Page 1

INSTRUCTIONS

Cat.

No.

8119

A

October,

1981

WS4S

UT

- 1

iiMmr

Page 2

r -

,X

'

•-.'

^ -T

I'l

^•-

xt

-'j

•! ^ : •

.

Page 3

(i

i:i?)Cz

WS42/UTS

i

••

S

'X

«••••

BlSau-'^

Vcm<n\^i}^tz 2

ffiUWlt

3-Ka>««tSS®

—^'—Icov^T

^-•y-t

SiKiX-f

ttS!«ttl3®

—^'—O

t

ywy'f

x7

)S')«v>±(Oitg

ffliit#

-/i-

f-y

K5«ti|iitgr«ii!i!

^I)y

ycoiR

h o v Y 4

;5lJiiWS42l^fflmBJ?t=(Cat.

1

I

i

•H'llt

xtgy^E

No. 8115) ^

r'^i

</.:'$

••

v^„

t<

3

6-7

~5

fl

2

2

3

3

4

4

5

7

^'-coaiaijiKjrafiti

ttffl±(oaa:

*-e)'j®<7)i9a

Jt/X

fiy

fiy

ty

yu-y^

•

^/X

xiliiiiBF

XX

h a —? 11

xffiaffiffl

xft^fS:®

xcor&i-> 12

Xy>'^-

ii%ffii;y<-y(2)SSa

T^,18i)^r

T=ftWix. 13

^fL'i

EHrXi'-lrZiim^

mt<nfX^-tzXhmSi,

I)

^gcoawt

;

^-:S'-<ni^fRlYSM

English edition

starts

from

10-12

13-14

15-16

17^

page

9

9

10

10

12

12

17

13

15

16

21.

] —

Page 4

WS42/UT5

mt/c.

«ffi(7)jgv>3>

ifTlf^«-T-»l01iLii-o

sfeMij-av>«^-:>tt#,

oa>TV-('•••-*«#,

r-,

}i|ii(±,

n.m.9y

I-d-v-a',

u<ri^&.mw±,

ii±nc±ifT(ft:'»

^9<),

VV^*'±i")

ai".

^tih'^-'&v'V/^<n±

s+tswTf^oibn,

tt.

m^^litib

o

WS42/UT$

'j

-^a:c#w

to

^-;5'-(±.

i-Xi,

to

7J\0

WS42/UT=x>{i,

f^?ij:WS42-01X356/UT3

L

s 42 = X > tcj:o

-cM$

M<7)tl£/±®.CA'^0^CJ:oT.

i'>ymxK.'Y-i^t

T'E'iSJo

"Ct^TK

L ^"t"o

n-c

WS42/UT4#^Iil

t

U T 3

UTS

^

'J ^ = X >

h

m

lOOV

200

BE

V

vv-y

^

ffl %.

t0

H

•yT'E^—y

jiT-v

Wx-v^Ymm.

802009

802010

—

'j

>r-^

EPSIG-MT

EPS3G-MT

— 2 —

Page 5

0 1 &tA-#«cOW S xI)-XJEflv

MSft«•#ffiLT.

IE L < flit') Wl

®i

u

-rf

sTT

• \

It

WS42-01~07/UT

-159-

3-09

—^

-

1

r\

o

o

i'?j:±yvuy-f

K

<^PM¥iz

<

X <

-y

f-(i.

mifz

h

ic:fellah-4*

im

=X>T

(3M•)#{

Pit,

v-^J; n

—7';u

t r

T^f^V't

liZl±ib

•

®i#7v:

x7">'j>y-

|~o

—

2-09

G

-225-

WS42-30~33B/UT

3-09

s T

r>.

r«-

Nw/

92

-130 ^

6-

-140-

X «^20

'J -

K#j!^ii7C

+ T

-159-

r'^

-225-

u

xTv'j >^-—h®

o

O

O

— 3

Page 6

(t^o

Hifx

• \) -

9 > T

^ ^

0

3^#i!nLr,

ifstOfW^o

• a -y

•^X<

y

—7'>'uTM{-

fz^^\

uy-f

<

V^„

—(7)If

»yhvy

^-y-cotr-y

KHilfi.

X T

-^/u

••/

7°;uT'±i^'C

•

Kc7)^/g^80'-90'

h J:

<

»y

K

h-^>D-y

^•'o

@

K®^

111.

III4^#ML-C,

c7)try |- "7 > a v

®{co3i'<'o

• -h y X h a

$ a i>i25mra7!?^1l^i?iX h o - y

t

Jii!.jii

U/<-®lC'>L3it>"7(J^'T'^ ^

-7>a.y

K^T',

K®^ril.^0iiL-C<

y u / K u

—yS^:rD.^fiNLr

r'to

cfc-^{C,

—®tJE.

</c'

t'-y

h

r

7.

a:25mm

Page 7

xx.*>

HI,

^0 f v

U/<—©$:

• J:

•7>oy

•f

a-7'roj55»tMS

H6.

v-k

$n/A

^^x®^(±TL-C.

—®£7)

•

?itiTl:li.

"

H6^#!fflLT.

iijiloi"

K®i^i^6DLT<

H7

4#!fflLt.

A^

j:.T

0~®SrllX')#lt2)o

KOT'.

^ o

JiT

X 'J > ^

+i-7"^«ML-C<

r^-b'^tilittgo^^urg

L*C<

/c'^

V

X 'J >

r-©;:?a0111Mfj1"

I

I

• >^x®^IllL-CHf«1r^iL-C</c'$v^„

HR

f-y

^ - b

p®

h

••^1

p

OV

1. 3 > 7°!^

2.-b-y

$"4~5kg/cirf(ClHl^Mi"-^o

K

^>'<7)^^itl

jiT7

Ku->

• Kw>-7!)<^<y

{cyj|£Ai"-5) 0

A

fcf-K

•ji(7)ll$•)^ X

•y't—5kg/cni'{:iK^i'i^i"-So

K>'U®^iniLT,

^

li.

#®^^'PL±ifT(Ci'-r

Vyu^tcjiL,

3 > h P

-7

h*—

Ku

—

K X b—

'-C'ML-C<

iTI±

^ 0

ii"o

p m L r < ^

^Tx

^i"o

K7>hcj

U

—7 —®

— 5 —

Page 8

T

ooo©

\

Page 9

r/i"

• - K

wu

/w ^

±yw±uuX'^^k

h

a--7-<7)P0S.X-f

*b'yhL'Tia^'^'C

^$^¥11(1119-12)

1.^

—0©$:=J

—

"7—I

2.'n£Tl5iX^

tSo

ti'o

—

5/Ei®X^

Y^<^)zi

-y

^ zi y Y —

I

xylltiJl^^LiAtfo

1. t h W ^ :3

l/M

LL

/u"C<

L

^-e</;:'$

'y^(±.

^

'•2P0Sj{c

2.

=

-1^^

L r V^^ ^ t ^ fit

3. =

x>^«4'{c.

(±,

7V

—')

4.{|iW^SX>cl^{c7'i

^to

{|»M^os:fc(±,

l^li.

s^?.

m?)Jii$:-9Jo/::'). o/"c<h ^

t-±A.<^X'Z'BLM<

/j^Ao

5.mmmn^rx^-xymifzyii)j^.

^

—(C^Lii

> h ^

i^-(7y%J±^<m\\^tinmir6zt^'^n

X;^

—(±,

fjL'ffl

L^-<'^'C'<

6.-<>'Uh<7)3g:tj(±,iEL < v^'<>'H^fh5li-C'lkg

X)

:l7^iJ

nx 18

mmb

O J;•)(C

X.

5c^uIILiA

L T^fo-r</i^ V^

¥?fi^i>iv}i^iSiiva^TX

ttcox\

L-C</.; $ VX„

• ililil-#'^t.a

•

?3^i"#'<i>

4-0

7.

tto

A:'^v>„(1114)

•

{-4

i h

^to

u-^<—

/<^xOc7)5iii$(i.

#±iim7!>^'¥^5£{3

0 ^ 1"o

T.

^<^x0(7)?jl5

^ {±, 5 {-

^ti^m'^hm^x'm^.Lxi

4

0.

;f>

y

r

(II13)

tto

»o^-<

tiii

X'^

')

tSo

6.

^k<n^mx%mi!LMm

-i.

^Yi\lAiz^b-±^o

^^.

i^•±MAiztho{^^>

t^ji'

•^i"x

Ti-x.

€7l^>x>f

•

jlTxU

y 7 y h o

F 7!7-'<—CO"*^— ^

>';^^-^^Tx•^ir^7)^#'^(±,

•yf-^^fOFFjCt'&o

Y7t-^^-}V<7^V'^-9

ho

•yf-^rrpNjtcLT.

—7—

^"ab^ho)

M#c7)3

-f)

D)

/n)

IkLT^^4v^o

h

D-7

S

x>(cIrxO'^t{t-t^^4v^„

I-l^-7-(-^^^ML-Cv^4v^

—^ i

/

®

18mm

KT'I^^

HIH

—®$:

9.:^-^

-{c^LjX;^.

ULiitfo

ij

u > h

a---7—Ic^Liitfo

Korr^xy

> h D

S

xvtJtc

—7

— 7 —

Page 10

• i

X>c7)ii;^(i.

-Aiaj)

-C'lEiEl:l{^»-C#^1-o

(I2115c7)B

c

(±<4afi9.it)

B

(a2

T'^ihL^to

• ')

=

#(i.

•

t^c7)#ji<7)±{fT(f(i>

<

HH"::

i-v(9jttc,

a:;&^"C# ^

}i|ii}Srx'f

Z<nxy(

y^li^

^ ^ flF

l^1'?^iAti'o(B->A)

t3m-^{cj^t„(A->B)

?b(c!?'§AiRL^L

^1-„

i"o

5-tt-ttcWiiS-±lffcv^i

•y^OS-}i|iL-C</^5v>o

+7"i-3>f1"„

iposcts

A

(iBi»«

a:

+2inaa

2P0Stctsa:

ttA^'Tt'^lSjhtSo

{A->C)

L ^ ') m.

to(C<-^B)

#i|lirx^

(A->B->D)

jt-feHlCOl^T

-yr/ja:

KT'#

IPOSC-bv

to

r;u^ifi^<^;fita:,

^ 1"„

2P0S{c-t-x

-y

t$:Wt„

Yt^t.

m'm-C±?E.^,ri2;?jl:L^

ht-2>a:.

m'±^z.^.X'W±Ltlro

POS.

(016^

X^vf-0-Cii

|llli7!?>'±A<^o

tfI'X7&<±Tt^

itA^'JiT^|!jhLs

«2)

m'±X'W±t.

W:sL^<±^<ho

iWTTi^±Ls

POS.SW

jZ.li.

L

@16

is^#

e pos<a®>i-f

— 8 —

Page 11

017

*C^^1"o

:3 > h a

—-7—

f"0Nj

0umj-^t.

2. 0 ^ b 4- V^

=

xXiPO

'tgn^^

""ONj

{cEliigLii-o

S.^Vu

4.v^^/Ur

|!UL

y ^

K{cjffi^4'(i^^0g&c7)f()j^{c

tto

^^^

U.

>() 1 h

D)

5 X > J: ^ — Vs X h

^-lirAo

^OFFj

{c1-|)

|'pi!</0^<L

<

(i's-^Rlrlc

^<^Xl^<s:

tcLT,

axXiMi-

{j

r^|&

tto

M-

j:o-C.

<

^-lir^o

•y7V^0

— 9 —

Page 12

y

^(Dm

r}±

•

3.-K^f1-:T-nKi!l.'.'f-C'^-&J:•?(C,;f>

:

'Mx>f

u/n'—0A»i^{±-f

•y^$:'"ONj{c

LTia

:^®liSJi (018-20)

y_i:yx©(i.

Bnm.

"? o

•

JELv^^y

^y>^O^Wj^^LX.

-'u—cfc

xWTii^

:fe/

L^*v^-c<

< o

xi^j75<i:i'^L->cEn<7)">/j

/jf

"3(c

SPjft

—

10—

/"t-Ji®<7)(i{?«P»

^ii

5>

Page 13

h

p—

^

a

.SimCO

m^lts

•

^-'JOi:^h6bs—BLx-v7

•

U^<—Qtyy'7"/

(021-23)

7s<r>tEM.^s

W^<-©^i/j:<>^Lr^T9c

tLtto

h,©^7'J—{cLT

1 inralcj^o

© 0

zz.

O o

a:

1.5mm-

o

iC

© A

fe(

© 0

—b:1

O

1121

~2mm

b

i'o

PiUli.

©T'It^o

1-2

mm<7)

^^

tLt

-t-x©5.t/-^-y

(s:

ler

h

o\

mi

a=r'

1123

O 0 ©

-'y'

xafrfi'feg

(024>

~\y'X^;£/X7'/'^o;^i<i:

1 o

25)

c

"vj-^i^:0.5-1.Omm

Ts-^O.^Wj^'LX^j

0.5~

c:

V

^ \

1124

^

1125

1.0mm

l\

—11—

Page 14

0.5mnn

^<h'r^^\zlEy»)

"^7

7M&±Wi::&:&7

>feV

X^j<lEVtA<r> ^ / X^jlr^}

(c

-2,

j: ^ 6 o

m%m.

