Page 1

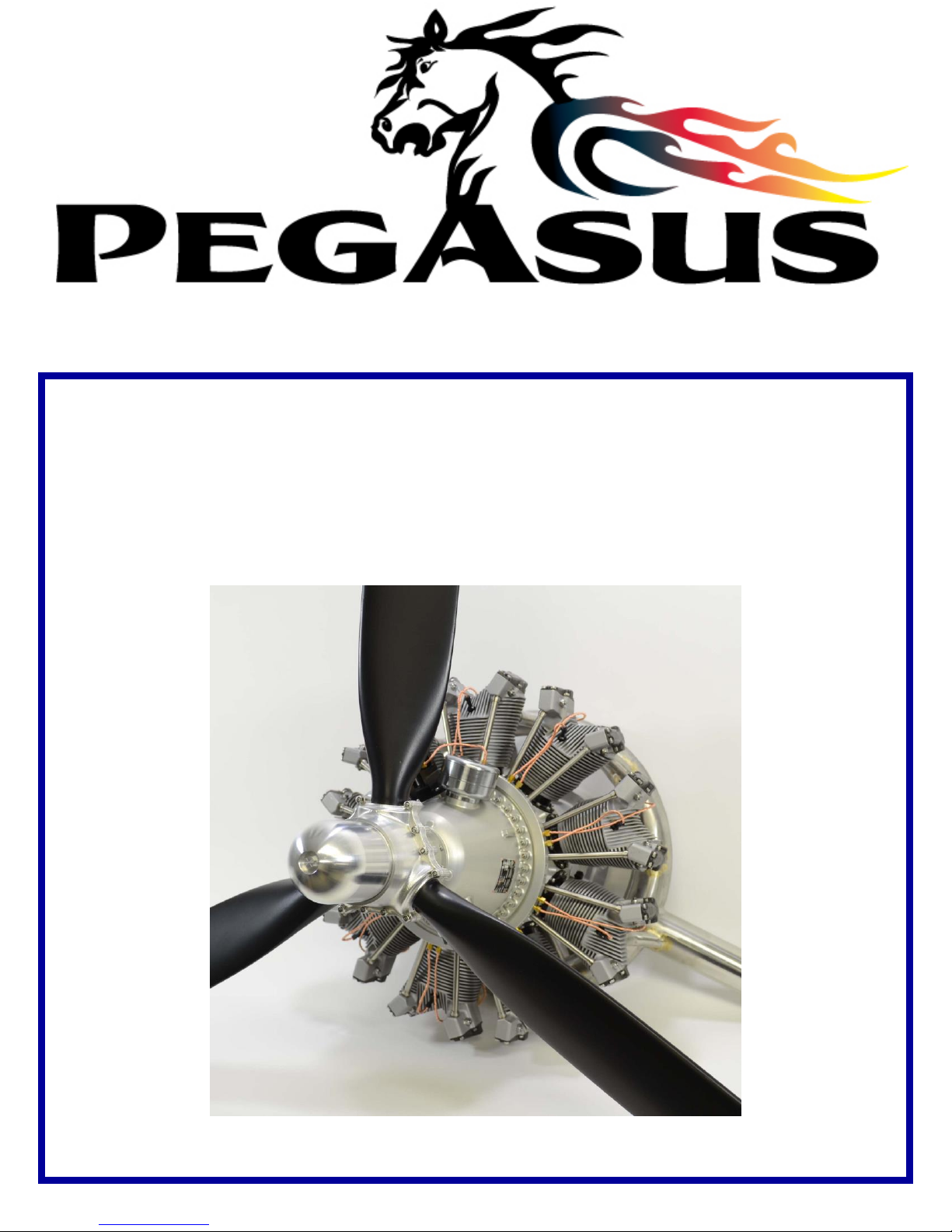

4-CYCLE MODEL ENGINES

R-9/2800-200

AUTHENTIC SCALE MARK I SERIES

SCALE 9 CYLINDER (200 CC) RADIAL ENGINE

OPERATING, MAINTANCE AND SAFETY MANUAL

VOLUME 1 REVISION 4

Page 2

CAUTION before attempting to mount and run

your engine on a test stand or aircraft, this manual should be

completely read and understood. If you have any questions,

concerns or things that you do not fully understand, you should

contact the Customer Services Department at PEGASUS AIRCRAFT

ENGINES, 1-888-898-7841 between the hours of 9:00 AM and 5:00

PM, EST, Monday through Friday. You can also send an email to

david@pegasusengine.com.

CONGRATULATIONS, you have purchased one of the finest

miniature radial engine available on the market today! The

PEGASUS AIRCRAFT ENGINES R-9/2800-200 radial engine is

an almost exact replica of the front half of the full scale Pratt &

Whitney R2800 TWIN WASP radial engine. The engine is a total of

200cc in 9 cylinders and is 1/5th scale.

All PEGASUS AIRCRAFT ENGINES are CNC machined from high

quality, alloy bar stocks and have unsurpassed fit and finish. Unlike

other engines offered on the market today, the PEGASUS

AIRCRAFT ENGINES line of engines are completely assembled in

the USA using the highest quality materials and components

available.

