Page 1

Pegasus FlyAway Kit 1

___________________________________________________________________

Pegasus FlyAway Kit

A Portable Weather Station

User Manual

Version 1.10

All specifications subject to change without notice.

Printed in U. S. A.

Columbia Weather Systems, Inc.

Page 2

Pegasus FlyAway Kit 2

___________________________________________________________________

© Copyright 2002 Columbia Weather Systems, Inc. All Rights

Reserved.

Proprietary Notice: Pegasus FlyAway Kit, Capricorn 2000 and

Capricorn 2000MP are trademarks of Columbia Weather Systems,

Inc. The information and drawings contained herein are the sole

property of Columbia Weather Systems, Inc. Use of this publication

is reserved exclusively for customers of Columbia Weather

Systems, Inc. and their personnel. Reproduction of this material is

forbidden without the express written consent of Columbia Weather

Systems, Inc.

Columbia Weather Systems, Inc.

Page 3

Pegasus FlyAway Kit 3

___________________________________________________________________

Welcome!

Welcome to the Pegasus family of users and congratulations on

your purchase of the Pegasus FlyAway Kit Portable Weather

Station.

The Pegasus FlyAway Kit is quite easy to install and you may be

tempted to skip the installation procedure or other portions of this

manual. We recommend that you resist that urge. A thorough

knowledge of these installation and calibration procedures will

greatly increase the usefulness and the accuracy of your instrument.

In particular, a proper installation will help prevent problems with

both operation and maintenance.

Please read this manual completely prior to installation.

Columbia Weather Systems, Inc.

Page 4

Pegasus FlyAway Kit 4

___________________________________________________________________

Important Notice: Shipping

Damage

BEFORE YOU READ ANY FURTHER, please inspect all system

components for obvious shipping damage. The Pegasus

FlyAway Kit is a high precision instrument and can be damaged by

rough handling. Your unit was packaged to minimize the possibility

of damage in transit. Therefore, we recommend that you save the

shipping container for any future shipment of your Pegasus unit.

In the event your order arrives in damaged condition, it is important

that the following steps be taken immediately. The title transfers

automatically to you, the customer, once the material is entrusted to

the transport company.

NOTE: DO NOT RETURN THE INSTRUMENT TO COLUMBIA

WEATHER SYSTEMS until the following steps are completed.

Failure to follow this request will jeopardize your claim.

1. Open the container and inspect the contents. Do not throw

away the container or any damaged parts. Try to keep items

in the same condition as originally received.

2. Notify the transport company immediately in writing,

preferably by facsimile, about the shipping damage.

3. Wait for the transport company’s representative to inspect

the shipment personally.

4. After inspection, request permission from Columbia

Weather Systems for return of the damaged instrument by

calling the Capricorn Service Department, (503) 629-0887.

5. Return approved items to us at the following address:

Columbia Weather Systems, Inc.

2240 NE Griffin Oaks Street, Suite 100

Hillsboro, OR 97124

6. After return authorization is issued and we receive the

instrument, an estimate of the cost of repair will be sent to

you for submittal to the transport company as a claim.

Columbia Weather Systems, Inc.

Page 5

Pegasus FlyAway Kit 5

___________________________________________________________________

Table of Contents

WELCOME! .......................................................................... 3

IMPORTANT NOTICE: SHIPPING DAMAGE............... 4

SECTION 1: INTRODUCTION .......................................... 8

THE CAPRICORN 2000 SYSTEM................................................................ 8

SPECIFICATIONS .......................................................................................8

Temperature ........................................................................................8

Barometric Pressure............................................................................ 8

Wind Speed.......................................................................................... 8

Wind Direction ....................................................................................9

Relative Humidity................................................................................ 9

Wireless Transceiver ........................................................................... 9

Battery Power...................................................................................... 9

Control Module ................................................................................... 9

System Weight ..................................................................................... 9

SECTION 2: PHYSICAL DESCRIPTION....................... 10

CONTROL MODULE ................................................................................ 11

Control Module Connections ............................................................ 11

Wind sensor components................................................................... 13

TEMPERATURE SENSOR .......................................................................... 15

RELATIVE HUMIDITY SENSOR ................................................................ 16

TRIPOD................................................................................................... 17

Specifications .................................................................................... 18

WEATHERMASTER 2000 SOFTWARE (OPTIONAL) ............................... 19

WEATHER VIEW 32 SOFTWARE (OPTIONAL)....................................... 20

RETRIEVERCC PALM OS SOFTWARE (OPTIONAL) .............................. 21

Features............................................................................................. 22

Requirements..................................................................................... 22

WEATHER DISPLAY CONSOLE (OPTIONAL)............................................ 23

SECTION 3: INSTALLATION ......................................... 24

SECTION 4: DISPLAY CONSOLE AND SOFTWARE

INSTALLATION................................................................. 27

WEATHER DISPLAY CONSOLE................................................................ 27

WEATHERMASTER 2000 SOFTWARE .................................................. 27

WEATHER VIEW 32 SOFTWARE .......................................................... 27

RETRIEVERCC PALM SOFTWARE ....................................................... 27

Columbia Weather Systems, Inc.

Page 6

Pegasus FlyAway Kit 6

___________________________________________________________________

SECTION 5: OPERATION................................................ 28

RS-232 MODEM SERIAL PORT ................................................................ 28

RS-232 AUX SERIAL PORT ..................................................................... 28

COMMUNICATION .................................................................................. 28

SETTING DATE AND TIME........................................................................ 29

DISPLAYING DATE AND TIME.................................................................. 29

DISPLAYING CURRENT SENSOR READINGS.............................................. 29

The POLL command.......................................................................... 29

The SAMPLE command..................................................................... 30

The Short commands ......................................................................... 30

DATALOG............................................................................................... 31

SETTING DATALOG INTERVALS .............................................................. 31

SETTING HI/LO INTERVALS .................................................................... 31

DISPLAYING THE DATALOG ....................................................................32

RESETTING HI/LO .................................................................................. 32

RESETTING THE DATALOG ...................................................................... 33

DISPLAYING CURRENT HI/LO ................................................................. 33

SETTING BAROMETRIC PRESSURE ALTITUDE AND OFFSET ...................... 33

DISPLAY CURRENT SETTINGS ................................................................. 34

CONTINUOUS DISPLAY OF DIRECTION..................................................... 34

CONTINUOUS DISPLAY OF WIND INFORMATION ...................................... 34

SECTION 6: CALIBRATION ........................................... 37

CALIBRATING THE BAROMETRIC PRESSURE SENSOR ............................. 37

Altitude Setting .................................................................................. 37

Optional Calibration Procedure .......................................................37

CALIBRATING THE WIND SENSORS ........................................................ 38

CALIBRATING THE TEMPERATURE SENSORS .......................................... 38

CALIBRATING THE HUMIDITY SENSOR ................................................... 39

SECTION 7: MAINTENANCE ......................................... 40

CONTROL MODULE ................................................................................ 40

TEMPERATURE SENSOR MAINTENANCE .................................................40

WIND SENSOR MAINTENANCE ............................................................... 40

RELATIVE HUMIDITY SENSOR MAINTENANCE ....................................... 41

SECTION 8: TROUBLESHOOTING............................... 42

TEMPERATURE SENSOR TROUBLESHOOTING.......................................... 42

COMMUNICATION PROBLEMS ................................................................ 42

SECTION 9: USER SUPPORT INFORMATION ........... 44

LIMITED WARRANTY ............................................................................. 44

EXCLUSIONS ...................................................................................44

RETURN FOR REPAIR PROCEDURE.......................................................... 45

Columbia Weather Systems, Inc.

Page 7

Pegasus FlyAway Kit 7

___________________________________________________________________

REFERENCE....................................................................... 47

GLOSSARY ............................................................................................. 47

Aspirating Radiation Shield .............................................................. 47

Barometric Pressure.......................................................................... 47

Celsius Temperature Scale................................................................ 47

Dew Point.......................................................................................... 47

Fahrenheit Temperature Scale.......................................................... 47

Heat Index ......................................................................................... 47

Relative Humidity.............................................................................. 48

Sea Level Pressure ............................................................................ 48

Wind Chill ......................................................................................... 48

UNIT CONVERSION................................................................................. 49

Speed ................................................................................................. 49

Temperature ......................................................................................49

Distance............................................................................................. 49

Pressure............................................................................................. 49

TABLES AND FORMULAS ........................................................................50

Wind Chill Chart ...............................................................................50

Wind Chill Equation.......................................................................... 50

Heat Index ......................................................................................... 51

Dew Point.......................................................................................... 52

Columbia Weather Systems, Inc.

Page 8

Pegasus FlyAway Kit 8

___________________________________________________________________

SECTION 1: INTRODUCTION

The Capricorn 2000 System

The Pegasus FlyAway Kit portable weather station combines digital

quality and professional-grade equipment with the need for a highly

mobile weather station to create a state-of-the-art, rapid deployment

weather monitoring system for Emergency Operations.

Pegasus is specifically designed for firefighters, HazMat,

Emergency Management, and Disaster Preparedness personnel

when weather monitoring is crucial to the public’s safety.

Pegasus allows Accident and Incident Commanders to create a fully

functional weather operation within minutes, automatically collecting

weather data and providing a cost-effective force-multiplier not

available in any other portable weather station.

Specifications

Temperature

Type: digital semiconductor

Range: -67° to 257°F

Accuracy: ±0.9°F

Resolution: 0.01°F

Barometric Pressure

The barometric pressure sensor is located inside the Control

Module and is part of the weather station circuit board.

Type: silicon shear stress strain gauge; temperature compensated

and calibrated

Range: 27 to 33.96 in. Hg

Accuracy: ±0.03 in. Hg over range (at sea level, with temperature

between 32° and 182°F)

Resolution: 0.01 in. Hg

Wind Speed

Type: chopping disc anemometer, three cups

Range: 0 to 125 mph

Columbia Weather Systems, Inc.

