PT573 Series

Medium Duty Pan/Tilt

Installation/

Operation Manual

C332M-D (10/98)

Pelco • 3500 Pelco Way, Clovis • CA 93612-5699 USA • www.pelco.com

In North America and Canada: Tel (800) 289-9100 or FAX (800) 289-9150

International Customers: Tel (1-559) 292-1981 or FAX (1-559) 348-1120

CONTENTS

Section Page

1.0 GENERAL..................................................................................................3

1.1 IMPORTANT SAFEGUARDS AND WARNINGS ...............................3

2.0 DESCRIPTION ..........................................................................................4

2.1 MODELS............................................................................................4

2.2 OPTIONS...........................................................................................4

2.3 CERTIFICATIONS .............................................................................4

3.0 INSTALLATION ..........................................................................................5

3.1 MOUNTING .......................................................................................5

3.2 CAMERA/ENCLOSURE MOUNTING ...............................................5

3.3 WIRING .............................................................................................5

3.3.1 Mating Connector Assembly ....................................................7

3.4 LIMIT STOP ADJUSTMENTS ...........................................................9

3.5 FRAME SCAN ADJUSTMENT .........................................................10

4.0 OPERATION ..............................................................................................11

5.0 TROUBLESHOOTING..............................................................................12

5.1 SERVICE MANUAL ..........................................................................12

6.0 MAINTENANCE........................................................................................13

6.1 TIGHTENING DRIVE CHAINS .........................................................13

6.2 CHAIN DRIVE LUBRICATION ..........................................................13

7.0 SPECIFICATIONS ....................................................................................14

8.0 WARRANTY AND RETURN INFORMATION ...........................................16

LIST OF ILLUSTRATIONS

Figures Page

1 Sealant Locations ..............................................................................5

2 Connector Assembly..........................................................................7

3 PT573R/PT573-24R Wiring Schematic .............................................8

4 PT573R/PT573-24R Series Limit Stop Adjustments .........................9

5Frame Scan Adjustment Location .....................................................10

6 Servicing the Pan/Tilt ........................................................................13

7 Dimension Drawing...........................................................................15

LIST OF TABLES

Table Page

A Requirements to Wire Power to Pan and Tilt Motors .........................6

REVISION HISTORY

Manual # Date Comments

C332M 9/89 Original version.

C332M-A 10/91 Rev. A. Revised to include model PT573-24R/HB.

C332M-B 5/95 Rev . B. Section 4.4, Connector Assembly , re vised. Figures

C332M-C 8/96 Rev. C. Added Figure 1, Table A and Section 7.0. Re vised

C332M-D 10/98 Changed manual to new f ormat. Added certifications. Re-

7-9 revised. to reflect new ground wire color (green). Section 6.3, Drive/Chain Maintenance, added. Standardized

voltage references to 120 VAC throughout and changed

applicable specifications.

manual text. Modified Figure 2. Combined wiring schematics into one figure. Deleted model PT573-24R/HB.

vised installation instructions. Moved exploded assembly

diagram and parts list to maintenance/service manual.

Revised Troubleshooting and Maintenance sections.

2 Pelco Manual C332M-D (10/98)

1.0 GENERAL

1.1 IMPORTANT SAFEGUARDS AND WARNINGS

Prior to installation and use of this product, the following WARNINGS should be

observed.

1. Installation and servicing should only be done by qualified service personnel

and conform to all local codes.

2. Unless the unit is specifically marked as a NEMA Type 3, 3R, 3S, 4, 4X, 6, or

6P enclosure, it is designed for indoor use only and it must not be installed

where exposed to rain and moisture.

3. The weight of the camera/lens and enclosure shall not exceed 40 lb (18.14 kg).

4. Only use replacement parts recommended by Pelco.

5. After replacement/repair of this unit’s electrical components, conduct a resistance measurement between line and exposed parts to verify the exposed

parts have not been connected to line circuitry.

