Page 1

INSTALLATION/OPERATION

100 Series Camclosure

®

Integrated Camera System

®

With LowLight™ DSS Technology

C2460M-A (7/03)

Page 2

CONTENTS

Section Page

IMPORTANT SAFEGUARDS AND WARNINGS.............................................................................................. 3

REGULATORY NOTICES ...................................................................................................................... 3

WELCOME ................................................................................................................................................... 4

INSTALL THE BACK BOX ............................................................................................................................. 5

REMOVE THE LOWER DOME ............................................................................................................. 5

INSTALL THE BACK BOX .................................................................................................................... 5

ATTACH DIRECTLY TO A WALL/CEILING ................................................................................. 5

ATTACH DIRECTLY TO CONCRETE WALL/CEILING.................................................................. 6

ATTACH TO A 4S ELECTRICAL BOX ......................................................................................... 6

MOUNT TO A PLASTER RING .................................................................................................. 7

CONNECT POWER WIRES ........................................................................................................................... 8

INSTALL THE CAMERA MODULE ................................................................................................................ 9

CHECK HEATER JUMPER ................................................................................................................... 9

INSTALL AND POSITION THE CAMERA ........................................................................................... 10

MAKE CAMERA SETTINGS ......................................................................................................................... 11

ZOOM/FOCUS ................................................................................................................................... 11

DIGITAL SLOW SHUTTER (DSS)........................................................................................................ 11

AGC (AUTOMATIC GAIN CONTROL) ................................................................................................. 12

BLC (BACK LIGHT COMPENSATION) ................................................................................................ 12

VERTICAL PHASE ADJUSTMENT (24 VAC OPERATION ONLY) ........................................................ 12

HOW TO ADJUST THE PHASE CONTROL ............................................................................... 12

VARIFOCAL LENS AUTO IRIS LEVEL ADJUSTMENT ........................................................................ 12

REINSTALL THE LOWER DOME AND TRIM RING ....................................................................................... 13

SPECIFICATIONS ........................................................................................................................................ 14

WARRANTY AND RETURN INFORMATION.................................................................................................. 15

LIST OF ILLUSTRATIONS

Figure Page

1 Installation Directly to a Wall/Ceiling .......................................................................................... 5

2 Installation Directly to a Concrete Wall/Ceiling ........................................................................... 6

3 Installation on a 4S Electrical Box ................................................................................................ 6

4 Mounting to a Plaster Ring ........................................................................................................... 7

5Terminal Block for Input Power ..................................................................................................... 8

6 Heater Jumper and Camera Connector Locations ........................................................................ 9

7 Default Switch Settings and Location of Camera Adjustments .................................................. 11

8 Window Adjustment .................................................................................................................... 13

2 C2460M-A (7/03)

Page 3

IMPORTANT SAFEGUARDS AND WARNINGS

1. Installation and servicing should be done only by qualified service personnel and conform to all

local codes.

2. Unless the unit is specifically marked as a NEMA Type 3, 3R, 3S, 4, 4X, 6, or 6P enclosure, it is

designed for indoor use only and must not be installed where exposed to rain and moisture.

3. Use only installation methods and materials capable of supporting four times the maximum

specified load.

4. Use stainless steel hardware to fasten the enclosure to outdoor surfaces.

5. To prevent damage from water leakage when installing an enclosure outdoors, apply sealant

around the bolt holes between the enclosure and mounting surface.

CAUTION

Heater elements could be hot! When camera power is on, use caution

when adjusting the camera.

REGULATORY NOTICES

This equipment has been tested and found to comply with the limits of a Class B digital device,

pursuant to part 15 of the FCC rules. These limits are designed to provide reasonable protection

against harmful interference in a residential installation. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with the instructions,

may cause harmful interference to radio communications. However there is no guarantee that the

interference will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning the equipment off

and on, the user is encouraged to try to correct the interference by one or more of the following

measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and the receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

• Consult the dealer or an experienced radio/TV technician for help.

C2460M-A (7/03) 3

Page 4

WELCOME

Thank you for purchasing Pelco’s Camclosure® integrated camera system with LowLight™, DSS

(digital slow shutter) technology. Your new ICS100 Series surface mount dome system includes a

high-resolution, low light, color camera with auto iris and varifocal lens.

