Series

Technical

Manual

^PEBASUS

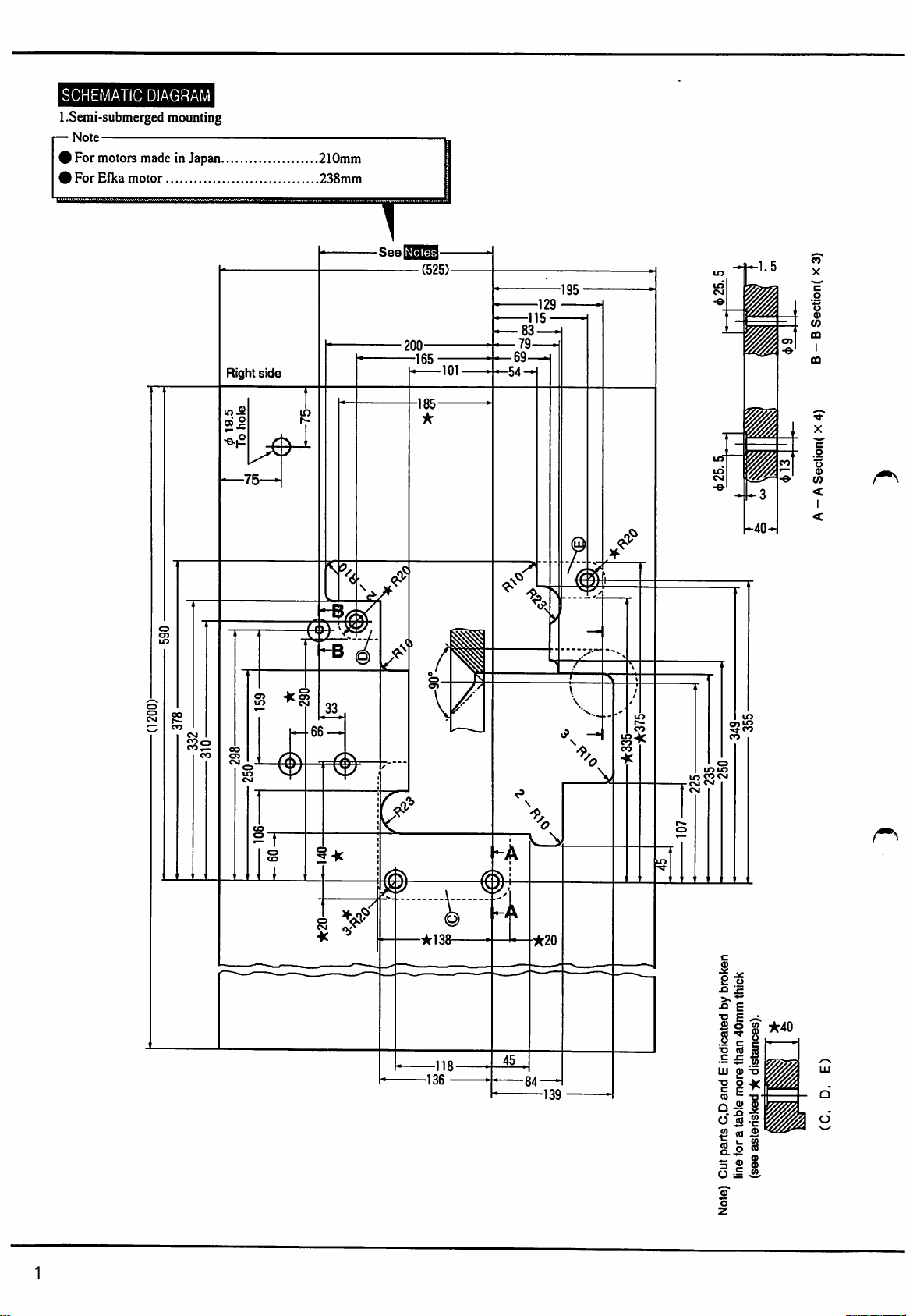

