Page 1

W600/UT

Device

Thread

bed

trimming

interlock

mechanism

machine

INSTRUCTIONS

^PEGASUS.

for

cylinder-

Page 2

urmmni^am

UT

Component

lists

UTfl!®§l3S.S 1

mm

fflSe6tliS?(DKy

S^38?i±i:^S0®y{^i:rZ)>/c

^0}iUZ)>/c

o-f<cDmm

UTg$ro^Mi5lig

5-6

uTmm(Dmk)m-tt:mm

ittttSff±roSSgiS(±SISyML/©i3^)

tt{£isfl?±0iiiEi5

fPffijgltliS§0tClffiSS®5 9

W:L±\i:^'i

Vl/^-r

±3i^ii^U(7)SISS 15

(®tiicsfflij±^i33y)

X7-3CUTg|S<7)«gBBlgtX7-iB@

^SLhfaiy

(x7-^§j±^wy)

XT'-S

xp-^±g6ySisy

(±ifBy

^(D3»fcK!g^^5^/K7)iSSS

^^j-izoi\z

OSHiilgSSgB

Ki:x;^fe0l®l5

UTgS(7)^BB|gfcX7-iB@

^«)y

y

©fflizRifissi

offljzSi/ISS

) s

11-14

18-20

21

-24

25

26

UT

Component

Sewing

2

2

3

Motor pulley

Installing the position detector 28

Installingthe electric presserfoot lift 29

list 27

machine

and

instaiiation

V belt 28

Threading

4

7

9

10

10

10

10

16

17

Threading

Connecting

Connecting

instaiiing

Needle

position

top

cover

Needle positionadjustment

Belttension and treadle toeing force adjustment 35

Positioning the operation

Treadle

Presser

foot

Adjustingthe motor maximum

Selecting

Adjustingthe solenoid and knife holder assembly

Thread

wiper adjustment 41

Thread releaser adjustment 42

Operation

(Electric

topcoverthread trimmerwhichtrimsthe thread

Connecting cords and air lines for the pneumatic UTdevice

Assembling and adjusting the electric top cover thread trimmer

(Pneumatic top

side)

Connecting cords and air lines forthe pneumatic UTdevice 51

Assembling and adjusting the pneumatic top cover thread trimmer- 52

cords

cordsofthe

and

thread

liftswitch

the

needle

detector

electric UT

adjusting

adjustment

trimmer) 33

detector

stop

adjustment 43

device

the

UT

device

(without

top coverthread and for pneumatic

(with

electrictop cover thread

speed

position 36

trimmer)

from

cover

thread

trimmer which trims

the

thread

31-32

37-40

the rightside)

44-46

47-50

from

the

left

34

35

39

36

Page 3

W600/UT

fc,;

^-5^-

W664-08,33,358,81

W644-

W664-01,03,05,71

W664-01,03,08

01,03,05,08,33,358,71,81

W664-08,33,358,81

W644-01,03,05,08,33,358,71,81

W644-01,03,05,71

W664-30,32,34,35A

W644-30,32,34,35A

W664-32

W664W644-

W664-30,32,34,35A

W644-30,32,34,35A

W664-01,03,08,

W664-

W664-30,34,35A

W664-33

W664-32

01,03,05,08,33,358,71,81

01,03,05,08,33,358,71,81

01,03,08,358,71,81

UT109

ufiib

UT111

Ufl12

UT211

yfgjg

UT312

Uf313

UT314

Uf3l5

UT316

UT317

UT320

Uf321

UT333

UT334

UT414

Uf415

UT434

Uf435

UT436

Uf437

UT438

Uf439

UT440

PEGASUS.

Page 4

1.

2.

1^0

^;i/hia.

MSv/K;l/hsa®lK/c^c^o

u-S3i^^33m

o^-^'-T^-u-ia.

Lz^<msbz<ic-ai\o

6,000

5,500

5,000

4,500

4,000

K/c^t

^;uh

^0

(^/cia^ti^^)

60Hz

120

110

100

90

80

riiy±fi?)S

3^—U—t7)^hS

50Hz

145

135

125

110

100

(mm)

T = W X L

(a)

3

:0_5,_^_|j_|^^_;

—:5—^umjysi«a\

(200~250kg/cm)

^ %

>;_3;_ij-^-5-^

[«itii§iro®y«it75

1.

©~@00ic;Kymr<;cauo

Q

Page 5

©

_)

G

32

m

u

)U

\0

V

t

@)@

©

UJUJ83-V

\t

o]

O

CO

Page 6

TO

±(c±ifrTSUo

^SiiUlto/cB,

T^j^ys}¥^r=&i:0{jl®

CT)

ICMUrT

p

Page 7

\

©

@)

^ « n

n

in

J)

^

©)

lO

Page 8

n

3fe«)y

i

•

5.

(llfei:ili<7)M) H(CD-Ki:7U':/3^©5®fflUrBR

m-i^o

6.

/csuo

5l^o

roNj

roFFj

icur.

5v:^(^0^75[^®iii88ur<

mM:3:^^^-@^mzmmi.z<tc

(cLr</cSi^o

A

Page 9

@ H •IS

X

CSffi)

i

SCO

sfeB(?±®!ia5

(±!iBy®LRt)fX7-a±l

1.

tl/'^-©S^hL.

:i^y©®»r</cSlV

2.if±5Ej#.0iili5

ti-±5Ej5^r'±«)r<;cSUc

Z(Dt:B.

JVJK/rW-i/KDP^-i7i:T-A(^«EDWnru

^y©®i?g«?)r<;cSUo

3.

ifT5E;^0liii5

(^fe)

ro(Dg|5SteV+t-SM®04^/i:\(cte':;h

ur<;cat^o

§^•±5E,'^.t)^6$t(Clgi5

4.

®icM-ri:ffZ)rF5EKS"c<?±u^-ro

roNj

ur<7c3l

(cur.

y^iioyro

/\VKzrv^-;i/S(DUrP

^:S^;us4'3i{iz

5. }¥X^^VL/y-f'K(7D4'liD-K<?DD:;^::?5'-©SD:^hD-

5-

6.

S-

©^•vhD-^-ic;S^ur<;cai^o

7.

(g)

(:t3^5^3V)

h:iJ(c}gmur</cauo

(.m)

mizmmi^z<iz^i\o

-

7--:>

7

r 0 c t u r <

/caI^o

Page 10

tt-figl¥±®!Si5

(®ma±K6y

y

sy

©tii

1.

2.

3.

/cal^o

/cSUo

±\§±m

ur^ttSo

roNj

(cur.

mm:3:^os-

55>^'oi5i^^i^s5i^L.r<

(sm.

roFFj

(cur<;cSUo

:i^y®®§afi)r<;c$o\o

@)

±{jl®^l±i^<i) (Hfe) <^®a5®l2Vtf-SM®(^4^/C\(C^

t>t?,

4.

Tff

±{iz^0lii0

c±^±nmus%\zmmLz

7.3^U':^5^-sS9EriSic:G:si^ic;=^

^o

(#fe)

0®SI5gteVtt-gl[®0«(cte':^

l-UT:</c5l^o

<7z^i^o)

vs#-c0

ur^t^r

m

</c

o c y

5.

^ICil^i:ffOT5EiSr^±U^-ro

5-(C.

1^0

roNj

icur.

::75'-05Dyha-5-(Cg8cUr<7c5O^o

8.

iD(D3:^cps-^^^mzi-[^

(S)

ra:i^r:75'-®SDVhD-5-IC,

(5®)

sms±if6yjii«]fflA.cD^

^o

^s^iiy^^tLiU

FiUlC^mur<;c5

m[zmmLz<rzzsi\o

2.0mm

NEESLEPO^

!»»»€

VOkT'Nl*tl«

I"—-

/^lA

•Mi

M-M m

Vrt

1

-

3 4

(T^i3]y)

ON SW2

LF-PSA

12

W^^'0lcmz±:^V®^W^LZiy

:^'l'»:/5^®<7)ISW50NfiiJ(cii)[)y®^5i:^-5'-l3±ll6y^W —

yffl(c/3:y^-9-„

o

'E-s^-{^xmim(omiz[ty,^^^=j-is\N[toFF

0lXSg(c/3:oru^^o

(±g?y

Ci:

Ct C2 A

LF-PSA.**i»W

swi

12

3 4

C±

C1 C2 A

(±-T^«]y)

ON SW2

OFF

iSW CCH AW +1 -t-2 LKB HBK

®^ONilJlC±lf§

ISW CCHAW+1+2LKB

HBK

8

Page 11

1.

^;Uh05gt}(3IEU<ilt5Lr</cHUo

1

kg

4^<£ji(s]^lcC6Z)<^D;cy.

/sy^'To

2.

^^)\ym^^^t}(Dmm

1

5mm

/c^OCctoCWUr

O

/ay^To

3.

Iigi5^:^»:^

ODbhD-5-.

i&^ttss(i)SK:)o<

b/

SSIC

^;^b@^0br/\:;^E5TObr</c^C^c

h@®«gfi?)rSlSbr<;c3l^o

^-5'-lc:|lfflOM®Sci;<a3§|^<;c

yaic-rs-rtjfxOTy^-To

^0D{a®z)\6

f¥x<D}i§(iz®^r'fcicMbT:, :;^=;©s3Sgfi?)r<;cSi>o

CH

bbOMiJZ)\6llli5

b r

</c^l

U)

r\

Page 12

0

55^^'0)ijg(a.

o

^^^)y^0^¥x0±lrF(1'(a.

O

S£^v0<?±'f'ia.

nn^vBrn^o

^5^;i/OS^)iabtfiriS(csiSDrssTo

^5^;KDiga»^ijgur@fiic'f7

==^y3^-'j-®#-cgfiii:g<(sl-rc

1P0S.(-)

2POS.(-)

^-5'-®*S5igl

SCTo

tf±5&iSff±

t)T5EjSff±

^«)y

ffxXCfo

StT5&S-if±5&S^«y

^(D»,

)fx±(:fo

^yyw±^iz.

(7Mx

OC(7);^-f':/TO.

rg^To

(ii)

ijfin

(S±i

o

^feiioijgtj-rffx^i-j'/cuinsa.

®)

S}fUT:</c$Uo

:i-3^5^3>'r"9-c

• V

ha-5-y

7j<=;v3X

(t^)

jfxji^;^^

iJ^<2Aj<5;=/3:^-c-ro

hurc^sB#«.

l.l.|l|lMilM«.M.»U«»B«»ll.UlUUJ»l.iMllllMHIWmjlHI.HI

riiJR

O

finite

(IPOS.)

L/SCl 5

(C^

6:^g<

U r I

^^To

\

UrB,

e.OOOISigUU:

(2P0S.)

LOW

HIGH

tf-^D

10

Page 13

Vbyf

1.

VL/y-<h'0)iIi)a«.18.6mmrTo

;^l-'2^/^-@-C»Ur</c3Uo

(SI?)

3mm)

SAnrTSUc

36mm

zTAij/'^-Os^Kur,

y

r-To

•t^^h<B^^sbzmmLz<ic-ai\o

3. jl^g^l®0TOfilS5(as :^V<B<D^iL\t\e^V®(r>^€\^Z

m

36mm

±'V h ®

4.

</cSl\o

v^o

ris±«)Surasur

:^^(DmB^\^m^o)z.

§

tsicMSis

</cSUo

u

mro)z.

sfifiorasur

^:^roili5

W5^5i:S(a.

iej-rtf5g±{il^lcUrTaUo

igi!)b/t-©s#rs<i&Z)\t?5ci:o(curz)\6

1.

Tx

® la.

65,5mm

TSUo

o

•:JvVn.iTsSv©^n\^z.

h ©

i:

TTo

©

T^®

T^^ys±ic±if;cts.

Z)<}g84

LG:t

)<i:

(D^iC\t\e>T>^

SSfifi^riHSBUr

5 (c±«):^^y ©

18.6mm

® / L

)\,-j'(-B^

65.5mm-

rfQOQ.X)

0

—66.5mm-^

©-fT^fctXr

—i

J:5IC

2.

T>(;^0tu^<i5e(Dili5

T:><::^®oiu^(?)OTiav

t^7St^®U)b-i\-©

±ISb:^V®^^<SbZ. T^;^a©€8U^ICS)Z)\U-CPIi5L

r</c$i^o

3.

(2)

(Dim(TX:^5t3S^^)U-/^-(^fi^a!l^\69mm)

:^^@(D^m\ZXX±'^tS'^

y©S3{fi«)r.

1 1

K(DIS^^<ize(Diil(5

h'®Z)<Sl<^8®-rSJ:5IC.

giiSur<;cSi^o

rT:><

±5^^

S<gM

—

@

Page 14

A,T>^:^±Tm

(2)

(Dm.

( ) "CT^;^©

t^lS®»<;U-/K-®0±®IC^<^g4-rScfco(C.

±fi?):^=;©s«r.

l,^c

5.

22mm

r-To

h@S5ftfiOr.

ss±Tici&Z)M/rpg5ur<

liSBUr

<;cSl^o

f/^

h@0

/cs

-m[^mr<Dv.

6.

±l50llg5Z3<^a?*SL/;c6.

o

T>(:^©Dm^mm(DizB{z.

7.

i\rd:i\im

OT^rammr-^o

l^o

si^urT^Oo

1mm^SCilo

(m^m)

)X(DZt:^mV&\.^Z<Jc^l\o

h'

® ®

vz^3^^:j^(B(D^mmD\e>ti3-®^

pieurTa

®

(B)2mm

®n0Dj'

L

—Ij-

©1mm

—

—3mm

o

0

0

12

Page 15

1.

