Page 1

Cat.

No.

82 40 (

023-41

0-039)

FOR THE NEW

TOP

WILLCOX

EED

UR

&

GIBBS

PULLE

F

DEV

-4

SERIES

IC

E

WiLLCOX

&

giBBS

..

inc.

Page 2

TABLE OF CONTENTS

lrnm:lering

Features

Recommended operations

Installation

Adjusting the

For rough adjustment

For fine adjustment

Lubrication

Adjusting the position

Sidewise setting

Front

Adjusting the

Position

PARTSLIST

(1) URF-321 5- 6

(2)

Specific parts/KS LNumerical index

feed

amount

to

rear setting 3

pressure

of

Roller

URF-321

Feed

of

parts

of

roller

of

feed

roller

of

feed

roller 4

Frame when

321

it

is

raised

PAGE

5-

10

7- 8

9- 10

11

- 12

1

1

1

2

2

2

2

2

3

3

4

FEATURES

The-teed mechanism of-the U R F-device is-driven

by the machine

synchronized

addition, the

feed

amount

adjusted.

As

the

feed

0

also

feed

amount

dogs

are

0

is

movement

This feature

would occur no

when sewing

equipped

lower plies in the

amount.

with

Feed

with

dogs

feeds

at the

of

idle under Needle

also

in

as

the machine runs.

can

ply

two

with

URF-321

pulley

Roller 0

feed

the

a stop. URF-321 repeats this

bring the result that there

same

and

that

of

the

feed

the material,

same

time

feed

dogs.

shift

and

plies.

