Page 1

W5oa

Series

WSOOseries

Flatbed

INSTRUCTIONS

interlock

machines

^PEGASUS

Page 2

=s/>^a5MiM2®SBuCx

i\nn^s

^un<zmm<n^i\m-^Si^^mi\SL

L/^^o

z<Dm^m^<ii<^may

<izfsbiz.

smcD^mm^s

INTRODUCTION

Thank

W500

This

maintenance

the

Please

before

you

very

Series

instruction

machineinthe

machine.

study

operating

and

this

much

manuai

safety

the

for

best

manual

machine.

purchasing

describes

precautions

possible

very

daily

conditions.

carefully

Pegasus

routine

to

keep

Page 3

s:$:09®«f^#js®'g'or.

•CTSt>o

•

g^®CA?)0SB'pa5sa®BS'o^uT:®sg-€>c:i:

5E?»ICJgSJ-C^®reS9IZi8'09VUT:®SU«:

t>-CT^5l\o

rTSt\o

i5>>®/S«f>K85x

z^®r7?e>fjQo•cTSl^o

— ^

ffllSSv

5iKlS5lt®e®!l»g*aS^fflo'Cx

C7^>v5^sc€-s'-«c:®ffl®aaiz«x

!csv>zffpffi)L/sg-®-c®B5rg-o

as^ffloe^-fex

e±c{^siu

as®

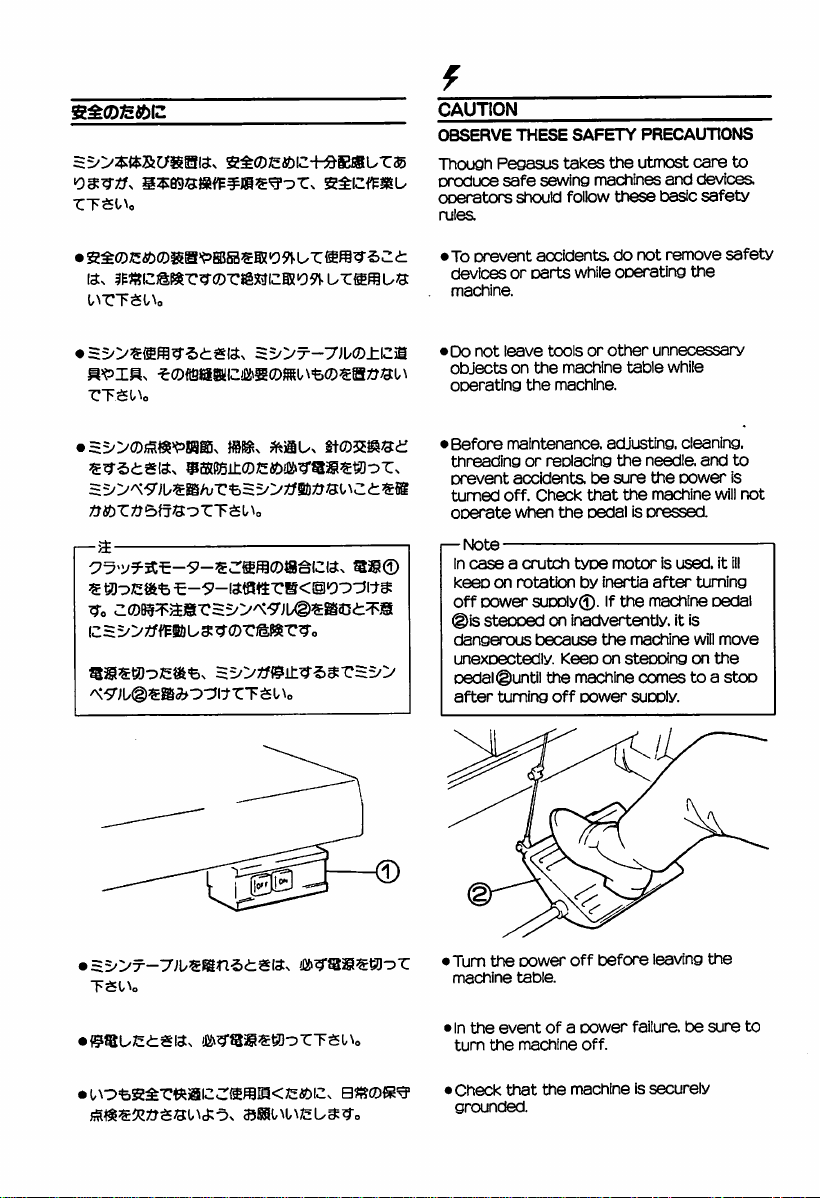

CAUTION

OBSERVE

TTiough

DToduce

ooerators

rules

• To

devicesoroarts

machine.