The LowLight color camera has extended DSS settings to enhance the low light performance of the

camera by automatically adjusting the number of fields of integration. This slows the picture frame

rate and increases the camera’s sensitivity in low light conditions.

Prior to installation and operation of your new system thoroughly familiarize yourself

with the information in this manual.

4 C2460M-A (7/03)

Page 5

INSTALL THE BACK BOX

REMOVE THE LOWER DOME

Loosen the tamper-resistant screws with the supplied 1/8-inch hollow screwdriver bit. Remove the

lower dome and place it to the side.

INSTALL THE BACK BOX

IMPORTANT

The installation methods for the ICS100 back box

include the following:

• Attach Directly to a Wall/Ceiling

• Attach Directly to a Concrete Wall or Ceiling

• Attach to a 4S Electrical Box

• Mount to a Plaster Ring

Select the best method for your installation, and

then refer to the following pages for instructions.

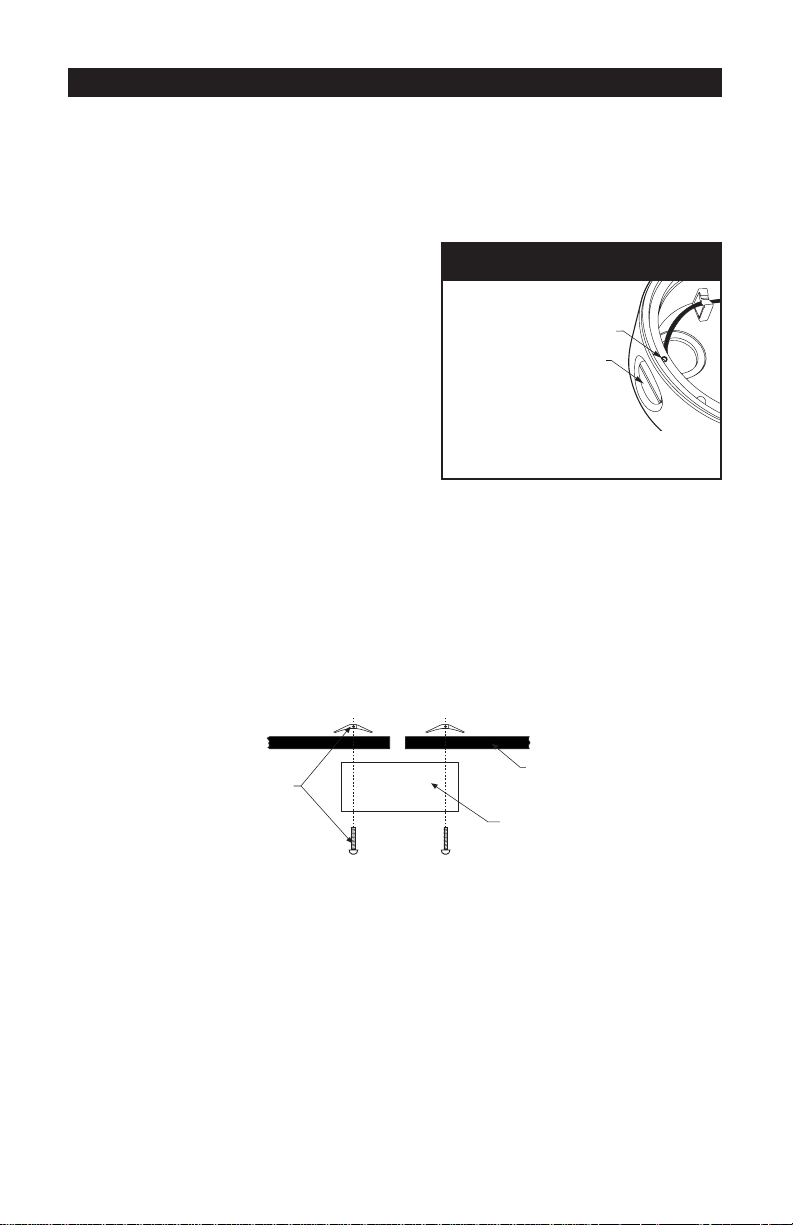

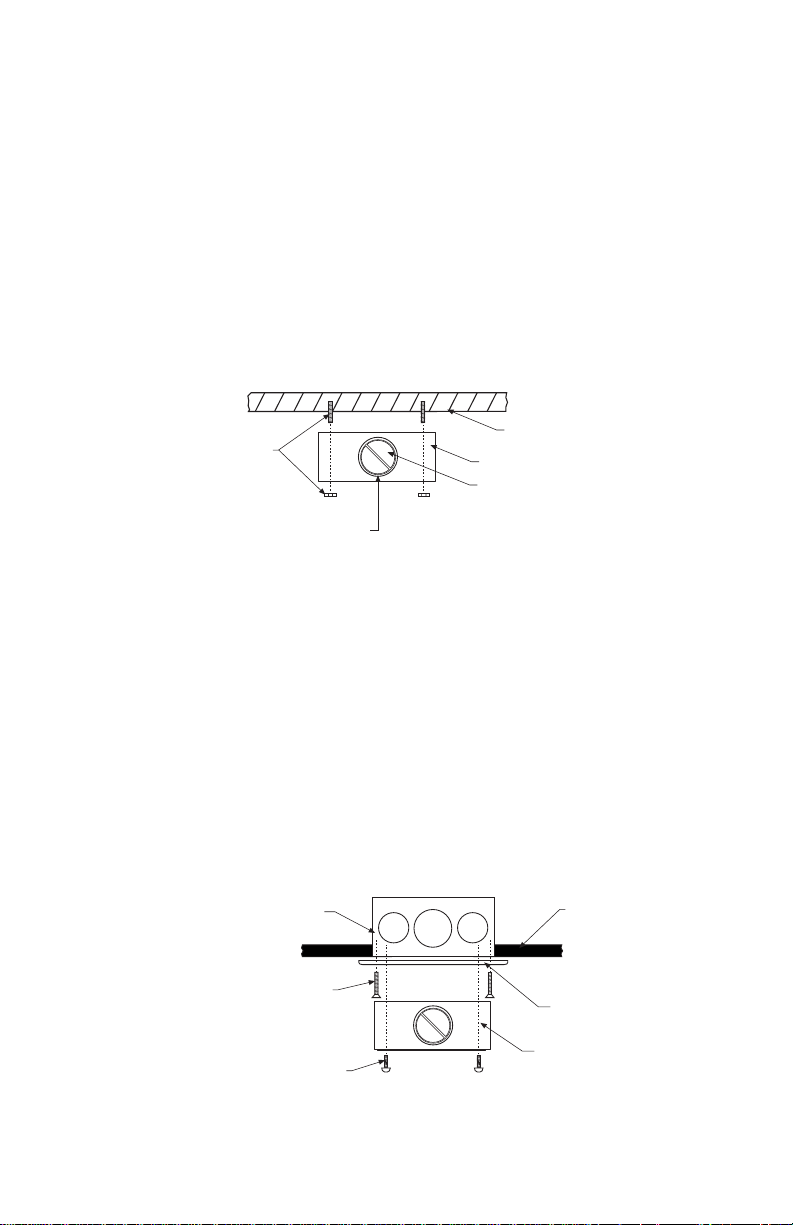

Attach Directly to a Wall/Ceiling

Refer to Figure 1 for the following steps.

1. Cut a small hole in the ceiling or wall and pull video and power wires into the base.

2. Attach the back box to the wall/ceiling (hardware not supplied).

3. Connect the video cable.

MOUNTING

HARDWARE

(NOT SUPPLIED)

To maximize tamper

resistance

when not

using the

side conduit

SET SCREW

CONDUIT

PLUG

opening for

wire connections,

verify that the conduit

plug and set screw are tight.

WALL OR

CEILING

BASE

Figure 1. Installation Directly to a Wall/Ceiling

C2460M-A (7/03) 5

Page 6

Attach Directly to Concrete Wall/Ceiling

Refer to Figure 2 for the following steps.

1. Attach the base to the wall or ceiling (hardware not supplied).

2. Do one of the following:

Not Using Side Conduit Opening - Verify the set screw and side conduit cover are tight.

Using Side Conduit Opening - Loosen the set screw and remove the conduit plug. Install a

3/4-inch (1.91 cm) conduit fitting and tighten the set screw.