6. The installation method and materials should be capable of supporting four

times the weight of the enclosure, pan/tilt, camera and lens combination.

The product may bear the following marks:

This symbol indicates that dangerous voltage constituting a

risk of electric shock is present within this unit.

This symbol indicates that there are important operating and

maintenance instructions in the literature accompanying this

unit.

CAUTION:

RISK OF

ELECTRIC SHOCK.

DO NOT OPEN.

TO REDUCE THE RISK OF ELECTRICAL SHOCK,

DO NOT REMOVE COVER. NO USER-

SERVICEABLE PARTS INSIDE. REFER SERVICING

TO QUALIFIED SERVICE PERSONNEL.

CAUTION:

Please thoroughly familiarize yourself with the information

in this manual prior to installation and operation.

Pelco Manual C332M-D (10/98) 3

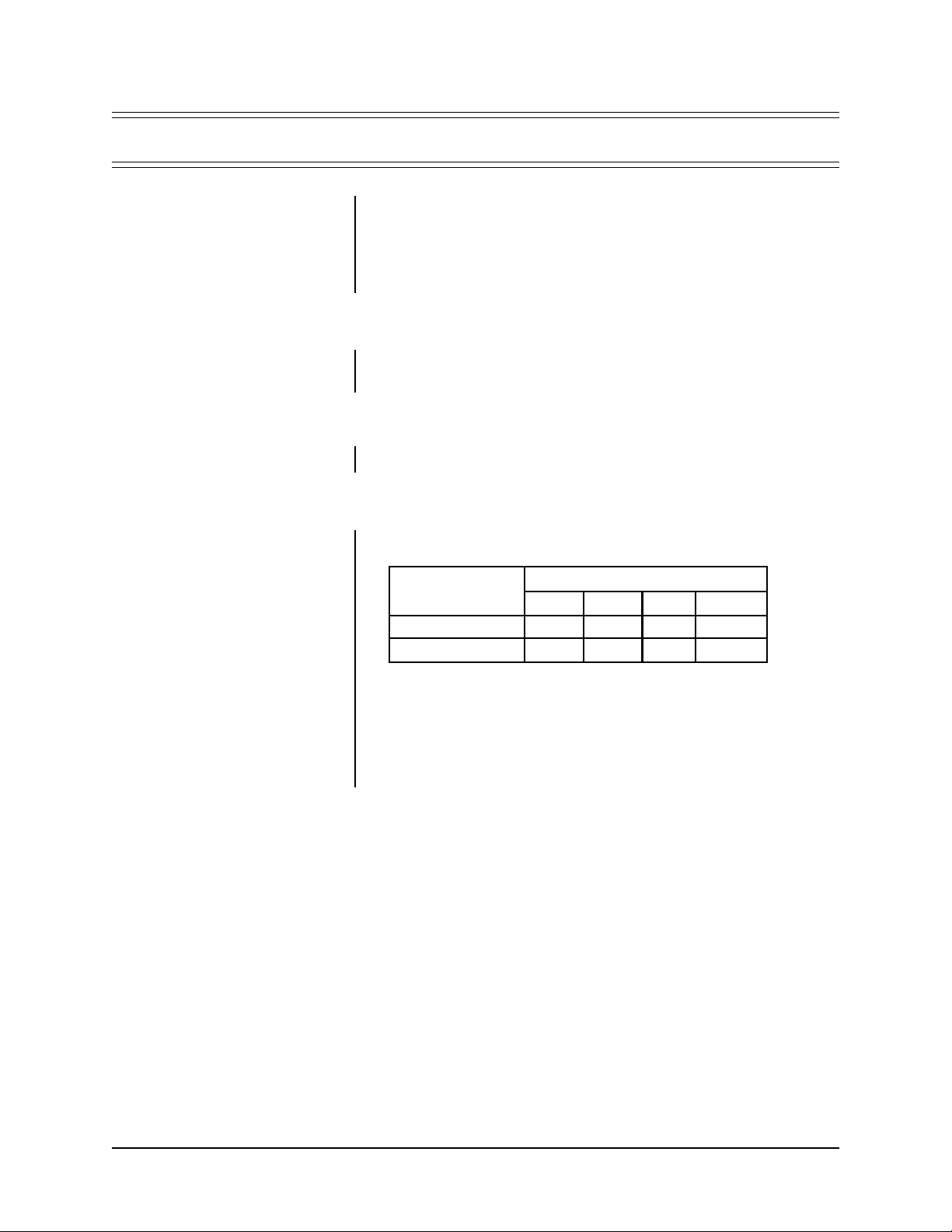

2.0 DESCRIPTION

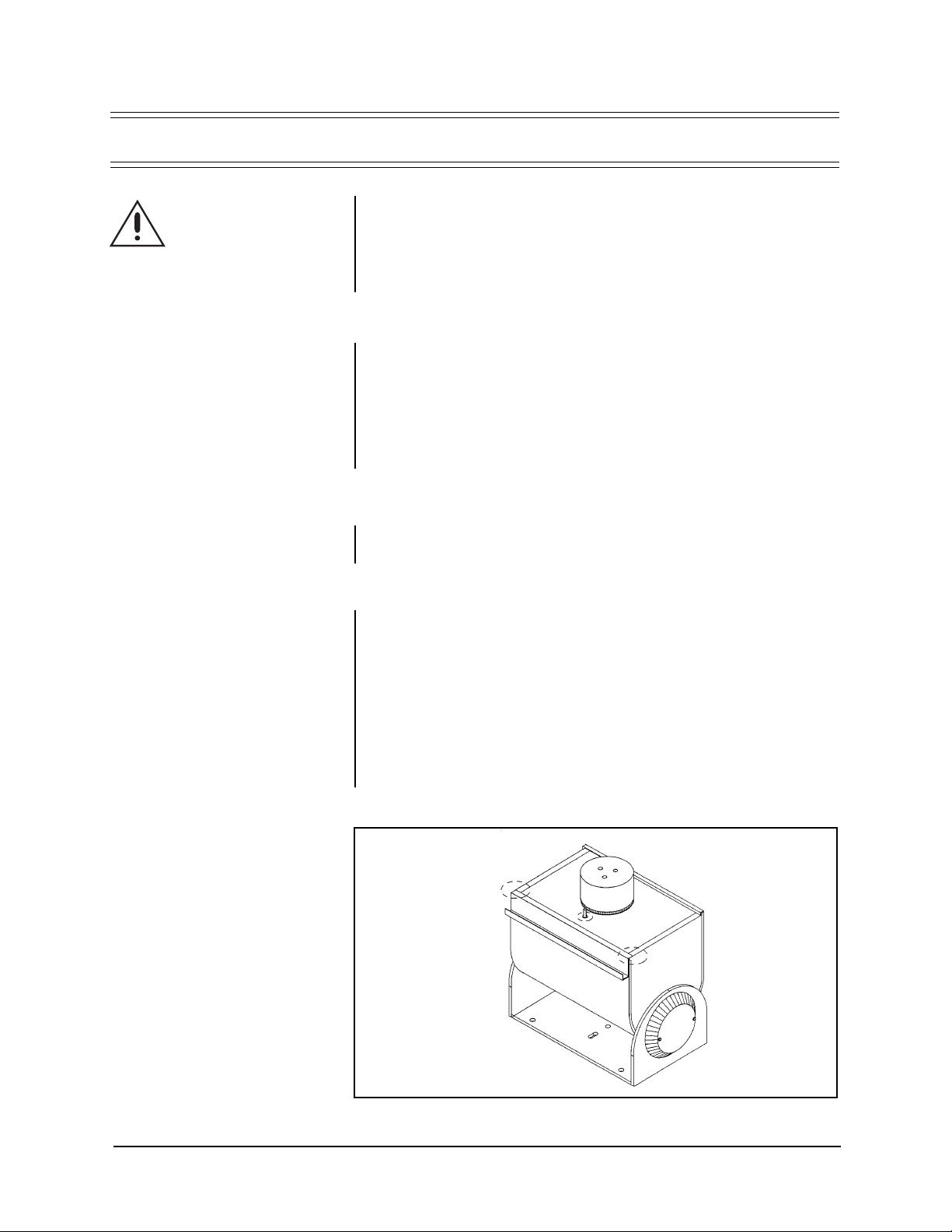

The PT573R and the PT573-24R are medium duty, indoor/outdoor pan/tilts designed for V330APT retrofit applications . Both units feature rugged worm gear final

drives to minimize backlash and prev ent wind drift, and are fully adjustable for wear .

They also have adjustable dur ation (2-9 seconds) frame scan capabilities. The housings are made of aluminum and will accept enclosure, camera and lens combinations up to 40 pounds (18.14 kg).

2.1 MODELS

PT573R Medium-duty, indoor/outdoor, 120 VAC.