•Do

objectsonthe

ooerating

•

Before

threadingorreolacing

orevent

turned

ooerate

—Note

In

keenonrotation

off

©is

dangerous

unexoectediy.

oedai

after

THESE

Pegasus

safe

sewing

should

orevent

not

caseacrutch

accidents,donot

leave

the

maintenance,

accidents,besure

off.

Check

when

oower

suooiy®.ifthe

steooed

because

©until

turning

toolsorother

machine.

the

on inadvertently, it is

Keeoonsteooing

the

off

SAFETY

takes

the

machines

follow

these

while

ooerating

machine

table

adjusting,

the

that

the

oedalisoressed.

tyoe

motorisused,itiii

by

inertia

the

machine

oower

PRECAUTIONS

utmost

care

and

devices,

tesic

safety

remove

the

unnecessary

while

cleaning,

needle

and

the

oower

machine

after

turning

machine

machine

will

on

comestoa

suooiy.

to

safety

to

is

wiii

oedal

move

the

stoo

not

•

l9SU;e<!:^i3:x

T'^l/^gBmstSSx il»g'aS=5S)^T •Turn the oower off before

machine

>In

the

turn

•Check

grounded.

table.

eventofa

the

machine

that

oower

off.

the

machineissecurely

failure,besure

leaving

the

to

Page 4

S/X

CONTENTS

BEFORE

Lubrication

Manual

Filling

C)^W)iSU75

Threading

OSyiL0(2-3:$:it)

Threading

OS3iU0(4^:St)

Threading

TEST

ofxE^roisas

Presser

O^Jt(0^(W562-542)

Diff.

Oa!ltt®Mli5(W561-541)

Diff.

oat

Stitch

OaL^@SS0lSli5

Stitch

lubrication

the

SEWING

foot

feed

feed

length

length

OPERATING

HR

diagram

diagram

pressure

retio(W562'54a

retio(W561'541)

0*562-542)

0*562-542)

0*561-541)

0*561-541)

device

(2-3-needle)

(4-needle)