X(D}^i^

<!:

^ 'J lif t

^ ^ ^0.5mra{C'^i^i"o 31, ^ /

A

?^[S

i B

UlUc

Injii,^

{c^^i-

{c »

cot

X(0

/ X ^

^ ,

JU-^LX\

&t^&th\

•^\

c7)iiz0j^jitiiLiiS

b-^J-ac^^^^.O.SramfC'g'h-yr-t

(i.

'^y

^<t-'I±::/joj!l.l^'^f(±,^^xO$rllltt:^To-t

^{cHlti,

pjzlait

l£yx^^

^<nmu^h7£yxm^.<mii>xi^z'Mti^mm

LX<

ffo'C<

t.

^<^^}±^<^A\<=a-

^T%^^

tto

01to

X

X ^<7£^z,'}f.<n t

<

<

i.

a

:0.5mm

b

:0.5mm

12-

Page 15

rii-

^30

itit-iaSSrL-Cv^Jto

r>±

'•

tfett"5)L.

!

1-.

Ic

-fe"yhi"^ o

-t?-

i

(B

u

[1132

yu/^Ku^^-

a^?£$:8.5mmlC,

0

~o.3mintc:^^j:9yyy^

'ho

^^'JO^^hibXXrio

±^ik-(n

$lil©<7)tljft h ^ 2 mrat^I'^bi"<>

0(7ym"ik<r>mn,^ <

ti^0i:^hibXXfi

if±MAX\

;^^A>f©<7)7fe^®7&^

±^©^7'y'^-•y

Ky^^—©^r-t

to

o

0^t)12.5minaJ^ J:

htO-f ^

y

7(-a

i-t

f]

o

.

0-

0~0.3mm

-0

0

mmtho

ti^0^^hib.

Xyx>/

\'0^W}^'LX

^T 7 o

— —

12.5mm

V"»o

—

13—

Page 16

C. ^

-^J-^ ^ L

i} 9 > :^;<50^^'^, a =^:-j30mra • b

mm

• d =^^16mra • e =jf:'l 0 ~ 1 mm(C'^i9-tf"'C <

|2134<7)

a • b♦c • d • e <50#

It

=|^13mni

to

• c

=15

©

^ n ^ ^

ij

9>4<Km}<^t

^ m

1.-H^.>'Mihm9yy

mS4<r>t1iZ^oSmmiZ^h-^X

I X

X <

2. ^r>^jO_hi®56> io ^

-c</;:$v^

e 0 ~ 1 mm(3'^i9-ti''C> a

TIto-C

c '

d(^^-mi:'^h-\tX

<

@^»c.

9cr)t'>0^'io.

9yy

mmt.

' O •

^^i^ib^^M^xXr-oXits

^;coMf({ciSL/::-^-&{c,

(b^^MibX^n^X

wm

0

t).

<

x©$r5ifea6t:^f

-C'l^3lOmra{C>^;b-y:

<

t h .

W.<L-C

^f^<^lil^tT^

<

<

o

b •

f

-14-

Page 17

use

r}±

^0.5min(C>^h-l^Ti>

r)±

EHt;^^-

•

<o

mmmu

A.EHrKO^:

;5'-0^EHtX;J'-O3

tho

2.AC100V<7)M»(cE

ULiA^.

(«#-t#73500l!-lOOVffl)

(M#-t#742095)'(i.

HtX:5'—9'0^

X^

•yf-0^fONj{c1-|,„

0 aoms,: ^

<o 1

-yta.

1

""pPFj

S

x>11^0=?

h©<50l-

SU^T'to

CtriJ

Rt/

0.5mm

0

f

/

-/=i^

[i37

AC100V

L ui:^

y > L T iD 0 . y u />fK u-

DM^

y > L T ^ v>

•wmTjsy y y\0-/}^.^M K

(•7;7';f>.y

iwm^^yyyo^<.^Mthmmx\

{C-b-yhi"

i.yy

y ^ Vu

mfTs y y

"2)

h©)

I

o

h-f:^'l>z^t'W)^-^fzf:fl.fX\

ro^'m

Z3^

—

15—

Page 18

—

t-ct

51

•/i

K { 6

MmiO#)!?,)

Rl/oy

m?D?:x^

r

"riD^^i"o

^ ^ ^*0.5rain{C'i^;b-li'Ti> < o

1.Wij#ittl4^$lii:3—

bto

Y

u-y-{z^l^tfztt.

v^^rONjtcLTHfnl^.^L^i-o

BCSVmfz^Mti^

K(7)=7;f.

rJ'

—-y

J; 1

2. T X h /<-(7)0jlllj^ Ijim=J— KCOrh

fllll

rXrJ'-li.OV^^LTiiO.

©

(-7

r 4"-y h©)^ b T ^ >C

5V(c=S.--g>o

^ "i'o

Vwy-fKw-^^-

lEclj

$ -It /-j

$

x>

hL

hO^oi"

rO^T

^^-(7)igjjl{C, 0

/-c'{tT\

© ©

0.5mm /

Ezn^

•fx^-:f}<5Vi:mn<LX^^6o

- ©

(-^r?>

•y h©)^ :^^4- ^^

3.il:4'^x©^iQ)'i)i?^,

•y

h©<7)r|>.i:.{C'^h-y:-7,„

T X ;7

i~ ^ o

4.

rX;J'-^<5

-/)>

0V ^ ^<i-irifiIS|T\ffiTi/j^^a'.^©^

4-^

••/YO^rhX-eilVjinfcT'^

vuy

>f

VU^--7,^

ifdj^-t^:

V^ , 5V

'fl^iffij'l^th^©(7)If>l!i^^^7'f.

6 /Ii'ltiiii < {c-fe y h

^

—

16—

Page 19

^ m

>f)

;fe/x^

V

x;&>'^t^{cT

M

it

^ ^ X ^

^L

h o

pmtiM

10~12M

IIH

m

±

tc

•bT)

tl

tj:

a)

;feryx3gto^':fe/x

O "C ^ O

ffl

2.;£y'

3.;^.-^

X;{?>';^x$:

Oil#. ^7!?^^-^{3lQ)|>^-C'V^

9 t <

tux

ho

x-^mw

L r

X^j!£-r^<Olz-t-y

^XCO'X'A.-/)^

lU±;£{ctU'i)J;9{c.

^•\tho

•

;fe/xxFD

;£

y XililLg^xT)#®!!!^ ^ 1" ^ o

— x>jiUU t L T <

x±Mi:

h

i^m.^

^ i t h

IX

Vtho

^ 1mm

•4^/7.^j'£{z

f -y ^ 'J

lOM

12H

12i'i

\m

12M

lOM

14K

X

1!)

4^

4.^y'Xc7)7r:^„

^ -y ^ t^'-o X

5.

Xi^itlX^^^j:^^

>f)

a)

1.;^.-^

t<^mi

d)

2.

3 > h D

—-7

—

;&y'X$r{lliE(J® < )1"'i)7!?\ Wraut

^^tho

^ t ^ 9 — L

mmu^^mxi±.

3 > h o

—-7

—

j^tfo

rrr??.txmt

h,

4

M.

7M

6 ~ 7 M

7M

—

17—

Page 20

/^

HI

(«iiS:^>4)

M ^

mmthM

m

UN

U 1

U

isb 1

tC

JU h

1 ^

tt

1 ^

iliiUT

t^

" S

(± a °

L'^

nbxf

•b}]

1.^^

2.>fj^

3.

4.T^^I'l'J^:^?^'IELvMlA{a:(c-fe-/ h ^

2. u ^ ^ ^ co^< ^^0

X^<^-C7)y<;f>Hl7:j<5jfiV»„

T

t7)

KJ)^LffI;

;l'L-Cv^4'V^o

l> L T

?!;<TJEii

L t ^^1) 0

-g)

0

;&y

V

x/<^^^iELv^iiic{c-b.y

'''^•t-^l±$:3i}{

T:^;<7)»^

i"'5

-2)

i?i>ifl;t:< 1"-&0

T^.1>I'^^IEL<

Or

ho

„

-t-y

i

ht^o

'irho

h L

12M

12K

14M

13H

14M

1

17M

'

12H

H

W 2

ts 2

13

tV

^

J:.

b

S

m m

m

m K

^ b

4^

7.

iV

0

^ (7>

v.^

Si

7&^'

o

3.j:.T-)±7:>^'^iiLLTv^^„

4.

'I'lLfll^^f-

5.1'l'i|v)rt

2.Vu/-(

3.71^/^

<7)

i(i „

u > h n

Vm)]UXUM^H^o

Ki

=»>

h 0 — 7 —

—7—^<7)1^^

^(7)

^•^i^^Wiib^iDiro

mizvt-ox.

^T—^Mho

mm-fho

sLr~-}±{Y-i^f±)^

{C-^:b-lf"'5>o

lEK^f^-tho

LLlt'^i^o'Cx

yu-y-f

Ellllc^'^^o

lEK^mtho

i ~

1

Skg/citf

17M

5K

5K

6~7K

17M

6~7H

1

1. rj > h D

2.

y u / ^ K

—7—(7)7f:^„

r? > h D

y

u-yy

—7—^:^1^'

-ho

1.

S

1. ^

t>

<7)hIC'Ii^^J^o

^iEL<-t-y

hi

'ho

^ 4

^A °

y 1/ y ^ K

yu-yy

18—

3.

13M

Page 21

ItL<(±x

111 7 i ;u

y-0}a»

yi>i9 - o

^AiSST'illfiLJ-»•

9-fi>•y(;>««r

i . -t- h

A'??

U<W<

•ft4/jrfin

/)'h>)t-to I

1 - 2

</:So„

7 1 n,

JRj'l-tf

yfli:1ffi7

9-It,

J-Co

< n

9-<nmf!^iUr

P9

9(0(2)fli;Sr:fft!ii:.j|<ii

i

(3)

7 ^

9-f

7'Srft|$^S-tt4/-»b!|s«pU

9 -f i V

T'UWmtOtt^lJWSrlfltt

S

l»o

i/i.

7 9

7-f-•7-U-#;i.f,qai3f;4f-Ci

A -

X-Cft

V'Attfi-1

</iS

l»o

ft

C/»fliSlll(Sni«01

L ft

1>T</icf

ftCf.

mSEHTiftcSfe^liJMwWteSrfrftiK

as u rA*^ ffiffl u

/MA'7-(iVri;j;<

B.

'e-h»Hirx!l27)J;AU»WL

SOo

WWHlitfiA-tUfjJffl

i»o

u r </is

t-ciaiffi

iftiauft

•

L T <

rfififll

v».

t

T <

i/i

l|iT

1

i-r.

(21 7 9 /

(. JKO/N'JU h

'{'7

7 V L

U

77

X7

9.\-sni!i=i'-yOi:,

'

i

101

/i

TO-r.

•V7-(150*)

h-C4.

[0.

STfttfi.

.-l-.

LS-J»R!v'T

fc]. y ^

(±«:i»/;!fc(SA«i»i(»ir'WsiK'vr

S

01.

8<rmill^i4\ir<

d).

mft:«5:ftl+Ti»fti»t-A-

- V

tl

IIIA'

z<n{ii.^ii'h,

K L./-iicffl(-.iW«5i'

797-f-7'77-7

i -

n,,

h

Oo

-f - >

T'fiSliaS/n/MSr'I'fiA-

7'ifSi:«ii<

liPL-7iir

PT*«.<

/:fl.Jli;Jc(nJ;••,

T <

-r-1}-9A'f

ifis#StAj(«llcf-

B.5f3t:Ayif>ii-i07.-f

O 4- -U -V

h.

il'7'9

X y V

</iJf

i»„

/iSi'c

-V/7)7-(

<

77.(

cf-tlS

< /•

x-

0).

li^.'I*.

L ffi-iyrt

<

^fliffliiw

> fR •. r

(h). 7 V •/ L S:

W is JR 0 . m (liM S:M trs L r < /_' &i >,.

l.l I- -0 - I- lu

li|.

IJcj.

frai

.y.-CX ,

lOOInKJ.

#9 il; Sr < •)iSL

A,.

rWiJIK

Tin

Ai^Ko

b L d- L

ajfti?MA'JJ-Cy4i»±M«A'.Hj<

h

A.A'iftillLfti,»l«ll-A'./,

0 i -Co

4 C i

10jS«Afft-t-

SrffiiS

t, T <

A-iFi'o

I-

/uA'lOlte

-f-j.-7-U(i|^4l!g5>7)tfS/1ifl1A'A7T

l»4To

4

faffP<AiSt'.

