Page 1

INSTRUCTIONS

FW600

Cat.

No.

9A2009

A

'j

With

cover

December,

thread)

1984

FW400

High

First

edition

Second

(issued

edition

(issued

speed,

in

December,

in

2-

June,

(JtSlft

or

3-needle

1984)

1985)

'j

Without

Interlock

W

liS

(1984^^12

(1985:^6

cover

thread)

machines

UJ

ILL

t

cox

Page 2

1./n:;i. h ^yf-(±,

2. 5 y

>^-

0

#{tr

</;

$

5 y >

$ y >(7)#f^,

^rM?c75±.

^1*0

^:fo\

^(nLi3^rzVkiV\z, ^ y

tz<rz^\z^

C(7)|5&B^#li$g-ttTv^a 5 y

f^^co

>

(I^+5>rgeJt<

L ^ -tt^;^>^^

2.lt{ijEl

3.^l±IEl < ®$nT<-^^-r;6^o

4.:S

e$^30mm<" h 7

5.^

^

6.

<IXi'H^!t

bnrt-^^i-Tis

yJ^^'V'X

5 y X-An/iiScoM

^

iU r - y CO 2 ^^cO^cOPbI

L

^^^coifi^ n r c ^ ^

<

is

1

9

:fe'®M'-^i^Li-ro

V^ x 1"

(I

-fc 0 X

tJj'o

T

Hi:

A

3.r-7';i<'^li^n§

^^aJor

<

(h

^{±^

§li>

- ^ -

$

<-^0

yf-gr^oT,

q::.!:

tcff o T

vi ^ C

mm±(o^m

1. c i

(±

b'

46

CO 1 t!; H TbI

2.

li b iOT 5 y

^

A'r>

fz ^ y

$

CS

3. $ y

>;'^(i^

PbIC,

-9T<

>

>

5^/^

4.f^Ci{±b46T;!>^b

^Hf

b

A^I-t&^^T < Ai^cio

9

V t ^

^j-

1

liN

i:

yf-

7f-|:^oT<

<i:

(h ^ b

li.

531

(i'b

T < /i

oT*.^

co

<

^iS ^ b T <

b

juy— y (0 2 Tpccoi^co

^ > >I^D|jCOift

L

i

f^mtm-otzmz

1. 5 y > ^»LT<

2. ^ 4311

L T <

fnl

v^o

^ o /i

T-r

;!)^ C i

l+IS>

-"l--

5.^(±,

^>5ib®cOJi0Ib

<5ibT<

Page 3

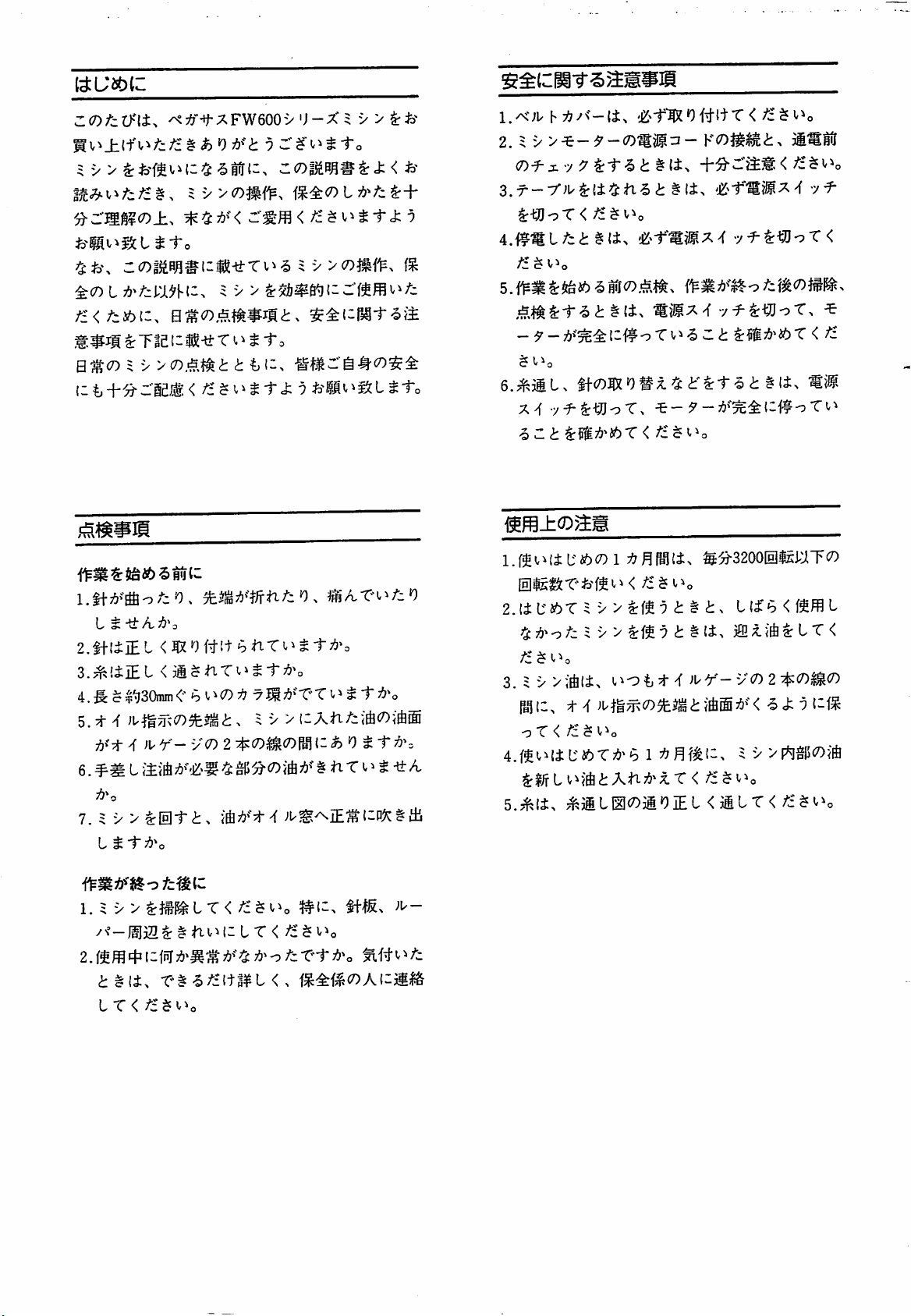

24*30'

la

CO

I

1X1

=E—^—

'

2@400W^7

Vi < /£ $ v^o

2.^";uh(i>

M§yv^;uh

{--^O

V^O

—

5i

rtfS^CD-^—^ ~ 7^—^J

^1

•;

-

—

7f-^-5'-|rfeM

;!?>b 5 V

<

5

nin#.{i

fz

i;

m

^

i^XDUm^ t ^-^-7 - 'J-t<Dmi^

V

><7)^:9'lEllEtS:

2

,900

3

,200

3

,400

^

3

3

4

4

4

,600

,800

,000

,200

,500

^-9-

6 0 Hz

5

0

5

5

6

0

6 5 ,

6

5

7

0

7

5

8

0

-f-

•;

-

5 0 Hz

6

6

7

7

8

8

9

9

m)

(mm)

0

5

0

5

0

5

0

5

-2-

Page 4

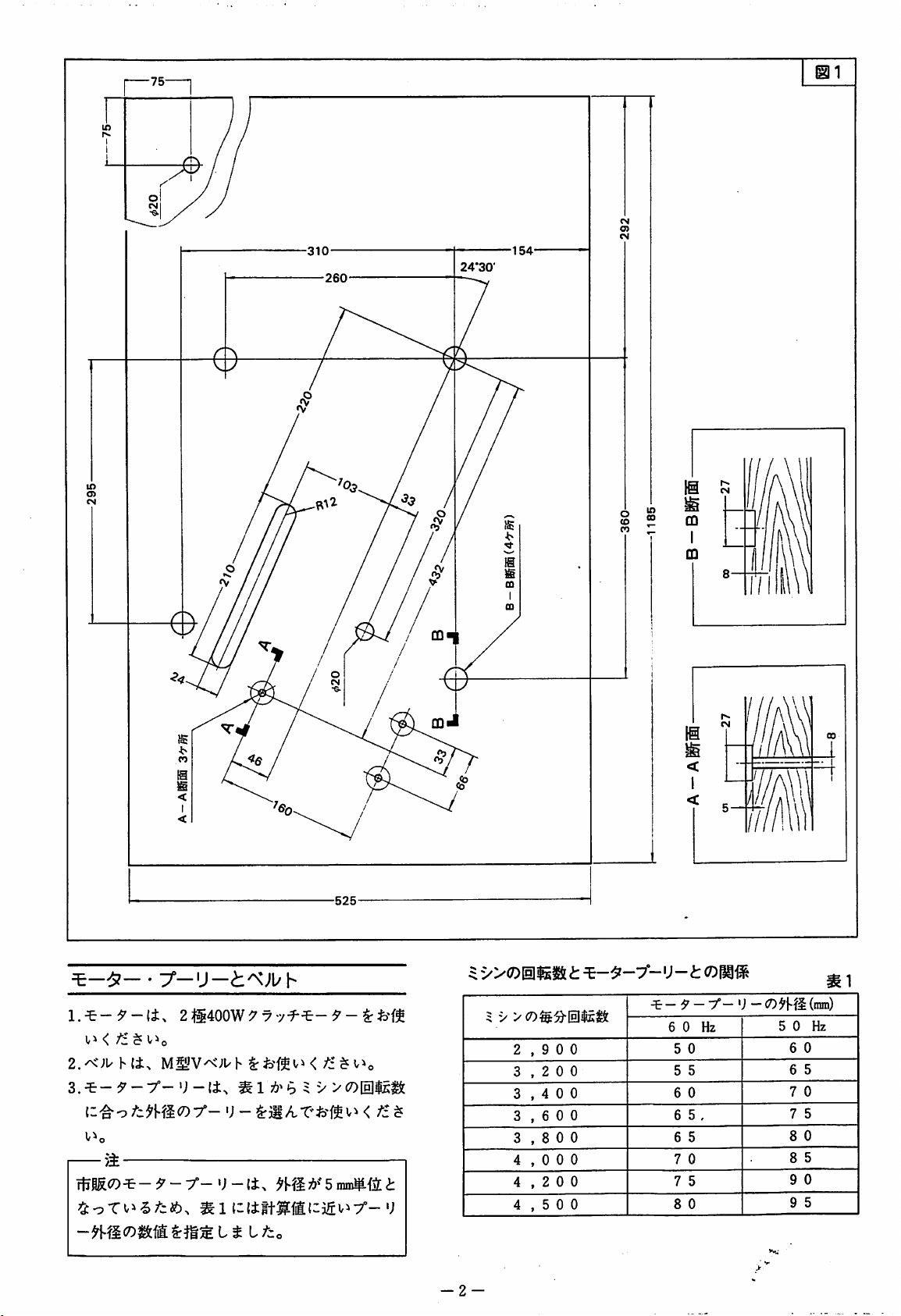

^

~

FW600'>U-X5

t

^i~o

V

^fi®50imn<7)T--/

0

2.ID 2 !:##{-.

<fz^

v^o

3.123

<

—

/i

4.12 4 ^##(-^

5.12 5 ^##1-.

(tr

<

6.126

T-o

^5:

b > :7

O~0<7))iill 5 V

>

©-®(7)Jiiih/nc;L'

^7^7

ix/■?-©<>

-if

'J x A - X

(zfj < {iS

h

-9-V©

-3-

G

Page 5

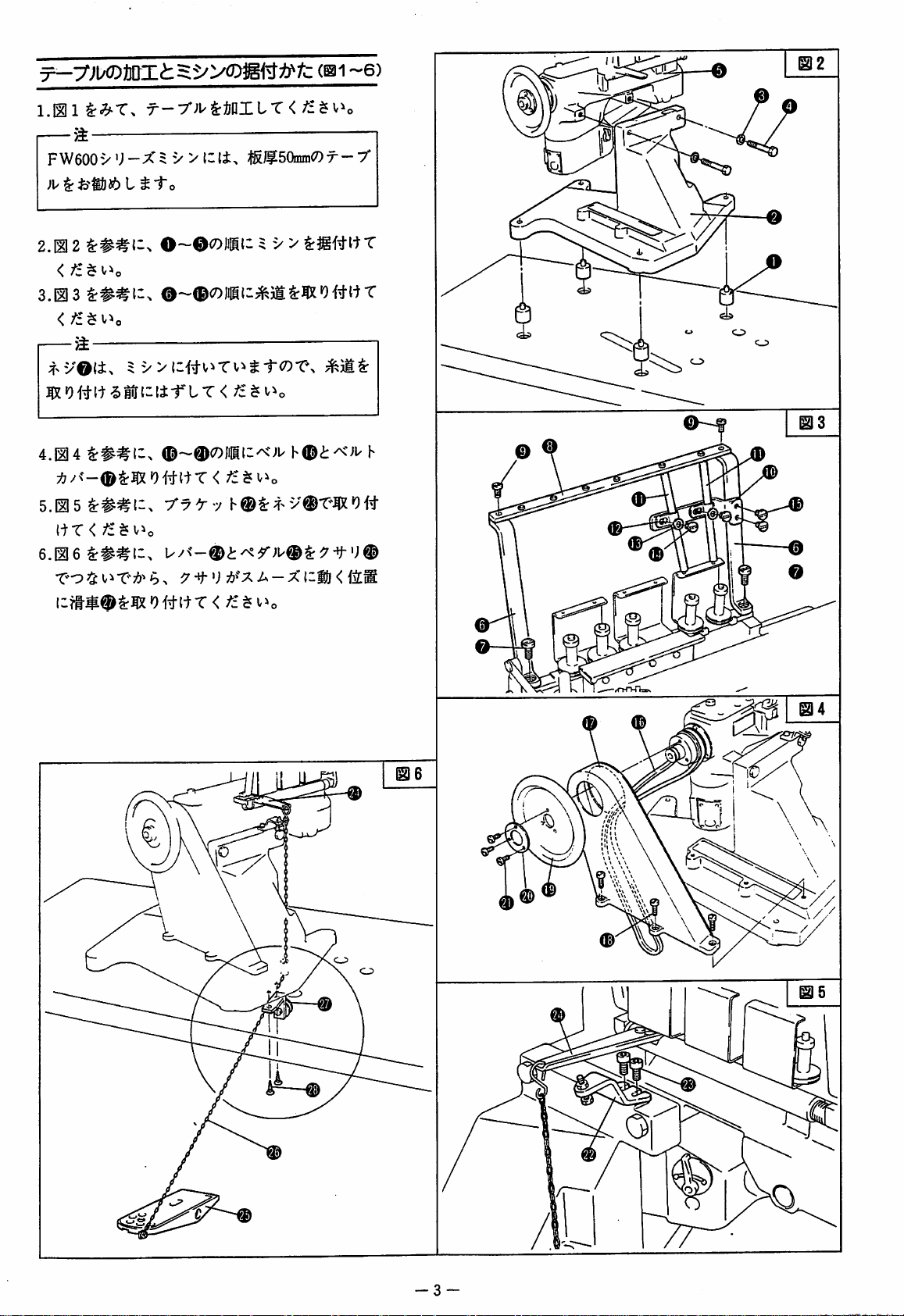

}¥x^UH(DiiS5

lfT<

$ t Th

Ol-^^ck9{::»LT<

#(i>

±Tizm^^ir<fz^\^^o

(117)

7i>^'o

/i

<h § >

:i-7

h©^§ifei6T.

U/<-®7&f;r-

y

^^vOi:

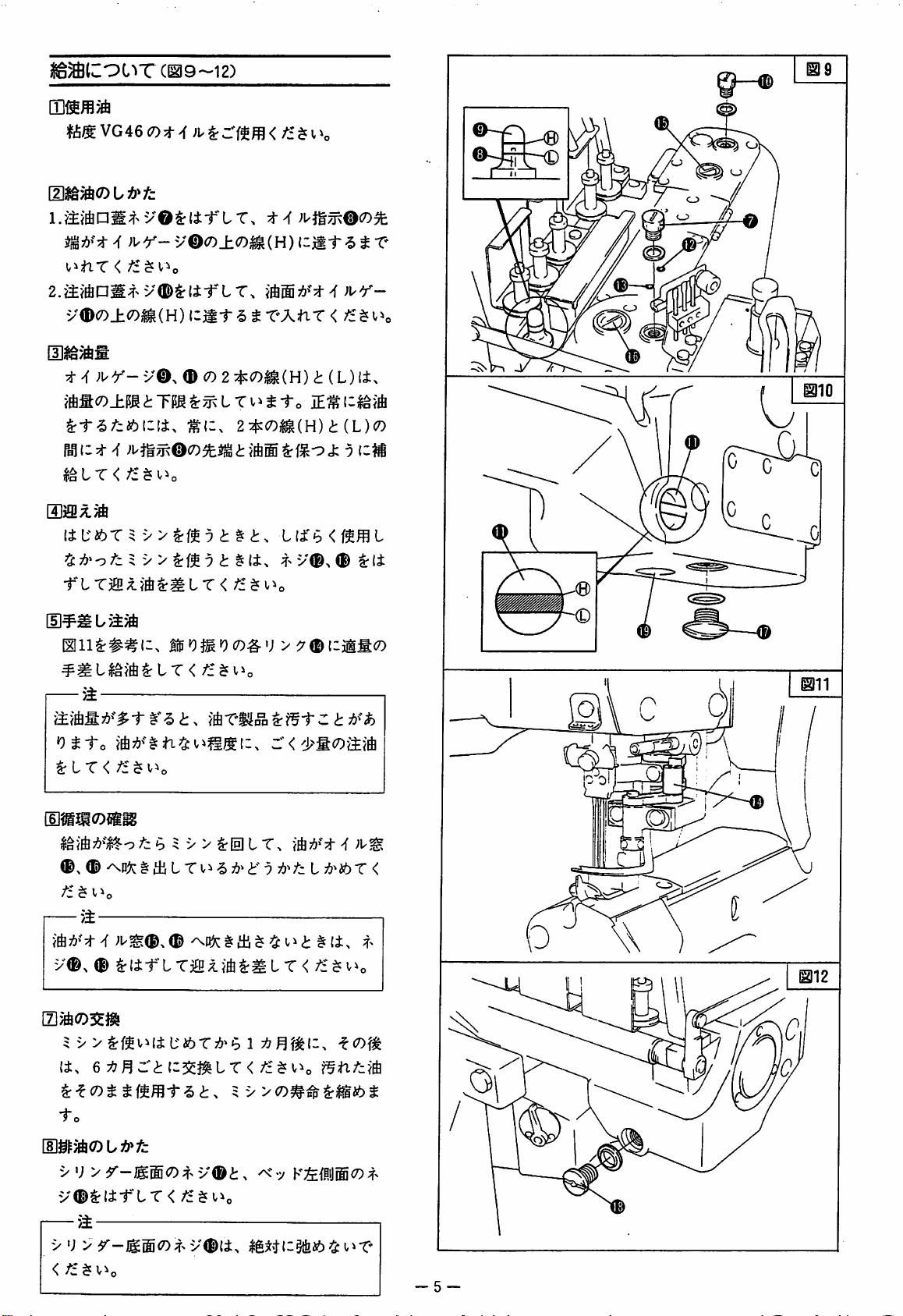

FW601AC

FW603AAX240

FW603AC

FW603AC

FW603AC

FW603ADX356

FW403AC

FW403A E X256

FW403A F X248

X240

X240

X248

X356

X248

#x^Og(a)

8.0tmn

❖

7.5niin

7.0nnn

>f

lO.Omm

❖

❖

CD

m2

(f

5 y >CO0|s:^[S]{i,

■f-')-m^'b^r.