0.5mm

i:g(CO

T^::^(7)i5M(C^Dt?^-ro

SUo

T>^;i)¥i/'\:5^®!ii5

1.

oic.

1.

RS)

«):;^=;©S5tfi«>riigi5ur

^=&T3feZ)<x::i»6t£(t^5/d:iu5ic>

SUo

,5mmrTo

T><::^}¥i/t:i^t)PKic»^-r0r\

(TiB#S8)

IC.

T;>^;^}¥x/t:i^0gO^Gl^(a.

±ett:^v®^^<!bzm^Lz<rc-a^\o

IC>

±>^^(09cM®^

±fi^:^y®S§te«)rPS0L^T

•g^^t^rissBurT

±^^9cMt)\e>2mm(DiiLm(.m

T>(;^t¥'f7lJ:Q:Scfc

±y;?.$t^t>\62mmO{iIg

T><;?.i^¥?jli:/3:5a:5IC.

</c3t\o

rPlBurT

(0#

©

\

^—t

Ty:^ege

,^7]t'{

rVM-u-irv«i

@

A

\

t;

±

2mm

cacacQL

o :t^s;®s&(c(5]-r^:x

±>i.:x

1.

ots.

•

±>(;^•

v ®

::^

^3fi«)r

T^ot\^<Dj\:^Eym<w^-^c

^-®i:o^^^^£ia7~7,5mm

M Ur <

/c^l

rTo

^zrrr:::::

2mm

—

T

t

!i

I-

7~7.5mm»

13

Page 16

1.

:^Z)^^$i^)U/3:l^cfc^(c,

T>^^t.±>^:^m\^^oii€{z±>^

:x:^^3gF«9®s^¥Url^^•ro

A-xizm<mm[z.

J

:^5;(Q)g»rA:t^E<jDiggi5surTa

jgC

14

Page 17

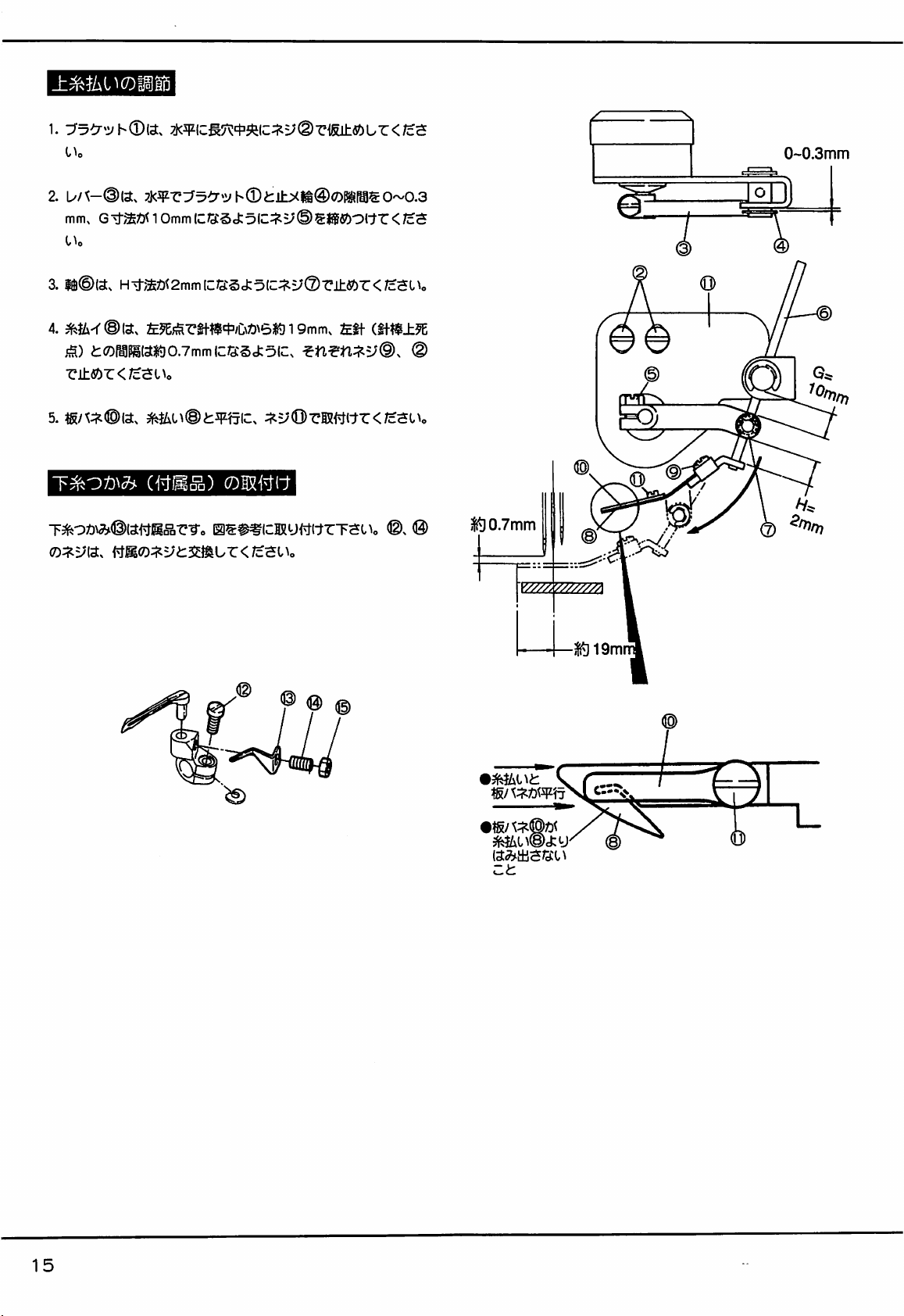

1. 7j<5ji(c^7^c|:^ic:i^=;(Drisu:«!)ur</c5

l\c

2.

L//t-®ia.

mm,

7j<5|ir3^^^»i'h©fcll::><M@OMSO~0.3

G^^Z)n0mm(CG:§J:5«v(i)g«l«)O(tr</cS

0~0.3mm

3.

4.

, H^mti^2mmlZU^<i:3[Z:!?.VQ>V±SbZ<Jc^l\c

m-rSia:,

£^^S^t^^?'^'/^:^Z)^63K319mm,

£tf

(if^±5E

j^) tW^PiraO.TmmlClGScfcolC, (D

r±«)r<;cauo

5.

t^ox)^^©«{^j1d°q-c^o

mLi^(Bt:w-^[z.

(WBS)

©ISI'JW

0€#%icaRy(^(trTSUo

:!^vOvmmz<m^i\o

® ©

®,

®

sg

0

0.7mm

^zzzzmzzzzzi

»gi9m

%

ct

15

Page 18

1.

10mm(c:^5; ®

rffiy

f^Cfr</cSl^

® ic:i^y @

rsieur

</csi

\o

10mm

3. M^PMi:^§fi;><®<Dm<^MZ)to~o.5mm(cQ:§cfc5(c;. b

/

4.

fa@)iaA^j^Z)l37mm(CG:5ctDlC:i^=;®®±fiOr</c^Fl^o

t}Sy^<DMa

E =

o-

^ y =6JS<TOu r

o

±fifey^i2)y/3:L(^^^

r=6,

o±®6y^i5!]y^yroii^

G =

wur

6.5mm,

u

^iPS^(7/^:o^{5lSlci2':^hUr</cal^o

15mm(CTOUr<;cSl\o

^:75b::7(i)0:;^y®sjgfi?)oitr</cSUo

B =

6mm,

C =

7mm,

F =

9mm(CiiML/'C<7cSUo

</c

s I \o

D=

8.5mm,

±ies^;^

®

©

o

16

Page 19

^^^t^r</cSUo

(iES{ii®(Z)wia.

9MS#RSur</cSUo)

0.5mm

h0.5mm

(e

0

17

Page 20

0)Mlll

"t: Fff HI

DD

UI

9t

s m 3

P a

«S «

r?t

/\

Ul

f9t ^

m 3 ^

w ^ ^

^ ^

rS W

# S

c wf m

s fn

H

c

u

s

ono

\/;

00

Page 21

l§IO)ci:o(c

;;tr-KDVhD

;^t:-

[<3y

hn-^-Qia^

t:-h'Sl^li5US"§"<,

h'

;^t:-

^rosJiiCct

e-Sfeic

K=>i)

19

y.

±T><

ut:-h*=P)

liS^^>ii^^mL^•ro

ic(iug-prz)\6,

u

/so/cy.

©

^>t?ica(c:

C^t^-

Page 22

^ui

5~7kg/cm2

!^u±c±Z}aj^-ro

(cM

Ur</c^O^o

®

•?(Z)Wc$mES

®

o

ip-E^±c:f5i:gia,

oxT'-Eswstsia.

t)'jS-lDi^W)L^'^(DZC:)iMXJz^{,\o

^:;'V5®sa:^f^ic(iu-c<;c5Uo

£:5iqnci5]ur</c5Uo

KL/Vrostdd

s^EXiasicffurM

U

ur</c$

20

Page 23

sms:±g5

y y

ffltisoli;

® ®

^150

2.

•rse

3.

4.

5.

gOTMrS<iS<:?®5ilS-r5o

A^/^=120mm

6"^^=

59mm

G^^=13mm(c:/d:S1i(CU/^-®S|S)S-rSo

Osnmso

(a)

0-U-M551:$:j&aA-a(CiiDn55®5i^-rSo

ib)

mmmLizmz-i5(DBoJco-u-mmvm^n?>

?s?ii^"rSo

iogm±o

(J^ie)

21

Page 24

»H!

sr

XI

y m

^ y 3

y K

@1

g

>J

^

/fl

n scr

»tn

C I

s ©

h-

©^

S

b y

i ®

|B

Page 25

±treu^®y,

1.

by^-(D^Tie(o^/"£(c^i^rBSf^it§o

A =

23mm

(0-U-5'-1'3^)

2.

zcomzji^trv

ySo

3.

HbbSjigur.

a

;?.3/b':y5^-®j$t

•^jss3i2<-r5o

h ® g±fio:;^b' (D

h®

±ifByMyg^sii)fp3t?5o

vmm-^^0

h'@i:<DMia2mmgJg(C^

(Eioas)

i

(7)Bf

A =

30mm

cty^M^nai^isoianoA

(HFgB)

l§l(7)Af/^S:g<T5o

—

2.0mm

23

Page 26

II

• 13

I

VI/

K

iT'-auT^groEss

(£iJ±S^®y

;

IT-it)

•

H • H

(l»l^)

'pmn-ii

m)

i§i(^j:o(c@5i®sur

imwm.

^oDfteoDnsis^/^ia.

^irc#i(is#Rsur<;c5Uc

<

;cSt\o

5~ioM0mmscuTgg(^D-

24

Page 27

C"

fsn

r

rS

ni

"H

na

U M

h" w

ri

3

9t

c

'-SSf

r\

A

\J

I

I

>J

fX

nt

m

fSft

(X

Si

y

IS

I

n:

a

C

n;

I

II

V.'

"t:

Ti

m

«4

I •

541

C IT T-

S >J

•§

«4

e>J

C

' nil

It

e>j

S

ri

H ' U

n S

0

C

a I

fit

-t;

I

1 wt

T.

^ im

u

©

U 01

rr

I

•

*0

T

^ d

^ I

w

\C

H-

nil

II

n

•HD

9tt

r

vc4

01

Vi'

®

y.

m

^

5M-

® y

u;

g Kt

•>

T

®

0

nil

c

y

It

"H

3

"nf

ri

gh

;S

Pft

®

a

r\

3

n:

-n

yi

nn

e>j

fv y

A

<]

$}

541

3 I

rit

0

C

9?

a

01

•>

Sio

III

©

n

n:

E

§ m

i

C

r|

:s

v3

s

n

Page 28

1. CgJ

5^X

±^VVimLZ<Jc^^\o

2.

z>^vo.

BS{^(tr</c^t^o

-DVO

ibS-o^D.u-s-(B(D'y^^®^±{z^\-o^^t:

'ui

tim^iLZ.

5~7kg/cm2

O

X7-Es±(:f§i:g(a.

o

O

ziyyiy^u-^-mo^xy-m^m-oz^.