Page 9

Pegasus FlyAway Kit 9

___________________________________________________________________

Accuracy: ±1 mph from 5 to 20 mph, ±5% from 20 to 125 mph

Mechanical Threshold: 0.5 mph

Resolution: 1 mph

Wind Direction

Type: wind vane using digital gray code

Range: 360 degrees.

Relative Humidity

Type: Capacitance

Range: 0 to 100%

Accuracy: ±3% (or better) from 10 to 90% RH at 68° F

Temperature Effect: <±1.5% RH from 14° F to 140° F

Stability: ±2% RH over 2 years

Resolution: 1% RH

Wireless Transceiver

Frequency: 2.402 - 2.478 GHz, FHSS (license-free)

Range: Up to 500 feet (152 m) indoors; Up to 10,000 feet (3050 m)

line-of-sight

Output Power: 200 mW

Battery Power

Output: 12 VDC, 12 AH, 32-hour operation

SLA (Sealed Lead Acid) Gel Batteries

Control Module

Dimensions: 14 x 11 x 6.5 inches

Weight: 6.7 lbs/3 kg.

System Weight

Weather station and caring case: 38 lbs

Tripod and canvas bag: 17 lbs

Battery system and case: 23 lbs

Columbia Weather Systems, Inc.

Page 10

Pegasus FlyAway Kit 10

___________________________________________________________________

SECTION 2: PHYSICAL

DESCRIPTION

Columbia Weather Systems, Inc.

Page 11

Pegasus FlyAway Kit 11

___________________________________________________________________

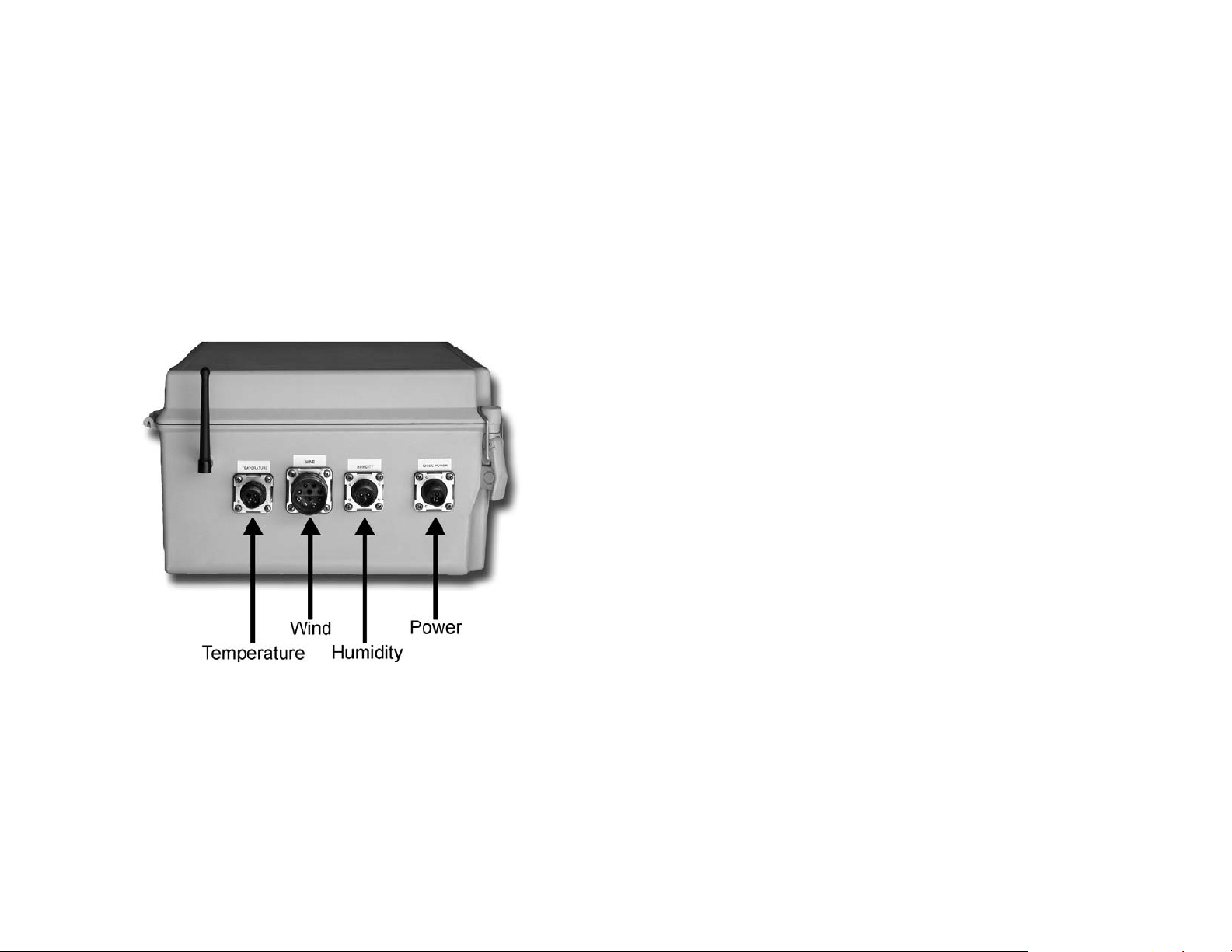

Control Module

The Control Module consists of the System board and a 2.4 GHz

transceiver housed in a weatherproof fiber glass enclosure with

external sensor and power connectors.

The System board has an on-board barometric pressure sensor and

a system fuse (including a spare fuse). The System board also has

in-line rechargeable batteries to preserve the datalog and system

configuration when power is absent.

The Control Module dimensions are: 14 x 11 x 6.5 inches and

weighs: 6.7 lbs/3 kg.

Control Module Connections

Columbia Weather Systems, Inc.

Page 12

Pegasus FlyAway Kit 12

___________________________________________________________________

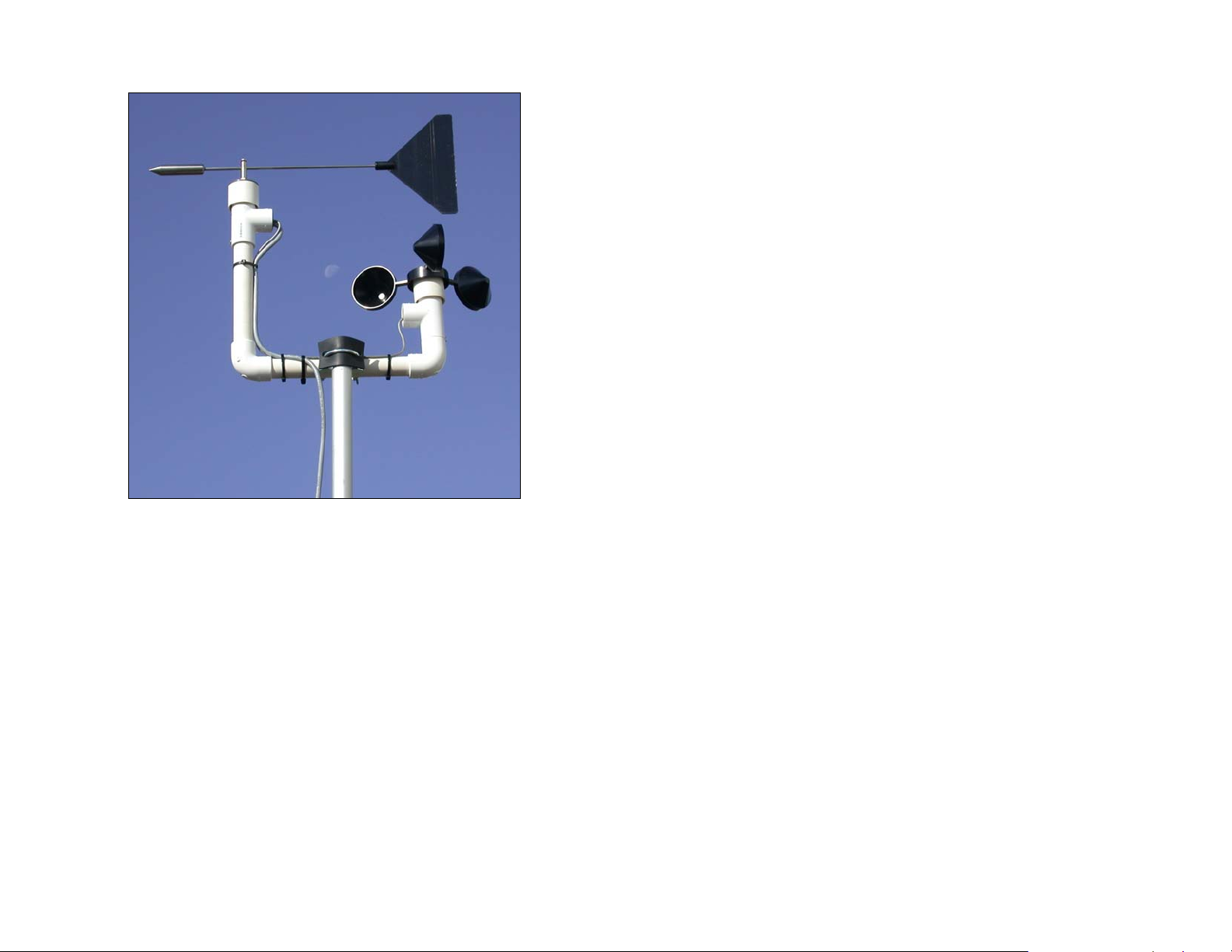

Wind sensor

The wind speed and direction sensors use a solid state, infrared

optical design to decrease wear and improve reliability. These

rugged sensors, with a design incorporating years of experience

and testing, are enclosed in a rugged PVC housing surrounding

stainless steel parts. These sensors operate in extreme temperature

and wind conditions for years.

Columbia Weather Systems, Inc.