Because

can

timing

its movement

the feed

can

dogs

and

When

Plate,

no

seam

feed

and

dogs

keep

the

when finely

Feed

in the

the

Feed

puckering

the machine

the upper

in

the

. In

same

Roller

same

feed

Roller

and

same

is

IN ORDERING

URF-321, the Synchronized Top

supplied

specify the required machine type number

well

Note: The

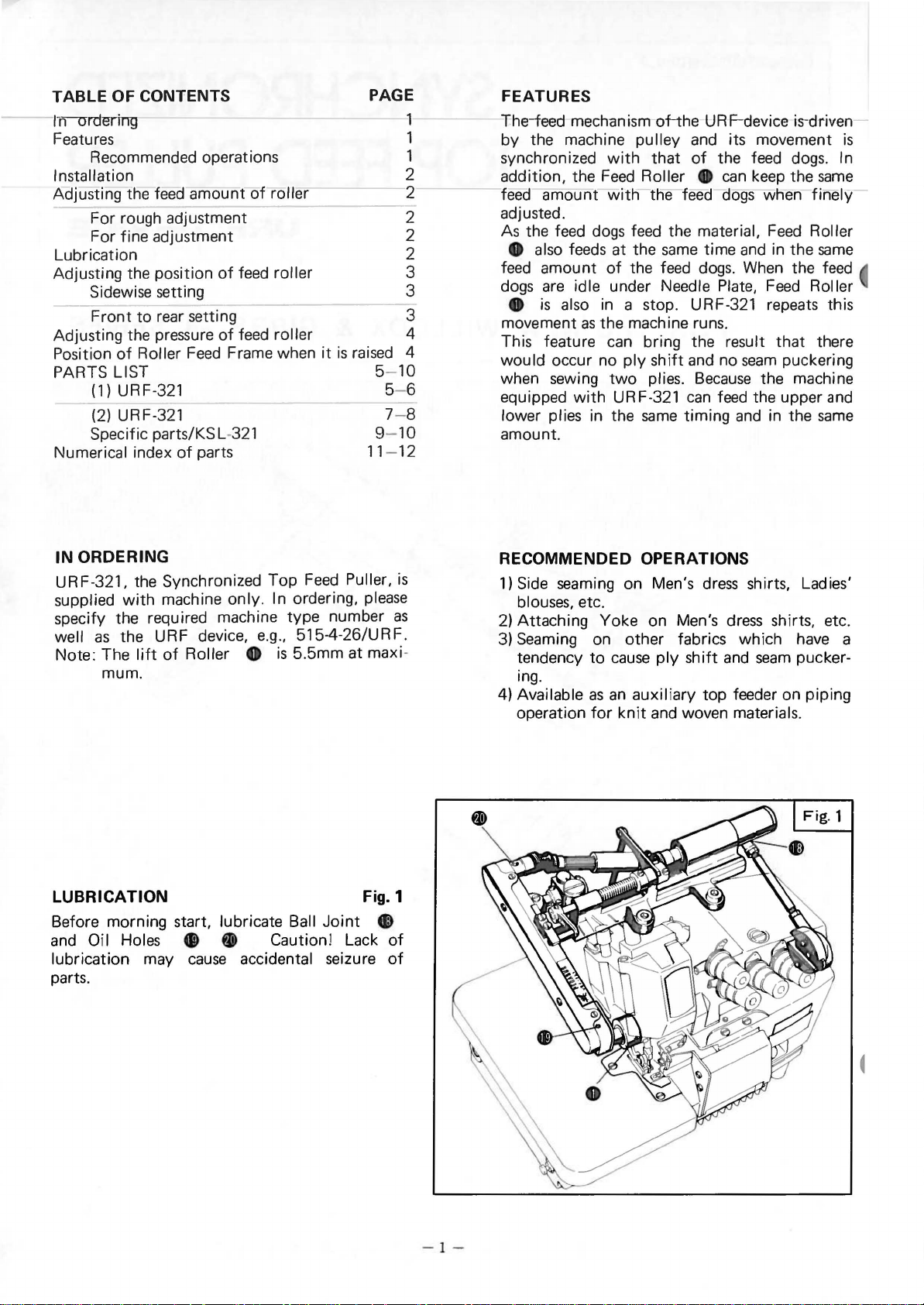

LUBRICATION

Before morning start, lubricate Ball

and

lubrication may

parts.

with

machine only. In ordering,

as

the URF device,

lift

of

mum.

Oil Holes

e.g.,

Roller 0

(I

e Cautionl Lack

cause

accidental seizure

Feed

Puller,

515-4-26/URF.

is

5.5mm at maxi-

Fig. 1

Joint

please

41

of

of

is

as

RECOMMENDED OPERATIONS

1)

Side

seaming

blouses, etc.

2)

Attaching Yoke on Men's

3)

Seaming

tendency

ing.

Available

4)

operation

on Men's

on

other fabrics which

to

cause

ply

as

an

auxiliary top feeder on piping

for

knit

and

dress

dress

shift

and

woven materials.

shirts, Ladies'

shirts, etc.

