Page 1

PEGASUS

INSTRUCTION

CLASS

AS7k:

R57L

ASUS

Page 2

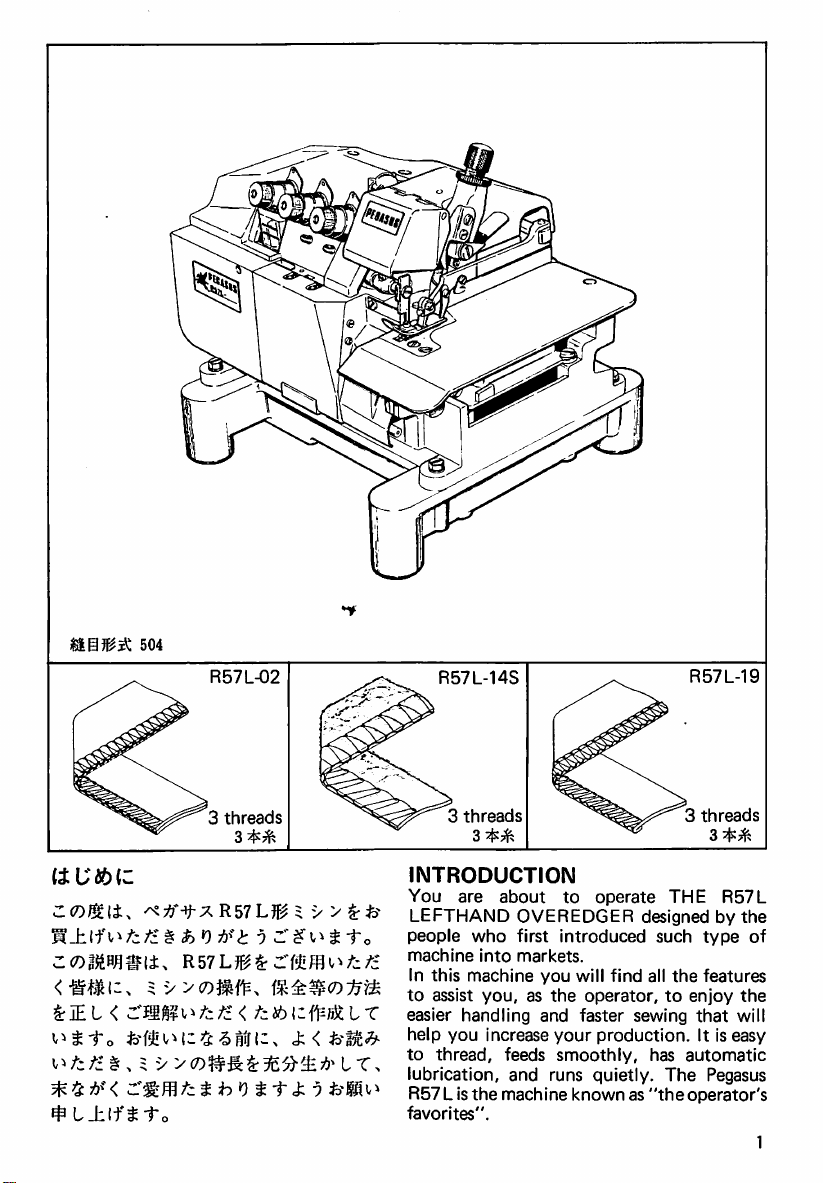

504

R57L-02

3

threads

R57L-14S

3

threads

3^^

R57L-19

3

threads

3^^

INTRODUCTION

You

are

^lEL

<

^^fzfz § , = y

^

L±lf^

to

§

i)

0

1

<

7^i6i;fWLT

J

I'o

LEFTHAND

about

people

machine

In

to

easier

help

to

who

into

this

machine

assist

you,

handling

you

increase

thread,

lubrication,

R57 L is

favorites".

the

to

OVEREDGER

first

introduced

markets.

you

will

as

the

and

faster

your

feeds

smoothly,

and

runs

machine

known

operate

THE

designed

such

find

all

the

operator,

to

sewing

production.

has

quietly.

as

"the

The

R57L

by

type

features

enjoy

that

It

is

automatic

Pegasus

operator's

the

of

the

will

easy

1

Page 3

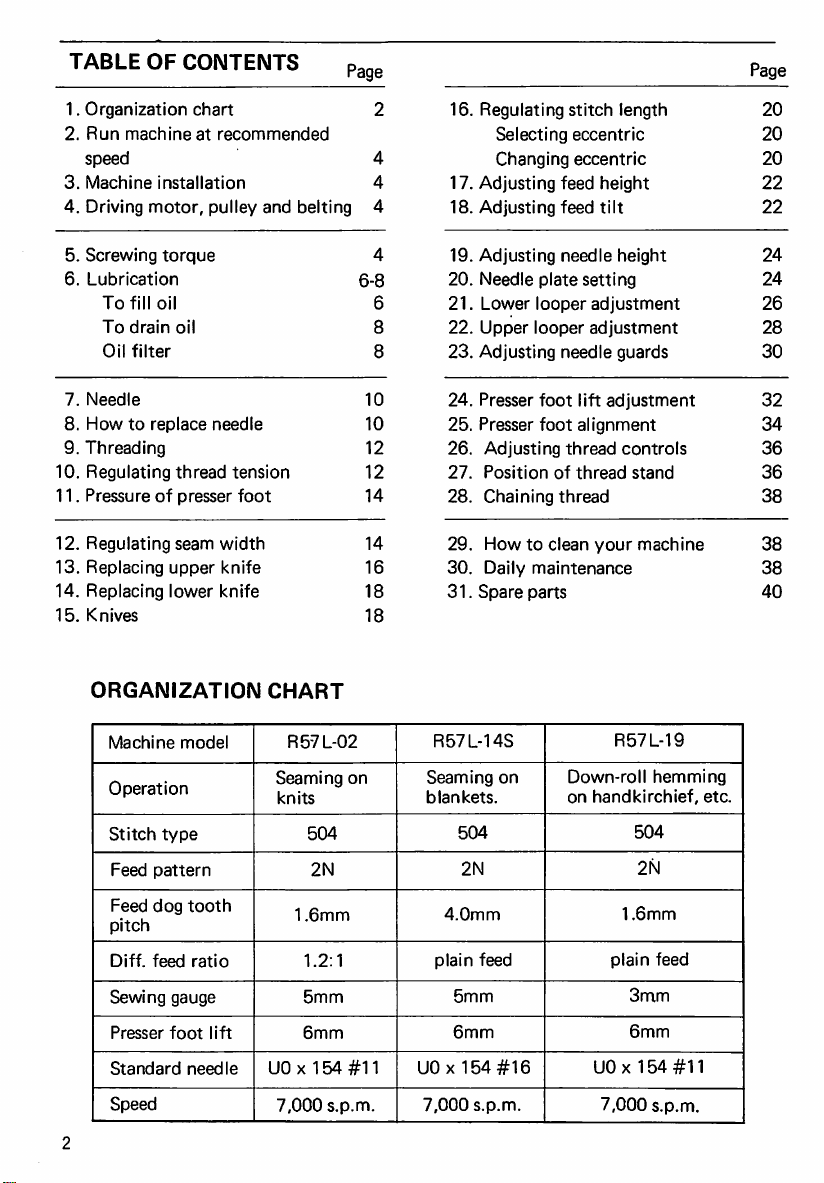

TABLE

1.

Organization

2.

Run

OF

machine

speed

3.

Machine

4.

Driving

installation

motor,

CONTENTS

chart

at

recommended

pulley

and

Page

belting

Page

2

4

4

4

16.

Regulating

Selecting

Changing

17.

Adjusting

18.

Adjusting

stitch

length

eccentric

eccentric

feed

height

feed

tilt

20

20

20

22

22

5.

Screwing

6.

Lubrication

To

fill

To

drain

Oil

filter

7.

Needle

8.

How

to

9.

Threading

10.

Regulating

11.

Pressure

12.

Regulating

13.

Replacing

14.

Replacing

15.

Knives

ORGANIZATION

Machine

Operation

Stitch

torque

oil

oil

replace

needle

thread

of

presser

seam

upper

lower

model

type

tension

foot

width

knife

knife

CHART

R57L-02

Seaming

knits

504

on

6-8

10

10

12

12

14

14

16

18

18

4

6

8

8

19.

Adjusting

20.

Needle

21.

Lower

22.

Upper

23.

Adjusting

24.

Presser

25.

Presser

26.

Adjusting

27.

Position

28.

Chaining

29.

How

30.

Daily

31.

Spare

R57L-14S

Seaming

blankets.

504

needle

plate

looper

looper

needle

foot

foot

of

thread

to

clean

maintenance

parts

on

height

setting

adjustment

adjustment

guards

lift

adjustment

alignment

thread

controls

thread

stand

your

machine

R57L-19

Down-roll

on

handkirchief,

hemming

504

24

24

26

28

30

32

34

36

36

38

38

38

40

etc.

1.6mm

plain

3mm

6mm

UOx

7,000

2N

feed

154

s.p.m.

#11

Feed

pattern

Feed

dog

pitch

Diff.

feed

Sewing

Presser

Standard

Speed

tooth

ratio

gauge

foot

needle

lift

1.6mm

1.2:1

5mm

6mm

UOx

7,000

2N

154#11

s.p.m.

4.0mm

plain

5mm

6mm

UOx

7,000

2N

feed

154

s.p.m.

#16

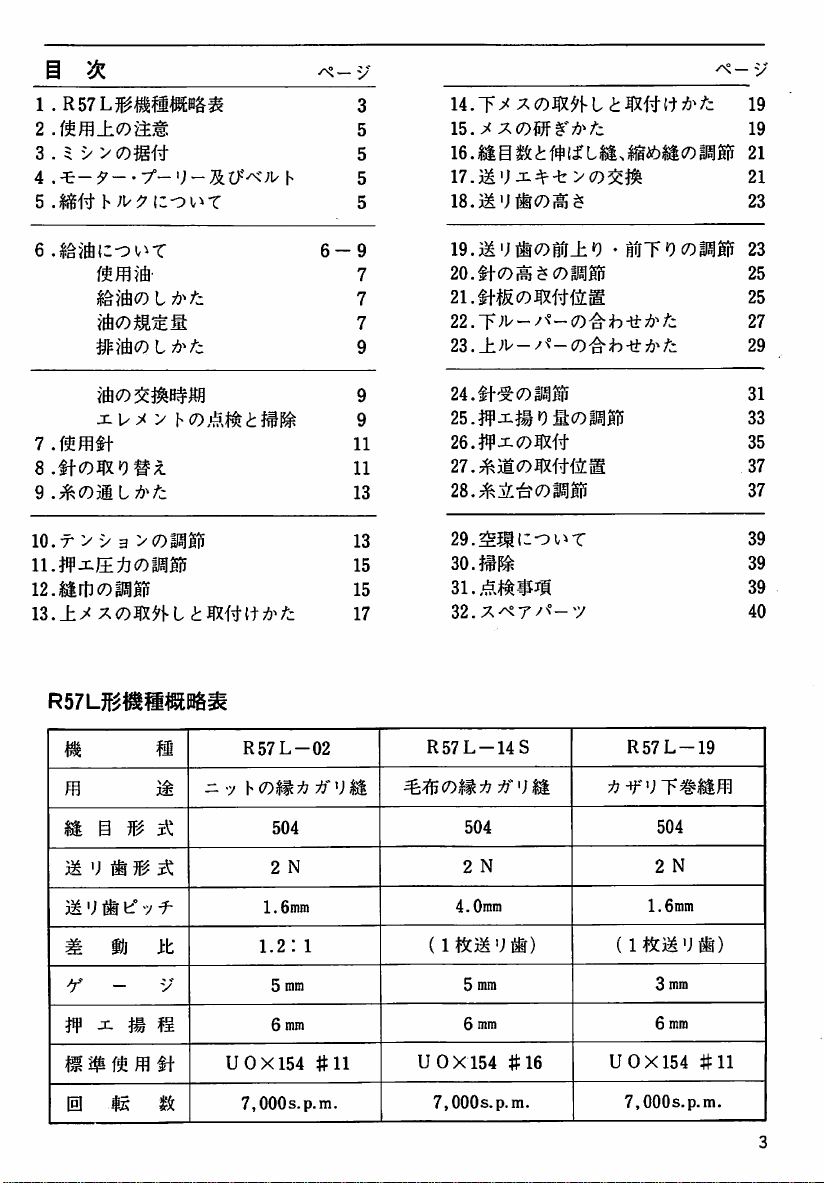

Page 4

s

^

1

.R57L1^M«^

3 . 5 y vco^-f^

4

.^-9--

-f~

-

y"

3

5

5

h

5

5

14.T^

15.