Page 13

Pegasus FlyAway Kit 13

___________________________________________________________________

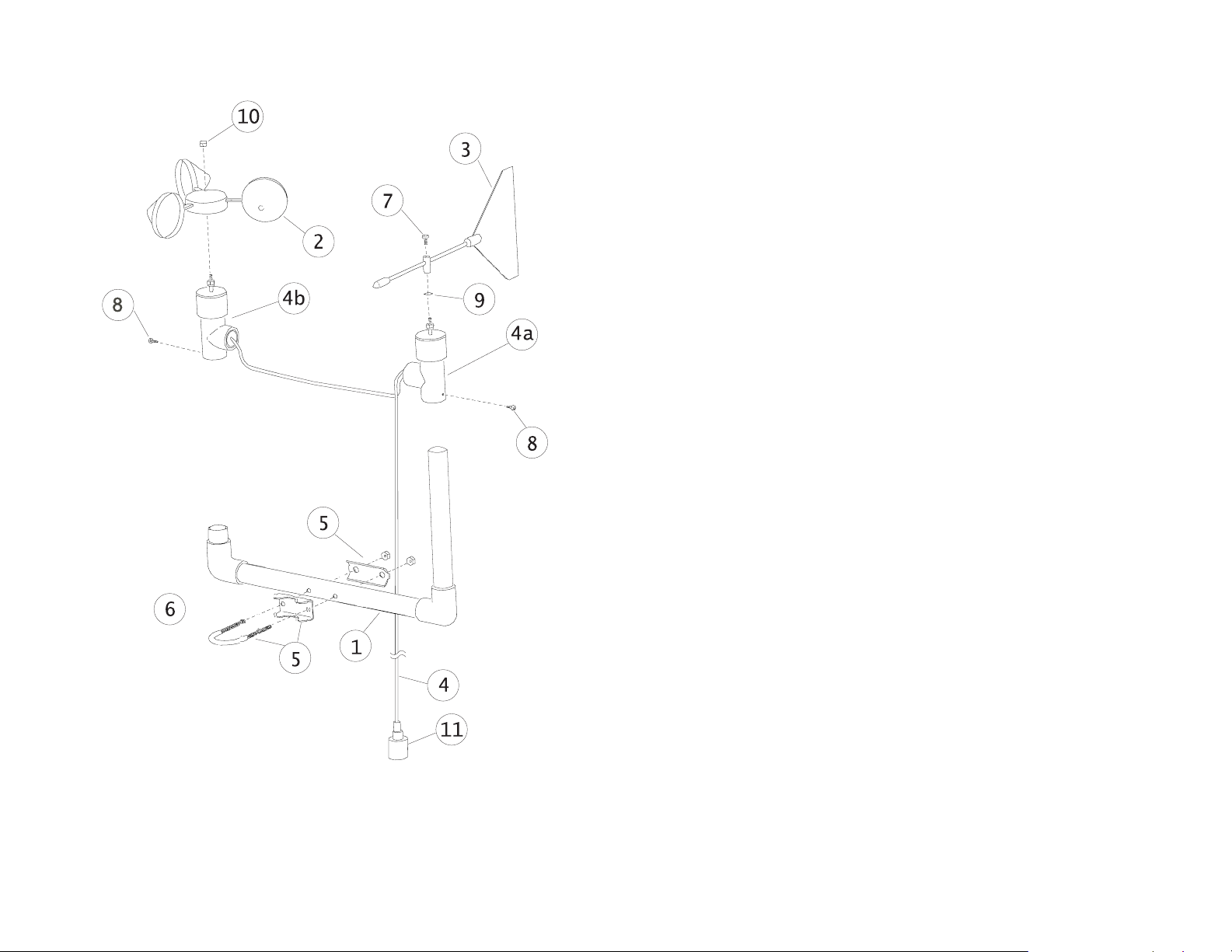

Wind sensor components

Columbia Weather Systems, Inc.

Page 14

Pegasus FlyAway Kit 14

___________________________________________________________________

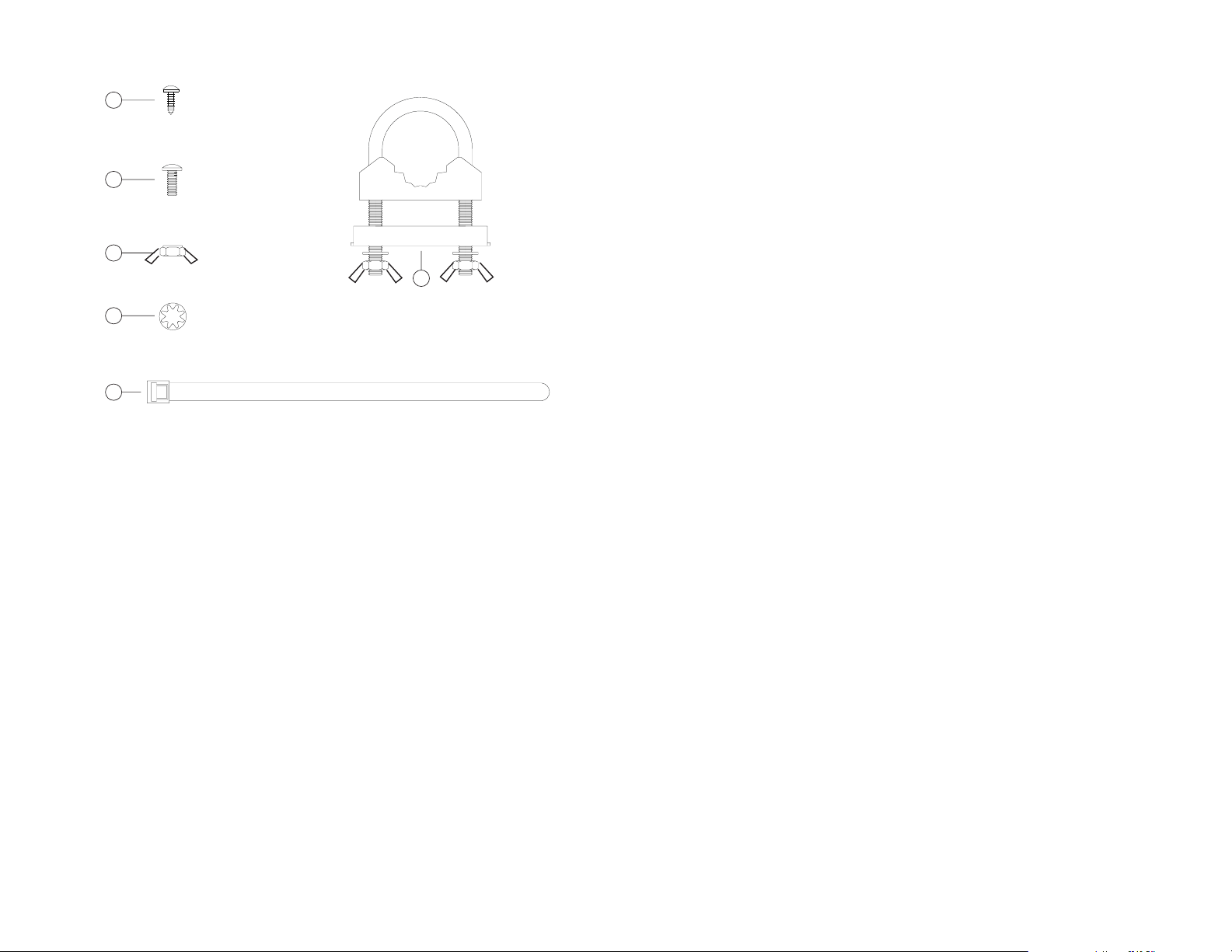

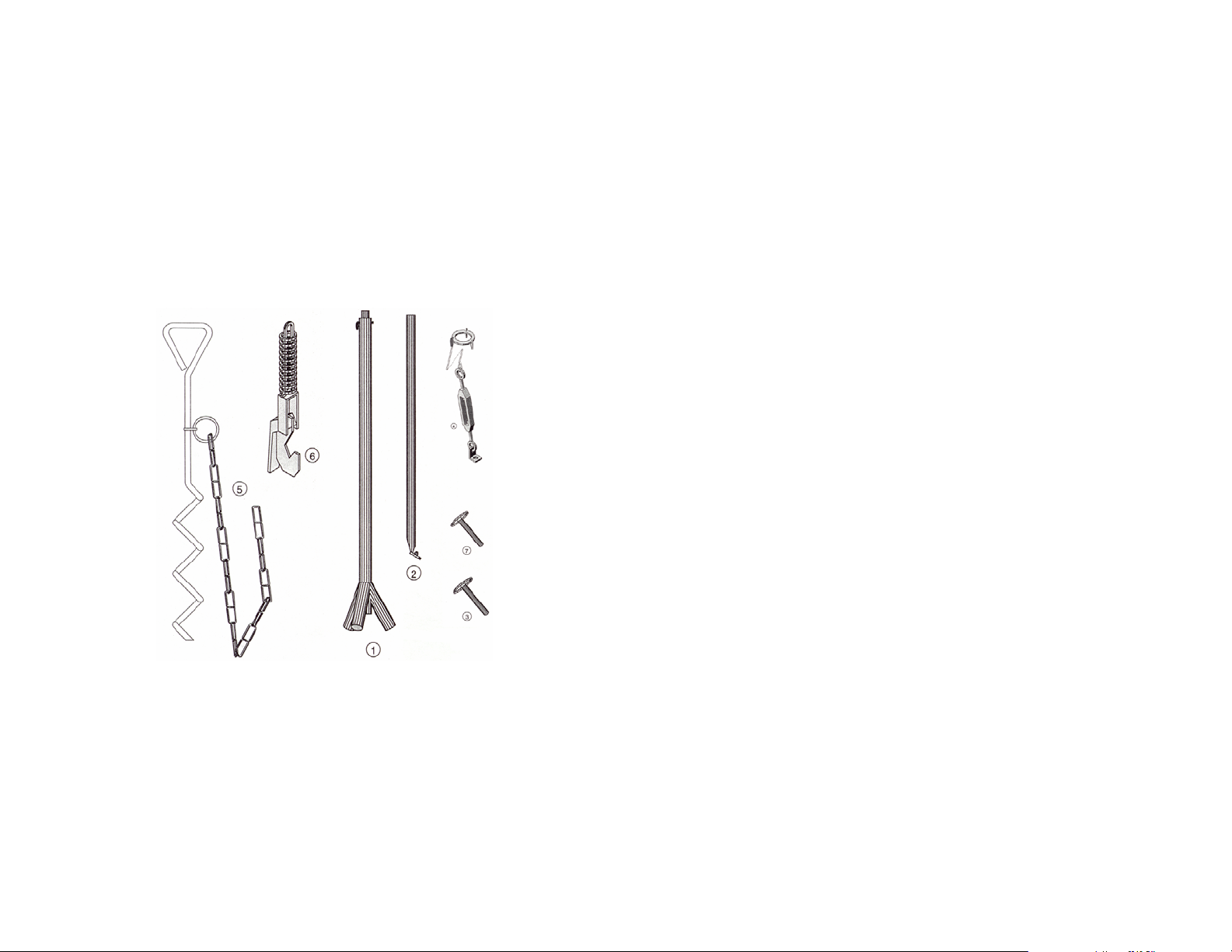

Hardware Kit Assembly Kit

8

SHEET METAL SCREW

FOR CROSS-ARM SUPPORT,

STAINLESS STEEL (QTY 2)

