Page 1

INSTRUCTIONS

W562>W542

Cat.

No.

9A2030

A

March,

1984

FLATBED

t

iliitZcox

INTERLOCK

First

edition;

o-giBBS

STITCH

issued

MACHINES

in

March,

1984

ujiL.L.cax

cgiBBS

Page 2

INTRODUCTION

This

booklet

operation

should

become

derive

and

be

useful

familiar

the

best

contains

maintenance

to

use

you

with

from

some

of

and

the

it.

notes

the

W500,

should

machine

on

help

and

the

which

you

to

to

FOR

(1)

Make

(2)

Take

Machine

the

(3)

Turn

the

(4)

Turn

power

(5)

Make

when

(6)

Be

sure

you

needles.

SAFETY

sure

care

machine

off

work

off

failure.

sure

you

sure

Motor

thread

Belt

when

Motor

before

Motor

table.

Motor

Motor

clean

to

turn

has

the

Cover

is

properly

you

connect

as

well

as

switching

Switch

or

whenever

Switch

has

completely

inspect

off

the

power

completely

machine

Power

when

on.

in

the

the

machine.

stopped

or

replace

fitted.

Cord

you

check

you

leave

event

stopped

and

make

when

to

of

the

DAILY

Before

(1)

(2)

(3)

(4)

(5)

After

(1)

(2)

(3)

morning

Check

Check

Check

Check

behind

Check

normal.

specified

lubricated

close

Remove

machine.

If

any

it

to

repair.

Be

machine.

MAINTENANCE

start

each

Needle

all

Needles

threading

about

30mm

Presser

the

of

Foot.

oil

jets

Check

level

and

enough.

work

dust

trouble

the

plant

sure

to

place

is

not

are

correctly

is

correct.

of

thread

in

Oil

Sight

oil

is

maintained

the

hand-oiled

and

lint

or

disorder

mechanic

Dust

damaged

set.

chain

Window

parts

deposits

is

found,

for

adjustment

Cover

over

or

bent.

remains

are

at

the

are

on

the

report

or

the

PRECAUTIONS

(1)

Do

not

s.p.m.

for

(2)

Before

or

if

the

couple

moving

(3)

Always

on

Oil

Sight

(4)

Change

weeks.

(5)

Thread

Diagram

run

the

machine

the

first 4 weeks.

starting

of

parts.

keep

the

machine

machine

weeks,

oil

level

Gauge.

oil

at

correctly

on

Page

at

for

is

idle

manually

between

the

end

as

shown

7.

more

than

the

first

for

more

lubricate

the

of

the

in

4,500

time,

than

a

the

two

lines

first

4

Treading

Page 3

TABLE

Pattern

Table

Driving

Belt

The

Machine

Lubrication

Replacing

Silicone

Needles

Replacing

Threading

Regulating

Adjusting

Adjusting

Adjusting

Adjusting

Adjusting

Adjusting

Setting

Setting

Presser

Stitch

Diff.

Adjusting

Needle

Looper

Adjusting

Adjusting

Adjusting

Setting

Adjusting

Setting

Setting

Adjusting

Adjusting

Synchronizing

Adjusting

Adjusting

Under

Metering

Lace

Setting

Changing

Replacing

OF

paper

cut-out

motor

guard

and

turning

feed

guide

direction

speed

oil

oil

for

needles

thread

needle

spreader

needle

thread

needle

looper

looper

thread

foot

pressure

length

ratio

needle

height

setting

needle

feed

feed

position

spreader

position

thread

foot

spreader

the

looper

fabric

device

(LG210)

tape

binder

the

timing

CONTENTS

for

and

pulley

filter

H.R.

thread

guides

adjustment

adjustment

setting

height

tilt

guide

lift

needle

timing

trimmer

maximum

semi-submerged

installation

and

belting

belting

of

machine

device-

tension

thread

thread

guide

guard

thread

and

guard

takeup

thread

guard

(front)

takeup

guard

looper

takeup

,

of

spreader

stroke

of

spreader

timing

between

avoiding

thread

bar

and

motion

(FT140)

looper

needle

(MD230)

feed

ratio

belt

installation

bracket

guide

and

looper

back

and

forth

movement

Page

2

3

3

4

4

4

5

6

6

6

6

7

8

8

8

9

9

9

10

10

10

11

11

11

12

12

13

14

14

14

15

15

15

15

16

16

17

----n

17

18—19

20—22

22

23

23

24—25

-1

-

Page 4

r-Note:-

•

For a machine

•

For a machine

equipped

equipped

with

with

the

the

under

fabric

needle

positioner,

trimmer

(the

cut

the

FT

device),

portion

d).

