1-5: Fluorescent/General

Enable this option to adjust the camera for best operation under fluorescent lighting.

Set SW1-5 to OFF for fluorescent lighting. Set it to ON for general lighting. The default setting is ON.

NOTE: If you use fluorescent operation, you should use AC line lock for best results.

SW1-6: General/Maximum Wide Dynamic Range

Maximum wide dynamic range (WDR) supports about 36 dB of additional dynamic range over a standard

camera. Use it for installations that require the maximum WDR.

General WDR supports about 20 dB of additional dynamic range over a standard camera. Use it for

installations that do not require the maximum WDR.

Set SW1-6 to ON to select maximum WDR. Set it to OFF to select general WDR. The default setting is ON.

SW1-7: Digital Slow Shutter

The default shutter speed for NTSC is 30 frames per second (fps). It is 25 fps for PAL. This is also known as

SENS 2X.

You can decrease the shutter speed to 7.5 fps (NTSC) or 6.25 fps (PAL). This is known as SENS 8X, which

improves low light sensitivity.

Set SW1-7 to ON to select SENS 2X. Set it to OFF to select SENS 8X. The default setting is ON.

SW1-8: Day/Night Operation (DW models only)

NOTE: On CW models, SW1-8 is unused and does not affect camera operation.

DW model cameras regularly check the brightness level of the field of view to determine when to switch

between day (color) and night (black-white) operation. Use SW1-8 to set the general light levels at which

the camera will automatically switch.

Set SW1-8 to ON (dark) to use standard thresholds to switch between color and black-white operation.

This is the default.

Set it to OFF (dusk) to use higher light thresholds to switch between color and black-white operation.

Actual brightness threshold levels are affected by camera angle, amount of zoom, field of view, lens, and

type of lighting. The switching process lasts from seven to 10 seconds.

C3432M-F (6/08) 27

Page 28

Figure 20 and Table D show how the camera switches between color and black-white operation for each

setting.

MODE

COLOR

B-W

MODE

RISING LIGHT LEVEL

MODE

COLOR

3.0 lux

FALLING LIGHT LEVEL

1.0 lux

B-W

MODE

MODE

COLOR

B-W

MODE

RISING LIGHT LEVEL

FALLING LIGHT LEVEL

MODE

COLOR

B-W

MODE

7.0 lux

4.0 lux

DARK

DUSK

Figure 22. DW Models Threshold Switching Levels

Tab le D . DW Models Switching Thresholds

Dark (ON) Dusk (OFF)

Color to B-W 1.0 lux 4.0 lux

B-W to Color 3.0 lux 7.0 lux

NOTE: These switching thresholds are approximate and were measured using a 3.0 mm to 9.5 mm lens at

f/1.0. Use the thresholds in Table D as a guide when installing the unit.

AUTO IRIS LEVEL ADJUSTMENT

The electronics of the IP110-DW and IP110-CW Series Camclosures automatically adjust the camera to

the auto iris. Auto iris level adjustments are not necessary.

28 C3432M-F (6/08)

Page 29

Camera Positioning

Manually rotate and tilt the camera module to position the camera. Then tighten the tilt screws (axis 1 in

Figure 23).

NOTE: Do not over-rotate the module. Excessively turning the module in one direction could result in

damage to the wiring.

ì Tilt 140° (20°-160°) î Pan 360° ï Rotation 360°

Figure 23. Positioning the Camera

C3432M-F (6/08) 29

Page 30

Install Dome and Trim Ring

1. To adjust the dome liner refer to Figure 24 and complete the following steps:

a. Align the screw holes in the trim ring with those in the back box to identify the proper dome

liner position.

b. Loosen the three Phillips screws located in the trim ring.

c. Insert the blade of a standard screwdriver in one of the adjustment grooves. Rotate the dome

liner to position the viewing window over the camera lens.

d. Tighten the three Phillips screws to lock the dome liner in place.

ADJUSTMENT

GROOVE

LINER

LOOSEN SCREWS

Figure 24. Dome Liner Adjustment

2. Align the screw holes in the trim ring with those in the back box.

3. Tighten the tamper-resistant screws through the trim ring into the back box. Use the supplied

1/8-inch hollow screwdriver bit.

