Page 1

Catal

OFFER

EASIER

OPERATION

y

'j

>

Cylinder

a; 7 K 2 ' 3 ^

Bed

2,3-Needle

ni-i. : xt.

-

it ^ y

Interlock

Machines

>

Page 2

l:-

8t>

tc

aamii--cS)isii.fc%>0cov>-ctt,

c:®SiBji*tt.

■i

—ii

—Sc^JIfelCtfcSiaMS

■iWStB#(»4fiS#^)S:J^IRK:Ufe5'>vR0!ilS®S#,

i->xW(Dmmw

S:^fc-a:TS«tTfe

t^K.

brv>35:v>3Stt,

mn&fS'

U

tt.

i®<^|gS:it6^CU^:v>-eTSv^.

5 d fc.

-tix

®#,

S®.

^vr

JaT®#S!#S;^fc

Jtofc<^lB#-efe5cifc.

Page 3

a

[

1

[

2

]

I

3

[

4

1

(

5

[

6

I

[ 7 }

^

—il—ffl#

—

^moKD^m—

l»g^:$03eiS!!-

]

f--:rji/0Mx

]

] 5

]

1

] 5i/V©IiI«g:^rl$IO?l8g-

■

1 1

2 ] #^u?tr6

3

J

4

]

5 ] XL/;tV

g^fim

]

]

h^v'<—(0^#-

hO,^,tta;^5i5i-

i:

^

^(Dll6^<Dm^-

mzM-r^/u-A-(DiiLumn-

—

v>

-c:

^^-5=-

(fis^aa#)

cDW

]

1

]

x:/Uy^r-0igy

8

J

9

J

(«)

(t?r)

CDMfflS

®®|J8

10 ] 3asyB0tj±;&^yt?rT;&^y®»ffli-

11 ] 2SyB0iS$©jHai

12 ] i^x»yji©sji5

■

^mj=ticonm^

1 ] Bsptfc^© ^ i/>0D^S(lJfc2

]

1:1.3

P^± 1 :

1.8

Page 4

a

^

-<

0S3I®

0(^Mvt—

^

^

-< 5 >

CO

y^—

19

19

19

19

20

20

20

21

21

21

22

22

MD23 1 (zfA^y^iS)

1

2

3

J^?A

^ y y

4

5

U~x|gf^

6

7

8

if

7-yyB

g

10

i/-xtf>rK

11

^

Ai^ y ai

y—7sii^

^

0151^4

(T)

UiiOMI®

yy

K0®tfifit

^

^^®£<;Dg^@15

:^3g|^02a®!

ff

x0tir±;&^yfi0^fi5-

±:^

T:3<X^;

±jiX05««|

"F;^X03fi5|j|

It

Qymx-iUUo>m^-

(LG2

10)

O^f®-

KlOl^T

—^

icov»"r-

cm:d2

CFT240)

3

1)

23

23

23

23

~

~

—

24-25

23

24

25

25

25

26

26

26

26

27

27

27

27

^^5^

( 1

]

[ 2 ]

( 3 ]

( 4 ]

y

CO

B®@iS c I?. F )

—

n-5-0ffxJEtJ0Sif®-

^^0aiya:0S3f®

— 1 —

28

28

28

28

Page 5

^

<5D

^

a^^co

tc)

U # v>T

tfc.

t"

d|iA,^^®fc«?)0^i:4^g|5aS:®y^UT^^-r'5c:i:ti,

0

tc

®(y ^ u

o^iyy^mm-t^t^lt.

X'to

'B-fMM^^-oX.

v>„

o^-zr;v^^ih^t^\t.

'-^;i/h:^j

v>-5 d ii

r

u

^yyT-zrjv(D±KmMc'^xM.

^

yy^^)v^^/uX^

i^f^-rmaSSr^oTT^v^o

>'-<-,

t r T $ v>

-CT ^ v>

o

^

o

't<Di&(D^(D\tm'

yyfi^±t'DX\,>^:itt:Wtii^it>x

ddTlt,

glcov-^T,

^k:bfcA^-3t:iEU<»f^bTT^v^.

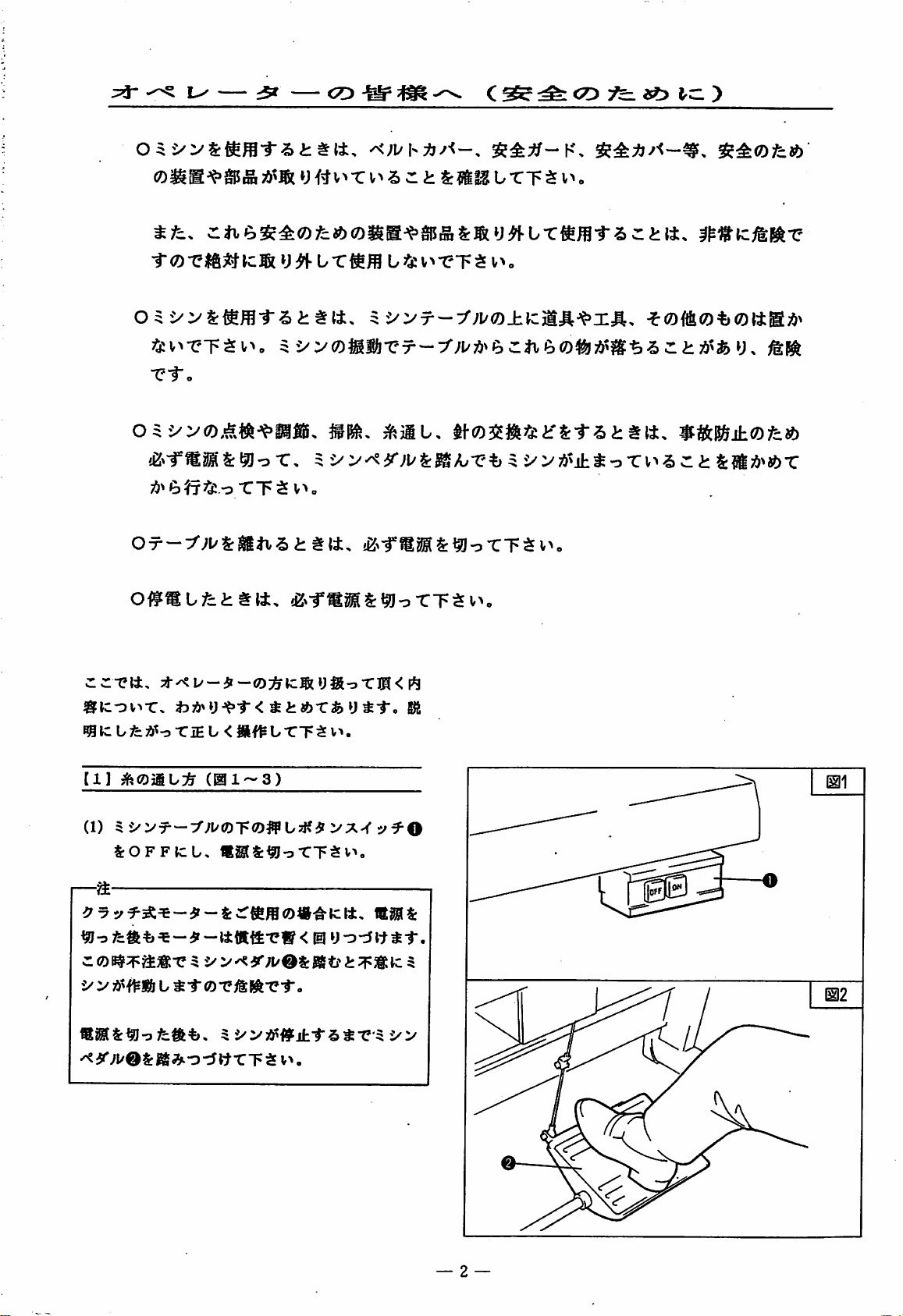

[11

5fe03Sb5^

(1)

5i/VT-:'';KJDrOff

SrOFFtcU.

—a

^ o fca % ^ -

d

®

y y WS& u ^"T

^a*';i/0Srg[;^o^[t-CTSv>.

t);i>^y-^-r<^i;«?>Tfey^1-,

(igi~3)

«S&^oTT$V^.

ar - It tttt

^yy^

0T?i&lift-ci"«

-e w <

UsKif

VX'<y^O

HI

y-o-ti

gft

1^1

It i 1".

— 2 —

Page 6

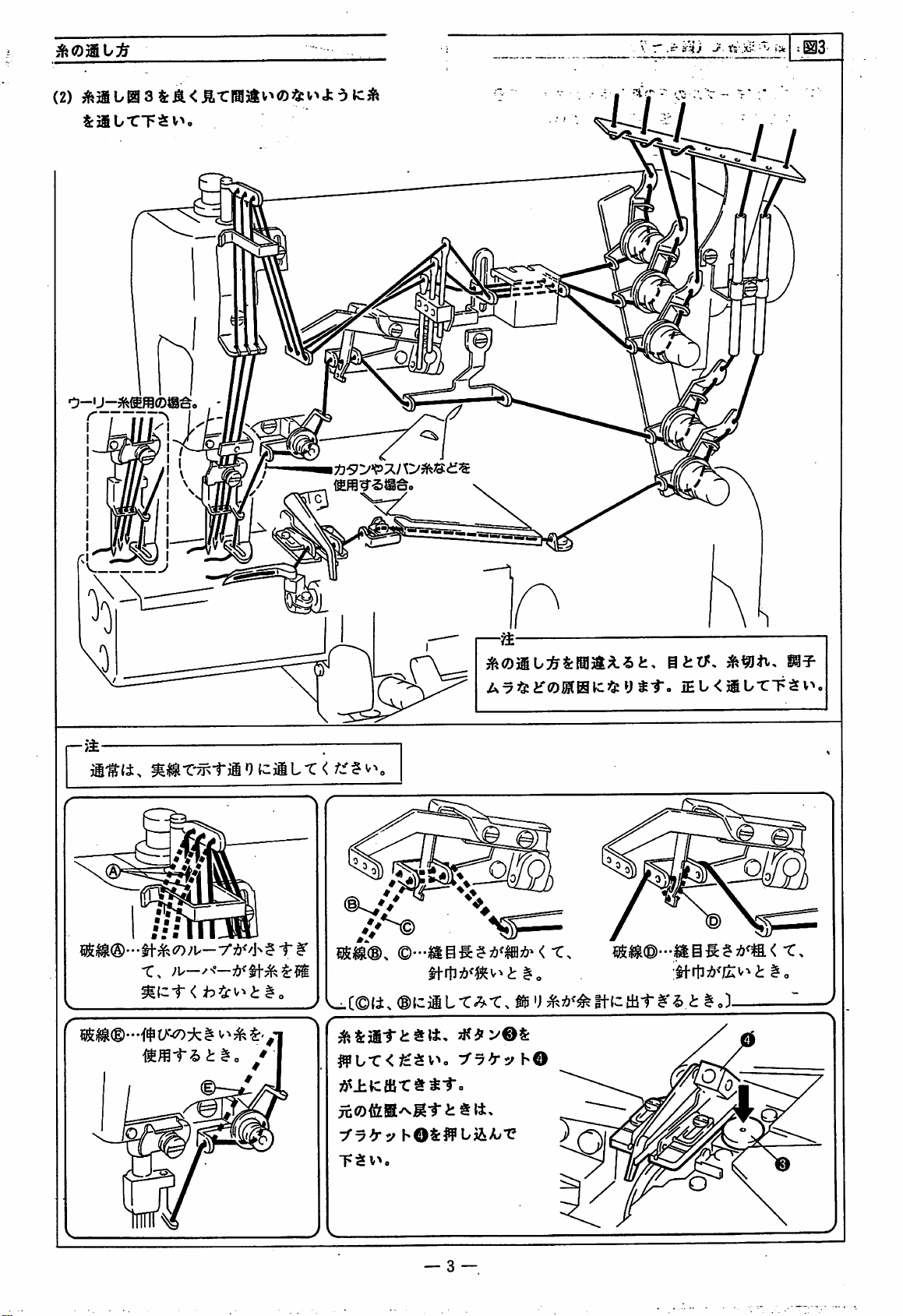

(2)

^3iU03S:A<^-cra^v^®35:v^J:dk:ife

SrjfiUTT^vn

0-ij-

tisypTsny^B-ii^

\ T .i' ifHJ

fv . ,

r»,

J-

Xs

.'Xi-

>;«

—>i'

"N

/"

®^',

//^

K

,C©(±.

#b-C<^:Sv>,

'fyb'v

T;S

v>.

A735:iroMHlC55:y

©•••ass?A'W><

m

:fy^yhO

hOS:?PbjiiAy'C

t-r«

iEb

OUTT^

t.

'J

^s;!f<^if-(ztiit$^'^.t^oX

v>,

-c.

y

V.

— 3 —

Page 7

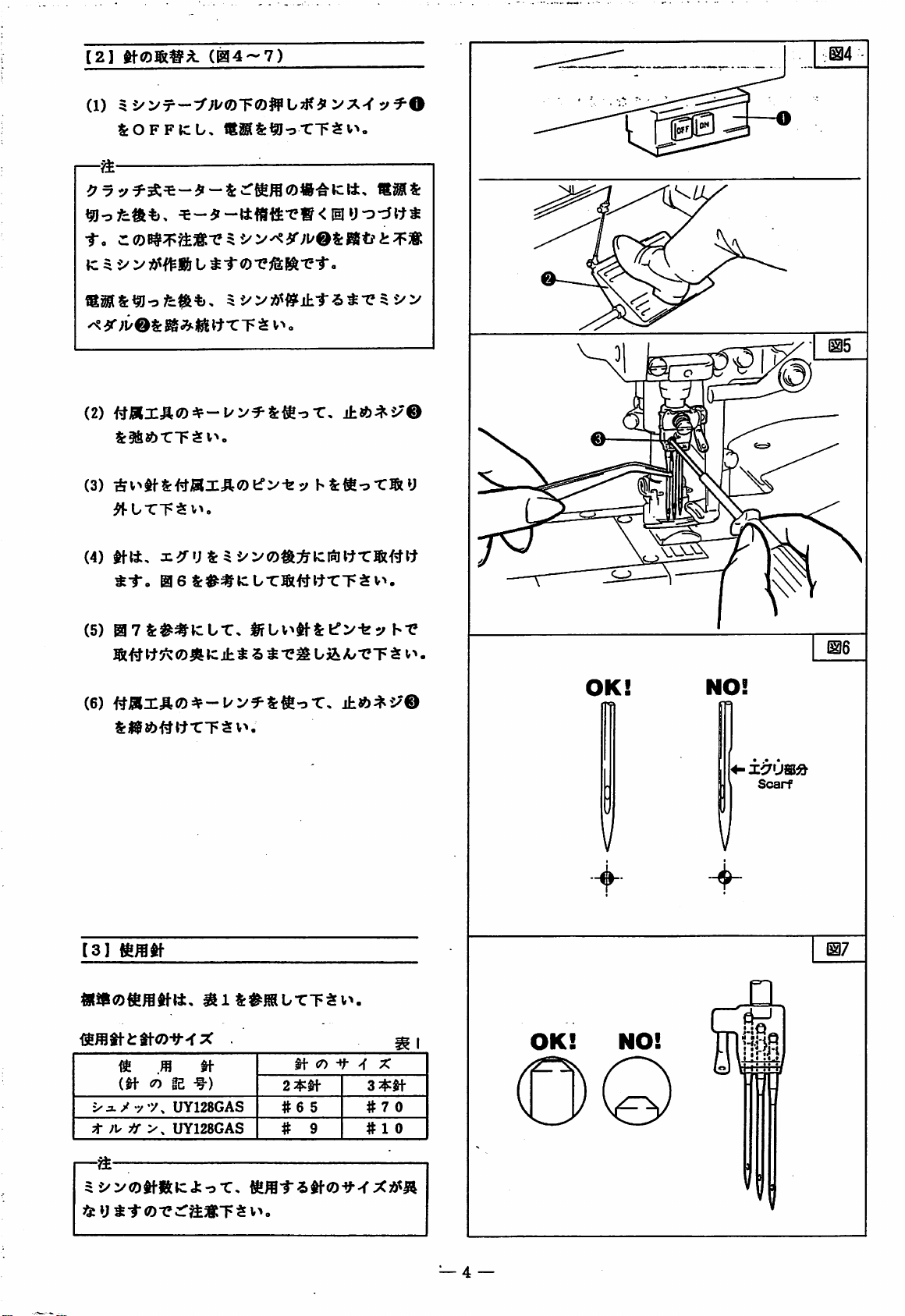

[2]

(1)

5

SrOFFKlU,

(04-7)

yf-O

—^

f.

