Page 1

INSTRUCTIONS

Cat.

No.

9A2539

March,

1986

KS

*

KHdevices

VERTICAL

KS

FOR

CHAIN

E32,

E51,

L32, L52,

TYPE

(MRILA)

CUTTERS

E52, E56,

ETS51,

FLAT

KM

TYPE

CHAIN

FOR

^

L132, L152,

R53,

(TKiiSt)

E32,

R57.

CUTTERS

L32,

L132.

PEGASUS

Page 2

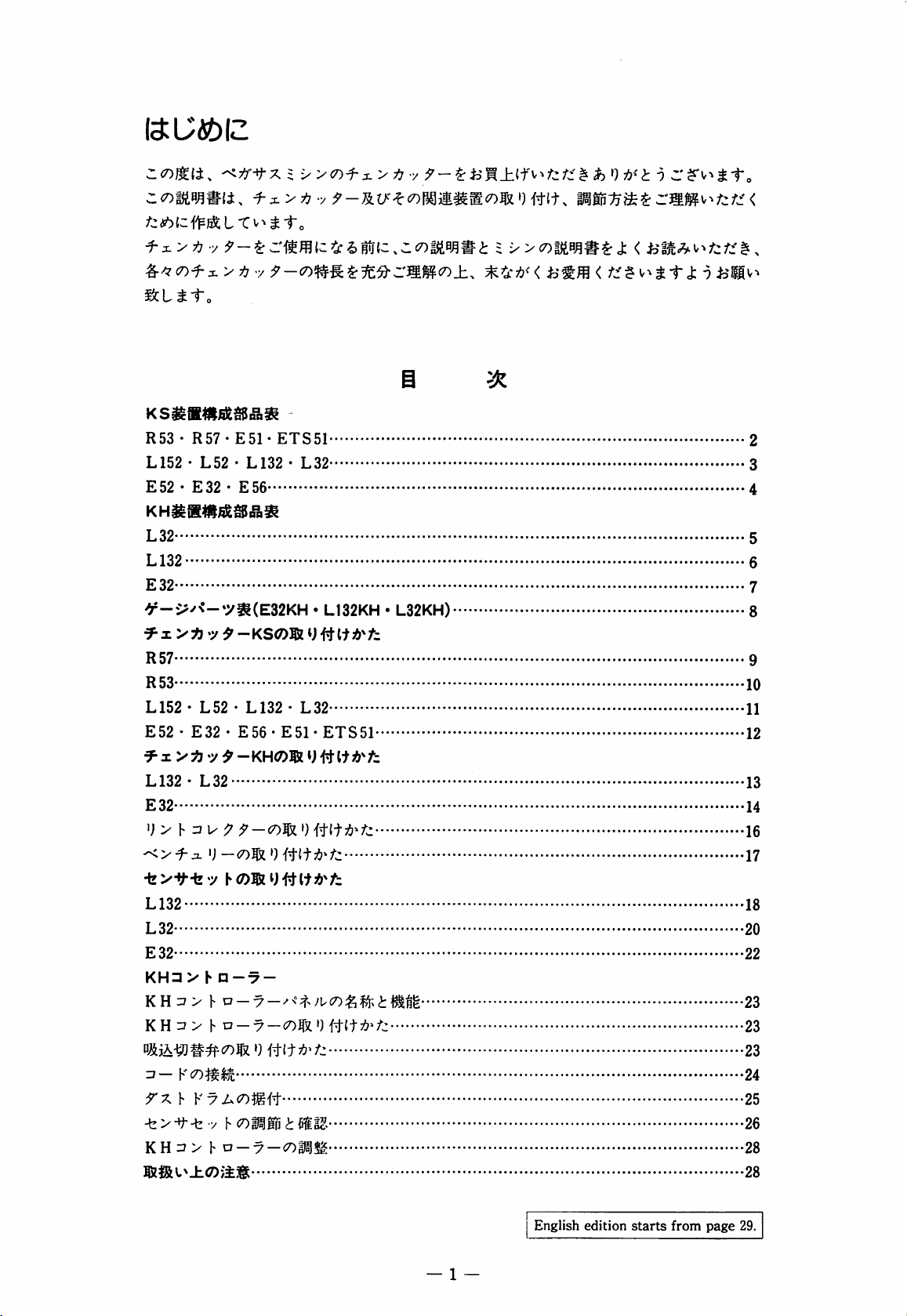

z.<r>mmWU.

^i>7:7

-y

#^<7)-f-i > 7(7 y 9-<r>^^^1t^:rMm<n±..

iicL^1"o

s

R53-

R57-E51-ETS51

L152 • L52 • L132 • L32

E52 • E32 • E56

L32

L132

E32

^-*>'<-'y^(E32KH • L132KH • L32KH)

■?=■ I >

R57

R53

L152 • L52 • L132 • L32

E52-

•^x

L132 • L32

E32

^)> V ziu 9 ^—(r>'S^^)iil-fi}^tz

•fe^i^-b'y

L132

L32

E32

KH3>

K H =7 > ^ o —7

KH=7>

n-

rx

-fe>^t-b y h

K H ^ > h D —7

ffi

f|Rt^±<7>j±S

-y ^ -KS<7)5Z U #iii!)^tz

E32-

E56-E51-ETS51

-y

^-KHOffil

'j—

h

P-^-

—

h

')

mt^tz

h

K7A<7)®#

<7)|^|p

^

—X)g^ig

Hg

^x

</•::'?

it

J:

-7

2

3

4

5

6

7

8

9

10

11

12

13

14

16

17

18

20

22

23

23

23

24

25

26

28

28

English

— 1 —

edition

starts

from

page

29.

Page 3

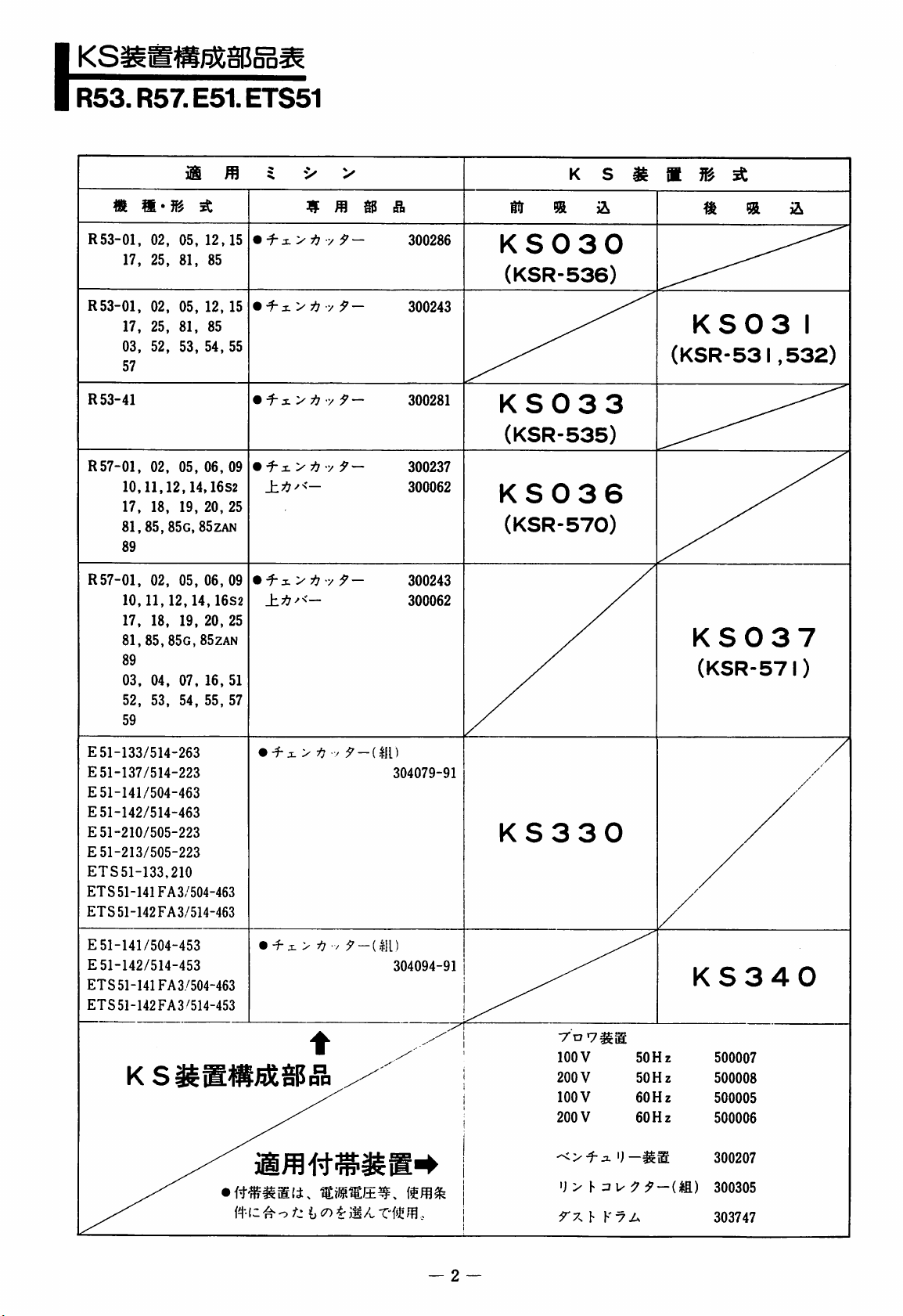

KS^TO^§B§a^

R53.R57.E51.ETS51

m

m

K S

m

M

^

R53-01,

17,

R53-01,

17,

03,

57

R53-41

R57-01,

10,11,12,14,

17,

81,85,

89

R57-01,

10,11,12,14,16S2

17,

81, 85,

89

03,

52, 53,

59

02,

05,

25,

81,

02,

05,

25,

81,

52,

53,

02,

05, 06,

18, 19,

85g,

02,

05, 06,

18,

19,

85g,

04,

07,

54,

12,15

85

12,

85

54,

16s2

20,

85zan

20,

85zan

16.

55,

15

55

09

25

09

25

51

57

■f- i >

"1-

%

^

tI?

•/ ^ —

X. y i] ■ 9

x>

^

xy

i] ' •/ 9

xy

i] ' /•

t(r

300286

%

KS030

%

&

(KSR-536)

—

9

—

300243

300281

KS033

KS03

(KSR-531

I

,532)

(KSR-535)

•

300237

300062

KS036

(KSR-570)

9-

300243

300062

KS037

(KSR-571)

E51-133/514-263

E51-137/514-223

E51-141/504-463

E51-142/514-463

E51-210/505-223

E51-213/505-223

ETS51-133,210

ETS

51-141FA3/504-463

ETS51-142FA3/514-463

E51-141/504-453

E51-142/514-453

ETS

51-141FA3/504-463

ETS51-142FA3/514-453

ft-C

•

-f

•

-f X >

O

X>^

/

9-{m

304079-91

KS330

■/

^-(m)

304094-91

KS340

50 H z

60

Hz

y

\-zjy 9 9-im)

i

^

A

.

9'7^\-V7A

500007

500008

500005

500006

300207

300305

303747

—

2

Page 4

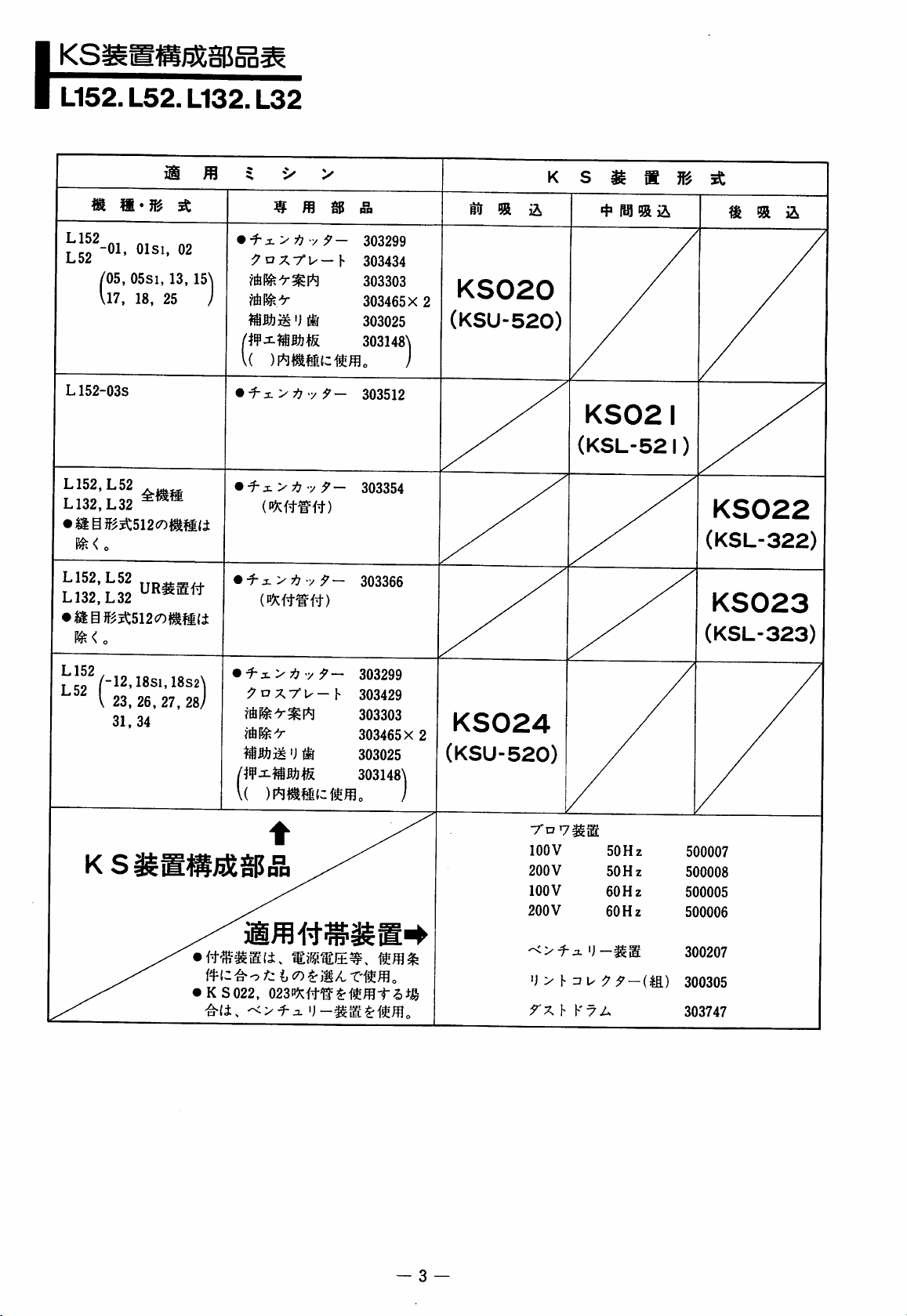

\

KSi

L152.

L52.

□POD-

L132.

L32

L152

-01,

/05,

\17,

Olsi,

05S1,

18,

L52

L152-03S

L152,L52

L132,L32

•

IISff^^512c7)|^MIi

^<o

L152,L52

L132,L32

il

13,

25

02

15\

^

I

•

:7Dxr^—h

(

•

^:L>:^-y9~

mmm

z.y

V

'j

®

i] - y 9 ~

9-

9 -

303299

303434

303303

303465 X 2

303025

303i48\

j

303512

303354

b5

®

a

KS020

(KSU-520)

K s

KS02I

(KSL-52I)

m

4* ® ®

m M

^

m

&

KS022

(KSL-322)

KS023

i^<o

L152

,

j^g2

/"12,18si,

V

23

31,

,

18si,

, 26,

34

18s2\

18S2^

27,

28)

•

9 3.

KS022,

>

-y 9 —

9 O X7°U—

'J

lif

023^n^^itmir6m

303299

h

303429

303303

303465X

303025

2

303148j

KS024

(KSU-520)

7

lOOV

200V

lOOV

200V

rxhKxA

O

y

}•

Zi]^ 9 9-m)

50Hz

50Hz

60Hz

60Hz

(KSL-323)

500007

500008

500005

500006

300207

300305

303747

3

—

Page 5

\

KSi

E52.

E

E32.

m

m-m

52-130/504-263

132, 133,

210,210C,211,221

231,

243/514-363

E56

iS

^

137,140

242/504-263

^

^

^

^>-h

m m

-y

9-

&

301148

K

M

KS002

(KSE-20)

s

^

m

M

m

^

m

E52^t^m

•

131/512-353

135

243/512-353,263li^<

E52^mm

•

131/512-353

135

243/512-353,363l±f^<,

E32^^M

•

450(il^<

E52-192

E56-111,

E56^^M

•

131/512-253

263/512-253,263lil^<„

0

120,

133,

210,

242/504-263

243/514-263

130,132

211,231

•

„

•

^:L>ij-y9-

mmit)

•

•

i-j.yi] y 9-

•

t

y 9-

-y

9-

-y

9-

301000

301122

301515

301149

301015

KS006

(KSE-60)

rD7^M

100

200

100

200

V

V

V

V

50

50

60

60

KS003

(KSE-30)

KS004

(KSE-30A)

KS005

KS007

(KSE-70)

Hz

Hz

Hz

Hz

500007

500008

500005

500006

mz^-o

f-o.

fzij

(7)

rime

i) > h

— 4 —

9

9-m)

300207

300305

303747

Page 6

\

KHi

L32

EfiSaBSa;

L32

L

32-36-3X4

38-3X4

L32

m

•

^s-y-h-y^-

^^'Dxr^-h

•

^z.yij-y9-

^axrU'-f

•

-b>-»f-byh

T-A(;fe)

x'j=i>/M7'(±)

i

±

"

y-

'J

-

iffl

x.\

E

•

f-i

>717

;ynxyw-h

m

^

Y— X ^

•/;5'-

303753

303758

303753

303758

303823

303424-FD

303418

303714

303708

5077

303973

-y

303754

303758

3^

US! % ^

KHO

(KHL-1

/

KHO

(KHL-1

K H

1

4

OA)

1

5

OB)

^

g

KH064

(KH/AV)

^

L

32-70-5X5

86-5X6

•

KH3>

m

b

D-7-(i,

m

•

•

^

Ys-yij

;7nxyu-h

-tvy-t/h

T-A(;£)

i+#7t7^<-

1

y-

tt-

^

"

±

'J

-

ji

isj

1

-y}^-

m m

t

303754

303758

303823

303424-FD

303418

303714

303708

5077

/

303973

yoy^B

100

200

100

200

V

V

V

V

50

50

60

60

Hz

Hz

Hz

Hz

500007

500008

500005

500006

KH065

(KH/AV)

yxhKyA(M)

K H =J > h o —y

(AV::J>hn

100V

200V

220V/240

380V/415

yoy^B

100

V

200

V

100

V

200V

V

V

50

50

60

60

—7

Hz

Hz

Hz

Hz

303713

303747

—

—)

760061

760062

760063

760064

500007

500008

500005

500006

'Jvh^uy^y-lliD

— 5 —

300207

300305

Page 7

KHi

L132

I

L132-05,

•

L132-36-3X4,

•

L132

•

L132

L132-40,

•

L132-40,

•

•

06.

36,

37,

mUB^k 2 N

umm

maifm

%\mm

mmm2

2

2 N laii-

41

2

41

m

• *f—i>

07,

38.