3. Connect the video cable.

MOUNTING

HARDWARE

(NOT SUPPLIED)

SET SCREW

CONCRETE WALL

OR CEILING

BASE

CONDUIT PLUG

Figure 2. Installation Directly to a Concrete Wall/Ceiling

Attach to a 4S Electrical Box

Refer to Figure 3 for the following steps. The installation instructions assume that the 4S electrical

box was previously installed.

1. Attach the ICS100-AP adapter plate (not supplied) to the 4S box with the two 8-32 x .750-inch

flat head screws supplied.

2. Pull video and power wires into the base, and attach the base to the adapter plate with the

three 8-32 x .375-inch pan head screws supplied.

3. Connect the video cable.

4S ELECTRICAL

BOX

8-32 X .750 FLAT HEAD

SCREW (SUPPLIED)

WALL OR

CEILING

ADAPTER PLATE

8-32 X .375 PAN HEAD

SCREW (SUPPLIED)

BASE

Figure 3. Installation on a 4S Electrical Box

6 C2460M-A (7/03)

Page 7

Mount to a Plaster Ring

Refer to Figure 4 for the following steps. Installation instructions assume that the 4S electrical box

and plaster ring were previously installed.

1. Pull video and power wires into the base.

2. Attach the base to the plaster ring.

- Use the two 8-32 x .750-inch pan head screws to attach the base to a 401 plaster ring.

- Use the three 6-32 x .750-inch pan head screws to attach the base to a 404 plaster ring.

3. Connect the video cable.

4S ELECTRICAL

BOX

SCREW (SUPPLIED);

SEE TEXT FOR SIZE

Figure 4. Mounting to a Plaster Ring

WALL OR

CEILING

401 OR 404

PLASTER RING

BASE

C2460M-A (7/03) 7

Page 8

CONNECT POWER WIRES

Depending on the input voltage, connect either the 12 VDC or 24 VAC input power wires to the

terminal block inside the base. Refer to Figure 5 for the location of the terminal block.

DC Operation – Refer to the enlarged portion of Figure 5 for the 12 VDC (+) and ground (-)

connections.

AC Operation – It does not matter which terminals the power wires are connected to. However, if

you are wiring more than one Camclosure system to the same transformer, connect one side of the

transformer to the same terminal on all units, and connect the other side of the transformer to the

remaining terminal. Failure to connect all of the units the same way will cause the cameras to be

out of phase with each other and may produce a vertical roll when switching between cameras.