Cl0^^^j®x5

K^i/>

^

————

U

^-tOX^IiftX-r.

ItTT ^ V^

(2)

&3fi8brT$v^,

(3)

^l^#tS:#jaX:ir®fcrv-fes;

^UTTSv^.

(4)

mt.

0

6Sr#^k:UT®t#itTT5^v>.

i:^3K

o

jhA^t^©

hS:«BoX5(y

(5)

07S:#^JCtT.

(6)

#jaX:ft©=*-UV^Ic^oT,

S:tjfsb{^t^rT^v^.

llfUv^lf^fcrvfey

[3]

(S6fflti-i:tta)-y--fX

^

m ^

m

(n

le

Uyi28GAS

t

fi'

UY128GAS

.

^)

ti-

2

2^^

#6

# 9

(7)

5

-f

3

#70

#10

hX

X

4^:^

OK!

m

NO!

^—;

5

5/vo^«k:J:oT,

55: y t^®Xcr^STS

v^o

— 4 —

Page 8

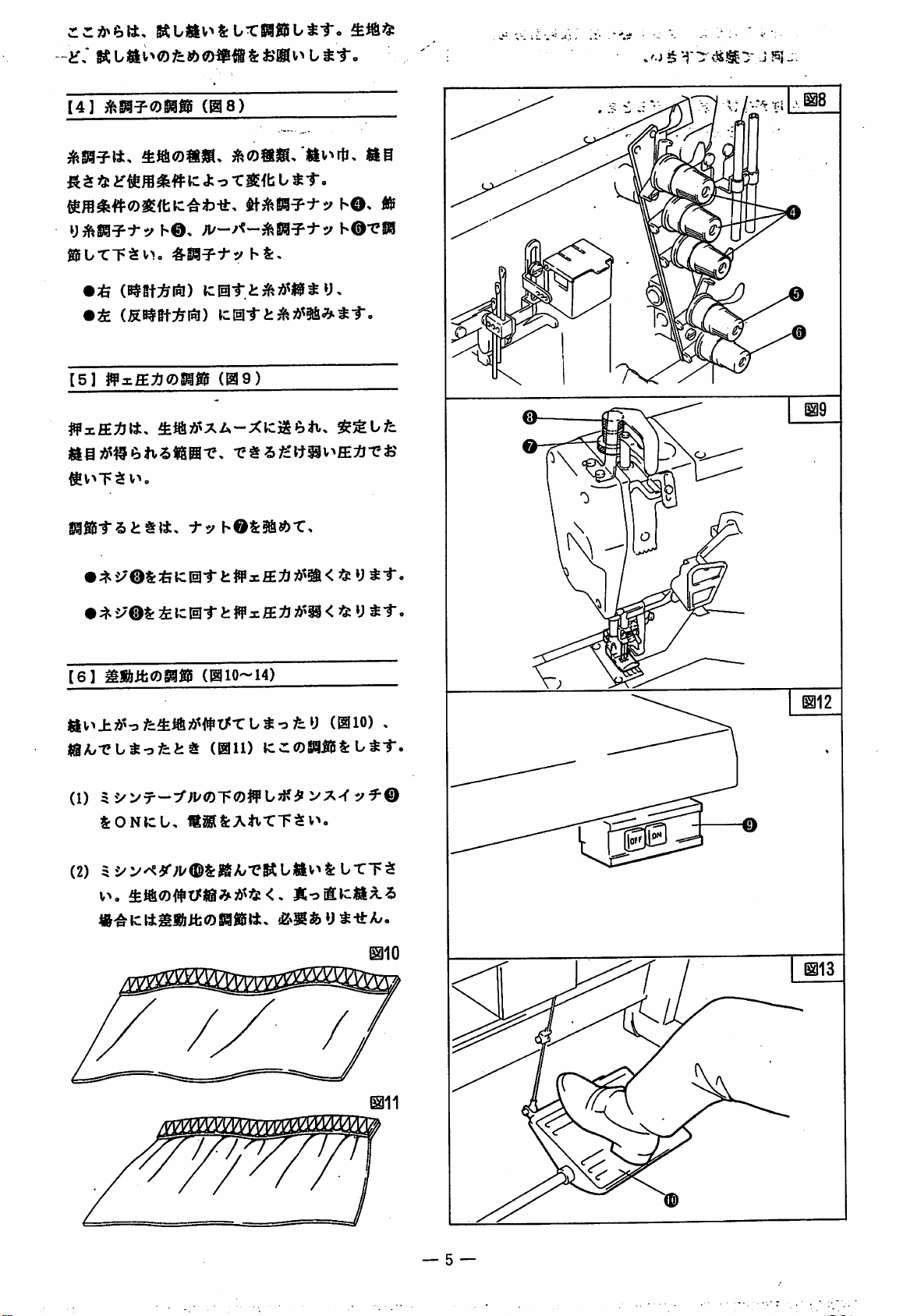

°4-^n5»BSin?'''ki5ia5^

[^

55^

2?:#

fl

gES©^BS^

::i#^ra;?

%i?5L:i.nJ!S

'¥1$:?9'4-!!S^

(8B)

T

^4-£6S-g^

(^¥45^2^)

W©0:3r^#

(6B)

•4-$

n

q>3^3.

*?H

'iQ!gg?©H'^4

urn

m

^©H

°4-¥«9gvC«^^4.1il-i

•

TiT

t

(i)

5

®/?

4-0

^

'n-iNo?

•

4.

$

n

35:

>

gg

vV

3ff

^

(H~oTgi)

'

fi

'1

(Ti0)

tf

}(2n

#0951©^r/:—:&</?

(OTEI)

•vi^iLaiiY^^a

2m

—

s

—

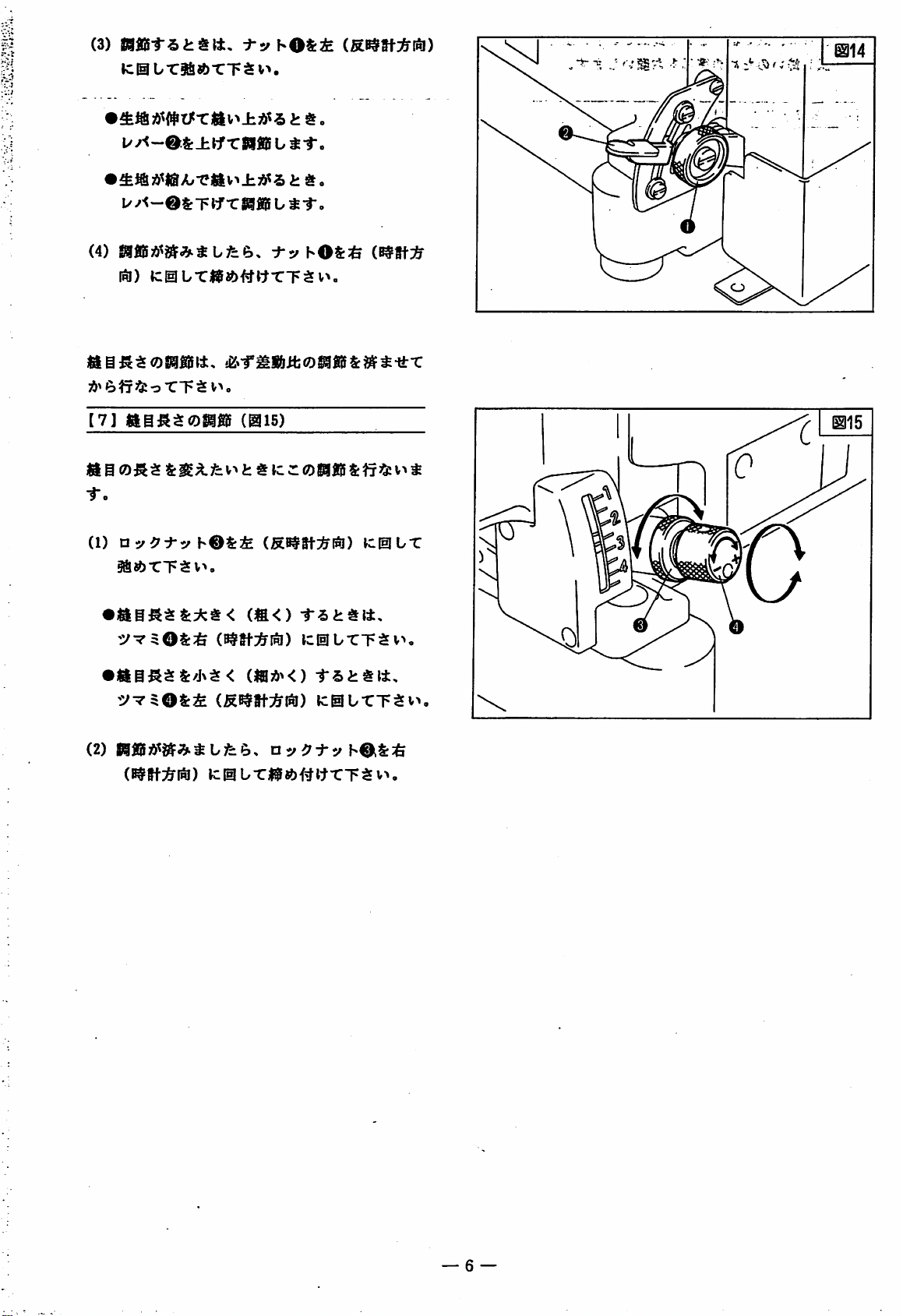

Page 9

(3)

k:0Ur5a«?)TT$v>.

t^o

t:S!«5 U i

U-®

(4)

iRl)

^raTTS

[7]

1AU^:^(0mm

i(4

0

-r.

(1)

Uy^Xy

gfi««)rT$v>.

S: T T

SgfiB U ^

f.

i-yhO^^

k:gILT)R^^^)f^^^'CT$v^,

V^o

(@15)

Sr^^fe

v>

i: # »c ^ 0®!«f

hOtitE

(S^tf:i^l^)

lcliIbTT$v>,

S:^5^

JCIULT

v>

^

5/T$OS:^

(2)

|g«5;!)^^^-^4bfce.,

C^fft^^lSl)

k:@bTiRf«)#ltrT$v>.

kiBb-CTtEV^

nyi;Xyh^^:^

— 6 —

Page 10

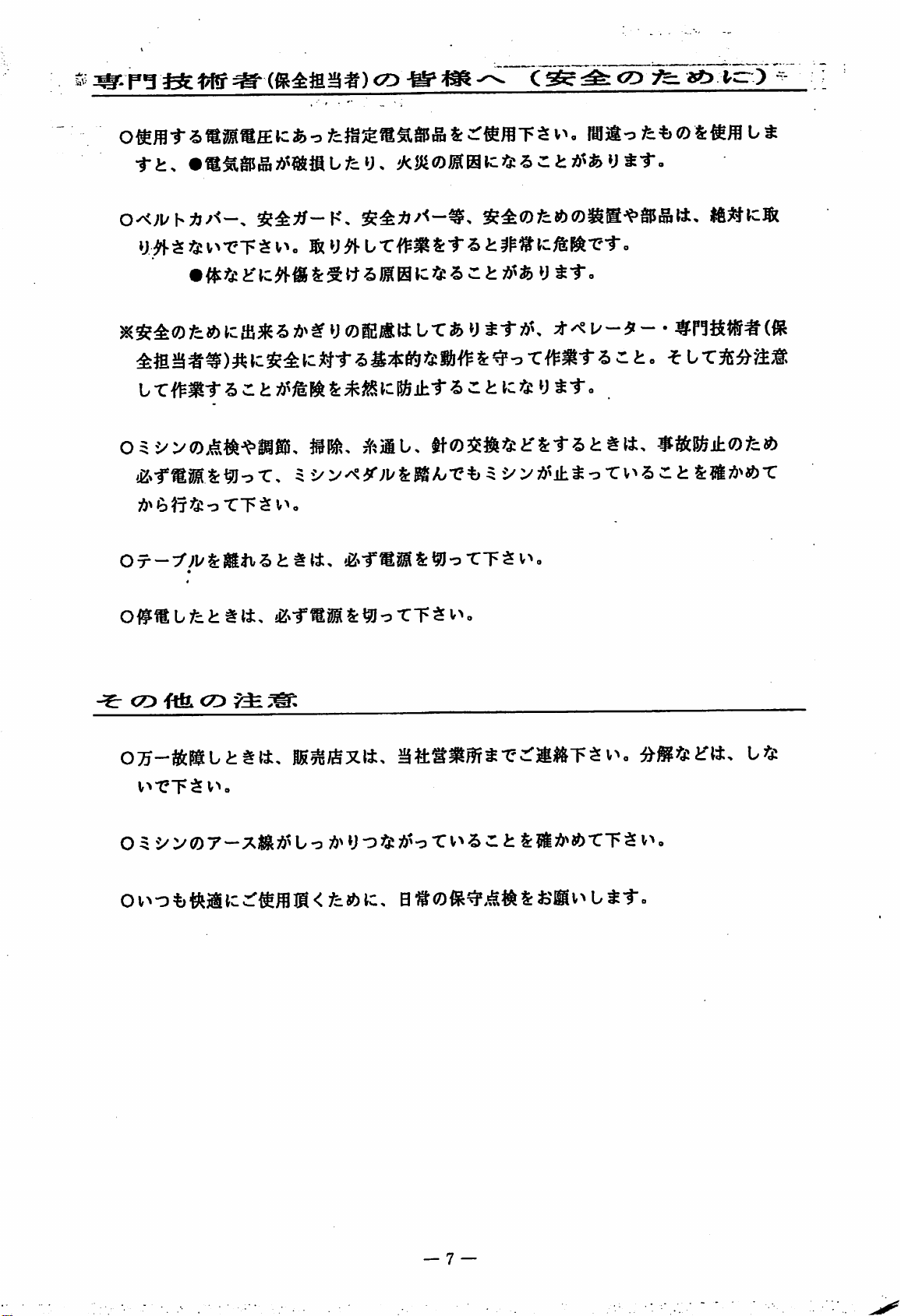

5;

oegM'taSMffiKifeofcJg^fiaSaSiwfiefflTSv^.

cssedkcq fe^

^

■rt,

iAcjKwMHK^isitji^feyif.