•

A:«

ft

C

(41

nrWllieoiiflft

7 7 7 -f- 7 .f V r A'MI

A'.® < ft o A: n

A'«<];

L J

-CtOT'-'Afeli^WlSSrA-WJ:

(;5:}ftt.T<

eaiizoj:

S:>P-Cfc57!lti|S7)oi»A:

A'HM

X7K»'<-

AiSi'o

ai;77

i -Co

/

«-KV7777

fc^«7)-C

v-cr^T

77-ffls-f-il'

t

Iti-

4 fc1?

n 4

»«flf

"i

/

cwd-M

X

9^

, +

-ryX

, h

m'i>*

7

SA

/*7y>7

;»:(;

7 7 •>'>

"fUltSSr'lli'tfcS,

t -Co

aiAfft

S

l»o

n«M

t"///?-

l/rLiWWWfc'JlflftL

9^y

-f-ffiPttfrSatS L T < Ai

7777-M

A I

fryK

7777797Vf

(DntiSi^ryj'J.

.

(2)i!li)fi:Stlt««'"'-J:

(3ma»'Hli3lcoikX<ny^'9

t-h

{4)4 UftW>4 y)(!iiifllUSa ft H L i -C.

ism

L t 'isiifflijsffi ft

(6)lttj8iftA/L.

{6y<rt\^M

:^T7>(Sftgftia*2L4-C.

>-»«6c;og(fe

0.

0.

7'i/>

hiS«iA'(;,'<r/Hi:'''CBISt7-'/>

ftlfi«[LTK4

0.

'<r.'H::'-^BBftl&!fl»'«imuttl}iiLTK4

laUftHLT.

0.

rrL«."<#'/i'-b>-V-f[|SftJR')

AifcA41-.

4_r

>wftWtil;?-«-i-C.

OifilftliiftHLl-C.

9 i ')

t"-?

7-ftHL4-C.

.hae«oifi>7)ii«fiT-aiAii;v

')a<«rMiftnL

7

Pa^-^^-fttA^

-<y^^i'-fei'-»CR»ftlBc')mL4-t-.

4i-.

4-C.

>1.L/.;iS»7)(«iJt-T-ai

4 -•)-,

hffitti

5 4:7>

Page 22

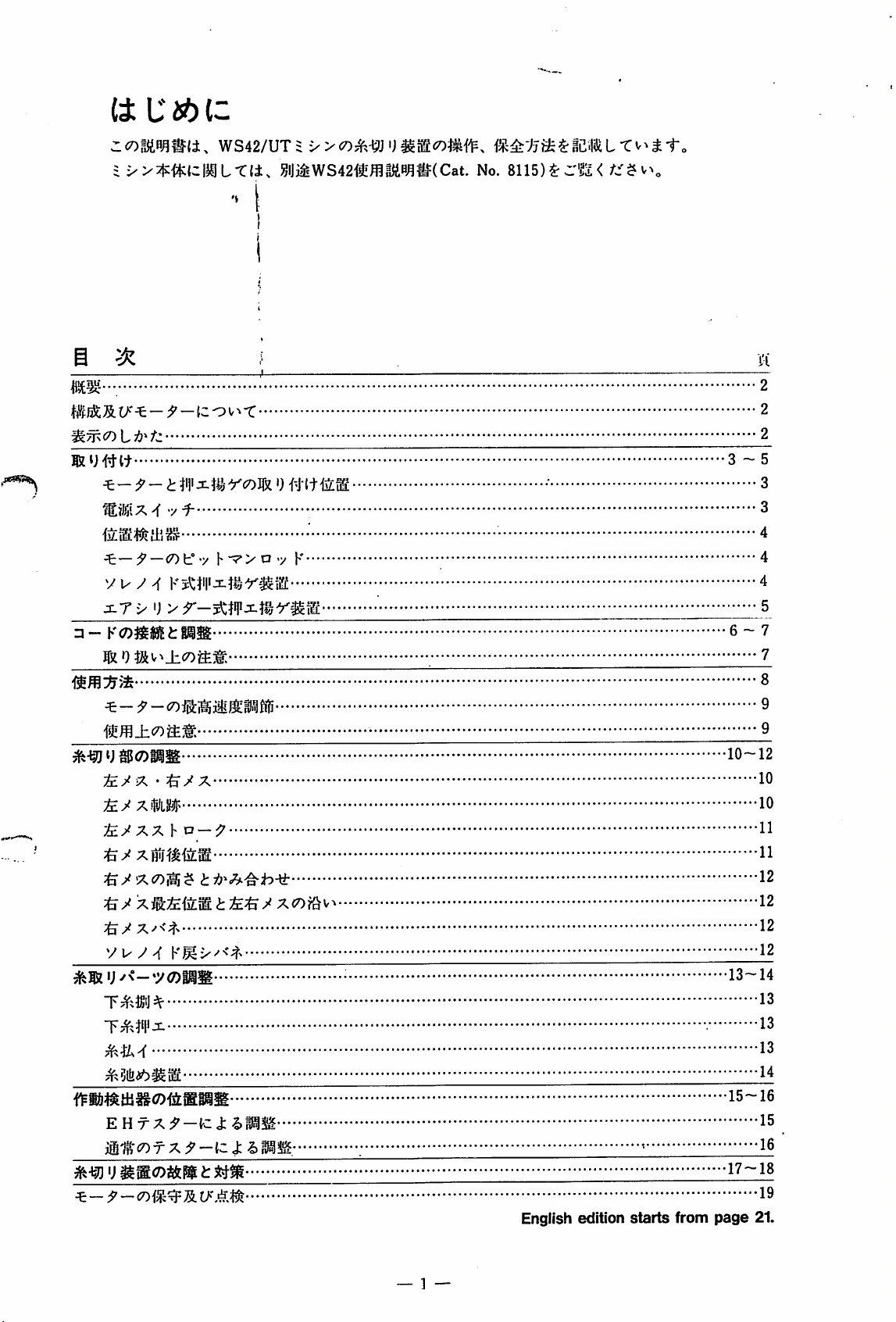

INTRODUCTION

This

manual

Mechanism

Forother

contains

usedonthe

instructions,

the

refer

opeialing

WS42/UT

to the

and

se-

machine.

WS42

vicing

instructionsofthe

instruction

manual

Thread

(Cat.No.8115).

Trimming

GENERAL

The

WS42/UT

motor.

trimming, thread wiping and foot lifting.

Pressing

under

Then

lifts.

The

the

the

needle plate.

the

wiper

The

presser

TABLE

COMPONENTS

IDENTIRCATION

WIRINGOFMOTOR

SETTING

INSTALLATION POSITIONS OF MOTOR AND

POWER SWITCH 23

SYNCHRONIZER 24

MOTOR

SOLENOID

AIR CYLINDER OPERATED

CORD CONNECTION AND ADJUSTMENTS

CAUTION

OPERATION

CAUTION

ADJUSTMENTS ON THREAD TRIMMING MECHANISM

LEFT

LEFT

LEFT

RIGHT

RIGHT

RIGHT

RIGHT

SOLENOID

ADJUSTMENTS

LOOPER

LOOPER

THREAD

THREAD

ADJUSTMENTS

ADJUSTMENTS

ADJUSTMENTS

TROUBLE

MAINTENANCE

PITMAN

OPERATED

KNIFE/RIGHT

KNIFE

KNIFE

KNIFE

KNIFE

AND

KNIFE

LEVER

THREAD

THREAD

WIPER

RELEASER

SHOOTING

DESCRIPTION

machineisdrivenbyan

microprocessor-based

pedal

backward

takes

out

foot

OF

CONTENTS

AND

MOTOR

FOR

ROD 24

KNIFE

MOTION

STROKE

POSITION

HEIGHT

LEFT

KNIFE

SPRING

SPRING

ON

THREAD

TAKEUP

RETAINER

FOR

SAFETY

WITH

WITH

AND

INSPECTION

at the end of

the

needle

canbemovedupor

220/380V

FOOT

AND BRUSHING

EH

ORDINARY

LIFTER

FOOT

"Back

and

ALIGNMENT

HANDLING

DETECTOR

TESTER

electromagnetic

precision

sewing

threads

downbypedal

LIFTER

controller

causesthe

from

the

FOOT

clutch

controls

presser

LIFTER 23

type

needle

looper

foot,

thread

and the

actionatthe

needle

positioning,

startof

~

forth" 31

MOTION

'• 32

PARTS

TESTER

OF

MOTOR

positioning

thread

to becut off

presser

foot

sevying.

PAGE

22

22

22

23-25

24

25

26-27

27

28

29

30-32

30

30

31

32

32

32

33-34

33

33

33

34

35-36

35

36

37-38

39

—21—

Page 23

COMPONENTS AND MOTOR

The

WS42/UT

and

WS42 machine equipped with

mechanism.

The

standard

suitable for

useaslistedinTable

machine consists of a foot lifter, motor

the

thread trimming

motorisPANA-STOP

the

voltage

and

1.

phase

E.

Various

are

provided for

motors

VOLTAGE

lOOV

200V

220/380V

415

V

220V

PHASE

1

3

3

3

I

PART

802009

802010

802011

802012

802013

NO.

PANASTOP E

EPSIG-MT

EPS3G-MT

EPS3G-MT 22P/380V

EPS3G-MT

EPSIG-MT

TYPE

lOOV

200V

415V

220V

Table

1

NO.

IDENTIFICATION

The

machine is shown by

and

the

UT

a slash

device

/.

Example : WS42-01x356/UT3.

UT

type

DEVICE

UT2

the

machine type, gauge

number.

Between

ORGANIZATION

UTS

Machine incorporating

PanastopEmotor

Solenoid

operated

foot

lifter

them

PLEASE

When

with

is

UTS

the

thread

Air-cylinder

operated

foot

lifter

NOTE:

using motors

the

sequence

CHART

trimming

Motors

Solenoid

operated

foot

other

chart

UT4

mechanism

other

lifter

than

Panastop

separately

than

Panastop

Air-cylinder

operated

foot

E, please proceed

available.

UT6

E

lifter

WIRING

FOR

When

For a 220V power supply, open Cover O and re

wireasshown.

shipped, this motor is wired for 380V.

OF

THE

220/380V(Part

MOTOR

N0.802011)

WIRING

FOR

220V

Green

i

BLACK

(for

—22—

LAMP)

12V

20W

WIRING FOR

(when

shipped)

BLACK

(for LAMP)