have

seam

pucker-

a

- 1 -

Page 3

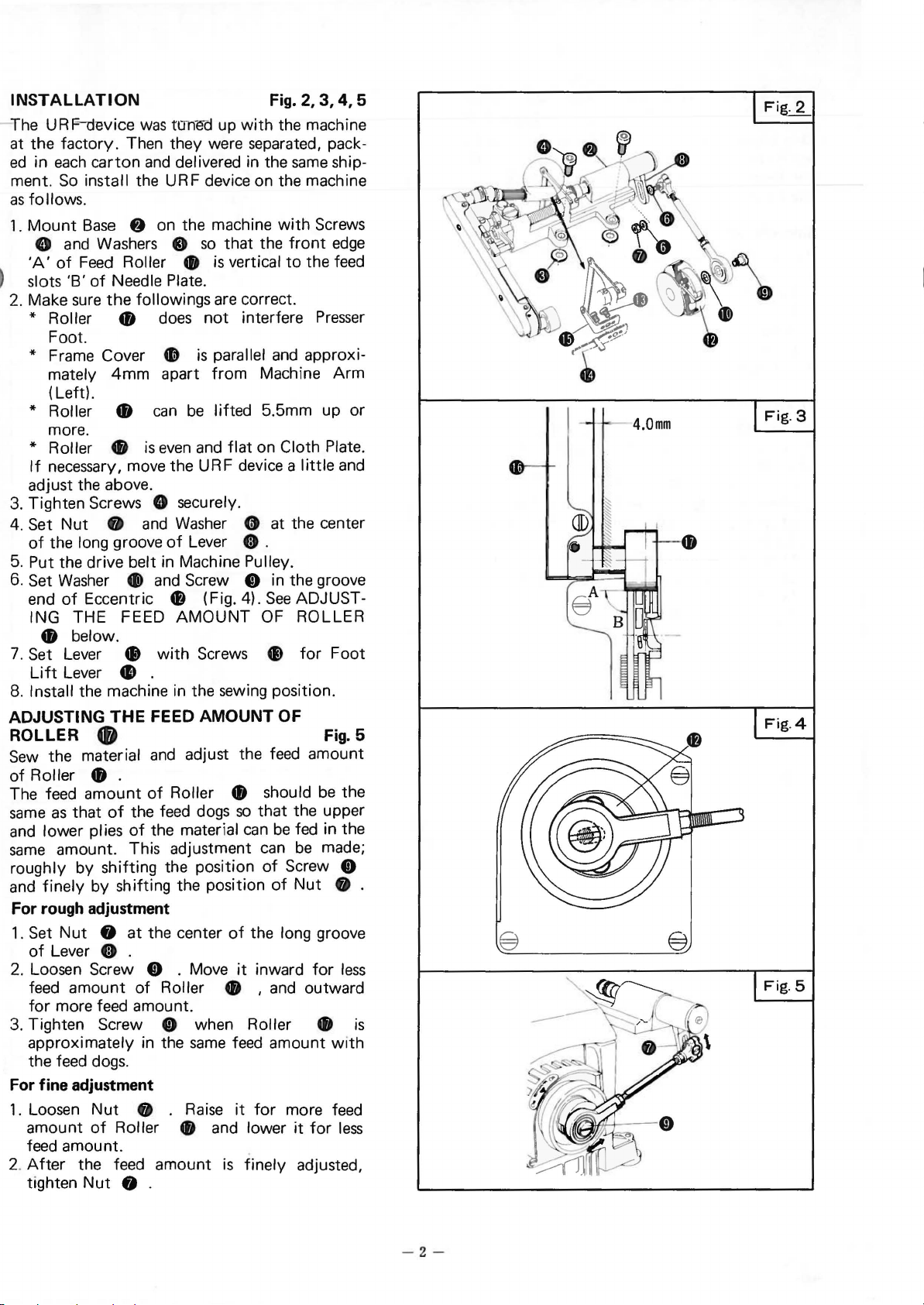

INSTALLATION

1he

URF-device

at the factory. Then they were separated, packed

in

each

carton

ment.

as

1.

2.

So

follows.

Mount

8

and

'A'

of

slots 'B'

Make

sure

install the URF device on the machine

Base

Feed

of

* Roller

Foot.

* Frame Cover e

mately

(Left).

* Roller

more.

* Roller

If

necessary, move the URF device a

adjust the above.

3.

Tighten Screws 8 securely.

4.

Set

Nut

of

the long groove

5.

Put the drive belt

6. Set

7. Set Lever

8.

ADJUSTING THE FEED AMOUNT OF

ROLLER

Sew

of

The feed amount

same

and

same

roughly by shifting the position

and

For

1.

2.

3.

For

1.

2.

Washer

of

end

ING

Lift

Install the machine

Roller

Set

of

Loosen Screw 0 . Move

feed

for

Tighten Screw 0 when Roller

approximately in the

the feed dogs.

Loosen

amount

feed

After

tighten

Eccentric

THE FEED

4D

below.

Lever e .

the material

4D

as

that

lower plies

amount. This adjustment

finely by shifting the position

rough adjustment

Nut

Lever 8 .

amount

more feed amount .

fine

adjustment

Nut

of

amount .

the feed amount

Nut

was

tan-eel

and

delivered

8

on

the machine

Washers 8

Roller

Needle Plate.

the

followings

4D

4mm

4D

4D

is

0

and

41)

41

so

4D

does

not

is

apart from Machine Arm

can

be

even

and

Washer

of

Lever C) .

in

Machine Pulley.

and

Screw 0

48

(Fig. 4).

