Page 1

Cat.

No.

9603

.&.

April, 1990

W

Series

SALES

MANUAL

First edition; Issued on April, 1990

Series

PEGASUS

~

-

/

Page 2

VV5

VV

6 0 0

VV

7 0 0

0 0

2,3-NEEDLE

2,

2,

PEGASUS

W

Series

FLAT

3-NEEDLE

3-NEEDLE

CYLINDER

SHORT

SALES

(Interlock

BED

INTERROCK

BED

FREE

BED

TYPE

MACHIHE

ARM

FOR

COVERING

MANUAL

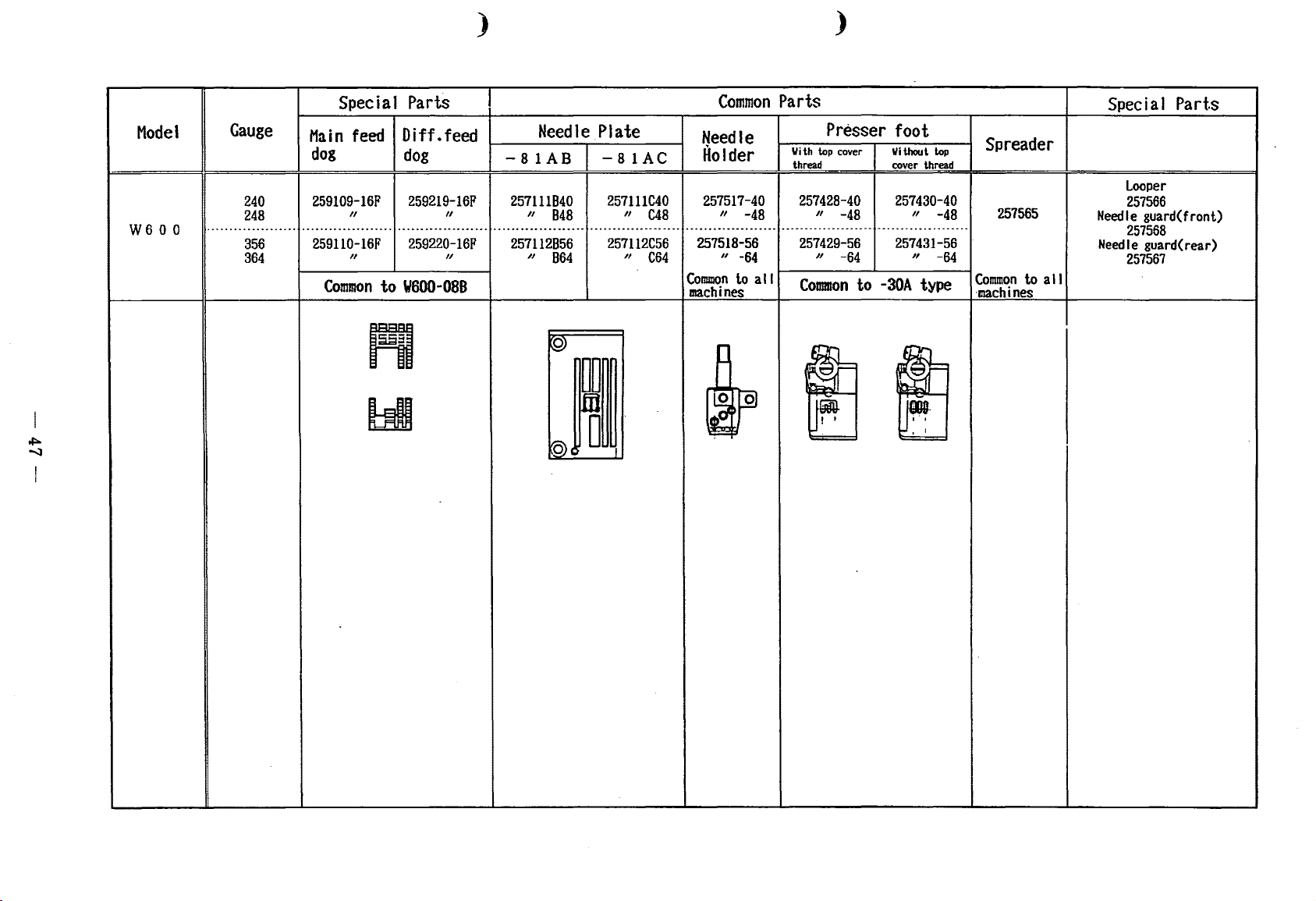

Machine)

FOR

DECORATIVE

TYPE

STITCHING

Sales point 1

[User

1

2

3

4 Force-drain

5

6 Front

7

8

9

10

friendliness

Body

color····---···

Equipped

HR

devices·······

of

needle bar

Cooling fan

Cylinder

Short

Versatile

Wide

Easy

Special bearing

with

and

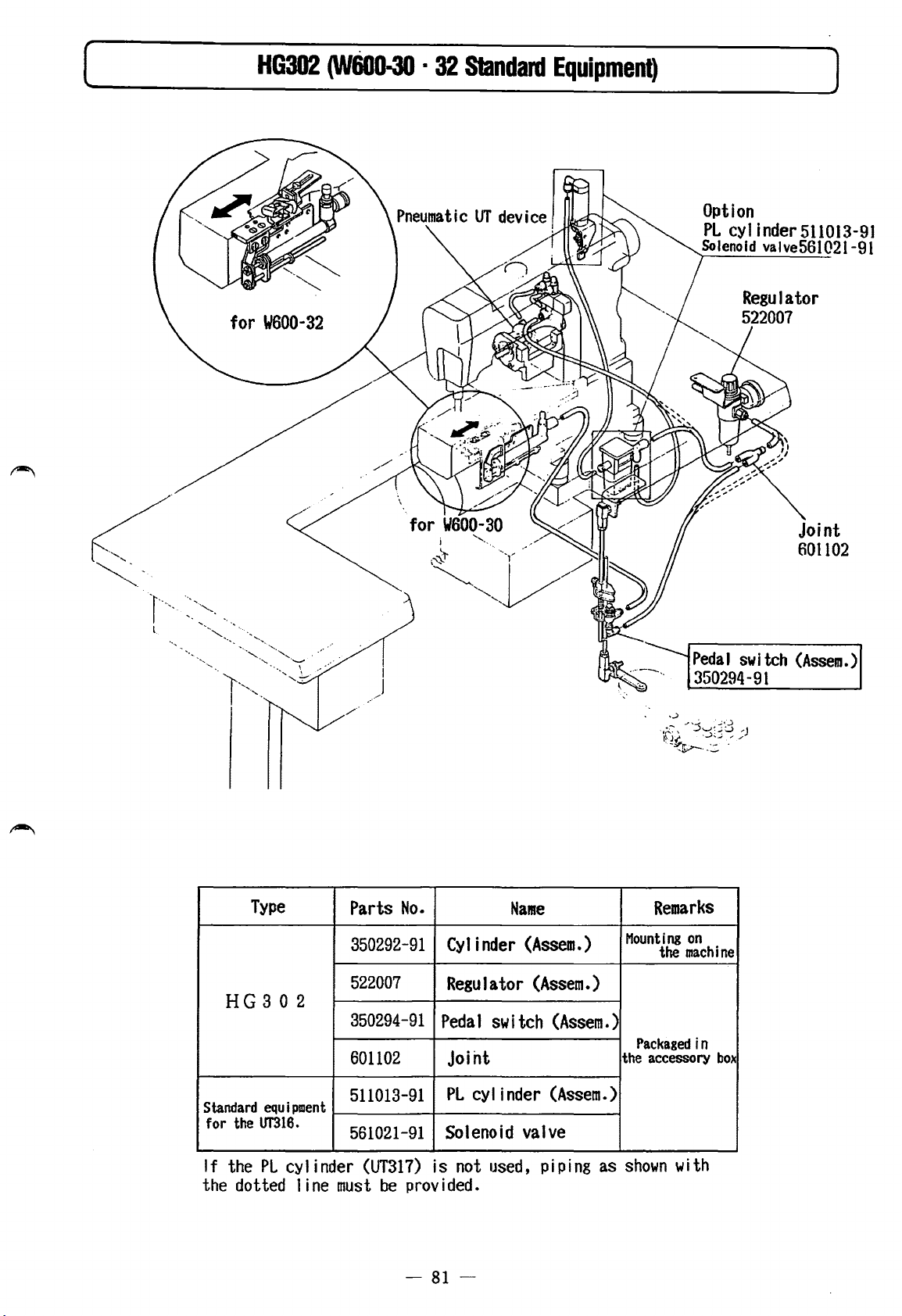

side covers can:be

bed

bed

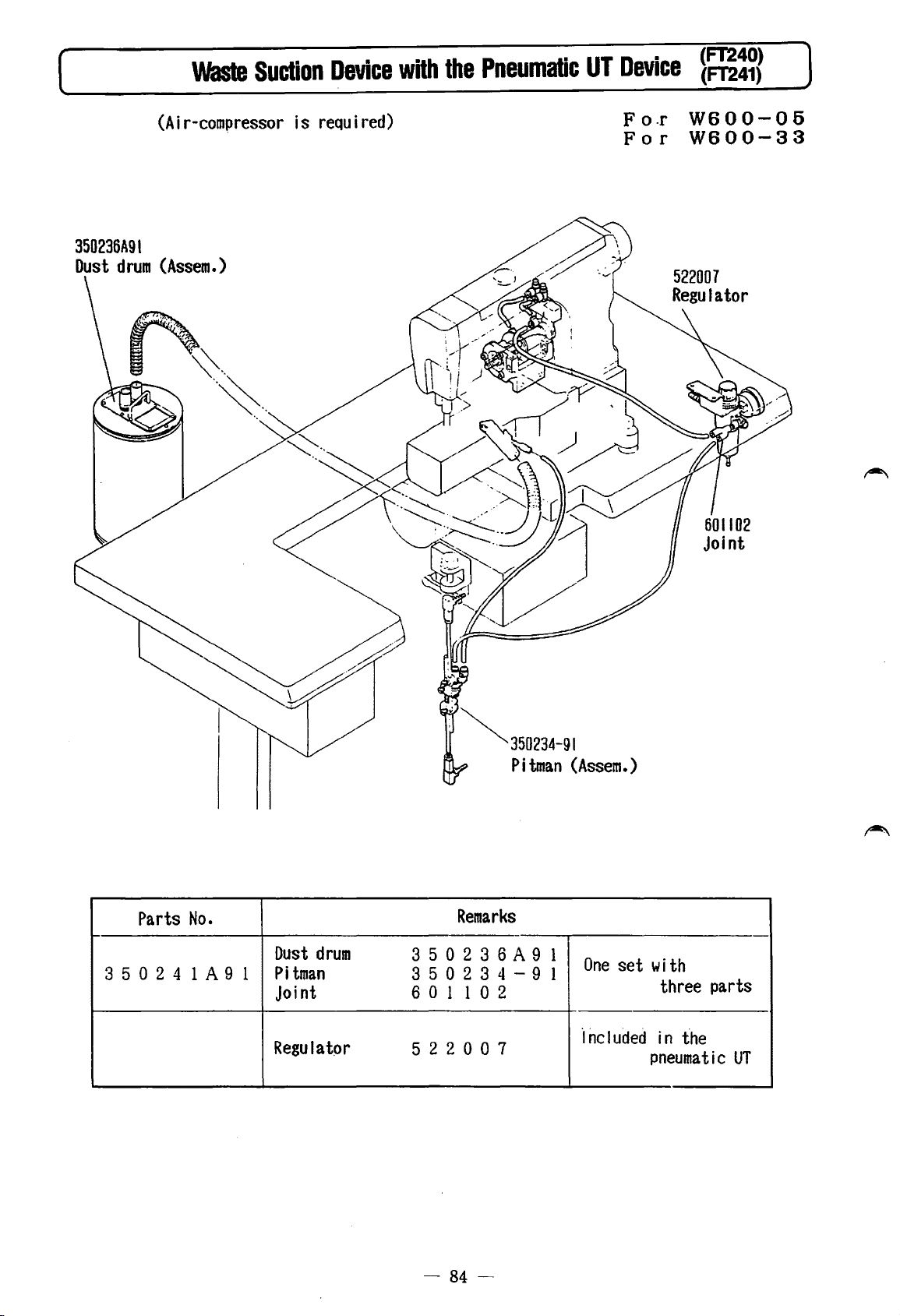

for

and

variety

1 ooper thread thread i ng-·-

arm

shaft

Sales point 2

and

standard features]

..

----------·

lubricant

......................................................................

lubrication

and

bed

for

lubricant~

wide-open--

that

provides

better

easier covering

fully

I

eft

hand

of

subclasses·---

is

and

fi I ter-system

cylinder--

....

-·--·much

operation--·--

operation--...... 3

equipped

mach i ne.................

used

on

crankshaft-

..

······1

for

.....

..................

..

·--·

..

-··--·· 4

[Description

"Beautiful

1

1 Idea I I

1

2 Convertible needle thread

3

2

2

2

3

3

3

4

Three

4 Retractable needle

to

"Different

r--1

Feed--in_g_M_ec-ha-n-is-m-.1

5 Lever

for

Main

6

differential

7

0 i a I type

Pushbutton type

Capab

8

9

The

path

10

Feed

of

mechanical

stitches

oop i ng

retainer

types

provide beaut i

prevent skipped

mechanisms

on

adjusting the

feed

I e

of

main

that

dog

opera

bracket

of

needle

the

right

is

I i

nked

feed--

st

i tch I ength

stitch

condensed

feed

dog

the

differential

feed

dog

angle adjustment

construction]

with

something

elegant about

t i

orr

.............. -..........

..................

fu I stitches-···-

guard

stitches·-.................

account

for

hand

differential

-...................

plate

high

side

that

quality"

to

............. -.............

·adjustment...

length

adjustment.........

st i tch-··-.................

follows the

fo

11

ows..............................

same

..............................

them"

_...

5

5

..

- 6

6

feed•7

_.

7

8

9

9

9

9

I Looper Mechanism I

11

Linear horizontal looper

12

Looper

adjustment

I Spreader Mechanism I

13

Modified spreader

to

prevent

being

B

dis

right

lodged

...................................................

trajectory

needle

......................................................

motion-···-···-10

from

~

..

10

10

Page 3

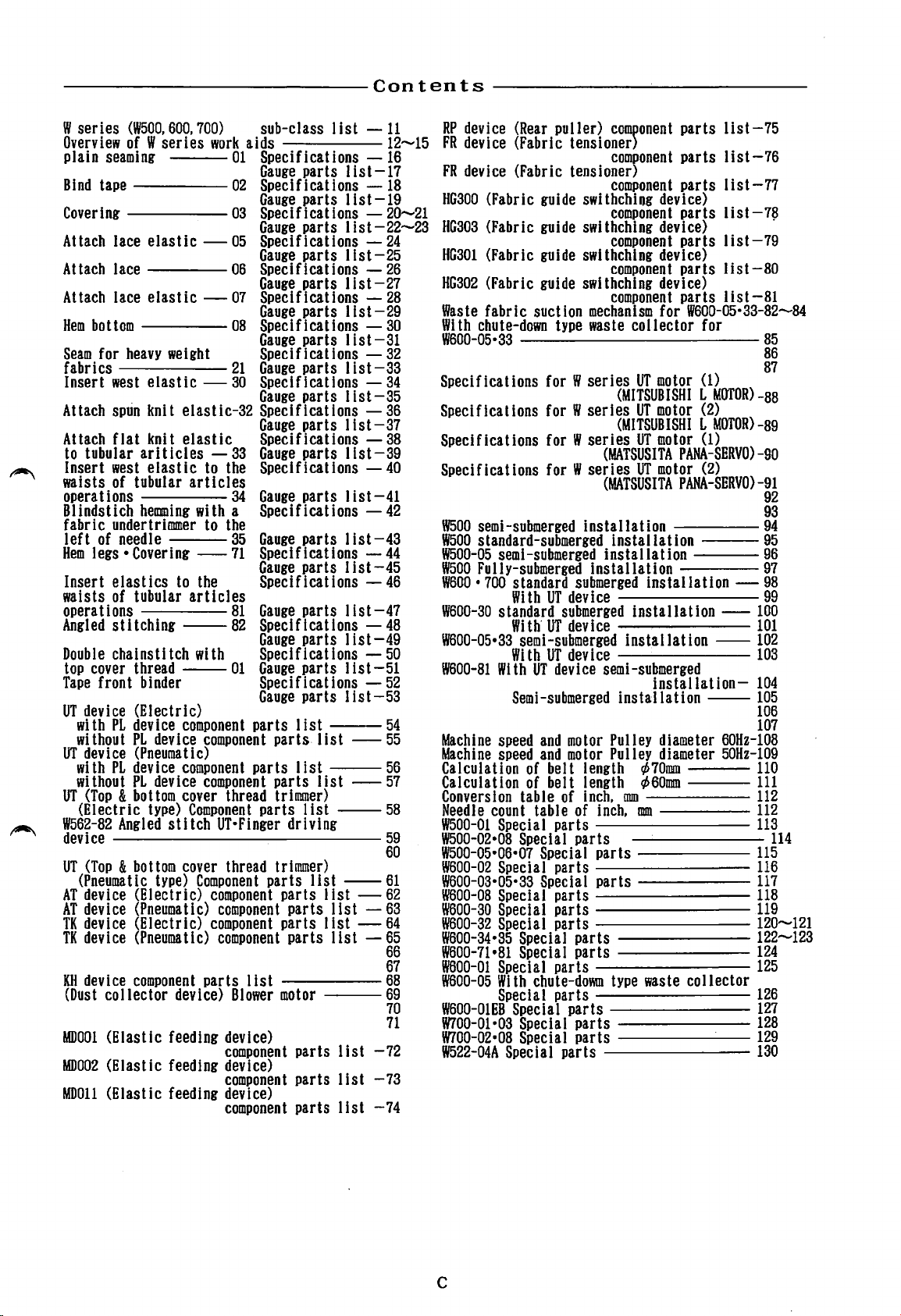

---------------Contents

------------------

W series

Overview

plain

Bind

Covering

Attach

Attach

Attach

Hem

Seam

(W500,600,

of

W series

seaming

tape

-----02

-----

lace

elastic -

lace

----06

lace

elastic -

bottom----

for

heavy

weight

fabrics

Insert

west

elastic -

.

