First

Printing

©

1991

December

PEGASUS

1991

SEWING

Series

MACHINE

MFC.

Service

CO.,

LTD

Manual

Cat.

No.

9627

First

Printing

©

1991

Series

December

PEGASUS

1991

SEWING

Service

MACHINE

MFG.

Manual

CO..

LTD

A.

3.

Sales

Points

B.3.

Model

Code

C.3.

Installation

D.3.

Threading

E.3.

Specifications

F.a.

Adjustment

G.3.

at

Device

G.b.TK

H.3.

Device

Comparison

(Schematic

Specifications

Table

diagram)

G.C.

KS

G.Cf.

KH

Device

Device

B.b.

F.b.

Model

Auxiliary

Needle

Thread

Thread

guide

Adjustment

G.O.

EH

G.f.

PL

Code

Take-up

Specifications

Device

Device

G.g.

BT

G.h.

AL

F.C.

Looper

Thread

Adjustment

Device

Device

Thread

Take-up,

guide

Specifications

G.f.

BL

Device

)

PEGASUS.

Cat.

No.

9627

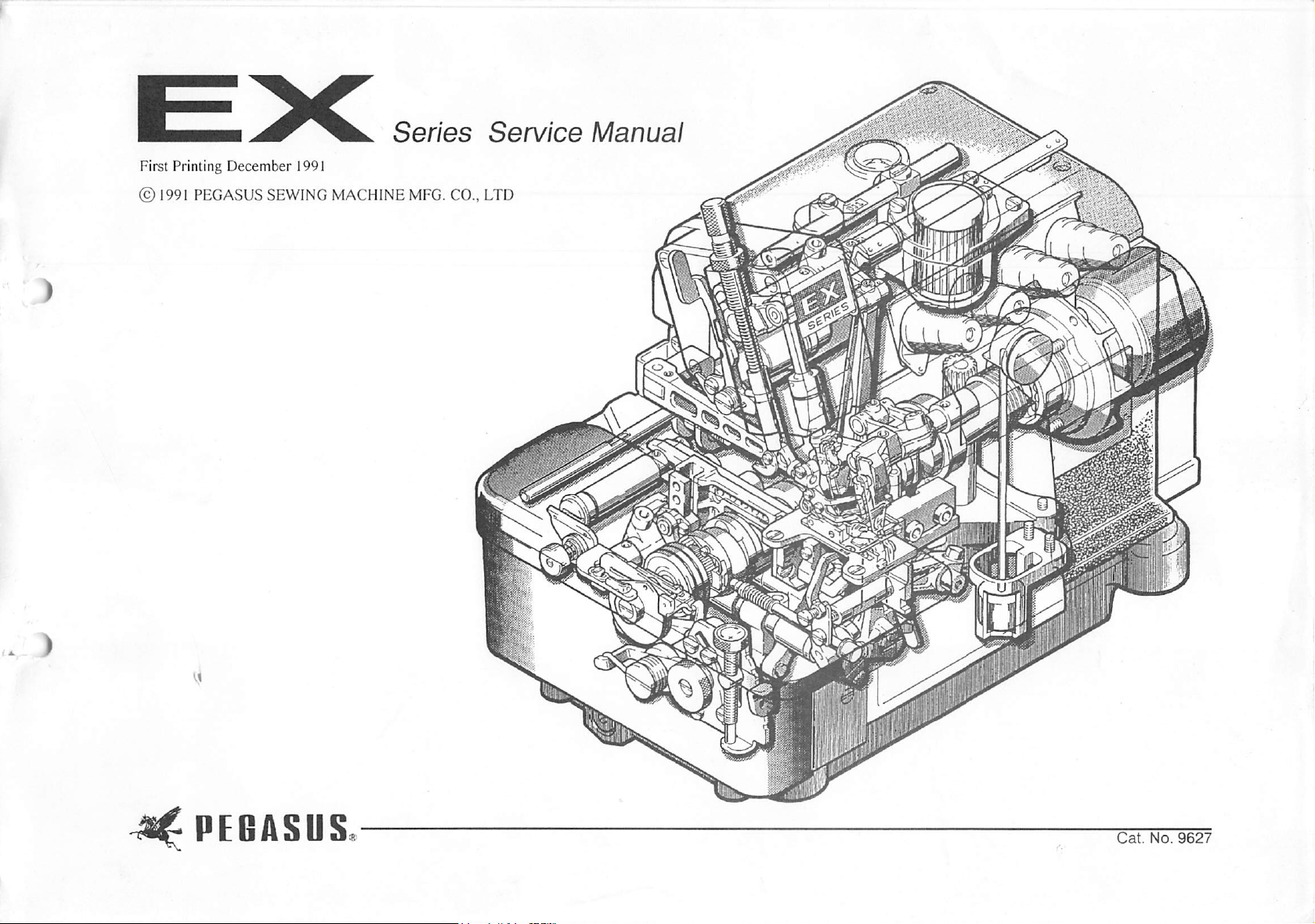

What

has

To

Solves

the

offer

the

problems

better

Series

sewing

in

sewing

light

been

developed

performance

weight

fabrics

(stitch

formation)

for?

Provides

medium

To

improve

Offers

Offers

Parts

to

and

the

The

alignment

an

adjustment

Sales

1.

Provides

The

EX

take

up

new

features

2.

Offers

Whether

expected

launched

machines.

adjustment,

the

same

weight

ease

of

operation

ease

of

maintenance

be

adjusted

machine

provides

points

Series

timing

and

the

the

operation

of

the

the

EX

You

sewing

excellent

fabrics

sewing

as

the

previous E Series

functionally

have

been

reduced

requires

mark

so

came

and

only

that

replaces

rational

smooth

out

of

amount,

designs

that

ease

is

easy

machines

Series

will

which

surely

and

needle

based

external

the

maintenance.

the

thorough

the

effects

enable

of

operation

or

is

appreciate

replacement.

performance

to

minimum

adjustment.

scale

in

making

and

beautiful

research

the

material

the

EX

Series

not

affects

not

on

the

unique

as

easy - to - use

how

carefully

on

stitches

on

varying

and

the

to

sew

smoothly

only

the

concepts

of

machines

the

thread

tensions,

shape

of

each

even

operator,

workers

EX

but

first

as

possible

Series

is

relationship

component

extra

light

also

the

quality

and

foremost

and

performs

designed

every

between

part

would

as

well

as

of

the

and

accurately

time

the

needle

have

on

medium

hands - on

you

weight

sewn

products

without

perform

and

the

the

seam.

These

fabrics.

and

experience

sacrificing

any

operation

looper,

the

with

balance

efforts

are

productivity.

sewing

operation,

their

being

like

threading,

between

represented

quite

the

by

Knowing

Pegasus

high - precision

thread

thread

many

what

is

has

tension

3.

Offers

Parts

making

tfie

to

be

adjusted

an

adjustment

ease

have

provides

of

maintenance

been

reduced

rational

to

minimum

maintenance.

and

the

machine

requires

only

external

adjustment.

The

alignment

mark

that

replaces

the

scale

in

First

l^lallDg

EX

Scries

A.

December

Service

a. 0 -

1991

Manoal

001

)

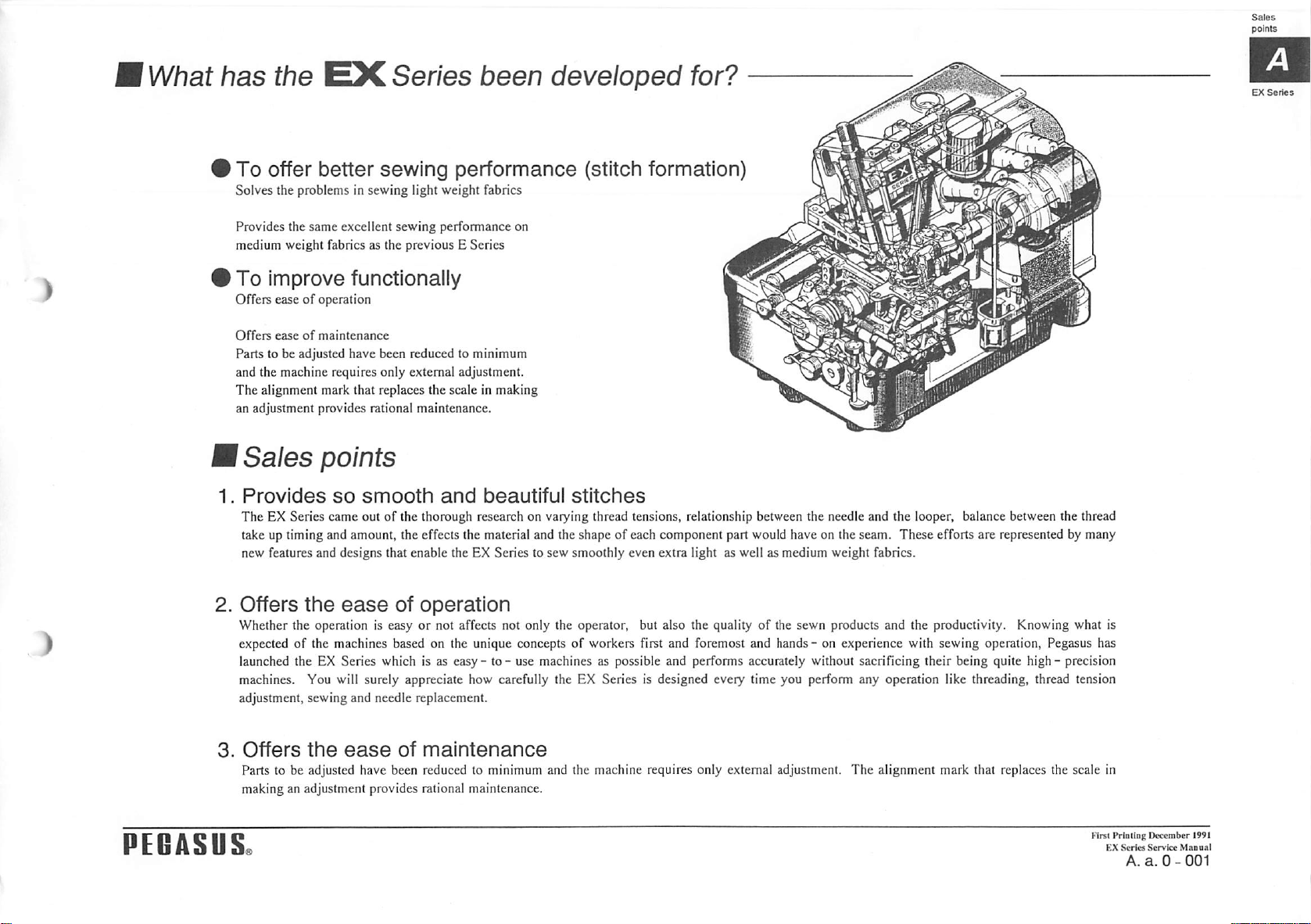

Comfortable

>

Noise

reduction

We

have

succeeded

compared

competitors'

there

and

operators.

is

left

quiet

working

to

those

machines,

much

less

environment

in

minimizing

of

conventional

considering

of

nuisance.

noise

what

This

which

is

and

vibration

Pegasus'

little

or

noise

offers a gentle

so

vital

for

)

Nice

The

that

the

get

and

gentle

simple

and

lights

up

pursuit

of

along

well

design

compact

and

is

gentle

easier

operation

with

the

design

and

to

your

in

machine

like

the

eyes

which

good

sand

beige

all

came

the

operator

friends.

color

out

can

of

)

Minimal

A

installation

machine

on

The

design

table

little

clearance

table

the

oil

pan

rear

installation

as

the

cushion

positioning.

vibration

has

been

provided

rubber

on

and

the

installation

to

absorb

vibration.

holder

to

conventional

one

the

mounting

holder

the

machine

so

that

between

the

plate

to

the

is

of

the

it

can

be

front

of

the

machine

same

used

for

)

PEGASUS.

Absorb

vibration

First

EX

PriDlIng

December

Series

Service

A.

a. 0 -

199!

Maoual

002

New

)

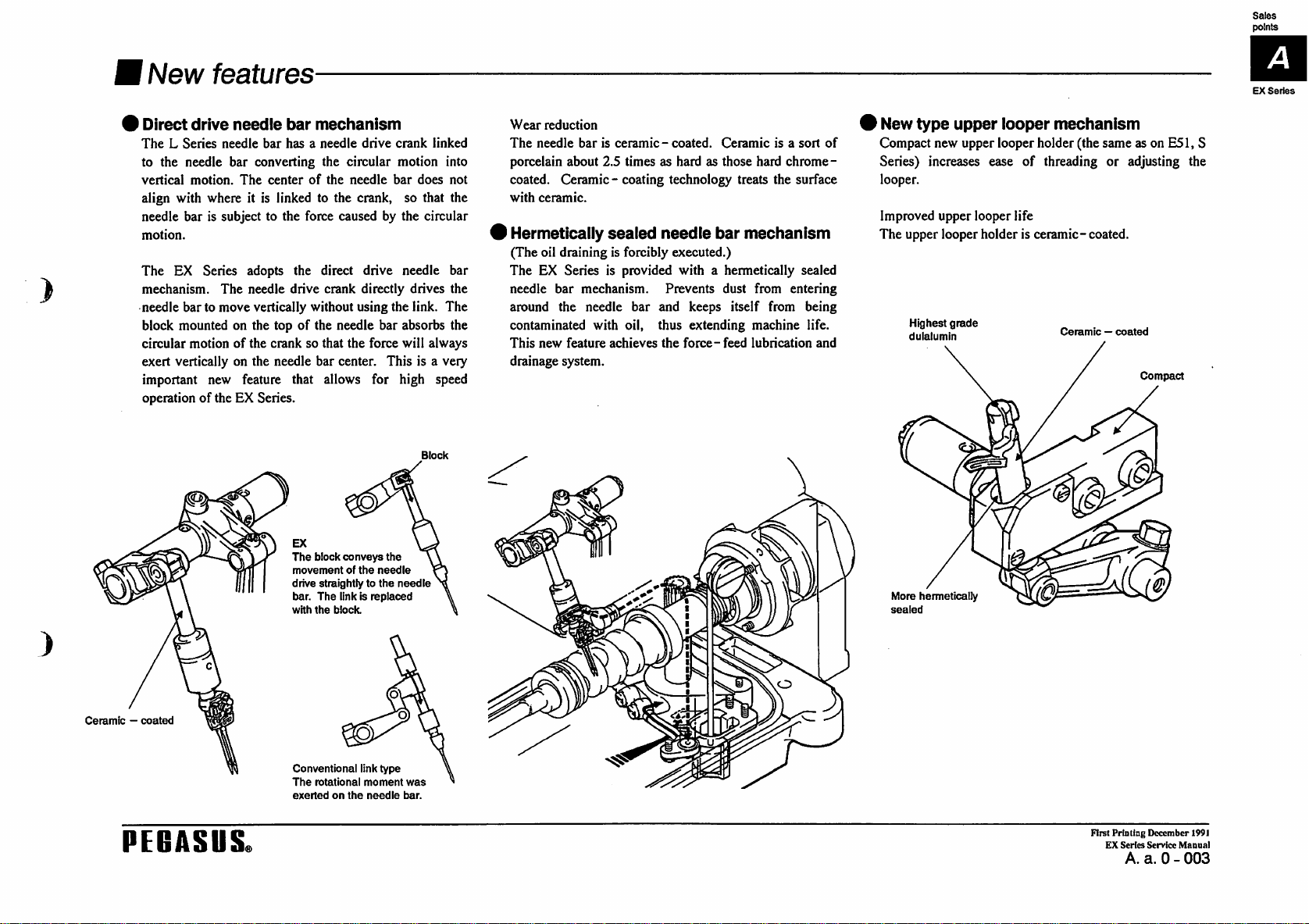

Direct

The L Series

to

vertical

align

needle

motion.

The

mechanism.

needle

block

circular

exert

important

operation

drive

the

needle

motion.

with

bar

EX

Series

bar

to

mounted

motion

vertically

of

features

needle

needle

bar

The

where

is

subject

The

move

on

of

on

new

feature

the

EX

bar

bar

has a needle

converting

center

it

is

linked

to

the

adopts

the

needle

drive

vertically

the

top

the

crank

the

needle

that

Series.

mechanism

the

of

the

to

the

force

direct

crank

without

of

the

needle

so

that

bar

allows

drive

circular

needle

crank,

caused

by

drive

directly

using

the

bar

the

force

center.

