Page 1

CAMERA SYSTEMS

PRODUCT SPECIFICATION

®

ICS300 SERIES WALL/CEILING

IP66

300 Series Camclosure™ Camera System

INTEGRATED CAMERA SYSTEM, INDOOR/OUTDOOR, WALL OR CEILING

Product Features

• Fully-Integrated Enclosure With Camera and Lens Package

• Rugged, Impact- and Vandal-Resistant

• Easy to Install

• Versatile, Aesthetically Pleasing “Track Light” Design,

Mounts to Wall or Ceiling

• Tamper-Resistant Hardware

• Concealed Cabling

• 12 VDC or 24 VAC Operation

• Low-Temperature Operation to -50°F (-46°C); de-ices to

-10°F (-23°C)

• Clear Window

• NTSC/PAL or EIA/CCIR Camera Formats

• All Color Cameras Feature Digital Signal Processing

• Fixed Focal Length Lens of 2.9 mm, 6 mm, 8 mm, or 12 mm

• Varifocal Lens of 3 mm to 6 mm with Auto Iris, Available

with High Resolution Color Camera

• AC Line Lock with All Color Cameras in 24 VAC Operation

• All Lenses, Except Varifocals, are Pre-focused at the

Factory

• Meets NEMA 4X and IP66 Standards (when installed)

• Optional Conduit Adapter Available

300 SERIES

CAMCLOSURE

The 300 Series Camclosure™ Integrated

Camera System incorporates a camera and lens

package into a small, unobtrusive, medium-security

enclosure. The system is quick and easy to install in a

variety of indoor or outdoor applications. It is ideal for

residential, office, mall, hospital, school, parking

garage, correction and detention, and other mediumsecurity installations subject to vandalism.

The 300 Series System ships with a sun shroud

and 4S adapter plate to mount the unit to a standard

4-square electrical box. The sun shroud is designed for

outdoor installations and reduces internal temperature

by 10 degrees F (6 degrees C). An optional conduit

adapter (ICS300-COND) allows the unit to be used in

applications requiring conduit.

All models are designed for either 12 VDC or 24 VAC

operation. Each unit is provided with two quickconnect mating connectors with leads; one for 12 VDC

and one for 24 VAC. Just select the appropriate

connector for your application, wire the leads to your

power source with wing nuts, and snap the connectors

together -- it’s that simple!

Camera options include 1/3-inch format CCD color

imager (standard or high resolution) and monochrome

imager (standard resolution) with fixed focal length

lenses of 2.9 mm, 6 mm, 8 mm, and 12 mm. Cameras

with a varifocal lens have a 1/4-inch format high

resolution CCD color imager.

International Standards Organization Registered Firm ISO 9001 Quality System

DataFAX Documents SPEC: 22408 MANUAL: 224086 (ICS300), 22966 (ICS300-COND)

(Product specifications and manuals also available through Pelco Online at www.pelco.com)

C2408/REVISED 10-00

25

Page 2

CAMERA SYSTEMS

TECHNICAL SPECIFICA TIONS

ICS300 SERIES WALL/CEILING

ELECTRICAL

Input Voltage 12 VDC or 24 VAC (±10%)

Camera <3 watts

Heaters 10 watts when active; thermostati-

cally controlled

Video Connector BNC

GENERAL

Pan/Tilt Adjustment Manual

180° pan; 180° tilt

Construction Aluminum base and cover, steel

camera mounting bracket

Environmental

Environment Low temperature, indoor/outdoor

Operating Temperature -50° to 122 °F (-46° to 50°C);

de-ices at -10°F (-23°C)

Thermostat Operation Heater is thermostatically

controlled to activate

ON at 50°F (10°C) and

OFF at 80°F (27°C)