30 C3432M-F (6/08)

Page 31

Service Connector

The IP110 Series Camclosure integrated camera system includes a service connector that outputs camera

video. Use it at the installation site to set up the field of view and focus the camera.

SERVICE

CONNECTOR

Figure 25. Service Connector

Pelco offers two optional items (CST150 and ICS-SC) that plug directly into the service connector. Before

using either option, you must loosen the tamper-resistant screws to remove the trim ring from the back

box. Use the supplied 1/8-inch hollow screwdriver bit.

The CST150 has a 3-foot (0.9 m) cable and microdisplay for viewing camera video. Plug it into the service

connector and view the video.

NOTE: The three buttons on the CST150 are not used with the IP110 Series Camclosure.

The ICS-SC has a 4-foot (1.2 m) cable with a service connector and a BNC connector. Plug the service

connector into the unit. Then connect the other end to any standard BNC (VIDEO IN) connector on a

monitor.

To assemble a longer service cable for the Camclosure integrated camera system, purchase the following

from a local electronics supply store:

Qty Description

1 2.5 mm monaural headphone plug

1 CPM 88 miniature coaxial connector

1 RG174/U coaxial cable

To assemble the cable:

1. Attach the CPM 88 miniature coaxial connector to one end of the cable. Follow the directions

supplied with the miniature coaxial connector.

2. Attach the 2.5 mm monaural plug to the other end of the coaxial cable (refer to Figure 26):

a. Remove the support sleeve from the plug.

b. Slip the support sleeve over the end of the cable.

c. Prepare the cable.

C3432M-F (6/08) 31

Page 32

d. Solder the center connector of the cable to the center pin of the plug.

e. Thread the braid of the cable through the hole in the crimp pin.

f. Solder the braid to the top of the crimp pin.

g. Crimp the end of the crimp pin around the cable.

h. Reassemble the support sleeve and the plug.

CENTER CONDUCTOR

COAXIAL

CABLE

BRAID (SHIELD)

2.5 MM MONAURAL

HEADPHONE PLUG

Figure 26. Attaching the 2.5 mm Monaural Headphone Plug

32 C3432M-F (6/08)

Page 33

Reset Button

Use the reset button located on the board inside the back box to access the following modes:

Mode Function Unit Status Indicator Light

Configuration Starts reset LED

selection sequence.

Reboot Restarts the unit. Flashes green and red simultaneously, when entering

Reset Resets unit to factory

default settings and

then restarts unit.

Cancel Cancels any

configuration or reset

action.

To access one of these modes:

1. Press and hold the reset button. The unit starts cycling through the modes; hold the button for four

seconds to access (cycle through) each mode. The unit status indicator flashes the color for the

current mode (refer to the table above).

2. When the color of the desired mode appears, release the button.

NOTES:

• If there is no configuration activity for 15 minutes, the camera will automatically exit the reset

mode.

• The LED is not lit during normal operation.

Flashes green.

this mode. The LED then flashes green when mode is

selected and during the reboot.

Flashes red when entering this mode. Flashes red when

mode is selected, and then flashes green when camera

restarts. Camera is offline during reset mode.

No light.

RESET

BUTTON

RED / GREEN LEDS

Figure 27. Location of Reset Button and LEDs

C3432M-F (6/08) 33

Page 34

Troubleshooting

Problem Possible Cause Suggested Remedy

No video PoE power issue • Check Cat5 cable connection.

• Verify PoE is enabled.

• Disconnect the Cat5 cable from the PoE and then

reconnect the cable. Check the LED inside the back

box to see if it is flashing green, indicating the

camera has power.

Power issue (24 VAC) • Check the 24 VAC power supply connection.

• Disconnect the network cable and then reconnect it

to the camera. Check the LED inside the back box to

verify if it is flashing green, indicating the camera

has power.

Network connectivity issues • Check network cable connections.

• Disconnect the network cable and then reconnect it

to the camera. Check the LED inside the back box to

verify if it is flashing green.

• Replace network cable with new cable. If new

cable does not work, contact Pelco Product Support

at 1-559-292-1981 or 1-800-289-9100.

Defective camera • Check the camera’s 10-pin connector inside the

Image too dark/

black image

34 C3432M-F (6/08)

Installation error • Make sure the lens cover in not installed.

back box to make sure it is connected.