PEGASUS AIRCRAFT ENGINES has developed one of the best

customer support programs offered by any engine manufacturer.

When you call or email our Customer Services, you will be in contact

with an expert on your particular engine not a lay person hired to

answer the phone. What ever problem you are experiencing or

question you may have will be addressed quickly and expertly by

one of PEGASUS AIRCRAFT ENGINES qualified representatives.

Page 3

WARNING this miniature engine is not a toy but

rather a power source for the propulsion of an R/C aircraft. It is

expressly forbidden to use this engine to power any manned or

human carrying aircraft or vehicle. Any misuse, abuse, incorrect

handling or crash damage can cause the engine to malfunction.

Such malfunctions could result in injuries to you and bystanders as

well as damage to the aircraft and property. In any of the above

mentioned situations, the engine should be returned to the factory

or an authorized repair station for evaluation and repair before

reinstalling on the aircraft for continued use.

Minimum age for operating this engine is 14 years of age. Young

people should be accompanied by an older, more experienced R/C

modeler.

Miniature engines have all the trappings of the full scale engines

such as becoming extremely hot when operating or after shut

down. First, second and third degree burns are a real possibility.

Fuel, oil fluids and exhaust emissions can be considered toxic. You

should understand the hazards of gasoline and be cautious not to

allow it to come into contact your eyes. Do not ingest even the

smallest amount. Washing your hands after contact with model

fuel is strongly suggested. Always keep fuel out of the reach of

children and pets.

Propellers are extremely dangerous whether they are full scale or

model. Caution should be exercised at all times when the engine

is running.

Page 4

RIGGING YOUR ENGINE

FUEL SYSTEM: To rig your R9 engine for fuel, first you will need a

32 to 50 ounce fuel tank. The fuel tank must be adapted to use

gasoline. Your local hobby dealer can sell you the necessary parts

to accomplish this. All fuel lines need to be Tygon flexible fuel

tubing or gasoline compatible equivalent. When rigging the fuel

lines, run a line from the pickup port on the fuel tank to the electric

fuel pump (end with hex). Next run a line from the fuel pump (flat

end) to the port on the side of the carburetor. The top port (on the

carburetor) is a vent that allows the diaphragm in the carburetor to

work. If using a fuel filter, make sure it is gasoline compatible and

install it between the fuel tank and the fuel pump. The vent line on

the fuel tank needs a large loop of line affixed to the top of the fuel

tank and then exit on the outside of the airplane. The large loop (on

top of the fuel tank) insures that the vent line will not leak fuel. No

pressure line is required. Ad a third line to the fuel tank with a

stopper on the end. This line is used to fill the tank with fuel.

The fuel pump should be powered by a 6 to 12 volt battery. 2000 to

5000 mAh NiCad, NMH or LiPo is recommended. If using the larger

mAh battery, the one battery can be used for both the fuel pump and

the CDI ignition system. It is recommended to have a separate

on/off switch for the fuel pump. This allows you to prime the engine

without the ignition being on.

IGNITION SYSTEM: When rigging the CDI ignition box to your

engine, start by determining which cylinder is #1 cylinder. Hold the

engine with the scale magneto facing straight up. The scale

magneto is the black part between the two scale distributors (round,

silver canisters) on the nose cone housing of the engine. With the

engine in this position, look at the bottom most cylinder of the 9

cylinders. This is #1 cylinder. The spark plug wires starts at #1

cylinder and progresses in a counter clockwise direction (when

looking at the front of the engine, propeller end).

Page 5

Place #1 spark plug wire on #1 cylinder’s spark plug and #2 spark

plug wire on #2 cylinder’s spark plug (just to the right of #1 when

looking at the front of the engine). Continue this progression until

you have all spark plug wires installed.

Install the grounding leads that are sleeved to the spark plug wires

by first attaching the lead to the upper most screw on the intake

tube’s brass retainer ring. Next install the other end of the

grounding lead wire to the ground wire on the CDI ignition box. This

is a black wire protruding from the ignition box with a ring connector

affixed to the end of the wire. All nine grounding leads need to be

attached to the ring connector on the ignition box ground wire using

a small bolt, 2 washers, lock washer and nut. On later models, the

ignition box has a nine lead extension with bullet connectors for

greater ease of rigging.

