REV. 01/04

Use manual

ELECTRICAL BOARDS FOR REFRIGERATING INSTALLATIONS

READ AND KEEP

REV. 02-18

ENG

ELECTRONICS BOARD

ECP200 BASE 4 / 4A

E. BOARD ECP200 BASE 4/4A

110300BVD***

110400BVD***

110750BVD***

1101000BVDB*

110300BVDE**

110300BVDEM*

110400BVDE**

110750BVDE**

1101000BVDE*

110300BUVD**

110400BUVD**

110750BUVD**

1101000BUVD*

1101500BVDE*

1102000BVDE*

1102500BVDE*

110BUVDE**

REV. 01/04

CHAP. 1

CHAP. 2

CHAP. 3

CHAP. 4

ENGLISH

The ECP200 BASE 4/4A electronic board is installed in the following families of Pego

standard electrical panels:

It can also be installed in special panels.

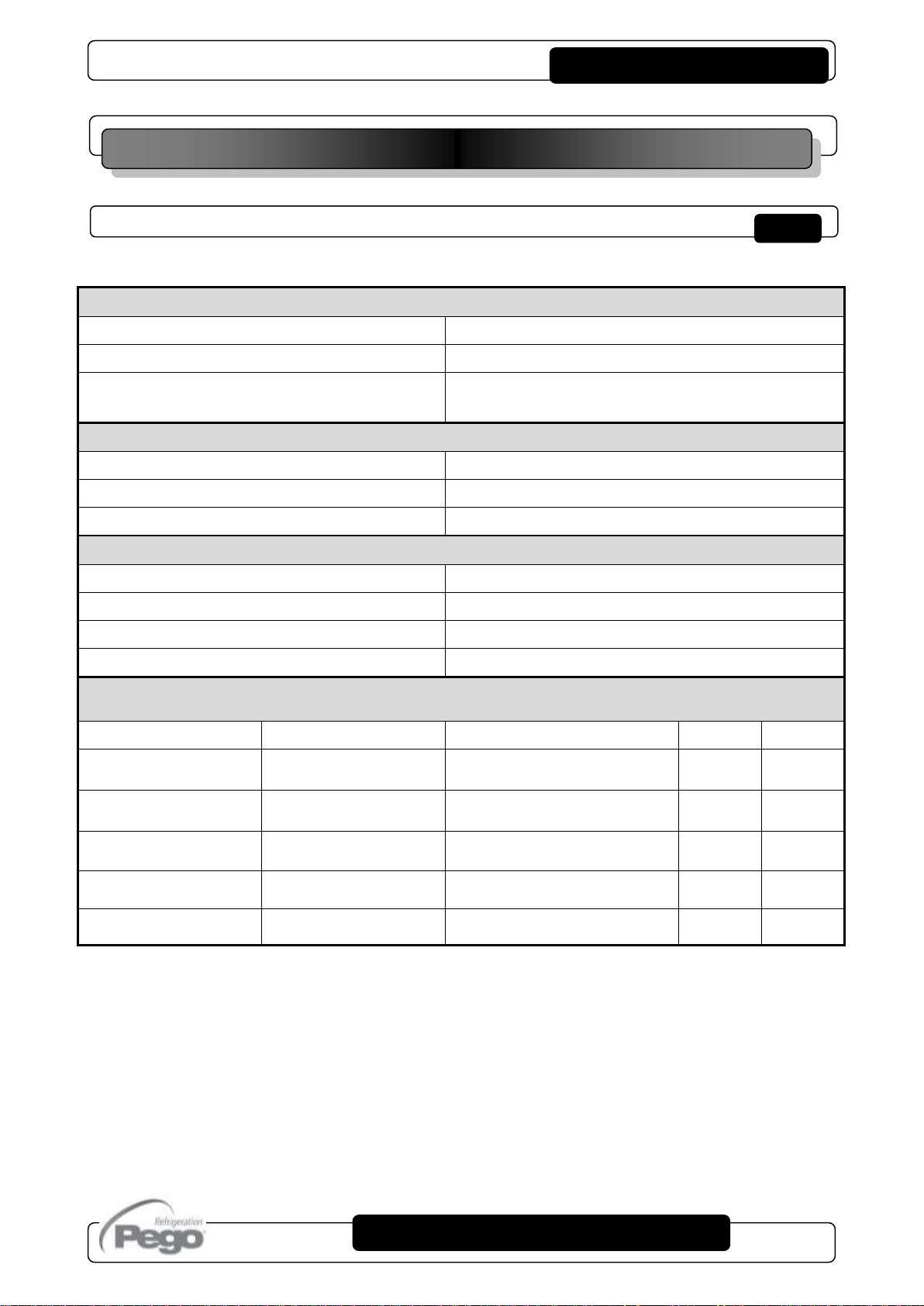

TECHNICAL CHARACTERISTICS

Pag. 3 1.1 Technical characteristics

PARAMETER PROGRAMMING

Pag. 4 2.1 Control panel

Pag. 4 2.2 Frontal keypad

Pag. 5 2.3 LED display

Pag. 6 2.4 General

Pag. 6 2.5 Key to symbols

Pag. 6 2.6 Setting and displaying set points

Pag. 7 2.7 Level 1 programming

Pag: 7 2.8 List of Level 1 variables

Pag. 8 2.9 Level 2 programming

Pag. 8 2.10 List of Level 2 variables

Pag. 10 2.11 Compressor activation/deactivation conditions

Pag. 10 2.12 Manual defrosting

Pag. 11 2.13 Hot gas defrosting

Pag. 11 2.14 Pump down function

Pag. 11 2.15 Password protection

OPTIONS

Pag. 12 3.1 TeleNET monitoring / supervision system

Pag. 12 3.2 Net configuration with Modbus-rtu protocol

Pag. 13 3.3 ALARM RELAY / RS485 switching

TROUBLESHOOTING

Pag. 14 4.1 Troubleshooting

APPENDICES

Pag. 15 A.1 ECP200 BASE 4 wiring diagram

Pag. 15 A.2 ECP200 BASE 4A wiring diagram

E. BOARD ECP200 BASE 4/4A

USE MANUAL

Rev. 02-18

Power supply of the electronics board

Voltage

230 V~ 10% 50-60Hz

Max power (only electronics)

~ 7 VA

Rated current

(With all loads connected)

16A

Climatic conditions of the electronics board

Working temperature

-5 ÷ +50 °C

Storage temperature

-10 ÷ +70 °C

Relative ambient humidity