38-3x4

N

N

n

olJoa-

m

^

08

• X > 717 / :? — 303753

39

^ o 7. V u — h

•

-f" X >

77

o X 7' u —

•

-b > -H--b y h

ti-#77-'<—

7 T >

It

t/x

I

•

f-x > 7i7 y rJ'—

a

7, 7 u — h

' -f" X >

'

% & s- > f]

•

7!? ^ —

^ a x-ru

-t

T

—A(&)

st#7:7^<—

■7 r >

It

m

W

-fe > T'-b y h

It

}r-:

^

^7 D X 7 U — h

9o

77U—

V T >

I

•■/

y

/•9 —

r

:?'

—

h

9-

—

hP

—

h

>■' ^

}■

h

ng

303764

303753

303764

303783

303424-HD

303812

303729

<—

-v

303753

303777

303753

303777

303783

303424-HD

303812

303729

303754

303764

303754

303764

303783

303424-HD

303812

303729

K

KHO

(KHL-1

KHO

I

OA)

I

(KHL- I OA)

KHO

I

(KHL- I OB)

H

a

^

0

KH060

(KH/AV)

I

KH06

I

(KH/AV)

2

KH062

(KHy/AV)

L132

•

m}inm2Nk:m

L132-70-5X5

86-5x6

KH7>hn-7-(i,

K

H

m

•

^x>77y;7—

:7 a X

% s- > f] • •/ 9

:7 D X 7 u — h

•

-b > 7

Ittt^7;7''<—

■7 T >

II|tjj

#

jr.

7°

U- — h

-b • •/

I

V—

h

—

303754

303777

303754

303777

303783

303424-HD

303812

303729

•;

a

nn

KHO

(KHL- I OB)

7'D

100

V

200

lOOV

200

i)>}-ziu99-{m

50

V

50

60Hz

V

60

Hz

Hz

Hz

I

3

500007

500008

500005

500006

300207

300305

KH063

(KH/AV)

7xhK7A(M)

K H 7

(AV7

lOOV

200

V

220V/240

380

V/415

7'D

100

V

200

V

100

V

200

V

h D

—7

t o —X

V

V

50

Hz

50

Hz

60

Hz

60

Hz

303713

303747

-)

760061

760062

760063

760064

500007

500008

500005

500006

— 6 —

Page 8

\

KHi

E32

m

WOO-

m

i

^

^

>

^

&

mtim

K

&

A

H

m

s

m

A

E32-410,

•

mRifm2N

E

32-410-2X4

•

E32-411,

E

32-411-3X4

420

420-3X4

2 N

430

430-3X4-5x5

•ii-mmu2Ni;in'

E

32-440,

543

450,

541,

•

•

•

•

•

•

542

mi-j.>/j y 9

n

-y

f-

;;^oX7°U—b

It

m

y 9-

^u7.-rv-\

-b>^t-byb

7 T >

W

JZ

]

i-j.>ij-y 9 -

n-

M

&z.>tiy

^nx7°u-h

-fe>-t-b y h

7 T >

7nxrw-h

9-

-

wi

301030

301243

mm

301030

301243

301408

301274

301030

301241

301030

301241

301408

301274

301235

301241

mBiE

KHOO

(KHE-1

KH002

(KHE-1

KH003

(KHE-1

OA)

OA)

OB)

1

KH05

1

(KH/AV)

KH052

(KH/AV)

E

32-450-5X6

• K H 3 > h n

cr>i:m^X'imo

3®

—7

•

i-:L>i]y9

•

-by-^-tz-y

7 T >

—

TO ^

t

h

-

B

301235

301241

301409

301274

/"j

t

7*0

100

200

100

200

V

V

V

V

7^®

50

50

60

60

Hz

Hz

Hz

Hz

500007

500008

500005

500006

KH053

(KH/AV)

rxhKxA(M)

KH=»> h o-x-

(AV:3>

lOOV

200V

220V/240V

380

7*0

100

200

100

200

V/415

7^®

V

V

V

V

1«o

V

50

Hz

50

Hz

60

Hz

60

Hz

—X

303713

303747

—)

760061

760062

760063

760064

500007

500008

500005

500006

')-^m

'l>h^i^9f-m)

7

—

300207

300305

Page 9

E32KH¥-i>^<-y

}f^

E32-420

E32-430

E32-450

E32-410

E32-4I

^

it

516-213-

516-233- 3 X4

516-335- 5 X6

516-212-2

1

516-232- 3 X4

m

II

LI32KH>5r-v^^<-»y

Y—

NGX

5X5

5X6

i'(ma)

SW

3X4

3X4

LI

(LI

LI

(LI

L1

(LI

LI

(LI

W.

32-36

32-37)

32-38

32-39)

32-70

32-71)

32-86

32-87)

y-i^'

3X4

5X5

X4

ft

303833

303834

303835

ft

ifi

II

210273

210273

210274

210274

210272

210273

(M)

208065

208066

208063

208064

®

')

(if

ft

msm

208218

208219

208215

208217

301318

301319

301320

301321

301317

301319

>)

^

(if

301303

II

301301

301304

210579

210581

II II

210582

210892

210893

208531

II

II

204683

210492

210494

210495

210889

210890

^

204062

204702

204703

U

JU—

II

M

ff (la)

301303

301300

301301

301304

301302

301300

•—

nw

2

4

4

6

~ m m

-'L—-'n"—

204314

II

204431

II

A

208531

II

II

204683

208531

II

ft-SrC

C)

204042

II

II

II II

±;u—

210364

210365

II

II

210364

II

ft-SrC

D)

204522

II II II

II

ft

208909

208910

±XYUyr-

^

II

210512

210513

II

210512

II

II

± / X

202527 A2

201121A

II

ft

ii

2

2

2

#

DCX27

#11

DCX27

#14

DCX27

#21

DCX27

#11

DCX27

#11

N

N

W

W

^

u (if

b° • Y

1

.Omm

1.6mm

1.6mm

2.5mm

L32KH^-v>^<-»y

TO

®

L32-36

(L32-37)

L32-38

(L32-39)

L32-70

(L32-7I)

L32-86

(L32-87)

•

E32 • L132 • L32^,

Y— X (mm)

NGXSW

3X4

3X4

5X5

5X6

ft

303839

303833

303840

303841

ili

'J

jSfe

(M)

208065

208066

208063

208064

•

Y-i^<n^<-'yli-^m^mX'tc

Mmm')

208218

208219

208215

208217

wMm

(s

301303

II

301301

301304 204683 204703

208531

II

II

;&;u—>->

204062

204702

204702

2

4

4

6

~ M m

;u——

204314

II

204431

II

A

ft'S;(C)

204042

II

II

II

ft'§:(D)

ft

204522 208909

II

II

II II

208910

_h X X

^

202527

II

II

201121A

II

ii

t° • ■/ Y

2

N

1

A

2

2

2W

.Omm

N

1.6mm

W

1.6mffl

2.

5mm

Page 10

R57

I

(I]/<-.y<7)|SzytttL(Ell )

o~0<7)jnMtc(±-rto

(2l/<-'y<7>SE#^(1lfiEx

•

}Lti^

<-0

i:

(300062

5^1

•

i-:^yp^

-y

yf-(300243)com^li,

LT. ^ >'

ycoi

04)

I

•

^

0^At\tniz^-±XmWX

^ittix

i.o!mizmmLx<f^^^\

'j

J; 9 (2

.±j}

LT < /".:'$

v-»„

2

)

mii:0m

itto

<

^0.5-

i^gp(i.±yx^^

%

02

^<—^y<7>®zu#tt(0

m

1

It^O

mi

^ X >

R57-01 • 02 • 05 • 06 • 09 • 10

R57-03 • 04 • 07 • 16 • 51 • 52

xep{±,

O

•

Ccotfi5B^#{;He«cL/>;R57KSco43i

717

-y y -

11 • 12 • 14 • 16S2-17-18

19 • 20 • 25 • 81 • 85 • 89

53 • 54 • 55 • 57 • 59

f-x->7'7>

"

i X >

Xto

1)

.

(if L /:; t ^

(300243) ^ ffl 1"

"

i> $ xXi,

ft

It#

(Xi^cowmzm

m ^ ^

300115

300116

5877431

-i)

"

P

0

m m

X

O

X>

1^^7)

—

0.5-

I.Own

CS.T

-.1

10.5

9

Page 11

\

R53

|I|/<--yOT®iJttt

VA

y^-ro®iJ#lt(E16)

0~®i7)»S(cR')Wt?)„

•

^x>7>

i>;u^4if{cr*Tr

^

•

f-x>7:7

yy-(300243)<0»-g-li,

5>)3Esrii

J: 9 {3

ft < /■>; ? ^'■'o

-y

^li-rL-t,±^^T^c7)7!7»;^'^v^?f

l.OmmtcMgRft

<

L(EI5)

i

>7:7

Plp{i.±7'X^^

7u-A<D^

$

V

i^0.5~

ff

@5

f—O

o

@6

•

r-ij-^dlft.

Ill5^##(c.

(i-rLZ-ci

tt^o

^2

•X

<J:

R53-01 • 02 • 05 • 12 • 15 • 17

R53-03 • 52 • 53-54

xenii,

O

"

i X >

iS

25 • 81 • 85

•^x.=-yXy>

i:

5

V

>

•55-57

"

ft

i

^mubX < Z-^'

^<7)il&X>IilH{3^0#

^

^

m

300117

300118

=

"

X

0

x>

©

07

4—

#

—

10

—

Page 12

L152.

L52,

L132.

L32

^5aiiit:303299(^x:i>^'-7VK:#-xtt4Sffl)

L152 • L52

[I]/<-'yc7)ga u itt L (0

!2l'<-'y<7)^fi|(5#6.

[gy<-.y(7)5[iH^W(EI8)

ms

(t^o

[iT

i-„

^3

8)

1*19)

<7)1^collateSio#

•

*#.Ha.)

•

mm.

tm'roit.

=t=rBmi^^:303512

303354,

L152,L52,LI32,L32

[]]/<--y(7)

X > ^'y

©-©conicfx')

•

i-^>y7-y

X

<

iJlit'L

^

la

^

0.5~

1.

OmmlC

>

yj

■y:$'-®^±.rizmy)'ix'ii^'tt,

in'imi.

303366

(J # 11C^

Hgp

n^xyyitm-mn

10)

L-C

^

li^xyy

T

<

KS020,0241Fffl^<-*y

iJ

B

i£)

L52-01.

L152-01.

OlsK

Olsj.

ijcn^zsi^m

Sgg°pS-^

303434

303429

303303

303465

303025

303148

02.

31.

02. 31.

<

34(i.

34ii..

t^^ebX

B #

r1i

rti

m

ii^XlOv^-C

iv>;zov>-t

mx

<

ft

O

O

-

o

o

j

I L__

'o

Page 13

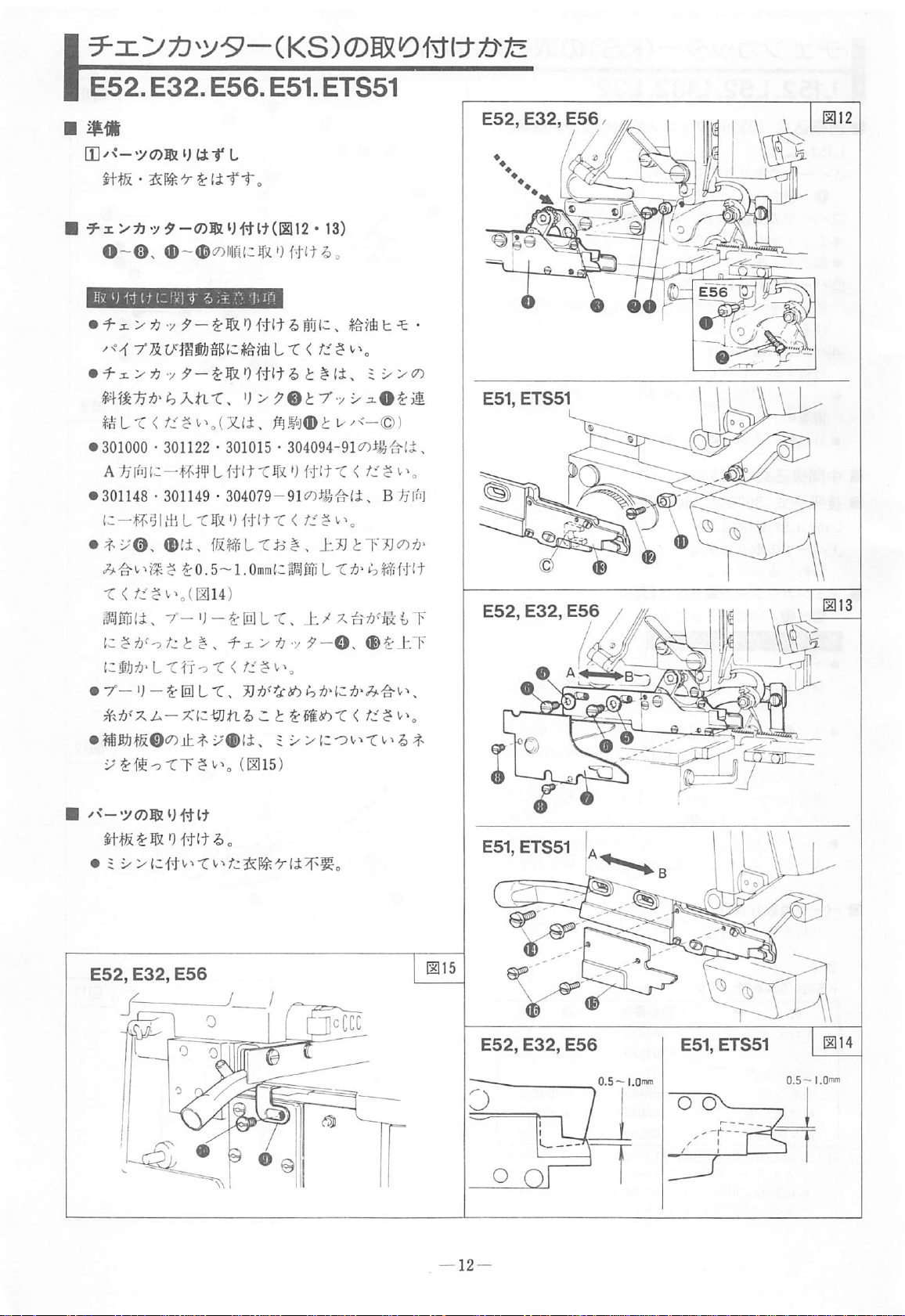

E52.E32.E56.E51.ETS51

mm

[]]/<-'y<7)®:UU:-r

^:L>i3'y9-<7>JSLi)iit.imn • 13)

O-®.

•

301000 • 301122 • 301015 • 304094-91c^^^^^^ti.

A

•

301148 ■ 301149 ■ 304079-91(/>^^-'^f±,

iz

•

t>i-'0,

T < /^■?v^,(E]14)

mmt,

iz

^zmt^lX'ii;nX<

®~®<7)iiiii(c^zgfW^.

fi

-4T4¥ L ftt t T

1

tti L xm 0 iwx

®li,

^0.5~1.0mm(3i^§RL'C7:)'i^l?i5-#ft

r-O-^IULT,

tz t ^ . ■i':i. > ij

L

L

-r < fJf

'J >':?®t7*vxi0^ii

'Ht(t T <

«LTiJ^,

±/

■•/

f—Q s ®^_hT

?

u•-<-©)

/f ^ ^

B:^l^i]

±J}tyj)cO:^^

E52,

E32,

**11

E56

7^^=f:

^.ib^'X2.-X^z-^tl^Zt

•

fflfifi

^®c7)iL^

/<—•y(7)B2t)44-l+

x®(±.

(iai5)

^msbX<

=

E52, E32,

E56

0.5—

I.Omti

Page 14

L132.

t

L32

016

(D/<--y«)®

ij

(it

^ n XT'u—

•

<Z)5ZU

•

f-i>y7v

xri^-h

Sr-k-y

^ D X7"u- h 5.

h^X < /i$v^(018)

L

h

016$:#Mo

^x-rv

^4

h

^Utto

-i^jEx

016)

'y t ^jl^o

#1^(017)

i

t^xO$:5fei6-Ci^lnt

(h

C7)P^

$:^^J0.

i7D

4minC

2.5-^^-

I

R5

,<~r"

12.6 n I

T 4 ^

34

I

b-

20

Rl

-75.3

~~r~

23.5

J_

.45*

017

')

t0.5inm±(C^>{fT<

^

^i^^0.3nim{cMLT < /j:-^«.^(02O)

36»

LT^f o X

•

r-U-^lULT,

^.:f3'XJ.-XlZ-^g}tllZt

m4

iS

ffl $

m.

m

L132

L132

L32

2

2

3

3W

2N~3W

<

>

N

W

N

/

1®

/ ^

(D

1 (

^mibX

Di^PfJ-#"^

303764

303777

303758

'

o,

1

7

(A

|>

<

018

#

m

016

016

016

020

0.4nvn

019

[—G.3mm

—

13-

Page 15

E32

(if

L

Itts • ^^.^]kl/9^x-rv-

h

^(i-ri".

30.6

30.6

11121

,

7

• ^ a

•

X7V—

h

(l|jE-r-2>^i^(i,

iS

5

->

>

wt

m

E32

E32

2

3

3W

2

N

W

N

^5

12121

-y

t

301243

301241

—

12121)

h

#

m

12121-1

12121-2

.t

23.5

21-1

R2

. J

45^

6.9r;

1l

-2.3

U7

J_.