AMOUNT

with

Screws

in

the

48

and

adjust the

.

of

Roller

of

the

feed

dogs

of

the material

0 at the center

of

Roller

same

0 .

Roller

0 .

Raise

4D

up

is

are

parallel

lifted 5.5mm up or

sewing

and

Fig.

2,

with

the machine

in

the

same

with

Screws

that the

vertical

correct.

interfere

flat

front

to

the

Presser

and

approxi-

on Cloth Plate.

little

0 at the center

in

the groove

See

ADJUST-

OF ROLLER

41

for

position.

feed

amount

4D

should

so

that the upper

can

be

fed in the

can

be

of

Screw 0

of

Nut

of

the long groove

it

inward

4D

,

feed

it

for

lower

is

finely adjusted,

for

and

outward

amount wi

more

it

for

3,

4, 5

ship-

edge

feed

and

Foot

Fig.

be

the

made;

0 .

less

4D

feed

less

th

5

is

--1--

4---

Fi~

-

4.

0

mm

Fig.3

Fig.4

Fig.5

- 2 -

Page 4

ADJUSTING

ROLLER

This setti

no

has

any

ng

further adjustment

been

reason.

THE POSITION OF FEED

Fig.

is

correct at the factory

unless

moved from its original position

Feed

and

requires

Roller 8

Sidewise setting

Roller 8 should align

1 . Loosen Screw

2. Move

3.

Front

Roller 8 should

Plate,

ed

1 . Loosen Screw

2.

3. Tighten Screw

Base 8 as

Make

mately 4.0mm apart from Machine Arm

(Left).

Tighten Screw 0

sure

Base

to

rear

setting

and a lift

when

it

Move

Base

of

the round cut portion

(Left).

Make

Cloth Plate

sure

Foot.

of

is

lifted up.

8

Roller 8

and

with

Presser

0 .

required.

8

is

parallel

be

even

5.5mm should

f)

.

so

that lnoller

is

does

not

interfere

f)

.

and

and

flat

also

is

in the middle

of

Machine

even

Foot.

approxi -

on

be

and

with

6,

7, 8

for

Cloth

obtain-

Arm

flat

on

Presser

Fig.6

Fig.7

Fig

5.5mm

.8

- 3 -

Page 5

ADJUSTING THE

The pressure

be

Pin

41

Lever

Pin

and

just

0 up

4D

tighten

4@

Base

should

proper stitch formation.

Pull

1.

left.

2.

Loosen Screws

3.

With Spring 'a' hooked on the Hinge Frame,

set

obtained. Tighten Screws

4.

Placing Pin

ing Screws

of

5.

Replace

PRESSURE

of

Feed

Roller

enough

to

feed

and

swing

48

and

so

that a proper

41

on

Base

Screws

48

, eliminate the sidewide play

8

and

Pin

OF

on

material

Base

Screws

41)

8 , turn Collar

48

.

When

0 in position .

FEED

Fig.

the material

and

8

41)

pressure

tighten-

9, 10

obtain

to

the

is

Fig,_9

Fig.1

0

POSITION OF

UP.

Rubber 'C' is filled

is

raised

up, Rubber 'C' should

0 . This

rubbing. Screw

stopper

reset Collar

on Hinge

1.

2.

3.

4. Tighten Screws 0

of

Release

left.

Loosen Screws 0

With

Base

not

touching Hinge 0 , turn Collar

until

Screw 0

ing

these

play

but

moved up

BASE

with

is

to

keep

0

Base

8 from raising up.

410

so

0 .

Pin 0

and

8 high, making

is

screws,

assure

no binding when

and

down.

6)

WHEN

grease.

Rubber 'C' from wear by

for

Collar

that Rubber 'C'

swing

and

0 .

stopped by

and

avoid any

not

Base

0 .