Attach

Attach

to

Insert

waists

spun

flat

tubular

west

of

knit

elastic-32 Specifications

knit

elastic

arit icles --33

elastic

tubular

operations

Blindstich

fabric

left

hemming

undertrimmer

of

needle

Hem 1 egs • Covering

Insert

waists

elastics

of

tubular

to

operations

Angled

Double

top

Tape

UT

UT

UT

W562-82

device

UT

AT

AT

TK

TK

KH

(Dust

MD001

MD002

MD011

stitching

chainstitch

cover

thread

front

binder

device

with

without

device

with

without

(Electric)

PL

device

PL

device

(Pneumatic)

PL

device

PL

device

(Top & bottom

(Electric

type)

Angled

-------------59

(Top & bottom

(Pneumatic

device

device

device

device

device

type)

(Electric)

(Pneumatic)

(Electric)

(Pneumatic)

component

collector

(Elastic

(Elastic

(Elastic

--82

--

component

component

cover

stitch

cover

device)

feeding

feeding

feeding

700)

work

sub-class

aids

01

Specifications --16

Gauge

Specifications --18

Gauge

03

Specifications

Gauge

05

Specifications --24

Gauge

Specifications

Gauge

07

Specifications --28

Gauge

08

Specifications

Gauge

Specifications

21

Gauge

30

Specifications --34

Gauge

Gauge

Specifications

Gauge

to

Specifications

the

articles

Gauge

34

with

a

to

-

Specifications

the

Gauge

35

Specifications

71

Gauge

the

Specifications

articles

Gauge

81

Specifications

Gauge

01

Speci

Gauge

with

Specifications

Gauge

parts 1 ist

component

parts list

component

thread

Component

parts 1 ist

UT•Finger

thread

Component

component

component

component

component

parts list

Blower

device)

component

device)

component

device)

component

list --11

12~15

parts

list-17

parts list -19

--

parts I ist

20~21

-22~23

parts I ist -25

--26

parts I ist -27

parts 1 ist -29

--30

parts 1 ist -31

--32

parts 1 ist -33

parts I ist -35

--36

parts 1 ist -37

--38

parts I ist -39

--40

parts list -41

--42

parts 1 ist -43

--44

parts I ist -45

--

46

parts 1 ist -47

--

48

parts list -49

flcat

ions

--50

parts list -51

--52

parts

list-53

----54

parts.

1 ist

-55

56

parts list

-57

trimmer)

--58

driving

60

trimmer)

parts list -----61

parts

list-

parts list

parts

list-

parts list

62

--63

64

--65

66

67

68

motor

69

70

71

parts list -72

parts list -73

parts list -74

RP

device

FR

device

FR

device

HG300

HG303

HG301

HG302

Waste

With

(Rear

(Fabric

(Fabric

(Fabric

(Fabric

(Fabric

(Fabric

fabric

guide

guide

guide

guide

suction

chute-down

W600-05•33

Specifications

Specifications

Specifications

Specifications

W500

semi-submerged

W500

standard-submerged

W500-05

W500

W600 • 700

semi-submerged

Fully-submerged

standard

With

W600-30

standard

With·

W600-05•33

semi

With

W600-81

With

UT

Semi-submerged

Machine

Machine

Calculation

Calculation

Conversion

Needle

W500-0l

W500-02•08

W500-05•06•07

W600-02

WB00-03·05·33

W600-08

W600-30

W600-32

W600-34•35

W600-71•81

W600-0l

WB00-05

speed

speed

of

of

table

count

Special

Special

Special

Special

Special

Special

Special

Special

Special

With

and

and

table

Special

Special

chute-dowm

Special

W600-01EB

W700-0l•03

W700-02•08

W522-04A

Special

Special

Special

Special

puller)

component

tensioner)

component

tensioner)

component

swithching

component

swithching

component

swithching

component

swithching

component

mechanism

type

waste

for

W series

(MITSUBISHI L MOTOR)-88

for

W series

(MITSUBISHI L MOTOR)-89

for

W series

(MATSUSITA

for

W series

(MATSUSITA

installation

installation

installation

installation

submerged

UT

device

submerged

UT

device

-submerged

UT

device

device

semi-submerged

installation--

motor

Pulley

motor

length

length

inch,

of

inch,

Pulley

belt

belt

of

parts

parts

parts

parts

parts

parts

parts

parts

parts

parts

parts

type

parts

parts

parts

parts

parts

parts

parts list--76

parts list--77

device)

parts

device)

parts

device)

parts

device)

parts list--81

for

collector

UT

UT

UT

WS00-05•33-82~84

for

motor

(1)

motor

(2)

motor

(1)

PANA-SERV0)-90

UT

motor

(2)

PANA-SERV0)-91

installation -

installation--

installation

installation-

diameter

diameter

¢70mm

¢60mm

mm

mm

waste

collector

list-75

list-7~

list-79

list-80

85

86

87

92

93

94

95

96

97

98

99

100

101

--

102

103

104

105

106

107

60Hz-108

50Hz-109

110

111

112

112

113

114

115

116

117

118

119

120~121

122~123

124

125

126

127

128

129

130

c

Page 4

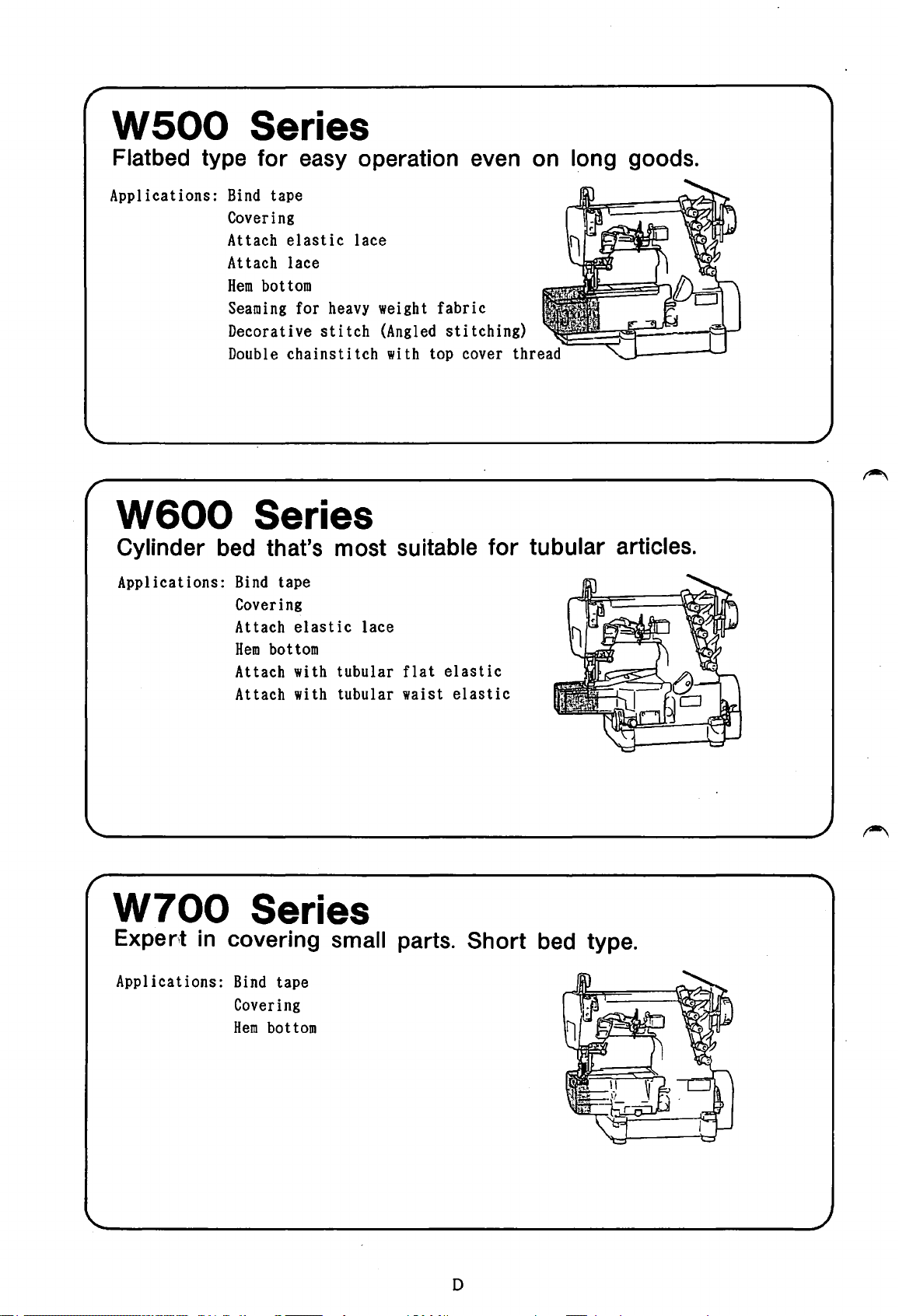

W500

Flatbed type

Series

for

easy operation even on long goods.

Applications:

W600

Bind

tape

Covering

Attach

Attach lace

Hem

Seaming

Decorative

Double

elastic

bottom

for

stitch

chainstitch

Series

lace

heavy

weight fabric

{Angled

with top cover thread

stitching)

Cylinder bed that's most suitable

Applications:

Bind

tape

Covering

Attach

Hem

Attach with tubular

Attach with tubular waist

elastic

bottom

lace

flat

elastic

elastic

for

tubular articles.

W700

Series

Expert in covering small parts. Short bed type.

Applications:

Bind

tape

Covering

Hem

bottom

D

Page 5

Sales

<User

1.

[Body

Sand

gentles

factory.

2.

[Equipped

Points

friendliness

Color]

beige

color associated

to

operators, this color

(Common

with

lubricant

(1)

and

standard

to

features>

W500/W600/W700)

filter]

with

beautiful

goes

well

beaches

with

modern

in

South

fashionable

Pacific."

Nice

looking

and

A lubricant

l_ubric~nt

Replaci.ng

outside.

(Common

a

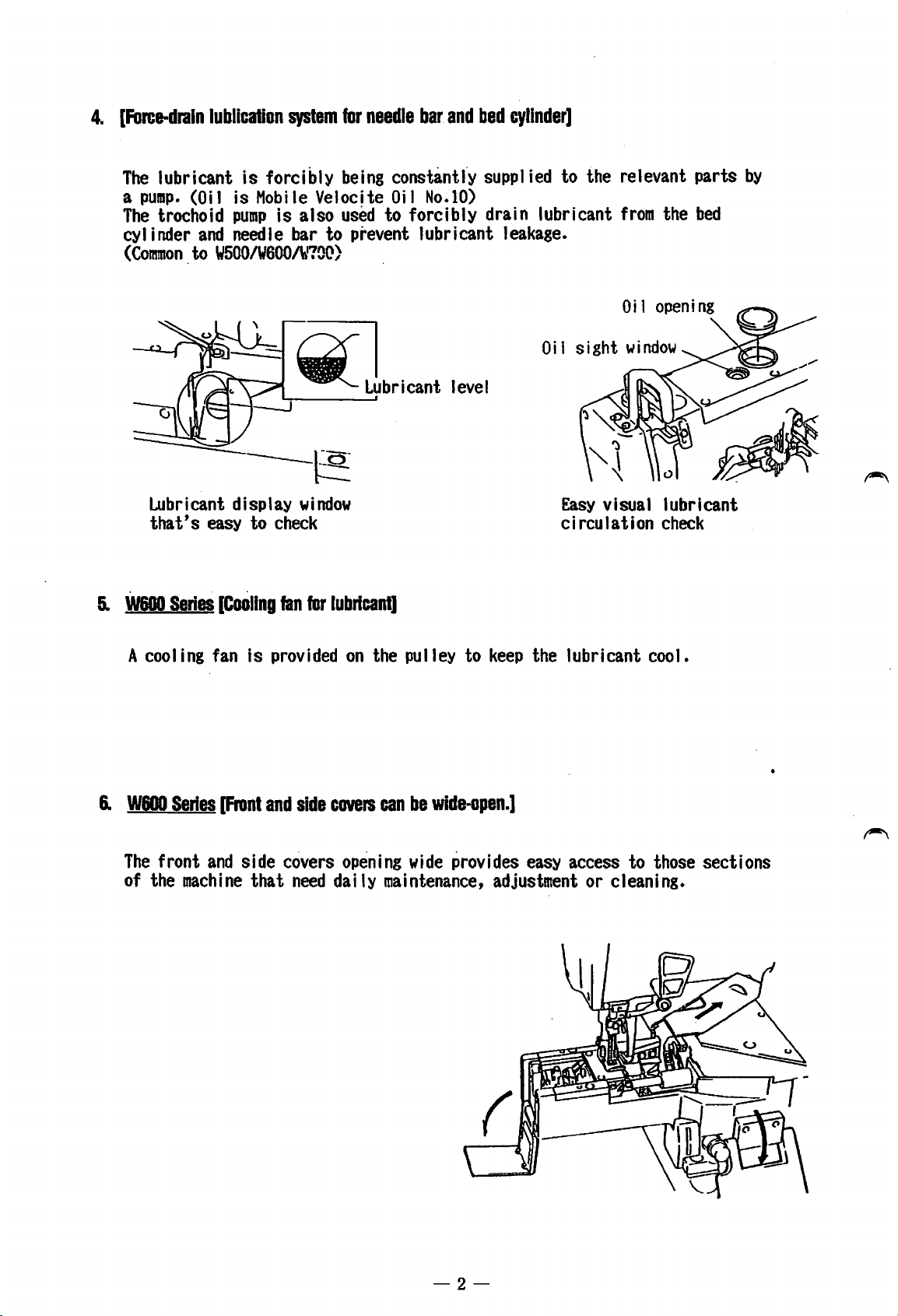

[HR

Comes

needle

thread

to

devices]

wfth

that

or

filter

__

ci

rculates_

f i Iter· is

is

provided

kept

very

easy

W500/W600/W700)

HR

devices

would

tend

(upper

to

fabric vulnerable

to

remove

small

clean.

and

can

be

done

Remove

and

lower)

become

hot.

to

heat.(~ommon

as

This

standard

allows

dirt

from

the

from

ever 6 months

equipment

for

high

speed

to

W500/W600/W700)

lublicant

to

clean.

to

cool

operation

so

off

the

the

on

HR

(upper):to

prevent

plain

HR

(lower):to

prevent

plain

-1-

thread

thread

thread

breakage.

broken

breakage.

tension

thread

or

or

Page 6

4.

[Force-drain

The

lubricant is forcibly

a

pump.

The

trochoid

cylinder

(Common_to

lublication

(Oil

is

pump

and

needle

W500/W600/W7nQ)

system

Mobile

is also

bar

Velocite

for

being

used

to

prevent

needle

constantfy

Oil

to

forcibly

bar.

and

bed

supplied

No.lO)

lubricant

cylinder]

drain

leakage.

to

the

lubricant

relevant

from

the

parts

bed

by

Lubricant

that's

. .

5.

W&OO

Series

A

cooling

6.

W600

Series

·~~

display

easy

(Cooling

fan

is

(Front

to

check

fan

provided

and

a:

window

for

side

lbricant

lubricant]

on

the

covers

can

level

pulley

be

wide-open.]

to

keep

Easy

circulation

the

lubricant

visual

lubricant

check

cool.

The

front

of

the

and

side

machine

that

covers

need

opening

daily

wide

provides

maintenance,

-2-

easy

adjustment

access

or

cleaning.

to

those

sections

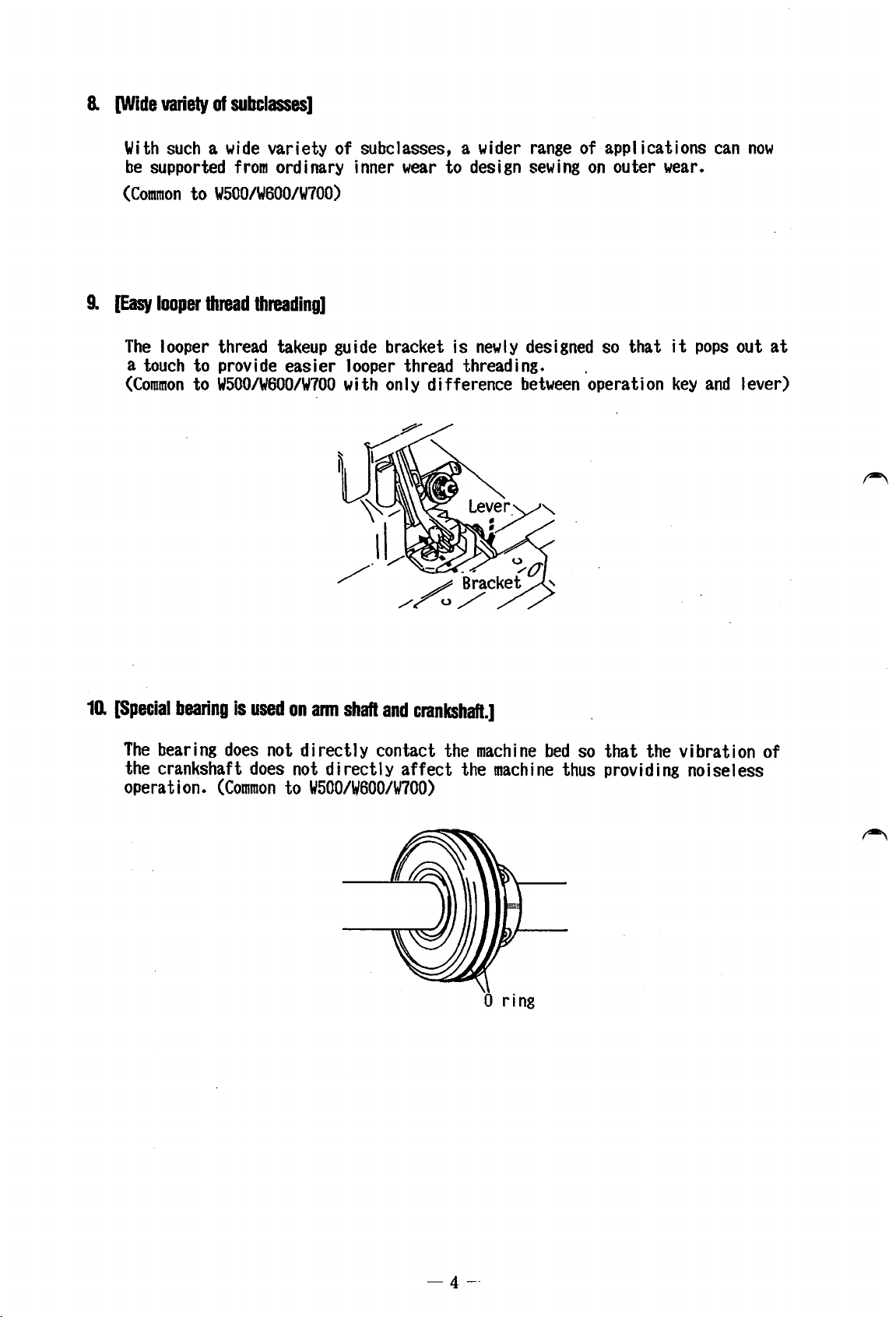

Page 7

7.

W&OO

Series

The

external

the

sewing

's

wear

W664-01PR

[Cylinder

or

with

WS62(conventiona1

(The

W500

is a flatbed specially

large

W700

The

provide

small

(W500

size fabric

Series

left

[Short

edge

easier operation

as

400mm,

is a flatbed,

perimeter

process

arm

holes

rear

bed

of

the

this

bed

that

provides

of

the

involving

is

made

small

now

puller:310mm

type):350mm

and

the

W700

for

easier

bed

c~erlng

is cut

on

small

provides

and

the

W600

much

better

cylinder is

tubular articles

easy

and

designed

is a short

operation

as

close

pieces.

covering

operation

is a cylinder

operation)

only

smooth.

for

bed.)

on

small

as

23mm

With

270mm,

the

Handling

such

as

pieces)

to

the

needle

~ylinder

ori

tubular articles.

bed.)

the

fabric for

necks

bar

on

center

peripheral

children

·

to

as

W700

Series

A

lefthand

it

is; a rare

sides

of

blanket

[Versatile

machine

lefthand

or

and

is

towel.

fully

equipped

very

difficult

machine.

lefthand

This

machine)

to

find

provides

anywhere

in

simultaneous

'

W700L

-3-

the

world.

sewing

on

But

both

here

Page 8

8.

[Wide

With

be

supported

variety

of

subclasses]

such a wide

from

variety

ordinary

of

subclasses, a

inner

wear

to

wider

design

range

sewing

of

applications

on

outer

wear.

can

now

(Common

9.