23.5

21-2

c

R2

I

45*

6.9'-

7

J

-4.5

-14

—

Page 16

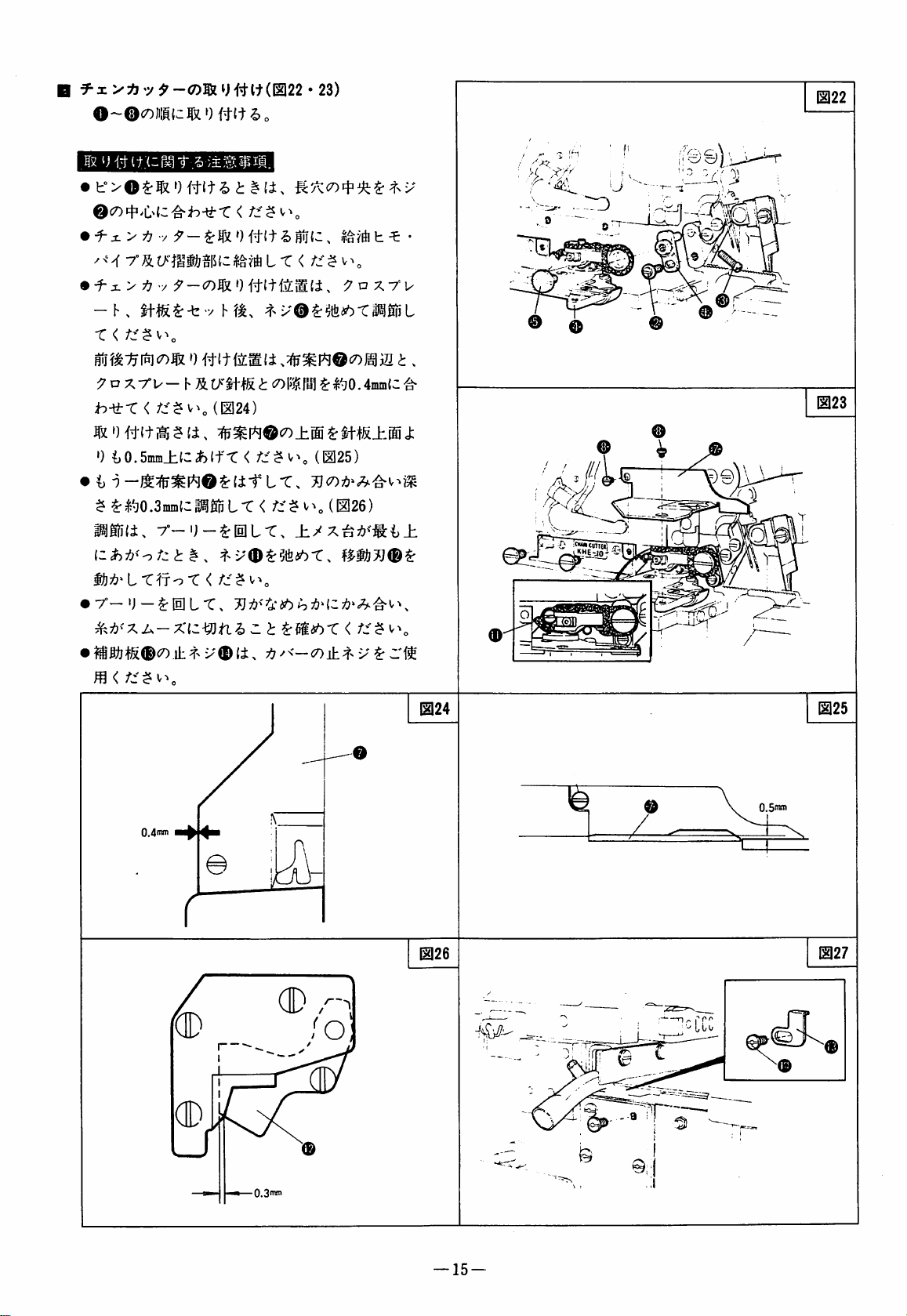

naiEiBBraEii

•

0c7)4i>i:^(C'^b-^r < f::^^\

•

f-x > 7!7 V :?'

-C<

0 #tt

—c7)^»)

l> i ^

®

1122

o

^oX7°U—hS.

ib-ti-r

')

$

i^gfili,

<

^0.5mm±{C#)lfr < fz^^\

^|J^0.3min{c|^gnL-C < /::$

r-g-^ElL-C.

(/§ttS i <7)

(1224)

{zhi3<-otzt^.

Myf?' L T^to T <

•

<7).ill

0.4f^

X®

(i,

li^

fjg ^ I^jO . 4mni{3

(1125)

i]^<—

(1126)

Z'^

@24

^ttlTTU)

@25

@26

O.Snw

—

15

—

@27

Page 17

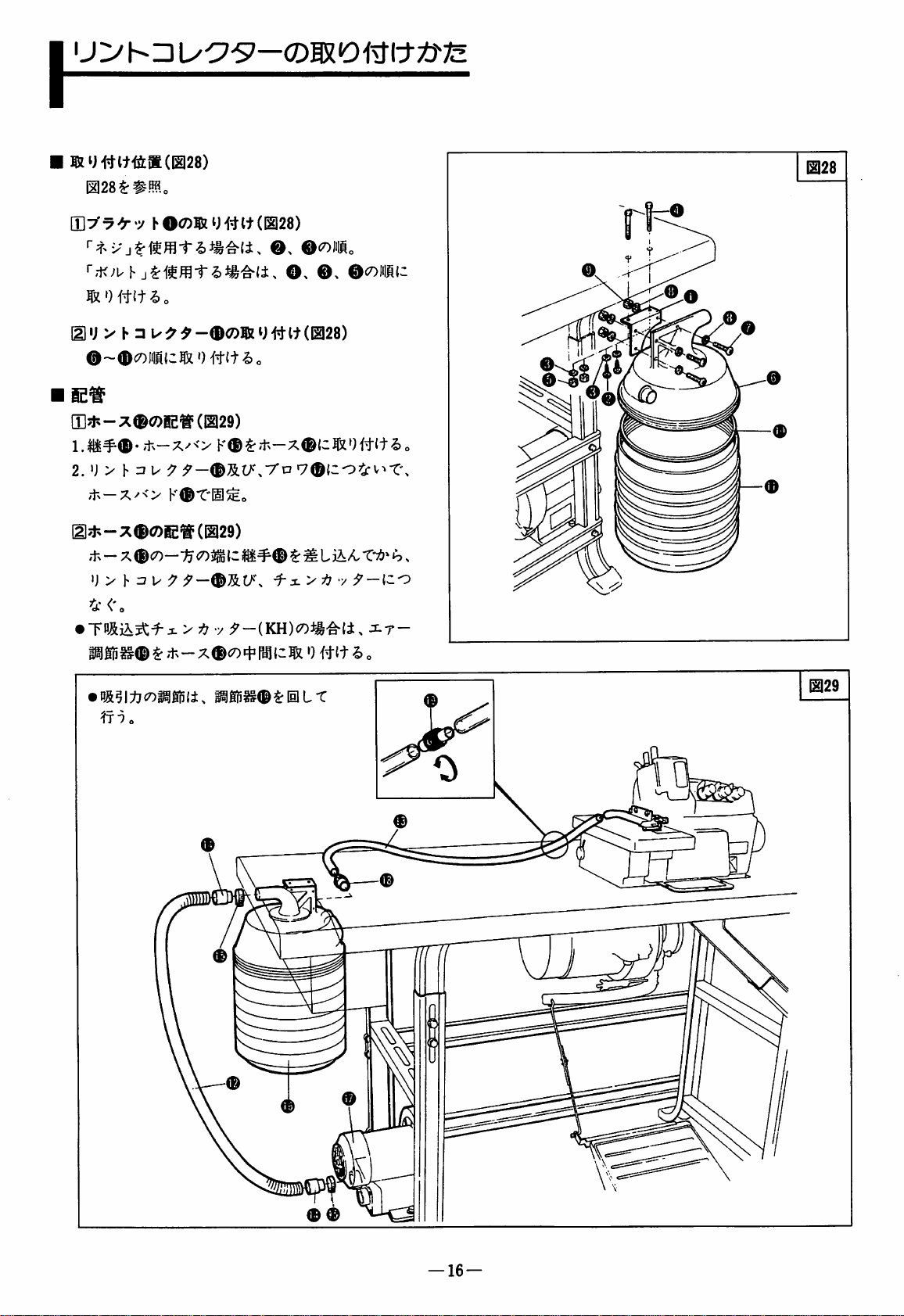

\

E128^#Mo

{y\y

^^ y hO<7)®U#lt(12128)

■"'-K^uh

^')fW-2>o

mi; > h □ u^^-®<7)®iy#it(028)

©-©council

(I]?f.-X®(7)E^(|2129)

2. U > h r? u ^

.tx

—X^<>

m?^-:^©<^E®(029)

rf

-x — X

©CO—

ij > h

r? U ;J'-©S.O\

4-<'o

•

P»©^d-^-X©cotr^tc^»){W^o

0#(t-2)0

K©^:'^'^—x©{clx')#lt^o

©^lO\7'o

K®T'gl^o

> 7

-y

f-i

;?'-(KH)co^i'^(i,

©>

®,

7©(20^v^t:\

^

t

>7-y

©colic

:f-{30

J^r-

b

©

s

WMij

©

© ©

—

16

—

Page 18

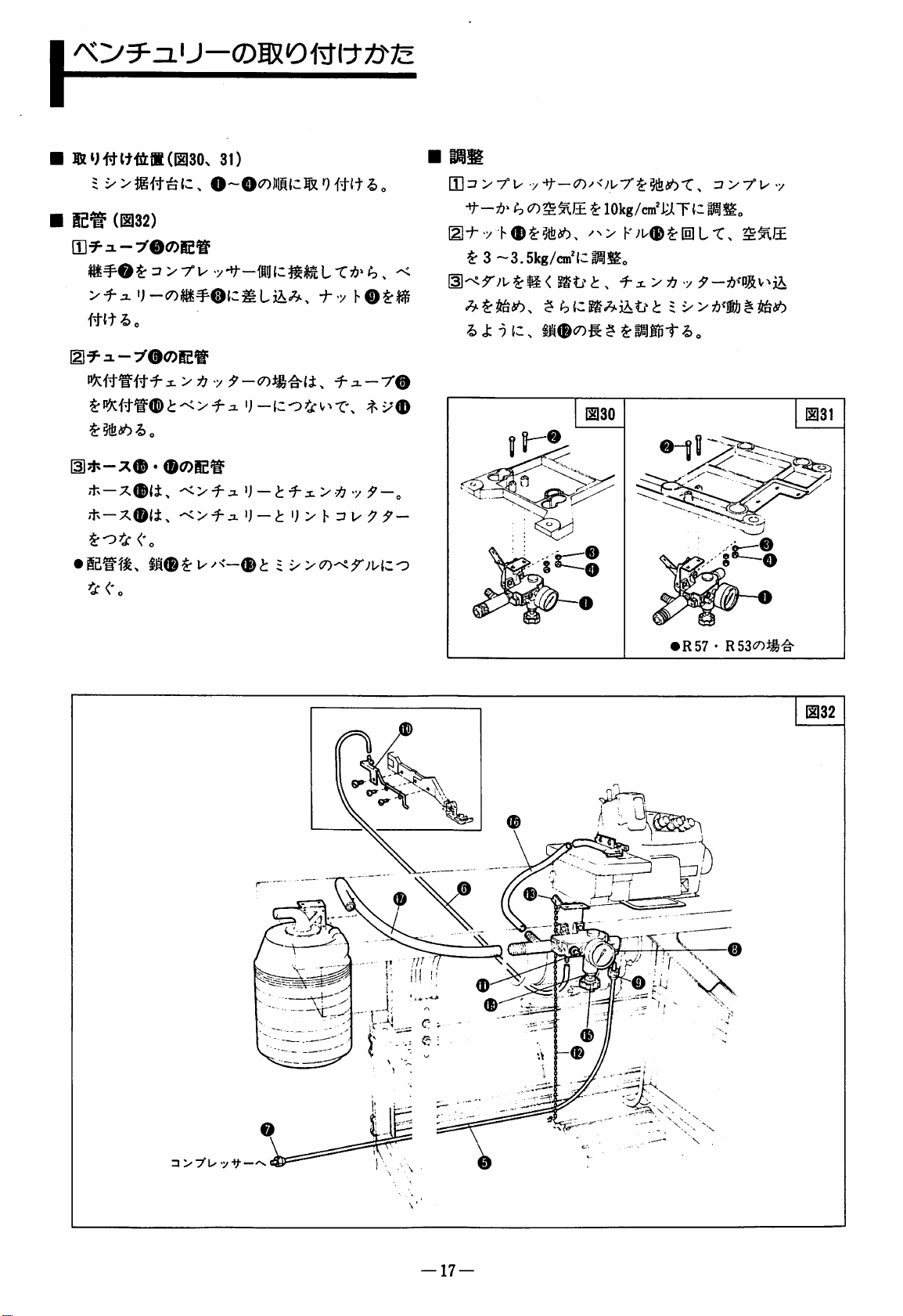

\

ix>$g#^{c.

|£^

(11132)

[I]f^3.-:/©<7)ie^

31)

O~©<7)Jii(c^0#it^o

[Hz/>7°U

-t-Ti/'

^3~3.5kg/cin'(Ci^^|,

y-t

—C7)y<yU7'$:§tfei6t:,

<7)^^|± ^ 10kg/cm^l.JlT{:il^!^o

Ziy-fUy

^

mi>o

[iif=-i-y®<7)ie^i=

y

o

(l?^-:^© • ©(7)iei=

'+^

—X©|i^

itx—X©(±,

^o=S:<%

•

^<-0

^>-i-SL

-O-f-jL

i-'y

f-i-r©

^) — ti-:SL>'

'j

—i";>huu:7

= x>c7)-<r>'Hco

tf

"/

f—o

f

—

R57 • RSSWl-g-

^32

©

—

17

—

©

©

Page 19

tzytf-tz^y

L132

I

[I]y<-y<7)|SHj

(i t L

0-ii>cr>miziitto

• T - A (&)

[l/x--»y<7)5iU4tlt

033^

^0

#Mo

me

KH060~063li:ffl^<-'y

r-M^)

7 T >

It

If

i

##(c

{2

ft ^ r V >

(i t L

(033)

0 6 •

I, p gR X #

i ^ <y)i^colUMJc

303424-HD

303812-HD

303729

■(gJEx

034)

CO ^ N-- • y

m

034-l#.fKi

034-2#.»«

fl^iE^"T

n

II

0^e

®

0

')

#tt

0

0®

#

-

43.7

-J

—

18

Page 20

(11135)

n]^m(7)W^Vt^^^^2Nj(D i '>>(L132-36 • 38«07-

39^)

7.-<-^-O^CP't>^Oty'y'r'y

b®c7)

11135

(E)

x-^--

d

h

86,

7'7^-x

>

88^)

LTl^S $ vV(L132-

yy'r y h®x>g5\(i)^Mo-t:.

[lCP'b>-»f<7)=f-K(i.

v®T"4

^36^##(c^u

ij?f\^±.sbh.

rx^-y f $•

v

7°

O

0

0

11137

[I]/<-«y(7)lttj(i-f

0~®o)iIM{z(i-f

l(®37)

i-„

[2l/<-»y<7)5tS&(^6)

7 T >®

[I]^<-*y(7)5zij'ftlt(I1137)

ma?

(t^o

•

'j-(Cr[D]

•

Z3-

^##(3,

K{i.-< y K-^§>i^gfeliL4-v^J:

lj

Ji-

(itLtii

t

It

t

(11137)

^xxmn

^Oi^coJilMic^'ift

-)

(c

#(t

!>

y-

ihy)^..

»?

„

—

19

Page 21

\

L32

[D/N--'y<7)5iij

•

T-a(;£),

•

T—A

l3l^<-»y<?)®iU#It

mas • 39^##{c(itLtc

(it L (EI38 • 39)

th#7:7^<-(i.!2l4060ii0{c>fliiEo

(;£) H oi

^-C V ^ ^ Pin

m7

-^je.

'y(i,

(11138 • 39)

t |i<7)i|frc7)jiiK{c^>)

;f.

#{tl>o

• ^ X > y? y -

(KH)

')

#{t

Mo

CP-b>'-9-<7)5iiJ#lt(I1141)

[1141^##{C

m h 7 ^ ^

-ff

i

X

L T Ll- ^ >'(L32-86,

88^)

iii4o)

X

iV'Xcov"'

t:

7'y^-yh^

{i.

-y

($),

13M

0

o

\i:5,

^

0

1

ryy-y

S^¥HU{3?iaiLT^0#lt-2)o

CP-fe>-'t<7)n-h'®(i,

•r®^lt/^^x®T'4

Kw * 9.b

/ 4.5

40-2

ijfh^itubho

^

>r

'•

\

y'y'T'y h ^

I2|42$:##C

-43.7-

-44.2-

y'j

y

KH064 • G653§:ffl/<-'y

m

#

r-A(^£)

f>

1)

=?

h 7 y

•/_

i;_

if

tf

i

>^<^

ts

7(±)

303424-FD

303418

303714

303708

5077

303973

I1140-1#8S

i2]40-2#ra

dlJE^'ai

II

II

II

II

II

—

20

Page 22

[T]yN'-y<7)5iij

(i-f

L(043)

0~©<7)|iiI{c(iT-to

|2]/<-»y(Z)3^SI(a7)

r-

u

^y<-yoj^

043

'J-tCigij

i)

It

(043)

0te«^m«<7>5iiJ#lt(044)

1.7°-

'J-{C'<;uh

2.043|:#MLT.

•

-<;uh

717'-K=^^')#{t-Cv^'g>

IIl®I*l#lttS[g(045,46)

045^##{3^^ai^affi^7°-

(cr&jtt

1.

OmmtC

T. a ®

i:

-2)

7°-

o

<7)ii&c7)iii

'J

-iSUffi

t

{c

m.

►)

m

i

o

=

,

O

^

'j—<7)4i>i:>:^f^

^0.5~

044

V

045

•

7-K7!?^'7°-g-^t^ML^v^J:7(c,

h

®C7)J; 7 {cjhi6l>o

KT\

7>

046

046

—

21

Page 23

I

E32

CP-b

047^##{c

fZ^tho

[EE32-430,

X^-'^r-O^'Ty'r

[11E32-430,

U

=

440

1175-2^^^fflo

AA0Ul9\-<Dii^>

@{i.

1202$ri^fflo

•

7°®^tr/'^^

v®-C'3

K®(±,

7!7P;fl:±i6-2>o

Iil^^a3SS(7)liiU#lt

(047,48)

-/

h®^

=x><7)r^{c|i

|2]48^##{Ci7 U -y

1

047

E32-430«440

ftl

[E^<-'y0®iUtt-r

7

T

L(049)

04£^aiSS®<7)®l U 4^

049^##{c^»HW-g>o

•

3—K(i.

<7)51

049^##{3,

{t^o

'j

-©{cruj

^8

KH

7t>

It

ijftlt

IK

h

(049)

\.i'fLfzt^<r>m<r>]mzW)ii

ij

✓\ — *y

t

It

(049)

301274

9{3±i6-5)o

m #

//

II

049

L

. ,1

®

22

—

Page 24

[E-f

>7"^

C P -fe

L ^ 1".

yr>cr>-7r^^

-(INDICATOR)

{CLOTH

C P -fe > -'t

-(COUNTER)

-y

^

m\ L ^

h

1"=

DETECT

^

igSfr L -C V ^

ON)

^

iNOICATOft

o

e

[4]MIBSi5(SEN

C

P-fe

>

ADS)

[lJiv.^tei6(START)

^

•^—Iz^?: U ^

to

(FINISH)

wmcomm^

-i-7—

^

ti

ymcnmnz^W61

L

^to

•y^(POWER)

=7 > h n —7

(Sl/^-f

O'y h 5

'Mx>f

—(7)'^il?;x

vt^^oNj

KH 3 > h □-7-<7)®I

r — 7'; u c?)

•

KHr>>

;£

101T ® U © ~

h

o-7-ii.

^ L i

to

,

'f

v-f-f'to

tJ-ft

tt

(EI51)

®

I'iC 'J

'til"r€f±l3i^:-l:/j^jc7)

w

.^.^TL^t<

It t §

<

PEGASUS.

^<5^0

POWER

« M

o

tt(Ill52)

Page 25

3-

(IIB®a-K

0(7)3-KS:a?©-0-©<7)1^.

i.

(053,54)

— 9 —

c7)X'f

053

(£t.o

x^tC)^^LT

054

0+aia-

t«83-K©-©.©?:««1-2,t#l±,

Tr - r

K

(055)

3

(f. 7 ^' - m&t

ft

®(7)h-—

^i-Tffl'TOig S 4-(3:a U jt)')

i

o

Kat/'XT-r)U

?)

o

|B|6,

055

□

24

Page 26

\

(12156)

mmm<^xom'^ ^ i^ t iiAMtc

t^C^LX<

i^ox-m.