OT'to

^3ll> ff^^giJ§;^0|El^C^c7)ii:Tl^^to

/i

fz^^fziyy

?t;6^i6T7!?^b>

5±

I^xm.

t^-(7)^^-^x^

^@fi$^<!:1^ffl^#i::«i:oT(i.

y-

'J

-

<fz^

^COi

:t;g|

:&I1I

^

0

F

W601A C X

FW603A A X240

FW603AC

FW603ACX248

FW603ACX356

FW603ADX356

FW403AC

FW403AE

FW403AF

^

240

X240

X248

X256

X248

®

15

[3

4

.200

f/

'/

f/

//

//

4,500

'/

'/

Ie

^

HRii^^0|^^.(ll8)

HR^gCOy'j

^I'^AfiT

zm^^'b

9^t->

::3

>

<

/£$

v^o

y U n

■^@(::ffi^&tT</i^i^o

>7i-'f

y'j 3 >

;i.

n^

t-f

-4

-

Page 6

(1^9-12)

VG

46

C7)

^

)VY->0(D±0m{H)izmt

v®iSrlitXT.

v®(7)±o^(H)

^

izmt ^ t

</i $ V

\

TXtir < /i^Uo

t ^ )l^Y-

Ph^

izt^

I^LT

[Siffixjft

TLT3ai;l}6^^LT<

[5]^^

L

llll^##li,

—

>±

'Otto

^LT<

{mmomm

®,

©

fz ^ l^o

a

V©. © C7) 2 :^<DmH)

#(l.

<

fz I "y

>

t ^ it.

0O^t9CO#V

/£

b 5 V > ^0 L T.

§

ai L T1.^ ^ i"

;i/^©,©

2i^<7)m{H)t{L)(D

t

}ft®

r"

9

v©^ © ^l±t'LT3ffi^iA^IILT<

<!:

(L)

(±.

J:

9

L(±'b<f^fflL

v©, © ^

<

li

-f

l^'ibX<

/f^i^o

®

O)

it.

eijBXtiz^mir

2:^<r>ttmmt^t.

to

V

•; > r-mm(7)t

v®^lirLT<

——

V

•;

>

<

fz^

V^o

v©t.

v©(±^

<

ly><Dm^i:mi!bt

f§nfz'<^

^

k;&{iij®co

^^ttiz^isb ^ i^T'

9>\

t

-5-

Page 7

(013)

l-JiLT < /f $ v>

II ^ -

•; - G ^ 7°

ffl

(7)Bf

li

B-63

5^

—

6

Page 8

3

>iDiiS5

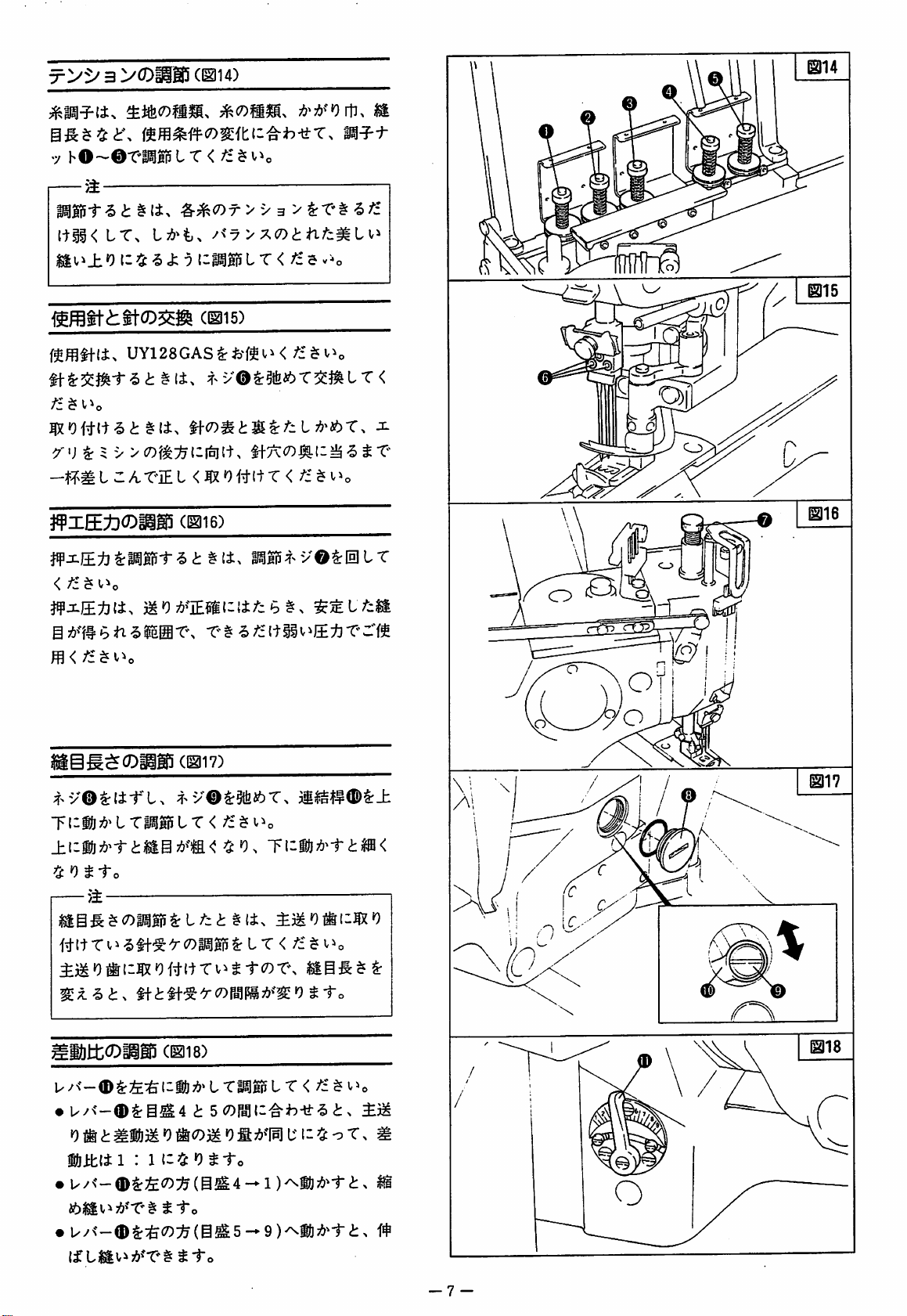

(iai4)

mm^i^<7)mti-'^h-ttr.

7

hO-©T«lT<

—

>i—~~"

#^(7)r>V3

ItIK

f^ffll+li>

^"'j ^ 5 V >(7)f^:^t:i[^(t.

#XEt)CDiiS5

W^J±ti^:m^i-^t^it.

<

J¥xii:^(i,

Sj{>^i#bn'5iEiir\

LT.

0

i: ^ ^

<fc

UY128GASffM^>'^<

#li>

3/uT'IEL<|X0itltT<

;'£ $ i^o

^M0

76?IE^i(I{±;^cb§^

^<y>^<Dtnfzmi^'

9

(^15)

^<D^t^^:fzl^^tbX.

L T <

If7\c7)^i:^^

(1^16)

M;r^v©^0tT

e/i(tiiv^j±:bT'rft

m^f-t

/£ 5 V-.0

mb

x

ST-

/i^v^o

^16

[@g$OiiS5

^^y®^l±-r"l.

Tl-iJ7&^LT|)gii5LT<

^'OtXo

/i

# [ t T V ^ <5

illtt^DiigiJ

•

U/<-®^i^4

0

ti[

(h

fiiklil : 1

•

U/<'-0i:ia<7):^(S^4--l)^W}7!)'i-ts

46^Slvi7&fT'§

•

^y^'—®$:q&(7):^(@^5-» 9 )^i!)7i?'i"

(f

LiS|v^;{>^'T'§^1-o

(1^17)

^>y®^§lbi6T.

tl-^ ^ C7)

ii

(1^18)

t

iz!i

Otto

115 ^ L T <

tc7)r%

L

Tli|gi5L r <

;^£ ^ V ^ o

/£

$

bMl ^ o

T.

<i:>

-7

-

Page 9

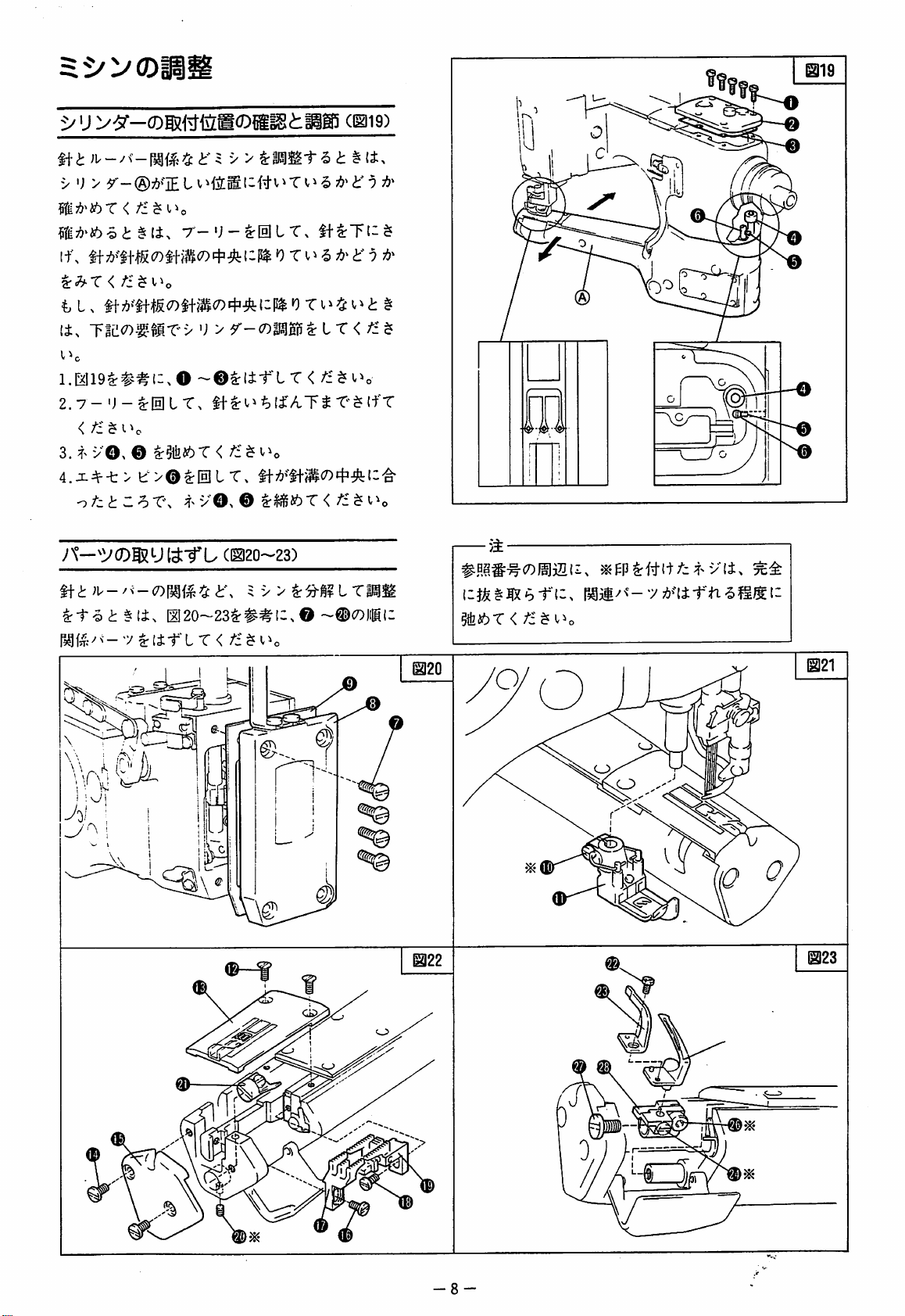

cbi9)"

)i--/«-IM«4t';

>

•;

>

?i;!)'i6«<!:

lf>

If

^h-X < ti ^ i^o

li^

-rm<n:^mx>

V^O

l.E?I19t:##(;.0

2.7-'J-^Ih]LT.

<

/:

3.

il±.

$

vO^ © K^kt>X < /i $ v^o

-> > SrMSi-S

')

>

If^t^^li'ATS

4.x^-t > e>@^lpllT.

-^tztZhXs

A'—^VOgSUt^-fL

Mf^:/v^7^[irLT<

^>v©.

©

(1120-23)

I120~23^##(:,©

/£

i

1

f}'

LT<

th7!»^"lf-;^(7)4.:^(:'^

#0e#-^C7)1^7Sf->

I - J-fe § IX b -f " t

~©C7)|i|Mli

?ife46T

v(i>

^

<

-f

"n

-5

UfS. I -

\e

-8

a

mz

Page 10

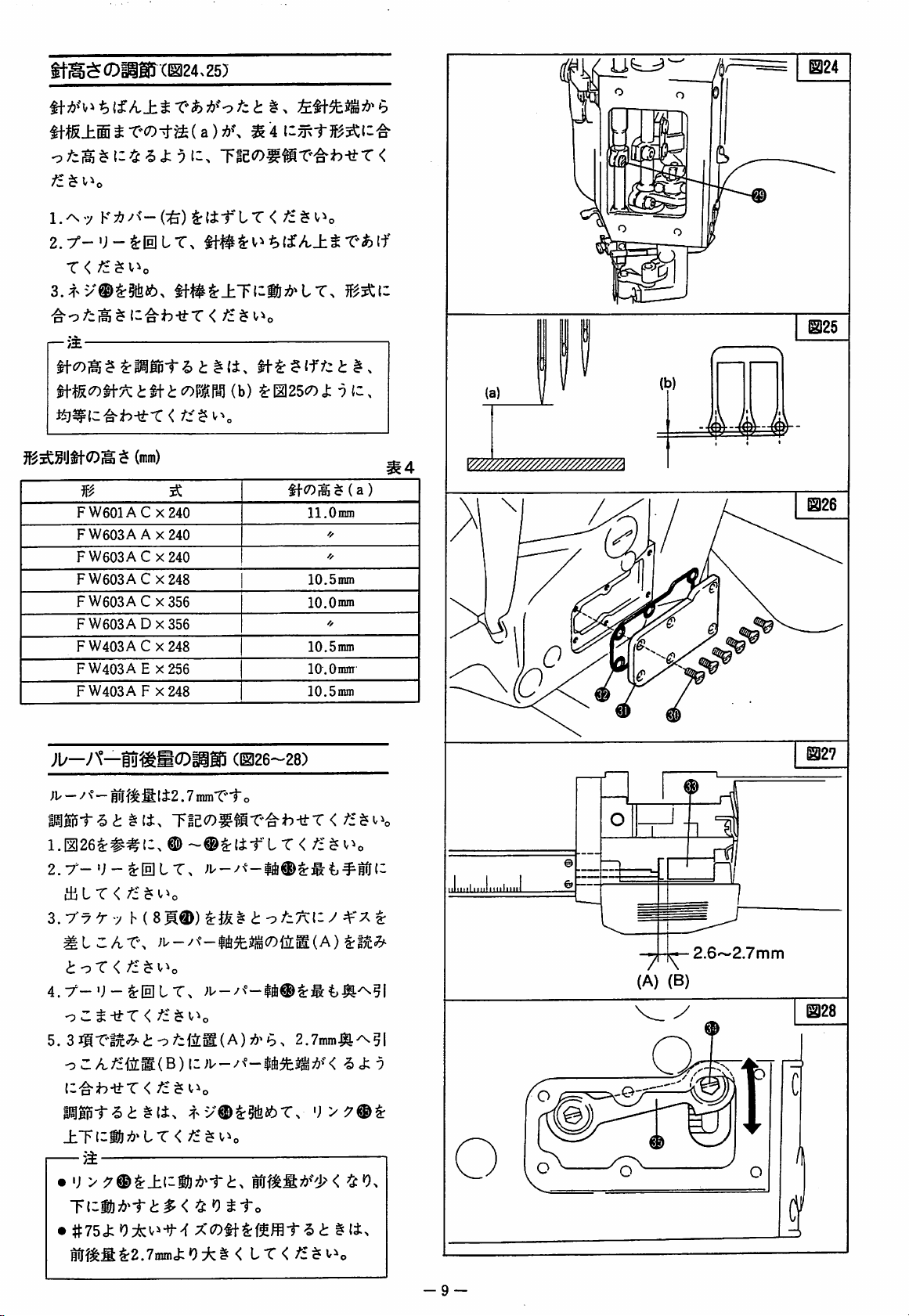

itB^CDiiSr(IS24.Z5)

W^^(a):d>\

1.^7

[—>$

K7:?^<-(^)

T < fz^\^^o

mJi<r>^^tiitcr,Bm

(mm)

m

FW601AC

FW603AAX240

FW603AC

FW603AC

FW603AC

FW603ADX356

FW403AC

FW403A E X256

FW403A F X248

^

X240

X240

X248

X356

X248

^

4

iSrli-ftT<

(b)

^[2]25<7)J: ^ C.