;^ X COW

16.M@l<fi#(^LM>liMcoM

17.31';

Ji^-t>co3c^

18.3^';iiiCOi^$

§"

75^

i'i

i

Wft

75^

V

19

19

21

21

23

l&VftCO

t

8.#i-C0^«9#^

9.^(Dmi-A'fz

10.T

y y a y

(DM'B

11.#J^l±;fl<7)MSi5

12.Mltico|)^gif

IZ.±.^

7^<DW\-LtM\is\ii3^tz

m

^

u m ^

m

- y hcOft:^

3i

R57L-02

504

6-9

7

7

7

9

11

11

13

13

15

15

17

if^)M.

lo.jM'iiifcoir^o • MT';coiisigi!

20.thcoi^$coMgi5

2i.m&(Dmmm

22.~f

}\/~y^—(D'ah^^^fz

23.±)V-^^-(D^h-^^-rz

24.tt-^col)J10

26.#J:.(7)|X#

27.^)1

CO

WfiM

28.^3i-^(7)M0

29.^i|(;ov^T

30.

Z2.y.^7^^-y

R57L-14S

504

R57L-19

504

23

25

25

27

29

31

33

35

37

37

39

39

39

40

2

1.6mm

(1

tiCT^

0X154

7,000s.

N

•;"®)

3

mm

6

mm

#11

p.m.

m^)

M^)

m

w

li

^

[H

mm

m^ y ^

hj

— y

^

m

15

^

it

m

M

1^:

U

2

1.6mm

1.2:1

5

6

0X154

7,000

N

mm

mm

s.

#11

p.m.

(1

U

0X154

7,000s.

2

N

4.0ram

i!$t3M

■;

®)

5

mm

6

mm

#16

p.m.

U

Page 5

RUN

MACHINE

RECOMMENDED

1.

Do

not

run

5,000

s.p.m.

2.

At

the

end

should

be

Thereafter

operated

3.

Oil

two

of

seizure

at

level

should

lines

lubrication

of

AT

SPEED

the

machine

for

first 4 weeks.

of 4 weeks,

drained

the

machine

normal

speed.

be

always

on

Oil

Sight

may

parts.

out

cause

at

more

original

and

replaced.

may

kept

between

Gauge.

accidental

than

oil

be

Lack

DRIVING

BELTING

Each

machine

belt

of

the

1.

Clutch

watts

{1/2HP).

2.

Belt: V belt,

3.

Motor

pulley:

Machine

Motor

measured

MOTOR

should

following

motor: 3 phase, 2 pole,

Type

Pulley

Pulley

at

its

PULLEY

use a motor

specifications:

M.

as

shown

in

Table

Diameter

Diameter

outer

is

60.0mm.

should

diameter.

AND

1.

and

400

be

MACHINE

This

machine

submerged

effortless

The

contained

includes

pattern

installation

operation.

details

in

the

sheet.

INSTALLATION

is

designed

for

are

shown

shipping

sketch,

in

container,

description

for

semi-

efficient

the

and

Manual

which

and

SCREWING

The

figures,

illustrations

represent

when

the

tightened.

parts

recommended

that

the

tightened

TORQUE

which

and

the

relating

For

described

to

relating

with a correct

are

shown

expressed

correct

fixing

screwing

screws,

bolts

the

in

this

use

torque

screws

or

torque

in

by

'xxkg-cm',

torque

or

nuts

main

moving

book,

it

gauges

nuts

can

specified.

the

are

is

so

be

Page 6

i^m±<Dykm

^7}<Dl:^n

^t«l3&^(3H)^#{!^tT,

I

fz^i/ y co^@

2.

MW<7y

ti*^^x

3.

^

Pallia

lij^

<

)^'y—yW^(D

r^vzmnix

^^5000~55001Il#f

(;iS?

<fz^^^o

l;

fz

iEMco

015

'Z^-ft

^

vi-:?^j±i5IiT

^ - ^ - •

7'-«;

-:5lt>X;i/

f5^m^-^-(i.2ti400Wf^jti^

^)y V It.

v^o 5 V

u^v^)y V ^

>01515:i.

^-^7--7°-'J

Tieco^coMO

• 5 V

•

>

';

-OH^i(±^

rliMO^-^-

\Z\t.

imiil-55v^7°-U-mSOS5c

•

L5co

y-'J-|±.

eOmmT-To

N

y-j^

<tz^

^>>(Dmn

R57L?^cO$g{t:^^(±>

H^®At>'R57L?^}g#?F^gc^3:'#0^<

^

v^o

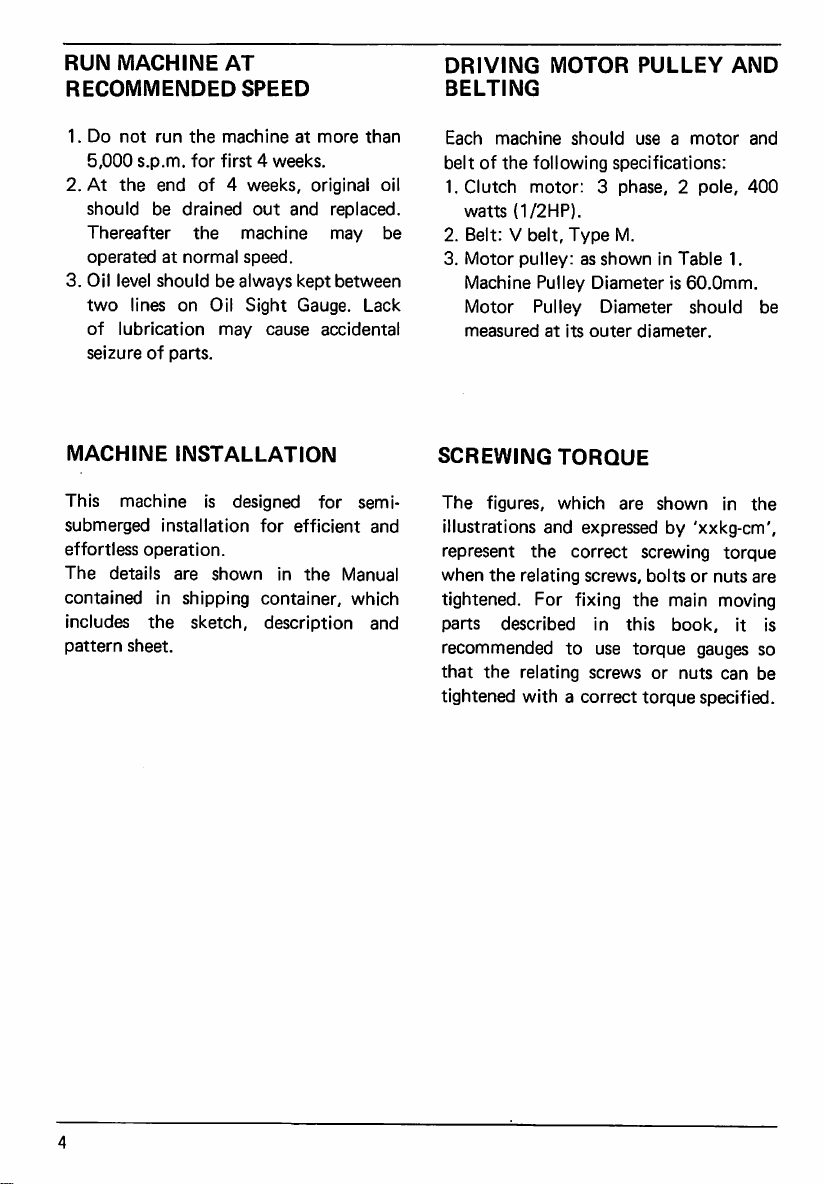

Tab.

5 y 7

Machine

^i:fcJ^^1?1-o

1

<7)^35-01515:

speecJ

(s.p.m.)

5,000

5,300

5,500

5,800

6,000

6,300

6,500

7,000

/i

^—^—'

^;^':7(cot^T

<ros^0;?#c7)^ 7 7

OOkg-cmi^^t/i

i;fs!!ffl L T

CDitJi.

7°—'J

Motor

pulley

60

Hz

85

90

95

100

105

110

115

120

-510^

ji^^CD^-.