►)

#it

dl/l-^-xO • 0 • @<^121=

l.li^©

^h\

2.056^##lc^/t>

KOt'gj^l-'&o

•

;tN-xO(i.

•

.t^-X^<>

'PLMiblzLXh*)

K®i^7n-Xc7)i^i!^(c^L

—X^o^v^Tx

(056)

<

/w$

tto

v-»„

d-x—X^<>

^tc<:

^7. h K7A©(7)Jgf^ita

T-7';uc7)^tIij{z®

•

D-&?l:^X)|^|pli,

ff

•)

o

i^lflS5©^IilL-C

<

„

(056)

mt>-700^m

l.;^-x0X)ii^^i

2..tv-X©cO:rx

^T':^X

i > t!/ y rJ'—

•

(056)

h

KxAfilJlw,

h

K-7A©{co^v»t:x

i I'li.

<'o

ni^ixp®tc^^.yr

xr-liln

;?-{C:rx

h

056

4

0

®

—

25

—

Page 27

tz

ytt-tz h (Dm^

LI32«L32(E!57,58

^57-58^##(c,

miri>.

£32(058,59

(USB

-

L32

-^9)

-559)

fxMmznti>±ncon^^

^9(7)=^li5^)!iCt^£oTl^

■/-IJ--(7)-7/;^-y

h

t

I

y > xm^'An-r

L132-E32

=

y

hzt

i>zt

^mmt

7r

^mutho

^PEGASUS.

h.

y h t

[a

POWER

n

Page 28

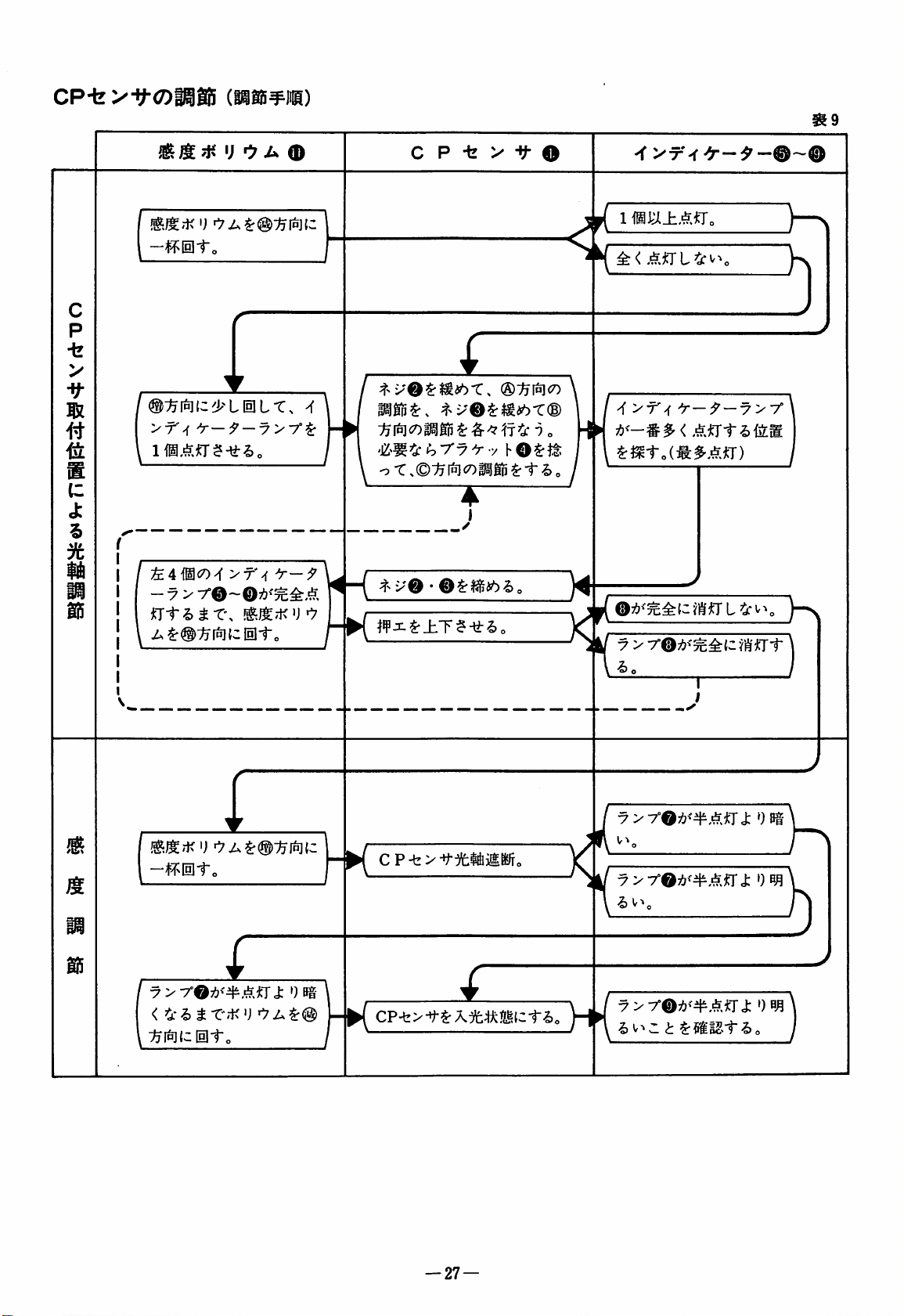

CP-fe

vy-oisas

(Ki5¥ll)

09

c

p

•fe

>

it

s

(C

J:

%

3fe

-fmto

>T'^

I

U A

f—9

>f'>f

®

C P -k > -If

O

1

mj;Ji±mr.

<

f

I

®:^f6]c7)

\

^

>f'^

^mtoiMi^An)

'y—

Ant

^—y

yy

i>iiLm

15

Jt

15

T\

M;KU

/^tr®":^f6j{wIili-„

i

—^=T^Ia]1"o

I

yyyO^^'tAM^

:^i^{clil-t-o

•)

Bg

CP-t>^t:)fcM0i/To

•7 > 7°@;&^'^^(zf^''j:Tt*

t(

I

yytO^'tAn^

i>

v-»o

7>r©;{?>#.^,iTJ:

H{

t

^mut6o

')

»)

—

27

—

Page 29

KHD>sn—

cz)i®i

ai.^t&i(C>^-f

v-ocmeo)

«t^ii?»j^'-fv-@(ia6o)

0

[z-®^c7>PJiix^7&>

•-^ # ;c V ^

V ^ j

miOIRlNJzODjil

1.K H ::? > h n —7

—i±.

1^3 ^ 7:^<7)P^i\At;

-V

[H

i-,

i

(7)

2.KH

3.KH3>

4. C P-fe>t(7)U > X®^^t>\

=» > h

n-7-[±,

I-#-

X

<

h

a-7-(i.^^U^v>-r-<

:^-i&itL/-^i^{±,

-nmm.

AfL-r.

^mtfztt

IC-

hyyyx^-^j:

nrv^ ^ to

i-3-y

^ts_hffi'75^|t®

CP-t>tt7)^#^

l

t-v^r- < z-:r^

igtt.

ttzu^^

ito

Uti.

Page 30

KS

Device-Component

KH

Device-Component

CONTENTS

Parts

Parts

List

R53

L52

E52

List

L32

R57

L32

E32

E51

E56

ETS51

30

31

32

33

Gauge

KS

KH

Installing

Installing

CP

KH

Installing

Checking

Adjusting

Parts

Chain

Chain

Sensor

Controller-Installation

for

E32

Cutter-Installation

Cutter-Installation

The

Waste

The

Venturi

Set-Installation

The

Dust

And

Adjusting

The

KH

KH

and

L32

R57

R53

L52 L32

E52

L32

E32

Receptacle

Device

L32

E32

Drum

The

Sensor

Controller

E32

KH

E32

E56

Set

Machines

E51

ETS51

34

35

36

37

38

39

40

41

43

44

45

47

48

50

51

53

Precautions

53

—

29

Page 31

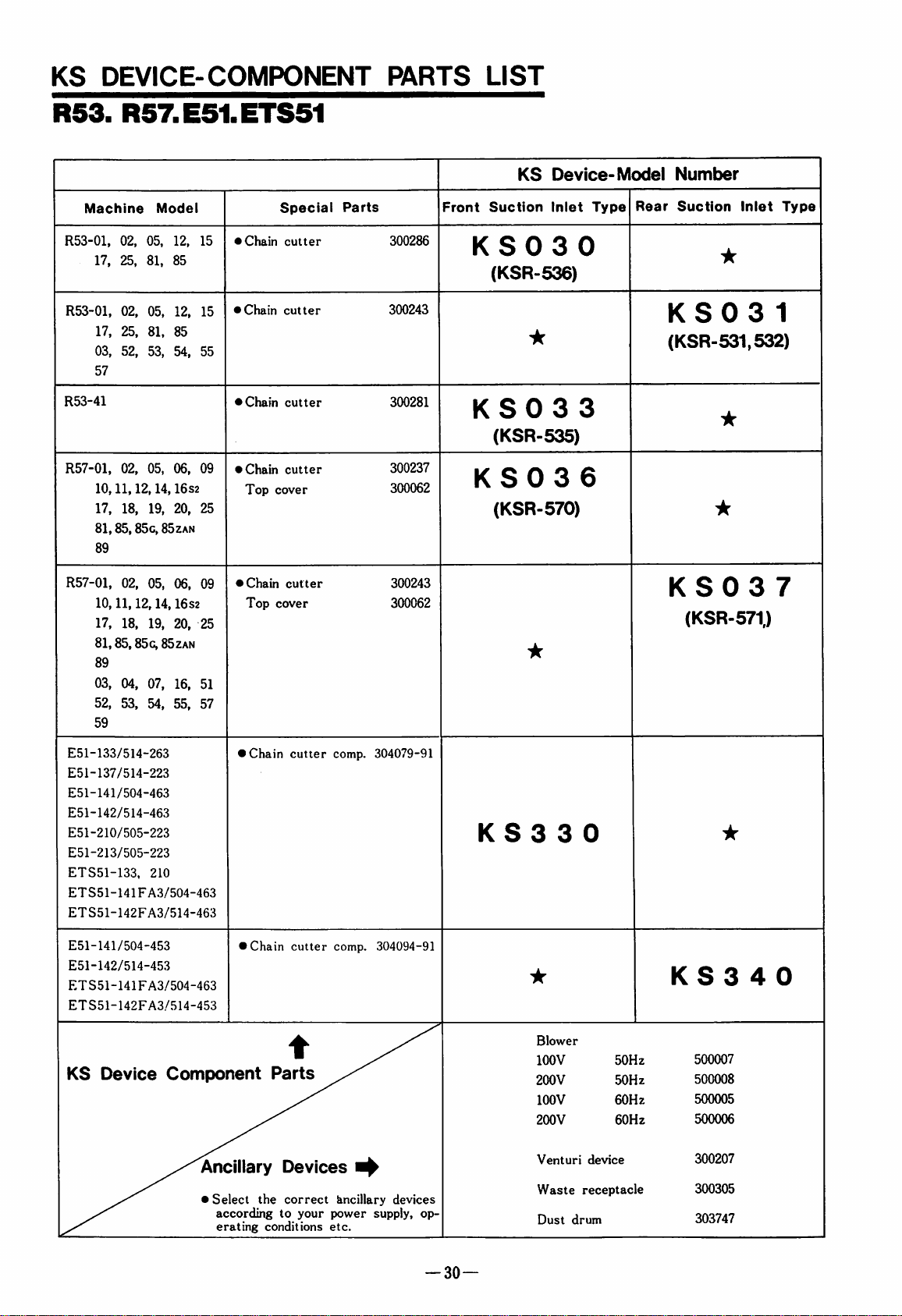

KS

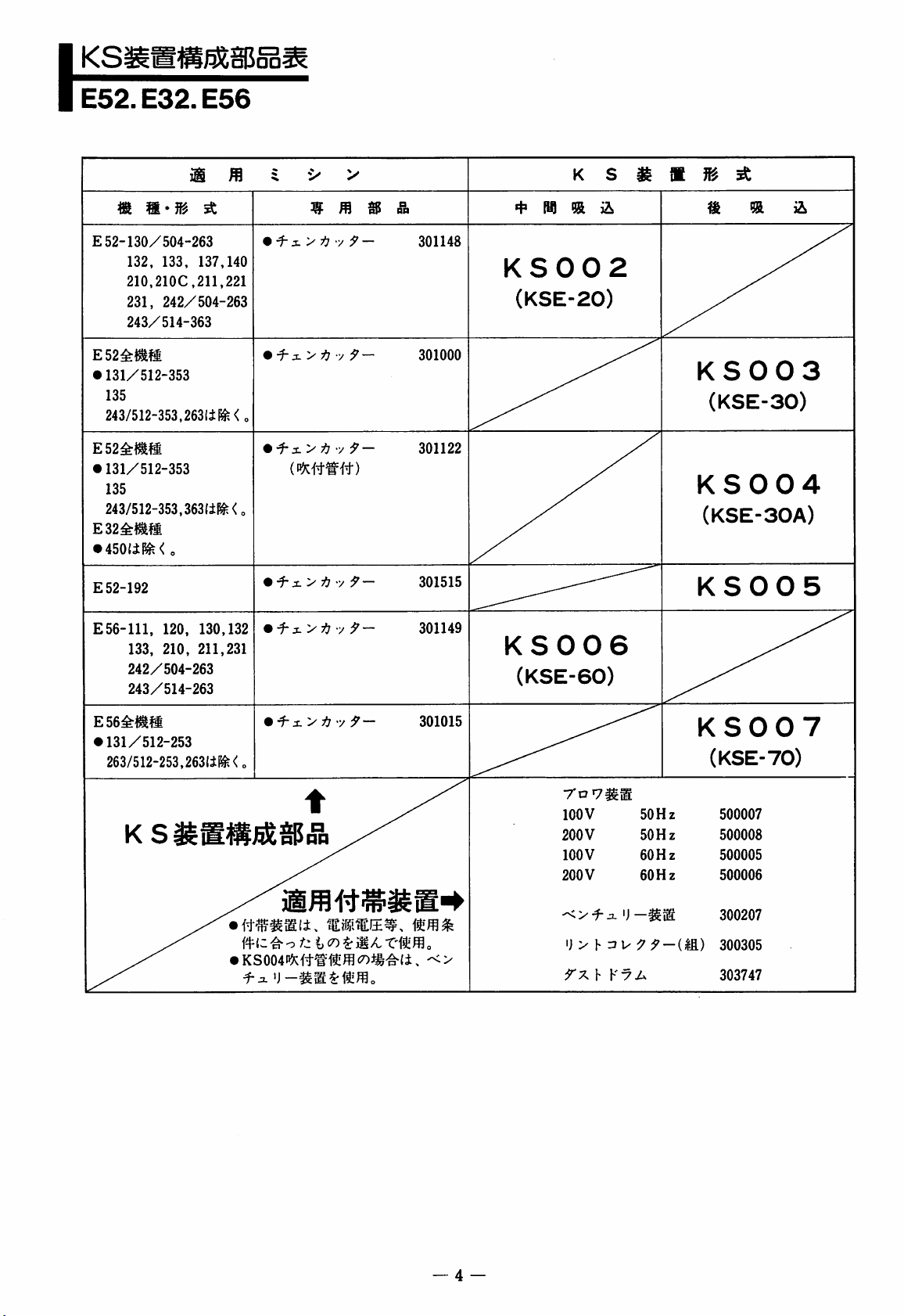

DEVICE-COMPONENT

PARTS

LIST

R53.

Machine

R53-01,

17,

R53-01,

17,

03,

57

R53-41

R57-01,

10,11,12,14,

17,

81,85,

89

R57.E51.ETS51

Model

02,

05,

12,

15

•

Chain

25,

81,

85

•

02,

05,

12,

25,

81,

85

52, 53, 54,

02,

05,

06,

16s2

18,

19,

20,

85g,

85zan

15

55

09

25

Chain

•

Chain

•

Chain

Top

Special

cutter

cutter

cutter

cutter

cover

Parts

300286

300243

300281

300237

300062

Front

KS030

KS033

KS036

KS

Device-Model

Suction

Inlet

(KSR-536)

*

(KSR-535)

(KSR-570)

Type

Number

Rear

Suction

★

KS03

(KSR-531,532)

★

★

Inlet

1

Type

R57-01,

E51-133/514-263

E51-137/514-223

E51-141/504-463

E51-142/514-463

E51-210/505-223

E51-213/505-223

ETS51-133,

ETS51-141FA3/504-463

ETS51-142FA3/514-463

E51-141/504-453

E51-142/514-453

ETS51-141FA3/504-463

ETS51-142FA3/514-453

02, 05, 06,

10,11,12,14,

17, 18, 19,

81,85,85c,

89

03,

04, 07,

52,

53, 54,

59

16s2

20,

85zan

16,

55,

210

09

25

51

57

•

•

•

Chain

Top

Chain

Chain

cutter

cover

cutter

cutter

comp.

comp.

300243

300062

304079-91

304094-91

★

K S 3 3 0

★

KS03

(KSR-571,)

★

K S 3 4 0

7

Blower

lOOV

200V

lOOV

200V

Venturi

Waste

Dust

KS

Device

t

Component

^^^nciliary

•

Select

according

erating

Parts

Devices

the

correct

to

your

conditions

power

etc.

^

kncillary

devices

supply,

op-

30

50Hz

50Hz

60Hz

60Hz

device

receptacle

drum

500007

500008

500005

500006

300207

300305

303747

Page 32

KS

DEVICE-COMPONENT

PARTS

LIST

L52.

Machine

L52

-01,

/05,

V17,

L52-03S

L52

, all

L32

•

excluding

512

L32

01

05si,

18,

models

models

model

SI,

02

13,

25

stitch

type

15\

•

Chain

Cloth

J

Oil

Oil

Auxiliary

/Uncurler

1

For

\brackets ( ).

•

Chain

•

Chain

(with

Special

cutter

plate

shield

shield

use

on

cutter

cutter

air

Parts

holder

feed

dog

the

blower)

303299

303434

303303

303465X2

303025

303148

machines

303512

303354

in

\

/

KS

Front

Suction

Inlet

Type

KS020

(KSU-520)

★

★

Device-Model

Mid-position

Inlet

Type

★ ★

KS021

(KSL-521)

★

Number

Rear

Inlet

KS022

(KSL-322)

Suction

Type

★

L52

, with

L32

•

excluding

512

models

('-12,

V

23,

31,

KS

Device

UR

device

stitch

type

18s.

18SSN

26,

27,

34

Component

•

•

28/

/Uncurler

j

Select

according

erating

•When

KS023

a

Venturi

Chain

cutter

(with

air

blower)

Chain

cutter

Cloth

plate

Oil

shield

holder

Oil

shield

Auxiliary

For

feed

use

on

the

\brackets ( ).

t

Parts

Ancillary

the

correct

to

your

the

chain

device

power

etc.

with

must

conditions

using

equipped

303366

303299

303429

303303

303465

X2

dog

303025

303148

machines

in

Devices

ancillary

cutters

an

devices

supply,

KS022,

air

blower

be

used.