-Z)^^orustgia>

tjys

-Z)^i'pi!jL

'i>u±ic±Z)aj^-g-o

(CM

Ur <

tc'Sl

V^^®^^mzMLZ<1z-^l\c

£;5(^(ci5]ur</c5c^o

/v\/yyy=fx—y-^w^iis

mr(Dzz:)m

< /c s i

0~0.5mm

0~0.5mm

rti^

®

^n-ymzoLy

T5lu(c:igffiogf7j<ffi7rv-;^©®^iasic}¥LrgfaiLr<

C^o

/c^

26

Page 29

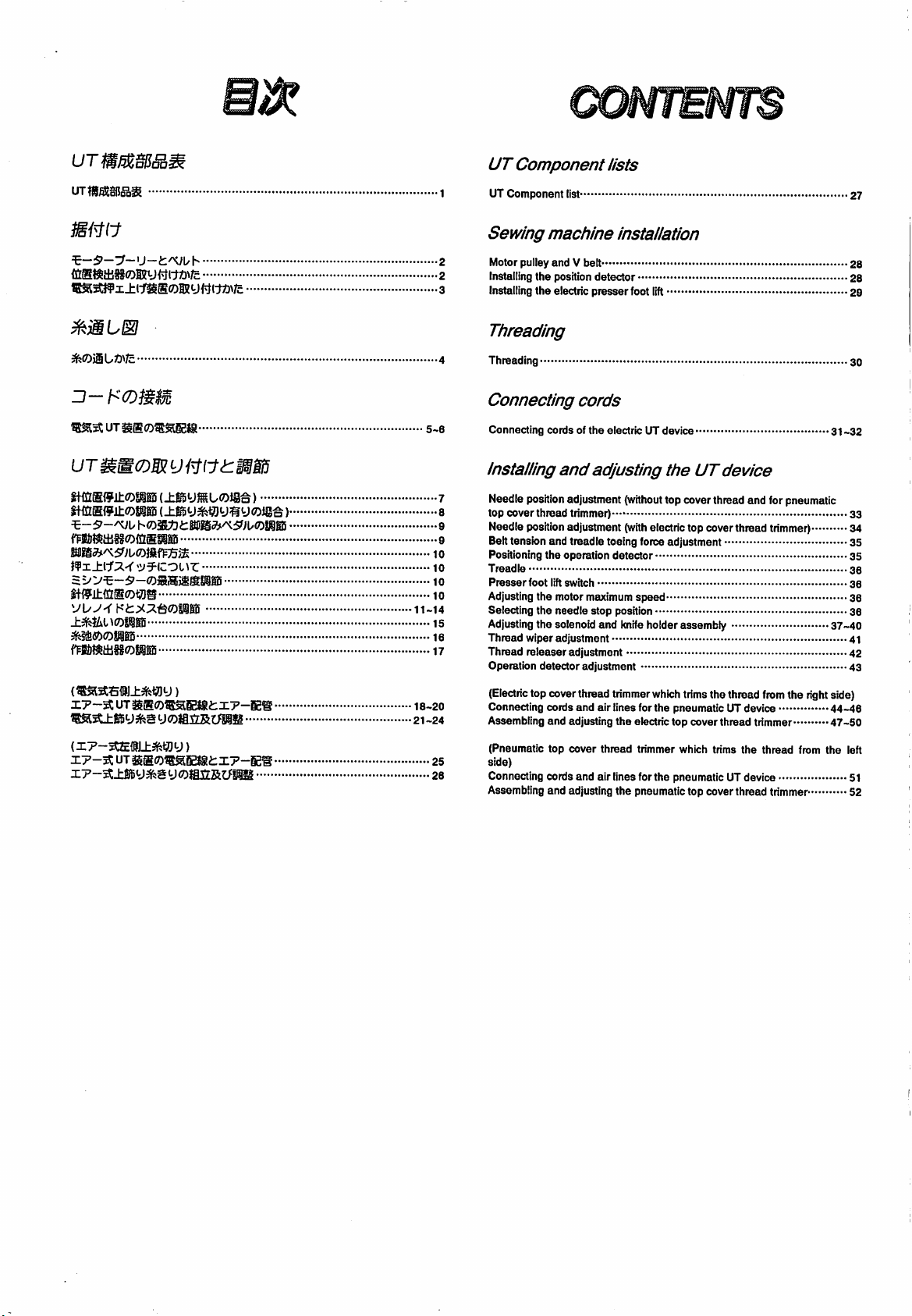

(\D

Machine

models

W664-08,33,358,81

W644-01,03,05,08,33,358,71,81

W664-01,03,05,71

W664-01,03,08

W664-08,33,358,81

W644-01,03,05,08,33,358,71,81

W644-01,03,05,71

W664-30,32,34,35A

W644-30,32,34,35A

W664-32

W664-01,03,05,08,33,358,71,81

W644-

01,03,05,08,33,358,71,81

W664-30,32,34,35A

W644-30,32,34,35A

W664-01,03,08,

W664-

01,03,08,358,71,81

W664-30,34,35A

W664-33

W664-32

UT

UT109

UTIlO

UT111

UT211

UJ212

UT312

ufsis

UT314

U^15

UT316

U^7

UT320

Ut321

UT333

UT334

UT414

UT415

UT434

UT435

UT436

Ut437

UT438

Uf439

UT440

UT^I

device

Thread

Electric

trimmer

type

W600/UT

mechanism

Pneumatic

type

Top

cover

Electric

(Component

thread

trimmer

mecharvsm

type

Pneumatic

type

Thread

Electric

wiper

type

list)

mechanism

Pneumatic

type

Foot

Electric

lifter

type

mechanism

Pneumatic

type

I

MITSUBISHI

LIMI-STOP

I

PANASONIC

PANA

SERVO

Motor

Motor

Motor

PEGASUS,

Page 30

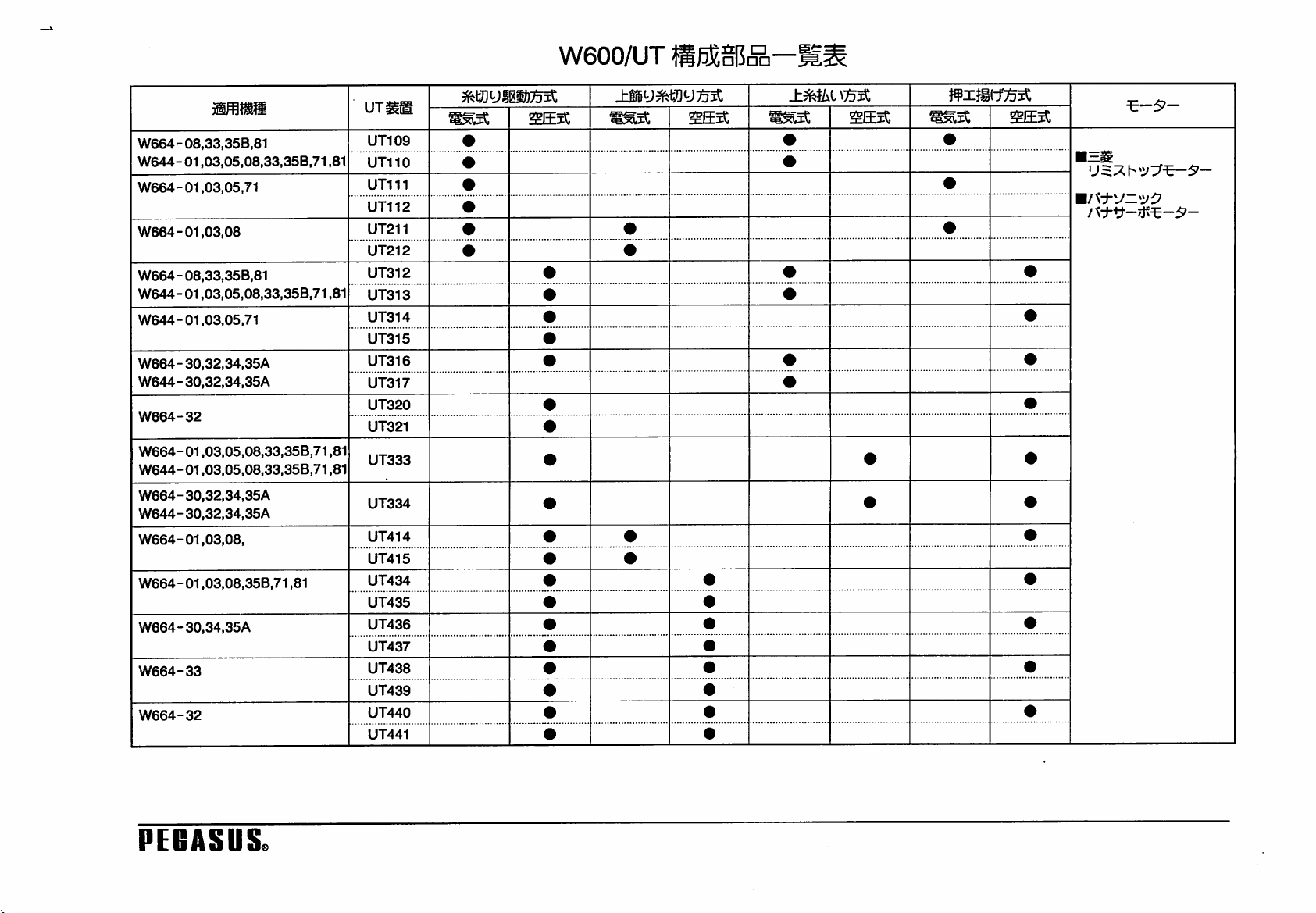

1

MOTOR

PULLEY

ANDVBELT

I

Following are the specifications for the motor and V belt.

1. Motor: Double pole,

2.

V belt:

Type

3.

Motor pulley: Select the proper motor pulley for the speed of

550W

clutch motor

M

the machine to be used by referring to the table

shown

below.

OWhen replacingthe motor pulley, fix the motor pulley with the

V belt or a rod and then tighten the nut.

Refer to the illustration of page 35 for the belt tension.

Relationship

Machine speed(s.p.m.)

6.000

5,500

5,000

4,500

4,000

between

machine

speed

and

motor pully

Motor pulley dlameter(mm)

60Hz

105

95

85

80

70

50H2

125

115

105

95

85

Tightening

T=Wx

(T should be

(Note)

Install

the

PANA-SERVO

pulley of

L

motor.

torque

200

tapered

to 250kg.cm.)

hole for

the

li

1. Install the position detector by referring to steps© to ® in the

right illustration.

(Fix pin screw

(g)

with nut

©.)

Page 31

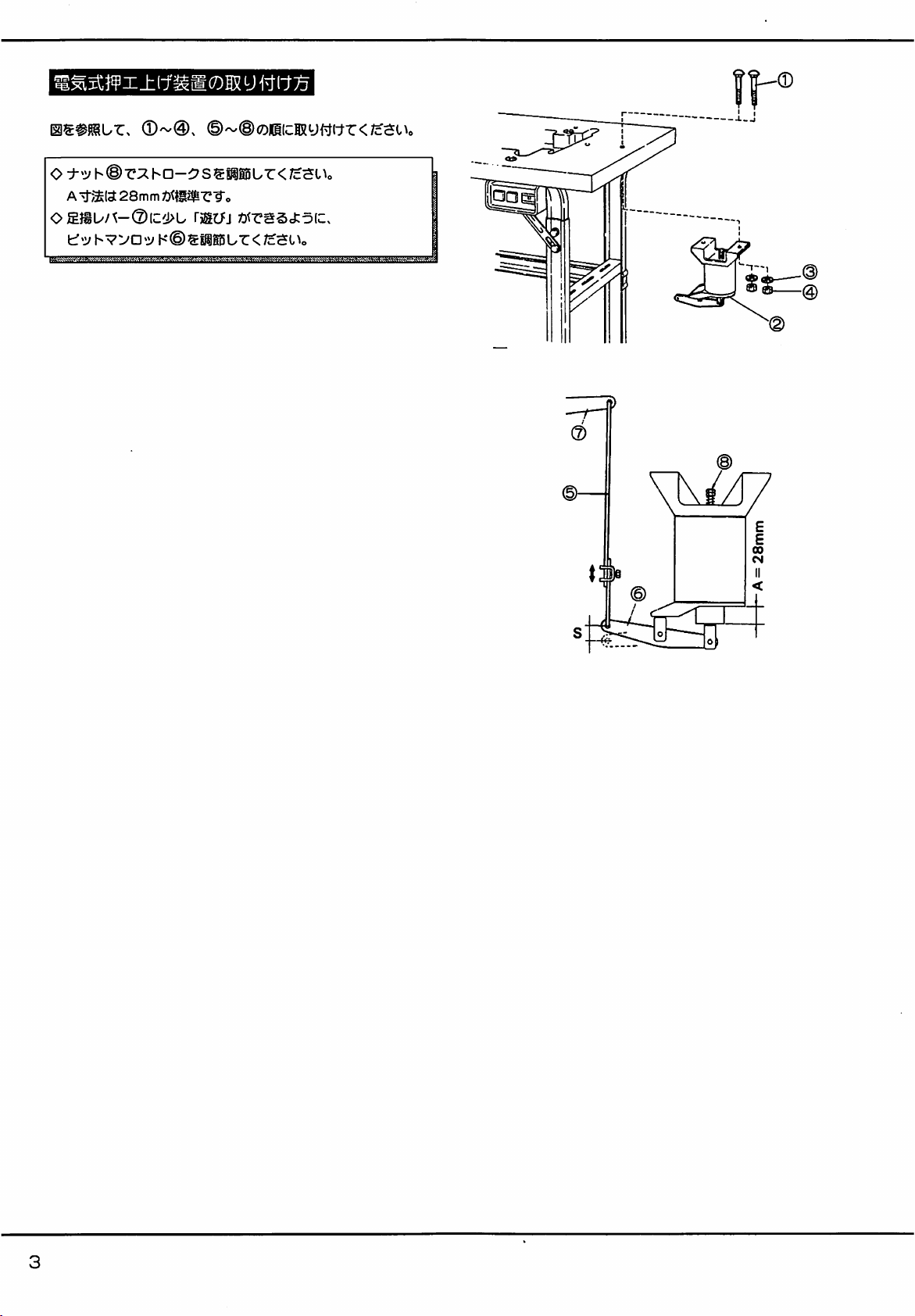

INSTALLING

Followsteps® to@ ,and© to(

(See the right illustrations.)

THE

ELECTRIC

PRESSER

FOOT

LIFT

O Adjust stroke "S" with nut

To

obtain

the

standard

®.

stroke, diniension"A"should be 28nim .