with

silicon

m

PAGE

2

3

oil

4

5

5

7

10

11

12

Thread

tentlon

MAINTENANCE

Cleaning

Replacing

Checking

Checking

Replacing

the

the

the

and

the

DURING

machine

needle

oil

circulation

replacing

oil

-1-

the

USE

oil

filter

13

14

15

16

17

18

Page 5

BB^Of^OPERATWG

{zArvc<n^i\o

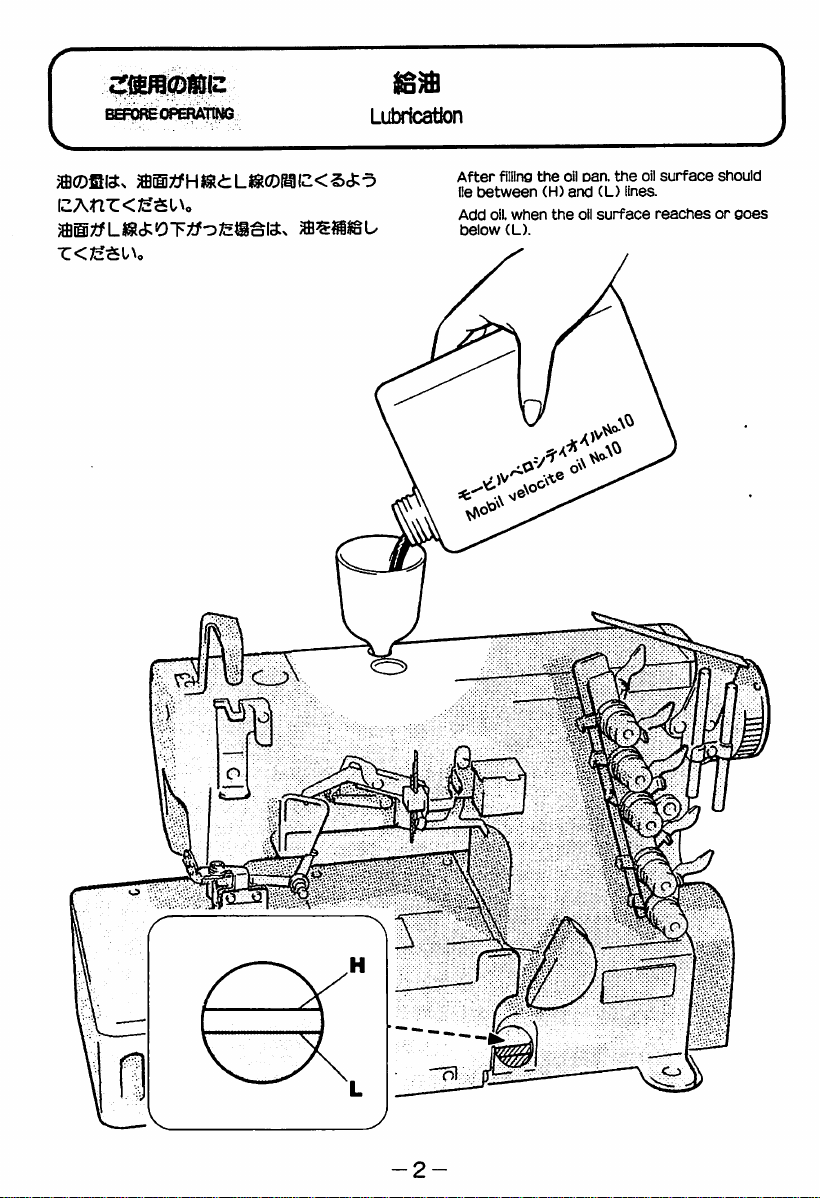

Lubrication

After

lie

Add

below

ffliing

between

oil.

(L).

when

the

(H)

the

oil

oaa

the

oil

surface

and

oil

(L)

surface

lines.

reachesorsees

should

1

2-

Page 6

BEFORE

OPBVmNG

Manual

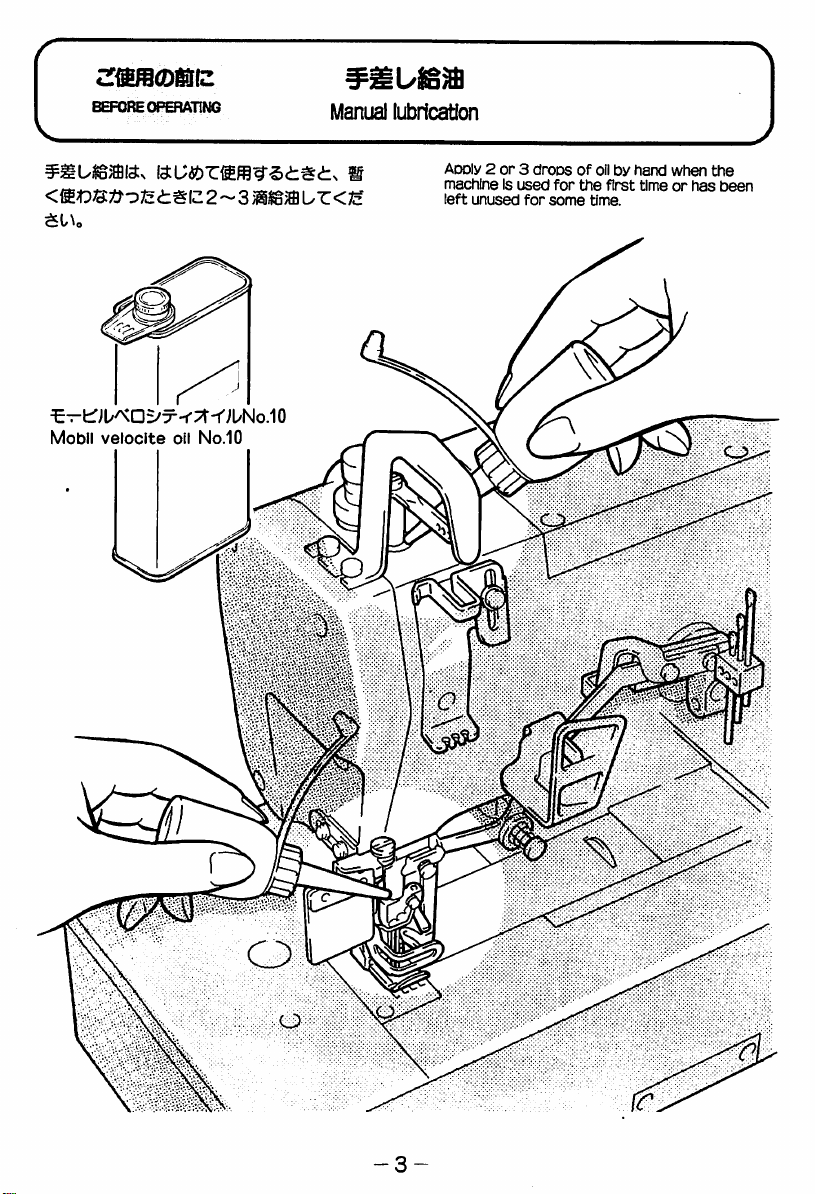

lubrication

$L\o

Mobil

veloclte

Aooly 2or3

2 ~ 3

oil

No.10

Lr<^

machineIsused

left

unused

droDsofoilbyhand

for

the

some

time.