CD^'RKmra)

diameter

(mm)

50

105

110

115

120

125

130

135

145

hopf'TN

h

;W7i±.R57L5^

CD y {I®

vdfttiiL/i

Hz

L

h^L'

Page 7

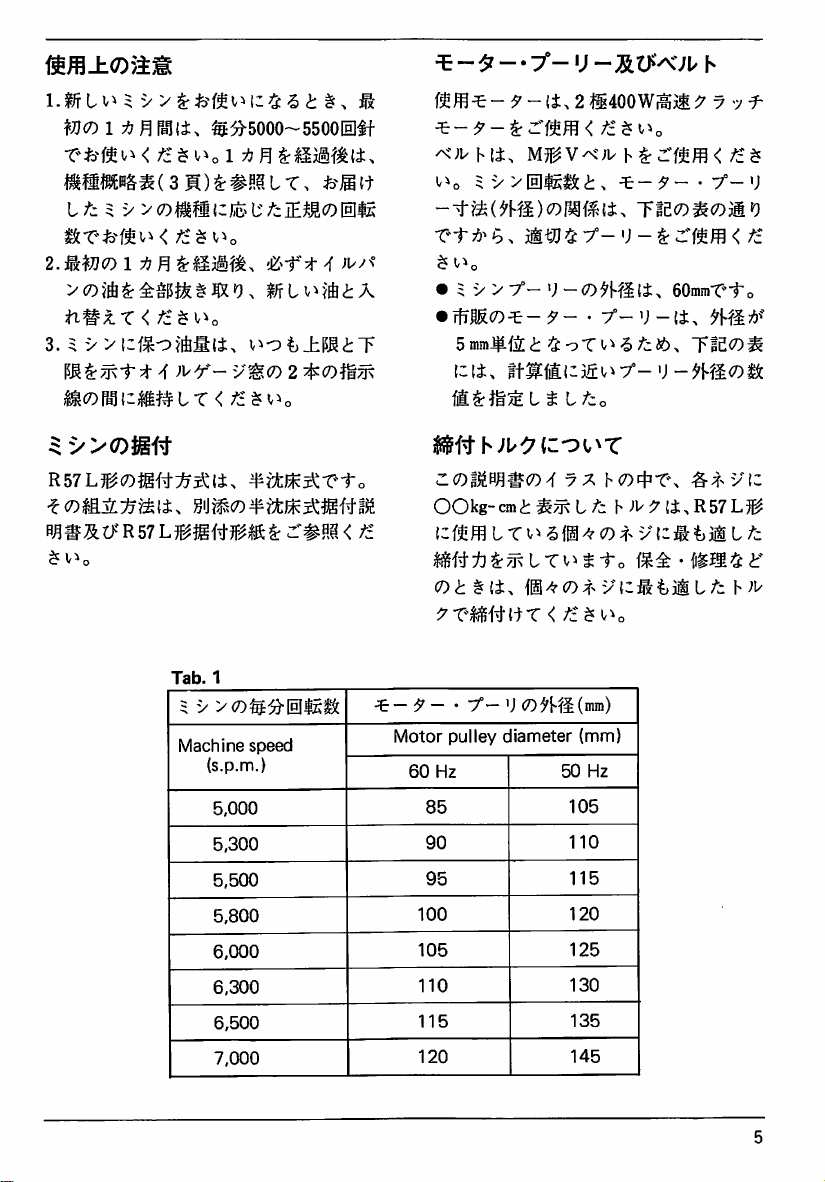

LUBRICATION

The

oil

was

when

shipped.

supplied

ing.

oil

Use

recommended

drained

or

from

Fill

Oil

equivalent

Pan

before

type

the

with

oil

only.

machine

factory

operat

To

fill

oil:

1.

Take

out

and

pour

c.c.

capacity)

line

'h'

2.

Replace

Caution:

Oil

fresh

of

Oil

Sight

Window

Keep

oil

lines

'h'

Splash

Sight

oil

into

until

oil

Gauge

O.

level

between

and

'8'

on

Fig.

1,2

Window

reservoir

reaches

upper

©.

the

Gauge

©.

(700

two

O

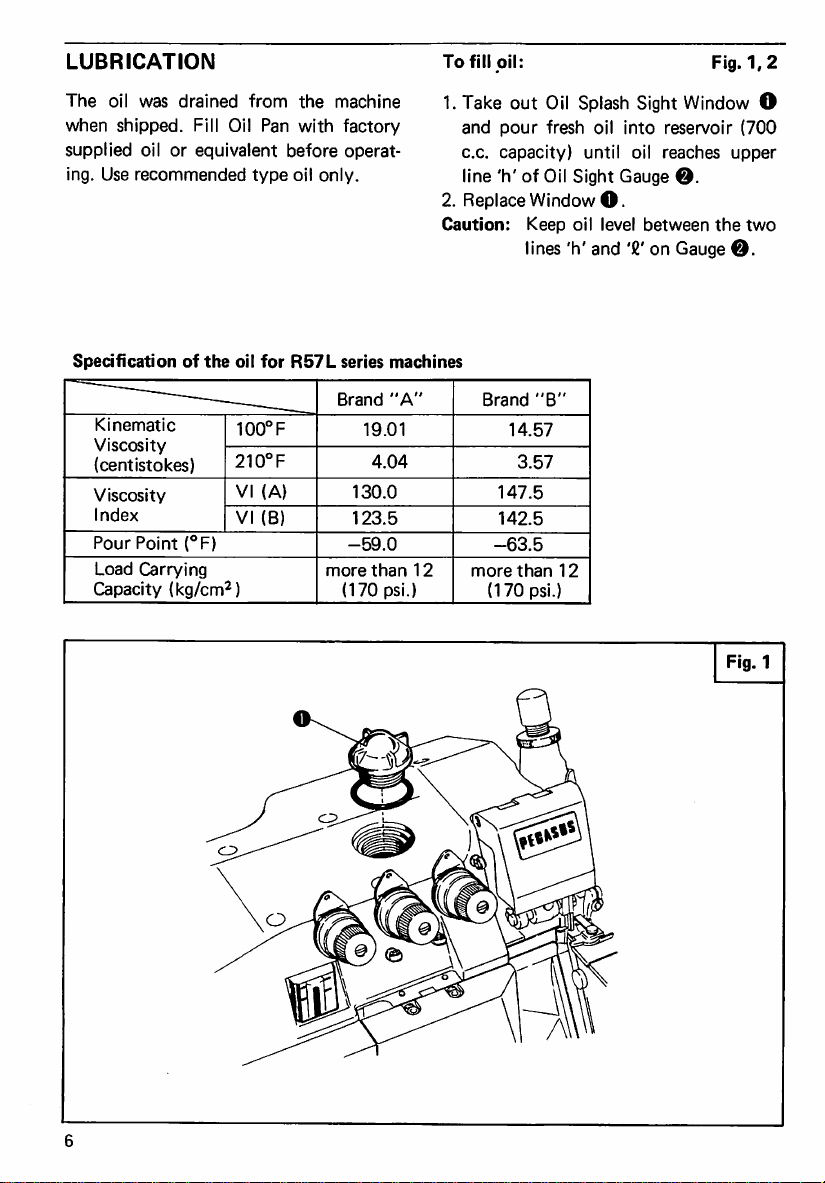

Specification

of

—■—

Kinematic

Viscosity

(centistokes)

Viscosity

Index

Pour

Point

(°F)

Load

Carrying

Capacity

(kg/cm^)

the

oil

for

100°F

210°F

VI

VI

(A)

(B)

R57L

series

Brand

19.01

130.0

123.5

-59.0

more

(170

machines

"A"

4.04

than

12

psi.)

Brand

more

(170

14.57

147.5

142.5

-63.5

3.57

than

psi.)

"B"

12

Fig.1

Page 8

mmm

R57Lj^lzimt6

i

7°-'J-S-F(70W-150)Cai:)fe-

:t>f

)l^Y-

v^0O±CO^

I

y

"P-SOCVC-V-f

ZZ:^^ht4

h t XAhX < ti

(1^2)

t ^ )\/Y-

yyizJE^^

M<7)±m

<

fz^

T§^ci§i±.

oT < /i ^ <^^0

yW,0(Dm^m h i

t

700cjc.(7)ifi;6^"|±Vi

L T Vi ^ -To

±(D^h^iO$rix

Z(D^tX^lzt

0 ^ 1"o

-^-SCli^^LT.

jg

(i.

t'ibX

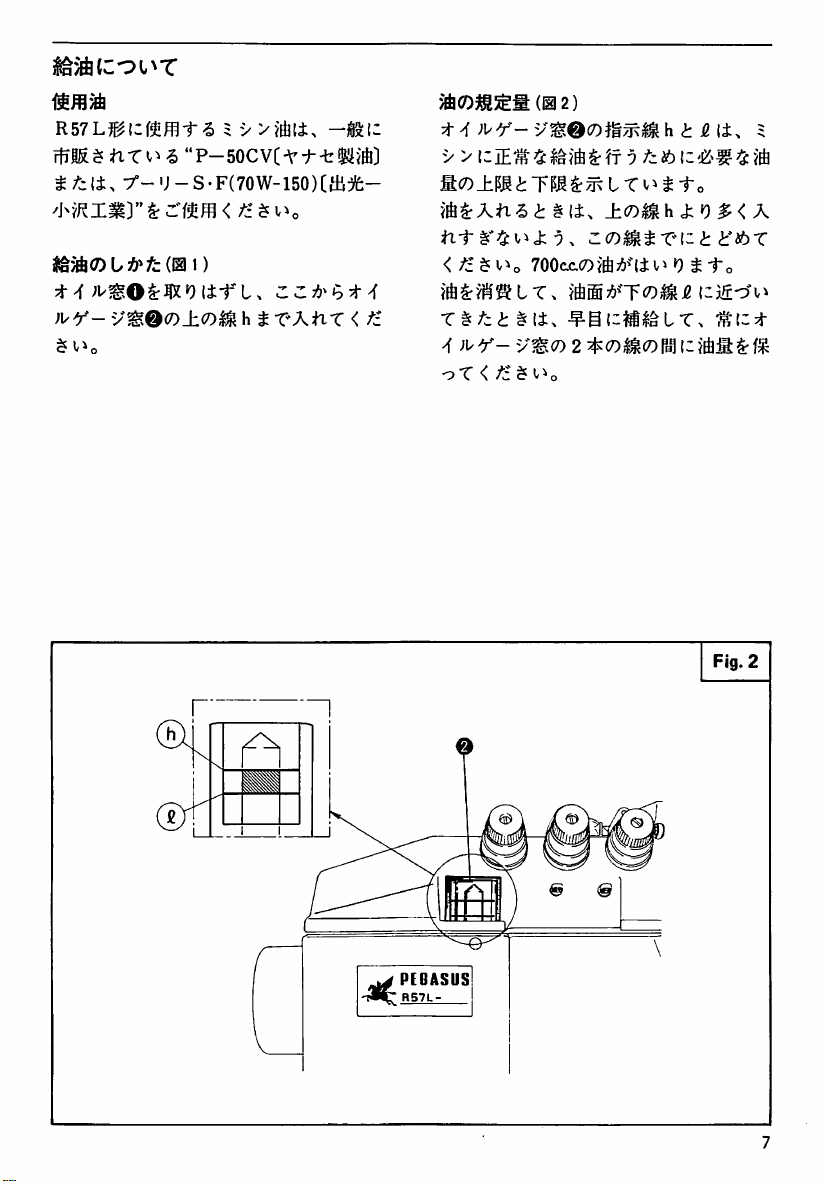

Fig.