cut

the

Rg.1

portion

-2-

Page 5

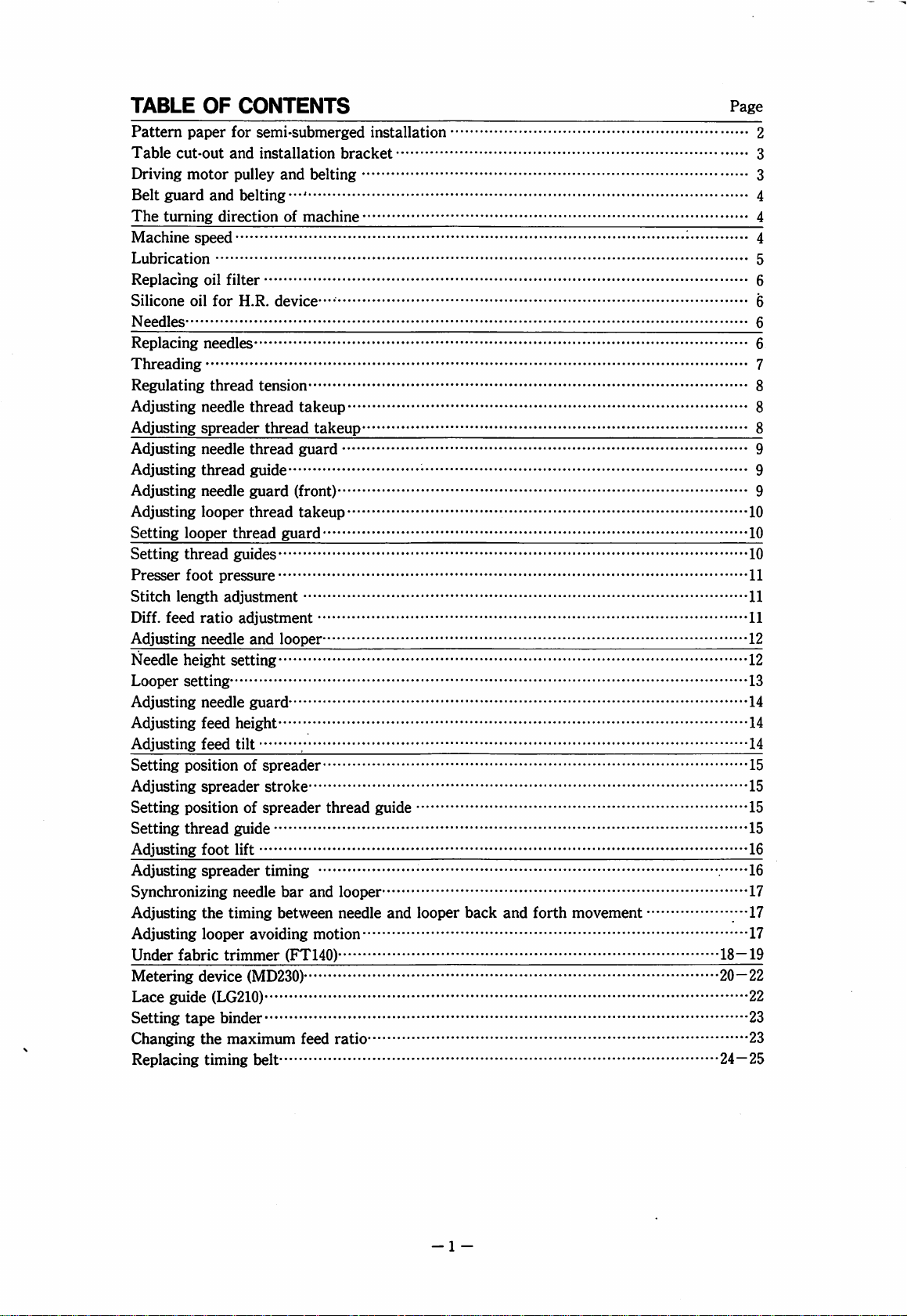

TABLE

CUT-OUT

The

semi-submerged

for

this

machine.

Cut

out

the

the

following

(1)

Refer

to

specified.

(2)

Refer

to

If

the

machine

fabric

r—

Note:

•

•

•

trimmer,

®

in

sequence.

Use a table

Remove

Use

Washers o if

Washers O if

AND

table

and

manner,

Fig.l

Fig.2

and

is

refer

of

thickness

INSTALLATION

BRACKET

installation

install

and

cut

the

out

the

set O ^ ® in

equipped

to

the

table

with

Fig,3

50mm.

the

table

is

47mm

and

is

standard

machine

table

as

sequence.

the

under

set

is

50mm.

or

less.

in

—

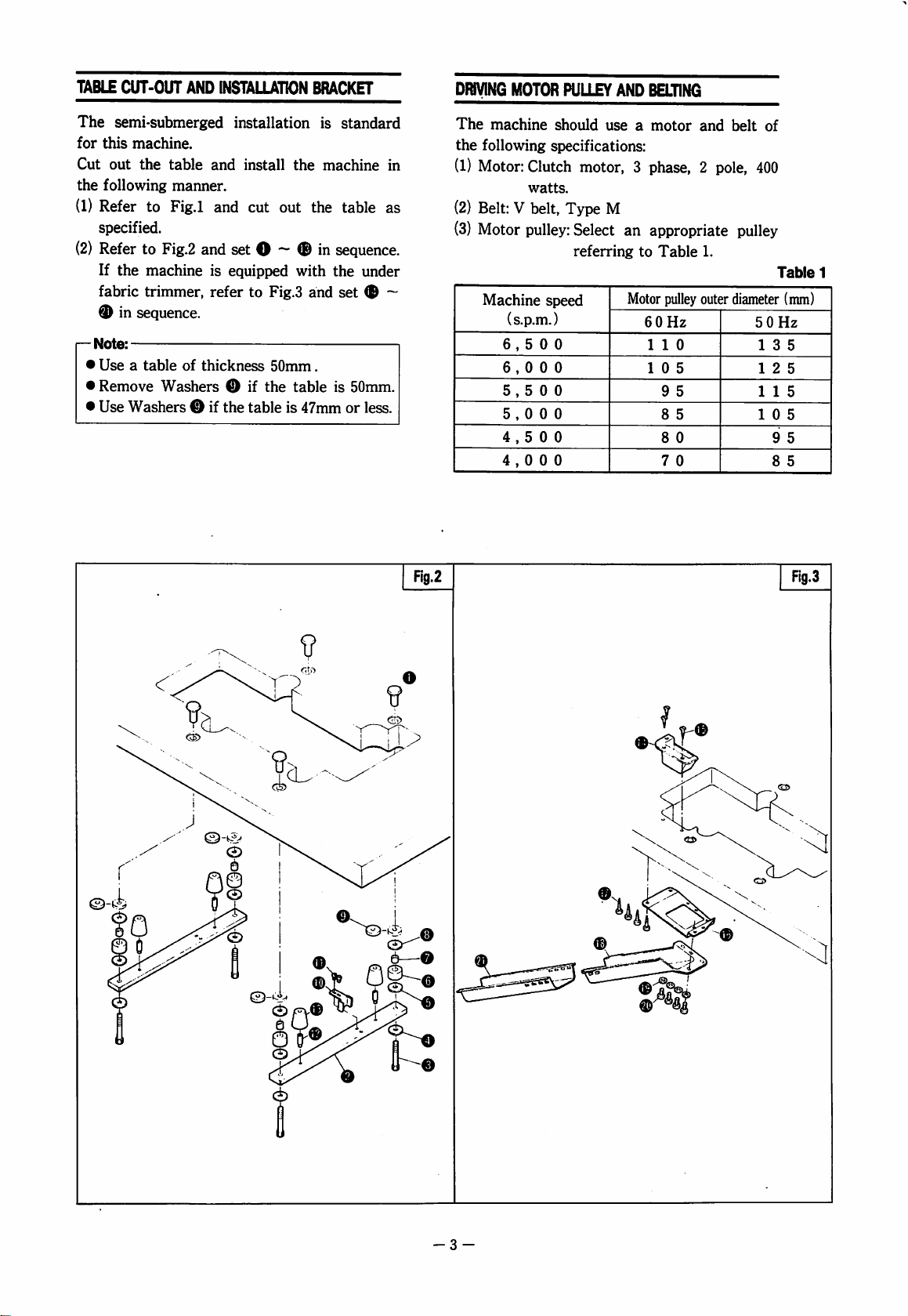

DRiyiNG

The

the

(1)

(2)

(3)

MOTOR

machine

following

Motor:

Belt: V belt.

Motor

Clutch

watts.

pulley:

Machine

speed

(s.p.m.)