PHYSICAL

Finish Gray polyester powder coat

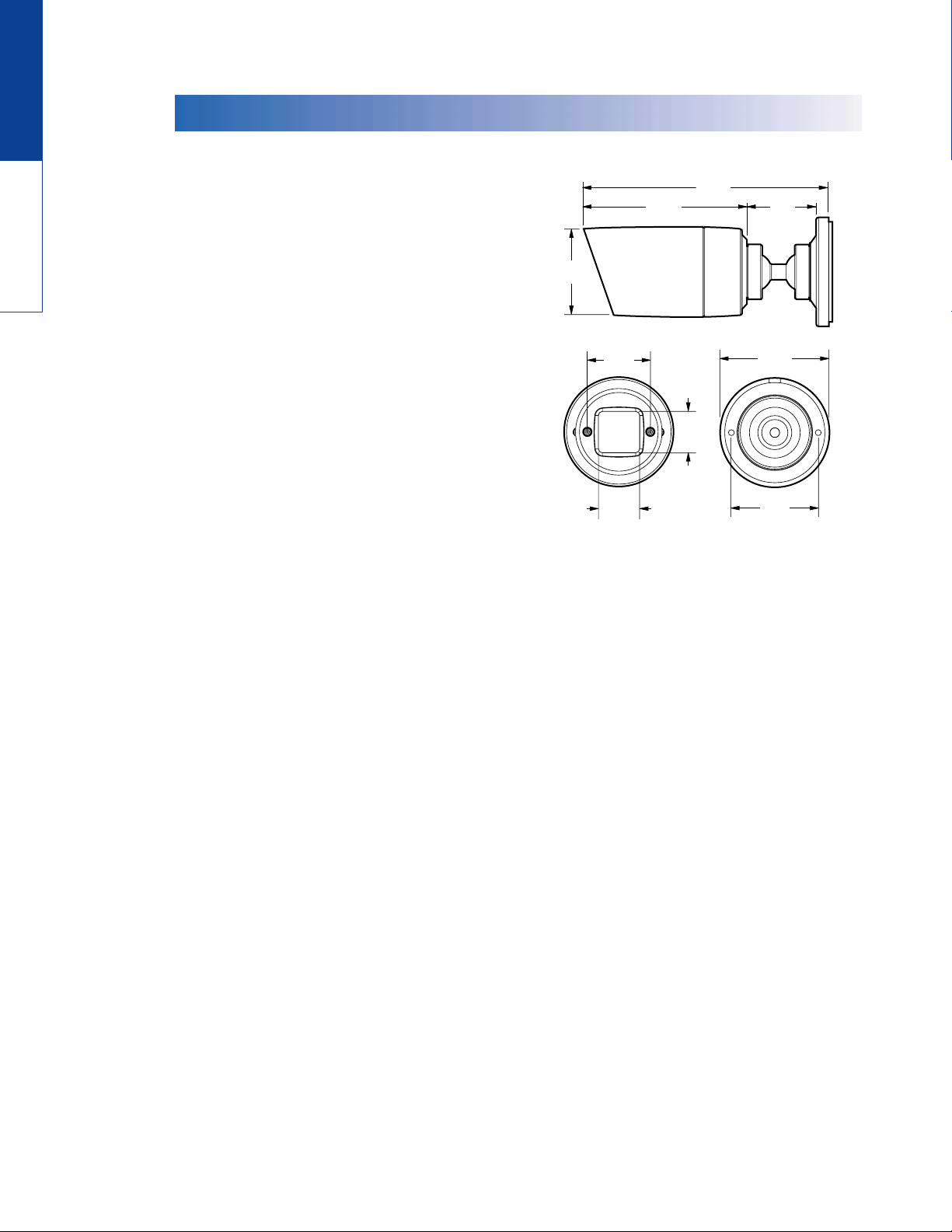

Dimensions

Camclosure 2.71 (diameter) x 7.79 (L) inches

(6.88 x 19.79 cm)

Sun Shroud 2.60 (H) x 6.13 (L) inches

(5.23 x 15.57 cm)

Snap fit design mounts sun shroud

to enclosure

Unit Weight 1.45 lb (0.66 kg)

Shipping Weight 2.0 lb (0.90 kg)

7.40

(18.79)

5.18

(13.20)

3.00

(7.62)

2.00

(5.08)

1.31

(3.32)

1.30

(3.30)

WINDOW VIEW BASE VIEW

NOTE: VALUES IN PARENTHESES ARE CENTIMETERS;

ALL OTHERS ARE INCHES.