$ ( a

ll.Oiran

❖

❖

lO.Sinm

lO.Onun

'/

10.5mm

10.0

mm

10.5mm

&

@25

(a)

«4

)

(b)

jb—A—|u^S(DiiS5

;i/

—y\°—gfjf^^ti2.7inmT'"i"

1.I126^##I2.

€)

(1^26-28)

~®trli-r"LT

2.7'-';-^0LT.

thLT<

3.

7'7 7 7 h (

fz^\^>o

8M®)

^lz/vX\

ioT < /i^v^o

o

Zt-^X < /£

5.

3

i^lni-ai

—

>±

^

i o 7^fiS(A)

^(±.

y\zmi3^-rtp<^^^tto

•

#75ck0i:(.^-if>f

irf^fi^2.7min3:'9:^i < LT

o

<

i: o /-7\i: ^ ^'7

:d* b %

2.7inm-^^5l

-5

'J

>

§li.

<

3:7

iml.iirtlitnl

^

2.6~2.7mm

(A)

(B)

@28

-9-

Page 11

Ot

fV

I

8

s

M-

ro

CO

/-N

vg^

v:

(k-

ae

•

t

<r

W

W

Or

f>

4

A

av

✓X

(>.

c~

RV

0

^

Ulc

rw

I

1

M,

d

1

1

-<0

X

—t-

3

«•'

v^.

?>1

SB

s?

M

f

f>

✓X

1

h"

OV

<-

P?v

m

rr

fV

10}

0

3

3

Opf

o

Ok

c

9+

0

nfr

M

o

nS

RV

bUQ

■^'

'

v:

1

CO/o

o

CO

o

1

-^o

Nv

RV

3

R^

«

(

w-

3

9«-

-A

i

r»

tt-

n5>

&-

■'

0.3'>-0.4mm

I

fV

t—'

h-»

CO

RV

ii

*vl.

to

1

ilSI

JBH-

fc

H'

—

v

O

QV

#

'i

fW

1

1

d

<-

15-

il

9>l

9t

O'

rv

■=n

VJ;

e

p?v

0

A

t=H

j

I

0

tr

'~\

m

o

vf'

:ao

'

s

f>

(k

A

yx

v;

-^'

f

<-

•m

n>

r!

i

<-

o

?>"

3

M

n>

9+

w

c~

0

0

V

l"

X

n

3

ii-

fX

a<-

0

tJ.

1

s

s

dv

»

(

10

<r-

f

OV

o

Co

p^V

mi

•a

?

o-<

f>

RV

o

n

c

0

w

fV

'

ct:

:ii

)

<

tf-

n>

Pli

(k-

5+

'~\

rA

ij-

(H-

y\

r-

A

"

1

X

I

vj„

z

0

Page 12

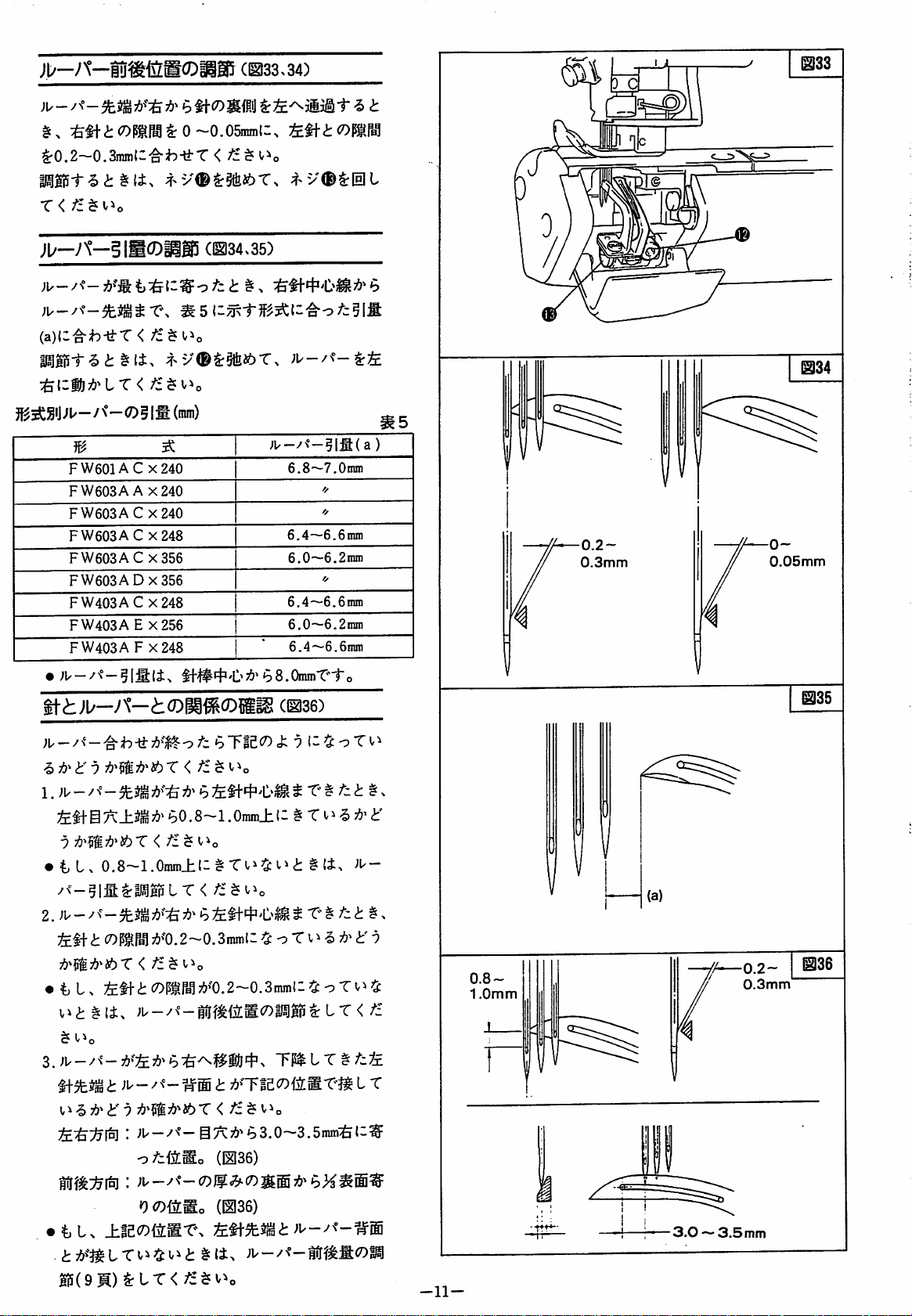

;i/-y\°-§Ti^fig0iig!r

§:>

:&t1-,i:COPOTt:0~0.05minli.

^0.2—0.Smnl^'^h-^X

^>v®^5fei6T.

T<

/£

(1^33.34)

<C

^■'V^^IeIL

^33

>11/—A°—glgCDIigi

(1^34.35)

(a)(:'^h-ti-T < fz^\^^o

FW601AC

FW603A A x240

FW603AC

FW603AC

FW603AC

FW603A

FW403AC

FW403AE

FW403A F X248

•

;F

—/N°—

—<75 5 Ifi

(mm)

X240

X240

x248

X356

0x356

X248

X256

tt<h>ll/—A—^(011^0

;u—y\°—5l:g( a )

6.8—7.0nraj

6,4—6.6mni

6.0—6.2nini

6.4—6.6nrai

6.0—6.2nini

6.4—6.6mm

b8.0min*Ci"o

{ili

(@36)

f/

❖

0-

0.05mm

tf

g|35

;u

—/\'

—

^ i"

9

IJW - ^

9

• i L.

-f - ^

0.8-1.Oiran±II#Tli^i^<h

T < /i ^ I.^o

< fz^^^o

/^^-?lffl^lllBi5LT<

2.

;i'-^

fe

tfi

COPtFal;{>^"0.2~0.3iran(l

<

tz^\^o

•

{>1. fcli*<i:OPtPB^7{)^'0.2~0.3mm(:^oTl^^

^

v^o

* ;U

—>'^°—@7a:7{>"b3.0—3.5ramq&(-^

o^cfiSo

bTIC^^cfc

b £ ti-

4-

9

^D ^ T'

b0.8~l.Oram±(: # T^

§{i^

rz^l^o

h

tX^tztt.

^ o T

yi^ix

(1^36)

#

-5

?!»'<!:'

)\^-

(i:-

^fzi£

^

9

^

8~

0mm

(a)

0.2—

0.3mm

®36

'9(7)fi[So

•

tL.

±fe(7)(3[ST\

liS(9M)^tT<^i$«/^o

(1136)

-11-

■rt*--

m—

5

mm

Page 13

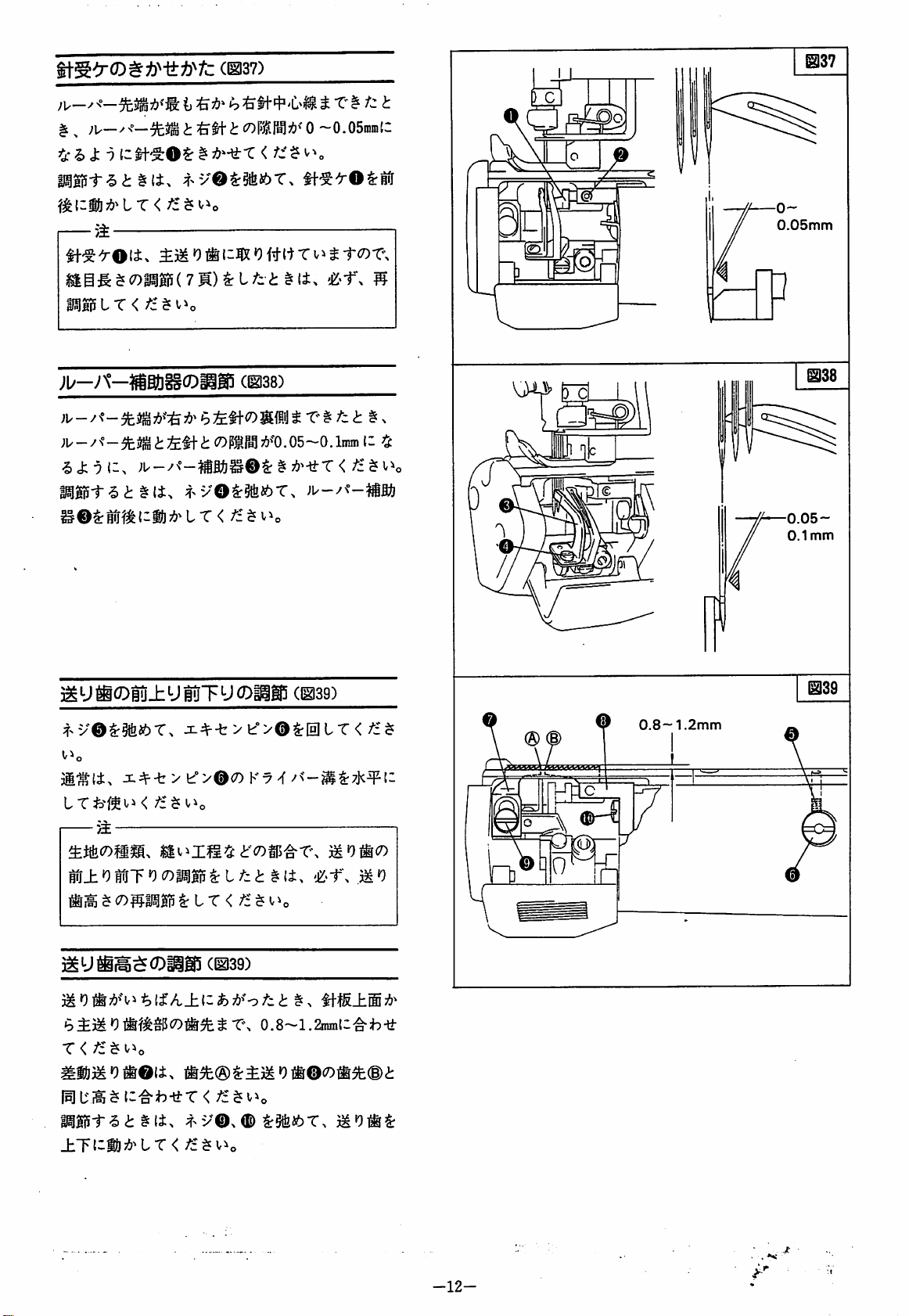

®37)

IJ-

@37

;U—

^ , ;U—

t^hXn

t3

|)||iSl-'5<h

>±—

IT

<

;b-A-^atl^CDpg5

; U - / ^ ^ £

§{i.

i)

i

^tl"

t

^

;f>

v©^§ife46T.

<

(1138)

tl-1C7)

^

0

~0.05nini(C

fJ:

$

it'^^OIrM

. 0 5 ~ 0.

T' ^ t

Imm

11

,QaS

o~

0.05mm

m

w

^

rc

0.05-

0.1mm

3MU^0lii±UluT'Jg)iii!i

^-v©^§tbfeT.

JC^-t>e>©c7)K7^v<-^^7K^i:

ii±»9HuTO(7)M^l;^;£:

'^±3iOliff^S15C7)#5fe^-r\

r

<fz^

^iS}i'9®©li>

iigiSi-^<i:

±Tl^ib75'^tT</£$v^o

Ji^-b > t''>©i^lHlLT

((^39)

#^(§)Sri)^0jir®cO®5fe(i)^

^(±s

(mag)

#(i.

0.8-l.2ma\Z^h^t

<

iiOiicT)

0.8—

@39

1.2mm

•12-

■ .

*»t

Page 14

3-

Q

lif

m

©

Q^,

4-»

to

CO

©

^

^

9^

o

3

^ ^

^

5$

p^

imt

3;

Ot:

p^

mi

®

^Df

^

e

w

n

#

>1-

©

©

©

'

r-

m

H

9fr

(V

4

(

S

5

S

tHWX

©

'^

CT

n

y

(6

3

«V

4

W

4-»

00

y

$

l-»

9+9+

«£>

y

^

9+

CO

O

y

$

9+

Off

-^'

y

ij.

A

c

S

9+

'

'

©

q:

9t

^

r>

^

p?v

^

o»

c

'p

's>

s>

©

r>.

I

n

'S

b"

vT'

Si

O

I

Ii^

f>.

1^4

&

n

rov

M

wi:

tJ-

0>

y

^

0

"

O

vS

3

ru

null

<r

?

III

6^

p^

iy

<-

Of

y

y

©

e

4

C>«

4

XV

©

e

y

y

i:

3

n

iSS

18.0mm

19.0mm

20.0mm

0

B»U

BUtt

!$

Jtg

c

1

r-

mi

ti-

isB

h-

4

vT'

v:

v:

Of

b-

Of

J

©

{^

&

p^

©

H

3

-tI

r^

Hf

xa^

O

<"

o«

ir

9>

•''V

vJ

a.

f>

fV

y

(t

3$

>

p^

©

*y

0

0^

xa^

X;

A

&

y

xa^

9+

0-'

Off

y

fV

3

•y*!

V

M

y

iW

A

y y

3$

s,

H

■^'

©

y

fc

<-

r>»

A

Of

O

9+

iy

62113

9^^

O

w

iutH

IN9

<-

iy

9+

-fr

p^

CO

O

Of

n

T)

3

3

-^'

4

(

-^'

f>.

?>J

p^

•H6

1

3

Xaja

0

m

•KVy

u

<r

(7'

/V

(»

(V

Of

vJV

f>»

fV

Of-

<-

m

fit

1

0

vT'

Of

W

c

va^

5$

A

✓N.

go

m

sT

4

(

w

a-

iP

>}

vaj.

xa^

■^'

©

^r

1^5

H|>

©

3

n

Vj»

///

©

y

n>

3

Wt

T#

fe

b"

m

)<')l

□>

PJf

©

p^v

©

HI

H

m

3

n>

p^

1

1

V.