O To producea little play on foot lift lever (2), adjustpitmanrod

29

Page 32

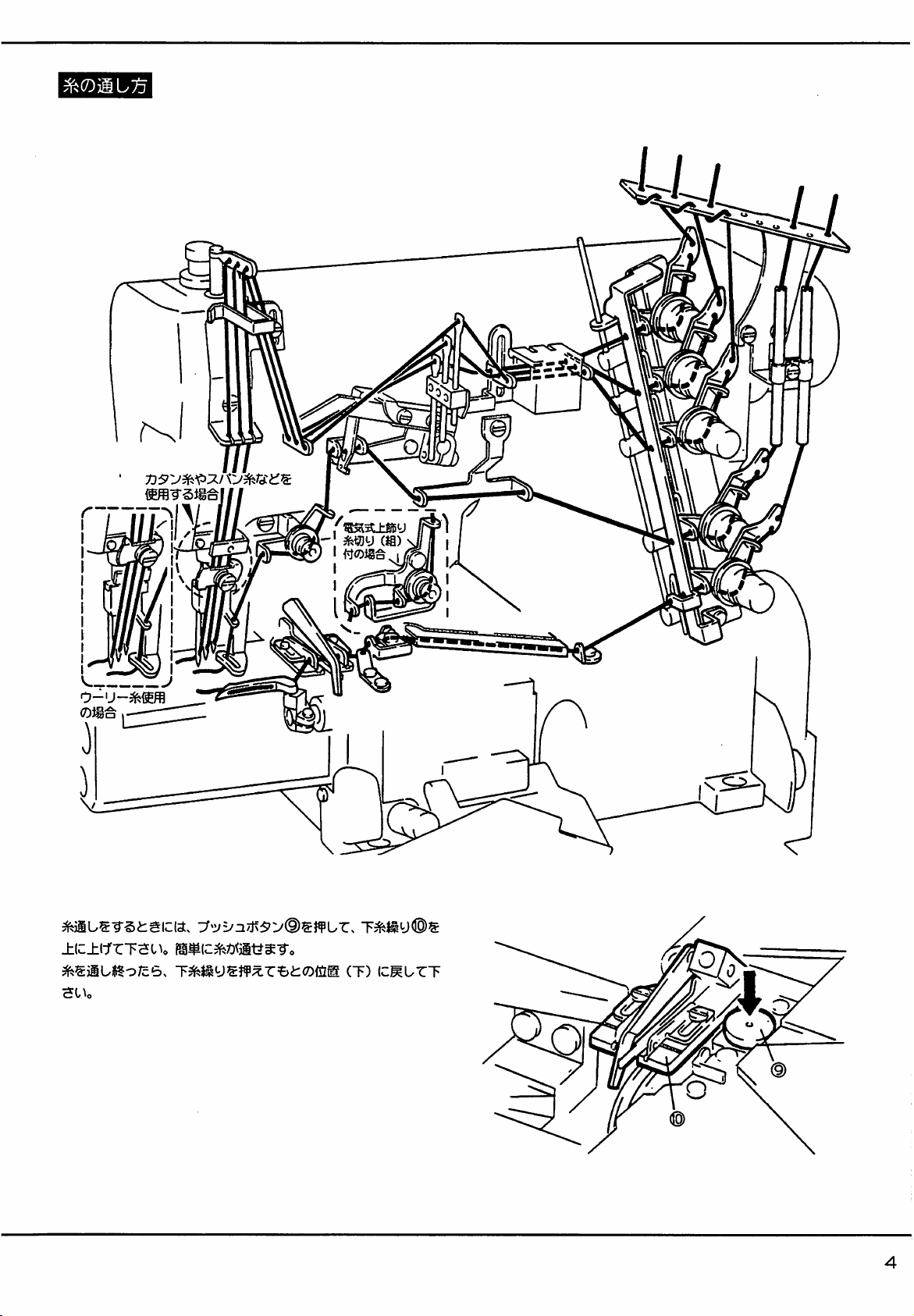

THREADING

For

spun

cotton

thread

thread

TO

and

For woolly

Press

machine easily.

Pressthe looper

the

machine.

thread

pushbutton®

/

and

lift

thread

take- updownand

o

I

looperthread

I Ifthetop cover

' thread trimrrer

I

(assy^is

take-up (©to

replace

it afterthreading

i^d;

thread

the

30

Page 33

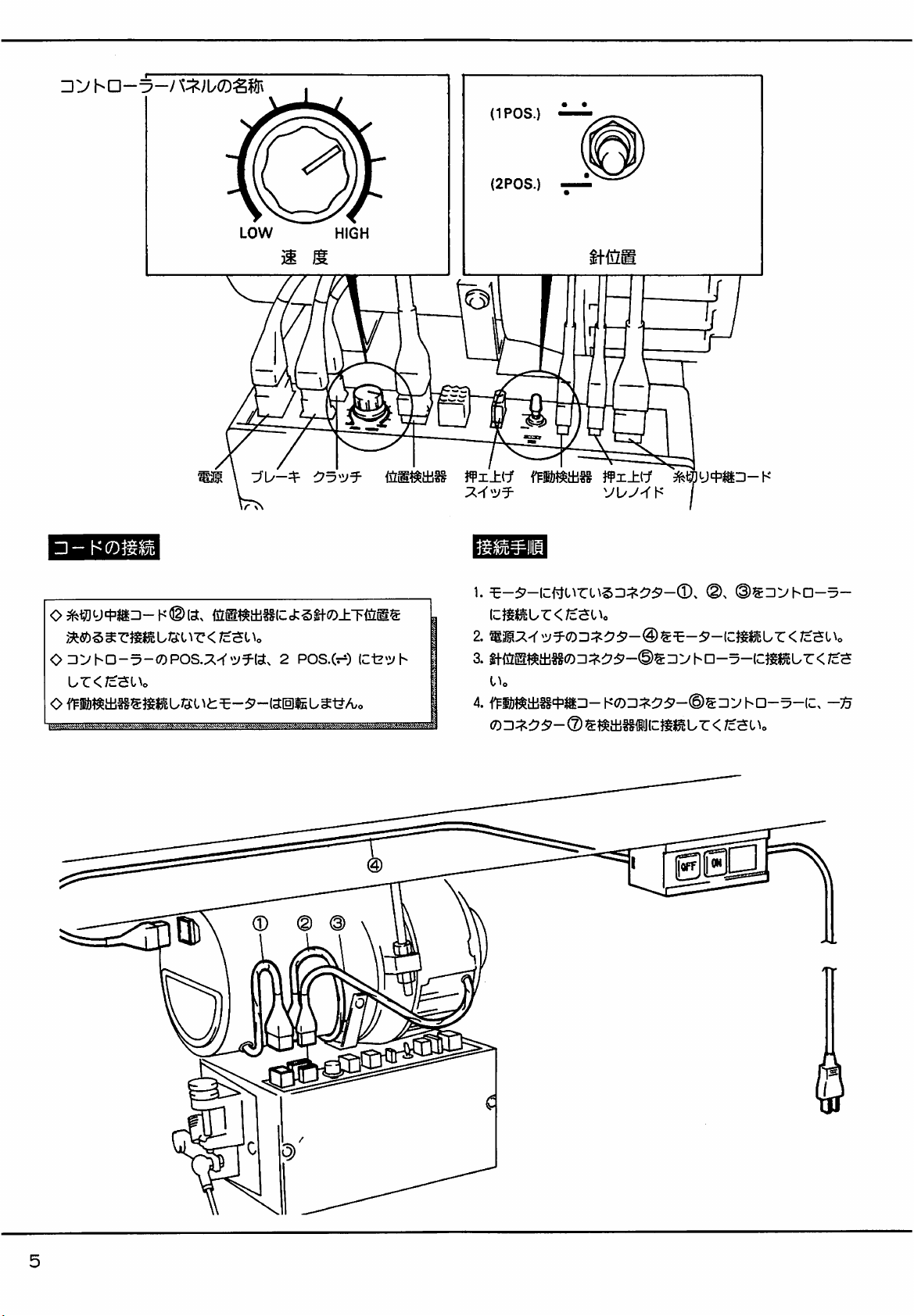

Descriptions of

the

control box

(IPOS.)

(2P0S.)

LOW

HIGH

Speed

Powert

CONNECTING

CORDS

O Do not connect threadtrimmer relay cord

lowest needle positions have been determined by the position

detector.

O Set the POS. switch on the control box to 2 FOS.(r^).

O Besure to connect the operation detector to the motor to run the

motor.

BraKe

Cutch

()|)

until

Position

detector liftswitch

highest

and

Needle

Presserfoot

CONNECTING

1. Connect connectors

Operation

detector

box.

position

Presserfoot

liftsolenoid relay cord

STEPS

®,

(§) and O of the motor to the control

^Thread trimmer

/

2. Connect connector@ of the power switch to the motor.

3. Connect connector (§) of the position detector to the control

box.

4.

Connect

connector © of theoperation detectorrelaycord to the

control box and another connector(2)to the operationdetector.

UD

31

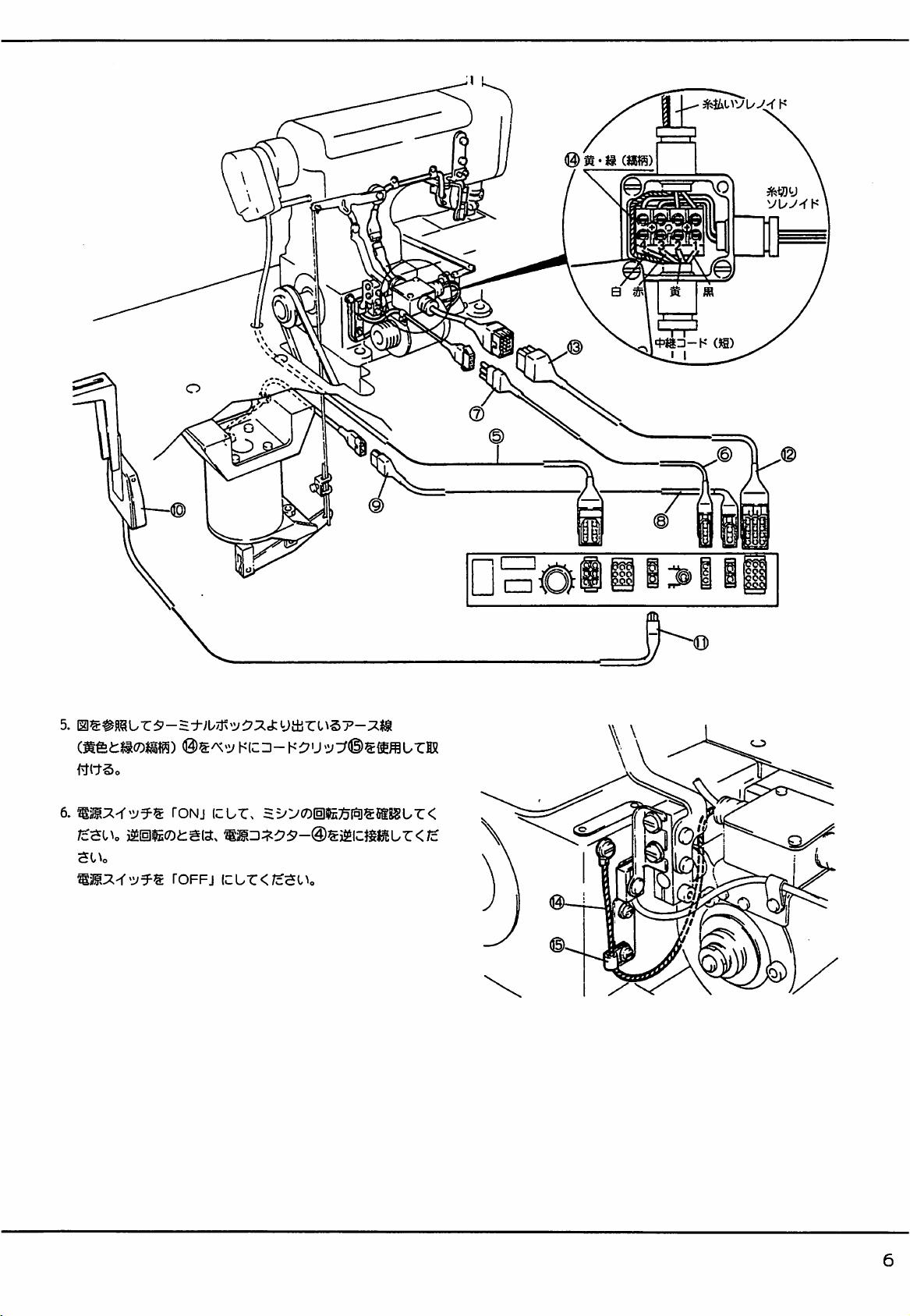

Page 34

n

ellow

green

Whrte

and

stripes

Red

Relay

CM

®

Yellow

n

cord

, .

Black

(short)

Hi

Thread

solenoid

trimmer

'

5. Fix groundwire@ of yellowand green stripeson the

bed with cord clip

6. Turn the machine on to check the rotating direction.

If the

machine

connector@ upsidedown.