2.21

(5.61)

3.48

(8.84)

2.76

(7.01)

CERTIFICATIONS/RATINGS

◆ CE and FCC, Class A (models with monochrome cameras

only, excluding auto iris models)

◆ CE and FCC, Class B (models with color cameras only,

excluding auto iris models)

◆ UL listed to Standard 2044

◆ cUL to CSA C22.2 No.1

◆ Meets IP66 when installed properly

◆ Meets NEMA 4X when installed properly, includes:

– Corrosion protection test; NEMA 250, Section 6.9

(exceeds IEC 68-2-11)

– Rust resistance test; NEMA 250, Section 6.8

– Hose down test; NEMA 250, Section 6.7

– Exceeds SAE J1211 dust test

◆ Tested in accordance with MIL-STD 810E as follows:

– Shock test; Section 516.4 (exceeds IEC 68-2-27)

– Humidity test; Sections 520.1 and 507.3 (exceeds IEC

68-2-30)

– Vibration test, Section 514.4 (exceeds IEC 68-2-6)

◆ ASTM Shipping Standard

◆ ISTA Shipping Standard

All tests are performed in accordance with ISO Guide 25

and ANSI/NCSL Z540-1

26

Page 3

TECHNICAL SPECIFICA TIONS

CAMERA SYSTEMS

ICS300 SERIES WALL/CEILING

CAMERA SPECIFICATIONS

Black & White Color Color Color

Standard Resolution Standard Resolution High Resolution, Fixed Focal Lens High Resolution, Varifocal Lens

(Models ICSxxx-MAx/ (Models ICSxxx-CAx/ (Models ICSxxx-CRx/ (Models ICSxxx-CRVx/

ICSxxx-MCx) ICSxxx-CCx) ICSxxx-CSx) ICSxxx-CSVx)

Signal System EIA or CCIR NTSC or PAL NTSC or PAL NTSC or PAL

Imaging Device 1/3-inch CCD 1/3-inch Interline Color CCD 1/3-inch Interline Color CCD 1/4-inch Interline Color CCD

Scanning System 2:1 Interlace 2:1 Interlace 2:1 Interlace 2:1 Interlace

Sync System Internal 12 VDC: Inter nal 12 VDC: Internal 12 VDC: Internal

Horizontal

Resolution EIA: 420 TV lines NTSC: 350 TV lines NTSC: 470 TV lines NTSC: 480 TV lines

CCIR: 420 TV lines PAL: 350 TV lines PAL: 460 TV lines PAL: 480 TV lines

Signal-to-Noise

Ratio 50 dB 48 dB 48 dB 48 dB (AGC Off)

Min. Illumination

Sensitivity 0.1 lux (f2.0) 1 lux (f2.0) 1 lux (f2.0) Less than 1.2 lux (f1.2)

Video Out 1 Vp-p Composite 1 Vp-p Composite 1 Vp-p Composite 1 Vp-p Composite

(75 ohm) (75 ohm) (75 ohm) (75 ohm)

Gain Control Auto Auto NTSC: Auto On/Off by DIP switch

Exposure Electronic Shutter Electronic Shutter Electronic Shutter Electronic Shutter

(1/60 - 1/100,000) (1/60 - 1/100,000) (1/60 - 1/100,000) (1/60 - 1/100,000)

White Balance (not applicable) Auto NTSC: Auto Auto

Backlight

Compensation Auto ON, OFF (switchable) NTSC: Auto Auto; adjusts AGC and AES

Power Source* 12 VDC, 24 VAC 12 VDC, 24 VAC 12 VDC, 24 VAC 12 VDC, 24 VAC

*24 VAC power is recommended when installing any Camclosure

24 VAC: External (VD Lock) 24 VAC: External (VD Lock) 24 VAC: External (VD Lock)

™

Integrated Camera System under flourescent lighting conditions.

