Page 1

Cat.

No.

9644

January,

1993

W500

Series

Technical

Manual

A

^PEGASUS

Page 2

"r-ZJMim

=

=$/:yo(sllEl5

HRg®/\(7)i^;S

n-(7)axyg^

M^^iU^OtHUAn

^ryVBya^MW^

e5U^JSU(7)l®li5

ti-5i!5gV(7)pl0

}¥xEtK7)Pli5

J2S^S(7)TO

^iilt^PSS

iftii\/-j\-(D^r:)mMz

;i/-/\-0^ot?t)\;c

)^U®<7)^S<^iig0

iMu®«±ysfiTy<7)pg5

lf5U^§lF*3(7)IRyf^(tfil®

g5u^§g|79^ii(7)Ky{^(:r

;

;

1

2

2

3

3

3

4

5

5

5

5

5

6

7

7

7

8

8

8

9

9

9

10

10

10

n

11

12

13

13

13

u

i4

14

u

ffxjiyat^TO

^ycf

FT140(><;^g®)lCOlir

FT140(X;^^®)/\(7)ijig;S

FT140( X yMM)

?P3Sl^opei5

FTl4O(X;^g®)f¥l0tf|±tja(7)ilg0

±XX(7)5S^

TX::^^£SfiI®(7)lSI0

±x;^^(7)ffiy{^(t;iS(DiiS0

MD230(=rAil^U^®)lCOlir

MD230(IfZx)llUg®)L/-::^3gF*3(7)ffiy{^(t

MD230{

MD230(

dfZxiHUg®)

ZTAj^Ug®)

MD230(irZx)^U^®)$flS^^O]iig;ffi

MD230(

MD230{

MD230(

MD230(

/W

zF

dfAiHUg®)

ifZxiiug®)

zTAii^ug®)

H

(LG210)

:JA3g|^OlXyf^(t{5l®(^!lli5

zfAinyttiUSoiiss

^yys

icotir

(7)B8y^(tt)i/c

(T)

yomm

oaxy

S>^^yC^^I\y[-(D^tSk

h(Dt)\mtt

^y^tf-vizoi\z

W562-21

HMSiUS

15

15

le

la

16

17

17

17

17

18

18*^

18

i8

19

19

19

19

19

19

20

20

21

21

21

22

22

23

24

^

24

25

25

Page 3

Pattern

paper

Cutting

the

Rest

Motor

Belt

The

Machine

Lubrication

Replacing

Silicone

table

board

for

pulley

guard

and

turning

speed

oil

oil

for

^''^Needles

Replacing

In

Threading

Regulating

Adjusting

Spreader

Adjusting

Needle

Needle

Adjusting

Setting

Setting

Presser

Stitch

Diff.

Adjusting

^^•^Needle

Looper

Adjusting

Adjusting

Adjusting

Setting

Adjusting

Setting

Setting

and

feed

out

length

needles

of

thread

needle

thread

needle

thread

guard

looper

looper

thread

foot

ratio

needle

height

setting

needle

feed

feed

position

spreader

position

thread

for

semi - submerged

and

assembling

semi-

submerged

and V belt

belting

direction

filter

H.R.

device

thread

takeup

tension

thread

takeup

thread

guide

(front)

thread

thread

of

machine

takeup

adjustments

guard

adjustments

adjustments

takeup

guard

guides © and

pressure

adjustment

adjustment

and

looper

setting

guard

height

tilt

of

spreader

stroke

of

spreader

guide

installation

the

machine

installation

bracket

(2)

thread

guide

27

28

28

29

29

29

30

31

31

31

31

31

32

33

33

33

34

34

34

35

35

35

36

36

36

37

37

38

39

39

39

40

40

40

40

Adjusting

Adjusting

Adjusting

Adjusting

looper's

Adjusting

Under

foot

lift

spreader

left-to-right

the

back

looper

fabric

timing

timing

timing

between

and

forth

avoiding

trimmer

(FT140)

movement

Lubrication(fn'140)

Adjusting

Adjusting

Replacing

Replacing

Position

Adjusting

Metering

Setting

Lubrication

Lubrication

LIbrication

Setting

Setting

Adjusting

Adjusting

Lace

Setting

Setting

Changing

Replacing

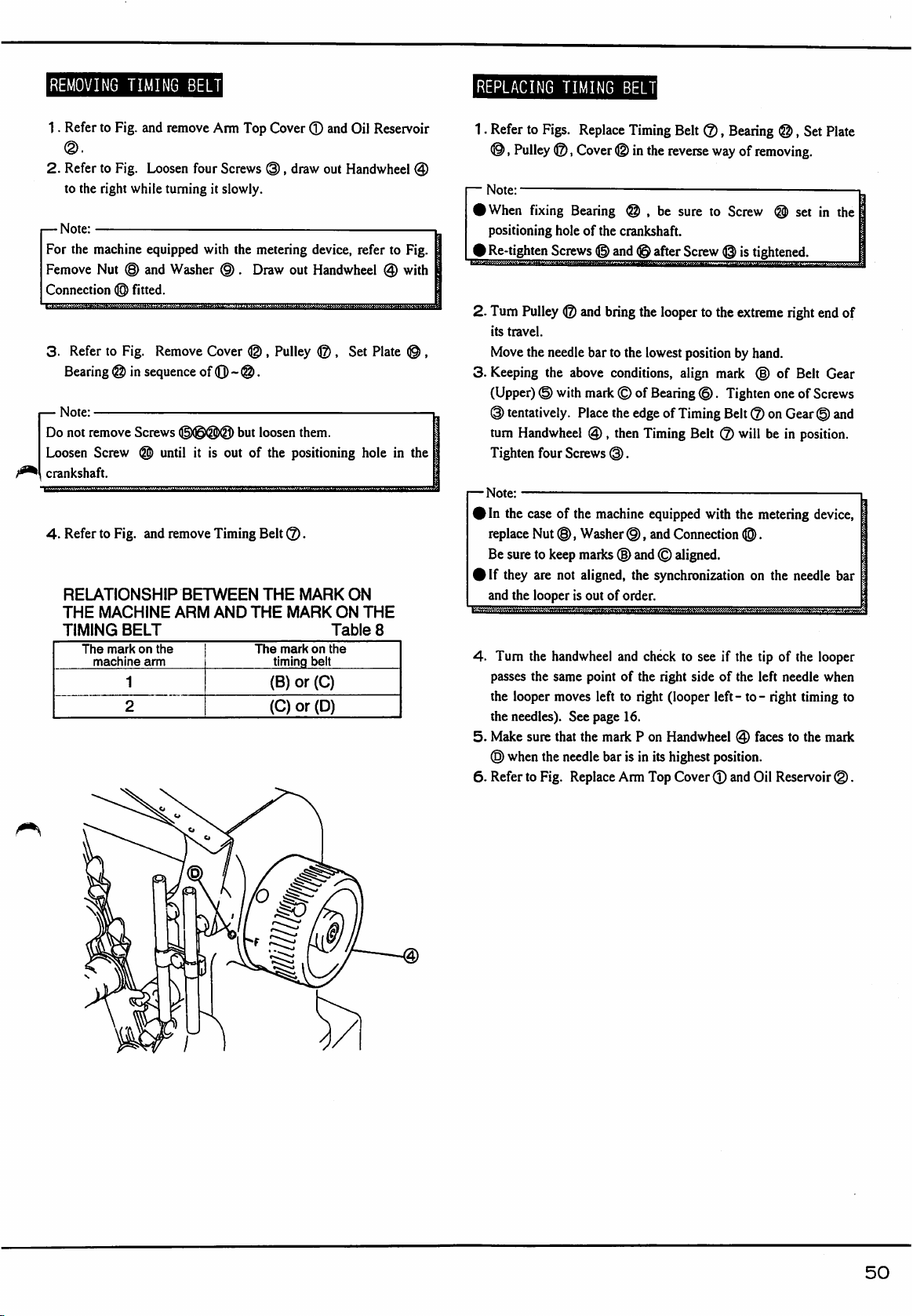

Removing

Replacing

Timing

Standard

fabric

presser

upper

lower

of

lower

the

height

device

lace

guide

(MD230)

to

clutch

to

bearings

lace

guide

positions

elastic

pressure

guide

(LG210)

lace

guide

tape

binder

the

maximum

timing

timing

timing

cauge

adjustments

guide

(FTMO)

foot

tilt

(f=Tl40)

knife

knife

knife

holder

of

upper

(MD230)

(MD230)

(MD230)

(MD230)

(lower)

of

elastic

feeding

rate

(MD230)

feed

belt

belt

belt

for

(MD230)

of

the

looper

needle

motion

knife

guides

(MD230)

(MD230)

ratio

W562-21

to

and

holder

the

needle

41

41

42

42

42

43

43

43

43

44

44

44

44

45

45

45

45

45

45

46

46

47

47

47

48

48

49

50

50

51

51

Page 4

®§B®igi0cfc5icji2jDiur</c5Uo

•®:A:(a^iCPLgsasy^Ji-jffl7^-c-rc

©as®

so

cfcDiciisoiur < ;cst\o

4-013

x"v

019.5-

■75

O

»

4-025.5

357

312-

-203

—50

—

-102-

^72

n

"T

1

lA

^

CM

■33<

/

—66

€

ill

i

23

32

1—48-H

69-

-247-

284-

316-

362-

Page 5

v—^iioymnt..

1.

2.

m%^z.

</c5U

5'-3^';^S^)DIUr<;c^t^o

(S)~®o)(iicsgi^^sffiyf^(tr</cSUo

lif^^oiiiEiaTiBog^-ceor<

;cso^o

1.

Ho

Z

^;uh(a.

3.

=F-s-y-u-[t.

U-®)g^^33fi!t^

2M550W^il::75':/5'^-5'-Sa3mi<;cS

Ml!V^Uhg33<iH</^SHo

mt)\s^vy(DMmL{Z'^':>m^mo)y-

</cSHo

O W >/U-:3:

O

Wim

O

WiMt)^A7mmWrF(D^-:y)\y(Di^^[t.

/cSl\o

^

w500=^'j-a(7)jgM(a.

UT

50mm

^-To

^uiiircCtrOT^r.

ci§).

V(C(a> ^ SOmm

as

[259001]

fS^mt^WV^o

gc:ax0±,

(D'T-yil'%

z:$\m<

=E-S-y-U-<D^

(s.p.m)

6,000

<

5,500

5,000

4,500

4,000

60H2

120

110

100

90

80

(mm)

50Hz

145

135

125

110

100

C2)

r

©-©

Page 6

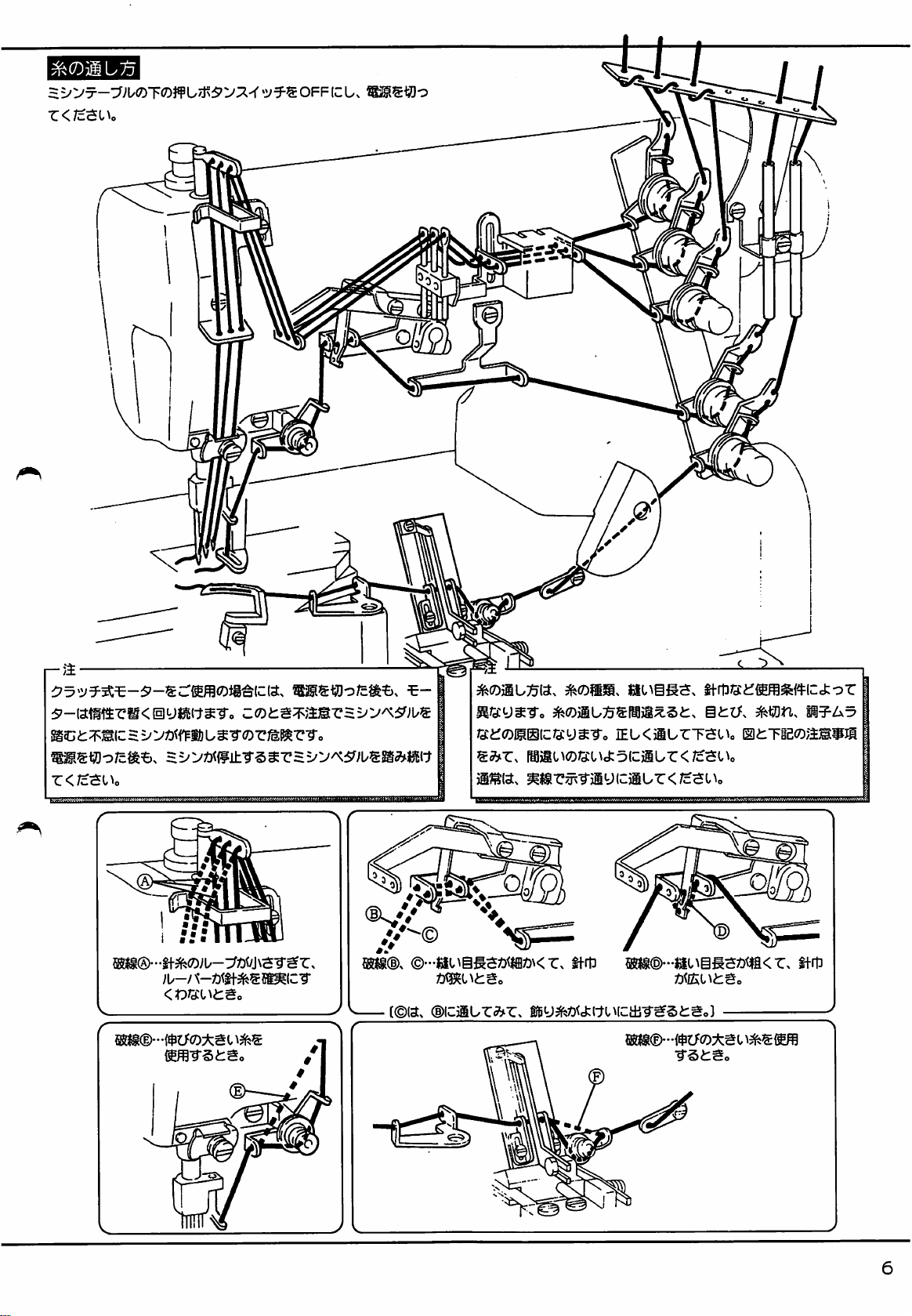

1.

sixyf^(-jr<;cSi^o

2.

ctoic.

t-5?-o^ssiSg0ur<;c3Uo

vyo&ixij^

urx

3Kj2cm

^;uhtiyt-®

<r6u^yL/SZ)i;coc

ai'vroiiesraia,

=^V®0giS!

a2(c.

33MI

r-a

mK/cSl^o

JBs:slJ®mlIi£ago1^rl^^■ro

\±i-f

I\tziz{,\m^

^oJB^(c^o/cI^llEl&r33m^<;cst^o

i^-u-fliovsar,

tl-OT^X

^1

^^6ii^/d:^-5'-3^-u-SJg^^33

siayrT.

at^ggsrcCiTfi!

?f^s:sy^S0iEa

m

W562 - 01

W542 - 01

W562 - 02

W542 - 02

W562-03

W542 - 03

W562 - 05

W542 - 05

W562 - 06

W542 - 06

W562-07

W542 - 07

(s»)

n-

2M\-

o o

o

o

o

o

o

o

o

o

o

o o

o

3M\-

o

o

o

o

o

o

o

o

o

o

(s.p.m)

6,000

6,500

6,000

6,000

6,500

6,000

6,000

6,500

6,000

5,500

5,500

6,000

6,500

6,000

5,000

5,000

a)MDSiS(ifZso2y«S)^j5->via,

a)ifaicj:o-c.

iHiea0ffi®sjB3a)^39ysTc

aais.oooserTo

c:a3B</csUo

Page 7

1.

2.|gjffl0U^

l\n■c<;cSl^o

a

f&mm

7^^)lCt-V®(D2:$:(0t§i

;UNalOS33®l^</cSl^o

zi^^)\y':f-v®(r>±(r>u

CH) L (L)

(3.

;fflfi(^±iJgi:TPg

(h)

lE^'XiliSJffiS-rS/cfi^XCia.

5d:olc?iiSSUr<;c$0^o

4.

i:g(a.

5.

€90!)ISiS

'Dimnsbz<rz^i\o

gft$@ic2~3/i#iiU/:ijfisur</cat^o

r-a

;W:^^;US(§K\oagtl3S/d:c^i:g(ax

m)

6.

^ur<;c$Uo

IL/;<yhOiis^^SLr<;cat^o

i-a

^IC.

(H) t (L)

8ii

(7)Pi(C;i®Z)K

gic35mLr<;c5Uo

7.Sfa©U75

;U/OaM

axb^vhO/iStttSSSi

XL/^^'

^o

h©Z)<U5Q:imSo/ci:gia.

6^j^c:i:ic^hLr;iS^ur<;c5Uo

r-a

Bu.

^S(^aa^^{s;cnrt\§0(c:.

^<'?«j§®-rst)v

y©® ^ U r </cSt

iE^G:i!iS)ffiZ)<rg^ia

:i--r;u®@^oasits-^;Sfi

i^uuxu^:yh^::2:smur<;cSt^o

Page 8

t

fi

m

H

0.'

r

y

rr

T

Xt

?

n

0

T

®

m

r

d

A

3

fit®fU

n

r

d

fit

nt

jmi

<-

d

08

0

<-

A

o

rx

<~

rr

08

d

9+

H

r

y.

ami

3

Vi'

H

is

w

i

D

3

1

i

3-H3

m

vj

V

v:'

nt

@

u

d<—0J

r

s

iji

3

IS

fit

?l§i

^

w

aii

I

v:'

v:

ill

d

A

u

fit

fU HIc

»

W

[T

'

V/

Vd

@

M

i

w

Ci

w/

c

(W

«

SJ

A

v3

Ht

t

u

V.'

EB-

fi

d

®

^

I"'

m

o-'

d

«

A

JflF

(V

8

}1

??5

t

fi

0

;5

M

Vi'

¥

fi

s

y.

v3

vr

4

v:

✓

rj

9t0d

-<

c

-<

c

4

ulo

N)

CO

lO

00

3

CD

(7)

H

M

A

4

8

>

(/)

CO

>

«}

0

VC

i

H+

v4

[A

1

A

CO

m

OF

^

n

01

gt

,

■HE

d

vc4

t

Tl

Tl

O

ri

fi

c

Ft

a

■)>t

rS

t

fi

s

0

w

e>J

c

d

c

rr

w

m

A

S

3

v::;

a

d

^ji

;□}

A

d

n»

rit

A

t

fi

m

rit

gg

C

c

m

o

5

s

^

t

H

^Ot

fi

v_

III

ri

3

m

°

I

t

U1

Vll

i=F

n

-H

c-

01^

t

fi

d

08

B

^1

3

0

I

«3j

9tf

m

fi

r

rr

«4

>

v:

08

o

CH

s

w

rc

&i

T.

