Page 1

®

DD08 Intercept Dome

Series Fixed mount

Installation/Operation Manual

C290M-A (6/99)

PELCO • 3500 Pelco Way, Clovis, CA 93612-5699 • USA • (800) 289-9100 or (1-559) 292-1981

FAX (800) 289-9150 or (1-559) 292-3827

Page 2

TABLE OF CONTENTS

Section Page

1.0 WARNINGS........................................................................................................................................1

2.0 SCOPE...............................................................................................................................................2

3.0 DESCRIPTION...................................................................................................................................2

3.1 MODELS ..................................................................................................................................2

3.2 CERTIFICATIONS ....................................................................................................................2

4.0 INSTALLATION ..................................................................................................................................3

4.1 FIXED MOUNT INSTALLATION AND REMOVAL ....................................................................3

4.1.1 Installing Fixed Mount ..................................................................................................3

4.1.2 Removing Fixed Mount ................................................................................................5

4.2 LENS WIRING..........................................................................................................................6

4.3 CAMERA/LENS INSTALLATION..............................................................................................6

5.0 ADJUSTMENTS.................................................................................................................................6

5.1 OPERATION.............................................................................................................................6

6.0 CARE AND MAINTENANCE ..............................................................................................................7

7.0 SPECIFICA TIONS..............................................................................................................................7

8.0 EXPLODED ASSEMBL Y DIAGRAM ..................................................................................................8

8.1 MECHANICAL PARTS LIST .....................................................................................................9

8.2 ASSOCIATED HARDWARE.....................................................................................................9

9.0 WARRANTY AND RETURN INFORMATION...................................................................................10

LIST OF ILLUSTRATIONS

Figure Page

1 Back Box Power Switch Location....................................................................................................4

2 Removing Safety Pins.....................................................................................................................4

3 Removing/Attaching Dome to Fixed Mount.....................................................................................4

4 Installing Fixed Mount .....................................................................................................................4

5 Guide Pin/Latch Locations ..............................................................................................................5

6 Fixed Mount/Back Box Electrical Interconnect................................................................................5

7 Locking Fixed Mount in Place .........................................................................................................6

8 Bezel Attachment ............................................................................................................................7

9 DD08 Fixed Mount Exploded Assembly Diagram ...........................................................................8

REVISION HISTORY

Manual Date Comment

C290M — Original version.

C290M-A 6/95 Rev. A. Revised to show rocker style power switch.

6/99 Added Section 3.2, Certifications.

®PELCO and the PELCO logo are registered trademarks of PELCO.

©Copyright 1995, PELCO. All rights reserved.

12 PELCO Manual C290M-A (6/99)

ii

Page 3

INSTALLATION/OPERATION MANUAL

DD08 INTERCEPT DOME SERIES

FIXED MOUNT

1.0 WARNINGS

Prior to installation and use of this product, the following

WARNINGS should be observed.

1. Installation and servicing should only be done by

qualified service personnel and conform to all local

codes.

2. Unless the unit is specifically marked as a NEMA

Type 3, 3R, 3S, 4, 4X, 6, or 6P enclosure, it is

designed for indoor use only and it must not be

installed where exposed to rain and moisture.

3. Only use replacement parts recommended by

PELCO.

The product bears the following marks:

This symbol indicates that dangerous voltage

constituting a risk of electric shock is present

within this unit.

4. After replacement/repair of this unit’s electrical

components, conduct a resistance measurement

between line and exposed parts to verify the exposed

parts have not been connected to line circuitry.

5. The installation method and materials should be

capable of supporting four times the weight of the

enclosure, pan/tilt, camera and lens combination.

This symbol indicates that there are important

operating and maintenance instructions in the

literature accompanying this unit.

CAUTION:

TO REDUCE THE RISK OF ELECTRICAL

SHOCK, DO NOT REMOVE COVER. NO

USER-SERVICEABLE PARTS INSIDE.

REFER SERVICING TO QUALIFIED

SERVICE PERSONNEL.

RISK OF ELECTRIC SHOCK.