[Easy

The

to

looper

looper

a

touch

(Common

to

to

W500/W600/W700)

thread

threading]

thread

provide

W500/W600/W700

takeup

easier

guide

looper

with

bracket

thread

only

difference

is

newly

designed

threading. .

between

so

that

operation

it

key

pops

and

out

at

lever)

10.

[Special

The

operation.

bearing

the

crankshaft

bearing

is

does

(Common

used

not

does

to

on

arm

shaft

and

crankshaft.]

directly contact

not

directly affect

W500/W600/W700)

the

the

machine

machine

0

ring

bed

thus

so

that

providing

the

vibration

of

noiseless

-4-

Page 9

Sales

<Description

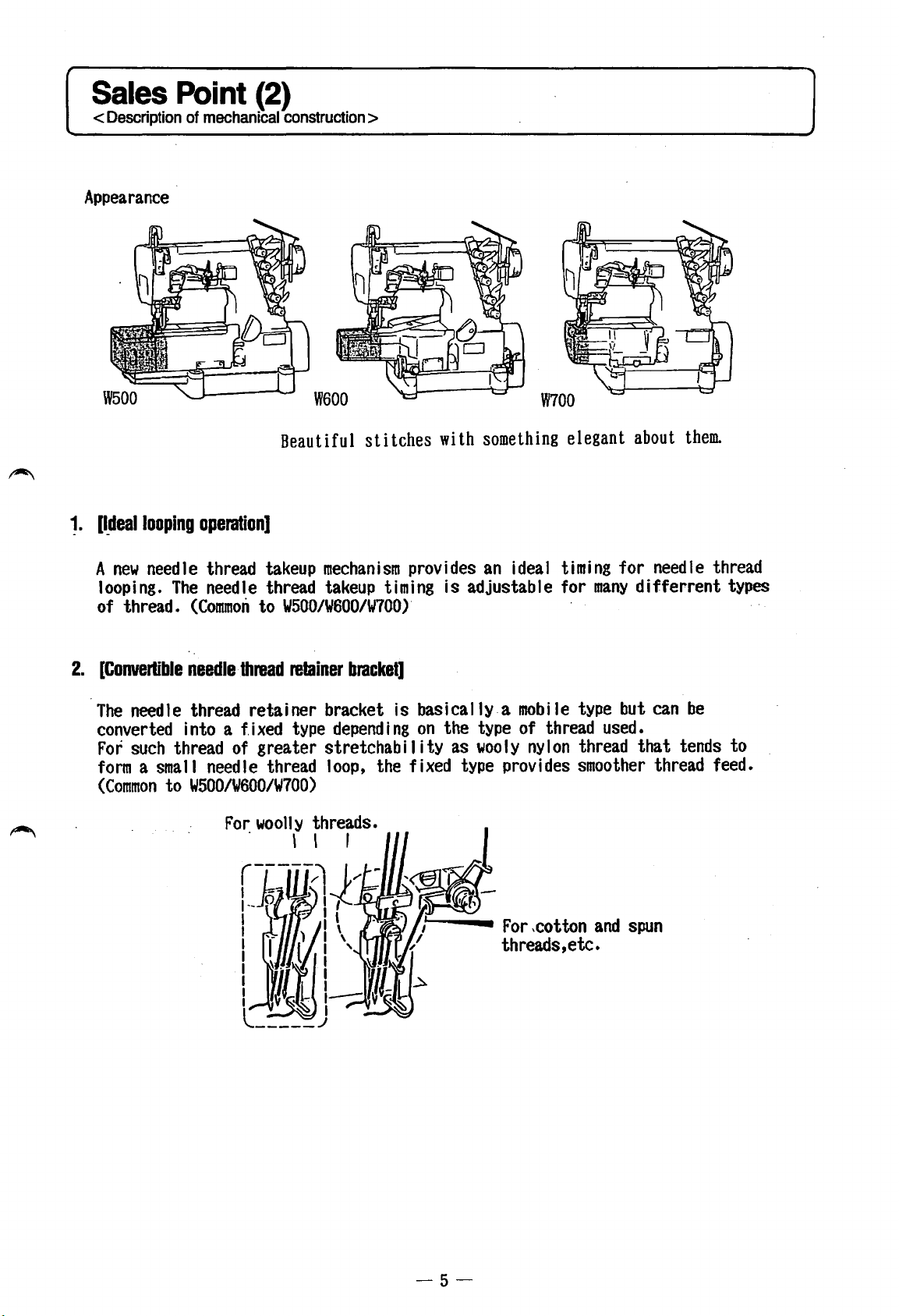

Appearance

Point

of

mechanical

(2)

construction>

1.

[l_deal

looping

A

new

looping.

of

thread.

2.

[Convertible

The

needle

converted

For

such

form a small

(Common

operation]

needle

thread

The

needle

(Common

needle·

thread

to

thread

retainer

into a f. i xed

thread

of

greater stretchability

needle

to

W500/W600/W700)

Beautiful

takeup

thread

stitches

mechanism

takeup

timing

provides

W500/W600/W700)·

retainer

type

thread

bracket]

bracket

depending

loop,

the

is basically.a

fixed

with

something

an

ideal

is adjustable for

mobile

on

the

type

of

as

wooly

type

provides

timing

thread

nylon

elegant

for

many

type

but

used.

thread

smoother

about

then

needle

differrent

can

be

that

tends

thread

thread

types

to

feed.

-5-

Page 10

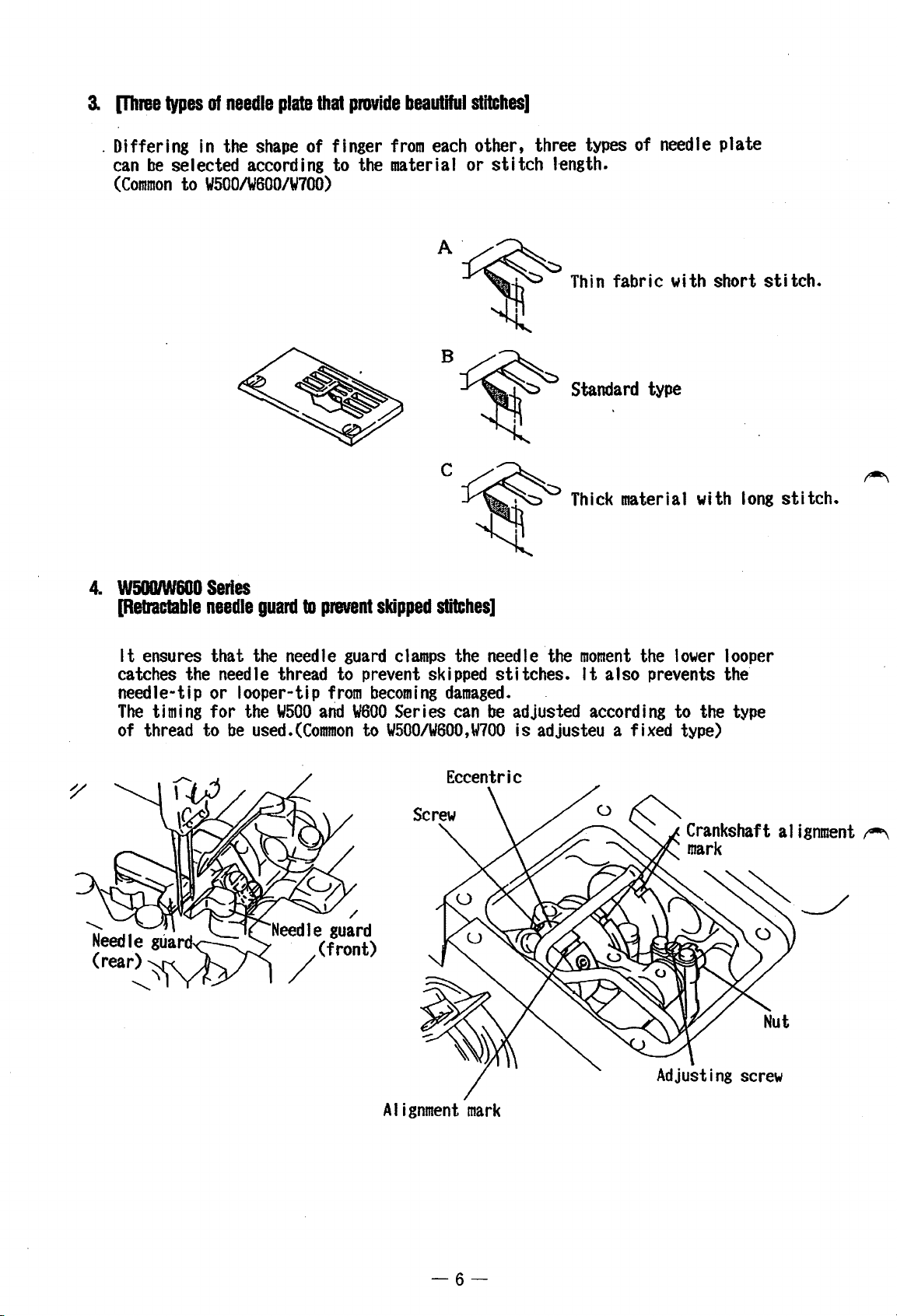

3.

[Three

.

Differing

can

(Common

types

be

selected

to

of

needle

in

the

W500/W600/W700)

plate

that

shape

according

of

finger

to

provide

the

beautiful

from

material

stitches]

each

other, three

or

stitch

types

l·ength.

of

needle

plate

4.

W5001W600

[Retractable

It

ensures

catches

needle-tip

The

timing

of

thread

Series

needle

that

the

or

for

to

guard

the

needle

needle

be

thread

looper-tip

the

W500

used.(Common

to

prevent

to

from

arid

A~

B

C

skipped

guard

prevent

becoming

W600

to

W500/W600,W700

stitches]

clamps

skipped

damaged.

Series

~

~

the

needle

stitches. It also

can

be

adjusted

is

adjusteu a fixed

Thin

Standard

Thick

the

moment

according

fabric

type

material

the

prevents

with

short stitch.

with

lower

to

looper

the

the

type)

long

type

stitch.

A I i

gnment

Eccentric

mark

Crankshaft

mark

alignment~

-6-

Page 11

''Different

mechanisms

account

for

high

quality''

Feeding

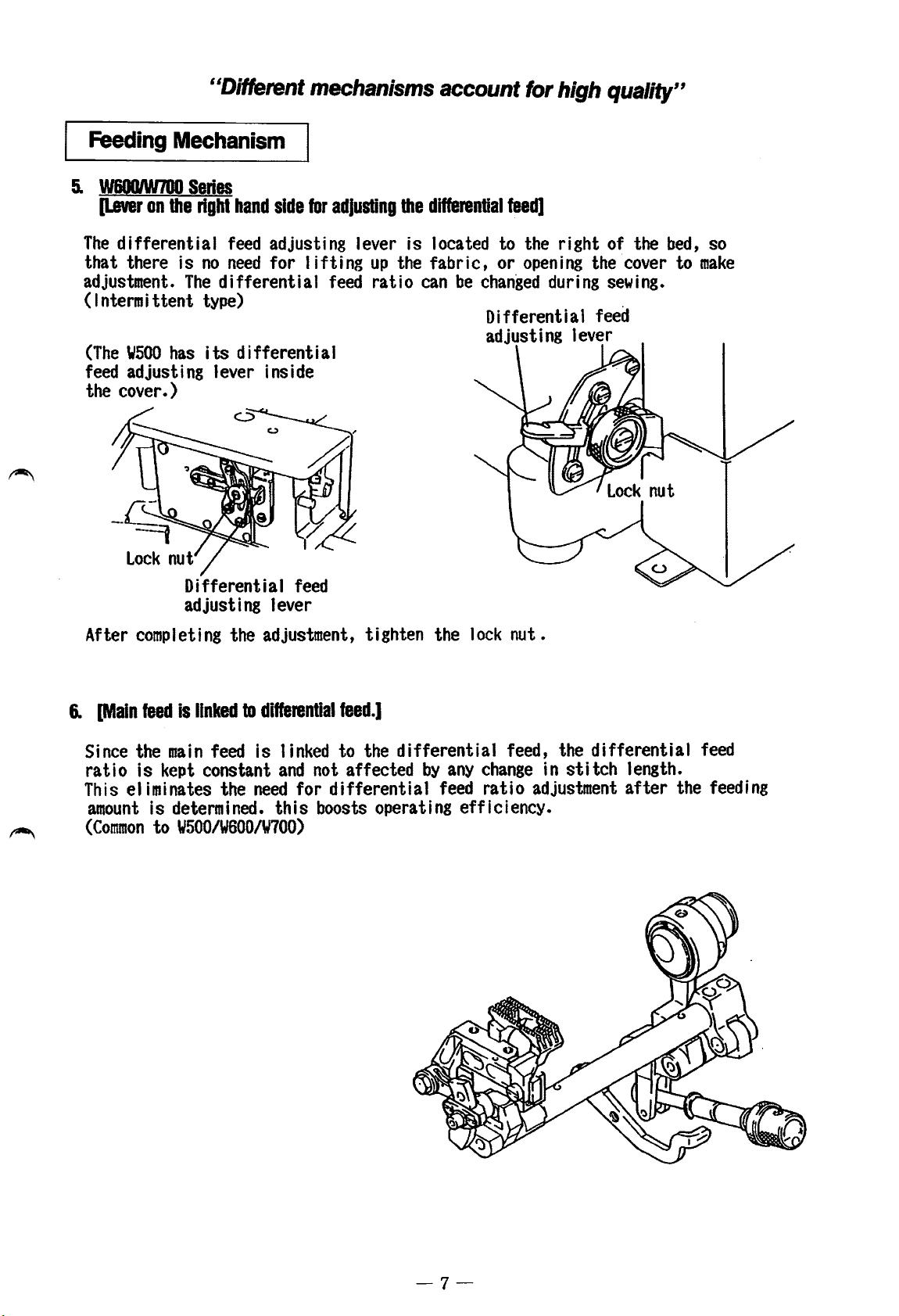

5.

WMW71JQ

[Lever

The

that

adjustment.

(Intermittent

(The

feed

the

on

differential

there

W500

adjusting

cover.)

Mechanism J

Series

the

right

hand

side

feed

adjusting

is

no

need

for lifting

The

differential

type)

has

its

differential

lever

Differential

adjusting

inside

lever

for

adjusting

feed

feed

lever

up

ratio

the

differential

is

located

the

fabric,

can

feed]

to

or

be

changed

Differential

adjusting

the

right

opening

during

lever

of

the

cover

sewing.

feed

the

bed,

to

so

make

After

6.

(Main

Since

ratio is

This

eliminates

amount

(Common

completing

feed

is

the

main

kept

the

linked

to

feed

constant

the

is

determined.

to

W500/W600/W700)

adjustment,

differential

is

linked

and

not

need

for differential

this

boosts

tighten

feed.]

to

the

affected

operating

the

lock

differential

by

any

change

feed

ratio

efficiency.

nut.

feed,

the

in

adjustment

differential

stitch

length.

after

the

feed

feeding

-7-

Page 12

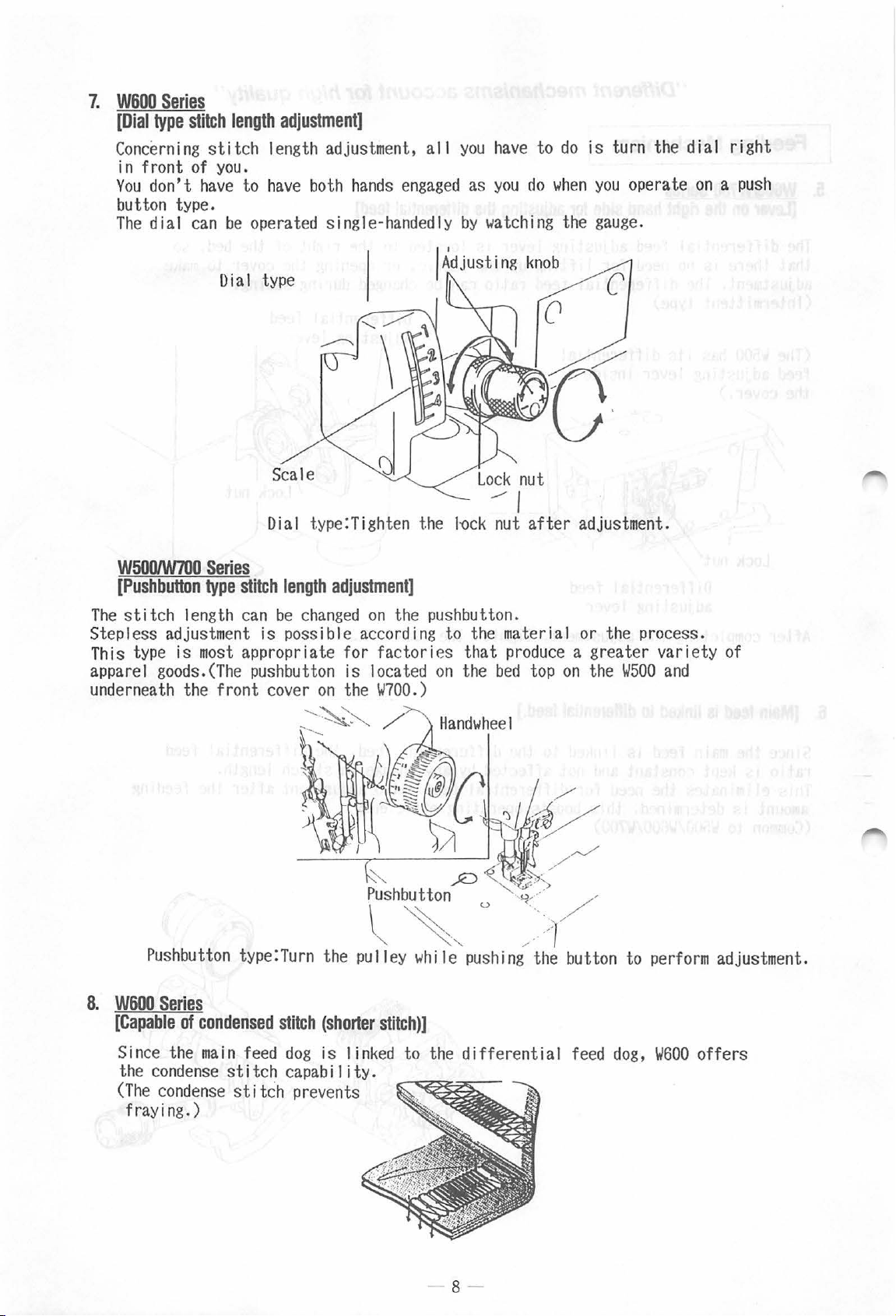

7.

W600

Series

[Dial

type

Concerning sti

in

front

You

don't

button

The

dial

stitch

of

have

type

can

length

adjustment]

tch

len

gth adjustment,

you.

to

have

both

hands

.

be

operated single-handedly

Dial

type

al 1 you

engaged

'Adju

have

as

you

by

watching

sting

to

do

when

knob

do

is turn the dial right

you

the gauge

operate

.

on a push

W5001W700

[Pushbutton

Series

type

Scale

Dial

stitch

type:Tighten

length

adjustment]

Lock

nut

- I

the

l~ck

nut

after adjustment.

' /

~

\ush~n o ·~~

~

<Z~~

--

~<

.·:

~

.

__

///

8.