CX

VJI

fv

m

A

08

m

or

&i

9+

s

t

I

fi

>}

t

1

fi

d

r

vr

U

cr

0!

>

ri

stn

3

nt

rn

A

t

®

fi

g

&/

>}

ri

HO

m

m

n

c

Vr

u

or

01

6^

fi

r

7"

nt

A

d

01

nt

ri

?-

/\

||

n

»

ra

48

<r~

m

0

()

Page 9

i

m

aa

I

v:r

vd

sg

d

l+f

VJI

1

et

IS

A

MA

vr

9+

i\

fS?t

fit

sSt

c~

P\.

F$

|D|

0

O

r+1

d

n

fit

1

m

III

Vd

A

V.'

d+

m

nft

d

i

•>^

v4

d

III

t

m

H+

fit

fi

0

VI'

III

d

o

(^t

C«

m

1

rH

*

t

fi

m

a

a

9?

:iia

rc

t

fi

gi

m

gi

c

a

d

w

c

9tt

9L4-

ri

£»

a

*

g4

a

5Hf

«

e

9?

a

vot

d

$11

bt

Mlfl

gs

c

vc4

gM

at

t

bt

fi

W

0

c

ri

01

n

vC

g4

m

<-

an

Ml

Or

cyj

£5

A

d

c

A

m

d

c

fit

A

d

c

*

"H

fit

m

QQ

01

m

9?

B

(\

c;i

fV

m

o

O

o

0

t

1

fi

H]

c

III

'

fl

<-1-

m

V

a

n

4

m

r

w

ri

m

Q>

o

fl

a

(V

«4

d

s

9tt

Ft

oj

I

nftis£u

rrs

cr»

Page 10

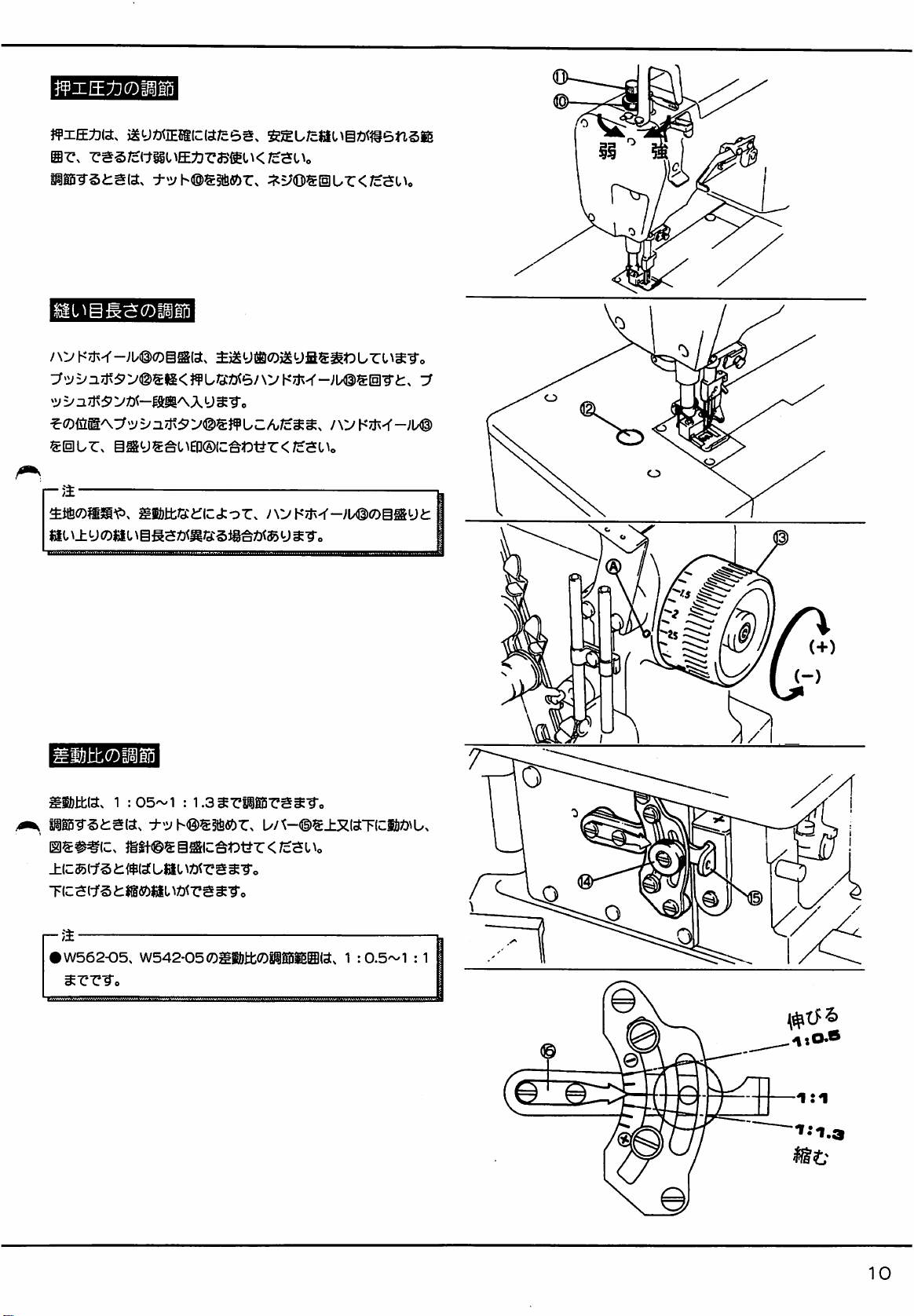

3

VCDlilD

zim\^z<iz^{.\o

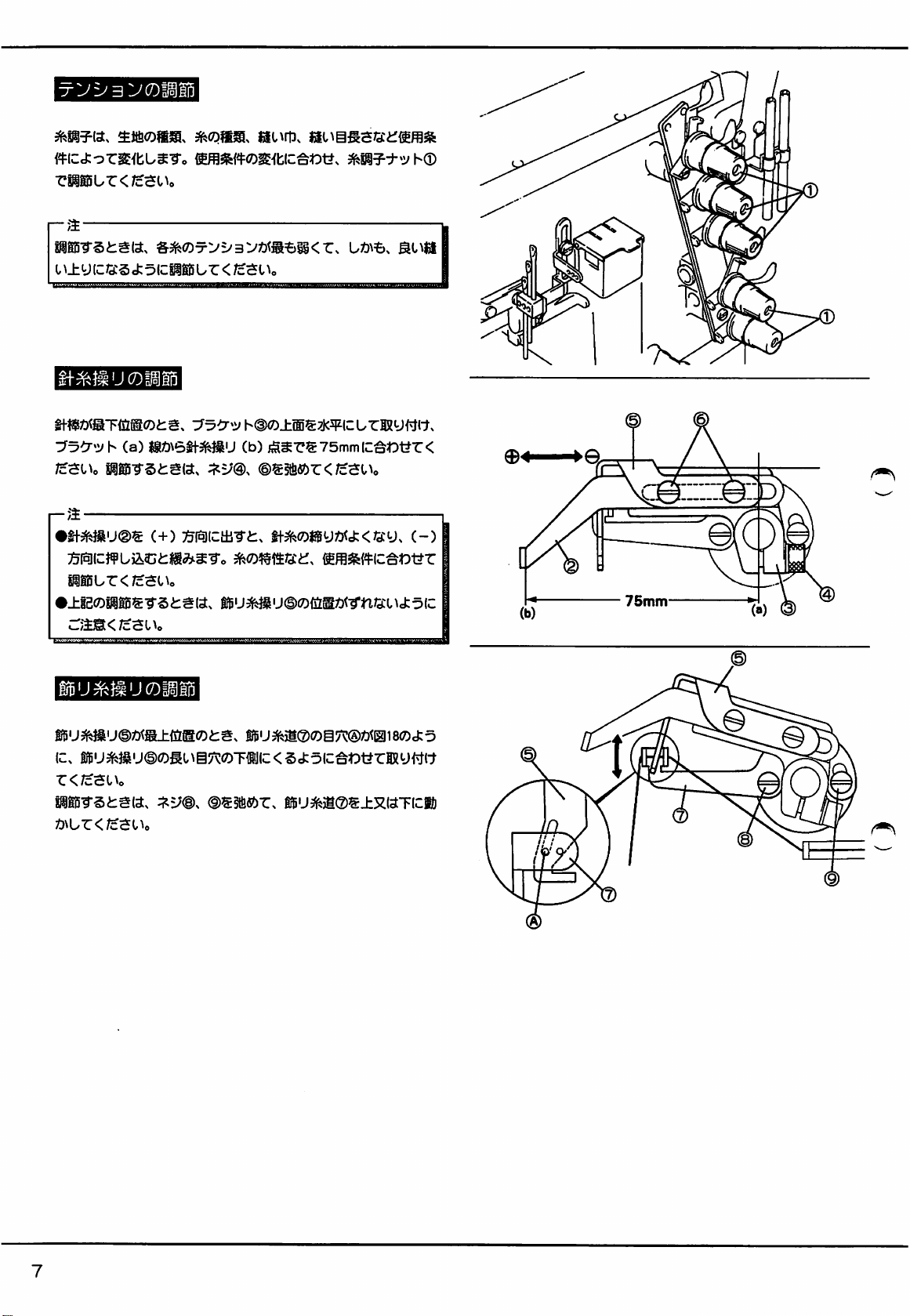

r-'^

IS8i5-r3i:g«.

I

^± y IC/3:5

=&^(^5rV=^3V»t®=6^<r^

ct

5ICP® U "C

§f^^ucoiii5

y3Cr^u h (a)

/cSUo

r_;j

•ff3fe}su@®

:?5(^(c:}¥ua,ct]ige^s-ro

pieur</cao>o

•±igoisii5g-rstgia.

am<jz^i\o

«gO\6tl-^U

:f^m

(+)

:^(^lcai•r^:^

ifBu^^u(i)0{jigZ}<-rn/3:ud:^(c

L»\=&.

</cSt

^o

h@(7)±®®7j<5p(curffiy(^t-^.

(b)

jjSSrS

©®§fi«)r<;cSt>o

ti-M550«Byz)<cfc</3:y.

75mm

IC^*Dt?r

6!fflifewc^t)i7r

<

c-)

75mm

iU5fe}iuroisi5

®BU^U©/)^®±ia@Oi:g,

ic.

iifiu^}iiu©<Dgug7toT«ijic<5ctoc^TOraRyi^ft

r<;cSl^o

Siii5T§tg«.

Z)\ur</c^o^o

lrBU^)i®(7)g7^®Z)<iai80ci:5

g$u^)i®®±xiaTic®

Page 11

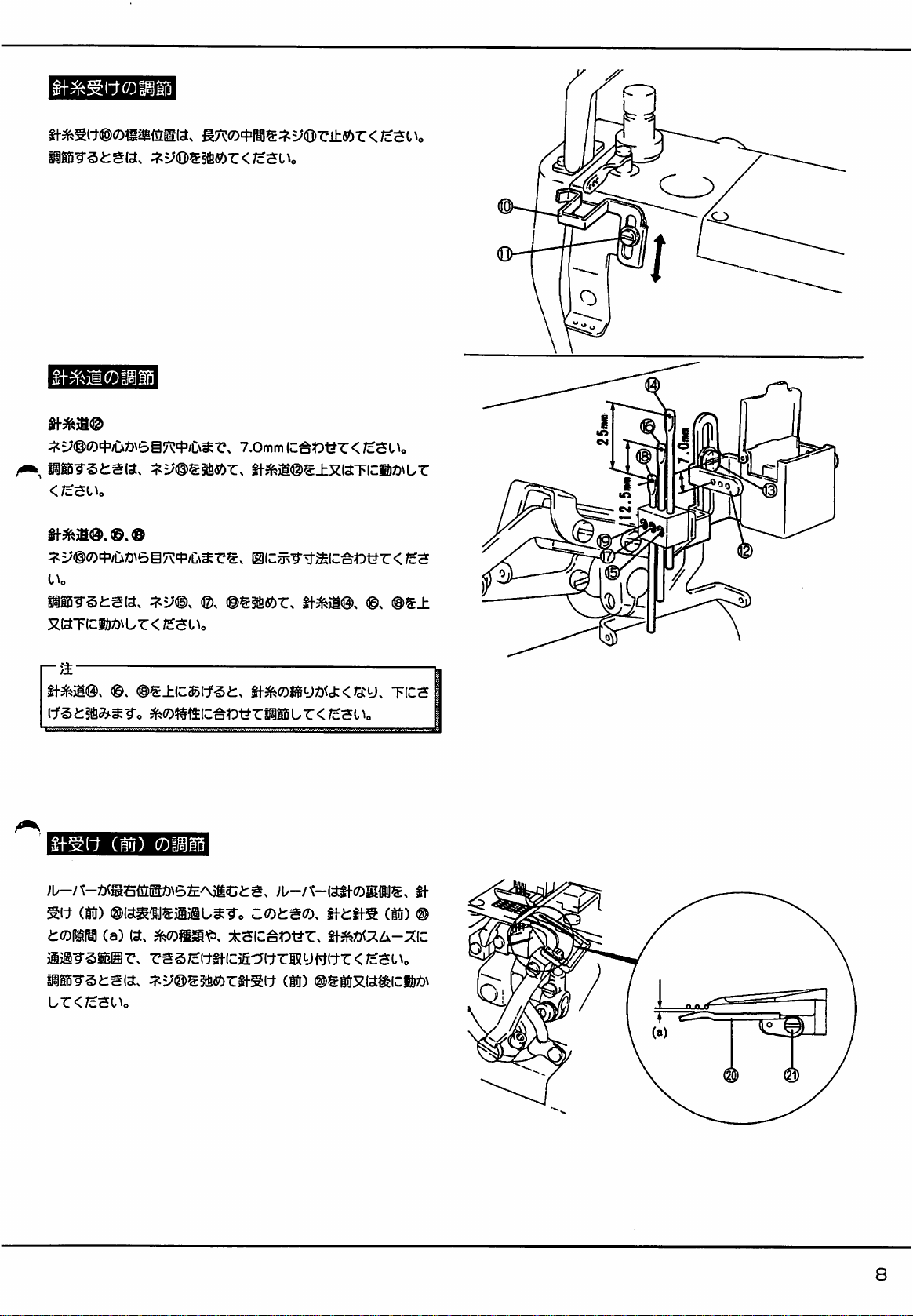

PI5"9"Si:g(a.

:^V(Q>^^6bZ<1z^l^o

1

:^V®(D^iOit)\e>m7^^ii:\^Z.

k

liSB'TStgia.

C^o

!i@0^si:sia.

R[AT{zm\LZ<1c^{,\o

r-m

(fSi:5fi5^*-^-ro

ff^lt

^v®.

©.

®5±ic^(-j'5i:.

^(D!ffttic^t)t?riig0L.r</cSUo

®.

®ssfi(»r.

(tu)

7.0mm(C^tDl?r<;c3l^o

tf^ji®S±XISTICii)Z)M^r

©.

®s±

tics

S(7

(Id)

®iasijsiij@iu^-ro

i;(7)li®

iiji-^sii50r>

MTStSISs

L/r<;cSc\o

(a)

it.

:!fcS(c^*Dt?r,

•css/cl7^^■(cifi-::^(:^rIxy^^(7r<;cSl^o

Ty®S§ftfi^rti-S(t

i^m'i^^-Xlz

(Id)

®=£ld3^«^(Ci!}X)\

(id)

®

(i)

8

Page 12

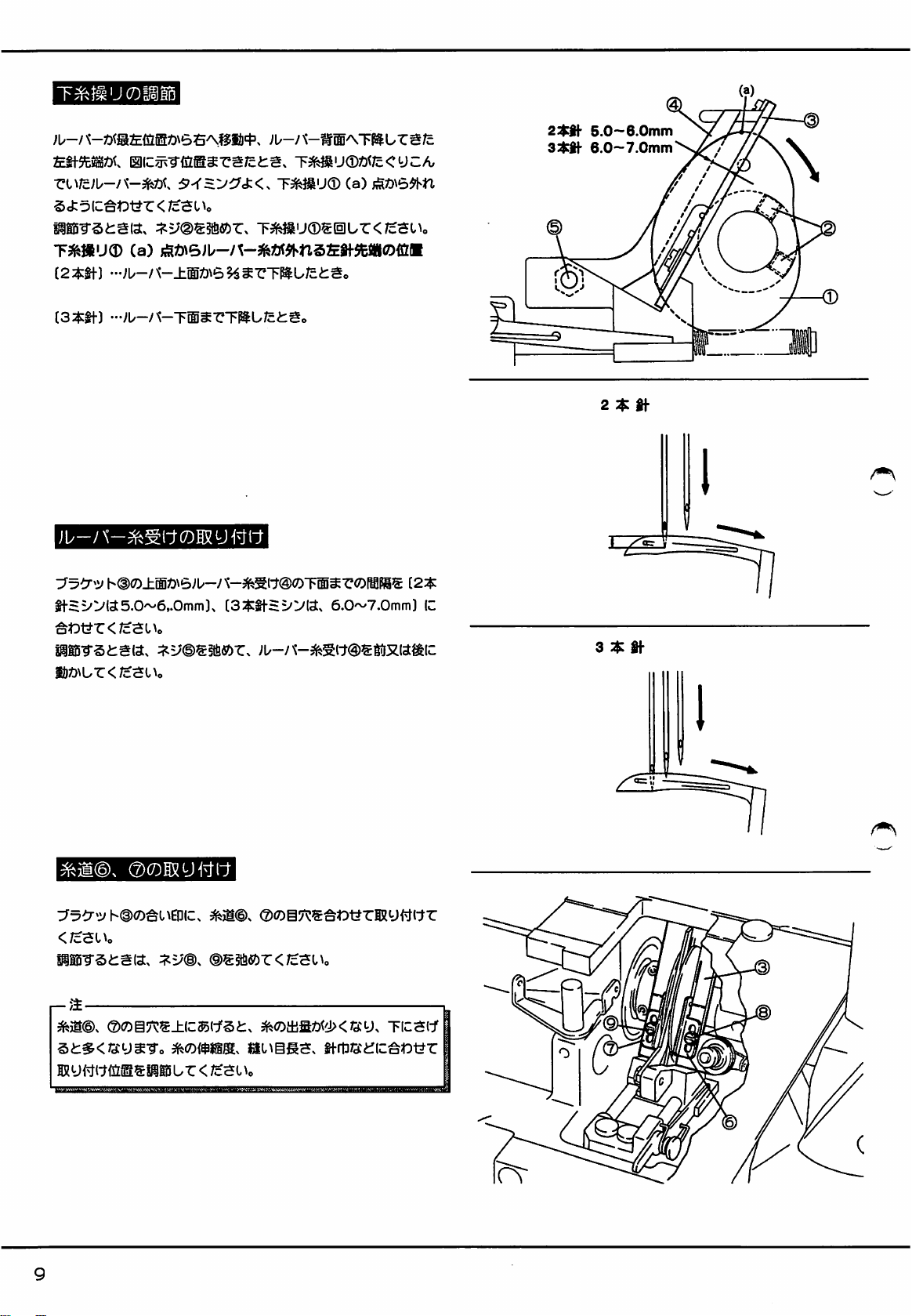

;u-/

rU/c;i/-/X-3l^<.