CAUTION:

DO NOT OPEN.

Please thoroughly familiarize yourself with the information in this manual

prior to installation and operation.

PELCO Manual C290M-A (6/99) 1

Page 4

2.0 SCOPE

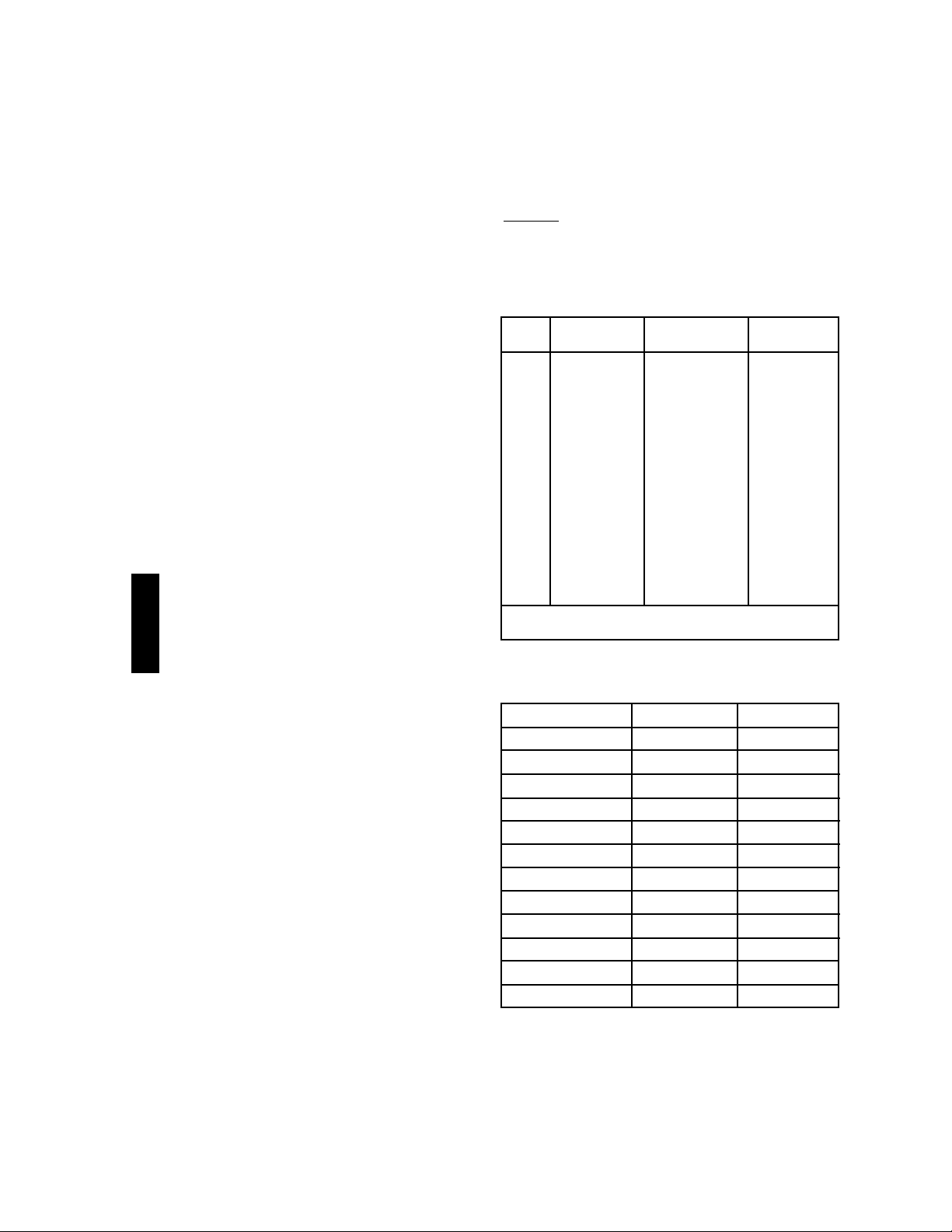

3.1 MODELS

The information contained in this manual covers the

DD08 Series fixed mount for the IDS08 Series Intercept

Domes.