0'<;i/h:*j^^-,

• # Jfe

J:*

»c

^1-«

S: S tf S

(S S C

38^40fca)»cai3i55;i»sy0saittttTfey

i a A'^B^S:*«SC66jtt5

O5->V0,^.«^-¥'llfii,

»l^,

iK>-f®8SS:^!Io-C, 5 •>

3^*

6

07-—-fn/i:Mi\'^ttit,

0#(®L/fci:«t±.

o

X~F

■S

V'*«

!2<-f®®(S:MorT3Sv^.

!K>-r«MS:^oTTSin

§Sc:^OfcftoSB-S>Sisatt,

«: S c: t }»< y 11",

;i\

:t^i'—9—

d

ii

K^j: y tl".

#i'0?Siji«Ci:*S:t5.i:«lt,

5

•>

o

Tv^S d t

•

-tLTJSt&aS

*SlitBfejt0fc0

S:Ji!l>0-C

r

CD

ftfcCO

o:5-iSfeiSbt«tt,

V^T?Tc5V^.

O 5 •> V 0 T - X H

isasaxii,

Ti^

1/-o

3l> y t3 % A'O r V ^ 5 d

Ov>o%ttacc^«6fflIM<fc0U:.

stt®«f?fST?d:ai»Tsv..

i: & il

H#0R^,^lftS:effiv''bfr.

0

"C T tS V ■<.

u^c

— 7 —

Page 11

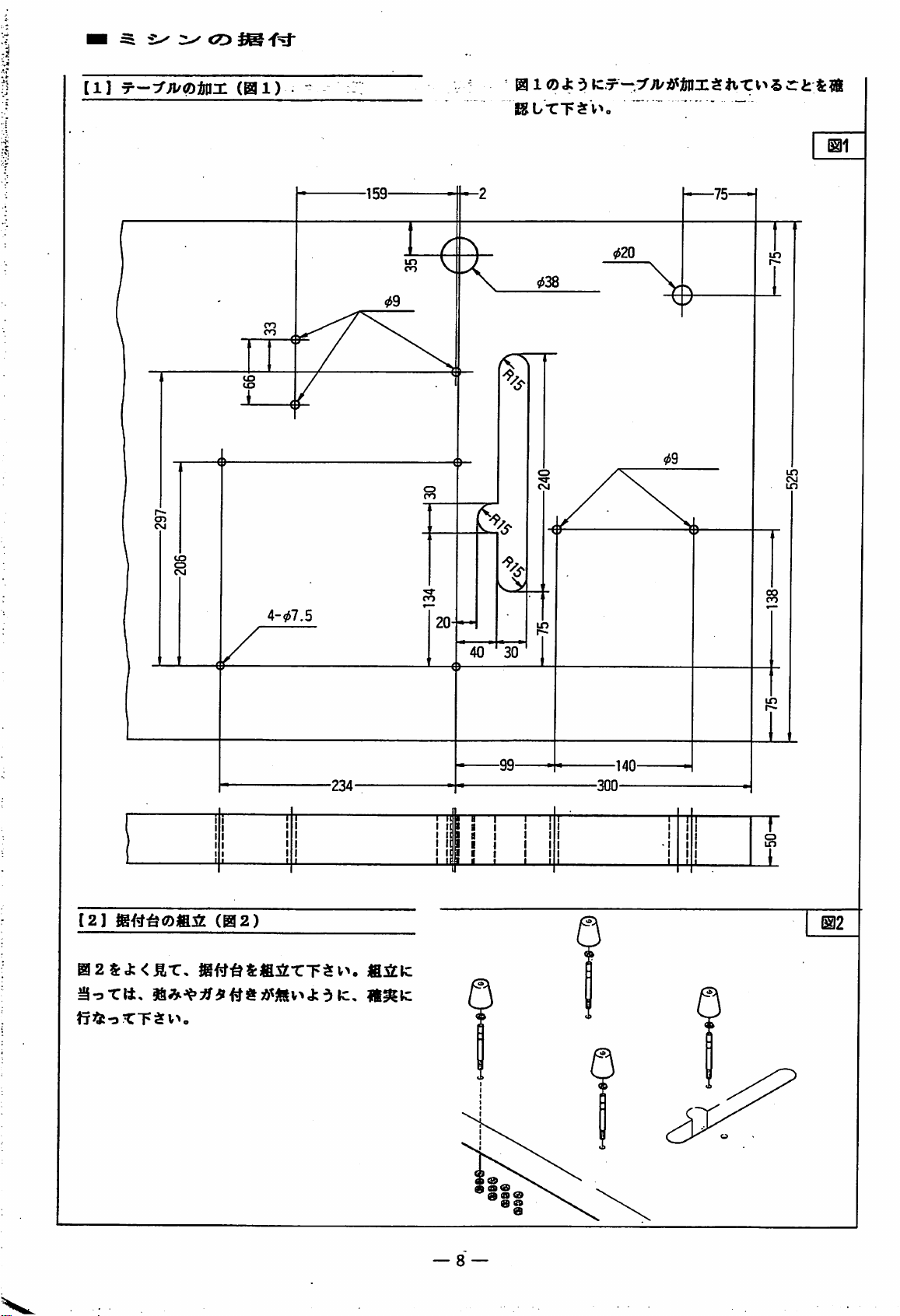

^

^

^

[1]

(01)

01 ® ^ d »c.^-:::^;i/;&^iinx$liTv>s

Vi-

L/X"F

v^o

ri:

&?S

@1

[2]

02&J:<£t,

(02)

4-9J7.5

fi

iCk:

40

30

m

— 8 —

Page 12

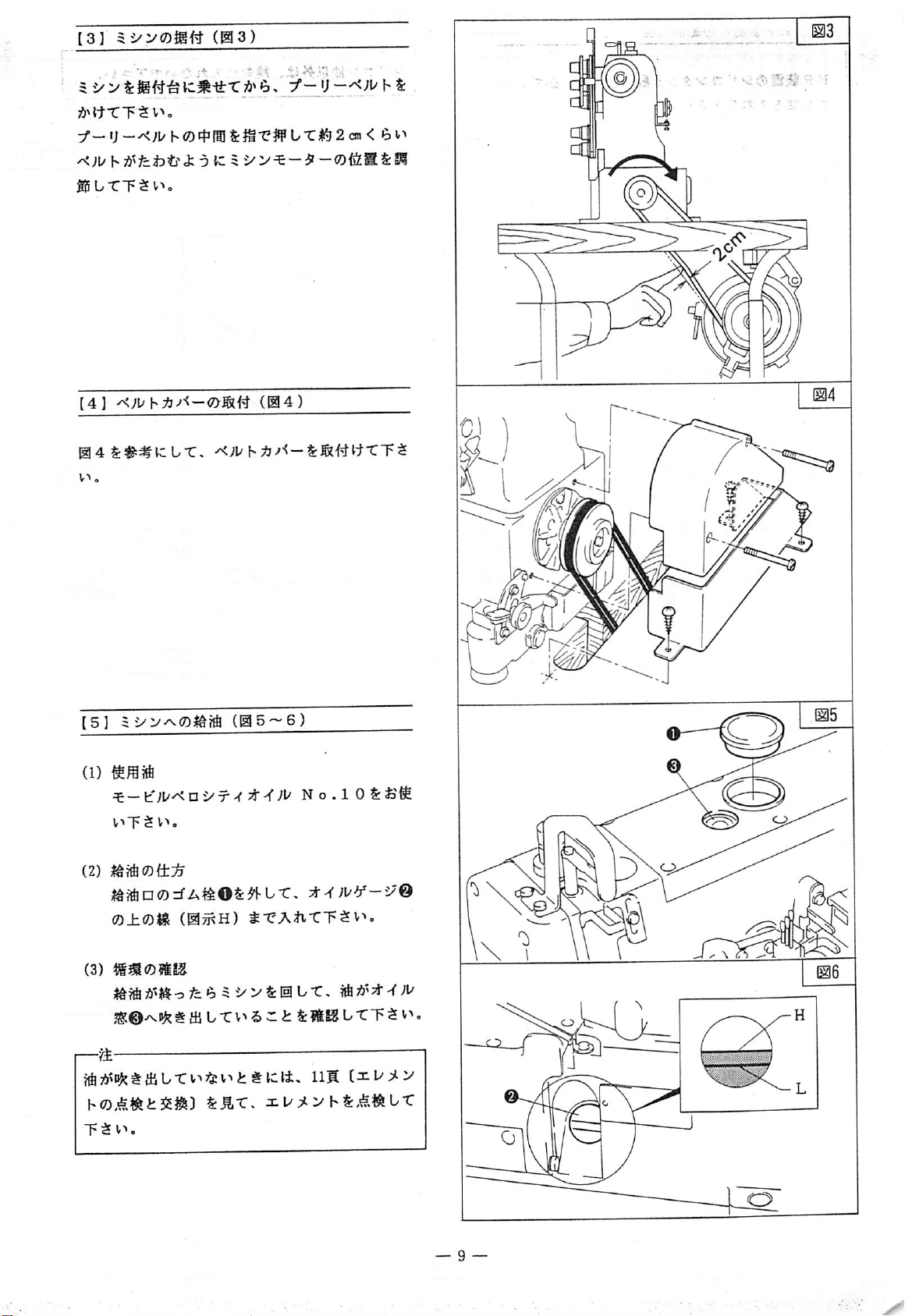

[3]

5

-> V S:

A^ttTT^v^.

y_ij_x;tyf,®cf>raS:J^-e#tTi^^2OT<

(03)

fj'

^

&

e>P

A^fct)tf

liSLTTi^l'''-

[4]

4t##lcUT,

J:

oizi

-©ffiSS:®

B

i

(04)

—

(5]

(1)

^

—t'yi'^n

V^*P

cE

V^

o

(2)

0±<Dm

(3)

JS?fiA»J^ofcei5i/VS:I51U-C,

JS^©^^ t m L T

—^

T$v-»,

(0^H)

(@5'-6)

i'-r

^-eA^-cTSv^,

v^-5 ^ i:

No.lOSriaS^

S:

?I3S

L-CT 5 .

i

Page 13

[61

HR^BOJ/U3

3

V?ftl:An-CT$V>.

(07-8)

[7]

^^>g)[51fe:)^|^g)jf|Sg

y-c*r,

$:18

0'

@Ur,

^U§^-CT$v>.

(^9)

it

(±)

:&|5I

tcafeu

07

08

09

—

10-

Page 14

[T]

(OTil)

ui

[e)

f)

^^—

iilTc^

z;^

9

^^(om

:r

^

^?¥sli-?

^-1

?

i-1

mm)

^

^

'fKD

?

(H)

(1)

^^£-Zr)0#4#

^

(H)^0?:$:Z0?©i:--^^''i'4^

"4-?

.A

A

$

7;

>

i-n

[t')

>

4^

[9)

w<-

^/'iT

(210)

5.c>q£0^

^

>14-f!^©.^

(STSl)

S3r

I

m

Page 15

wm

wrn^^

J5*

^ ^

[1]

(D^m

(0jRa)

Sk::^SJ:dVc,

(1)

fe

S^"r±lj'TT$v>o

(2)

^rtJ

icj© b fc

(0^b)

(ai4-i7)

^1

Tffi®il^T?Wasu-CT$v>-

CO

tf#©S:±XttTVcS&d^br,

CO

iS $ tSlffli b TT $ v^

&i^^tcSlfflSbTT$v>.

;u®

„

[2]

tf-K:j^'r^;!/w'<~ofeBasiflg

fc

ti-rti

t

ll

3.2n

4.

4.8n

5.6n

6.4n

SISr*

^

2

«

On

ti

a

9.1

n

00

8.6 n 1

l*^

tl

:£tMt^$(a)

lU

8.2 n 1

5.6n

7.4

n

(0^a)

$m.t

^cS5fiiibTT$v^.

l±:fe t ft b r 015 b TT $ v>.

<7)M^

6.4n

(018-23)

^2tci3^f^rfik:iSb

7.8

7.4

n

n

^

o

(o)

<o)

2

fS19

n

3.2n

4.0n

4.8n

5.6n

6.4n

2

m

tl

9l§»a)

4.7'^5.0n

4.3'^4.8n

3.9'^4.2n

3.5'^3.8n

3.1-3.40

tf

5.6n

6.4n

m

9I$S(a)

3.5—3.80

3.1-3.40

—

12—

Page 16

(2)

fe kr^

1

mm±0fe®tC^S

e.

/£? t -e3f5

* k ilSKUTT^

e.

v*.

"~"PI

iTt't

-.

^-e^l^fe

»

.".

.-

■-. = •-

-.•

:4i'C.>11?5

wS.

b'C'F t V'*

11,.

'.

-

.0-6

o, " -.

'

-'•» 3 v.*»

JU

jii. j yS;'

.^PmmrfeSce

<;

-; . 1 T ■

lik

!'•

v.

;-l A ••

/

t

V

1.0mm

(3)

fe

ttle,

laSrO.Q S —

GM

^r|i^f|jii>^-e3f5fett,

"1p $ V*

SIfiJif-St

v>.

^

«■

tli,

S:

^t5Xl±«

mmlCbTTtV^,

0~0.0

lcS& U T

SmmlCbT

®fiji t TT

t

1^20

1^21

r-a

;i/-y<~5feig

:fe$t t ;i/

[31

®iaic-!f-<XO^fe"3fe^tie®i§A.fe

11

ic d 0 ® fflS S:

;i/—

0fitas-etfettle,

(@^b)

^T'S3l5brTtv>,

(1)

@

®^ieM;!»^ieg?tt-rSJ:dieTS50^

Xie^t)-fr-c,

SI®S&^y®b-CTti>«

(2)

@igie«v>^tS:l&ffl-rstto

:fyh©S:5&0,

1^

€)

tf fe V ^

^-f

fe €)

5

ti-0a®

Vi?

KWiii^bxmm^.

-e." & iSiil-^

b ^ "T.