5

^

2

PEGASUS

R57L

Page 9

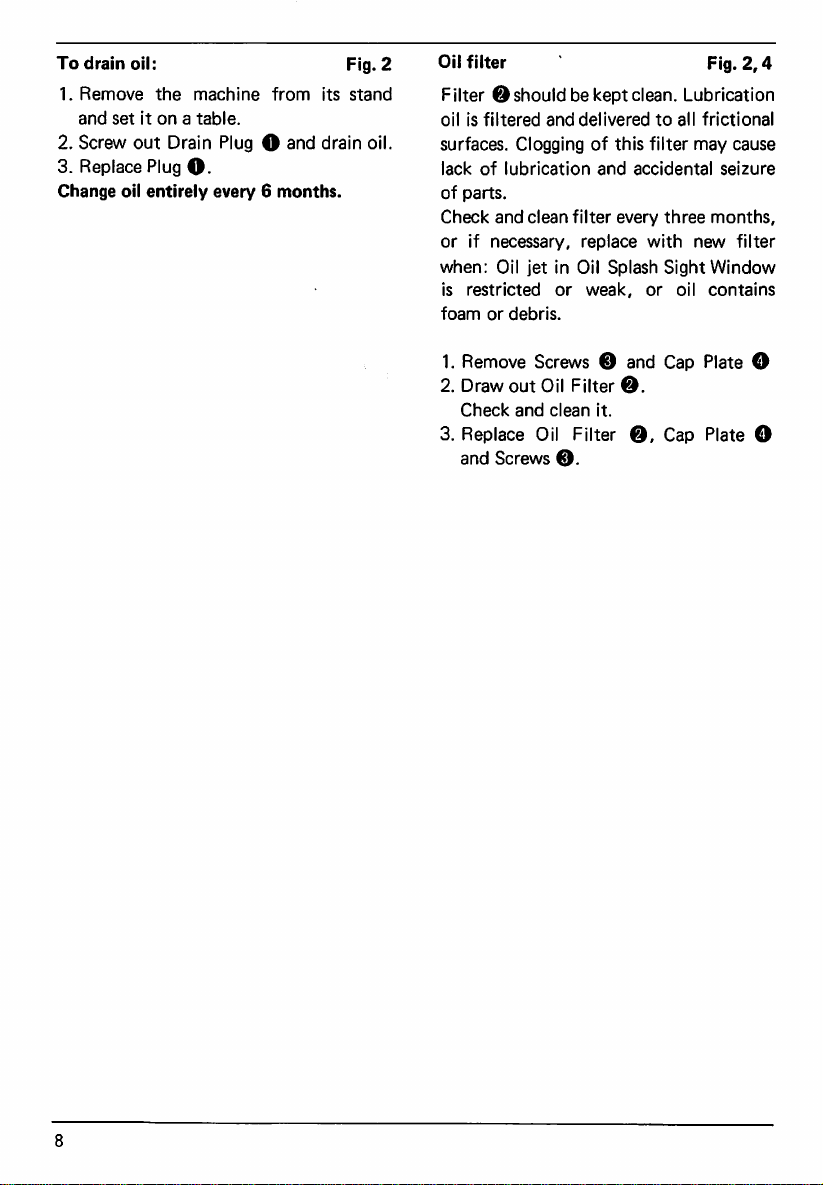

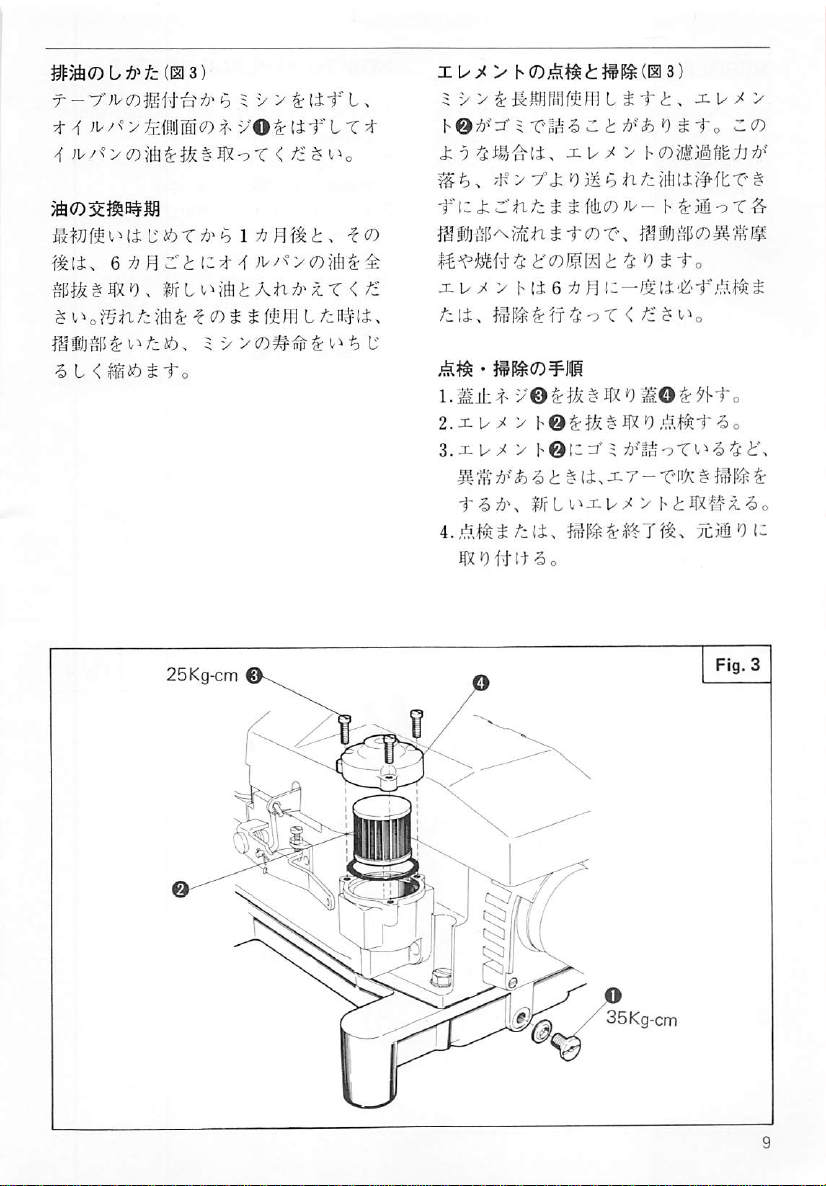

To

drain

1.

Remove

and

2.

Screw

3.

Replace

Change

oil:

the

set

it

out

Plug

oil

entirely

machine

on a table.

Drain

Plug O and

O.

every 6 months.

from

Fig.

its

stand

drain

oil.

2

Oil

filter

Filter 0 should

oil

is

filtered

surfaces.

lack

of

of

parts.

Check

or

if

when:

is

restricted

foam

or

1.

Remove

2.

Draw

Check

3.

Replace

and

and

Clogging

lubrication

and

clean

necessary,

Oil

jet

in

or

debris.

Screws © and

out

Oil

and

clean

Oil

Screws

0.

be

kept

clean.

delivered

of

this

and

accidental

filter

every

replace

Oil

Splash

weak,

Filter

©.

it.

Filter

0,

Fig.

Lubrication

to

all

frictional

filter

may

seizure

three

months,

with

new

Sight

Window

or

oil

contains

Cap

Plate

Cap

Plate

2,4

cause

filter

O

O

Page 10

(0

3)

t 4 ;b/x° > £#JlS<0

4

b 5 V > ^l±-f

vO^lt-f L T

L,

xiy^>

5

^

hOTlj^'r'A

J;

KC7);i^^i:J§l^(0

V V & i^wifiofs

9

ni

JZU

bi-ri,

t

;<

y

3)

t

xb^v

Ao

bCO

f^[±,

•& L <

%iinxt\zii^

rrtvMftiAn:^'^r

its()S-ro

</i

-fizJzXhfzt

SftlicoJU-

MHjSii^i^nS-fc?)T^

xu^vMieT:?!^

fzit.

1.m±x

2.xu^

>

3.xu^ > !>@i;=7A

i±,

Ifrbi^xu^

A(i.

m'oiii-f^o

h

[i;'£'f,-;.it^^

<

fz^^-^o

XT - Tnx ^ Jf ^ ^

>

Ttm^iz

Page 11

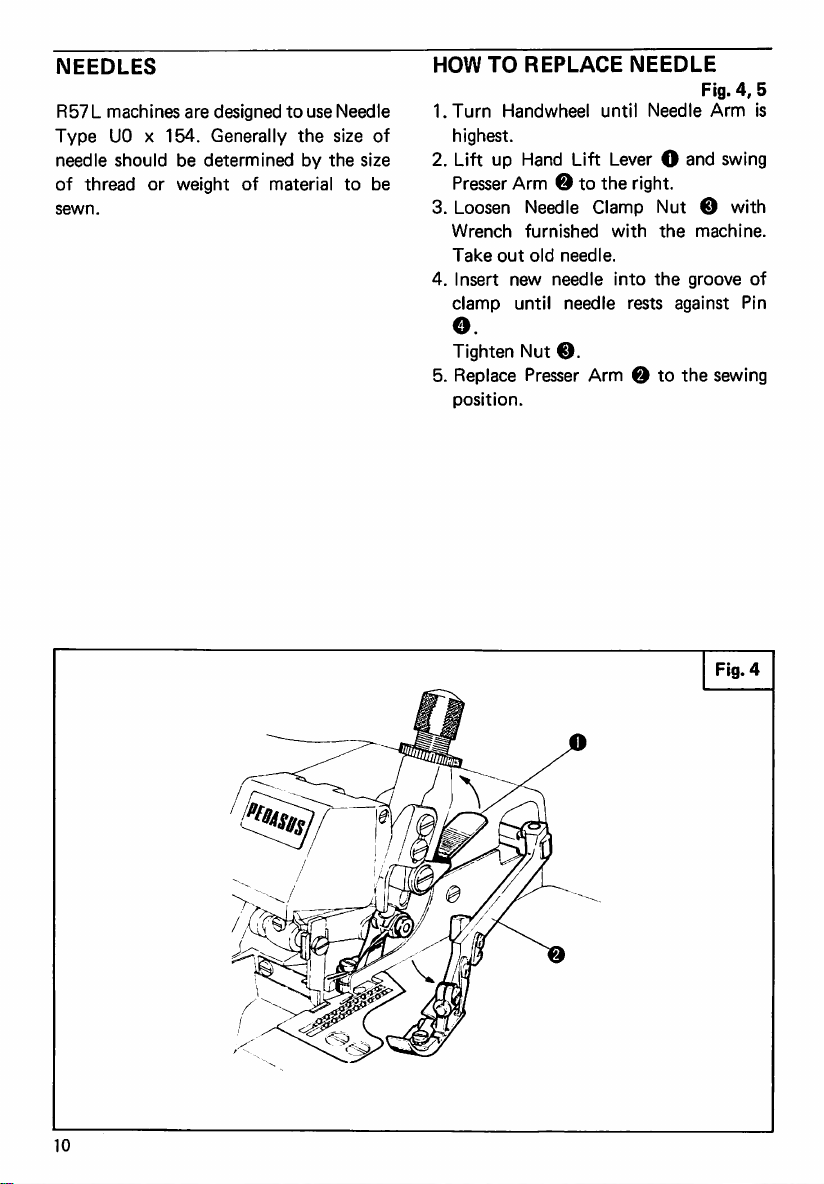

NEEDLES

R57 L machines

Type

DO x 154.

needle

of

thread

sewn.