^O

V

3 3

ve^

V

3

y

©

9+

o

3

S

1

H

3

{»

2{:

c

xnn

tmrn

M

9>

a-

1

1

V

y

Or

a-

9t

-!>

A

n

ytm

Sin

3

r>

HBi

t^

^sS

a

©

li^

vT'

VO^

Piv

w

w-

xa^

p^

c

w

a-

w-

Na^

r>*

A

r*

rA

-V-

Of

vT'

w

fV

O

3

i./

<-

0

I

OJ

Page 15

^

^(i^_hi;

•')

©^N I T, X h 7 T';r^

<7)n.K

msrM(r>^m(n^^^^b

A ® s

T-^'j23mmlI ^ S

Ji, _ y

V^

^<^>'),

^< L ^-To

f) 0 ^Jii6

ij-<

(1143)

J:

•)

i:-^h-tf-T<

i"o

-5

(h

^

>0;!?'

< ^ •')

tto

V©

'J

")

ai

@43

>

f

L

to

0

@44

if5LJ^iiiUa)iiM5

(^44)

^^»)©C7)B

ot

<"±^r^<

MBi5i-'5 ^ t{i>

T. X h 7 7°^^

<

^i:

9

i

0

^<9.

fp U H

1.^6(1.

(a ) ^

-ti-T < v^o

f)©

^5ii6 « <i:

;fc-<

bt<!:'>< ^ f)

U

gij(I(7)-ttr

^El+7)>b5.0~5.5mm(7).i5(g)t;^g|^P^J^7{)'-<

7'b^7

h®^0i^7&'b>

J:9t:'^h-a-T<

^>v©^3tbi6.

y©7!)^'U > X'CO-iaJ

<iZe

(1^45)

;^^0©^Ifi]L

»9

Z^(D^4i:i-

f)

th

S-To

L

1.^^1-0

^^7©,

<

m'om'o

^

FW601AC

FW603A A x240

FW603ACX240

FW603AC

FW603AC

FW603A

FW403AC

FW403AE

FW403A F X248

X240

x248

X356

0x356

X248

X256

im)

5.0-

5.5mm

10.5mm

10.Gram

9.5mm

@45

to

00

lfPUIiUSCDiiS5

m^m<oo<7)m^&ii:

1.^7

2.-f 7 h®^5fefcT. n 7

K:<7/<-(:&)

<

/£

^

•9^

(1146)

i^xto

^l±rLT<

K©^;£^(-i!j7&^LT

^ ^ 1-0

-14-

@46

14mm

Page 16

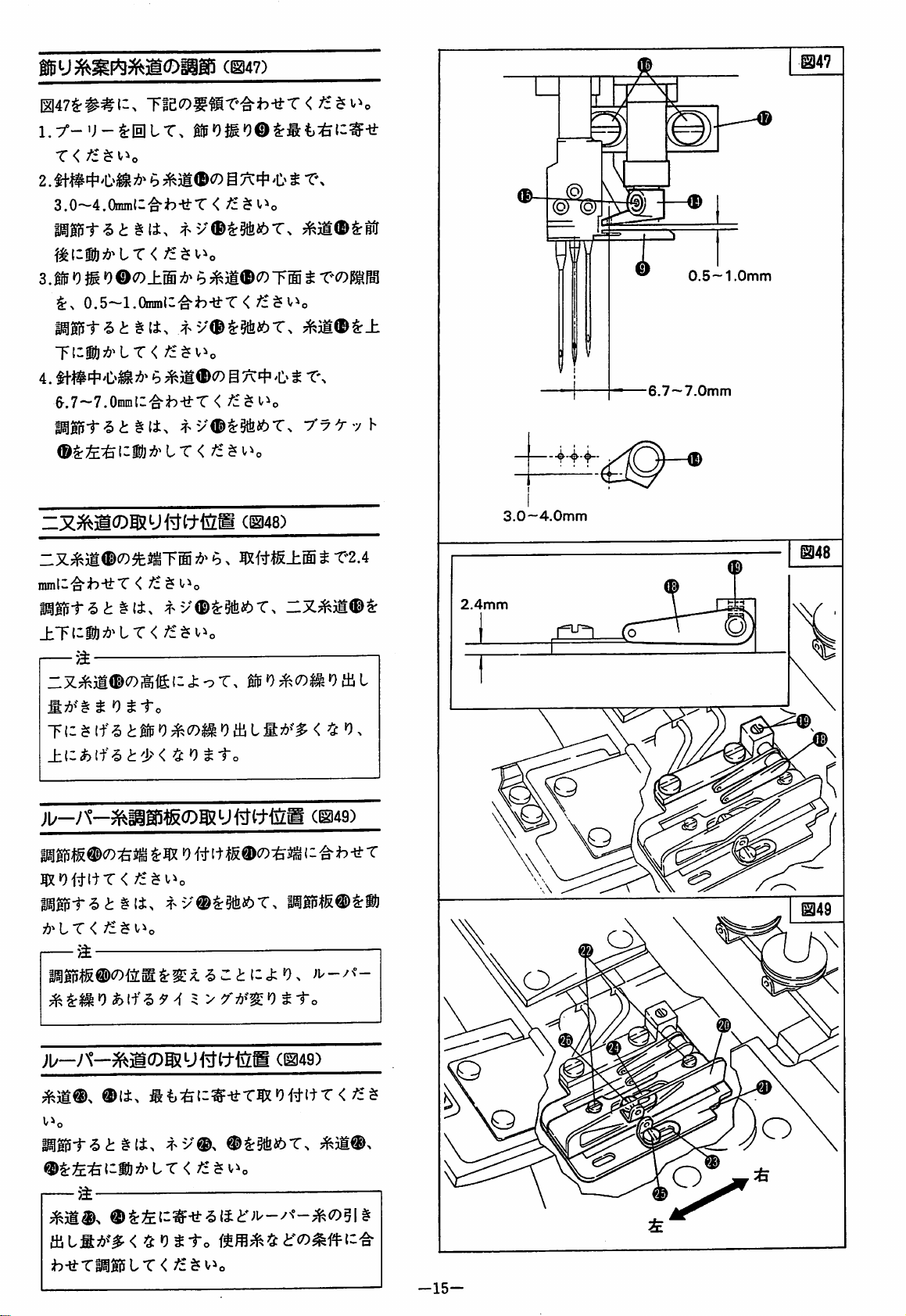

ci^47)

1.y-u-grHitT,

X<fz^

2.

3.0~4.0inin(;'^b-ltT < /£ ^ V^o

b

X\

J

,

@,

(Q)

--

@47

A

(Q)"

r

/£$v^o

®

o±®

i:.

0.5-1.0iran(:-^h-li:T<

r\zm^'ix<fz^\.^o

4.

&.7-7.0niiiii:'^h-ti-T

Mt^<!:§:

li.

~3^^Mg)g)?UWttlNlM

rx^ii^co^fe^^T®

±ycm^'ix<fz^i^o

_.^

i:Z;^5:jI®<7)i^fg:{ii;oT,

b

b

4^y®^§fetoT.

g

7=^4^ t X\

<fz^

(1^48)

7&^ b >

mtm±^

T® t x^<Dmr^'\

;^£$vio

gfp0^(7)^0

XyX-yh

t

X2A

tB

W

3.0~4.0mm

2.4mm

L

'4

^

^

^

■6,7—7.0mm

0.5-1

0mm

T1-^

^0#ltT<

|^li5t^<J:

^^lX<fz^\.^o

jb-y\-^^cDi;m^c-tlizM

Iigi5t'5<h

—

if-5

<h

§li.

#l±>

IfP 0 ^

(7)^ 0 iB L fl

/£$t^o

f>y®l:$fetoT,

5

f->y®^

tT < /£^i^o

®tr§tfei6T.

c^49)

xi-o

(1149)

;^3i®^

0.

@49

fBtfi7&^'#<

b-<i:T^gi5LT<

^5:0^1-0

/£^Vio

-15-

Page 17

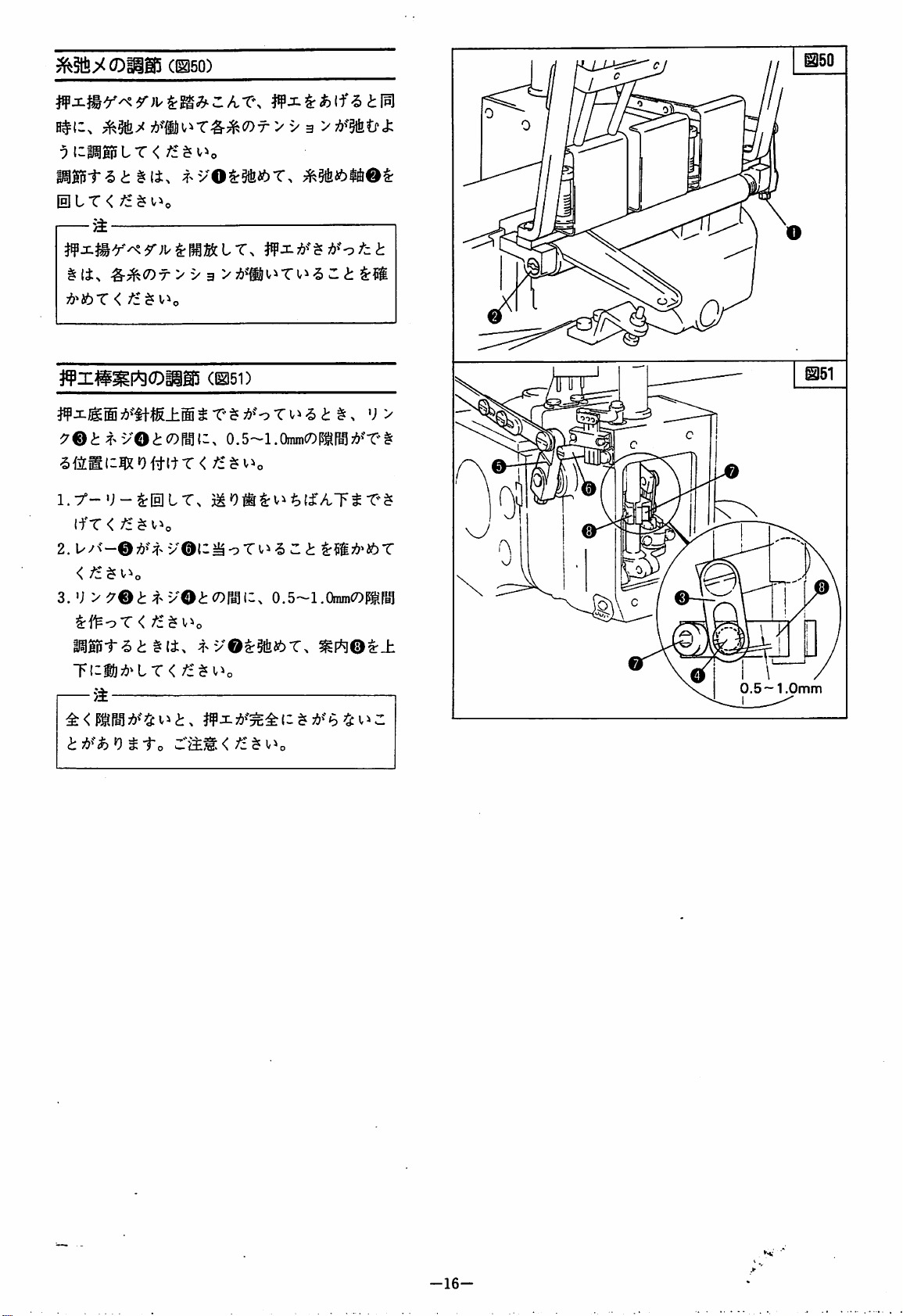

S^§te;><a)iiS5

H#i;.

;^§fe^

#lix

^^<Dt>

7&^i6T<

ff

X#^p*gCDiig5

7®

^

(1^150)

y

3

/£

(11151)

VO<1:^7)Paid.

> V 3

>7i>^"§fitfc!:

0.5-1.OinmCT)

t

ifr

<

2.

3.

'J

y9Bt^^yOt(7^mi:-.

l^@5t6<J:

'r\zm^'ix<fz^\.^o

—jt

v®t;^oTi^6

§(±.

O.S-l.OmmCOPtrBl

H^yOz:mibX.

^?S;{>»toT

mP^Oi:±

0.5 — 1,0mm

-16-

Page 18

u

^

3^

mm

C

s.p.m.

FW601ACX240

FW403ACX248

FW403AEX256

FW403AFX24B

FW603AAX240

FW603ACX240

FW603ACX248

FW603ACX356

FW603ADX356

4.0

4.8

5.6

4.8

4.0

4.0

4.8

5.6

5.6

2

4

1.4 - 4.1

1.4-4.1

0.8 - 1.4

-

1.4

8.5

10.0

8.0

4,200

4,500

4,200

U

>

•

• U r—t—tl'^^ftv-'-Cv-'^to

h

hu-—-f—

h

IJ

>

• f |-|j5ic7)jR{c

0 it,

v> i tc

Page 19

MEMO

-18-

Page 20

INTRODUCTION

This

booklet

operation

and

machines.

before

derive

DAILY

Before

1.

2.

3.

4.

5.

6.

7.

After

1.

2.

3.

use

of

the

best

MAINTENANCE

starting

Check

damaged.

Check

Check

Check

formed.

Check

lines

Check

lubrication

Check

while

Clean

needle

If

it

rapair.

Place a dust

needle

needle

threading

thread

oil

of

oil

oil

oil

running

close

the

plate

any

trouble

to

the

of

machine.

plant

contains

maintenance

Careful

indicator

gauge.

is

parts.

monitor

work:

reading

the

machine

use

from

work:

is

in

sound,

is

correctly

is

correct.

chain

of

not

color

the

machine.

it.

tip

short

Especially,

and

looper.

or

irregularity

mechanic

cover

over

some

of

of

will

condition

set.

about

is

between

for

is

changed

for

the

machine.

notes

the

SOnan

FW

this

help

length

on

series

booklet

you

and

the

the

manual

to

green

clean

around

is

found,

report

adjustment

the

to

not

is

two

or

FOR

SAFETY

1.

Make

sure

2.

Be

well

with

energizing.

3.

Turn

the

4.

Be

an

5.

Make

the

off

work

sure

electric

sure

checking

6.

Make

when

replacing

NOTES

1.

Run

the

2.

In

after

drops

3.

Keep

level

lines

4.

Change

one

5.

Thread

the

ON

new

maximum

using

stop-page

of

the

indicator

of

month

illustration.

Belt

careful

power

Motor

table.

to

turn

breakdown.

to

and

cleaning

sure

Motor

the

machine

Needles,

USE

machine

for

the

machine

oil

manually.

machine

oil

gauge.

oil

entirely

in

operation.

your

machine

Guard

in

connecting

source

Switch

off

Power

turn

off

has

etc.

at a 20%

the

for

some

oil

is

always

at

is

properly

the

and

whenever

Switch

Power

the

Switch

machine.

completely

requires

less

speed

first

one

month.

for

the

first

time,

lubricate

level

so

that

between

the

end

of

correctly

according

fitted.

machine

checking

you

leave

in

case

of

before

stopped

threading,

than

time

and

2~3

the

oil

the

two

the

first

to

-20-

Page 21

-19-

Page 22

CONTENTS

Driving

Table

Presser

Turning

Machine

Silicone

Lubrication

Threading

Regulating

Needles

Presser

Stitch

Diff.

Cylinder

Disassembling

Needle

Looper

Looper

Looper

Synchronizing

Adjusting

Adjusting

Checking

Needle

Looper

Feed

Feed

Needle

Needle

Needle

Looper

Spreader

Setting

Spreader

Spreader

Setting

Setting

Setting

Thread

Presser

Specifications

Operators

Table

Parts

motor

cutting

foot

oil

foot

length

feed

height

pulley

and

lift

direction

speed

for

the

thread

pressure

control

ratio

adjustment

adjustment

adjustment

avoiding

holder

height

and

adjustment

needle

clearance

distance

the

relationship

guard

adjustment

auxiliary

dog

tilt

adjustment

dog

height

thread

thread

thread

thread

guide

presser

support

takeup

thread

position

of

stroke

thread

position

position

position

release

bar

of

of

of

adjustment

guide

Manual(For

of

Adjusting

Checker

adjustment

motion

adjustment

takeup

adjustment

guide

adjustment

and

belting

machine

of

H.R.

tension

installation

machine

device

adjustment

looper

between

setting

and

looper

between

needle

needle

between

adjustment

spring

adjustment

adjustment

adjustment

adjustment

spreader

adjustment

spreader

looper

looper

thread

thread

thread

operators)

Standards

timing

and

looper

and

looper

needle

and

guide

guide

plate

eyelets

for

FW600,

point

looper

FW400

^

22

23

24

24

24

24

25

26

27

27

27

27

27

28

28

29

29

30

30

30

31

31

31

32

32

32

32

33

33

33

34

34

34

35

35

35

35

36

36

50

•53

-21-

Page 23

Fig.1

-310-

260

24*30'

-154-

o Si

to

CO

C

0

t)

<D

CO

^

CD

1

OQ

I' /A \ 1

rtl

I! / '

\

h'\\

\\

A\i

\

li

U

DRIVING

The

the

following

1.

Motor:

2.

Belt: V belt.

3.

Motor

MOTOR

machine

Clutch

watts.

pulley:

-525-

PULLEY

should

use a motor

AND

BELTING

and

specifications:

motor, 3 phase, 2 pole,

Type

M

Select

referring

an

appropriate

to

Table

1.

belt

of

400

pulley

Relation

Machine

between

speed

2

,900

3

,200

3

,400

3

,600

3

,800

4

,000

4

,200

4

,500

Machine

(s.p.m.)

0

(0

<

<

Speed

Motor

6 0 Hz

5

0

5 5

6

0

6

5

6

5

7

0

7

5

8

0

c

o

0>

1

and

pulley

m

•/Aw

/

/;

h\\

i I i

i

Motor

Pulley

diameter

5 0 Hz

6

6

7

7

8

8

9

9

Table

(mm)

0

5

0

5

0

5

0

5

1

-22-

Page 24

TABLE

INSTALLATION

1.