\

/

op-

★

KS024

(KSU-520)

Blower

lOOV

200V

lOOV

200V

Venturi

Waste

Dust

★

★

50Hz

50Hz

60Hz

60Hz

device

receptacle

drum

KS023

(KSL-323)

★

500007

500008

500005

500006

300207

300305

303747

-31-

Page 33

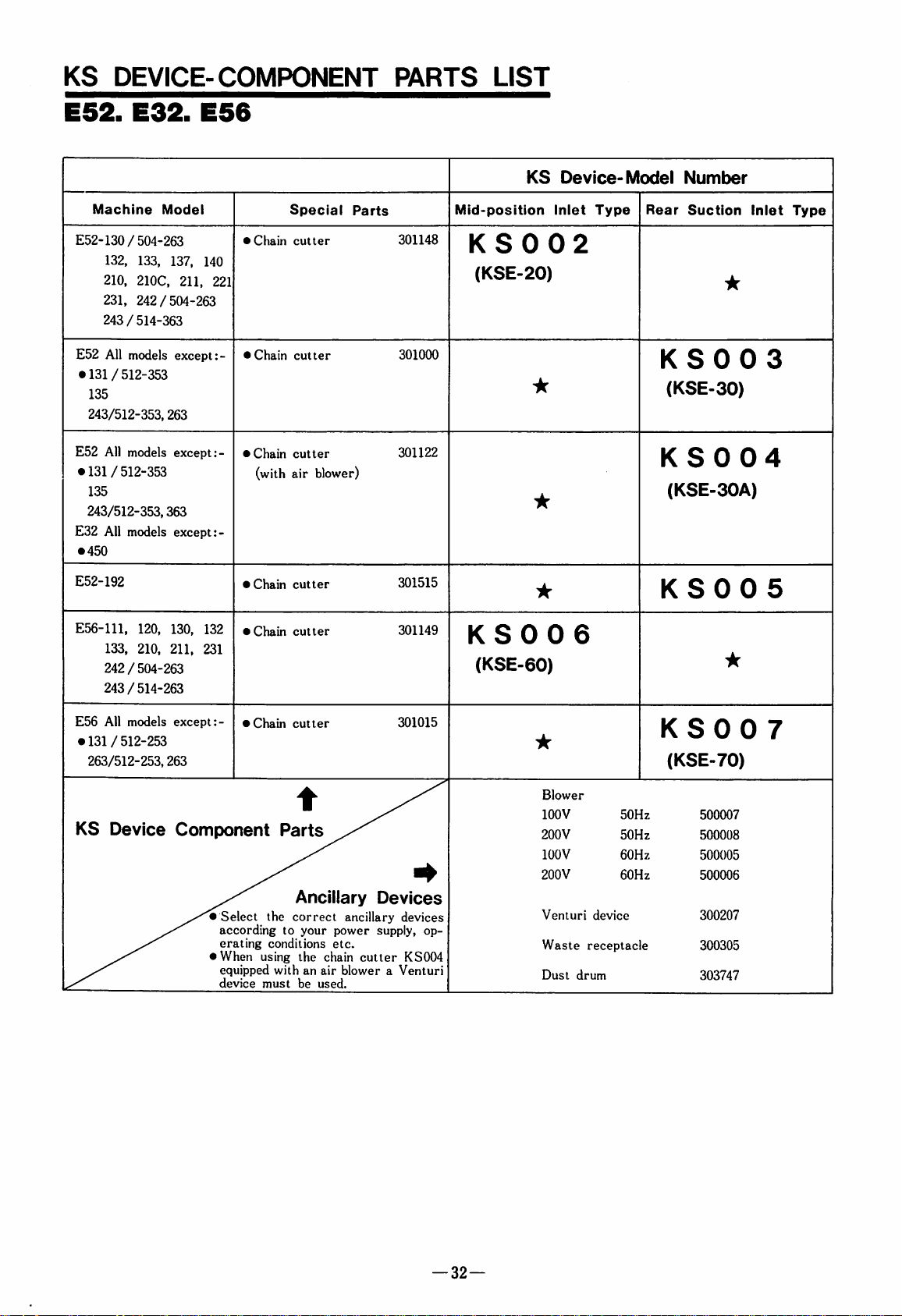

KS

DEVICE-COMPONENT

PARTS

LIST

KS

Device-Model

Number

Machine

E52-130/504-263

132, 133,

210,

231,

243/514-363

E52

All

•

131/512-353

135

243/512-353,263

E52

All

•

131 / 512-353

135

243/512-353,363

E32

All

•

450

E52-192

E56-111,

133,

242 / 504-263

243/514-263

Model

210C,

242 / 504-263

mcxiels

models

models

120,

210,

211,

137,

140

211,

221

except:-

except

except

130,

132

231

•

Chain

•

Chain

•

Chain

(with

•

Chain

•

Chain

Special

cutter

cutter

cutter

air

blower)

cutter

cutter

Parts

301148

301000

301122

301515

301149

Mid-position

KS002

(KSE-20)

*

★

★

KS006

(KSE-60)

Inlet

Type

Rear

Suction

KS003

(KSE-30)

KS004

(KSE-30A)

KSOO

★

★

Inlet

5

Type

E56

All

models

•

131 / 512-253

263/512-253,263

KS

Device

except

•

Chain

Component

Select

according

erating

•

When

using

equipped

device

must

cutter

t

Parts

Ancillary

the

correct

to

your

the

an

be

used.

power

etc.

chain

air

conditions

with

301015

Devices

ancillary

blower a Venturi

devices

supply,

cutter

op-

KS004

★

Blower

lOOV

200V

lOOV

200V

Venturi

Waste

Dust

50Hz

50Hz

60Hz

60Hz

device

receptacle

drum

KSOO

(KSE-70)

500007

500008

500005

500006

300207

300305

303747

7

—

32

—

Page 34

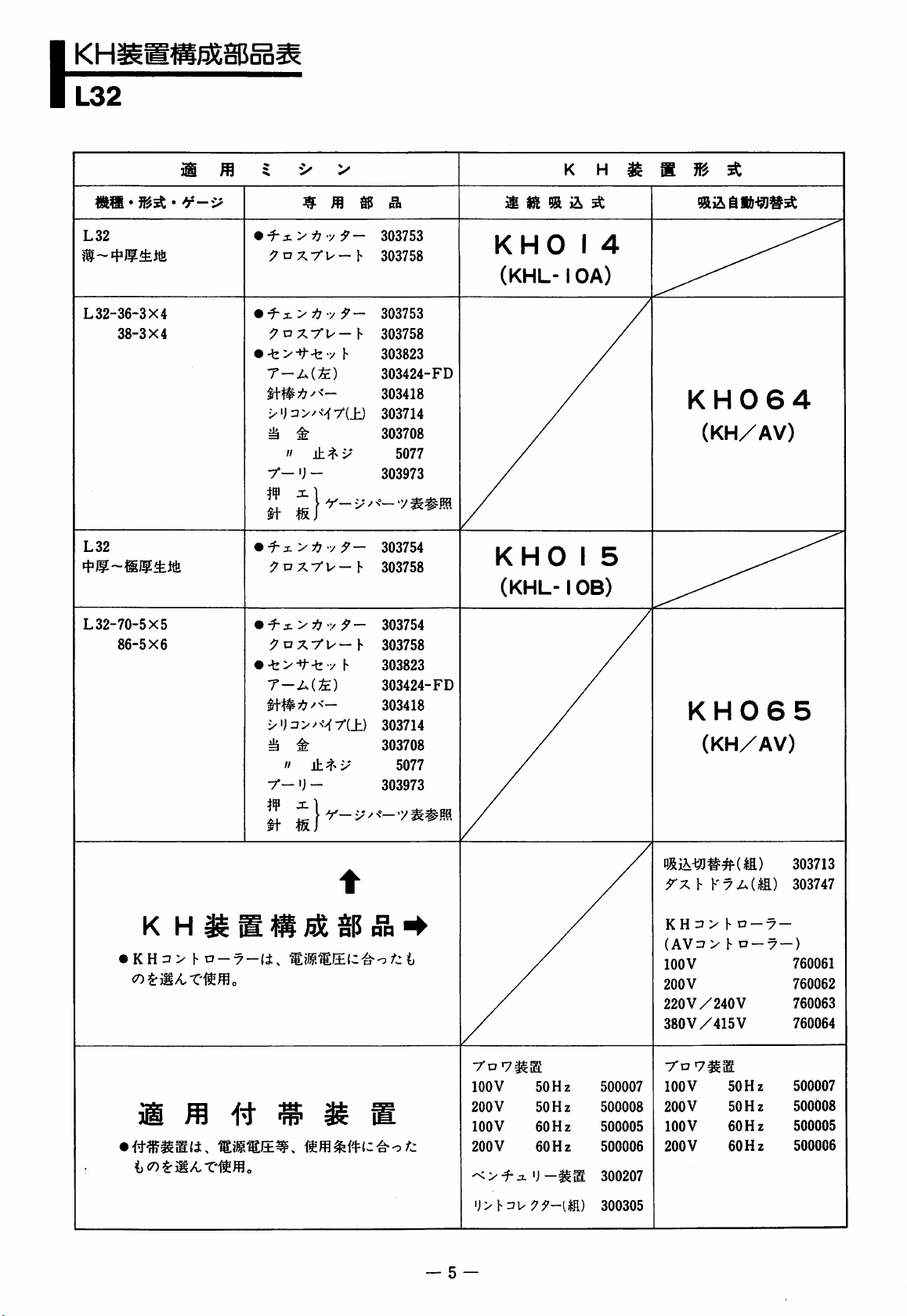

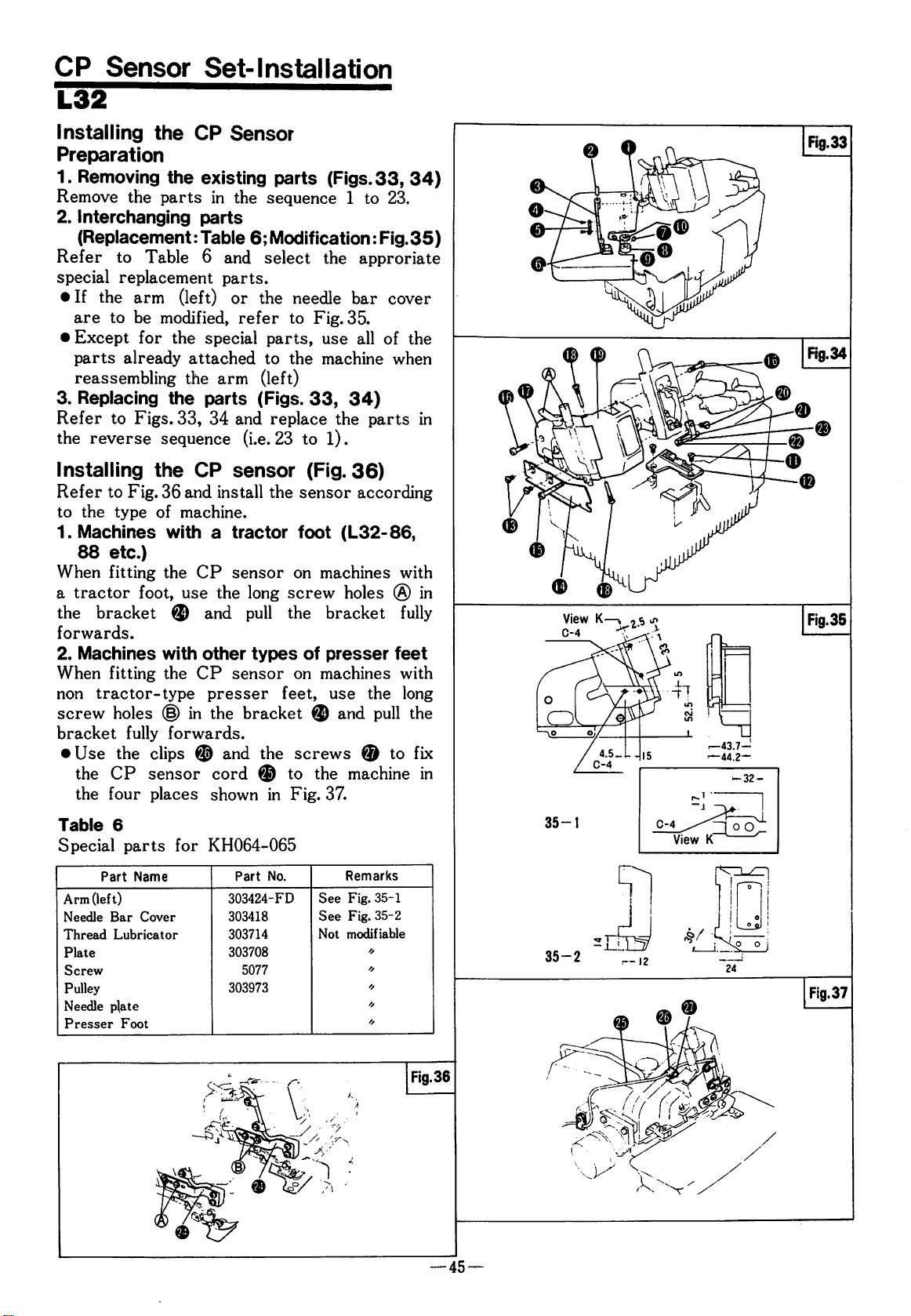

KH

L32

DEVICE-COMPONENT

PARTS

LIST

KH

Device-Model

Number

Machine

L32

Light

to

materials.

L32-36-3X4

38-3X4

L32

Medium

weight

materials.

L32-70-5X5

86-5X6

medium

to

extra

Model

weight

heavy

Special

•

Chain

Cloth

•

Chain

Cloth

•

Sensor

Machine

Needle

Silicone

Clamp

Clamp

Pulley

Presser

Needle

•

Chain

Cloth

•

Chain

Cloth

•

Sensor

Machine

Needle

Silicone

Clamp

Clamp

Pulley

Presser

Needle

Parts

cutter

plate

cutter

plate

set

arm

(left)

bar

cover

pipe

(upper)

screw

foot i Ref.

plate ' parts

cutter

plate

cutter

plate

set

arm

(left)

bar

cover

pipe

(upper)

screw

foot i Ref.

plate ' parts

303753

303758

303753

303758

303823

303424-FD

303418

303714

303708

5077

303973

to

Gauge

list

303754

303758

303754

303758

303823

303424-FD

303418

303714

303708

5077

303973

to

Gauge

list

Continuous

Type

KHO

Suction

1

(KHL-10A)

★

K H 0 1 5

(KHL-10B)

★

4

Automatic

Switching

Vacuum

Type

★

K H 0 6 4

(KH/AV)

★

K H 0 6 5

(KH/AV)

t

KH

Device

•

Select

power

Ancillary

•

Select

power

Component

the

correct

supply.

Devices

the

correct

supply,

operating

KH

controller

ancillary

devices

conditions

Parts

according

according

etc.

to

to

your

your

Blower

lOOV

200V

lOOV

200V

Venturi

Waste

33

*

50Hz

50Hz

60Hz

60Hz

device

receptacle

500007

500008

500005

500006

300207

300305

Changeover

assembly

Dust

drum

KH

controller

(AV

controller)