(@24~25)

o

I:

:&^Si

"CIS 3 -3 . 5 m m

;i/—MfitE®

(022-23#®)

f>®S:0^A:;&

^«

3.0 — 3.5mm

(3)

:^2^hOS:§a0,

m

(^IT)

ie«id>bTSifi5i-S.

tr>®%05^B:fe

—

13

—

Page 17

C4]

-•

-:

m

'

v\f

(om

—

■'

^

mzs-zs)

rs:x^

i:

-

;■ ; k;

-

fi

ii^

^ • '

.

®

ao®

m^A)

l/3TtC3f5'5J:'3k:,

^

l:rft

OS:

(2)

±XltT

v>.

•

:6^

i:

;i/

k:«l

?&» b r

i: 0 MSh®

0 ~ 0 . 0 5 m m klJfe S J: d k::^S/OSrSa®.

^OS:

~F $ V'^

0-0.0

#Btf

o

k:S&

;!>> U r

^St^^S:^Xtt:&k:@bTSi«lb-CT5v>.

^

WfilS U T T ^

BRIBI

-4-

®lfi5 U T

[5]

(ttr)

V^o

(1)

:^i^'OS:9a®.

0br.

»l«ibrT3§Jv>,

(2)

^5/'OS:««),

Jc|&;5»br,

(if)

(ir)

RRIBI

RRfB!

®afig

(Bi29)

©i:®RRiai

mma)

T8E®5l«-e8aiJib-CT;S

(le)

©i:feXttik:

(lajRa)

(SiT)

©S:#B?fXtta

(05ta)

S:5afi5bTT$v^.

li,

10

—

14—

Page 18

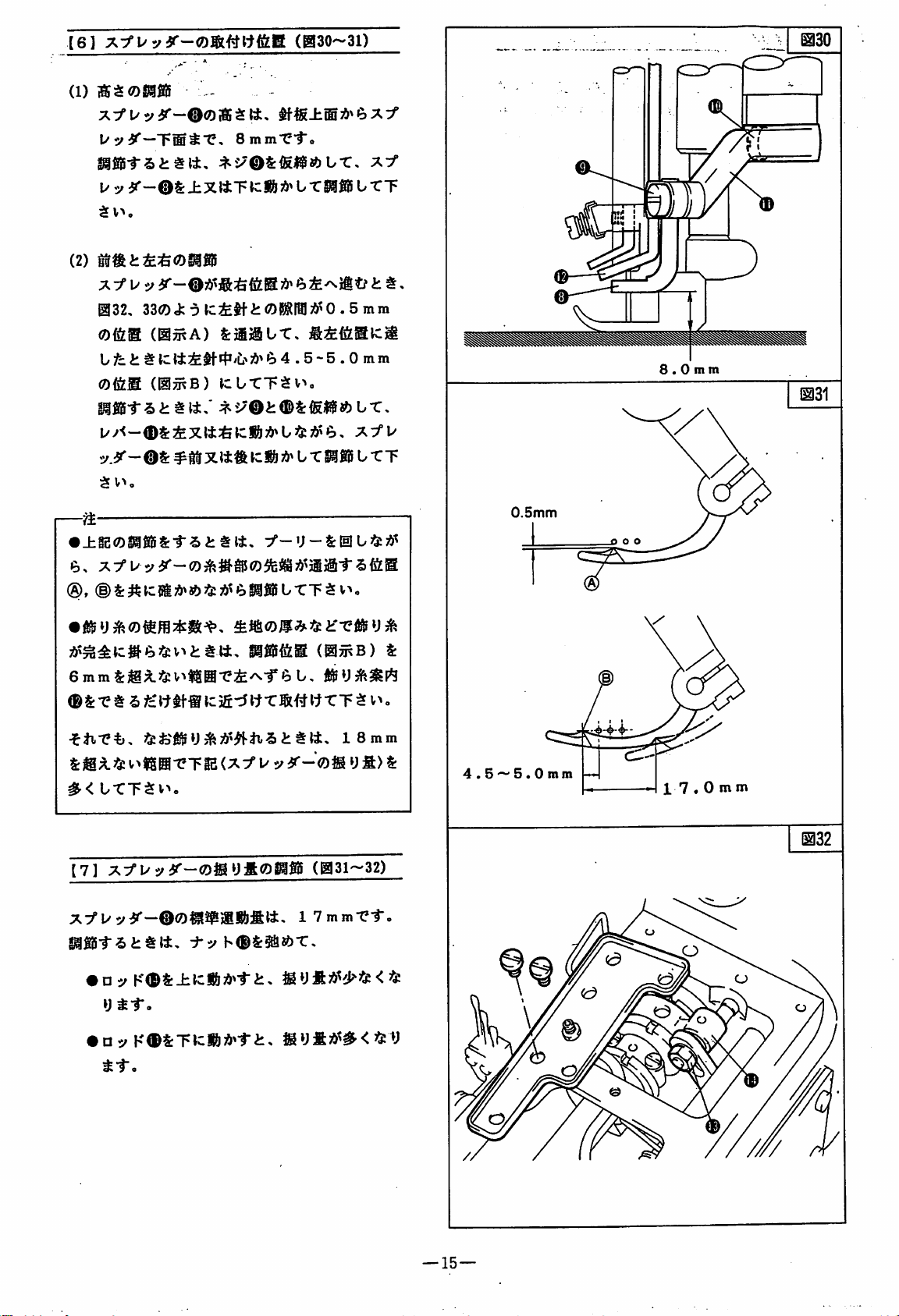

[6]

(1)

]®$<oeifi5

x:f

(B30-31)

-

tf|g±©A^6x:f

l/yi''—Tffi^'C,

1/y

i^-®S:±XtiTtcS&;i^

$

V'^

c

(2)

tB^i:fe:&(Z)SSfiiS

©32,

33(2)<fc-5

0&m

(@wA)

bfci;

©feM

(©5^B)

l/y<-<D$:iXli:fe»cSiA^U«7i>e>,

y.3^-®S:

$

vn

•

±g2(3!)SI0SS:-r"5i:^tt,

to.

®,

(DS:^lc5i;0^8?)'5:7!>^e)g®J®bTTSv^,

8mm"e-fo

trS3f®

tcitfilORSraA'O . 5

fe

iijaUT,

4 . 5-5 . 0

icUTTSv^,

»Ci& U T

^fiJS U TT

tTT

mm

mm

0.5mm

8.0mm

K

f<:

1131

6mmS:jg?L3&V^t$H-ei/^-re)b,

®

&t S fc

#<

bt:T$v>-

[7]

•

Dy

•

'lttf-®

i>IS0"eTi2

A:/l/y

-5t$l±,

lC)fi-:5ItT®#

y

<X:f U y

3^-g)^yftCDTO

:^y

h®&5atf>T,

K®S:±tcl&3&^-ri:.

y

tto

□y

K®S:TtC«/>^-rt,

tf»

i;

ii

iSyfid^#<55:V

WTT^

18mm

y fi>

(031-32)

17mm-C-r.

y

v>o

S:

4.5'-'5.0mm

-«-

17

.0

mm

1132

—

15—

Page 19

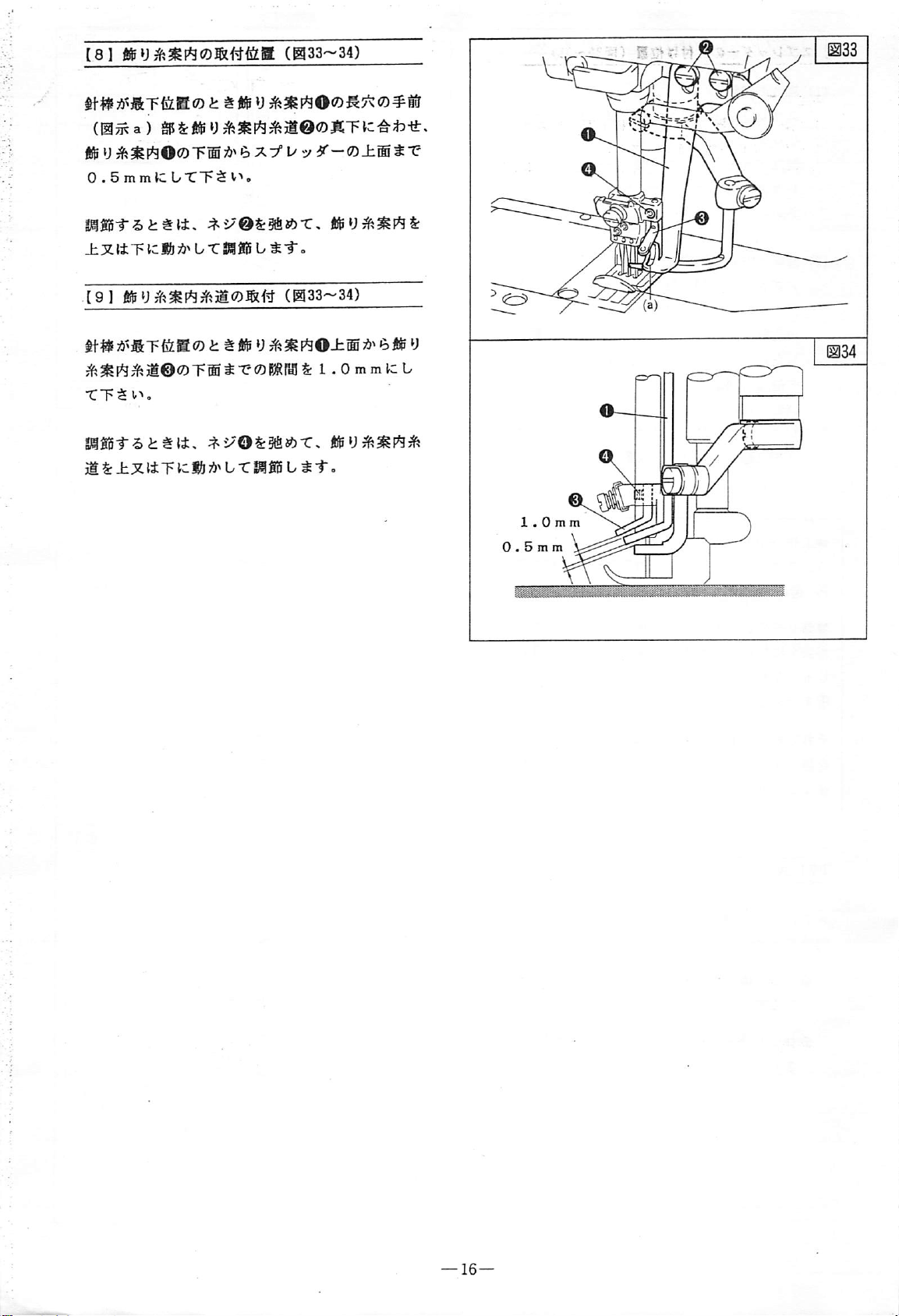

t8l

(0^a)

ftfe U ift^P^OcOT®?!'^

0.5mmlcL/TT$^^o

(033-34)

5/^''"®

Jt®

I ia33

S"e

mJ55-t-5i:ttt.

± X (± T left b T

191

i^i§^[^3^it©0T®tr-CD|®®$: 1 .OmmlCb

TT^v^.

S3®S^-5b^t4,

ig

S:

±X1±T

^2/'@S:5fi8?)T,

S3

«iS b ^-r.

(0

:^i/"OS:§fiJ?)T,

icfii b r

S3g5 b ^ t -

33-34)

4®

U

Page 20

44

W-

8

hr

a;

pa

»

qi

w-

44

*

f

c;

It

0

m

o:

-4

c

4

vZ

■

COcnCO

m

m

o:

41

It

m

IV

0

0>

c:

m

-7i

8

c:

19

IV

rr

IWf

#

(?*•

8

bi

««•

yp

«•

0

nv

It

1^

H

8

4

4

8

3

c

CO

nt-

SI

H

m

r

m

•J

a>

CO

IWr

IV

'

1?

m

ft

c

4

■4

4

8

fW

4

1

CO

^3*

o

"4

CO

H

CP

%

fT

%

4

r

■4

n?r

4

fv

IV

01

a

4

0

4

m

m

vZ

S«

»

41

4-

>4

It

u

-H

Sfi:

9r

up

fl

BD

IV

ff

n

QtB

O'

H-k

<z

m

J>

Ht-

M

o

M*

tsd

r-^

H

m

4-

8

n

95-

It

■

It

0

Sr

ft

?T

A

-4

qi

4-

»

c

M

It

vZ

o

4

03

51^

r\

la

Id

■w

0

m

0

3

O

00

CO

ISl

KSI

It

*

f

<4

rr

??

"4

»

c>

CI

IV

o

5+

r?

bif

O*

n

(VIr

0T

w-

d

pa

Ui

m

}

h-

03

•

K',

4-

»

c

w

A

w*

35

ss

rr

(W(

11^

8

"4

8

o:

>

<-

r\

AV

"4

u',

tt

I

»•

It

Si

<-

e

IW

vS

m

0

w-

d

H

Cl

TIr

4-

£#

<•

0

fW

•

4.

q*

w-

pa

(

(

c:

4

-4

nv

r

H

4

1^

o

Pl>

c:

^

-4

®

S-

SMi'

bj.

41

frt-

<•

bl-

Wr

-rl

oo

CO

CO

>

nf

£h

o

K'.

Swi^

<-

Sf:

B B

B

B

®

9tV

d<

n

(Vfr

1

N,

r

%

®

n

r

d

o

H

Jso

CO

cn

cn

03

rJ

pa

r»

m

e

4*

4

^4

¥

B

o

B

CO

B

cn

B

CO

I

--q

4*

T

e

n

C

gl

GO

H

a;

®

>•

(

e

w-

ri

94*

d«

T

e

(V

-tI

8

>fc

-4

551

8

r?

qi

4&

q:

r\

-tI

5ft

fW

cx

4

Jit

CO

#

o

S

H-*

cn

z:

o

ac

z:

cn

o

tpw

cn

Si

cn

O)

•

«

cn

cn

•

Page 21

[1]

(@40)

lrO.6

•

A-Oamml

icmWVcSilS)

r—

a^$lc<koTtt.

[2]

^S&lbl : 1.3

—

151.3

4.5mm

6^)

O0jt«?)^i^0S:04O<Z)feS

:

1.3

J:y±ic±j&»€)^jci>«ke>

11± 1 :

1.8

(S3fiiS^'

(@41-42)

ilS^#

1:1.3

•

i^i

ic^Pfibt-r.

(1)

ll±-e«effl-rs«-&K:l±.

TS2®gi^T'S!S5brT^fv>o

lii^$fSi®Si'v5O:^S^0(2®)

IfvOOiSS:.

(iS^aS)

UTT^V^o

(2) X Hy^'«-OOjh«)4^i^©S:3fl«)'C,

:&aftcJ:y^l61bS:

3.3mm

SrSfisi),

;&*€) 3 . 2 mmffiS<k O Kl^®i

042©

fea (g3«ib>'<-©®'^v^-7-i7A^0^

1 : 1.8©a^^c-^^ffig)

S:S6;^b-craffl!b-CT$v^-

—B.

d : 1.311T)

5«-&, fcr>o©«i.