The CDI ignition is powered by a 6 to 8.4 volt battery. 2000 to 5000

mAh NiCad, NMH or LiPo battery is recommended. As stated

above, one battery can be used if it is a high capacity battery (5000

mAh) for both the ignition and fuel pump (not to exceed 8.4 volt). If

using one battery, it is recommended to check the amount of charge

in the battery between flights. A separate switch (from the fuel

pump) is recommended for the ignition system. Also recommended

is transmitter operated switches (one for the ignition & one for the

fuel pump) that will allow you to kill the engine remotely in case of an

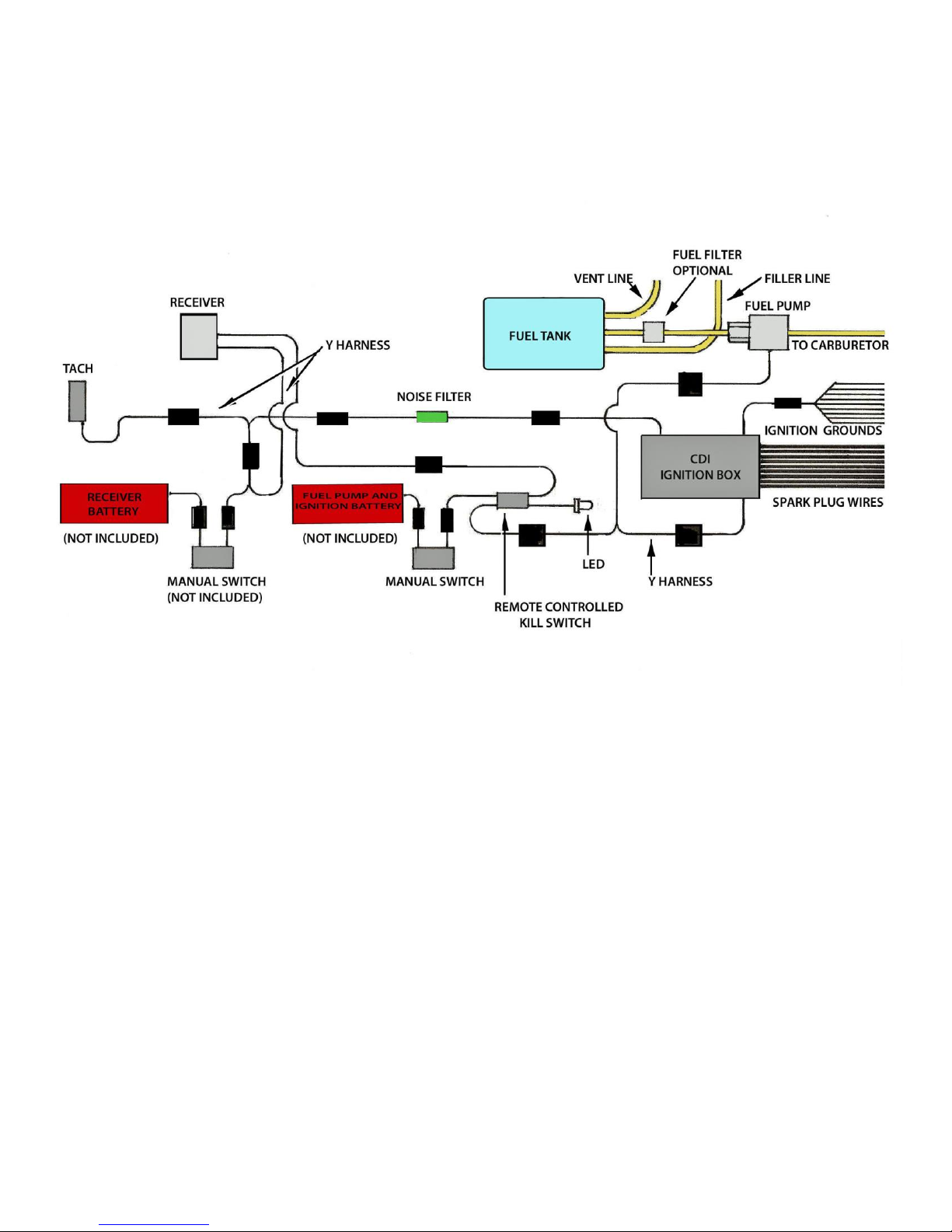

emergency. See diagram below for the engine’s suggested fuel and

ignition rigging in your airplane.

Page 6

ENGINE COMPONENT RIGGING SCHEMATIC

The above schematic is a suggested way to rig the components of

your engine. It is situated to use a single battery (not to exceed 8.4

volts) for both the CDI ignition and the fuel pump. Separate

batteries can be used for the CDI ignition and the fuel pump if you

choose. The above schematic is a way of saving weight by using

only one battery. NOTE: Only one mechanical switch is shown to

operate the fuel pump and CDI ignition. Another mechanical switch

can be installed between the Y harness and the CDI ignition box to

allow you to turn off the ignition while priming the engine.

Also shown is the receiver battery. In the above schematic, the

Tach. is powered by the receiver battery as the Tach. draws very

little current. NOTE: Be careful not to cross polarity when plugging

in the various electrical connectors. Always check that the color

coded wires match up. The grey lead from the sensor cartridge to

the CDI ignition will only plug in one way.

Page 7

STARTING THE PEGASUS RADIAL ENGINE

All radial engines have an inherent tendency to possibly become

hydraulically locked. This means that the 3 bottom cylinders can

become flooded with fuel and oil causing the engine not to turn

over. Before attempting to start the engine, always roll the engine

through several revolutions (making sure the ignition is turned off

before rotating). If the engine does not want to rotate past a

certain point, do not try to force it. At this time, you will need to

remove the spark plugs from the 3 bottom cylinders and rotate the

engine until all excess fuel and oil is pumped out the spark plug

hole. Reinstall the spark plugs and continue the starting procedure.

