Page 1

INSTRUCTIONS

W1500

Series

2 or 3-needle flatbed interlock stitch machine

Thank you very much for purchasing Pegasus W1500

Series machine.

This instruction manual describes daily routine

maintenance and safety precautions to keep the

machine in the best possible conditions.

Please study this manual very carefully before operating

the machine.

Page 2

Page 3

C

CONTENTS

CONTENTS

Adjusting the feed dog height

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Adjusting the presser foot lift

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21

Adjusting the needle height

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22

Adjusting the looper

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23

Adjusting the needle guard (rear)

. . . . . . . . . . . . . . . . . . . . . . .

24

Adjusting the needle guard (front)

. . . . . . . . . . . . . . . . . . . . . . .

24

Changing the maximum differential feed ratio

. . . . . . . . . . . . . .

25

Checking and cleaning the oil filter

. . . . . . . . . . . . . . . . . . . . . .

26

Adjusting the amount of backward tilt on the presser

foot (for W1562-05)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27

FT device (for W1562-05)

Manual lubrication

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27

Adjusting the fabric guide

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27

Replacing the upper knife

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27

Replacing the lower knife

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

28

Adjusting overlap of the knife cutting edges

. . . . . . . . . . . . . . . . .

28

Adjusting the lower knife holder left to right

. . . . . . . . . . . . . . . . . .

28

MD device (for W1562-05)

Installing the lace guide

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

29

Greasing

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

29

Adjusting the lace guide (lower)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

29

Adjusting the elastic guide

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

30

Adjusting the feeding amount of the elastic

. . . . . . . . . . . . . . . . . .

30

Adjusting the roller pressure

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

30

Inserting the elastic into the roller

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

31

Adjustment dimensions

Comparison table of equivalent sizes

Standard needle

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

32

Subclass specifications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

33

Copyright

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

Directives

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

1.Introduction

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2

2.I

ndications of dangers, warnings & cautions

.

2-3

3.Safety precautions

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4

4.Notes for each procedure

. . . . . . . . . . . . . . . . . . . . . . . .

4-6

5.Location of warning labels and safety devices

. . . .

7

6.Protectors for safety

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8

Assembling the machine rest board

. . . . . . . . . . . . . . . . . . . . . .

9

Sewing machine installation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9

Installing the belt cover

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9

Operating direction of the machine pulley

. . . . . . . . . . . . . .

9

Lubrication

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10

Silicone oil for H.R. device

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11

Threading

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12-13

Adjusting presser foot pressure

. . . . . . . . . . . . . . . . . . . . . . . . . .

14

Adjusting the differential feed ratio

. . . . . . . . . . . . . . . . . . . . . .

14

Adjusting stitch length

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14

Adjusting the thread tension

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15

Cleaning the machine

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15

Replacing the needle

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16

Oil replacement

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16

To drain the oil

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16

Adjusting the needle thread guard

. . . . . . . . . . . . . . . . . . . . . .

17

Adjusting the needle thread guides

. . . . . . . . . . . . . . . . . . . . .

17

Adjusting the looper thread take-up

. . . . . . . . . . . . . . . . . . . .

18

Adjusting the looper thread guides

. . . . . . . . . . . . . . . . . . . . . .

18

Adjusting the spreader

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Adjusting the top cover thread guide

. . . . . . . . . . . . . . . . . . . .20

Page 4

Copyright@@@@@@@@@@@@@@@@

●This instruction manual may not be reproduced, transcribed, transmitted, distributed or translated into any

language, in whole or part, in any form or through a paper or electronic medium, without the prior written

permission from Pegasus Sewing Machine Mfg. Co., Ltd.

●Disclaimer

The contents described in this instruction manual are intended for giving information and subject to change

without notice. We assume no responsibility for these information, and any errors and/or incorrect descriptions

that may appear in this instruction manual.

●Pegasus Sewing Machine Mfg. Co., Ltd. has a policy that we always modify the performance and/or

specifications of this product introducing the state-of-the-art technology. Accordingly we reserve the right to

change the specifications and/or design without notice.

●This instruction manual is valid for all the models and subclasses listed in the chapter "Specifications."

Directives@@@@@@@@@@@@@@@@

This machine is constructed in accordance with the European regulations contained in the conformity and

manufacturer's declarations. In addition to this instruction manual, strictly observe all the generally accepted,

statutory regulations, legal requirements and all the environmental protection regulations.

Also rigidly adhere to the regionally valid regulations of the social insurance society for occupational accidents or

other supervisory organizations.

Besuretostudyverycarefully

for

for

safety.

safety.

1

Page 5

Indicates an immediate hazard to life or limb.

Indicates a potential hazard to life or limb.

Indicates a possible mistake that could result in injury or damage.

DANGER

WARNING

CAUTION

1.Introduction@@@@@@@@@@@@@@

●This is the instruction manual that describes how to use this product safely.

●Read this instruction manual and learn very carefully how to operate, adjust and service this sewing machine

before beginning any of the procedures.

●You should realize first that there is always the risk of contacting moving parts, such as needles because you

have to work at point-blank range to them when you are operating industrial sewing machines.

For safety it is essential that we supply safe products and you use them correctly and safely.

There may be some safety measures that you yourself must take.

Therefore, you should read and understand very carefully this instruction manual together with that of the driving

equipment and take necessary safety measures in order to use this machine efficiently and effectively.

2.

Indications of dangers, warnings and cautions

@

To prevent accidents and ensure safety, warning indications which show the degree of danger are used on our

products and in this manual.

Study the contents of these indications carefully and follow all warnings and instructions.

Indication labels should be found easily.

Attach new labels when they are stained or removed.

Contact our sales office when new labels are needed.

Symbols,signsand/orsignalwordswhich

Symbols,signsand/orsignalwordswhich

attractusers'attention

attractusers'attention

2

Page 6

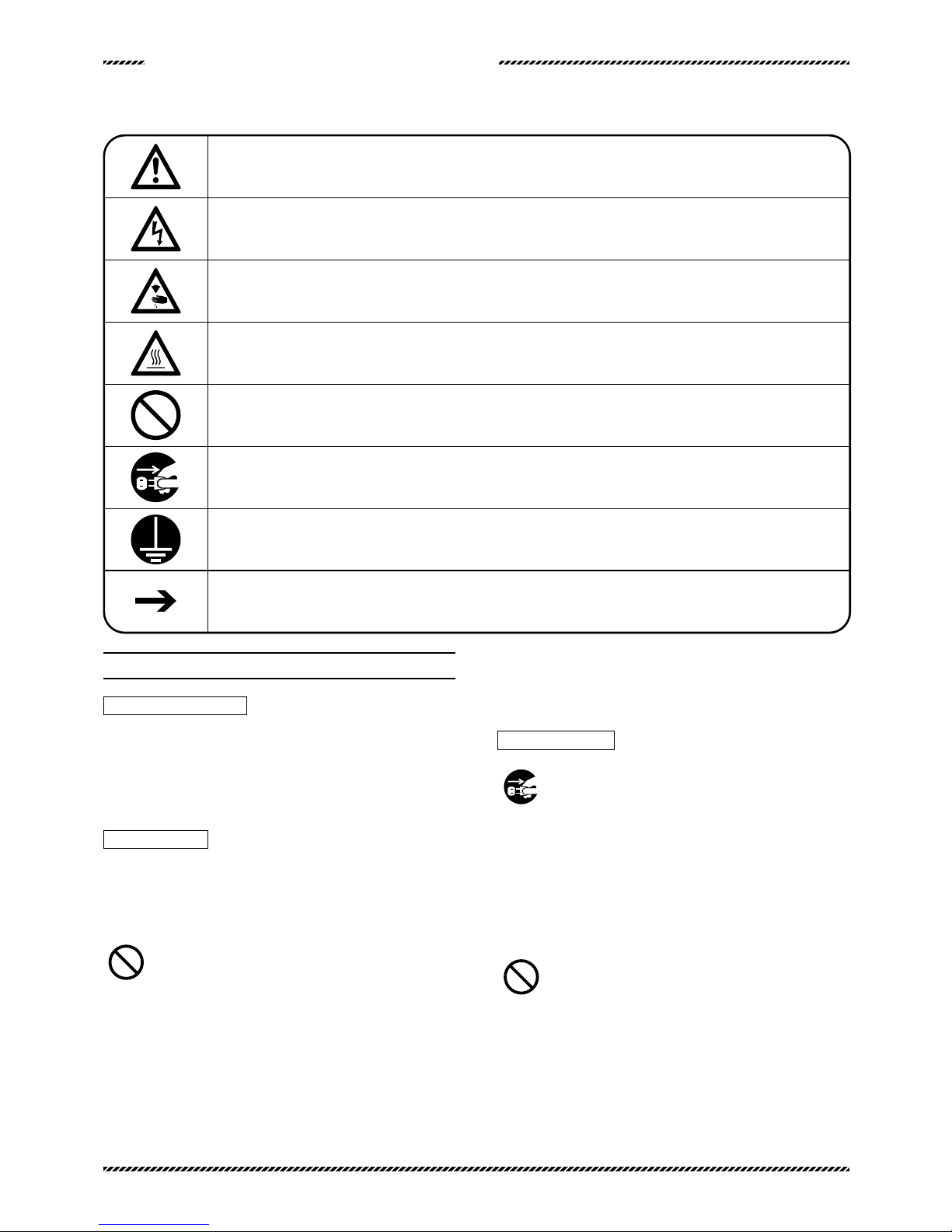

Be sure to ground the machine and labor saving device securely.