Lower than 90% Hr

General characteristics of the electronics board

Type of sensors that can be connected

NTC 10K 1%

Resolution

0,1 °C

Sensor read precision

± 0,5 °C

Read range

-45 ÷ +45 °C

Output characteristics of the electronics board (free voltage contact)

Description

Installed relay

Card output characteristics

BASE 4

BASE 4A

Compressor

(Relay 30A AC1)

10A 250V~ (AC3) (2HP)

(100000 cycles)

X

X

Elements

(Relay 30A AC1)

16A 250V~ (AC1)

X

X

Fans

(Relay 16A AC1)

2,7A 250V~ (AC3)

X

X

Room light

(Relay 16A AC1)

16A 250V~ (AC1)

X

X

Alarm / Aux (Optional)

(Relay 8A AC1)

8(3)A 250V~

X

CHAP. 1 - Technical characteristics

CHAPTER 1: TECHNICAL CHARACTERISTICS

TECHNICAL CHARACTERISTICS OF THE ELECTRONICS BOARD

Page 3

E. BOARD ECP200 BASE 4/4A

USE MANUAL

Rev. 02-18

AUXILIARY RELAY CONTROL (on the version with alarm relay, it manually

controls the relay if parameter AU=1)

UP / MUTE BUZZER ALARM

STAND BY (the system shuts down and the LED flashes)

Room temperature SETTING

DOWN / MANUAL DEFROST

ROOM LIGHT

CHAP. 2 - Parameter programming

CHAPTER 2: PARAMETER PROGRAMMING

CONTROL PANEL

FRONT KEYPAD

Page 4

E. BOARD ECP200 BASE 4/4A

USE MANUAL

Rev. 02-18

Cold room temperature / parameters

Stand-by (flashes on stand-by. Outputs are deactivated)

Room light (flashes if door switch activated)

Cold (indicates activation of compressor)

Fans

Defrosting

Ausiliary

Alarm/warning

CHAP. 2 - Parameter programming

LED DISPLAY

Page 5

E. BOARD ECP200 BASE 4/4A

USE MANUAL

Rev. 02-18

CHAP. 2 - Parameter programming

2.4

GENERAL

To enhance safety and simplify the operator’s work, the ECP200 BASE has two

programming levels; the first level (Level 1) is used to configure the frequently-modified

SETPOINT parameters. The second programming level (Level 2) is for general parameter

programming of the various controller work modes.