lOOV

200V

220V / 240V

380V/415V

Blower

lOOV

200V

lOOV

200V

50Hz

50Hz

60Hz

60Hz

valve

303713

303747

760061

760062

760063

760064

500007

500008

500005

500006

Page 35

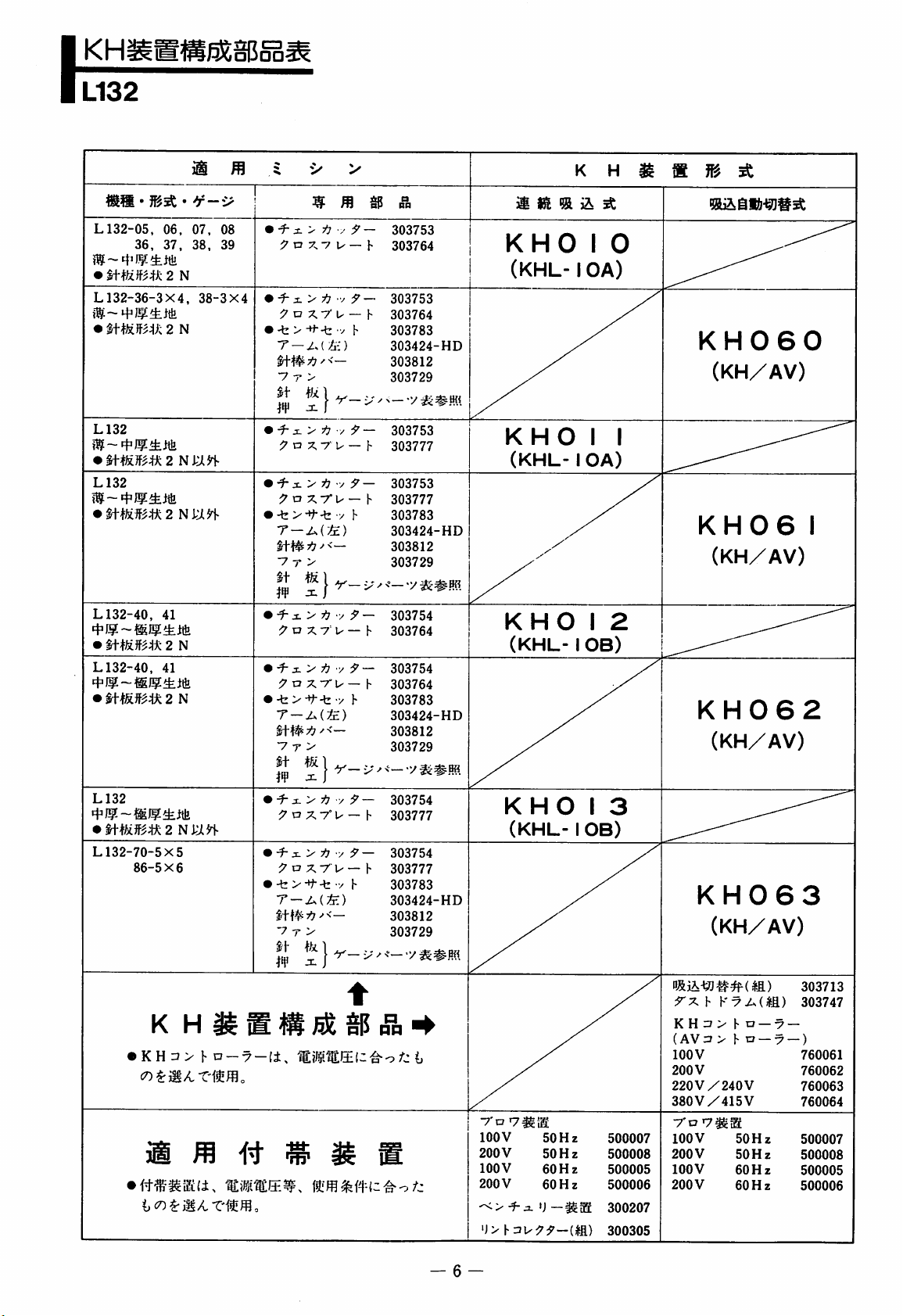

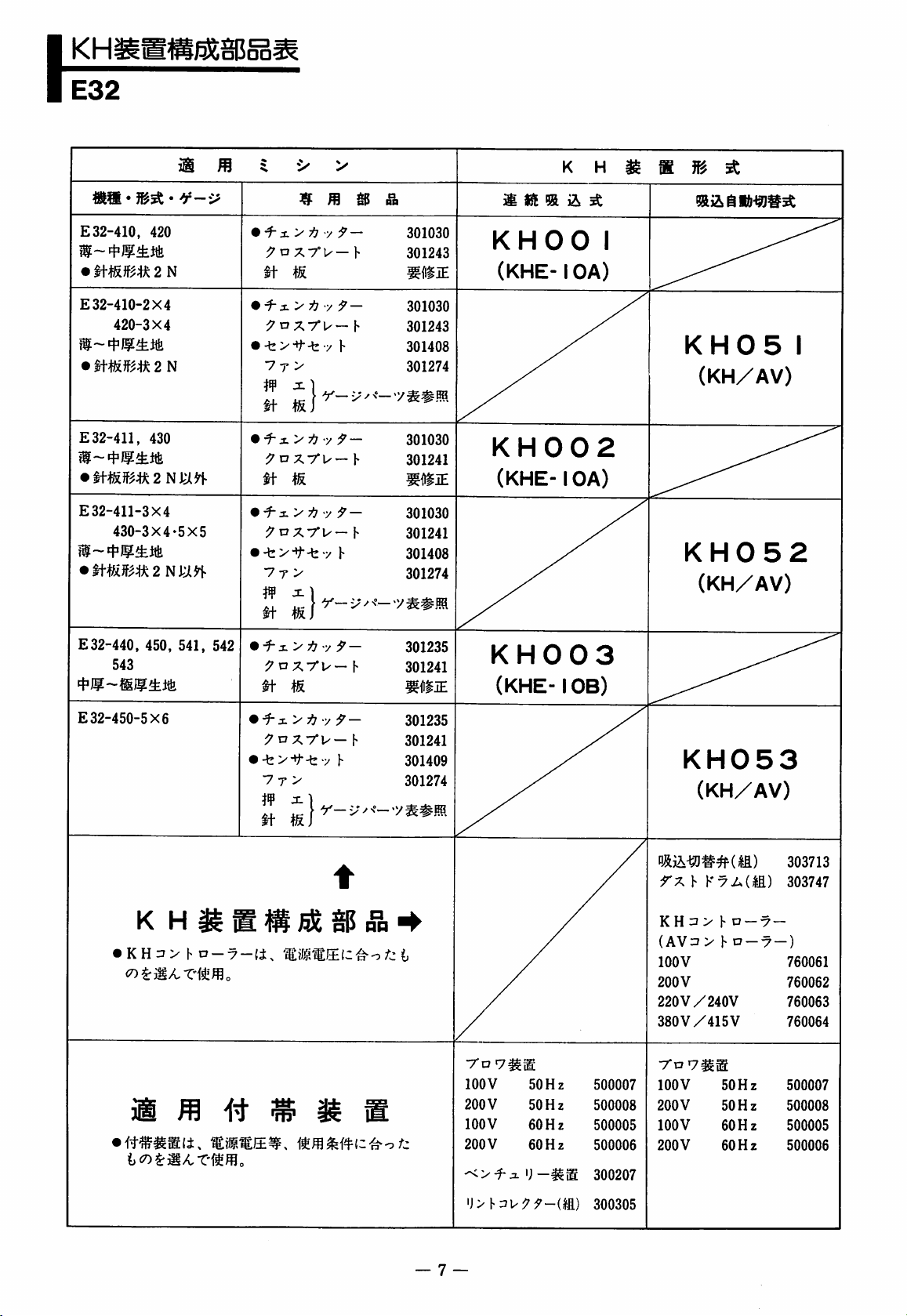

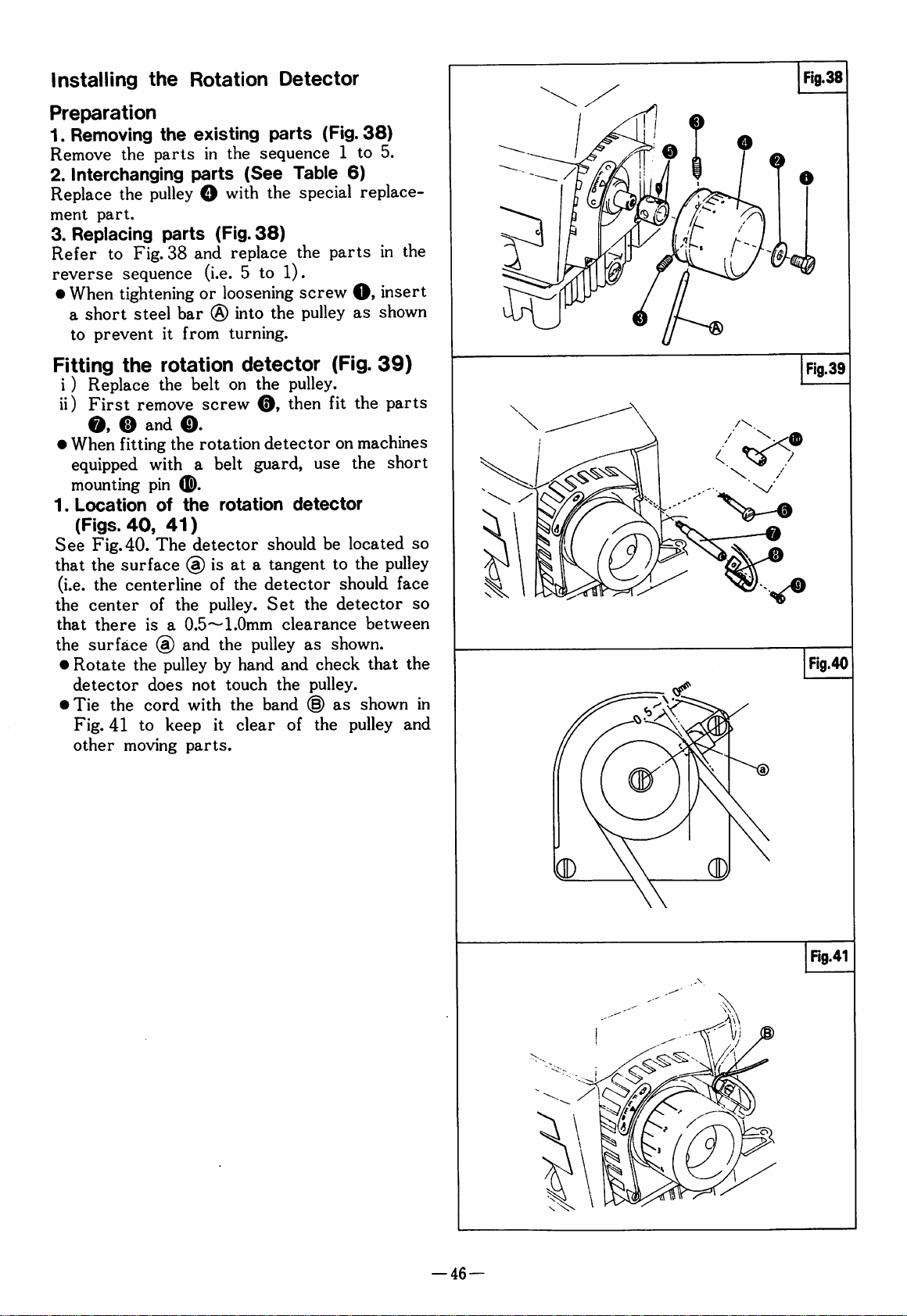

DEVICE-COMPONENT

Machine

Model

Special

PARTS

Parts

LIST

KH

Continuous

Type

Device-Model

Suction

Automatic

Switching

Number

Vacuum

Type

E32-410,

Light

to

materials.

•

Machines

needle

E32-410-2X4

420-3X4

Light

to

materials.

•

Machines

needle

E32-411.

Light

to

materials.

•

Machines

type

needle

E32-411-3X4

430-3X4-5X5

Light

to

materials.

•

Machines

type

needle

E32-440,

543

Medium

weight

materials.

420

medium

with

plates.

medium

with

plates.

430

medium

without

plates.

medium

without

plates.

450,

to

extra

weight

2N

weight

2N

weight

weight

541,

type

type

2N

2N

542

heavy

Chain

Cloth

Needle

•

Chain

Cloth

•

Sensor

Fan

Presser

Needle

•

Chain

Cloth

Needle

•

Chain

Cloth

•

Sensor

Fan

Presser

Needle

•

Chain

Cloth

Needle

cutter

plate

plate

cutter

plate

set

foot

plate

cutter

plate

plate

cutter

plate

set

foot

plate

cutter

plate

plate

Ref.

parts

.

Ref.

to

to

parts

301030

301243

modification

required

301030

301243

301408

301274

Gauge

list

301030

301241

modification

required

301030

301241

301408

301274

Gauge

list

301235

301241

modification

required

K H 0

0

(KHE-10A)

K H 0 0

(KHE-10A)

KH003

(KHE-10B)

1

K H 05

(KH/AV)

1

2

K H 0

(KH/AV)

5

2

E32-450-5X6

KH

Device

•

Select

the

power

supply.

Ancillary

•

Select

power

Devices

the

correct

supply,

Component

correct

KH

ancillary

operating

•

Chain

cutter

Cloth

plate

•

Sensor

Fan

Presser

Needle

plate

Parts

controller

conditions

according

devices

according

etc.

set

fool

.

Ref.

parts

to

to

to

Gauge

list

your

your

301235

301241

301409

301274

Blower

lOOV

200V

lOOV

200V

Venturi

Waste

50Hz

50Hz

60Hz

60Hz

device

receptacle

500007

500008

500005

500006

300207

300305

K H 0 5 3

(KH/AV)

Changeover

asembly

Dust

KH

controller

(AV

lOOV

200V

220V/240V

380V/415V

Blower

lOOV

200V

lOOV

200V

valve

drum

controller)

50Hz

50Hz

60Hz

60Hz

303713

303747

760061

760062

760063

760064

500007

500008

500005

500006

—

34

Page 36

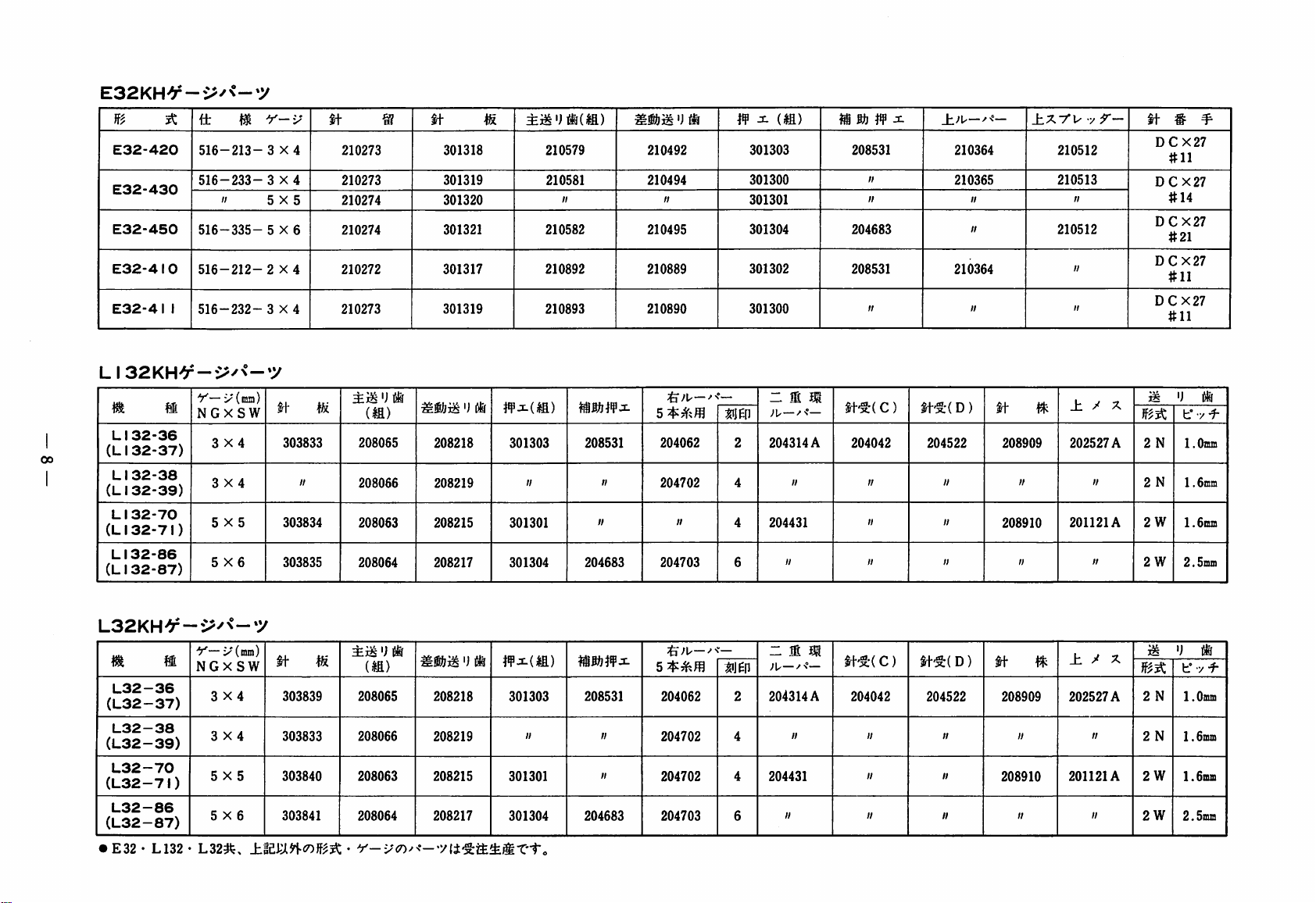

GAUGE

E32KH

PARTS

FOR

E32

KH

AND

L32

KH

MACHINES

E32-420

E32-430

E32-450

E32-410

E32-411

E32-420

E32-430

E32-450

E32-410

E32-411

L32KH

Type

Type

Spec.

Gauge

516—213—

516-233- 3 X4

516-335- 5 X6

516-212-

516-232- 3 X4

Presser

3X4

5X5

2X4

foot

301303

301300

301301

301304

301302

301300

comp.

Needle

210273

210273

210274

210274

210272

210273

Fabric

208531

>/

204683

208531

f/

clamp

guard

Needle

301318

301319

301320

301321

301317

301319

Upper

210364

210365

o

ff

210364

//

plate

looper

Main

feed

dog

210579

210581

'/

210582

210892

210893

Spreader

210512

210513

'f

210512

<>

comp.

Diff.

feed

210492

210494

210495

210889

210890

Needle

DCX27

DCX27

DCX27

DCX27

DCX27

DCX27

dog

❖

size

#11

#14

#14

#21

#11

#11

Type

L32-36

{L32-37)

L32-38

(L32-39)

L32-70

(L32-71)

L32-86

(L32-87)

Type

L32-36

(L32-37)

L32-38

(L32-39)

L32-70

(L32-71)

L32-86

(L32-87)

Guage

NGXSW

3X4

3X4

5X5

5X6

Double

chain

204314A

204431

(nun)

looper

❖

Needle

plate

303839

303833

303840

303841

Needle

(f

ront)

204042

'r

'/

guard

Main

dog

208065

208066

208063

208064

feed

comp.

Needle

(rear)

204522

>/

'/

Diff.

dog

guard

feed

comp.

208218

208219

208215

208217

Needle

208909

'f

208910

Presser

foot

301303

301301

301304

clamp

comp.

❖

Upper

202527A

201121A

Fabric

guard

208531

204683

knife

Upper

loo]

aer

(5-thread)

204062

'f

f/

Pattern

2N

2

N

2W

2W

204702

204702

204703

Feed

Mark

2

4

4

6

Pitch

l.Ghtm

l.Goun

1.6min

2.5imn

—

35

—

Page 37

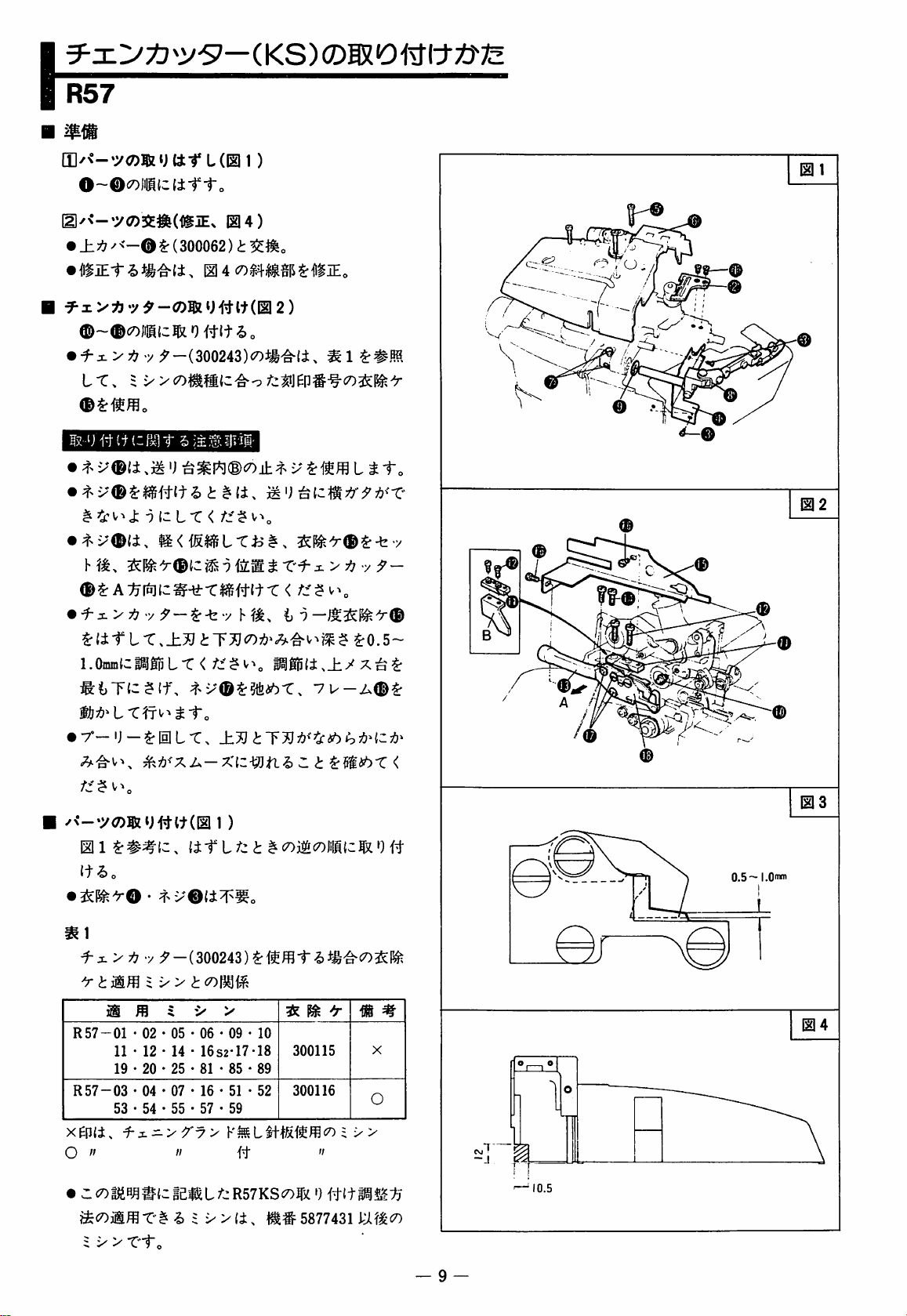

KSChain_Cuttei^^^

R57

Preparation

1.