If you use the machine and/or labor saving device incorrectly, you may get an electrical shock.

If you use the machine and/or labor saving

device incorrectly, your hands and/or fingers may

be injured.

Be sure to follow the instructions when you operate the machine and/or labor saving device.

Unplug the machine or shut off the power when checking, adjusting and/or repairing the

machine and/or labor saving device, or when lightning may strike.

Denotes the normal rotating direction of the machine pully.

Never do this.

Indicates a danger of burn injury due to high temperature.

3.Safety precautions

①Applications, purpose

Our industrial sewing machines have been developed in order to

increase quality and/or production in the sewing industry.

Accordingly never use our products for other than intended use

described above.

②Circumstances

The environment in which our industrial sewing machines are used

may seriously affect their lives, functions, performance and/or

safety.

For safety, do not use the machine under the

circumstances below.

1.Do not use the machine near objects which make noise such as a

high-frequency welder, etc.

2.Do not use or store the machine in the air which has vapor from

chemicals, or do not expose the device to chemicals.

3.Do not leave the machine outside, in high temperatures or the

direct sun.

4.Do not use the machine in the places of high ambient

temperature and humidity that seriously affects sewing machines.

Symbolsandmessages

Symbolsandmessages

5.Do not use the machine on the condition that the voltage fluctua-

tion range is more than ± 10% of the rated voltage.

6.Do not use the machine in the place where the supply voltage

specified for the control motor cannot be properly obtained.

③Safety measures

(1)Safety precautions when you perform maintenance on

the machine.

●Always turn off the power, unplug the machine and then make

sure that the machine does not run by pressing the treadle

before performing any maintenance, such as checking, repairing,

cleaning, etc. However, if you need to perform these procedures

with the power on, to prevent accidents due to the unexpected

start of the machine and users' misoperation, estabish your oun

procedures for safety and follow them.

●Always turn off the power and unplug the machine

before performing the procedures shown below.

・Lubrication

・Threading

・Cleaning

・Replacing the needle

・Checking/replacing the oil element

・Replacing the oil

Besuretostudyverycarefully

for

for

safety.

safety.

3

Page 7

●Always turn off the power before performing the procedures

shown below.

・Adjusting the stitch length

・Adjusting the differential feed ratio

●Only well-trained people should perform routine daily

maintenance and/or repair the machine.

●Do not modify the machine yourself.

※Consult your local Pegasus' sales office or representative for

modification.

(2)Before operating the machine

●Check the machine head and unit for any damage and/or faulty

function at the start of each day.

If there should be something wrong with the machine,

immediately perform repairs and/or other necessary procedures.

●Check by hand to see if the needle holder is secured.

※Be careful of the needle point.

●Before starting the machine, make sure that the presser foot is

positioned correctly (turn the machine pulley slowly by hand to

see if the needle point is centered in the needle drop hole on the

presser foot).

●Check to see if the presser foot is secured (raise the presser foot

by the foot lifter and press it by hand front to back and left to

right).

(3)Training

●To prevent accidents, operators and service/maintenance

personnel should have proper knowledge and skills for safe

operation.

To ensure so, managers must design and conduct training for

these people.

4.Notes for each procedure

CA

CA

UTION

UTION

①Unpacking

1.The machine is packaged in a cardboard box before shipping.

Unpack your machine in orderly sequence while checking them

right-side up by referring to the indications, such as logo, etc.

printed on the boxes.

2.Never hold the area near the needle and/or thread guide related

parts when taking out the machine from the cushion.

Otherwise it may cause injury and/or damage to the machine.

3.Take out the machine very carefully while checking the position of

the center of the gravity.

4.Keep the cardboard box and packing carefully in case secondary

transport is needed in the future.

Disposal of the packaging

●The packaging material of the machine consists of wood, paper,

cardboard and VCE fiber. The proper disposal of the packaging

is the responsibility of the customer.

Disposal of machine waste

1.The proper disposal of machine waste is the responsibility of the

customer.

2.The materials used on the machines are steel, aluminum, brass

and various plastics.

3.The machine waste is to be disposed of in accordance with the

locally valid environmental protection regulations. A specialist

should be commissioned if necessary.

※The parts contaminated with lubricants should be disposed off

separately according to the locally valid environmental protection

regulations.

Transport within the customer's premises

●The manufacturer assumes no liability for transport within the

customer's premises. Care should be taken to transport the

machine in an upright position avoiding it from dropping or falling

down to the ground when it is moved.

4

Page 8

WWARNING

ARNING

Cables

1.When connecting the cables between the machine and the motor,

be sure to turn off the power and connect each cable connectors

securely.

2.Do not strain the cables in use.

3. Do not bend the cables excessively.

4.When connecting the cables that are close to the moving parts,

such as pulley or V belt, keep a distance of 25mm at least

between them.

5.Protect each cable using a cover or adjusting its position if

necessary.

6. Never use staples to fasten the cables.

Otherwise it causes a short circuit and/or a fire.

CA

CA

UTION

UTION

Motor

1.Install the machine motor correctly by referring to the instruction

manual supplied by the manufacturer.

2.Select the machine motor equipped with the pulley cover so that

any part of your body etc. is not caught in the belt.

CA

CA

UTION

UTION

Ground

1.Connect each of the ground wires in the sewing machine system

to the ground terminal. Do not connect to another devices'.

2. Connect the ground wires securely to the indicated ground

points on the machine head.

WWARNING

ARNING

④Handling machine oil

1.Never start the machine with no oil in the reservoir.

Use HIGHSPEED SEWING MACHINE OIL specified by Pegasus

(Equivalent of ISO requirements: Viscosity Index of VG22).

2.If machine oil gets in your eyes, it may cause eye irritation.

To prevent the machine oil from getting in your eyes, wear a pair

of protective glasses.

※Should machine oil gets in your eyes, wash them with fresh water

for 15 minutes and then go to see a doctor.

Besuretostudyverycarefully

for

for

safety.

safety.