This

for

crank

linked

motion

bar

does

so

that

the

circular

needle

drives

link.

absorbs

will

always

is a veiy

high

speed

Block

into

not

the

bar

the

The

the

Wear

reduction

The

needle

bar

is

porcelain

coated.

with

I

Hermetically

(The

The

needle

around

contaminated

This

drainage

about

2.5

Ceramic - coating

ceramic.

sealed

oil

draining

EX

bar

the

new

system.

is

Series

is

mechanism.

needle

with

feature

achieves

ceramic - coated.

times

as

hard

as

technology

needle

forcibly

provided

bar

oil,

executed.)

with a hermetically

Prevents

and

keeps

thus

extending

the

force-feed

Ceramic

those

hard

treats

bar

mechanism

dust

from

itself

machine

lubrication

is a sort

chrome-

the

surface

sealed

entering

from

of

being

life.

and

)

New

type

Compact

Series)

increases

looper.

Improved

The

upper

Highest

dulalumin

upper

new

upper

upper

looper

grade

looper

looper

ease

looper

life

holder

mechanism

holder

of

threading

is

ceramic-

Ceramic — coated

(the

same

coated.

as

on

or

adjusting

Compact

ESl,

the

EX

Series

S

EX

The

block

conveys

movement

drive

straightly

bar.

The

wKh

the

block.

of

the

link

Is

the

needle

to

the

needle

replaced

)

Ceramic - coated

Conventional

The

exerted

PEGASUS.

rotational

on

the

link

moment

needle

type

was

bar.

More

hermetically

sealed

First

Printing

EX

Scries

A.

December

Service

a. 0 -

1991

Manual

003

Sales

points

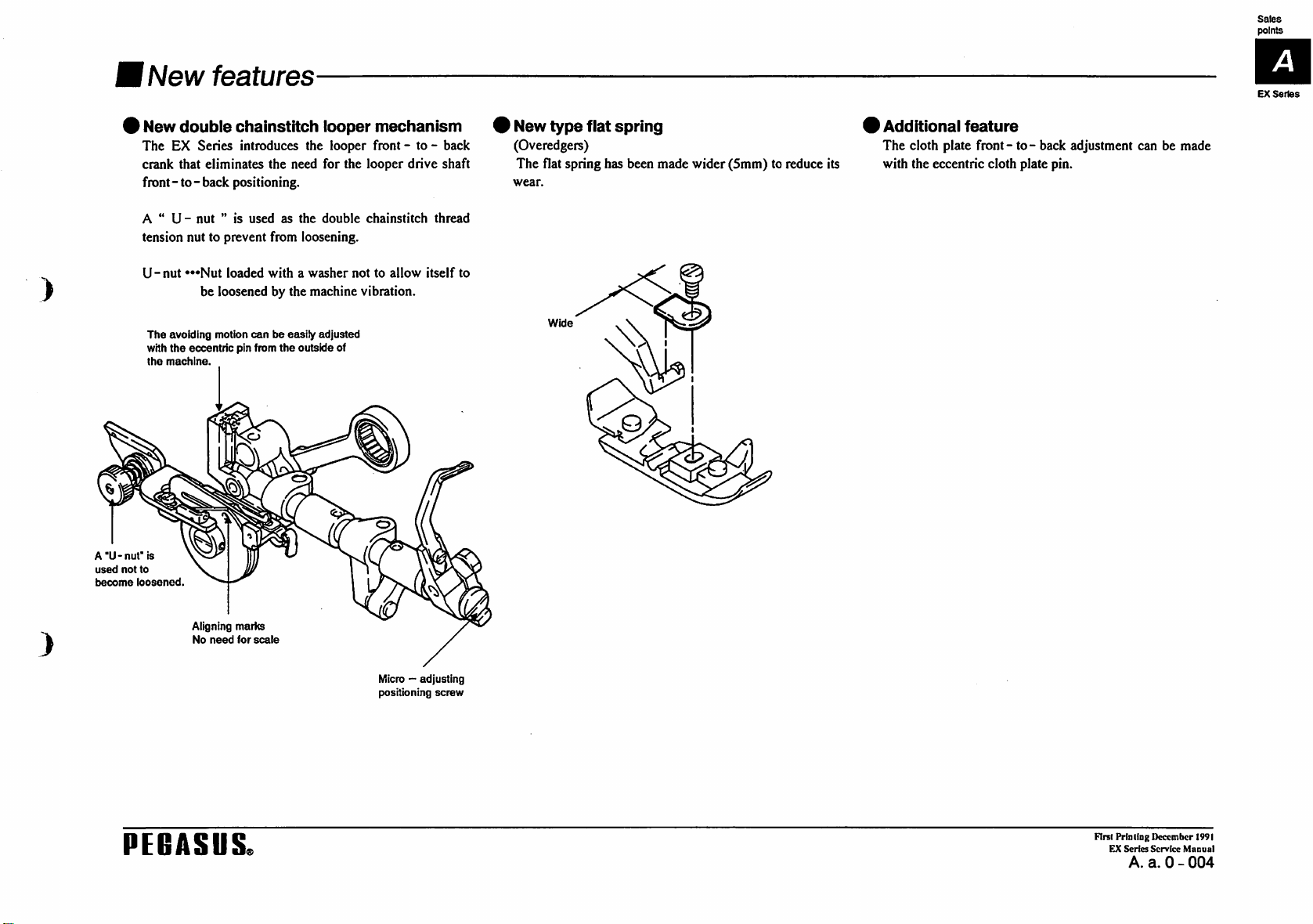

New

)

New

The

crank

features

double

EX

Series

that

eliminates

front - to - back

A " U - nut " is

tension

nut

to

prevent

U-nut

•••Nut

loaded

be

loosened

The

avoiding

the

eccentric

motion

with

the

machine.

chainstitch

introduces

the

the

need

looper

looper

for

positioning.

used

as

the

double

from

loosening.

with a washer

by

the

machine

can

be

easily

the

outside

adjusted

pin

from

mechanism

front - to - back

the

looper

chainstitch

not

to

vibration.

of

drive

allow

shaft

thread

itself

to

New

type

flat

(Overedgers)

The

flat

spring

wear.

Wide

spring

has

been

made

wider

(5mm)

to

reduce

its

>

Additional

The

cloth

with

the

eccentric

feature

plate

front - to - back

cloth

plate

pin.

adjustment

can

be

made

EX

Series

A

"U-nut"

not

is

to

loosened

Aligning

marks

No

need

for

scale

Micro — adjusting

positioning

screw

used

become

PEGASUS.

First

EX

Printing

December

Series

Service

A.

a. 0 -

1991

Manual

004

)

Smooth

)

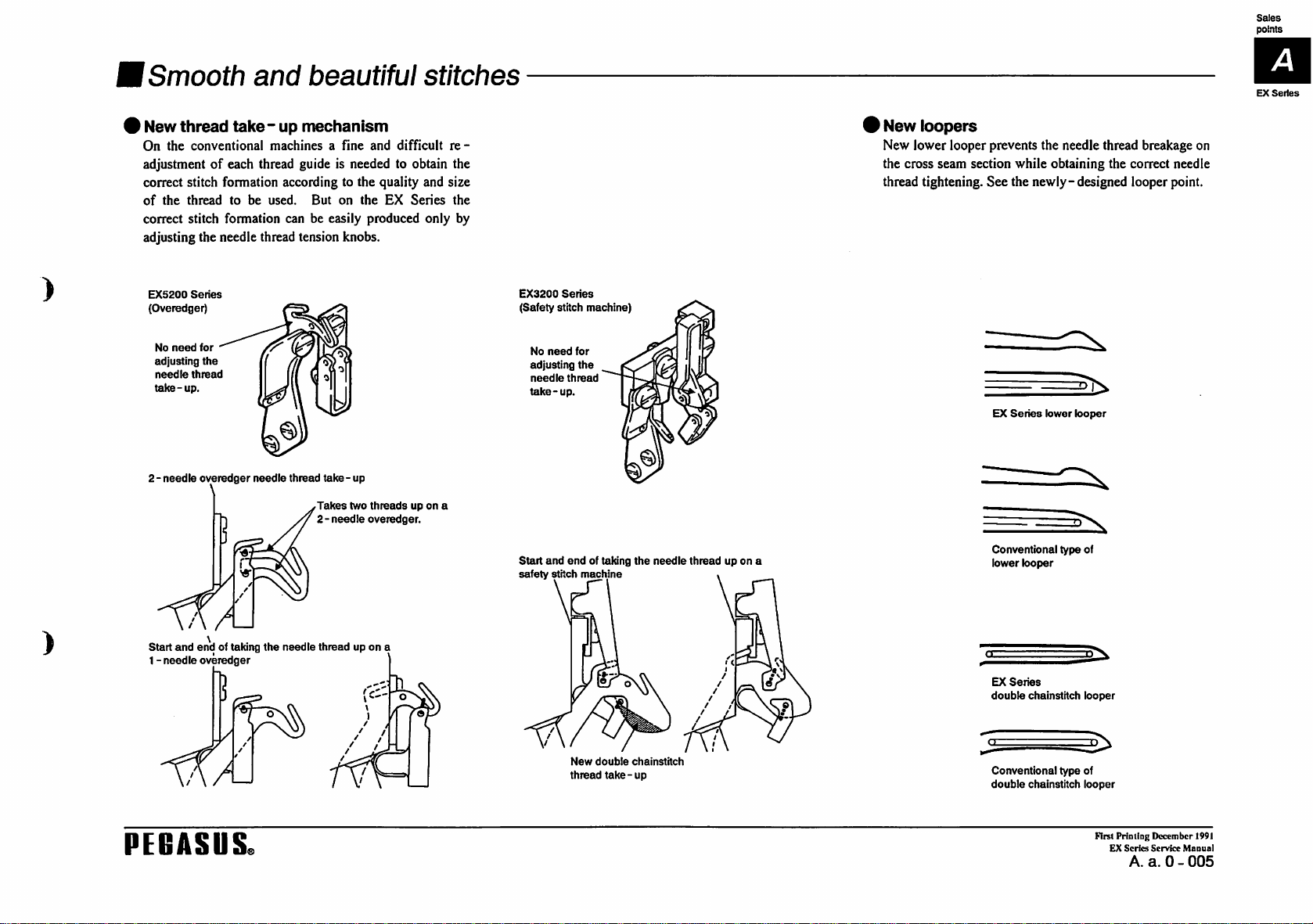

New

thread

On

the

conventional

adjustment

correct

of

the

correct

adjusting

EX5200

(Overedger)

No

adjusting

needle

take-up.

stitch

thread

stitch

the

Series

need

for

the

thread

of

and

take - up

machines a fine

each

thread

formation

to

formation

needle

according

be

used.

thread

can

beautiful

mechanism

and

difficult

guide

is

needed

to

to

the

quality

But

on

the

EX

Series

be

easily

produced

tension

knobs.

stitches

re

obtain

the

and

size

the

only

by

EX3200

(Safety

stitch

No

need

adjusting

needle

take-up.

Series

for

the

thread

machine)

'

New

New

lower

the

cross

thread

loopers

looper

prevents

seam

section

tightening.

See

EX

the

needle

while

obtaining

the

newly-designed

Series

lower

looper

thread

breakage

the

correct

looper

on

needle

point.

EX

Series

)

2 - needle

Start

1 - needle

overedger

and

end

overedger

of

taking

needle

the

needle

thread

Takes

2-

thread

take-up

two

needle

up

threads

up

overedger.

on

a

on

a

Start

and

safety

end

stitch

PEGASUS,

of

machine

New

double

thread

taking

the

chainstitch

take-up

needle

thread

up

on

a

Conventional

lower

EX

Series

double

Conventional

double

type

looper

chainstitch

type

chainstitch

of

looper

of

looper

First

EX

Printing

December

Series

Service

A.

a.

Manual

0-005

1991

Smooth

)

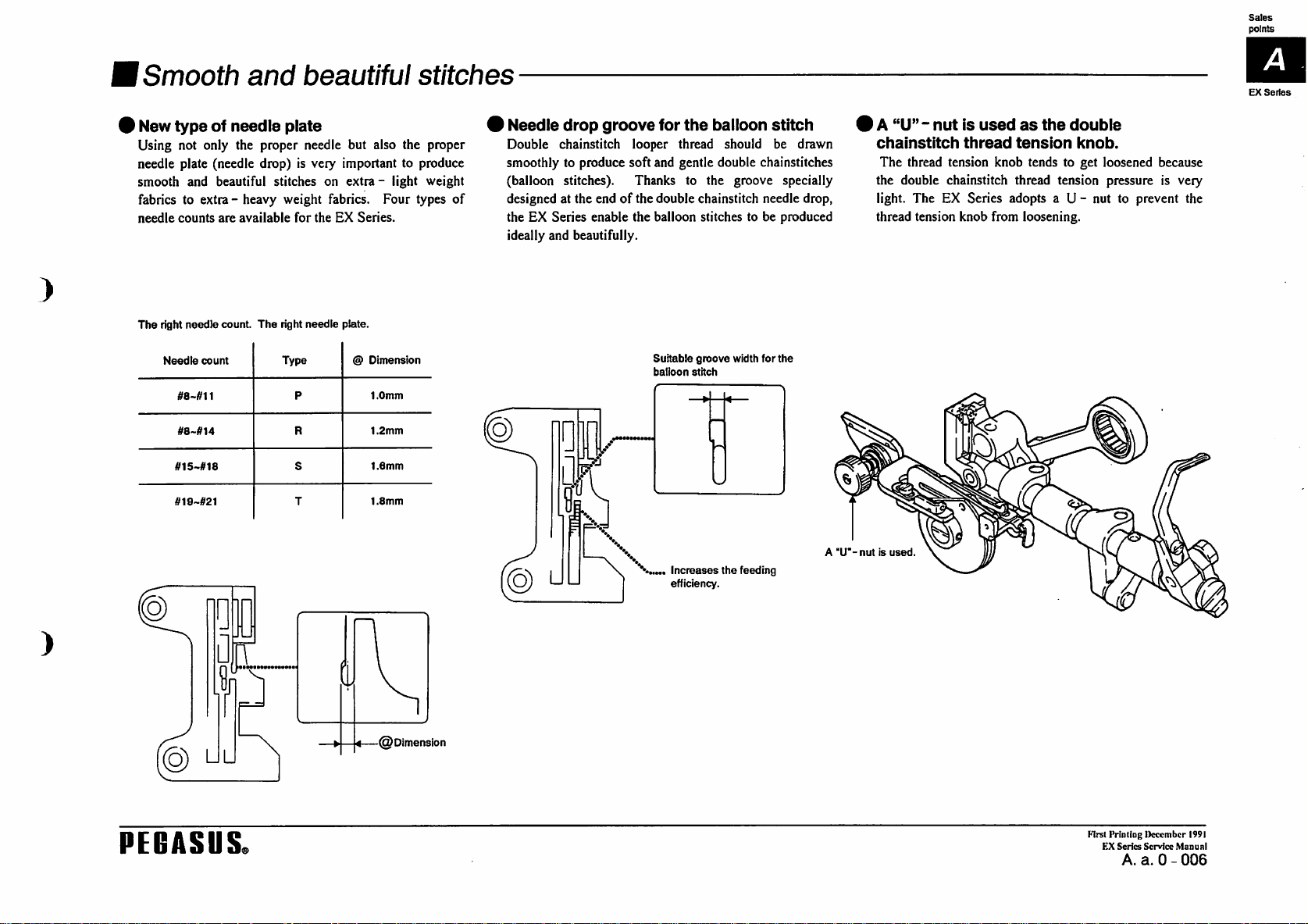

New

type

Using

not

only

needle

plate

smooth

fabrics

needle

The

and

to

counts

right

needle

Needle

extra - heavy

count

and

of

needle

the

proper

(needle

drop)

beautiful

are

available

count.

The

beautiful

plate

needle

but

is

very

important

stitches

on

weight

for

the

right

needle

Type

P

extra-

fabrics.

EX

Series.

plate.

@

also

the

to

light

Four

Dimension

1.0mm

stitches

'

Needle

proper

produce

weight

types

of

Double

smoothly

(balloon

designed

the

ideally

drop

chainstitch

to

produce

stitches).

at

the

EX

Series

and

beautifully.

groove

looper

soft

end

of

enable

the

for

and

Thanks

the

double

balloon

Suitable

balloon

the

balloon

thread

should

gentle

double

to

the

groove

chainstitch

stitches

groove

width

stitch

stitch

be

drawn

chainstitches

specially

needle

drop,

to

be

produced

for

the

IA

"U" - nut

chainstitch

The

thread

the

double

light.

The

EX

thread

tension

is

used

as

thread

tension

chainstitch

knob

tension

knob

tends

thread

Series

adopts a U - nut

from

loosening.

the

double

knob.

to

tension

get

loosened

pressure

to

because

is

very

prevent

the

)

#8>#14

#ig~#21

PEGASUS.