W600

[Capable

Since

the

(The

Pushbutton

Series

of

condensed

the

main

condense

stitch capability.

condense stit

type:Turn

stitch

feed

dog

ch

prev

the pulley

\

(shorter

is I

ents

stitch)]

inked

~"

while

to

the

pushing

/ ·/

the

differential

fraying .)

- 8 -

button

feed

to

dog,

perform

W600

offers

adjustment.

Page 13

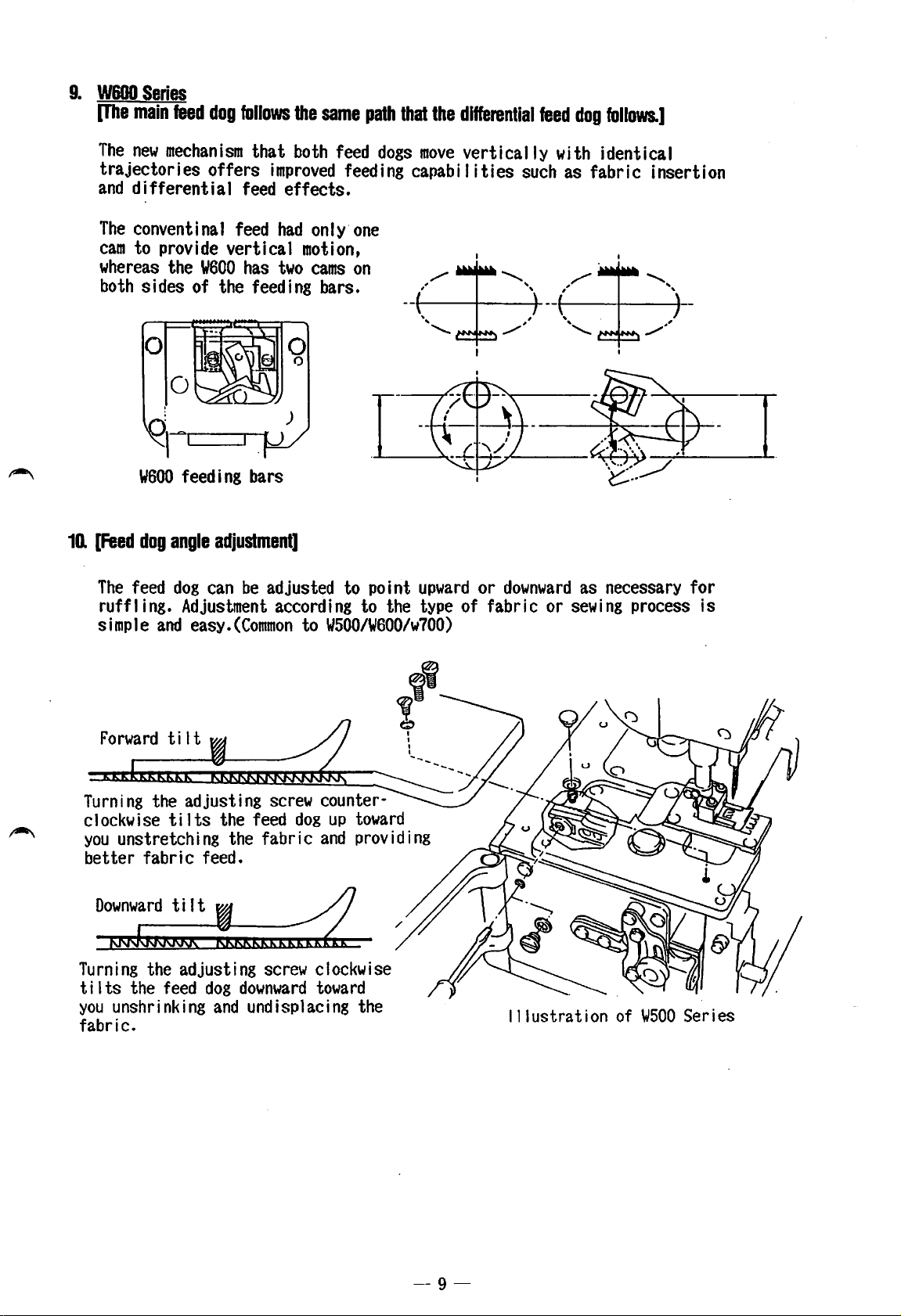

9.

W&DO

Series

[The

main

feed

The

new

mechanism

trajectories offers

and

differential

The

conventinal

cam

to

provide

whereas

both

the

sides

0

0

WSOO

feeding

10.

[Feed

dog

angle

dog

follows

that

feed

feed

vertical

WSOO

has

of

the

feeding

bars

adjustment]

the

same

both

feed

improved

effects.

had

only·one

motion,

two

cams

bars.

0

0

)

path

dogs

feeding

on

that

the

differential

move

vertically

capabilities

·1-----1-----+

feed

dog

follows.]

with

identical

such

as

fabric insertion

--

("

b_

-,~/'

I

~-

The

feed

dog

ruffling.

simple

Turning

clockwise

you

and

the

tilts

unstretching

better fabric

Downward

tilt!

~

Turning

tilts

you

fabric.

the

the

feed

unshrinking

can

be

adjusted

Adjustment

according

easy.(Common

adjusting

the

the

screw

feed

fabric

feed.

__

KK&KKK~

adjusting

dog

and

screw

downward

undisplacing

to

point

to

the

to

W500/W600/w700)

counter-

dog

up

toward

and

providing

~

/

clockwise

toward

the

upward

type

of

or

downward

fabric

Illustration

or

sewing

as

necessary

of

process

W500

for

is

Series

-9-

Page 14

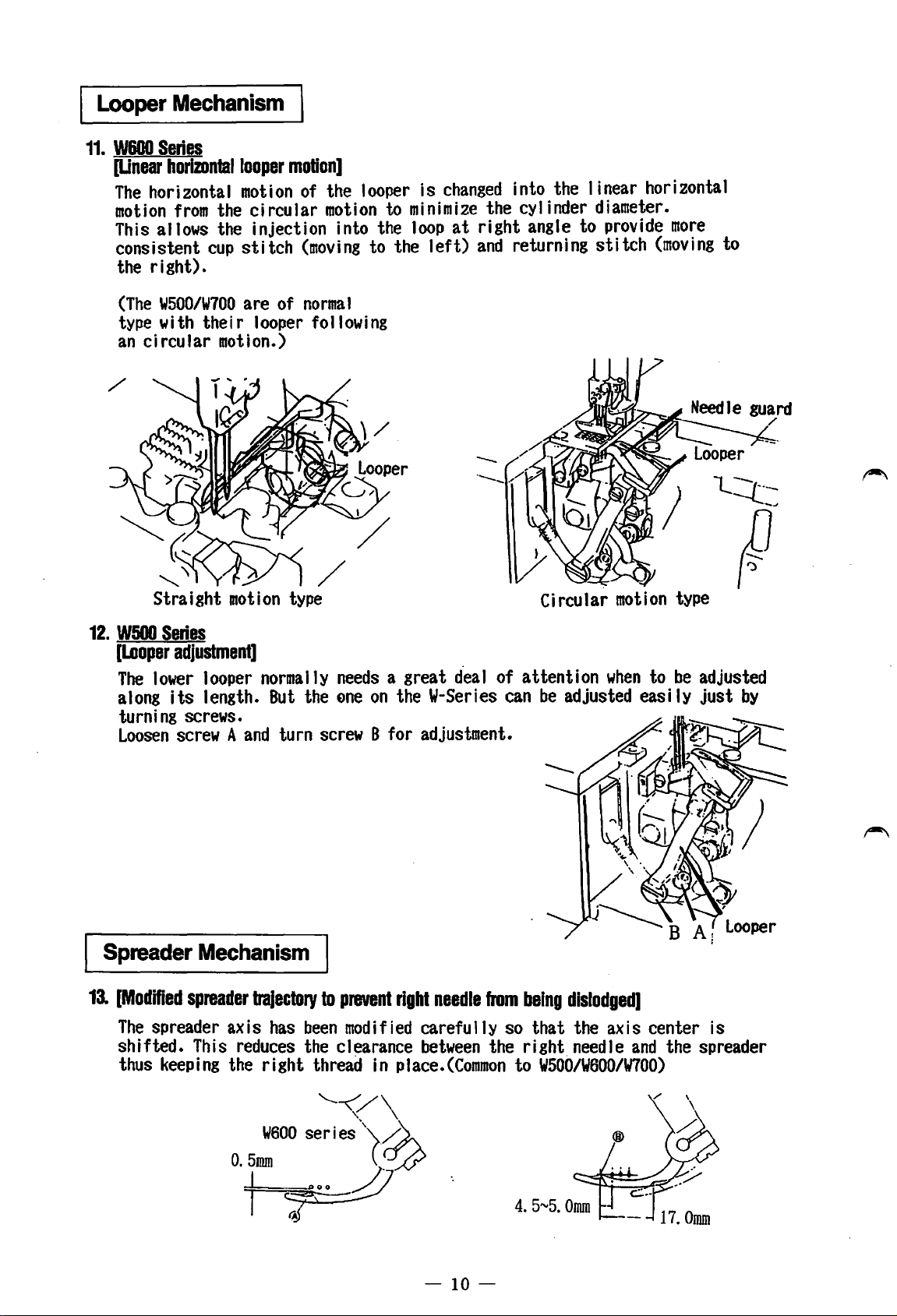

Looper Mechanism

11.

W&OO

Series

[Unear

The

motion

This

consistent

the

(The

type

an

horimntal

horizontal

from

the

allows

the

cup

right).

W500/W700

with

their

circular

motion.)

looper

motion

circular

injection

stitch

are

motion]

of

looper

of

the

motion

into

(moving

normal

following

looper

to

the

to

the

is

changed

minimize

loop

at right

left)

and

into

the

the

cylinder

angle

to

returning stitch

linear

horizontal

diameter.

provide

more

(moving

to

12.

W500

(Looper

The

along

turning

Loosen

Straight

Series

adjustment]

lower

its

looper

length.

screws.

screw A and

motion

normally

But

type

turn

the

screw

needs

one

on

B for

a great

deal

theW-Series

adjustment.

--

of

Circular

attention

can

be

motion

when

adjusted

Needle

-~-

Looper

type

to

be

adjusted

easily just

guard

by

Spreader Mechanism

13.

(Modified

The

shifted.

thus

spreader

spreader

This

keeping

trajectory

axis

has

reduces

the

right

to

been

the

clearance

thread

prevent

right

modified

in

place.(Common

needle

from

carefully

between

the

being

so

that

right

to

W500/W600/W700)

'--<~\

W600

series''\./~

0.5mm

I

~AOO

,~

tA

(~~

~-

-10-

dislodged]

the

axis center is

needle

and

the

spreader

Page 15

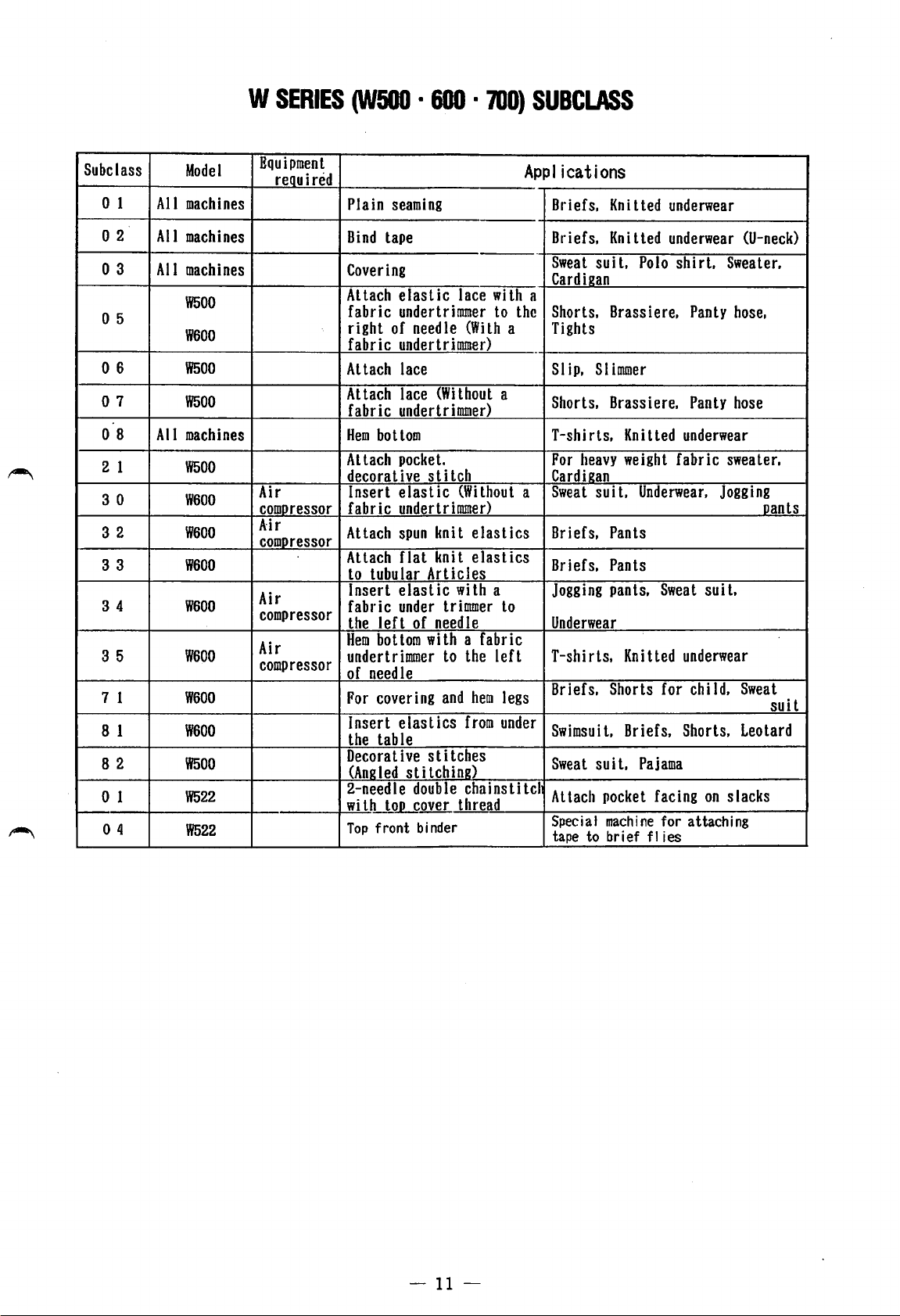

W

SERIES

(W500 • 600 • 700)

SUBCLASS

Subclass

0 1

0 2

0 3

0 5

0 6

0 7

0 8

2 1

3 0

3 2

3 3

3 4

3 5

7 1

8 1

8 2

0 1

0 4

Model

All

A

11

machines

All

machines

W500

W600

W500

W500

All

machines

W500

W600

W600

W600

W600

W600

W600

W600

W500

W522

W522

machines

Equipment

required

Air

compressor

Air

compressor

Air

compressor

Air

compressor

Applications

Plain

seaming

Bind

tape

Covering

Attach

fabric

right

fabric

Attach

Attach

fabric

Hem

At

decorative

Insert elastic

fabric

Attach

Attach

to

Insert elastic

fabric

the

Hem

undertrimmer

of

For

Insert elastics

the

Decorative

(Angled

2-needle

wit~LJ&~L...cover

Top

elastic

undertrimmer

of

needle

undertrimmer)

lace

lace

(Without

undertrimmer)

bottom

tach

pocket.

stitch

undertrimmer)

spun

knit

flat

knit

tubular

left

bottom

Articles

under

trimmer

of

needle

with a fabric

to

needle

covering

and

table

stitches

stitchin~)

double

front

binder

lace

with

to

(With

a

(Without a Sweat

elastics

elastics

with

a

to

the

left

hem

legs

from

under

chainstitcl

thread

a

the

a

Briefs.

Briefs.

Sweat

Cardigan

Shorts.

Tights

Slip,

Shorts.

T-shirts.

For

Cardigan

Briefs.

Briefs.

Jogging

Underwear

T-shirts.

Briefs.

Swimsuit.

Sweat

Attach

Special

tape

Knitted

Knitted

suit,

Brassiere,

Slimmer

Brassiere.

heavy

suit.

Pants

Pants

pants.

Shorts

suit.

pocket

machine

to

brief flies

underwear

underwear

Polo

shirt.

Knitted

weight

underwear

fabric

Underwear.

Sweat

Knitted

underwear

for

Briefs.

Shorts.

Pajama

facing

for attaching

Panty

Panty

Jogging

suit.

child.

on

(U-neck)

Sweater.

hose.

hose

sweater.

Pants

Sweat

suit

Leotard

slacks

-11-

Page 16

[

WORK

AIDS"(

UT(Bottom cover thread trimmer)

1 )

l

Type

moo

~00

101

105

102

106 110

103

107

104 108

301

305

302

306

303 307

304

308 315

332

331

Bottom

thread

Electric

~600

109

0

0

111

0

112

0

312

313

314

316

317

320

321

333

cover

trimmer:

Pneuaatic

Thread

Electric

0

0

0 0

0 0

0

0

0 0

0 0

0

0

0 0

wiper

Pneumatic

withouL

*1

*1

*1

*1

*1

*1

Presser foot

Electric

Pneumatic

0

0

0

0

0

0

0

lifter

wl

thout

0

0

0

0

0

0

Applicable

W542-01.

W644-01,03,05,08,33,

W742-01.

(~2)W664-08,33,81

W562-01,03,08,21

W664-01,03,05,

\Y!62-01,03

W542-0L

W644-01,03,05,08,33,

W742-0l.

(~2)W664-08,33,81

W5o2-01,03,08,21

W664-01,03,05,

W762-01,

W644-30,32,34,35

(~2)W664-30,34,35

W664-32

W562(542)-01,03,08,

W762(742)-0l,

W664(644)-01,03,05,08,33,

03,

08

03

03, 08,

03

03

Models

71,81

71

71,81

71

W542-21

03

71,81

*1

Thread

*2

Parts for

*

Thread

334

wiper

top

wiper

0

(electric

cover

thread----Packaged

(pneumatic

type)----Packaged

type)

should

be

0

in

the

in

the

attached

accessory

accessory

to

the

box.

box.

left

of

the

0

needle

W664(644)-30,32,34,35

bar.