7

TOP SCREW

FOR DIRECTION VANE,

STAINLESS STEEL

10

TOP LOCK NUT

FOR WIND SPEED SENSOR,

STAINLESS STEEL

9

INTERNAL STAR WASHER

FOR WIND DIRECTION SENSOR,

STAINLESS STEEL

6

BLACK PLASTIC TIE-WRAPS (QTY 6)

1. Cross Arm Support

2. Wind Cup Hub Assembly (with spare top lock nut)

5

U-BOLT

ASSEMBLY

PLATED STEEL

3. Wind Direction Vane (with spare top screw)

4. 10-foot wind sensor cable with connector assembly

4a. Wind Direction sensor body (white, T-shaped, heavy duty PVC

fitting with two cables protruding)

4b. Wind Speed sensor body (white, T-shaped, heavy duty PVC

fitting with one cable protruding)

5. Hardware Assembly Kit

6. Black plastic tie wraps (UV-resistant)

7. Top screw (for clamping the direction vane shaft to the vane

holder), stainless steel

8. Stainless steel sheet metal screws (for mounting wind sensors

to Cross Arm Support)

9. Top lock nut (to be placed on threaded shaft of wind speed

sensor, above wind cup assembly

10. Top lock nut (to be placed on threaded shaft of wind speed

sensor, above wind cup assembly), stainless steel

11. Wind Sensor Cable Connector

Columbia Weather Systems, Inc.

Page 15

Pegasus FlyAway Kit 15

___________________________________________________________________

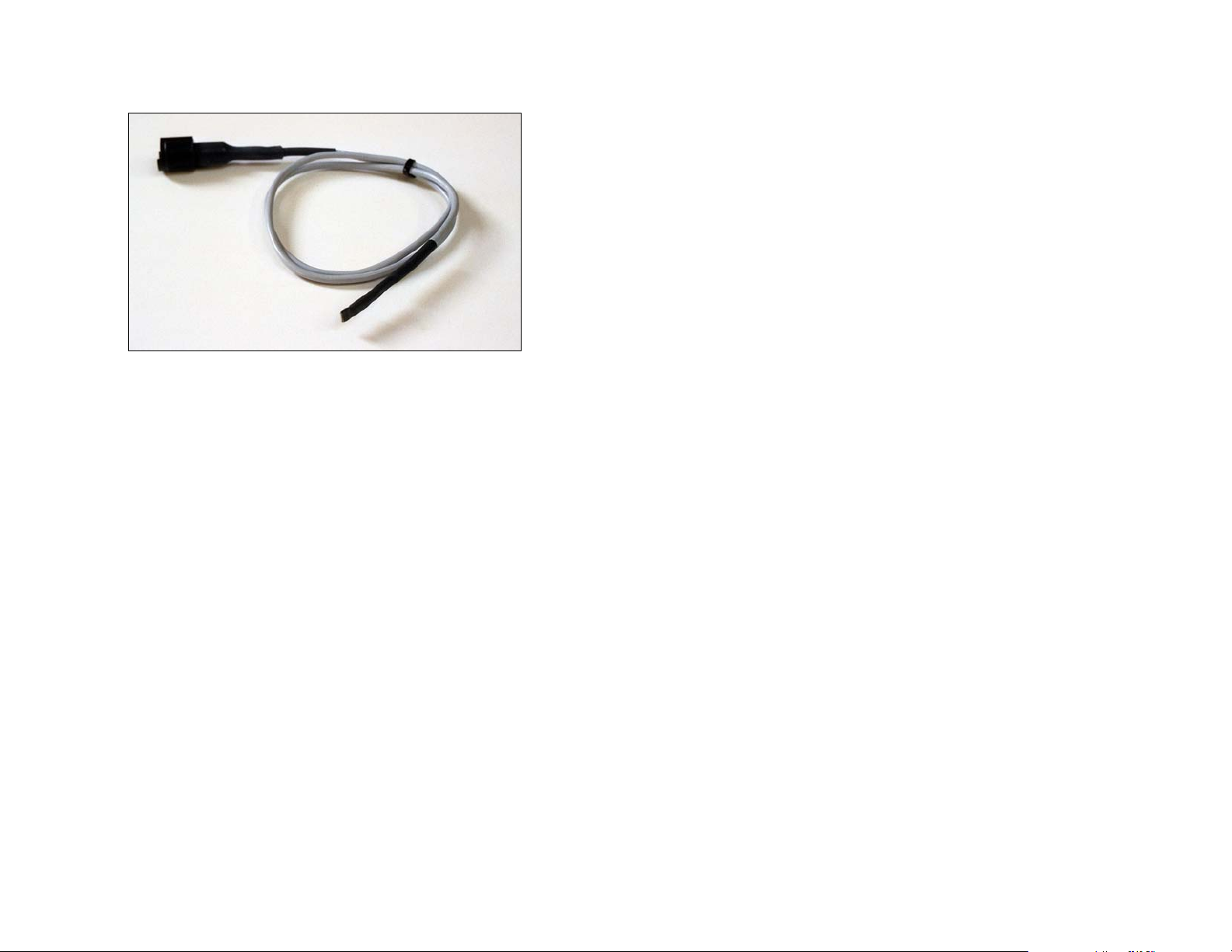

Temperature sensor

The Pegasus comes standard with one temperature sensor with 10

feet of cable. This digital, semiconductor-type probe reduces

susceptibility to noise interference, and increases accuracy. The

sensor is calibrated at the factory traceable to NIST standards.

Columbia Weather Systems, Inc.

Page 16

Pegasus FlyAway Kit 16

___________________________________________________________________

Relative Humidity sensor

This optional capacitive relative humidity sensor is compact and

easy to use. It is easily installed in the self-aspirating radiation shield

for protection from the sun and rain. This sensor offers long-term

stability with minimal drift. Because the sensor is a capacitive

device, it will not be affected by surface contamination in unclean

environments. Since the sensor element is socketed and laser

trimmed it can be easily replaced in the field without any additional

calibration. The relative humidity sensor comes with a standard 10foot cable and a quick disconnect connector.

Columbia Weather Systems, Inc.

Page 17

Pegasus FlyAway Kit 17

___________________________________________________________________

Tripod

Tripod Model T-1000 is designed to provide up to 10 feet of stable,

secure support for your meteorological sensors.

The T-1000 is constructed from welded aluminum and is powder

coated for appearance and longevity. The 15-pound tripod can

Columbia Weather Systems, Inc.

Page 18

Pegasus FlyAway Kit 18

___________________________________________________________________

easily support up to 60 pounds of equipment. The tie-down kit

allows for additional security in high-wind areas.

Set up takes less than five minutes. Simply insert the legs into the

main body and install the stainless steel retainer pins. Extend the

mast to the desired height and insert another retainer pin. Install

the guy wires and you’re ready to go!

Specifications

Capacity: Supports up to 60 lbs.

Shipping Weight: 17lbs

Shipping Box Dimensions: 63" x 8" x 8"

Item # Description Qty

1. Body/Mast Assembly 1

2. Legs 3

3. Legs retainer Pins 4

4. Guy Wire Ring with 1

3 Wires and Turnbuckles

5. Anchor Screw with Chain 1

6. Spring Clamp 1

7. Mast retainer Pin 1

Columbia Weather Systems, Inc.

Page 19

Pegasus FlyAway Kit 19

___________________________________________________________________

WeatherMaster 2000 Software

(optional)

WeatherMaster 2000 is a professional grade weather monitoring

software. This software package is designed for specialized markets

that require robust weather calculations, interoperability with

computer models, and data interfaces to other industrial systems.

WeatherMaster 2000 utilizes Microsoft Access database for easy

data access and manipulation.

WeatherMaster 2000 is also capable of monitoring multiple stations

via a wireless link.

Columbia Weather Systems, Inc.

Page 20

Pegasus FlyAway Kit 20

___________________________________________________________________

Weather View 32 Software (optional)

Operating in Windows graphic environment, Weather View 32 helps

you monitor, record, and store local weather data for current or

future analysis.

Weather View 32 offers:

• User-defined real time monitoring display

• Internet and email interface

• Calculated parameters including wind chill, dew point, heat

index and degree days

• Monthly calculations for degree days heating and cooling

• Full-featured graphing and printing capabilities

• Six separate alarms functions

• A Climatological database that covers the U.S. and Canada

• Modem access for remote weather stations

Columbia Weather Systems, Inc.

Page 21

Pegasus FlyAway Kit 21

___________________________________________________________________

RetrieverCC Palm OS Software

(optional)

TM

RetrieverCC

communication with the Capricorn 2000

TM

Kit

weather stations. The RetrieverCC, running on a Palm

provides a user-friendly PalmTM program for

TM

and Pegasus FlyAway

handheld, communicates with the weather station via an RS-232

port to view current weather data, extract logged data and perform

other configuration functions.

RetrieverCC can download the datalog from multiple weather

stations for export to a PC for additional data analysis and storage.

Columbia Weather Systems, Inc.