B

R

S

T

1.2mm

I.emm

1.8mm

wr

A

"U'-

nut

Is

used

u

Increases

efficiency.

the

feeding

4—©Dimension

Flrsl

Printing

December

Service

1991

Manual

006

EX

Series

A.

a. 0 -

)

Smooth

I

New

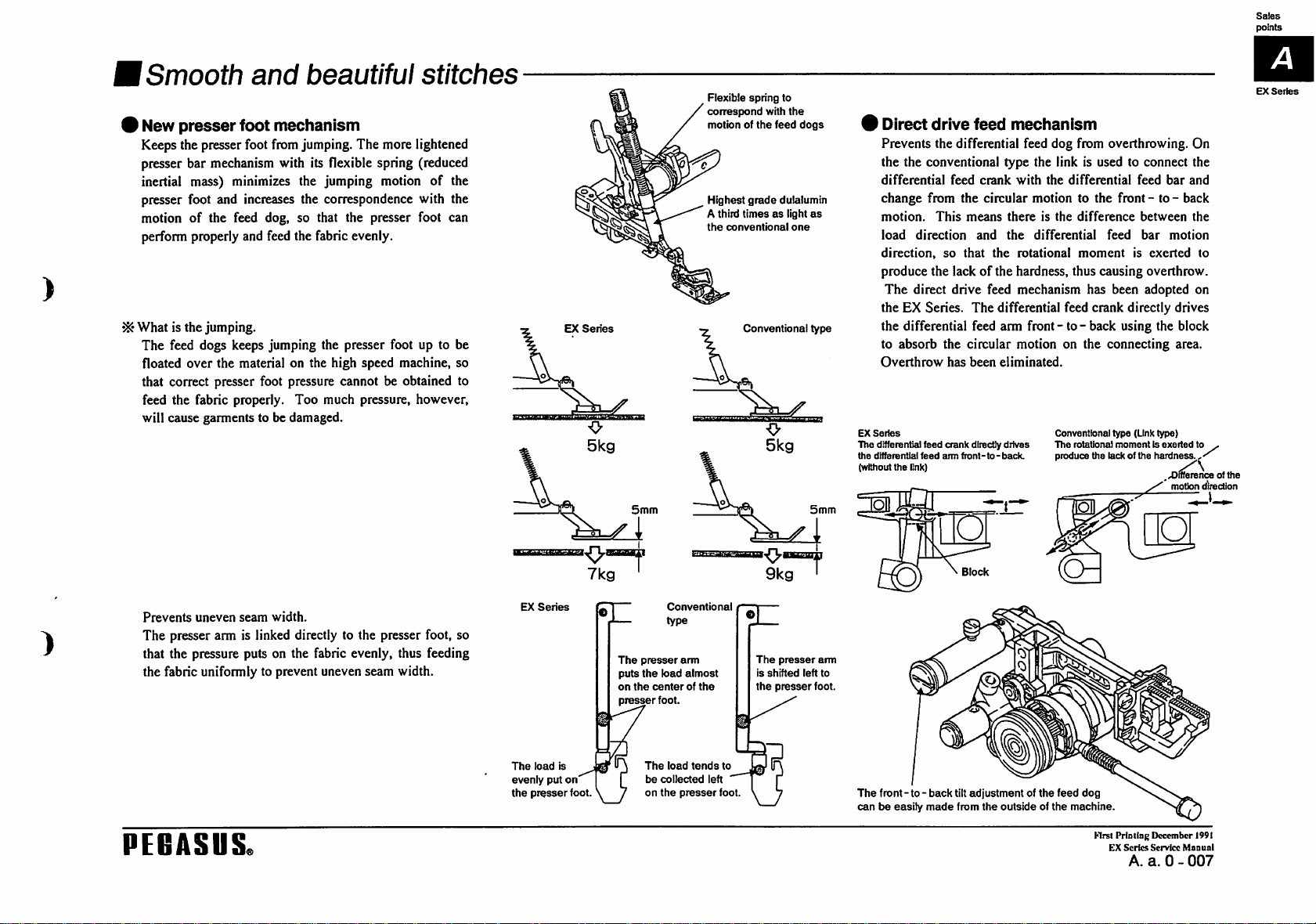

presser

Keeps

the

presser

inertia!

presser

motion

perform

iSJ

What

is

the

The

feed

floated

that

correct

feed

the

will

cause

foot

presser

foot

bar

mechanism

mass)

minimizes

foot

and

increases

of

the

feed

properly

over

fabric

and

jumping.

dogs

keeps

the

material

presser

properly.

garments

and

mechanism

from

with

the

dog,

so

feed

the

jumping

on

foot

pressure

Too

to

be

damaged.

beautiful

jumping.

the

the

The

its

flexible

jumping

correspondence

that

the

presser

fabric

evenly.

the

presser

high

speed

cannot

much

pressure,

stitches

more

lightened

spring

(reduced

motion

with

foot

foot

up

machine,

be

obtained

however,

of

to

the

the

can

be

so

to

EX

Series

5mm

Flexible

spring

conespond

motion

of

the

Highest

grade

A

third

times

the

conventional

Conventional type

to

with

the

feed

dulalumin

as

light

one

dogs

as

5mm

I

Direct

Prevents

the the

differential

change

motion.

load

direction,

produce

The

the

EX

the

differential

to

absorb

Overthrow

EX

Series

The

differential

the

differential

(without

the

drive

feed

the

differential

conventional

feed

crank

from

the

circular

This

means

direction

direct

Series.

so

the

and

that

lack

of

drive

The

feed

the

circular

has

been

feed

crank

feed

link)

directly

ann

front-to-back,

mechanism

feed

dog

type

the

link

with

the

differential

motion

there

is

the

the

differential

the

rotational

the

hardness,

feed

mechanism

differential

arm

eliminated.

drives

feed

front - to - back

motion

on

Conventional

The

produce

from

overthrowing.

is

used

to

feed

to

the

front - to - back

difference

feed

moment

thus

causing

has

been

crank

directly

is

using

the

connecting

type

the

(Link

moment

lack

of

the

rotational

On

connect

between

bar

the

bar

and

the

motion

exerted

to

overthrow.

adopted

on

drives

the

block

area.

type)

Is

exerted

to

hardness.

,

inference

motion

direction

EX

Series

^

of

the

EX

Prevents

The

presser

that

the

the

fabric

uneven

seam

arm

is

pressure

puts

uniformly

width.

linked

directly

on

the

to

prevent

to

the

fabric

evenly,

uneven

presser

thus

seam

width.

foot,

so

feeding

Series

The

load

evenly

the

presser

is

put

on

PEGASUS,

7kg

foot.

FE

The

presser

puts

the

on

the

center

presser

The

be

on

Conventional

type

arm

load

almost

of

foot.

load

tends

collected

the

presser

the

left

to

foot

9kg

The

presser

is

shifted

the

presser

'

left

foot.

arm

to

The

front - to - back

can

be

easily

made

Bock

tilt

adjustment

from

the

of

outside

the

of

the

feed

machine.

dog

First

Prlntlni;

EX

Series

A.

December

Service

Manual

a. 0 -

1991

007

Sales

points

)

Smooth

>

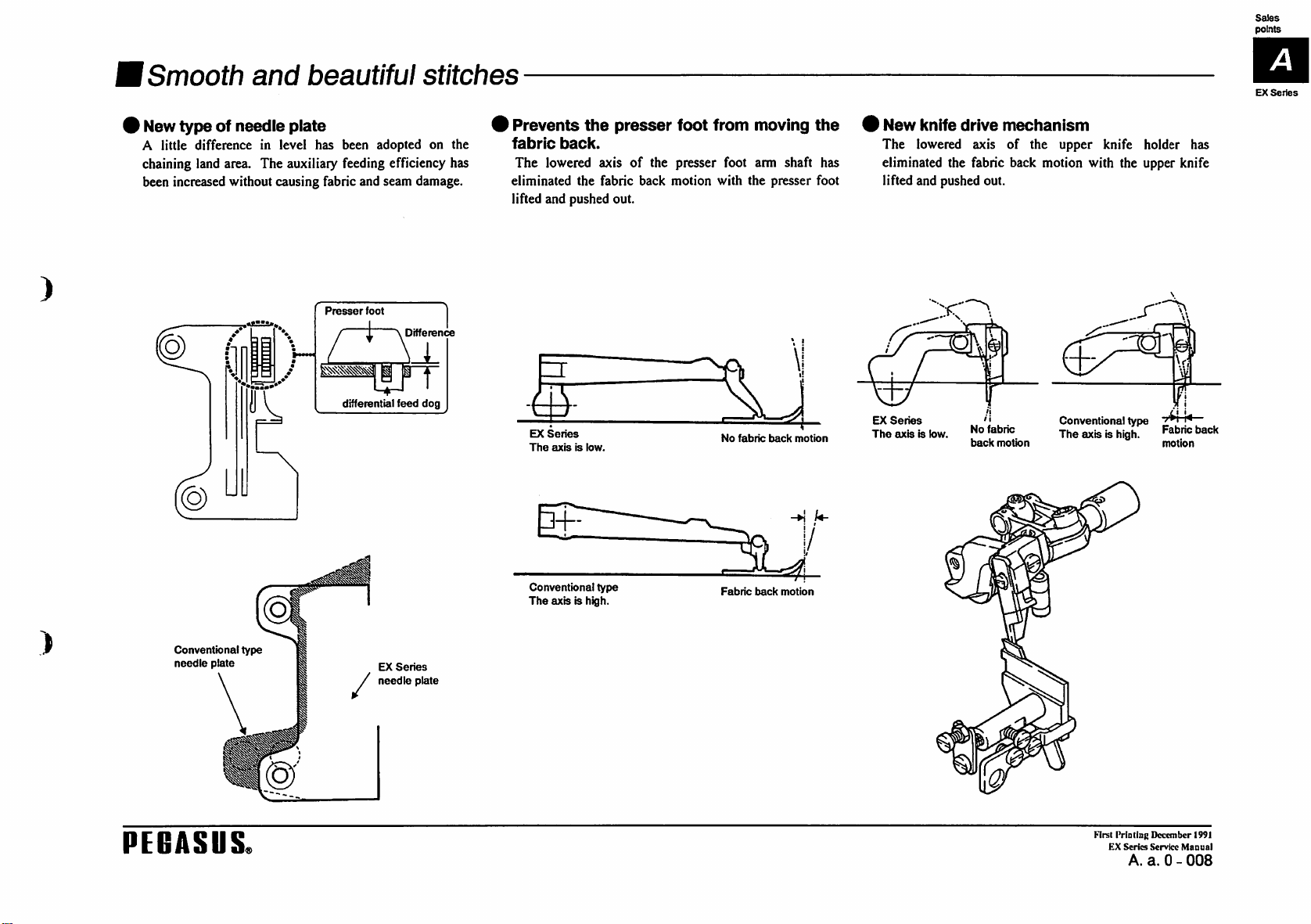

New

type

A

little

difference

chaining

been

land

increased

and

of

needle

area.

without

UL

plate

in

level

The

auxiliaiy

causing

beautiful

has

been

feeding

fabric

and

Presser

foot

/ i \ Differ

stitches

adopted

on

efficiency

seam

damage.

Difference

/

differential

feed

dog

the

has

I

Prevents

fabric

eliminated

lifted

The

EX

Tfie

back.

lowered

the

and

pushed

Series

axis

is

the

axis

fabric

out.

low.

presser

of

foot

the

presser

back motion

from

foot

with

No

fabric

moving

arm

shaft

the

presser

back

motion

the

has

foot

'

New

knife

The

lowered

eliminated

lifted

and

EX

Series

The

axis

is

low.

drive

axis

the

fabric

pushed

out.

No

back

mechanism

of

back

fabric

motion

the

upper

motion

Conventional

The

knife

with

axis

is

the

type

high.

holder

upper

knife

Fabric

motion

has

back

Conventional

The

axis

Conventional

needle

plate

type

EX

Series

needle

plate

PEGASUS.

is

type

high.

Fabric

back

motion

Firsi

EX

Prinllng

December

Series

Service

A.

a. 0 -

1991

Manual

008

)

Ease

>

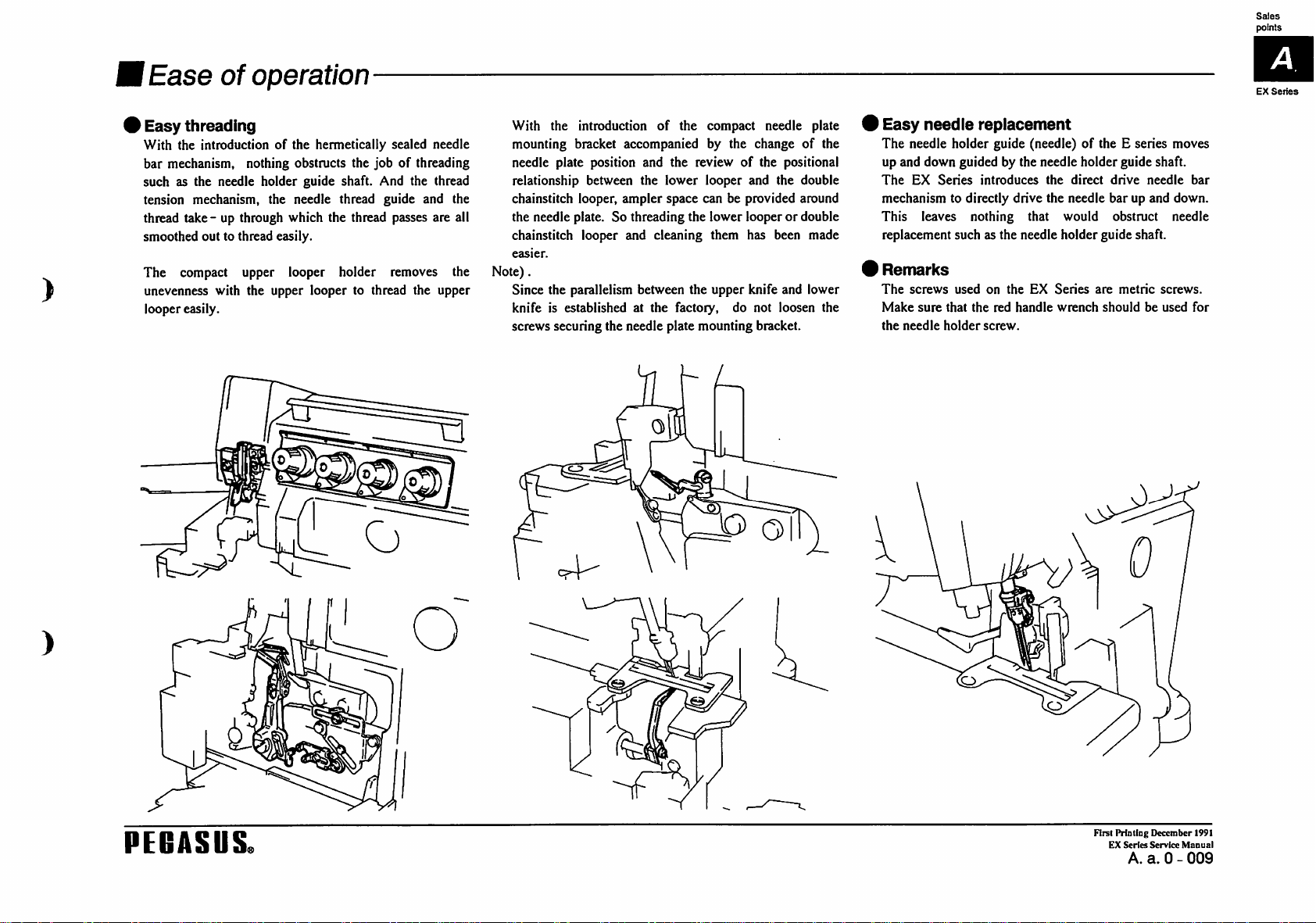

Easy

threading

With

the

introduction

bar

mechanism,

such

as

the

tension

thread

smoothed

The

unevenness

looper

mechanism,

take - up

out

compact

easily.

of

operation

of

the

nothing

needle

through

to

thread

upper

with

the

obstructs

holder

guide

the

needle

which

easily.

looper

upper

looper

hermetically

shaft.

thread

the

holder

sealed

the

job

And

guide

thread

passes

removes

to

thread

of

needle

threading

the

thread

and

the

are

all

the

the

upper

With

the

mounting

needle

plate

relationship

chainstitch

the

needle

chainstitch

easier.

Note).

Since

the

knife

is

established

screws

securing

introduction

bracket

position

between

looper,

plate.

looper

parallelism

the

of

accompanied

and

the

ampler

So

threading

and

cleaning

between

at

the

needle

the

compact

by

the

review

lower

looper

space

can

the

lower

them

the

upper

factory,

plate

mounting

needle

the

change

of

the

and

be

provided

looper

has

knife

do

not

bracket.

plate

of

the

positional

the

double

around

or

double

been

made

and

lower

loosen

the

)

Easy

needle

The

needle

up

and

down

The

EX

Series

mechanism

This

to

leaves

replacement

'

Remarks

The

screws

Make

sure

that

the

needle

holder

replacement

holder

guide

guided

by

introduces

directly

such

used

drive

nothing

as

the

on

the

the

red

handle

screw.