• Use a service connector to check camera operation.

Connect one end of the service connector to the

service connector input inside the back box. Then

connect the other end of the service connector to a

monitor.

• Replace camera module with new camera. If the

new camera does not work, contact Pelco Product

Support Department at 1-559-292-1981 or

1-800-289-9100.

• Make sure camera is not located in an environment

with zero light.

• Use a service connector to check camera operation.

Connect one end of the service connector to the

service connector input inside the back box. Then

connect the other end of the service connector to a

monitor.

• Replace camera module with new camera. If the

new camera does not work, contact Pelco Product

Support at 1-559-292-1981 or 1-800-289-9100.

Page 35

Problem Possible Cause Suggested Remedy

Image too light Installation error • Check DIP switch settings.

• Use a service connector to check camera operation.

Connect one end of the service connector to the

service connector input inside the back box. Then

connect the other end of the service connector to a

monitor.

• Replace camera module with new camera. If the

new camera does not work, contact Pelco Product

Support at 1-559-292-1981 or 1-800-289-9100.

Image only

displayed in

black and white

Flickering in

image

Camera not

discovered

Color level setting • Check DIP switch settings.

• Use a service connector to check camera operation.

Connect one end of the service connector to the

service connector input inside the back box. Then

connect the other end of the service connector to a

monitor.

• Replace camera module with new camera. If the

new camera does not work, contact Pelco Product

Support at 1-559-292-1981 or 1-800-289-9100.

IR cut filter setting • Check DIP switch settings.

• Use a service connector to check camera operation.

Connect one end of the service connector to the

service connector input inside the back box. Then

connect the other end of the service connector to a

monitor.

• Add direct light to camera. Wait 30 seconds to see

if IR cut filter is functioning.

• Replace camera module with new camera. If the

new camera does not work, contact Pelco Product

Support at 1-559-292-1981 or 1-800-289-9100.

Flickerless setting • Check DIP switch settings.

• Check power supply specifications.

• Replace camera module with new camera. If the

new camera does not work, contact Pelco Product

Support at 1-559-292-1981 or 1-800-289-9100.

No camera power Verify the camera is powered correctly with PoE or

with 24 VAC. Confirm power consumption with Web

interface of PoE-capable switch or through blinking

green LED during camera power up.

Network conflict • Verify the camera is physically connected to the

same network as the PC running the Device Utility.

• The utility will not work on a network that blocks

multicast traffic.

• Confirm the green LED blinks when power is

applied to the camera, indicating network

connectivity.

C3432M-F (6/08) 35

Page 36

Problem Possible Cause Suggested Remedy

Network not

working

Unable to sync to

®

an Endura

system manager

or NTP server

after changing

networks

Faulty cable connection Check all cable connections and ensure all plugs are

properly plugged in.

Incorrect serial device

configuration

A hub will not work with the available network

bandwidth shared across all ports. Use a Fast Ethernet

switch, Gigabit Ethernet switch, or a cable modem

router with an n-Port switch.

Network connectivity issues Contact your network administrator.

Network connectivity issues • Disconnect the power cable (either PoE or 24 VAC)

and then reconnect it to the camera. Power is

indicated by the LED. The LED will flash (green) five

times per second for approximately two minutes if

the camera has power.

• Reset the camera’s factory defaults. Refer to Reset

Button on page 33.

36 C3432M-F (6/08)

Page 37

Specifications

GENERAL

Pan/Tilt Adjustment Manual

Pan 360°

Tilt 80° (20° to 100° range)

Rotation 360°

Construction Aluminum with steel camera mounting bracket and polycarbonate dome

Cable Entry One 0.75-inch (1.91 cm) NPT threaded opening on side; two 0.75-inch

Finish Gray polyester powder coat

Light Attenuation

Smoked f/1.5 light loss

Clear Zero light loss

Unit Weight 2.2 lb (1.0 kg)

ELECTRICAL

Ports RJ-45 connector for 100Base-TX

Cabling Type Cat5 or better for 100Base-TX

Input Voltage 24 VAC (18-36) or PoE (IEEE802.3af)