When the engine is cold, first be sure the Ignition switch is off, the

fuel pump is on and the choke is closed. Flip the prop

approximately 5 times. This will prime the engine with fuel. Next

with the choke in the open position, set the throttle to about ¼

throttle. Turn the ignition switch on and start the engine. To insure

that all cylinders are firing, you can use a temperature gun to check

the exhaust temperature near the cylinder head. All cylinders

should be similar in temperature and the engine running smoothly.

To start the engine when it is hot or warm, first turn the fuel pump

on and the ignition off, close the choke and flip the prop 2 or 3

times. Open the choke, turn the ignition on and set the throttle just

above idle to start the engine. Our test engines usually start with

one flip of the propeller blade.

OPERATING AND TUNING

Operating and tuning your PEGASUS AIRCRAFT ENGINES radial

engine is not difficult but requires attention to carburetor tuning,

propeller choice, periodic valve adjustment & lubrication, correct

(fresh) fuel and overall awareness of its general condition.

Page 8

Fuel for your radial engine should be a high quality gasoline of at

least 91 octane. The recommended oil is Klotz KL-189 and should

be mixed 50:1 for break and normal use. Adding nitro methane or

methanol for any reason will not enhance the engine’s performance

but rather cause undue wear, overheating and the voiding of your

warranty.

Starting with the carburetor adjustments, both the high speed

and low speed needle valves are pre set at the factory for correct

fuel delivery under normal operating conditions (air temperature,

barometric pressure and elevation). The elevation of your location

is important to properly tuning your carburetor. The elevation of

the PEGASUS TECHNOLOGY factory is 188’ above sea level. You

can find out the elevation of your area by calling your local airport.

Depending on your location, minor adjustments may need to be

made but major adjustments are a mistake. Minor adjustments

usually consist of no more than 1/8 turn in either direction of the

low and high speed needles valves. If you loose your place (with

the needle valves) the low speed needle is 2 turns out (counter

clockwise) and the high speed needle is 6 turns out (counter

clockwise) from completely closed. This is the factory settings.

It is critical to insure that your linkage and servo throw do not allow

the throttle plate to move past center line (FULL OPEN POSITION)!!.

This could cause an unsafe loss of power and or stall of engine. It is

important to use a stiff linkage rod to prevent High G forces from

flexing the linkage rod into a position that could allow the throttle

plate to move past full open position!!

For the start up and initial break-in period of your engine, be sure

the fuel to oil ratio is 50:1. Run the engine at approximately 1/2

throttle for at least 4 tanks of fuel (32 oz or 1000 ml per tank).

During this period, vary the throttle up and down slightly. Run the

engine 5 to 10 minutes at a time letting it cool down between runs.

Do not try to idle the engine during the first 15 minutes of break-in

as doing so can cause an adverse and degenerating affect on the

cam, cam lobes and cam followers.

Page 9

To properly adjust the engine after a break-in period of at least 1

US gallon of fuel, bring the engine to full throttle. Using a

tachometer, lean the engine (using the high speed needle) until it

turns its highest RPM (never more than 4200 RPM depending on

prop selection). Do not attempt to lean the engine to produce more

than 4200 RPM. The electronic ignition has a built in rev limiter

preset at 5100 RPM but this setting is only for safety purposes. It is

not meant to be the maximum RPM setting for the engine.

After the engine is turning the recommended RPM (without loosing

RPM), turn the high speed needle valve counter clockwise 1/8 turn.

This will insure the engine has sufficient fuel when the aircraft starts

accelerating forward and the prop loads by cutting through clean air

instead of cavitating the air when run in a static situation.

Once you have the high speed needle valve set and the break in

period is complete, the low speed needle valve can now be

adjusted. A common misconception is that the low speed needle

valve only affects the idle performance of the engine. In reality, the

low speed needle valve affects both the idle and mid range of the

engine. The high speed needle valve only affects peak power

settings. If the engine idles rough and is sluggish when the throttle

is advanced, the low speed needle valve needs to be leaned (turn

clockwise no more than 1/8 of a turn initially). Continue turning the

low speed needle clockwise in 1/16 turn increments until the engine

idles smoothly (app. 750 RPM) without trying to die and responds

fast and crisp to throttle advance. Between each adjustment, the

engine needs to be revved up to clear out excess fuel and oil.

At this point your engine is adjusted well enough to make the first

flight. Further “tweaking” of the high and low speed needles may

be necessary to get the ideal performance for your area. As the

seasons change, adjustments may be necessary to keep the engine

Page 10

running at peak performance. In cold weather the air is denser thus

more fuel is needed and in hot weather, the opposite applies.

FRESH AIR INTAKE

When using an engine cowling, such as in the case of most WWII

fighter planes, a fresh air intake must be established on the outside

of the fuselage. This is necessary due to hot, contaminated air

inside the cowling. In testing we have found that the engine will

loose power and RPM if a fresh air source is not supplied to the

carburetor.

In fabricating a fresh air source for your engine, a plenum area

must be established just in front of the carburetor.