first

for

when

timeorhas

the

been

u

Page 7

itfi5i^«inii35it©3S«t)iz>

L45(io)

D€C:ffi«<

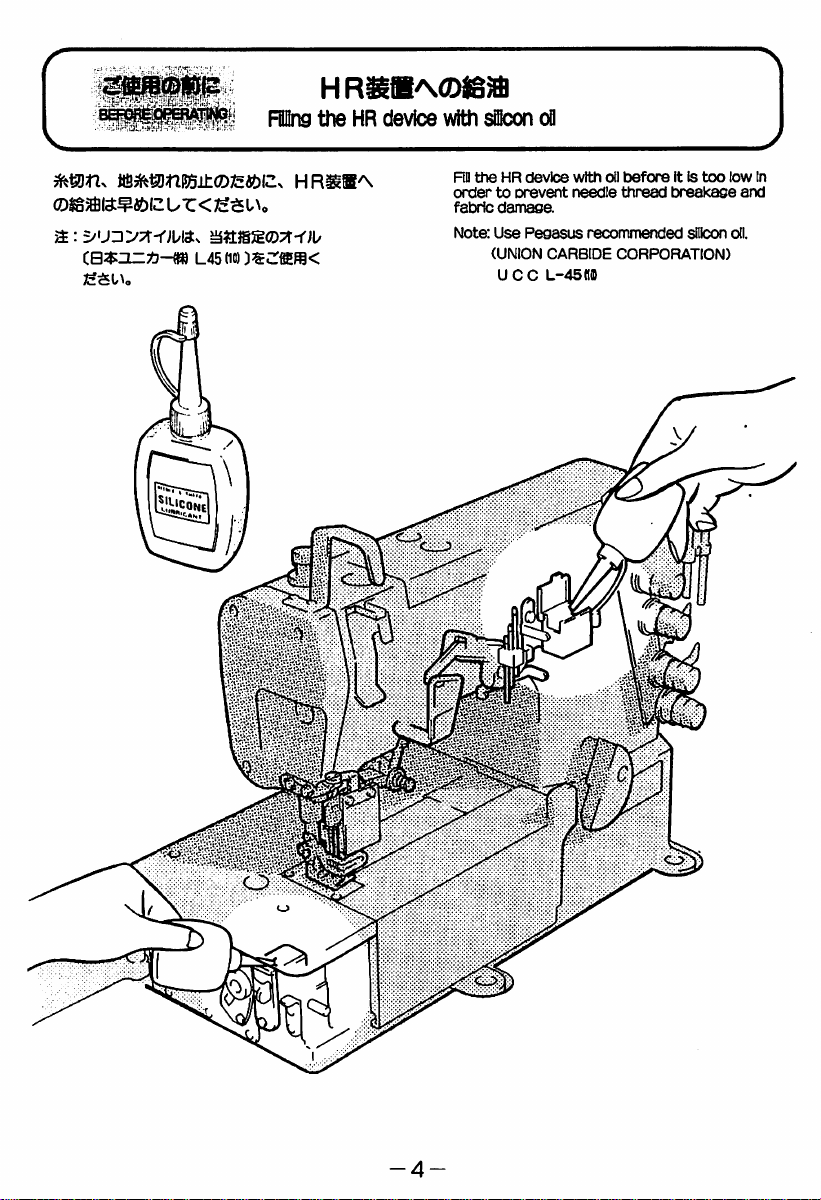

Fing

theHRdevice

hr^b^

with

sScon

RD

theHRdevice

ordertoprevent

fabiio

damage.

Note;

Use

(UNION

UCC

Peoasus

CARBIDE

L-45fliD

with

oil

needle

recommended

CORPORATION)

tieforeItis

thread

breakage

too

silicon

low

on.

and

In

O

-4-

Page 8

BETOREOPERATINQ

^

Ooen

the

eye

guard

and

three

covers.