should

or

be

weight

are

designed

Generally

determined

of

to

use

Needle

the

size

by

the

material

to

of

size

be

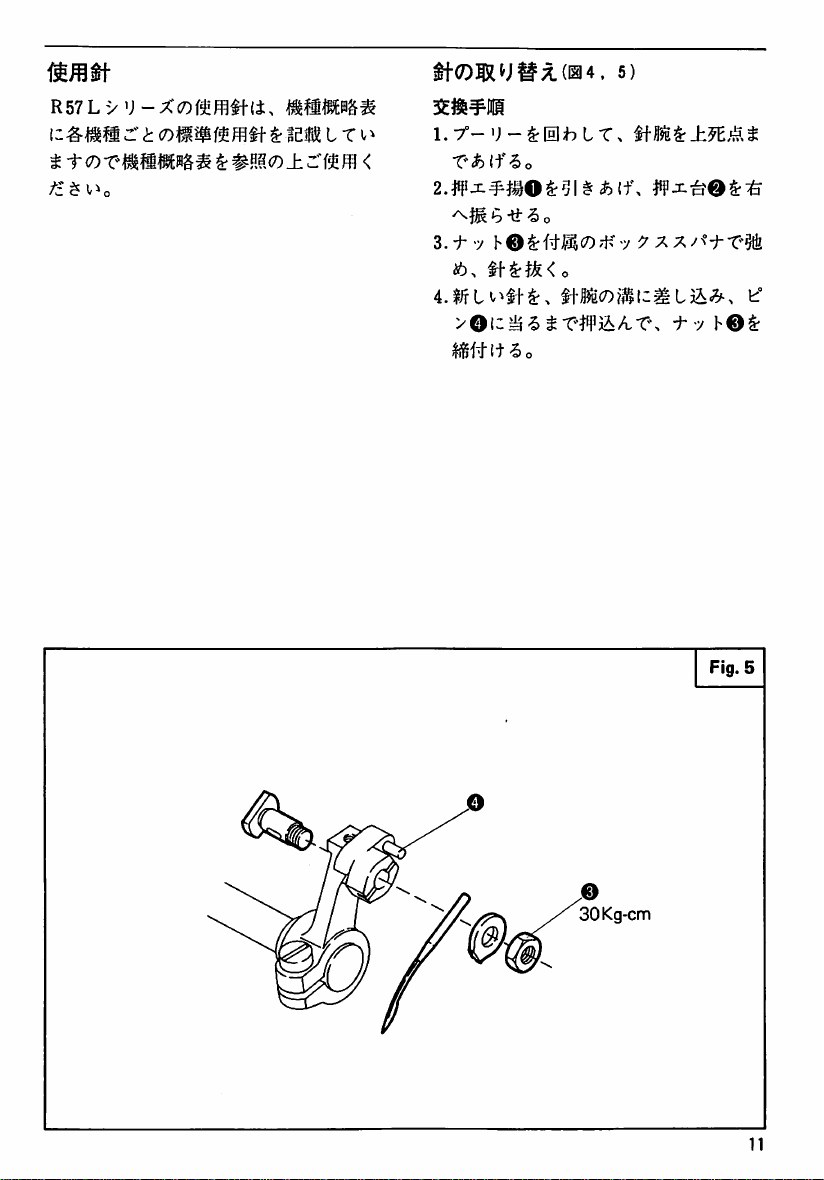

HOW

TO

1.Turn

highest.

2.

Lift

Presser

3.

Loosen

Wrench

Take

4.

Insert

clamp

O.

Tighten

5.

Replace

position.

REPLACE

Handwheel

up

Hand

Arm e to

Needle

furnished

out

old

needle.

new

needle

until

Nut

©.

Presser

until

Lift

Lever O and

the

Clamp

with

into

needle

Arm 0 to

NEEDLE

Needle

right.

Nut 0 with

the

machine.

the

groove

rests

against

the

Fig.

4,

Arm

swing

sewing

5

is

of

Pin

Fig.

10

4

Page 12

mmm

R57Ly

t

fz $ V^o

:r't

coiiSf^

^

ffl

it ^ iei( t r

^ mM<D±z'im

ti-<?)|RU^X(l2l4.

1.7°-U-^0hLT.

<

•ti"

-5

o

3.^7

hO^iifB,<D^-K7

i6,

5)

■:^7

h0^

Fig.

30Kg-cm

5

11

Page 13

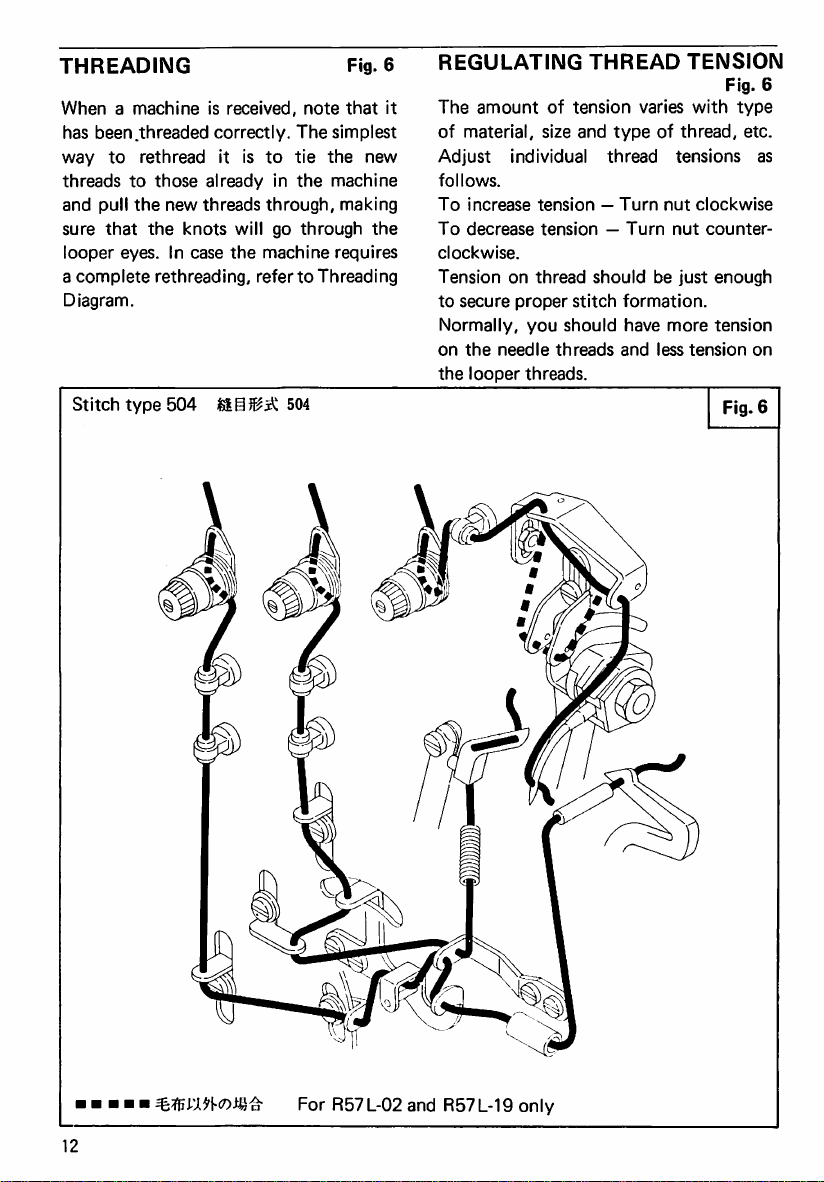

THREADING

When a machine

has

been

.threaded

way

to

rethread

threads

and

sure

looper

a

Diagram.

to

pull

the

that

eyes.

complete

Stitch

type

those

new

the

knots

In

case

rethreading,

504

is

received,

correctly.

it

is

to

already

threads

through,

will

the

machine

in

go

refer

504

Fig.

note

that

The

simplest

tie

the

the

machine

making

through

requires

to

Threading

new

the

6

it

REGULATING

The

amount

of

material,

Adjust

follows.

To

To

clockwise.

Tension

to

Normally,

on

the

individual

increase

decrease

on

secure

the

needle

looper

thread

proper

you

threads.

THREAD

of

tension

size

and

varies

type

thread

tension — Turn

tension — Turn

should

stitch

formation.

should

threads

have

and

TENSION

with

of

thread,

tensions

nut

clockwise

nut

counter

be

just

more

less

tension

Fig.

6

type

etc.

as

enough

tension

on

Fig.

6

For

R57

L-02

and

R57

L-19

only

12

Page 14

h

e.

^.mn

0.

MJio/i!

■fo

:^li[2I(7)M0

/ijfi L 75^/l ^ It-to

J: 9 UjfiL S 1*o

i<7)aa%ilZ

UIEL < Mtr

x> V a

It

<

ir<Dx\

•y

hT-S^lfft

C

co^i-^.

T.

■f

n(f

><7)ilS5(ii6)

T < fz

^

^^s(Dt

CO

y y ay

b

tit

t

IK

J: 9 Ull^gfi

to

(B)co_hco@7t76^b,

J; 9 Iwiili L i

504

R57L-02

l+^)i(C)co@

-fo

R57L-14S

R57L-19

13

Page 15

PRESSURE

Pressure

means

Screw

Pressure

enough

stitch

spoil

than

cause

1.

2.

3.

of

of

®.

on

to

formation.

material

it

needs.

uneven

Loosen

To

increase

Turn

To

decrease

Turn

After

obtaining a proper

tighten

OF

PRESSER

Presser

Pressure

Presser

feed

Lock

Screw 0 clockwise.

Screw 0 counter-clockwise.

Foot

Foot

material

Too

and

give

Too

feeding

or

Nut

0.

pressure:

pressure:

is

Regulating

and

much

it

little

stitches.

FOOT

Fig.

regulated

Thumb

should

be

obtain

proper

pressure

more

stretch

pressure

7

by

just

may

may

pressure,

Nut

0.

REGULATING

The

position

needle

regulates

1.Turn

2.

3.

4.

5.

6.

7.

Handwheel

at

its

lowest

Loosen

Push

right

tighten

Loosen

and

the

obtained.

Tighten

Loosen

will

Tighten

Lower

Lower

as

screw

Upper

move

right

screws

screw

return

screw

of

Upper

the

position.

Knife

far

as

O.

Upper

or

left

to

position

O-

SEAM

Knife

seam

until

Knife

Holder

Holder 0 to

it

will

Knife

Clamp

Knife

until

desired

0.

O,

then

by

WIDTH

to

the

width.

Upper

Knife

Screw

go

and

Screw

Clamp O to

width

the

Holder

spring

action.

Fig.

8

inside

is

O.

the

lightly

0

is

0

y

Note:

Needle

widths

are

obtained

proper

width

required.

Plates

are

available.

size

Needle

for

with

various

Best

use

Plate

for

seam

results

of

the

seam

Fig.

7

14

Page 16

^X-h-'h.

1"o

V-y 9 i--y

A'7

7°0lrlHl

;^f

^(,^0

LT?f

^rt]0pgi5(ia8)

1.7°-';-^[llLT.

X^M^o

±^^yO^UUir^o

3.fS^;r^y©^§ii6.

-t^T.

7

:5">l

±><XJS^O^M

i

^/i

L;&^i6.

Fig.

25Kg-cm

e

'i25Kg-cm

8

15

Page 17

REPLACING

1.

Loosen

2.

Push

Lower

right

as

tighten

3.

Remove

Wrench,

and

4.

tighten

5.

Turn

screw

withdraw

Replace

screw 0 completely.

Handwheel

Clamp O is

6.

Set

the

overlaps

as

shown

©

securely.

7.

Loosen

will

return

8.

Tighten

THE

Lower

Knife

Knife

far

as

it

O-

Upper

furnished

with

blade

Lower

screw

screw

Knife

knife

new

at

its

so

Knife

in

Fig.

O,

to

position

O.

lowest

that

UPPER

Fig.

Holder

Screw

Holder 0 to

will

go

and

Screw 0 with

with

the

machine,

downward.

knife

but

until

Upper

position.

its

cutting

by

0.5 — 1.0mm

10.

Retighten

then

the

Holder

by

spring

KNIFE

9,10

O.

the

lightly

do

not

Knife

edge

screw

0

action.

Fig.