[—

For

thickness

2.

3.

—

Remove

guides.

4.

5.

6.

CUTTING

Refer

to

Fig. 1 and

Note:

FW600

50mm

Refer

to

Fig. 2 and

in

sequence.

Refer

© — ®

to

in

Note:

Screw O before

Refer

to

Fig. 4 and

Cover

Refer

Screws

Refer

©

position

®, © — © in

to

Fig. 5 and

©.

to

Fig. 6 and

with

Chain © and

where

(Figs.i-6)

series

is

Fig. 3 and

sequence.

the

AND

MACHINE

cut

the

table.

machine, a table

recommended.

install

the

machine O —

attach

attaching

attach

Belt © and

Thread

the

sequence.

attach

connect

chain

Bracket © with

Lever © to

attach

Pulley © to

can

move

smoothly.

of

plate

Guides

thread

Belt

Pedal

©

the

©

-23-

G

Page 25

PRESSER

FOOT

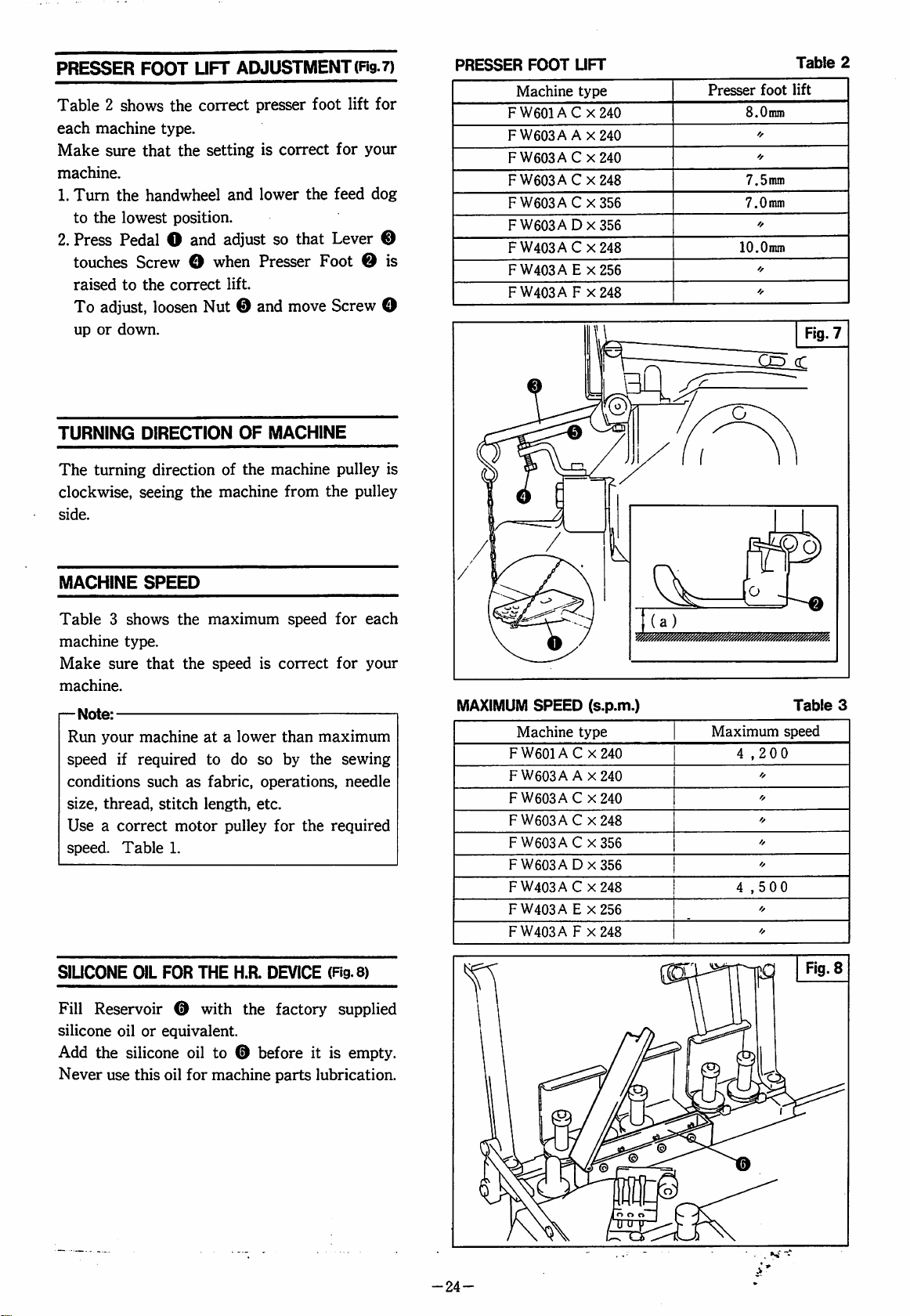

Table 2 shows

each

machine

Make

machine.

1.

2.

sure

Turn

to

the

Press

touches

raised

To

adjust,

up

or

type.

that

the

handwheel

lowest

Pedal O and

Screw O when

to

the

loosen

down.

UFT

ADJUSTMENT

the

correct

the

setting

and

position.

adjust

correct

lift.

Nut © and

presser

is

lower

Presser

foot

correct

the

so

that

Foot © is

move

(Fig.

7)

lift

for

for

your

feed

dog

Lever

Screw

©

O

PRESSER

FOOT

Machine

FW601AC

FW603A A x240

FW603ACX240

FW603AC

FW603ACX356

FW603A

F

W403A C X

FW403A E X256

FW403A F X248

UFT

type

X240

X248

0X356

248

Presser

8.0nmi

7.5mni

7.0

10.0mm

foot

❖

mm

❖

❖

'f

CDcC

Table

lift

2

TURNING

The

clockwise,

side.

MACHINE

DIRECTION

turning

direction

seeing

SPEED

Table 3 shows

machine

Make

machine.

r—

Run

speed

conditions

size,

sure

Note:

your

thread,

type.

that

machine

if

required

such

stitch

Use a correct

speed.

Table

the

the

maximum

the

at a lower

to

as

fabric,

length,

motor

1.

OF

of

the

machine

speed

do

is

so

operations,

etc.

pulley

MACHINE

machine

from

the

speed

correct

than

maximum

by

the

for

the

required

pulley

pulley

for

each

for

your

sewing

needle

is

MAXIMUM

FW601A C X240

FW603A A X240

FW603AC

FW603AC

FW603AC

FW603A

FW403A C X248

FW403A E X256

FW403A F X248

SPEED

Machine

(s.p.m.)

type

X240

X248

X356

0x356

Maximum

4

,200

o

f/

o

ff

"

4,500

'f

f/

Table

speed

3

SlUCONE

Fill

silicone

Add

Never

OIL

FOR

THE

H.R.

Reservoir © with

oil

or

equivalent.

the

silicone

use

this

oil

oil

for

to © before

machine

DEVICE

the

(Fig.

factory

parts

supplied

it

is

lubrication.

8)

empty.

-24-

Page 26

LUBRICATION

The

oil

was

shipped.

So,

fill

the

it

for

the

first

(ngs.9-12)

drained

machine

time.

from

with

the

oil

before

machine

starting

when

[DLubrication

Use

of

UTo fill

1.

Take

head

upper

2.

Take

level

Gauge

IDOil

level

The

two

and ® indicate

limits

level

both

mPrlmlng

When

is

idle

Oil

VG46.

oil

out

of

Oil

line

out

reaches

or

Screw © and

Level

(H)

of

Screw © and

the

®.

lines

'H'

the

of

the

oil

between

Oil

oil

the

for

the

Gauges © and

machine

more

Screws © and © and

priming.

equivalent.

pour

oil

until

Indicator © reaches

Oil

Gauge

upper

and

maximum

level.

two

©.

pour

oil

line

'L'

on

Always

lines

(H)

until

(H)

Oil

Gauges

and

keep

and

minimum

®.

is

used

for

the

first

than

two

weeks,

drop

oil

into

there

the

the

the

oil

of

Oil

©

the

oil

(L)

for

time

or

remove

for

HlManuai

Refer

Link © of

i—Note:

Excess

minimum

moil

After

see

and

I—

Note:

If

remove

(2011

Change

machine,

Dirty

machine.

[8|To

Remove

and

I—Note:

Never

cylinder.

oiling

to

Fig.

11

and

Spreader.

oil

may

stain

necessary

circulation

oiling,

that

©.

no

oil

Screws © and © and

change

oil

drain

Screw © on

loosen

check

run

the

oil

jets

jets

in

Oil

oil

one

and

thereafter

may

reduce

oil

Screw © at

the

Screw © at

apply

the

amount

the

machine

in

Oil

Sight

Windows © or

month

the

the

bottom

left

side

hand

oiling

fabric,

of

oil.

and

Sight

Windows

add

oil.

after

the

every

the

half a year.

service

of

of

life

the

the

bottom

to

each

Add

a

check

to

©

©,

start

of

of

the

cylinder

bed.

of

the

a

-25-

W.

Page 27

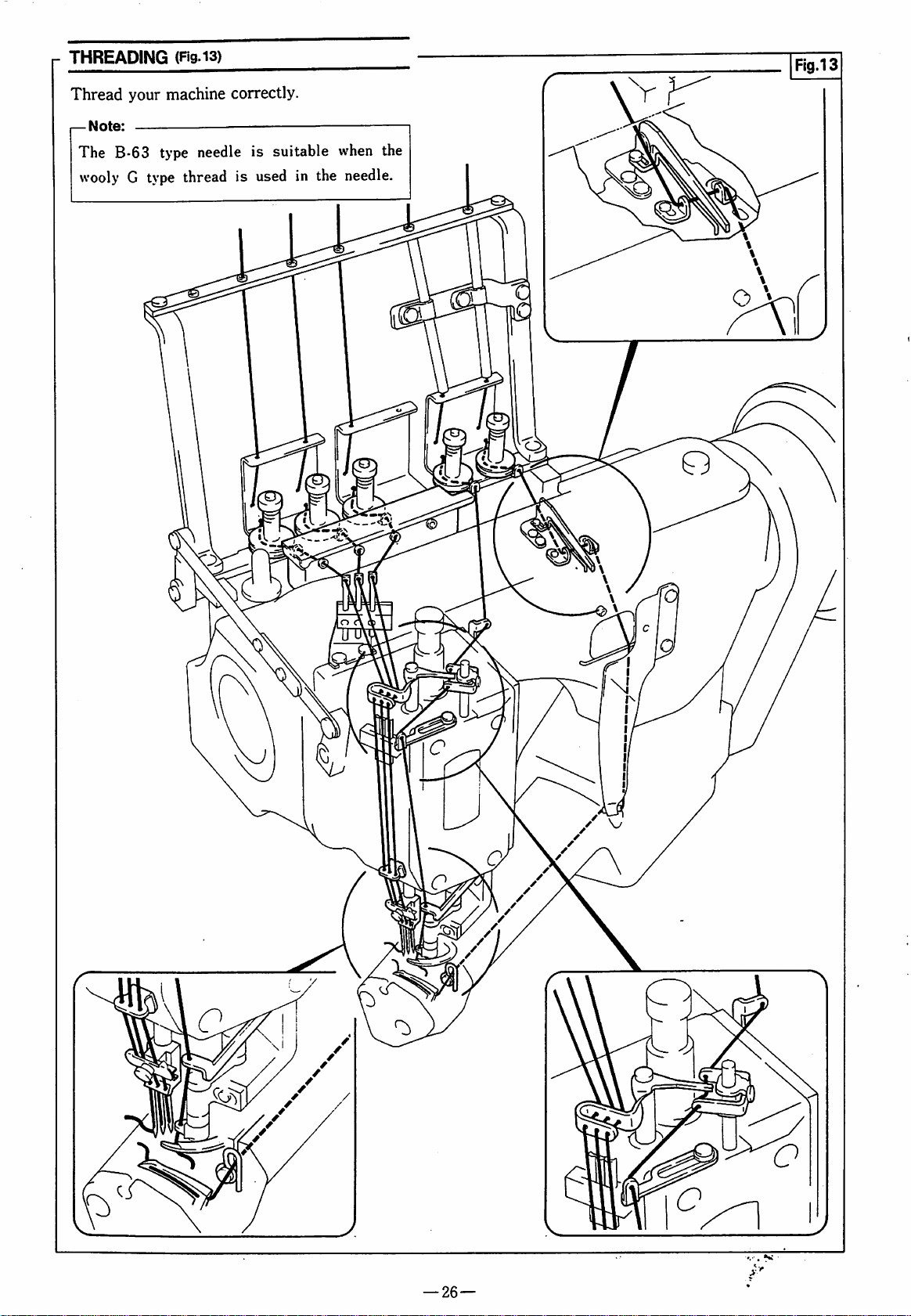

THREADING

(Fig.i3)

Thread

—

The

Note:

your

B-63

type

wooly G type

machine

correctly.

needle

thread

is

suitable

is

used

in

when

the

needle.

the

—

26

—

Page 28

REGULATING

THREAD

TENSION

(Fig.i4)

Adjust

O — ®

as

—Note:

NEEDLES

Use

Loosen

Insert

scarf

PRESSER

To

Adjusting

Adjust

making

results.

the

according

fabric,

Adjust

possible

balanced

the

thread,

each

while

sewing

needle

Screw © and

the

needle

to

the

adjust

the

Screw

the

sure

thread

(Fig.i5)

back

FOOT

pressure

tension

to

the

sewing

seam

width,

thread

system

tension

making

results.

UY128GAS.

replace

as

far

as

of

the

machine.

PRESSURE

pressure

of

©.

as

weak

positive

feeding

with

Tension

conditions

stitch

as

sure

the

it

will

go,

(Fig.l6)

the

presser

as

possible

and

length,

weak

neat,

needle.

facing

foot,

neat

sewing

Nuts

such

etc.

as

well

the

turn

while

A

Fig.16

STITCH

Remove

Link © up

LENGTH

Screw

or

Move © up

down

for a shorter

f—

Note:

When

making

needle

the

DIFF.

Move

diff.

•

•

•

guard

correct

FEED

Lever ® right

feed

ratio.

When © is

the

diff.

feed

To

gather

(4-^

1).

To

stretch

(5->

9).

CONTROL

©.

Loosen

down.

for a longer

stitch.

this

adjustment,

on

the

relationship

RATIO

set

at

the

ratio

the

fabric,

the

fabirc,

Screw @ and

stitch

main

feed

with

ADJUSTMENT

or

left

center

is

1:1.

move © to

move © to

(Fig.i7)

move

and

move

also

re-set

the

dog

and

keep

the

needle.

(Rg.i8)

and

adjust

between 4 and

the

left

the

right

©

the

5,

-27-

Page 29

MACHINE

ADJUSTMENTS

CYUNDER

When

that

Cylinder

needle

slot

of

the

center,

1.

Refer

2.

Turn

lowest

3.

Loosen

4.

Turn

the

Screws

DISASSEMBLING

If

it

is

and

re-adjust

in

sequence.

ADJUSTMENT

adjusting

should

the

to

Handwheel

point.

Screws

Eccentric

center

O.

necessary

the

(S)

is

in

pass

needle

adjust

Fig.

0

19

of

the

and

O,

each

machine

sewing

the

the

plate.

position

remove O —

to

0

Pin ® to

(Rgs.20-23)

to

disassemble

timings,

(Rg.i9)

parts,

correct

center

If

it

of

lower

the

set

needle

slot,

remove © to

make

position.

of

each

does

Cylinder

sure

Each

needle

not

pass

®.

©•

needle

each

needle

and

the

to

the

tighten

machine

to

©

^

Note:

Screws

numbers

to

them

with ^ marks

should'not

such a degree

are

ready

to

be

removed

that

the

be

removed.

on

the

parts

reference

but

loosened

secured

by

\

-28-

a

Page 30

NEEDLE

The

left

surface

point.

for

each

Make

machine.

To

adjust:

1.

Remove

2.

Turn

to

3.

Loosen

down,

—

Note:

In

even

NEEDLE

HEIGHT

needle

needle

height

point

when

the

Table 4 shows

machine

sure

that

the

the

head

the

handwheel

the

highest

Screw

and

adjusting

for

each

HEIGHT

Machine

FW601AC

FW603A

FW603AC

FW603AC

FW603AC

FW603ADX356

FW403AC

FW403A E X256

FW403A F x248

position.

obtain

the

needle.

(mm)

type

X240

A

x240

x240

X248

X356

X248

ADJUSTMENT

is

the

gap

and

the

needle

is

the

correct

type.

height

cover

(right).

and

move

the

the

correct

needle

height,

Fig.

(a)

needle

at

the

is

correct

raise

needle

height.

25.

Needle

(Rgs.24,25)

between

plate

upper

needle

for

the

needle

bar

set

gap

height

11.0

f/

❖

10.5mm

10.0mm

"

10.5mm

10,0mm

10.5mm

the

top

dead

height

your

bar

up

or

(b)

Table

(a)

mm

Fig.25

(a)

4

(b)

/A

/A

A\

LOOPER

The

To

1.

2.

#

3.

4.

5.

r—

AVOIDING

looper

adjust

Refer

Turn

to

avoiding

to

Fig.

the

handwheel

the

most

Insert a gauge

for

Bracket

Measure

Turn

®

to

Measure

gap

To

up

Note:

►

To

move

To

move

►

When

increase

position

the

handwheel

the

most

position

between

adjust,

or

down,

decrease

Link ® up.

increase

Link ® down.

using

the

(2.7mm).

MOTION

motion

26

and

protruded

or

vernier

(A)

retracted

(B).