Turn

the

machine

(Jl).

rotates

off.

in the

reverse

direction,

connect

machine

power

1i>i

ii

32

Page 35

green

stnpes

Whtte

Red

_ , Relay cord (short)

Thread

tnmhter

solenoid

Ye

low

Back

n

NEEDLE

POSITION

ADJUSTMENT

(without top cover thread and for pneumatic top cover thread

trimmer)

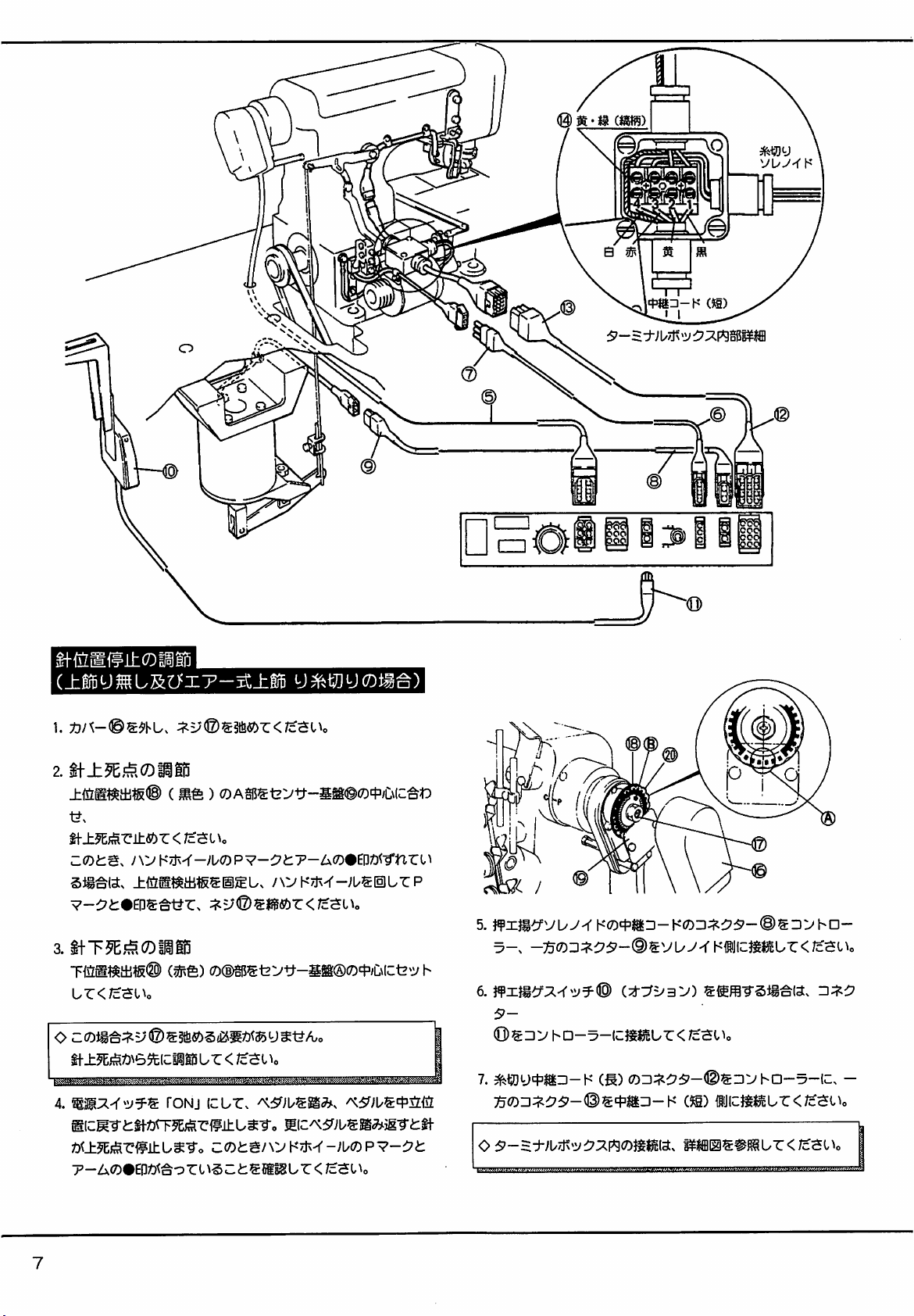

1.Removecover ® and loosenscrew

®.

2. Adjusting the highest position

AlignA portion of upper positiondetectingplate® (black) with

the center of sensor baseplate © and then set the needle at its

highest position.

If

markPon

the

handwheel

and

the

black

circleonthe

arm

do

not align, fix the upper position detecting plate and turn the

handwheel to align mark P with the black circle, then tighten

screw

®.

3. Adjusting the lowest position

AlignB portionof lowerposition detecting plate @ (red) with

the center of sensor baseplate A.

O When adjusting the lowest position, there is no need for

looseningscrew

®.

The highest position adjustment must be made first.

Insideofthe

termina

box

•

'1

5. Connect connector(D of the presserfoot lift solenoid relay cord

to the control box and another connector (§)to the solenoid.

6. If presser foot lift switch © (option) is used, connect connector

O to the control box.

7. Connect connector © of the thread trimmer relay cord (long) to

the control box and another connector © to the relay cord

(short).

OPefer

4. Turn the machine on and treadle in the neutral position. The

to the illustrationofthe insideofthe terminal box shown

above

for

the

connectioninthe

needle stops at its lowest position. Then heel the treadle to stop

the needle at its highest position, and check to see if mark P on

the handwheelis aligned with the black circle on the arm.

terminal

box.

33

Page 36

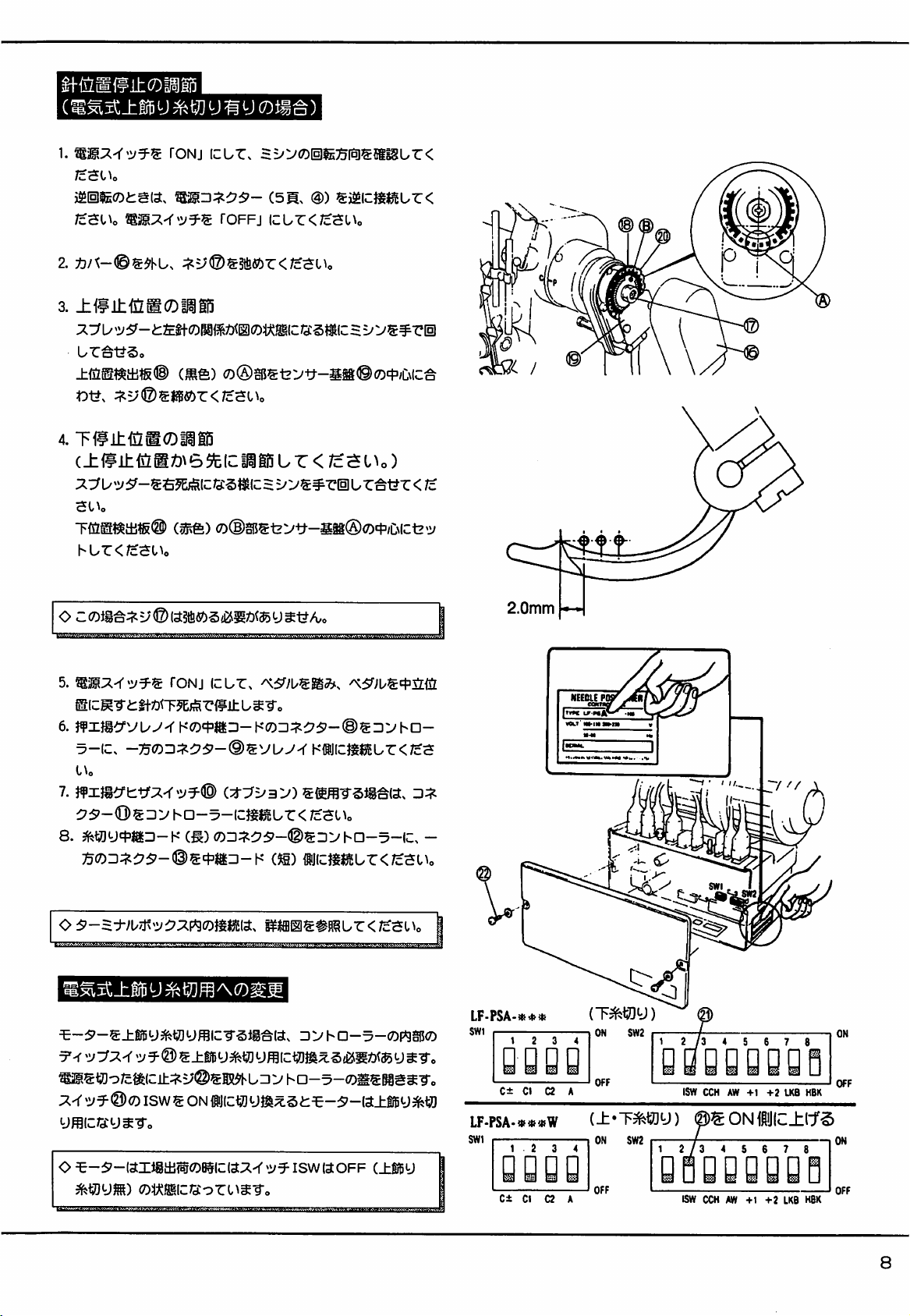

NEEDLE

POSITION

ADJUSTMENT

(with electric top cover thread trimmer)

1. Turn the machine on to check the rotating direction.

If the machine rotates in the reverse direction, connect power

connector(See illustration @ of page31.)

Turn

the

machine

off.

upside

down.

2. Remove cover © and loosen screw

3. Adjusting the highest position

©.

Turn the handwheel by hand to make correct relationship

between the spreader and the left needle as shown in illustration

.Align A portion of upper position detecting plate ® (black) with

the center of sensor baseplate © and then tighten screw

4. Adjusting the lowest position

®.

(The highest position adjustment must be made first.)

Turn the handwheel by hand so that the spreader will reach its

extreme position to the right.

Align B portion of lower position detecting plate @ (red) with

the center of sensor baseplate A.

O When adjusting the lowest position, there is no need for

looseningscrew

©.

5. Turn the machine on and treadle in the neutral position. The

needle stops at its lowest position.

6. Connectconnector

(§)

of the presserfoot liftsolenoid

relay

cord

to the control box and another connector (§)to the solenoid.

7. If presser foot lift switch ® (option) is used, connect connector

© to the control box.

8.

Connect

connector

© of the

thread

trimmer

relay

cord

(long)

the control box and another connector ® to the relay cord

(short).

2.0mm

IMI

jlWM.

1

to

<C>Refer

Change the motor application with one of dip

control

Turn the machine

to the

illustrationofthe

21) for the connection in the terminal box.

TO

SET

THE

MOTOR

TOP

COVER

box.

THREAD

off

and remove screws © and the cover of the

inside

APPLICATION

TRIMMER

of the

TO

terminal

THE

switches

ELECTRIC

control box. Then move (ISW) of dip switches to ON in order

to apply the motor to the top cover thread trimmer.

O Dip

34

thread).

switch

ISWisfactoiy-set

to OFF

(without

box

(page

© in the

top

cover

(Underbed thread trimmer)

LF-PSA-»*»

swi

C±

C1

02

LF-PSA-**«W

SWI

1 2

C± 01 02 A

A

ON

OFF

ISW

CCHAW-t-1+2LK6

Set

dip switch

ISW

OOHAW+1+2LKB

HBK

(0)

KBK

(Topcover thread trimmer and underbed thread trimmer)

to ON.

ON

Page 37

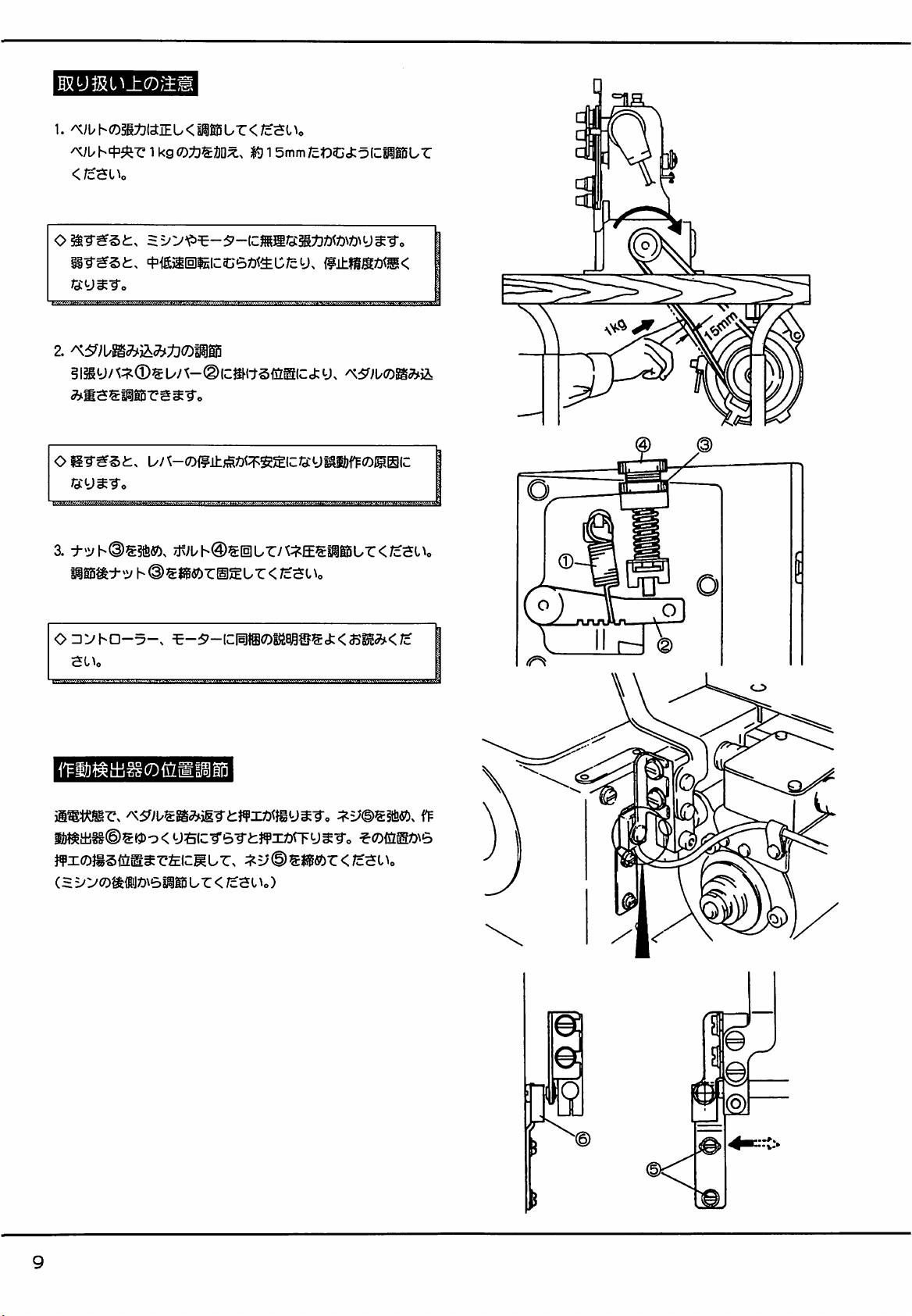

BELT

TENSION

ADJUSTMENT

1.