(needle)

the

needle

the

direct

the

needle

that

would

needle

holder

EX

Series

wrench

of

the E series

holder

guide

drive

bar

up

obstruct

guide

shaft.

are

metric

should

be

moves

shaft.

needle

and

down.

needle

screws.

used

bar

for

)

PEGASUS.

First

Prlntitig

EX

Seizes

A.

December

Service

a. 0 -

1991

Manuai

009

Sales

points

)

Ease

>

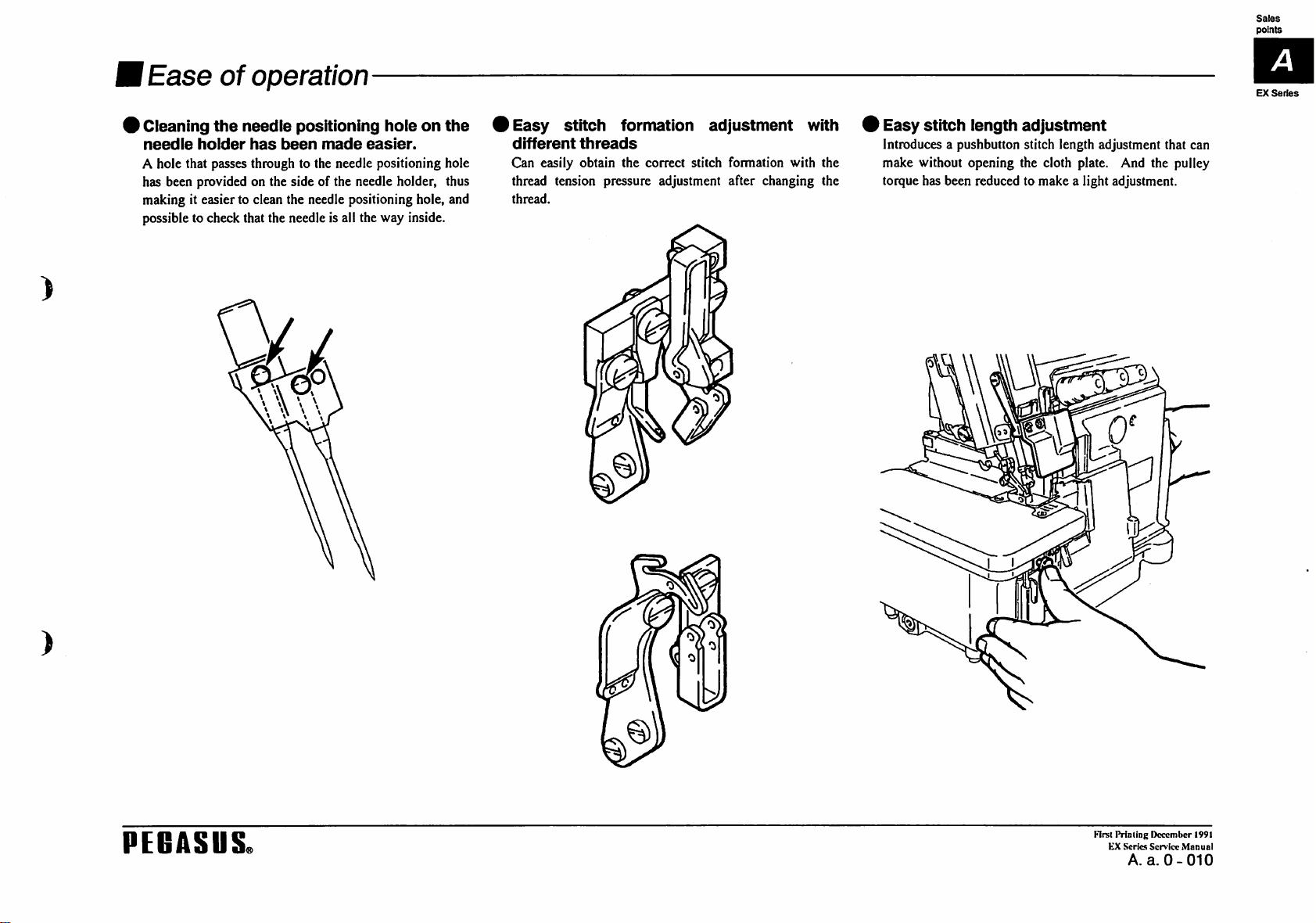

Cleaning

needle

A

has

making

possible

hole

that

been

holder

provided

it

easier

to

check

of

operation

the

needle

passes

to

that

positioning

has

been

through

on

the

clean

the

the

needle

to

side

made

the

needle

of

the

needle

positioning

is

all

hole

easier.

positioning

needle

holder,

hole,

the

way

inside.

on

the

hole

thus

and

1

Easy

different

Can

easily

thread

tension

thread.

stitch

threads

obtain

pressure

formation

the

correct

stitch

adjustment

adjustment

formation

after

with

changing

with

the

the

'

Easy

stitch

Introduces a pushbutton

make

without

torque

has

length

opening

been

reduced

adjustment

stitch

length

adjustment

the

cloth

plate.

to

make a light

that

And

the

pulley

adjustment.

can

EX

ft

Series

)

PEGASUS.

First

EX

Printing

December

Series

Service

A.

a.

Manual

0-010

1991

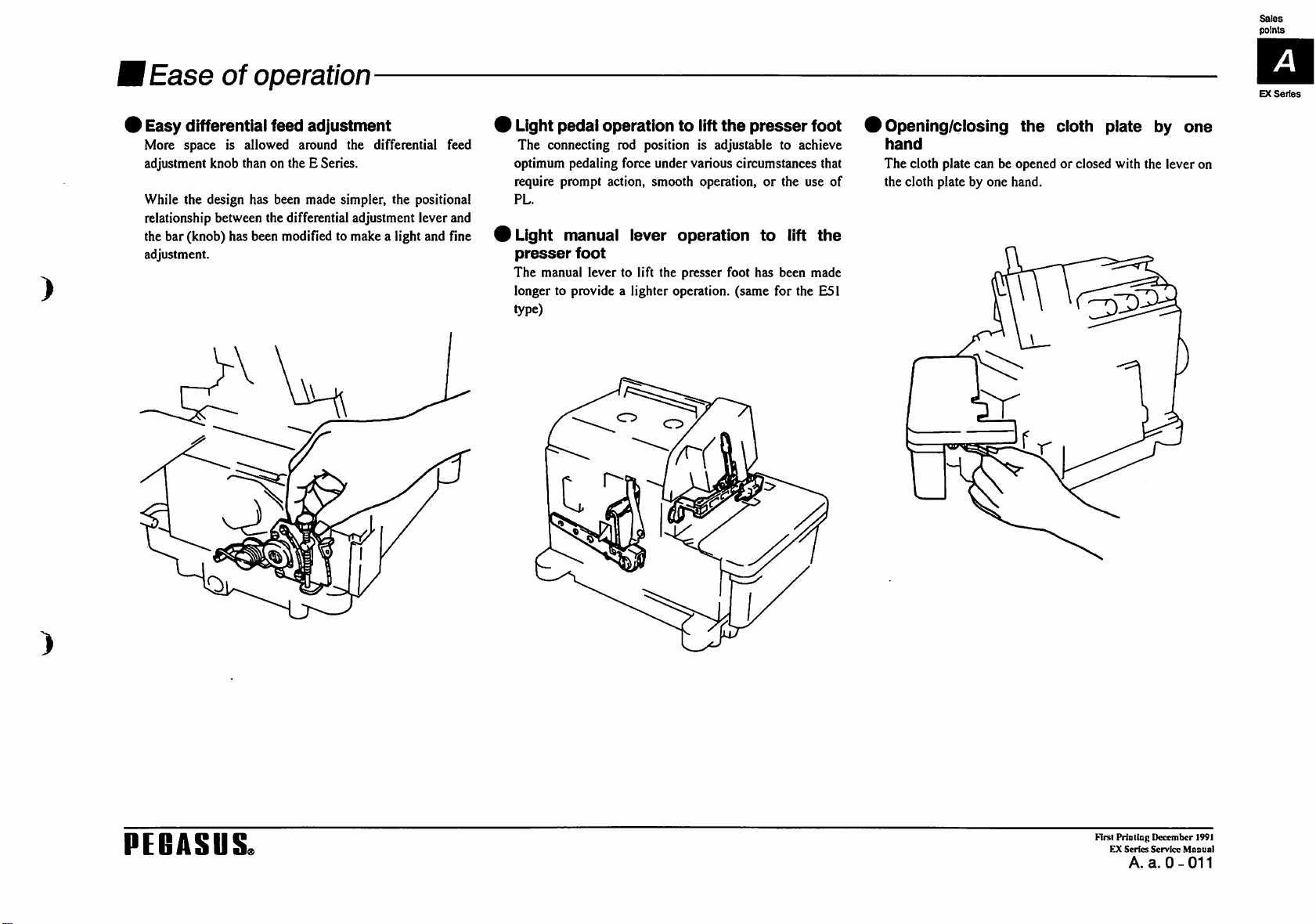

Ease

I

Easy

More

adjustment

While

relationship

the

bar

adjustment.

of

differential

space

is

knob

the

design

between

(knob)

has

operation

feed

adjustment

allowed

than

has

around

on

the E Series.

been

made

the

differential

been

modified

the

simpler,

adjustment

to

make a light

differential

the

feed

positional

lever

and

and

fine

1

Light

pedal

The

connecting

optimum

require

PL.

'Light

presser

The

manual

longer

to

type)

operation

rod

position

pedaling

prompt

manual

force

under

action,

smooth

lever

foot

lever

to

lift

the

provide a lighter

to

lift

the

presser

is

adjustable

various

circumstances

operation,

operation

presser

foot

operation,

(same

or

to

has

for

to

achieve

the

use

lift

been

the

foot

that

of

the

made

E5i

I

Opening/closing

hand

The

cloth

plate

can

be

opened

the

cloth

plate

by

one

hand.

the

cloth

or

closed

plate

with

the

by

lever

one

on

EX

Series

PEGASUS,

First

EX

PriDliDg

December

Scries

Service

A.

a.0-011

1991

Manual

Ease

)

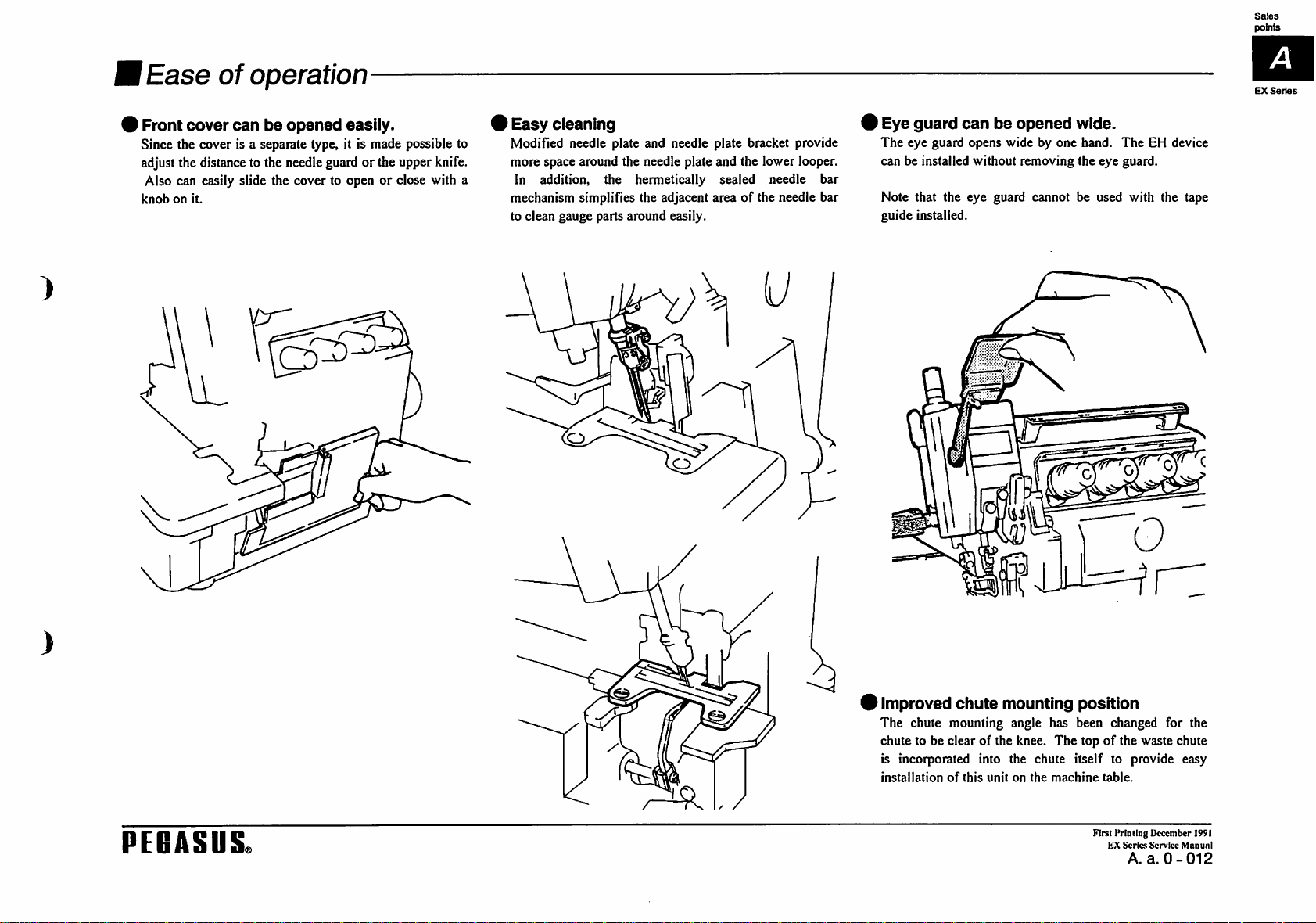

Front

cover

Since

the

adjust

the

Also

can

knob

on

it.

of

operation

can

be

cover

is a separate

distance

easily

to

the

slide

opened

needle

the

cover

easily.

type,

it

guard

to

open

is

or

made

the

upper

or

close

possible

to

knife.

with

a

I

Easy

cleaning

Modified

more

In

mechanism

to

needle

space

addition,

clean

gauge

plate

and

around

the

needle

the

hermetically

simplifies

parts

around

the

needle

plate

plate

and

sealed

adjacent

area

easily.

bracket

the

lower

needle

of

the

needle

provide

looper.

bar

bar

I

Eye

The

eye

can

be

Note

guide

guard

can

guard

opens

installed

that

installed.

the

eye

without

be

opened

wide

removing

guard

by

one

cannot

wide.

hand.

the

eye

be

used

The

EH

guard.

with

device

the

tape

>

PEGASUS,

)

Improved

The

chute

chute

to

be

is

incorporated

installation

chute

mounting

clear

of

the

into

of

this

unit

mounting

angle

has

been

knee.

The

the

chute

itself

on

the

machine

position

changed

top

of

the

to

provide

table.

First

Priming

EX

Series

A.

for

waste

chute

December

Service

a.