(A)

and

loosen

Screw ® and

the

looper

the

looper

needles

gap

to

ADJUSTMENT(Ftgs.26-28)

is

2.7mm.

remove # —

and

bring

®.

Looper

Shaft

position.

calipers

of

the

and

bring

position

Make

(B)

is

thicker

more

3.0mm.

avoiding

avoiding

than

in

looper

shaft

Looper

(B).

sure

move

motion,

motion,

than

the

standard

the.

hole

tip.

Shaft

that

Link

#75,

the

®

1

1 i . 1

lllllllllllltllll

oitJ

0

_

0

-

2.6~2.7mm

(A) (B)

Fig.28

-29-

Page 31

LOOPER

HOLDER

AND

LOOPER

SETTING

(Rg.

29)

Fig.29

Attach

^

LOOPER

Turn

of

Adjust

To

Note:

When

its

tip

shaft.

the

the

gap

adjust,

Looper

tightening

looper

Holder O and

is

on

the

HEIGHT

handwheel

below

(a)

to

loosen

Looper

Screw

spot

0.3

Screw O and

0,

make

surface

ADJUSTMENT

and

bring

the

needle

—0.4mm.

of

the

highest

plate

turn

0.

sure

the

looper

(Fig.

Screw

that

30)

part

finger.

0.

Fig.30

OM

SYNCHRONIZING

TIMING

1.

Remove

2.

Turn

bar

Check

Turn

same.

be

To

©

Use

(Figs.

parts © — © in

the

handwheel

is

4.0mm

the

the

handwheel

In

both

in

the

same

adjust,

the

loosen

mark

31,32)

looper

on © as a guide

NEEDLE

sequence.

forward

up

from

the

lower

point

against

backward

cases,

level

against

the

looper

Screws 0 and

AND

LOOPER

until

the

dead

the

and

point

the

needle.

turn

Coupling

for

adjustment.

needle

point.

needle.

do

the

should

CBI

\

©

-30-

Page 32

ADJUSTING

NEEDLE

When

the

right

between

the

looper

dead

the

AND

looper

0 — 0.05mm,

looper

To

point

adjust,

loosen

CLEARANCE

LOOPER

passes

point

to

point

and

the

and

the

left

Screw ® and

BETWEEN

POINT

behind

the

left,

and

the

the

set

clearance

needle

to

(Rgs.33.34)

needles

the

clearance

right

needle

between

0.2 — 0.3mm.

turn

Screw

from

to

the

®.

ADJUSTING

NEEDLE

Table 5 shows

machine

correct

Check

centerline

is

To

looper

LOOPER

for

the

at

the

adjust,

right

SETTING

Machine

FW601ACX240

FW603AAX240

FW603AC

FW603AC

FW603AC

FW603ADX356

FW403AC

FW403A E X256

FW403A F X248

DISTANCE

AND

LOOPER

the

type.

your

Make

machine.

distance

and

the

right

dead

loosen

or

left.

type

X240

X248

X356

X248

BETWEEN

(ngs.34,35)

correct

(a)

looper

point.

distance

sure

that

between

the

point

when

Screw ® and

(a)

for

the

setting

right

needle

the

looper

move

Distance

6.8~7.0inin

❖

❖

6.4~6.6mm

6.0

—6.2niin

ff

6.4

—S.Smin

6.0

—6.2niin

6.4

—6.6nim

each

is

the

Table

(a)

r

V

1

5

h-O-

/'

0.3mm

0.05mm

Fig.35

CHECKING

BETWEEN

Make

between

1.

•

2.

•

3.

•

•

•

sure

needle

Turn

from

behind

the

If

Turn

from

If

from

the

the

the

Make

sure

top

not,

re-adjust

the

the

behind

Make

point

Turn

the

sure

and

not,

re-adjust.

the

the

point

touches

The

looper

the

needle

The

needle

thickness.

If

not,

re-adjust

THE

NEEDLE

again

and

handwheel

right

left

needle

that

the

of

the

needle

handwheel

right

left

needle

that

the

needle

handwheel

left

to

the

eye

centerline.

point

RELATIONSHIP

AND

LOOPER

the

correct

looper.

and

move

to

the

left

until

centerline.

point

is

0.8—1.0mm

eye.

the

distance

to

the

the

gap

is

the

right

back

center

is

1/3

the

looper

(a).

and

move

left

until

centerline.

between

0.2 — 0.3mm.

and

move

until

of

the

looper.

is

3.0 — 3.5mm

of

the

avoiding

(Rg

36)

relationship

the

looper

its

point

is

above

the

looper

its

point

is

the

looper

the

looper

the

left

needle

from

looper

blade

motion.

0.8-

1.0mm

J

(a)

I i

0.2-

/

0.3mm

1

3.0 ~ 3.5

Fig.36

mm

-31-

Page 33

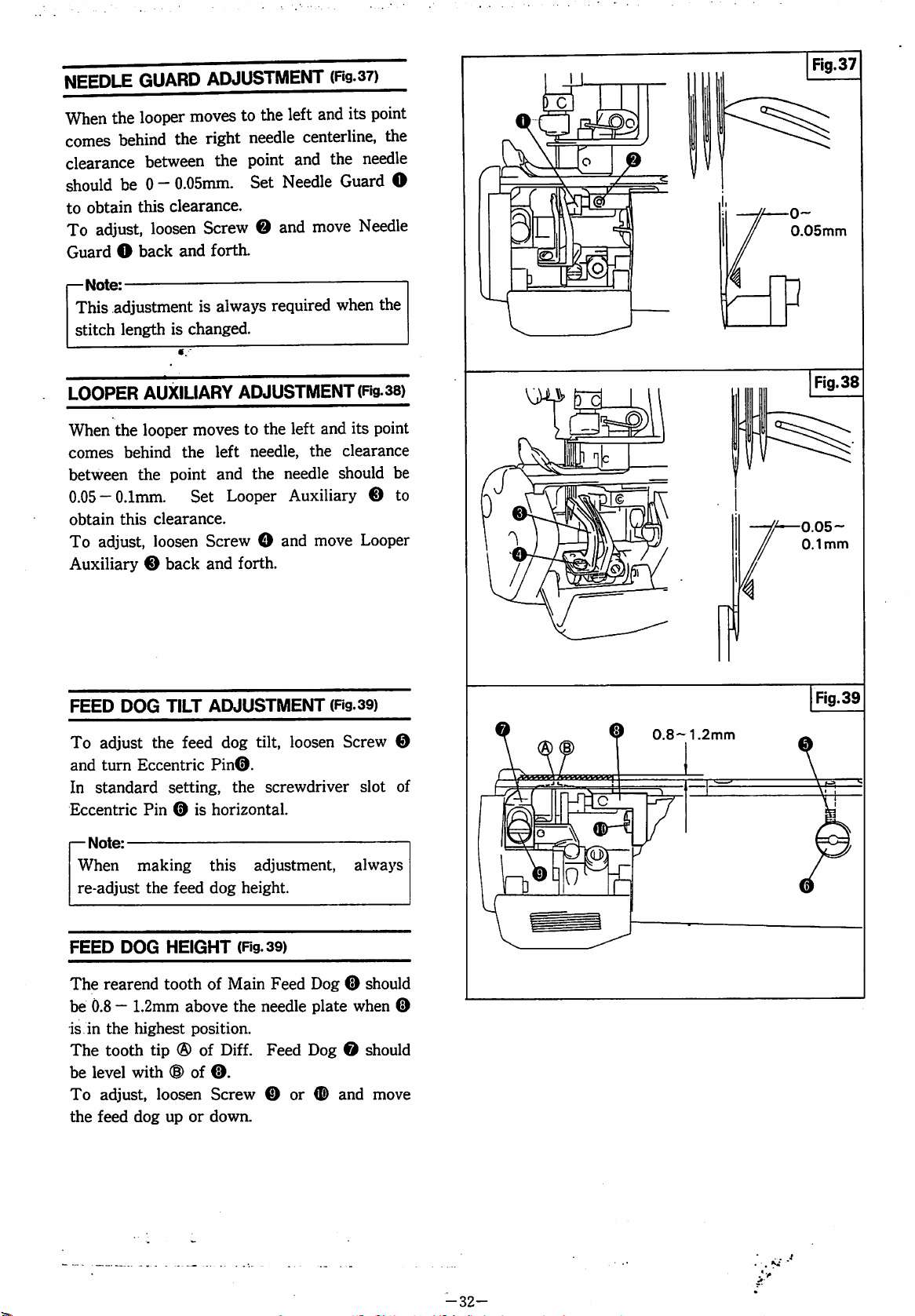

NEEDLE

When

comes

clearance

should

to

obtain

To

Guard O back

(—

Note:

This

stitch

GUARD

the

looper

behind

between

be 0 -

this

adjust,

loosen

—

adjustment

length

ADJUSTMENT

moves

the

to

right

the

0.05mm.

clearance.

Screw @ and

and

forth.

is

always

is

changed.

the

left

needle

point

Set

centerline,

and

Needle

required

(Rg-37)

and

its

the

needle

Guard

move

Needle

when

Fig.37

point

the

O

0-

0.05mm

the

LOOPER

When

comes

between

0.05

obtain

To

Auxiliary ® back

FEED

To

and

In

standard

Eccentric

—

Note:

When

re-adjust

AUXILIARY

the

looper

behind

the

—0.1mm.

this

clearance.

adjust,

adjust

turn

loosen

DOG

TILT

the

Eccentric

setting,

Pin ® is

making

the

moves

the

point

Set

feed

feed

ADJUSTMENT

to

the

left

left

needle,

and

the

Looper

the

needle

Auxiliary ® to

Screw O and

and

forth.

ADJUSTMENT

dog

tilt,

loosen

Pin®.

the

screwdriver

horizontal.

this

adjustment,

dog

height.

(Fig.

and

its

clearance

should

move

(Fig.39)

Screw

always

38)

point

be

Looper

©

slot

of

(^31

®

0.8-1.2mm

0.05-

0.1mm

Fig.39

FEED

The

be

is

The

be

To

the

DOG

HEIGHT

rearend

0.8 — 1.2mm

in

the

tooth

level

adjust,

feed

tooth

highest

tip ® of

with

(S)

loosen

dog

up

(Fig.39)

of

Main

Feed

Dog ® should

above

the

needle

position.

Diff.

of

®.

Screw ® or ® and

or

down.

plate

Feed

Dog ® should

when

move

®

-32-

Page 34

NEEDLE

Set

and

1.

(D = 18.0mm

2. ® =

3. ® =

—

Set

needle

the

thread

each

the

eyelet

19.0mm

20.0mm

Note:

each

thread

looper.

to

THREAD

distance

Thread

be

used.

GUIDE

between

of

(D,

(the

(the

(the

can

Adjust

ADJUSTMENT

the

®

as

left

needle

center

right

Guide 0 ® ® so

be

needle

needle

smoothly

this

according

bracket

follows.

thread)

thread)

thread)

that

cast

off

(Fig.

40)

surface

the

from

to

the

NEEDLE

THREAD

ADJUSTMENT

Set

Needle

it

lightly

To

adjust,

r—

Note:

When

foot

turned

loop

the

needle.

this.

NEEDLE

Thread

contacts

loosen

the

fabric

on

the

way

backward.

tends

to

Spring ® functions

THREAD

ADJUSTMENT

Set

each

upper

2.3mm

Bar

the

lowest

To

adjust,

Thread

above

Thread

Guide ® when

position.

loosen

Supports ® up

PRESSER

(Fig.4i)

Presser

Screw

®.

Screw 0 and

is

removed

of

sewing,

In

such

be

formed

on

SUPPORT

(Fig.42)

face

of

Needle

the

eyelet

Screws 0 and

or

down.

SPRING

Spring ® so

turn

Knob

from

the

presser

the

handwheel

case, a thread

the

front

side

to

prevent

Thread

center

the

Supports

of

needle

bar

move

that

®.

is

of

Needle

is

in

Needle

/

I I I I ir

2.3mnn

Fig.41

—

Note:

Needle

improve

having

also

when

As

needle

the

Thread

tightening

been

to

assist

the

each

Support 0 can

thread,

type

of

Support ® functions

released

to

produce a good

looper

make

the

thread

catches

each

needle

from

the

the

needle

be

adjusted

adjustment

used.

to

thread

looper,

shaped

after

and

loop

thread.

for

each

according

to

-33-

teiete^

Page 35

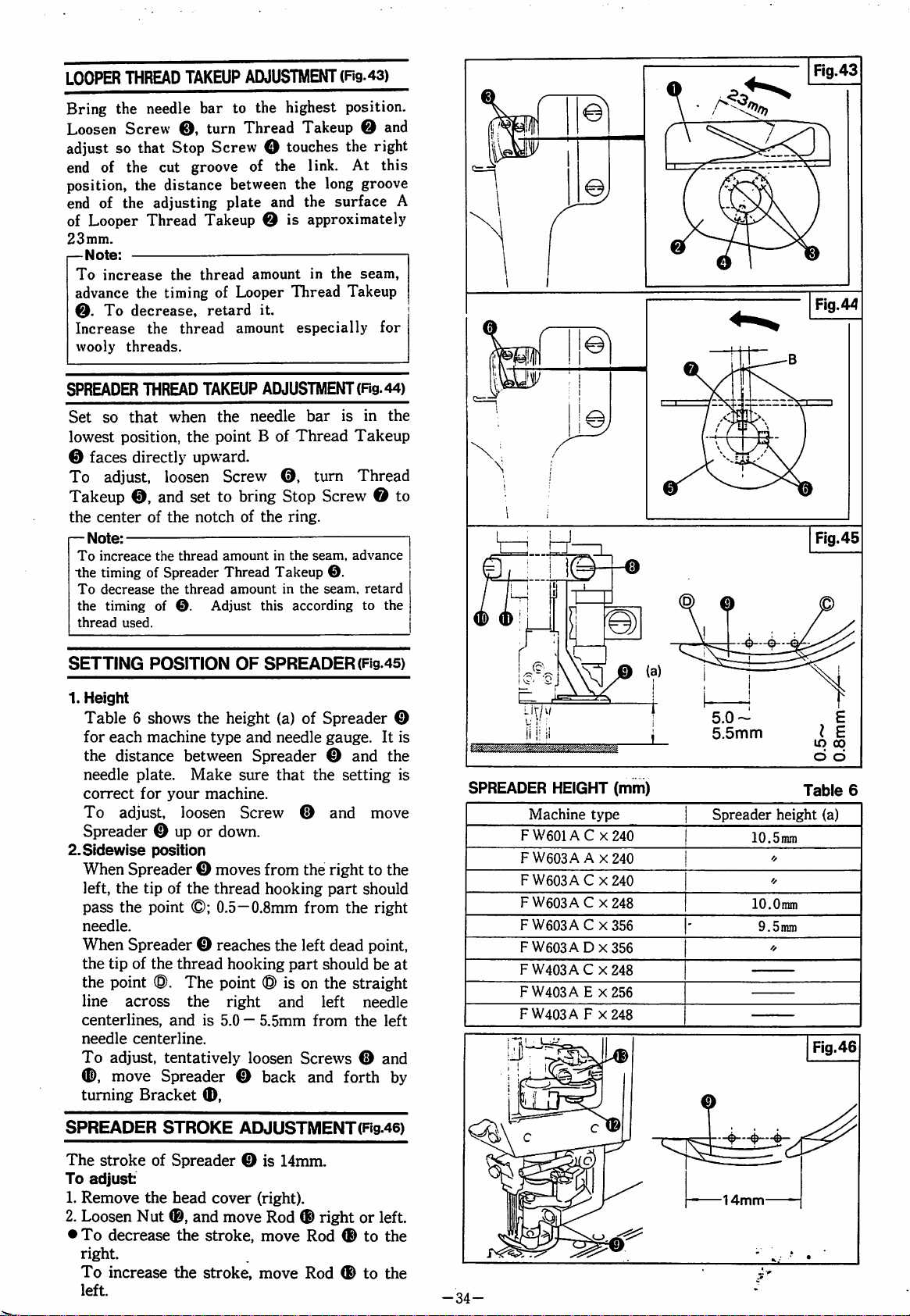

LOOPER

THREAD

TAKEUP

ADJUSTMENT

(Rg.43)

Bring

Loosen

adjust

end

position,

end

of

23mm.

—Note:

SPREADER

Set

lowest

the

the

Screw

so

of

the

the

of

the

Looper

To

increase

advance

©.

Increase

wooly

©

To

Takeup

—

Note:

To

the

To

the

thread

the

To

decrease,

threads.

so

that

position,

faces

directly

adjust,

©,

center

increace

timing

decrease

timing

used.

needle

that

Thread

the

THREAD

of

of

bar

to

©,

turn

Stop

Screw O touches

cut

groove

distance

adjusting

between

plate

Takeup © is

the

thread

timing

of

Looper Thread

retard

thread

when

the

amount

TAKEUP

the

point B of

upward.

loosen

and

the

the

Spreader

the

of

set

notch

thread

thread

©.

Adjust

Screw

to

bring

amount

Thread

amount

the

highest

Thread

of

Takeup @ and

the

the

and

amount

it.

especially

ADJUSTMENT

needle

Thread

©,

Stop

of

the

ring.

in

the

Takeup

in

the

this

according

position.

the

right

link.

At

this

long

groove

the

surface

A

approximately

in

the

seam,

Takeup

for

(Rg.

44)

bar

is

in

the

Takeup

turn

Thread

Screw © to

seam,

advance

©.

seam,

retard

to

the

SETTING

1.

Height

POSITION

Table 6 shows

for

each

machine

the

distance

needle

correct

To

plate.

for

adjust,

Spreader © up

2.Sldewlse

When

left,

pass

needle.