IT

IS

When

rub

41!>

If

will

sure

Rubber 'C'

Pin

When

excess

Base

RAISED

Fig.

Base

on

Hinge

acts

necessary,

not

8

to

4D

.

tighten-

sidewise

8

9,

as

11

8

a

rub

the

Fig. 11

GD

is

- 4 -

Page 6

- 5 -

Page 7

REF.

NO.

PART NO.

WPRODUCT

N

CODE NO. DESCRIPTION

(1)

URF-320

QT.

303480 323-900-065 URF-321

303481

1

2

3

4

5

6

7

8

9

10

11

12

13 2237 323-600-067 screw 4

14 303492

15

16

303473

303521 323-508-021

303522

5274 323-600-263 screw

303175 323-608-001 ball stud

5266

303176

5048

303493 323-728-016

303178

303179 323-640-032 " spring

201029 323-618-002

200555 323-634-004 " retaining ring

303182 323-720-002

323-895-001

323-692-042

323-728-015

323-600-265 " clamp screw

323-620-045

323-600-

323-620-046 pin

323-620-04 7 lock pin 1

028

Feed

Name

Roller

Roller feed hinge, complete 1

Feed

17 205097 323-615-026

18 5317

19 303185 323-780-015

20 303186 323-540-037

21

22 303187

23

24 303485 323-780-016

25 303486

26

27 5408

28

29

30

31

32

33 303523 323-676-057 Timing

34 303195

35 303509 323-636-021 Universal

36 5234

37 5116

38 303202

39

40

41

42

43

44

45

46

47

48

49 2922

5292

202047 323-653-205 oil

303191 323-546-005 Timing belt pulley

303192

303487

303485 323-780-016

303486

303193

303204

303221 323-750-012

5152

303223

1216

5430 323-620-048 fixing pin

5137

2905

303224

303225

323-600-355 screw

Feed

323-600-341 screw

323-764-005

323-690-00 1

323-600-129 screw

323-540-038

323-653-021

323-690-001 Oil mark

323-676-056

323-550-005 Timing belt

323-600-297 screw

324-600-207

323-6 76-058 Roller clutch bushing

323-760-001 Roller clutch

323-600-061 screw

323-51

0-1

00

323-600-068

323-630-202

323-600-074

323-51

0-099

323-663-034 gasket

323-600-229

Feed

Oil mark 1

Feed

Feed

Roller feed frame cover

Feed

head

complete 1

roller drive mechanism

(Includes parts

plate

feed

frame

hinge

" " "

" thrust collar 2

roller 1

washer 1

cap

roller shaft 1

roller

gear

felt

"

cap

"

shaft 1

oil

"

"

roller

gear

belt pulley shaft bushing

joint

roller pressure lever

screw 2

"

screw

roller

gear

screw

felt

"

cap

bushing

nut

cover

of

Ref.

Nos

. 1-48)

pin

" screw 1

seat

1

1

1

1

2

1

1

1

1

1

1

1

2

4

1

1

1

1

1

1

1

3

1

1

1

1

2

1

2

2

2

1

1

3

- 6 -

Page 8

\

I

- 7 -

Page 9

REF.

NO.

(2) URF-321

PRODUCT

PART

NO. CODE NO. DESCRIPTION QT.

NEW

5152

2

3

4 303203

5

6

7

8

9

10 5426

11

12

13

14

15

16

17

18 5184

19

20 1175-3 323-600-019 screw 2

21

22 202576 323-615-201 spacer 2

23

24

25

26

27 5080

28

29

30

31

32

33

34

35

36

37 202433 323-615-027

38

39

40

41

3044 323-630-001

303181

303205 323-540-039

303206 323-615-041 washer

1175-3

303213

303215

303216 323-640-033 spring

303217

2237

303218 323-680-015

2213

303525 323-530-039

303222

303524

4504 323-600-374 Roller feed hinge

303496 323-546-006

303207 323-546-007

303208 323-580-085 Roller feed eccentric

5118

303279 323-800-07 4 plate

5081 323-600-009 screw 1

303245 323-535-006

303209 325-535-001 Roller feed drive connection

303210 325-671-005 ball bearing

303212 323-535-007 Roller feed connecting rod

28-1

89-1

201579 323-5

1170-1 323-600-020

201580 323-604-020 ball stud

3144 323-630-220

303211

204520 323-615-233 thrust washer

303204 323-760-001 Roller clutch 2

323-600-061 Roller feed hinge lock pin adjust screw

nut

feed hinge

323-505-018

323-530-037 Roller feed adjust lever

323-600-019 screw

323-530-038

323-620-049

323-630-035

323-680-014

323-600-067 "