(0^ a 0)

brT$v>.

€> 0 . 5 mmiiSS

ais$a®2^^5o

JCXhy^-?-

KMbr^mir

J:

"3

b®

^«!iJt:l.3i'l±

(a)

mwiAmm

KUtt^

(a)

—

18—

Page 22

@43

(11

$:7k¥K:U-CT$v^

®3fi5"r^i:#l±,

h

S:

•

•:f=y>TyV

t-eoWlf!SfeS: 7 SmmtCbrT^V^o

®

S:

•:fe

mm

e ) :^mKWiii'irt,

ijtto

•;&

(05^ © )

—^

t'lx35:

V"*

J:-5

(043)'.. . ■

ten!

brUgBUTT$

(0^a)

ic|&

75^ b r

bTT5

hOff)±m

-fy>Ty

U

Sifi5 b r T $

i:,

v^o

.

(@/Ttb)

v>

o

7

5mm

[2]

#f-jfe^0^giS

^

'>"®0

7 . 0 m m

f^»b>

(^44)

io

IC

bTT 5 V'*o

ji®®

:^i/'®S:5aJ?)T.

&

±X»iT

vC?

17?

SIfiJi-rSiittt,

0

tc|&

75^

b-ClSf® b TT $ v^

S: 0 44(C5tt*

ifiS

®.

tf^ftii®, ® , ® &±XttTJCftA^bTm

bTT^V^o

• ± t

• T U:

[3]

ii

t-2:

if

S)

Ti^-r

i:

if

04§tttc

t)iif T »i{® b TT ^ v^,

if.^^tt0^85

t y ^ t o

(045)

^

t*-

i

tX'O)

tf-i^iai®

„

ic b TT 5 .

®S:§fi«)T,

/

~~

[4] fi(^yjfi^y0^gfi

«&y^«fey®;5»®±fi:aoi:5^,

5^

(05^

c)

;!>»@460<J:e»»c,

B5^0T^C3!$S

y ® S:

±XttT

ic®

(046)

«^y5^^3t®0B

fi

Sy^lfey®®!^

J;

ic

bTTv>.

®&§a«?)-c,

;«)> b rSiSB b TT $ V>,

isyji55«si

—

19

—

Page 23

[5]

@48.

T3fei»yO?!i»fc<'yiiA^'Cv>fe

e. ^ #i 5 J:

gSSSf-Silttt,

IsIUTg3llSL-CT$V'»,

"5

tc U r T S V ^,

:^i^@S:§a«?)-C,

TifeiiyOCa)

[6]

(@47)

1^48

C

3

I

t

TT^

Ifzt^

1^49

-f^fxv

^T?oraPS

v:feif)

^fe<t-CT$v>o

[7]

asi-fik:j®i:-csj®ib^f.

.0,

0&§fl«)"C.

;&»UTS3®fUTT$v>,

•;i/—

S

•

;i/—

ifejiO,

(@5^b)

ifejiO.

v^

o

0C5B5^0fia&«Sc«id»U-CT^

V>o

\Z\tm<

0(D^ni-t

U-CT^v^o

{23{5:ti-5

-fvd-vhO)^^

0®i5^0ffias:##trxtt^tc«i

S:#. < as

©O0j^(3DfitSS^tuSc|&7&^UTT

^

S:

ii>35c < as U fc i:

(@50)

Ufev> ^ #

(@3^o)

t

K\t

S:

—20—

Page 24

■1

[IJ

(@51~52)

-<

a

£9 1 mm

S3 1 m m

@51

;u~y'?-^fej(gAV

@51®

J:

^

|&<fc#®i''r5Vi^<fc

TgB®^M-eMbTT$v>.

(1)

:^5/(D(42t:)

Hlb-Cv

m^'Lzmssbrr^\r>o

•/Nv

KJh>r-;i/S:

^r>r

K^N>r-;i/^

5t>r

5>i^;!^s<:tey^-ro

U)K;lmm^<35cy

S:®®,

(±)

(@w

(@^

V

®®-fey

+

)

-

)

tf-

—;^®S:

httSS:

-|g

1mm

[2]

(@53)

Vif®ISgjSti.

giSSl-'S!:

@bTg®llStTT$V'»o

ttt,

[3]

®3»'<

-^PP

@bT®ifi5b-CT.5v>.

$

(@5^C)

icx#-feV®®'^PP

5

>'^®iia

h®^01

(@3j^B)

&—

(@54)

^i^©S:5fiJ«)-C,

(05^A)

x#-fev®S:

(@5^D)

x#-fev®S:

@53

h®

Sr

if

&

TgSISb-CT^v^,

^1"o

'b

i®

:/3&':^ t <

—21—

Page 25

[4]

(055)

ittOO-^PP

x#-b>00'&®

(0^B)

S:-SS[$-frTT$tv

:^S^®(24c)

-fe V 0S:

[51

t|-0±Tjl8&tc^1'-5#|-^Siy

(05%)

in t TSIfiB

1/r T 5

v>.

(056)

S:6.5mmJCfCT;SEV>o

©5'

m^A)

S:9fi«>T,

-<

x:^

5

\Z

T,

SaiiiL/TT^t^.

—

5S/>0a51^^lCtt.

3feyrir-5#^tt,

ti-OiTjlS&lcfcv^UT,

^^)U-:ft)h}^^ < y

tto

^

—22—

Page 26

ziT

ru«& ■ ^

-M

[1]

MD23

d ; 2

^®

3

1

0

1

rt]i^fe40ffimi

®

8S3 fiiS

^

K-DV^X

-e03*A.

0.9-3T5mmO|gSr\

ait-

^to

'

U'-X

Pi

@57

O

o

e

[2]

[31

|&?a

(1358-59)

[4] 7 y

:7x>i5^©t.

X^^ALT<

ov»T<'-»<i>tv©^{it

x'j-ro,

l&?An^t->*©^(itL-C.

(057)

(B58)

L'C.^t:

.

©~©<7)iii(c

iiac7)irij

<

@58

[5]

^tx®^{ittr.

1SiJc7)A

[6]

d)

l/-X3fefi

(060)

.-e#'6mtMc3£-cf{t-t:^0'ftitr

(B59)

/ux^axLr

(T)

0ft#t^feS08SfflS

<

/::'$v-o

@60

<

—

23—

Page 27

I

im

(H61)

Ua:^

C-"'/vS

V./"»Jf

S52ii

@61

; $

j:

9

,

p-i

r1]

[I]|fxC#v.^TUSA'>f

L

oomm

o

—7—<D(C

<D:^y(

mmi^Os

3'A3^^^

j:-O

KOCy&o-C,

o<Dmm

0-7-©.

5g|^©tO<7)F0ltzJE5i{cAi>^gtc^

'

K<Z>IS®

r)

ztti^J;:iiz^h

t:>

aHO

JE5ilcg6tJ<7)^2;®-.ii»)

.-

-:

L.^-,

Gk

©

Plp1--i)t^(±.

[81

JA^uffluacpgag

3'A^»j^Sc7)^2^6^^iiQ£llLS{±.

\mmit^(Di^ U m

mmx^tto

mm-ti>t^ii.

(+)iig»3iiti>

mcnitt,

-^-

±g2(DS3iii^i:f"e.

^^i>'©.

®l:3lfei6,

(B62)

^-to

LS(7)8i9;

0.9~-2.2min(7)^H-C

.mx'yv^i:^ibx.

mihLmp<§^<^j:n.

^rO

i-To

^F^O,

Tie<7)2

mm^

(-)

—24—

Page 28

'

0

ai

Lfi«;:h4-i;5.;oeHT.

-

@6

l.^^-fe>®c7)it;f.i.'#

^K&$rB^lf-:^f^jc|iIL-C.

(

+

)«(c|5il-i,

i-it-

±seoaiB/^(tT-,

T^toT

<

ai)itiL«i'|t<i:9

Si:

Tie/rvi-gXTjisgBj

(2:45:)

Ill

v>igt)

ifj

LaA<#(,ii

/.',?:::

(_)

n

@65

[9]

^>i/ay0mWi

^IaILT<

tio]

b-;^ir-fK

i'-x;(r-f

m,

$gL*:ass#si;i^i;^

(@65)

X-y

(LG2

10)

i

k:^v>T

~

u.

■ftS!l2:ant5r')i't,5:i^—xS'jii, i jg

X

@66

fill

®9#itT<ir§i,.

Kg)»<i>H

(066)

—

25—

Page 29

F

-=r

T

2

4

•j"-

.-•'.-.i ' -

O

ft 2 4

5^ y «

Oi

U

ffl

5

^ib'it^iro

rii

y

H0<3D?ft5^®l-'

[2]

btt*.

(@67)

(^68)

S:

tTT^Vn

^

1^68

Pif5i"-5

tt

;6

i;

^t±»

:^t;©$:gfi8?)"C#^rtOS:iX

Jcl&7&^

b-CiailS b TT ^ v>,

[31

zfA,

b-x,

If

St,

S:XA-Xlci3|y

^filii-Sttli,

(B^St:;^!^)

[4]

±>^Xg)gfJ^gg

^isaa-c-eiSSfcifSK

tf,

fy

hOS:9fi«?>t:,

nifilbTSlfilibTT^v^-

(^70)

1^69

(@69)

rfA"^#^

^^i/'®«:^

c

bt-r.

tt

,

•

nfiJ^-^V'»iEflS:5fi<'t'S

y

h©S::feK:0brT$V'».

.BiS^-&v>JEfJ

S8lt5f*y

S:S < f

H@S:ilc!5lb-rT$vv

t

S111±,

—

26—

Page 30

[5]

T^:^^:fe:&fegg)Sgai

m

(05^a)

t-r.

It,

TffB^H^-CSIfflJU-CTSv^o

(B71)

.

(1)

i/-®,

®k=fA3fert®0:^i/'®S:3fl8?)-C,

>i

x^

:fex

It

;&

k:

«i b T

(2)

Ji>ixOjE:^jS3f®S:^yiib-CT;SV'»o

[6]

±XX^0g(f!ftfil;^g)^fig

±^x®A^ST&a0i:t,

JC,

±>lX#®0®<tttiS^S:Sil®bSt-,

y-'J-S:®b-C±^X®S:S:

SSfiii b TT

(072)

±^xoifeiS8i:T;i

^

T

^

I

0 . 5 m m

1^72

S:

±XltT

[7]

(1)

(2)

(3)

ICS& b T0fi5 b TT

±XX0.35il

:^i/-®$:^bT,

V>o

jgfbi^±XX®0jS®

■CTSv^o

(072)

☆v>J:;*X®S:^1-bTT$

(0aKb)

Uff

bott-C,

3f-y~S:0b"C±::*X®S:ftTfitSt-bT,

±>ix®5fejSi:T;*x®0Bfi^-^v^Sg$

0>.5mm)

It®

S &

S:5lKbTT5V^o

ssesafis

b-CT S v>

$

o

-

S:±^X^

±:^X-&0

(^

I8J

(1)

T,

^i>T>ix.®&^1-b-CT^v>.

(2)

±>ix^®S::feK:#4tT,

T5V>.

(072)

_hji

X^®&:felCl0F-ti-

3Kbv^T-5i;^®'&

(4)

±T>iX®ratC5feS:Aix,

T^-U-feabT

—

27—

(3)

:7'-U-S:0b"C

Page 31

mm

V

[21

#±tfl/>^'<~0^VV3^.(H73)

■-

-

:.

[11

Rpmm^^(D^iyyi:p^tbrmv

mm)

ic,

[31

n-y-0pj:m:^(Dmm

n

—5-©0ffxiBE:?ji±.

It.

mSS^iyOt::^

V"*,

(B73)

^^bi&?6&b-cT^v>,

V>^0(DiA:^&(2

(m73)

tElbTT^v^.

iclilbTT^

w<

ttc,

izlt.

l/>'"<-©Sr±if-CT$vn

RPilgSr^fflbTiaSI-^.ii^tctt.

[41

^momvMomss

5

5/V

toizLtto

ay

ay

S:«v>Ji«i)-5*2: H b*&33lU fc'l"

t-y

hOimtbr.

KOfeitf-Si:,

KOfeTlf-Si:,

i:

ttt,

S&U

:^y

xkVMlt0<^V^to

(H73)

heSrSfife-C,

U^i-0

U

y

tl".

m/z

0

©

0

—28—

Page 32

'i

-29—

- . • •*. • •• . .

• • ••

.

Page 33

C

1

d 1 di

L'

vJ

»•?'t}

>■••

This

instruction

"anufactured

PEGASUS

refer

This

*

Instruction

personnel

adjustment

is

rh»

the

following

*

You

mounting,

*

You

adjust,

such

to

their

instruction

manual

must

must

be

be

and

manual

as

machine

respective

manual

manual

part

to

provide

and

maintenance

unless

requirements.

capable

adjustment

familiar

maintain

describes

by

PEGASUS.

motors,

includes;

part

for

for

engineers

instruction

machine

operators

information

procedures.