This manual pertains only to the fixed mount. Proceed with installation of the fixed mount and the

camera/lens once back box installation has been

completed.

3.0 DESCRIPTION

The IDS08 Intercept Series of domes allow you to

select any combination of available features to create a

custom dome system. This integral system includes

fixed mount or dome drive (pan/tilt), Coaxitron

receiver/driver and factory installed camera/lens package.

To facilitate this, we use a building-block approach in

assembling the desired components to fulfill the job

requirements. The blocks are broken into four sections.

They are:

1 Dome Drive (DD08)

2 Dome Receiver/Driver (DRD08)

3 Back Box (BB08)

4 Imager/Optics Package (IOP08)

The dome system is shipped in two separate boxes:

1 box containing the Back Box

1 box containing the Dome Drive, Dome, Dome

Receiver/Driver (when ordered) and Imager/

Optics Package (factory assembled)

The model designator is DD08XXX, where each “X”

represents a feature that is essential for operation.

Example: DD08 E 3 0 Dome drive with SL and

presets, variable pan speed,

and black opaque dome

with smoked window

Dome Dome

Model Dome Drive Pan Speed Color

DD08 A= Fixed 0 = None 0 = Blk

mount 1 = 12°/sec opaque

B = 355° 2=24°/sec with

C = 360° SL 3 = Variable* smoked

D= 355° & window

Presets 1 = Blk

E = SL & opaque

Presets with

clear

window

2 = Chrome

3 = Gold

* 0 to >200°/sec

3.2 CERTIFICATIONS

UL CE

DD08A00 X

DD08B10 X X

DD08B11 X X

DD08B20 X X

DD08B21 X X

DD08C20 X X

DD08C21 X X

DD08C30 X X

DD08D11 X X

DD08D20 X X

DD08E30 X X

DD08E31 X X

2 PELCO Manual C290M-A (6/99)

Page 5

4.0 INSTALLATION

4.1.1 INSTALLING FIXED MOUNT

4.1 FIXED MOUNT INSTALLATION AND

REMOVAL

CAUTION

Switch the rocker style power switch

in back box to the OFF position before installing or removing fixed

mount.

No wiring interface is required between the back box

and the fixed mount. All wiring connections are

achieved when the mechanical connection of the

fixed mount is made.

Ensure the fixed mount will interface electrically with

the back box you have chosen to use. Refer to the back

box manual, C456M, if necessary.

To install the fixed mount:

1. Turn off back box power switch, if applicable to

your back box. (See Figure 1 for switch location.)

2. Remove the hairpin style safety pins from the two

latches in the back box (see Figure 2).

3. Remove dome from fixed mount. This is only a

pull apart procedure (refer to Figure 3.)

4. Grasp the fixed mount with two hands as shown in

Figure 4.

5. While lifting the unit up into the back box, find the

two (2) V-opening latches and two (2) guide pins

at the rear of the back box (see Figure 5).

NOTE: Ensure that you install the fixed mount

in correct rotation to the back box so that the

electrical connector on top of fixed mount lines

up with mating connector in back box (see Figure 6).

6. Upon locating the guide pins, wiggle the unit back

and forth to ensure the guide pins are aligned with

the two (2) Delrin bushings on the fixed mount. At

that instant, push the mount up until the two (2) Vshaped latches engage and lock the mount in place

(see Figure 7). Be sure the latches are completely

closed by pulling down on the latch arm as a check.

7. Insert the two hairpin style safety pins previously

removed in step 2 into the latches to prevent inadvertent release of fixed mount from the back box.

8. Install camera/lens of choice, positioning onto

mount with sufficient clearance for dome attachment.

9. Remove lens cap.

10. Install dome onto fixed mount (refer to Figure 3),

aligning window slot of dome with lens.

NOTE: The fixed mount may also be installed/removed (or bicycled) with the camera/

lens already installed on mount, if needed.