5

WWARNING

ARNING

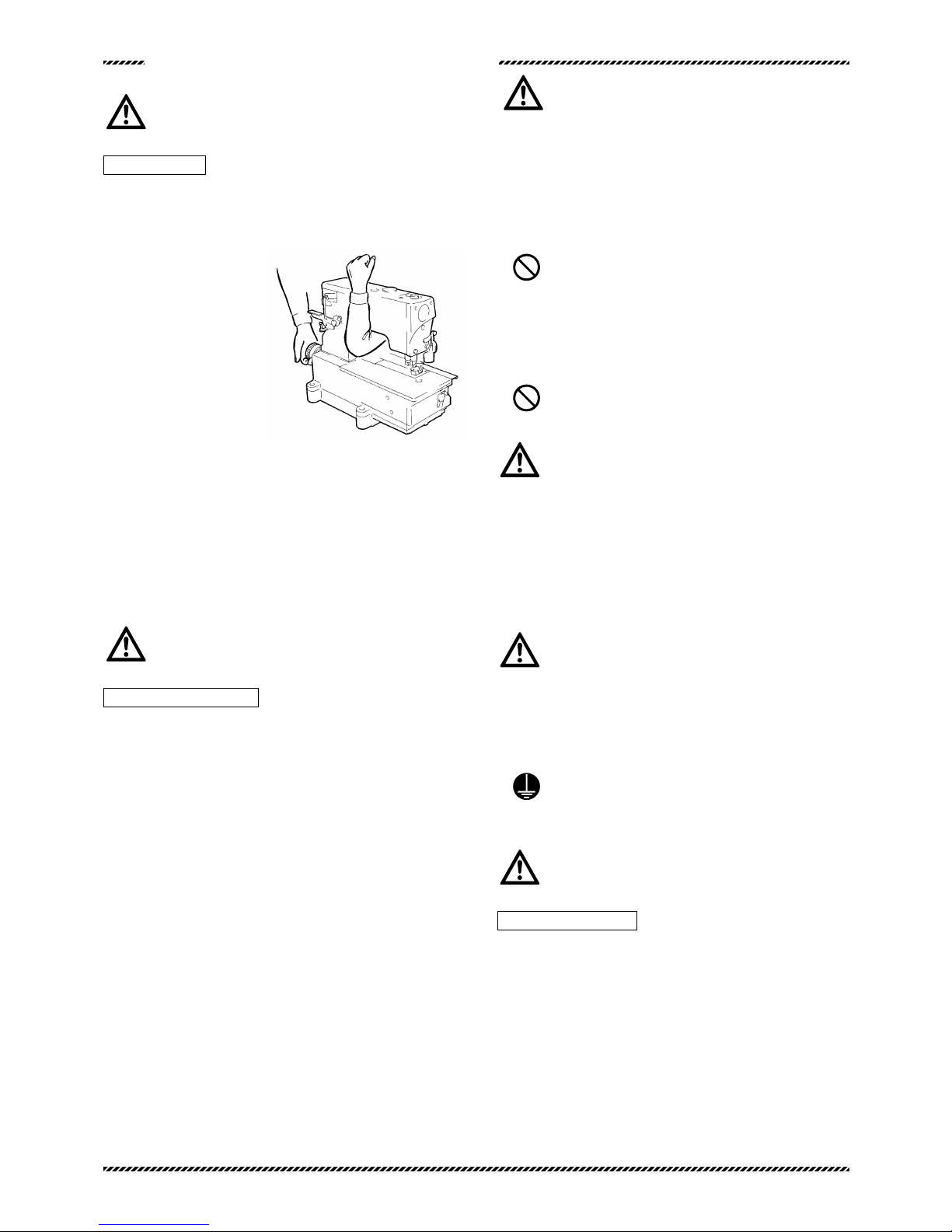

②Transportation

1.The machine should be carried by at least more than two people

when it is mounted on the table and/or a hand truck.

Be sure to use a hand truck for other transportation.

2.To carry the machine, hold

the machine pulley tightly

with your right hand and the

machine arm with your left

upper arm.

If the machine and/or your

hands are stained with oil,

the machine may be easy to

slip out of your hands and

fall to the floor.

Therefore, wipe off the oil carefully.

3.Care should be taken to avoid excessive shock and shake when

the machine is mounted on the table and/or transferred using a

hand truck. Otherwise the machine may fall down.

4.Wipe off the oil from the machine before packaging it again for

secondary transport. Otherwise the machine may easily slip out

of your hands or the bottom of the box may come off while in

transit.

CA

CA

UTION

UTION

③Installation, preparation

Machine table

1.Use the machine table (table board, metal legs) that completely

carries the machine and is fully resistant to warping while the

machine is running.

2.Arrange the working environment for easy operation by

considering where to place the machine and the brightness

around the working area. If the illumination is insufficient, control

or change lighting as required.

3.Attach a non-slip pad to the treadle (foot switch).

Otherwise the operator may slip off the treadle while running the

machine, causing trouble.

4.Adjust the height of the table according to a working posture of

the operator.

Page 9

3.Avoid skin contact. Immediately wash contacted areas

completely with water and soap.

4. Never swallow machine oil.

5.Keep machine oil out of the reach of children.

※If swallowed, do not induce vomiting.

Immediately go to see a doctor.

6.Dispose of the waste oil and/or containers properly as demanded

by law. If you have further questions on its disposal, consult the

store or shop at which you purchased it.

7.After opening the oil container, be sure to seal it to prevent dust

and water from getting into the oil and keep it in the dark to avoid

direct sunlight.

WWARNING

ARNING

⑤Before starting the machine

Machine table

1.Before turning the power on, visually check the cables and

connectors for defective conditions, such as damage,

disconnection and/or loosening.

2.Never bring your hands close to the needle and/or pulley when

turning on the power.

3.When the machine is used

for the first time, turn on the

power and then check the

rotating direction of the

machine pulley.

The machine pulley should

turn clockwise as seen

from the machine pulley.

4.Well trained operators should use the machine after studying

these precautions and the instruction manual carefully.

5.Regarding symbols that indicate a danger or a warning, read and

study "2. Waning indications" carefully and give training on safety

to the operators as required.

6.Run the machine at the speed less than 3/4 of its maximum for

the first one month.

WWARNING

ARNING

⑥Precautions while you are running the machine

1. Do not run the machine with the safety devices removed,

such as eye guard, finger guard, pulley cover, etc.

2. Never bring your hands under the needle while running the

machine.

3.A clutch motor keeps on running for a while after the power is

turned off. Therefore, be careful even after the power is turned

off as the machine could start running by pressing the machine

treadle.

4. To prevent accidents, never bring any part of your fingers,

hair and clothes near the machine pulley, V belt, motor pulley,

thread take-up and needle bar. Also never leave scissors,

tweezers, tools, etc. around these areas.

5. If you use the machine with the FT device, do not bring any

part of your hands and fingers too close to the FT during sewing.

Otherwise it may cause accidents and physical in jury.

6.Always turn off the power while the machine is not used or before

leaving the machine table.

7.In the event of a power failure, be sure to turn off the power.

8.While operating the machine, wear clothes that cannot be caught

in the machine.

9. Do not put any tools or other unnecessary objects on the

machine table while running the machine.

CA

CA

UTION

UTION

⑦Maintenance, Check, Repair

1.Well trained people should perform maintenance, check and

repair of the machine after studying these precautions and the

instruction manual carefully.

2. If it is necessary to lay the machine backward for

maintenance, check and repair, always turn off the power, unplug

the machine and press the treadle to make sure that the machine

dose not operate before beginning any of the procedures.

3. Before installing/removing the V belt, always turn off the

power, unplug the machine and press the treadle to make sure

the machine does not operate.

4.Carry out daily maintenance work and periodical inspections

properly by following these precautions and the instruction

manual.

5.Employ Pegasus' genuine parts when repairing the machine

and/or replacing the parts. We are not responsible for accidents

caused by any improper repair/adjustment and substituting other

parts for thoes manufactured by Pegasus.

6.Do not attempt to modify the machine at your own discretion.

We are not responsible for accidents caused by the modification.

7.Be sure to replace the safety devices and/or safety covers that

are temporarily removed for maintenance and/or adjustment.

8.After performing maintenance, check and repair, make sure that

turning on the power does not pose any danger to you.