Figure 5. Terminal Block for Input Power

8 C2460M-A (7/03)

Page 9

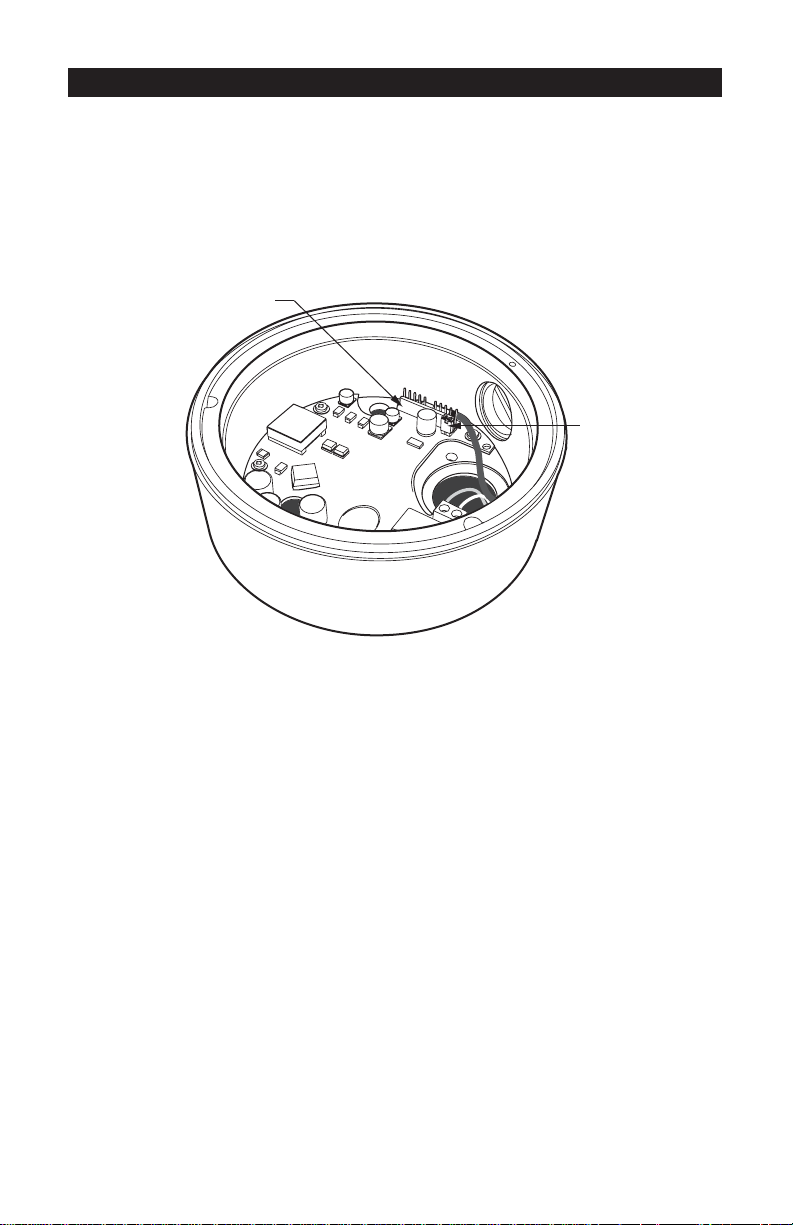

INSTALL THE CAMERA MODULE

CHECK HEATER JUMPER

The Camclosure is equipped with a heater to defrost the dome. Some installations may not require

this heater. If the unit will never be subjected to a frost temperature, you can disable the heater,

saving power requirements. To disable the heater, remove the jumper cover from the J1 jumper

block (refer to Figure 6). It is recommended that the jumper cover be left in the unit by installing it

on one of the jumper pins.

CAMERA CONNECTOR

J1 JUMPER

Figure 6. Heater Jumper and Camera Connector Locations

C2460M-A (7/03) 9

Page 10

INSTALL AND POSITION THE CAMERA

1. Plug the video connector from the camera into the mating connector inside the back box (refer

to Figure 6).

2. Position the camera so that the tab on the camera bracket is pointing out of the enclosure,

away from the ceiling or wall. Refer to the following illustrations for proper camera orientation.

CAMERA BRACKET

TAB ALWAYS POINTS

OUT OF THE

ENCLOSURE

TOP OF

CAMERA

CAMERA BRACKET

TAB ALWAYS POINTS

OUT OF THE

ENCLOSURE

Wall Mounting – The camera bracket

tab points out of the enclosure and the

top of the camera points up towards

the tab.

Ceiling Mounting – The camera bracket

tab points out of the enclosure and the top

of the camera is pointed in the opposite

direction.

3. Install the camera bracket. Gently squeeze the bracket, place it against the shoulder inside the

back box, and gently release.