PELCO Manual C290M-A (6/99) 3

Page 6

Figure 1. Back Box Power Switch Location

Figure 3. Removing/Attaching Dome to Fixed

Mount

Figure 2. Removing Safety Pins

4 PELCO Manual C290M-A (6/99)

Figure 4. Installing Fixed Mount

Page 7

L = Latch

P = Pin

4.1.2 REMOVING FIXED MOUNT

To remove the fixed mount:

1. Remove the back box bezel/trim ring as described

in back box manual, C456M, and the dome.

2. Turn off back box power switch, if applicable to

your model (see Figure 1).

3. Remove the two hairpin style safety pins from the

back box latches (see Figure 2).

4. Open only one of the latches by pressing the latch

arm with your finger.

5. Grasp the unit with one hand to prepare for the 510 lb (2.27-4.54 kg) load. Now press open the other

latch with your other hand and lower the fixed

mount.

NOTE: When handling the mount please treat

it with care for there are components that could

possibly bend or be damaged.

Figure 5. Guide Pin/Latch Locations

Fixed Mount Electrical Connector Back Box Mating Connector

Figure 6. Fixed Mount/Back Box Electrical Interconnect

PELCO Manual C290M-A (6/99) 5

Page 8

Figure 7. Locking Fixed Mount in Place

5.0 ADJUSTMENTS

To adjust the horizontal and vertical position of the

fixed mount perform the following steps:

1. Remove dome as per instructions in Section 4.1.1,

step 3.

2. Loosen the horizontal positioning lock-down knob;

then rotate mount to the desired position and retighten knob.

3. Loosen the vertical positioning lock-down knob

and adjust tilt table to desired position; then retighten knob.

4. Attach the dome to the drive as described in Section 4.3, step 3, Camera/Lens Installation.

5.1 OPERATION

4.2 LENS WIRING

Refer to back box manual, C456M, for wiring pinouts

and wire lens according to manufacturers instructions .

4.3 CAMERA/LENS INSTALLATION

Install the camera/lens you have selected for use with

the IDS08 series dome as follows:

1. Attach camera/lens to the tilt table using the 1/420 x 1/2" fastener (supplied), mounting through

the tilt table into the camera. Only snug the fastener at this time to allow for camera/lens positioning.

2. Connect camera power spade lugs and coax video

cable.

3. Ensure there is sufficient initial clearance between

the camera/lens and dome as you carefully attach

dome to fixed mount. Align the two (2) ball studs

on the dome to the two (2) ball stud receivers on

the fixed mount and push dome until a snapping

sound occurs (refer to Figure 3).

Upon completion of the fixed mount and camera/lens

installation and positioning adjustments of the fixed

mount, the Intercept Dome is ready for operation.

Reach into the back box and turn the power switch ON

(if applicable to your back box).

CAUTION

The fixed mount should never be installed

or removed when power switch is in the

ON position.

Now attach the bezel or trim ring to the back box as

shown in Figure 8. Align the three bezel pins with the

large hole in the back box brackets; push the bezel up

and rotate clockwise to latch.

Installation of your Intercept Dome is now complete

and dome is ready for operation.

4. Position camera/lens and route wiring as necessary to achieve clearances. This procedure may require removing and reattaching dome a few times

to obtain correct position.

5. After satisfactory clearances have been achieved,

remove dome and tighten camera/lens fastener.

6 PELCO Manual C290M-A (6/99)

Page 9

7.0 SPECIFICATIONS

MECHANICAL

Pan: 360° movement in horizontal plane

Tilt: -90° movement from horizontal

plane

Approximate

Camera/Lens

Size: Maximum total length of camera/

lens 6.50" (16.5 cm), including

BNC cable connection to camera;

max. lens width 4.50" (11.4 cm);

max. lens height 3.25" (8.25 cm)

Figure 8. Bezel Attachment

6.0 CARE AND MAINTENANCE

Regularly scheduled maintenance will prolong the operational life and appearance of the equipment.

IMPORTANT

The acrylic dome is an optical surface.

When cleaning the inner surface of the

dome and viewing window, treat as carefully as you would a fine camera lens.