6,500

6,000

5,500

5,000

4,500

4,000

PULLEY

should

AND

BELTING

use a motor

and

specifications:

motor, 3 phase, 2 pole,

Type

M

Select

referring

an

appropriate

to

Table

1.

Motor

pulley

outer

60

Hz

1 1 0

1 0 5

9

5

8

5

8

0

7

0

belt

of

400

pulley

Table

diameter

50Hz

13

12

1 1 5

10

9

8

(mm)

5

5

5

5

5

1

3

Fig.2

Fig.3

9

C£>

D

-3

-

Page 6

BELT

GUARD

(1)

For

safety,

Screws 0 on

(2)

Adjust

be

2cm

middle

Adjust

AND

be

the

tension

bent

of

it.

the

height

BELTING

sure

to

fit

machine.

of

the

inward

of

the

Belt

Guard O with

belt

when

you

motor

so

that

press

to

do

it

can

this.

the

THE

TURNING

The

turning

clockwise,

side.

MACHINE

Make

Type

maximum

^

Note:

The

maximum

depending

operation,

etc.

DIRECTION

direction

seeing

SPEED

sure

your

Plate O and

speed

as

speed

on

sewing

needle

Select a correct

Table 1 suitable

OF

of

the

machine

machine

run

it

listed

in

may

conditions

size,

thread,

motor

to

your

operation.

MACHINE

Machine

from

type

number

not

exceeding

Table

2.

have

to

be

decreased

such

as

stitch

pulley

size

Pulley

its

right

with

the

fabric,

length,

from

is

MAXIMUM

MACHINE

W562-01

W542-01

W562-02

W542-02

W562-03

W542-03

W562-05

W542-05

W562-06

W542-06

W562-07

W542-07

W562-21

Note:

If

the

SPEED

the

machine

maximum

Number

2-needle

O

O

o

o

o

o

o

o

o

o

o

o

o

is

equipped

-speed

is

of

needles

3-needle

o

o

o

o

o

o

o

o

o

o

o

o

with

5,000

s.p.m.

O

MAXIMUM

the

metering

Fig.5

Table

SPEED

(S.P.M.)

6,000

6,500

6,000

6,000

6,500

6,000

6,000

6,500

6,000

5,500

5,500

6,000

6,5 0 0

6,0 0 0

5,0 0 0

5,0 0 0

5,0

0 0

device,

2

-4

-

Page 7

LUBRICATION

The

oil

was

shipped.

starting

1.

Lubricating

Use

equivalent.

2.

To

Take

oil

level

Sight

3.

Oil

Always

the

Window

4.

Manual

Before

if

the

of

weeks,

So,

it

for

Mobil

fill

oil

out

Screw O and

reaches

Window

level

keep

oil

level

©.

oiling

starting

machine

manually

drained

fill

the

the

first

Oil

Velocite

enough

is

oil

the

upper

©.

Replace

oil

between

machine

is

idle

lubricate

from

the

machine

time.

No.

10

pour

fresh

line

Screw

in

the

two

lines H and L of

for

the

for

more

Needle

machine

with

(ISO

'H'

of

oil

VG22)

oil

until

Oil

when

before

Level

O.

machine

first

time,

so

that

than a couple

Bar

©.

or

the

or

5.

Oil

circulation

Be

sure

Window

(—

If

check

6.

Change

After

-

Be

cause

shorten

7.

Take

8.

If

cannot

months

^

If

restricted

check

replace

o.

Note:

oil

does

Oil

Oil

Change

oil

that,

Note:

sure

excess

To

drain

out

Oil

Filter

Oil

Filter 0 is

be

at

Note:

oil

and

check

to

check

Filter

after

change

to

the

oil

Screw 0 and

that

not

splash

®.

the

oil

change

wear

life

time

first I month

oil

clogged,

kept.

the

jet

it

with

Check

time

of

in

Window O is

or

weak,

clean

Oil

new

oil

is

splashing

inside

Window

in

every 6 months.

because

on

of

the

drain

dirty

moving

machine.

oil

from

nomal

and

clean 0 every

the

regular

abnormally

or

oil

contains

Filter 0 or

Oil

Filter.

if

inside

0>

operation.

oil

can

parts

and

here.

lubrication

6

oil

change.