SJ:5(C^tDyr<;cSL\o

:;^y<Dg»r^

T^»U®

(2:$:tf)

(a)

iS;t)>6JU-/\-Jfe«^nS£Sf$tMOfflll

•••;i/-/^-±®;t)\6%^rTKUmtSo

ii-j

T^u®Z)<;c<ryc^

T3i5i^U®Ca)

TM!5^u®siiur</c$Uo

s/c

2:<^f

3:$:if

6.0—7.0mm

5.0—G.Omnn

\

(3:$:gt-)

^l-5>'Via5.0~6,.0mm),

^t)1?r</cSUo

^K)Z}^ur<;cSl^o

•"yU-/\-T®S"CTISIU;ci:So

h(i)<7)±®t)\6yU-/X-^g(t@OT®^'CO®RiS

[2:$:

6.0~7.0mm)

2*«f

(C

3 * if

hoo^uaic,

<;c3l^o

pg0TSi:S«.

r-fi.

s^^<?3:y^To

3feii©.

®!g§fi«)r</cSUo

ur

</c^Uo

®(Dg7^g^tDt?rBRy<^ttr

Page 13

H

w

m

d

VQ|

nit

exdfx

d

^-

s

c

fit

ex

a

nit

w

*

n

m

m

H-

v2

T

©

t

{Li

fit

IT'

ra

c~

d

at

t

fi

3

d

r

fit

fiO

fU

v:i

<r^

m

0

t

fi

©

d

c

IT'

m

d

:s

ex

s

IS

fit

C"

m

0

/\

>&

fit

A

U

vf

r\i

t

fi

n

tft

m

v£

3

d

t

fi

-7:

Vi'

P

EF

r

S

Hr

III

$f

P

@3

d

A

9i:

Vd

>

''

tt

Vd

m

1

QU

1

Q

t

fi

1

P

t

fi

m

)t^

QD

m

Q>

PF

m

n

i@

Kf

*

c

$?

/\

%

>

91t

c

t

Vd

v:

fi

©

<r^

ri

s

©

n

9t

fx

^

ex

P,

B

S

«4

a

D>

IS

3

c

©

c

m

en

\L

IT'

0

fi

r

CJ

ct

d

:::

'

3

□>

St

I

T.

A

fit

m

54t

rlt

fU

/\

vr

-K

$f

A

54t

c

"

^

tJ

c

d

9tt

«4

i^t

fx

*£4

A

QD

U

Or

m

c

m

V

9f

-7:

a

©

V.'

©

Vl'

U

V;

c

fg

m

m

i+f

$

9tt

(Jk

_j

rS

U1

o

(P

(D

Page 14

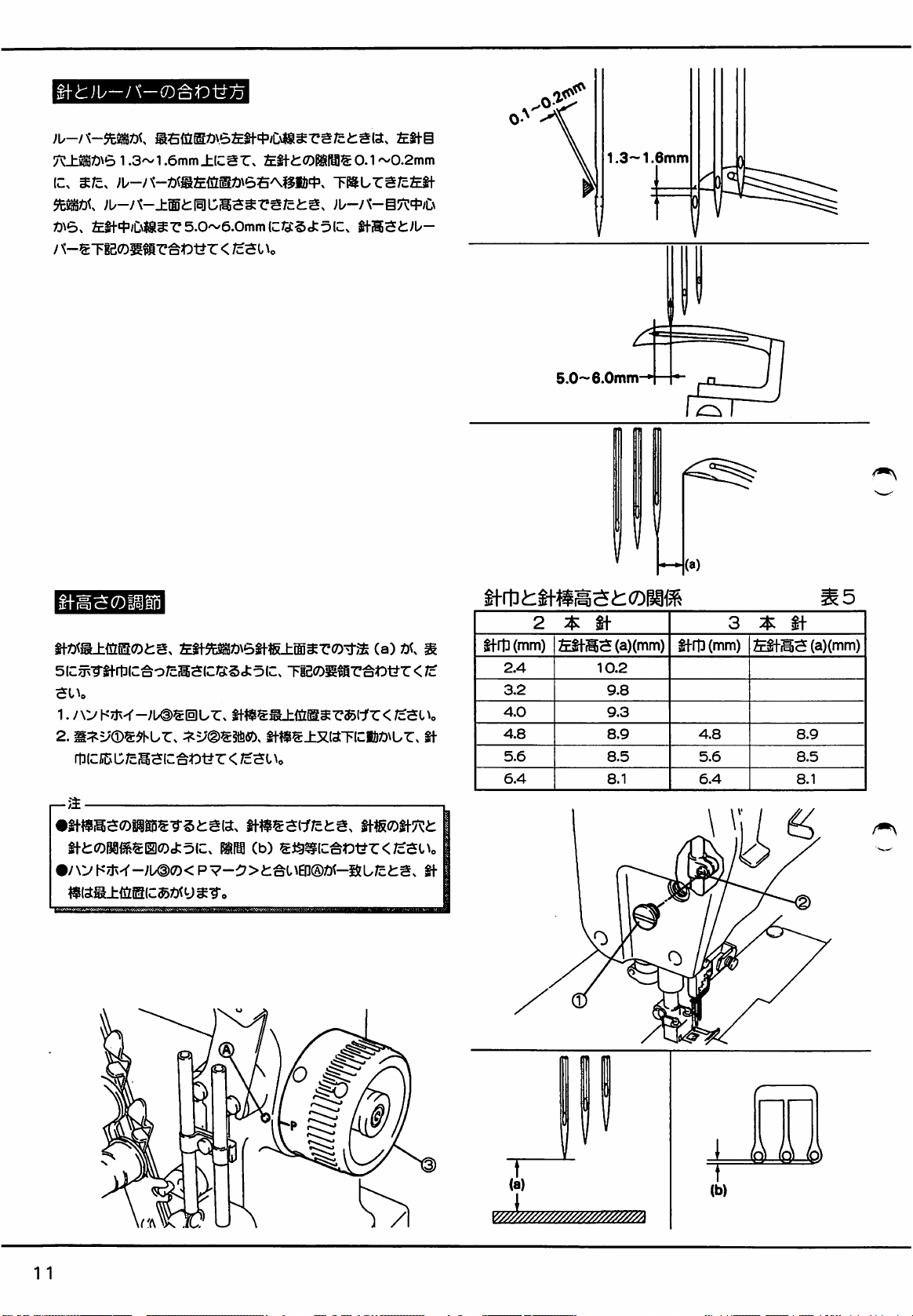

7X±^»>6

ic.

mics

ssfizE»\6iE§f=|3/C\i®^rs/c^s«,

1.3~1.6mm±icsr.

~0.2mm

T^urs;c£Sf

1.3~

1.6mm

io\e>. fc^4'/C\|g^r5.o~6.0mmic/3:§«j:5ic;.

/

r <

/cao

\o

lf-SSi:yi/-

§fraS®iSi5

OC

5iz^Tiirtiiz^otcm^iofs^J:o(z.

^l^c.

1. / \y

K^v'f-^uosiiiur.

2.

rt]

(CIS

L:

/ciiSIC^tJ-HT < est

r-;i

^fttSiaoPSDSTS^gia.

ftt:Og||0^SI2l(^«i:5(c;. M (b)

>/\yl<An-i'-;i/(i)0<PV-^>i:^t^0]®/)^-i5iU;ci:S.

TieoMfir^ot^r<

ftt$®±x«Tic»ur.

fH^eSCf/cfcS.

SJ9^1C^r31?r<;c5Uo

JsC

<

/c3t\o

ft^^ftTv:^:

fc

ft

ft

5.0-6.0mm

rsr

(a)

ft®

£ft®$

5litf£

ft®

(mm)

(a)(mm)

(mm)

(a)(mm)

2.4

10.2

3.2

9.8

4.0

9.3

4.8

4.8

8.9

8.9

5.6

8.5

5.6

5.8

6.4

4.6

8.1

8.1

r

wMM'//////////mmz{

1 1

i o

1

(b)

O-gj)

Page 15

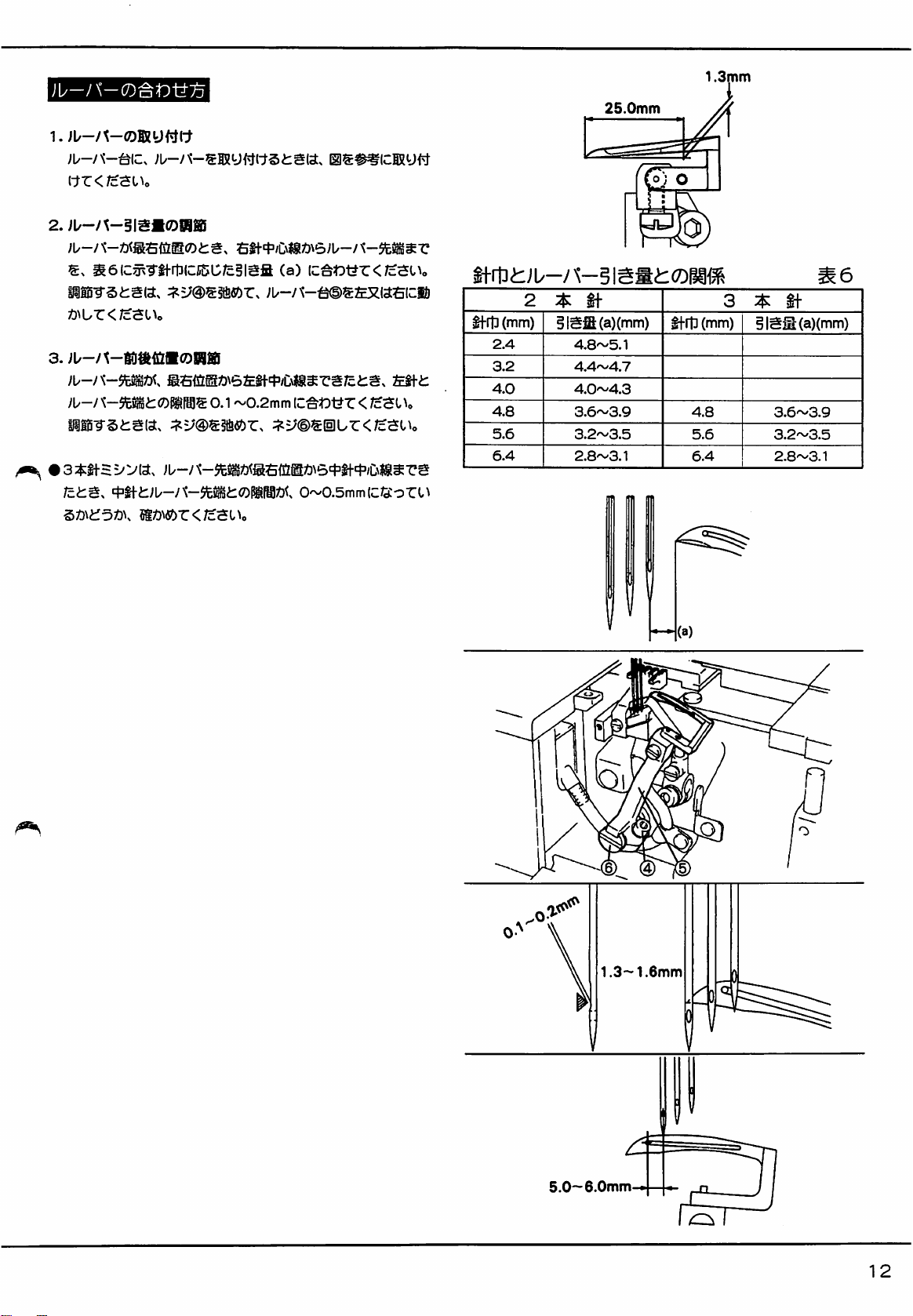

(tr<;csi^o

2.

JU-/X-§IS«09ia

1.3mm

25.0mm

aeiCg^TlfrtDlccSC/cSISfi

na-rs^ss.

^M^r</cSi^o

;u-/

TO

^5i:s«.

/ci:g,

^ntL'DtiK

^5;@g§fi«)r.

0.1

(a)

;u-/^-^s£x«sci&

~0.2mm

IC^WC

:;^=;®®(iur<;cSUo

0~0.5mmlc/S:-oru

<

/cSO

tf

rtD

(mm)

2.4

a2

4.0

4.8

5.6

6.4

2 :$:

§ISS(a)(mm)

4.8~5.1

4,4~4.7

4.0~4.3

3.6~3.9

3.2~3.5

2.8~3.1

If

^rt]

(mm)

4.8

5.6

6.4

(a)

BISM(a)(mm)

3.6~3.9

3.2~3.5

2.8~3.1

1.3—1.6mm

CO

5.0—6.0mm

12

Page 16

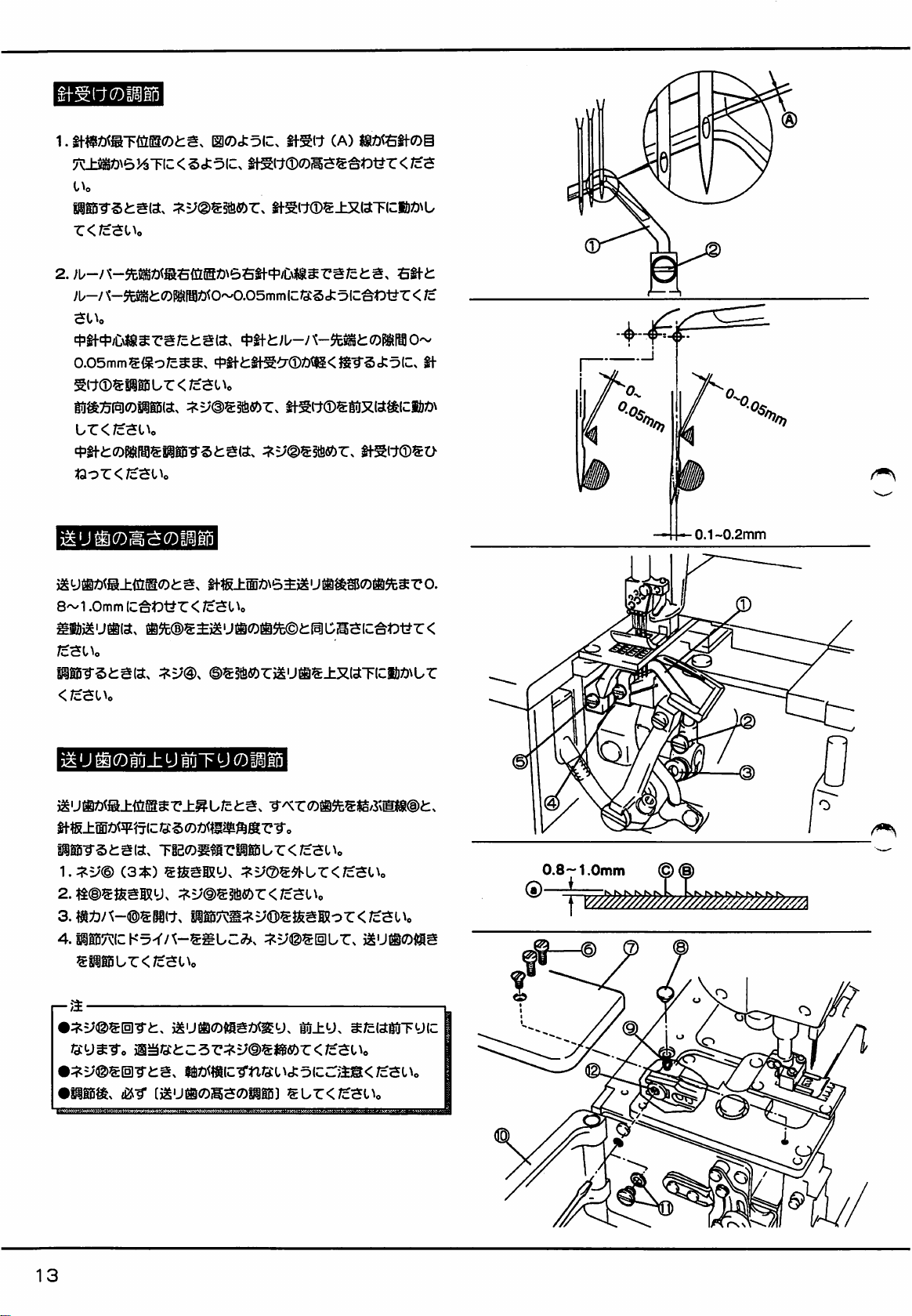

tfgc?

(a)

RJ:^0N6HTIc:<Sci:5(C.

IV

issi5-rsiis«.

r</c3iv

yi/-/

K-$t^i:(7)MZ)<0~0.05mmlc:?cC5cfco(C^t)yr < /c

stv

=1=^c»3/C\i®^rs/ci;gia.

:;^5;(Dgst6«)r.

thStt®s±x«Tic:i&^^u

O-OSmmgiSo/cSS.

S(t®Spgi5Ur</c3Uo

ur<;c5iv

ig/)<agi-o@

tf

taor</c$tv

jMUffi®liS®iSli5

8~1,0mm

/cSlV

<;c5iv

jn u ffi

3^u®Z)<s±{a®sr±#U/ci:g.

isai-rsfcsia.

2.

:^(DgJSSffiy.

3.

4.!ii07^{ch'5'i'/\-smuctf^*.

(C^t)t?r < /cStV

0Su± y fuT y ©HIS

Tie(7)^Tirs®S5ur</c3Uo

(3^:)

:r^y@®3fifiOr<;c5Uo

®mu"c<;cscv

©s»T:j^uffis±xaTic®Z)\ur

:;^=;®g^ur<;c5Uo

TO

5tM:;^y(D®^gBSor</cStV

:;^=;©giiur,

0.8—1.0mm

®—'-

T

/'^

0.1~0.2mm

©d)

^55

•:;^y®gi5i-ri:,

^cy^To

iiS^J3:i:c5r:i^y®€^g<;or<;c3iv

i^-r

()isufflo®soiig0]

iu±y.

®ur<;cstv

^/siagtiTyic

13

Page 17

1.