0-012

the

easy

1991

ManunI

)

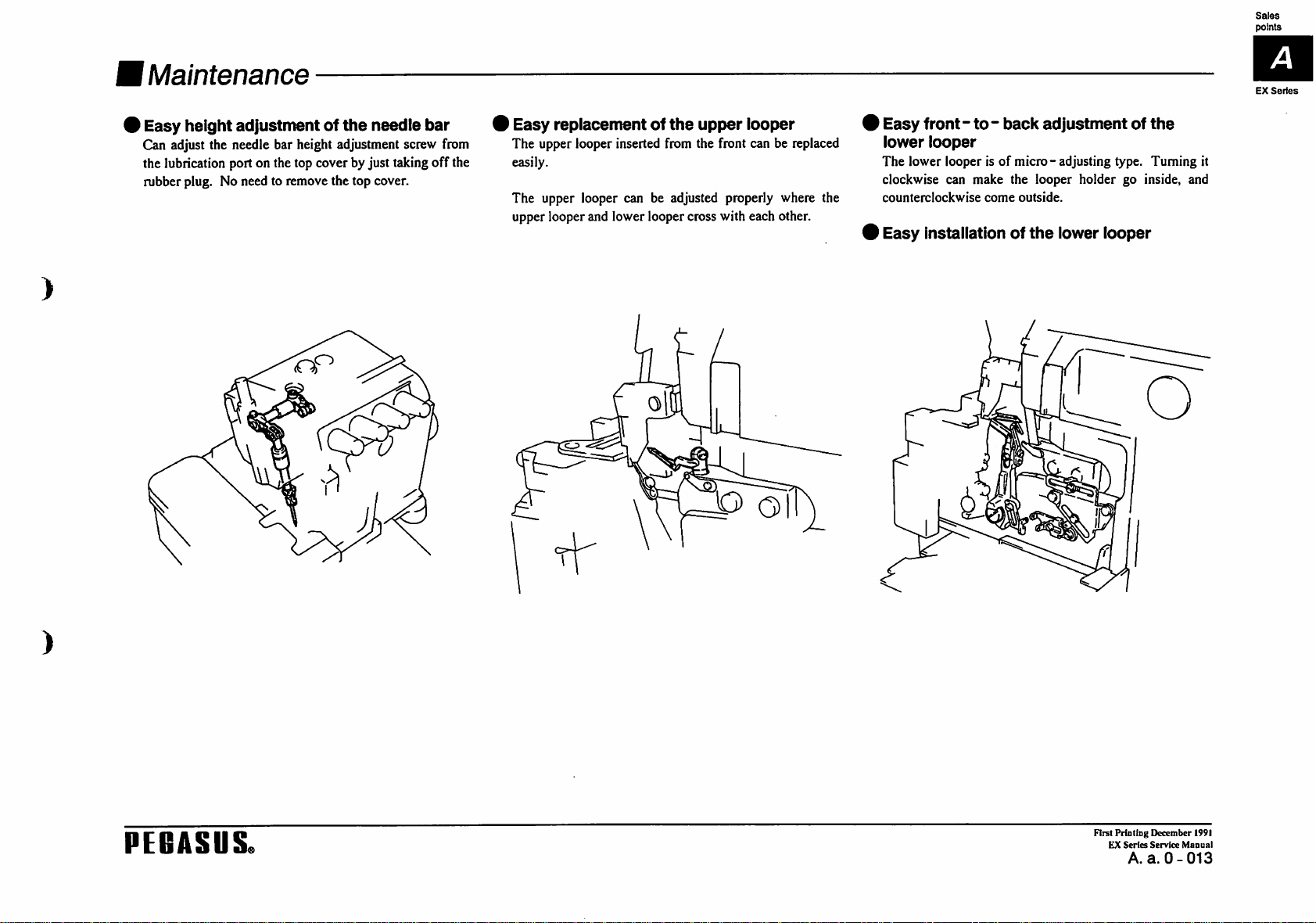

Maintenance

)

Easy

height

Can

adjust

the

lubrication

rubber

plug.

adjustment

the

needle

port

on

No

need

of

bar

height

the

top

cover

to remove

the

needle

adjustment

by

the

top

just

taking

cover.

screw

bar

from

off

the

)

Easy

The

upper

easily.

The

upper

upper

replacement

looper

inserted

looper

can

looper

and

lower

of

the

from

be

adjusted

looper

cross

upper

the

front

properly

with

looper

can

be replaced

where

each

other.

the

'

Easy

front - to - back

lower

looper

The

lower

looper

clockwise

counterclockwise

I

Easy

can

Installation

adjustment

is

of

micro - adjusting

make

the

looper

come

outside.

of

the

holder

lower

looper

of

the

type.

go

inside,

Turning

it

and

)

PEGASUS.

First

Printfog

EX

Series

A.

December

Service

Manual

a.

0-013

1991

Sales

points

Maintenance

)

Easy

installation

guard

On

the E Series a wrench

movable

the

relationship

looper

screw

The

can

and

needle

compact

upper

between

holder

driver.

movable

receive

two

the

left

needle.

guard,

looper

to

secure

needle

needles

of

the

but

holder

the

upper

the

guard

has

evenly

movabie

was

required

the

EX

Series

and

modified

looper

movable

needle

been

modified

between

needie

to

secure

has

introduced

positional

and

the

guard

such

the right

the

lower

with

a

that

it

needle

>

Easy

front - to - back

doubie

It

the

outside,

adjustment.

chainstitch

is

front-

to-

to - back

looper

holder

thus

adjustment

iooper

back

micro-

adjustable.

micro - adjustable

go

inside,

providing

easy

screw

and

and

accurate

of

the

Turning

clockwise

counterclockwise

the

front

can

make

come

front - to - back

I

Easy

avoiding

double

The

removing

Conventionally

changed

loop

front - to - back

looper

adjustment

loop

the

To

securing

chainstitch

EX

Series

the

cover

the

front - to - back

where

the

all

over

does

where

the

looper

front - to - back

remove

the

cover

the

the

looper

not

looper

motion

adjustment

iooper

allows

adjustment

again.

cover

plate

for

plate.

avoiding

enters,

But

change

the

enters,

adjustment.

plate,

without

so

an

adjustment

motion

point

it

of

on

point

eliminating

taking

of

has

required

the

double

the

of

just

loosen

adjustment

the

EX

the

it

out

of

the

only

by

has

needle

thread

to

make

chainstitch

Series

this

needle

thread

the

need

for

the

screw

completely.

EX

Series

a

PEGASUS.

First

EriDlIng

EX

Series

A.

December

Service

a.

0-014

1991

Manual

)

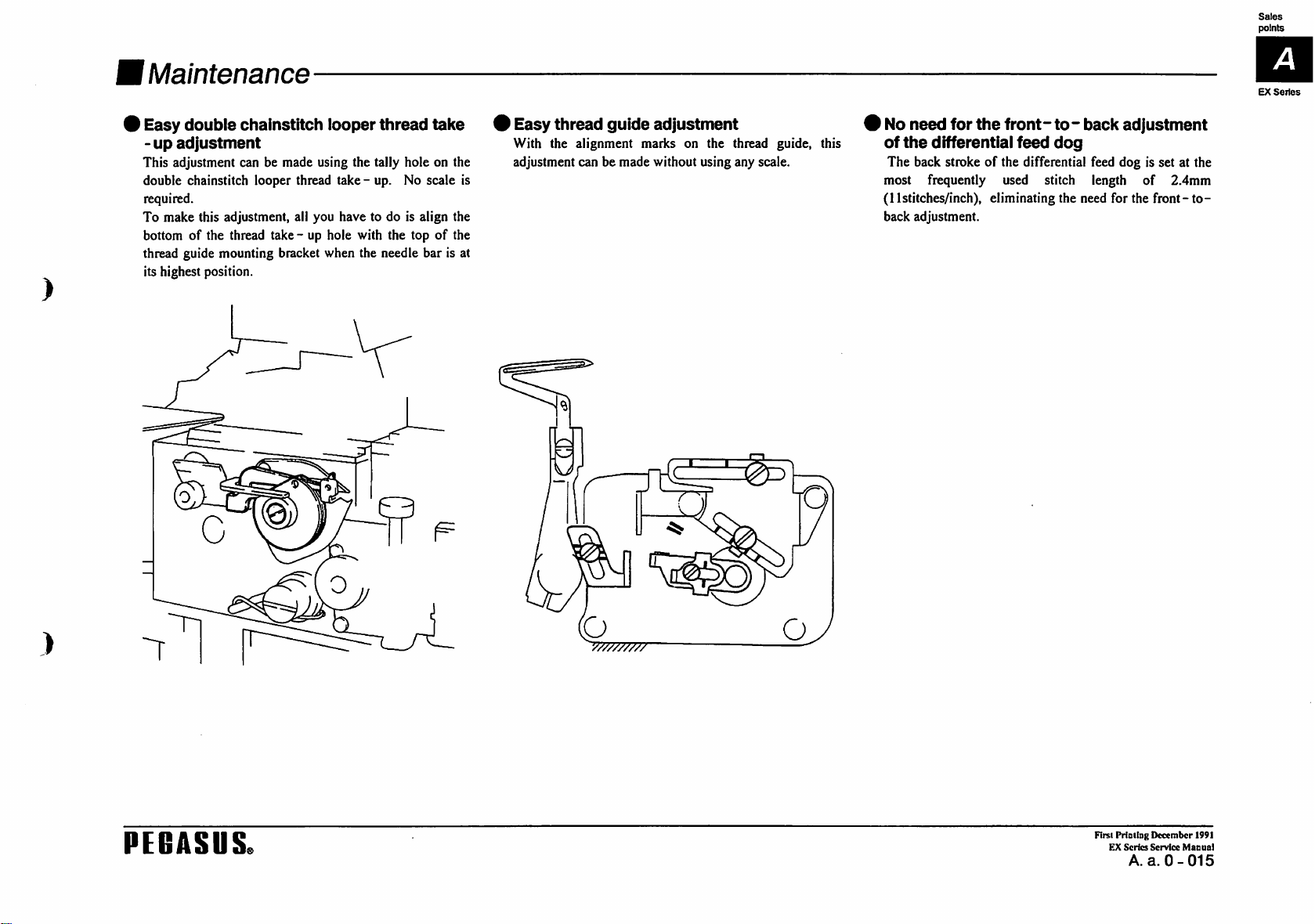

Maintenance

I

Easy

double

-up

adjustment

This

adjustment

double

chainstitch

required.

To

make

bottom

of

thread

guide

its

highest

chalnstitch

can

looper

this

adjustment,

the

thread

mounting

position.

be

made

thread

all

take - up

bracket

looper

using

the

take - up.

you

have

hole

when

thread

tally

to

do

with

the

the

needle

take

hole

on

No

scale

is

align

top

bar

of

is

the

is

the

the

at

I

Easy

thread

With

the

alignment

adjustment

can

guide

marks

be

made

adjustment

on

the

thread

without

using

any

guide,

scale.

this

)

No

need

for

of

the

differential

The

back

stroke

most

frequently

(11

stitches/inch),

back

adjustment.

the

front - to - back

feed

dog

of

the

differential

used

stitch

eliminating

the

feed

length

need

for

dog

adjustment

is

set

at

the

of

2.4mm

the

front - to-

EX

Series

)

PEGASUS.

777777777

First

PriollDg

EX

Series

A.

December

Service

a.

0-015

1991

Manual

Maintenance

)

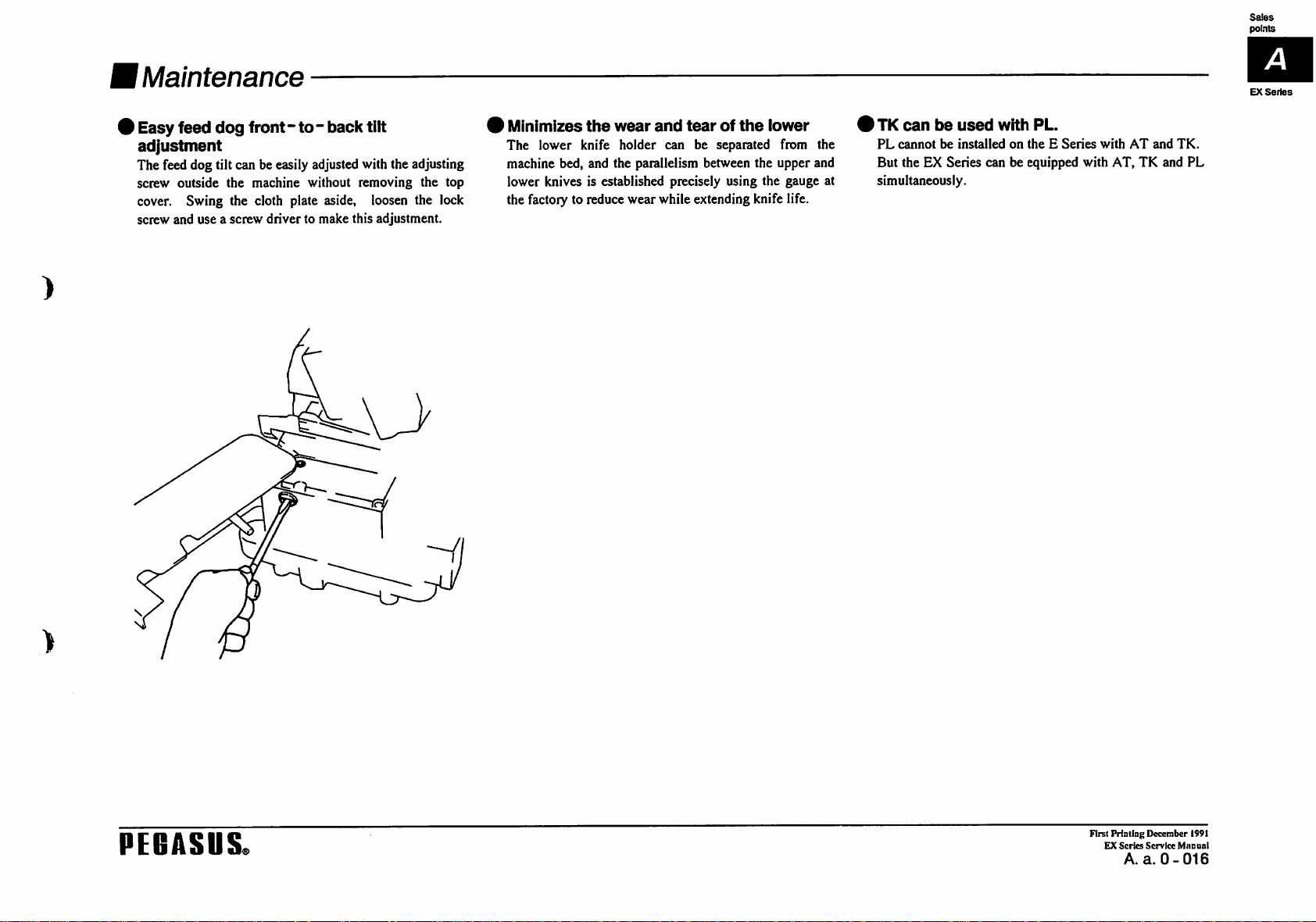

Easy

feed

dog

front-to - back

adjustment

The

feed

dog

tilt

can

screw

outside

cover.

screw

and

the

Swing

the

use a screw

be

easily

machine

cloth

plate

driver

to

tilt

adjusted

without

removing

aside,

make

this

with

the

adjusting

the

loosen

the

lock

adjustment.

top

I

Minimizes

The

lower

machine

lower

the

bed,

knives

factory

the

wear

knife

holder

and

the

is

established

to reduce

and

tear

can

be

parallelism

between

precisely

wear

while

extending

of

the

lower

separated

using

the

the

from

upper

gauge

knife

the

and

life.

at

ITK

can

be

used

PL

cannot

be

installed

But

the

EX

Series

simultaneously.

with

can

on

be

PL.

the E Series

equipped

with

with

AT,

AT

TK

and

and

TK.

PL

EX

Series

PEGASUS.

First

PriDling

EX

Scries

A.

December

Service

Mnoual

a.

0-016

1991

Maintenance

)

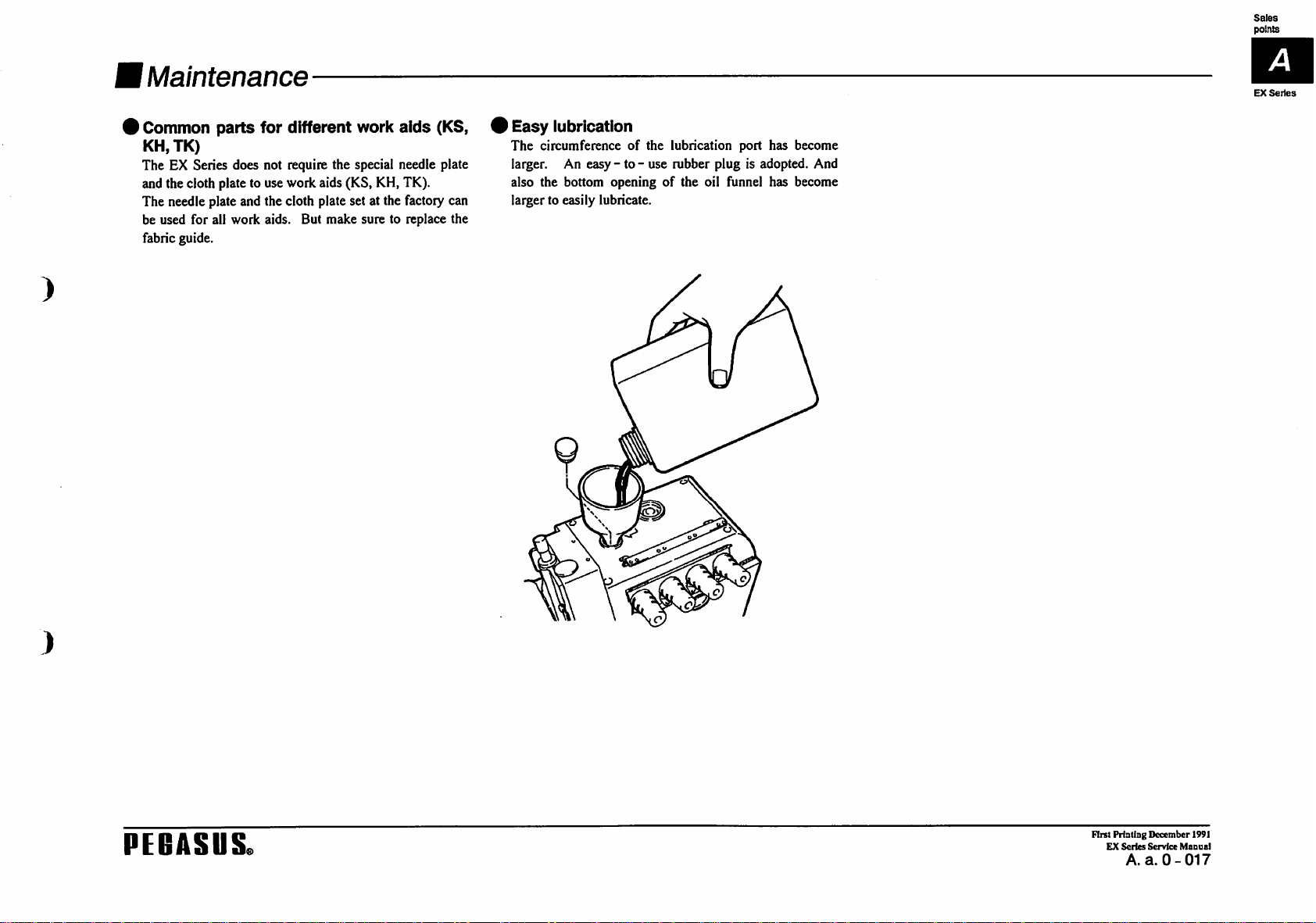

Common

KH,TK)

The

EX

and

the

The

needle

be

used

fabric

Series

cloth

plate

for

all

guide.

parts

does

plate

to

and

work

for

different

not

require

use

work

the

cloth

aids.