Power Consumption <7.5 W, <13 W with heaters

Alarm Input 10 VDC maximum, 5mA maximum

Alarm Output 0 to 15 VDC maximum, 75 mA maximum

Service Connector Internal to housing 3-connector, 2.5 mm connector providing NTSC/PAL

VIDEO

Signal System NTSC or PAL

Compression MPEG-4, MJPEG in Web viewing mode

Video Streams 3, simultaneous

Video Resolutions NTSC

4CIF 704 x 480 704 x 576

2CIF 704 x 240 704 x 288

CIF 352 x 240 352 x 288

QCIF 176 x 120 176 x 144

Bit Rate Configurable 20 kbps to 2 Mpbs per stream, implements EnduraView

Video Access form

Web Browser Camera live view for up to 10 video sources

Users 10 simultaneous users, unlimited number of users using multicast

Minimum Web Browser

Requirements PC (Pentium

RAM 512 Mbyte

Ethernet Card 100 Mbit

Web Browser Internet Explorer 5.5 (or later) or Firefox 1.5 (or later)

Screen Resolution 1024 x 768 pixels or higher, 16- or 32-bit pixel color resolution

(1.91 cm) openings on NEMA cover

Auto MDI/MDI-X

Autonegotiate/Manual setting

24VAC: <0.5 A, <0.9 A with heaters

video outputs

PAL

®

4 microprocessor, 1.6 GHz) with Windows® 98,

Windows 2000, Windows XP (or later) or Mac

™

®

OS X 10.3.9 (or later)

C3432M-F (6/08) 37

Page 38

ENVIRONMENTAL

Environment Low temperature, indoor/outdoor

Operating Temperature -50° to 122°F (-46° to 50°C); de-ices to 25°F (-4°C)

Thermostat Operation Heater is thermostatically controlled to activate < 41°F (<5°C)

CAMERA

Service Connector 3-conductor, 2.5 mm connector for video output to optional ICS-SC cable

Imaging Device 1/3-inch imager

Picture Elements NTSC

PAL

DW/CW 720 (H) x 540 (V) 720 (H) x 540 (V)

DN/CH 768 (H) x 494 (V) 752 (H) x 582 (V)

Dynamic Range

DW/CW 102 dB typical/120 dB maximum

Signal System NTSC or PAL

Scanning System

DW/CW 2:1 interlace/progressive scanning (DIP switch selectable)

DN/CH 2:1 interlace

Synchronization Internal

Electronic Shutter Range Auto (1/15 to 1/22,000)

LENS

Type Varifocal with auto iris

Focal Length 3.0 mm ~ 9.5 mm

9.0 mm ~ 22.0 mm

Format Size 1/3-inch

Operation

Iris Auto (DC drive)

Focus Manual

Zoom Manual

Ø 5.50

(13.97)

3.63

(9.22)

Ø 3.79

(9.63)

3.03

(7.70)

5.28

(13.41)

NOTE: VALUES IN PARENTHESES ARE CENTIMETERS; ALL OTHERS ARE INCHES.

(Design and product specifications subject to change without notice.)

38 C3432M-F (6/08)

Page 39

PRODUCT WARRANTY AND RETURN INFORMATION

WARRANTY

Pelco will repair or replace, without charge, an y merchandise proved defective in material or workmanship for a period of one year after the date of

shipment.

Exceptions to this warranty are as noted below:

• Five years on fi ber optic products and TW3000 Series unshielded twisted pair (UTP) transmission products.

• Three years on Spectr a® IV products.

• Three years on Genex® Series products (multiplexers, server, and keyboard).

• Three years on DX Series digital video recorders, DVR5100 Series digital video recorders, DigitalSENTRY® Series hardware products, DVX Series

digital video recorders, NVR300 Series netwo rk video recorders, and Endura® Series distributed network-based video products.

• Three years on Camclosure® and Pelco-branded fixed camera models, except the CC3701 H-2, CC3701H-2X, CC3751H-2, CC3651H-2X, MC3651H-2,

and MC3651H-2X camera models, which ha ve a five-year warranty.

• Three years on PMCL200/300/400 Series LCD monitors.

• Two years on standard motorized or f ixed focal length lenses.

• Two years on Legacy®, CM6700/CM6800/CM9700 Series matrix, and DF5/DF8 Series fixed dome products.