PT573-24R Medium-duty , indoor/outdoor, 24 VAC.

2.2 OPTIONS

HB/570 Blanket heater in cover. Allows operation to -50°F (-46°). 75

watts total. 120 VAC, 50/60 Hz.

2.3 CERTIFICATIONS

The products identified below have been tested and certified for agency compliance as noted.

Model CE FCC UL CSA/cUL

PT573R X

PT573-24R X

Applicable CE, FCC, UL, and CSA/cUL standards:

• UL Standard 2044

Additional applicable ratings:

• NEMA T ype 3R

• IP 32

Agency Compliance Certification

4 Pelco Manual C332M-D (10/98)

3.0 INSTALLATION

CAUTION:

The PT573R

and PT573-24R are designed for upright or inver ted operation and

should never be mounted

horizontally.

NOTE:

When mounting the pan/

tilt outdoors in the inverted position

(base up), RTV silicone sealant,

such as Dow Corning Type 732 or

equivalent, should be applied to the

areas indicated in Figure 1.

The PT573R and PT573-24R are designed to mount onto a horizontal surface in

the upright or inverted position.

In order to ensure proper wiring and system operation of all components, it is recommended that you test the pan/tilt and the associated control equipment in your

facility before field installation. Refer to Sections 3.3 through 3.5.

3.1 MOUNTING

Attach the pan/tilt unit to a mount, following the instructions that accompany the

mount. To ensure maximum pan travel, mount the pan/tilt so that the fix ed limit stop