8.3~8.7mm

wrstsia.

(ciS75\ur<;cSL\©

"C?"©

7.3^U'i'5?-®s_h52aT

Elc^ctoC,

MlCjib/ci^Sia,

sJ;oic^wr<;cSu©

SilEiTStaia,

6.

1.±g2c?DMI0S-?Si:gias

£2+t(7)M^^0.5mm£7)^5®^iiiSLr,

S$ft^'/i:\/3\63.5~4.0mmM®Cfig-r

^v@i:©SlSSg6^)UT:.

T^-U-SDLJXti^e.

sss®,

u©

X3\^)\6m\i;Sia,

;S®e5.0mm^C^^Cl\Sg£/\-r6L..

■enrsaa.

(c.

;^:?b':^5^-0jiyfi®^<ur<;csu©

:3.:7L^':;5?-®(7)fi''JSia 1 6mm

WTstsia.

^.J>-h±m^$hl..

Z<Ic-&i\o

2.

:h':;S©^»,

Tt?.<Dmnv^mz<7zzi\o

^i^-vmissBSor,

a^:j®%±RUT\zm\\^Z<Jc^l^o

®s

17.0mm®S^?d:ii?i®

r-r©

E£to

U/t-©^[5IL«M

r < ms

IfB

1.0mm

0.5mm

\

mmmmnMi^^mmmm

0.5mm

1J

8.3~8.7mm

ca)

PISTSi:3(3.

(7-C</£3Uo

MT§t:3(3.

1

.OmmlC^tOt?.

:i^y®®!fi(St)T:<;cSUo

gp^ifeu^

g7^^HIEffl(Cfgi7rSSy^^

3.5-4.0mm

16.0mm

^

Page 18

}¥x5±(f/ci:g.

lC5^Tfl5iCIC^o;c^^lcO:5«J:5(C.

Sl^o

i.^^-u-smur.

iiiuffig®T{5i®^rT-c<;cSt\o

Tie<7)^fi"Clll8i5Lr<;c

(a)

mi

a

4.±iB.

J:olcTOUr.

}¥x®gj&iC(c^o;c^osasr±i:fr<

•±':;h@S«5fi?)r<;c$Uo

Jf5^sij}¥x±i:fj

W562-01

W562 - 02

W562 - 03

W562 - 05

W562 - 06

W562-07

a)

fHSlCctor.

/'SiiK/cSUo

}¥X_

7

li-|BJSyJ9x±l:fS(mm)

2 :$:

6.3

6.3

6.3

5.3

5.3

5.3

§f

3

5.0

5.0

5.0

5.0

5.0

5.0

^

L":/5^-ro

iBog?ir^*3ttr</cSc^o

1.P-A±M®^hU.

r<7cai>o

2.:i^5;(2)

(2:$:)

5*-f s V

:|^y©®J£Sffior.

;lS(-J®5miC^6L

±ffiO^l^ED©tx^teV0^l,\ED®

15

Page 19

Z)<Sf(7)S{|iJg£^i&<K=6.

1.

p-A±^s^hur<;cat\o

2.:^v®

9^l\yb'=^v

r-;4

(4:$:)

(±)

®Ol2':/|-{fl®S-r6Ur</cSt^o

a:^h*/!fx-r-;K®glslUT:,

(±) (+)

r;u-/s-|fi^op|j5j

su;ci:g(a.

2ESfaM

iJlc-rs^i:,

ti-M

(Si-|$i:;u-AfcSaii!}

4

q:

fc

sj

1201^155

ti-^±T3iifllcWT5;u-/

®(c^t)t^r<;c^Uo

Ur</cSl^o

^-i5^3i®ro5'-r

Ji^^y<^(o^i\^©^03yoyvy

S^'::?(^!SS0«.

h(73^t\ED

;u-/x-Su^i

;i/-/'^-Z)^;£^$!j<K(ciati-(7)g{ijgiiiaUx

3)

(c^wc.

Ti2<^^fi-cpg0ur<;c$o«

a^ifi<

B§ic:(aii-(7)

^

1.

-fv

hOSSfifiO.

fi

ic^t)t?r<;cSi^o

y^To

^;i

•±i2(7)Sili5SL/c^g(S.

silsur,

!ili5:;^y®SIslUT:.

s>^^yxutnx^\^t.B\t.

tfo+t-raic^o/clu^

s

m^Lz<ic^i\

16

Page 20

tMC^lU^W^To

St^o

lS0Sg/)\6Stl-^rg-SOrtJCJIl^^-ro

pasTSiisia.

<;cSUo

:i^=;(i)e§fifi?)r.

m^i^@®£X(as(cii)Z)\ur

ff

x®iu±yM

W500-05IC®fflU"Ct^SffXia.

}¥x(§)(7)|fi±yfiZ)TO-cg^-ro

Uo

t&m^axnu'DZ.

PSS-rSi^SO:.

zsixpmm^^ix-Xic^^jmro

:^':y

h©S3tfifi?)r^

zSlxs

M\W3:t:<DW^P^^[Z

}¥x@(^^|fissi-fr < /cS

:;^v©S(lIUr<;c5t^o

17

Page 21

ISor.

f-a

5^uc^±;><;^SIRyms^:g«.

tf

irUU±x::^t55mur</cS0^o

5^

Uff

^0(tr:i^v®S«gmr

</c5Uo

2.3/-u-^iiur.

3.

±T><;^t^p^(c^sAn.

<;cSUo

Tx::^ro3ca

2.

y39t^i^Wi±mtmcu^[z^t:>tiz.

;c^l^o

3.

±Tx;^op^ic^sAn,

r</cso^o

T^::^QJe6C1!

±x:7.®gT{LZ®^rTi-/x

y-^j--^mi>z^ymn^wy^i^z

:i^=;®s§fi«)r.

3^-u-sisiLr.

T>^ym^uz<tz^i\o

T><;^(0)ST>t^^®o3l(c5u

Tx;^i:±x;^

0.5mm

n

^vmmsbz<

x;^iions{iZ)\«)

siiBs

S-S(7)rt]|cm§/cfiOlclig0U^-ro

^

l,^o

Mm</)m^rd:^i&mwumz.

:^y®i::(B^^(sbz.

Txy^©^<mizmk).

±><:xs©HxyMwssropiS

^t)t^r<;c^^,^o

iiS0-r5i:sia.

7.^®®±3^(aT(cibZ)\ur < ;c^t^o

^m^e^ymmmz

msis^v®^^uz<ic^

sic^y^-^o

^50.5mm(C^^5J:5lc

±x

18

Page 22

u

fit

nit

>

I

9tt

n

u

I

ri

5>tt

m

3

U

I>

d

<~

m

C

3

fit

a

W

c

>J

Rt

t

(X

£f

fi

C

ff

LIM

'

a

n

(X

d

3:

u

d

Vi

^

v:i;^ c

t

fi

t

fi

a

t

fi

A

>

01

v:i

d

A

Rf

fit

vj

®

(T >Jd

n

'

fit

m

v_

m

m

c

d

<—

m

o

(X

@

t

fi

C

^

3

(H

vc

^

d

t

^

fi

^

s

o

n

91-

>J

'

d

M

□>

fit

A

n»

©

t

\L'3k:

fi

III

*

rN

«4

O

I

U

'

0

3

On

C

I

t

fi

5

s

^

c

m

o

c

Ff

>J

(X

w

SS

t

fi

Oft

fit

fx

d

(W

9?

IS

3

S

□>

c

d

9+

3

@

I

ri

ys

r

01

o

Or

MA

n

01

ut

t

fi

a

□>

®

fit

Ot

n

c

°

O

S

A

M30

(X

01]

-HD

(It

t

fi

S

c

n

0);

c

i

fj

c

B3-

□

m

OJ

vi:

I

c

c

^

m

fit

I

r

a

t

yj

fi

>j

3

s

yi

a

§

-jj-

3

In]

vi:©fi

>3

d

C

t

r

d

t

®

A

d

fi

nft

d

d

m

A

fit

□

n

O

u

a

®

Or

f»

vs

^

d

/\

d

§

rl

9+

^

^

VI

9+

d

Q>

^

cf

'

A

t

fi

3

m

fit

c

°

Sg

s

5

w

>J

©

21:

a

^

^

3

fit

>^

c

vC

»I1

II

m

"H

3

n

U

w

rr

m

<-

■

9?

m

r-

T

)<iH

n

(X

3

ll£

m

"H

U'

(^

vO

Page 23

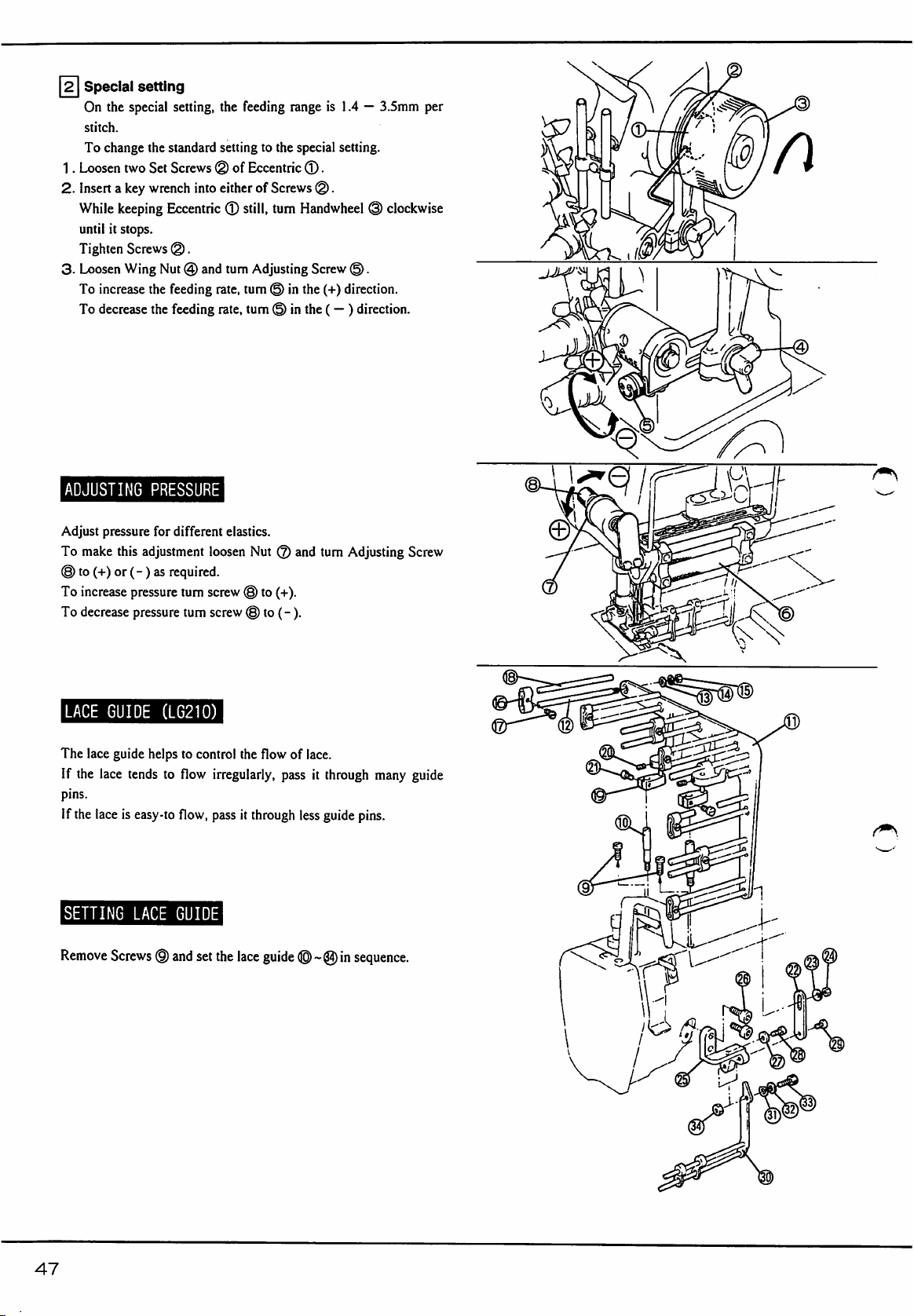

irac01XyWltffiB®lSli5

dfAi:glSSSnuiCi^U^t)t?§<t5lc.

(DwnvmBLz<tc-ai^o

[i]

^¥XC^^L^rl^S^^-1'

:b'^h'©(c;eorjiiyi^.^n§iTA»^.

/cffls^i^yiz^^nscfcoic^otjr

r<;cSl^o

[2]

9g(^©x

□-3-®iCctor.

Ts

rti(c^t)-HTaxyi^i:rr

WT§i:S(a,

^

paLr</c3i^o

Is]

pa-rsi:sia.

aur<;c5t^o

©(Dia

ixyai5n/cifAWx(^:df-r

iE5icgfit)M®'\jiiy)i^nSci:5ic,

®0»a

k

@ia,

D-^-®,

:iE?$ic:

ASfassicBsy

irArtD|c^t)y-CTiB

K0Ha

msiP.

</c5Uo

13^

M©S£X(SaiCi@ffiU

<

/cat^o

®(?DF^g3ii@L/c=rAZ)<,

{^cj-c

</c^Uo

sif«3®.

aiuiiiicjsu

t^©rao

sgp^g®.

®®&5^ias(c:p

©sita

©s&xiaac

?lF«3@i:

w

©

iJAi^y

d'Ai^U^^<?DS:$:6^/3:j^yttlUfiia.

^To

jj]

«ima^02iymus0sa

^

wrstgia,

(+)

i—ji

±ie(^m;c(fc.

^=Tyi>3V(r>mm\

tij

</3:y^-r<,

L/m

0.9~2.2mmOaSrWCSS-ro

h®s§fi«)r>

Scti\jiiyii}Lfij!)<'#6n/eCUiigia,

=&f?fTO7or</cS0\o

TiB(7)2

iia:i^9®s0Lr

(-)

{sijicm-ri:.

21

<;c

'j>

m

20

Page 24

2]

4$glJtta^0]2IUUUS0na!

i

A^3.5mm(r>mmvmmTBmto

sutt^iciny

vmmuz<tc^i\o

'\.iL^\2y(S>(r>±:^v®

2.

:;^5;(D(^if56Z)M

ni:oizLz^v:^v®^mi^z.

3.

ra

±i5(Z)!lli5mrv

bbBboinasj

h@s5ififi?)r.

(+)

ffl

ijicisl^t,

<G:y^-ro

:$:IC.

/wh^Tn-rjuDSKit^i^icioiur^

iliyi±iUfiG<^<G:yv

=&#ft?TOor</cai\o

tti

(2$)

mm^v®^m\^z<rc^i\o

g§fifl?)r<;c^l^o

^-bV5'®ilUC^"C,

T'vs^avroiffl®

x^i2b®s@$ur<

(-)

fJicu^i:.

Tieos^

/)

ms/ix

v

i!>

TlBx

dfA0ips^tJH(ci;5Dr5^b=/3b®slS0U^To

la.

Tstsia

(+)

U-;3,tF-f

h'la,

3!En®jiiE'rs;c«)(^g®rTo

g«oi:g(a,

u5b-:^®«iDtsia.

u-;^±r'f

i§is#%ic,

w^bmjssffiy,

Pa3:i^=/®®(g]Ur</cSt^o

ijic,

i§<-^5i;aia

H:

CLG210)

Kroisy

icot^r

^f^iysj/ttnic/ayc^B/cCL/-;^

'j><ur<;c5Uo

wit

®~@oi(i(cKyi^(tr<;cSo^o

(-)

E:tJS3S<

«iJ(c|diuz:<;cSOo

\^-:^<r>^mm

jtis«n«<S£Lr

21

Page 25

W562,

®#%icTig<^ii^rKy

1.

2.

3. / W

^'5^-

r>

:;^y®re£ur<;csi\.

•

W562-01.

•

W542-01.

W500=/U-a55^y(^55.

(1

:0.5~1 : 1.3)

02. 03.

02. 03.

f^itr < /cat^o

h®si5^)y\-(c:isy{xj(tr

h@S/W

ti\S

V5^-®IClRy|;}(tr

S

©IC:

06.

07

06.

07

±i50JB^(a.

(1 : 0.5~1 : 1.8)

</c5Uo

mVlEi

E

<;cSOc

0

ffl

®iEtfr</cSUo

r-;i

±12.

iEMi&a)^®siS(:f/c±g(s.

omym.

g|S#%(C.

vz:mm<ic^i^o

b/X-®(7)®)<i5

22

Page 26

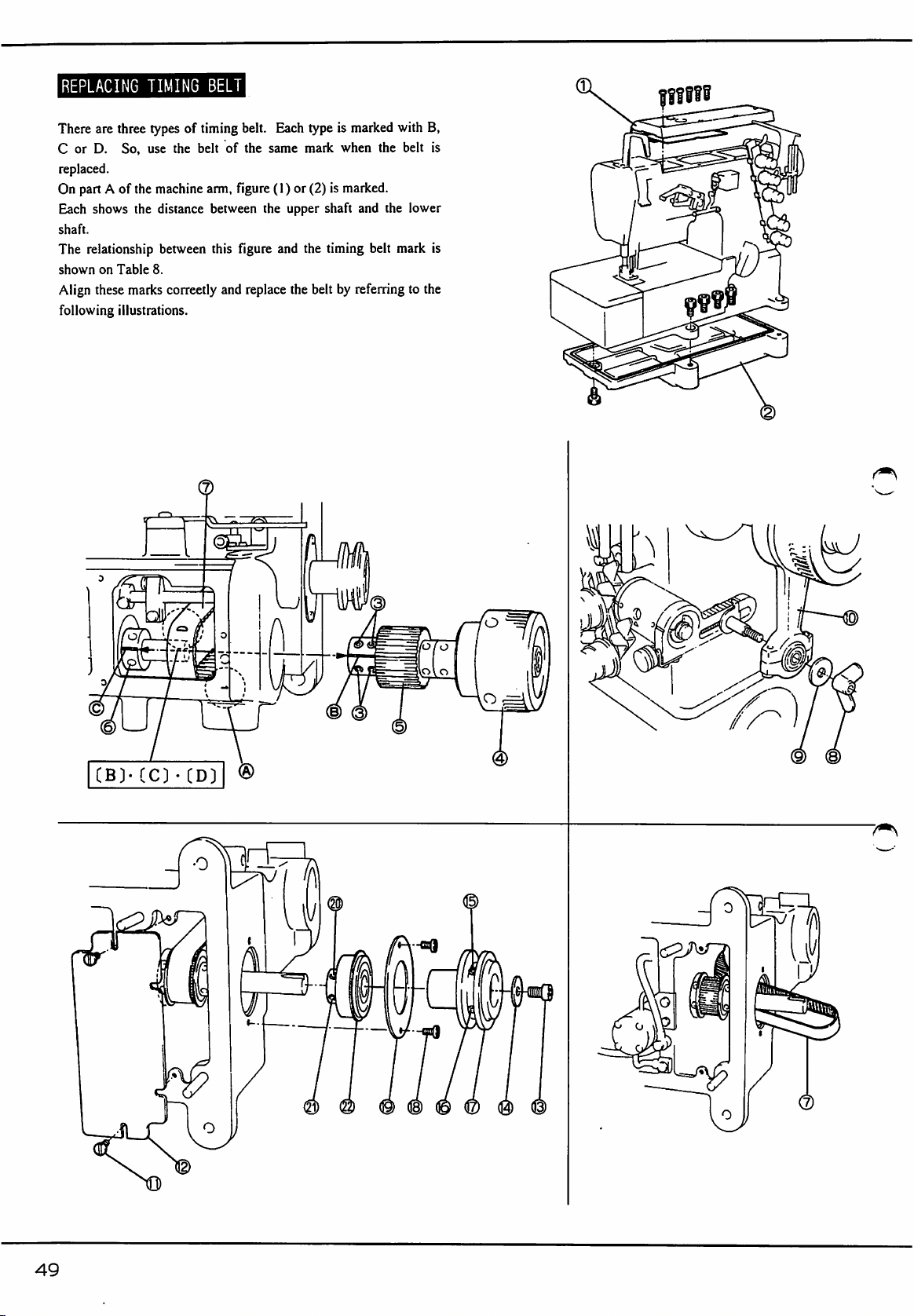

(B]-[c]-(D]

mic.