323-600-237

323-530-040 Connect lever 2

323-600-079 screw 2

323-530-041 Roller

323-600-060

323-600-008 Pulley

325-630-207

325-630-210 " (front)

25-0 15 Roller feed ball

323-600-375

Roller

shaft

Feed

roller pressure lever

pin 1

"

nut

collar (left)

Roller feed

feed

Pulley, complete

parts

Pulley

screw

position screw 1

Roller feed connecting rod, complete

(Includes

nut

(rear)

cap

screw 2

Ball bearing screw

base

screw

(right)

screw 2

"

foot

lift

intermediate lever 1

foot

lift

lever 1

base

screw 2

with

of

Ref. Nos. 23-26

parts

of

Ref. Nos. 29-38)

joint

" washer 2

,

nut

2

2

1

2

1

1

2

1

1

1

1

- 8 -

Page 10

- 9 -

Page 11

REF. RODUCT

NO.

PART NO. CODE

NO.

KSL-321/SPECI FIC PARTS

DESCRIPTION

QT.

303371

303497

1

2

3

4 5346 323-600-366

5

6

7

8 4009-1 323-600-014

9 5408

10

11

12

13

14

15

303227 323-508-022

4009-1 323-600-014

303298 323-900-068

303293 323-873-011

303230 323-530-036

303278

303295

5409

303074 323-873-003

5022 323-600-251

303229

5022

300135A

323-900-066

323-900-067

323-643-011 spring

323-630-028

323-600-129

323-630-027

323-560-059 fabric guard

323-600-251

323-620-031

head

KSL-321

(Includes parts

Chain cutter frame, complete

(Includes parts

Chain cutter frame

screw

Movable

(Includes parts

Movable

screw

drive

adjust screw

Stationary

screw

Movable

complete

of

Ref. Nos. 1-20)

of

Ref. Nos. 1-14)

blade, complete

of

Ref. Nos. 3-11)

blade

lever

screw

nut

screw

lock

nut

blade

screw

blade drive lever pin

1

2

1

1

1

3

3

1

16

17

18

19

20

21

22

23

24

25

26 303479

303482

1216

303472

1333 323-600-048

303086 323-639-022

303477

303478

303474 323-508-023

303475

303476

323-639-037

323-600-068

323-683-022

323-592-002

323-502-013

323-500-024 Machine arm (left)

323-510-101 Machine

323-560-060 Cloth plate fabric guard

Air

blower

screw

clamp

screw

tube

Other relating parts

Presser

bar, complete

Presser

arm

Machine frame

top

cover

for

1

1

URF-321

1

-10-

Page 12

CROSS

NUMBER

INDEX

NEW PRODUCT

CODE NO.

323-500-024

323-502-013

323-505-018

323-508-021

323-508-022

323-508-023

323-510-099

323-51

0-1

323-510-101

323-525-015

323-530-036

323-530-037

323-530-038

323-530-039

323-530-040

323-530-041

323-535-006

323-535-007

323-540-037

323-540-038

323-540-039

323-546-005

323-546-006

323-546-007

323-550-005

323-560-059

323-560-060

323-580-085

323-592-002

323-600-008

00

PART NO. PAGE

303475

303478

303181

303521 9

303227

303474

303224

303223

303476

201579

303230

303203

303213

303525

303222

303524

303245

303212

303186

303192

303205

303191

303496

303207

303195

303229

303479

303208

303477

5080

13

13

11

13

13

9

9

13

11

13

11

11

11

11

11

11

11

9

9

11

9

11

11

9

13

13

11

13

11

REF

NO.