bubbles,

necessary,

- 5 -

Page 8

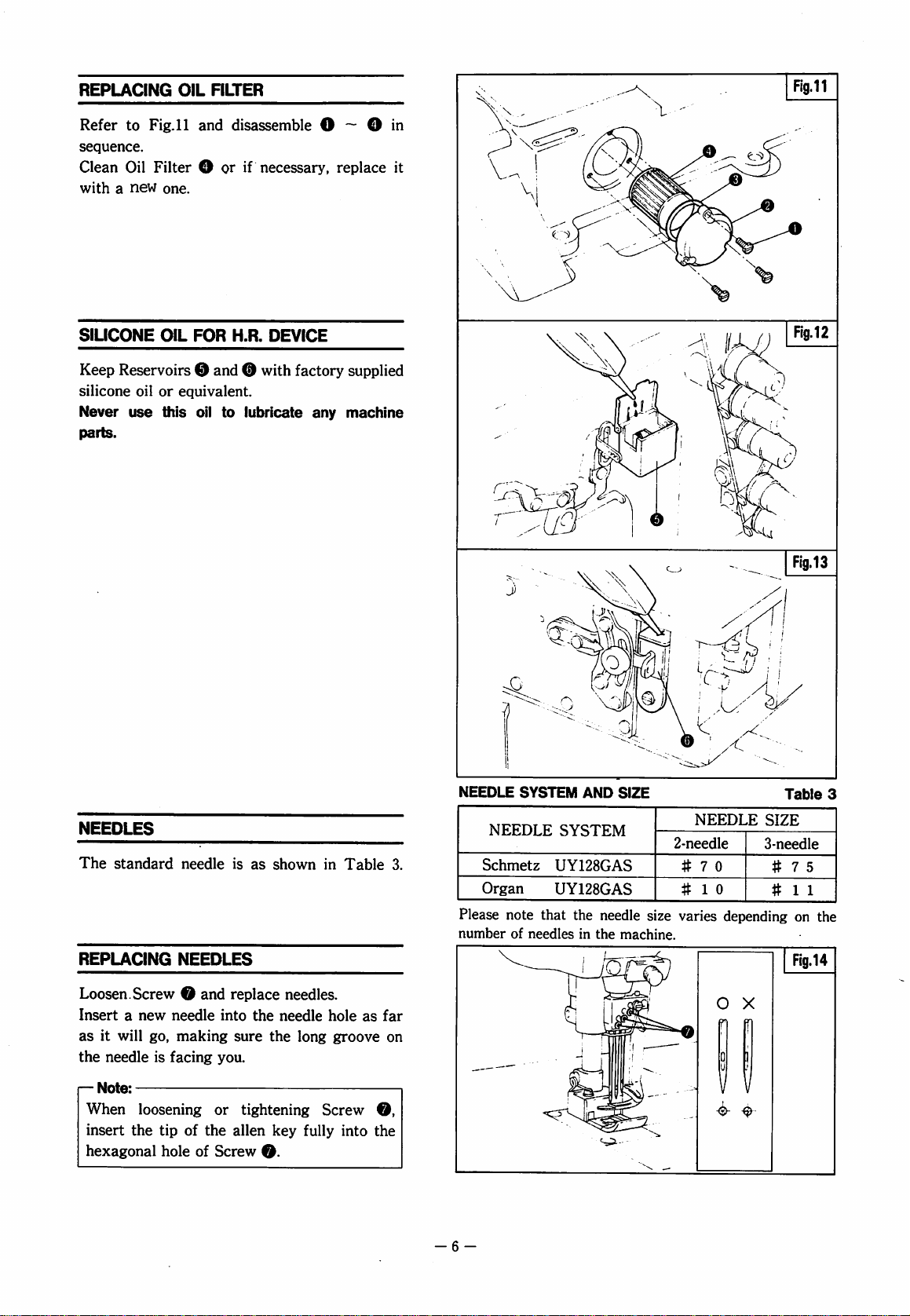

REPLACING

Refer

to

Fig.

sequence.

Clean

Oil

with a new

OIL

FILTER

11

and

disassemble O O

Filter O or

one.

if

necessary,

in

replace

it

SILICONE

Keep

silicone

Never

parts.

OIL

FOR

Reservoirs 0 and 0 with

oil

or

equivalent.

use

this

oil

H.R.

DEVICE

to

lubricate

factory

any

supplied

machine

NEEDLES

The

standard

REPLACING

Loosen.

Insert a new

as

the

—

When

insert

Screw O and

it

will

go,

needle

Note:

loosening

the

is

hexagonal

needle

NEEDLES

needle

making

facing

tip

of

hole

of

is

as

replace

into

the

sure

you.

or

tightening

the

alien

Screw

0.

shown

needles.

needle

the

long

key

fully

in

Table

hole

as

groove

Screw

into

far

on

©,

the

3.

-6

NEEDLE

NEEDLE

Schmetz

Organ

Please

note

number

-

of

SYSTEM

SYSTEM

UY128GAS

UY128GAS

that

needles

AND

the

needle

in

the

SIZE

size

machine.

NEEDLE

2-needle

#70

# 1 0

varies

depending

Table

SIZE

3-needle

#75

#

1 1

on

3

the

Page 9

THREADING

Rg.15

Thread

threading

stitches,

your

may

or

uneven

machine

cause

thread

stitch

correctly.

Incorrect

breakage,

formation.

skip

for

stretchy

threads.

I

^

*

for

coarse

stitch

and

seam

width

only.

threading,

come

push

Bracket

out.

threading,

position.

its

for

stretchy

threads.

•for

and

width

fine

stitch

narrow

only.

length

seam

length

wide

(DWhen

Lever o and

O

will

©After

finishing

push

Bracket O into

original

-7

-

Page 10

REGULATING

THREAD

TENSION

Changes

etc.

Adjust

To

To

ADJUSTING

In

©

in

To

The

and

should

f—

Note:

•

•

of

require

individual

increase

Turn

Nut O clockwise.

decrease

Turn

Nut O counter-clockwise.

the

standard

should

the

To

be

lowest

adjust,

distance

the

line

be

87mm.

tighten

Thread

To

loosen

the

(—)

Take

care

threads,

tension:

loosen

Takeup © in

direction.

Takeup © from

seam

width,

re-adjustment

thread

tension:

NEEDLE

setting,

horizontal

position.

Screw

between

(b)

of

the

tension

THREAD

the

when

©.

the

the

needle

To

adjust

needle

thread,

top

line

the

the

not

needle

to

thread,

move

its

original

stitch

of

thread

as

follows:

TAKEUP

edge

of

the

needle

(a)

of

Bracket

thread

loosen

Screws

move

(+)

direction.

move © in

Spreader

Thread

position.

length,

tension.

Bracket

bar

is

©

takeup

©.

Needle

I

87mm

—rr?—N

Fig.l7

/Ctr

T

H

(a)

ADJUSTING

The

eye

(A)

to

the

comer

when

Spreader

highest

To

Thread

position.

adjust,

loosen

Guide © up

SPREADER

of

Thread

of

Spreader

Thread

Screws © and

or

THREAD

TAKEUP

Guide © should

Thread

Takeup

Takeup © is

©,

and

down.

come

in

its

move

©

-8-

Page 11

ADJUSTING

Set

Needle

its

elongated

To

adjust,

NEEDLE

Thread

hole.

loosen

Guard

Screw

THREAD

at

GUARD

the

center

of

ADJUSTING

The

standard

as

shown

To

adjust,

Guide ® up

Note:

To

tighten

To

loosen

Adjust

Lower

threads

THREAD

position

in

Table

loosen

or

down.

the

thread,

the

thread,

according

Thread

are

Guide ® when

used.

GUIDE

of

Thread

4.

Screw ® and

raise

Thread

lower

®.

to

the

type

of

weak

Guide ® is

move

Thread

Guide

thread

used.

synthetic

®.

SETTING

Needle

thread

Looper

thread

Position

of

®

POSITIONS

Polyester

spun

Polyester

spun

Lowest

OF

THREAD

Polyester

spun

Wooly

(G

Lowest

GUIDE

type)

Wooly

(H

Wooly

(G

Center

Table

type)

type)

4

ADJUSTING

As

the

looper

Guard

(Front) ® passes

Set

Needle

to

the

through

To

adjust,

Guard

Guard

needle

the

loosen

(Front) ^ back

NEEDLE

passes

(Front)

but

only

gap

(a)

Screw ® and

GUARD

behind

smoothly.

in

one

and

the

front

(D

as

piece

forth.

(FRONT)

needles.

of

close

of

Needle

the

needles.

as

possible

thread

move

Needle

passes

-9

Flg.21

-

Page 12

ADJUSTING

LOOPER

THREAD

TAKEUP

Looper

looper

needle

1)2/3

2)

To

Thread

thread

point

down

Fig.

23.

level

with

machines.

adjust,

Thread

SETTING

Set

the

Looper

5.0—6.0mm

6.0—7.0mm

To

Thread

adjust,

SETTING

Align

the

the

aligning

To

adjust,

Takeup O should

at

the

point

is

in

the

following

the looper

the

looper's

Fig.