Removing

Remove

2.

Interchanging

•

Replace

part

(Part

•

If

the

used

then

shown

the

the

parts

the

top

No.

special

in

replacement

modify

Fig.

4.

existing

in

Parts

cover O with

parts

the

sequence 1 to

(Modification,

the

300062).

part

the

existing

(Remove

machine

the

hatched

(Fig.

1)

Fig.

replacement

is

not

9.

4)

being

arm

as

portion.)

Installing

Install

•

When

300243),

the

of

your

Installation

•

For

screw.

•

When

is

no

•

Temporarily

guard

the

Chain

the

parts

in

installing

use

the

number

corresponding

machine.

Hints

screw

use

tightening

sideways

play

tighten

®,

push

the

direction ® until

the

fabric

guard ® and

screw ® securely.

•

After

fabric

overlap

~

upper

screw 0 and

the

•

Rotate

the

and

fitting

guard ® once

of

the

1.0mm.

To

knife

overlap

the

upper

that

and

they

clamp

is

pulley

the

upper

make

then

0.5—1.0mm.

lower

cut

Cutter

the

sequence

the

chain

fabric

screw

guard ® marked

(See

the

feed

Table

®,

in

the

screw

chain

it

comes

chain

again,

and

this

adjustment,

all

the

move

by

hand

blades

the

thread

(Fig.

cutter

to

the

2)

10

to

(Part

model

1).

bar

guide

check

feed

(D,

that

bar.

fit

the

cutter ® in

into

contact

then

tighten

cutter,

lower

way

the

remove

then

adjust

blades

lower

down,

frame ® until

and

check

engage

smoothly

cleanly.

16.

No.

with

No.

(0)

set

there

fabric

the

with

the

the

the

to

0.5

the

loosen

that

o

0.5~l.0™>

Replacing

Refer

in

•

Table

Relationship

guard

R

R

(X)

(O)

to

the

The

be

installed.

when

Machine

57-01 • 02 • 05 • 06 • 09 • 10

11 • 12 • 14 • 16S2-17-18

19 • 20 • 25 • 81 • 85 • 89

57-03 • 04 • 07 • 16 • 51 • 52

53 • 54 • 55 • 57 • 59

indicates

indicates

Parts

Fig. 1 and

reverse

fabric

1

sequence

guard O and

between

using

model

machines

machines

(Fig.

1)

replace

the

(i.e. 9 to

screw @ need

machine

the

chain

without a chaining

with a chaining

model

cutter

Fabric

guard

300115

300116

land.

land.

existing

parts

1)

and

fabric

(300243)

Remarks

X

O

not

Ml

•

Note

that

mentioned

5877431

—

36

—

0.5

and

the

R57KS

here

after.

only

set

refer

to

up

instructions

machine

No.

Page 38

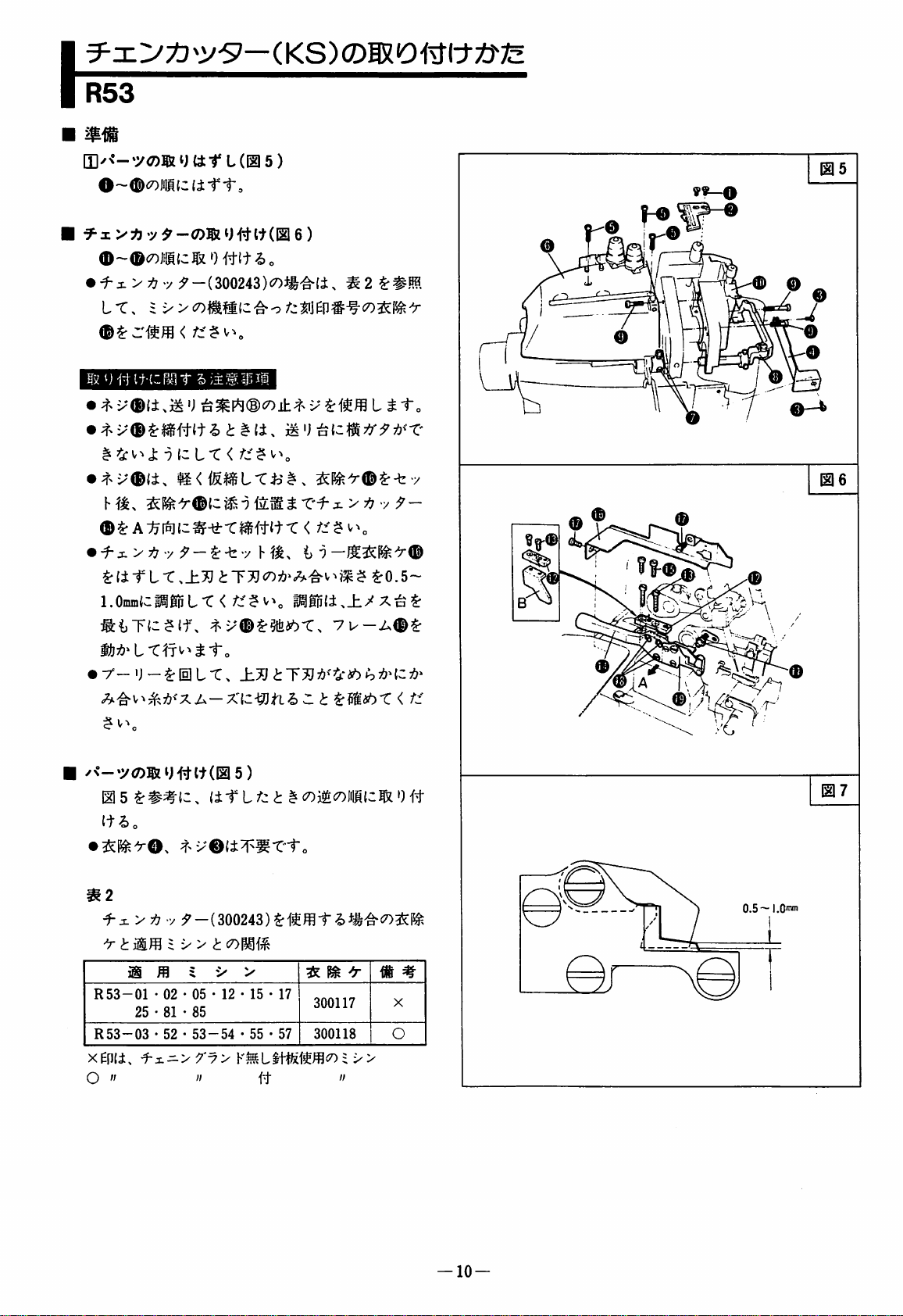

KS

R53

Chain

Cutter-Installation

Preparation

1.

Removing

Remove

Installing

Install

•

•

•

•

the

When

300243) , use

the

number

of

your

Installation

For

screw

screw.

When

is

no

Temporarily

guard

the

the

parts

the

parts

installing

the

corresponding

machine

Hints

tightening

sideways

tighten

®,

push

direction ® until

the

®

•

After

fabric

overlap

~

1.0mm.

upper

fabric

securely.

guard ® and

fitting

guard ® once

of

the

To

make

knife

clamp

screw ® and

the

•

Rotate

the

and

overlap

upper

that

the

and

they

is

pulley

Existing

in

the

Chain

in

the

fabric

use

Cutter

the

sequence

chain

guard ® marked

(See

the

feed

Table

screw

play

in

the

screw

the

chain

it

comes

then

the

chain

again,

upper

then

0.5~

lower

cut

and

this

adjustment,

all

the

move

1.0mm.

by

hand

blades

the

thread

Parts

(Fig.

5)

sequence 1 to

(Fig.

6)

11

to

17.

cutter

to

(Part

the

model

2).

bar

guide

(B)

®,

check

feed

®,

cutter

into

tighten

cutter,

lower

way

the

engage

that

bar.

fit

the

in

contact

the

screw

remove

then

adjust

blades

lower

down,

loosen

frame ® until

and

check

smoothly

cleanly.

10.

No.

with

No.

set

there

fabric

the

with

the

the

to

0.5

the

that

!

Fig.

5

Table

Relationship

guard

R

(X)

(O)

2

between

when

Machine

53-01 • 02 • 05 • 12 • 15 • 17

25.-

R

53-03 • 52 • 53-54

indicates

indicates

using

model

81 • 85

machines

machines

machine

chain

•55-57

without a chaining

with a chaining

model

cutter

Fabric

300117

300118

land.

(300243)

guard

land.

and

Remarks

fabric

X

O

0.5~

I.Oiwn

Fig.

7

—

37

—

Page 39

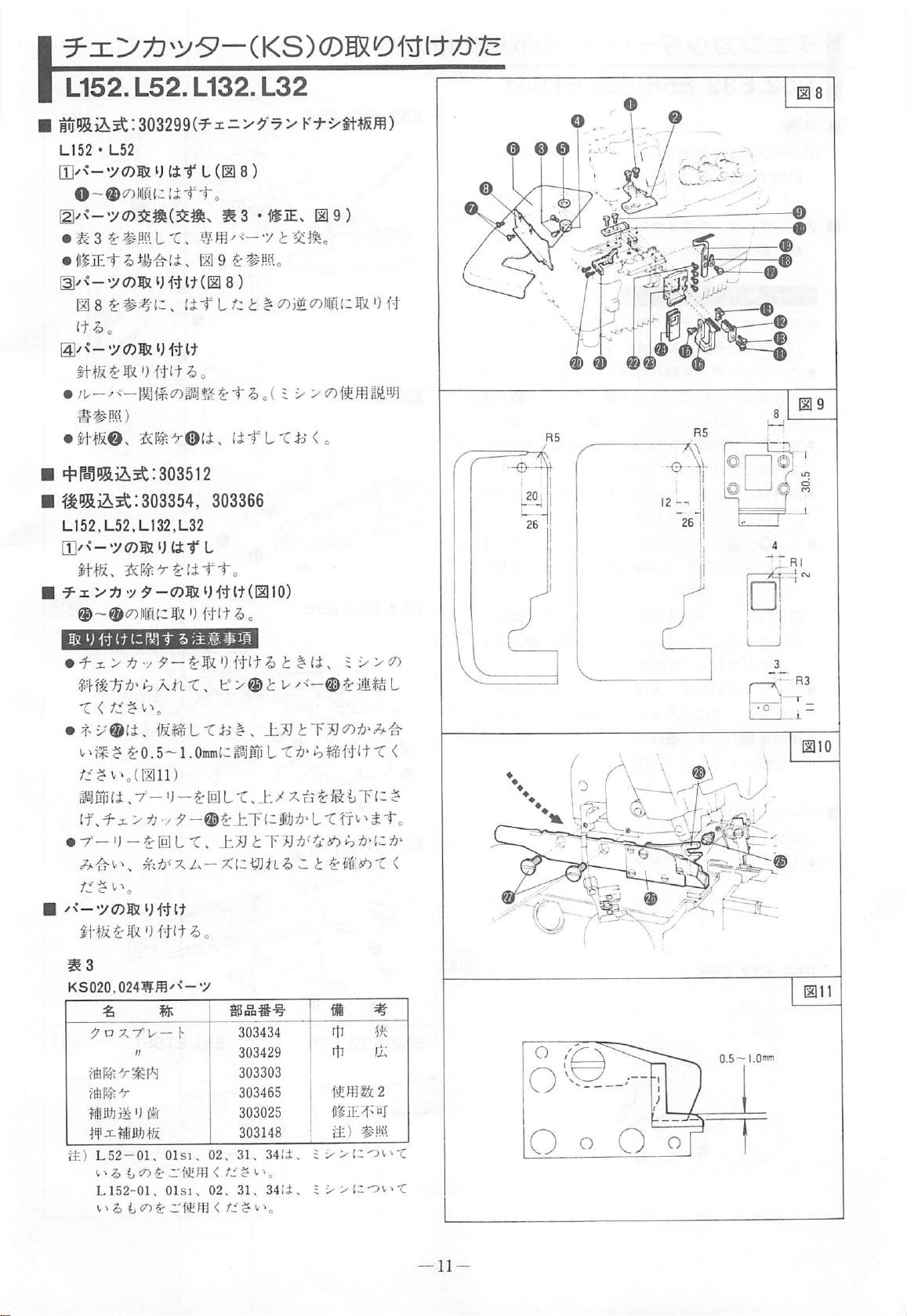

KS

Chain

Cutter-Installation

L52.

Front

for

L52

1.

Remove

2.

•

If

used,

appropriate

•

If

to

3.

Refer

in

•

Make

before

fabric

Mid-position

L32

Suction

Needle

Removing

the

parts

Replacing

Table

the

the

Fig.

Replacing

to

the

reverse

the

3;

Modification:

special

refer

existing

9.

Fig. 8 and

adjustments

replacing

guard

plate

the

to

parts.

parts

parts

sequence

0.

Suction

Inlet

existing

existing

replacement

with

in

the

Type

(303299)

chaining

parts

sequence 1 to

parts

Fig.

parts

Table 3 and

are

to

be

replace

to

the

the

(i.e.

the

looper

needle

24

lnletType(303512)

land

(Fig.

8)

24.

(Replacement:

9)

are

to

be

replace

modified,

existing

to

1).

related

plate @ or

the

refer

parts

parts

the

□

Rear

Suction

L52,

L32

1.

Removing

Remove

Installing

Fit

the

Installation

•

To

locate

cutter

as

shown

•

Lightly

overlap

~1.0mm

To

make

and

bring

position.

down

•

Rotate

and

lower

they

cut

Replacing

Replace

Table

Special

3

the

the

needle

the

parts

until

in

lever ® on

from

the

by

fasten

of

the

before

this

the

Then

the

the

pulley

blades

the

the

the

needle

Parts

InletType(303354,303366)

existing

plate

Chain

the

sequence

Hints

back

the

arrow

the

screws

upper

tightening

adjustment,

upper

knife

move

adjustment

and

engage

thread

existing

plate.

for

KS020

parts

and

the

Cutter

25

pin

of

the

machine

insert

(See

0,

and

lower

them

rotate

clamp

the

chain

is

check

smoothly

cleanly.

parts

and

024

fabric

(Fig.

to

guard.

10)

27.

the

at a slant

Fig.

10).

and

adjust

blades

fully.

(Fig.

the

to

its

lowest

cutter

up

correct.

that

the

and

chain

the

to

0.5

11)

pulley

and

upper

that

0.5-^

I.Onvn

Part

Cloth

plate

Insert

Plate

Oil

Splash

Auxiliary

Presser

Guard

Feed

Foot

Name

Dogs

Uncurler

Part

303429

303303

303465

303025

303148

Number

303434

Remarks

Narrow

wide

Two

Not

See

pieces

modifiable

note

Note

used.

38

that

on

L52-01,

—

Olsl,

02, 31,

34

the

standard

part

may

be

Page 40

KS

Chain

Cutter-Installation

Preparation

1.

Removing

Remove

Installing

Fit

the

Installation

•

Prior

the

oil

•

To

locate

chain

slant.

(See

•

When

301122,

backwards

When

304079-91

•

Lightly

overlap

1.0mm

To

make

bring

the

Then

the

adjustment

•

Rotate

lower

the

thread

•

Use

the

machine

jtlate

©.

the

the

needle

the

parts

in

Hints

to

the

wick

and

(block

the

cutter

installing

mo\'e

blades

from

arrow

301015

in

installing

pull

fasten

of

the

before

this,adjustment,

upper

the

the

pulley

engage

cleanly.

existing

to

existing

plate

Chain

the

sequence O to

installation

pipe

(D)

link 0 on

the

Fig.

the

or

304094-91).

the

direction

Part

it

fully

the

screws

upper

tightening

parts

and

the

Cutter

of

the

as

well

the

back

12).

chain

cutter

A.

Nos.

forwards

0, 0 and

and

lower

them

as

(lever

of

rotate

knife

clamp

chain

is

correct.

and

to

cutter

check

smoothly

screw 0 attached

fasten

the

cloth

fabric

(Fig.

12,13)

®,

tD

chain

the

moving

©)

bush

O.

the

machine

(Part

No.

fully

push

301148,

in

301149

the

direction

adjust

blades

fully

(Fig.

the

pulley

its

lowest

up

and

down

that

the

and

that

plate

guard.

to

®

cutter,

oil

parts.

insert

the

at

a

301000,

it

fully

or

B.

the

to

0.5

~

14).

and

position.

until

upper

and

they

cut

to

the

auxiliary

E52, E32,

E51,

E52, E32,

E56

ETS51

E56 / ./

0

ja

Replacing

Replace

The

needed.

E52, E32,

the

the

needle

fabric

guard

E56

existing

plate.

already

parts

on

the

machine

is

not

Fig.

15

E51,

E52,

ETS51

E32,

I

E56

0.5 ^ I.O'""'

E51,

ETS51

0.5-

I.Onim

o

ov

1

39-

Page 41

KH_Chain_Cutter;^^

L32

Preparation

1.

Removing

Remove

plate.

2.

Interchanging

(Replacement:

•

If

the

be

used,

•

If

the

refer

the

the

needle

special

replacement

refer

existing

to

Fig.

16.

existing

plate,

fabric

existing

Table

to

cloth

parts

4;

Table

plate

parts

guard

Modification

cloth

4.

is

to

and

Fig.16)

plate

be

modified,

cloth

is

to

Installing

Fit

the

Installation

•

When

be

aligned

•

Prior

oil

the

parts.

•

The

adjusted

fitting

the

chain

clearance

well

and

Note

be

installed

surface

surface

•

To

the

overlap

the

parts

pin O is

as

to

the

oil

wick

position

by

the

needle

cutter

around

as

the

needle

too,

that

is

of

adjust

the

clothguide

is

0.3mm

adjustment,

upper

knife

screw O and

it

is

correctly

•

Rotate

and

they

the

lower

cut

the

Chain

in

the

Hints

fitted,

shown

installation

and

of

loosening

is

clearance

plate

the

in

such a way

0.5mm

the

needle

overlap

Cutter

sequence 1 to

the

in

Fig.

of

pipe

as

the

chain

the

plate

and

in

the

the

cloth

between

should

Cloth

be

plate

higher

plate

of

plate 0 again.

(See

rotate

to

its

highest

move

adjusted.

pulley

blades

thread

Fig.

the

pulley

position.

the

lower

and

check

engage

cleanly.

(Fig.

driver

17)

6.

slot

17.

the

chain

well

as

the

cutter

should

screw O after

cloth

plate.

correct

position

plate

guide 0 as

the

0.4mm

(See

cloth

guide 0 should

that

its

than

the

(See

the

20).

Fig.

blades,

The

correct

To

make

and

move

Then

blade 0 until

that

the

smoothly

and

should

cutter,

moving

be

When

the

plate

Fig.18).

upper

upper

19).

remove

this

the

loosen

upper

that

Table

Special

Model

L32

4

cloth

Machine

No.

plates

Model

Needle

2N

~3W

Plate

for

KH

Cloth

Part

303758

device.

Plate

No.