It is not possible to access the Level 2 programming directly from Level 1: you must exit

the programming mode first.

KEY TO SYMBOLS

For purposes of practicality the following symbols are used:

• () the UP key is used to increase values and mute the alarm.

• () the DOWN key is used to decrease values and force defrosting.

SETTING AND DISPLAYING THE SET POINTS

1. Press the SET key to display the current SETPOINT (temperature).

2. Hold down the SET key and press the () or () keys to modify the SETPOINT.

Release the SET key to return to cold room temperature display: the new setting will be

saved automatically.

Page 6

E. BOARD ECP200 BASE 4/4A

USE MANUAL

Rev. 02-18

VARIABLES

MEANING

VALUE

DEFAULT

r0

Temperature difference compared to main SETPOINT

0.2 - 10 °C

2°C

d0

Defrost interval (hours)

0 - 24 hours

4 hours

d2

End-of-defrost setpoint.

Defrost is not executed if the temperature read by the

defrost sensor is greater than d2

(If the sensor is faulty defrosting is timed)

-35 - 45 °C

15°C

d3

Max defrost duration (minutes)

1 - 240 min

25 min

d7

Drip duration (minutes)

At the end of defrost the compressor and fans remain at

standstill for time d7, the defrost LED on the front panel

flashes.

0 - 10 min

0 min

F5

Fan pause after defrost (minutes)

Allows fans to be kept at standstill for a time F5 after

dripping. This time begins at the end of dripping. If no

dripping has been set the fan pause starts directly at the

end of defrost.

0 - 10 min

0 min

A1

Minimum temperature alarm

Allows user to define a minimum temperature for the room

being refrigerated. Below value A1 an alarm trips: the alarm

LED flashes, displayed temperature flashes and the buzzer

sounds to indicate the problem.

-

-45°C

A2

Maximum temperature alarm

Allows user to define a maximum temperature for the room

being refrigerated. Above value A2 an alarm trips: the

alarm LED flashes, displayed temperature flashes and the

buzzer sounds to indicate the problem.

-

+45°C

tEu

Evaporator sensor temperature display

(displays nothing if dE =1)

Displays

evaporator

temperature

read only

CHAP. 2 - Parameter programming

2.7

LEVEL 1 PROGRAMMING (User level)

To gain access to the Level 1 configuration menu proceed as follows:

1. Press the () and () keys simultaneously and keep them pressed for a few seconds

until the first programming variable appears on the display.

2. Release the () and () keys.

3. Select the variable to be modified using the () or () key.

4. When the variable has been selected it is possible:

• To display the setting by pressing SET key.

• To modify the setting by pressing the SET key together with the () or () key.

When configuration values have been set you can exit the menu by pressing the () and

() keys simultaneously for a few seconds until the cold room temperature reappears.

5. The new settings are saved automatically when you exit the configuration menu.

LIST OF LEVEL 1 VARIABLES (User level)

Page 7

E. BOARD ECP200 BASE 4/4A

USE MANUAL

Rev. 02-18

VARIABLES

MEANING

VALUES

DEFAULT

AC

Door switch status (with door closed)

0 = normally open

1 = normally closed

0

F3

Fan status with compressor off

0 = Fans run continuously

1 = Fans only run when

compressor is working

1

F4

Fan pause during defrost

0 = Fans run during defrost

1 = Fans do not run during

defrost

1

dE

Sensor presence

If the evaporator sensor is disabled

defrosts are carried out cyclically with

period d0: defrosting ends when an

external device trips and closes the remote

defrost contact or when time d3 expires.

0 = evaporator sensor present

1 = no evaporator sensor

0

d1

Defrost type, cycle inversion (hot gas) or

with heater elements

1 = hot gas

0 = element

0

Ad

Net address for connection to TeleNET

supervision system or Modbus

0 ÷ 31 (with AU=3)

1 ÷ 247 (with AU=7)

0

Ald

Minimum and maximum temperature

signalling and alarm display delay

1…240 min

120 min

C1

Minimum time between shutdown and

subsequent switching on of the

compressor.

0…15 min

0 min

CAL

Cold room sensor value correction

-10…+10

0

CHAP. 2 - Parameter programming

2.9

2.10

LEVEL 2 PROGRAMMING (Installer level)

To access the second programming level press the UP () and DOWN () keys and the

LIGHT key simultaneously for a few seconds.

When the first programming variable appears the system automatically goes to stand-by.