Page 22

Pegasus FlyAway Kit 22

___________________________________________________________________

Features

• Operates on most Palm Handhelds (see Requirements).

• Easy list-based selection of the weather station functions.

• Parses data output into easily readable fields.

• Data capture capability.

• Retains multiple data-capture sessions (capacity subject only to

available memory).

• User-named data-capture sessions.

• Review of existing data capture sessions on the handheld.

Requirements

• A Palm device running Palm OS® version 3.1.1 or later (Palm V-

series, IIIx, IIIe, IIIxe, IIIc, all m-series, i-series, and also an OS

upgraded Palm III).

• Palm Desktop Software installed on the PC.

• An RS-232 serial cable for the handheld.

• A Capricorn 2000 serial cable (included with software).

Retriever CC is a trademark of Chesapeake Technology

International

Palm is a trademark of Palm, Inc.

Columbia Weather Systems, Inc.

Page 23

Pegasus FlyAway Kit 23

___________________________________________________________________

Weather Display Console (Optional)

The Capricorn 2000 Weather Display uses “intelligent” touch-screen

technology. With its programmable microprocessor and abundant

memory, the Capricorn 2000 Weather Display can display weather

information, perform complex computations, and store relatively

large amounts of weather data.

The Capricorn 2000 Weather Display is also available in Aviation

and Agricultural Editions:

Aviation Edition: Density Altitude with additional wind speed and

direction calculations and charts.

Agricultural Edition: Evapotranspiration and degree day

calculations.

The Weather Display is also available in a 19” rack-mount chassis.

Columbia Weather Systems, Inc.

Page 24

Pegasus FlyAway Kit 24

___________________________________________________________________

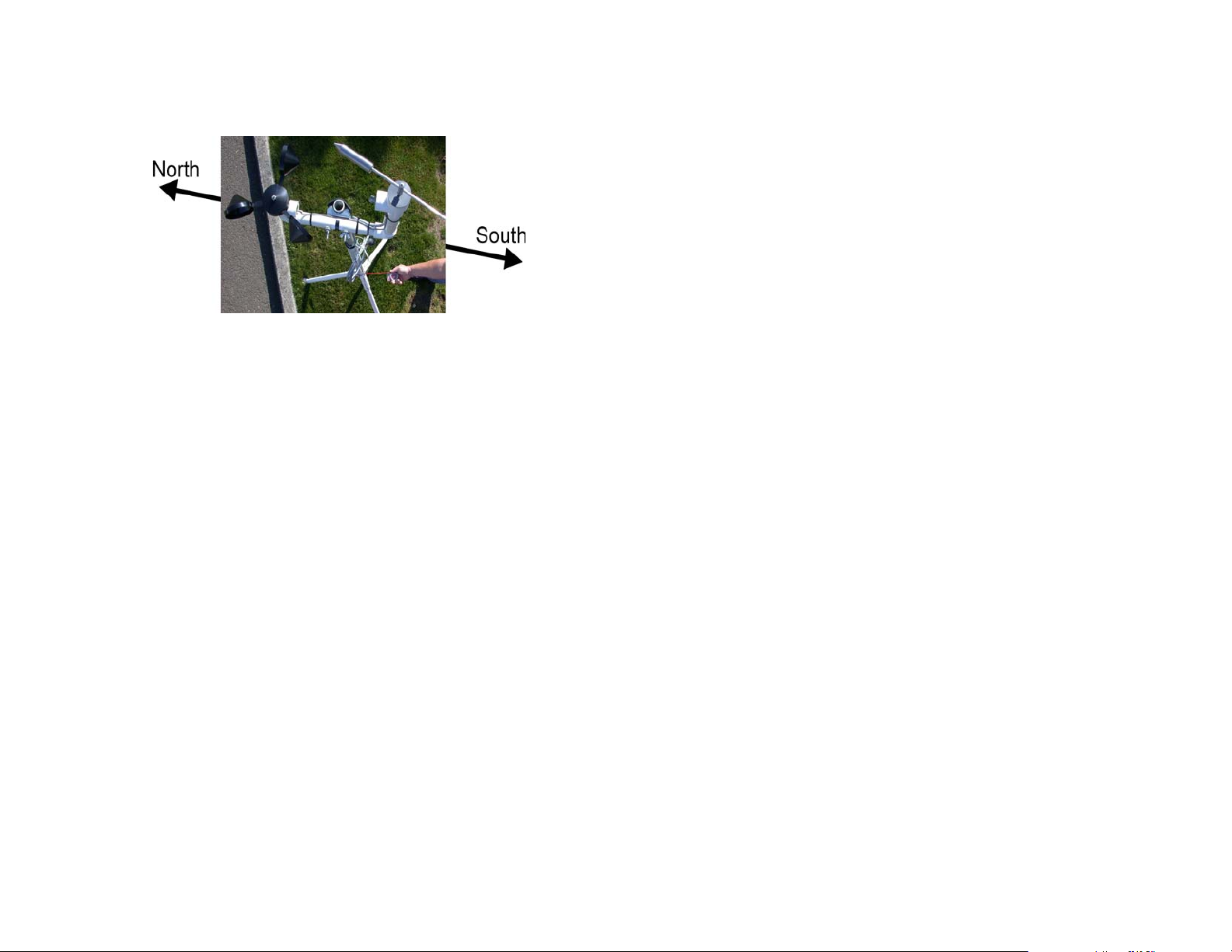

SECTION 3: INSTALLATION

1. Install the radiation shield by slipping it over the sensor

mast extension. Do not tighten wing nuts at this time.

2. Slip the guy wire collar over the sensor mast

3. Install the wind sensor assembly on the top of the mast.

Align the North mark on the wind sensor clamp to the North

mark on the mast and tighten the assembly using the two

wing nuts.

4. Connect the three legs using the pins as shown below.

Columbia Weather Systems, Inc.

Page 25

Pegasus FlyAway Kit 25

___________________________________________________________________

5. Extend the mast to full length and secure with the attached

pin. Be sure that the North marks on the sensor mast and

the tripod body are aligned.

6. Tighten the guy wire turnbuckles so that the sensor mast is

aligned up right.

7. Position the radiation shield toward the lower part of the

sensor mast extension and tighten using the two wing nuts.

Columbia Weather Systems, Inc.

Page 26

Pegasus FlyAway Kit 26

___________________________________________________________________

8. Using the attached compass, orient the entire tripod system

to magnetic North. The wind sensor cross arm assembly

should be aligned with the North/South direction and the

wind cups are pointing to North as shown below.

9. Secure the tripod using the spring-loaded chain attached to

the corkscrew drilling stake (for soil) or the pavement spike

(for hard surfaces). Pavement spikes can be purchased

from local hardware stores.

10. Attach the Control Module to the tripod using the buckle

strap.

11. Connect the sensor cables to the Control Module.

12. Place the battery in its case at the base of the tripod.

Connect the power cable to the battery terminals first and

then to the Control Module external connector.

The system is now operational and is ready to transmit weather

data.

Columbia Weather Systems, Inc.

Page 27

Pegasus FlyAway Kit 27

___________________________________________________________________

Section 4: Display Console

and Software Installation

The Pegasus FlyAway Kit offers several options to view and collect

the weather data. All of these options (with the exception of the

RetrieverCC) use a wireless link to communicate with the control

module.

Weather Display Console

Please refer to the Weather Display user manual for installation and

operation instructions.

WeatherMaster 2000 Software

Please refer to the WeatherMaster 2000 user manual for installation

and operation instructions.

Weather View 32 Software

Please refer to the Weather View 32 user manual for installation and

operation instructions.

RetrieverCC Palm Software

Please refer to the RetrieverCC user manual for installation and

operation instructions.

Columbia Weather Systems, Inc.

Page 28

Pegasus FlyAway Kit 28

___________________________________________________________________

Section 5: Operation

The Pegasus communicates with a computer or Weather Display

console via wireless interface. The Control Module has two ports

available on the back panel (RJ-11 jacks).

RS-232 Modem serial port

This is the main serial port in the system. It is usually connected to

the radio transceiver for communication with a computer or a

Weather Display.

RS-232 Aux serial port

This is a secondary serial port. It is usually used for direct

communication with a computer or a Palm device.

Communication

Normally the weather software or the Weather Display is used for

monitoring. Configuration is done through the menu selection of the

software or the display console.

The commands described in this section are used when the user

wishes to communicate directly with the system using a “terminal”

software program such as Hyper Terminal (available with Windows

operating systems).

The protocol for both serial ports is the following:

Bits per Second (baud rate): 9600

Data bits: 8

Parity: None

Stop bits: 1

Flow control: None

All commands must be entered using upper case letters and

followed by a carriage return.

The weather station will return "ok" after the results of each

command. If the command is incorrect, the weather station will

return "?".

Columbia Weather Systems, Inc.

Page 29

Pegasus FlyAway Kit 29

___________________________________________________________________

Setting date and time

SET-DATE: This command is used to set the internal calendar to

the appropriate date. It uses space delimiters between the month

field, the day field, the year field, and the command field.

Example: 12 25 96 SET-DATE sets the date to 12/25/1996 and 1 5

01 SET-DATE sets the date to 1/5/2001

SET-TIME: This command is used to set the internal clock to the

appropriate military time (24 hours clock). It uses space delimiters

between the hours field, minutes fields and the command field.

Example: 13 46 SET-TIME sets the time to 1:46 PM

Displaying date and time

DATE-TIME: This command is used to display the system date and

time. When used the weather station will return the date followed by

the time, comma delimited.

Example: 02/11/1998,13:20ok

Displaying current sensor readings

There are three ways to display current sensor readings:

The POLL command

POLL: This command is used to display the current sensor readings

in a report format. When a POLL command is issued, the weather

station will interrogate all the sensors and will display the

information

Example:

11:00 Time

02/11/1998 Date

50.14 Degrees F Temperature 1

70.89 Degrees F Temperature 2

68.33 Degrees F Temperature 3

64.46 Degrees F Temperature 4

29.88 Inches Hg Barometric Pressure

006 MPH Wind Speed

SE Wind Direction

073 Percent Relative Humidity

00.06 Inches Rain (Today)

04.43 Volts Leaf Wetness

01.30 Volt X1

04.58 Volts X2

ok

Columbia Weather Systems, Inc.