24

22

3

2

1

23

47

42

25

34

5

4

8

16

17

19

31

20

28

5

26

23

34

13

26

24

21

27

NEW PRODUCT

CODE

NO.

323-620-045

323-620-046

3-620-04 7 303492

32

323-620-048

323-620-049

323-630-001

323-630-027

323-630-028

323-630-035

323-630-202

323-630-220

323-634-004

323-636-021

323-639-022

323-639-037

323-640-032

323-640-033

323-643-011

323-653-021

323-653-205

323-663-034

323-676-056

323-676-057

323-676-058

323-680-014

323-680-015

323-683-022

323-690-001

323-690-001

323-692-042

PART

303176

303178

5430

303215

3044

5409

303295

5426

5137

3144

200555

303509

303086

303482

303179

303216

303278

303487

202047

303225

303193

303523

303202

303217

303218

303472

303486

303486

303473

NO.

PAGE

9 7

9

9

9

11

11

13

13

11

9

11

9 15

9

13

13 16

9

11 11

13 6

9

9

9

9

9

9

11

11

13

9

9

9 1

REF

NO.

10

14

44

9

2

10

7

10

45

38

35

20

11

29

23

48

32

33

38

12

14

18

25

31

NEW PRODUCT

CODE

NO.

PART

NO.

PAGE NO.

REF

-

l

323-600-009

323-600-014

323-600-014

323-600-019

323-600-019

323-600-020

323-600-028

323-600-048

323-600-060

323-600-061

323-600-061

323-600-067

323-600-067

323-600-068

323-600-068

323-600-074

323-600-079

323-600-1

323-600-129

323-600-229

323-600-237

323-600-251

323-600-251

323-600-263

323-600-265

323-600-297

323-600-341

323-600-355

323-600-366

323-600-374

29

5081

4009-1

4009-1

1175-3

1175-3

1170-1

5048

1333

5118

5152

5152

2237

2237

1216

1216

2905

5184

5408

5408

2922

2213

5022

5022

5274

5266

5234

5292

5317

5346

4504

28

11

13

13

11

20

11

11

35

9

13 19

25

11

41

9

11

13

9

13

11

43

9

13

17

46

9

11

18

27

9

13

49

9

15

11

12

13

14

13

9

9

36

9

21

9

18

9

13

11

21

9

323-720-002

2

8

7

8

1

9

4

6

4

323-728-015

323-728-016

323-750-012

323-760-001

323-760-001

323-764-005

323-780-015

323-780-016

323-780-016

323-800-074

323-873-003

323

-873-011

323-895-001

323-900-065

323-900-066

323-900-067

323-900-068

324-600-207

325-535-001

325-630-207

325-630-21

325-671-005

303182

303522

303493

303221

303204

303204

303187

303185

303485

303485

303279

303074

303293

303481 9

303480

303371

303497

303298

5116

303209

0

303210

28-1

89-1

9 3

9 9

9

9

11

9

9

9

9

11

13

13

9

13

13

13

9

11

11

11

11

16

40

39

41

22

19

24

30

26

11

3

37

29

32

33

30

~

11

323-600-375

323-604-020

323-608-001

5-026

323-61

323-61

5-027

323-61 5-041

323-615-201

323-615-233

323-61

8-002

323-620-031

303211

201580

303175

205097

202433

303206

202576

204520

201029

300135A

11

9

9

11

11

11

11

9

13

39

36

5

17

37

6

22

40

12

15

-11-

Page 13

PART

NO.

NEW

CODE

PRODUCT

NO.

REF

PAGE NO.

CROSS NUMBER INDEX

PRODUCT

PART NO.

NEW

CODE

NO

.

PAGE NO.

REF

PART NO.

NEW

CODE

PRODUCT

NO

.

R

PAGE NO.