©

30Kg-cm

25Kg-cm

16

9

Page 18

(1219.10)

l.ii:^>

2.±^-«y©^Jfe^0.

■to

3.rrtv^±^

m±ib-t6o

4.y-';-^0LT^

.>5 i T- ^ (f\

_h^ X <h T ^ ^ ;!)noigl(7)

J: 9 l:i0.5~1.0inin;6'tf^'^

^

^^h-itX^

jh^-y'O^liii'f^lt'So

5.±;t^y0^5ifei6'5o

•y 9 ^)

fz

Z. t ^

T

"a0Irfii"t

±^X^|XO(ir

±^>y0T-

9

±/

fz I ^'ib.

^

^

jh

Fig.

10

Upper

knife

X

Needle

top

fi-IH

plate

surface

l-Jfn

0.5~

I.Onnm

\\\\\\\\\\\\\\\M

Lower

knife

X

17

Page 19

REPLACING

1.

Loosen

2.

Push

Lower

right

as

tighten

3.

Loosen

and

withdraw

4.

Insert

Clamp,

cutting

of

Needle

Tighten

5.

Turn

Handwheel

Clamp O is

6.

Loosen

will

return

7.

Tighten

THE

LOWER

Lower

Knife

Knife

Holder O to

far

as

it

will

screw

O-

Lower

new

setting

screw

knife

edge

Plate

at

Knife

knife

the

is

level

as

®.

until

its

lowest

downward.

into

blade

shown

screw O then

to

position

screw

O.

Fig.

Holder

Screw

go

and

Clamp

Screw

Lower

so

with

in

Upper

position.

the

Holder

by

spring

KNIFE

11,12

lightly

Knife

that

the

top

Fig.

Knife

action.

O.

the

O

the

12.

0

KNIVES

Knives

may

while

is

Upper

tors

since

carbide

sharpened

must

be

sharpened

making

maintained

Knife

or

return

it

is

alloy

by a diamond

be

kept

by

sure

that

as

shown

may

be

to

made

from a special

material,

sharp.

use

the

in

Fig.

sent

to

us

for

and

grinder.

Fig.

13

Lower

Knife

of a grinder

correct

angle

13.

our

distribu

resharpening

tungsten

must

be

Fig.

25Kg-cm

18

O

25Kg-cm

11

Page 20

(011.12)

.><X0?3Ft>/=(013)

2.i--y

h®^§l646,

XDf^lz^ljh^s

±mt.

b-a-T.

T^xc7)^5fe^l0li;;^$(C'&

i-y

4.7°-•;-^®

5.±;T>

vOiSr^ifeto-So

7

^'J

Vimo-)^ 0 \z%\Wi

h©^lii5#{t^o

LT.

ii^x^O^T^

i

Fig.

^

12

^■t(DX\

<

ti

^\^o

aT^

tT^

A_h^xii,

LT.

tzt-^.

li,

tXo

<r h VMiSff

T^^^fiffri£LT<

IEflil-5ffViT'<

#31(7)^*7

^ f C ^ h

;'K-Ii^ft(7)±^

5ffrii:t

-f

^

Li-to

1^(;©gP(;

13@^#0S

v^o

^

ttz

Fig.

t

13

ys*"

Upper

Needle

top

surface

ft-tS±ig

ESSSSSSS,

Lower

I

yy

plate

knife

<

X

knife

-±^

X

0,5 ~ 1.0mm

19

Page 21

REGULATING

Stitch

combination

eccentrics

actuates

Inner

The

indicates

However,

or

Selecting

When

feed

that

material

When

feed

that

material

Changing

1.

2.

length

of

to

be

differential

eccentric O actuates

number

less

stamped

the

number

the

stitches

depending

eccentric

the

stamped

eccentric

of

main

feed

will

tend

the

stamped

eccentric

of

main

feed

will

tend

eccentric

Remove

Crankshaft.

Screw

machine,

Feed

R57L-14S

Nut O and

extractor,

into

Eccentric © (Spacer © for

and

STITCH

is

determined

main

and

differential

used.

Outer

feed.

on

of

stitches

made

upon

the

number

(e.g.

#8)

is

eccentric

to

shrink

number

(e.g.

#14)

eccentric

to

stretch

Washer @ from

furnished

screwholeof

-19)

and

take

LENGTH

Fig.

14,15

by

eccentric

main

feed.

feed

eccentric

per

inch.

may

vary

more

material.

of

differential

smaller

(e.g.

#12),

in

stitching.

of

differential

is

larger

(e.g.

#10),

in

stitching.

Fig.

14,15

with

Differential

it

out.

the

feed

©

than

than

the

3.

Screw

Main

for

out.

4.

Be

are

Clean

dirt

the

5.

Face

(rightward)

extractor

Feed

R57L-14S

sure

to

clean.

Eccentrics

and

dust

machine.

the

into

screw

hole

Eccentric O (Eccentric

and

-19)

and

take

Eccentrics

deposits

extruded

and

and

in

oil

before

portion

insert

mating

to

remove

placing

outward

Main

Eccentric O (Eccentric © for

R57L-14S

mating

crankshaft

6.

Face

(rightward)

Eccentric © (Spacer ® for

and

groove

7.

Replace

8.

Tighten

the

the

-19)

with

Washer

Nut

and

-19)

eccentric

key.

Use

extruded

and

insert

in

the

crankshaft

the

key.

©and

O.

on

the

crankshaft

groove

with

extractor.

portion

outward

Differential

R57L-14S

mating

Use

extractor.

Nut

O.

Fig.

of

©

it

parts

all

in

Feed

the

Feed

the

14

O

35Kg-cm

20

Page 22

(7)iili5(®i4,

'J

j:.^-tr

15)

><Dm<On^\~^iO

^S!B[(7)iS85

iH

'J

-I- ^ -t > (I

8 i l^p

(±>

12t|-coM@

-fe

>

IfeJtilcofilIMm;

li,

^nXi^tXofzt

ntz:^

, 12<hP|J$n/i

f'ii/IK/i ^ (,^0

oTMlElSi(l±,

Xo

iss«)^a)Pgi5

XJl

•;

(DJz^-b

#

{f L M11 ^ S

fOiW

<

CO

3^

'j

>

liX-2<l-::X

mm

[IIEi3{3M

25mmll!]c7)^g

25mmfiJllC8if

^

-f o ^!eM-^X

.

i-o

XXill^XfM Ub-

XifeS'l*,WII ? ->

LX ^ >0

^

J-^-t

fz/zl.

mDjM

iim

tXo

(±\

>

'J

5i';iJe-ti><7)5^i^(isii4.

1X^McOX/n°XX-3MO

O ^ ikM n ;M<fe0 ^ li

2.Um(DJL^-t

>fk^

X'X

15)

>jhX-y

o

^0j3^ 0 J. ^ -t > © • X3^ U j:. ^ -t

o

^

-s

o

•

R57L-14S

ij

7-0 • 3^ U +

X3M'3

X3M';

JcJr-t

4.m!})M 0 J- ^ -fc > ©COMPP ^ HfltiJ

It,

^>®J3^

zli tt

CO ^ ^

5.

rM^e

• 5 V

•

>liX^f-J-(t-5rrLc^3^'J

l±,

nliX'X < ?3ti^,

3^

'J

-I-

tr

(4lM)l-5?i'5cc03^'J-x + -t

Tc^SXCOX,

•

R57L-19C0^^-^|±,

>@SrtfeIlX-5o

>OcoMPP^3'M!!ijl-i^5]{t,

>OcO^-?iSf^<i:,

T#3At;>o

•;

jc ^ -tr

>0£7)

tr - ?iVji

ft

-t

<

>(±.

/i

h-It T t>l'iZi

$:

c^o

3^ 0 tr

hO^

o

$«ft

J-tr-t

-t > —

x^geiiKL

3i

0-xtr-t

>—

X^ilico

t;

{t

#nS(0Xrrfi1ij < /i $ c^o

h

>

[fi]

,

-5

o

>

Machine

model

^

R57L-02

R57L-14S

R57L-19

fjti

in

machine

Main

= V >cOx^-tr

:!•

31

U

#12

#

#6

eccentrics

Diff.

#10

5

>

u

in

acc.

box

ft-®

CO

X:^-fe

#8

#14

#5.5

#7,

>

#8

Fig.

Feed

35Kg-cm

15

21

Page 23

ADJUSTING

R57L-14S

Standard

above

at

its

1.

Loosen

2.

Turn

3.

Move

Tighten

R57L-02

Standard

mm

at

its

Differential

straight

of

1.

Loosen

2.

Turn

3.

Set

then

4.

Tighten

5.

Set

are

Feed.

and

height

the

top

back

tooth

Screw

Handwheel

Feed O as

Screw

height

above

the

back

tooth

edge

Feeds.

Screws O and

Handwheel

Main

Diff.

Screws O and

Auxiliary

0.5mm

FEED

R57L-19

HEIGHT

of

Feed

surface

when

e.

of

Feed

until

Fig.

Feed

required.

0.

of

Main

Feed

top

surface

when

Feed

should

can

be

Feed 0 first

Feed

©.

Feeds

placed

0.

until

Feeds

of

be

as

©.

Feed 0 so

below

from

16,17,18

is

1.0-1.2mm

Needle

is

highest.

is

highest.

is

1.0-1.2

Needle

are

highest.

set

so

that

across

the

are

highest;

required

that

its

those

of

Fig.

Plate

Plate

a

top

and

teeth

Main

16

ADJUSTING

Feeds

are

factory-set

Feeds

are

level

above

the

top

By

this

setting.

back

tilt

or

higher

rear,

when

Feeds

Generally

Feeds

Knit

Woven

1.

Loosen

2.

Turn

3.

Turn

set

are

highest.

material;

material;

Lock

Handwheel

Pin © until a proper

obtained.

tightening

strongly

the

Note:

inward

sidewise

When

is

necessary

height,

FEED

surface

Feeds

Feeds

front

(Standard).

level.

so

when

in

are

highest.

to

TILT

that

they

of

will

the

as

back

Screw © for

until

Feeds

Tighten

Screw

play

the

®,

in

in

Feed

feed

Screw

order

tilt

to

too.

Fig.

the

teeth

first

appear

Needle

Plate.

have a front

front

than

follows

tilt

Pin

0.

are

when

highest.

tilt

©.

When

press

Pin

to

eliminate

Bars.

is

changed,

adjust

the

Fig.

19

of

to

the

is

©

it

feed

17

1.0 ~ 1.2mm

/

22

McT^V

mm

20Kg-cm

Page 24

jM

'J

TWtt^

1

$(016.

17,

T^'1.0~1.2mra(I'^-ti-

to

(R57L-14S • 19)

18)

511

•;

m0m±

tStijiSL/ci

®

mm^m

1. fc:°

t ^

>± t V®

<D

u

hut

0±#L.

omm

±X(DM9cti^U±

75^^^

^?ife46

^o

Jt

(019)

T't

o

0.

mm|;-^-ti-T±t

2ft5MUii-&

l.ii)i';ii[0^±T(cilj7{;^-ti:.

j:0.iMU®f^gP(7)li^St'1.0-1.2

ra

ni|I'^-ti-T±t

2.

HiJlji

^

b ^ Is]

^l3^:.tLT0.5mmTt;^lf^

(R57L-02)

'J

]t®CO

b'

vO^ISf^tt

iif5fe ^ ±)M

^

T'.