5i/Vlc=6WS§SiO)it\S^'rEPi:Ur,

?

(IX

(2)

gMuru^"ro

§0(c^ijEDsnru§»^i:.

ms^^Zs

r<;c5ix

F^3lu<^^3:t^ct5lcl§^^Dt^•c.

5'^=:/::?^i/hogg^efiiZ)\«)v

^i'y(0±mt:T

tgg^sQiL/csao^

t-a±ms^l.

Tie(Z)s^r5smu

P-Zx®a5(CjK

t-Ix®

Sj

off

23

Page 27

2.

|§1S#%(C.

y

0

r-;i

Lz.

7-ix±m!3)tt'<M\y®^^Lz<jc-aL\o

:^v®

(4^:)

ISJ61

^r

§|gtsc^r</c^c^o

y\VK7jx-r-JU§)SKDo<

</cSL

0S#%(c;±':/h<i>>

1.

1§]S#%(C.

r-;±

•$as®®IXy

lESiic

Asfiigic^^^t?r < /csi

y»s«)r<;csu„

^hU/ci:aoi20l(l(c;.

K

©13.

Zf-U-@.

Itst

{gg0«?>

lD/'^-©^mk)mZ<Jc^L\c

:;^y®<z)$t®Z)rFiffi(7)f52®3^(s:)5v:ic

brass.

^o

^^i?®seg{titrz)\6.

boti\

3.

@®^KU^<;c^l^o

©i::®.

/c/cu.

6.

^yy(DM£D

o~@0iiict)/'^—®>

®{t.

^^(cj£giR6-ric§fi«)5;ci-jicLT:<;c

5''i'=vr:^^;uh<2)®^hur<;cauo

1

2

(B)

(C)

y—u—@.

m/c(^

s;c(3

(C)

(D)

w.

2.

t^-u-S0Lr.

rl!)»^ur.

3.

±B<Dn^UoJcmms

eD®s±ic0(-j.

:iT{il®srTr</cSt^o

$a§®(?DSi^ED©i:-iSrrstcsr

^^;i/h®sw.

c^r.

Tcii y (cix y ftit r <

-rnst.

■r.

2JlOTOSffio/c^^.

SOaL

^0]©^»<-ix-r s c 3 r

/cSl^o

(4:$:)

4.3^-u-s0ur.

^ssMz</c^Uo

5.y-u-^muz.

rpj

7-yt^yi<(D^iW®/)^-sibzust>\t:3AK

r</cSUo

6.0s#%(c.

tf^»<®±{5i®0ts.

p-A±^.

lllOct5(c:^;uh=^^v

(±)

®Z3<ia§©ic^5^r}¥U

ss5«)r<;£sc^o

/cs t b

(±)

5^ t a

:y

3Z)v

(fftyu-/

(lem^m)

t--i';i//r-y®5ixy{t(tr</cso^o

;^i:ic.

C±)

OSUED®il.

h®s

Z)Mt r <

ma-mmcDm

^-£505^^

/\yi<7n^-Mc^

ssm

5y

s

m

y

24

Page 28

C<^5'-1' = V::?S5i^lCiEU<^Ot?S7cfi?)(C, -tZfV

s-i^yw-v

ano

(#510-91)

®ffl®Lw^-rOTcr^ijffl<;c

mm

c^-y)

£SfiS$A

JU-/\-§«B

Cmm)

(mm)

WS62 - 21(356)

(mm)

Cmm)

(mm)

9.3

3.7-4.0

9.7-10.2

5.5-6

18-18.5

W562 - 21(364)

8.8

3.3-3.6

9.7-10.2

5.5-6

18-18.5

®

nX

25

auaaaF

ff

X±tf«G

(mm)

(mm)

CS.P.M)

1.2-1.5

7.0

5,000

1.2-1.5

^W>////////7Z7Z^

7.0

5.000

Page 29

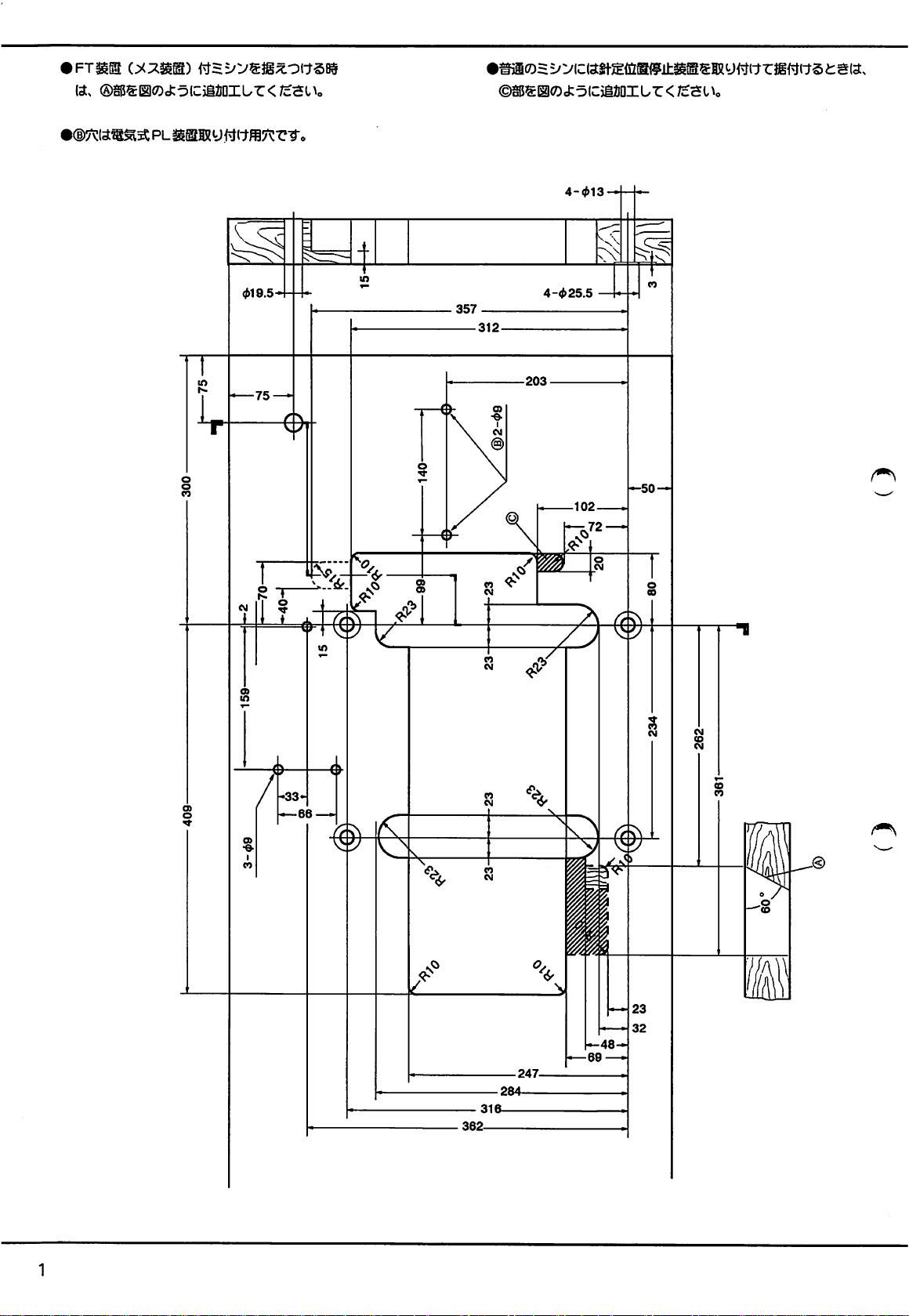

•

Add

with

I

The

the

part

FT.

hole

marked

marked

(A)

(B)

is

as

shown

provided

fitting

when

installing a machine

electric

PL.

I

Add

with

the

the

needle

4-025.5

part

marked

positioner.

(C)

as

shown

when

installing a machine

-33

►

ii

—48

27

Page 30

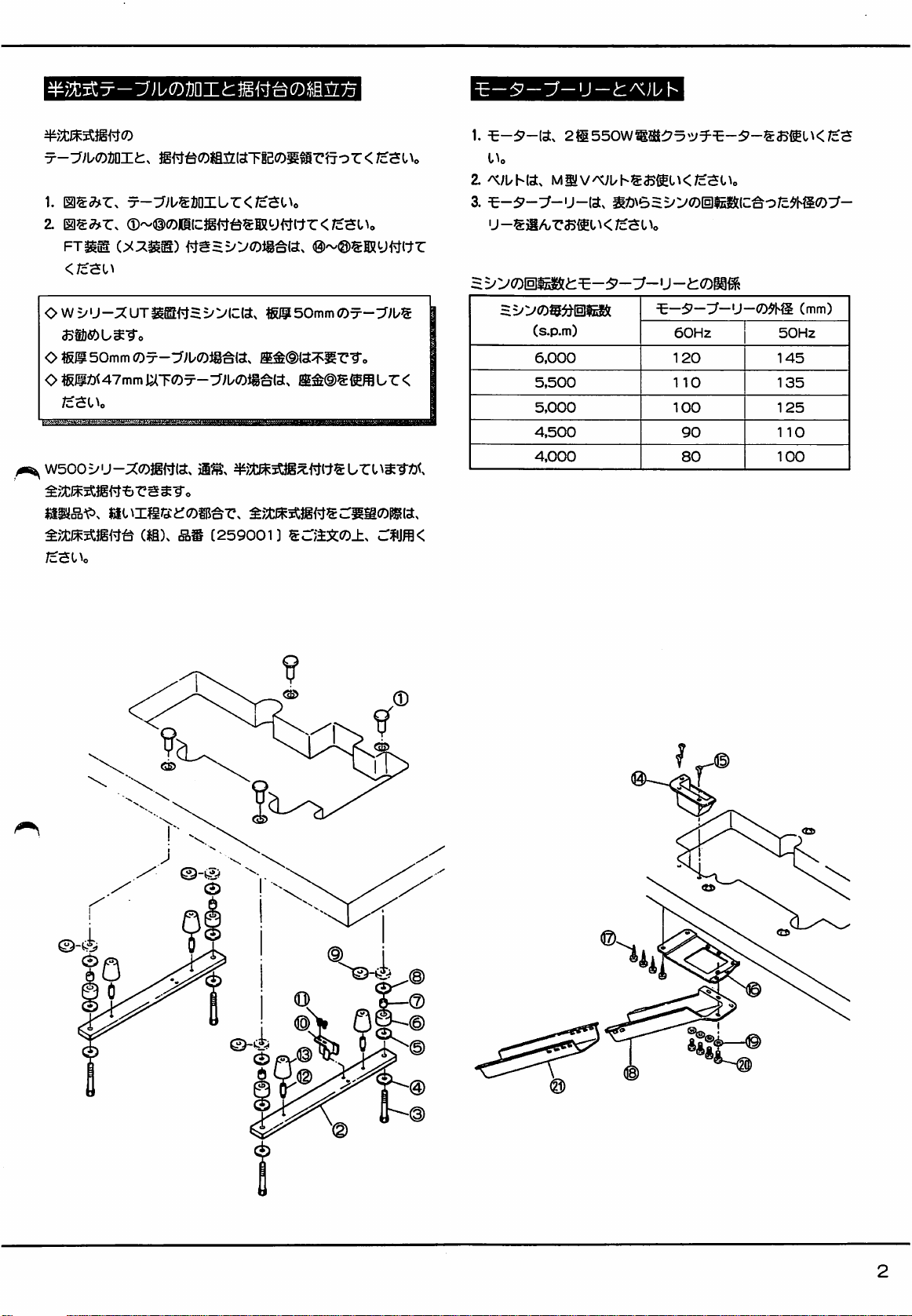

CUTTING

REST

Semi-submerged

machines.

Following

the

machine

1.

Cut

2.

Assemble

the

THE

TABLE

BOARD

the

right

FOR

installation

are

the

procedure

rest

board.

table

by

the

machine

illustration.

AND

ASSEMBLING

SEMI-SUBMERGED

is

adopted

for

cutting

referring

to

pages @ to

rest

board

INSTALLATION

for

the

table

®.

by

following

THE

the

W500

and

steps®

MACHINE

Series

assembling

to®

in

MOTOR

Following

1.

2. V belt:

3.

PULLEY

Motor

Motor

are

Double

Type

pulley:

AND V BELT

the

specifications

pole,

550W

M

Select

the

proper

the

machine

shown

below.

for

the

clutch

motor

motor

to

be

used

motor

pulley

by

and V belt.

for

the

referring

to

speed

of

the

table

O A table

O

O

Generally,

machines.

applied,

If

please

the

50mm

Washer®

Washer®

the

However,

too.

your

sewing

place

part

number

an

thick

is

recommended

is

not

needed

for a table

is

needed

for

tables

semi-submerged

the

articles

order

for

259001

installation

fully-submerged

or

operations

the

fully-submerged

50mm

less

than

for

the W Series

thick.

47mm

thick.

is

used

for

installation

require

such

installation kit

with

UT.

W500

series

can

be

installation,

under

Relationship

Machine

between

speed(s.p.m.)

6,000

5,500

5,000

4,500

4,000

machine

speed

Motor

60Hz

105

95

85

80

70

and

motor

pulley

diameter(mm)

I

\

pully

50Hz

1

25

1

15

105

95

85

r

Q

28

Page 31

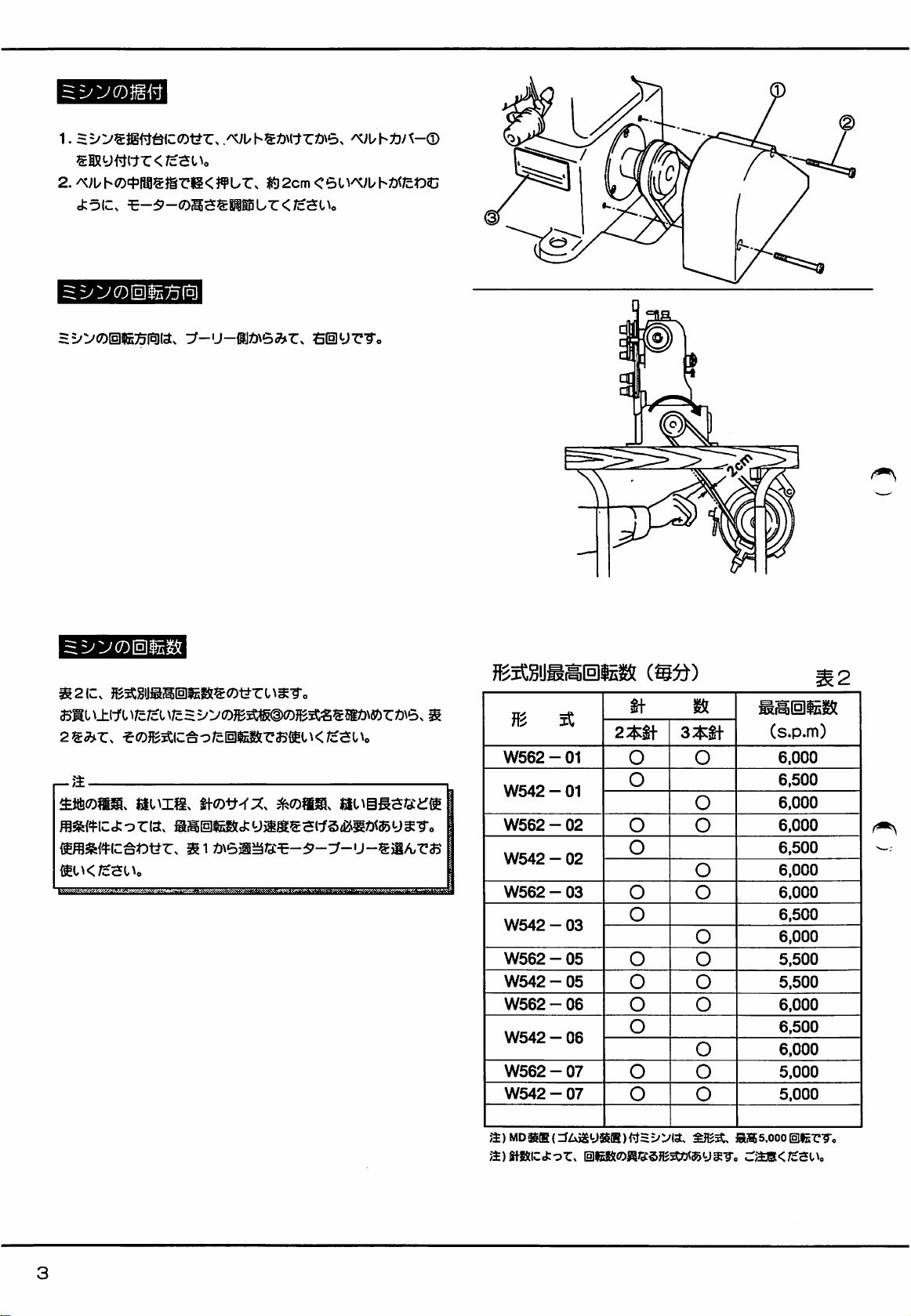

BELT

GUARD

1.

For

safety,

machine.