6

Page 10

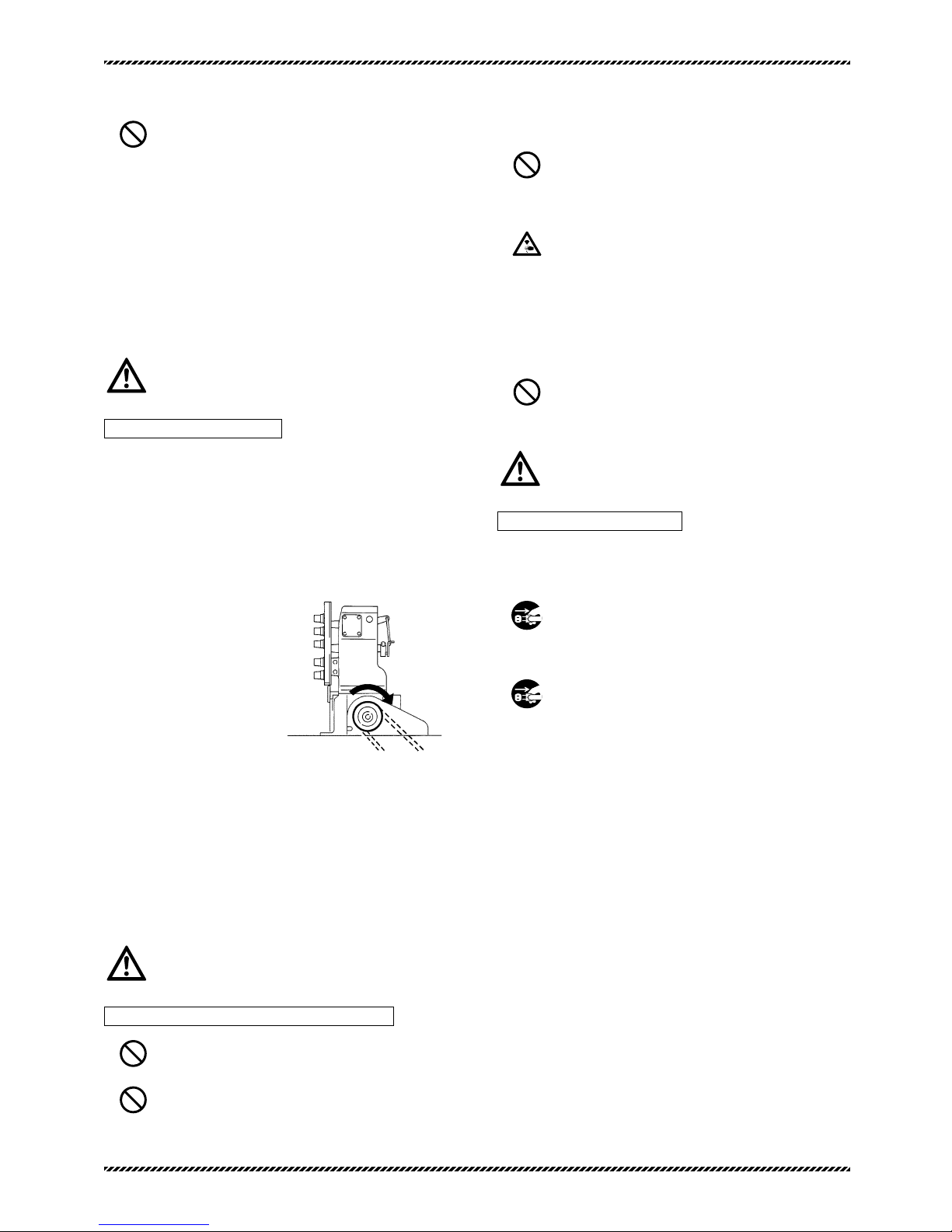

Eye guard

Side cover

Sliding plate Front cover

Pulley cover

5.

Location of warning labels and safety devices

Besuretostudyverycarefully

for

for

safety.

safety.

Finger guard

7

Page 11

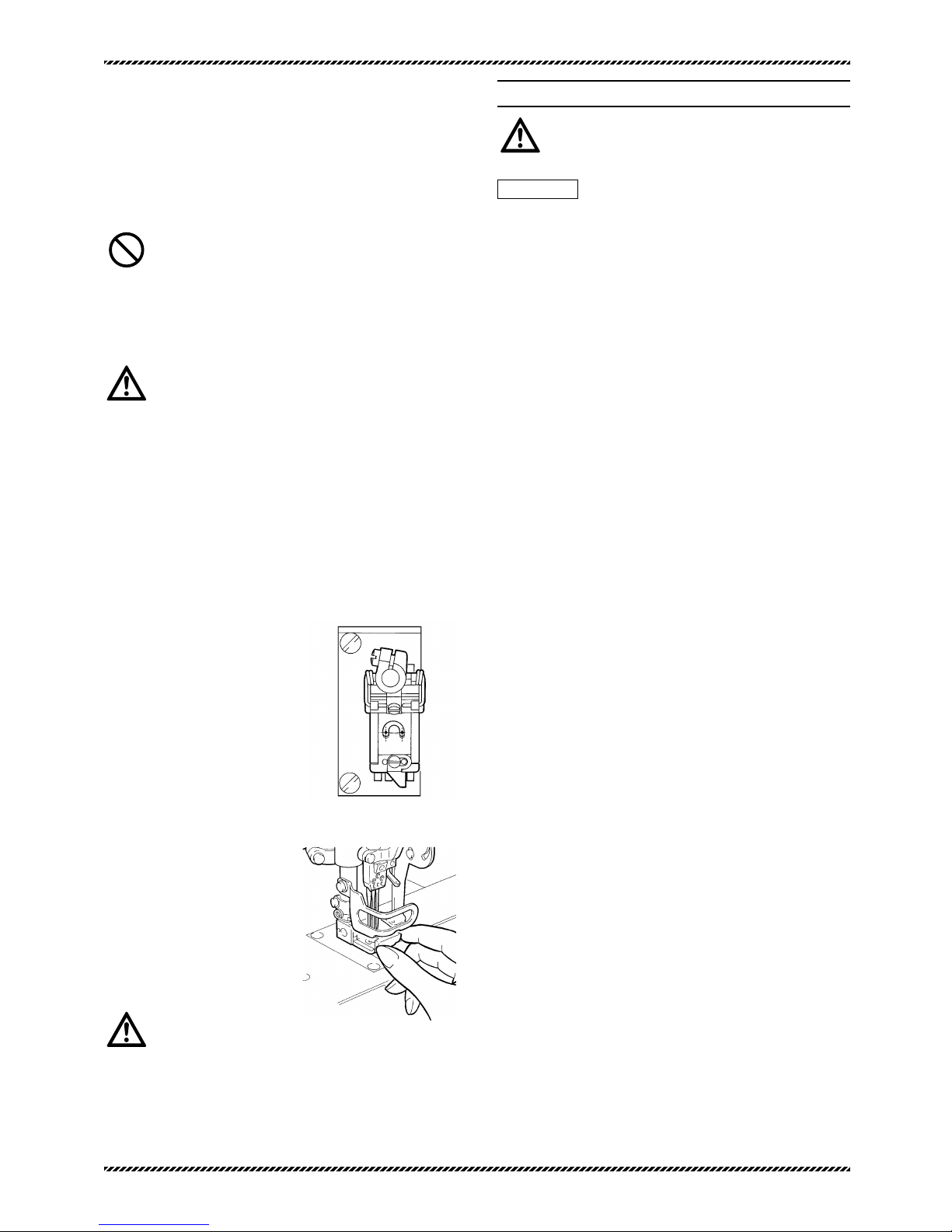

6.Protectors for safety

This chapter describes each protector for safety. Therefore, read

and study the following carefully.

CA

CA

UTION

UTION

Protectors for safety

(1) Eye guard

Never leave the eye guard open.

For the safety of eyes, do not operate the machine with the eye

guard open. The eye guard will prevent any pieces of the broken

needle from getting into your eyes if the needle should break during

sewing.

(2) Finger guard

Never insert any of your fingers.

To prevent the needle that moves up and down from contacting any

of your body, the finger guard is installed close to the needle.

However, there is clearance above the finger guard for easy

threading. Be careful that the needle may penetrate any of your

fingers if you insert it into this clearance.

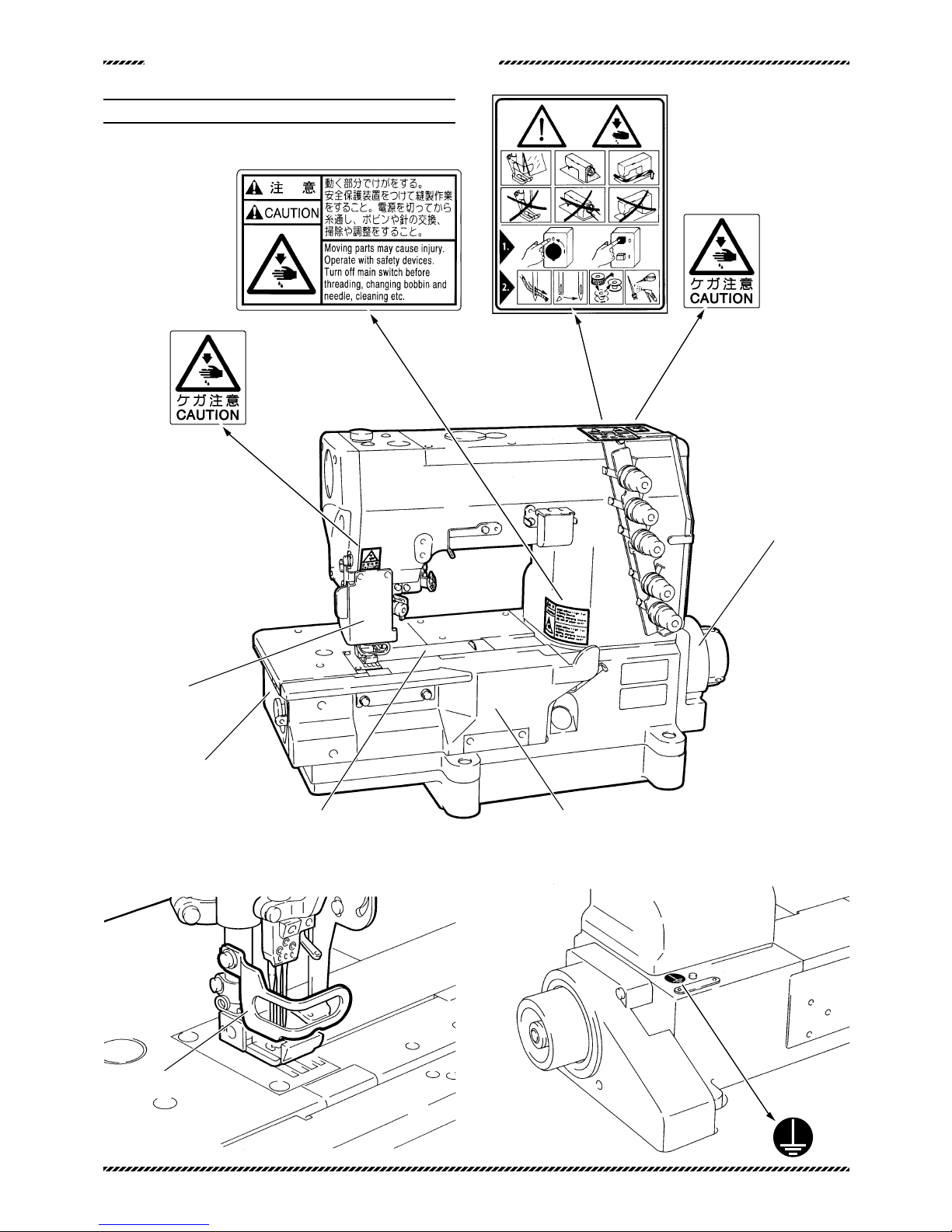

(3) Pulley cover

Never remove.