■requiring

you

are

of

using

and

maintenance

with

the

the

machine

special

adequately

safely

procedure

the

sewing

For

those'not

tables or

manuals.

and

service/maintenance

on

the

installation,

expertise

the

tools

of

the

to

safely.

machines

manufactured

legs,

qualified

for

machine.

install,

and

th^ir

by

please

mountino

and

knowledge

and

can

meet

installation,

mount,

t^tL^Srocedurer^'''"

carefully

before

you

get

down

—

31

Page 34

TABLE

OF

CONTENTS

PAGE

I

To

[ 1 3

[ 2 3

[ 3 3

[43

[ 5 3

[ 6 3

[73

Threading

Replacing

Needles

Regulating

Adjusting

Adjusting

Adjusting

To

Personnel

im

Installa-tion

[ 1 3

[23

[33

[ 4 3

[53

[ 6 3

[73

Table

Setup

Installation

Mounting

Lubrication

To

Checking

Operators

Needles

Thread

Presser

Differential

Stitch

All

Fill

Engineers

Preparation

of

Machine

Belt

Oil

the

—

Tention

Foot

Length

Rest

of

Machine

Cover

for

HR

Turning

(Following

Bust

be

observed

"

Pressure

Feed

Ratio

of

board

Machine

-

And

Service

Device

Direction

of

Machine

37~38

-

-

-

34

34

36

36

37

37

38

39

40

40

41

41

41

42

42

for

safety.)-

~

/

Maintenance

■1

Lubx-ica-ticn

[ 1 3

[23

[ 3 3

[ 4 3

[ 5 3

Adjustment:

1

2

3

4

5

6

7

[

8

[

9

[

10

[

11

[

12

Oil

Level

Manual

Oil

To

Oiling

Change

Drain

Checking

Needle

Setting

Adjusting

Height

Position

Adjusting

Adjusting

Setting

Adjusting

Setting

Setting

Adjusting

Adjusting

Adjusting

Position

Position

Thread

—

Oil—

and

Replacing

Setting

Looper

Needle

Needle

Spreader

Feed

Feed

Foot

and

of

Looper

Avoiding

Guard

Guard

of

Spreader-

Stroke

of

Spreader

Guide

Tilt

—

Height

Lift

—

Oil

Filter

Maintenance

Motion"

(Rear)

(Front)

^

—~

Thread

Guide

43

43

43

43

43

44

44~45

45

46

46

47

47

48

48

~

49

49

49

■

Dif

f

[ 1 3 The

[ 2 3

Machines

To

Use

er-entiai

the

Differential

of

Sandard

Feed

Ratio

Specifcation

Feed

Ratio

Range

Use

the

—

32—

Adjustments

Differential

1:1.3

Feed

1:1.8

Ratio-

50

50

Page 35

TABLE

■

NeedXe

Ad3ust:inent:s

1 1 Adjusting

2 ] Adjusting

3 1 Adjusting

4 ] Adjusting

5 ] Adjusting

6 ] Setting

7 ] Setting

■

TXinXne

1 ]

Adjusting

2 ] Adjusting

3 ] Adjusting

4 ] Adjusting

5 ] Adjusting

Looper

Thread

OF

CONTENTS

T'thr'eaci

Needle

Needle

Needle

Spreader

Looper

the

the

Needle

Thread

Thread

Thread

Thread

Thread

Guide O and

Adjustment:

Timing

Timing

Guard

Spreader

Needle

Thread

Takeup^

Guide

Guard

Thread

Takeup

Takeup^

Guard

between

between

(Rear)

Timing

Takeup

Talceup

—

®

Needle

Needle

Timing—

—

Timing

and

and

Looper

and

Looper's

Thr*ead

—

Back

and

GuXde

Forth

Movement

^

PAGE

51

51

51

51

52

52

52

53

53

53

54

54

■

Met:ar*d.ns

1 ] M D 2 3 1 (Metering

2 ] Setting

3 ] Lubrication

4 ] Lubrication

5 1 Lubrication

6 ] Setting

7 ] Setting

Lace

Position

Position

8 1 Adjusting

9 1 Adjusting

10 1 Lace

11 1 Setting

■

Undeir

1 ]

2 1 Adjusting

Guide

Manual

Lace

Oiling

3 1 Adjusting

4 ] Adjusting

5 ] Position

6 ] Adjusting

7 ] Replacing

8 ] Replacing

Device

Guide^

to

clutch

to

Bearings

of

of

Elastic

Tention

(L G 2 1 0)

Feeding.

Guide—

Fabric

—

Fabric

Tilt

Presser

of

the

Upper

Lower

Guide

of

Presser

of

Lower

Knife

Height

Knife

Knife

Device)

Lace

Elastic

Upper

of

Adjustment:

—

Guide

(Lower)

Guides-

Rate^

—

Trimmer

Foot^

Knife^

Holder

Upper

Knife

—

Adjustment

Holdei

——~~~~

C

A/H

H) 2 3

1)

55

~~

~

~~~

~~~~

~~~

~~

;

~

~~

C

I'' T 2

~~~

"""""

~~

4 O )

—

~

—

~

~~

55

56

56~57

58

58

59

"

59

■■

R.

P

( 1 ]

[21

[ 3 1

[ 4 1

Device

Manual

Manual

Adjusting

Adjusting

Oiling

Lever^

Pressure

Feeding

Adjustment

—

of

Roller^

Amount

of

Fabric

——

—

33—

~

~~

~

Page 36

To

Oper-ators

./

r

K t

K..-'

•:

i

:

V-'

,

I • . .

r ; '

Following

*

Be

sure

cover,

the

Do

prevent

*

It

safety

machine.

not

replace

is

dangerous

machine

of

the

machine

*

To

prevent

off

and

pedal

or

*

Turn

*

Be

This

understand

Operate

before

replacing

the

sure

part

properly

must

to

be

fit

observed

such

guard,

these

accidents,

to

table

when

may

an

accident,

the

machine

maintenance,

the

power

to

of

instruction

off

turn

this

as

the

manual

for

device

safety

device

leave

you

cause

tool

operate

them

make

does

needle,

before

power

instructed.

not

provides

for

operating

safety,

or

parts

cover,

or

parts

or

the

to

sure

run

adjusting,

leaving

off

when

for

etc,

for

any

objects

machine.

fall

that

when

cleaning,

the

the

the

brief

this

safety

before

safety

on

The

off

the

the

power

pressing

table,

power

machine.

fails.

and

as

belt

operating

to

the

vibration

table,

is

turned

the

machine

threading

easy-to-

This

and

ing

part

easy-to-understand

Operate

[1]

(1)

Turn

the

supply.

—

Note

In

case a crutch

ill

turning

pedal 0 is

is

dangerous

move

the

stop

of

this

properly

Threading

keep

unexpectedly.

pedal 0 until

after

(Fig.l~3)

OFF

the

machine

on

rotation

off

power

stepped

turning

because

manual

as

instructed.

push

table

button

and

type

motor

by

supply.

on

inadvertently,

the

Keep

the

machine

off

provides

instruction

switch O under

turn

is

inertia

If

machine

on

stepping

power

supply.

the

off

the

used.

after

the

machine

will

comes

brief

operat

power

It

it

on

to

a

—

34—

Page 37

Threading

(2)

Refer to

correctly.

For

woolly

r~—

use

with

threads

Fig.

3,

and

pass

threads

For

use

spun

with

cotton

threads,

etc.

and

r—Note:

Generally,

Dotted

Dotted

pass

lines

line

•When

©•••When

threads

used.

threads

the

catch

the

because

needle

the

as

looper

does

needle

threads

of

too

small

thread

loops.

stretch

are

^

^

*

shown

not

by

continuous

Dotted

When

bracket

its

Inco^rlct

thread

Thread

lines.

lines

(D,

©-When

is

fine

gauge

threading,

©will

original

eject.

position,

threading

breakage,

your

machine

the

stitch

the

needle

length

the

To

push

and

narrow.

press

may

uneven

cause

stitch

correctly.

Dotted

line

button©.

replace

the

it

J.n^

bracket©-

skip

formation-

•When

is

coarse

gauge

The

stitches,

the

stitch

length

and

the

is

wide.

needle

—

35

—

Page 38

[2]

Replacing

(1)

Turn

—

Note

In

case a cruteh

tuLinn''

pedal a if

?» 5 ®

fr

hl

stoD

after^""*^f^

P

after

(2)

Loosen

(accompanied

(3)

Remove

pincette

thf

fMr"ff^^®

fSl

fhffk!

(5)

Refer

into

the

go

by

(6)

Tighten

Needles

OFF

the

"potation

Stepped

because

turning

screw © by

the

old

(accompanied

to

Pig. 7 and

needle

using a pincette.

screw @ by

(Fig.4^7)

push

button

type

motor

by

inertia

on

inadvertently,

the

'^®®P

machine

off

power

using

tool).

needle

tool).

facing

Its

Insert a new

hole

as

using

by

switch O under

'

la

used.

after

'=''®

"lachlne

machine

®"

alien

using

far

alien

will

stepping

comes

supply.

to

key

a

scarf

toward

to

Pig.

needle

a2

It

till

key.

"

It

it

on

a

k

6

r

3]

Needles

The

standard

needle

system

needle

bchmetz

^Jrgan

needle

and

size

system

UY128GAS

UY128GAS

Is

as

shown

#6

# 9

NEEDI

5

In

.E

Table

SIZE

o-needle

laoie

#70

# I 0

1.

1

—36—

OK!

NO!

a

Page 39

by

triaX

on

the,

sewina

J.>^Get

machine

readv

fs

to

be

fabrtc>:.

ad

jus

etc

C;4l

Regulating

Changes

stitch

thread

According

needle

tension,

Use

*

To

*

To

[5]

Presser

possible,

fabric

To

of

length,

tension.

to

thread

nut0,

each

tension

increase

Turn

decrease

Turn

Adjusting

foot

while

and

adjust,

Thread

fabricsV-threads",Jseam

etc;C.

sewing

tension

looper

tension:

the

nut

tension:

the

nut

Presser

pressure

obtain

loosen

r(^tion

require

•'.

conditions,

nutO»

thread

nut

as

follows:

clockwise.

counter-clockwise.

Foot

Pressure

still

should

sufficient

proper

stitch

nut O and

(Fig.8)

width,

re-adjustment

•

adjust

spreader

tension

(Fig.9)

be

as

light

to

feed

formation.

by

thread

nutO.

as

of

e3a

■■f

r>

»•

a.''•f'

«*'«)»rfW

Rg.9

i

*

To

increase

*

To

decrease

[

6]

Adjusting

(Fig.l0'~14)

This

adjustment

fabric

(Fig.

(1)

Turn

the

supply.

(2)

Do

machine

differential

if

without

Turn

Turn

is

11).

ON

machine

trial

the

presser

the

screw 0 clockwise.

presser

the

screw @ counter-clockwise.

Differential

stretched

is

the

push

table

sewing

pedal

straight

stretching

to

0.

feed

foot

foot

Feed

be

made

(Fig.

10)

button

and

turn

by

stepping

The

adjusting

ratio

seaming

or

gathering.

pressure:

pressure:

Ratio

when

or-

switch O under

is

is

the

gathered

on

the

on

the

not

necessary

possible

Rg.12

sewn

power

Rg.10

Rg.11

—37—

Page 40

(3)

To

adjust,

and

loosen

turn

nut O counter-clockwise

it.

,pnlws8

j

^When

, * • ad

*

When

adjust

(4)

After

and

The

stitch

after

[7]

Adjusting

To

change

is

to

(1)

Turn

loosen

_the

fabric

just

to

move

the

fabric

to

move

adjustment,

tighten

length

adjusting

Stitch

the

be

stitch

made.

rock

nut e counter-clockwise

it.

..is

sewn

to

lever O upward.

is

sewn

lever

turn

it.

adjusthient

differential

Length

length,

to

©downward.

nut O clockwise

(Fig.

stretch,

gathered,

must

be

feed

ratio.

15)

this

adjustment

done

and

*

For

longer

clockwise.

*

For

shorter

counter-clockwise.

(2)

After

clockwise

stitch

stitch

adjustment,

and

tighten

length,

turn

length,

turn

rock

it.

turn

nut

knobO

knob

©

O

—

38—

Page 41

To

/Maintenance

AIX

•the

Engineers

Personnei

end

Service

Following

*

Use

specified

power

cause

*

Do

not

safety

Though

operators,

operate

operating

danger

*

To

prevent

the

power

threading

*

Turn

*

Be

the

sure

must

supply

excessive

be

voltage.

replace

guard,

for

the

engineers

the

machine

with

beforehand.

an

turned

or

replacing

power

to

turn

observed

electrical

The

heat

such

safety

sake

or

device

cover,

of

safety

and

abiding

utmost

care

accident,

off

before

the

off

before

the

power

for

safety.

parts

burnout.

use

or

parts

etc.

the

or

components

of

wrong

for

to

prevent

utmost

parts

safety

care

service/maintenance

the

basic

be

will

sure

prevent

that

maintenance,

needle.

leaving

off

when

the

the

power

rules

the

motor

adjusting,

table.

fails.

suitable

or

components

as

belt

accidents.

is

taken,

personnel

on

safety.

operators

is

not

cleaning

for

the

may

cover,

the

should

Thus,

from

the

running

with

0"ttier

*

Should

Do

not

*

Check

the

*

Perform

the

cautions

the

attempt

that

machine.

daily

best

machine

to

the

machine's

routine

possible

fail

disassemble.

to

operate,

grounding

maintenance

condition.

contact

core

procedure

us

is

connected

to

or

our

keep

distributor.

firmly

the

with

machine

in

—

39—

Page 42

Inst

alXat:

JLon

of

Machine

[ 1 ]

Table

Preparation

(Fxg>l)

Check

1.

to

prepare

the

table

as

shown

in

Fig.

Fig.1

[2]

Setup

Assemble

Fig.

2.

assembled

of

Machine

the

rest

Make

sure

securely

4-tii7.5

Rest

board

that

without

board

(Fig.2)

as

illustrated

everything

any

backlash.

is

in

fi ^

I a

I t

Rg.2

—

40—

Page 43

[3]

Installation

Set

the

to

fit

Adjust

that

press

of

[4]

pulley

the

it

the

the

machine

Mounting

machine

tension

can

be

middle

of

on

belt

2cin

of

motor

Belt

Cover

Machine

rest

boardf

on

machine.

of

the

bent

inward

it.

Adjust

to

do

(Fig.4)

(Fig.3)

and

pulley

when

this.

belt

the

be

sure

so

you

position

i

Refer

[5]

(1)

<2)

to

Lubrication

Lubricating

Use

To

fill

Take

into

reaches

(3)

Oil

Be

sure

inside

—

Note

If

oil

[Checking

check

the

Fig.

4,

mount

(Fig.5~6)

Mobil

oil

Velocite

oil

out a stopcock

oil

reservoir

the

upper

circulation

to

window

does

not

and

oil

check

check

e.

'

splash

Replacing

filter.

the

oil

Oand

until

line

that

inside

belt

No.