Page 30

Pegasus FlyAway Kit 30

___________________________________________________________________

The SAMPLE command

SAMPLE: This command is used to display the current sensor

readings in a one line record format (the same format as the

datalog). The record starts with the letter S followed by the date and

time of the sample, followed by the sensor values and ends with a

check sum value. All of these fields are comma delimited.

Example:

S,02/11/98,11:09,36WD,003WS,00.06R,072RH,29.88P1,+050.59T1,+070.77T2,+068.23T3,

+064.60T4,04.43LW,0.00X1,0.00X2,6007ok

Where, WD is wind direction, WS is wind speed in MPH, R is rain

fall in inches, RH is relative humidity percentage, P1 is barometric

pressure in Inches-Hg, T1 through T4 are the four temperature

sensors in degrees F, LW is leaf wetness in volts, X1 is typically

solar radiation (5.00 volts equals 2000 Weather Master 2000-2) and

X2 is used for additional sensors (X1 and X2 channels are not

available with the Pegasus FlyAway Kit).

Temperature channels that are not defined or connected will have a

+255.00 reading.

Wind direction is displayed in a 64 degree compass as follows:

0 N

4 NNE

8 NE

12 ENE

16 E

20 ESE

24 SE

28 SSE

32 S

36 SSW

40 SW

44 WSW

48 W

52 WNW

56 NW

60 NNW

The Short commands

WD: will display wind direction in a 64 compass points

WS: will display wind speed in MPH

R1: will display the rain fall for the day in inches

RH: will display relative humidity percentage

P1: will display the barometric pressure in inches-Hg

Columbia Weather Systems, Inc.

Page 31

Pegasus FlyAway Kit 31

___________________________________________________________________

T1: will display the temperature for the first temperature probe in

degrees F

T2: will display the temperature for the second temperature probe in

degrees F

T3: will display the temperature for the third temperature probe in

degrees F

T4: will display the temperature for the fourth temperature probe in

degrees F

LW: will display leaf wetness in volts. The range may vary per

sensor. Typically, 0.5 volts indicates saturated condition and 4.5

volts indicates dry conditions.

X1 and X2 channels are not used with the Pegasus FlyAway Kit

Datalog

The Pegasus weather station has a built in circular datalogger. The

datalog holds records of sensor readings (Samples) and High/Low

information. Both types of records (Samples and High/Low) are

recorded at user defined intervals.

The datalog can hold up to 511 records. A Sample occupies on

record and High/Low information occupies four records.

Setting datalog intervals

The interval for the Sample records in the datalog is user selectable.

The interval duration is restricted to the following: 1, 2, 3, 4, 5, 6, 10,

15, 20, 30, and 60 minutes.

n MEAS-INT: This command sets the Sample interval in the datalog.

n is the interval duration in minutes.

Example: 15 MEAS-INT will cause the weather station to save a

Sample record every 15 minutes.

Setting Hi/Lo intervals

The interval for the High/Low records in the datalog is user

selectable. The interval duration is restricted to the following: 1, 2, 3,

4, 6, 8, 12 and 24 hours.

n HI/LO-INT: This command sets the High/Low interval in the

datalog. n is the interval duration in hours.

Example: 12 HI/LO-INT will cause the weather station to save

High/Low records (total of four records) every 12 hours.

Columbia Weather Systems, Inc.

Page 32

Pegasus FlyAway Kit 32

___________________________________________________________________

Displaying the datalog

ALL: This command will display the complete datalog (511

maximum records)

Example: In this example the Sample interval is set at one minute

and the High/Low interval is set at one hour and the datalog has 13

record (9 Sample records and 4 High/Low records).

13 records

S,02/11/98,13:56,32WD,007WS,00.07R,074RH,29.85P1,+052.31T1,+071.62T2,+069.17T3,

+065.57T4,01.88LW,0.00X1,0.00X2,6015

S,02/11/98,13:57,32WD,005WS,00.07R,074RH,29.86P1,+052.74T1,+071.83T2,+069.26T3,

+065.69T4,01.70LW,0.00X1,0.00X2,6019

S,02/11/98,13:58,32WD,006WS,00.07R,072RH,29.85P1,+052.76T1,+071.64T2,+069.35T3,

+065.75T4,01.74LW,0.00X1,0.00X2,6020

S,02/11/98,13:59,32WD,006WS,00.07R,071RH,29.85P1,+052.94T1,+071.86T2,+069.36T3,

+065.81T4,01.74LW,0.00X1,0.00X2,6022

H,02/11/98,14:00,013,13:25WS,081,13:40RH,29.86,13:27P1,+053.23,14:00T1,+072.27,13:

52T2,+069.59,13:31T3,+065.88, 14:00T4,01.70,13:57LW,0.00,14:00X1,0.00,14:00X2,8351

L,02/11/98,14:00,013,13:25WS,067,13:25RH,29.84,13:25P1,+050.17,13:39T1,+071.29,13:2

6T2,+068.33,13:42T3,+065.34, 13:25T4,04.41,13:27LW,0.00,00:00X1,0.00,00:00X2,8349

S,02/11/98,14:00,28WD,000WS,00.07R,071RH,29.85P1,+053.23T1,+072.02T2,+069.26T3,

+065.88T4,01.76LW,0.00X1,0.00X2,5998

S,02/11/98,14:01,28WD,003WS,00.07R,071RH,29.85P1,+053.67T1,+072.52T2,+068.91T3,

+065.88T4,01.78LW,0.00X1,0.00X2,6018

S,02/11/98,14:02,32WD,006WS,00.07R,069RH,29.85P1,+053.70T1,+072.86T2,+068.89T3,

+065.86T4,01.84LW,0.00X1,0.00X2,6027

S,02/11/98,14:03,32WD,003WS,00.07R,068RH,29.85P1,+053.73T1,+073.13T2,+069.21T3,

+065.86T4,01.88LW,0.00X1,0.00X2,6009

S,02/11/98,14:04,28WD,005WS,00.07R,067RH,29.85P1,+053.41T1,+072.48T2,+069.36T3,

+065.86T4,01.94LW,0.00X1,0.00X2,6021ok

Note that the Sample records start with the letter S and the

High/Low records start with the letter H and L respectively.

NOW: This command will display the last record in the datalog

n GET: This command will display a user defined number of records

in the datalog, where n is the number of records.

Example: 10 GET will display the last ten records in the datalog.

Resetting Hi/Lo

RESET-HI/LO: This command will erase the high/low values from

memory for the current high/low interval.

Columbia Weather Systems, Inc.

Page 33

Pegasus FlyAway Kit 33

___________________________________________________________________

Resetting the datalog

RESET-DATA: This command will erase the datalog and will insert

one current Sample record.

Displaying current Hi/Lo

HIGH: This command will display the current high record. The High

record starts with the letter H followed by the date and time the

record was requested followed by the high values and the time for

wind speed, relative humidity, pressure, temperatures, leaf wetness

and two undefined sensors (X1 and X2). The high value of wind

speed is the wind gust.

Example:

H,02/11/98,14:00,013,13:25WS,081,13:40RH,29.86,13:27P1,+053.23,14:00T1,+072.27,13:

52T2,+069.59,13:31T3,+065.88, 14:00T4,01.70,13:57LW,0.00,14:00X1,0.00,14:00X2,8351

LOW: This command will display the current low record. The Low

record starts with the letter L followed by the date and time the

record was requested followed by the low values and the time for

wind speed, relative humidity, pressure, temperatures, leaf wetness

and two undefined sensors (X1 and X2). The low value of wind

speed is the high 4 second sustained wind average.

Setting temperature offsets

Temperature offsets are used to calibrate the temperature probes.

n TCAL#: This command is used to enter an offset for a temperature

probe. Where n is the offset in 1/100 of a degree F and # is the

temperature probe number.

Example: 231 TCAL2 adds 2.31 degree F to the temperature

reading from temperature probe two and -231 TCAL2 subtracts 2.31

degrees F from the reading.

Please refer to the Temperature Calibration section for more

information.

Setting barometric pressure altitude

and offset

n ALT: This command sets the altitude of the weather station, where

n is the altitude in feet.

Example: 225 ALT sets the altitude to 225 feet above see level.

n BAR-OFFSET: This command is used to enter an offset to the

barometric pressure reading, where n is the offset in 1/100 of In.Hg.

Columbia Weather Systems, Inc.

Page 34

Pegasus FlyAway Kit 34

___________________________________________________________________

Example: 34 BAR-OFFSET adds 0.34 in.Hg to the barometric

pressure reading and -34 BAR-OFFSET subtract 0.34 in.Hg from

the reading.

Please refer to Barometric Pressure Calibration for more

information.

Display current settings

PARAMETERS: This command displays the current weather station

settings and the number of records in the datalog.

Example:

Date & Time 02/11/1998,17:31

Measurement interval 1 minutes

Hi/Lo interval 1 hours

Records in memory 262

Pressure offset 38

Altitude 225

Temperature 1 offset 255

Temperature 2 offset -25

Temperature 3 offset 55

Temperature 4 offset 155 ok

Continuous display of direction

NORTH: This command continuously displays the wind direction.

This command is used for locating the north direction on the wind

sensor. An <Esc> followed by a carriage return terminates this

command.

Continuous display of wind information

1 XFER: This command continuously displays a Sample record

every one minute and wind speed and direction every one second.

The wind speed and direction record starts with the letter W

followed by three digits for wind speed in MPH followed by two digits

for wind direction.

Example:

W00124

S,02/11/98,17:44,24WD,001WS,00.08R,085RH,29.82P1,+048.56T1,+070.85T2,+067.24T3,

+065.08T4,01.74LW,0.00X1,0.00X2,6014

W00224

W00224

W00124

Columbia Weather Systems, Inc.

Page 35

Pegasus FlyAway Kit 35

___________________________________________________________________

W00124

W00124

W00120okok

An <Esc> followed by a carriage return terminates this command.