24.

loosen

Takeup

LOOPER

distance

Screws Q and

O.

THREAD

between

Guard O to:

for

2-needle

for

3-needle

loosen

eyes

loosen

Screw

THREAD

of

Thread

mark

on

Screws 0 and

GUIDES ® and

Bracket

(a)

release

when

the

the

left

position.

for

2-needle

lower

edge

Bracket

machines.

machines.

for

turn

GUARD

machines.

3-needle

Looper

and

©.

Q

Guides 0 and O with

0.

0.

3-needle

2-needle

6.0—7.0mm

Fig.23

—Note:

When

the

looper

looper

should

according

gauge.

To

seam,

To

seam,

thread

be

lightly

to

threads,

increase

move 0 and 0 down.

decrease

move 0 and 0 up.

is

at

between

the

amount

the

amount

its

left

dead

Guides 0 and

tensioned.

stitch

length

of

thread

of

thread

point,

Adjust

and

needle

in

in

the

0

this

the

the

1

3-needle

Flg.24

-10-

Page 13

PRESSER

FOOT

PRESSURE

Presser

possible,

and

Loosen

STITCH

While

®

foot

obtain

Nut ® and

pressing

until

Button

while

proper

LENGTH

Turn ® further

Release

•

For a longer

direction.

•

For a shorter

direction.

—

The

approximate

®.

Note:

figures

pressure

still

should

sufficient

stitch

formation.

turn

Screw

ADJUSTMENT

Push

Button

drops

in.

for a desired

stitch

length,

stitch

length,

on

Handwheel

stitch

length.

be

as

to

feed

and

turn

Handwheel

stitch

turn ® in

turn ® in

®

light

as

fabric

adjust.

length.

the

(+)

the

(—)

show

^

rVfAA'

DIFF.

The

Loosen

change

To

stretch

To

gather

r—

Note:

Fig.

setting

•

The

W542-05.

FEED

diff.

feed

Nut

the

the

30

shows

Lever

diff.

feed

RATIO

diff.

the

ADJUSTMENT

ratio

is

move

feed

ratio.

fabric,

fabric,

ratio

move

approximate

is

from

1:0.7

Lever ® up

move

Lever ® upward.

Lever

iB

diff.

feed

1:0.7

to

1:1

to

1:1.3

or

down

downward.

ratio

for

W562-05'

to

by

-11-

Page 14

ADJUSTING

When

the

looper

centerline,

top

of

from

When

is

flush

distance

left

needle

Adjust

the

the

needle

the

left

with

between

in

the

it

left

centerline

NEEDLE

point

should

needle

should

needle

the

following

top

the

AND

is

be

1.2—1.5mm

eye,

be

comes

of

looper

should

manner.

LOOPER

behind

the

and

the

0.1—0.2mm.

down

the

looper

eye

center

be

5.0—6.0mm.

left

needle

above

clearance

and

its

blade,

and

the

point

the

the

5.0—6.0mm

1.2~

Rg.31

1.5mm

Flg.32

Flg.33

NEEDLE

The

standard

The

needle

the

left

surface

when

position.

Raise

the

and

adjust

To

adjust,

0,

and

move

—Note:

•

After

needle

hole

in

is

even.

•

When

the

mark ® on

the

mark

HEIGHT

setting

height

needle

the

needle

the

height

remove

the

this

adjustment,

passes

through

the

needle

Fig.

36.

the

needle

(S).

SETTING

is

as

is

the

point

and

needle

bar

Cap

needle

bar

to

as

shown

Screw

bar

make

the

plate

bar

is

in

the

handwheel

shown

distance

the

in

(a)

the

needle

is

in

highest

in

Table

O,

loosen

up

or

down.

sure

center

of

and

that

its

highest

should

Table

between

plate

the

highest

position

5.

Screw

that

each

the

needle

the

gap

position,

meet

5.

(b)

NEEDLE

Needle

space

2.4mm

3.2mm

4.0mm

4.8mm

5.6mm

6.4mm

HEIGHT

2-needle

Needle

10.2—10.7mm

9.8—10.3mm

9.3—

8.9—

8.5—

8.1—

height

(a)

9.8mm

9.4mm

9.0mm

8.6mm

(a)

Needle

space

4.8mm

5.6mm

6.4mm

3-needle

Needle

8.9—9.4mm

8.5—9.0mm

8.1—8.6mm

Table

height

(a)

5

(a)

/'■'i • •/.'

-12-

Flg.35

Flg.36

Page 15

LOOPER

SETTING

0.9mm

R9.38

The

standard

Make

sure

that

machine.

The

distance

centerline

is

at

in

the

[IISETTING

Refer

to

the

right

following

LOOPER

to

Fig.

mADJUSTING

Set

the

distance

To

adjust,

Holder 0 right

IHGLEARANCE

LOOPER

Set

and

looper

centerline.

To

adjust,

•

In

the

looper

centerline,

0—0.5mm.

POINT

the

clearance

the

looper

point

case

point

loosen

loosen

setting

the

the

(a)

looper

dead

is

setting

is

from

point.

steps.

38

and

set

DISTANCE

(a)

correctly.

Screw O and

or

left.

BETWEEN

between

point

to

is

behind

Screw O and

of

3-needle

is

behind

the

clearance

as

shown

is

correct

the

point

when

Set

the

the

looper.

(a)

Table

NEEDLE

the

0.1—0.2mm

the

turn

machines,

the

middle

in

Table

for

right

the

distance

6.

move

Looper

AND

left

when

left

needle

Screw

when

needle

should

6.

your

needle

looper

(a)

needle

the

0.

the

be

DISTANCE

Needle

space

2.4mm

3.2mm

4.0mm

4.8mm

5.6mm

6.4mm

BETWEEN

2-needle

Distance

4.6—4.9mm

4.2—4.5mm

3.8—4.1mm

3.4—3.7mm

3.0—3.3mm

2.6—2.9mm

25.0mm

(a)

NEEDLE

Needle

space

4.8mm

5.6mm

6.4mm

i-H(a)

AND

LOOPER

3-needle

3.4—3.7mm

3.0—3.3mm

2.6—2.9mm

Table

Distance

(a)

Fig.39

6

1.2—1.5mm

/ Fig.40

Fig.41

"■Q

Fig.42

5.0~6.0mm

-13-

Page 16

ADJUSTING

NEEDLE

GUARD

Needle

clearance

looper

point

that

and

looper

centerline.

1.

2,

ADJUSTING

When

position,

Adjust

on

To

the

Guard O should

between

point

is

behind

the

clearance

the looper

point

Adjust

O

when

Fig.