Belt

tension

Adjustthe belt tensionso that 1 kg pressureon the center of the

belt allows approximately 15mm deflection.

O Excessive tension may overload the machine and motor.

If

the tension is not sufficient, the machine at medium or low

speed may not run evenly and also the needle may not stops

correctly.

2. Treadle toeing force adjustment

The treadle toeing force can be adjusted by selecting where to

hook tension spring

O If the force is tog light, the stop position of the lever may not be

fixed, causing trouble.

AND

TREADLE

(X)

over lever (§).

TOEING

FORCE

I

n

3. Loosen nut (3) and tum bolt @ to adjust the spring pressure.

Then tighten nut ® securely to set the spring pressure.

O Read and study the instruction manual packaged in the control

box and motor carefully.

POSITIONING THE OPERATION

The presser foot is lifted up by heeling the treadle when the

machine is on. Loosen screw (§)and slide operation detector

the right slowly to lower the presser foot.

Then replace the operation detector to the left until the presser foot

is raised. Tighten screw

(This adjustment should be made from the rear side of the

machine.)

©.

DETECTOR

<§)

to

1

Page 38

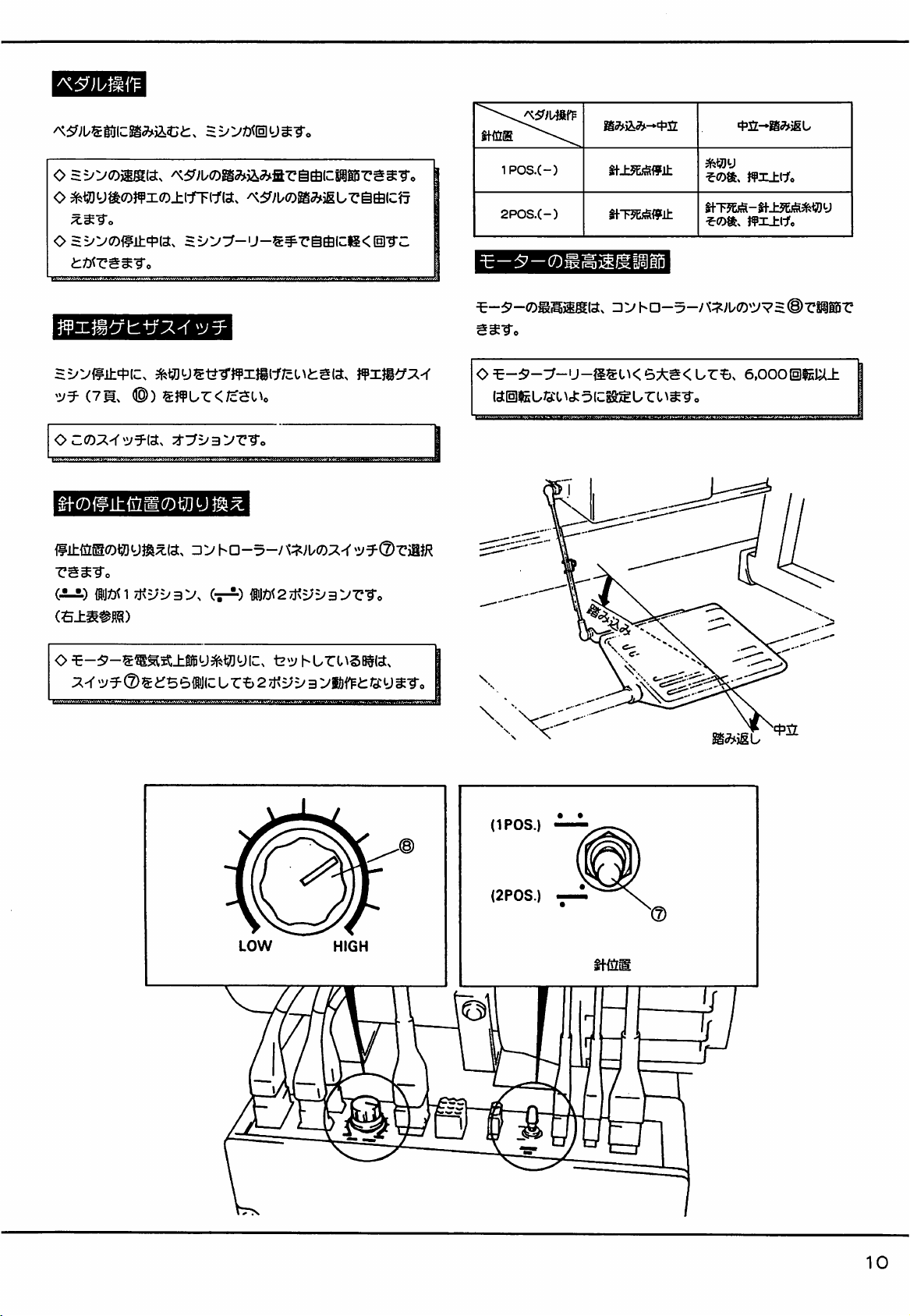

TREADLE

Toeing the treadle starts the machine.

O The machinespeedcan be adjusted freely by the toeing amount.

O The presserfoot can be lifted up or down readilyby heelingthe

treadle

after

the

thread

has

been

trimmed.

O The machine pulley can be turned by hand easily while the

machine is stopped.

PRESSER

FOOT

LIFT

SWITCH

To lift the presser foot up without trimming the thread while the

machineis stopped,press presserfoot lift switch

®.

(See illustration® of page 33.)

O The presser foot lift switch is optional.

Treadling

Needle

positten^^^

IPOS.(-)

2P0S.(

-)

ADJUSTING THE

Toe

treadle-•

Stops

position.

Stops

positions.

MOTOR

Neutral

at highest

at lowest

MAXIMUM

Neutral-•Heel

Thread

trimmed,

presser

foot lifted.

Stops

at lowest position. —

Needle

goes

position to trim thread, and

then

presser

up at

foot

treadle

then

highest

lifted.

SPEED

The motor maximum speed can be obtained by dial 8 on the

control

box.

O The motor does not run at more than 6,000 r.p.m., however

large the motor pulley diameter is.

SELECTING THE NEEDLE STOP

POSITION

The needle stop position can be selected by switch (2) on the

control

box.

(•2-i)

indicates 1 position and indicates2 position.

(See the table shown on the right side above.)

O If the motor application is set to the electric top cover thread

trimmer,@position

selecting eitherofthe two positions.

operation

canbealways

performed

by|

(IPOS.)

(2P0S.)

Needle

position

To

heel

the

Neutral

treadle

©

36

Page 39

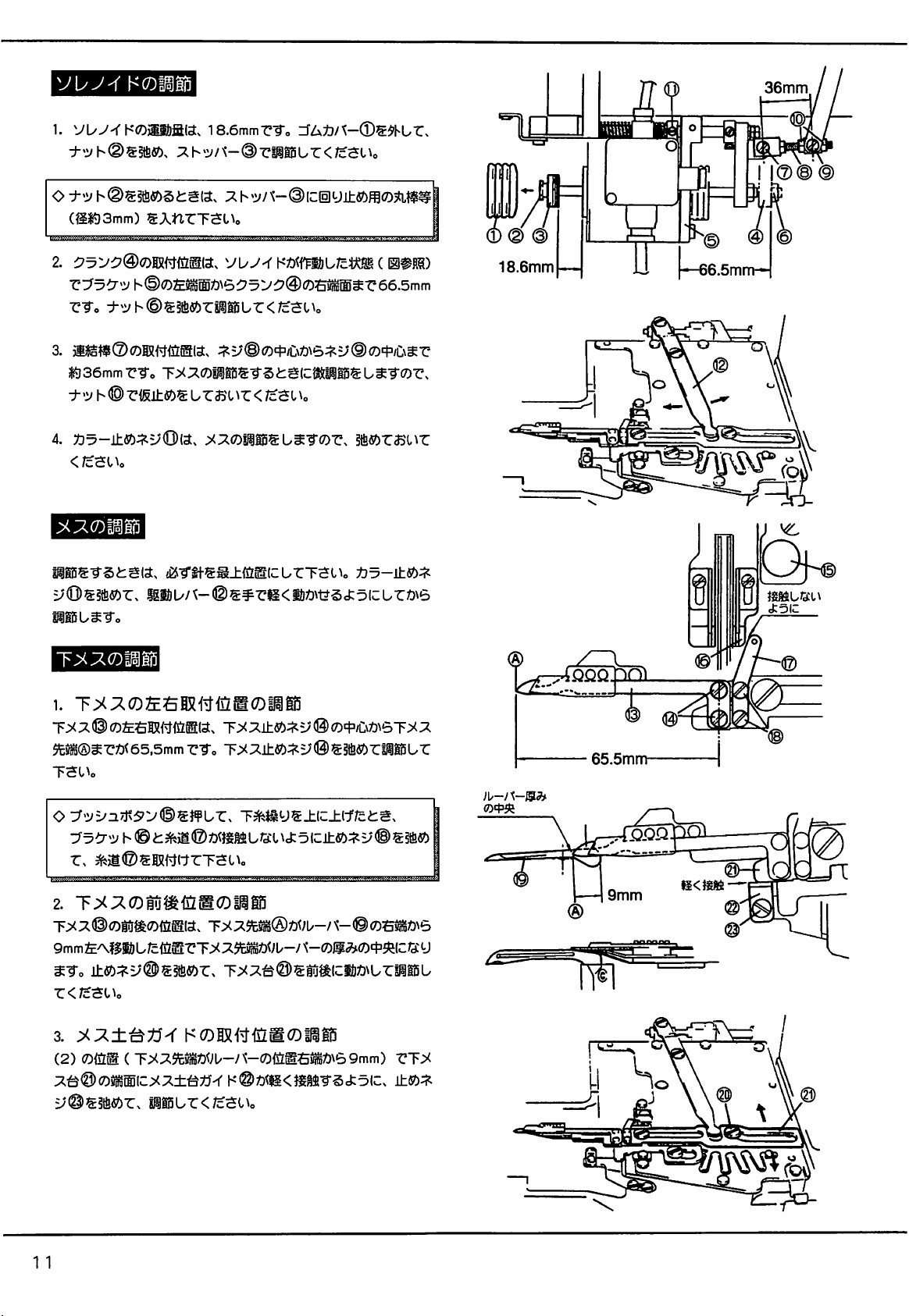

ADJUSTING

I.The

amountofthe

Remove

rubber

THE

cover

SOLENOID

solenoid

® ,

solenoidby meansof stopper(§).

movement

loosen

shouldbesetto18.6mm.

nut

<§)

and

then

adjust

36mm

the

0®

OWhen

2. Position crank @ so that the distance between the left end of

inserted

loosening

nut@,an

intostopper® inorderto

approximately

prevent

3mm

from

rod

should

rotating.

be

bracket® and the right end of crank @ will be 66.5mm with the

solenoid activated as shown in the right illustration. Loosen nut

® to makethis adjustment.

3. There must be a 36mm distance between the center of screw ®

andthat of screw

Since fine adjustment is made when adjusting the lower knife,

fix the connectingrod temporarilywith nut

4. Loosen collar set screw

ADJUSTING THE KNIVES

The needle should be at the highest position of its travel to make

this adjustment. Loosening collar set screw

drive easily by hand. Then adjust the knives.

(§)

in orderto mountconnecting rod(2).

®.

(Q)

in order to adjust the knives.

(Q)

can make lever ®

7r

18.6mm

—66.5mm—

©

Do

each

not

touch

with

other.

LOWER

1. Horizontal positioning adjustment of the lower knife.

KNIFE

The distance between the center of lower knife set screw 0 and

tip A of the lower knife should be 65.5mm. To make this

adjustment,loosen lowerknife set screw

ADJUSTMENT

0.