Threadng

The

looper

comes

Knot

the

oreset

thread

being

thread

the

Wt

Press

out

used

nfiachlne.

down

thread

thread

together

take-up

and

the

to

^

Replace

take-up

the

after

}fU§IT.

looper

threading.

thread

5SR«)-C8tCaUEUT:<

Neede

thread

Trim

the

knots

throuoh

off

the

oassino

needletorethread.

»

eue;(fiiiT:<

L/-C»6, _

Looper threadi Top cover thread!i

Trim

oassing

loober.

neatly

eyeofthe

the

knots

throuoh

je^siv.

before

Li:-

sarjfli%«gist±i

off

neatly

the

after

eveofthe

m

ttx

5ifeauia3S^rEU<j^%€a

^ L/t:<s^5Uo(6'7M)

Be

suretothread

correctlybyreferringtothe

threading

diagram.

-5-

the

(See

machine

P.6'7)

Page 9

BEFOREOKRATiNG

Threading

^ r

diagram

(2*3-

needle)

J

Broken

For

Solid

For

W561

W561

^W561

more

lines

normai

•W562-21

-22

lines®

stretchable

thread

-22

thread

©

icjBur=&o>s^Trs5i«s=

If

the

top

loose,

use

J l^lf

the

top

too loose

too

loose

broken

line(§), use

cover

broken

cover

after

after

thread

line(§).

thread

threading

threading

broken

is too

is still,

with

with

line

fi6y^ft<USy9"Sf5«lo=

If

the

top

cover

broken

©.

tight,use

<^11

thread

line

©

is too

©.

^

For

able

more

threads.

stretch-

y

For

able

less

threads

stretch-

Broken

lines ©

For

more

stretchable

thread

-6

Page 10

cTfififflCDilC

BBKWEOPERATOiG

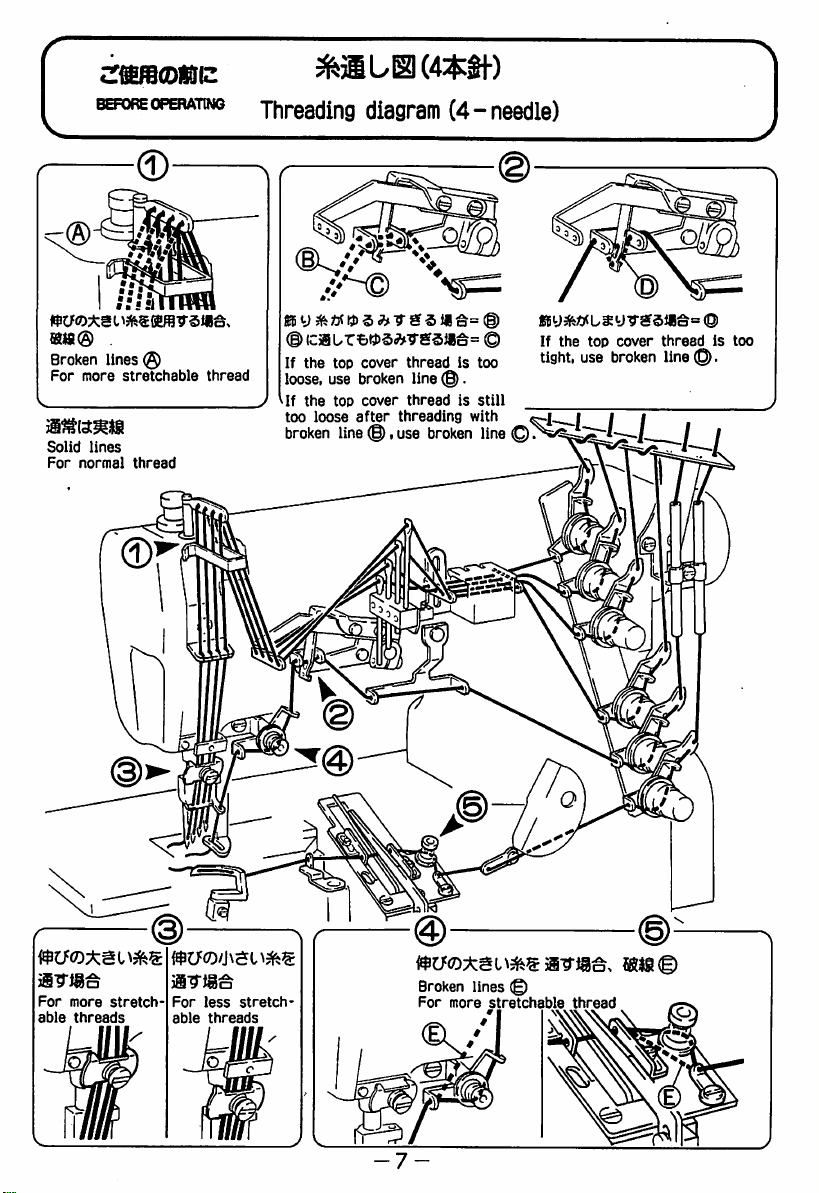

Threading diagram (4-needle)