'J

> ± t

1.0-1.2

-So

^■m±m

6o

(iOc')))!

vO

to

Fig.

18

•

3

if

c^3^1fb(^m)cOli'^liHtTlCLJto

CO

ii; ^ c7)

i]^)y

LottTiht

^ff

0

rjigif

ifl?±0

O

i § li.'iJ't.iM'l

tf

9

f: L ^

v®^^i6T<

25Kg-cm

o i to

to

tfz.

K0l§lfe^7&^'®

Fig.

19

®25Kg-cm

25Kg-cm

23

Page 25

ADJUSTING

The

needle

machine.

from

surface

highest.

careful

Needle

of

1.2mm

needle

1.Turn

2.

3.

4.

This

the

of

When

to

is

Needle

apart

hole.

Handwheel

highest.

Loosen

Drive

Arm

Move

Arm e and

of

Needle

Tighten

NEEDLE

height

height

point

Needle

making

set

Needle

centered

Plate

from

Clamp

©.

as

required.

Screw

HEIGHT

is

10.3mm

means

of

Plate

and

the

Needle

as

in

the

to

when

this

adjustment,

shown

the

needle

its

front

bottom

until

Screw O for

make

the

O.

Fig.

20,

for

this

distance

the

top

Needle

in

Fig.

hole

edge

of

Needle

Needle

position

21

is

be

21;

is

the

is

NEEDLE

As

shown

centered

Plate

edge

bottom

setting),

Sidewise

This

no

further

PLATE

in

Fig.

in

the

(sidewise

should

setting

be

of

the

when

it

setting

is

correct

adjustment

setting),

needle

is

Bracket O has

reason.

1.

Tentatively

O

with

key

in

the

2.

Loosen

Move

required.

Tighten

Front

to

When

always

1.

Loosen

2.

Move

required.

Tighten

set

Screws

of

Bracket O fits

bottom

surface

Screws

Bracket O right

Screws

back

setting

fixing

Needle

keep

this

setting

Screws © for

Needle

Screws

SETTING

21,

Needle

needle

1.2mm

hole

lowered.

at

is

been

Needle

©,

©.

©.

Plate

correct.

Plate

back

©.

Fig.

should

hole

of

and

its

apart

from

(front

the

factory

required

moved

Plate

making

of

on

sure

in

the

Needle

for

or

on

machine,

Needle

Plate.

or

front

21,22

be

Needle

front

the

to

rear

and

unless

any

Bracket

the

groove

Plate.

left

as

as

Fig.

20

Fig.

10.3mm 1 \/

o

35Kg-cm

24

21

Page 26

t § ^

^

T\

Mii!l3}fi!loT>

X^-fo

1.x-

ifmmm X V

2.tf-|r ^ (fXz t ^

'C.»^iE?it-A-5

Wj/)^LXmBt6o

3.

7°-

'; - ^

o

HI L T

Mii!(-}B!l-oT^

X y O

^

1+15±IS

ci:

0

10.3mm;6^'^^"\l'?i

imt 6 o

J: 9 ,

A/i

/i

t>'f+

^

10.3nini|;'^h t T ^ t+

t+

-5

o

22)

^

21110+; 9 I3#+|S a J; 0 1.

li-??|«+>'C.'

tto

X

2.7°-'j-^ULT,

3,

ti-

M • ^:^r^<7)is@s

l.±+^y©^ll<rai--5o

2.l1-+5^Mf^t-i)!l?&'L > a

yO^UUt^o

b

aV.S

b

,'^,{l|+;6^+ig-t-

4"C.^

5

16tZ6tX\

,#.+;

1.2mmt;'^h L T.

iffz t ^

2minM:^0

J; 9 ^#{t

$

tf-So

±+^v@

Of+i+^'C,'

±+-

v©

s

Fig.

20Kg-cm

©

25Kg-cm

22

25

Page 27

LOWER

When

Lower

its

point

should

centerline

Also,

the

Looper

Needle

in

Set

the

apart

and

the

scarf

Looper

center

from

you

(0-0.1

can

LOOPER

Looper

be

of

Needle.

mm

of

Needle.

as

its

of

Needle,

make

ADJUSTMENT

is

extremely

5.3mm

point

clearance)

point

Needle,

when

this

apart

should

in

the

and

Needle

adjustment

Fig.

from

just

when

rear

0-0.1

is

23,24

right,

the

touch

it

is

and

at

mm

lowest,

easily.

1.

Insert

Looper

far

as

it

Tighten

rests

against

Looper

2.

Lightly

Looper

3.

Turn

Handwheel

4.

Move

Lever 0 as

Turn

Handwheel

from

the

centerline

extreme

If

necessary,

for a fine

5.

Tighten

into

will.

go.

Screw

O.

the

shank.

loosen

Lever

right

Clamp

0.

Looper

be

5.3mm

position.

move

adjustment.

Screw

0.

Looper

making

flat

Lever 0 as

sure

its

portion

head

of

the

Screw 0 for

until

Needle

is

lowest.

required.

and

check

the

distance

point

to

the

Needle

at

Looper's

Lever 0 just a little

Fig.

5.3mm

"025Kg-cm

-07OKg-cm

26

23

Page 28

^i^iH-COPf.PBKiO-O.lminC-g'b-ti-Si-o

(D y ^ 0 i;±

2.mU^^yO^^<UUi'^o

3.

7"-'j

-1:® L T,

^

Hi:.

"F

^

h-it

^o

-

-It^o

5.

_hieO~

^M

t <7)Pf,Pt}]

0.

IramW

"t

J;

0.

ti-4"i:^

vO

(t 6 o

#i'^"f^.'?i'.l-ii®

® ^ ^ i -

^0-0.

^

lniml^-^b

L

i-C-5.

3mm(l

tz

>

;u-

h

0.1mm

Fig.

24

27

Page 29

UPPER

When

should

the

centerline.

When

Looper,

without

Clearance

1.

LOOPER

Upper

be

Looper

Upper

they

striking.

Insert

Lever

the

back

right

edge

Lightly

2.

Lightly

Upper

3.

Turn

Handwheel

4.

Move

Crank © up

the

distance

mentioned.

5.

Turn

Handwheel

that

the

Looper

the

distance

eye

center

Looper

should

(Clearance

'B' = 0.2mm)

Upper

and

tighten

loosen

Looper

preset

edge

of

Looper

Screw

Lever

Looper

'a'

Clamp

until

clearance

ADJUSTMENT

Fig.

is

highest,

of

3.0mm

and

the

crosses

be

as

near

'A' = 0.5mm.

into

the

clearance

of

Looper

Lever

O.

Screw O for

Crank

Looper

or

down

of

3.0mm

slowly

'A'

is

0.5mm.

and

25,26.

there

between

Needle

Lower

as

possible

Looper

from

to

at

4.0mm.

©.

is

highest.

and

obtain

above-

observe

27

the

6.

When

clearance

0.5mm,

Turn

Handwheel

Move

Looper

3.0mm

Turn

clearance

7.

When

move

highest

and

abovementioned.

Turn

clearance

8.

clearance

9.

When

tighten

distance

Handwheel

clearance

Crank

obtain

Move

Looper

the

Screws O and

point,

Handwheel

move

until

inward,

abovementioned.

'A'

is

0.5mm.

'A'

downward.

move

the

'A'

is

0.5mm.

in

'B'

is

0.2mm.

above

'A'

is

more

than

Crank © upward.

Looper

is

highest.

and

obtain

the

again

and

check

the

is

less

than

0.5mm,

At

Looper's

Looper

3.0mm

and

its

holder

setting

outward,

distance

check

until

is

complete,

the

the

©.

Fig.

25Kg-cm

—4.0mm

©

lOOKg-cm

28

25

Page 30

±.)\/—ji-(0^t>-\tiy'tz

-@yA:4"ll'^

^O.BmmlZ^

±;i/-/N°-a fij;

T'4.0min|;fM(l-^h

<imt^o

2._h;u-yN°_gff^ 7 >

<

MUir ^ o

3.7°-'J-'^|pILT.

.'rApfiS ^ -ti"

4.

_h

;u - ^

i;,

fjT&a,

4''O^T'3.0min(I-^b1-o

-

(DptR{] A >6^'0.

T'S.OmmT'i-o

^0.2nim|I'^b-ti: i i~o

f),

"S*

o

^° - 7!)^'±^,'S

Smint;

(025-27)

LTx

ih^-

vOSr^

±;i^-/>°-$r±5E

CO t ^

cotl"

yy

^e^±Tiz

OT

V^

-S i t'

^

«9,

It

9

6.0.

SmmtU-hCO^^-a

0J-;U_y-?_3fj^ V y

izWi^'i'o

-/^°- ^ ±^,|5

—

CO

jtjffl ^ 3.

T

Pf.

fH] A ;!)fO.

"1"

-So

@0.5mml.U±co<i:§li.

7,0.

Bmml-UT'CO^^'o

l±

C^O^'Pl^±j

Izfjg

Ommi;

5nim

11 ^ o T V i -5

<'9SLM^t

l±

0±;^-/^°-j^^^;7 7 >

izWi^'iTo

;u _ y f ^

tllig $ -tt ^ o

0±;W-/^°-|r'"^l#itiLTj

"ah-f

o

©±

;i/- / N° - i

T.

P^rai A 7!>^0.

El"-So

"F

^

5mmll ^ oT

©O.SmmWTcOi

"f-So

8.

±!e

3.

Omra^i^

t>'0.

5mra ^ t

•r\

B

^0.2tmlZ'^h-\t 6 o

$-It ^ „

i"

o

3.0nim|;

^ ^ ^-tt

Mttl

^

;{)^^

Fig.

3.0mm

26

0.5mm

o / 0.2mm

Fig.

27

29

Page 31

ADJUSTING

Rear

needle

When

Lower

and

at

the

center

Guard

should

deflecting

1.Turn

Lower

center

2.

Loosen

Guard

3.

Move

Guard

deflecting

it.

Handwheel

Looper

of

Screw 0 for

Bracket

Bracket O so

just

Tighten

Needle

deflection

NEEDLE

guard

Looper

of

just

is

Needle.

O.

touches

it.

Screw

point

Needle,

touch

until

in

the

that

0,

making

by

Needle

GUARDS

Fig.

is

in

Rear

Needle

the

rear

and

Rear

Rear

Needle

Guard.

28,29

the

rear

Needle

without

point

at

the

Needle

Needle

without

sure

of

no

Front

needle

When

Needle

a

slight

Needle

and

1.

Turn

2.

Loosen

Guard

Move

Guard

Tighten

guard

is

lowest,

clearance

Handwheel

Front

Needle

(0.1-0.2mm)

until

Screw O for

Bracket

0.

Bracket © so

is

0.1

•0.2mm

Screw

O.

there

Guard.

Needle

Front

that

Front

apart

from

Fig.

should

between

is

lowest.

Needle

Needle

Needle.

29

be

Fig.

30

28

Page 32

tfS(B)

;u-/N°-

0^15

(028,

29)

28[10cI:9I;>

^

T

o

l.t|-^(B)»f^,

6o

T'fJf

i£:

;i/ - /^•-

«<!:

t|-(7)

5n d Pt

0.1 ~ 0.2mm

11

F«1

r.