The machine pulley and V belt are covered with the pulley cover.

The machine pulley and the V belt rotate at high speed during

sewing. To prevent accidents, operate the machine with the pulley

cover installed in place.

(4) Pulley

Check the direction in which the machine pulley rotates.

It should rotate clockwise as seen from the pulley.

(5) Presser foot

Never insert any of your fingers.

There is a clearance of more than 5mm between the top

surface of the needle plate and the presser foot.

Be careful that none of your fingers are caught in this clearance.

Never insert any of your fingers under the presser foot when raising

the presser foot with the knee switch or automatically raising it with

the treadle.

(6)Front cover

Never leave the front cover open.

The looper travels left to right while drawing an arc as seen from the

front of the machine. To prevent the looper from contacting any

part of your body, be sure to operate the machine with the front

cover closed securely.

(7) Side cover

Never leave the side cover open.

The looper travels left to right while drawing an arc as seen from the

front of the machine. To prevent the looper from contacting any of

your body, be sure to operate the machine with the side cover

closed securely.

(8) Sliding plate

Never leave the sliding plate open.

The looper thread take-up rotates in order to supply the required

amount of looper thread during sewing. To prevent the looper

thread take-up from contacting any of your body, be sure to operate

the machine with the sliding plate closed securely.

8

Page 12

9

1

2

3

4

4

2cm

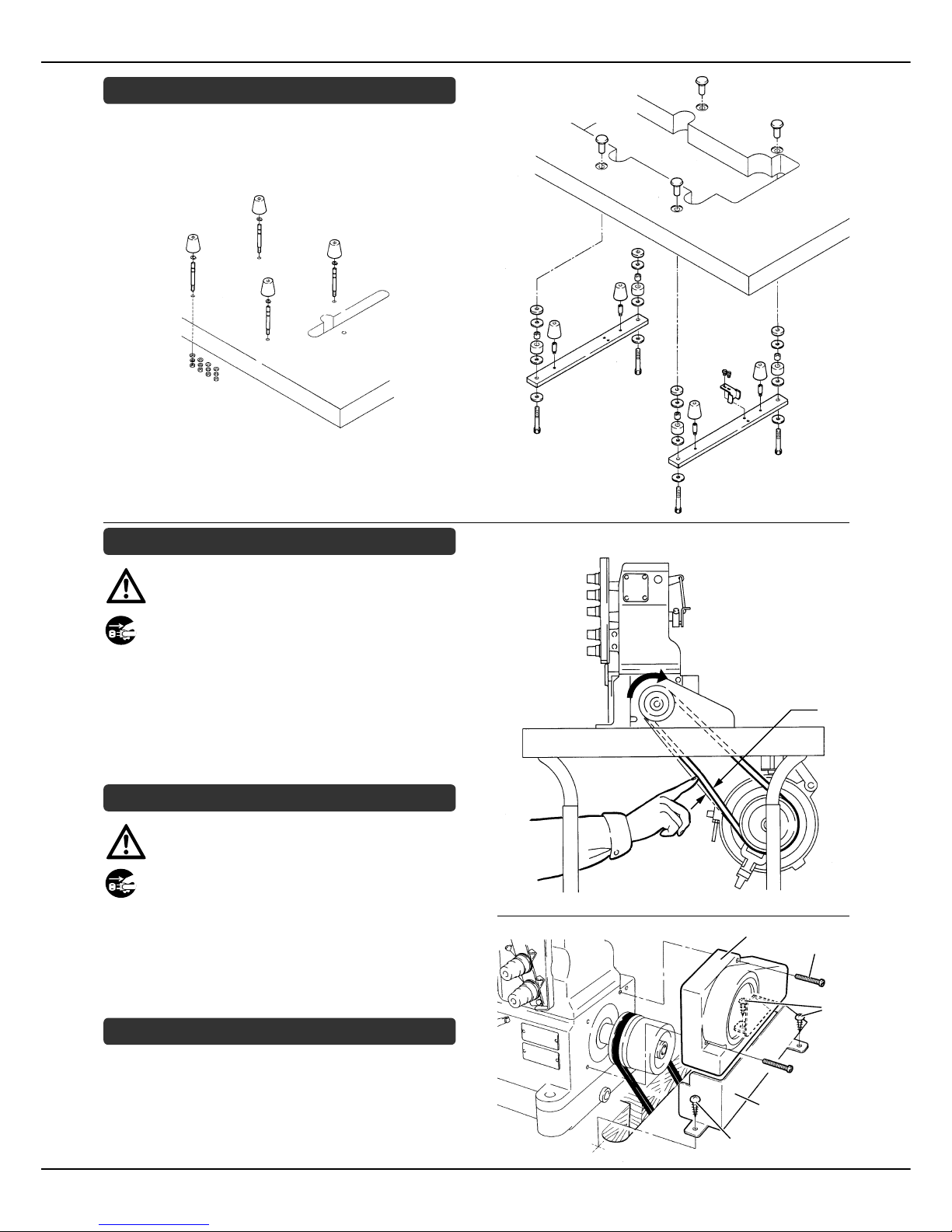

Assembling the machine rest board

Assemble the components comprising the machine rest board by

referring to the illustration below. Be sure to secure all rods, nuts

and bolts firmly with no shake.

Sewing machine installation

CA

CA

UTION

UTION

Always turn off the power, unplug the machine and then well-

qualified technicians should install the machine.

Mount the machine on the machine rest board first. Put the V belt

in place. Position the machine motor so that an approx. 2cm

deflection can be obtained by pressing the center of the belt

(see the illustration).

Installing the belt cover

CA

CA

UTION

UTION

Always turn off the power, unplug the machine and then well-

qualified technicians should install the belt cover.

Install belt cover 1 on the machine with screws 2.

For non-submerged installation, install belt guard 3 onto the

machine table with wood screws 4.

Operating direction of the machine pulley

The machine pulley rotates clockwise as seen from the end of the

machine pulley.

(Semi-submerged

installation)

(Non-submerged

installation)

Page 13

10

2

1

HIGH

S

P

EE

D

SEW

I

NG

MACHI

N

EO

IL

H

L

3

HIGH SPEED SEWING

MACHINE OIL

4

Lubrication

CA

CA

UTION

UTION

When lubricating the machine and/or replacing the oil, use

Pegasus recommended oil. Using other oils may damage the

machine.

1. Oil

Use the oil "HIGH SPEED SEWING MACHINE OIL" specified by

Pegasus (ISO Viscosity Grade 22).

2. To fill the machine with oil

Remove cap 1.

Add the oil until the oil level (see oil gauge 2) reaches (H).

After filling the tank with oil, replace cap 1.

3. Required amount of oil

(H) on oil gauge 2: Upper limit

(L ) on oil gauge 2: Lower limit

The oil level should always lie between (H) and (L).

4. Manual lubrication

CA

CA

UTION

UTION

Always turn off the power and unplug the machine when you

apply oil by hand.

Apply two or three drops of oil to needle bar 3 by

hand when the machine is used for the first time or left unused for

some time.

5. Checking oil circulation

Once the machine has been properly filled with oil, press the

machine treadle to run the machine and check oil gauge

window 4 to see if the oil is flowing.

Page 14

11

2

1

Silicone oil for H.R. device

CA

CA

UTION

UTION

Always turn off the power and unplug the machine when you

fill the HR device with silicone oil.

Fill silicone oil tanks 1, 2 with silicone oil.

To prevent thread breakage or fabric damage, add the silicone oil

before it is too low.

Page 15

12

Threading

CA

CA

UTION

UTION

Always turn off the power and unplug the machine when you

thread the machine.

1.

Open eye guard 1 and covers 2 , 3 and 4.

2.

Press lever 5 and bracket 6 comes out toward you. After

threading, press bracket 6 into place.

3.