• Two years on Spectra III™, Spectra Mini, Esprit®, ExSite®, and PS20 scanners, including when used in continuous motion applications.

• Two years on Esprit and WW5700 Series win dow wiper (excluding wiper blades).

• Two years (except lamp and color wheel) on Digital Light Processing (DLP®) displays. The lamp and color wheel will be covered for a period of

90 days. The air filter is not covered un der warranty.

• Two years on Intelli-M® eIDC controllers.

• One year (except video h eads) on video cassette recorders (VCRs). Video heads will be covered for a period of six months.

• Six months on all pan and tilts, scanners, or preset lenses used in continuous motion applications (pre set scan, tour, and auto scan modes).

Pelco will warrant all replacement parts and repairs for 90 days from the date of Pelco shipment. All goods requiring warranty repair shall be sent

freight prepaid to a Pelco designated locatio n. Repairs made necessary by reason of misuse, alteration, normal wear, or accident are no t covered under

this warranty.

Pelco assumes no risk and shall be subject to no liability for damages or loss resulting from the specific use or application made of the Products. Pelco’s

liability for any claim, whether based on breach of contract, negligence, infringement of any rights of any party or product liability, relating to the

Products shall not exceed the price paid by the Dealer to Pelco for such Products. In no event will Pelco be liable for any special, incidental, or

consequential damages (including loss of use, loss of profit, and claims of third parties) however caused, whether by the negligence of Pelco or

otherwise.

The above warranty provides the Dealer with spe cific legal rights. The Dealer may also have additional right s, which are subject to variation from state

to state.

If a warranty repair is required, the Dealer must contact Pelco at (800) 289-9100 or (559) 292-1981 to obtain a Repair Authorization number (RA), and

provide the following information:

1. Model and serial number

2. Date of shipment, P.O. number, sales order number, or Pelco invoice number

3. Details of the defect or problem

If there is a dispute regarding the warranty of a product that does not fall un der the warranty conditions stated above, please include a written

explanation with the product wh en returned.

Method of return shipment shall be the same or equal to the method by which the item was received by Pelco.

RETURNS

To expedite parts returned for repair or credit, please call Pelco at (800) 289-9100 or (559) 292-1981 to obtain an authorization number (CA number if

returned for credit, and RA number if returned for repair) and designated return location.

All merchandise returned for credit may be subject to a 20 percent restocking and refurbishing charge.

Goods returned for repair or credit should be clearly identified with the assigned CA or RA number and freight should be prepaid.

1-8-08

REVISION HISTORY

Manual # Date Comments

C3432M 3/07 Original version.

C3432M-A 5/07 Cable harnesses modified per ECO 07-17470. Added picture elements to specifications.

C3432M-B 8/07 Added FCC Class B and revised DIP switch setting adjustments.

C3434M-C 11/07 Revised figures 20 and 22.

C3432M-D 1/08 Added Open Source Software Notice.

C3432M-E 4/08 Removed references to JRE per CN21186.

C3432M-F 6/08 Changed static IP address to new default 192.168.0.20 per CN21529.

Pelco, the Pelco logo, Camclosure, Esprit, Endura, ExSite, Gen ex, Legacy, and Spectra are registered trademarks of Pelco, Inc.

Endura Enabled, EnduraView, and Spectra III are trademarks of Pelco, Inc. ©Copyright 2008, Pelco, Inc.

DLP is a registered trademark of Texas Instruments, Inc.

Microsoft, Windows, and Internet Explorer a re registered trademarks of Microsoft Corporation.

Firefox is a registered trademark of the Mozilla Foundation.

Pentium is a registered trademark of Intel Corporation. All rights reserved.

Page 40

Worldwide Headquarters

3500 Pelco Way

Clovis, California 93612 USA

USA & Canada

Tel: (800) 289-9100

Fax: (800) 289-9150

International

Tel: +1 (559) 292-1981

Fax: +1 (559) 348-1120

www.pelco.com

ISO9001

Australia|Finland|France|Germany|Italy|Macau|The Netherlands|Russia|Singapore

South Africa

Spain|Sweden|United Arab Emirates|United Kingdom|United States

|

Loading...

Loading...