OPress pushbutton0 to raise the looper thread take- up, and then

install thread guide 0 by loosening set screw 0 so that bracket

16and thread guide ® will not touch with each other.

Z

Front-

to-

back positioning adjustmentofthe lower knife.

To position lower ® knife front to back correctly, tip A of the

lower knife should be centered over the looper when tip A has

moved9mm to the left from the rightedgeof looper

®.

This adjustment can be made by loosening set screw 0 and

shifting lower knife holder0 frontto back.

3. Positioning adjustment of the knife holder guide.

With the lower knife tip positioned at the place described in

above (§)(9mm away from the right edge of the looper), adjust

knife holder guide @ by

loosening

set screw

0.

Be sure that

knife holder guide @ contacts the end surface of lower knife

holder© slightly.

Center

over

®

the

tip A

looper.

r-ZZl—

65.5mm

Light

©

contact

——

37

Page 40

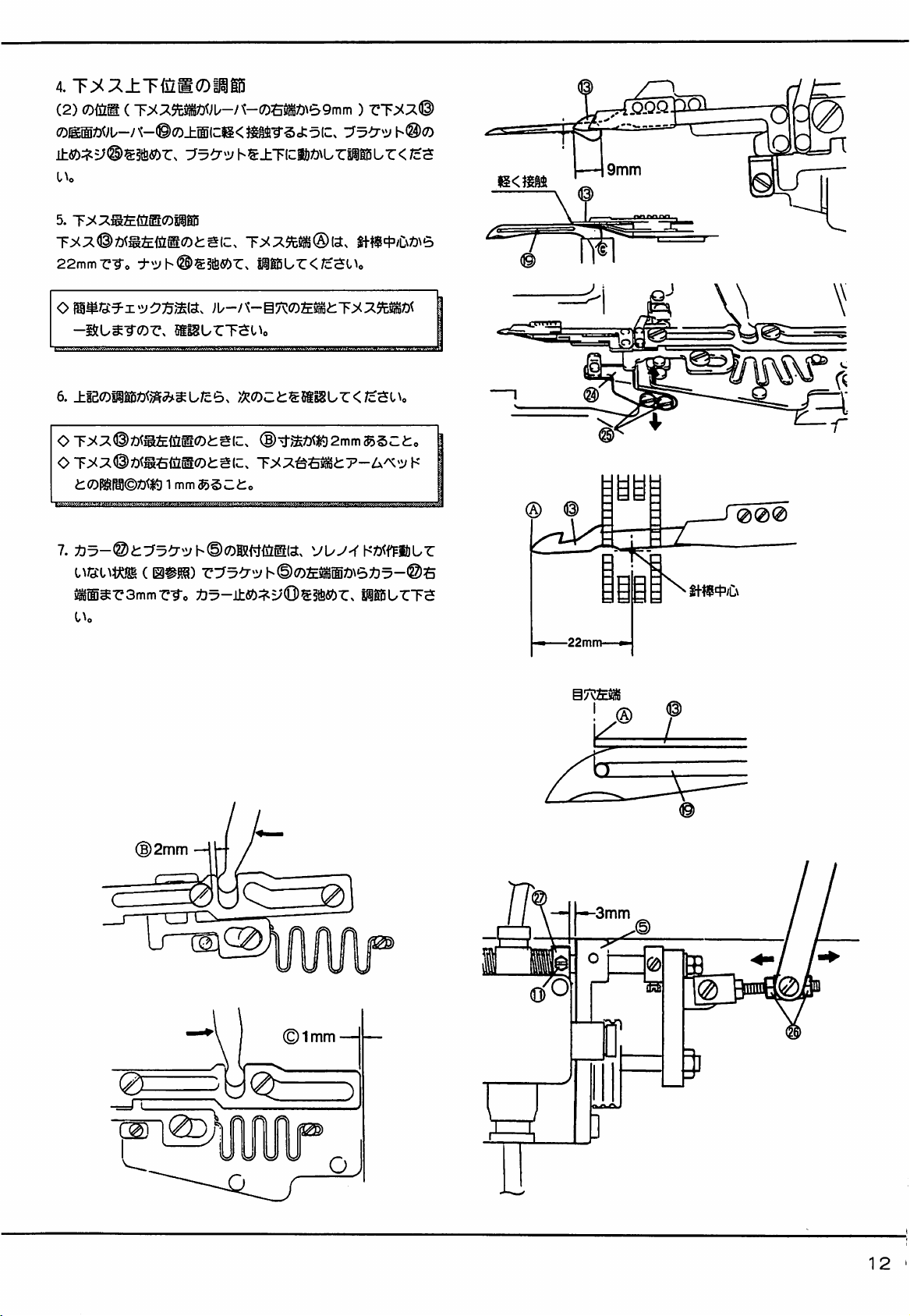

4. Vertical positioningadjustmentof the lowerknife.

With the lower knife tip positioned at the place described in

above 2 (9mm away from the right edge of the looper), move

the lower knife up or down as required by loosening set screws

® on bracket ® to make this adjustment. Be sure that the

bottom surface of lower knife ® contacts the top surface of

looper®

slightly.

5. Adjusting the lower knife at the extreme left end of its travel

With lower knife ® at the farthest position to the left,loosen nut

@ to adjust the lower knife so that the distance between tip A of

the

lower

knife

and

the

centerofthe

OTo

make the above adjustment easily, check to see if the left

needle

bar

willbe22mm.

edge of the looper's eye aligns the tip of the lower knife.

6. Confirm the following after the above adjustment has been

made.

ODimension B should be approximately 2mmwith lower knife®

at

the

extreme

OThe

clearance between the right end of the lower knife holder

and the arm bed should be approximately Imm with lower knife

left

endofits

travel.

® at the extreme right end of its travel.

Light

contact

® ®

(g)

Centerofthe

needle

bar

7. Loosen set screw

(Q)

and then position collar @ and bracket (§)

when the solenoid is not activated (see below). Make sure that

the clearance between the left end of bracket® and the rightend

of collar (§) is 3mm.

(B)2mm

(Z>

(g)1nim —

-Left

edge-^

of

the

looper's

eye

o

Q)

0

38

Page 41

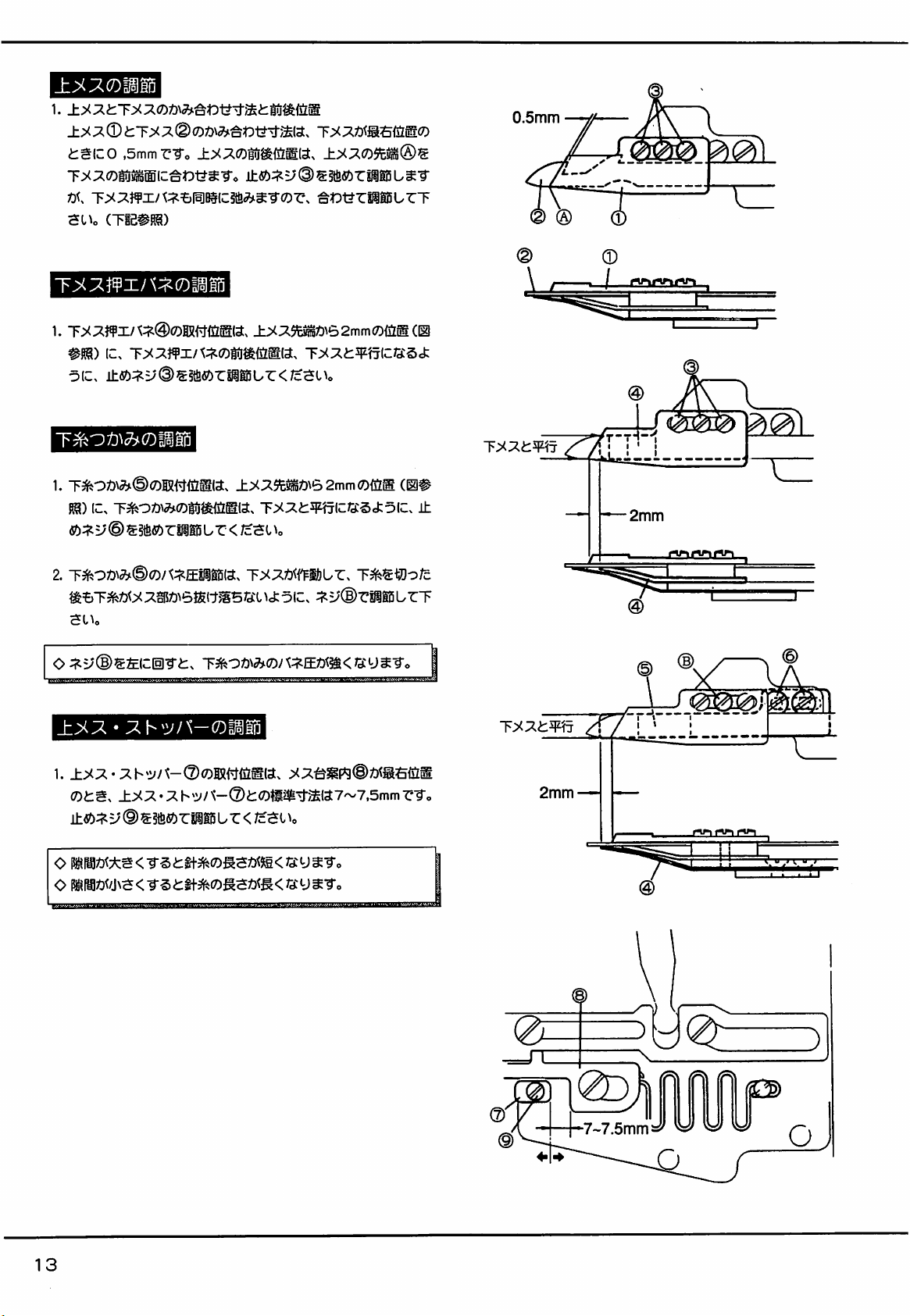

UPPER KNIFE

ADJUSTMENT

1.Overlapand front- to- back positioningadjustments of the upper

and

lower

knives

This adjustment achieves the correct overlap of upper knife ®

and lower knife @ . There should be 0.5mm when the lower

knife is at the farthest position to the right. To adjust the upper

knife front to back, align tip A of the upper knife with the front

edge of the lower knife by loosening set screw @ . When

making the above adjustment, the lower knife clamp spring can

be loosened, adjust the lower knife clamp spring simultaneously.

(See the following.)

LOWER

KNIFE

CLAMP

SPRING

ADJUSTMENT

1.Position lowerknifeclamp spring@ 2mm to the right from the

tip of the upper knife as shown in the right illustration. Adjust

the lower knife clamp spring front to back by loosening set

screws

@.

Be sure that the lower knife clampspring is parallel

with

the

lower

knife.

UNDER

THREAD

HOLDER

ADJUSTMENT

Parallel

lower

0.5mm

with

knife

the

C

/Ll^i—i

2mm

1.Positionunder thread holder (§) 2mm to the left from the tip of

the upper knife as shown in the right illustration. Adjust the

underthread holder front to back by looseningset screws©.Be

sure that the looper thread holder is parallel with the lower knife.

2. Under thread holder © holds the under threads at the knife

portion after the under threads have been cut. Adjust the looper

thread

holder

with

screw

B.

increase the under thread holder spring pressure, turn screw

B

counterclockwise.

UPPER KNIFE STOPPER

ADJUSTMENT

1.Positionupper knifestopper(2)to providea 7-7.5mm clearance

between knife holder guide © and upper knife stopper ® when

knife holder guide is all the way to the right. Loosen set screw

© to make this adjustment.

^Increasing the clearance reduces the needle thread length.

ODecreasing the clearance increases the needle thread length.