In case the machine is threaded previously

A:Knot the preset thread and the thread being used together

to thread the machine.

B:

Needle thread

Trim the knots off neatly before

passing through the eye of the

needle to thread.

C:

Looper thread,

Top cover thread

Trim the knots off neatly after

passing through the eye of the

looper.

Be sure to thread the machine correctly by referring to the threading

diagram. (See page 13)

1

4

2

3

A

B

C

5

6

6

Page 16

13

For more

stretchable thread.

4.

Threading diagram

Page 17

14

Adjusting presser foot pressure

The presser foot pressure should be as light as possible, yet

sufficient to feed the fabric correctly and provide the uniform stitch

formation.

Loosen nut 1. Adjust the presser foot pressure. Adjustment is

made by turning screw 2 clockwise or counterclockwise using a

coin. Tighten nut 1.

Adjusting the differential feed ratio

1.

Loosen nut 3 for the differential feed ratio adjustment.

To increase the differential feed ratio, lower lever 4.

The finished fabric is shrunk.

To decrease the differential feed ratio, raise lever 4.

The finished fabric is stretched.

2.

After this adjustment tighten nut 3.

Adjusting stitch length

CA

CA

UTION

UTION

Always turn off the power and unplug the machine when

adjusting the stitch length.

1

. While pressing the push button 5, turn the handwheel 6 to

seek the position at which the push button 5 goes further into

the depth.

2.

Then, keeping the push button 5 pressed, turn the handwheel

6 and set the desired scale to the aligning mark A.

Note

Stitch length adjustment must only be made after the differential

feed ratio has been changed.

1

2

HeavyLight

3

4

To stretch

To shrink

5

A

6

Coarse

Fine

Page 18

15

4

5

6

7

Adjusting the thread tension

To obtain the proper thread tension, adjust needle thread tension

knobs 1, top cover thread tension knobs 2 and looper thread

tension knob 3.

To tighten the thread, turn each knob clockwise.

To loosen the thread, turn each knob counterclockwise.

Each thread tension should be as light as possible, yet be sufficient

to produce balanced and beautiful stitches.

Cleaning the machine

CA

CA

UTION

UTION

Always turn off the power and unplug the machine when you

clean the machine.

1.

Open front cover 4 and slide plate 5. Loosen screws 6 and

remove needle plate 7.

2.

Clean the grooves of the needle plate and the area around the

feed dogs.

3.

Replace needle plate 7 with screws 6. Then close front

cover 4 and slide plate 5.

1

2

3

To loosen

To tighten

Page 19

16

2

OK! NO!

Scarf

1

OK! NO!

Replacing the needle

CA

CA

UTION

UTION

Always turn off the power and unplug the machine when you

replace the needle(s).

1.

Loosen screw(s) 1 using a red-handled key wrench (1.5mm).

2.

Remove the old needle(s) by using a pincette (provided as

accessories).

3.

Fix the needle so that its scarf faces the rear side of machine.

4.

Insert a new needle into the needle hole as far it will go by

using a pincette.

5.

Tighten screw(s) 1 using a red-handled key wrench (1.5mm).

Oil replacement

Replace the oil one month after the first use and thereafter

every six months. If you keep using the old oil, it may cause the

damage to the machine.

To drain the oil

1.

Drain the oil by removing screw 2 on the left side of the oil

pan.

2.

Tighten screw 2 after draining.

Page 20

17

4

5

3

To loosen the

needle thread

To tighten the

needle thread

For cotton

threads

For woolly

threads

For spun/polyester

threads

1

1

1

Not activated

(1) (2) (3)

Left needle thread

93 mm

5

Adjusting the needle thread guard

CA

CA

UTION

UTION

Always turn off the power, unplug the machine and then well-

qualified technicians should adjust the needle thread guard.

Loosen screw 2. Adjust needle thread guard 1 to the appropriate

position according to the type of thread being used (see the

illustration right). Tighten screw 2 temporarily.

・To decrease the size of the needle thread loop, move needle

thread guard 1 up.

・To increase the size of the needle thread loop, move needle

thread guard 1 down.

Move guard 1 up and down so that the needle thread loop is formed

properly.

Tighten screw 2 after this adjustment.

(1)In the case of the threads that are not stretchable, such as

cotton threads (The needle thread loop tends to be formed

large and lie down.)

(2)In the case of the stretchable threads, such as woolly threads

(The needle thread loop tends to be formed small.)

(3)In the case of the threads that are slightly stretchable, such as

spun threads

Adjusting the needle thread guides

The distance from the center of the eyelet on left needle thread

guide 5 to the top surface of the needle plate should be 93mm

(standard).

Adjustment is made by loosening screws 3 and moving thread

guide 4 up or down (see the illustration on the right). After this

adjustment tighten screws 3 temporarily.

・To loosen the needle thread, move needle thread guide 4 up.

・To tighten the needle thread, move needle thread guide 4 down.

Tighten screws 3 after this adjustment.

2

1

Page 21

18

3 5

4 2

The point of the left needle has reached the bottom

end of the looper blade.

Position of the point of the left needle when

the looper thread is released from point A on

looper thread take-up 1.

1

2

A

Adjusting the looper thread take-up

CA

CA

UTION

UTION

Always turn off the power, unplug the machine and then well-

qualified technicians should adjust the looper thread take-up.

When the left needle has reached the point shown in the illustration

while the looper is moving to the right from the extreme left end of

its travel, the looper thread should be released from point A on the

looper thread take-up.

To make this adjustment, loosen screws 2 and turn looper thread

take-up 1 as required.

After the above adjustment, tighten screw 2.

Adjusting the looper thread guides

CA

CA

UTION

UTION

Always turn off the power, unplug the machine and then well-

qualified technicians should adjust the looper thread guides.

Loosen screws 2 and 3. Center screws 2 and 3 in the slots on

looper thread guides 4 and 5 respectively (standard) by adjusting

looper thread guides 4 and 5 (see the illustration on the right). After

this adjustment tighten screws 2 and 3 temporarily.

・To increase the supply of looper thread, move looper thread

guides 4 and 5 in the direction of A.

・To decrease the supply of looper thread, move looper thread

guides 4 and 5 in the direction of B.

After this adjustment is made, tighten screws 2 and 3.

2

3

5

4

To increase the supply

of looper thread

To decrease the supply

of looper thread

A

B

To decrease

To increase

Page 22

19

6

4

5

7

D

1

4

B

0.5 mm

B

1

4

7

5

1.0 mm

0.5 mm

1

5.0 mm

17.0 mm

B

1

3

2

A

Adjusting the spreader

CA

CA

UTION

UTION

Always turn off the power, unplug the machine and then well-

qualified technicians should adjust the spreader.

1. To adjust the spreader

(1) To adjust the spreader height :

Adjust distance A from the top surface of the needle plate to the

bottom surface of spreader 1. Select the distance according to

the machine being used by referring to the table of adjustment

dimensions (see page 32). Adjustment is made by loosening

screw 2 and moving spreader 1 up or down.

After the above adjustment is made, tighten screw 2 temporarily.

To adjust the spreader front to back :

When point B on the spreader has comes close to the left

needle while spreader 1 is moving to the left from the extreme

right end of its travel, there should be a distance of 0.5mm from

point B to the left needle. Adjustment is made by moving

spreader 1 front to back.

After this adjustment is made, tighten screw 2.

(2) Left-to-right adjustment

When spreader 1 is at the extreme left end of its travel, there

should be a distance of 5.0mm from the center line of the left

needle to point B on the spreader. Adjustment is made by

loosening screw 3 and moving spreader 1 left to right.

After this adjustment is made, tighten screw 3.

2. Adjusting the spreader thread guide

(1) When spreader 1 is at the extreme right end of its travel, there

should be a clearance of 0.5mm between the bottom surface of

spreader thread guide 4 and spreader 1. Adjustment is made

by loosening screws 6. After this adjustment is made, tighten

screws 6 temporarily.

(2) Align the center of the slot of spreader thread guide 4 with point

B on the spreader. Adjustment is made by moving spreader

thread guide 4 left to right. After this adjustment is made, tighten

screws 6.

3. Adjusting the thread guide

(1) When the needles are at the bottom of their stroke, position

thread guide 5 just above front end D of the slot on thread guide

4. Adjustment is made by loosening screw 7.

After this adjustment is made, tighten screw 7 temporarily.

(2) There should be a clearance of 1.0mm between thread guide 5

and spreader thread guide 4. Adjustment is made by

moving thread guide 5 front to back.

After this adjustment is made, tighten screw 7.

Page 23

20

Adjusting the top cover thread guide

CA

CA

UTION

UTION

Always turn off the power, unplug the machine and then well-

qualified technicians should adjust the top cover thread guide.