2.

Adjust

when

Adjust

THE

TURNING

The

turning

machine

AND

be

the

tension

you

press

the

height

direction

from

its

right

BELTING

sure

to

fit

Belt

of

the

belt

the

middle

of

of

the

motor

DIRECTION

of

Machine

side.

Guard ® with

so

that

it

can

be

it.

to

do

this.

OF

MACHINE

Pulley

is

clockwise,

Screws

2cm

bent

seeing

(§)

on

inward

the

o

J—

o

MACHINE

Make

it

not

—

Note:

The

sewing

stitch

Select a correct

operation.

SPEED

sure

your

exceeding

maximum

conditions

length,

etc.

machine

the

speed

motor

type

maximum

may

such

as

pulley

number

speed

as

have

to

fabric,

operation,

size

from

with

Type

Plate @ and

listed

in

Table

be

decreased

Table 1 suitable

depending

needle

2.

size,

thread,

to

run

on

your

MAXIMUM

MACHINE

W562 - 01

W542 - 01

W562 - 02

W542 - 02

W562 - 03

W542 - 03

W562 - 05

W542 - 05

W562 - 06

W542 - 06

W562 - 07

W542 - 07

Note:

If

the

maximum

SPEED

2-needle

machine

Is

speed

Num

ber

nec

dies

3-needle

O

O

O

O

O

O

o

o

o

o

o

1

equipped

is

5,000

with

s.p.m.

of

O

O

O

O

O

O

O

O

O

O

O

the

metering

Table

MAXIMUM

SPEED

(S.P.M)

6,000

6,500

6,000

6,000

6,500

6,000

6,000

6,500

6,000

5,500

5,500

6,000

6,500

6,000

5,000

5,000

device,

2

the

29

Page 32

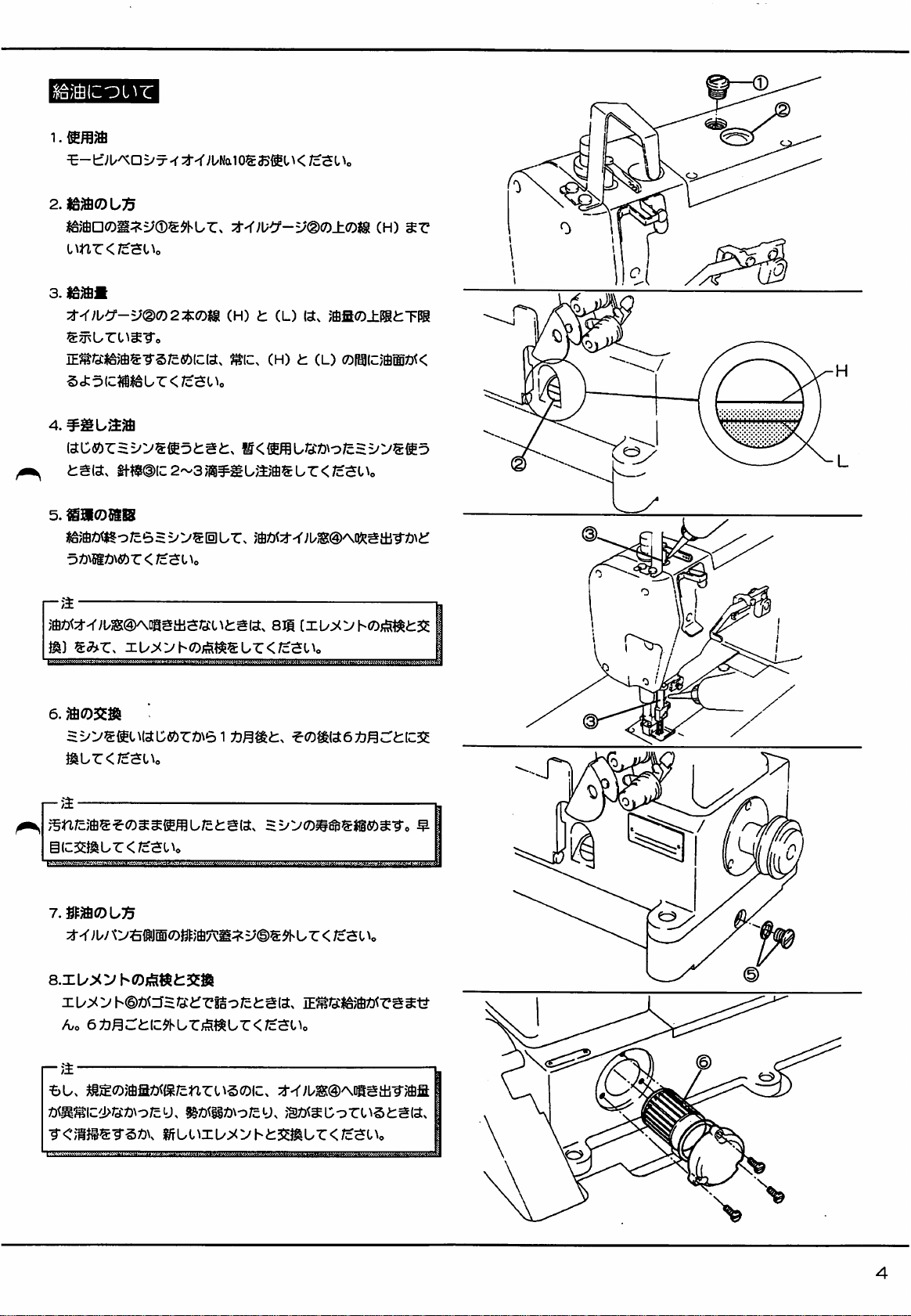

LUBRICATION

The

oil

was

machine

1.

2.

3.

4.

with

Lubricating

Use

Mobil

To

fill

oii

Take

out

the

upper

Screw

0.

Oil

level

Always

between

Manual

Before

idle

keep

two

oiling

starting

for

more

Bar0.

5.

Oil

circulation

Be

sure

to

drained

from

oil

before

starting

Oii

Velocite

oil

the

No.

Screw ® and

line

'H'

of

Oii

enough

oil

lines H and L of

machine

than a couple

check

check

that

oil

machine

it

for

10

(ISO

pour

fresh

Level

Sight

in

the

machine

Window

for

the first

of

weeks,

is

splashing

when

shipped.

the first

VG22)

oil

until

time.

or

the

Window

so

0.

time,

or

manually

inside

Window

So, fill

equivalent.

oil

level

reaches

(g) . Replace

that

the

oil

level

if

the

machine

lubricate

Needle

@.

the

is

is

—

Note:

If

oil

does

6.

Oil

Change

Change

After

that,

—

Note:

Be

sure

to

moving

parts

7.

To

drain

Take

out

8.

Oil

Filter

If

Oil

Check

change.

—

Note;

If

oil

jet

contains

replace

it

not

splash

inside

Window

oil

after

the

first 1 month

change

oil

every 6 months.

change

oil

because

and

shorten

the

life

oil

Screw © and

Filter © is

and

clean © every 6 months

in

Window

bubbles,

with

new

drain

clogged,

(g)

is

check

and

Oil

Filter.

abnormally

clean

@,

in

operation.

dirty

oil

time

of

oil

from

nomal

lubrication

at

Oil

check

Oil

Filter©.

can

cause

excess

the

machine.

here.

cannot

the

time

of

the

restricted

Filter © or

or

wear

be

kept.

regular

weak,

or

if

necessary,

on

oil

oil

30

Page 33

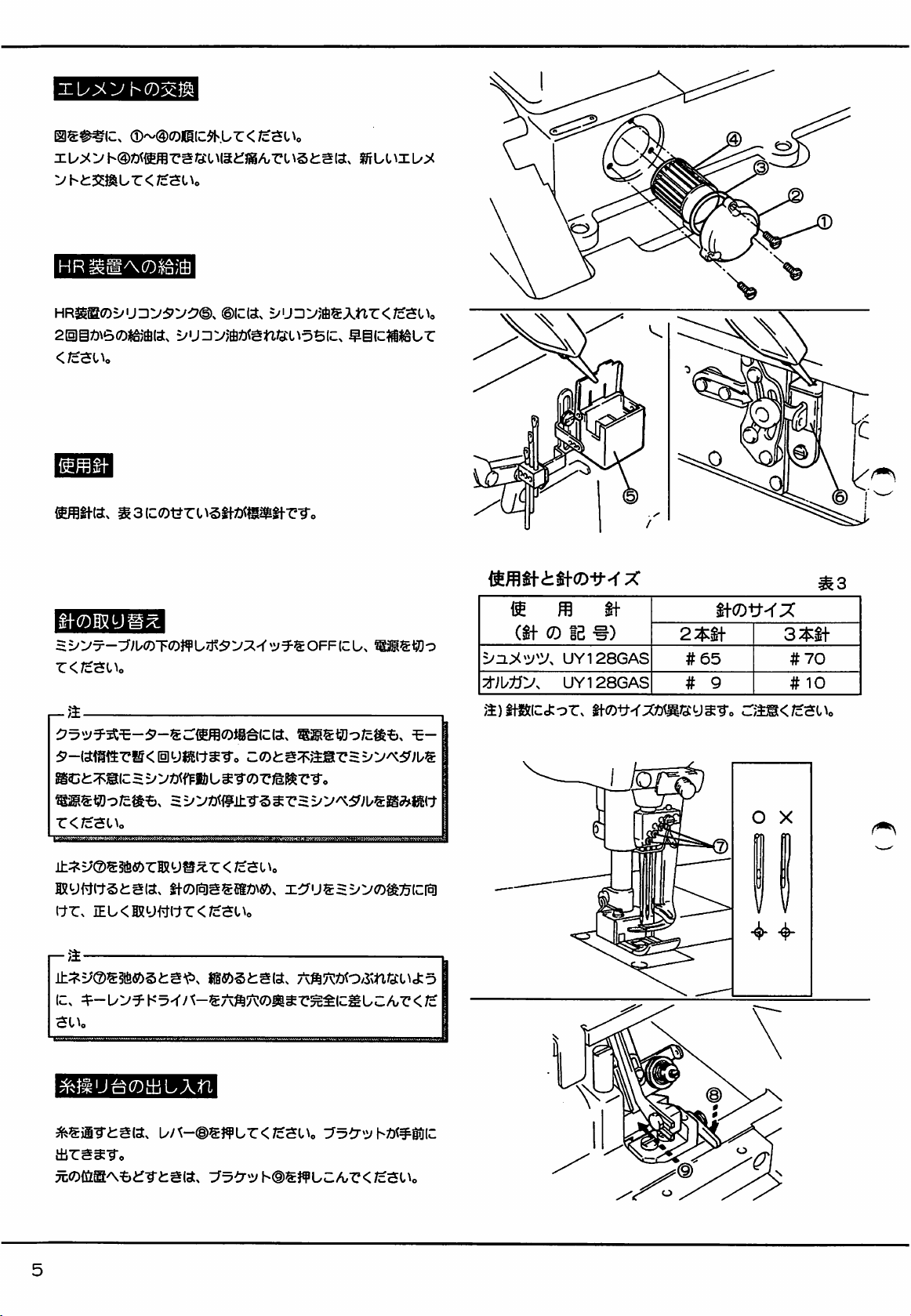

REPLACING

Refer

to

Fig.

Clean

Oil

Filter®

OIL

FILTER

and

disassemble ® @

or

if

necessaiy,

in

sequence.

replace

it

with a new

one.

SILICONE

Fill

Reservoirs ® and ® with

Do

not

NEEDLES

The

standard

REPLACING

use

OIL

any

other

needle

NEEDLES

FOR

is

as

oil

shown

H.R.

the

except

DEVICE

silicone

for

the

in

Table

3.

oil

before

silicone

it

is

too

oil.

low.

NEEDLE

NEEDLE

Schmetz

Organ

Please

of

needles

note

in

SYSTEM

SYSTEM

UY128GAS

UY128GAS

that

the

the

machine.

needle

AND

size

SIZE

2-needle

#65

#

9

varies

depending

NEEDLE

Table

SIZE

3-needle

#70

#10

on

the

3

number

Turn

the

machine

p

Note;

If a clutch

power

is

turned

pressed.

the

Loosen

Fix

—

When

key

IN

When

front.

To

power

Screw @ and

the

needle

Note:

loosening

fully

into

AND

threading,

To

off.

motor

is

used,

off.

prevent

is

turned

off

with

its

or

tightening

the

hexagonal

OUT

OF

press

replace

it

into

it

will

keep

The

machine

accidents,

until

replace

scarf

be

the

machine

needles.

faced

to

Screw

hole

of

THREAD

Lever

TAKEUP

(B • The

its

original

on

running

will

operate

sure

to

keep

stops.

the

rear

of

®,

insert

Screw

@.

BRACKET

bracket

will

position,

push

by

inertia

when

the

the

treadle

the

machine.

the

tip

come

Bracket

after

treadle

on

of

the

alien

out

to

(§)

in.

the

is

after

the

31

Page 34

THREADING

Turn

the

machine

off

I—Note;

If a clutch

power

is

turned

pressed.

the

power

Dotted

f

Dotted

motor

To

prevent

is

turned

lines®.

line®

is

used,

it

off.

The

machine

accidents,

off

until

.When

not

threads

small

loops.

TT

.When

threads

will

keep

be

the

machine

the

catch

needle

the

on

will

sure

looper

the

because

stretch

are

used.

running

operate

to

keep

stops.

does

needle

of

too

thread

by

inertia

when

the

the

treadle

Dotted

after

the

treadle

is

on

after

lines®,©.

(Apply © if

r-Note;-

Threading

thread,

Refer

to

Generally,

.When

the

is

fine

and

gauge

narrow.

the

spreader

depends

stitch

length,

Fig.

and

pass

stitch

length

the

needle

thread

on

the

needle

the

following

threads

as

Dotted

appears

too

Dotted

sewing

gauge,

remarks,

shown

line®

much

line®

condition

etc.

and

by

continuous

...When

is

coarse

needle

under

®.

]-

...When

threads

such

pass

threads

lines.

the

stitch

and

gauge

the

stretch

are

as

the

is

used.

the

length

wide.

type

of

correctly.

32

Page 35

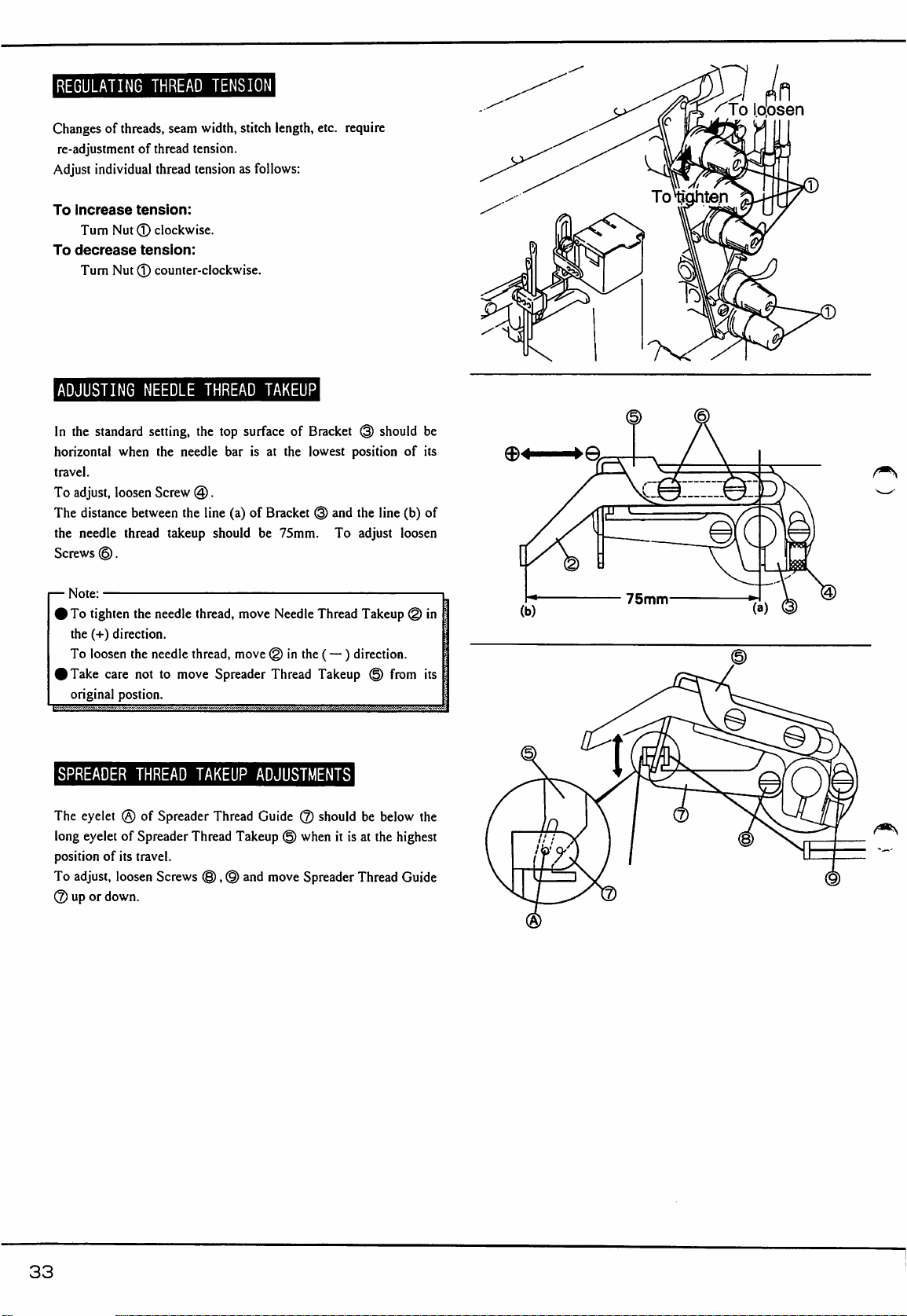

REGULATING

Changes

Adjust

To

To

of

threads,

re-adjustment

Increase

Turn

decrease

Turn

of

individual

tension:

Nut ® clockwise.

tension:

Nut ® counter-clockwise.

THREAD

seam

thread

tension.

thread

tension

TENSION

width,

stitch

as

length,

follows:

etc.

require

^To

Idosen

ADJUSTING

In

the

standard

horizontal

travel.

To

The

the

Screws

—

Note:

I

To

the

To

I

Take

original

when

adjust,

loosen

distance

needle

©.

tighten

(-I-)

direction.

loosen

care

postion.

SPREADER

The

eyelet

(§)

long

eyelet

of

position

To

©

of

its

adjust,

loosen

up

or

down.

NEEDLE

setting,

the

Screw

between

thread

takeup

the

needle

the

needle

not

to

THREAD

of

Spreader

Spreader

travel.