(Super HAD)

PAL: Manual (0-20dB)

PAL: Manual

PAL: Manual On/Off

CAMCLOSURE

LENS SPECIFICATIONS

Fixed Focal Length Lenses Varifocal Lens

Color B/W Color B/W Color B/W Color B/W

Focal Length 2.9 mm 3.0 mm 6.0 mm 8.0 mm 12.0 mm 3.0 to 6.0 mm

Format Size 1/3-inch 1/3-inch 1/3-inch 1/3-inch 1/4-inch

Relative Aperture (F) 2.0 1.8 2.5 1.8 2.5 2.0 1.2 to 1.5

Operation

Iris Fixed Fixed Fixed Fixed Auto (f1.2 to f300)

Focus N/A N/A N/A N/A Manual (minimum 50 cm)

Zoom N/A N/A N/A N/A Manual

Angle of View**

Horizontal 90° 87° 42° 38° 32° 29° 21° 72° to 36°

Diagonal — — — — — — — — 96° to 46°

Vertical 69° 67° 33° 30° 25° 23° 17° 52° to 26°

**Focal length specifications presume a 10% Horizontal and 4% Vertical monitor overscan.

27

Page 4

CAMERA SYSTEMS

CAMCLOSURE

ICS300 SERIES WALL/CEILING

MODEL NUMBERS

®

300 SERIES SYSTEM MODELS

Camera Type Lens/Iris NTSC PAL EIA CCIR

Color, 2.9 mm ICS300-CR3 ICS300-CS3 — —

High Resolution 6 mm ICS300-CR6 ICS300-CS6 — —

8 mm ICS300-CR8 ICS300-CS8 — —

12 mm ICS300-CR12 ICS300-CS12 — —

3-6 mm with Auto Iris ICS300-CRV3A ICS300-CSV3A — —

Color, 2.9 mm ICS300-CA3 ICS300-CC3 — —

Standard Resolution 6 mm ICS300-CA6 ICS300-CC6 — —

8 mm ICS300-CA8 ICS300-CC8 — —

12 mm ICS300-CA12 ICS300-CC12 — —

B&W, 3.0 mm — — ICS300-MA3 ICS300-MC3

Standard Resolution 6 mm — — ICS300-MA6 ICS300-MC6

8 mm — — ICS300-MA8 ICS300-MC8

12 mm — — ICS300-MA12 ICS300-MC12

OPTIONS

ICS300-COND Conduit adapter. Can be adapted

1.73

(4.39)

4.36

(11.07)

NOTE: VALUES IN PARENTHESES ARE CENTIMETERS;

ALL OTHERS ARE INCHES.

to any vertical or horizontal

mounting surface.

4.20

(10.67)

5.00

12.7

RECOMMENDED POWER SUPPLIES

(For use with 24 VAC models only)

TF2000 Power supply for 24 VAC

MCS Series Multiple 24 VAC camera power

MCS*E Series Multiple 24 VAC camera power

WCS Series Multiple 24 VAC camera power

cameras, 20 vA. (For single

camera application.)

supply, indoor. (For multiple

camera application.)

(See C653

spec)

supply, indoor. (For multiple

camera application.)

(See C655

spec)

supply, outdoor. (For multiple

camera application.)

(See C654

spec)

28

Indicates change or addition since last revision.

Pelco • 3500 Pelco Way • Clovis, CA 93612-5699 • Pelco Online @ www. pelco.com

In the US and Canada: Tel (800) 289-9100 • FAX (800) 289-9150 • DataFAX (800) 289-9108

International Customers: Tel +1(559) 292-1981 • FAX +1(559) 348-1120 • DataFAX +1(559) 292-0435

Camclosure™ is a trademark of Pelco.

Specifications subject to change without notice.

©Copyright 2000, Pelco. All rights reserved.

Loading...

Loading...