^ r

^ ® (4$Sf)

Broken

For

Solid

For

more

lines

normal

lines@

stretchable

thread

thread

®

ICjBL/TB«>3^7S3JI6=

If

the

top

cover

loose,

use

If

the

top

too

loose

too loose after threading with

broken

line

broken

cover

after

(g),

threadistoo

line(g).

threadisstill

threading

use

broken

with

line

8fiy^««bay9-gsiis=(

If

the

top

tight,use

cover

broken

^1-—/

Q

threadistoo

line

/

/

(Q).

For

able

more

threads

stretch-

f/

For

able

less

threads

stretch-

mrmt

Broken

lines ©

For

more

stretchable

y

K.

thread

-7-

Page 11

zmmLz<Jc^i\o

ns®0r.

•cs3;clts§<u•c<;cal^o

Loosen

adjusting

screw

©to

It

sufficienttoobtain

formation.

adjust

should

beaslightaspossible,

nut0and

the

presser

the

proper

turn

foot

stitch

adjusting

pressure.

yet

be

Light

Heavy

Page 12

l-i'J

®±TICi!)^^^Urii6i5U^

(W562,542)

unitoiiflf

DIff.

®o/\-

feed

ratto

adjustment

Loosen

downtoobtain

ratio,

nut

then

(D and move

the

tighten

correct

nut

®.

the

differential

lever

up ®

and

feed

-9-

^

To

stretch

Page 13

U

:^V®^mibT<JccSl\o

CW561,541)

}§§i-@S±Tlc:

mm&comm

Diff.

feed

ratio

adjustment

Open

side

®and

obtain

the

tighten

cover®

move

correct

screw®.