To

so

that

is

1/3

below

the

43.

adjust,

needle

loosen

Guard O up

To

obtain

loosen

back

the

adjust,

feed

the

Screw © and

and

forth.

the

main

set

the

the

diff.

same

level

loosen

dog

up

is

0—0.05mm

the

point

is

the

the

or

above

FEED

height

feed

or

work

the

right

needle

when

right

needle

between

is 0 —

behind

line

top

is

in

centerline.

the

0.05mm

the

(A)

of

of

the

right

the

lowest

middle

Screw O and

down.

clearances 0 —0.05mm,

move

Needle

HEIGHT

feed

dog

is

in

to

0.8 — 1.0mm.

dog

so

that

as

the

main

feed

Screws O and

down.

so

that

and

the looper

middle

when

Needle

needle

position.

move

Needle

Guard

the

highest

the

point B is

dog

point

©,

and

the

the

Also

needle

the

needle

Guard

eye

O

C.

move

0.1

~0.2mm

ADJUSTING

The

teeth

the

needle

above

the

To

adjust;

1.

Remove

2.

Remove

3.

Open

4.

To

adjust

into

the

[—

Note:

•

The

Set

tighten

•

Make

when

•

Remember

the

feed

FEED

of

the

plate

needle

three

Plug 0 and

Side

Cover 0 and

the

adjusting

feed

tilt

is

Screw 0 to

Screw

sure

that

Screw 0 is

to

tilt

adjustment.

TILT

feed

dogs

should

surface

plate

Screws 0 and

feed

0.

when

surface.

loosen

tilt,

insert a screwdriver

hole

altered

adjust

the

the

shaft

turned.

by

correct

the

remove

and

turning

does

feed

be

level

they

first

Cover

Screw

0.

Screw

turn

Screw

Screw

position

not

slide

height

with

appear

Rg.46

0.8—1.0mm © (p)

0.

0.

®.

0.

and

out

after

-14-

Page 17

SETTING

POSITION

OF

SPREADER

HEIGHT:

needle

SIDEWISE

should

in

front

reaches

should

left

To

1.

Lightly

turning

forth

Screw

i—Note:

After

the

for

2.

Move

height

ADJUSTING

The

plate

surface

POSITION:

pass

the

of

the

its

left

be

at

the

needle.

adjust:

loosen

Lever

to

set

9.

making

handwheel

Spreader

9.

Spreader # up

to

9.2 — 9.7mm.

SPREADER

height

point

left

dead

point

the

the

and

of

the

spreader

should

needle.

be

9.2 — 9.7mm.

The

hooking

(A)

approximately

When

point,

the

hooking

(B)

3.5 — 4.0mm

Screws 9 and

move

Spreader ® back

sidewise

above

check

position.

adjustments,

points

or

down,

Tighten

STROKE

from

the

spreader

from

#.

(A)

and

and

Screw

the

point

0.5mm

point

the

While

and

Tighten

turn

(B)

set

its

0.5mm

1.0mm

9.2~9.7mm

Needle

top

surface

Fig.49

plate

The

stroke

1.

Remove

shift

2.

Loosen

•

To

To

SETTING

Set

the

the

eye

the

between

0.5mm.

SETTING

When

set

the

Cover

Nut © and

decrease

increse

POSITION

part

of

Guide ® when

lowest

Thread

THREAD

the

needle

the

clearance

Guide ® and

The

eye

of

forwards.

of

Spreader

arm

cover

®.

move

the

stroke,

the

stroke,

OF

SPREADER

(a)

of

Thread

position.

Guide ® and

GUIDE

bar

is

between

Thread

Thread

Guide ® to

is

16.0mm.

and

Screws

Rod ® up

move

move

Rod ® down.

Guide 0 just

the

needle

Also,

set

®,

or

down.

Rod ® up.

THREAD

GUIDE

below

bar

the

clearance

Spreader ® to

in

the

lowest

Spreader

position,

Thread

1.0mm.

Guide ® should

and

is

in

face

0.5mm

3.5~4.0mm

16.0mm

-15-

Page 18

ADJUSTING

The

standard

The

foot

presser

presser

To

1.

2.

3.

4.

foot

foot

adjust:

Turn

the

to

their

Loosen

Lower

the

In

that

Lock

Lever o and

correct

the

above

its

this

Machine

W562-01

W542-01

W562-02

W542-02

W562-03

W542-03

W562-05

W542-05

W562-06

W542-06

W562-07

W542-07

FOOT

setting

lift

is

the

and

the

is

raised.

hand

wheel

lowest

position.

Nut © and

height

(a)

condition,

head

touches

position

type

with

UFT

is

as

shown

distance

needle

and

lower

tighten

raise

Presser

for

your

Screw

adjust

Lever

Nut

Presser

2-needle

7 . 0

mm

7 . 0

mm

7 . 0

mm

7 . 0

mm

7 . 0

mm

7 . 0

mm

6 . 0

mm

7 . 0

mm

6 . 0

mm

7 . 0

mm

6 . 0

mm

7 . 0

mm

in

Table

(a)

between

plate

when

the

feed

®.

Foot O to

machine.

Screw © so

O.

©.

foot

3-needle

5 . 0

7 . 0

5 . 0

7 . 0

5 . 0

7 . 0

5 . 0

7 . 0

5 . 0

7 . 0

5 . 0

7 . 0

Table

lift

7.

the

the

dogs

7

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

ADJUSTING

To

adjust

the

needle

1.

Remove

and

move

2.

Loosen

mark © of

of

the

Tighten

SPREADER

the

timing

bar:

the

arm

Oil

Guard © to

two

Screws

the

eccentric.

Screw

of

cover.

©.

upper

©.

TIMING

Spreader

Remove

one

Position

shaft

with

against

Screws

side.

the

the

©

aligning

mark

®

-16-^

Page 19

SYNCHRONIZING

The

looper

when

The

looper

bar

begins

behind,

at

exactly

To

adjust:

1.

Remove

2.

Loosen 4 Screws

shift

•

To

needle,

•

To

needle,

-

Note:

The

when

Synchronization

the

avoiding

In

this

should

the

needle

should

to

and

then

the

the

the

position

advance

shift

retard

shift

looper

looper

the

needle

motion

case,

holder

may

adjust

rise.

same

arm

the

the

the

the

NEEDLE

be

at

bar

is

in

begin

to

The

return

level.

cover.

®,

turn

of

Upper

in

looper

position

looper

position

is

at

the

bar

is

in

between

change

is

adjusted.

as

above.