This consists of a box area that is considerably larger than the

carburetor’s intake throat. If a plenum area is not used, it will cause

the engine to loose power and RPM plus not respond well to throttle

increases.

Periodic maintenance and inspection is a must on this very

complex engine. Your radial engine should be inspected

periodically, approximately every 1 hour of run time, for loose

fasteners (bolts, nuts, screws, etc.). Checking the tightness of all

fasteners is a good ideal. Never over tighten any fastener. The

screws and nuts are very small (to obtain the scale look of the full

scale engine).

After 20 hours of run time, all the screws holding the cylinders to

the crankcase need to be replaced. These screws are sold in sets

and are not covered by the warranty as they are considered

expendable items. Go to the parts exploded view to find screws and

Page 11

reference number to the parts list. When installing the cylinder hold

down screws always use a good grade of RED thread locker. For all

other screws use BLUE thread locker.

Re-lubricating the rocker arms should be done after every 10 hours

of run time. The rocker arms should be lubed with a high grade,

thick Molly lube.

Be cautious not to over lubing the rocker arms.

Too much lube will fill the pushrod tubes and hurt performance. A

good idea is to keep a log of run time on your engine. This will help

you know when to lube the rockers, adjust the rockers, inspect the

engine, etc. For your convenience, we have enclosed a log book

with your engine.

Also check for loose components by observing if any black residue is

omitting from between parts and components of the engine. This

black residue is finely ground metal mixed with oil that seeps from

between engine parts when the parts are loose or not sufficiently

tight. DO NOT run the engine until this situation is properly

addressed.

Valve Rocker adjustment is a critical part of your engine’s

performance. To ignore adjusting the rockers will lead to excessive

wear of the valve train and considerable loss of performance.

Adjusting the intake and exhaust rockers of each cylinder is

relatively easy to do but requires attention to finesse. If the rockers

are too loose the engine will loose performance and be hard to

start. If the rockers are too tight, it will cause excessive wear and

engine failure. The rockers need to be adjusted after the break in

period is completed and then every 10 hours there after.

Page 12

To adjust the valves, start by removing the rocker covers and spark

plugs from the cylinder heads. While looking through the spark plug

hole, rotate the crankshaft until the piston comes to TDC (top dead

center) with both rocker arms in the horizontal position (both valves

closed). You will note that both rocker arms are slightly loose in

this position. This should be the combustion stroke where you can

rock the crankshaft side to side without the rockers moving. If the

rockers move immediately when the crankshaft is slightly rocked

either way, this is between the exhaust stroke and intake stroke.

This position should not be used to adjust the valves as it is easy to

make a mistake in this position.

Using a box end (closed end) 7mm wrench and a 2mm socket head

wrench (Allen wrench), loosen either of the rocker arms one at a

time. Completely adjust one rocker arm and retighten before

starting on the other. Either the exhaust side or intake side can be

adjusted first. The sequence does not matter.

The adjustment starts by loosening the adjuster screw’s lock nut

with a box end 7mm wrench while holding the adjuster screw in

place with a 2.5mm socket head wrench. The engine needs to be

completely cooled down to room temperature (app. 70°) before

starting the rocker adjustments. At this point, turn the adjuster

screw down (clockwise) until it just removes all slack from the

rocker. A feeler gage is not necessary for these adjustments. Be

cautious not to turn the adjuster screw too far as you only want the

slack removed. When you are satisfied that all the slack is

removed, tighten the lock nut while holding the adjuster screw

firmly in place with the Allen wrench. In some cases, tightening the

lock nut will change the setting you have established. If this occurs,

loosen the lock nut and start the procedure over until the setting

stays constant after the lock nut is tightened.

Page 13

Type

Radial, Gasoline, CDI Spark

Ignition

Scale

1/5th

Cylinders

9

Cooling

Air

Engine Displacement

12.2 cu. in. (200 cc)

Capacity Per Cylinder

1.33 cu. in. (22.22 cc)

Bore

29 mm

Stroke

32 mm

Power

15 hp

RPM Range

750-4200

Maximum RPM

4200

Engine Diameter

281 mm

Engine Length

275 mm

Weight w/o prop

13 lbs.

Fuel Usage

2.5 oz Per Minute

Recommended 2 blade

Propellers

32-14 Xoar (for break-in),

32-16 Xoar & 32-18 Xoar

Carburetor

1 Zama

Exhaust

Stainless Steel Collector Ring

w/smoke oil nipple (included)

Use the same procedure to adjust the other rocker arm. With both

rocker arms adjusted, replace the rocker covers. Use blue thread

locker on the rocker cover’s screws. The rocker cover’s screws are

very small, do not over tighten them. Now proceed to adjust the

remaining valves using the same procedure described above.

Always do only one cylinder at a time.

ENGINE SPECIFICATIONS

Page 14

SAFETY WARNINGS

*This model engine is not a toy! It is a sophisticated power

system to power model aircraft and should never be used for

any other purpose.

*Keep all loose items away from the propeller when the

engine is running.

the engine is running.

*Keep bystanders at least 30’ away while engine is running.