Loosen screw

1 so that there should be a distance of approximately

20mm (see the illustration) between the left end of spreader thread

guide 2 and the left end of top cover thread guide 3 (standard

position). Then, tighten screw 1 temporarily.

・To decrease the supply of top cover thread, move top cover

thread guide

3 to the right.

・To increase the supply of top cover thread, move top cover

thread guide

3 to the left.

Tighten screw 1 after this adjustment.

A fine adjustment can be made by knob 4.

・To decrease the supply of top cover thread, turn knob 4

clockwise.

・To increase the supply of top cover thread, turn knob 4

counterclockwise.

3

1

4

To increase

3

To increase the

supply of top

cover thread

To decrease the

supply of top

cover thread

To decrease

2

Approximately

20mm

Page 24

21

7

6

8

5

B

4

3

Adjusting the feed dog height

CA

CA

UTION

UTION

Always turn off the power, unplug the machine and then well-

qualified technicians should adjust the feed dog height.

When the feed dogs are at their highest point of travel, there should

be a distance of 0.8~1.2mm from the top surface of the needle plate

to extended line A from the tips of main 1 and differential 2 feed

dogs. Adjustment is made by loosening screws 3 and 4, and

moving feed dogs 1 and 2 up or down.

After the above adjustment, tighten screws 3 and 4.

Adjusting the presser foot lift

CA

CA

UTION

UTION

Always turn off the power, unplug the machine and then well-

qualified technicians should adjust the presser foot lift.

When presser foot 5 is raised, adjust distance B from the top

surface of the needle plate to the bottom surface of the presser foot.

Select the distance according to the machine being used by

referring to the specifications (see page 33).

1.

Turn the machine pulley until the feed dogs are at their lowest

point of travel.

2.

Adjust the presser foot lift by lowering lever 8.

Note that the presser foot should not be in contact with the

spreader.

3.

Loosen nut 6. Adjust screw 7 so that it contacts lever 8.

Then tighten nut 6.

1 2

A

Page 25

22

a

b

Adjusting the needle height

CA

CA

UTION

UTION

Always turn off the power, unplug the machine and then well-

qualified technicians should adjust the needle height.

Adjust distance a from the point of the left needle to the top surface

of the needle plate when the needle is at the top of its stroke.

The distance varies according to the machine being used.

Refer to the table of adjustment dimensions (see page 32).

1.

Turn handwheel 1 and align mark A on the machine with

mark

P

○

on the handweel to bring the needle bar to the top of

its stroke.

2.

Loosen screw 2. Adjust the needle height by moving needle

holder 3 up or down.

●Adjust the relationship between each needle and needle drop

hole so that clearance b is equal after the needle height

adjustment (see the illustration). Then tighten screw 2.

A

1

P

2

3

Page 26

23

0.05 - 0.1 mm

2

3

Adjusting the looper

CA

CA

UTION

UTION

Always turn off the power, unplug the machine and then well-

qualified technicians should adjust the looper.

1.

Adjusting the looper-needle setting distance

Adjust looper-needle setting distance A from the center of the

right needle to the point of looper 1 when the looper is at its

farthest position to the right. Select the distance according to

the machine being used by referring to the table of adjustment

dimensions (see page 32).

Adjustment is made by loosening screw 3 on looper holder 2

and moving looper holder 2 to the left or right.

After the adjustment, tighten screw 3.

2.

Adjusting the looper avoiding distance

When the point of the looper has reached the center of the left

needle from the extreme right end of its travel, there should be

0.05~0.1mm front-to-back clearance between the left needle

and the point of the looper.

● For 3-needle machines

When the point of the looper has reached the center of the

middle needle from the extreme right end of its travel, there

should be 0-0.05mm front-to-back clearance between the

middle needle and the point of the looper.

Adjustment is made by loosening screw 3 on looper holder 2

and moving looper holder 2 forward or backward.

After the adjustment, tighten screw 3.

● When the point of the looper is passing the center of the

right needle from the extreme right end of its travel (the

rear needle guard is not effective), the right needle slightly

contacts the point of the looper.

1

A

Page 27

24

4

5

6

B

0.3 - 0.5 mm

0-0.05mm

0-0.05mm

1 1

1

3

2

Adjusting the needle guard (rear)

CA

CA

UTION

UTION

Always turn off the power, unplug the machine and then

well-qualified technicians should adjust the needle guard (rear).

1.

Line A on needle guard (rear) 1 should be positioned 1/3

below the top end of the right needle's eye when the needle is

at the bottom of its stroke. To make this adjustment, loosen

screw 2, move needle guard (rear) 1 up or down. After this

adjustment, tighten screw 2.

2.

When the point of the looper has reached the center of the

right needle from the extreme right end of its travel, there

should be 0~0.05mm front-to-back clearance between the

right needle and the point of the looper. Adjustment is made

by loosening screw 3 and moving needle guard (rear) 1

forward and backward. After adjusting, tighten screw 3.

3.

For 3-needle machines :

When the point of the looper has reached the center of the

middle needle, the middle needle must slightly contact needle

guard (rear) 1 with 0~0.05mm front-to-back clearance

between the middle needle and the point of the looper.

Adjustment is made by loosening screw 2 and swing needle

guard (rear) 1 to the left or right. After adjusting, tighten screw

2.

Adjusting the needle guard (front)

CA

CA

UTION

UTION

Always turn off the power, unplug the machine and then well-

qualified technicians should adjust the needle guard (front).

There should be a clearance of 0.3~0.5mm (See B) between the

needles and needle guard (front) 5 when looper 4 is moving to the

left in the back side of the needles. To make this adjustment, loosen

screw 6 and move needle guard (front) 5 backwards or forwards.

Finally, tighten screw 6.

1

2

A

1/3

5

6

Page 28

25

1

:1.

8

8

6

7

Changing the maximum differential feed ratio

The differential feed ratio is set to 1:0.9~1:1.3 at the factory.

Always turn off the power, unplug the machine and then well-

qualified technicians should adjust the differential feed ratio.

In the case of a differential feed ratio of 1:1.3~1:1.8

CA

CA

UTION

UTION

If you use the machine with a differential feed ratio of

1:1.3~1:1.8, the feed dogs may strike the needle plate and be

damaged. Check to make sure the movement amount of the

feed dogs is less than 3.2mm.

1.

Setthestitchlength(mainfeeddogmovement)at

lessthan3.2mm.

2.

Removescrew1,nut2 andspringwasher3.

3.

Removesidecover5 byremovingscrews4.

4.

Loosenscrew7.Movestopper6 downallthewayto

thebottom.Tightenscrew7.

5.

Replacesidecover5 withscrews4,andattachnut2

andspringwasher3 ontoadjustinglever8 with

screw1.

To shrink

To stretch

1:1

.3

1

:

0.9

6

9

9

6

7

7

1

4

5

2

3

Page 29

26

Checking and cleaning the oil filter

CA

CA

UTION

UTION

Always turn off the power, unplug the machine and then well-

qualified technicians should check and clean the oil filter.

Checkandcleantheoilfiltereverysixmonths.

Tocheckandcleantheoilfilter

1.

Remove screws 1 and 2. Remove oil reservoir 3.

2.

Loosen screw 4. Remove inner and outer filters 5 and 6.

Then check and/or clean these filters.

3.

Reinstall oil reservoir 3, filters 5 (inner) and 6 (outer).

1

4

5

6

3

2

Page 30

27

1

3

2

4

5

6

7

9

8

7

9

8

Adjusting the amount of backward tilt

on the presser foot (for W1562-05)

CA

CA

UTION

UTION

Always turn off the power, unplug the machine and then wellqualified technicians should adjust the amount of backward tilt on

the presser foot.

For W1562-05 Adjust the amount of backward tilt on presser foot

1 according to the elastic lace and fabric to be used. Adjustment is

made by loosening nut 2 and turning screw 3 as required.

●To increase the amount of backward tilt, turn screw 3 clockwise.

●To decrease the amount of backward tilt, turn screw 3 counter-

clockwise.

FT device (for W1562-05)

Manual lubrication

CA

CA

UTION

UTION

Always turn off the power and unplug the machine when you

apply oil by hand.

When the machine is used for the first time or left unused for some

time, put oil to upper knife crank 4 until the oil wick is fully lubricated.

Adjusting the fabric guide

Adjust the amount of the fabric to be trimmed.

Adjustment is made by loosening screws 6 and moving fabric guide

5 to the left or right.

Replacing the upper knife

CA

CA

UTION

UTION

Always turn off the power, disconnect the power cord and

then only well-qualified technicians should replace and adjust the

knife.

Pay close attention to the knife edges not to injure your

hands and/or finger.

1.

Turn the machine pulley until upper knife 7 is at the top of its

travel. Remove screw 8. Then replace the upper knife with

the new one.