(H)

oil

Oil

cover,

10.

pour

the

fresh

oil

of

oil

is

splashing

window,

Filter]

oil

level

gauge

m

—

see

and

Page 44

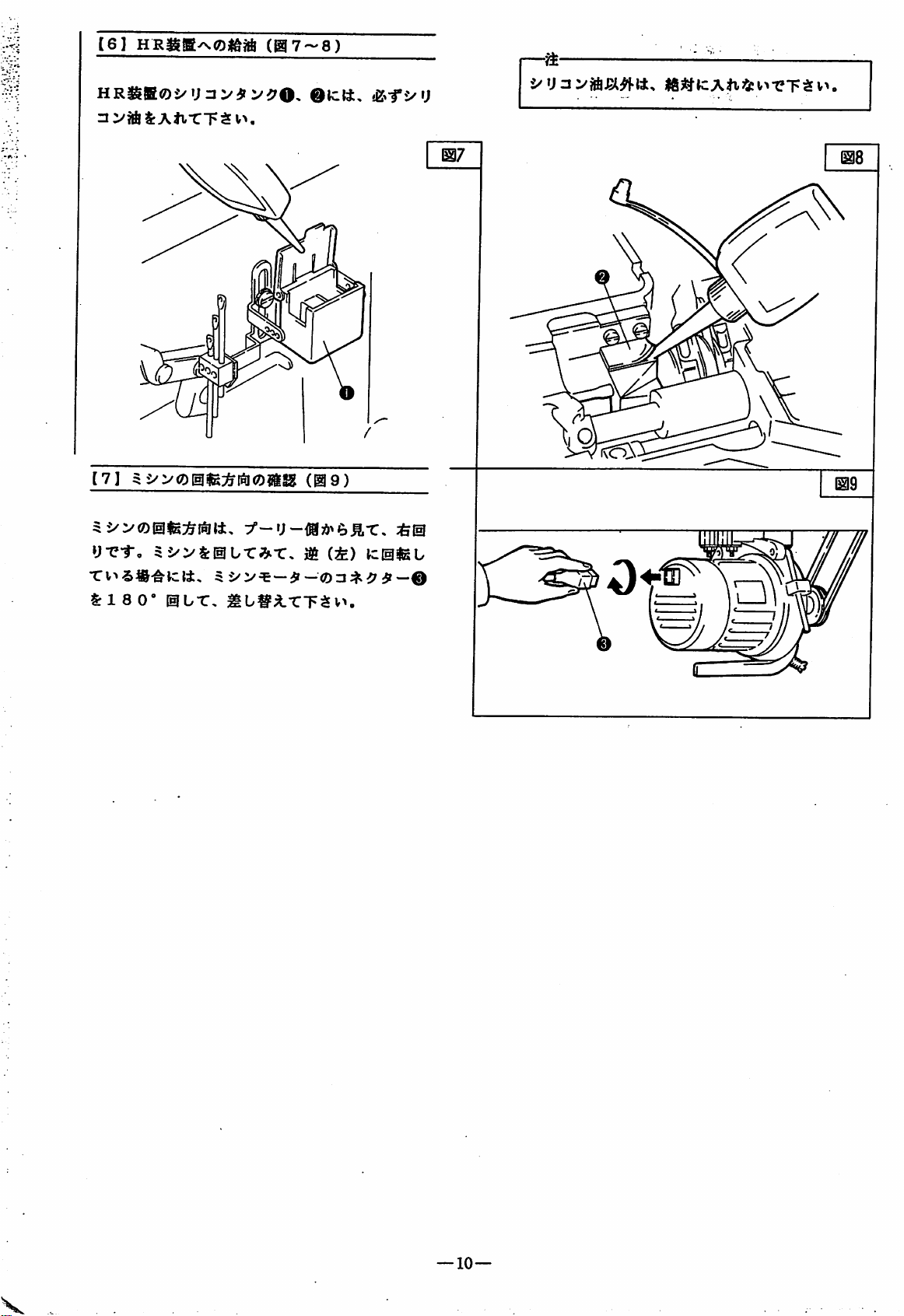

[61

To

Fill

silicon

Fill

the

oil

Oil

for

silicon

always.

HR

Device

reservoirs

Oand 0 with

(Fig.7—8)

Note

Never

oil.

use

any

other

oil

except

for

silicon

[7]

Checking

Machine

The

turning

clockwise^

side.

clockwise

motor

If

),

180°

the

Turning

(Fig.9)

direction

seeing

it

turns

turn

and

reinsert.

Direction

of

the

reverse

the

machine

machine

(counter

connector 0 of

of

pulley

from

is

its

right

machine

Rg.7

Fig.8

Rg.9

—

42

—

Page 45

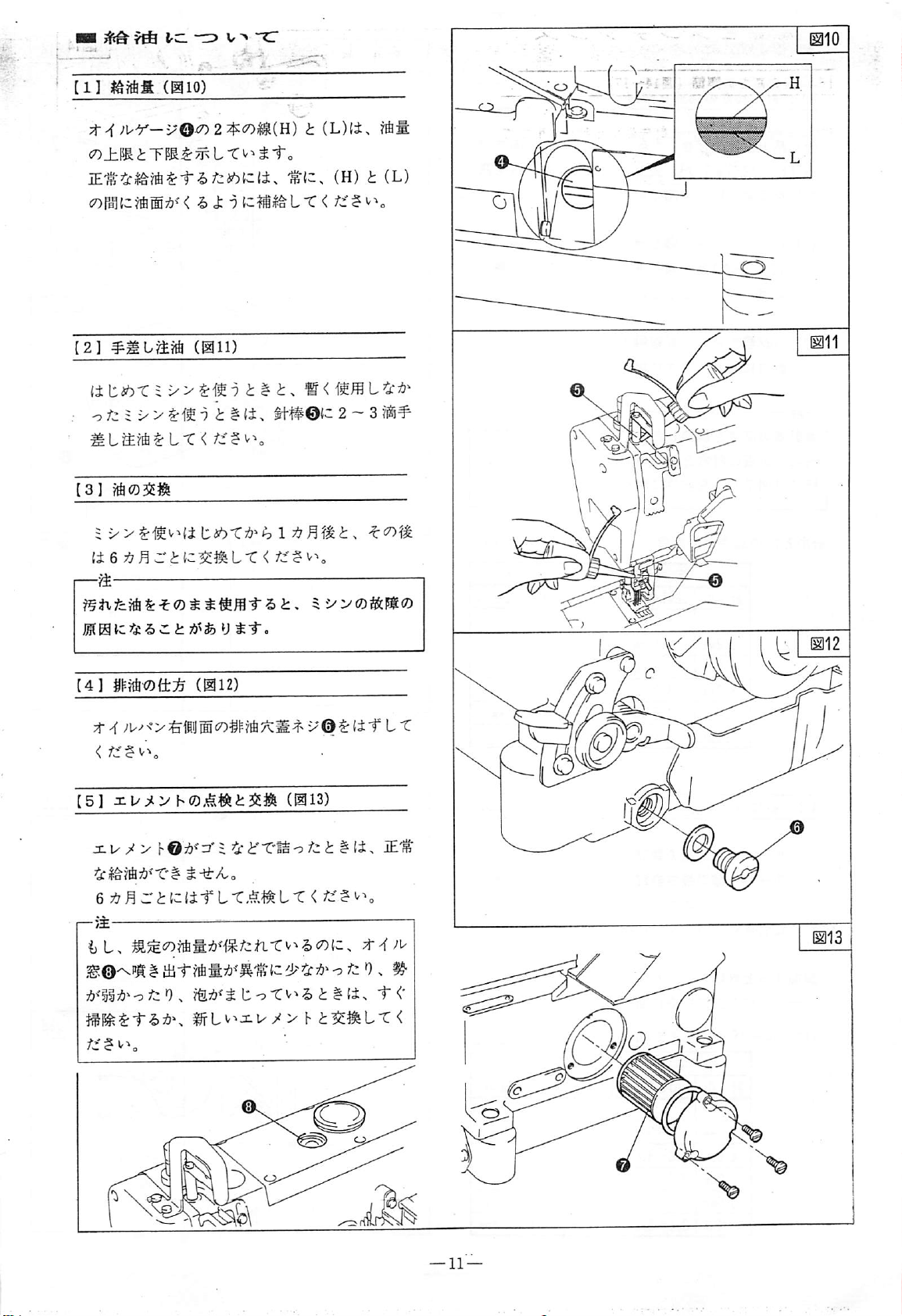

[1]

Lubrication

Oil

Level

(Fig.

10)

Always

that

H

[2]

Before

time,

than a couple

lubricate

[3]

Change

operation.

6

—

Be

cause

shorten

keep

the

and L of

oil

Manual

starting

or

if

Oil

Change

oil

months.

Note

sure

to

excess

the

oil

Oiling

needle

after

enough

level

gaugeO*

(Fig,

machine

the

machine

of

weeks,

bar

the

After

change

wear

life

oil

in

is

the

between

11)

for

the

is

idle

manually

0.

first 1 month

that,

time

oil

on

change

because

moving

of

the

machine

two

lines

first

for

oil

dirty

parts

machine.

so

more

in

every

;

oil

and

can

[4]

To

Drain

Take

out

oil

from

[5]

Checking

If

oil

lubrication

Check

time

If

restricted

filter © is

and

of

oil

bubbles,

if

necessary,

filter.

Oil

(Fig.12)

screw 0 of

here.

and

Replacing

cannot

clean

the

jet

check

it

regular

in

Window O is

or

weak,

and

replace

drain

clogged,

be

every 6 months

oil

kept.

change.

plug

Oil

Filter

normal

and

abnormally

or

oil

it

contains

oil

filter

with

new

clean

drain

(Fig.

at

the

€

oil

13)

1

Page 46

Adjus'tmen't

[1]

Needle

The

standard

The

needle

between

plate

highest

(1)

the

surface

position.

When

positionr

should

(2)

To

adjustr

needle

needle

needle

Note

After

the

passes

hole

(b)

this

screw

through

in

is

even

Height

setting

height

left

when

the

needle

the

meet

the

loosen

bar e up

bar

height

gauge.

adjustment,

make

the

needle

as

shown

si

Setting

is

is

the

needle

the

needle

bar

mark P on

mark

screw0,

or

down,

corresponding

sure

the

center

plate

in

nd

M

ain't

(Fig.14'^17)

as

shown

distance

point

is

in

A.

prior

that

of

and

Fig.

in

(a)

and

the

bar

is

its

the

highest

handwheel

and

and

adjust

to

tighten

each

needle

the

needle

that the

17.

Table

in

move

to

©nance

1.

needle

the

O

the

the

gap

Needle

2-needle

Needle

gauge

3.2mm

4.0mm

4.

8inm

5.6mm

6.

4mm

[2]

(1)

Height

Left

height

9.1mm

8.6mm

a

.2mm

7.8mm

7.4mm

Setting

Adjusting

Set

to

The

needle

when

position.

To

looper

Position

the

the

needle

distance

centerline

the

adjust,

holder 0 right

needle

(a)

distance

distance

gauge

(a)

looper

loosen

Needle

gauge

5.6mm

6.4mm

of

Looper

(a)

(a)

correctly

as

to

shown

from

the

is

O

screw 0 and

or

Table

3-needle

Left

needle

height

(a)

7.8mm

7.4mra

(Fig.IS'—23)

according

in

the

looper

Table

right

point

right

most

move

left.

1

Fig.18

2.

I

Looper

2-needle

Needle

gauge

3.2mm

4.0mm

4.8mm

5.6mm

6.4mm

Setting

Distance

4.7 — 5.0mm

4.3'-4.6mm

3.9 — 4.2mm

3.5—

3.1 — 3.4mm

3.amm

(a)

Needle

gauge

5.6mm

6.4mm

Table

3-needle

Distance

3.5 — 3.8mra

3.1 — 3.4mm

2

(a)

—44—

.(a)

Rg.l9

Page 47

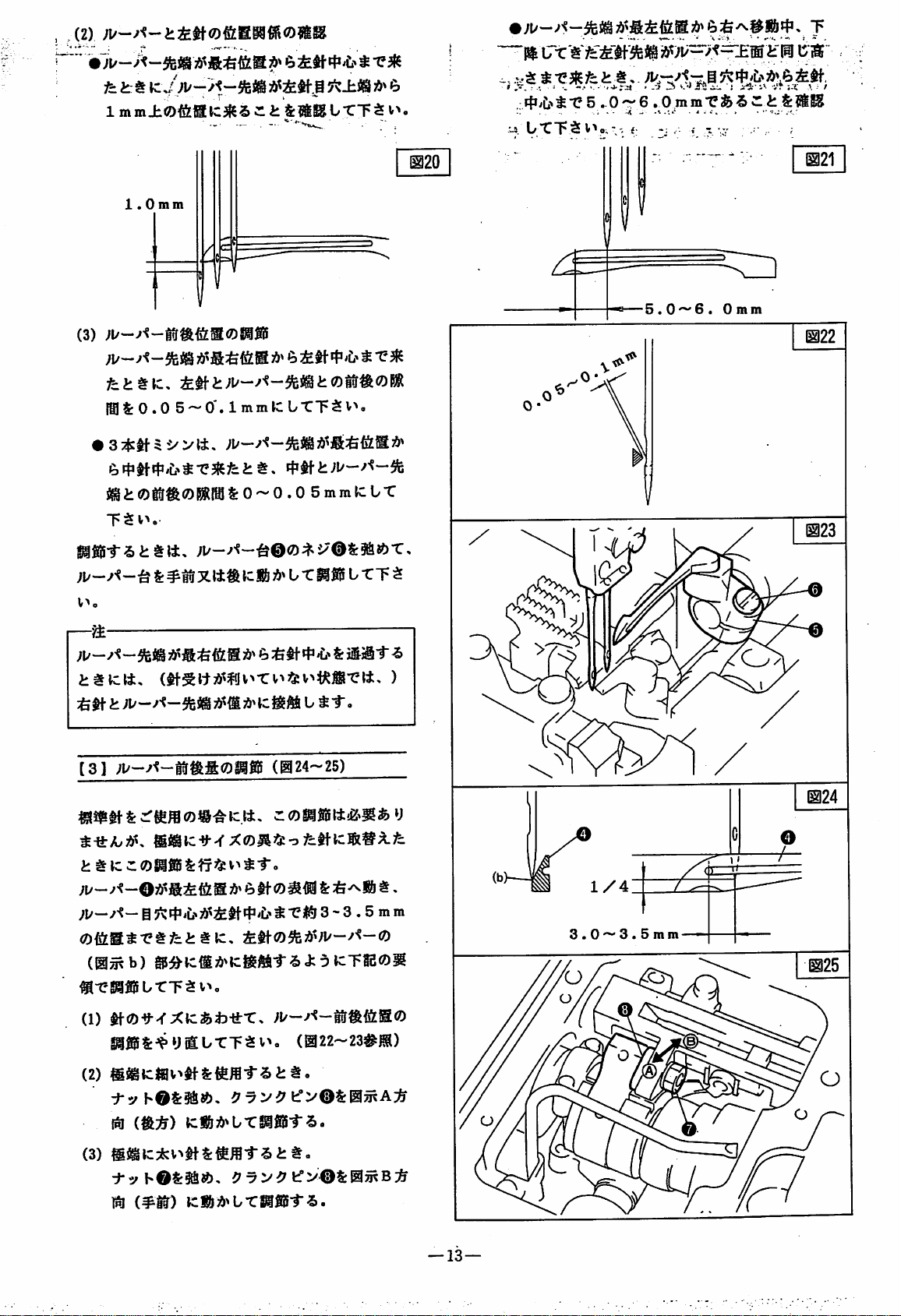

(2)

.Checking

i~needle,:

*

When

needle

above

(Fig.

the

the

looper

centerline,

the

top

20)

1. 0 mm

position

.—-

point

it

of

the

left

of

looper

is

behind

should

needle

be

and

the

Irom

eye.

left

left

Rg.20

*

When

point

looper

looper

centerline

(Fig.

the

is

blade^

eye

21)

left

flush

center

should

needle

with

the

distance

and

be

comes

the

top

the

left

5.0%6.0mm.

dovm

and

of

the

between

needle

tis

the

(3)

*

To

and

The

in

passes

right

that

[3]

adjust,

Note

Clearance

point

Set

the

needle

0.1mm

the

In

the

needle

the

should

clearance

and

when

left

the

case

looper

centerline,

left

be

needle

loosen

move

looper

right

contact

Adjusting

the

most

the

needle

slightly

right

pisition

needle

Looper

between

the

looper

the

needle

looper

centerline.

of

3-needle

point

0.05*^0.1mm.

and

screw 0 of

holder

and

needle

guard

Avoiding

needle

between

is

behind

the

the

back

the

looper

when

the

centerline

(under

does

and

the

point

point

to

is

machines»

the

clearance

looper

looper

or

forth.

looper

the

condition

not

work).