Do not use liquid of any kind on

coated inner surface of dome.

If dust or other debris accumulates on the inside of the

lower dome, remove with clean air pressure only. Compressed air cans are available from commercial photographic equipment and supply dealers.

Connectors

Video: BNC

Camera Power: Spade lugs

GENERAL

Construction

Fixed Mount: Aluminum with stainless steel

hardware

Lower Dome: Acrylic hemisphere available in

the following types:

Black opaque with smoked window (1 f-stop light loss)

Black opaque with clear window

(virtually zero light loss)

Chrome or Gold (2 f-stop light

loss)

Weight: 2 lbs 4.8 oz. (1.04 kg).

Clean the outer surface of the dome and the inner

surface of the viewing window with a non-abrasive cleaning cloth and anti-static cleaner that is safe for

use on acrylic plastic. Do not use kerosene or similar

substances that can scratch the surface.

PELCO Manual C290M-A (6/99) 7

Page 10

8.0 EXPLODED ASSEMBLY DIAGRAM

Figure 9. DD08 Fixed Mount Exploded Assembly Diagram

8 PELCO Manual C290M-A (6/99)

Page 11

8.1 MECHANICAL PARTS LIST

The following parts list corresponds to the exploded assembly diagram in Figure 9.

Item No. Quantity Description Part Number

1 2 Bushing, delrin 3/8" ID x 5/8" OD 80010004

2 2 Push nut, .625" OD 80010011

3 1 Bracket, drive mount, upper 8004034COMP

4 1 Connector, receptacle, 25 position CON10J025Z41T

5 1 Bracket, spindle, fixed mount 8004037COMP

6 1 Tilt table, fixed mount 8004021COMP

7 1 Frame 8", fixed mount 8004022COMP

8 2 Pin, latch, dome drive 8004145COMP

9 1 Dome, 8-1/2", acrylic

Black opaque w/smoked viewing window 80810011-0

Black opaque w/clear viewing window 80810011-1

Chrome finish f/2 80810011-2

Gold finish f/2 80810011-3

10 2 Ball stud PT180410000

11 2 Knob, grey, 1/4-20 tapped CM1610003

12 2 Receiver, ball stud PT180410001

13 6 Pin, crimp, loose piece (not shown) CON66107-2

(for use with item #4)

14 1 Connector, BNC, crimp, for RG174 coax CONCPM88-174

(not shown)

8.2 ASSOCIATED HARDWARE

Item No. Quantity Description Part Number

A 2 Screw 1/4-20 x 1" flat hd phil, SS ZH1/420X1.00SFS

B 1 Screw 1/4-20 x 1" soc hd c/s,SS ZH1/420X1.00SS

C 1 Nut, lock, hex, 1/4-20, nylon insert, SS ZH1/420NUTCHN

D 2 Screw 6-32 x 3/8" pan hd phil, SS ZH6-32X.375SPP

E 4 Washer, internal star #6, SS ZH6LWSIS

F 2 Screw 6-32 x 1/2" pan hd phil, SS ZH6-32X.500SPP

G 4 Screw 8-32 x 1/2" pan hd phil, SS ZH8-32X.500SPP

H 4 Washer, internal star #8, SS ZH8LWSIS

I 2 Screw 6-32 x 3/8" flat hd phil, black oxide ZH6-32X.375BPF

J 2 Spacer, 1/4" hex x 1/2" L, 6-32 tapped SPA8423

K 1 Washer, fender, 1/4 x 1.5 x 14 ga, black oxide ZH255X1.50X62

L 1 Washer, split lock, 1/4" SS ZH1/4LWSSL

PELCO Manual C290M-A (6/99) 9

Page 12

9.0 WARRANTY AND RETURN

INFORMATION

WARRANTY AND RETURN INFORMATION

WARRANTY

Pelco will repair or replace, without charge, any merchandise proved defective in material

or workmanship for a period of one year after the date of shipment.

Exceptions to this warranty are as noted below:

• Five years on FT/FR8000 Series fiber optic products.