Screws

THREAD

the

top

needle

@.

the

line

should

thread,

thread,

move

Spreader

TAKEUP

Thread

Thread

©,

TAKEUP

surface

bar

(a)

move

move @ in

of

is

at

the

of

Bracket @ and

be

75mm.

Needle

the

Thread

ADJUSTMENTS

Guide @ should

Takeup © when

(§)

and

move

Spreader

Bracket @ should

lowest

position

the

To

adjust

Thread

Takeup

(—)

direction.

Takeup © from

be

it

is

at

the

Thread

of

line

(b)

loosen

below

highest

Guide

be

its

of

in

its

the

75mm

33

Page 36

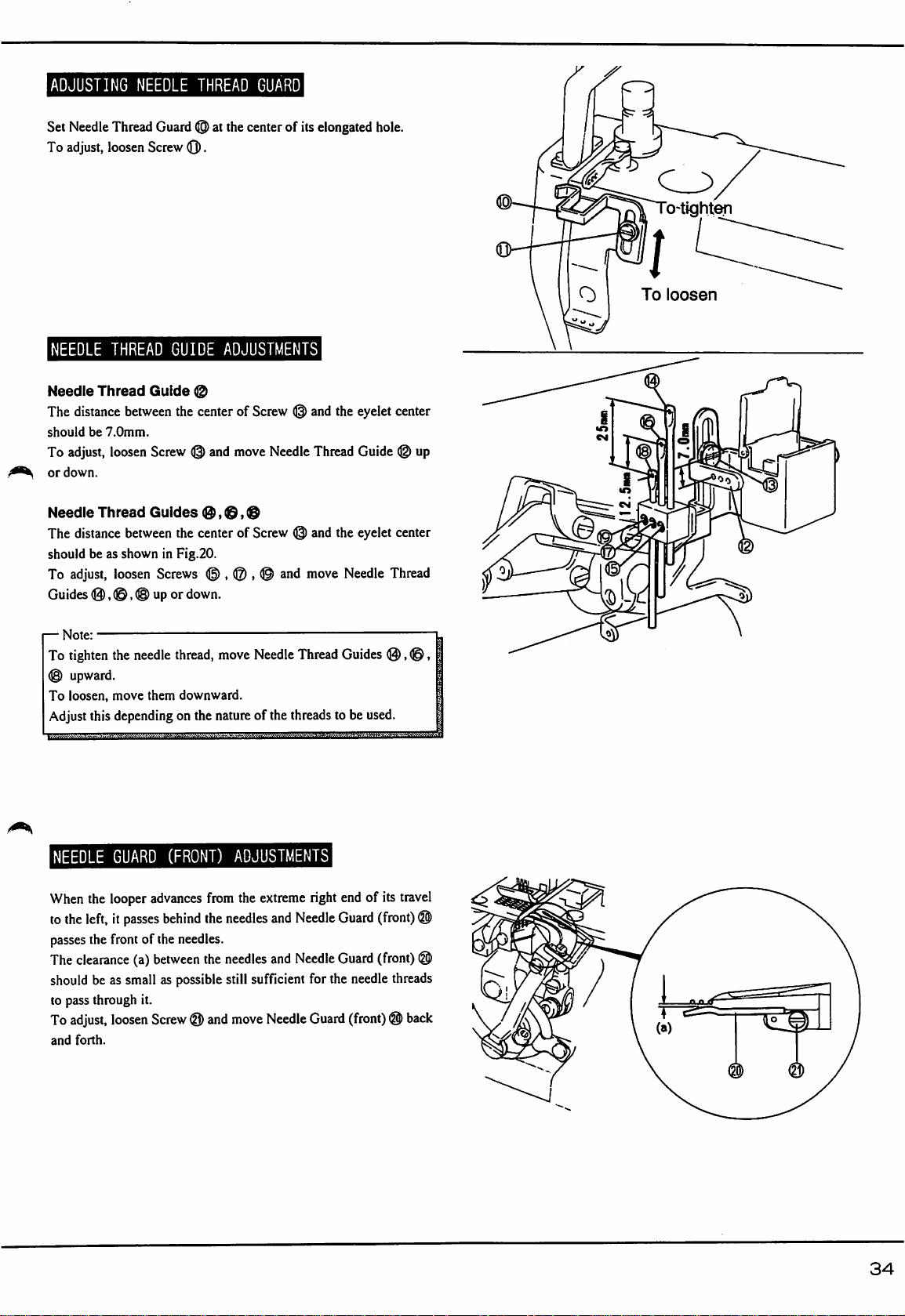

ADJUSTING

Set

Needle

To

adjust,

loosen

NEEDLE

Thread

Guard

Screw

THREAD

(@>

at

(Q).

the

center

GUARD

of

its

elongated

hole.

aM

c_^

o-tight^

To

loosen

NEEDLE

Needle

The

distance

should

be

To

adjust,

or

down.

Needle

The

distance

should

be

To

adjust,

Guides

(0,

—

Note;

To

tighten

©

upward.

To

loosen,

Adjust

this

THREAD

Thread

Guide

between

7.0mm.

loosen

Screw

Thread

between

as

shown

Guides

loosen

©, ® up

the

needle

move

them

depending

GUIDE

the

the

in

Fig.20.

ADJUSTMENTS

(g)

center

(g)

and

0,

@®

center

of

Screw ® and

move

Needle

of

Screw © and

Screws © , ® , © and

or

down.

thread,

move

Needle

Thread

downward.

on

the

nature

of

the

threads

the

Thread

the

move

Needle

Guides

to

be

eyelet

center

Guide

(g)

eyelet

center

Thread

®,

used.

up

©,

NEEDLE

When

to

the

passes

The

should

to

To

and

GUARD

the

looper

left,

it

passes

the

front

clearance

pass

adjust,

forth.

(a)

be

as

small

through

it.

loosen

(FRONT)

advances

of

the

between

from

behind

the

needles.

the

as

possible

Screw © and

ADJUSTMENTS

the

extreme

needles

and

Needle

needles

and

Needle

still

sufficient

move

for

Needle

right

end

Guard

Guard

the

needle

Guard

(front) © back

of

its

travel

(front)

@

(front)

threads

©

©

©

34

Page 37

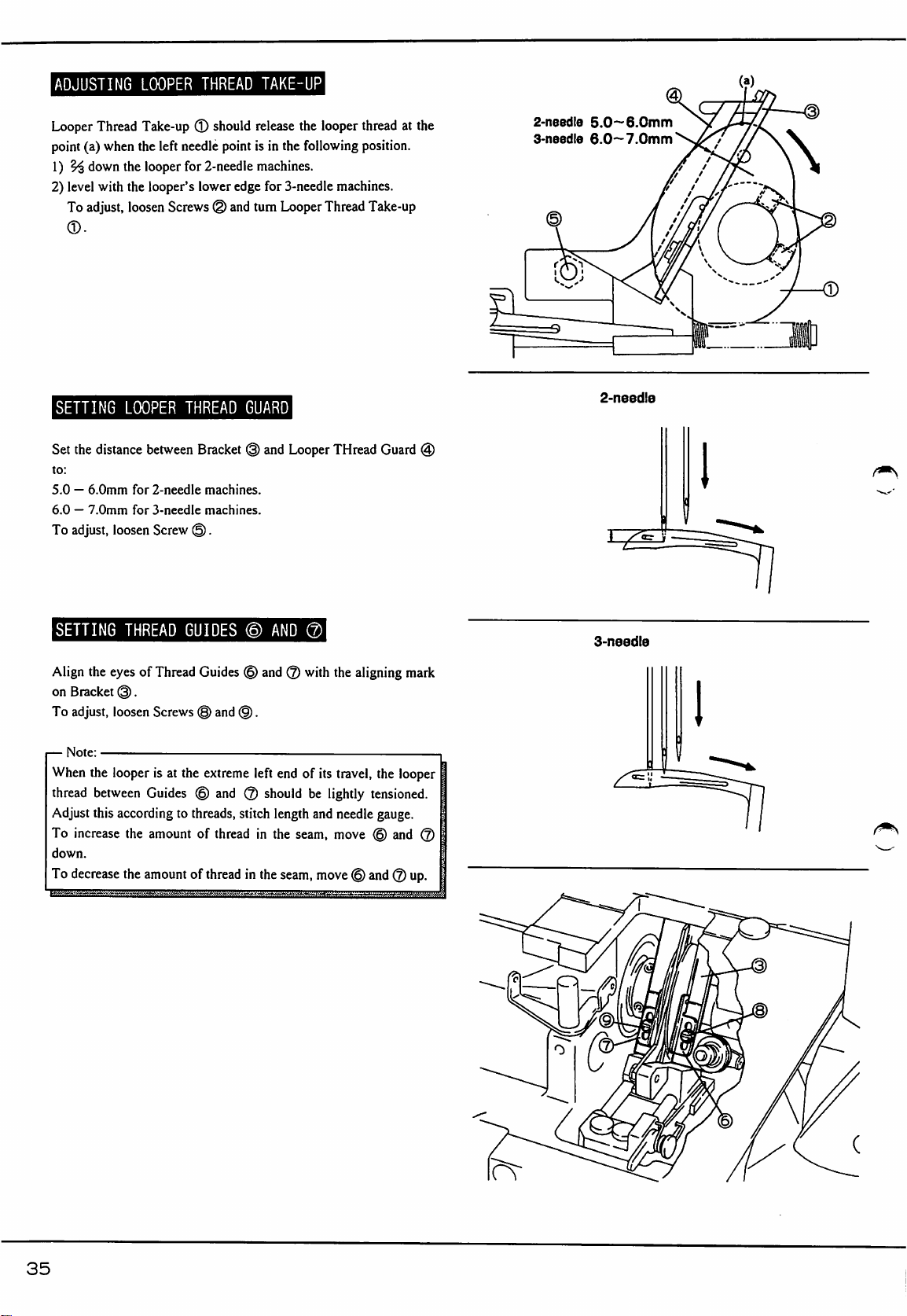

ADJUSTING

LOOPER

THREAD

TAKE-UP

Looper

Thread

point

(a)

when

1)

down

2)

level

with

To

adjust,

SETTING

Set

the

distance

to:

5.0 — 6.0mm

6.0 — 7.0mm

To

adjust,

Take-up ® should

the

left

needle

the

looper

for

the

looper's

loosen

LOOPER

between

for

for

loosen

lower

Screws © and

THREAD

Bracket @ and

2-needle

3-needle

Screw

@.

release

point

is

in

2-needle

machines.

edge

for

turn

GUARD

machines.

machines.

the

looper

the

following

3-needle

Looper

Looper

machines.

Thread

THread

thread

at

the

position.

Take-up

Guard

@

2-need!e

3-needle

5.0—6.0mm

6.0—7.0mm'

2-needl8

SETTING

Align

the

on

Bracket

To

adjust,

—

Note:

When

the

thread

between

Adjust

this

To

increase

down.

To

decrease

THREAD

eyes

(§).

loosen

looper

GUIDES © AND

of

Thread

Guides ® and

Screws ® and

is

at

the

extreme

@.

Guides ® and @ should

according

the

the

to

threads,

amount

amount

of

stitch

of

thread

thread

left

in

in

the

@

(2)

with

the

end

of

its

be

lightly

length

and

the

seam,

move

seam,

move © and @ up.

aligning

travel,

the

tensioned.

needle

gauge.

(§)

and

3-needle

mark

looper

(2)

35

Page 38

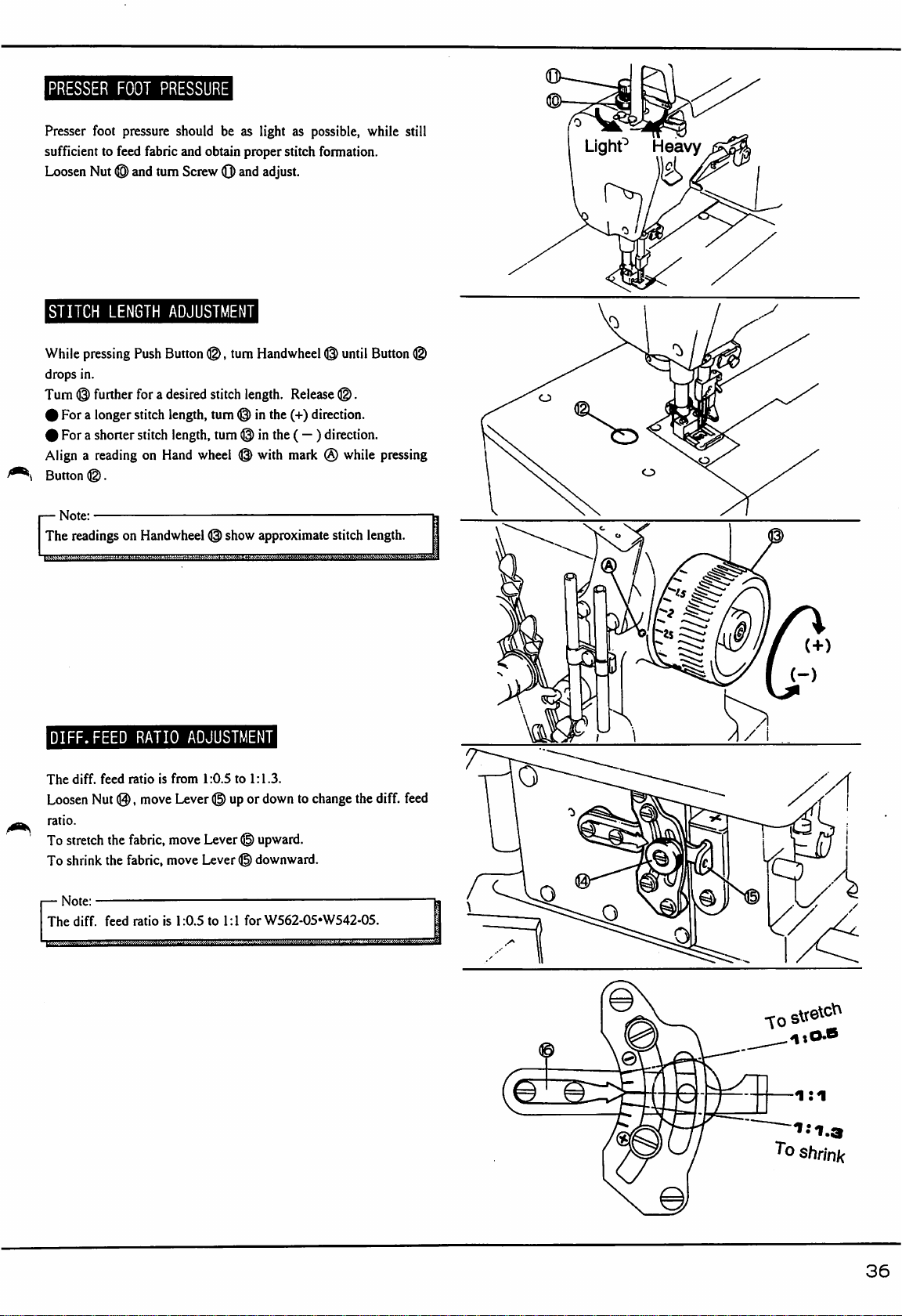

PRESSER

Presser

sufficient

Loosen

FOOT

foot

to

feed

Nut ® and

PRESSURE

pressure

should

fabric

and

turn

Screw

be

as

obtain

proper

(Q)

and

light

as

stitch

adjust.

possible,

formation.

while

still

STITCH

While

drops

Turn © further

0

#

Align a reading

Bunon

—

Note:

The

DIFF.FEED

LENGTH

pressing

in.

Push

for a desired

For a longer

For a shorter

stitch

stitch

on

©.

readings

on

Handwheel

RATIO

ADJUSTMENT

Button

©,

stitch

length,

turn © in

length,

turn © in

Hand

wheel © with

|)

show

i

ADJUSTMENT

turn

Handwheel © until

length.

Release

the

(+)

direction.

the

(— ) direction.

mark ® while

approximate

Button

©.

stitch

length.

©

pressing

The

diff.

Loosen

ratio.

To

stretch

To

shrink

—

Note:

The

diff.

feed

Nut

the

the

feed

ratio

is

®,

move

fabric,

fabric,

ratio

is

from

1:0.5

to

1:1.3.

Lever © up

move

move

1:0.5

or

Lever © upward.

Lever © downward.

to

1:1

for

down

to

change

the

W562-05*W542-05.

diff.

feed

o

iSJ

1

shrink

36

Page 39

ADJUSTING

When

the

looper

be

1.3 — i.bmm

clearance

When

of

the

Adjust

the

the

looper

left

to

left

needle

in

the

NEEDLE

point

is

above

the

left

needle

needle

comes

blade,

the

distance

centerline

following

manner.

AND

LOOPER

behind

the

the

top

should

down

between

should

be

left

needle

of

the

left

be

0.1 — 0.2mm.

and

its

point

the

5.0 — 6.0mm.

centerline,

needle

is

flush

looper

eye,

with

eye

it

and

center

should

the

the

top

and

1.3-1.6mm

5.0—6.0mm

NEEDLE

The

standard

The

needle

and

the

position.

1.

Raise

wheel

2.