But

work

the

special

aids

(KS,

plate

set at

make

KH,

the

sure

to

aids

(KS,

needle

plate

TK).

factory

can

replace

the

I

Easy

iubrication

The

circumference

larger.

also

larger

An

the

to

easily

bottom

of

the

easy - to - use

opening

lubricate.

of

lubrication

rubber

the

plug

oil

funnel

port

is

has

become

adopted.

has

And

become

EX

Series

PEGASUS.

First

Printing

EX

Scries

A.

December

Service

a.

0-017

1991

Manual

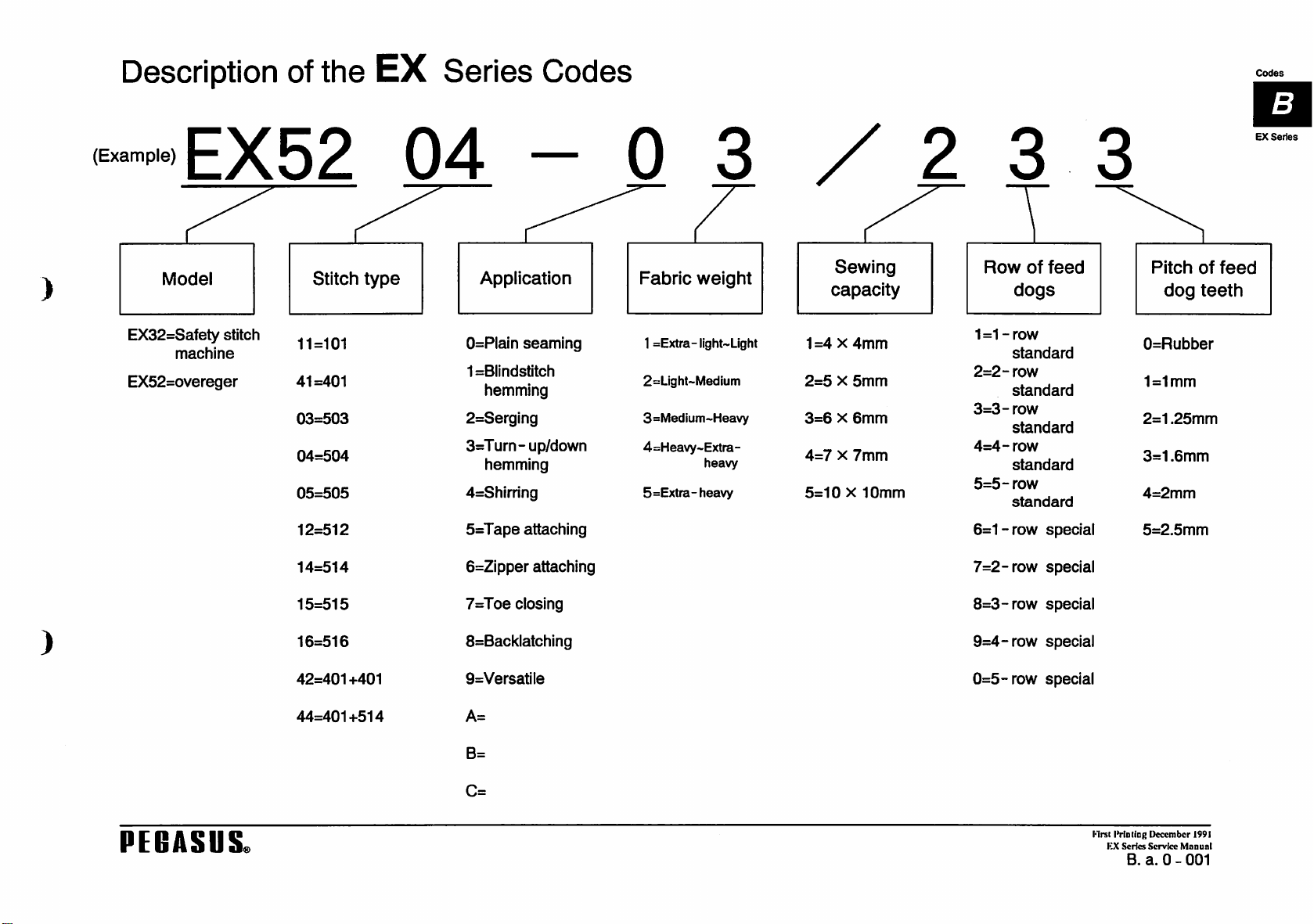

Description

(Example)

of

EX52

the

EX

Series

04

Codes

0

3

2

3

3

Codes

EX

Series

)

)

Model

EX32=Safety

EX52=overeger

stitch

machine

Stitch

11=101

41=401

03=503

04=504

05=505

12=512

14=514

15=515

16=516

42=401+401

44=401+514

type

Application

0=Plain

1

=Blindstitch

2=Serging

3=Turn-up/down

O

DC

>

4=Shirring

5=Tape

6=Zipper

7=Toe

8=Backlatching

9=VersatiIe

seaming

hemming

hemming

ii

II

II

attaching

attaching

closing

Fabric

1

2=Light~Medlum

3=Medium~Heavy

4=Heavy~Extra-

5=Extra-heavy

weight

=Extra-

light~Llght

heavy

Sewing

capacity

1=4 X 4mm

2=5 X 5mm

3=6 X 6mm

4=7 X 7mm

5=10 X 10mm

Row

of

1=1-row

standard

2=2-

row

standard

3=3-row

standard

4=4-row

standard

5=5-

row

standard

6=1-row

7=2-row

8=3-row

9=4-row

0=5-row

feed

special

special

special

special

special

Pitch

dog

0=Rubber

1=1

mm

2=1.25mm

3=1.6mm

4=2mm

5=2.5mm

of

feed

teeth

PEGASUSL

l<1rsi

I'rIoliDe

ICX

Series

B.

December

Service

a. 0 -

1991

Manual

001

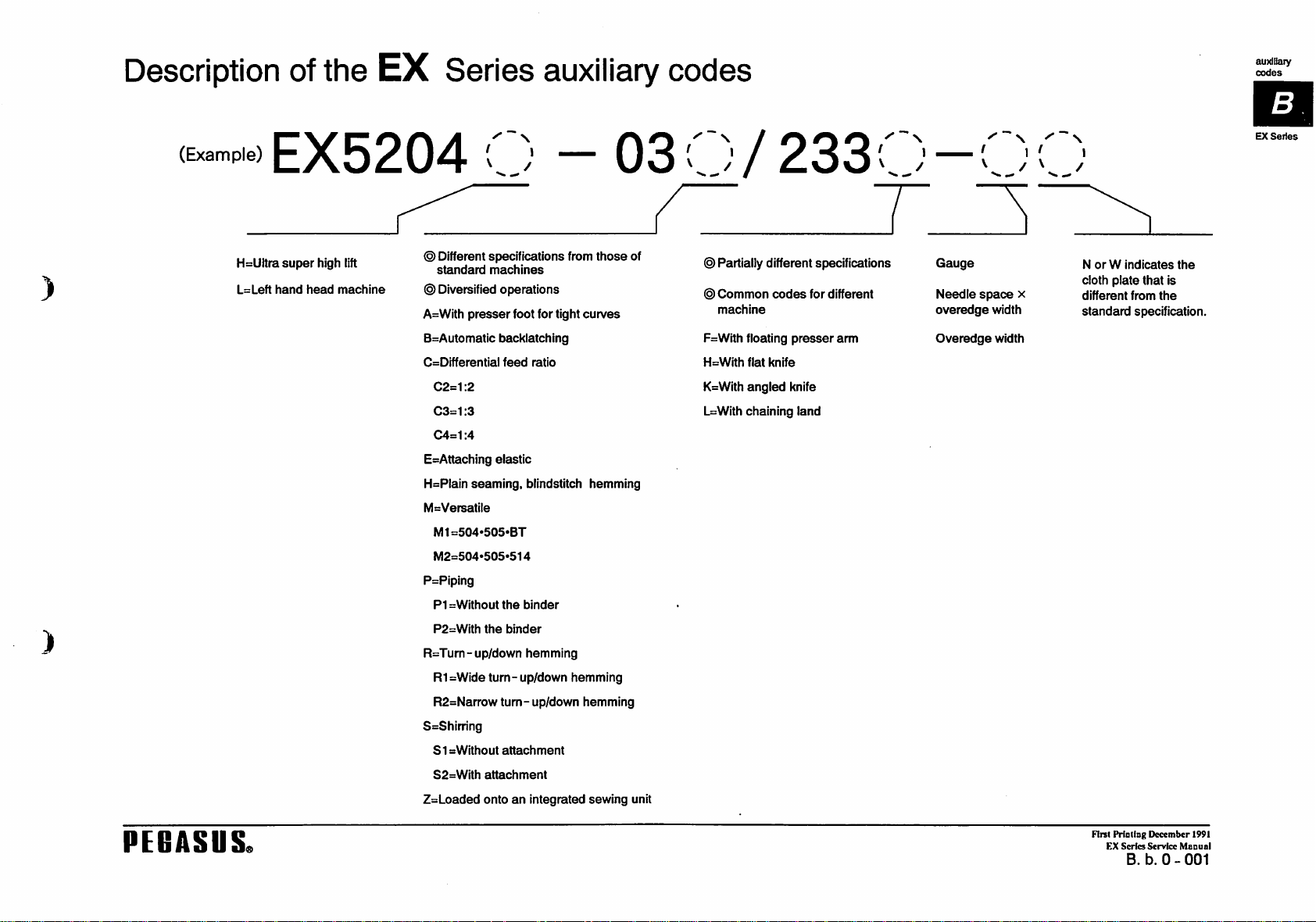

Description

of

the

EX

Series

auxiliary

codes

auxlltaiy

EX

Series

)

EX5204

H=Ultra

super

high

lift

L=Left

hand

head

machine

C

©

Different

standard

©

Diversified

A=With

B=Automatic

C=Differential

C2=1:2

C3=1:3

C4=1:4

E=Attaching

H=Plain

MsVersatile

l\fll=504*505'BT

M2=:504*505>514

P=Piping

PI

P2=With

R=Turn-up/down

R1

R2=Narrow

S=Shirring

81

82=With

Z=Loaded

specifications

machines

operations

presser

backlatching

feed

elastic

seaming,

=Without

=Wide

^Without

the

the

binder

turn-

turn-up/down

attachment

attachment

onto

foot

an

-

from

for

tight

curves

ratio

blindstitch

binder

hemming

up/down

hemming

hemming

integrated

sewing

03

those

of

hemming

unit

C)

/

©

Partially

©

Common

machine

F=With

floating

H=With

flat

K=With

angled

L=With

chaining

233

different

knife

specifications

codes

for

different

presser

knife

land

arm

Gauge

Needle

space

overedge

Overedge

width

width

N

or W indicates

cloth

x

plate

different

standard

from

the

that

is

the

specification.

PEGASUS,

First

Printing

EX

Series

B.

DGCcmbcr

Service

Manual

b. 0 -

1991

001

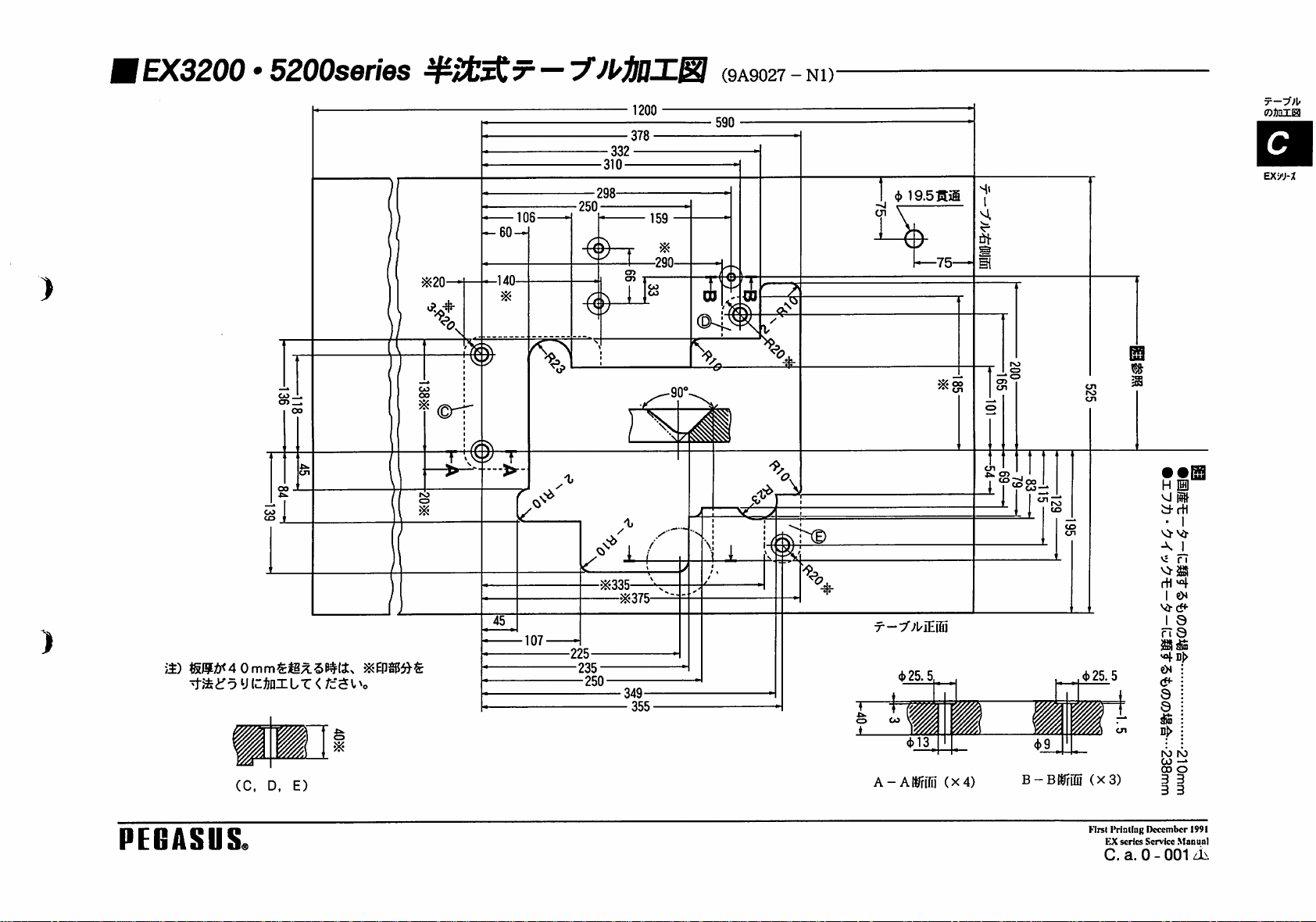

EX3200 • SZOOseries

(9A9027 - Nl)'

«j)

19.5Hii

9—y)\f

EXj/y-x

)

^;S^5yicADXUT</cai>o

(C.

D.

E)

PEGASUS,

T—yji/Jtm

A-Arnfii

(X4)

625.5

B-BKffQfl

(X3)

KirsI

EX

C.