*When the engine is running, it becomes very hot. Never touch

the engine or exhaust as severe burns can result.

*Never operate engine with a damaged propeller. The propeller

can come apart or disintegrate and cause severe injury to

yourself and bystanders.

*Keep children and pets at least 30’ away while engine is running.

*Never be in front of the propeller while engine is running.

*Make sure the propeller is tight and secure before starting the

engine.

*Always have a helper hold the airplane securely in place before

starting the engine.

engine. Install engine kill switch on the transmitter or airplane

to kill the engine.

Page 15

EXPLODED VIEWS

Page 16

Page 17

Page 18

Page 19

Page 20

ITEM

NUMBER

QTY.

PART

NUMBER

PART NAME

1 1 AS-21-901

CRANK SHAFT

2 1 AS-21-902

CRANKSHAFT SLEEVE

3 1 AS-21-903

NOSE CONE

4 1 AS-21-904

SCALE MAGNETO

5 2 AS-21-905

SCALE DISTRIBUTOR

6 1 AS-21-906

SCALE PROP CONTROLLER

7 1 AS-21-906A

SCALE PROP GOVERNOR,

ROLLER WHEEL

8 1 AS-21-907

SCALE OIL PUMP

9 1 AS-21-909

CAM

10 1 AS-21-910

CRANK SHAFT DRIVE GEAR

11 1 AS-21-911

CAM SECTION CRANKCASE

12 1 AS-21-912

CRANKCASE CORE

13 1 AS-21-913

INLET AND MOUNT

14

18

AS-21-914

CAM FOLLOWER

15 1 AS-21-915

MASTER ROD

16 8 AS-21-916

CONNECTING ROD

17 1 AS-21-917

LINK PIN RETAINING PLATE

18

18

AS-21-919

CAM FOLLWER BUSHING

19 1 AS-21-921

CRANKSHAFT COUNTER

WEIGHT

20 3 AS-21-922

COUNTERWEIGHT RIVETS

21 1 AS-21-924

EXHAUST COLLECTOR RING

22 1 AS-21-925

CAM DRIVE 35-10 GEAR_2 EA.

23 2 AS-21-929

FAN BOLT WASHER

24 9 AS-21-C00

CYLINDER HEAD, FRONT

25 9 AS-21-C02

PISTON ASSEMBLY

26 1 AS-21-C03

PROP HUB OUTER PLATE

27 1 AS-21-C04

PROP HUB-2 BLADE PROP

28 1 AS-21-C05

PROP HUB NUT

REPLACEMENT PARTS LIST

Parts numbers are for 1 each or 1 set as noted. For current

prices go to www.pegasusengine.com or call 1-888-898-7841.

Page 21

ITEM

NUMBER

QTY.

PART

NUMBER

PART NAME

29 1 AS-21-C06

CRANKSHAFT KEY

30 2 AS-21-C11

CAM IDLER GEAR SPACE

31 9 AS-21-C12

CYLINDER SLEEVE

32

36

AS-21-C13

10MM STUD, NOSE, SCALE

MAG, DISTRIB

33

18

AS-21-C15

STUD, NOSE CONE 31MM

34 9 AS-21-C16A

EXHAUST PUSH ROD 72MM

35 9 AS-21-C16B

INTAKE PUSH ROD

36 9 AS-21-C17A

EXHAUST GUIDE TUBE 65MM

37 9 AS-21-C17B

INTAKE GUIDE TUBE 64MM

38

36

AS-21-C18

PUSH ROD TUBE SCALE NUT

39

18

AS-21-C20

ROCKER

40

18

AS-21-C21

ROCKER ADJUSTER SCREW

41

18

AS-21-C22

ROCKER ADJUSTER BALL

42

18

AS-21-C23

ROCKER COVER

43

18

AS-21-C24

VALVE 13 MM DIA.

44

18

AS-21-C25

VALVE GUIDE

45

18

AS-21-C26

VALVE SPRING CAP

46

18

AS-21-C27

EXHAUST STUB TUBE

47

18

AS-21-C28

INLET TUBE

48

36

AS-21-C29

INLET AND EXHAUST CLAMP

49 1 AS-21-C30

VELOCITY STACK 19MM

50 8 AS-21-C33

LINK PIN

51

18

AS-21-C34

VALVE SPRING

52 9 AS-21-C36

SCALE SPARK PLUG

53

18

AS-21-C37

SCALE IGNITION RING WIRE

ADAPTOR

54 1 AS-21-C44

INLET FAN

55 1 AS-21-C45

CAM RETAINING PLATE

56 1 AS-21-C48

SENSOR CARTRIDGE 16 DIA.

57 1 AS-21-C52

CARB INSULATOR BLOCK

58

18

AS-21-C62

CAM FOLLOWER (ROLLER

SHAFT)

59

18

AS-21-C63

CAM FOLLOWER (ROLLER)

60

18

AS-21-C64

ROCKER PIN

61

18

AS-21-C65

ROCKER PIN SLEEVE

62 1 AS-21-C66

CAM BUSHING

Page 22

ITEM

NUMBER

QTY.