1. Select the variable to be modified by pressing the UP () and DOWN () keys. When

the parameter has been selected it is possible to:

2. View the setting by pressing the SET key.

3. Modify the setting by holding the SET key down and pressing the () or () key.

4. When configuration settings have been completed you can exit the menu by pressing

the () and () keys simultaneously and keeping them pressed until the room

temperature reappears.

5. Changes are saved automatically when you exit the configuration menu.

6. Press the STAND-BY key to enable electronic control.

LIST OF LEVEL 2 VARIABLES (Installer level)

Page 8

E. BOARD ECP200 BASE 4/4A

USE MANUAL

Rev. 02-18

Pc

Compressor protection contact status

0 = NO

1 = NC

0 = NO

doC

Compressor safety time for door

switch. When the door is opened the

evaporator fans shut down and the

compressor will continue working for time

doC, after which it will shut down.

0…5 min

0

tdo

Compressor restart time after door

opening. when the door is opened and

after tdo time, it’s setted back the normal

functioning giving door open alarm (Ed).

With tdo=0 the parameter is disabled.

0…240 min

0 = disabled

0

Fst

FAN shutdown TEMPERATURE

The fans will stop if the temperature value

read by the evaporator sensor is higher

than this value.

-45…+45°C

+45°C

Fd

Fst differential

0…+10°C

2°C

LSE

Minimum value attributable to setpoint.

-45... HSE °C

-45°C

HSE

Maximum value attributable to setpoint.

+45... LSE °C

+45°C

tA

NO – NC alarm relay switching

0 = activates when alarm is

on

1 = deactivates when alarm is

on

1

AU

Auxiliary/alarm relay control

0 = alarm relay

1 = manual auxiliary relay

controlled via AUX key

2 = automatic auxiliary relay

managed by StA temp.

setting with 2°C differential

3 = relay disabled / TeleNET

function

4 = pump down function

(see CHAP 5.15)

5 = free voltage contact for

condensing unit (AUX relay

and compressor relay in

parallel)

6 = contact for casing element

control (AUX relay closed

with compressor output

inactive).

7 = relay disabled / Modbus-

RTU function

0

StA

Temp. setting for aux. relay

-45…+45°C

0

In1

Man in cold room alarm

Select input INP1 on the board as

compressor protection alarm or as man in

cold room alarm (contact NC).

0 = compressor protection

1 = man in room alarm

0

CHAP. 5 - Parameter programming

CHAP. 2 - Parameter programming

Page 9

E. BOARD ECP200 BASE 4/4A

USE MANUAL

Rev. 02-18

P1

Password type of protection

( active when PA is not equal 0)

0 = only display set point

1 = display set point, AUX,

light access

2 = access in programming

not permitted

3 = access in second level

programming not

permitted

3

PA

Password

(see P1 for the type of protection)

0...999

0 = not active

0

reL

Software release

indicates software version

7

(Read only)

CHAP. 2 - Parameter programming

COMPRESSOR ACTIVATION/DEACTIVATION CONDITIONS

The ECP200 BASE controller activates the compressor when cold room temperature

exceeds setting+differential (r0); it deactivates the compressor when cold room

temperature is lower than the setting. If the Pump-down function is selected (Parameter

AU=4) refer to chapter 2.14 for the compressor activation / deactivation conditions.

MANUAL DEFROSTING

To defrost just press the dedicated key (see section 2.2) to activate the elements relay.

Defrosting will not take place if the end-of-defrost temperature setting (d2) is lower than

the temperature detected by the evaporator sensor. Defrosting ends when the end-ofdefrost temperature (d2) or maximum defrost time (d3) is reached.

Page 10

E. BOARD ECP200 BASE 4/4A

USE MANUAL

Rev. 02-18

CHAP. 2 - Parameter programming

HOT GAS DEFROSTING

Set parameter d1=1 to defrost in cycle inversion mode.

The compressor relay and defrost relay are activated throughout the defrost phase.

To ensure proper control of the system the installer must use the defrost output: this must

allow opening of the cycle inversion solenoid valve and closure of the liquid solenoid valve.

For capillary systems (without thermostat valve) it is only necessary to control the cycle

inversion solenoid valve via the defrost relay control.

PUMP DOWN FUNCTION

Pump down function is activated when parameter AU=4.

Connect pump down pressostat on the digital input 1-3. The compressor is directly

controlled by pressostat.

Connect evaporator solenoid valve on the AUX relay. The solenoid is controlled directly by

thermostat.