4. Turn on power to the camera and monitor.

10 C2460M-A (7/03)

Page 11

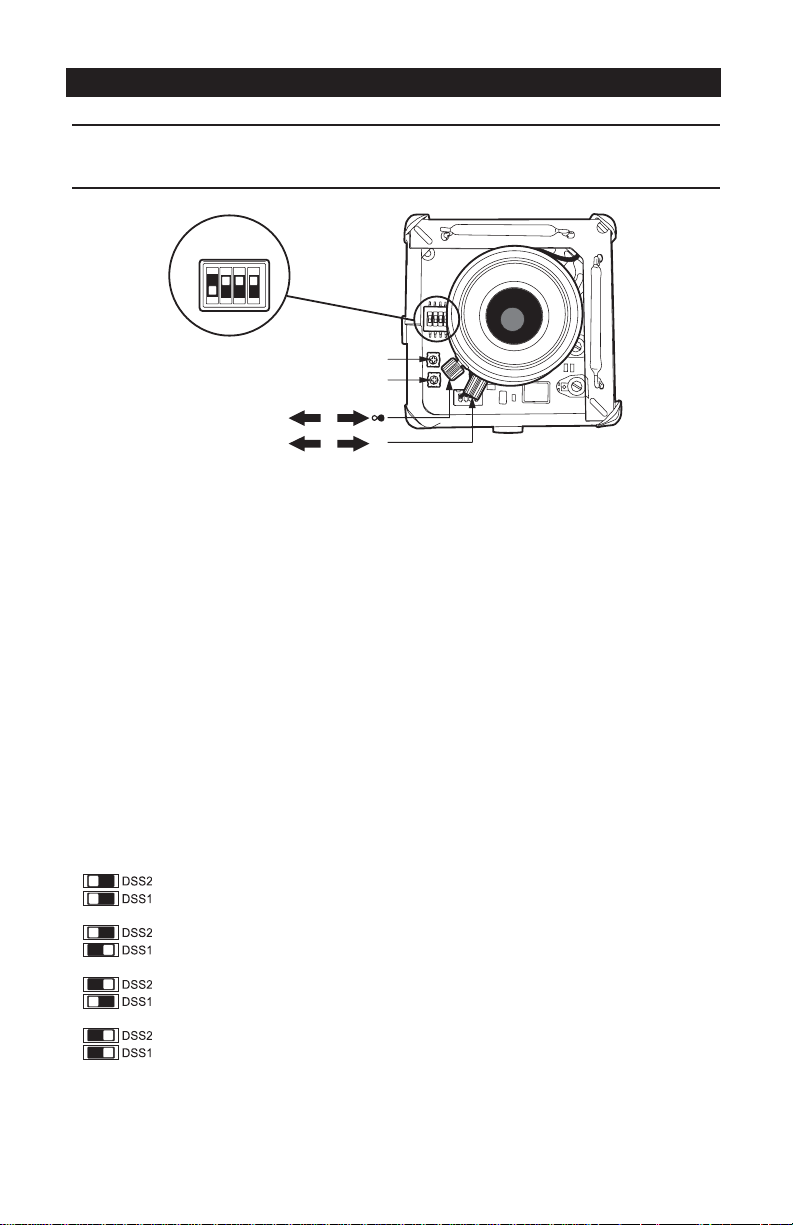

MAKE CAMERA SETTINGS

CAUTION: Heater elements could be hot! When camera power is on, use caution when adjusting

the camera. This applies to all models.

DSS2

DSS1

AGC

BLC

ON

OFF

WHITE INDICATES

SWITCH SETTING

N

W

ZOOM

FOCUS

LEVEL

PHASE

T

Figure 7. Default Switch Settings and Location of Camera Adjustments

ZOOM/FOCUS

1. Select a field of view by turning the zoom adjustment ring. Refer to Figure 7.

2. Tighten the zoom locking screw.

3. Adjust the focus by moving the focus locking screw clockwise/counterclockwise.

4. Tighten the focus locking screw.

DIGITAL SLOW SHUTTER (DSS)

Digital slow shutter slows the picture frame rate and increases the camera sensitivity under low

light conditions. Depending on the number of fields of integration, the picture will develop a

granular appearance and motion may show some lag, resulting in a stereoscopic effect or streaking

on fast moving objects. These effects increase as the number of fields of integration increase.

Available settings include the following:

ON OFF

30 fields of integration maximum (default setting) – 1/2-second scene update rate.

16 fields of integration maximum – 1/4-second scene update rate.

4 fields of integration maximum – 1/15-second scene update rate.

OFF – Disables the DSS mode.

Digital slow shutter automatically adjusts the number of fields of integration depending on the light

level of the viewed scene, up to the maximum determined by the switch settings.

C2460M-A (7/03) 11

Page 12

AGC (AUTOMATIC GAIN CONTROL)

AGC automatically adjusts the image to compensate for changes in light levels.

ON (Default setting) – Enables the AGC mode.

OFF – Disables the AGC mode.

BLC (BACK LIGHT COMPENSATION)

The BLC (backlight compensation) feature compensates for backlit scenes by enhancing objects in

the center of the scene.

OFF (Default setting) – Disables the BLC mode.

ON – Enables the BLC mode. Use this setting if a bright backlight is present and the subject in the

center of the picture appears dark or as a silhouette.