P0l^O.l~O.2mml-'^^-ti"T,

ih-T-vO

Fig.

29

25Kg-cm0

!

1

j-^

25Kg-cm

O

7

31

Page 33

PRESSER

ADJUSTMENT

Presser

machine.

In

lifted

Foot

by

Foot

other

6.0mm

Lift

Screw

words,

Lever O is

0.

FOOT

Lift

Presser

up

from

LIFT

is

6.0mm

Foot

Needle

lowered

and

Fig.

30,31

for

should

Plate

when

stopped

this

be

6.

Loosen

Keeping

Lever

play

from

Tighten

Screws

O,

clearance

Presser

O.

the

6.0mm

move

of

Arm

Screws

0.

lift

by

lowering

Stopper 0 until

0.3-0.5mm

0.

is

obtained

a

1.Make

2.

3.

by

turning

Loosen

When

Foot

just

Feed

Nut 0 and

Lever O is

Screw © and

of

2mm

from

Tighten

4.

Loosen

5.

Turn

obtained

stopped

Tighten

Nut

Nut

Screw 0 until

by

Nut

Dogs

Handwheel.

begins

obtain a play

Lever

0.

O.

when

Lever O is

Screw

0.

O.

30Kg-cm

below

Needle

Screw

0.

lowered

to

O.

be

the

and

lifted,

6.0mm

lowered

Plate

Presser

turn

clearance

lift

is

and

Fig.

30

O

30Kg-cm

32

Page 34

ff

X±UM0iill5(ia3O.

t^'6.0nimT'i"o

^If^o

2.^7

3.^if

±®J:0.

y©^0

©CT) a t

•y

h©^^#(t^o

0

IfxJS® i T'6.

^_hlf

-So

$

lt\

LTJE^^U^^—Ot

COPf,® ^ 2mrad'^h

30

#x)!s®

OmmCT)

ig $ S

J; 0 .If

LXi'

T'^fx

X

5.6.

OmmCO ^ lit# L ^

T\

1^

@i5

y©^J£^U^<-OC^^cfc 9 CM

L.

t-y

VOiiUUn^o

6.6.

OmmCO

"t

r± ^ lit# L fz

X h 7^'^°-©i^±Tl-ifl7!>^L.

©C0±®

O.SmmOPf,®

#tt§o

l±,

J;

0. X h

7/^°-©^-e0.3~

^-9<

oT^±^-vOl'lifj

t¥x{s®7{)WS_h®

L/illlli.tfx^e.Omm±(ffz

i

V

^cosmM^-v©i.

.

ttp x ^

tix^

-To

Fig.

25Kg-cm

0.5mm

31

33

Page 35

PRESSER

Presser

Plate

with

eliminate

(seepage

1.

Foot

and

that

of

Loosen

Hinge

Spring.

Its

14).

Loosen

Foot

Bracket.

2.

Move

Presser

hole

is

Plate.

3.

With

Presser

Plate,

tighten

4.

After

properly

pressure

14).

FOOT

needle

Needle

the

Screw O for

Clamp

aligned

ALIGNMENT

should

pressure

be

hole

should

Plate.

Screw 0 for

Foot 0 until

with

Foot 0 flat

Screw

0.

set,

on

Presser

Fig.

32,33

flat

on

Needle

be

aligned

For

this

setting,

of

Presser

Presser

Foot

Foot

Presser

its

needle

that

of

Needle

on

Needle

load a proper

Foot

(see

page

Fig.

34

32

Page 36

#1(7)

IX#

i:^<im-r^o

(032.

33)

1S±ffi ^ fef 7 ^ 'J

i

.

±V

Fig.

33

15Kg-cm

30Kg-cm

35

Page 37

ADJUSTING

CONTROLS

Thread

Thread

less

material,

Factory

positions

left.

1.

2.

3.

4.

5.

6.

Controls

Takeups

depending

etc.

setting

when

Lower

Horizontal.

Upper

The

edge

Auxiliary

O:

Its

edge

'C.

Lower

Its

lower

Upper

Lowest

Upper

Highest

THREAD

or

and

Guides

on

is

as

Lower

Looper

Looper

'C

eyelet's

Looper

Looper

in

Looper

in

2.5mm

Lower

edge

the

long

the

long

Thread

Thread

Looper

center

Thread

level

Thread

Thread

the

positions

vary

operation,

follows.

Looper

threads,

Check

is

extremely

Takeup

Takeup

below

Takeup

Thread

level

with

Guide

with

the

edge

Guide

groove.

Guide

groove.

Fig.

more

the

O:

0;

Guide

the

'C.

0:

34

of

or

O.

O;

©:

POSITION

Set

thread

stand

in

Fig.

35.

1.

Loosening

set

thread

2.

Obtain

80mm

Top

3.

Bar o should

front

4.

Tighten

the

between

Cover.

of

Oil

screws

OF

THREAD

in

position

screws

guide

bar O as

distance

bar O and

be

Sight

Window

0,

STAND

as

per

0,

0,

(D

follows.

of

approximately

above

and a little

©.

0, 0 and

Fig.

35

shown

and

0,

Machine

0.

Fig.

2.5mm

36

34

Page 38

(034)

5:^(011115(035)

xp'pm^j-

v(D ^ 7K¥

±

;i/ - /

mmll'^h-ttTlSJ'f'tlt

4."F^i^-^'?-tia!j^)I©ti^

- 7 ^gij

Wlt^o

•itrwit^o

6.±;u-7n°-^)I©i±. flXf«(O^Tfi

MT^Wtt-So

MT'TOtt^o

ioti-o

{3{4g ^ -It T mn

N° - ^

JgiJ ^ 0

C7) © ,^. ^ T%

-So

tr

0(0©

cofig

It ^ o

g:n:^±;u

[3-g-h-It

2.5

T

^Tieci^tfiSuWt-it^i-o

4'fOl^)i#0J:'}^

-±ffit

Mf^fiSli.

-5

^

ff^-oX < fS^

t^'SOmmT-l-o

»<»;

J: 9 tilX#!! J 1"o

(0

ll^g|5

(i.

1.^0

LT.

V

@000

±i3^<

4'R^^^^ii^©

^

T

Fig.

35

/

80mm

37

Page 39

CHAINING

THREAD

DAILY

MAINTENANCE

It

is

necessary

approximately

presser

will

After

that a continuous,

thread

foot.

HOW

foot

avoid

replacing

comes

TO

Cleaning

important

to

remove

foot

and

out

the

covers

lint

from

and

under

any

loose

covers

position.

and

to

have a chaining

10mm

when

starting

"skip-stitches".

needles

smooth

out

from

CLEAN

the

machine

operation.

any

parts.

swing

it

out

and

remove

around

lint

the

needle

or

use a lint

return

the

long

to

or

thread,

neat

under

YOUR

is a simple

It

is

not

Merely

to

the

all

loopers,

plate.

brush.

foot

to

thread

behind

sew.

the

This

check

chaining

the

presser

MACHINE

but

necessary

release

left.

thecollected

Swing

feed

Blow

the

slots,

out

Replace

the

sewing

Before

*

*

*

*

*

Check

in

oil

Check

damaged.

Check

Check

10mm

After

close

Remove

morning

oil

sight

needle

threading

chaining

long

machine

and

looper.

*

If

any

trouble

report

it

adjustment

*

Keep

record

and

thread

*

Dust

cover,

should

be

start

level

is

correctly

gauge.

is

correctly

is

correct.

thread

remains

of

work

dust

specially

to

or

behind

and

lint

around

or

irregularity

the

plant

repair.

showing

breakage a day.

furnished

placed

on

the

maintained

set

and

of

approximately

presser

deposited

needle

in

is

found,

foot.

plate

mechanic

number

of

with

machine,

machine.

needle

not

the

for

38

Page 40

^

ViD

^jf^oT < fz^

iz

X < fz^

5 y >(i.

$<^^0

'i^

=i

'J

i!&Pf

<.^0

tflS.

t

i-o

S^10mm^i/g(7)^ii

v^o

l+<;)ix#x.

#

nvMlJf^LT

jl'Jif.

T

^.mtKD'i^

6:it^fzL^^ib

>11'-/'?-,

LT

^

1"

<?:,

^ i 1"o

ff

LT < ;'i^v^o

-ox^mmi^^m^^^mitiTo

•

^4Ji^ ^ 'f

COPnlllf^^oTVi^-r;{>^o

</i

<

•n^m-ofz'o.

X'^^fz^

<

ffX#{t h hX^^

•

^lilEL

•

0c^

fi^y-

Lt'^/viy^o

<

10mm

ym<Dm^m

tir^'o

CO^H

ttz^

;6^o

htn

mK

tf(±iEL

• 5 y

•

• 5 y y [Z:^

y<Di§B^

/£ $ v^o

mfrti.

^

1^0

IX < fz^^^o

£^-rm^^izm^Lx

git/^i'coniljc^

<

<

fz^^^o

39

Page 41

B

Page 42

SPARE

Ref.

No.

^ §[5n°n#^-

mm

1

2

3

4

5

6

O0UOX154

O

7

00205573

0

8

9

O02O5612

10

0

0

11

12

13

14

15

O

0

00205500-8

0

16

17

18

19

O

20

0

0

21

22

0

0

23

PARTS

Part

No.

206233

205589

205586

205492

205655

UOX154

205674

205657

205675

205613

205607

205609

205500-5.5

205500-7

205500-14

205501

205600

205601

205599

205656

205660

205661

205662

Name

Oil

filter

Upper

looper

lever

" guide

Lower

looper

Needle

#11

Needle

#16

Needle

plate

Needle

plate

Presser

foot

Presser

foot

Presser

foot

chaining-off

Presser

foot

Upper

Lower

Feed

Feed

Feed

Feed

Feed

Feed

Feed

Main

Auxiliary

Differential

hinge

knife

knife

eccentric

eccentric

eccentric

eccentric

see

chart

needle

bearing

bar

lift

block

needle

bearing

dog

dog

feed

dog

feed

feed

#5.5

#7

#8

#14

below

dog

dog

spring

finger

Ji u ^ > h

11

ff

#11

tl- # 16

fffg

/1\

Tx

X

U +

❖

1

r

m

*)

J-.

Ff']3i

ii'jtii

')

mmm

-t

m

m

Qt.

tm

1

1

1

1

1

10

10

1

1

1

1

1

1

1

>

#5.5

#7

#8

#14

>J > y

1

1

1

1

1

1

1

1

1

1

1

Available

PP

Mark

o

0

0

feed

Part

No.

205500-5

205500-5.5

205500-6

205500-7

M.

R57L-14S

R57L-19

R57L-02

eccentrics

Mark

5

5.5

6

7

itk

iVmJIPiS.

Parts

Parts

Parts

Part

205500-8

205500-10

205500-11

205500-12

Meaning

for

R57L-14S

for

R57L-19

for

R57L-02

No.

only

only

only

Mark

8

10

11

12

Part

No.

itPnu#^

205500-14

205500-16

205500-18

205500-20

Mark

^JPP

14

16

18

20

41

Page 43

PEGASUS

SEWING

CO.,

LTD.®

MACHINE

MFG.

■

4Mip

Cat.

No,8093

Printed

in

November.

1977

in

Japan(n771

T430

Loading...

Loading...