PASSWORD FUNCTION

When parameter PA is setting with value different to 0 the protection function is activated.

See parameter P1 for the different protection.

When PA is setting the protection start after two minutes of inactivity. On display appear

000. With up/down modify the number, with set key confirm it.

Use universal number 100 if you don’t remember the password.

Page 11

E. BOARD ECP200 BASE 4/4A

USE MANUAL

Rev. 02-18

CHAPTER 3: OPTIONS

CHAP. 3 - Options

TeleNET MONITORING/SUPERVISION SYSTEM

For TeleNET connections to enable RS485 as indicated at chapter 3.3 and follow the

scheme below. Refer to TeleNET user manual for instrument configuration.

WARNING: During configuration, at entry “Module” to select the entry "Instrument ECP

Base Series / ECP Expert Series ".

NET CONFIGURATION WITH MODBUS-RTU PROTOCOL

For RS485 connections with Modbus-RTU protocol, to enable RS485 output as indicated

at chapter 3.3 and follow the scheme below.

Refer to MODBUS-RTU_ECP200T1 user manual (available on Pego Internet web site) for

MODBUS-RTU communication protocol specification.

Page 12

E. BOARD ECP200 BASE 4/4A

USE MANUAL

Rev. 02-18

CAP. 3 - Opzioni

3.3

ALARM RELAY / RS485 SWITCHING

Remove power from the electrical panel, open the front panel and unscrew the 6 fixing

screws of the electronic board.

Configure the jumper from JUMPER JP2

(placed on the front of electrical board near

the display far down on the right) following

one of the ensuing options.

RS485 output selection:

Insert the jumper JP2 on 3-2 position and set

the 2nd level variable AU=3 (TeleNET) or

AU=7 (Modbus-RTU).

The connection clamps are RS485_(A) and

RS485_(B) on board of electrical board.

Remember besides to assign an univocal net

address in the current instruments net. (Ad

2nd level parameter).

Warning! with this configuration auxiliary relay

is disabled.

AUX/Alarm relay selection:

Insert the jumper JP2 in 2-1 position and set

the 2nd level variable AU to a value different

from 3 and 7 according to the needed

function. Clamps of configurable relay clean

contact are on AUX/ALL output, on board of

electronic board.

Warning! with this configuration RS485

connection is disabled.