To

adjust,

the

needle

—

Note:

>

After

the

center

(b)

is

I

When

handwheel

HEIGHT

settings

height

is

needle

plate

the

needle

bar

@.

remove

bar

up

or

this

adjustment,

of

the

needle

even.

the

needle

should

SETTING

are

shown

the

distance

surface

to

the

Cap

Screw

down

as

make

hole

bar

is

at

meet

mark

in

Table

(a)

between

when

the

highest

®,

loosen

required.

sure

that

each

in

the

needle

its

highest

(§)

5.

the

left

needle

is

at

position

by

Screw

(§),

needle

passes

plate

and

position,

mark P on

needle

point

the

highest

turning

and

hand

move

through

that

the

gap

the

NEEDLE

Needle 1 Left

gauge(mm) I height

2.4

3.2

4.0

4.8

5.6

6.4

HEIGHT

2-needle

i

needle

(a)(mm)

10.2

9.8

9.3

8.9

8.5

8.1

(a)

Needle

gauge(mm)

4.8

5.6

6.4

3-needle

Left

height

Table

needle

(a)(mm)

8.9

8.5

8.1

5

T"

(a)

37

I

T

(b)

(]>

/p\

Page 40

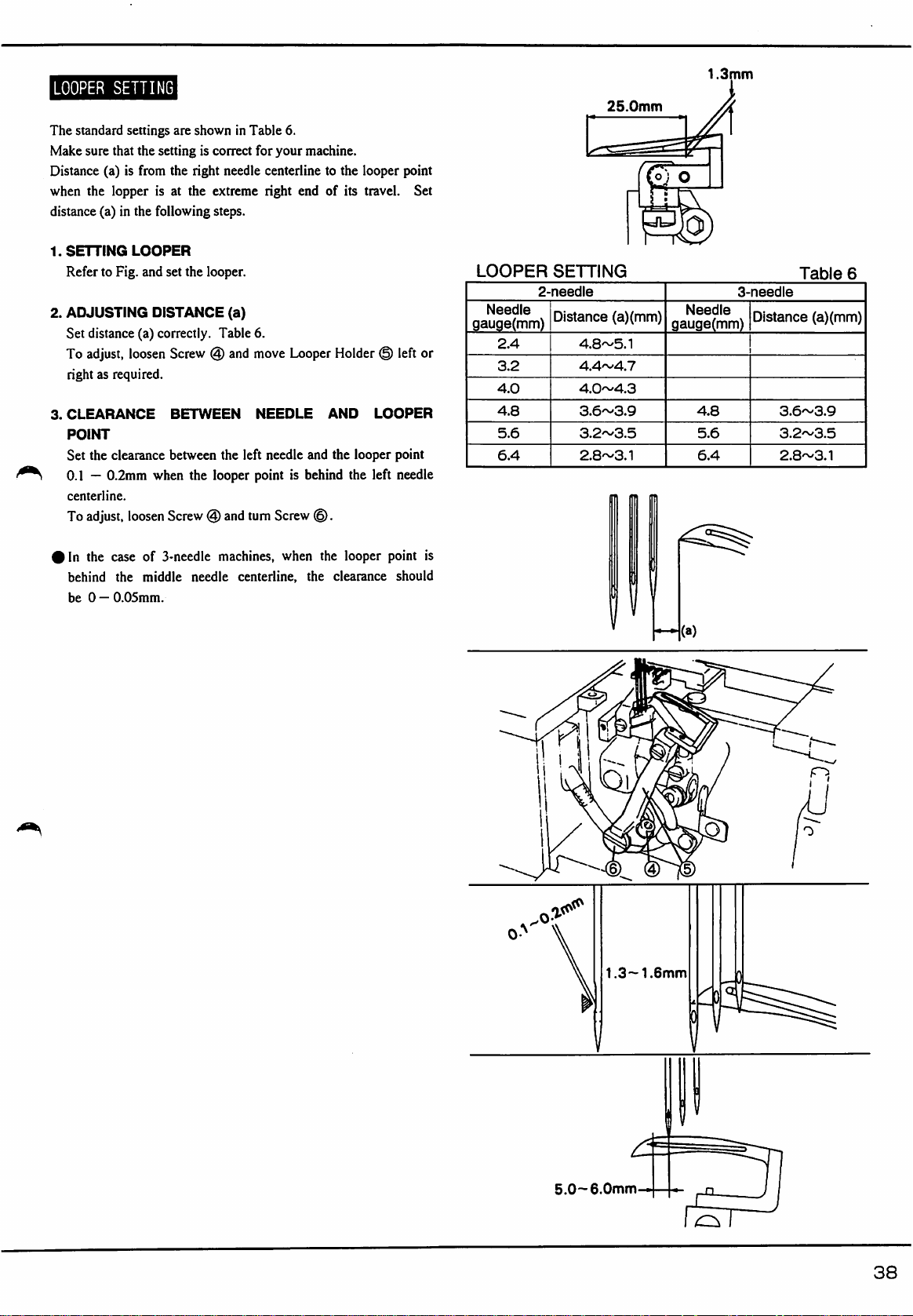

LOOPER

The

standard

Make

sure

Distance

when

distance

1.

2.

3.

(a)

the

(a)

SETTING

Refer

to

ADJUSTING

Set

distance

To

adjust,

right

as

CLEARANCE

POINT

Set

the

0.1 — 0.2mm

centerline.

To

adjust,

SETTING

settings

that

is

lopper

in

Fig.

are

the

setting

from

the

is

at

the

following

LOOPER

and

set

DISTANCE

(a)

correctly.

loosen

Screw @ and

required.

BETWEEN

clearance

between

when

loosen

Screw

shown

is

correct

right

the

extreme

the

looper.

the

looper

(§)

in

Table

needle

steps.

(a)

Table

the

left

and

turn

6.

for

your

machine.

centerline

right

end

6.

move

Looper

NEEDLE

needle

and

point

is

behind

Screw

®.

to

the

looper

of

its

Holder

AND

the

looper

the

point

travel.

(§)

left

LOOPER

Set

point

left

needle

or

LOOPER

Needle

gauge(mm)

2.4

3.2

4.0

4.8

5.6

6.4

SETTING

2-needle

Distance

4.8~5.1

4.4^4.7

4.0~4.3

3.6~3.9

3.2~3.5

2.8~3.1

25.0mm

(a)

(mm)

1.3mm

Needle

gauge(mm)

4.8

5.6

6.4

3-needle

Distance

3.6~3.9

3.2~3.5

2.8~3.1

Table

(a)(mm)

6

#ln

the

behind

be 0 —0.05mm.

case

the

of

3-needle

middle

machines,

needle

when

centerline,

the

the

looper

clearance

point

should

O

\

is

(a)

o

5.0—6.0mm

rsT

38

Page 41

ADJUSTING

Needle

Guard ® should

right

needle

point

is

behind

between

when

1.

2.

the

the

looper

Adjust

so

top

of

the

position.

To

adjust,

down.

To

obtain

and

move

NEEDLE

and

the

the

right

middle

point

that

the

right

loosen

the

above

Needle

GUARD

work

so

that

looper

point

is 0 —

needle

centerline.

needle

and

the

is

behind

the

line

(A)

of

Needle

needle

eye

when

Screw

(§)

and

clearances 0 —

Guard ® back

the

clearance

0.05mm

Also

looper

middle

needle

Guard ® is

the

needle

move

Needle

0.05mm,

and

forth.

when

that

the

point

is 0 —

centerline.

is

Guard ® up

loosen

between

the

looper

clearance

0.05mm

below

at

its

lowest

Screw

the

the

or

@

ADJUSTING

When

the

0.8 — 1.0mm.

Adjust

the

dog

point

To

adjust,

down

as

required.

ADJUSTING

When

the

angle

is

that

the

needle

To

adjust:

1.

Remove

2.

Remove

3.

Open

Side

4.

To

adjust

adjusting

—Note:

I

The

feed

tilt

by

turning

Set

Screw © to

I

Make

sure

turned.

I

Remember

adjustment.

FEED

main

feed

diff.

feed

C.

loosen

Screws @ and

FEED

feed

dogs

straight

plate

top

three

Screws ® and

Plug

(i)

Cover ® and

the

feed

hole

and

dog

tilt

Screw

the

that

the

to

adjust

DOG

HEIGHT

dog

is

at

dog

so

DOG

TILT

rise

to

line

(§)

across

surface.

and

loosen

remove

dog

turn

Screw

is

altered

(g).

correct

shaft

does

the

feed

its

hightest

that

©,

their

Cover

Screw

tilt,

position,

point B is

and

highest

all

move

the

tooth

(2).

even

the

position,

tips

®.

Screw

([]).

insert a screwdriver

®.

into

either

forward

position

and

tighten

not

slide

out

when

dog

height

after

set

the

height

with

main

feed

dogs

the

is

parallel

into

tilt

or

backward

Screw

@.

Screw © is

the

feed

to

feed

up

or

standard

with

the

dog

tilt

0.1~0.2mm

0.8-1.0mm

T

©

39

Page 42

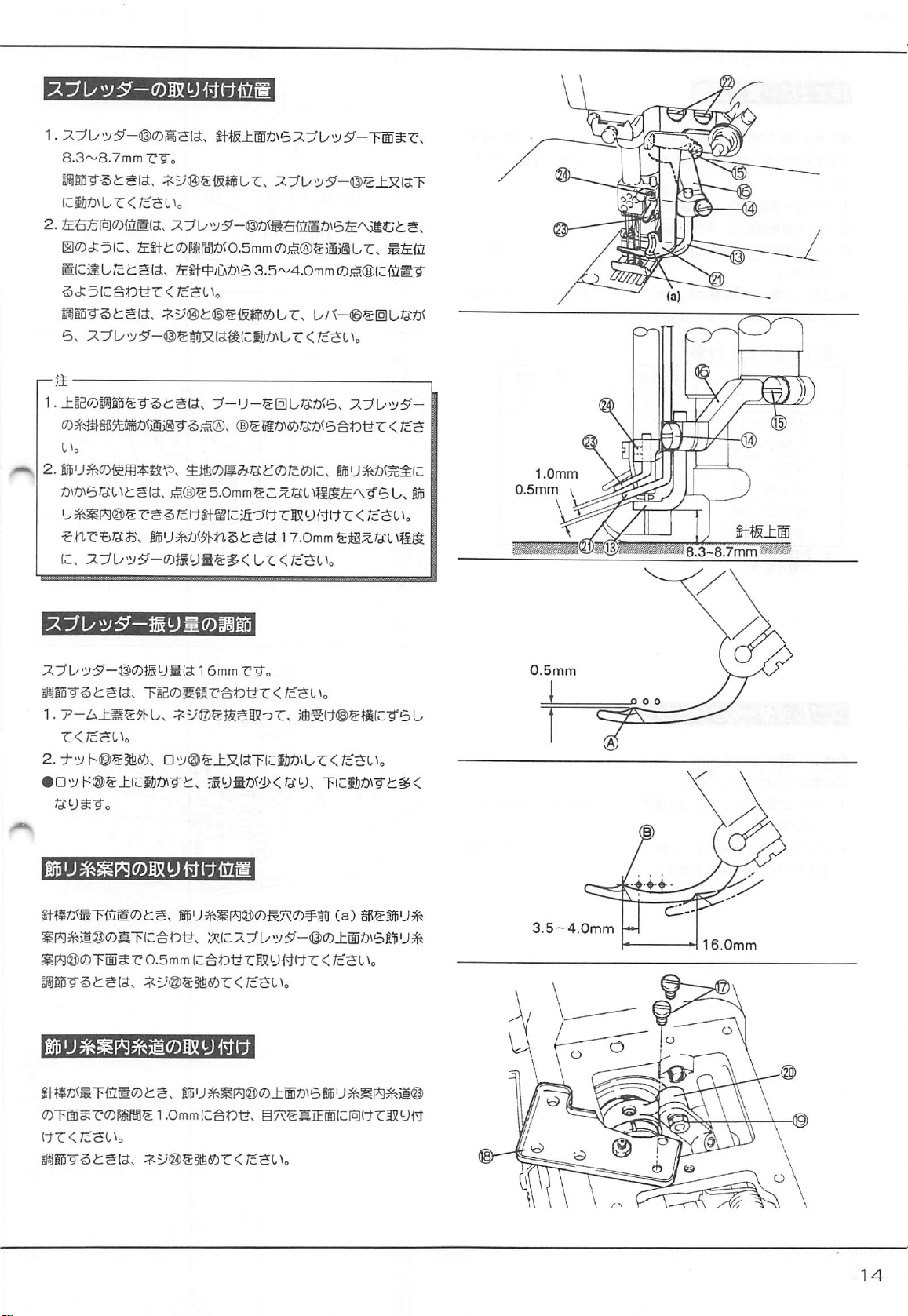

iSETTING

POSITION

OF

SPREADER

I

HEIGHT:

should

SIDEWISE

(A)

spreader

should

To

1.

The

be

8.3 — 8.7mm.

approximately

reaches

be

at

adjust:

Lightly

loosen

move

Spreader © back

position.

2.

Move

Spreader © up

9.7mm.

1.

When

making

check

points © ,

spreader

2.

If

the

spreader

number

the

point

Thread

Guide © as

If

the

spreader

adjustment,

not

exceeding

height

of

POSITION:

0.5mm

the

exreme

the

point

(B)

Screws @ and © .

Tighten

Tighten

Screw©.

Screw

the

above

(!)

passes.

thread

of

spreader

(g)

then

to

the

thread

increase

17.0mm.

threads

left

near

the

spreader

The

hooking

in

front

of

left

end

of

3.5 — 4.0mm

and

forth

or

down,

©.

adjustment,

where

the

is

hooked

or

the

not

exceeding

as

possible

is

not

hooked

the

following

from

the

needle

point

should

the

left

needle.

its

travel,

the

from

the

left

While

tuming

to

set

and

set

its

height

turn

the

thread

carrying

imperfectly

fabric

thickness,

5.0mm

and

to

the

needle

even

under

(the

plate

surface

pass

the

point

When

the

hooking

needle.

point

Lever © .

the

left-to-right

to

9.2

handwheel

notch

because

set

holder.

spreader

and

of

the

of

the

then

shift

Spreader

the

above

stroke)

—

1.0mm

0.5mm

Needle

top

plate

The

stroke

of

1.

Remove

2.

Loosen

0

To

To

Set

when

clearance

I

SETTING

When

between

1.0mm.

The

the

Nut © and

decrease

increse

part

(a)

the

needle

between

the

needle

Spreader

eye

of

Thread

Spreader©

arm

cover

move

the

stroke,

the

stroke,

move

of

Thread

Guide © just

bar

is

Thread

THREAD

GUIDEi

bar

is

Thread

Guide © should

is

16.0mm.

and

Screws

©,

Rod © up

move

Rod © up.

Rod © down.

below

at

its

lowest

Guide © and

at

the

lowest

Guide © and

face

and

shift

Cover

or

down

as

required.

the

eye

of

position.

Spreader © for

position,

Thread

Also,

set

the

Guide © for

forwards.

©.

Guide

©

set

the

0.5mm.

clearance

0.5mm

3.5—4.0mm

16.0mm

Page 43

ADJUSTING

The

standard

The

foot

lift

needle

plate

To

adjust:

1.

Turn

the

positions.

2.

Loosen

Nut

3.

Lower

Lever @ and

for

your

4.

In

the

above

Lever

@.

Lock

this

FOOT

settings

when

is

the

are

distance

the

presser

handwheel

(§)

and

tighten

machine.

condition,

position

with

LIFT

shown

and

raise

adjust

Nut

in

Table

(a)

between

foot

is

raised.

lower

the

Screw

0.

Presser

Screw

(§).

7.

the

feed

Foot

(5)

(2)

presser

dogs

to

correct

so

that

foot

to

their

its

head

and

the

lowest

ghight

(a)

touches

FOOT

Machine

W562-01

W562 - 02

W562 - 03

W562 - 05

W562 - 06

W562 - 07

Note:

The

number

ADJUSTING

To

adjust

left-to-right

movement

1.

2.

of

Remove

the

Guard © aside.

Loosen

two

mark

©.

Tighten

LIFT

type

of

needle

SPREADER

the

needle

arm

cover.

Screws

Screw

2-neeclle

varies

TIMING

timing

of

bar:

Remove

@.

Align

(2).

Foot

111

6.3

6.3

6.3

5.3

5.3

5.3

foot

lift.

the

Spreader

Screws

mark © of

Table

Ft

(mm)

3-needle

to

(§)

the

5.0

5.0

5.0

5.0

5.0

5.0

the

up

and

upper

7

and

down

move

Oil

shaft

with

41

Page 44

ADJUSTING

TO

THE

NEEDLE

In

coordinating

down

movement

the

top

of

the

left

side

of

the

left

to

the

left

(on

moves

to

the

right

illustration.

To

adjust:

1.

Remove

2.

Loosen 4 Screws

of

9

To

position

9

To

in

—

Note:

The

needle

Adjusting

change

In

this

the

Upper

Belt

advance

in

the

retard

the

the

(— ) direction.

looper

holder

bar

is

at

left-to-right

when

the

case,

adjust

LEFT-TO-RIGHT

left-to-right

of

the

needle

needle

the

back

(on

arm

cover.

®,

Gear

the

looper

(-•-)

direction.

looper

is

at

its

lowest

looper

as

timing

needle

eye

and

is

Just

the

side

of

the

front

turn

Handwheel ® and

(g).

timing

timing

against

the

extreme

position.

timing

avoiding

in

the

above.

bar,

same

the

side

of

TIMING

of

the

be

sure

the

point

both

needles)

of

the

against

the

right

the

looper

motion

OF

looper

the

distance

of

the

looper

when

the

and

when

needles).

shift

the

needle,

needle,

shift

end

of

its

to

the

is

adjusted.

THE

LOOPER

to

the

between

at

the

looper

the

See

the

the

position

shift

the

position

travel

when

needle

up

and

right

moves

looper

right

the

the

may

1

ADJUSTING

LOOPER'S

To

adjust

Eccentric ® with

ADJUSTING

The

looper

moves

when

the

motion

procedure.

1.

Loosen

To

increase

©

counter-clockwise.

—

Note:

t

After

the

needle

I

Please

necessary

size

THE

BACK

this

timing,

the

LOOPER

passes

the

to

the

left

and

looper

moves

correctly

the

needle

Nut

(Q)

the

above

bar

note

to

be

is

for

and

looper

adjustment,

and

that

adjusted

fitted.

TIMING

AND

FORTH

loosen

Screw ® and

mark

(§)

on

AVOIDING

back

side

the

looper

to

the

the

needle

turn

Adjusting

avoiding

To

decrease

looper.

the

If

looper

unless

BETWEEN

MOVEMENT

the

crankshaft.

MOTION

of

the

needles

passes

the

right.

Adjust

size

by

referring

Screw

motion,

it,

turn © clockwise.

check

the

synchronization

it

is

not

correct,

avoiding

otherwise

NEEDLE

align

the

when

front

of

the

looper

to

©.

turn

re-adJust.

motion

an

extremely

AND

mark © on

the

looper

the

needles

avoiding

the

following

between

may

not

different

be

42

Page 45

UNDER

The

The

The

the

LUBRICATION

Before

idle

FABRIC

fabric

trimmer

knife

movement

knives

trim

lace

fed

out

the

machine

for a period

TRIMMER

of

the

is

synchronized

the

excess

by

the

elastic

is

operated

of

time,

oil

(FT140)

W500

is a continuous

fabric

while

feeder

can

for

the

Crank

®.

with

sewing,

be

first

type.

the

feed

closed

time

or

dog

motion.

so

the

body

neatly.

after

it

has

and

been

ADJUSTING

Fabric

Guide

edge

and

the

To

adjust,

loosen

as

required.

ADJUSTING

The

presser

Adjust

this

thick

elastic,

elastic

can

be

To

adjust,

loosen

FABRIC

(g)

right

Screw

GUIDE

ensures a constant

needle.

(3)

PRESSER

foot

on

the

W500-05

according

tilt

then

to

the

front

fed

smoothly

the

Nut © and

and

move

FOOT

elastic

edge

of

under

turn

distance

Fabric

TILT

can

be

and

the

presser

the

Screw

between

Guide

tilted.

fabric

foot

presser

©.

the

(g)

right

to

be

sewn.

upwards.

foot.

fabric

or

left

For