IVintlag

December

scries

Service

a. 0 -

M

M

00

o

Manual

001A

I99i

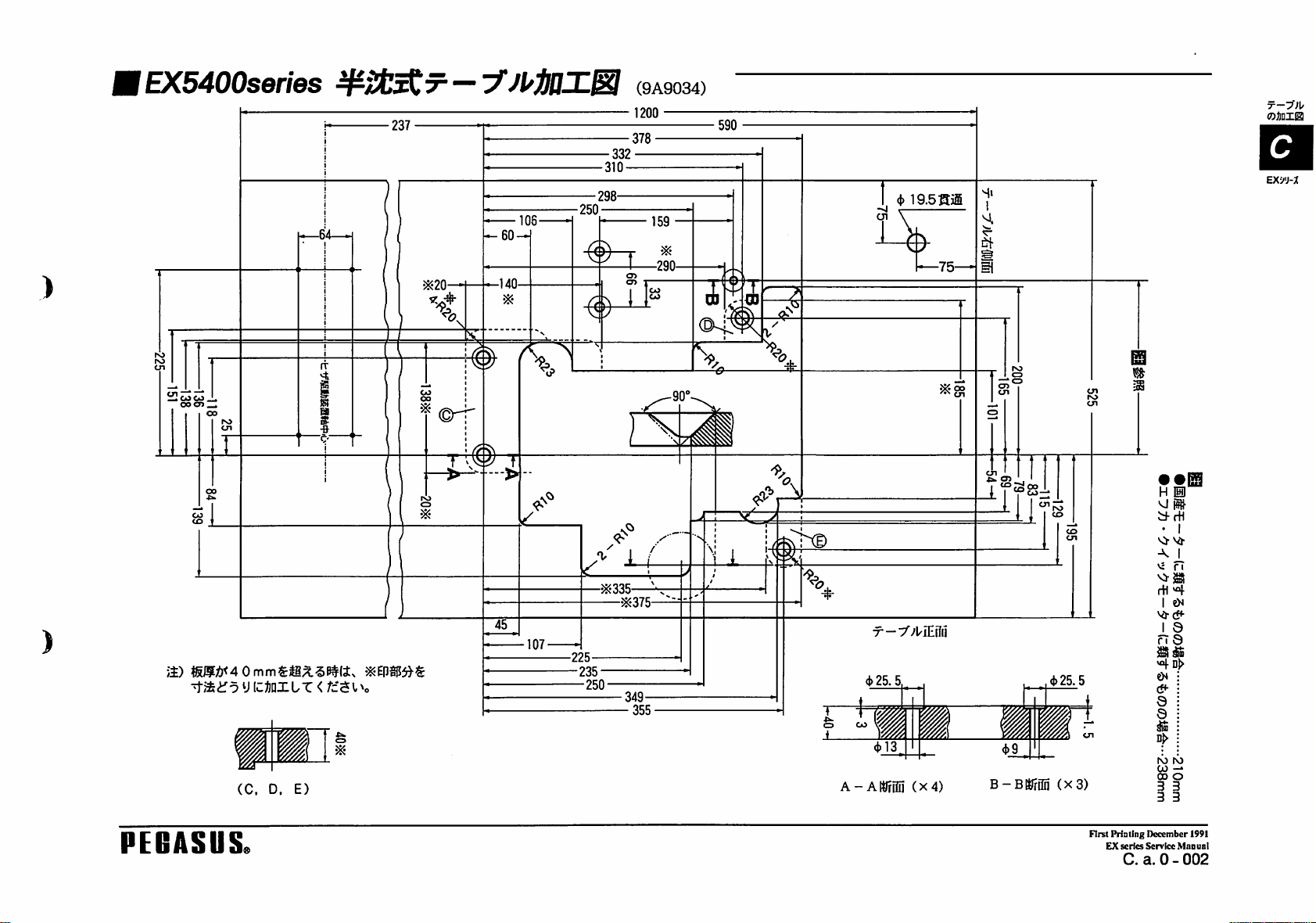

EX5400series

(9A9034)

({>

19.5|tiS

EXf'J-X

)

OOO)

\)

ICiPXLT < /c$Uo

(C.

D.

E)

^ (err

i

f

^

A-AWrifii

T-yjimii

(|)13

(X4)

j

m

_

B-

4)9

(x3)

D>

M

CO

CD

3

3

ro

—

O

3

3

PEGASUS.

First

EX

Printing

December

scries

Service

C.

a.

Manual

0-002

1991

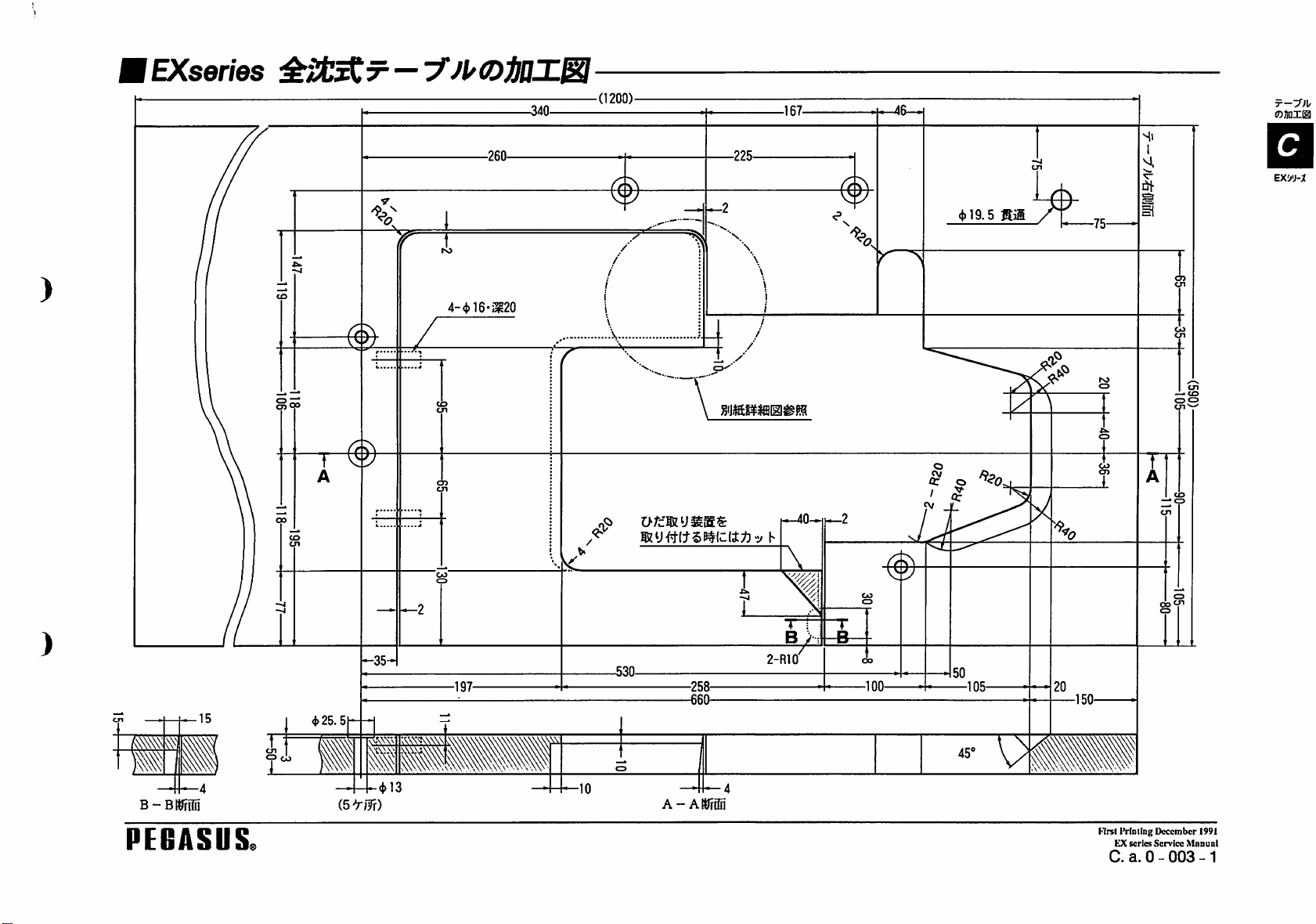

EXseries

■(1200)

4-4)16-3g20

)

•AW-^WW

B-BRfr®

PE6ASUS.

(s^rfr)

A-AWrffi

First

C.

I'rioting

EX

series

a.0-003-1

oo

December

Service

Manual

1991

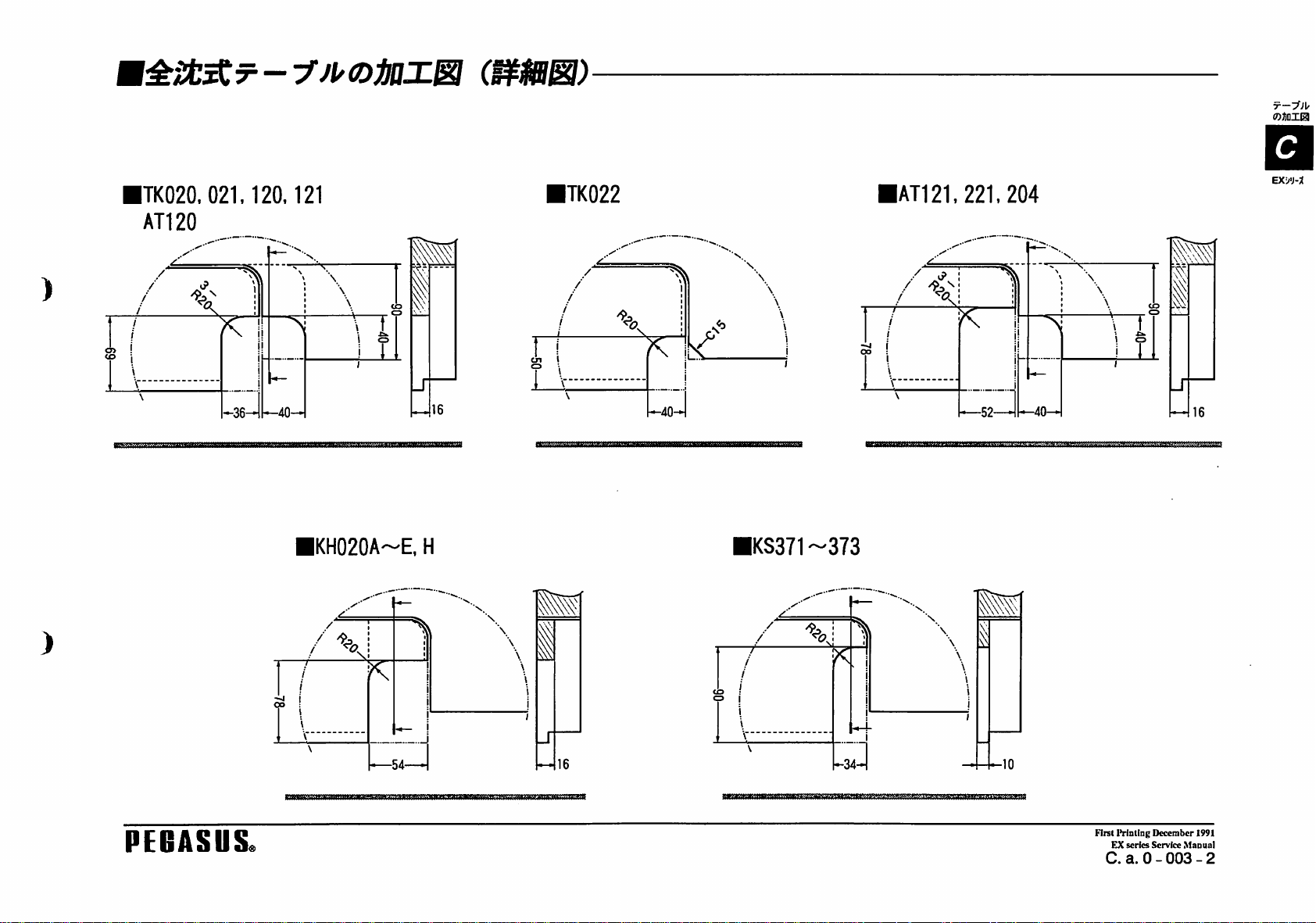

)

ITK020.

ATI

/

!

CO

j

\'

\

20

^

021.

K

-36-J

120.121

^ **v..

\

i

j

i

i

i

—40—

\

\

\

\ t

\ Q

i 1

1

ITK022

to

K

16

-40-1

IAT121,221,204

/ t?

/ 'k

/

OD

v

\

LJ

k-40^

16

IKH020A-E,

y'

/

/

/

/

00

!

1

\

H

1

-54—1

''N.

\.

\

\

\

1

16

PEGASUS.

IKS371

-373

'^O,

'

-34]

MnaBBaBn»«t«CTiwt»MWsarotm8ni»3iimi3STOtaiiaj!Bas3^^

-10

First

EX

C.