380V

12V

Green

20W

Page 24

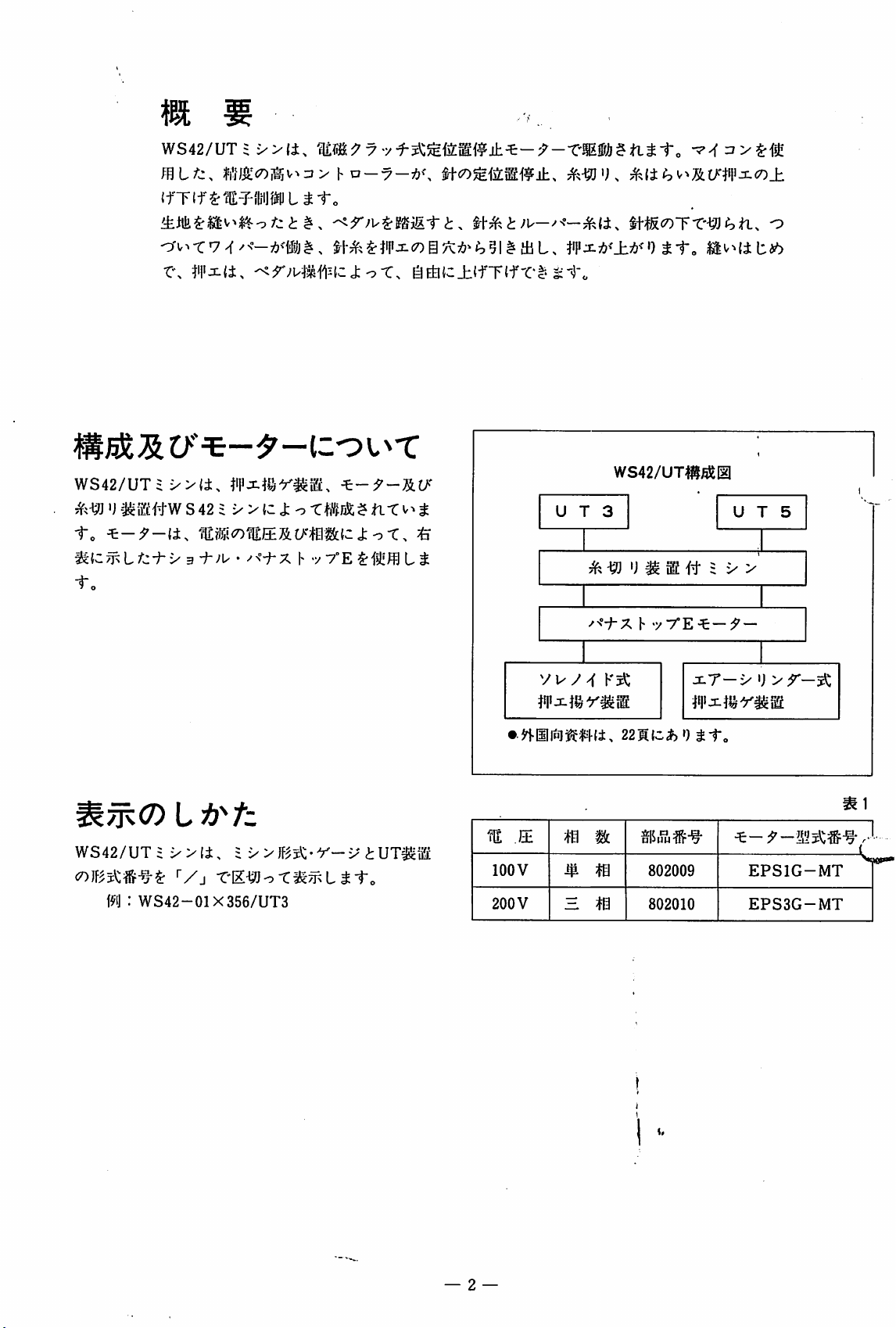

SETTING

INSTALLATION

FOOT

LIFTER

POSITIONS

OF

MOTOR

AND

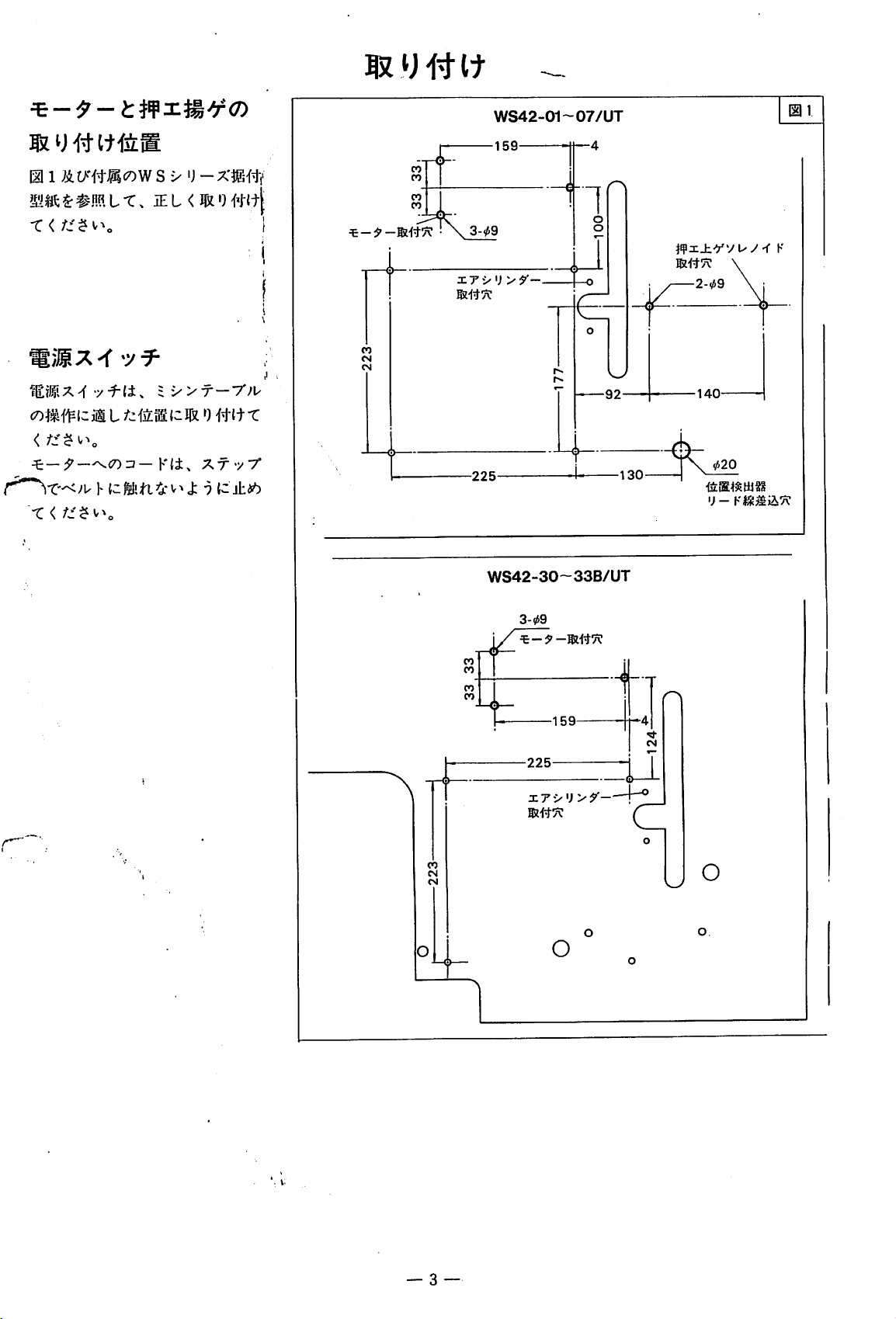

Refer to Fig. 1 and the supplied WS series pattern

paper,

correct

POWER

Install

and

install

positions.

SWITCH

the

power

the

motor

and

switchonthe

foot

lifterintheir

machine table in a

suitable position. Staple the motor cord so as to

keepitclearofthe

belt.

-rf-

WS42-01~07/UT

-159-

1

"TT

1

Motor

fixing

hole

3-09

Air-cylinder-

fixing

hole

o

o

G

Foot

solenoid

fixing

Flg.l

lifter

hole

225

WS42-30~33B/UT

3-09

Motor

fixing

-159-

-225-

Air

cylinder

fixing

hole

hole

92

-130

^ "

-140-

(k-

\

020

Synchronizer

lead

cord

inserting

hole

c

O

o

O

—

23-

Page 25

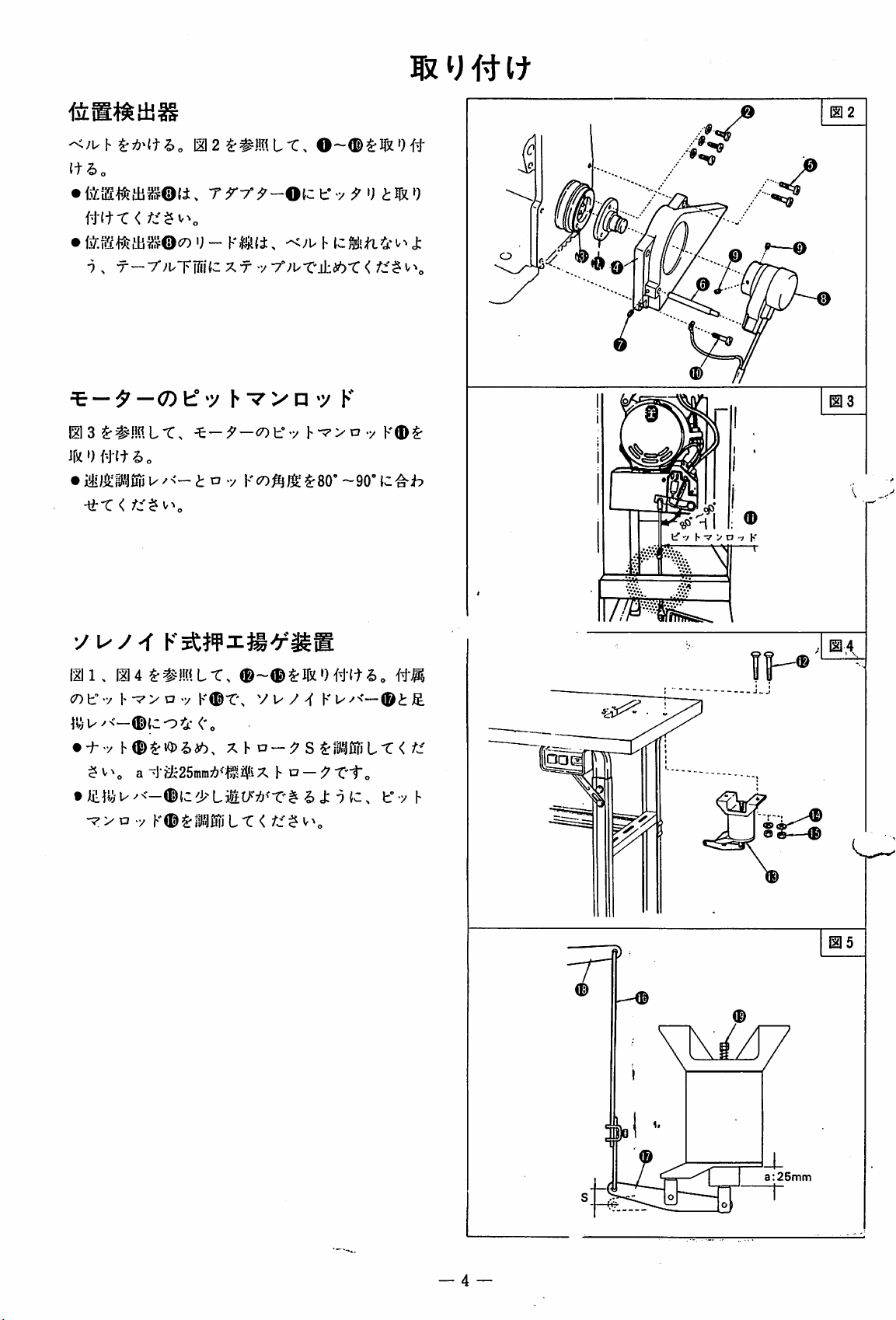

SETTING

SYNCHRONIZER

Put

on the drive belt. Refer to Fig. 2, and

parts O —

®.

• Synchronizer O and Adaptor O should be fixed

firmly.

• Staple the lead cord of Synchronizer O onto the

table to

keep

it free from

the

drive belt.

attach

MOTOR

Refer to Fig. 3, and install

•

Set

SOLENOID

Refer to Figs. 1 and 4, and install parts ® to

Connect

with

PITMAN

the

Solenoid

Pitman

speed

regulating lever

OPERATED

Rod

ROD

the

FOOT

Lever(Dand

®.

motor pitman rod

and

rodatSO'QO".

LIFTER

Foot

Lift

Lever

®.

• Loosen Nut and adjust the stroke S. Setting

distance "a" to 25mm provides standard stroke.

•

Adjust

has

Pitman

a little play.

Rod ® so

that

Foot Lift

Lever

®.

®

dD

T

—24—

a

:25mm

Page 26

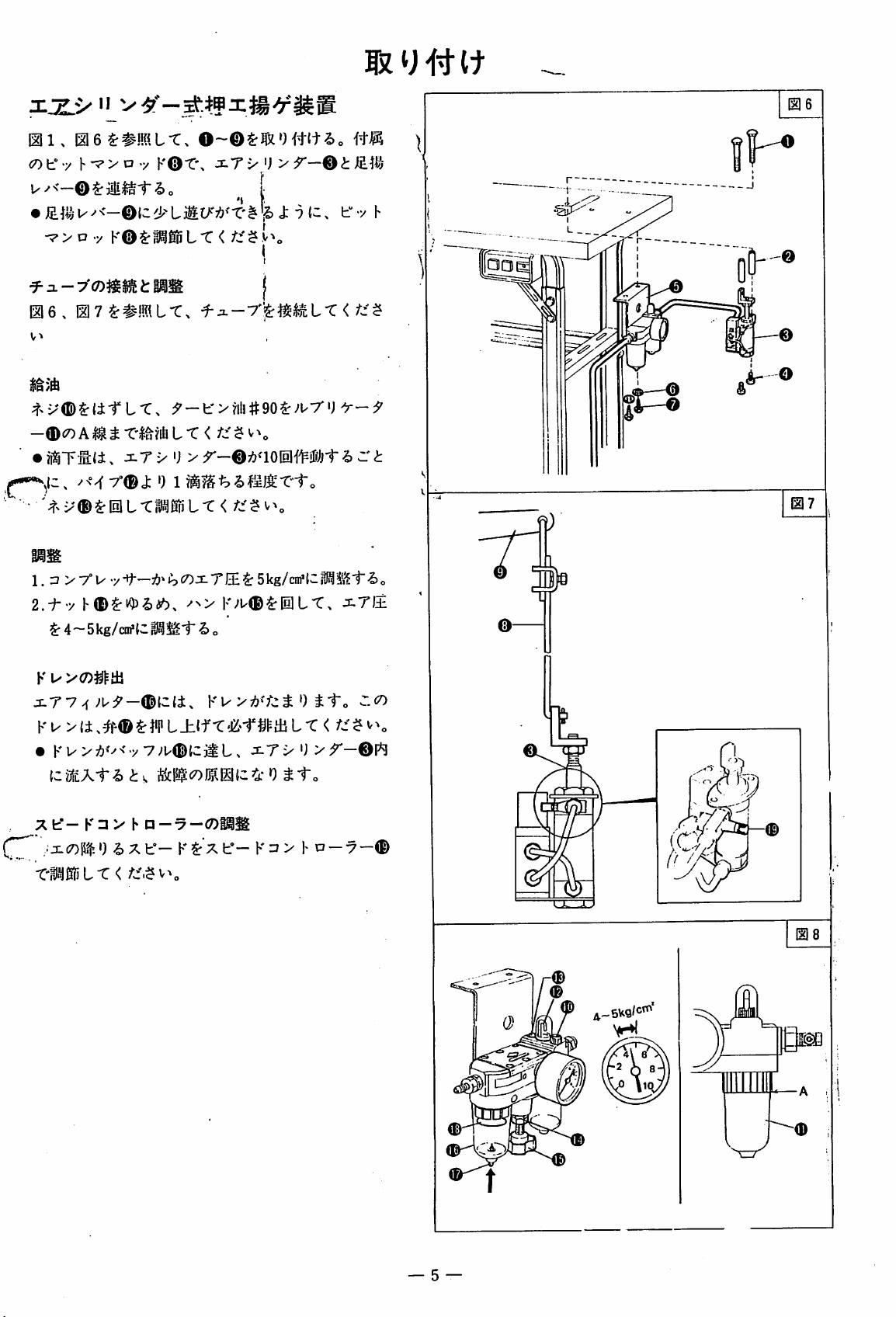

SETTING

IAIR CYLINDER

OPERATED

FOOT

LIFTER

Refer to Figs. 1 and 6, and install parts O to

Connect Air Cylinder ©

with

the

•

Adjust

has

TUBE

supplied

Pitman

a little play.