-12-

Page 17

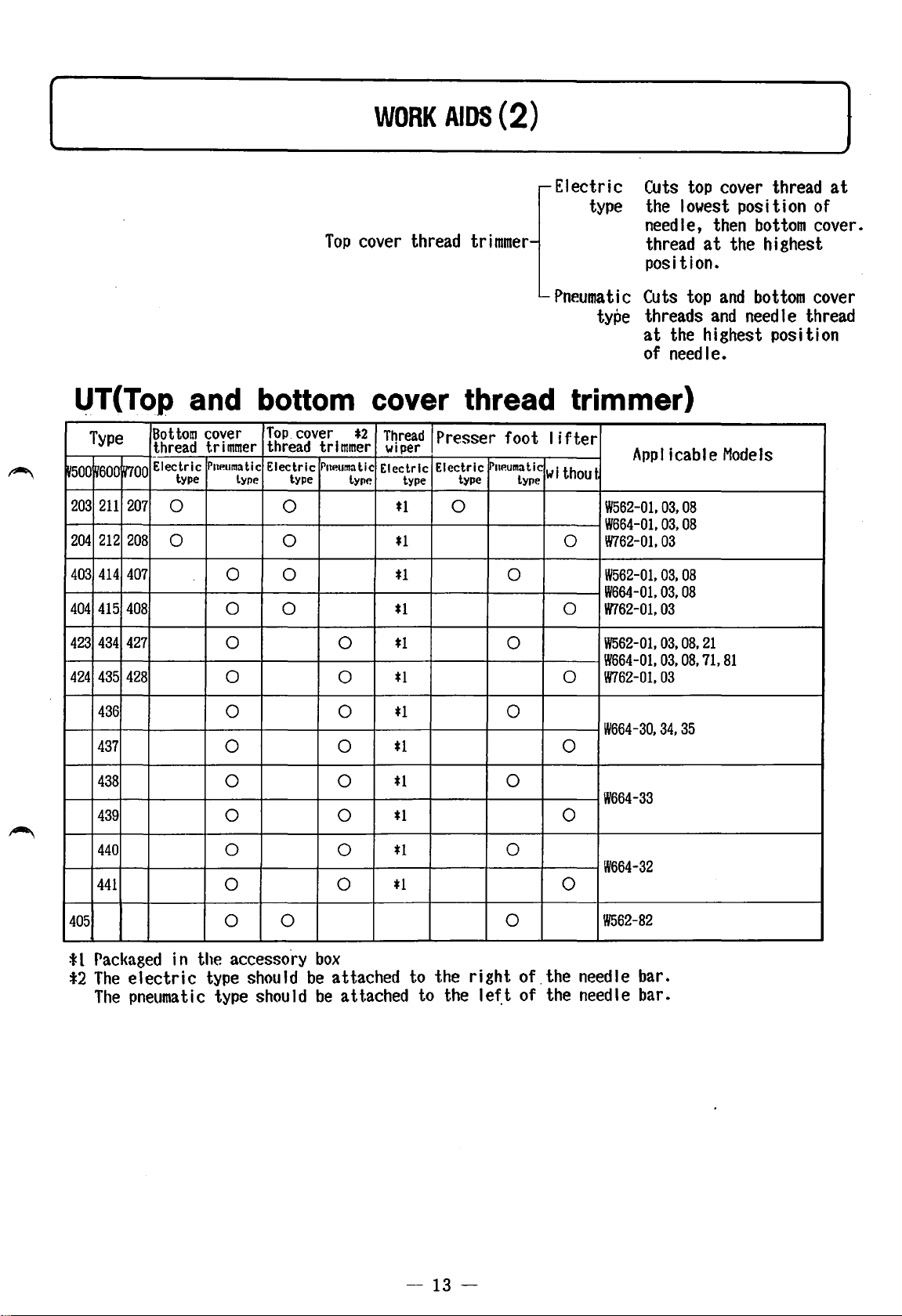

[

WORK

AIDS

(2)

l

~T(Top

Type

Y500

203

204

403

404

moo

~600

211

207

212

208

414

407

415 408

and bottom cover thread trimmer)

Bottom

thread t.r i

Electric

cover

Pm~umatic

type

0

0

Top

thread trimmer

mmer

Electric

l~pe

0

0

0 0

0

0

cover

type

Top

cover

*2

Pmmmatic

l~pe

thread

Thread

wiper

Electric

type

*1

*1

*1

n

trimmer

Presser foot

Electric

Pru~umatic

type

0

lype

0

Electric

type

Pneumatic

type

lifter

without

W562-01,03,08

W664-01,03,08

W762-01.

0

W562-01,03,08

W664-0l.

W762-01,03

0

Cuts

top

the

lowest

needle,

thread

at

position.

Cuts

top

threads

at

the

highest position

of

needle.

Applicable

03

03,

08

cover

position

then

the

and

and

needle

Models

thread

bottom

highest

bottom

at

of

cover.

cover

thread

423

434

424

435 428

436

437

438

439

440

441

405

* l

Pacl<aged

*2

The

The

427

i n

electric

pneumatic

0

0

0 0

0

0 0

0 0

0

0 0

0 0

the

accesso-ry

type

should

type

should

0

0

0

0

box

be

attached

be

attached

*1

*1

*1

*1

u

u

*1

*1

to

to

the

right of.the

the

lef.t

0

0

0

0

0

of

the

W562-01,03,08,21

W664-01,03,08,

W762-01,03

0

W664-30,34,35

0

W664-33

0

W664-32

0

W562-82

needle

needle

71,81

bar.

bar.

-13-

Page 18

[

WORK

AIDS

( 3)

l

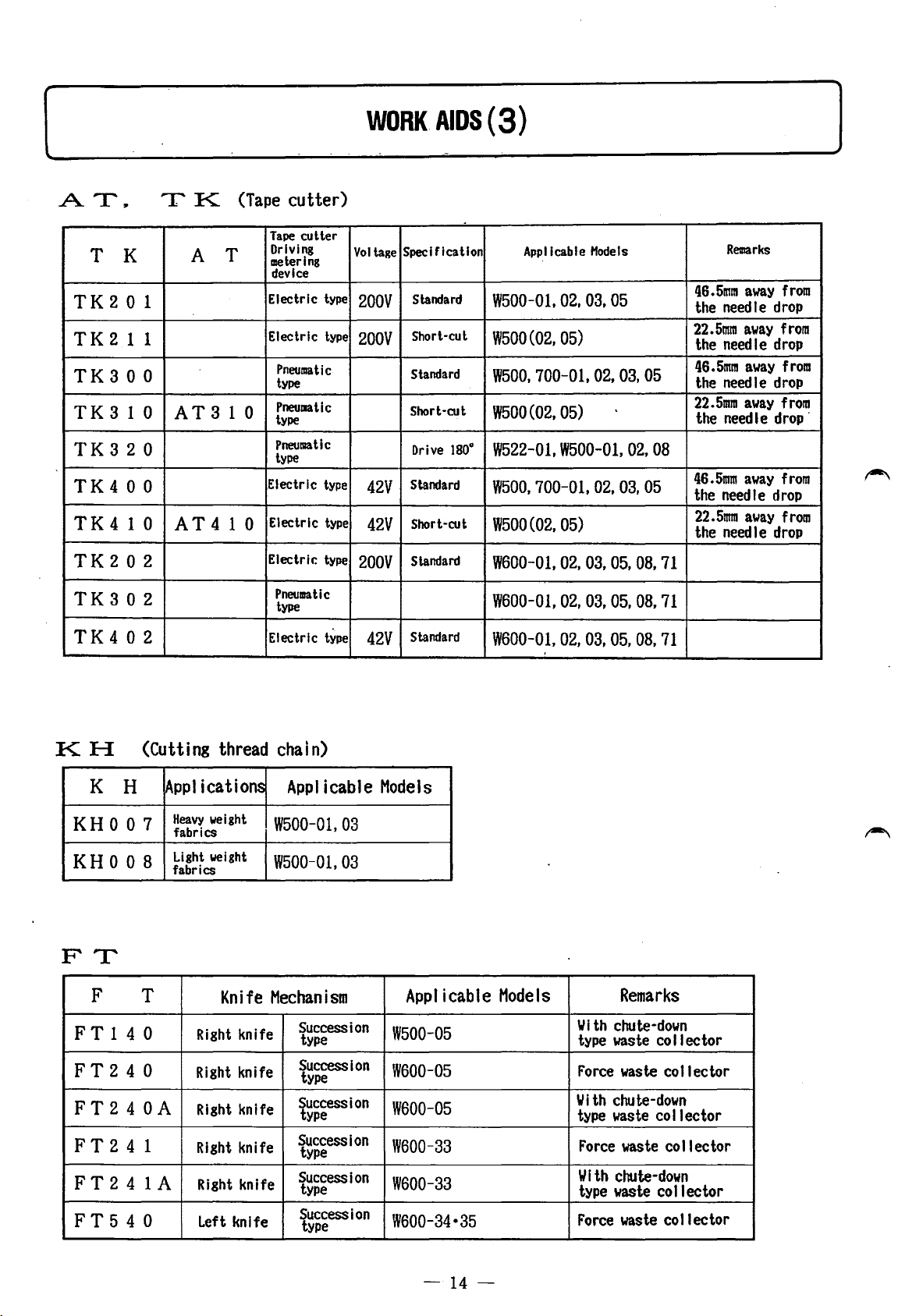

AT,

T K

TK201

TK211

TK300

TK310

TK320

TK400

TK410

TK202

TK302

TK402

T K

A

AT310

AT410

(Tape

T

cutter)

Tape

cutter

Driving

metering

device

Electric

Electric

Pneumatic

type

Pneumatic

type

Pneunmtic

type

Electric

Electric

Electric

Pneumatic

type

Electric

type

type

type

type

type

type

Voltage

200V

200V

42V

42V

200V

42V

Speci

ficatlon

Standard

Short-cut

Standard

Short-cut

Drive

Standard

Short-cut

Standard

Standard

Applicable

W500-01,02,03,05

W500(02,05)

W500,

700-01,02,03,05

W500(02,05)

180°

W522-0l,W500-01,02,08

W500,

700-01,02,03,05

W500(02,05)

W600-01,02,03,05,08,

W600-01,02,03,05,08,

W600-01,02,03,05,08,

Models

71

71

71

Reasarks

46.5mm

the

needle

22.5mm

the

needle

46.5mm

the

needle

22.5mm

the

needle

46.5mm

the

needle

22.5mm

the

needle

away

away

away

away

away

away

from

drop

from

drop

from

drop

from

drop·

from

drop

from

drop

~ ~

K

KH007

KHOOB

FT

F T

FT140

FT240

FT240A

FT241

FT241A

FT540

(Cutting

Applications

H

Heavy

fabrics

Light

fabrics

thread

weight

weight

Knife

Right

Right

Right

Right

Right

Left

chain)

W500-0l,

W500-0l,

Mechanism

knife

knife

knife

knife

knife

knife

Applicable

03

03

Succession

type

Succession

type

Succession

type

Succession

type

Succession

type

Succession

type

Models

Applicable

W500-05

W600-05

W600-05

W600-33

W600-33

W600-34•35

Models

With

chute-down

type

waste

Force

With

chute-down

type

waste

Force

WI

tb

type

Force

Remarks

collector

waste

collector

collector

waste

collector

chute-down

waste

collector

waste

collector

-14-

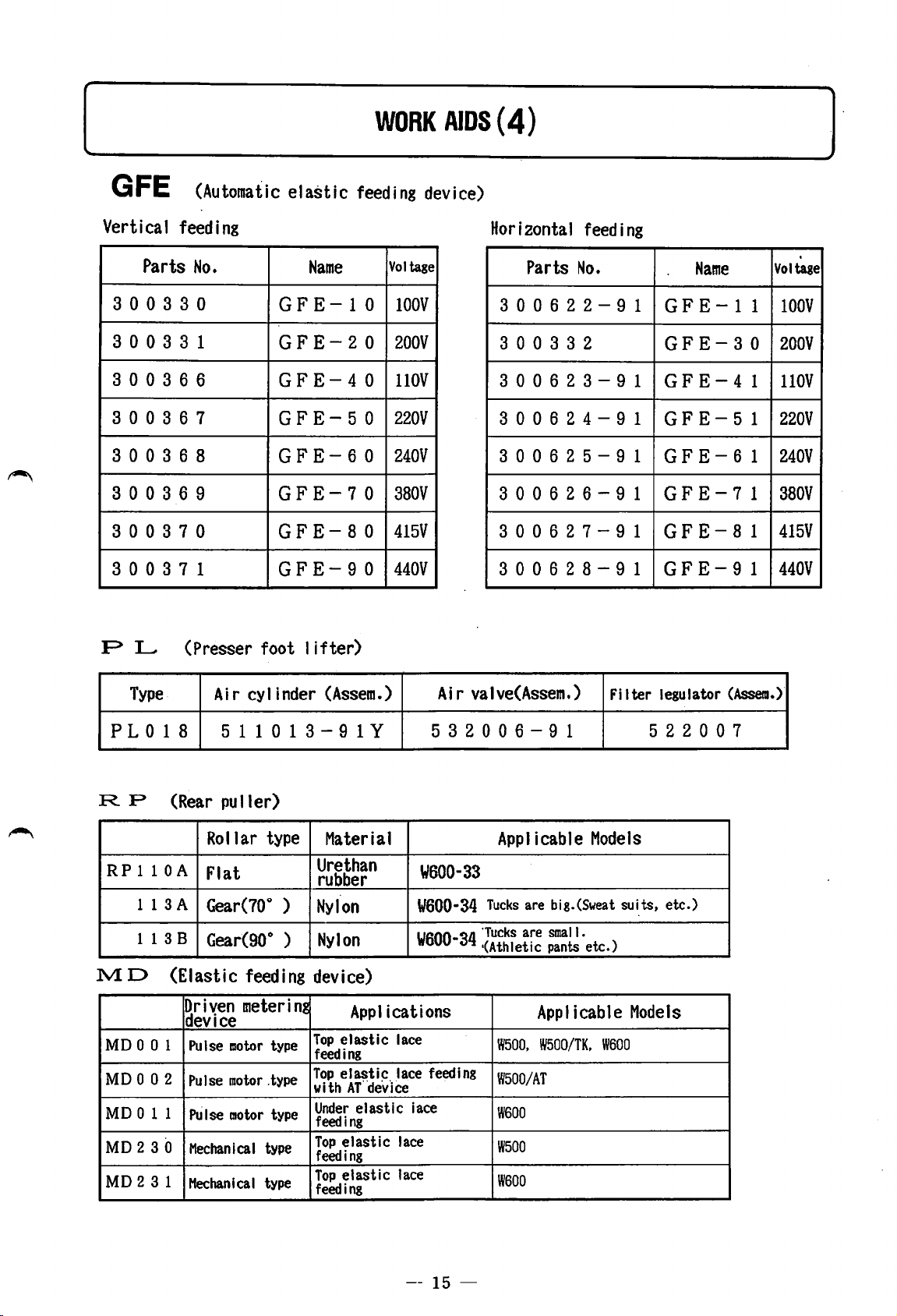

Page 19

[

_____________

w_o_R_K_AID_s_(4_)

____________

~]

~F=E:

Vertical

Parts

(Automatic

feeding

No.

3 0 0 3 3 0

3 0 0 3 3 1

3 0 0 3 6 6

3 0 0 3 6 7

3 0 0 3 6 8

3 0 0 3 6 9

3 0 0 3 7 0

3 0 0 3 7 1

elastic

Name

GFE-10

GFE-20

GFE-40

GFE-50

GFE-60

GFE-70

GFE-80

GFE-90

feeding

Voltage

100V

200V

110V

220V

240V

380V

415V

440V

device)

Hori2ontal

Parts

feeding

No.

3 0 0 6 2 2 - 9 1

3 0 0 3 3 2

3 0 0 6 2 3 - 9 1

3 0 0 6 2 4 - 9 1

3 0 0 6 2 5 - 9 1

3 0 0 6 2 6 - 9 1

3 0 0 6 2 7 - 9 1

3 0 0 6 2 8 - 9 1

Name

GFE-11

GFE-30

GFE-41

GFE-51

GFE-61

GFE-71

GFE-81

GFE-91

Voltage

100V

200V

110V

220V

240V

380V

415V

440V

P L (Presser foot 1 ifter)

Type.

P L 0 1 8

~I>

RP

1 1 0 A

1 1 3 A

1 1 3 B

MD

Air

cylinder

(Assem.)

511013-91Y

(Rear

puller)

Rollar

type

Flat

Gear(70o

Gear(90°

)

)

Material

Urethan

rubber

Nylon

Nylon

(Elastic feeding device)

Driven

meter

i

n~

device

Top

MD001

MD002

MD 0 11

MD230

MD231

Pulse

motor

type

Pulse

motor

.type

Pulse

motor

type

Meehan i ca I type

Meehan i ca I type

elastic

feeding

Top

elastic

with

AT.

Under

feeding

Top

elastic

feeding

Top

elastic

feeding

Air

5 3 2 0 0 6 - 9 1 5 2 2 0 0 7

W600-33

W600-34

WSOO

Applications

lace

lace

·dev.ice

elastic

feeding

lace

lace

lace

valve(Assem.)

Applicable

Tucks

are

'Tucks

-

34

are

•(Athletic

Applicable

W500,

V/500/AT

W600

W500

W600

Models

big.(Sweat

small.

pants

etc.)

W500/TK,

W600

Fi

Iter legulator (Assenl.).

suits, etc.)

Models

--

15-

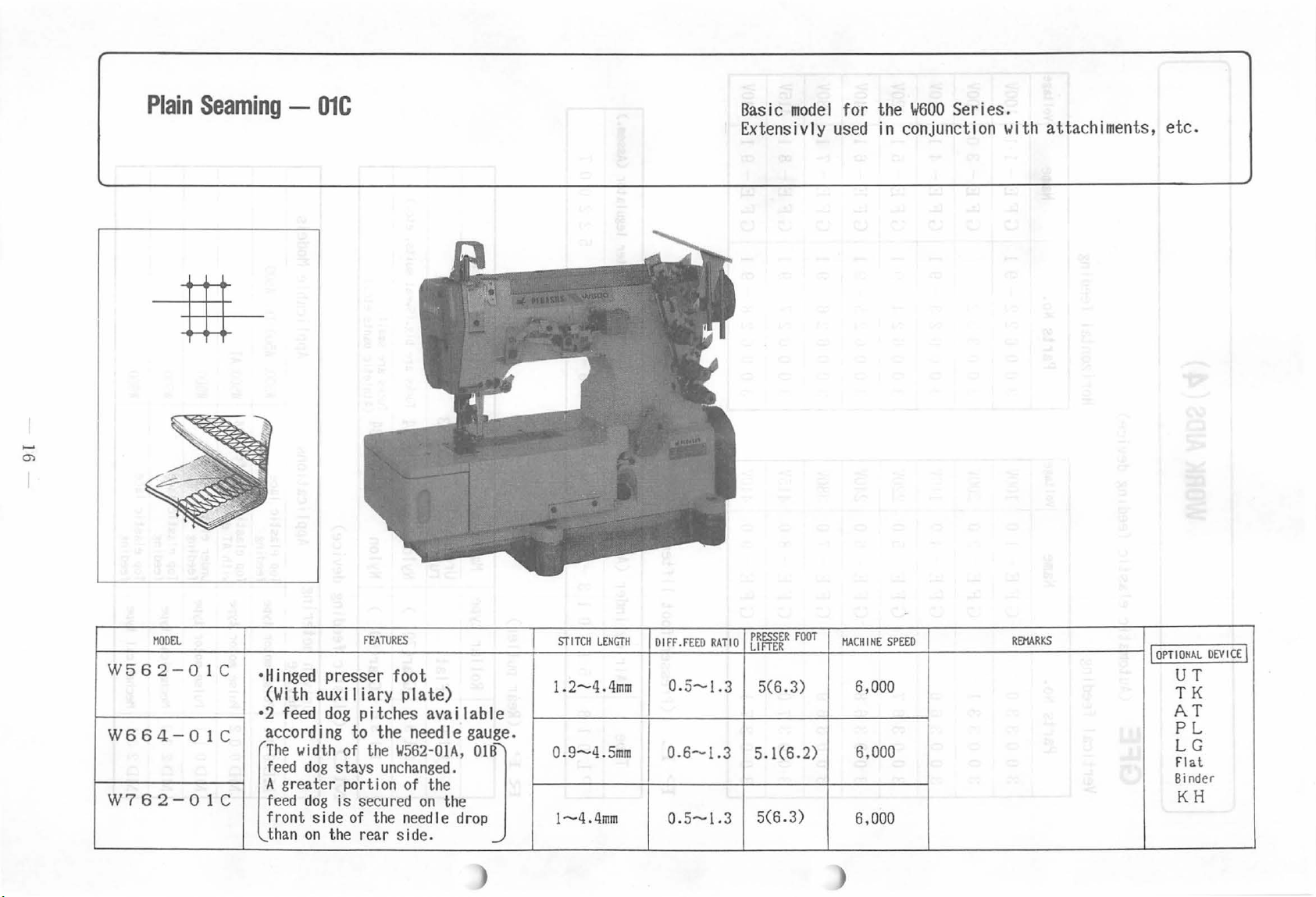

Page 20

Plain

Seaming -01C

Basic

model

Extensivly

for the

used

W600

in

conjunction

Series.

with

attachiments, etc.