Frlnting

December

scries

Service

a.0-003-2

1991

Manual

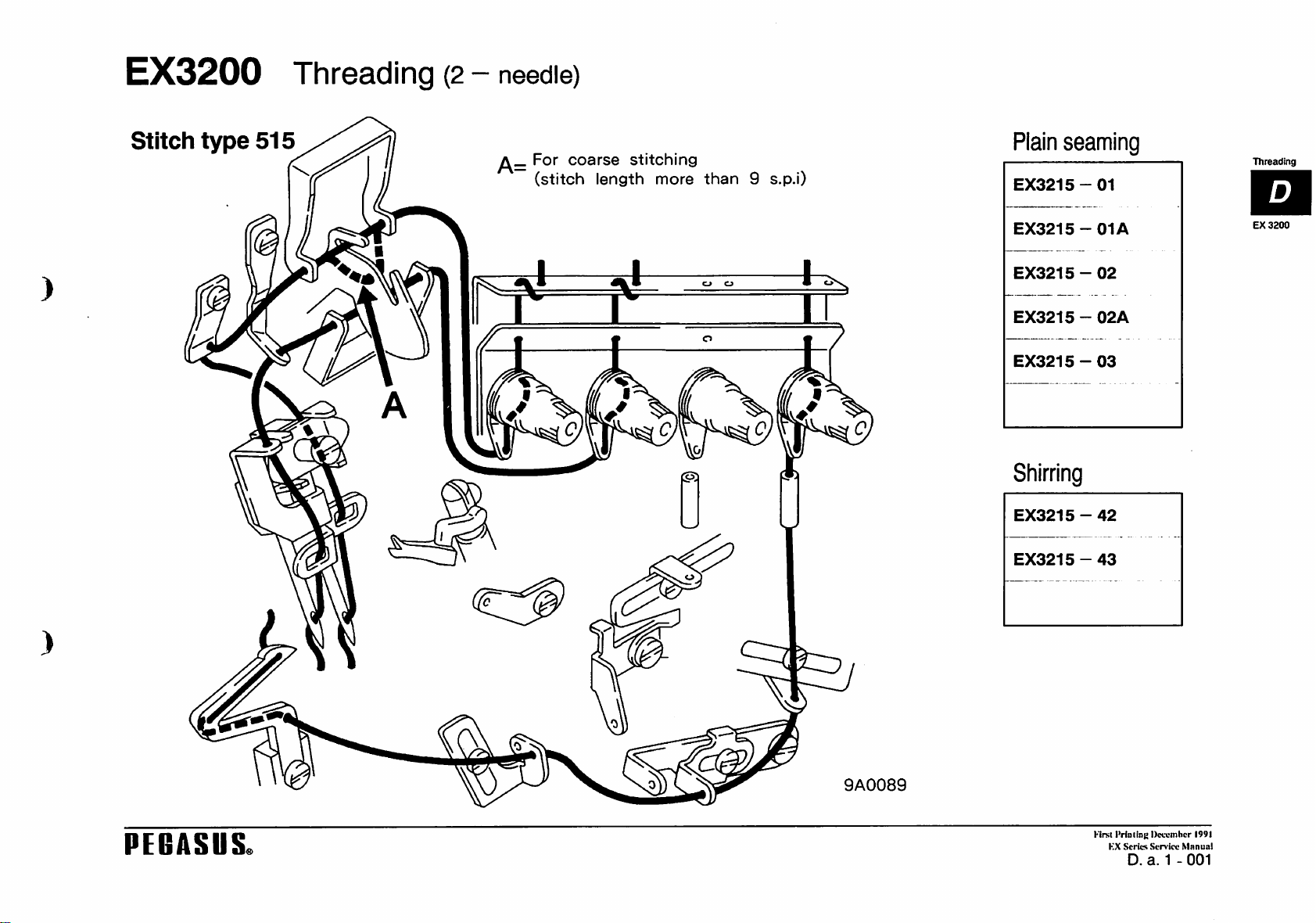

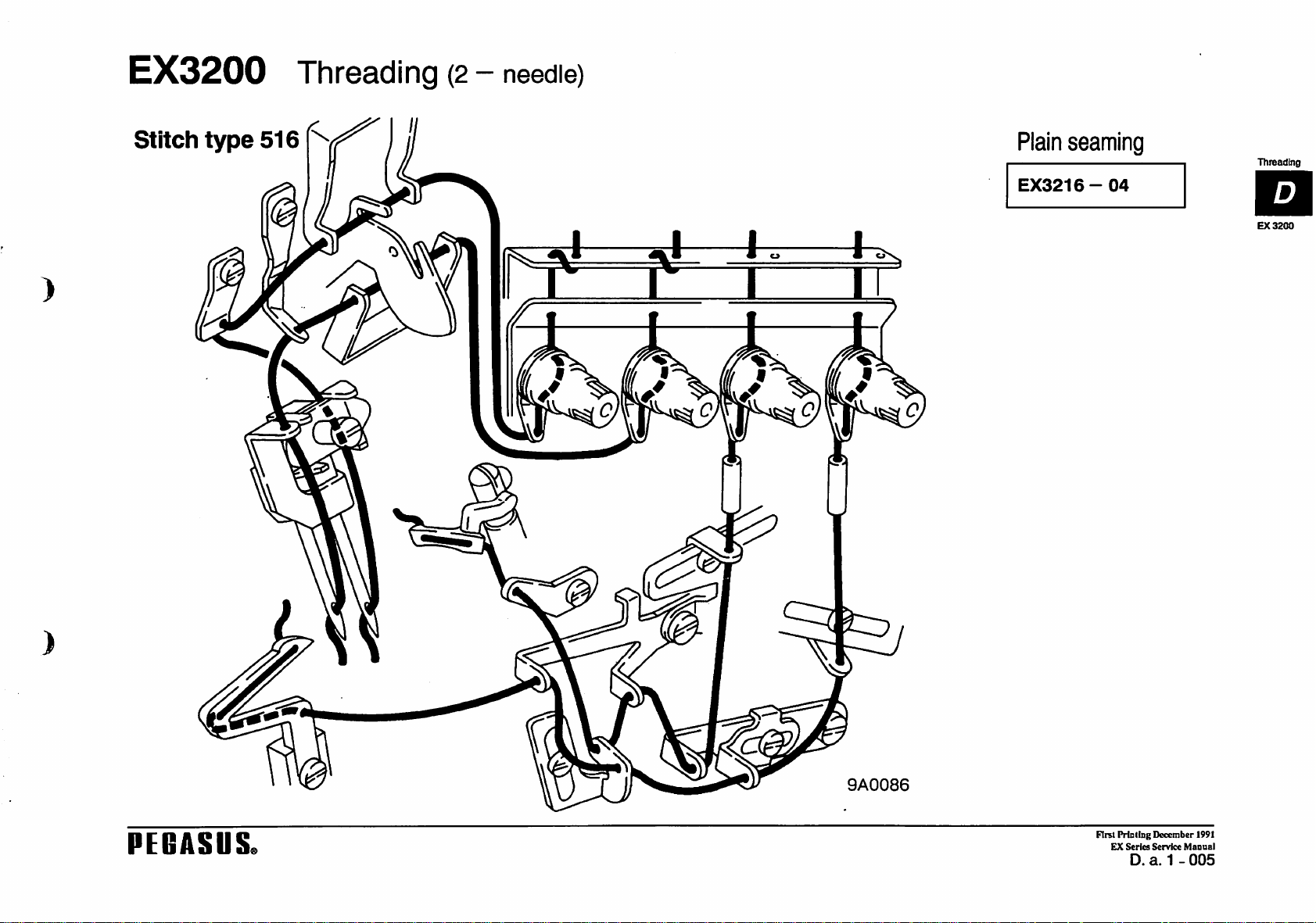

EX3200

Threading

(2

—

needle)

Stitch

type

515

F)or

coarse

(stitch

stitching

length

more

than 9 s.p.i)

Plain

EX3215 -01

EX3215

EX3215

EX3215

EX3215

seaming

01A

-

-

02

02A

-

-

03

Shirring

EX3215

EX3215 -43

-

42

Threading

z

EX

3200

PE6ASUS<

9A0089

Mrst

KX

IViollne

December

Scries

Service

D.

a. 1 -

1991

Mnnual

001

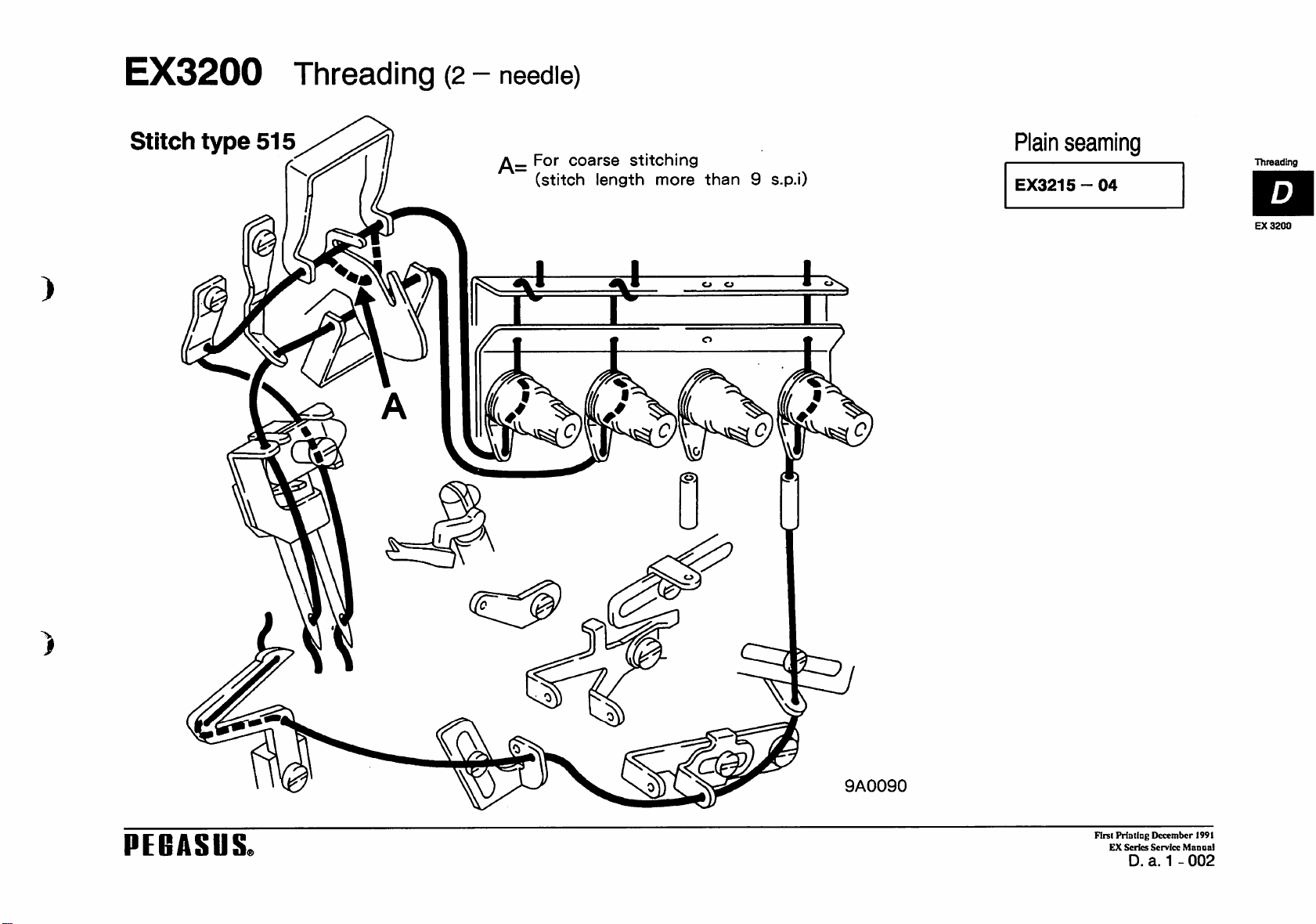

EX3200

Threading

(2

—

needle)

)

Stitch

type

515

For

coarse

(stitch

length

stitching

more

than 9 s.p.i)

Plain

EX3215 - 04

seaming

Threading

EX

3200

PEGASUS.

9A0090

First

PrintlDg

EX

Series

D.

December

Service

Manual

a. 1 -

1991

002

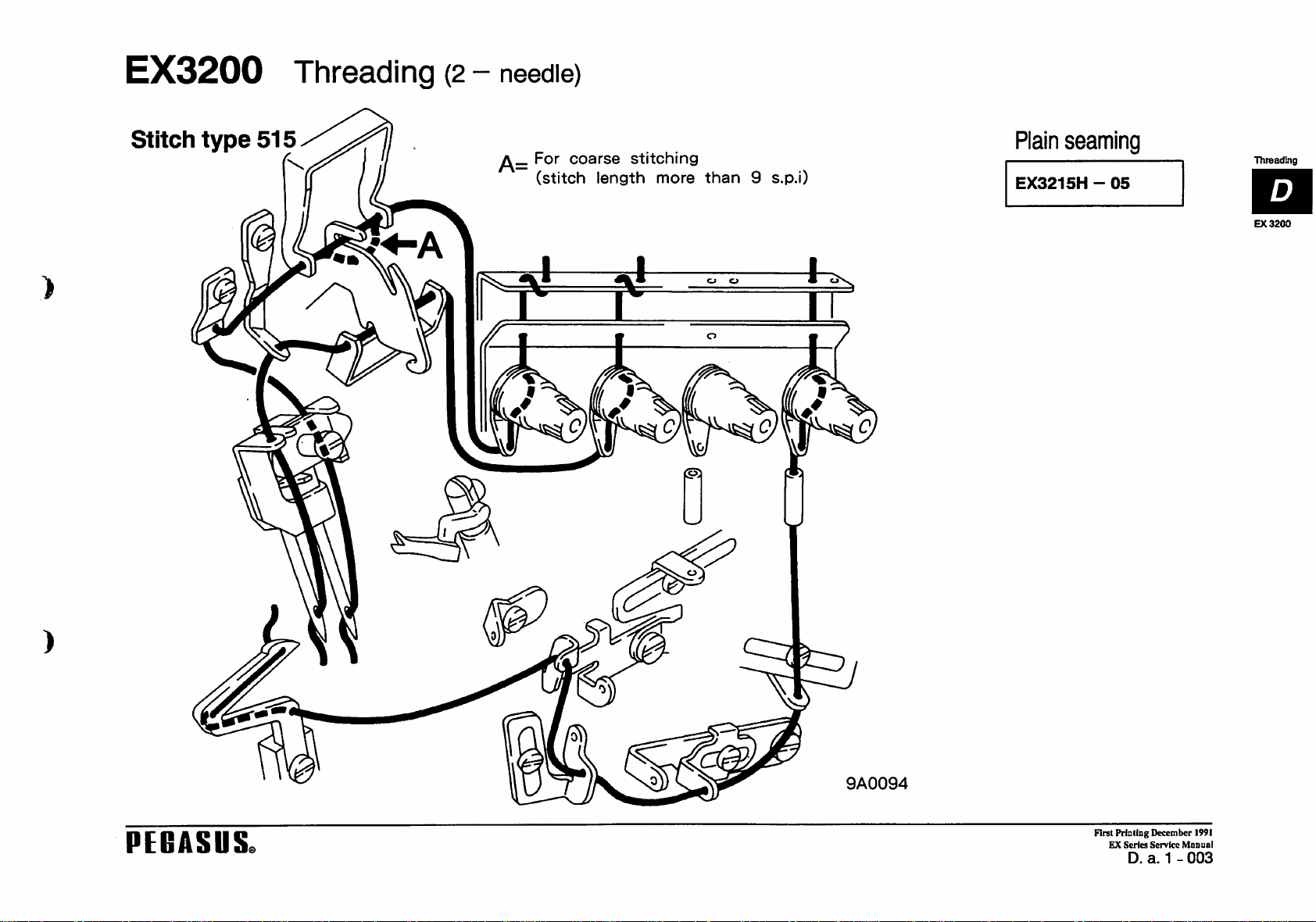

EX3200

Threading

(2

—

needle)

Stitch

type

515

For

coarse

(stitch

stitching

length

more

than 9 s.p.i)

Plain

EX3215H

seaming

-

05

Threading

EX

3200

)

PEGASUS.

9A0094

First

EX

Priallng

December

Series

Service

D.

a. 1 -003

1991

Manual

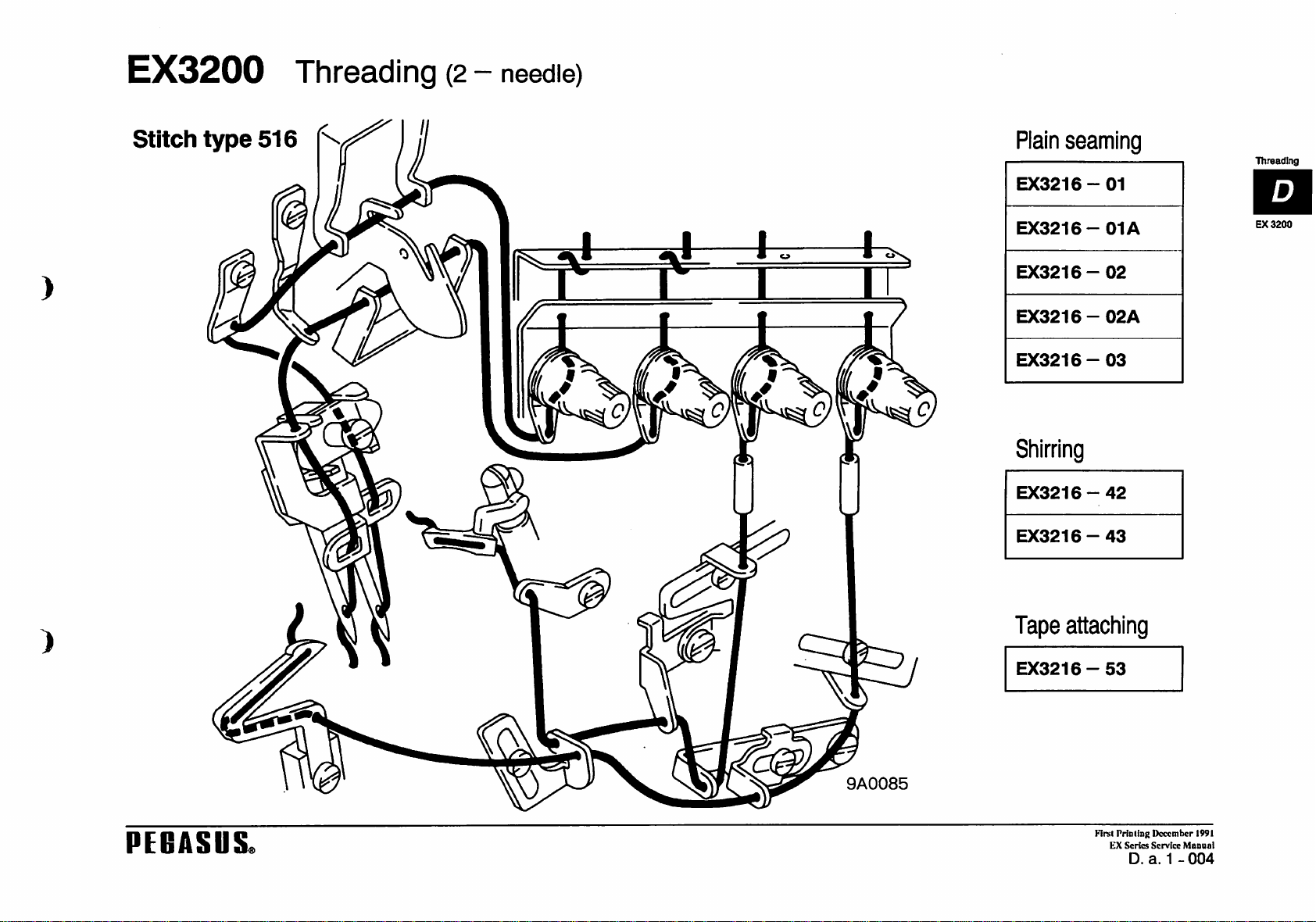

EX3200

Threading

(2

—

needle)

)

Stitch

type

516

Plain

EX3216

EX3216

EX3216-

EX3216-

EX3216-

seaming

-

01

-

01A

02

02A

03

Shirring

EX3216

EX3216

-

42

-

43

Threading

EX

3200

PEGASUS.

9A0085

Tape

EX3216 - 53

attaching

First

Printing

EX

Series

D.

December

Servlec

a.

1-004

1991

Mannal

EX3200

Threading

(2

—

needle)

Stitch

type

P

516

Plain

EX3216-

seaming

04

Threading

EX

3200

PEGASUS,

9A0086

First

Priollng

EX

Series

D.

December

Service

Manual

a. 1 -005

1991

Loading...

Loading...