Page 13

E. BOARD ECP200 BASE 4/4A

USE MANUAL

Rev. 02-18

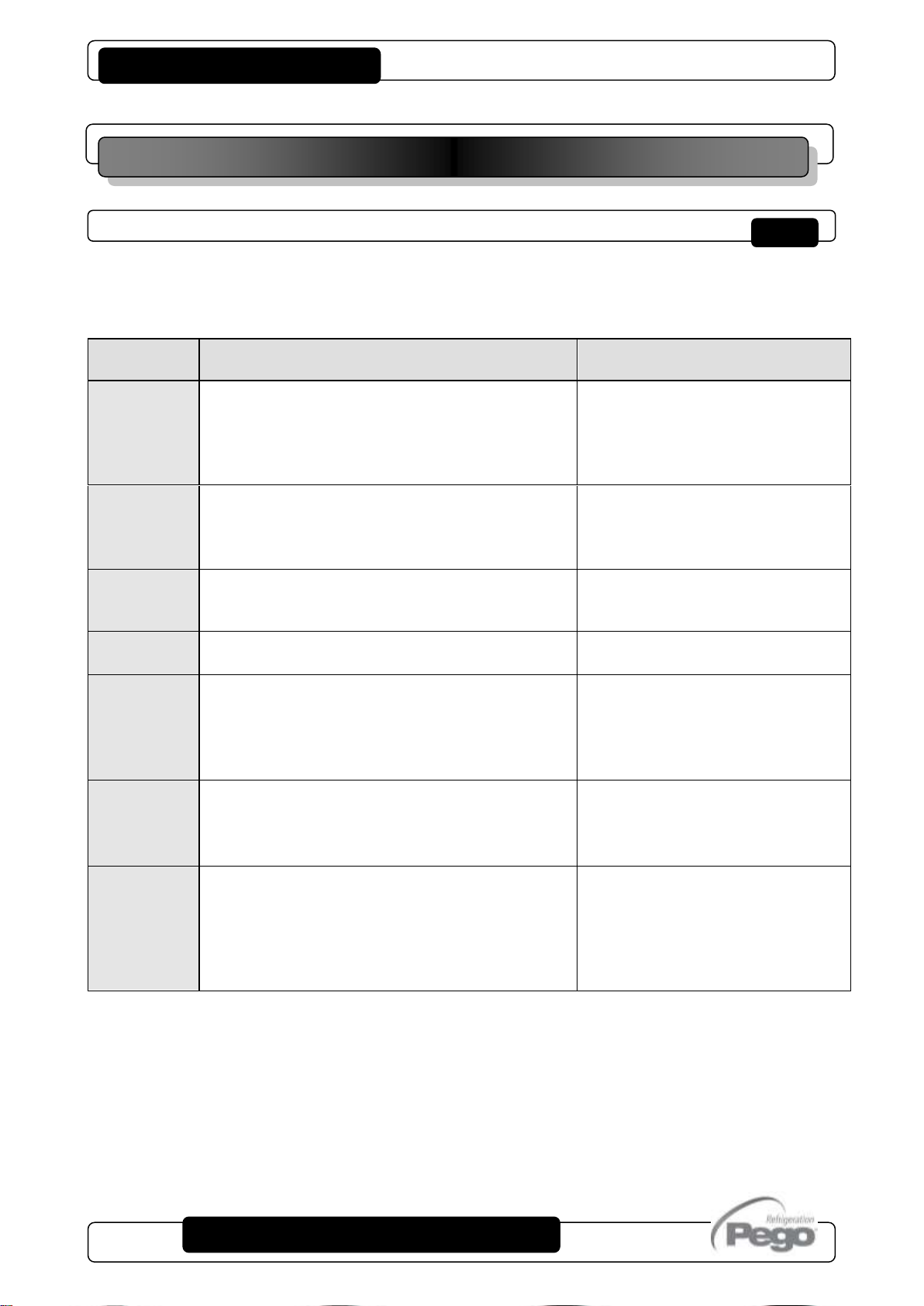

ALARM CODE

POSSIBLE CAUSE

SOLUTION

E0

Cold room temperature sensor not working properly

Check that cold room temperature

sensor is working properly

If the problem persists replace the

sensor

E1

Defrost sensor not working properly

(In this case defrosts will last time d3)

Check that defrost sensor is

working properly

If the problems persists replace

the sensor

E2

Eeprom alarm

An EEPROM memory alarm has been detected

(All outputs except the alarm one are deactivated)

Switch unit off and back on

E8

Man in cold room alarm

Reset the alarm input inside the

cold room

Ec

Compressor protection tripped (e.g. thermal

protection or max pressure switch)

(All outputs except the alarm one – where applicable

– are deactivated)

Check that compressor is working

properly

Check compressor absorption

If the problem persists contact the

technical assistance service

Ed

Open door Alarm. When the door is opened and after

tdo time, it’s setted back the normal functioning

giving door open alarm (Ed)

Check door switch status

Check door switch connections

If the problem persists contact the

technical assistance service

Temperature

shown on

display is

flashing

Minimum or maximum temperature alarm.

The temperature inside the cold room has exceeded

the min. or max. temperature alarm setting (see

variables A1 and A2, user programming level)

Check that the compressor is

working properly.

Sensor not reading temperature

properly or compressor start/stop

control not working.

CHAPTER 4: TROUBLESHOOTING

CHAP. 4 - Troubleshooting

4.1

TROUBLESHOOTING

In the event of any anomalies the ECP200 BASE warns the operator by displaying alarm codes

and sounding the warning buzzer inside the control panel. If an alarm is tripped the display will

show one of the following messages.

Page 14

E. BOARD ECP200 BASE 4/4A

USE MANUAL

Rev. 02-18

CAP. 6 - Diagnostica

Appendices

APPENDICES

Voltage free contact

Voltage free contact

ECP200 BASE4 WIRING DIAGRAM

ECP200 BASE4A WIRING DIAGRAM

Page 15

E. BOARD ECP200 BASE 4/4A

USE MANUAL

Rev. 02-18

Distributor:

PEGO s.r.l. reserves the right to make amendments to this user manual at any moment.

Via Piacentina, 6/b 45030 Occhiobello ROVIGO - ITALY

Tel. +39 0425 762906 Fax +39 0425 762905

e.mail: info@pego.it – www.pego.it

AFTER-SALES ASSISTANCE SERVICE

Tel. +39 0425 762906 e.mail: tecnico@pego.it

PEGO s.r.l.

Page 16

Loading...

Loading...