When

the

the

line

centerlines,

needle

To

©,

turning

position

Spreader © moves

the

tip

the

point

Spreader © reaches

tip

of

the

point

®.

across

centerline.

adjust,

move

Spreader © back

Bracket

OF

the

height

type

and

between

Make

your

loosen

or

of

the

©;

thread

The

the

and

is

tentatively

Spreader © and

sure

machine.

Screw

down.

thread

0.5—0.8mm

hooking

point ® is

right

5.0 — 5.5mm

loosen

©,

SPREADER

(a)

of

Spreader

needle

that

gauge.

the

©

from

the

hooking

from

the

left

part

should

on

the

and

left

from

Screws © and

and

(Fig.45)

setting

and

move

right

to

part

should

the

right

dead

point,

be

straight

needle

the

forth

©

It

is

the

is

the

at

left

by

SPREADER

Machine

FW601AC

FW603A A X240

FW603AC

FW603AC

FW603A C X356

FW603ADX356

FW403AC

FW403A E X256

FW403A F X248

HEIGHT

type

X240

X240

X248

X248

(mm)

5.0-

5.5mm

Spreader

lO.Smm

lO.Otnm

9.5nmi

lO

Table

height

(a)

00

6

SPREADER

The

stroke

To

adjust:

1.

Remove

2.

Loosen

•

To

decrease

right.

To

increase

left.

STROKE

of

Spreader © is

the

head

Nut

®,

and

the

stroke,

the

stroke,

ADJUSTMENT(Rg.46)

14mm.

cover

(right).

move

Rod ® right

move

Rod ® to

move

Rod ® to

or

left.

the

the

-34-

14mm

Page 36

SPREADER

THREAD

GUIDE

ADJUSTMENT

(Rg.

47)

Adjust

1.

2.

Turn

to

the

Set

the

in

the

the

right

centerline

Guide © to

To

adjust,

©

back

and

3.

Set

the

gap

©

to

0.5 — 1.0mm.

To

adjust,

©

up

or

down.

4.

Set

the

centerline

Guide © to

To

adjust,

Bracket

SETTING

THREAD

Set

Guide © and

To

adjust,

up

or

I—

Note:

To

lower

To

raise

©.

POSITION

GUIDE

the

distance

loosen

down.

increase

Guide

decrease

Guide

following

handwheel

dead

point.

distance

and

3.0 — 4.0mm.

loosen

forth.

between

the

Screw © and

between

loosen

distance

and

Screw © and

between

the

6.7 — 7.0mm.

loosen

(Fig.48)

between

the

bracket

Screw © and

the

thread

©.

the

thread

©.

manner.

and

bring

Spreader

the

needle

eye

center

of

move

Spreader © and

move

the

needle

eye

center

Screw

OF

SPREADER

Spreader

to

2.4mm.

amount

amount

of

©

and

move

in

the

in

the

Thread

Thread

Guide

©

bar

Thread

Guide

Guide

Guide

bar

move

©

seam,

seam,

2.4mm

3.0-4.0mm

i

rs

0.5—1.0mm

6.7--7.0mm

SETTING

THREAD

Set

Guide

right

To

adjust,

Plate

—

Note:

The

up

can

Guide

SETTING

THREAD

Set

Eyelets © and © at

To

adjust,

Eyelets © and

Note:

To

shift

To

decrease

shift

POSITION

GUIDE

Plate © to

ends

aligned.

loosen

©.

—

timing

for

be

changed

Plate

POSITION

©.

EYELETS

loosen

®.

increase

Eyelets © ©

Eyelets © ©

the

the

the

OF

LOOPER

PLATE

(Fig.

49)

Bracket © with

Screws © and

looper

by

thread

shifting

OF

the

LOOPER

(Fig.49)

the

right

Screws © and

thread

thread

to

to

amount

the

amount

the

right.

left.

shift

Guide

to

be

taken

position

extremes.

©,

and

in

the

seam,

in

the

seam,

their

of

shift

-35-

Page 37

THREAD

When

foot

simultaneously

tension.

To

Releasing

I—

Note:

When

releasing

a

tension

RELEASE

the

presser

lift

pedal,

adjust,

loosen

Shaft

the

the

is

applied

work

©.

presser

foot

ADJUSTMENT

foot

is

raised

the

thread

to

relax

Screw O and

foot

is

lift

pedal,

to

each

make

thread.

(Rg

by

pressing

release

each

turn

should

thread

Thread

lowered

sure

SO)

the

by

that

PRESSER

When

the

and

To

adjust'

1.

Turn

to

2.

Make

3.

Leave a clearance

Link 0 and

To

©

—

Note:

If

there

O,

BAR

GUIDE

the

presser

needle

Screw O to

the

the

plate,

the

hand

lowest

sure

adjust,

up

or

is

loosen

down.

no

presser

that

Screw

gap

position.

foot

ADJUSTMENT

foot

is

lowered

set

the

gap

between

0.5 — l.Omm.

wheel

and

bring

the

Lever 0 contacts

of

0.5 — l.Omm

O.

Screw O and

between

may

Link 0 and

not

be

fully

(Fig.5i)

and

sits

Link

feed

Screw

between

move

Guide

Screw

lowered.

on

®

dog

0.

0.5—

l.Omm

-36-

Page 38

SPECIFICATIONS

FW601ACX240

FW403ACX248

FW403AEX256

FW403AFX248

FW603AAX240

FW603ACX240

FW603ACX248

FW603ACX356

FW603ADX356

1.4-4.1

1.4 - 4.1

0.8-

1.4

0.8-

1.4

0.8 - 1.4

10.0

8.0

4,500

4,200

Seaming

Cover

on

stitching

Sportswear,

Cover

stitching

•

The

needle

Cover

stitching

•

With a retainer

Cover

stitching

•

Suitable

Cover

•

Suitable

Cover

Swim

Cover

Swim

Cover

Swim

•

The

for

stitching

for

stitching

suits,

stitching

suits,

stitching

suits,

needle

light

to

medium

on

light

to

etc.

on

heavy

fabrics.

plate

has a seam

on

light

to

needle.

on

underwear.

short

stitch

on

underwear.

long

stitch

on

light

to

sportswear,

on

sportswear,

on

sportswear,

plate

etc.

light

to

etc.

heavy

etc.

has a seam

fabrics.

medium

Sportswear,

guiding

medium

length

length

operations.

operations.

medium

medium

fabrics.

guiding

fabrics.

etc.

groove.

fabrics.

fabrics.

fabrics.

groove.

The

machine

fitted

with a retainer

needle

is

good

for

operations

where

the

looper

thread

is

difficult

to

be

fed.

Page 39

MEMO

-38-

Page 40

FW

Series

OPERATORS

MANUAL

'

^

jj

THREADING

■if-

thread

REPLACING

STITCH

DIfIeREKiTIAL

presser

silicone

LUHRICATION

m

cleaning

L

w

^

tension

CO

^

41^

The

length

X CO g ti

foot

o/l

}[»

1^

for

NEEDLE'

CON'i'KUL

EEED

pressure

the

g

CONTENTS

cont

kui.

hk

device

<k

^

d

^

®

7

^

Page 41

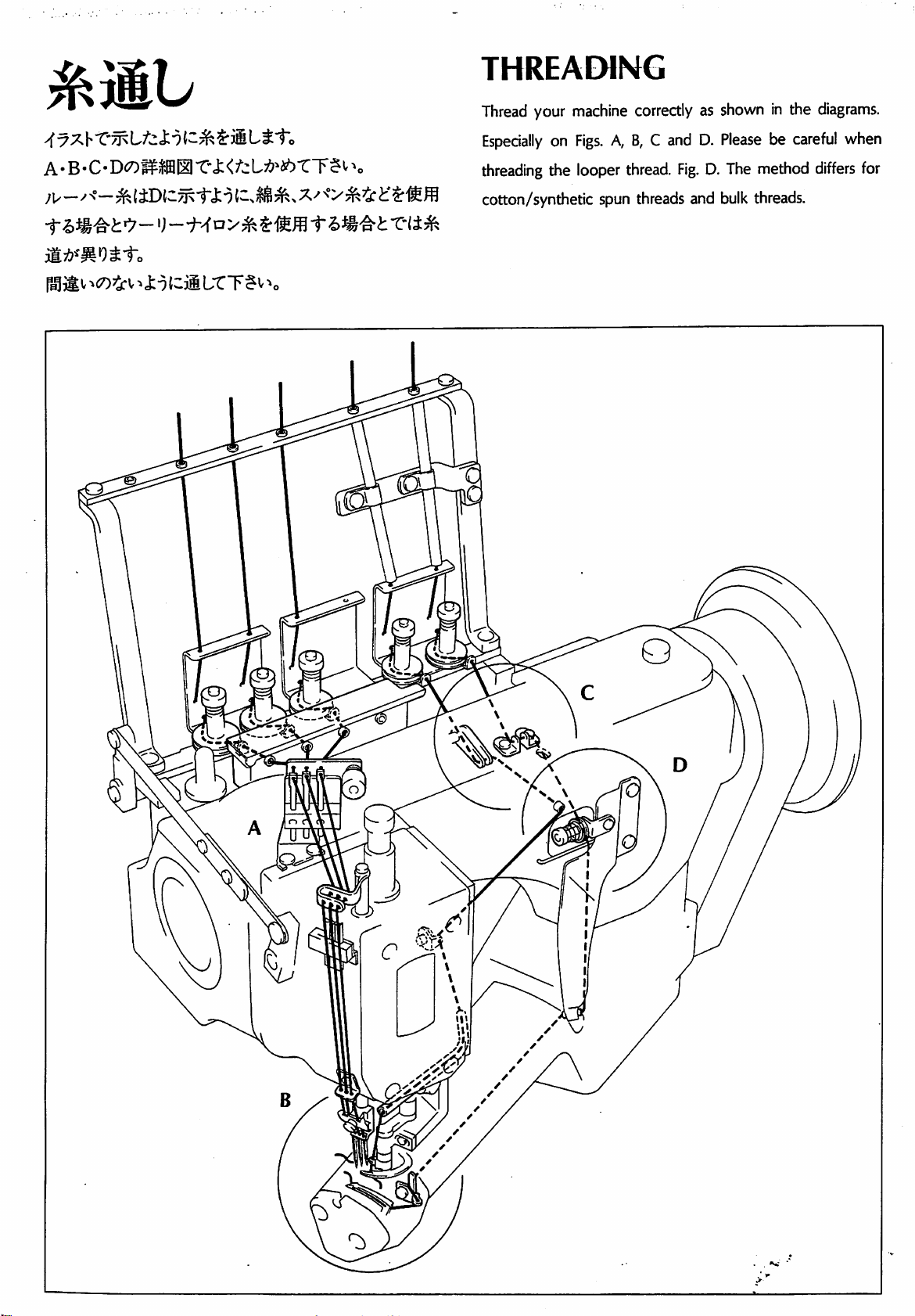

THREADING

A • B-C-D«r)gfMll

ilA^MOSto

T-j:

(cii

L"tT?v

<^cL;!>>a6rT§i'

V

Thread

Especially

threading

cotton/synthetic

your

machine

on

Figs.

the

looper

correctly

A,

B, C and

thread.

spun

threads

as

shown

D.

Please

Fig.

D.

and

bulk

The

method

threads.

in

the

diagrams.

be

careful

differs

when

for

H

Page 42

w

B

Bulk

threads

Cotton/synthetic

spun

threads

Page 43

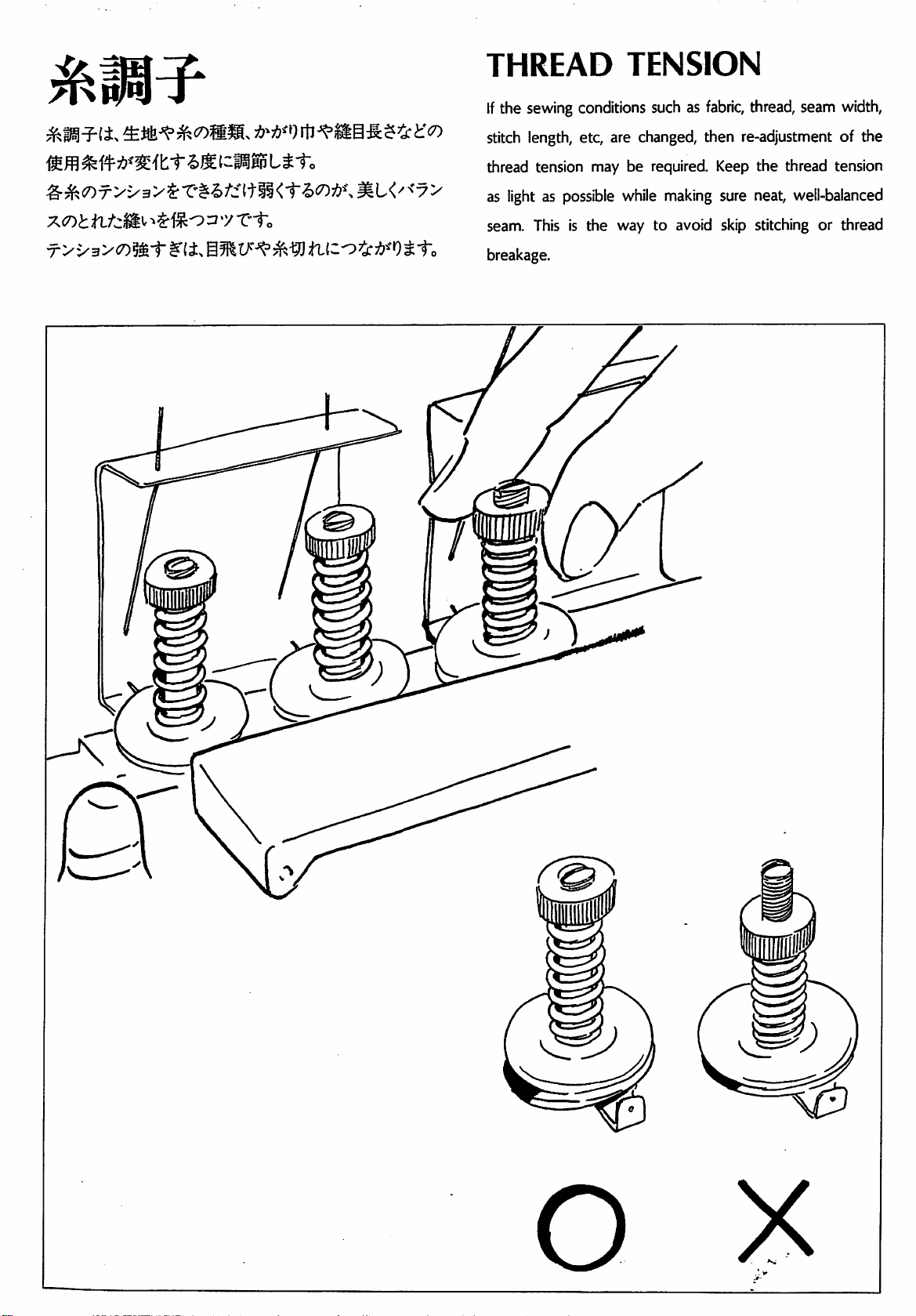

THREAD

If

the

sewing

stitch

length,

conditions

etc,

TENSION

such

as

are

changed,

fabric,

thread,

then

re-adjustment

seam

of

width,

the

^^OT>X3>$-"C^I>/ittll<1"l)W,^L<'^*-7>

^$1So3'y

T-f.

thread

as

seam.

breakage.

tension

light

as

This

may

be

possible

is

the

while

way

required

making

to

Keep

sure

avoid

skip

the

thread

neat,

stitching

tension

well-balanced

or

thread

Page 44

REPLACING

THE

NEEDLE

f>-fe-y

K7^/

<-

(iTtwili

S-f#f«|S]§$-5i75'AiU9o

ffi

ffl

«ti4UY128GASS-fi6uito

x-mncm

Ky^-'<-S-1s6o

LiiAr-TSi-

>0

Holding

the

tightening

into

tion

The

the

screw

the

of

needle

with

the

hole

the

damaged

of

needle.

system

o

needle

the

alien

screw,

the

screw.

Is

is

it

insert

UY128GAS.

with a pair

key

driver.

the

tip

Please

inserted

make

fully

of

tweezers,

When

of

the

alien

sure

into

the

loosen

loosening

of

the

needle

key

direc

hole

or

fully

?

Page 45

STITCH

CONTROL

LENGTH

T-,

T^}boT~F$*''*o

«:Sr#.

WAtcft®

tt

Wp®

$"£'T

Remove

ing

L

down

Please

to

to

the

link.

Move

for a shorter

note

that

re-set

the

do

this.

cap-screw.

the

after

needle

Loosen

link

up

stitch.

this

guard.

the

screw

for a longer

adjustment,

So,

please

stitch

it

will

ask

of

the

and

be

your

connect

move

it

necessary

mechanic

Page 46

/"c

tt

T-

T-#

DIFFERENTIAL

CONTROL

Differential

is

turn

If

you

feed

the

lever

turn

the

control

to

the

right

lever

to

is

very

the

left,

or

to

FEED

easy.

the

then

All

you

left.

you

have

can

gather

to

do

the

fabric.

stretch

If

the

you

fabric.

turn

the

lever

to

the

right,

then

you

can

Page 47

PRESSER

Turn

the

Keep

it

thumb

as

screw

light

as

FOOT

and

adjust

possible

while

PRESSURE

the

presser

making

foot

sure a neat,

pressure.

well-

riil;TSvv

balanced

seam.