Parallel

lower

with

knife

the

2mm-—

7-7.5mm»

39

Page 42

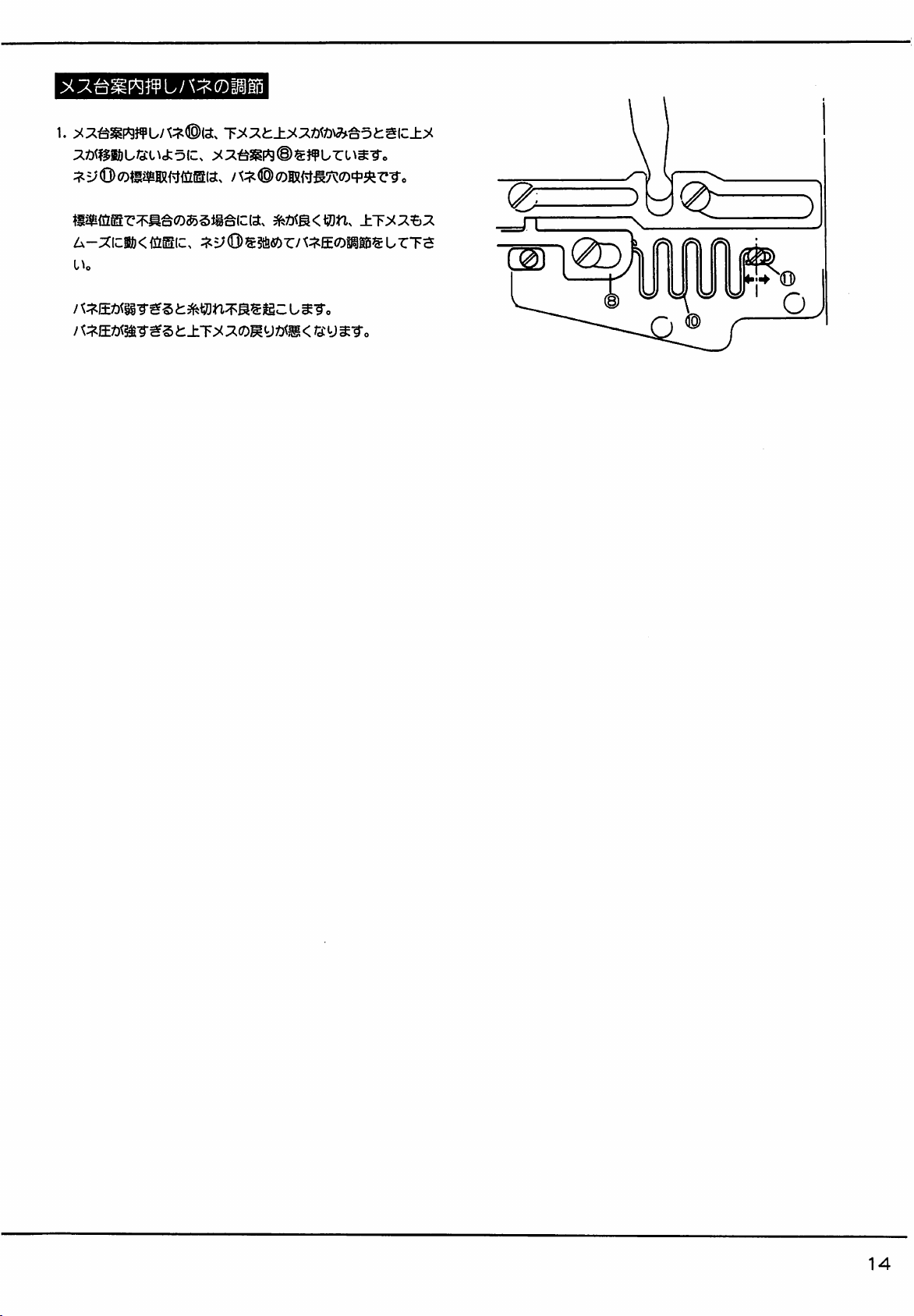

KNIFE

1.Knife

HOLDER

holder

to keep the upper knife in the position when the upper and lower

knives

overlap.

centered

In the standard setting, ScrewS should be in the center of the

elongatedholeof Spring

If the upper knife and lower knives are not activated properly in

the standard setting, adjust the spring pressure by loosening

screw (Q).

If the spring pressure is too heavy, the upper and lower knives

will not return home correctly.

in the setslotforspring

guide

GUIDE

clamp

In the

CLAMP

SPRING

spring(®presses

standard

®.

setting,

(@).

ADJUSTMENT

knife

holder

guide

screwOshould

®

be

I

(©

40

Page 43

W600

THREAD

WIPER

ADJUSTMENT

1.Temporarily fix

(2)

should

2.

Tighten

screw® to

There should be a 0 to 0.3mm clearance between bracket ® and

be in

bracket

the

centerofthe

position

® horizontally withscrewsi

slots.

lever@

horizontally.

Screws

stopperring@.Anddimension G is 10mm.

3.

Secure

shaft16with

4. Position thread wiper® with screws@ and

The distance between the left end of the thread wiper and the

center of the needle bar should be approximately 19mm when

the thread wiper is all the way to the left and the clearance

screw

17.

DimensionHshouldbe2mm.

®.

between the lef needle and thread wiper should be

approximately 8 mm.

5. Position thread wiper

(0).

LOOPER THREAD

Parts are packaged in the accessory box.

Install

looperthread hook® withscrew

parallel with flat spring

HOOK

INSTALLATION

0.

(@)

with screw

0~0.3mm

^8mm

#The

thread wiper

should be parallel

the

flat spring

with

)Flatspring

should

not

from

thread

QQ)

protrud^

wiper

©

41

Page 44

THREAD

RELEASER

ADJUSTMENT

1.On the

2. Loosen screw© of crank® and connect lever@ with cranks©

WSOO

and 700

with screw © so that the distance between the side of the bed

and

thatofthe

and© by meansof screw

crank

Series,

position

willbe33mm.

©.

thread

releaser

crank ©

10mm

3. Lever shaft © should be adjusted to provide a clearance of

0-

0.5mm between the tension disc and the finger of thread

releaser®.And then tightenscrew© of crank

4. Secure shaft © with screw @ so that dimension A can be 37mm.

<0>The

thread

releasing

between

Adjust the amount by referring to the following.

For

Adjust to reduce each distance shown above for stretchy threads

such as woolly threads.

OWithout top cover thread trimmer

Thread releaser © for top cover thread must be set to th

position

looper thread are loosened.

OWith

G

threadguide® andthreadreleaser

cotton

thread:

where

top cover thread trimmer

shouldbe15mm.

amount

can be

cannotbeaffected

decided

when

the

bythe

@.

needle

®.

relationship

thread

and]

©

©

S

42

Page 45

OPERATION

Loosen

detector

right positioning adjustment.)

DETECTOR

screws

® . Besurethat the

(2)

and

magnet

@ is

0.5mm

ADJUSTMENT

clearance

O.Smm.

(See

between

page

35fortheleft-to-

0

operation

43

Page 46

Machine

Yellow

Thread

trimmer

ground

and

solenoid

B

wire

green

stripes.

ackYeow

Relay

Thread

solenoi

Red

cord (short)

wiper

White

CONNECTING

WHICH

RIGHT

Connect

cordsasshowninthe

Refer to pages 31 to 36 of

TRIMS

SIDE

CORDS

THE

FOR

TOP

THE

PNEUMATIC

COVER

(Electric top cover threadtrimmer)

illustrations.

notes,

procedures

connecting cords of the electric UT device.

•

THREAD

and

UT.DEVICE

FROM

THE

adjustments

for

Machine ground wire

'Yetlow and

green

stripes

44

Page 47

Connect

air

lines

as

shown

below.

0

CONNECTING

DEVICE WHICH

FROM

THE RIGHT

Connect air lines by referring to the above illustration.

AIR

LINES

TRIMS

SIDE

OF THE PNEUMATIC UT

THE TOP COVER THREAD

(Electric top cover thread trimmer)

Connectedtothe

See

page

44 for connecting cords.

air compressor.

SPEED

Speed controller ®

andspeedcontroller

Too fast speeds may increase the noise level from the air cylinder

or cause thread breakage on some threads before the upper and

lower

CONTROLLER

knives

mates

ADJUSTMENT

regulates

(§)

with

the protruding speed of the

regulates the returningspeedof the

each

other.

knives

knives.

To adjust the speeds, loosen nuts @ and @ first. Then turn knobs

(D and 0 counterclockwise as much as possible (the speeds

increase.)and turn them clockwiseslowly (the speeds decrease.).

45

Page 48

ADJUSTING AIR PRESSURE

PullknobA of filter regulator® up. The knobclicksand lifts up

slightly.

OTo

OTo

Then

adjust

air

pressure

increasethe air pressure, turn knob ® clockwise.

decrease the air pressure, turnknob ® counter

toset5 -

7kg/cm'asrequired..

clockwise.

U

ONote

Drainage collected in filter regulator ® must be drained until

drainage level reaches baffle (g) by moving hose © to the left or

right.

that the cutter will be actuated by pressing the valve

actuator if air is left enough to operate the cutter in the tube even

after the air supply is shut off form the compressor.

DRAINING THE FILLTER

REGULATOR

/

46

Page 49

ASSEMBLING

COVER

Knives adjustment

1.

Remove

movedeasilyto directionF by lessthan approximately I50g.

AND

ADJUSTING

THREAD

TRIMMER

lever ® first. Then

THE

confirm

ELECTRIC

that knife holder ® is

TOP

2.Adjustand fix

screws © and © . Dimension A should be 120mm while

dimensionBshouldbe59mm.

3.Fix lever® so that dimension G can be

(2)shouldcontact

4. Assemble plate springs© and

5. (a) Confirmthat a wooly thread is cut smoothly.

(b) Make sure that the remaining part of the wooly thread to be

usedis held by

The tension in order to pull out the thread while retaining

the thread is more than lOg.

OAdjust pressure on plate springs

trimmed or held correctly.

movable

cushion

(Q)

knife@ andstationaiyknife@ with set

13mm.

Stopperscrew

rubber on lever®.Thentightennut

<Q).

after trimming.

and

(Q)

if the thread is not

(As

seen

from J side.)

47

Page 50

Adjust when the needle is at the lowest position of its travel.

1. The presser foot should be raised 3min above the top surface of

the needle plate (equivalent to 8 pieces of knit fabrics).

2. With movable knife @ out in the direction of the arrow, bring

movable knife (§)toward spreader©.But do not reach spreader

©.

(Set screws©,@ or ® are used to make this adjustment.)

3. Under the same condition of movable knife @ as described in ©

above install movable knife © so that the movable knife can

hook top cover thread E as it returns. (Screws

used to make this adjustment.)

After this adjustment, if the hook of movableknife © does not

reach top cover thread E with lever ® moved all the way in the

direction of arrow F, or the tip of the movable knife rams the

presser foot, adjust the knife front to back with set screw

Should be the case, repeat "Knife adjustment".

®@

or ® are

©.

i k N

Page 51

ADJUSTING

THE TOP

1.

Position

A = 23mm (standard)

B = 30mm (for thread with great elasticity such as woolly)

2.Fix

bracket

can be aligned (see B) when the solenoid is not activated. Then

check to see if the clearance between bracket (g) and solenoid @

is approximately 2mm.

3. Start the machine to operate the top cover thread trimmer.

Run the machine to operate the top cover thread cutter device.

a) If tip (D in the illustration below) of the spreader tends to

miss

THE

COVER

lever®

d) withset

the thread,

TOP

THREAD

according

screw

shorten

COVER

THREA^

TAKE-UP

tothe

following

® so thatall the

dimension

A.

TRIMMER

dimensions.

thread

AND

guide

holes

a

a

b) If the top cover thread slips from top cover thread holder

spring (F in the illustration below) before the thread gets

hooked on the left needle, lengthen dimension A.

lqji

I

f&Q

2.0mm

49

Page 52

Thread

tnmmer

Machine

Yellow

solenoid

ground

and

B

green

ack

wire

Yellow

stripes

Relay cord (short)

'Top

trimmer

cover

Red

thread

solenoid

White

CONNECTING

WHICH TRIMS THE TOP COVER THREAD

LEFT

SIDE

Connect

cordsasshowninthe

CORDS

I

(Pneumatic

FOR

top

THE

PNEUMATIC

cover

thread

illustrations.

trimmer

UT

FROM

)

DEVICE

THE

Refer to pages 31 to 36 of notes, procedures and adjustments for

connecting cords of the electric UT device.

Machine

.YeUow*and

ground

green

wire

stripes

50

Page 53

Connect

air

lines

as

shown

below

0

Connectedtothe

CONNECTING

DEVICE

THE LEFT

Connect air lines by referring to the above illustration.

WHICH

SIDE

AIR

LINES

TRIMS THE TOP

(Pneumatic top cover thread trimmer )

air

compressor

OF THE PNEUMATIC UT

COVER

THREAD

FROM

See

paqe 50 for

connecting

SPEED

cords

CONTROLLER

ADJUSTMENT

Speed controller 0 regulates the protruding speed of the knives

andspeedcontroller© regulates the returningspeedof the knives.

Too fast speeds may increase the noise level from the air cylinder

or cause thread breakage on some threads before the upper and

lower

knives

mates

with

each

other.

To adjust the speeds, loosen nuts ® and @ first. Then turn knobs

0 and O counterclockwise as much as possible (the speeds

increase.) and turn them clockwise slowly (the speeds decrease.).

51

Page 54

ADJUSTING THE TOP COVER THREAD TRIMMER

1. Adjust the top cover thread trimmer with set screws.

Be sure that A portion of the hook passes over the top cover

thread as shown in the right illustration.

2. Position the hook, spreader and'left needle correctly.

Refer to the right illustration for the relationship

above three parts.

between

the

Set

screws

Hook

Top

thread

cover

ADJUSTING

Pull knob A of filter regulator© up. The knob clicksand lifts up

slightly. Thenadjustair

<C>To

increase the air pressure, turn knob®

OTo

decreasethe air pressure, turn knob® counterclockwise.

ONote that the cutter will be

actuator if air is left enough to operate the cutter in the tube even

after the air supply is shut off form the compressor.

AIR

PRESSURE

pressure

toset5 - 7kg/cm'as

clockwise.

actuatedbypressing

required..

the valve

Screws

0~0.5mm

Left

J

0~0.5mm

need

II

e

Spreader

DRAINING THE FILTER

Drainage collected in filter regulator © must be drained until

drainage level reaches baffle B by moving hose © to the left or

right as required.

52

REGULATOR

/

Page 55

t553

;*;fRi1:SSE!lj«5-7-2

TEL

(06) 454-0561

PEGASUS SEWING

5-7-2,

Sagisu, Fukushima-ku, Osaka 553, Japan.

MACHINE

MFG.CO.,LTD.

Phona:

(06)454-0561

Cat.No.9A2570i\ October. 1992

The

(jescription

in

this

INTSTRUCTIONS

are

subject

to

change

First PrintingJanuary 1992

© 1992 PEGASUS SEWING MACHINE MFG. CO.. LTD

without

notice.

Loading...

Loading...