CONNECTION

Pitman

Rod © so

Refer to Figs. 6 and 7, connect

and

Foot Lift Lever ©

Rod

0.

that

AND

ADJUSTMENTS

Tubes

Foot Lift

correctly.

0.

Lever

©

m

LUBRICATION

Remove

here

•

ADJUSTMENTS

1.

Screw

into

The

oilshould drop from Pipe ® as one drop per

ten actions of Air Cylinder

Turn

Screw © and adjust this.

Regulate

©.

Lubricator

the

air

Pour

fresh

(D until it

pressure

®.

from

turbine

reaches

the

oil # 90

air

from

line A.

compresser

to 5kg/cm!

2. Loosen Nut (D, turn Handle © and regulate the

air pressure to 4-5kg/cm?

EXHAUSTING

Air

Filter

accumulates

DRAIN

the

drain.

Exhaust

the

drain

by pressing Valve ® up.

• If

the

accumulated

drain

exceeds

Buffer©and

enters into Air Cylinder©,the accident may be

caused.

ADJUSTING

SPEED

CONTROLLER

Adjust Speed Controller © so that the presser foot

is

lowered

smoothly.

25

Page 27

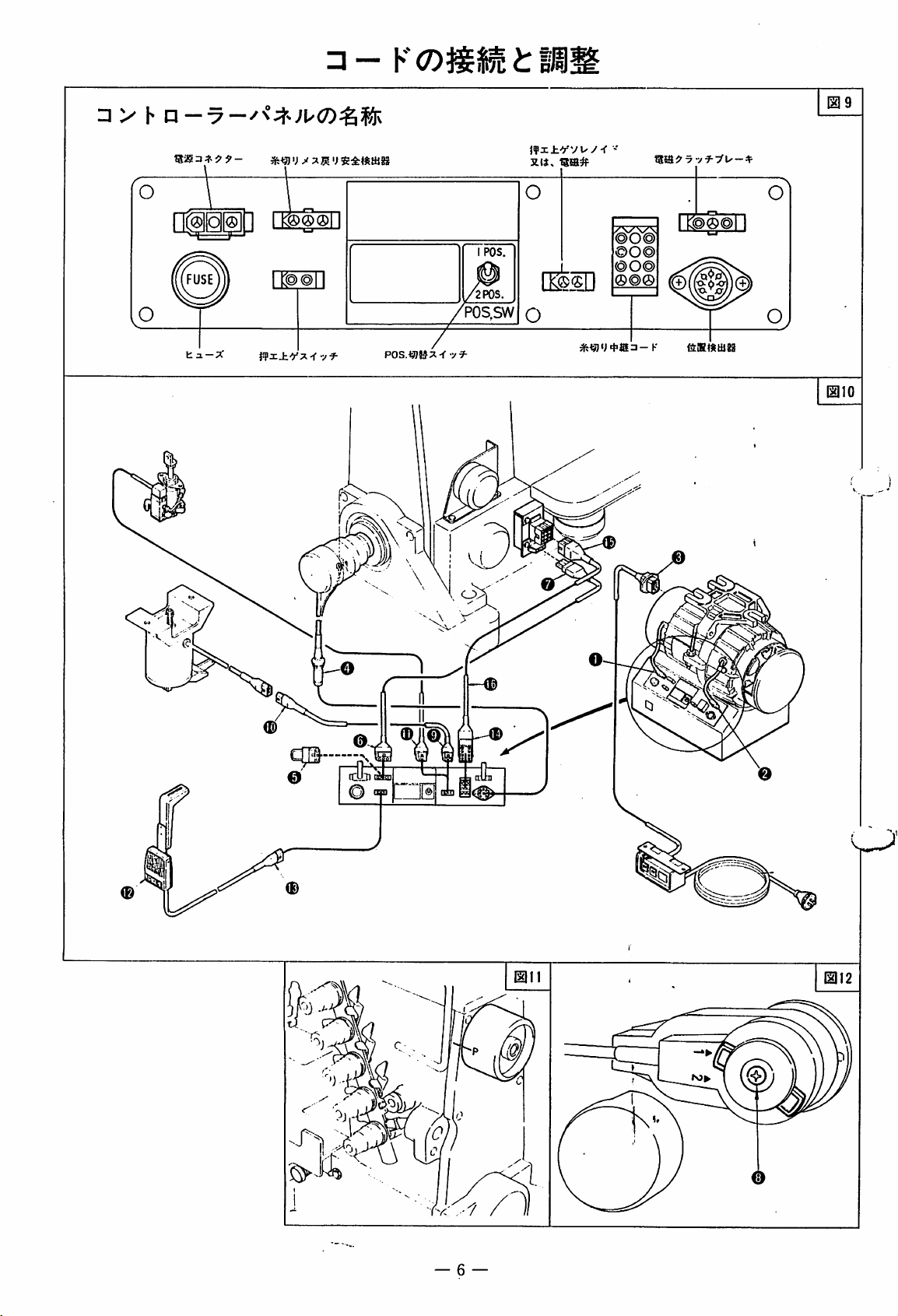

CORD CONNECTION AND ADJUSTMENTS

CONTROLLER

Power

source

connector connector

PANEL

Safety

detector

Foot

connector

lifter

Electro-magnetic

clutch

brake

Fig.9

® o ®

Fuse

Presser

lifter

®®®

g®

connector

foot

PCS.

switch

7

changeover

1

POS.

0

/^s.

o

o

Thread

trimming Synchronizer

junction

cord

connector

o

o

Fig.10

—

26

Page 28

CORD

CONNECTION

AND

ADJUSTMENTS

-NOTE:

Be

sure

to

motor

extend

and

machine to a good ground.

earth

(ground) wire from tlie

Donot connect Thread Trimming Junction Cord ®

until

the

highest/lowest needle stop positions have

been

setbythe

Set

the

POS

CONNECTING

1.

Insert

the

controller.

2.

Insert

Power

synchronizer.

switch

on

STEPS

Conneciiors O

Switch

the

controller

(Fig.

and

o

Connector

9-12)

of

© into

the

to

"2P0S".

motor

the

motor.

3. Insert Synchronizer Connector O into the cont

roller.

4. Pull

5.

Safety

the

controller,

Turn

and

check

If

the

out

Short

Circuit

Connector

©.

and

Detector Junction Cord Connector © into

and

the

power

machine

Connector © into

switch

the

directionofrotationofthe

on.

Press

runsinreverse,

the

the

pedal

re-insert

machine.

machine.

insert

a little

Power

Connector ® upside down.

Turn

the

6.Toset

1)Loosen

2)

With

the

mark

power

the

the

centerofthe

of

switch

needle

Screw

the

stop

©.

needleinits

scale

red

1.

off.

position.

lowest

magnetic

position, line up

platetothe

3)Bring the needle to its highest position. (To

do this, line up mark P on

the

line,on

4)Line up the

with

Screw

5)

Turn

the

belt guard.)

center

the

•

mark

®.

the

power switch on,

of the yellow magnetic plate

on

the

the

handwheel with

scale

2.

and

press down

Tighten

pedal.

Then

check

that

the

needle

stopsatits

lowest

position by returning the pedal to the neutral

position.

Further

est

7.

Insert

Cord

Insert

•

When

insert

controller.

8. When using Presser Foot Lift Switch

Connector®into

9.

Insert

tion

nector

check

that

the

position by pressing

Connector

into

the

the

using

Solenoid

other

© of

controller.

Connector

the

air cylinder operated foot lifter,

Valve

the

Connector<Dof

cord

into

the

controller

© into

the

machine.

needle

the

pedal backward.

Presser

(B)

into

Connector

controller.

the

thread

and

stops

Foot

trimming

the

at its high

Lift

the

solenoid.

© into

®,

other

Junction

Insert

into

•

the

the

junc

Con

CAUTION:

1.

Connect

inserting direction of

2.

When

off

3.

Note

is

switched

the

Dustinthe

4.

So

5. Do not use

try

of

6.