110DEL

W562-0IC

W664-0IC

·Hinged

(With

•2

feed

according to

The

width

feed

dog

FEATURES

presser foot

auxiliary plate)

dog

pitches available

the

needle

of

the

W562-01A,

stays unc

hanged.

gauge.

01~

srI

1

.2-4.4mm

0

.9-

A greater portion of the

W762-01C

feed

dog

front side

,t

han

on

is secured

of

the needle

on

the rear side.

the

drop

1-4

../

TCH

4.5mm

.4mm

LENGTH

Dl

FF

.FEED

0.5-1.3

0.6-1.3

0.5-1.3

RATIO

PRESSER

FOOT

LIFTER

5(6

.3)

5.1(6.2)

5(6.3)

MACH I NE

6,000

6,000

6,000

SPEED

REl1ARKS

I

OPTIONAL

UT

TK

AT

PL

LG

Flat

Bind

KH

DEVICE

er

I

Page 21

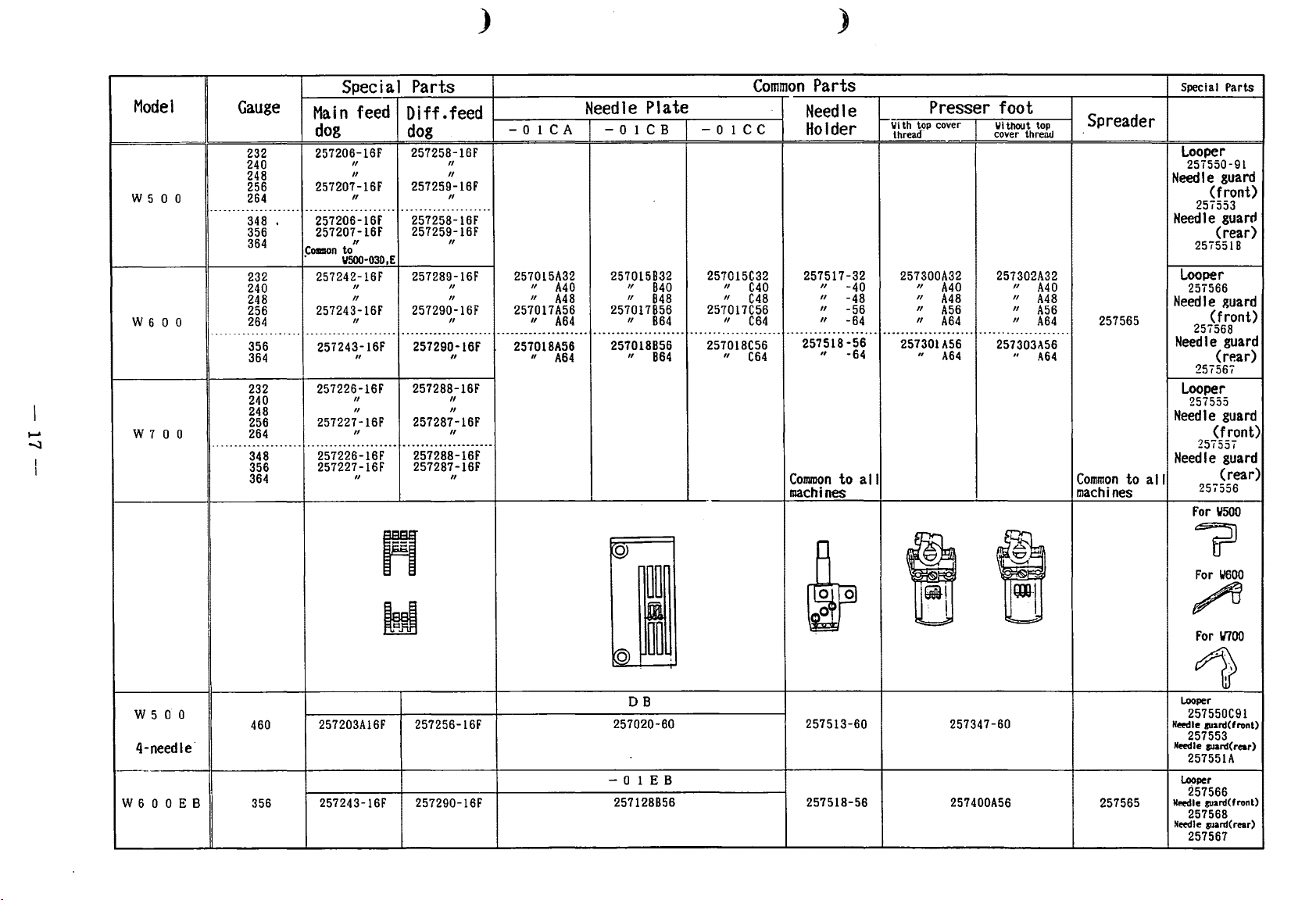

Model

w 5 0 0

W600

W700

Gauge

232

240

248

256

264

--------············

348

.

356

364

232

240

248

256

264

..........................

356

364

232

240

248

256

264

................................

348

356

364

Special

Main

feed

dog

257206-16F

II

II

257207-16F

"

........................

257206-16F

257207-16F

~ommon

II

to

W500·03D,E

257242-16F

II

"

257243-16F

II

............................

257243-16F 257290-16F

II

257226-16F 257288-16F

"

II

257227-16F 257287-16F

"

............................

257226-16F 257288-16F

257227-16F 257287-16F

Part.s

Diff.feed

dog

257258-16F

257259-16F

........................

257258-16F

257259-16F

257289-16F

257290-16F

.........................

..........................

"

)

Common

Needle

-01CA

II

II

"

"

257015A32

II

"

"

II

II

II

.........................

"

II

II

A40

II

A48

257017A56

II

A64

257018A56

II

A64

. ......................... ..................................

Plate

- 0 1 C B

257015832

II

840

II

848

257017856

II

864

257018856

II

864

0 1 c c

-

257015C32

II

"

257017C56

II

257018C56

II

C40

C48

C64

....................................

C64

Common

machines

)

Parts

Needle

Holder

257517-32

II

-40

-48

"

-56

"

-64

"

257518-56

II

-64

to a II

Presser foot

IIi

th top cover

thread·

257300A32 257302A32

A40

"

A48

"

II

A

56

II

................................. .................................

A64

257301A56

II

A64

llithout

top

cover thread

II

A40

II

A48

II

A

II

A64

257303.\56

,

A64

56

Spreader

257565

Common

machines

to a II

Special

Looper

257550-91

Needle

(front)

257553

Needle

2575518

Looper

257566

Needle

(front)

257568

Needle

257567

Looper

257555

Needle

257557

Needle

25i556

For

Parts

guard

guard

(rear)

guard

guard

(rear)

guard

(front)

guard

(rear)

W500

fl

~

w

50

0

460

4-needle

W600EB

356

257203A16F

257243-16F 257290-16F

257256-16F

rg>

~~

~

I

to)

257020-60

- 0 1 E B

257128856 257518-56

.

DB

257513-60

I

~

8

257347-60

257400A56

257565

7

For

W600

~

For

V700

~

looper

257550C91

Needle

guard(front)

257553

Needle

prd(resr)

257551A

looper

257566

Needle

guard(front)

257568

Needle

suanl(rear)

257567

Page 22

......

00

Binding

Tape -028

(with

-

tape

02C

cuHer

of

short

cut

type)

An interl

the

feed

inno

vations for

even

in

shoulder

ock machine for binding tape

dog

and

the presser foot specified for b

smoother

the area of cross

seam

ofT-shirts

binding,

seams

.

on

on

underwear

this

machine

the material

and T-shirts,

indi

ng

tape.

provides fine

such

as

files

etc.

With

Adopts

the various

seaming finish

of briefs or

MODEL

W562-02B

-

W664-02B

W762

-

02S

02B

•Hinged

•3

feed

according to the needle

lThe

width

feed

dog

So

is the

foot

bottom.

FEA11JRE

pre

sser foot

dog

pitches available

of

the

W562-02A

stays unch

width

of the

anged.

pre

gauge

sser

(02S-1.

.

J

srI

1

.2-

0.9-4.5m

1--4.

TCH

LENGTH

4.4mm

2-3. 3mm)

4mm

m

DIFF.FEED

0

.5-

I

0.6-1.3

0.5- 1.3

RATIO

!.3

PRESSER

LIFTER

5(6.3)

5.1(6.2)

5(6

.3)

FOOT

MACHINE

6

,000

6,000

6,000

.........................................

SPEED

RP

instal

REMARKS

device

led

is attached.

can

if.

not be

TK

device

I

ST

ANDARO

TRlO

jOPTIONAL

TK

AT

PL

LG

Binder

OEV

ICE

DEVICEj

I

Page 23

)

)

......

(!)

Model

w

50

W600

W700

Gauge

Main

dog

232

240

248

0

256

264

........................

348

356

364

232

240

248

256

264

......................... .........................

356

364

232

240

248

256

264

.....................

348

356

364

257214-16F 257260-16F

257215-16F

257216-16F

............................

257215-16F 257261-lSF

257216-16F

257244-16F 257291-lSF

257245-16F

257246-16F 257293-16F

257246-16F 257293-16F

257228-16F 257271-16F

257229-16F 257272-16F

257230-16F 257273-16F

....................

257229-16F

257230-16F 257273-16F

Special

feed

Parts

Diff.feed

dog

257261-16F

" "

II

"

"

"

"

"

II

II

257262-16F

........................

257262-16F

Common

257292-16F

......................

....................

257272-16F

"

II II

to

W500-02S

II

II

.....................

"

"

II

II

-02BA

257029A32

257030A40

A48

"

257032A56

II

A64

257031A48

257033A56

A64

Needle

...................... ..........................

Plate

-02BB

257029832

257030840

848

"

257032856

864

"

257031848

257033856

II

864

-02BC

257029C32

257030C40

II

C48

257032C56

C64

"

257031C48

257033C56

II

C64

Common

Parts

Needle

Holder

257517-32

-40

"

-48

"

-56

"

-64

"

. ....................

257518-56

-64

"

Common

machines

to a

W i

th

top

thread

257317A32

257318A40

II

257319A56

II

......................

257320A48

257321A56

II

II

Presser foot

cover

A48

A64

A64

Without top

cover

257322A32

257323A40

"

257324A56

"

....................

257325A48

257326A56

II

thread

A48

A64

A64

Spreader

257565

Common

machines

to a

Special Parts

looper

257550-91

Needle

suard(front)

257553

Needle

suard(rear)

2575518

Looper

257566

Needle suard(front)

257568

Needle

suard(rear)

25756i

1---·--·

looper

257555

Needle suard(front)

257556

Needle

suard(rear)

25755i

II

--

fll

~

-02SA

257023A32

257024A40

A48

"

257041A56

II

A64

257040A48

257025A56

II

A64

w

50

Short-cut

0

232

240

248

256

264

....................... ........................... ...................... ................................

348

356

364

257208-16F 257260-16F

257209-16F 257261-16F

II

257210-16F 257262-16F

"

257209-16F

257210-16F

"

"

"

257261-16F

257262-16F

Cocmon

tO

VS00-028

~~m~

fh

~

- 0 2 S B

257023832

257024840

848

"

257041856

II

.....................

864

257040848

257025856

II

864

-02SC

257023C32

257024C40

C48

"

257041C56

II

.....................

C64

257040C48

257025C56

II

C64

~

Common

machines

to a

~

..

.......................

II

257350-32

257351-40

II

-48

257358-56

II

-64

257359-48

257352-56

II

-64

~

257360-32

257361-40

-48

"

257362-56

II

.

...................

-64

257363-48

257353-56

II

-64

Common

machines

to a

II

Looper

257550-91

Needle

suard(front)

257553

Needle

suanl(rear)

2575518

C0111110n

to

\1500-028

.

Page 24

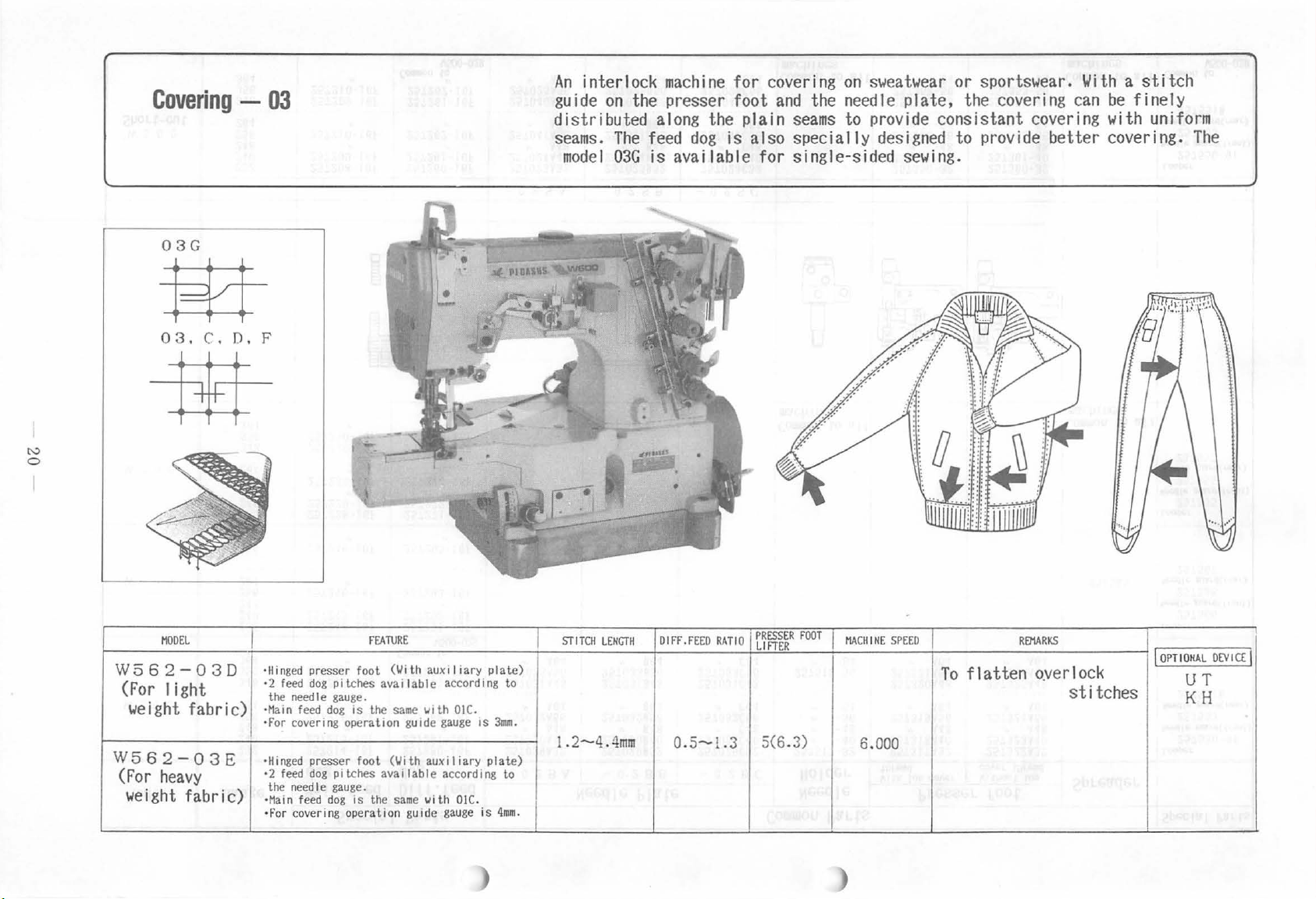

Covering -03

03G

m-

03.C.D.F

-m-

An

interlock mac

guide

distri

seams.

on

buted along t he plain

The

model

03G

hine

for covering

the presser foot

feed

dog

is also specially designed to

is avai

!abl

e for single-sided s

and

seams

on swe

the needl

to pro

atwear

or sport swear.

e plate, the covering c

vid

e consistan

ewing

.

t covering with

provid

e better covering. The

With a stitch

an

be

finely

uniform

HODEL

W562-03D

(For

I ight

we

ight fabri c)

W562-03E

(For heavy

weig

ht

fabric)

·llinged

presser fool

·2

feed

dog

the

needle

•Ma1n

feed

·

For

cover1ng

·Hinged

presser foot (Iii th

•2

feed

dog

the

need

Main feed

For cove

le

ring

·

·

pi

lches

gauge.

dog

IS

operat1on

pitches

gauge.

dog

IS

ope

FEATURE

(\Ji

th

availab

the s

avai lable according

the

ration

aux1

le according

ame

Yl lh

gu1de

gauge

auxi

same with

gui

de gau

I iary plate)

l iary plate)

OlC.

OIC.

ge

IS

is

to

3mm.

to

4mm.