EF

-

28-1

89-1

11

70-1

11

75-3

11

75-3

1216

1216

1333

2213

2237

2237

2905

2922

3044

3144

4009-1

4009-1

4504

5022

5022

5048

5080

5081

5116

5118

5137

5152

5152

5184

5234

5266

5274

5292

5317

5346

5408

5408

5409

5426

5430

200555

201029

201579

201580

202047

202433

202576

204520

205097

300135A

303074

303086

303175

303176

303178

303179

303181

303182

303185

303186

325-630-207

3 25-630-21

323-600-020

323-600-019

323-600-019

323-600-068

323-600-068

323-600-048

323-600-237

323-600-067

323-600-067

323-600-074

323-600-229

323-630-001

323-630-220

323-600-014

323-600-014

323-600-374

323-600-251

323-600-251

323-600-028

323-600-008

323-600-009

324-600-207

323-600-060

323-630-202

323-600-061

3 2 3-600-061

323-600-079

323-600-297

323-600-265

323-600-263

323-600-341

323-600-355

323-600-366

323-600-129

323-600-129

323-630-027

323-630-035

323-620-048

323-634·004

323-61 8·002

323-525·015

323-604·020

323·653·205

323-615·027

323·615·201

323-61 5-233

323-615·026

323-620-031

323-873·003

323-639·022

323·608·001

323-620-045

323-620-046

323-640-032

323-505-018

323-720-002

323-780.015

323·540.037

0

11

32

11

33

11

35

11

11

20

43

9

17

13

13 19

11

15

13

9

13

11

46

9

9

49

11

11

38

13

13

11

21

13 12

14

13

9 8

11

27

28

11

37

9

11

25

45

9

41

9

11

11

18

36

9

9

9

21

9

9

18

13

27

9

13

13 10

11

10

44

9

15

9

9

12

11

34

36

11

23

9

11

37

22

11

11

40

17

9

15

13

13

11

13

20

9

9

9

10

11

9

11

16

9

19

9

20

9

303206

303207

303208

303209

7

303210

303211

303212

303213

303215

303216

303217

303218

303221

303222

2

303223

303224

2

8

303225

303227

303229

303230

303245

303278

303279

303293

303295

303298

303371

303472

1

303473

303474

6

303475

303476

4

303477

303478

303479

4

303480

303481

9

303482

303485

303485

303486

303486

303487

303492

303493

303496

303497

303509

303521

303522

303523

303524

303525

5

7

3

323-61 5-041

323-546-007

323-580-085

325-535-001

325-671-005

323-600-375

323-535-007

323-530-038

323-620-049

323-640-033

323-680-014

323-680-015

323-750-012

323-530-040

323-510-100

323-51

0-099

323-663-034

323-508-022

323-560-059

323-530-036

323-535-006

323-643-011

323-800-074

323-873-011

323-630-028

323-900-068

323-900-066

323-683-022

323-692-042

323-508-023

323-500-024

323-51 0-1

323-592-002

323-502-013

323-560-060

323-900-065

323-895-001

323-639-037

323-780-016

323-780-016

323-690-001

323-690-001

323-653-021

323·620·047

323·728-016

323·546·006

323·900·067

323·636-021

323·508-021

323·728-015

323·676·057

323·530-04

323·530-039

01

1

11

11

11

11

11

11

11

11

11

11

11

11

11

13

13

13

11

13

11

13

13

13

13

13

13

13

13

13

13

13

13

11

13

11

11

6

23

24

29

30

39

31

8

9

11

12

14

40

9

17

42

9

47

9

48

9

1

13

5

6

26

3

7

18

1

9

23

24

25

21

22

26

9

9

16

24

9

30

9

25

9

31

9

29

9

14

9

9

9

35

9

2

9

3

9

33

9

19

16

--

--

-

-

11

11

11

22

9

26

9

28

9

32

9

34

9

38

9

4

39

9

41

5

303187

303191

303192

303193

303195

303202

303203

303204

303204

303205

323-764-005

323-546-005

323-540-038

323-676-056

323·550·005

323-676·058

323·530-037

323-760-001

323-760-001

323-540-039

-12-

Loading...

Loading...