Keep

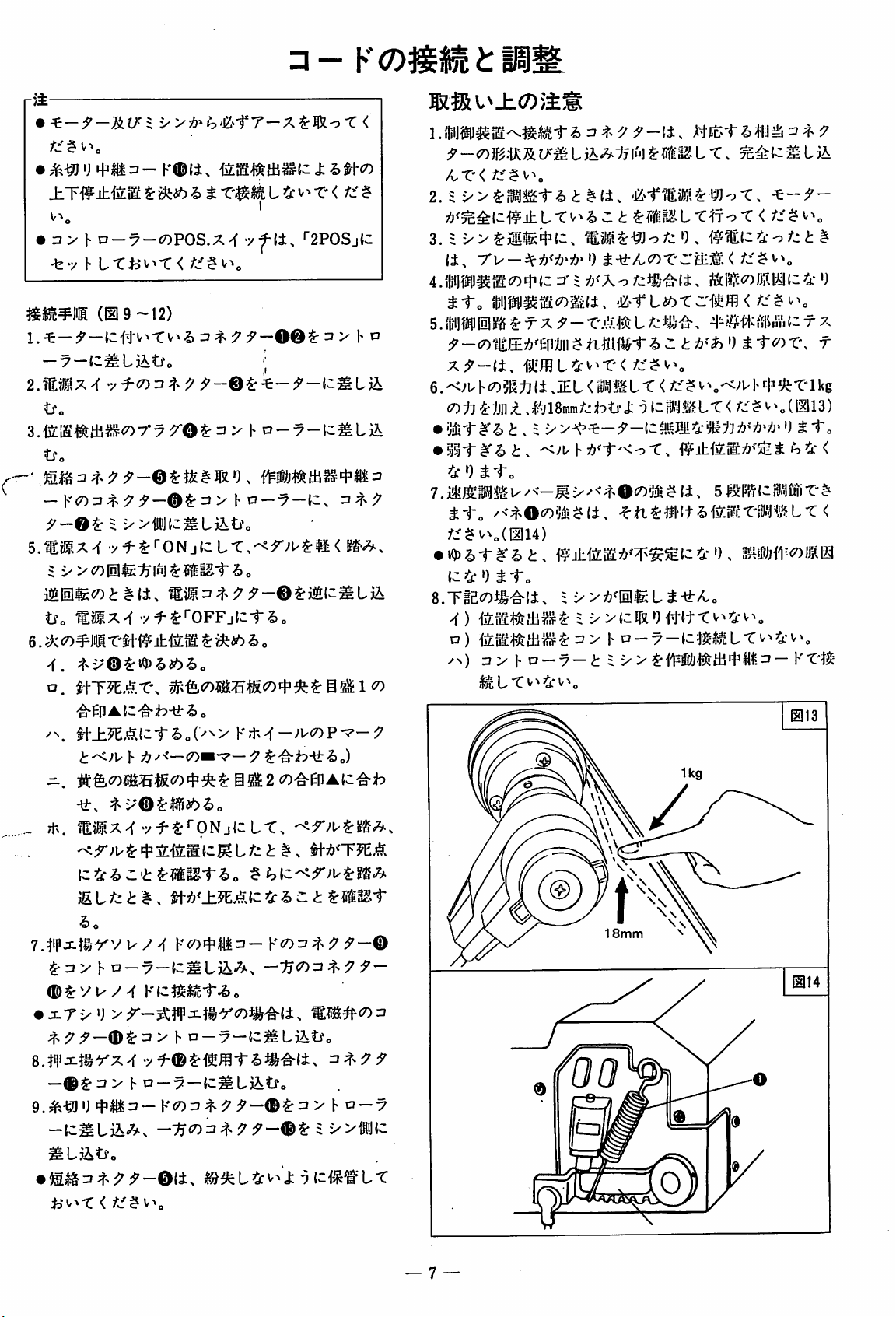

1-kg

tion of

•

Excessive

and

•

Insufficient

and

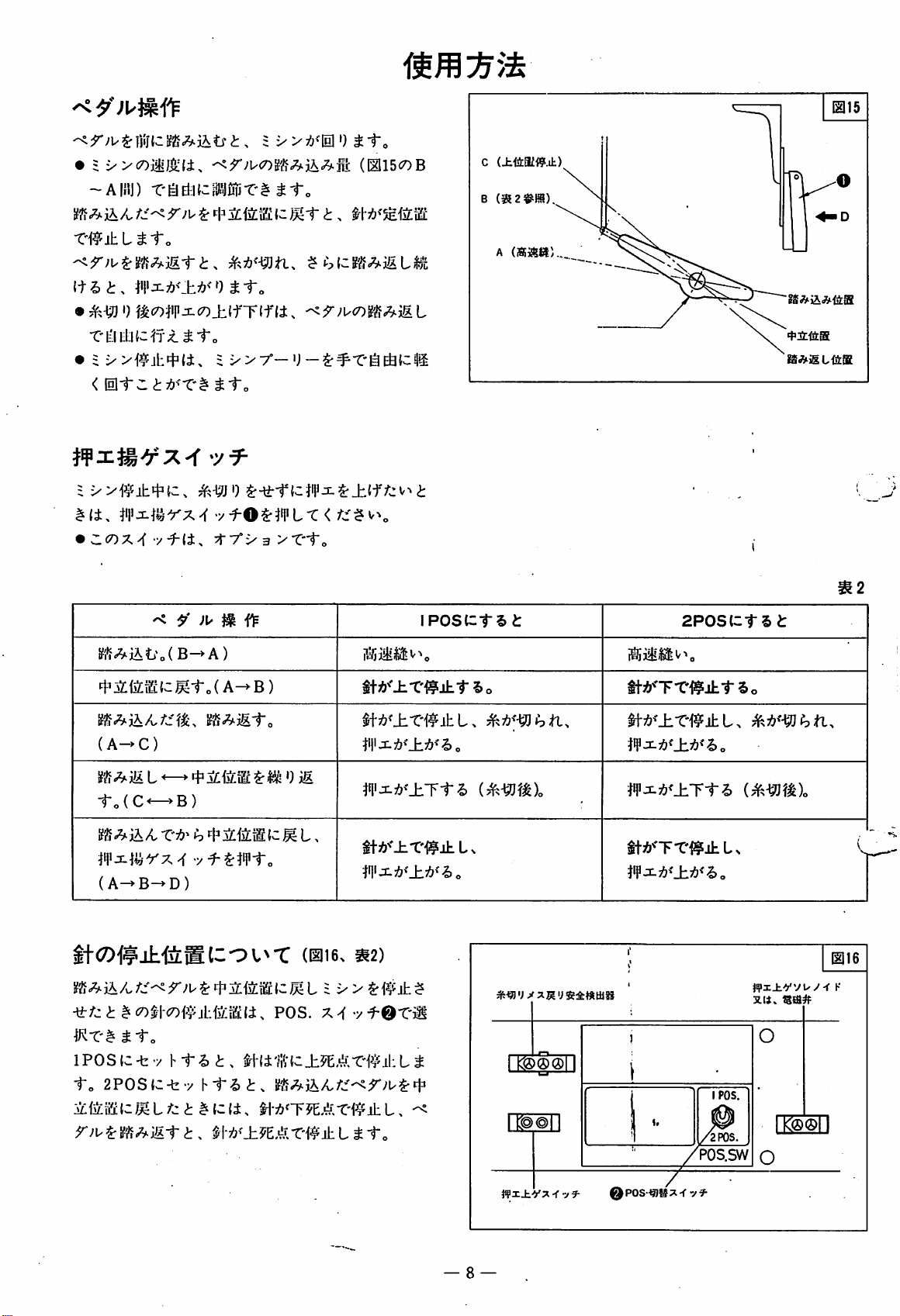

7.

The

canbeadjusted

Adjust

(Fig. 14).

• Insufficient

stopatdifferent positions

8.

The

1)

The

The

2)

3)

The

by

cords correctly,

adjusting

and

that

the

motor

the

off

the

does

machine

while

eventofpower

controller

alwaysbesuretoshut

any

testertocheck

because

the

the

forceonthe

motor.

the

the

tester

semiconductors.

belt tension correct.

centerofthe

about

18mm

belt

tension

belt

tension

needle

may

tension of Speed Regulating Lever Spring O

to 5 positions.

the

tension by changing

spring

machine

machineisnot

synchronizer is

controller

the

safety

will

and

detector

tension

not

making

the

mating

machine, be

not

rotate.

cannotbebrakedifthe

the

machine

sure

connectors.

sure

is running, or in

failure.

may

cause

it to malfunction.

the

controller

the

controller circui

voltage

may

damage

Adjust

belt

allows a

(Fig. 13).

may

overload

may

cause

the

not

stop

correctly.

the

hooking position

may

cause

and

result in malfunction.

run in

the

following cases.

equipped

not

the

with

the

connectedtothe

machine

arc

junction cord.

/

18mm

shape

the

cover.

it so

the

belt

the

and

power

power

some

that

deflec

machine

to slip,

needle

synchronizer.

controller.

not

connected

is

a

to

00

—27—

Page 29

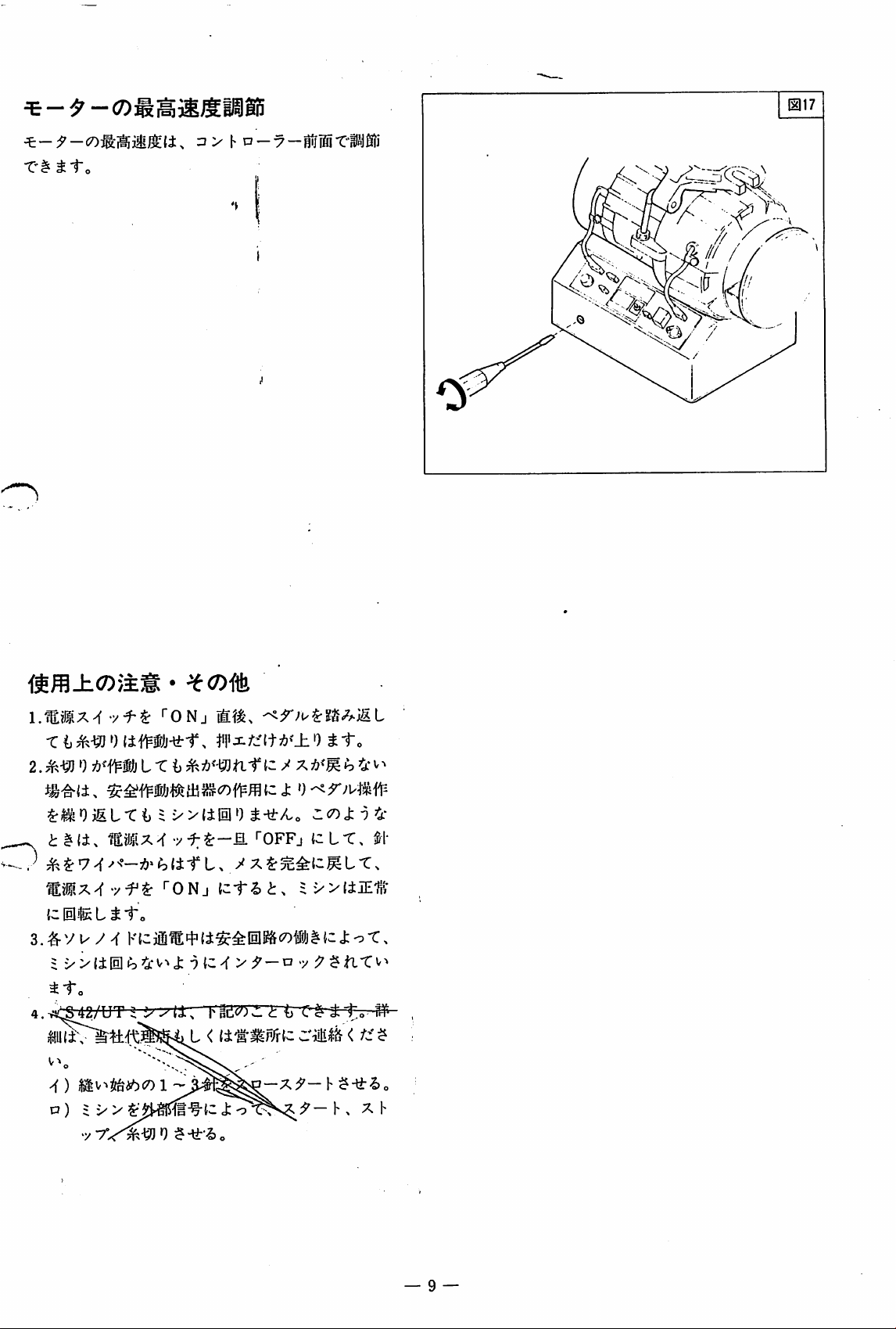

OPERATION

PEDAL

Press

•

Machine

B-A.

Return

needle

backward

pedal

•

• While

1

PRESSER

The

ACTION

the

After

foot

be

turned

pressed

can

pedal forward

speed

can

the

pedal to

stopsatthe

and

the

and

the

thread

be lifted up or down by pedal action.

the

machine

freely by hand.

FOOT

and

be controlled

the

neutral position

preset

position.

thread

the

presser

has

been

is stopped,

LIFT

SWITCH

the

machine runs.

between

Press

is trimmed.

foot lifts up.

trimmed,,

the

handwheel

distance

and

the

Keep

the

presser

presser foot lift switch O is available as option

pedal

to lift the presser foot up without trimming the

thread

while

PEDAL

the

machine is stopped.

ACTION

IPGS

the

the

can

C

(needle

B

(needle

or

as

A

(sewing)

SETTING

DOWN

preset)

UP)

UP

-

PEDAL

2P0S

SETTING

Forward

Neutral

Backward

Table

-"N

2

Press

pedal forward. (B—»A)

Return

Press

it

pedal to neutral.

pedal forward,

backward.

(A->C)

Press

pedal backward,

then

it to neutral. Repeat this.

(A-^B)

then

press

return

High-speed

Needle

Needle

stopsathighest

stops

threadistrimmed

lifts up.

Presser

(after

foot

threadistrimmed).

(C<^B)

Press

to

lift

neutral,

switch.

pedal forward,

then

press

then

presser

return

foot

it

Needle

and

presser

stops

(A->B->D)

I

NEEDLE

The

POSITIONING

needle stop position, when the machine is stop

ped by returning the pedal to the neutral position,

can be adjusted by the POS Switch

the

switchtoPOS

est

position. If

1 will

the

stop

switch is

the

set

©.

Setting

needleatits

high

to POS 2, returning

the pedal to the neutral position willstop the needle

at its lowest position and pressing the pedal back

ward will stop the needle

at

its highest position.

sewing.

at

highest

and

moves

at

up

highest

foot lifts up.

position.

position,

presser

and

position

Safety

connector

1

C®®®

foot

down

detector

High-speed

Needle

Needle

threadistrimmed

lifts up.

Presser

(after

Needle

and

presser

1

sewing.

stopsatlowest

stops

at

highest position,

and

presser

foot

moves

up

threadistrimmed).

stops

at

lowest

foot lifts up.

o

1POS.

position.

and

down

position

Foot

lifter

connector

foot

Flg.16

:®@

1

Presser

28—

foot

lift

switch

0 POS.changeover

switch

0

/2TOS.

/POS.SW

IK®®

O

Page 30

TOP

The

SPEED

top

speedofthe

OF

MOTOR

motorisadjustableasshown.

OPERATION

Fig.17

IMPORTANT

1. If

the

after

the

NOTES:

pedal is

power

pressed

backward

switchisturned

trimming mechanism does not function

the

presser

2.Ifthe

returntothe

trimming

will

work

the

pedal is

turn

thread

home

After

normally.

3.

While

the

machine

4.