ST

1.2--4.4mm

I TCH L

ENGTH

DI

FF.FEED

0.5

--

RATIO

1.3

PRESSER

FOOT

LIFTER

5(6.3)

MACHINE

SPEED

6.000

ROORKS

To flatten

Qverloc

stitc hes

k

I O

PTIO

KAL OEV

UT

KH

IU I

Page 25

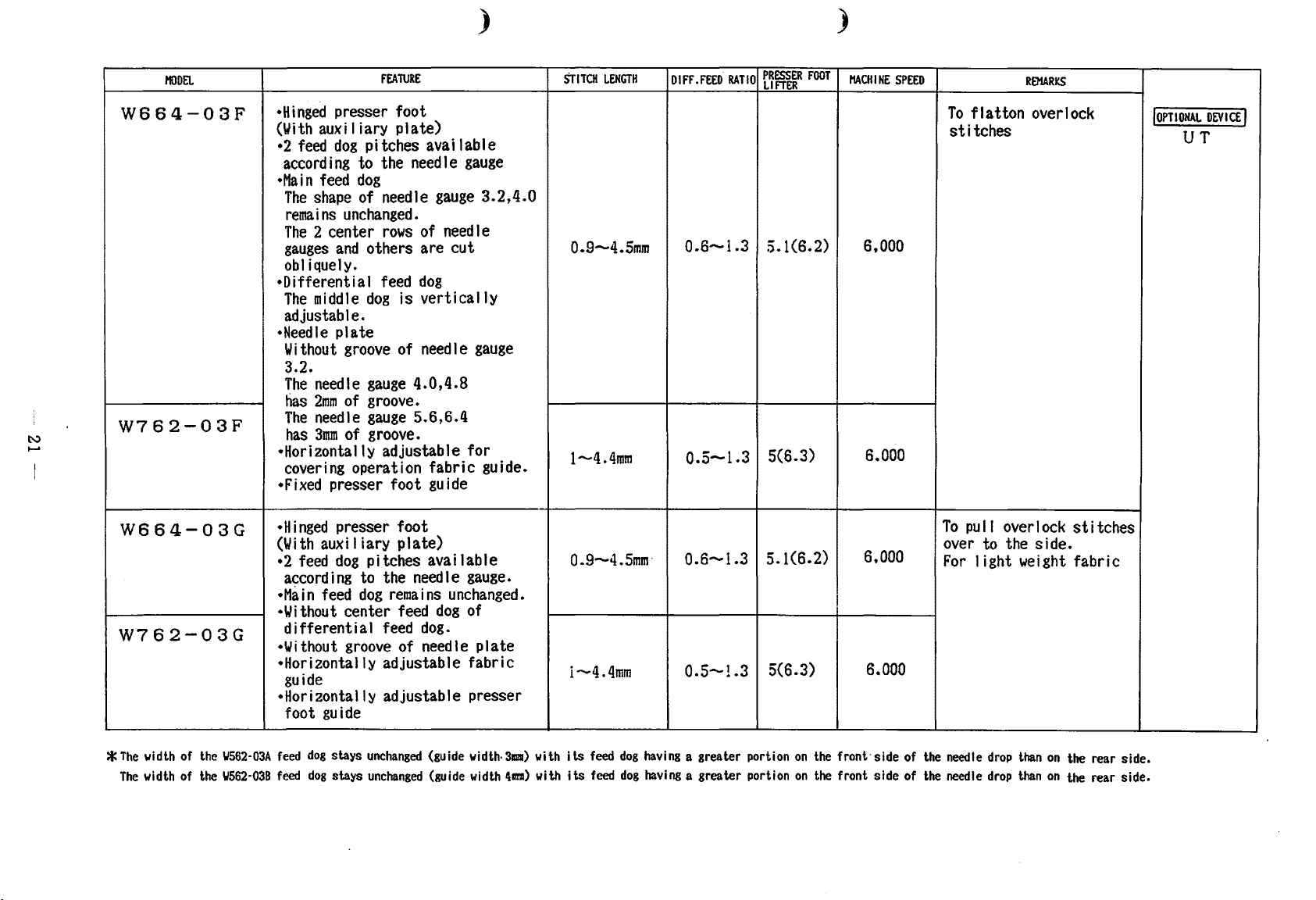

HODEl

FEA1\JRE

)

STITCH

LENGTH

DIFF.FEEO

RATIO

PRESSER

LIFTER

FOOT

)

HACHINE

SPEED

REMARKS

W664-03F

W762-03F

W664-03G

W762-03G

•Hinged

(With

•2

according

•Main

The

remains

The

gauges

obi

•Differential

The

presser foot

auxiliary plate)

feed

dog

pitches available

to

the

feed

dog

shape

of

needle

unchanged.

2 center

and

rows

others are cut

iquely.

feed

middle

dog

needle

gauge

of

gauge

3.2,4.0

needle

dog

is vertically

adjustable.

•Needle

Without

plate

groove

of

needle

gauge

3.2.

The

has

The

has

needle

2mm

needle

3mm

gauge

of

groove.

gauge

of

groove.

4.0,4.8

5.6,6.4

•Horizontally adjustable for

covering

•Fixed

•Hinged

(With

•2

feed

according

•Main

•Without

differential

•Without

operation fabric guide.

presser foot

guide

presser foot

auxiliary plate)

dog

pitches available

to

the

needle

feed

dog

center

groove

remains

feed

feed

of

unchanged.

dog

dog.

needle

gauge.

of

plate

•Horizontally adjustable fabric

guide

•Horizontally adjustable presser

foot

guide

Q.9-4.5mm

l-4.4mm

0.9-4.5mm·

1-4.4mm

0.6-1.3

0.5-1.3

0.6-1.3

0.5-1.3

5.1(6.2)

5(6.3)

5.1(6.2)

5(6.3)

I

6,000

6.000

6.000

6.000

To

flatton overlock

stitches

To

pull

overlock

over

to

the

For

1 ight

weight

side.

stitches

fabric

!oPTIONAL

UT

DEVICE

I

~The

width

of

the

The

width

of

W562·03A

the

W562·038

feed

feed

dog

dog

stays

stays

unchanged

unchanged

(guide

(guide

width·3mm)

width

4mm)

with

with

its

its

feed

feed

dog

dog

having

a greater portion

having

a greater portion

on

on

the

front·side

the

front side

of

of

the

the

needle

needle

drop

drop

than

than

on

the rear side.

on

the

rear side.

Page 26

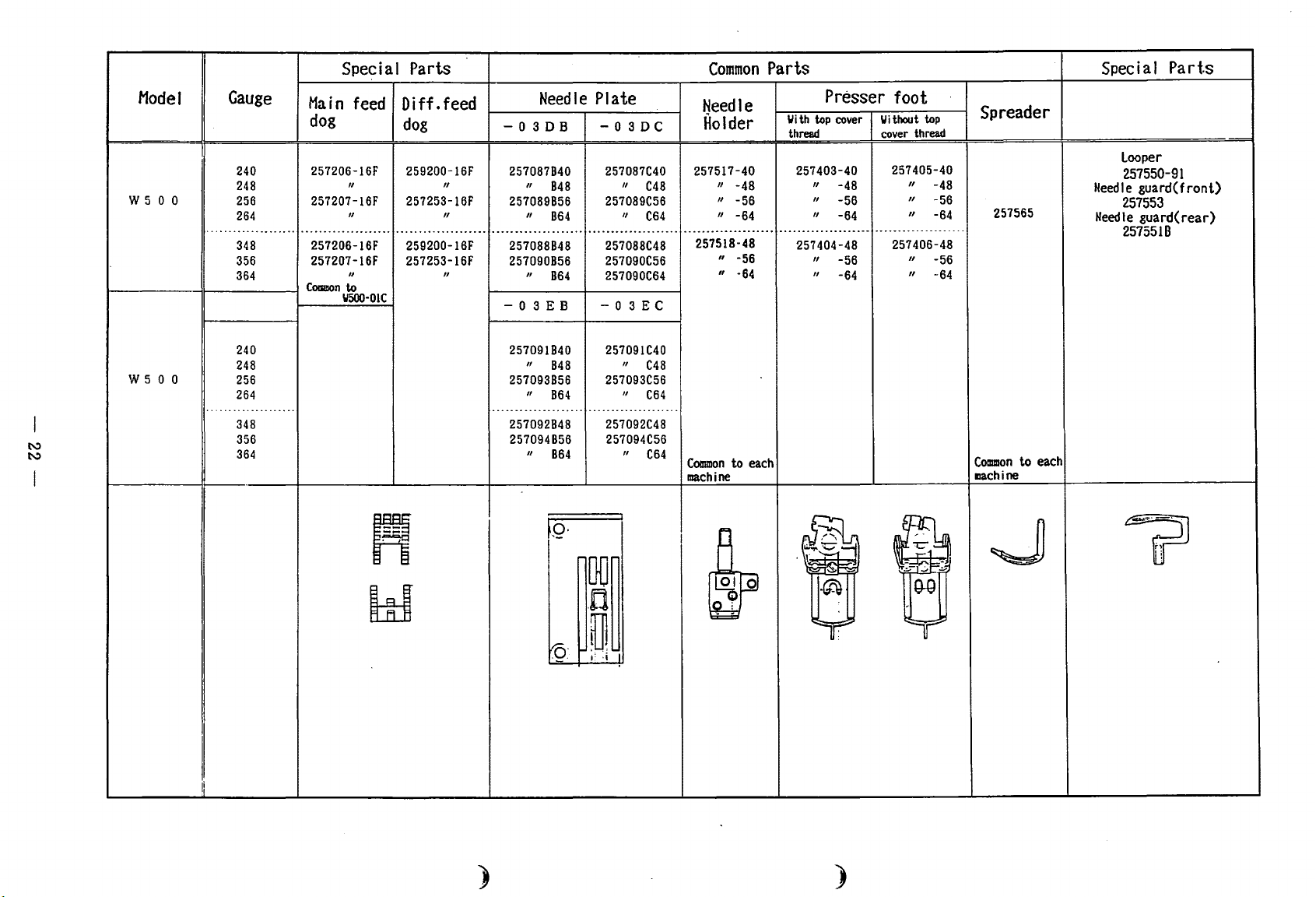

Special Parts

Common

Parts

Special

Part.s

Model

W500

w

50

.........................

0

...........................

Gauge

240

248

256

264

348

356

364

240

248

256

264

348

356

364

Main

feed

dog

257206-16F 259200-16F

II

257207-16F 257253-16F 257089856

II

...........................

257206-16F 259200-lSF

257207-IGF 257253-lSF

II

COIII!IOn

to

IJSOO·OlC

Oiff.feed

dog

II

II

........................

II

..........................

..

Needle

-03DB

257087840

II

II

257088848

257090856

II

-03EB

257091840

II

257093856

"

................................

257092848

257094856

II

-

"

w

Plate

-03DC

257087C40

848

864

864

848

864

864

II

C48

257089C56

II

............................

- 0 3 E C

.......................

C64

257088C48

257090C56

257090C64

257091C40

II

C48

257093C56

C64

"

257092C48

257094C56

C64

"

I

~Q·

_fl

00~

Needle

Holder

257517-40 257403-40

II

-48

II

-56

II

..

..............................

Common

machine

i

-64

257518-48

II

-56

II

-64

to

&

ij

D:

i'

·i I

W i th top

thread

...........................

257404-48

each

-

Presser foot

cover

II

-48

II

-56

II

-64

..............................

II

-56

II

-64

'

~

_...,.

-~

Without top

cover

thread

257405-40

II

-48

II

-56

II

-64

257406-48

II

-56

II

-64

~

-

-:c-

~

~~~~=~:~

'

to

-r-1

g{)

~

Spreader

257565

Coaon

to

machine

each

~

Looper

257550-91

Needle

257553

Needle

2575518

7

guard(front)

guard(rear)

I

!I

)

)

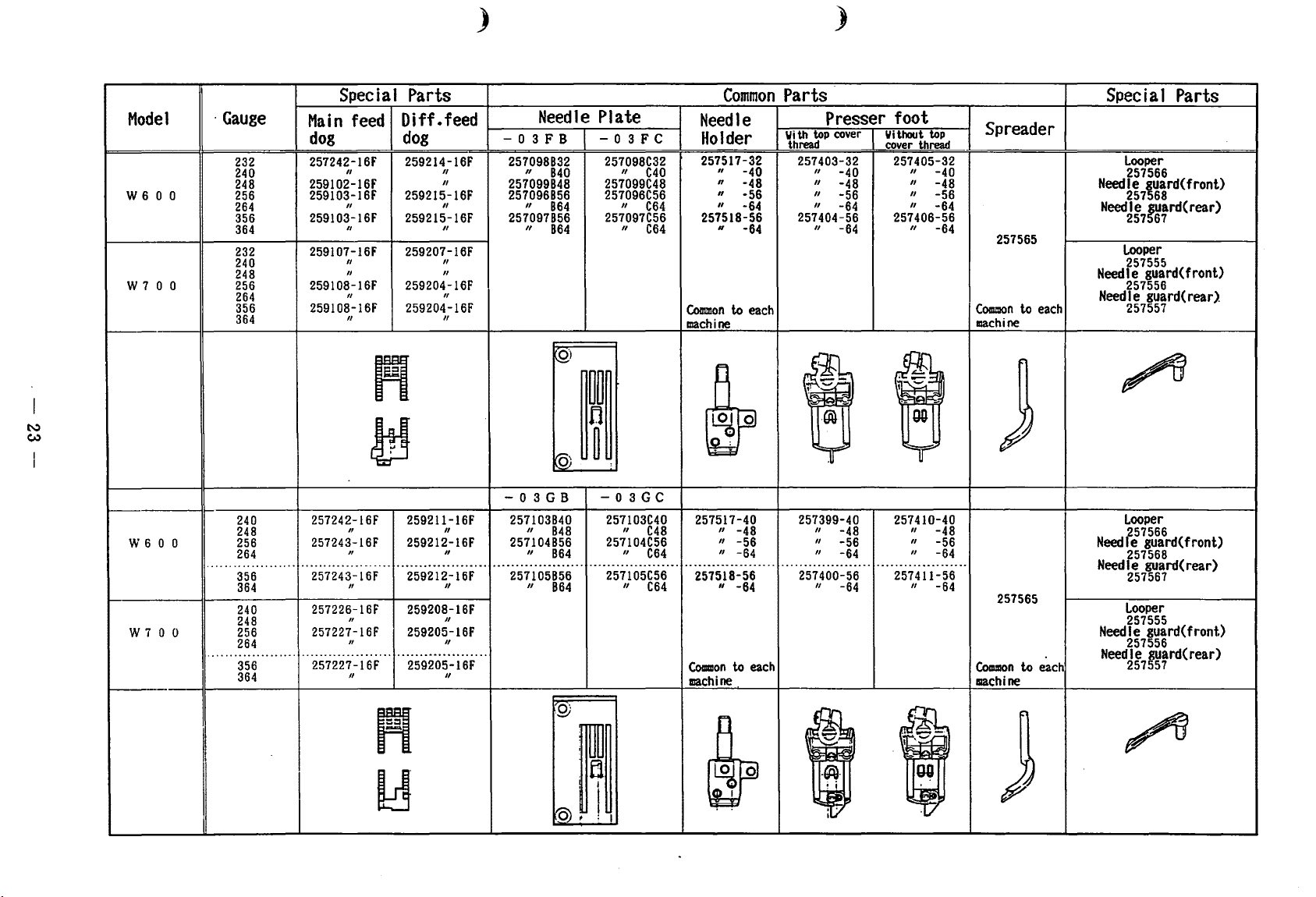

Page 27

)

)

Model

W600

W700

W600

W700

·Gauge

232

240

248

256

264

356

364

232

240

248

256

264

356

364

240

248

256

264

....................

356

364

240

248

256

264

.....................

356

364

Special

Main

feed

dog

257242-16F 259214-16F

II

259102-16F

259103-16F 259215-16F 257096856

"

259103-16F 259215-16F 257097856

II

259107-16F 259207-16F

"

"

259108-16F 259204-16F

"

259108-16F 259204-16F

II

Parts

Diff.feed

dog

II

II

II

II

II

II

II

II

Needle

-03FB

257098832

"

257099848

II

II

p;

!1!

-03GB

257242-16F 259211-16F

"

257243-16F 259212-16F

··············-·-···

"

257243-16F 259212-16F 257105856

"

257226-16F 259208-lSF

"

257227-16F 259205-lSF

"

......................... ........................

257227-16F 259205-16F

"

...........................

II

"

"

II

"

II

257103840

II

257104856

"

......................... ..........................

II

840

864

864

Plate

- 0 3 F C

257098C32

C40

"

257099C48

257096C56

II

C64

257097C56

II

C64

Common

Needle

Holder

257517-32

II

II

"

"

257518-56 257404-56 257406-56

II

Common

to

machine

-40

-48

-56

-64

-64

each

Parts

Presser foot

\lith

top

cover

thread

257403-32 257405-32

-40

"

II

-48

II

-56

II

-64

II

-64

_g)

~

~~

·®

~

~~~

-03GC

257103C40

II

848

864

864

C48

257104C56

C64

"

257105C56

II

C64

&

257517-40 257399-40 257410-40

-48

"

II

-56

II

-64

..........................

257518-56

"

Comon

to

machine

.........................

-64

each

!'!

-48

"

II

-56

II

-64

257400-56 257411-56

II

..........................

-64

\lithout

cover

II

II

II

II

II

top

thread

-40

-48

-56

-64

-64

Spreader

257565

Common

to

machine

each

e~

J

-48

"

-56

"

-64

"

II

-64

257565

Common

machine

to

each

Special

looper

257566

Needle

~uard(front)

257

Needle

257

Looper

257555

Needle

257556

Needle

257557

guard(front)

guard(rear)

~

looper

fi57566

Need

e guard(front)

257568

Needle

257567

looper

257555

Needle

257556

Needle

257557

guard(rear)

guard(front)

Parts

68

~uard(rear)

67

guard(rear)

-l

.g;

p;

~

~.

_m

G~~

l

::f?E

:El

~~

I,

&

-~·

.

I

~

~

1

~'1

. '

~

otl

J

~

Page 28

Attaching

(with

tape

Elastic

cutter

Lace -05

-058

of

short

cut

type)

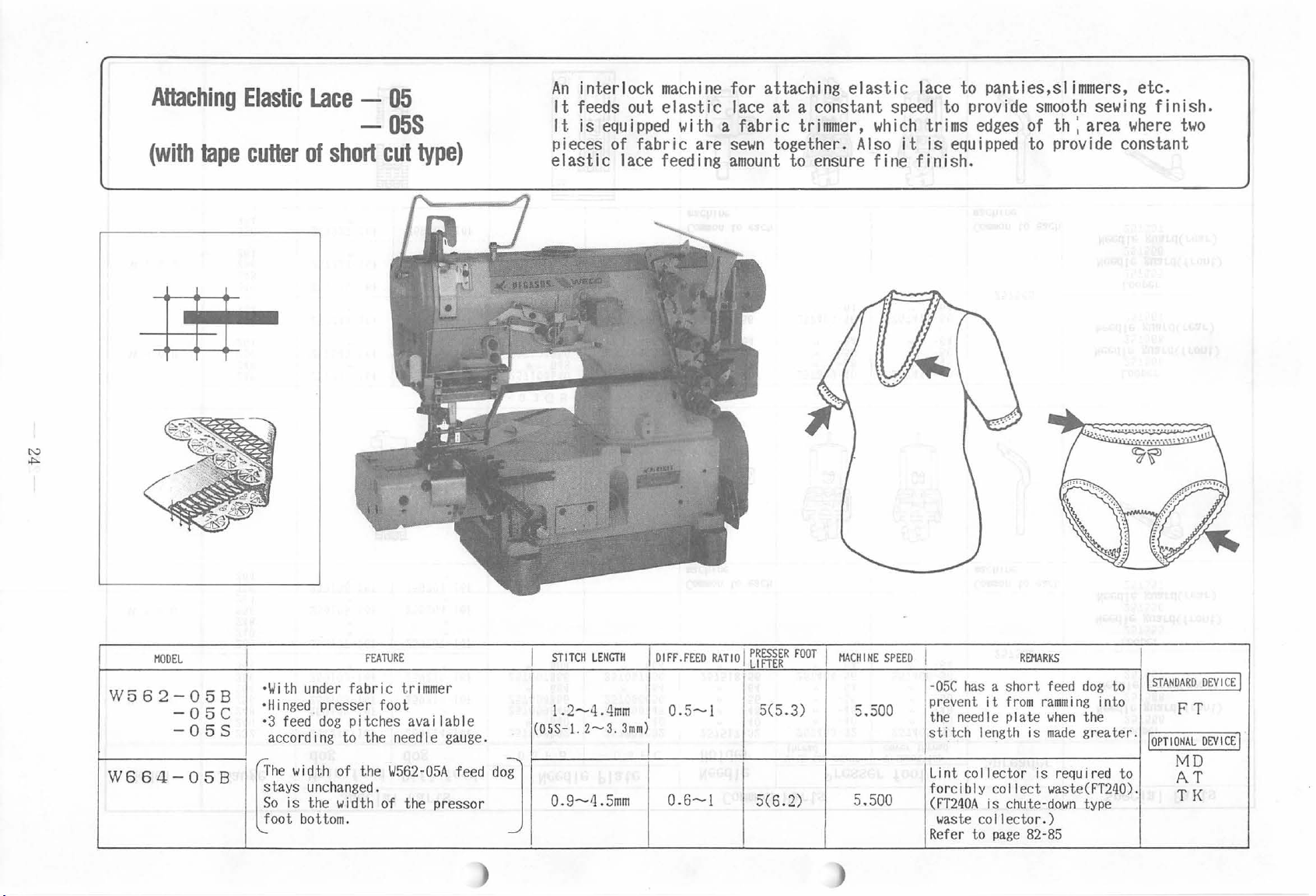

An

interlock

It

feeds out

It

is

pieces

equipped

of

machine

elastic

with

fabric are

elastic lace feeding

for attaching

elastic

lace at a constant

a fabric

sewn

amount

trimmer,

together.

to

ensure

lace to panties,sl

speed

which

Also

it

trims

is

fine finish.

to

provide

edges

equipped

immers

smooth

sewing

of th; area

to

provide

, etc.

finish.

where

two

constant

MODEL

W562

-

05B

-05C

-05$

W664-05B

I

•With

under

·Hinged

·3

according

[jhe

stays unchanged.