PART

NUMBER

PART NAME

63 9 AS-21-C67

CYLINDER SCALE OIL PIPE

64 1 AS-21-P001

SEALED BALL BEARING 17X35X10

65 2 AS-21-P002

BALL BEARING, 20X37X9

66 1 AS-21-P003

MASTER ROD BEARING, 15X21X16

67

36

AS-21-P004

ROCKER BEARING, 4X7X3

68 8 AS-21-P006

LOWER ROD BUSHING, 6X8X10

69

109

AS-21-P007

M2 X6, CYLINDER

70

112

AS-21-P008

M2 X 5MM SCREWS, ROCKER

COVER AND SCALE OIL PUMP

71

12

AS-21-P009

M3 X 10 SCREWS, SENSOR

CARTRIDGE

72 9 AS-21-P010

SCREWS,REAR MOUNT

73 4 AS-21-P011

M3X30 SCREWS, SCALE

DISTRIBUTOR

74

116

AS-21-P012

M2 SCREWS, INTAKE CLAMP,

SCALE OIL PUMP

75 2 AS-21-P014

M5X45 CARB SCREWS

76 6 AS-21-P015

M4X45 PROP BOLTS

77 9 AS-21-P016

¼ X 32 SPARK PLUG

78

54

AS-21-P017

M2 NYLOC NUT, FRONT STUDS

79

19

AS-21-P018

M3 NYLOC NUT, FAN BOLT,

ROCKER PIN

80

18

AS-21-P019

M4 LOCK NUT, ROCKER ADJUST

SCREW

81 1 AS-21-P020

20MM, EXTERNAL CIRCLIP

82 1 AS-21-P021

RETAINER, 15MM, WRIST PIN

83 1 AS-21-P022

C CLIP 5MM, CAM IDLER GEAR

SHAFT

84 1 AS-21-P023

INTERNAL CIRCLIP 35MM, CRANK

MAIN BEARING

85

18

AS-21-P024

E CLIP, 0.125”, VALVE

86 3 AS-21-P025

O RING 95 ID X 1.78, CAM

HOUSING, REAR MOUNT

87 9 AS-21-P026

O RING 30 ID X 1.78, CYLINDER

88

27

AS-21-P027

O RING 10.8 ID X 1.78, INLET

89 1 AS-21-P028

O RING 70 ID X 1.78, SENSOR

CARTRIDGE

Page 23

ITEM

NUMBER

QTY.

PART

NUMBER

PART NAME

90

18

AS-21-P030

O RING 4.00 OD X .75 CS, CAM

FOLLOWER

91 1 AS-21-P032

MAGNET 3 X 3, USE SOUTH POLE

92 1 AS-21-P033

CDI IGNITION KIT FOR ¼ X 32

SPARK PLUG

93 1 AS-21-P035

CARB

94 1 AS-21-P037

M3 X 25 FAN BOLT

95 3 AS-21-P039

M2.5 X 5MM SCREWS, MASTER

ROD RETAINING PLATE

96 4 AS-21-P040

M3 X 16 SOCER HEAD CAP SCREW,

TRIGGER RING

97 4 AS-21-P044

COPPER RIVET 0.8 X 5, DATA

PLATE

98 1 AS-21-P045

P&W LOGO PLATE

99 1 AS-21-P046

ENGINE DATA PLATE

100

18

AS-21-P050

ROCKER ARM PIN WASHER

101

1

AS-21-P051

IDLER GEAR BUSHING 5X10X12

102

9

AS-21-P052

WRIST PIN BUSHING 6X8X10

103

1

AS-21-P053

ELECTRIC FUEL PUMP, 3 PSI

104

1

AS-21-PO54

SET SCALE SPARK PLUG WIRES

TYPE 1

105

1

AS-21-PO55

ENGINE LOG BOOK

106

1

AS-21-PO56

“Y” HARNESS, 375 MM,PUMP SHUT

OFF

107

1

AS-21-PO57

LIPO BATTERY, 7.4 V-5000 MAH

108

9

AS-21-PO58

SET SPARK PLUGS ¼-28

109

1

AS-21-PO59

OPTIONAL KILL SWITCH

(ELECTRIC FUEL PUMP)

110

1

AS-21-PO60

OIL PEN

111

1

AS-21-PO61

MINI TACHOMETER

112

1

AS-21-PO62

POWER SWITCH AND CHARGER

PORT HARNESS

Page 24

ADJUSTABLE PITCH PROPELLERS

MOUNTING THE ADJUSTABLE PROPELLER HUB: To remove

the 2 blade prop hub, use a rubber strap tool (such as used to

remove automobile oil filters) to hold the hub while removing the

nut from the center of the hub. The nut turns counter clockwise to

remove. Do not use pliers, vise grips, etc to hold the hub. This will

cause the hub to be unbalanced and can cause engine damage.

After the 2 blade hub is removed, you can now install the 3 or 4

blade hub. Start by first removing the cir clip from inside the hub.

Next, install the hub and tork the nut to 25 ft lbs of tork. It is

important to use a tork wrench because over tightening the nut can

crush the bearing spacer inside the engine. The cir clip can now be

installed.