The

following

1)The

slowlyatthe

2)

The

thread

•

For

foot

lifts up.

knives

the

from

position

that,

the

machine

details,

failtotrim

home

position even though

mechanism

and

pressed

actuates,

the

machine

repeatedly. If this occurs,

power switch off, remove

the

wiper,

and

the

solenoids work,

so

thatitwill

features

can

startofsewing.

machine

canbestarted,

trimmed

contact

return

then

turn

machine

are

sew

by

means

our

the

the

thread

the

will

the

the

power

can

the

safety

not

run.

also available.

first

stopped

of external signals.

distributorsorcontact

us directly.

immediately

on.

the

and

the

safety

not

run

the

knives to

switch

be

started

circuit

1 to 3

thread

and

only

do

not

thread

detector

even

needle

the

on.

locks

stitches

and

if

up

the

—29—

Page 31

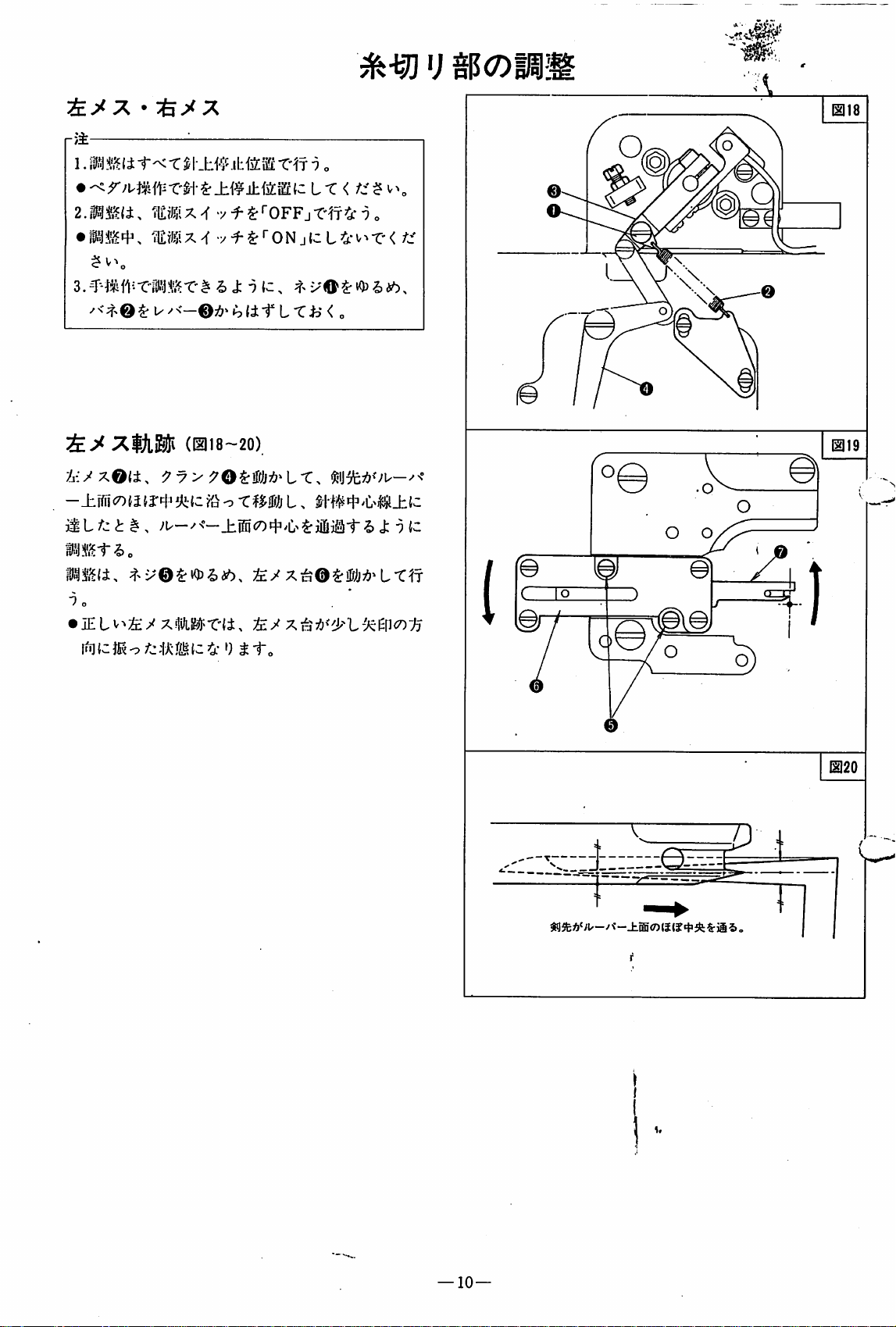

THREAD TRIMMING MECHANISM ADJUSTMENTS

LEFT KNIFE/RIGHT KNIFE

-NOTE:

1. Keep the needle in its highest position for all

adjustments.

• Bring the needle to its highest position by pedal

action.

2.

Power

• Never power ON during

3. Loosen Screw O and leave Spring 0 free from

Lever © so

hand.

OFF

for

safety

during

adjustments.

adjustments.

that

parts can be moved freely by

LEFT

The

approximately

When

it should beatthe

Move

To

Holder

KNIFE

MOTION

hook point of Left Knife © should travel along

the

•

adjust

When

it

reaches

CrankOand

this, loosen

©.

the

left

knife

centerofthe

the

centerline

centerofthe

check

Screw©and

motioniscorrect,

this.

looper

of

the

looper

shift

top

needle

top

Left

Left

surface.

surface.

Holder © may be turned a little in the direction

of

the

arrow.

bar,

Knife

Knife

Fig.20

1

The

hook

point

along

the

30

—

should

centerofthe

travel

looper

approximately

top

surface.

Page 32

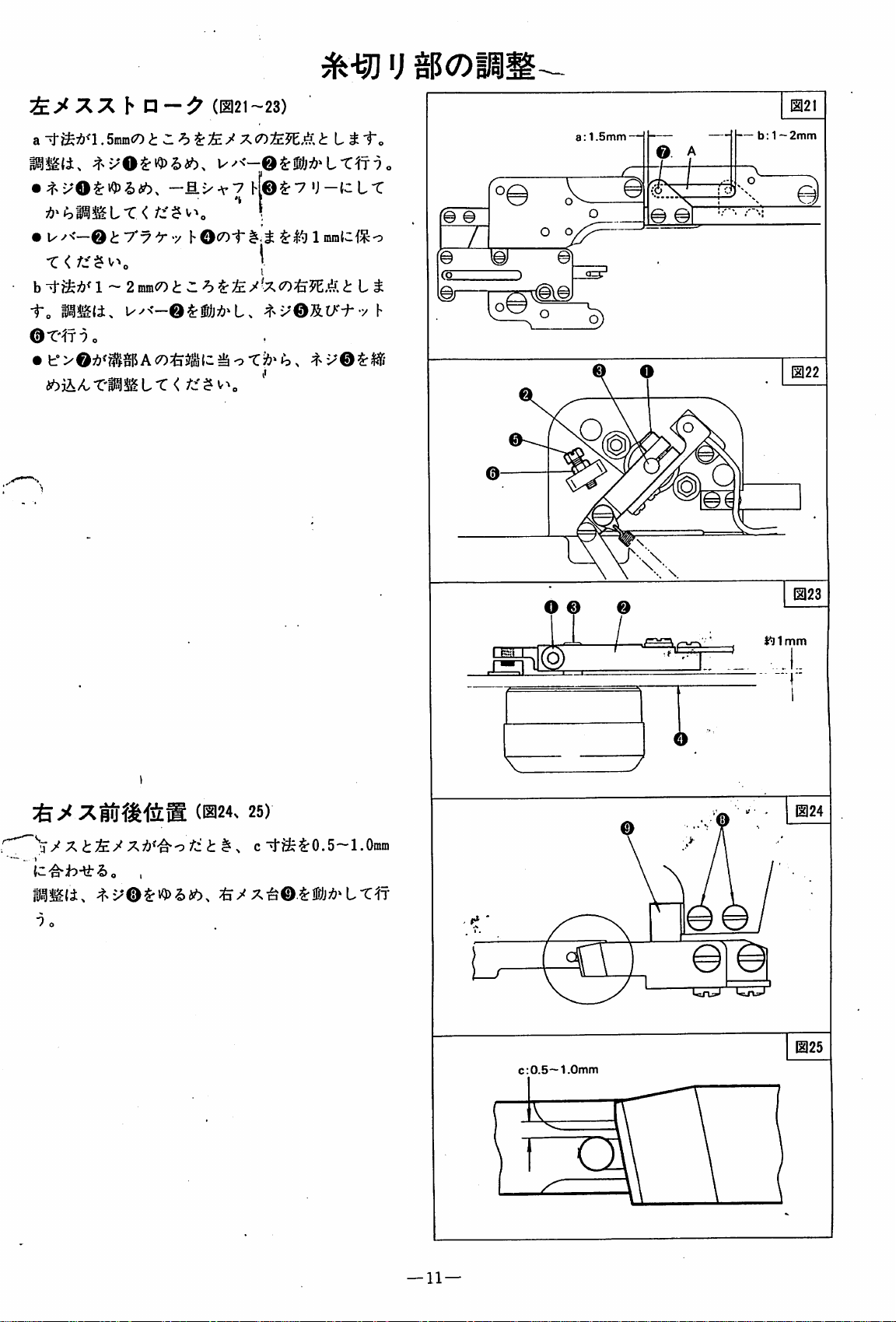

THREAD

I

LEFT

The

isatits left dead point.

To

The

isatits right dead point.

To

Screw©and

KNIFE

gap

"a" should be

adjust

• Loosen

start

adjustments.

•

Keepa1mm

o

gap

"b"

set

this gap, limit the stroke of Lever © by

STROKE

this, loosen

Screw

O

gap

should be

Nut

©

between

TRIMMING MECHANISM

1.5mm

ScrewOand

and

l-2mm

when

make

Shaft

Lever©and

when

the

move

© free

the

left knife

Lever

Bracket

left knife

• Touch Pin © to the right side of the groove A.

Then, shift Lever © by tightening Screw © and

adjust

this.

0.

and

(Ql

ADJUSTMENTS

Flg.21

a:

1.5mm-

© A

jZ

z

o o

O

© O

© ©

—b:l

~2mm

•

RIGHT

"Back

y

Adjust

knives

To adjust this, loosen

Knife

KNIFE

and

forth"

"c"to0.5-1.0mm

meet.

Holder

©.

POSITION

Screw

when

the

right

© and shift Right

and

left

im

c:0.5~

o © ©

Co)

1:0mm

Fig.23

1mm

'

Fig.24

©

44/

©

Uru-I

Fig.25

31

Page 33

THREAD

RIGHT KNIFE HEIGHT AND BRUSHING MOTION

The

right knife should lightly

and

slightly tilt to

makes

contact

To adjust this, loosen Screws

with

the

the

TRIMMING

brush

the

left

so

that

left

knife.

O.

left knife

only

MECHANISM

the

tip

ADJUSTMENTS

0.5mm

KNIFE

When

gap

dog

The

with

time.

ALIGNMENT

the

right knife is at

between

shouldbe0.5mm.

tip

partsAandBof

of

the

topofthe

the

right knife should

the

To adjust this, loosen Screw

RIGHT

When

gaps

To

To

Turning

to

Tighten

"a"

adjust

adjust

the

KNIFE

the

and

it to

left

SPRING

right knife isatits left

"b"

shouldbe0.5mm.

this, loosen

the

spring teasion,

the

right

increases

it.

Screw © after adjustment.

Screws©and

decreases

its

left

right knife

left

knifeatthe

0.

dead

turn

Screw

the tension

dead

and

make

O.

point,

the

the

feed

contact

same

point, both

O.

and

a:0.5mm

SOLENOID

Adjust

that

the

dead

point along

To

adjust

LEVER

the

tension of the solenoid lever spring so

SPRING

left knife returns smoothly from its right

the

right knife.

this,

loosen

Screws©and

shift

Latch

©

32

—

biO.Bmm

Page 34

THREAD

HANDLING

PARTS

ADJUSTMENTS

LOOPER

-

NOTE:

LooperThread

when

Attach

not hit Looper

•

LOOPER

-NOTE:

THREAD

TakeupO

the

threadistrimmed.

Looper

Thread

Thread

THREAD

TAKEUP

pullsout the looper thread

Takeup

Guide

RETAINER

:

0.

O so

that

it does

Looper Thread Retainer © prevents the looper

thread from slipping off the looper

thread.

i

Attach

pies

To

Looper

1/2

the looper groove.

adjust

this, loosen

Thread

Retainer ® so

Screw

O-

after

trimming

that

it occu

Fig.30

5

THREAD

SOLENOID

The

'J

is 8.5mm and

Bracket

To

THREAD

The

adjust

WIPER

LEVER

solenoid lever should be positioned so

the

0 is

clearance

gap between

0-0.3mm.

this, loosen

WIPER

"b"

BAR

should

Screw

be

O.

2mm.

Stop

Ring 0 and

Thread Wiper0 should be horizontal when passing

under

needles.

To

adjust

FINE

When

this, loosen

ADJUSTMENT

the

needle isatits highest position,

Screw

®.

Wiper © should pass the midway of the space

between

should

of

the

To

0.

• If

unplug Connector 0 (Fig. 35).

protrude

needle

adjust

Thread

the

needle

this, loosen

bar.

point

about

12.5mm

Screws0and

and

the

from

presser

the

shift

Wiper © is not necessary to be worked,

that

"a"

Thread

foot

and

centerline

Bracket

—j-

12.5mm

o

0--0.3mm

1—®

Flg.32

I

—33—

Page 35

THREAD

HANDLING

PARTS

ADJUSTMENTS

THREAD

The

as

follows.