VERTICAL PHASE ADJUSTMENT (24 VAC OPERATION ONLY)

When using more than one camera power supply, a brief vertical roll may occur on the monitor

when a camera view is switched. To eliminate vertical roll reverse the 24 VAC connections on one

camera. If both cameras are connected to the same transformer, this should solve the problem. If

reversing the connections does not solve the problem, adjust the phase control by synchronizing, or

line-locking, the cameras to one another.

How to Adjust the Phase Control

It may be necessary to have two people in communication when synchronizing the cameras: one

person at the camera and another person at the monitor to observe the vertical roll and the effect

of any adjustments made at the camera.

To synchronize the cameras:

1. Choose a reference camera to which all other cameras will be phased.

2. Select a camera and synchronize it to the reference camera by turning the phase adjustment

control (refer to Figure 7) clockwise and/or counterclockwise.

3. Each time an adjustment is made, switch back and forth between the camera you are adjusting

and the reference camera. Repeat this process as many times as necessary, until the roll

between the cameras is no longer noticeable.

4. Adjust the phase of all other cameras by repeating steps 2 through 3. Always adjust to the

reference camera selected in step 1.

NOTE: The preferred method for camera phase adjustment is to use a dual trace oscilloscope to align

the vertical synchronization pulses of the reference camera to the selected camera(s).

VARIFOCAL LENS AUTO IRIS LEVEL ADJUSTMENT

To adjust the auto iris level, turn the level adjustment counterclockwise to decrease the brightness level

and clockwise to increase the brightness level. Refer to Figure 7 for the location of the level adjustment.

12 C2460M-A (7/03)

Page 13

REINSTALL THE LOWER DOME AND TRIM RING

1. Domes with Liners (only) – Position the viewing window over the lens of the camera.

a. Loosen the three Phillip screws located in the dome.

b. Insert the blade of a standard screwdriver in one of the adjustment grooves. Move dome

into position.

c. Tighten the three Phillip screws to lock liner in place.

2. Align the screw holes in the trim ring with those in the Camclosure base.

3. Tighten the tamper-resistant screws with the supplied 1/8-inch hollow screwdriver bit.

ADJUSTMENT

GROOVE

DOME LINER

LOOSEN SCREWS

Figure 8. Window Adjustment

C2460M-A (7/03) 13

Page 14

SPECIFICATIONS

BACKBOX

Electrical

Input Voltage: 12 VDC or 24 VAC, ±10%, auto-sensing

Power Consumption: 13 watts or less

Video Connector: BNC

General

Operating Temperature: -50° to 122°F (-46° to 50°C)

De-ices to 25°F (-4°C)

Pan/Tilt Adjustment: Manual; 360° pan; 180° tilt

Construction: Aluminum with steel camera mounting bracket and polycarbonate dome

Finish: White polyester powder coat

Dimensions

Above Ceiling: 1.75 (H) x 3.50 (W) inches

(4.45 x 8.89 cm)

Below Ceiling: 2.42 (H) x 5.48 (W) inches

(6.15 x 13.90 cm)

Bubble: 3.75-inch diameter

Environment: Indoor/outdoor

Weight: 1.70 lb (0.77 kg)

CAMERA

Signal System: NTSC/PAL

Imaging Device: 1/3-inch interline transfer CCD

Resolution: 480 TV lines

Min. Illumination: 0.75 lux @ 40 IRE, DSS off, f1.6 @ wide angle

1.20 lux @ 50 IRE, DSS off, f1.6 @ wide angle

0.025 lux @ 40 IRE, 30 fields of DSS, f1.6 @ wide angle

0.040 lux @ 50 IRE, 30 fields of DSS, f1.6 @ wide angle

Lens: 2.6-6.0 mm or 4.0-9.0 mm varifocal, D-mount, f1.6

Synchronize: Adjustable AC line lock/internal, auto select

Iris Control: Electronic/automatic

Signal to Noise: 50 dB

AGG: Selectable, on/off

BLC: DIP switch selectable, ON/OFF

Auto Iris Type: DC drive

Shutter: 1/60-1/100,000 electronic, auto

Video Level: Adjustable

CERTIFICATIONS

NTSC Models: UL, cUL, and FCC Class B

PAL Models: CE Class B, UL, cUL, and FCC Class B

(Design and product specifications subject to change without notice.)