XSET: This command defines the frequency the Sample record is

displayed in the XFER output. The default frequency of the Sample

record in the XFER output is 60 seconds. This frequency can be

changed using the XSET command. For example, 15 XSET will

cause the Sample record to be issued every 15 seconds. XSET will

change the frequency of the XFER output on both serial ports.

CONT: This command will continuously output the Sample record at

a specified interval. For example, 5 CONT will output a Sample

record every 5 seconds. The time interval is limited to a range of 1

to 16 seconds.

S,05/01/99,09:44,40WD,000WS,00.00R,022RH,29.10P1,+070.70T1,+255.00T2,04.80LW,5.

00X1,0.10X2,4923

S,05/01/99,09:44,40WD,000WS,00.00R,023RH,29.09P1,+070.70T1,+255.00T2,04.80LW,5.

00X1,0.10X2,4932

S,05/01/99,09:44,40WD,000WS,00.00R,023RH,29.09P1,+070.70T1,+255.00T2,04.80LW,5.

00X1,0.10X2,4932

S,05/01/99,09:44,40WD,000WS,00.00R,023RH,29.10P1,+070.70T1,+255.00T2,04.80LW,5.

00X1,0.10X2,4924

S,05/01/99,09:45,40WD,000WS,00.00R,023RH,29.10P1,+070.70T1,+255.00T2,04.80LW,5.

00X1,0.10X2,4925

S,05/01/99,09:45,40WD,000WS,00.00R,023RH,29.10P1,+070.70T1,+255.00T2,04.80LW,5.

00X1,0.10X2,4925

S,05/01/99,09:45,40WD,000WS,00.00R,023RH,29.10P1,+070.70T1,+255.00T2,04.80LW,5.

00X1,0.10X2,4925

S,05/01/99,09:45,40WD,000WS,00.00R,023RH,29.10P1,+070.70T1,+255.00T2,04.80LW,5.

00X1,0.10X2,4925

S,05/01/99,09:46,40WD,000WS,00.00R,023RH,29.10P1,+070.72T1,+255.00T2,04.80LW,5.

00X1,0.10X2,4928

S,05/01/99,09:46,40WD,000WS,00.00R,023RH,29.10P1,+070.72T1,+255.00T2,04.80LW,5.

00X1,0.10X2,4928okok

An <Esc> followed by a carriage return terminates this command.

The output will stop after one more Sample record is issued. For

example, if CONT is set to repeat the Sample record every 15

Columbia Weather Systems, Inc.

Page 36

Pegasus FlyAway Kit 36

___________________________________________________________________

seconds (15 CONT) and an <ESC><RETURN> was entered, one

more Sample record will be issued before the double ok is displayed

indicating that the command is terminated.

Columbia Weather Systems, Inc.

Page 37

Pegasus FlyAway Kit 37

___________________________________________________________________

SECTION 6: CALIBRATION

Calibrating the Barometric Pressure

Sensor

The barometric pressure sensor is calibrated at the factory to a

highly accurate digital pressure gauge (±0.02% of full range) and

traceable to NIST and, therefore, it requires no further calibration.

The barometric pressure sensor in the Pegasus is temperature

compensated from 32° to 185° F and has an accuracy of ±0.03

in.Hg.

Altitude Setting

After calibration at the factory, the altitude is set to zero. To get an

accurate barometric pressure reading, the local altitude needs to be

set in the weather station.

To set the altitude, use the ALT command and enter the altitude in

feet. Please refer to Section 4: Operation for more information. The

altitude can also be set using weather software or display console.

Please refer to the software or display console user manual.

Note: The electronic transducer used to measure air pressure is

sensitive to changes in elevation of as little as 10 ft. (3 m).

Optional Calibration Procedure

Even though the barometric pressure sensor is calibrated at the

factory, the sensor can be re-calibrated on-site. This might be

required if the original barometric pressure offset has been erased

from memory, or if weather station needs to match a local source.

To re-calibrate the barometric pressure on-site:

Using a terminal program, set the barometric pressure offset to zero

by entering: 0 BAR-OFFSET

Wait approximately 5 seconds, then take a pressure reading using

SAMPLE, POLL or P1

Record the barometric pressure from a local reliable source at the

same elevation as the Pegasus.

Calculate the barometric pressure offset as follows:

Barometric Pressure Offset = Source Reading - Pegasus Reading.

Columbia Weather Systems, Inc.

Page 38

Pegasus FlyAway Kit 38

___________________________________________________________________

Enter the barometric pressure offset in 1/100 of in.Hg using the

BAR-OFFSET command.

Calibrating the Wind Sensors

The wind speed sensor contains no components that can be

calibrated by the user. Refer to the Installation Section for sensor

North orientation.

Calibrating the Temperature Sensors

All Temperature sensors are calibrated at the factory to a superior

grade ASTM mercury thermometer traceable to NIST. The

calibration offset is recorded on the temperature sensor and on the

end of the cable.

After initializing all the temperature sensors, enter the temperature

offsets using the TCAL command. Please refer to Section 4:

Operation for more information. TCal offsets are labeled on the

sensor cable.

To calibrate the temperature sensors on-site, perform the following

steps:

Prepare an ice bath by mixing two cups of crushed ice in two cups

of water. Use an insulated container for best results. Allow the

temperature throughout the ice bath to stabilize by waiting for about

twenty minutes.

Stir the ice bath to mix the ice and water, wait for the ice to separate

from the water, place the temperature sensor in the ice bath. Make

sure that the sensor is not in direct contact with ice.

Take a temperature reading from the Pegasus using SAMPLE or

POLL.

Calculate the temperature offset as follows:

Temperature offset = (32 - Pegasus reading) * 100

Enter the temperature offset using the TCAL command. Please refer

to Section 4: Operation for more information.

Record the temperature offset on a label attached to the sensor.

Repeat the process for any other temperature sensor.

Columbia Weather Systems, Inc.

Page 39

Pegasus FlyAway Kit 39

___________________________________________________________________

Calibrating the Humidity Sensor

The humidity sensor is calibrated at the factory and is traceable to

NIST. No field calibration is required.

Columbia Weather Systems, Inc.

Page 40

Pegasus FlyAway Kit 40

___________________________________________________________________

SECTION 7: MAINTENANCE

In normal use, the Pegasus should require very little maintenance.

In the event of any problems, follow the procedures contained in

Section 8: Troubleshooting, to determine whether the components

are defective. If defective and needs to be returned to the factory for

repair, refer to the Return For Repair Procedure in Section 9: User

Support Information.

Control Module

The Control Module contains sensitive electronic components and

should not be serviced by the user. If the LED on the inside circuit

board is not on, check for proper installation of the battery supply

system. Check to see if the fuse on the Control Module board needs

to be replaced. If necessary, replace it with a 1.0 amp 250V fast

acting fuse.

Barometric Pressure Sensor Maintenance

The barometric pressure sensor is located inside the weatherproof

enclosure and should not be serviced by the user.

Temperature Sensor Maintenance

Check the temperature sensor cables during installation and

periodically thereafter to make sure they contain no cuts, kinks or

other abnormalities.

Wind Sensor Maintenance

Do not attempt to oil, grease or otherwise lubricate the wind

sensors. The wind speed and direction bearings are permanently

sealed and should not be tampered with. If it appears that the

displayed wind speed values are substantially less than existing

conditions, or that the wind direction display is sluggish in

responding to changes in wind direction, it may be that the bearings

need service. This can be tested by spinning the sensors. They

should spin freely. If they do not, call the factory for service. All or

part of the wind sensors may need to be replaced. Since the circuit

is molded into the wind sensor housing, an electronic defect

requires replacement of the sensor. The wind sensors are not

designed for field repair.

Columbia Weather Systems, Inc.

Page 41

Pegasus FlyAway Kit 41

___________________________________________________________________

Relative Humidity Sensor Maintenance

The Relative Humidity sensor does not require any field

maintenance.

Columbia Weather Systems, Inc.

Page 42

Pegasus FlyAway Kit 42

___________________________________________________________________

Section 8: Troubleshooting

Temperature Sensor Troubleshooting

If the Temperature sensor is reading a few degrees off when

compared to a standard, the Temperature sensor may require recalibration. Please refer to calibration procedure in Section 6:

Calibrating the Temperature Sensor.

If the Temperature sensor is reading 255°F, the Temperature

sensor may be disconnected from the Control Module. Check the

cable from the sensor to the Control Module for any cuts or kinks.

Check any splices to ensure good connection. Check the cable

connection to the Control Module.

If replacing a Temperature sensor, all the new Temperature sensors

and any other Temperature sensors connected to the Control

Module should be re-initialized as follows:

1. Disconnect the temperature sensor from the Control

Module.

2. Disconnect the power connector from the Control Module

3. Reapply power to the Control Module

4. Connect the temperature sensor to the Control Module

5. Disconnect the power connector from the Control Module

6. Reapply power to the Control Module

The temperature sensor is now initialized and should be reading the

correct values.

Communication Problems

If the Pegasus is not communicating with the computer software or

the Weather Display, please check the following:

1. Check power connections to the Control Module. Check the

power LED on the circuit board inside the Control Module

enclosure. If the light is not on, make sure the battery

connected to the system is charged. Also check the onboard fuse. If blown, replace with the spare fuse located in

the middle of the board.

2. Check all communication cable/connectors to be sure they

are firmly connected.

Columbia Weather Systems, Inc.

Page 43

Pegasus FlyAway Kit 43

___________________________________________________________________

3. Check the line-of-site between the Pegasus and the

monitoring device. If the line-of-site is not direct, try moving

the Pegasus to an unobstructed location.

Columbia Weather Systems, Inc.

Page 44

Pegasus FlyAway Kit 44

___________________________________________________________________

SECTION 9: USER

SUPPORT INFORMATION

This section consists of the following items:

1. Two-Year Limited Warranty: Please read this document

carefully.

2. Return for Repair Procedure: This procedure is for your

convenience in the event you must return your Pegasus or

components for repair or replacement. Follow the packing

instructions carefully to protect your instrument in transit.