is directly opposite the center of the intended viewing area.

Make sure the mounting surface and the mounting method is strong enough to support four times the combined weight of the pan/tilt, enclosure, camera and lens. The

pan/tilt unit weighs 22 pounds (9.9 kg). Refer to the manuals for your enclosure,

camera, and lens for the weights of those units. The weight of the enclosure, camera, and lens must not exceed 40 pounds (18.14 kg).

3.2 CAMERA/ENCLOSURE MOUNTING

Attach the enclosure, camera and lens to the pan/tilt unit with 1/4-20 hardware (not

supplied). The enclosure, camera and lens must be correctly mounted and balanced

on the tilt table for proper operation.

3.3 WIRING

Cable distances fo r pan and tilt motors should not exceed the distances specified

in Table A. Cable fabrication must be in accordance with Section 3.3.1, Mating

Connector Assembly. The following are some recommended common installation practices.

1. Always use jack eted stranded m ulti-conductor interconnecting cab le betw een

the control and the pan/tilt unit, with additional conductors than needed for

future servicing and or additions.

2. Always use color-coded conductors for ease of wiring and to identify functions

at a later date.

3. Keep a wiring diagram with the system for later use and reference.

➛

➛

Figure 1 . Sealant Locations

➛

Pelco Manual C332M-D (10/98) 5

Loading...

Loading...