2.

To replace the upper knife, press end a of the upper knife to

upper knife holder 9, and then tighten screw 8.

9

a

Page 31

28

3

1

4

2

6

5

a:0.5mm

48

9

10

7

Replacing the lower knife

CA

CA

UTION

UTION

Always turn off the power and shut down the air compressor

first, and then well-qualified technicians should replace the knives.

Pay close attention to the knife edges not to injure your

hands and/or finger.

1.

Remove the side cover. Loosen screw 2. Remove lower

knife 1. Replace it with the new one.

2.

Move upper knife holder 3 away to the right. Fit lower knife 1

onto the groove on lower knife holder 4. Check to see if the

cutting edge is flush with the top surface of the needle plate.

Tighten screw 2.

Adjusting overlap of the knife cutting edges

CA

CA

UTION

UTION

Always turn off the power and shut down the air compressor

first, and then well-qualified technicians should adjust overlap of the

knife cutting edges.

Pay close attention to the knife edges not to injure your

hands and/or finger.

Turn the machine pulley until the upper knife is at the bottom of its

travel. Obtain 0.5mm overlap of the upper and lower knives (see a

in the illustration). Adjustment is made by loosening screw 6, moving upper knife holder 5 up or down. After this adjustment tighten

screw 6.

Adjusting the lower knife holder left to right

CA

CA

UTION

UTION

Always turn off the power and shut down the air compressor

first, and then well-qualified technicians should adjust the lower

knife holder left to right.

The distance from the right needle to where the fabric is to be cut is

determined by left-to-right position of lower knife holder 4.

Adjustment is made by loosening screw 7 and turning adjustment

screw 8 as required.

To move lower knife holder 4 to the left, turn adjustment screw 8

clockwise. To move lower knife holder 4 to the right, turn adjustment screw 8 counterclockwise. Loosen screw 9 and move auxiliary presser foot 10 to the left or right while moving the lower knife

holder. After this adjustment tighten screws 7 and 9.

Page 32

29

12

5

4

3

2

4

5

1

6

A

B

grease

7

grease

9

8

10

MD device (for W1562-05)

Installing the lace guide

Remove screw 1. Install the lace guide by referring to sequence 2

to 5 in the illustration on the right.

Greasing

CA

CA

UTION

UTION

Always turn off the power, unplug the machine and then well-

qualified technicians should lubricate the machine.

Put grease on the clutch and the bearing before they lack the

grease.

To put grease on the clutch

Turn the machine pulley until mark A is aligned with mark B.

Remove screw 6. Then put the proper amount of grease on the

clutch.

To put grease on the bearing

Remove screw 7. Then put the proper amount of grease on the

bearing.

Adjusting the lace guide (lower)

CA

CA

UTION

UTION

Always turn off the power, unplug the machine and then well-

qualified technicians should adjust the lace guide (lower).

Bring lace guide (lower) 8 as close to the needles as possible.

Check that lace guide (lower) 8 does not contact the spreader.

Adjustment is made by loosening screw 9 and turning stopper 10

as required. After this adjustment tighten screw 9.

Page 33

30

11

9

5

6

1

3

2

4

7

8

12

10

1314

To increase the

feeding amount

To increase

To decrease

To decrease the

feeding amount

16

15

Adjusting the elastic guide

CA

CA

UTION

UTION

Always turn off the power, unplug the machine and then well-

qualified technicians should adjust the elastic guide.

To adjust elastic guides 1 and 2

To feed the elastic onto the proper position on the fabric, adjust

elastic guides 1 and 2 according to the width of the elastic.

Adjustment is made by loosening screws 3 and 4 and moving elastic guides 1 and 2 to the left or right. After this adjustment tighten

screws 3 and 4.

To adjust elastic guides 5 and 6

To feed the elastic that is fed from the roller straight to elastic

guides 1 and 2, adjust elastic guides 5 and 6 according to the

width of the elastic. Adjustment is made by loosening screws 7 and

8 and moving elastic guides 5 and 6 to the left or right. After this

adjustment tighten screws 7 and 8.

To adjust elastic guides 9 and 10

To feed the elastic straight to elastic guides 5 and 6, adjust elastic

guides 9 and 10 according to the width of the elastic. Adjustment

is made by loosening screws 11 and 12 and moving elastic guides

9 and 10 to the left or right. After this adjustment tighten screws

11 and 12.

Adjusting the feeding amount of the elastic

CA

CA

UTION

UTION

Always turn off the power, unplug the machine and then well-

qualified technicians should adjust the feeding amount of the elas-

tic.

The feeding amount is adjustable from 1.0 to 2.7mm/stitch.

Adjustment is made by loosening screw 13 and turning adjustment

screw 14 as required.

●To increase the feeding amount, turn adjustment screw 14 clock-

wise.

●To decrease the feeding amount, turn adjustment screw 14 coun-

terclockwise.

Adjusting the roller pressure

CA

CA

UTION

UTION

Always turn off the power, unplug the machine and then well-

qualified technicians should adjust the roller pressure.

Adjust the roller 15 pressure according to the elastic to be used.

Adjustment is made by turning adjustment screw 16 as required.

To increase the roller pressure, turn adjustment screw 16 clockwise. To decrease the roller pressure, turn adjustment screw 16

counterclockwise.

Page 34

31

1

Inserting the elastic into the roller

CA

CA

UTION

UTION

Always turn off the power and shut down the air compressor

first, and then well-qualified technicians should insert the elastic into

the roller.

Open the roller first by pressing lever 1. Then insert the elastic into

the roller (see the illustration).

Page 35

32

♯

Nm

9

65

10

70

11

75

14

90

16

100

18

110

21

130

W1562-01J

-02G

-05B

×□□□□

232

□

9S

240

□

9S

248

□

9S

356

□

10S

364

□

10S

W1562-01J

-02G

-05B

×

□□□□

240

□

248

□

(-01Jnotincluded)

356

□

232

□

364

□

Standard lift

Standard lift

Standard lift

Standard lift

Standard lift

9.8

9.3

8.9

8.5

8.1

S

S

S

S

S

〃〃〃

〃

〃

9.3

8.8

8.4

8.0

7.6

T

T

T

T

T

8.8

8.8

8.8

8.8

8.8

4.6〜4.9

4.2〜4.5

3.8〜4.1

3.4〜3.7

3.0〜3.3

17.0

17.0

17.0

17.0

17.0

5.0

5.0

5.0

5.0

5.0

0.8〜1.2

0.8〜1.2

0.8〜1.2

0.8〜1.2

0.8〜1.2

(mm)

S : Needle plate finger 2.8mm thick (washer used onto looper)

T : Needle plate finger 3.3mm thick

Adjustment dimentions

Comparison table of equivalent sizes Standard needle

Organ

UY128GAS

Japanese size (Organ)

Metric size (Schmetz)

Page 36

33

Stitch type 602,605 Netweight(headonly) 44.4Kg

Needle size UY128GAS#9S

UY128GAS#10S

Gross weight (with accessories) 50.4Kg

Machine size(WxDxH) W:520mmD:265mmH:395mm Working noise level

n=5,400rpm:LpA≦78.0dB

Noise measurement according to

DIN4563548A-1

W1500 Series subclass specifications

W1500

Series

Application Subclass

Number

of

needles

Number

of

threads

Needle space (mm)

Max.

stitch

length

(mm)

Diff. feed tatio

Presser foot lift

(mm)

Max. speed

(rpm)

Remarks

Versatile W1562-01J

2 4 3.2・4 4.4 0.5〜1.3 6.3 6,000

3 5 5.6・6.4 4.4 0.5〜1.3 6.3 6,000

Binding tape W1562-02G

2 4 3.2・4・4.8 4.4 0.5〜1.3 6.3 6,000

3 5 5.6・6.4 4.4 0.5〜1.3 6.3 6,000

Attaching elastic

lace

W1562-05B

2 4 3.2・4 4.4 0.5〜1.3 5.3

5,500

(5,000withMD)

3 5 5.6・6.4 4.4

0.5〜1.3

5.3

5,500

(5,000withMD)

*If you use the machine with a differential feed ratio of more than 1:1.3, the main feed dog movement amount should be less than 2.5mm.

Page 37

34

Page 38

35

Page 39

36

Page 40

PEGASUS SEWING MACHINE MFG. CO., LTD.

5-7-2, Sagisu, Fukushima-ku, Osaka 553-0002, Japan.

Phone :(06)6458-4739

Telefax

:(06)6454-8785

Cat. No. 9A2175E1 July 2002

2002

PEGASUS SEWING MACHINE MFG. CO., LTD.

The description in this INSTRUCTIONS is subject to change without prior

notice for improvement.

Loading...

Loading...