BAR

AND

LOOPER

the

right

dead

the

lowest

move

looper

front

as

the

should

of

the

position.

needles

Handwheel ® and

Belt

Gear

timing

in

timing

in

its

the

when

against

the

(+)

against

the

(—)

right

dead

lowest

needle

the

direction.

direction.

position.

bar

looper

point

needle

pass

the

the

point

and

ADJUSTING

AND

LOOPERS

To

adjust

the

mark © on

on

the

ADJUSTING

The

looper

dead

point

needles

motion

1.

Loosen

To

increase

Adjusting

decrease

—Note:

•After

synchronization

looper.

•Please

may

otherwise

is

fitted.

THE

BACK

this

timing,

Eccentric ® with

crankshaft.

LOOPER

goes

and

to

the

right.

according

Nut ® and

the

Screw ® counter-clockwise.

it,

turn ® clockwise.

the

above

If

it

has

note

that

not

be

necessary

an

extremely

TIMING

AND

loosen

AVOIDING

behind

then

Adjust

to

the

the

returns

needle

turn

looper

adjustment,

between

been

the

looper

to

BETWEEN

FORTH

MOVEMENT

Screw O and

the

needles

in

front

the

looper

size.

Adjusting

avoiding

the

changed,

be

different

motion,

check

needle

avoiding

adjusted

size

NEEDLE

align

mark

©

MOTION

to

the

left

of

the

avoiding

Screw

®.

turn

To

the

bar

and

re-adjust.

motion

unless

needle

-17-

Page 20

UNDER

The

continuous

The

feed

The

so

metering

FABRIC

under

knife

dog

knives

that

fabric

type.

movement

motion.

trim

the

together

device,

it

Lubrication

TRIMMER

trimmer

is

synchronized

excess

with

can

fabric

the

be

sewn

(Fn40)

of

the

before

lace

neatly.

W500

fed

is

with

sewing

by

a

the

the

Before

time

time,

Adjusting

Fabric

between

To

Guide O right

Adjusting

The

Adjust

to

edge

can

To

the

machine

or

after

it

oil

Crank

O.

fabric

Guide O ensures a constant

the

fabric

adjust,

loosen

or

presser

presser

be

of

then

adjust,

this

according

sewn.

the

feed

loosen

foot

For

presser

smoothly

is

operated

has

been

idle

guide

edge

and

Screw O and

left.

foot

tilt

on

the

W500-05

to

the

thick

elastic,

foot

upwards.

under

Nut © and

for

the

for a period

distance

the

right

needle.

move

Fabric

can

be

elastic

turn

tilt

the

presser

Screw

and

the

The

fabric

elastic

first

of

tilted.

front

foot.

@.

-18-

Page 21

Replacing

1.

Turn

©

new

i—

Note:

Set

Upper

edge

2.

Turn

©

to

overlap

0.5mm.

3.

Insert a piece

and

upper

the

to

the

upper

Knife © with

(a)

is

flat

the

the

lowest

of

make

knife

handwheel

highest

knife.

on

handwheel

and

position.

Upper

and

position.

the

knives

of

thread

sure

that

the

bring

Upper

Replace

Screw ® so

Knife

Holder

bring

Upper

Make

sure

is

approximately

between

knives

the

cut

sharp.

Knife

with

that

its

©.

Knife

that

knives

a

the

0.5mm

Replacing

1.

Open

remove

2.

Shift

Insert

Holder

Lower

surface.

3.

Insert a piece

and

Position

The

determines

Adjust

and

elastic/lace

To

adjust,

Adjusting

To

move

clockwise.

counter-clockwise.

lower

the

side

Lower

Upper

Lower

®.

Be

Knife

make

sure

of

lower

position

the

this

so

that

the

fabric

neatly.

loosen

Screw

Holder © to

To

Knife

is

of

trimming

knife

cover.

Knife

Loosen

©.

Holder © to

Knife © into

sure

that

the

level

with

the

of

thread

that

knife

Lower

the

is

the

knives

holder

position

excess

sewn

between

Knife

fabric

together

Screws © ©

©.

the

left,

move © to

the

Screw © and

the

right.

Lower

cutting

needle

cut

Knife

edge

the

knives

sharp.

plate

Holder

of

the

knives.

is

trimmed

with

and

turn

Screw

right,

turn

of

©

the

turn

®

©

f—Note:

Re-adjust

the

is

made.

Adjusting

Set

that

the

upper

To

adjust,

Knife

the

presser

foot

the

the

height

the

overlap

knife

loosen

Holder © up

position

height

of

is

of

when

the

of

Upper

of

the

knives

in

the

lowest

Screw © and

or

down.

Knife

above

upper

Knife

is

position.

Guide © on

adjustment

knife

holder

Holder © so

0.5mm

move

when

Fig.

63.

Upper

-19-

Page 22

METERING

The

metering

(width

The

feeding

up

to

DEVICE

40mm)

range

(MD230)

device

feeds

accurately.

is

0.9 — 3.5mm

elastic

or

per

lace

stitch.

Setting

Refer

Lace

Lubrication

The

device

keep

Lubrication

Align

(A)

Remove

Remove

is

Lubrication

lace

to

Fig.

Guide

0(0-0

clutches

come

them

full

the

mark

on

Sleeve 0 with

Cap

Screw 0 and

full

with

grease

guide

67

pre-filled

to

Screw 0 and

to

Remove

in

and

bearings

with

grease.

clutch

(A)

on

the

check

or

not.

bearings

Screw O and

sequence).

of

the

with

grease.

Crank 0 and

mark

(A)

on

insert

the

whether

fit

metering

Always

the

mark

Plate

0.

grease.

the

clutch

To

lubricate

and

insert

The

amount

the

hole

B.

Setting

Set

to

To

iace

Lace

Guide

the

needle

adjust,

the

bearings,

grease.

of

grease

guide

(Lower) 0 as

but

not

loosen

Screw 0 and

remove

can

be

(lower)

touching

Cap

Screw

checked

close

turn

through

as

possible

the

spreader.

Stopper

0

0.

0^

V.

-20-

Page 23

Setting

Set

to

positions

the

positions

the

width

or

of

elastic

of

the

elastic.

guides

elastic

guides

according

dlGuide

9

HlGuides 0 and

HlGuides ® and

on

the

presser

Set

Guide 9 so

presser

To

foot

adjust,

sidewise.

that

in

the

loosen

Screw ^ and

correct

®

Set

Guides ® and ® in

To

adjust,

move

loosen

Guides 9 and ® sidewise.

Screws ® and and

®

Set

Guides ® and

foot

elastic

position.

line

so

that

Guides 9 and ® in a straight

To

adjust,

move

Adjusting

Two

settings

device.