14 C2460M-A (7/03)

Page 15

WARRANTY AND RETURN INFORMATION

WARRANTY

Pelco will repair or replace, without charge, any merchandise proved defective in material or workmanship for a period of one year after the date of

shipment. Exceptions to this warranty are as noted below:

• Five years on Pelco manufactured cameras (CC3500/CC3600/CC3700 and MC3500/MC3600 Series); two years on all other cameras.

• Three years on Genex® Series (multiplexers, server, and keyboard) and 090 Series Camclosure® Camera System.

•Two years on 100/150, 200, and 300 Series Camclosure Camera Systems.

•Two years on all standard motorized or fixed focal length lenses.

•Two years on Legacy®, CM6700/CM6800/CM6800E/CM8500/CM9500/CM9740/CM9760 Matrix, DF5 and DF8 Series Fixed Dome products.

•Two years on Spectra®, Esprit®, and PS20 Scanners, including when used in continuous motion applications.

•Two years on Esprit and WW5700 series window wiper (excluding wiper blades).

• Eighteen months on DX Series digital video recorders.

• One year (except video heads) on video cassette recorders (VCRs). Video heads will be covered for a period of six months.

• Six months on all pan and tilts, scanners or preset lenses used in continuous motion applications (that is, preset scan, tour and auto scan modes).

Pelco will warrant all replacement parts and repairs for 90 days from the date of Pelco shipment. All goods requiring warranty repair shall be sent

freight prepaid to Pelco, Clovis, California. Repairs made necessary by reason of misuse, alteration, normal wear, or accident are not covered under

this warranty.

Pelco assumes no risk and shall be subject to no liability for damages or loss resulting from the specific use or application made of the Products.

Pelco’s liability for any claim, whether based on breach of contract, negligence, infringement of any rights of any party or product liability, relating to

the Products shall not exceed the price paid by the Dealer to Pelco for such Products. In no event will Pelco be liable for any special, incidental or

consequential damages (including loss of use, loss of profit and claims of third parties) however caused, whether by the negligence of Pelco or

otherwise.

The above warranty provides the Dealer with specific legal rights. The Dealer may also have additional rights, which are subject to variation from

state to state.

If a warranty repair is required, the Dealer must contact Pelco at (800) 289-9100 or (559) 292-1981 to obtain a Repair Authorization number (RA), and

provide the following information:

1. Model and serial number

2. Date of shipment, P.O. number, Sales Order number, or Pelco invoice number

3. Details of the defect or problem

If there is a dispute regarding the warranty of a product which does not fall under the warranty conditions stated above, please include a written

explanation with the product when returned.

Method of return shipment shall be the same or equal to the method by which the item was received by Pelco.

RETURNS

In order to expedite parts returned to the factory for repair or credit, please call the factory at (800) 289-9100 or (559) 292-1981 to obtain an

authorization number (CA number if returned for credit, and RA number if returned for repair).

All merchandise returned for credit may be subject to a 20% restocking and refurbishing charge.

Goods returned for repair or credit should be clearly identified with the assigned CA or RA number and freight should be prepaid. Ship to the

appropriate address below.

If you are located within the continental U.S., Alaska, Hawaii or

Puerto Rico:

Service Department

Pelco

3500 Pelco Way

Clovis, CA 93612-5699

® Pelco, the Pelco logo, Spectra, Genex, Esprit, Camclosure, and Legacy are registered trademarks of Pelco.

© Copyright 2003, Pelco. All rights reserved.

If you are located outside the continental U.S., Alaska, Hawaii or

Puerto Rico:

Intermediate Consignee Ultimate Consignee

American Overseas Air Freight Pelco

320 Beach Road 3500 Pelco Way

Burlingame, CA 94010 Clovis, CA 93612-5699

USA USA

REVISION HISTORY

Manual # Date Comments

C2460M 4/03 Preliminary manual for beta testing.

C2460M-A 7/03 Final version.

C2460M-A (7/03) 15

Page 16

®

World Headquarters

3500 Pelco Way

Clovis, California 93612 USA

USA & Canada

Tel: 800/289-9100

Fax: 800/289-9150

International

Tel: 1-559/292-1981

Fax: 1-559/348-1120

www.pelco.com

ISO9001

Orangeburg, New York Las Vegas, Nevada Eindhoven, The Netherlands Wokingham, United Kingdom Montreal, Canada

Loading...

Loading...