Page 48

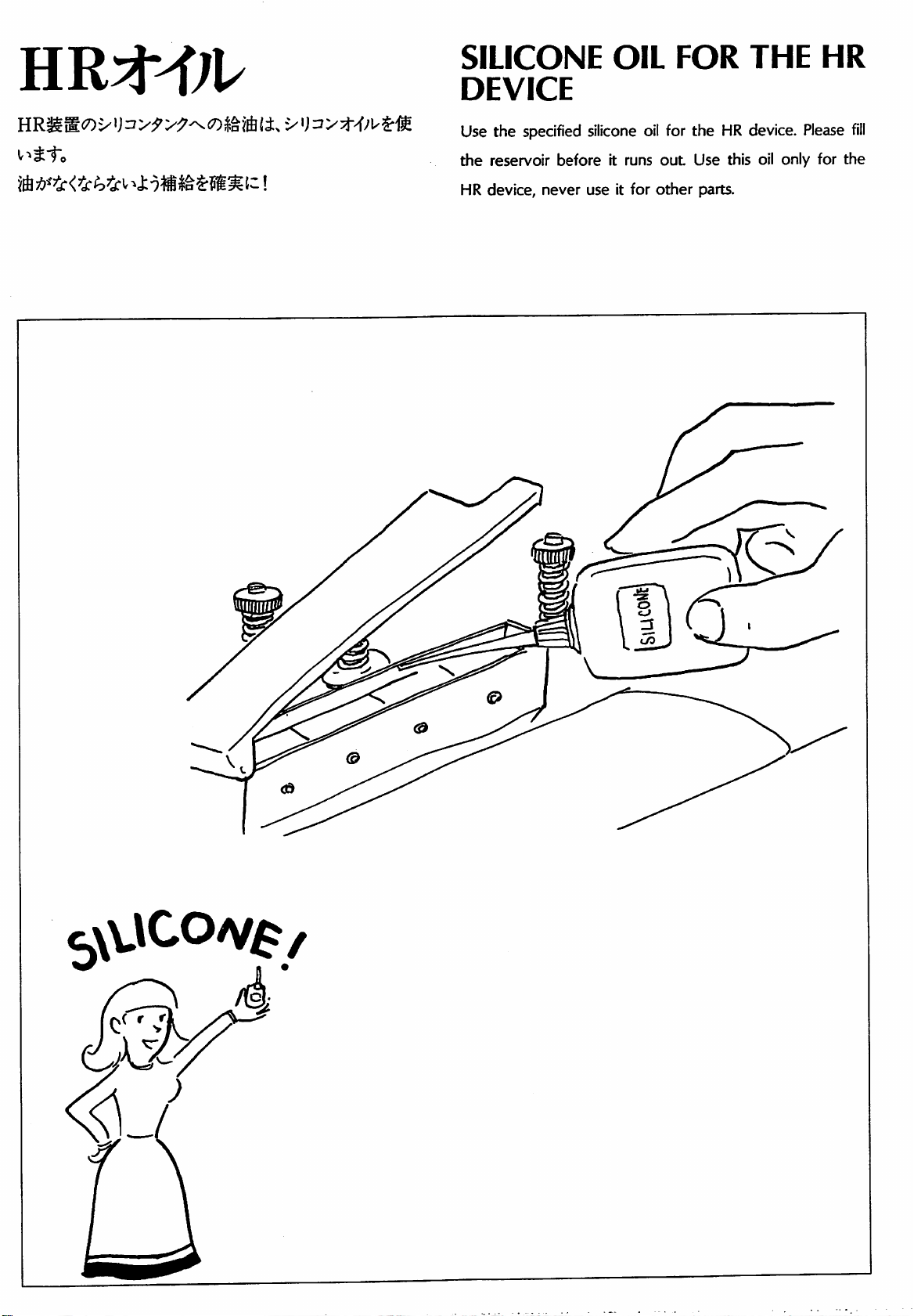

SILICONE

DEVICE

Use

the

specified

the

reservoir

HR

device,

before

never

use

OIL

siiicone

it

runs

it

for

oil

for

out

other

FOR

the

HR

Use

parts.

THE

device.

this

oil

Please

only

for

MR

fill

the

HUllIlf/lii

Page 49

LUBRICATION

bXl^W

There

screw

the

add

The

are

and

upper

oil

recommended

the

spreader

TWO

fill

the

line

of

before

the

drive

inlets

for

machine

the

oil

oil

level

level

oil

is

with

mechanism

iubricatton.

oil

sight

goes

of

VC46.

until

the

gauges.

below

by

hand.

Take

the

Oil

out

the

oil

level

reaches

Remember

lower

line.

each

link

cap-

to

of

|i*-^

31

Page 50

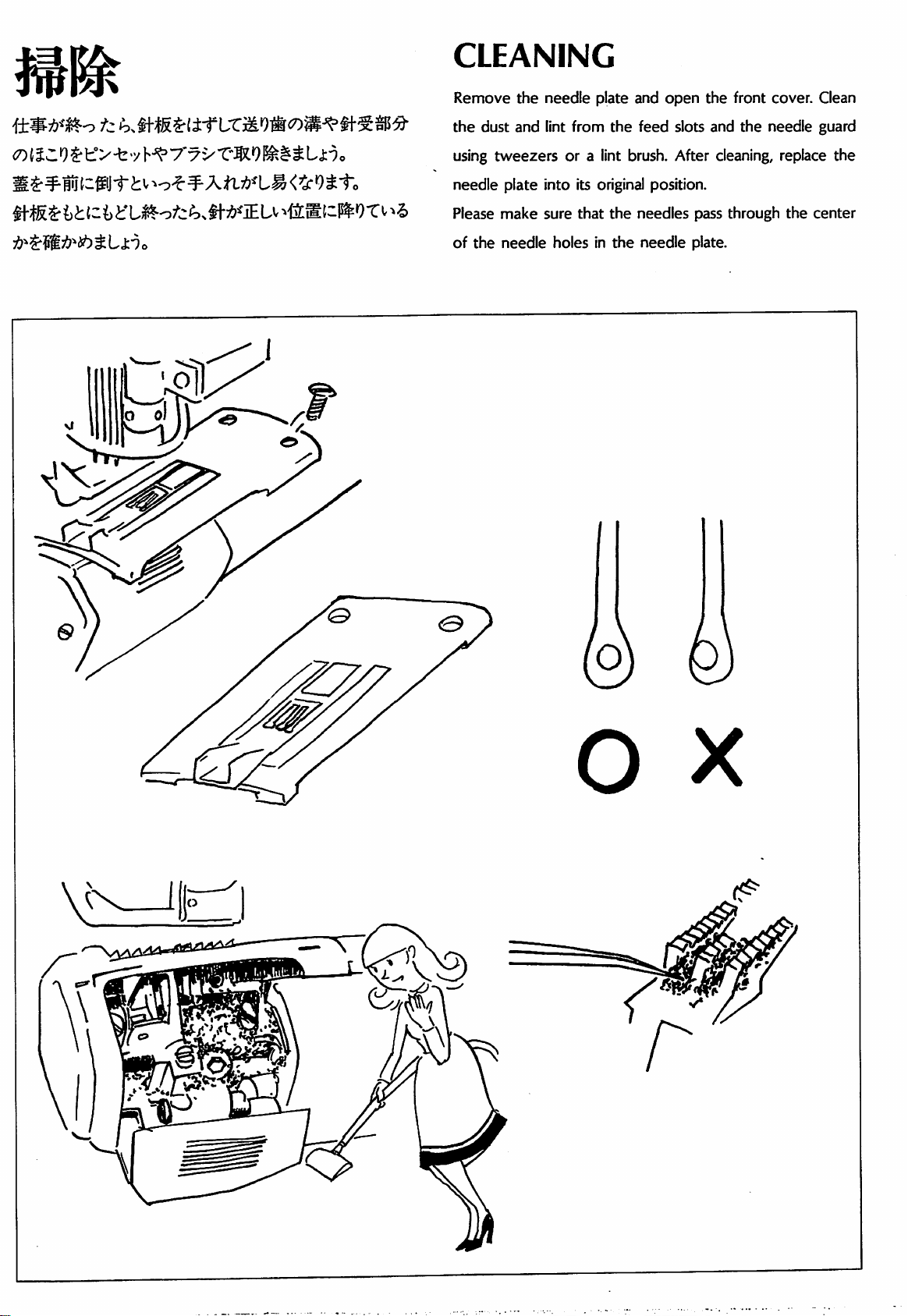

CLEANING

cotSCO^tV-fe-yh^ryvT-Sl'J^I^SLi-),

Remove

the

dust

using

tweezers

needle

Please

of

the

plate

make

needle

the

and

needle

lint

from

or a lint

into

its

sure

that

holes

in

plate

and

open

the

feed

brush.

original

the

needles

the

needle

position.

the

slots

and

After

cleaning,

pass

plate.

front

cover.

the

needle

replace

through

the

Clean

guard

the

center

S)

Page 51

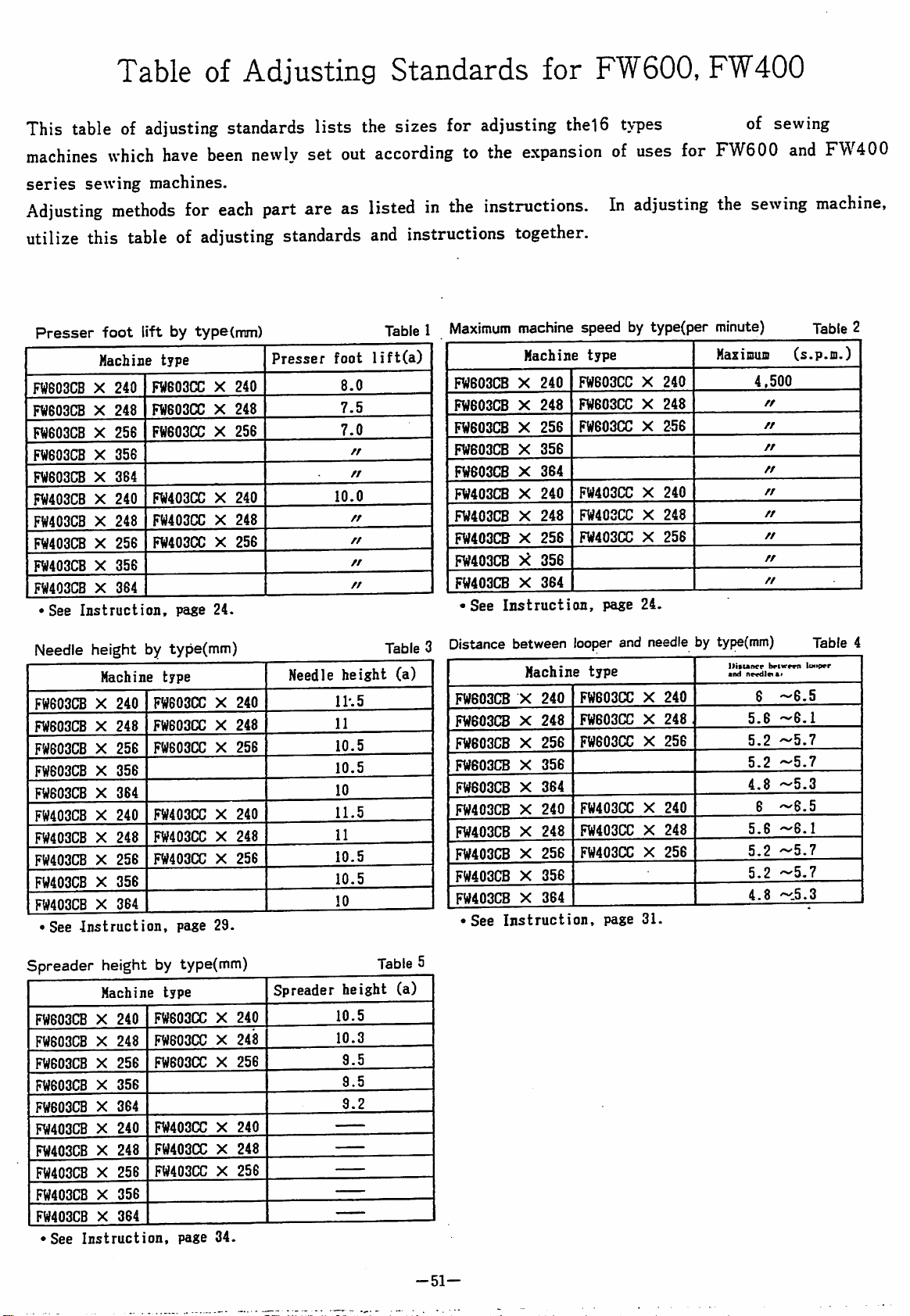

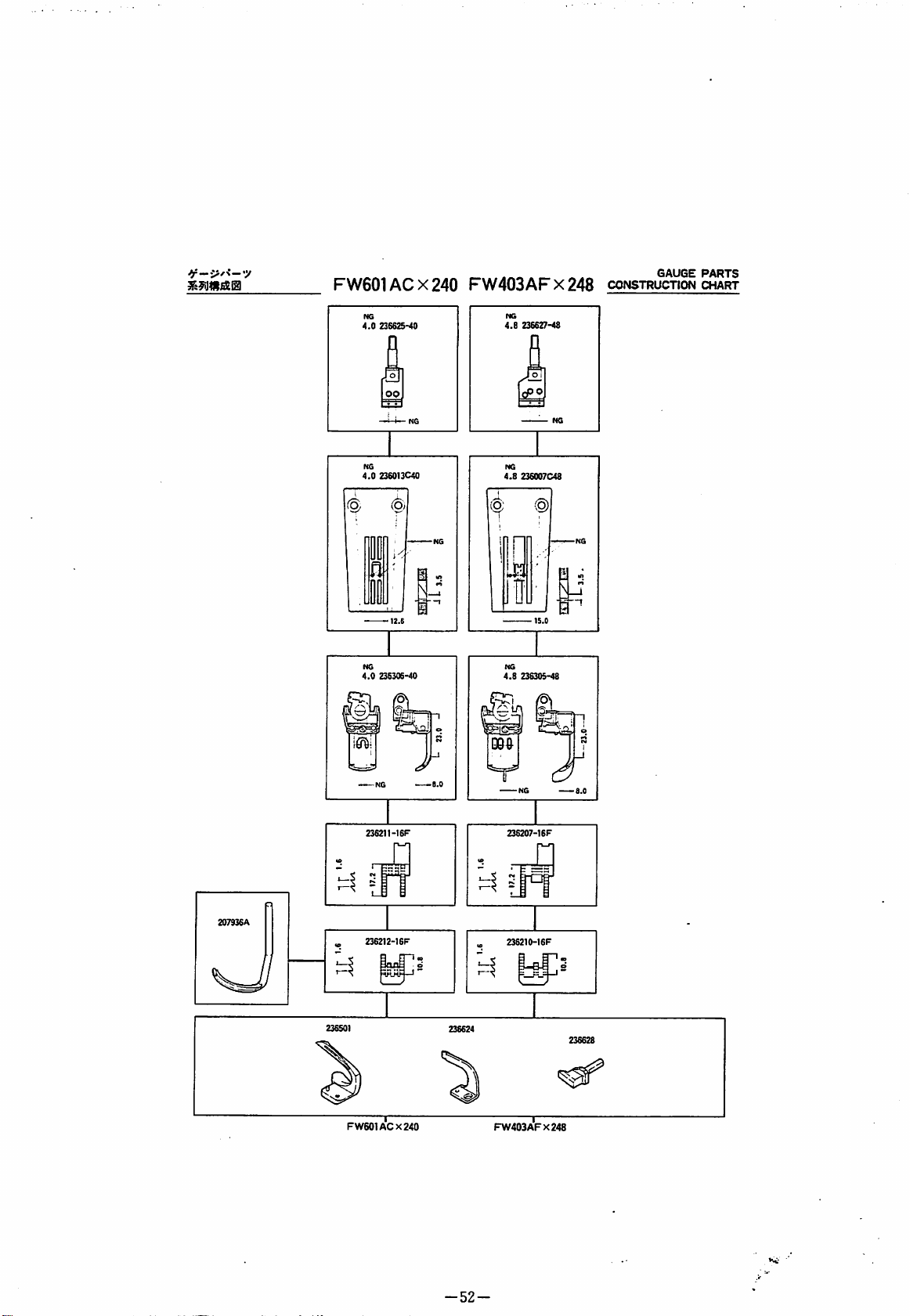

F

W

6

O O

•

F

W

4

O

O

^ i/ y (0

FW603CB X 240

FWe03CB X 248

FW803CB X 256

FW803CB X 358

FW803CB X 384

FW403CB X 240

FW403CB X 248

FW403CB X 258

FW403CB X 356

FW403CB X 364

^

$ -y y (D M ii:.

FW603CB X 240

FW803CB X 248

FW603CB X 258

FW803CB X 356

FW803CB X 364

FW403CB X 240

FW403CB X 248

FW403CB X 256

FW403CB X 358

FW403CB X 364

(aa)

^

FW803CC X 240

FW803CC X 248

FW603CC X 256

FW403CC X 240

FW403CC X 248

FW403CC X 256

(offl)

FW803CC. X 240

FW803CC X 248

Ftf603CC X 256

FW403CC X 240

FW403CC X 248

FW403CC X 256

FW6 0 0»

8.0

7.5

7.0

//

//

10.0

n

ft

ft

ft

11.5

11

10.5

10.5

10

11.5

11

10.5

10.5

10

FW4 0 0 y —

1

(a)

FW803CB X 240

FW803C6 X 248

FW603CB X 256

FW803CB X 356

FW803CB X 364

F»403CB X 240

FW403CB X 248

FW403CB X 258

FW403CB X 358

FW403CB X 384

^