Motion

looper

left

0.05

behind

middle

between

point

holder

point

point

from

(Fig.

24~

%

when

come

0

25)

5 . 0~

6. 0 mm

Please

may

otherwise

is

When

needles

position

center

centerline

make

needle

touch

manner.

(1)

(2)

note

not

be

fitted.

the

to

of

adjustment

and

each

Re-adjust

according

Fig.

In

case

used:

Loosen

back

rated.

(3)

In

case

used:

Loosen

forth

rated

that

the

necessary

an

extremely

looper

to

looper O goes

the

and

the

looper

is

approximately

the

looper

other

the

to

22

%23.)

an

nut 0 and

in

the

an

nut 0 and

in

the

.

right

extremely

extremely

from

clearance

eye

and

so

that

(b

slightly

looper

the

needle

move

direction

move

direction

avoiding

be

adjusted

different

in

front

its

left

between

left

needle

3.0%3.5mm,

the

top

shown

in

the

avoiding

size.

fine

needle

the

crank

of A as

thick

the

crank

of B as

size

of

the

most

the

of

left

in

Fig.)

following

motion

(Refer

illust

needle

illust

motion

unless

needle

is

pin

0

is

pin

0

3.0 — 3.5mm

to

—

45—

Page 48

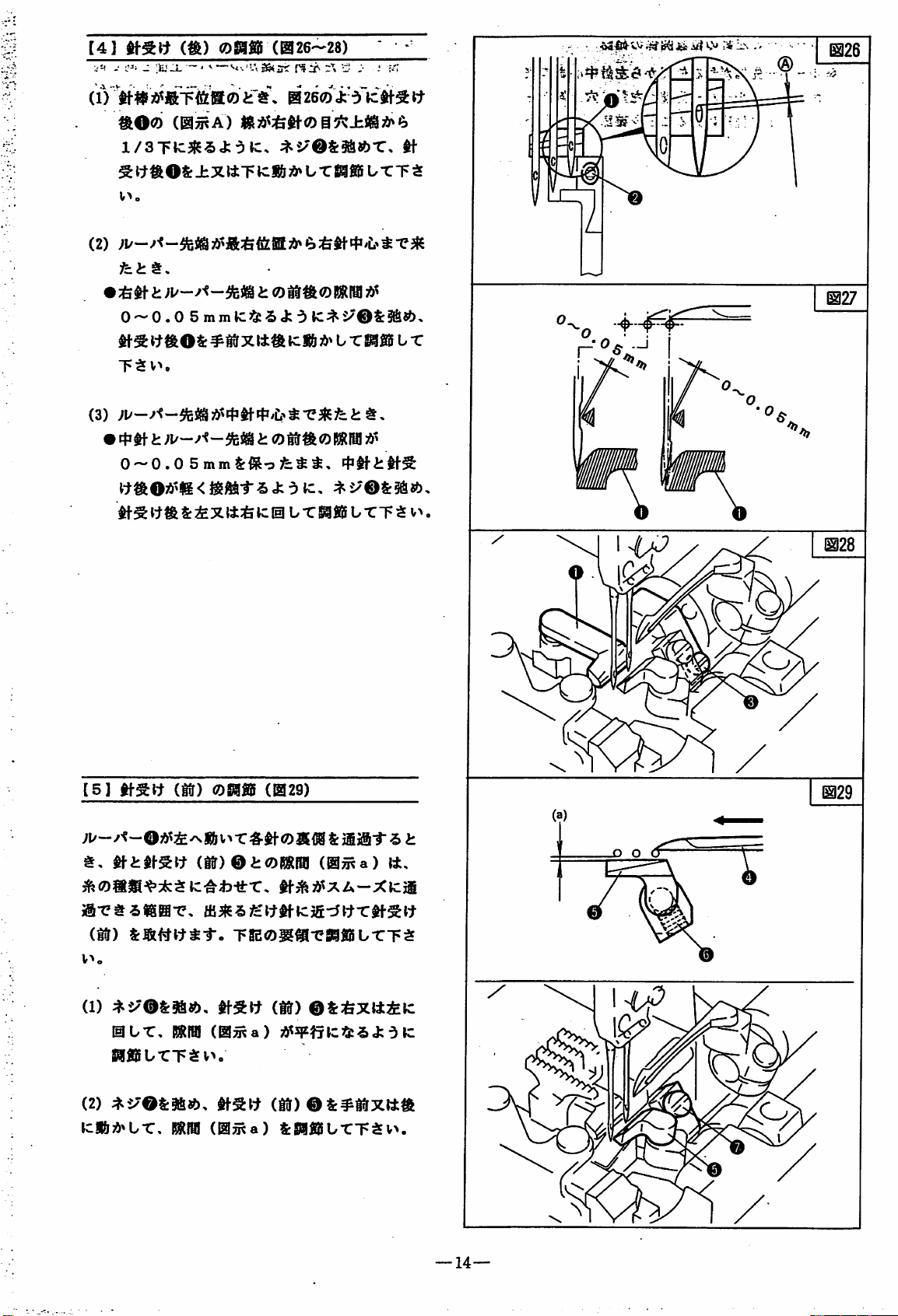

[4]

Adjusting

(1)

Adjust

guard

the

when

position.

To

needle

Needle

so

that

(rear)

right

adjust,

the

guard

needle

needle

Guard

the

©is

loosen

(rear) O uP

line

1/3

eye

bar

is

screw © and

(Rear)

below

as

(Fig.26'

(A)

of

the

shown

in

the

down.

needle

top

Fig.

lowest

move

'28)

of

26

(2)

When the

needle

position:

*

The

clearance

and

the

adjust,

(3)

*

guard

When

needle

The

(rear) O back

the

right

(rear) O touch

0'\»

0.05mm

needle

loosen

(rear)

looper

centerline

looper

loosen

between

point

screw e and

looper

centerline:

needle

each

clearance

and

the

or

looper

and

right.

screw

left

point

point

comes

from

right

the

is 0 'v.O.OSmm.

or

forth.

comes

and

the

needle

other

between

point.

turn

needle

the

right

most

right

move

the

needle

needle

middle

guard

slightly

the

right

To

guard

with

adjust,

I

To

[5]

Adjusting

When

the

passes

between

(front) 0 should

still

pass

Adjust

(1)

(2)

behind

the

sufficient

through

in

Loosen

(front) 0 right

clearance

Loosen

(front) 0 back

clearance

Needle

looper O advances

the

needles

it.

the

following

screw©,

(a)

screw©,

(a).

Guard

needles,

and

be

as

to

and

small

the

turn

or

left

be

move

forth

for

(Front)

to

the

the

needle

needle

manner.

needle

in

needle

clearance

guard

as

and

parallel.

and

(Fig.29)

left,

possible

threads

guard

adjust

guard

adjust

the

it

(a)

to

the

—46—

Page 49

[6

]'

Setting

'

1.

2.

• ■

Height:

from

the

S.Omm.

To

adjust,

move

the

Sidewise

should

0.5mm

the

position,

the

needle.

To

0.

in

spreader O reaches

point

adjust,

While

spreader 0 back

sidewise

Position'of

-.V

'

The'height

needle

tighten

Spreader

/ij

of

plate

screw 0 lightly

spreader O up

position:

pass

the

front

the

(B)

lightly

turning

position.

The

point

of

the

hooking

4.5'V'5.0mm

loosen

lever 0 ,

or

forth

(Fig.30^31)

-

,

'

the

spreader

surface

or

hooking

(A)

left

its

point

should

down.

approximately

needle.

left

should

from

the

screws 0 and

move

to

set

O

and

point

When

most

be

left

the

be

at

t E '>'1

i: j T

Ou

6

'j

rLiii)

Note

1.

When

the

where

spreader

2.

If

the

imperfectly

spreader

thickness,

the

spreader

possible

If

the

even

increase

stroke)

making

pulley

the

passes.

spreader

threads

left

not

threader

to

spreader

under

the

not

the

above

and

check

hooking

thread

because

then

shift

exceeding

the

needle

thread

the

above

following

exceeding

adjustment,

the

of

the

points

tip

is

hooked

the

fabric

the

point B to

part

or

S.Omm

guide 0 as

holder.

is

not

adjustment,

(the

18.0mm.

A,

of

the

number

and

set

near

booked

then

spreader

turn

B

of

as

0.5mm

4 . 5~5. 0 mm

8.0mm

Fig.

31

—

1

7.0mm

[7]

The

in

1.

2.

stroke

the

Remove

shift

Loosen

To

To

Adjusting

following

Spreader

of

spreader 0 is

the

arm

cover

.

nut 0 and

decrease

increase

manner.

cover

the

the

Stroke

and

move

rod 0 up

stroke,

stroke,

(Fig,31~32)

17.0mm.

screws

and

or

move

rod 0 up.

move

rod 0 down.

Rg.32

Adjust

down.

■47—

Page 50

[8]

Setting

Guide

Set

the

A

needle

Also,

thread

To

[9]

When

position,

thread

thread

To

part

just

below

bar

set

guide Q and

adjust,

Setting

the

guide O and 0 to

guide

adjust,

Position

(Fig.33"^34)

(a)

the

is

in

the

clearance

loosen

Thread

needle

set

the

should

loosen

of

Spreader

-

of

spreader

eye

of

the

lowest

between

spreader

screws

Guide

bar

clearance

screw

(Fig.33"^34)

is

in

face

O-

guide @ when

0.

Thread

th^ad

position.

spreader

to

0.5mm.

the

lowest

between

1.0mm.

forwards.

guide

the

spreader

The

eye

of

1.0mm

0.5mm

Page 51

[10]

Adjusting

When

-the

position,

straight

feed

dog

parallel

To

adjust,

of

differential

[11]

Adjusting

When

the

position,

line

(a)

and

differential

To

adjust,

the

feed

Feed

Tilt

(Fig.35~37)"'* ' "

feed

dogs

the

line

and

with

loosen

Feed

feed

set

across

loosen

rise

standard

(a)

angle

across

differential

the

needle

screw 0 and

feed

dog

Height

dogs

rise

the

height

the

tips

feed

dog 0 to

screws

dogs 0 and 0 up

to

the

highest

is

tips

feed

top

that

of

dog 0 is

the

plate

move

up

or

down.

(Fig.36~37)

to

the

of

of

0and0,

or

highest

the

main

0.8

down.

straight

feed

and

the

main

surface.

the

tip

dog

0

1.0mm.

move

0.8~1.0mm

[12]

The

When

lift

foot

To

adjust:

(1)

(2)

(3)

Presser

Machine

standard

Turn

to

Loosen

clockwise.)

Lower

to

In

so

this

Adjusting

the

is

and

their

Foot

setting

presser

the

distance

the

needle

the

pulley

lowest

nut 0 and

lever

the

correct

the

above

that

its

position

Foot

Lift

type

W664-01

W644-01

Lift

(Fig.38'-^39)

is

foot 0 is

(b)

plate.

and

position.

tighten

0and

raise

height

condition,

head

touches

with

nut

Presser

2-needle

5.

8mm

6.3mm

as

shown

raised,

between

lower

presser

for

adjust

0.

in

the

the

Screwi

your

lever

foot

3-needle

Table

the

foot

presser

feed

dogs

(Turn

foot

machine.

screw

0.

Lock

Table

lift

5.0mm

6.

3mm

3.

0

0

3

W664-05

W644-05

5.4mm

6.3mm

4.5rom

6.3mm

—49—

Page 52

[

Dd-f

11

ntial

The

Machines

the

Differential

of

Feed

Sandard

Feed

Specifcation

Ratio

Ratio

Use

(Fig.40)

Addustment;^^,;rj^^^

1^0

lsO.6

*

This

range

limited

inch).

Do

not

shown

is

factory-set

shown

Note

Depending

differential

may

damaged.

[2]

To

to

move

in

Fig.

in

Fig.

cause

Use

the

the

the

the

1:1.3 - 1:1.8

-

lrl-3

represents

4.5mm

(or 6 stitches

the

stopperO

40.

(The

to

keep

40.)

stitch

feed

feed

adjustment

the

length,

ratio

dog

to

Differential

(Fig.41-42)

stitch

from

the

1:1.3

using

greater

collide

Feed

Ratio

length

per

positi^

lever

line

as

a

than

1:1.3

and

Range

Q

be

Some

materials

differential

*

This

represents

to

3.3rom

Adjust

(1)

as

Loosen

length

follows.

pin O is

stitch

(2)

Loosen

stopper O to

mark

on

To

to

1:1.8

Fig.

Note

set

the

position

42.

the

standard

re-adjust

end

is

stitch

0.5mm

length

such

as

feed

(or 8 stitches

two

screws

adjust

3.2mm

length

screw

the

the

adjust

differential

the

(smaller

end

out

adjust

blanket

ratio

the

knob

adjust

of

greater

stitch

so

out

the

on

stopper O to

position

lever

on

the

of

pin O so

the

knob

length

per

on

the

that

bottom

knob

scale

feed

than

bottom

shown

require

than

inch).

stitch

the

shown

to

align

with

as

ratio

1:1.3),

that

of

as

the

1:1.3.

limited

end

of

of

the

as

(a).

move

the

the

shown

back

its

the

(a).

in

Differential

greater

surface

than

feed

1:1.3

ratio

(a)

To

set

feed

standard

the

ratio

differential

back

to

the

—

50—

Page 53

®PNe©dle

Xthreacd

Xalceup

Xhiread

[ 1 ]

Adjusting

In

the'

standard

Needle

bracket 0 should

needle

The

^

takeup

To

—

*

bar

distance

and

the

should

adjust,

Note

—

To

tighten

needle

thread

is

between

line

loosen

the

direction.

move

it

in

according

etc.

*

Take

care

the

to

not

takeup 0 from

[2]

Adjusting

Needle

The

distance

and

the eyelet

To

adjust,

thread

thread

guide 0 up

Needle

guide

between

loosen

Thread

settingr

be

in

be

center

horizontal

the

lowest

the

(b)

of

75mm.

screws O and

needle

takeup 0 in

To

loosen

{+)

the

direction.

thread

to

move

its

original

Thread

0

the

should

Screw 0 and

or

down.

GuXcle

Takeup

the

top

Acloust:ment:'s

(Fig.43)

edge

when

the

position.

line

(a)

of

the

needle

Bracket

thread

O.

;

thread,

the

move

the

(-)

needle

thread,

Adjust

characteristics,

spreader

thread

position.

Guide

(Fig.44)

center

be

of

7.0mm.

move

screw

needle

of

7 5 mm

0

Needle

The

and

Fig.

To

needle

To

thread

To

Adjust

istics

[3]

Set

the

To

[4]

The

should

thread

is

To

spreader

thread

distance

the

eyelet

44.

adjust,

loosen

thread