For

a =

d =

For

the

above

ADJUSTING

1.

The

gated

To

35).

2.

The

the

To

3.

Looper

Use

Set

typeofthread

To

4.

Needle

Use

Set

thread

RELEASER

clearances

cotton

about

about

elastic

"a", "b", "c", "d"

threads;

30mm,

16mm,

threads

clearances

e =

STEPS

b =

about

suchaswooly

slightly.

gap between Pin O and the end of the elon

hole should be

adjust this, loosen

about

Screw

distance between Guide O and the point of

thread

adjust

the

"e" to

release

this, loosen

thread

dimension

0-lmm,

bar

releasing;

for

then

to be used.

adjust this, loosen

thread

the

"b", "c"

tobeused.

releasing

dimensions

and

for

"d" according to

To adjust this, loosen Screws

and

about

13mm,

0-lmm.

threads,

3mm.

® on Crank 0 (Fig.

should

Screw

cotton

Screw

:•

cotton

©.

threadsasa

set

"a"

0 and

threadsasa

be

accordingtothe

000.

"e"

c =

about

©.

the

should

15mm,

reduce

10mm.

guide.

guide.

type

be

of

'

34-

Page 36

ADJUSTMENTS

FOR

SAFETY

DETECTOR

ADJUSTMENT

-NOTE:

Safety

have

has

Detector 0

returned

been

trimmed.

WITH

detects

to their

EH

whether

correct

TESTER

or not

position

the

after

knives

thread

Loosen Screw O and adjust the gap between Safety

Detector 0 and Magnet 0 to 0.5mm.

-NOTE:

The

EH

tester

(Part

No. 735001 for lOOV)

junction

tions.

•

ADJUSTING

1.

cord

(F'art No. 742095)

Turn

off

the

power switch for adjustments.

STEPS

Connect

also to3?Connector©of

Junction

Cord O to

2. Insert PowerPlug 0 into a AC

let.

TurnonSwitch

©.

are

available as op

Connector

the

EH

lOOV

and

©

tester.

power out

I—correct

I

When

the

positionofSafety

Lamp © lights up. When Solenoid Lever

[

moved

—wrong

If the position of Safety Detector 0 is wrong,

Lamp © does not light up. Or, even if Lamp ©

lights up, it will not go out unless Solenoid

(Magnet ®) is moved a considerable extent.

slightly,

Lamp©goes

Detector

out.

0 is

correct.

(E)

Lever©

its

and

is

Fig.36

0.5mm

Fig.37

AC100V

3. Loosen Screw 0 and line up the

Detector 0 with the center of Magnet

Set

Safety

Detector 0 as far as possible away

center

of Safety

©.

from Magnet 0 in the arrowed direction within

the range where Lamp © remains lit. Tighten

Screw

0.

4. Check that Lamp © goes out when Solenoid

Lever © is moved slightly. If not, repeat the

adjustment.

—35—

Page 37

•

ADJUSTMENT

-NOTE:

Connect

to

on

reads

the

both

the

the

power switch.

D(i)

5V.

ADJUSTMENTS

WITH

safety

machine

ORDINARY

detector

and

Set

junction cord (Fig.10)

the

controller,

the

tester

TESTER

and

turn

so

that

FOR

it

SAFETY

0.5mm

DETECTOR

Loosen

Screw

O

and

adjust

the

space

between

Safety Detector 0 and Magnet © to 0.5mm.

•

ADJUSTING

STEPS

1.Strip Connector Cap O from the safety detector

junction

2. Insert

of

into

—correct

cord.

the

the

junction cord

the

left lineofthe

"4"

tester

probe into

and

the"—"

junction

the

cord.

center

tester

When the position of Safety Detector 0 is correct,

the

tester

(Magnet

wrong

reads

OV.

When

0)

is moved slightly, the tester reads 5V.

Solenoid

Lever

If the position of Safety Detector 0 is wrong, the

tester

does

not

read

OV.

Or,

evenifthe

reads

OV, it will not read 5V unless Solenoid

Lever

© is

movedaconsiderable

3. Loosen Screw @

Detector 0 with the

Set

Safety Detector 0 as far as possible away

and

line up

center

extent.

the

of Magnet

centerofSafety

tester

©.

from Magnet © in the arrowed direction within

the

range

where

the

tester

remains

at

Tighten Screw ©.

4.

Check

Lever

If not,

that

the

tester

reads

© is moved slightly.

repeat

the

adjustment.

5V

when

Solenoid

line

probe

©

©

OV.

36

—

Page 38

TROUBLE

lUThread is not trimmed neatly.

SHOOTING

POSSIBLE

CAUSES

1.Right and left knives are not aligned completely.

1)Right

2)

3)Right

back

Right

and

left knives are not

position.

knife

does

andieft

knives do not overlap enough.

not

brush

left

correct

knife.

in front-

4)Right knife tip inclines front to back and only

one side of the tip brushes left knife.

2.

Left

knife

does

not

catch

3.

; 4.

Thread

Left

is not released

knifeisdefective.

thread

enough

well.

when

trimmed.

1)Edge of the hole is not sharp.

2)Thread hooking part or groove end is not smooth.

5. Needle does not stop exactly at highest position.

1)Synchronizer is not adjusted correctly.

2)

Belt

tensionisinsufficient.

3)Motor linings are worn down.

SOLUTIONS

Adjust by moving right knife holder.(This adjustment

can also be made by moving left knife holder. In this

case,

left

knife

Reset

motion

right knife.

shouldbechecked.

Move right knife to the left so that its tip protrudes

more

than

1mm

from

the

Check

left knife stroke, too.

holeofleft

knife.

Make both sides of right knife tip brush left knife at

the

same

time.

Re-adjust

left

knife

motion.

Release each thread enough.

Sharpen

Re-adjust.

Re-adjust.

or replace with

new

one.

Replace drive plate.

REF.

PAGES

30-32

31

32

32

31

32

30

34

24,27

27

m

Knives

1.

Thread

correctly.

do

POSSIBLE

cutting

not

move

junction cord is not

at

CAUSES

all.

connected

; 1)Connectors are not coupled correctly.

)

2)

Line

breakage.

2.

Controllerisdefective.

m Looper thread slips from looper

POSSIBLE

1. Right knife spring is not

2. Tension of right knife spring is not enough.

3. Looper thread is not loose enough.

4. Looper thread retainer is not

CAUSES

set

in proper position.

setatcorrect position.

at

SOLUTIONS

Re-insert connectors correctly.

Repair or replace.

the

Replace

start

controller.

of sewing.

SOLUTIONS

Reset right knife spring in proper position.

Increase spring tension.

Loosen looper

Reset looper

thread

thread

more.

retainer correctly.

REF.

PAGES

26-27

REF.

PAGES

32

32

34

33

—37—

Page 39

TROUBLE

SHOOTING

|4|Skip

Needle

stitches

POSSIBLE

threadisnot

occur

loose

at

CAUSES

enough.

[5|Knives do not return to

POSSIBLE

I.

Thread

2. Solenoid lever spring tension is not

3.

Thread

1)Some

2)

|6|

Presser

1. Knives do not

Some

is

not

trimming

screw

parts

foot

POSSIBLE

trimmed.

mechanism

is loose.

are

deformed.

does

return

CAUSES

gets

not iift up (air-cyiinder

CAUSES

to home positions.

the

home

enough.

caught

start

position

somewhere.

of sewing.

Loosen

after

Adjust as shown in

Increase

Re-tighten

Repairorreplace.

Adjust as shown in HI.

needle

thread

trimming.

spring

screw.

operated

SOLUTIONS

SOLUTIONS

(T|.

tension.

type).

SOLUTIONS

more.

REF.

PAGES

34

REF.

PAGES

37

32

REF.

PAGES

37

2. No air supply.

3. Air

4.

Solenoid

5.

Foot

correctly.

|7|

Presser

pressure

is too low.

valveisdefective.

lifter

and

foot does not

POSSIBLE

controller

CAUSES

are

iift

1. Knives do not return to home positions.

2.

Solenoid

3.

SoleiK)id

|8]

Thread

1.

Controllerisdefective.

coilisbrokenorburnt.

and controller are not connected correctly.

trimming

POSSIBLE

mechanism

CAUSES

Turn

on air supply.

Increase air pressure (gauge pressure) to 4-5kg/cm?

not

connected

Replace

Connect

solenoid valve.

correctly.

up (soienoid operated type)

does

Adjust

Replace

Connect

not function.

Replace

as shown in

solenoid.

correctly.

controller.

SOLUTIONS

(Tj.

SOLUTIONS

25

25

26-27

REF.

PAGES

37

'

26-27

REF.

PAGES

2.

Solenoidisdefective.

|9| Needle threads

POSSIBLE

1. Wiper is maladjusted.

2.

Wiperisdefective.

3.

Solenoidisdefective.

are

not wiped.

CAUSES

Replace

Re-adjust.

Repair or replace.

Replace.

solenoid.

38-

SOLUTIONS

REF.

PAGES

33

Page 40

MAINTENANCE AND

• For

the

details,

Hfj

ELMMATIM

^

Adjustmentofclutch

Ai Turn the adjustment screw countercltxkwise at least

iwo

turns.

B) Turn the adjustment screw clockwise carefully until

the rotation becomes tighter (At this point clutch air

gapiszero.)

Complete the adjustment by turning the adjustment

screw 150* clockwise (10 notches).

TROBtLEHiTHE

air

Clutch

end

gap

cover

please

miVE

Adjustment

refer to

IMIT

screw

fig. 12

INSPECTION

the

instructions provided with

Use of special lining application material

For

longer

be

coated

if

noiseisheardinthe

Note: Don't use

attached with the motor. The tube contains enough

lor 4

accordingly

Howtouse;

A)Motor disassembly (fig.14)

a) Switch

and

b) full out the three-pole connector from the control

box.

c) Remove the clutch end cover by unscrewing the

three

d) Removethe spline cover key, and the spring.

e) Remove the clutch disc from the output shaft, and

remove

Note:Be careful nor to drop otherwise

OF

MOTOR

the

motor.

lining

life,it isimportant that the

at least

once

once

a year. Also use the material

clutch

and

brake.

any

application material

applications,

oil

V-belt

bolts.

the

movable plates, nor to scratch or scar the lining

surfaces.

Don't permit dust to adhere to the lining surfaces

of the movable plates while they are disassem

bled.

and

the

material

the motor, and remove the pulley cover

nylon

ring

together

Spring

shouldbeused

with

the

Clutch

lining

other

brake

damage

should

disc.

end

than

cover

the

C) Application to lining surfaces

a)

Squeezeanamount

from the tube and apply to the lining surfaces of

either

the clutch or

Note:Becareful

this

precision, or the

evenifpoweristurned

b)

Firmly

press the

coated

surface (fig. 16)

c) Rotate the movable plates against each other,

(fig. 17)

d) Clean

away

between

the lining surfaces (fig 18)

equaltoabout2match

brake

in 8 places, (fig. 15)

nottoapply

may

causeamalfunctionofstopping

uncoated

any

excessive

fig. 15

fig. 17 fig. 18

too

much,

motor

migth not

on.

lining surface against the

material

which

comes

heads

because

'operate

out

fig.

Three-pole

dirt

adhered

waste

adhered

order

application

perform

please

friction'

dirty

the

connector

fig. 14

Use

adhered

to the

fig. 19

of dis

the

more

even

disc

filter

effici

to

a

of

if

re

Motor

B) Cleaningofmovable

Clean

the njovable plates,

each

soft,

to the lining surfaces.

D)

Applicationtoclutch

Clean

cogs of the clutch shaft, and apply the material evenly.

E) Motor assembly

Assemble

assembly.

F) Break-in

Perforip a

material to

a)

b)

Note: If

16

Cleaning of

Please clean the filter when it gets dirty. The

increases

ency.

Cleaning:

A) Remove the filter by pulling the part (A) shown in fig.

8) Clean up the filter.

C)

Replace

away

ventilalion

dry

away

operation

Switchonthe

After

break-in

than

100

too

faces. the

poweristurned

move

surfaces.

the

20.

the

Clutch

Spline

cover

Movable

plates

any

cotton

clothtoclean

any

the

motorinthe

break-in

the

lining surfaces.

the

motorisoperated

operationbyoperating

times.

much

motor

excessive

the

filter

motor

filter.

end

cover

and

wasteorother

clutch

away

shaft

waste

operation

might

on.

material

end

any

and

soon

notbeoperated

If this

channelofIhe

cotton

motor.

material is applied to the lining sur

temperature

plate

motor

interior

cover, flywheel and

motor-bracket.

cotton

dirt

opposite

after

normally,

the treadle

happens,

from

the

and

reduced

tA|

Reprinted

Panastop

from

the

operating

E by permision of

instructions

the

manufacturer.

of

—

39

fig.

20

Page 41

m m m §5

•

t553

IS (06)

454-0519at^)

5-7-2

Revised

Printed

edition.

in

.October,

1981 (11813H1225)

Loading...

Loading...