and

Indicator

differential

cover®,loosen

@ up and down to

screw

feedratio,

then

-10-

To

To

Stretch

shrink

m

Page 14

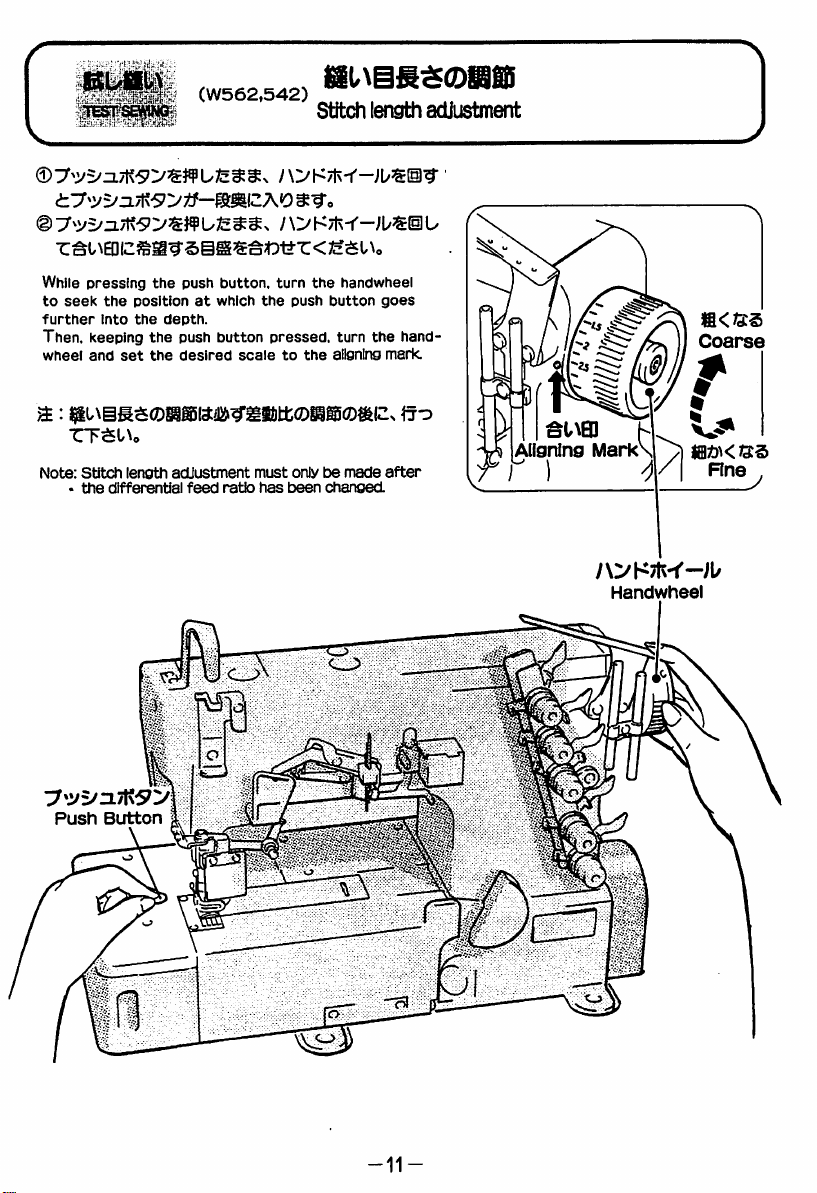

(W562,542)

t.-7^yy=Lif\5fyn-^\zK0

®y-i/yii7rsSfy^n\^nmm.

While

pressing

to

seek

further

Then, keeping

wheel

and

a:

^l\gg$®Saiiail»^^iStt©iS@5©^Cx

•CT^l\o

Note:

Stitch

•

the

the

the

positionatwhich

into

the

depth.

the

set

the

length

differential

acUustment

push

push

desired

feed

button,

the

button

scaletothe

must

ratio

has

turn

pressed,

Stftch

length

nyb^ts-r-Jb^mi,

the

handwheel

push

button

goes

turn

the

aligning

onlybemade

been

changed.

hand-

mark.

after

adjustment

Aligning

INQ]

Mark

Rne

A>K7n-f-jU

Handwheel

'7^yyn.7\^sy

Push

Button

-11-

Page 15

TEST

s^No

(W561,541)

Stitch length adjustment

/\>K7rx-<-ju

Handwheel

W

•^

Rne

Coarse

mttn-^^mi-^s

a:

ia@S^^SS®US^(Ss

Open

side

hand,

After

nut

cover0.

loosen

the

stitch

adjustment,besuretotighten

©again.

by

adjust

Note:

•CTSlNo

Note:

Stitch

length

the

differential

-12-

^ I

"Hi-

I -

/\:/i<7t\-t'-;ui)=£#-c@3£Li:s

^5;@5(iLriaiSLT:<32si\o

Holding

©and

feed

handwheel®still

turn

screw®

must

has

only

tjeen

ratio

to

loe

made

changed.

nut

length.

adjustment

after

Page 16

<;c^l^o

Make

tension

knob®,top

looper

knob (§).

adjustments

cover

To

loosen

with

thread

knob ® and lower

To

tighten

needle

thread

-13

Page 17

MAIlvfiNANCE

DURING

USE

52/>0JSK

Qeaning

the

machine

Mainly

feed

the

slotsofthe

rows

shouldbecleaned.

needle

olate

and

the

-14-

Page 18

MAINTENANCE

DURINGUSE

Reolacing

the

needle

OK!

^7DCigi:^T:s

iMA.

u^niom^vm\^'^hj-c<n-&i\o

♦

Check'the

scarfIsturnedtothe

*

Insert

fasten

needle

the

needletothe

securely.

NO!

carefullytosee

rearofthe

orooer

Standard

xt

Organ

needle

that

machine.

deoth.

UY128GAS

the

and

.r:-'

o

ItCD-tt-rt:

NEEDLE

2^it

2-needle

^

OK!

SIZE

3W~

3-needle

NO!

iC}£]

zi>[s.mBme>r^i^v<rz^i\c

[Note!Donot

Lr<;csu<,

Be

suretouse

red-handled•alien

packagedinthe

remove

the

the

key

accessory

screw.

wrench

box.