Limited Warranty

Columbia Weather Systems, Inc. (CWS), warrants the Pegasus

Weather Station to be free from defects in materials and/or

workmanship when operated in accordance with the manufacturer’s

operating instructions, for two (2) years from date of purchase,

subject to the provisions contained herein. CWS warranty shall

extend to the original purchaser only and shall be limited to factory

repair or replacement of defective parts.

EXCLUSIONS

Certain parts are not manufactured by CWS (i.e., certain purchased

options, etc.) and are therefore not covered by this warranty. These

parts may be covered by warranties issued by their respective

manufacturers and although CWS will not warrant these parts, CWS

will act as agent for the administration of any such independent

warranties during the term of this warranty. This warranty does not

cover normal maintenance, damage resulting from improper use or

repair, or abuse by the operator. Damage caused by lightning or

other electrical discharge is specifically excluded. This warranty

extends only to repair or replacement, and shall in no event extend

to consequential damages. In the event of operator repair or

replacement, this warranty shall cover neither the advisability of the

repair undertaken, nor the sufficiency of the repair itself.

THIS DOCUMENT REFLECTS THE ENTIRE AND EXCLUSIVE

UNDERSTANDING OF THE PARTIES, AND EXCEPT AS

Columbia Weather Systems, Inc.

Page 45

Pegasus FlyAway Kit 45

___________________________________________________________________

OTHERWISE PROVIDED HEREIN, ALL OTHER WARRANTIES,

EXPRESS OR IMPLIED, PARTICULARLY THE WARRANTIES OF

MERCHANT ABILITY AND/OR FITNESS FOR A PARTICULAR

PURPOSE ARE EXCLUDED.

This warranty gives you specific legal rights, and you may also have

other rights which vary from state to state.

Return for Repair Procedure

1. In the event of defects or damage to your system, first call

the factory Capricorn Service Department Monday through

Friday, 8:30 am to 4:00 pm PST, (503) 629-0887 to

determine the advisability of factory repair. The Service

Department will issue an RMA number (Return

Merchandise Authorization) to help us identify the package

when received. Please place that number on the outside of

the box.

2. In the event factory service is required, return your Pegasus

Weather Station as follows:

A. Packing

Wrap sensor or component in a plastic bag first.

Pack in original shipping carton or a sturdy

oversized carton.

Use plenty of packing material.

B. Include:

A brief description of the problem with all known

symptoms.

Your phone number.

Your return street shipping address (UPS will not

deliver to a P.O. box).

Write the RMA number on the outside of the box.

C. Shipping

Send freight prepaid (UPS recommended).

Insurance is recommended. (The factory can

provide the current replacement value of the item

being shipped for insurance purposes.)

Columbia Weather Systems, Inc.

Page 46

Pegasus FlyAway Kit 46

___________________________________________________________________

D. Send to:

Columbia Weather Systems, Inc.

2240 NE Griffin Oaks Street, Suite 100

Hillsboro, Oregon 97124

E. C.O.D. shipments will not be accepted.

3.

If your unit is under warranty, after repair or replacement

has been completed, it will be returned by a carrier and

method chosen by Columbia Weather, Inc. to any

destination within the continental U.S.A. If you desire some

other specific form of conveyance or if you are located

beyond these borders, then you must bear the additional

cost of return shipment.

4. If your unit is not under warranty, we will call you with an

estimate of the charges. If approved, your repaired unit will

be returned after all charges, including parts, labor and

return shipping and handling, have been paid. If not

approved, your unit will be returned as is via UPS COD for

the amount of the UPS COD freight charges.

Columbia Weather Systems, Inc.

Page 47

Pegasus FlyAway Kit 47

___________________________________________________________________

Reference

Glossary

Aspirating Radiation Shield

A device used to shield a sensor such as a temperature probe from

direct and indirect radiation and rain while providing access for

ventilation.

Barometric Pressure

The pressure exerted by the atmosphere as a consequence of

gravitational attraction exerted upon the “column” of air lying

directly above the point in question.

Celsius Temperature Scale

A temperature scale with the ice point at 0 degrees and the boiling

point of water at 100 degrees.

Dew Point

The temperature to which a given parcel of air must be cooled at

constant pressure and constant water-vapor content in order for

saturation to occur. When this temperature is below 0°C or 32°F, it

is sometimes called the frost point.

Fahrenheit Temperature Scale

A temperature scale with the ice point at 32 degrees and the boiling

point of water at 212 degrees.

Heat Index

The heat index or apparent temperature is a measure of discomfort

due to the combination of heat and high humidity. It was developed

in 1979 and is based on studies of evaporative skin cooling for

combinations of temperature and humidity.

Columbia Weather Systems, Inc.

Page 48

Pegasus FlyAway Kit 48

___________________________________________________________________

.

Relative Humidity

Popularly called humidity. The ratio of the actual vapor pressure of

the air to the saturation vapor pressure.

Sea Level Pressure

The atmospheric pressure at mean sea level, either directly

measured or, most commonly, empirically determined from the

observed station pressure.

In regions where the earth’s surface pressure is above sea level, it

is standard observational practice to reduce the observed surface

pressure to the value that would exist at a point at sea level directly

below.

Wind Chill

That part of the total cooling of a body caused by air motion.

Columbia Weather Systems, Inc.

Page 49

Pegasus FlyAway Kit 49

___________________________________________________________________

Unit Conversion

Speed

Kilometers per hour = 1.610 x miles per hour

Knots = 0.869 x miles per hour

Meters per second = 0.448 x miles per hour

Feet per second = 1.467 x miles per hour

Temperature

Temperature in °C = 5/9 (temperature in °F - 32)

Temperature in °F = (1.8 x temperature in °C) + 32

Distance

Millimeters = 25.4 x inches

Pressure

Millibars = 33.86 x inches of mercury

Kilopascals = 3.386 x inches of mercury

Pounds per square inch = 0.49 x inches of mercury

Standard atmospheres = 0.0334 x inches of mercury

Columbia Weather Systems, Inc.

Page 50

Pegasus FlyAway Kit 50

___________________________________________________________________

Tables and Formulas

Wind Chill Chart

Wind

70 60 50 40 30 20 10 0 -10 -20 -30 -40 -50 -60 -70

(MPH)

5 69 58 48 37 27 16 6 -5 -15 -26 -36 -47 -57 -68 -78

10 65 53 41 28 16 4 -9 -21 -33 -46 -58 -70 -82 -95 -107

15 63 49 36 22 9 -4 -18 -31 -45 -58 -72 -85 -98 -112 -125

20 61 47 33 18 4 -10 -24 -39 -53 -67 -81 -95 -110 -124 -138

25 60 45 30 15 1 -14 -29 -44 -59 -73 -88 -103 -118 -133 -147

30 59 44 28 13 -2 -17 -32 -48 -63 -78 -93 -109 -124 -139 -154

35 58 43 27 12 -4 -19 -35 -51 -66 -82 -97 -113 -128 -144 -159

40 58 42 26 10 -5 -21 -37 -53 -68 -84 -100 -116 -131 -147 -163

45 57 42 26 10 -6 -22 -38 -54 -70 -86 -101 -117 -133 -149 -165

50 57 41 25 9 -7 -23 -39 -55 -71 -86 -102 -118 -134 -150 -166

55 57 41 25 9 -7 -23 -39 -55 -71 -87 -103 -119 -135 -151 -167

60 57 41 25 9 -7 -23 -39 -55 -71 -87 -102 -118 -134 -150 -166

65 57 41 26 10 -6 -22 -38 -54 -70 -86 -102 -118 -134 -149 -165

70 58 42 26 10 -6 -21 -37 -53 -69 -85 -101 -116 -132 -148 -164

Temperature in °F

Wind Chill Equation

WC = 91.4 - ((0.474677 - (0.020425 * V) + (0.303107 * SQRT(V))) * (91.4-T))

Where:

WC = wind chill temperature

V = wind velocity in mph

T = air temperature in °F

Columbia Weather Systems, Inc.

Page 51

Pegasus FlyAway Kit 51

___________________________________________________________________

Heat Index

70 75 80 85 90 95 100 105 110 115 120 125 130 135

RH

64 66 73 78 83 87 91 95 99 103 107 111 117 120

0

64 69 74 79 84 88 93 97 102 107 111 116 122 126

5

65 70 75 80 85 90 95 100 105 111 116 123 131

10

65 71 76 81 86 91 97 102 108 115 123 131

15

66 72 77 82 87 93 99 105 112 120 130 141

20

66 72 77 83 88 94 101 109 117 127 139

25

67 73 78 84 90 96 104 113 123 135 148

30

67 73 79 85 91 98 107 118 130 143

35

68 74 79 86 93 101 110 123 137 151

40

68 74 80 87 95 104 115 129 143

45

69 75 81 88 96 107 120 135 150

50

69 75 81 89 98 110 126 142

55

70 76 82 90 100 114 132 149

60

70 76 83 91 102 119 138

65

70 77 84 93 106 124 144

70

70 77 85 95 109 130 150

75

71 78 86 97 113 136

80

71 78 87 99 117 140

85

71 79 88 102 122 150

90

71 79 89 105 126

95

72 80 90 108 131

100

Temperature in °F

Columbia Weather Systems, Inc.

Page 52

Pegasus FlyAway Kit 52

___________________________________________________________________

Dew Point

B = (ln (RH/100) + ((17.2694*T) / (238.3+T))) / 17.2694

Dew Point in °C = (238.3 * B) / (1-B)

Where:

RH = Relative Humidity

T = Temperature in °C

Ln = Natural logarithm

Columbia Weather Systems, Inc.

Page 53

Pegasus FlyAway Kit 53

___________________________________________________________________

Columbia Weather Systems, Inc.

2240 NE Griffin Oaks Street, Suite 100

Hillsboro, OR 97124-6463

Telephone

(503) 629-0887

Fax

(503) 629-0898

Web Site

http://www.columbiaweather.com

Email

info@columbiaweather.com

Catalog Number: 81642

Version 1.10

Printed in U.S.A.

Columbia Weather Systems, Inc.

Loading...

Loading...