One

is

standard

loosen

Guides ® and ® sidewise.

elastic

are

Screws ® and and

feeding

available

and

the

rate

for

other

is

is

fed

under

move

with

Guide

elastic

runs

line.

this

metering

special.

the

Guide

into

[DStandard

On

0.9 — 2.2mm

To

Adjusting

To

in

To

in

setting

the

standard

adjust,

Screw

increase

the

(+)

decrease

the

(—)

setting,

per

stitch.

loosen

the

direction.

the

direction.

Wing

feeding

feeding

the

feeding

Nut

rate,

turn

rate,

turn

range

and

turn

Screw

Screw

is

®

®

-21-

Page 24

mSpecial

On

1.4 — 3.5mm

To

setting:

1.

Loosen

2.

Insert a key

While

Handwheel 0 clockwise

Tighten

3.

Loosen

Screw

To

(+)

To

(—)

setting

the

special

per

change

two

the

standard

Set

wrench

keeping

Screws

Wing

©.

increase

direction.

decrease

direction.

the

the

setting,

stitch.

Screws

into

Eccentric O still,

0.

Nut O and

feeding

feeding

the

feeding

setting

to

of

Eccentric

either

of

until

turn

rate,

turn 0 in

rate,

fum © in

range

the

Screws

is

special

O.

0.

turn

it

stops.

Adjusting

the

the

/I

Adjusting

The

the

To

Screw

For

For

LACE

The

If

the

through

If

the

guide

SETTING

Remove

in

sequence.

tension

pressure

tension

adjust,

0.

more

feeding,

less

feeding,

GUIDE

lace

guide

lace

many

lace

pins.

Screws 0 and

of

Elastic

on

the

elastic.

loosen

Nut 0 and

decrease

increase

(LG210)

helps

tends

to

guide

is

easy-to

LACE

GUIDE

Feed

the

to

control

flow

pins.

flow,

set

the

Roller © changes

turn

Adjusting

the

tension.

tension.

the

flow

of

lace.

irregularly,

pass

it

lace

pass

through

guide ® ~

it

less

0

-22-

Page 25

SETTING

Refer

to

W562-02

1.

Attach

Screws

2.

Attach

3.

Insert

in a correct

TAPE

Fig.

(W542-02).

Bracket 9 on

9.

77

BINDER

and

set

Bracket 9 on

Binder 9 into

height

Tape

Binder ® for

the

front

cover

Binder ® with

Bracket

with

Set

Screw

with

Screws

Binder

0

0

CHANGING

W562-01,

W542-01,

In

these

(1:0.7—1:1,3

the

special

Refer

to

the

moving

i—Note:

Be

sure

needle

i—

Note:

When

feed

ratio,

or

shorter.

THE

-02,

-02, -03, -06,

subclasses,

in

one

Fig.

78.

range

that

plate

when

using

the

the

MAXIMUM

-03, -06,

-07

-07

the

maximum

standard)

(1:0.7 — 1:2).

Loosen

of

the

feed

making

can

Screw ® and

Lever

®.

dog

this

machine

stitch

length

FEED

feed

be

changed

does

not

adjustment.

under

the

should

be

RATIO

ratio

to

widen

hit

the

special

3.2mm

-23-

Page 26

REPLACING

There

are

is

marked

the

same

mark

On

the

part A of

(1)

or

(2)

is

Each

shows

and

the

crankshaft.

The

relationship

timing

belt

TIMING

three

types

with

when

marked.

the

distance

mark

BELT

of

B, C or

replacing.

the

machine

between

is

shown

timing

D.

So,

between

this

on

Table

belt.

Each

use

the

arm,

the

the

arm

figure

8.

type

belt

figure

shaft

and

Fig.79

of

the

br-

CB>

CO . CD]

Flg.80

Rg.82

Rg.81

F^.83

-24-

Page 27

Removing

1.

Refer

O

2.

Refer

out

it

slowly.

(—

Note:

For

device,

Washer

Connection © fitted.

3.

Refer

Set

r-

Note:

Do

not

them.

Loosen

positioning

4.

Refer

RELATIONSHIP

MACHINE

BELT

The

machine

timing

to

Fig.

79

and

and

Oil

Reservoir

to

Fig.80.

Loosen

Handwheel o to

the

machine

refer

©.

to

Fig.

Plate

remove

Screw © until

to

Fig.

ARM

mark

1

2

equipped

to

Fig.

Draw

82.

Remove

©,

Bearing © in

Screws

hole

in

83

and

BETWEEN

AND

on

the

arm

belt

remove

Arm

0.

four

Screws©,

the

right

with

81.

Remove

out

Handwheel O with

Cover

sequence

©©©©

it

is

the

crankshaft.

remove

THE

THE

MARK

The

timing

Timing

MARK

ON

mark

B

C

Top

Cover

while

turning

the

metering

Nut © and

®,

Pulley

of

©~(

but

loosen

out

of

Belt

ON

THE

TIMING

Table

on

the

belt

or

C

or

D

draw

(

the

©.

THE

8

Replacing

1.

Refer

Bearing

in

the

—Note:

•

When

©

crankshaft.

•

Re-tighten

©

2.

Turn

right

lowest

3.

Keeping

mark

mark © of

timing

to

Figs.

82,

©,

Set

reverse

fixing

set

in

the

way

Bearing

Screws ® and © after

is

tightened.

Pulley © and

dead

point.

position

<B

the

of

Belt

by

above

Bearing

belt

83.

Replace

Plate

®,

of

removing.

©,

positioning

bring

Move

hand.

conditions,

Gear

©.

Screws © tentatively.

Timing

Handwheel

in

—Note:

•

In

metering

and

Be

•

If

of

order.

Belt © on

O,

position.

the

case

Tighten

of

the

device,

Connection

sure

to

keep

they

are

not

the

needle

then

Timing

four

machine

replace

©.

the

marks © and © aligned.

aligned,

bar

and

Timing

Pulley

be

sure

©,

to

hole

Belt

Cover

Screw

of

the

Screw

the

the

looper

needle

to

bar

to

align

(Upper) © with

Tighten

Place

Gear © and

the

one

edge

turn

Belt © will

Screws

Nut

the

the

©.

equipped

synchronization

looper

©,

Washer

with

is

out

©,

©

the

the

the

the

of

of

be

the

©,

of

4.

Turn

looper

right

rise

5.

Make

faces

in

6.

Refer

and

Handwheel O and

starts

dead

from

sure

to

its

highest

to

Oil

to

point

its

lowest

that

the

the

mark ® when

position.

Fig.

79.

Reservoir

make

move

to

as

the

needle

position.

mark © on

Replace

©

Arm

sure

the

left

bar

Handwheel

the

needle

Top

that

the

from

its

starts

to

©

bar

Cover

O

is

-25-

Loading...

Loading...