ADJUSTING THE PROPELLER HUB: The 3 blade and 4 blade

prop hubs are statically adjustable. The pitch of the propeller

blades can be adjusted over a wide range of degrees from fine pitch

to course pitch. CAUTION: if the propeller blades are adjusted too

fine or too course, the propeller will not develop sufficient thrust to

pull your airplane at an acceptable speed (considerably above stall

speed). NOTE: The 4 blade propeller must be set with less pitch

than the 3 blade propeller if used in the same application. This is

due to the increased thrust capabilities of the 4 blade propeller. The

4 blade propeller also takes more power to pull when using the

same pitch as the 3 blade propeller.

To adjust the pitch of the propeller blades, first start by removing

the nose cone from the hub. Next loosening all the hub screws.

The blades can now be moved. Start by turning the adjuster wheel

inside the hub, left (counter clockwise) for less pitch and right

(clockwise) for more pitch. Turn the adjuster wheel until it gets

tight (do not force it). At this point, rotate the blades back and

forth until the adjuster wheel is again loose.

Page 25

Repeat this operation until the blades have moved to the position

you desire. A helicopter pitch gage can be used to check the pitch.

At this point, retighten the hub screws and re-install the nose cone.

CAUTION: do not over tighten the nose cone as this could cause

the threads to seize and make it impossible to remove.

Never adjust the pitch more than 5° at any one time without test

running the engine and measuring the thrust. Remember, the

engine should run between 3800 and 4200 RPM at full throttle.

During testing, we have found that the propellers will produce in

excess of 50 LBS of thrust. This is the measure you need to achieve

when adjusting the propeller blades.

SCALE SPARK PLUG WIRES

To install the scale spark plug wires and spark plugs start by gluing

the wires to the collector ring with high temperature RTV silicone.

The collector ring has 36 holes in it to accept spark plug wires. Use

the two holes directly in front of the cylinder to install the wires for

that cylinder. Skip 2 holes and repeat the procedure. When

completely dry, straighten the wires and form them to desired

shape. Next glue the scale spark plugs (on other end of spark plug

wire) to the holes provided in the front of the cylinder heads.

The wires that do not have spark plugs on them should be routed

over the head between the rocker towers and secured behind the

head. Included in the scale spark plug wire kit are 2 short wires

that go between the 2 distributor and the magneto.

MOUNTING YOUR RADIAL ENGINE

A mounting hole template is supplied with the engine. The template

shows the true center of the firewall as well as the center of the

necessary offset to compensate for the angle offset of the engine.

Page 26

The offset on the template is designed for a 2° down and 2° right

engine angle. By using the template, it will insure that the prop

hub, on the engine, is in the true center of the aircraft and cowling.

Contact cement the template to the firewall making sure the

template is centered and square.

Use the appropriate drill bit to drill the mounting holes. Engine

mounting bolts and blind nuts are not supplied with your engine.

Use a small amount of blue Locktite on each bolt to insure they stay

tight. The firewall that you are mounting the engine on should be

at least 3/8” thick, 5 ply, birch plywood or equivalent. If the firewall

does not meet these specifications, the firewall will need to be

strengthened. The firewall also needs to have reinforcement where

it attaches to the fuselage structure. Spruce wood ¾” triangular

stock or aluminum angles are good materials for this purpose. The

template also incorporates the mounting hole pattern for the

exhaust ring (exhaust ring mounting bolts and blind nuts are not

supplied with the engine).

WARRANTY

PEGASUS AIRCRAFT ENGINES warranties this engine to be free

of defects in materials and workmanship for a period of two year.

If the engine fails, runs poorly, produces irregular noise or does not

meet specified RPM, you may send it to the factory or a PEGASUS

AIRCRAFT ENGINES authorized warranty station for repair. If

cause of the deficiency is due to workmanship or materials, it will be

repaired at no cost to you except the cost of one way shipping.

This warranty does not cover cosmetic blemishes, discoloration or

finishes. Any misuse, abuse or crash damage is not covered by this

warranty. Any attempts to modify or reconfigure this engine will

void the warranty. Any attempt to repair this engine yourself or by

any other unauthorized person will void the warranty. Use of any

fuel other than that recommended will void the warranty.

Page 27

Any use of oil or oil quantity other than that recommended will void

the warranty. PEGASUS AIRCRAFT ENGINES will honor any

warranties expressed or implied by venders of the company. The

ignition system, carburetor and fuel pump have separate warranties

but will be covered by your engine’s warranty.

CONTACT INFORMATION

FOR SALES, WARRANTY AND ENGINE REPAIR

NORTH & CENTRAL AMERICA:

PEGASUS TECHNOLOGY INC.

1900 DOWNING STREET, SUITE A

MILLBROOK, ALABAMA 36054

USA

PHONE: 1-888-898-7841

FOR OTHER LOCATIONS FOR SALES, WARRANTY AND ENGINE REPAIR, SEE

OUR WEB SITE AT http://www.pegasusengine.com/.

Page 28

Loading...

Loading...