Remarks

Fig.16

—

40

—

(D

—0.3"*"

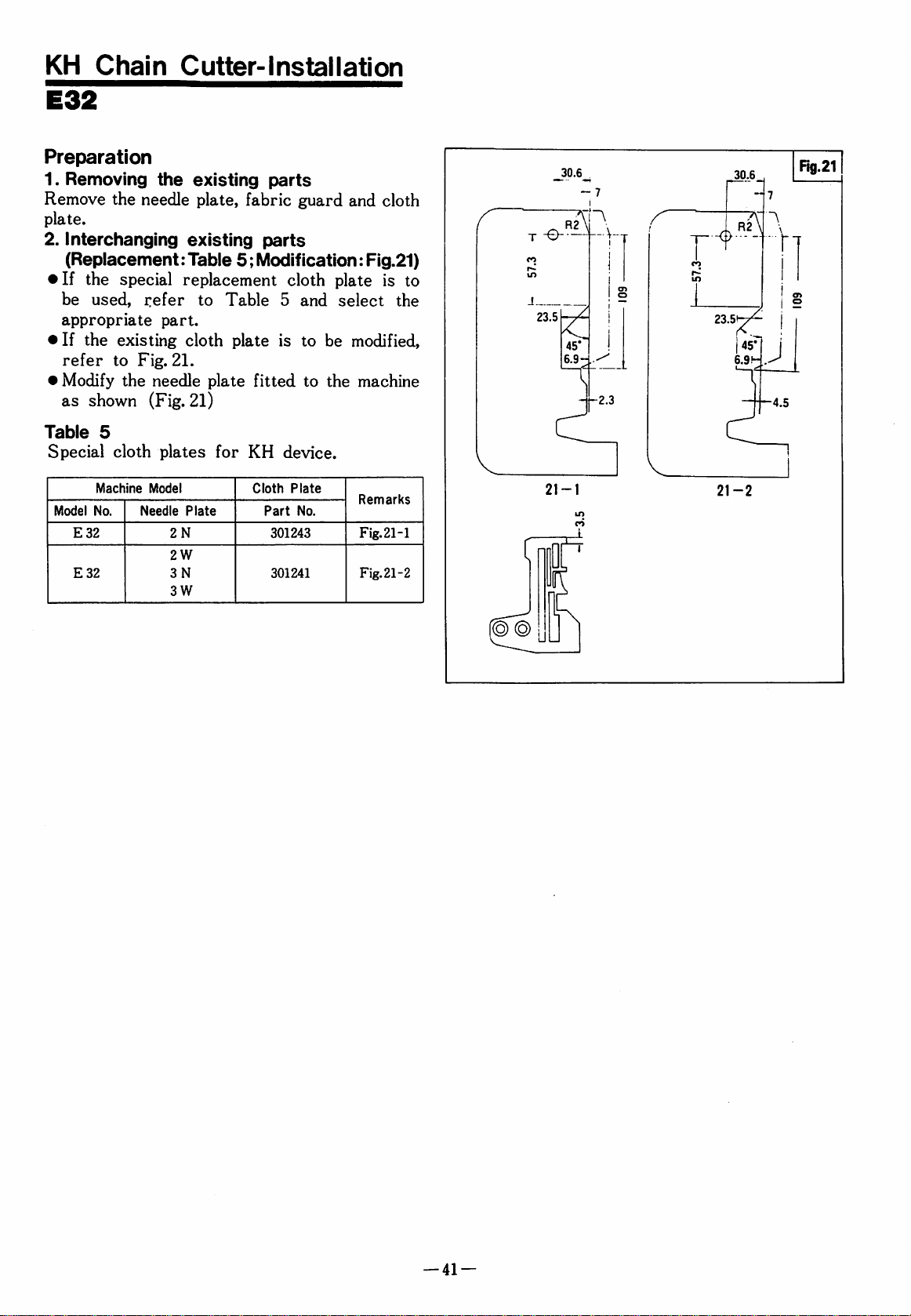

Page 42

KH

Chain

Cutter-lnstailation

Preparation

1.

Removing

Remove

the

needle

the

plate.

2.

Interchanging

(Replacement:

•

If

the

special

be

used,

appropriate

•

If

the

refer

•

Modify

as

shown

Table

Special

Model

No.

E32

E32

refer to

existing

to

Fig.

the

needle

(Fig.

5

cloth

Machine

Model

Needle

existing

plate,

fabric

existing

Table

5;

replacement

Table 5 and

part.

cloth

plate

21.

plate

fitted

21)

plates

2N

2W

3N

3W

Plate

for

KH

Cloth

parts

guard

and

cloth

parts

Modification:

cloth

is

to

to

device.

Plate

Part

No.

301243

301241

Fig.21)

plate

select

be

modified,

the

machine

Remarks

Fig.21-1

Fig.21-2

is

the

to

23.5

21-1

c

30.6

45*

6.9

30.6

-

7

i

V-r

-<>

R2

r

23.5

|45*

6.9!-

l

-2.3

Rg.21

t

1

.J

-4.5

c

21-2

—

41

—

Page 43

Installing

Fit

the

the

parts

in

Chain

the

Cutter

sequence 1 to

(Fig.

22,

8.

23)

f89Vi3--r

Installation

©When

that

©Prior

oil

parts.

•

The

pin O is

it

locates

to

the

oil

position

adjusted

cloth

plate

chain

cutter

clearance

well

as

the

and

needle

Note

too,

be

installed

surface

surface

©To

the

of

adjust

cloth

adjustment

this

adjustment,

the

upper

loosen

0

•

Rotate

and

they

•

Use

machine

screw ® and

until

it

the

lower

cut

the

to

Hints

fitted,

in

the

the

installation

wick

and

pipe

of

the

after

that

is

the

existing

fitting

by

loosening

is

in

around

clearance

plate

the

the

plate

is

knife

is

blades

the

should

the

cloth

in

such a way

0.5mm

needle

overlap

guide O again.

0.3mm

rotate

to

its

correctly

pulley

fasten

and

engage

thread

screw 0 attached

the

fasten

center

of

as

well

chain

the

cloth

between

higher

(See

cleanly.

cutter

the

needle

screw

correct

plate

be

0.4mm

plate

plate

of

the

Fig.

the

highest

move

adjusted.

check

smoothly

auxiliary

screw 0 so

of

the

long

hole.

the

chain

as

®.

position,

the

(See

guide O should

that

than

(See

blades,

The

26).

pulley

position.

the

that

cutter

the

moving

should

plate

When

be

and

the

the

guide O as

cloth

plate

Fig.24).

its

upper

the

upper

Fig.

25).

remove

correct

To

make

and

move

Then

lower

plate

the

and

®.

blade

upper

that

to

the

42

Page 44

Installing

the

Waste

Receptacle

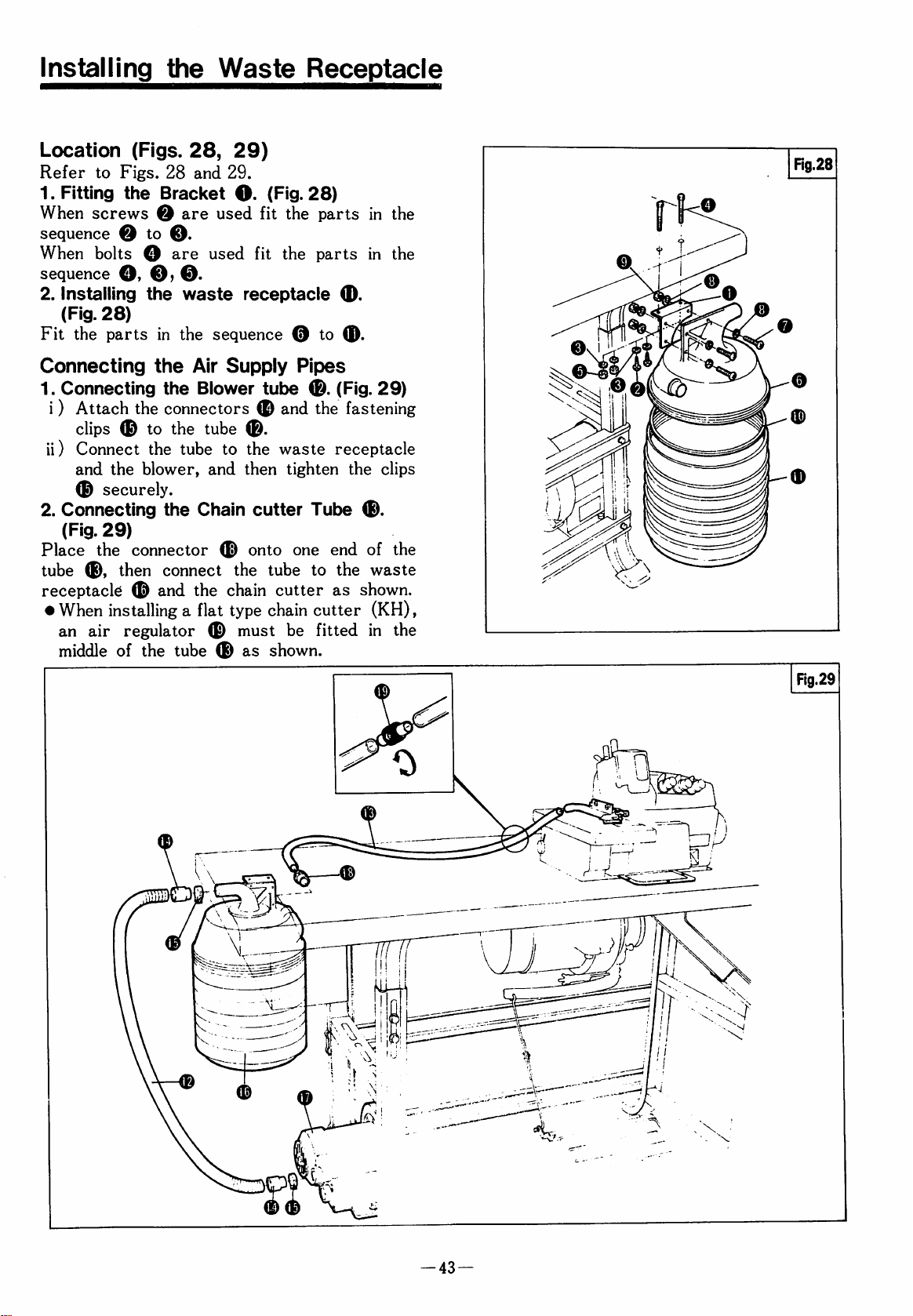

Location

Refer

1.

Fitting

When

sequence O to

When

sequence

2.

Installing

(Fig.

Fit

the

Connecting

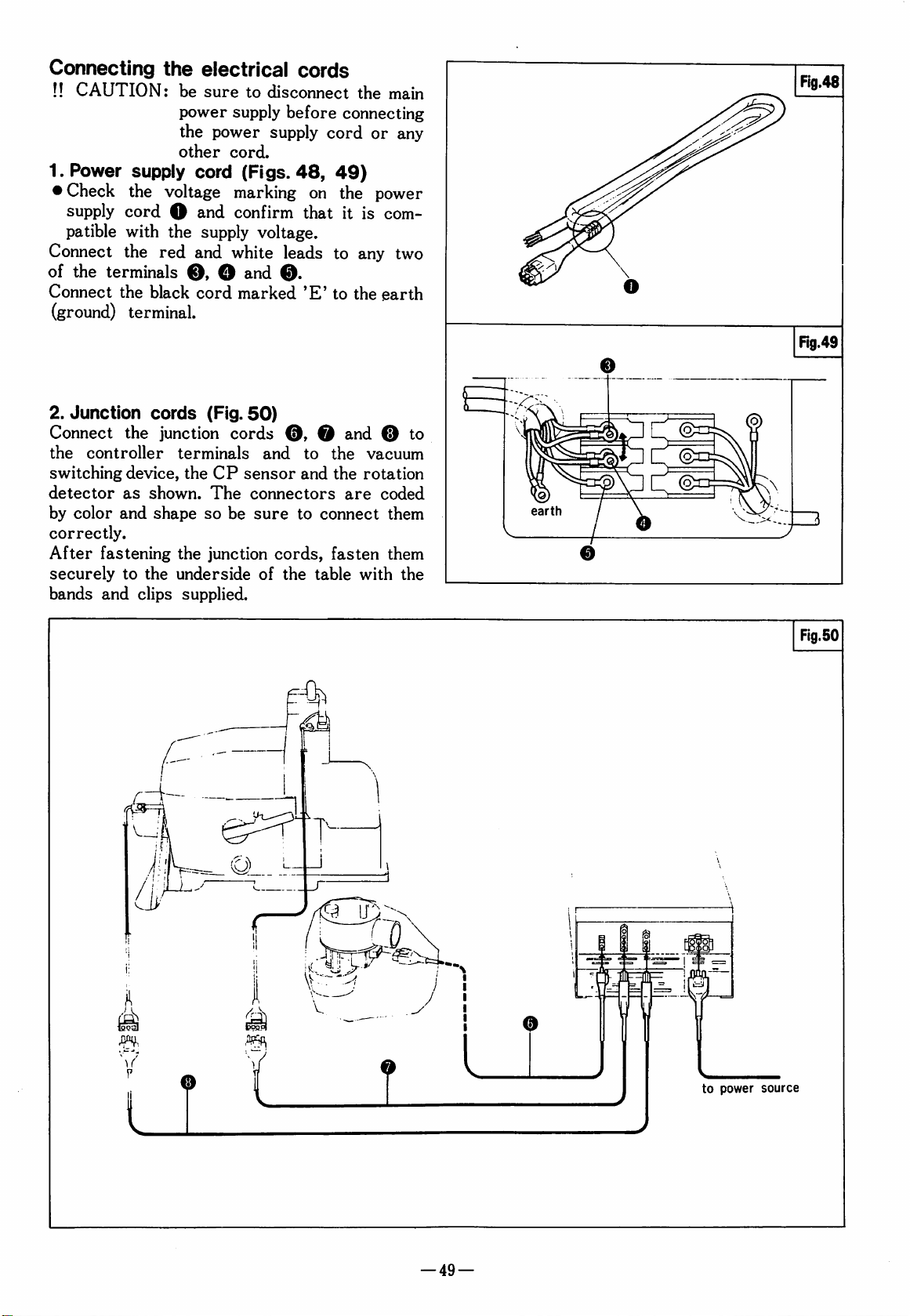

1.

Connecting

i)

Attach

clips 0 to

ii)

Connect

and

©

2.

Connecting

(Fig.

Place

tube

(Figs.

to

Figs.

28

the

Bracket

screws @ are

o.

bolts O are

O,

o,0.

the

28)

parts

in

the

the

the

the

connectors

the

the

tube

the

blower,

securely.

the

29)

the

connector

0,

then

connect

receptacle © and

•

When

an

middle

installing

air

regulator © must

of

the

a

tube

28,

29)

and

29.

O.

(Fig.

used

fit

used

fit

waste

Air

the

receptacle

sequence @ to

Supply

Blower

tube

and

Chain

flat

tube

0.

to

the

then

cutter

onto

the

tube

chain

type

chain

as

shown.

cutter

28)

the

parts

the

parts

0.

Pipes

0.

(Fig.

and

the

waste

tighten

receptacle

Tube

one

end

to

the

as

cutter

be

fitted

in

the

in

the

0.

29)

fastening

the

clips

0.

of

the

waste

shown.

(KH),

in

the

Rg.28

-43

—

Page 45

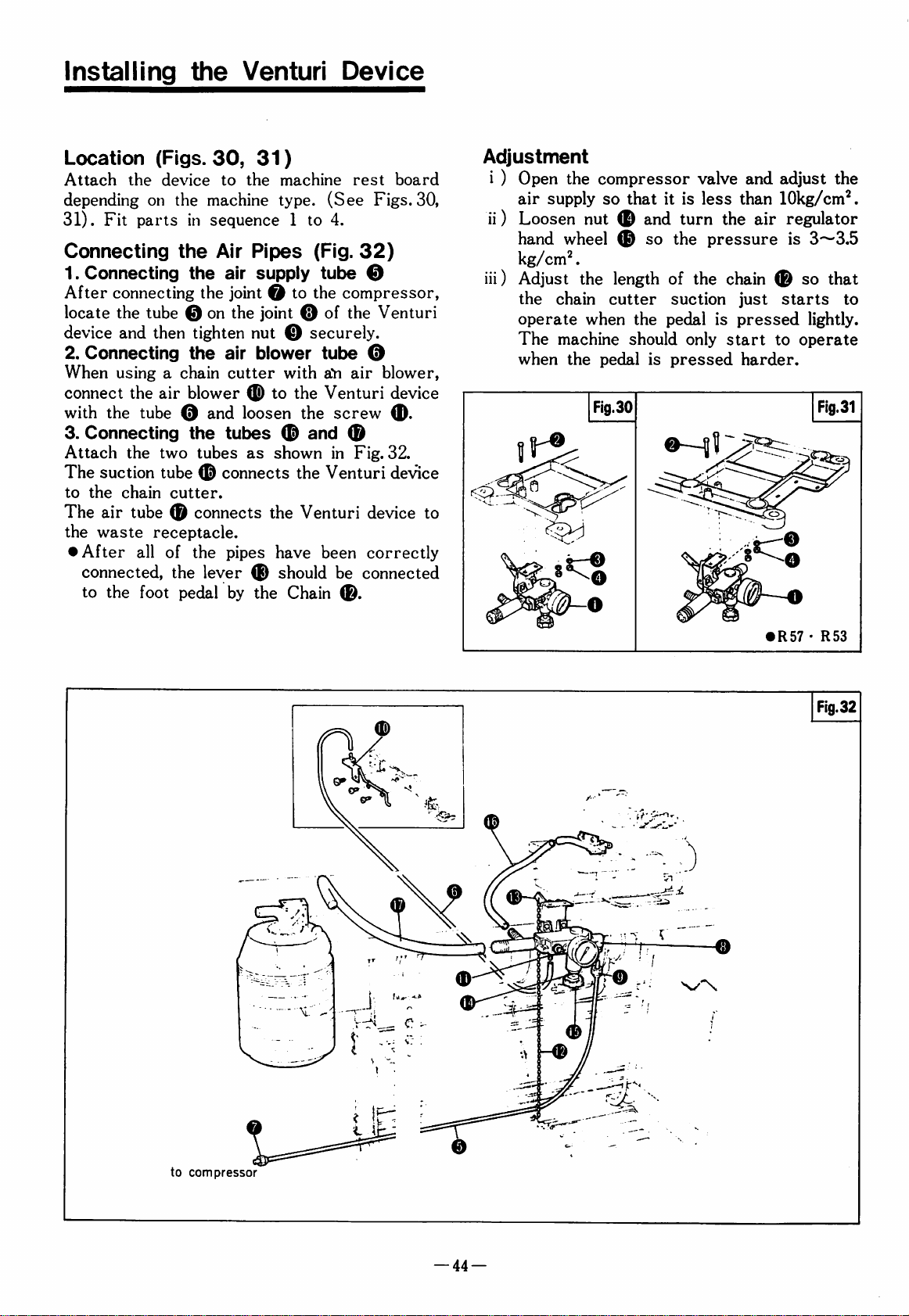

Installing

the

Venturl

Device

Location

Attach

depending

31).

Fit

(Figs.

the

device

on

parts