So

foot bottom.

presser foot

feed

dog

width

is

the width of the pressor

FEATURE

fabric

pitches avai !able

to

of the

trimmer

the needle

W562-05A

gauge.

feed

do~

STITCH

I

1.2

(OSS-1.

0.9

LENGTH

.......

4.4mm

2-3.

.......

4 .

3mm)

Smm

I D

I

I

IFF

0.5

0.6

FEED

•

.......

........

RAT

1

1

I 0 I

PRESSER

LIFTER

5(6.2)

FOOT

5(5.3)

I

MACH I HE

SPEED

5.500

5.500

I

-05C

has

prevent

the needle plate

stit

ch

Lint col lector is required to

forcibly collect

(FT240A

waste

Refer

RfJ1ARKS

a short

it

from

length

collector.)

to

is chute

page

82-85

is

feed

dog

ramming

when

made

waste(FT240)

-down

into

the

greater .

type

I

I

STANDARD

to

!oPTIONAL DEVICE!

.

FT

MD

AT

TI<

DEVI

CE I

Page 29

)

)

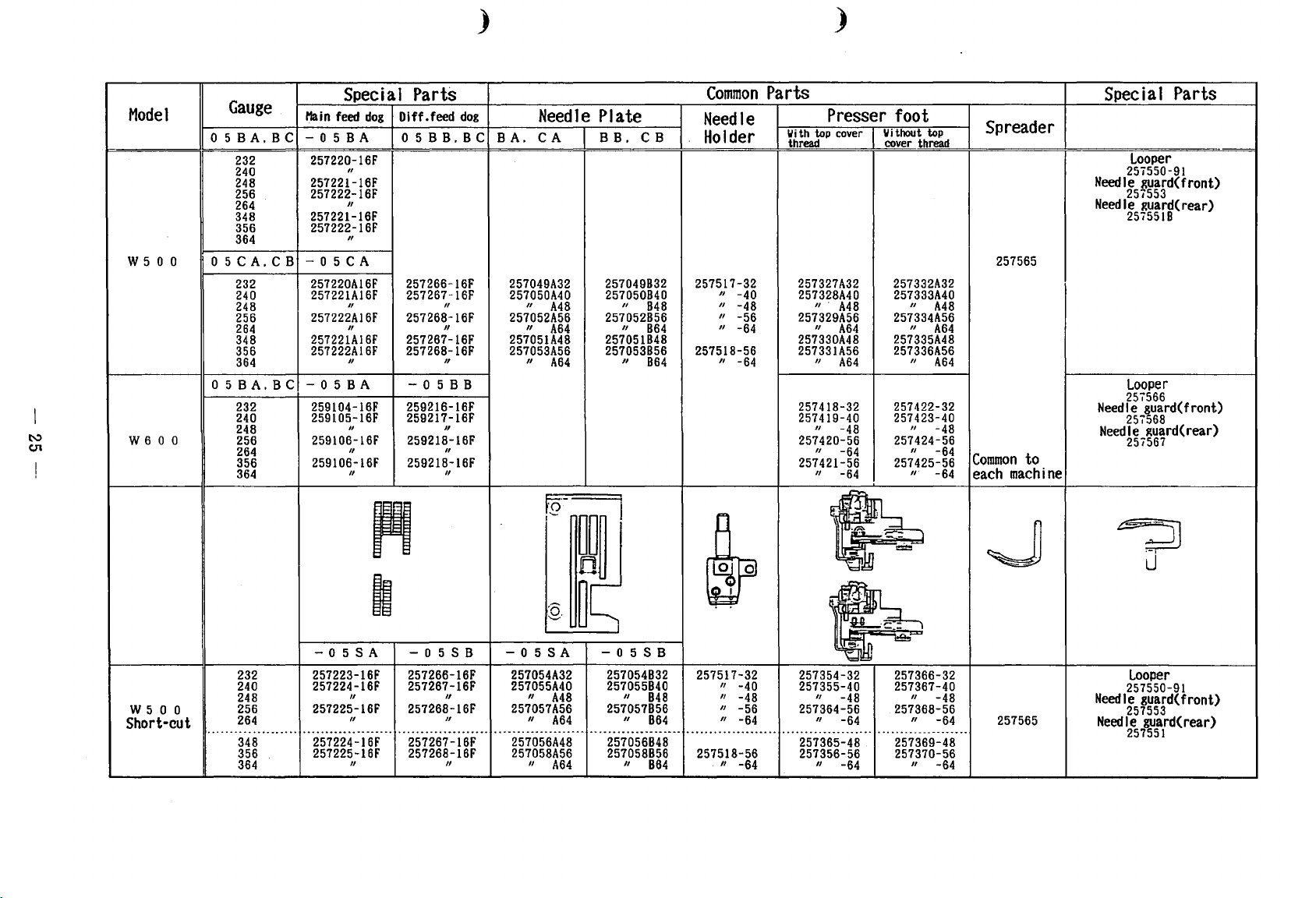

Model

W500

W600

Gauge

05BA.BC

232

240

248

256

264

348

356

364

05CA.CB

232

240

248

256

264

348

356

364

05BA.BC

232

240

248

256

264

356

364

Special

f1a

in

feed

dog

-05BA

257220-16F

II

257221-16F

257222-16F

II

257221-16F

257222-16F

II

-05CA

257220Al6F

257221A16F

II II

257222A16F

"

257221A16F

257222A16F

II

-05BA

259104-16F 259216-16F

259105-16F 259217-16F 257419-40

"

259106-16F

II

259106-16F

II

Parts

Diff.feed

05BB.BC

257266-16F

257267-16F

257268-16F

257267-16F

257268-16F

- 0 5 B B

259218-16F 257420-56

259218-16F 257421-56

"

II

II

II

II

dog

Needle

CA

B

A.

257049A32

257050A40

II

257052A56

II

257051A48

257053A56

II

A48

A64

A64

Fo·-

.._

I

Plate

B

B,

CB

257049832 257517-32

257050840

848

"

257052856

II

864

257051848

257053856 257518-56

II

864

I

Common

Needle

Holder

II

II

"

"

"

-40

-48

-56

-64

-64

Parts

Presser foot

With top cover

thread cover thread

257327A32

257328A40 257333A40

II.

257329A56 257334A56

II

257330A48 257335A48

257331A56 257336A56

II

257418-32

"

II

"

IIi

~~

~

A48

A64

A64

-48

-64

-64

Without top

257332A32

II

II

II

257422-32

257423-40

"

257424-56

II

257425-56

"

.

.

A48

A64

A64

-48

-64

-64

Spreader

257565

Common

each

to

machine

~

Special

Looper

257550-91

Needle

257553

Needle

2575518

Looper

257566

Needle

257568

Needle

257567

t:S

Parts

guard(front)

guard(rear)

guard(front)

guard(rear)

~:;jJ

L.J

Q.

-OSSA

257054A32

257055A40

A48

"

257057A56

II

A64

257056A48

257058A56

II

A64

w

50

0

Short-cut

h

-OSSA

232

240

248

256

264

........................... .............................

348

356

364

257223-16F 257266-16F

257224-16F 257267-16F

"

257225-16F 257268-16F

"

257224-16F 257267-16F

257225-16F 257268-16F

II II

- 0 5 S B

II

............................

II

..........................

&

~~

- 0 5 S B

257054832 257517-32

257055840

848

"

257057856

II

..

..............................

864

257056848

257058856 257518-56

II

....................... ...............................

864

-

.

~

II

-40

II

-48

II

-56

II

-64

II

-64

257354-32 257366-32

257355-40 257367-40

-48

"

257364-56 257368-56

II

-64

257365-48 257369-48

257356-56

II

········---------···

-64

-48

"

II

-64

257370-56

-64

"

257565

Looper

257550-91

Needle

257553

Needle

257551

guard(front)

guard(rear)

Page 30

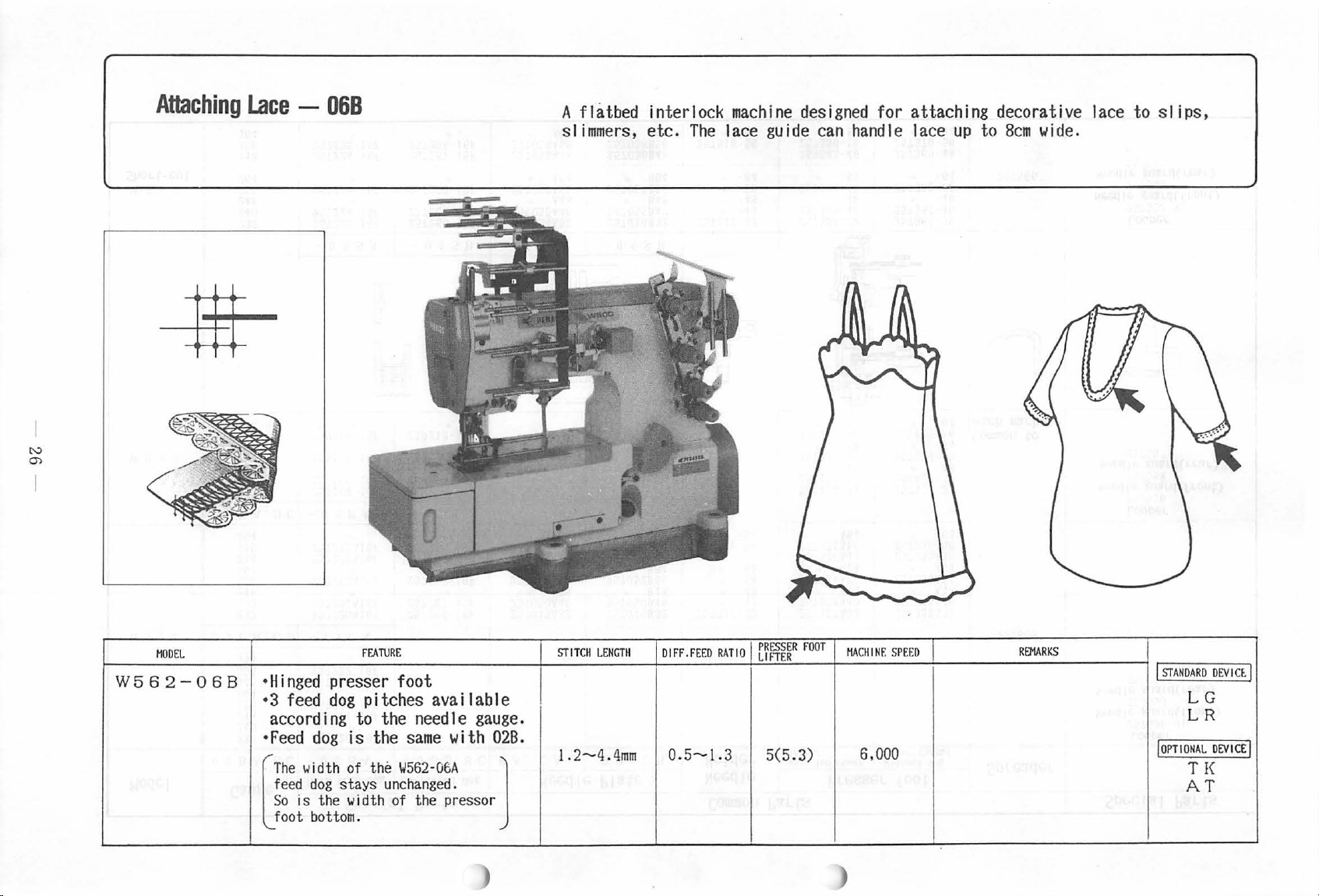

Attaching

Lace -068

A flatbed interlock

sl

immers,

etc.

The

machine

lace

guide

designed

can

handle

for attaching decorative lace to

lace

up

to

8cm

wide.

slips,

HODEL

W562-06B

•Hinged

•3

feed

according

•Feed

[_The

feed

So

foot

dog

width

dog

is the

bottom.

FEATURE

presser foot

dog

pitches available

to the needle

is the

of

stays

width

same

the

W562-06A

unchanged.

of

the pressor

with

gauge.

02B.

J

STITCH

I

1.2--4.4mm 0.5---

LENGTH

Dl

FF.

FEED

!.3

RATIO

PRESSER

FTER

5(5

FOOT

.3)

LI

HACHINf.

SPEE

6,000

D

Rf11ARKS

I

STANDARD

DEVICf.

LG

LR

!oPTIONAL

DEVICE!

TI<

AT

l

Page 31

)

)

l'\:)

-...J

Model

W500

Gauge

232

240

248

256

264

348

356

364

Special

Main

feed

dog

257214-16F

257215-16F

II

257216-16F

II

257215-16F

257216-16F

II II

Pll

I

PartS

Diff.feed

dog

257260-16F

257261-16F

II

257262-16F

II

257261-16F

257262-16F

Common

Needle

-06BA

257044A32

257045A40

II

257047A56

II

257046A48

257048A56

II

1:·,~~~

Plate

-0688

257044832

A48

A64

A64

Common

257045840

257047856

257046848

257048856

to

II

II

II

- o 7 B

I

848

864

864

Needle

Holder

257517-32

II

II

II

II

257518-48

II

II

&

-40

-48

-56

-64

-56

-64

Parts

Presser

With top cover

thread

257337A24

257338A40

II

A48

257339A56

II

A64

257340A48

257341A56

II

A64

:1_~

~

UIA

r=-

...._

~

,Q

.

,...

~

'-'

.

.Q.

foot

Without top

cover

257342A24

257343A40

II

257344A56

II

257345A48

257346A56

II

:

~Ir:::r

~

r~

~

thread

A48

A64

A64

)

I

Spreader

257565

~

Special

Looper

257550-91

Needle

257553

Needle

2575518

7

guard(front)

guard(rear)

Part.s

Page 32

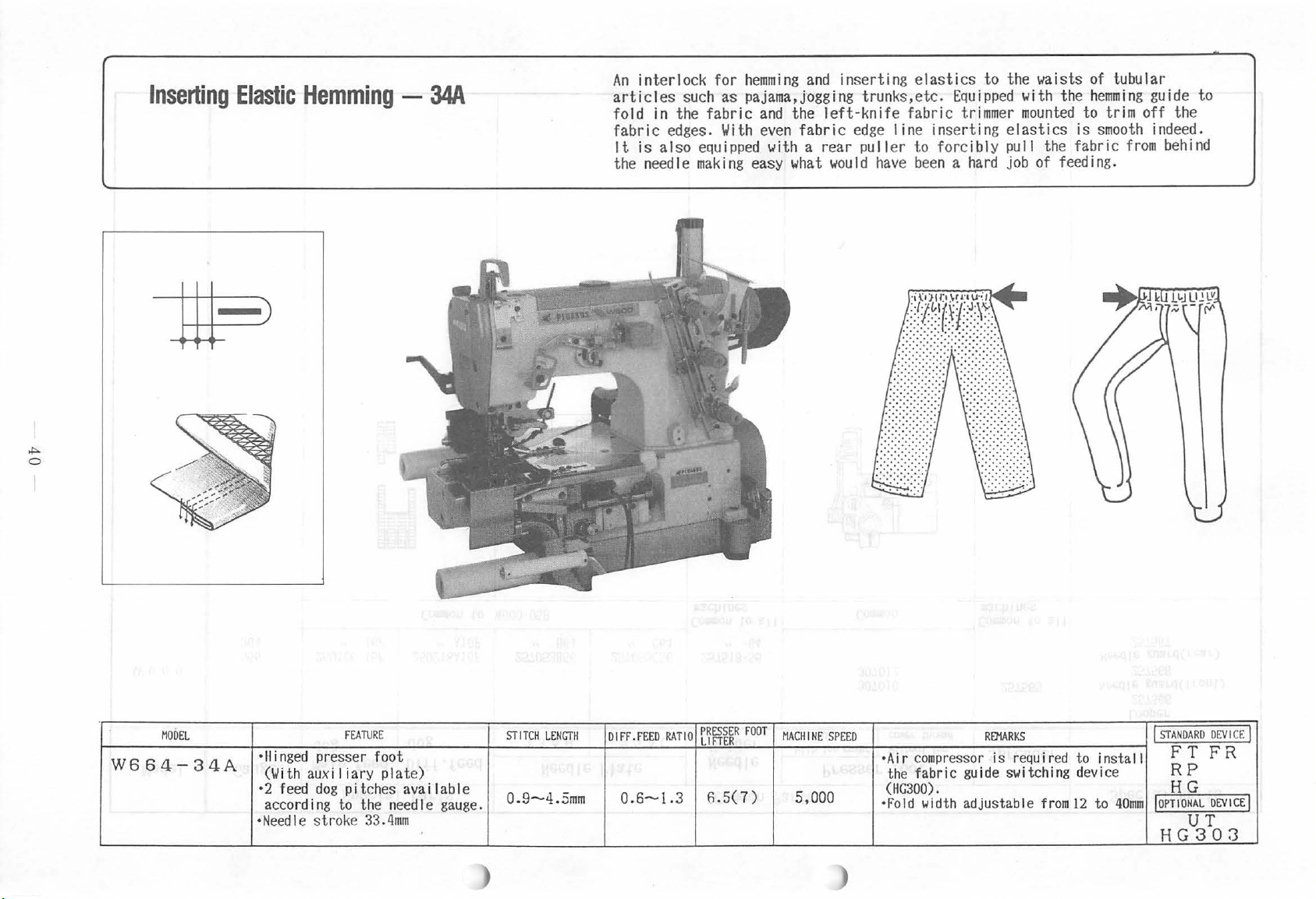

Attaching

Elastic

Lace -078

A interlock

The

feeding

and

the necessary

machine

amount

amount

for attaching

of

,the

upper

of

elastic laces

elastic

lace

on

panties,brassieres, etc.

elastrc feeding device

fed

out accurately.

can

be

adjusted easily

W562

HODEL

-

07B

•Hinged

•3

feed dog pitches

accord i

•reed

dog

•Needle

the

same

r-T

he width of the

stays un

So

is the widt h

bottom.

foot

FEAT\JRE

presser foot

ava

i I

ab

I e

ng

to the needle

is the

plate,presser foot is

with

change

same

06B.

W562-07A

d.

of

the pressor

gauge.

with

02B.

feed

dog_]

I

STITCH

1.

LENGTH

2--4.

4mm

DIFF.FEED

0.5--1.3

RATIO

L~~~~R

I

!

I

5(5.3)

FOOT

MACHINE

5000

SPEED