Page 19

iMiNANCE'

OUFQNaUSE

Tr-fyi/SJScDjSfis

Checking

theoDdrcuiatlon

O

O

OK'

rnnftrafi

-16-

Page 20

,MAimiNANCE

0UR1K0'U$E

7r1';nb;>^.>hla^

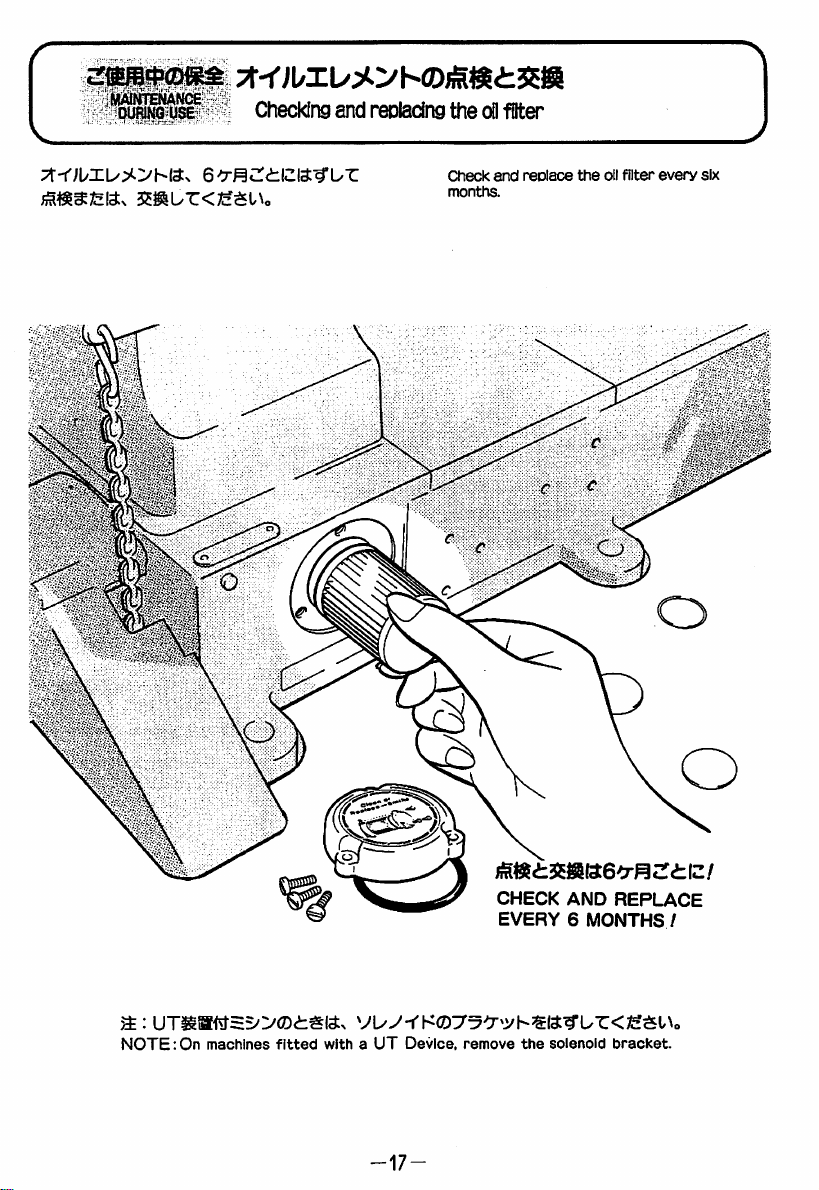

Checking

6<7-^c:<^cis^L.r

and

reoiadng

the

Cfieck

months.

oilfilter

and

reolace

the

oil

filter

every

six

a:

NOTE:On

machines

fitted

CHECK

EVERY6MONTHS

VL/y-f'KCD7'^'T')/h'£IS^U-C<^^St\c

withaUT

Device,

remove

the

-17-

AND

solenoid

REPLACE

/

bracket.

Page 21

MAINTENANCE

DURING USE

Replacing

the

oil

J

CD^I3:6'rM:rd:C3?g&UT:<E$l\,

Jgiffil3:2'S-y«e!SUT:<X!Sl\,

•g-

•

Reoiace

every

(See

the

six

D. 2 .)

oil

months

one

thereafter.

month

after

the

first

use

and

I

Page 22

t553

:*:figmSaE38{^5-7-2

TEL

(06)454-0561

PEGASUS

5-7-2,Sagisu,Fukush!ma-l(u. Osaka553,Japan. Phone; (06)

Cat.

NO.9A2033

©1992

PEGASUS

c<oeESB»8*icigc3nrcisi^SB.sia<oE«)?so<sETSci:o<39ysir.

The description in this

SEWING

A Printed

SEVirtNGMACHINE MFG. CO.. LTD.

INSTRUCTION

MACHINE

November,

BOOK

MFG.CO,LTD.

1992

are

subject to change without notification

454-0561

Loading...

Loading...