• Three years on Genex® Series products (multiplexers, server, and keyboard).

• Three years on Camclosure® and fixed camera models, except the CC3701H-2,

CC3701H-2X, CC3751H-2, CC3651H-2X, MC3651H-2, and MC3651H-2X camera

models, which have a five-year warranty.

• Two years on standard motorized or fixed focal length lenses.

• Two years on Legacy®, CM6700/CM6800/CM9700 Series matrix, and DF5/DF8 Series

fixed dome products.

• Two years on Spectra®, Esprit®, ExSite™, and PS20 scanners, including when used in

continuous motion applications.

• Two years on Esprit® and WW5700 Series window wiper (excluding wiper blades).

• Eighteen months on DX Series digital video recorders, NVR300 Series network video

recorders, and Endura™ Series distributed network-based video products.months on DX

Series digital video recorders, NVR300 Series network video recorders, Endura™ Series

distributed network-based video products, and TW3000 Series twisted pair transmission

products.

• One year (except video heads) on video cassette recorders (VCRs). Video heads will be

covered for a period of six months.

• Six months on all pan and tilts, scanners or preset lenses used in continuous motion

applications (that is, preset scan, tour and auto scan modes).

Pelco will warrant all replacement parts and repairs for 90 days from the date of Pelco

shipment. All goods requiring warranty repair shall be sent freight prepaid to Pelco, Clovis,

California. Repairs made necessary by reason of misuse, alteration, normal wear, or

accident are not covered under this warranty.

Pelco assumes no risk and shall be subject to no liability for damages or loss resulting

from the specific use or application made of the Products. Pelco’s liability for any claim,

whether based on breach of contract, negligence, infringement of any rights of any party

or product liability, relating to the Products shall not exceed the price paid by the Dealer to

Pelco for such Products. In no event will Pelco be liable for any special, incidental or

consequential damages (including loss of use, loss of profit and claims of third parties)

however caused, whether by the negligence of Pelco or otherwise.

The above warranty provides the Dealer with specific legal rights. The Dealer may also

have additional rights, which are subject to variation from state to state.

If a warranty repair is required, the Dealer must contact Pelco at (800)289-9100 or

(559) 292-1981 to obtain a Repair Authorization number (RA), and provide the following

information:

1. Model and serial number

2. Date of shipment, P.O. number, Sales Order number, or Pelco invoice number

3. Details of the defect or problem

If there is a dispute regarding the warranty of a product which does not fall under the

warranty conditions stated above, please include a written explanation with the product

when returned.

Method of return shipment shall be the same or equal to the method by which the item

was received by Pelco.

RETURNS

In order to expedite parts returned to the factory for repair or credit, please call the factory

at (800) 289-9100 or (559) 292-1981 to obtain an authorization number (CA number if

returned for credit, and RA number if returned for repair).

All merchandise returned for credit may be subject to a 20% restocking and refurbishing

charge.

Goods returned for repair or credit should be clearly identified with the assigned CA or RA

number and freight should be prepaid. Ship to the appropriate address below.

If you are located within the continental U.S., Alaska, Hawaii or Puerto Rico, send goods

to:

If you are located outside the continental U.S., Alaska, Hawaii or Puerto Rico and are

instructed to return goods to the USA, you may do one of the following:

If the goods are to be sent by a COURIER SERVICE, send the goods to:

If the goods are to be sent by a FREIGHT FORWARDER, send the goods to:

Service Department

Pelco

3500 Pelco Way

Clovis, CA 93612-5699

Pelco

3500 Pelco Way

Clovis, CA 93612-5699 USA

Pelco c/o Expeditors

473 Eccles Avenue

South San Francisco, CA 94080 USA

Phone: 650-737-1700

Fax: 650-737-0933

® Pelco, the Pelco logo, Spectra, Esprit, Genex, Legacy, and Camclosure are registered trademarks of Pelco.

™ Endura and ExSite are trademarks of Pelco. © Copyright 1999, Pelco. All rights reserved.

10 PELCO Manual C290M-A (6/99)

Loading...

Loading...