SCHEMATIC DIAGRAM

1.Semi-submerged mounting 1

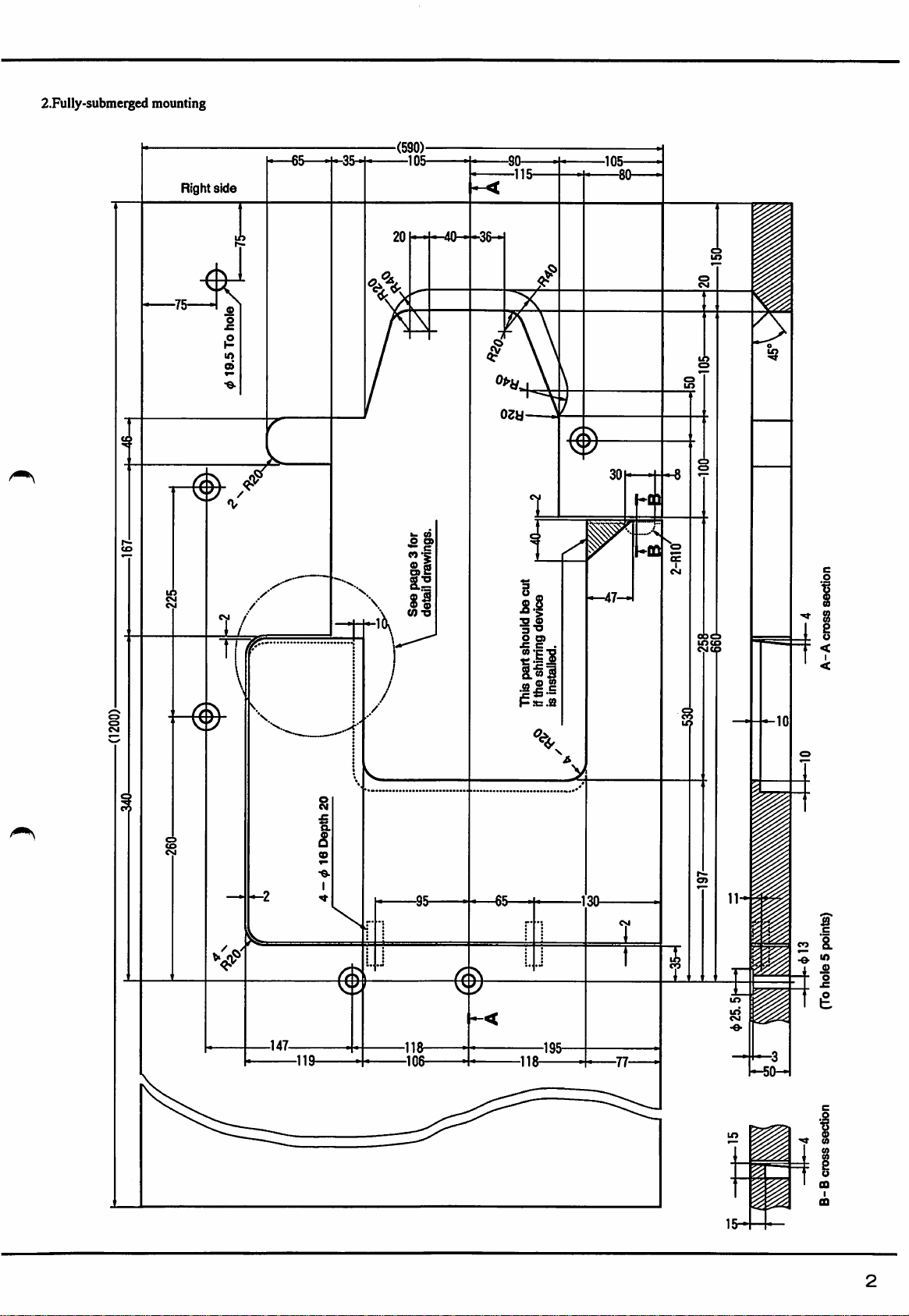

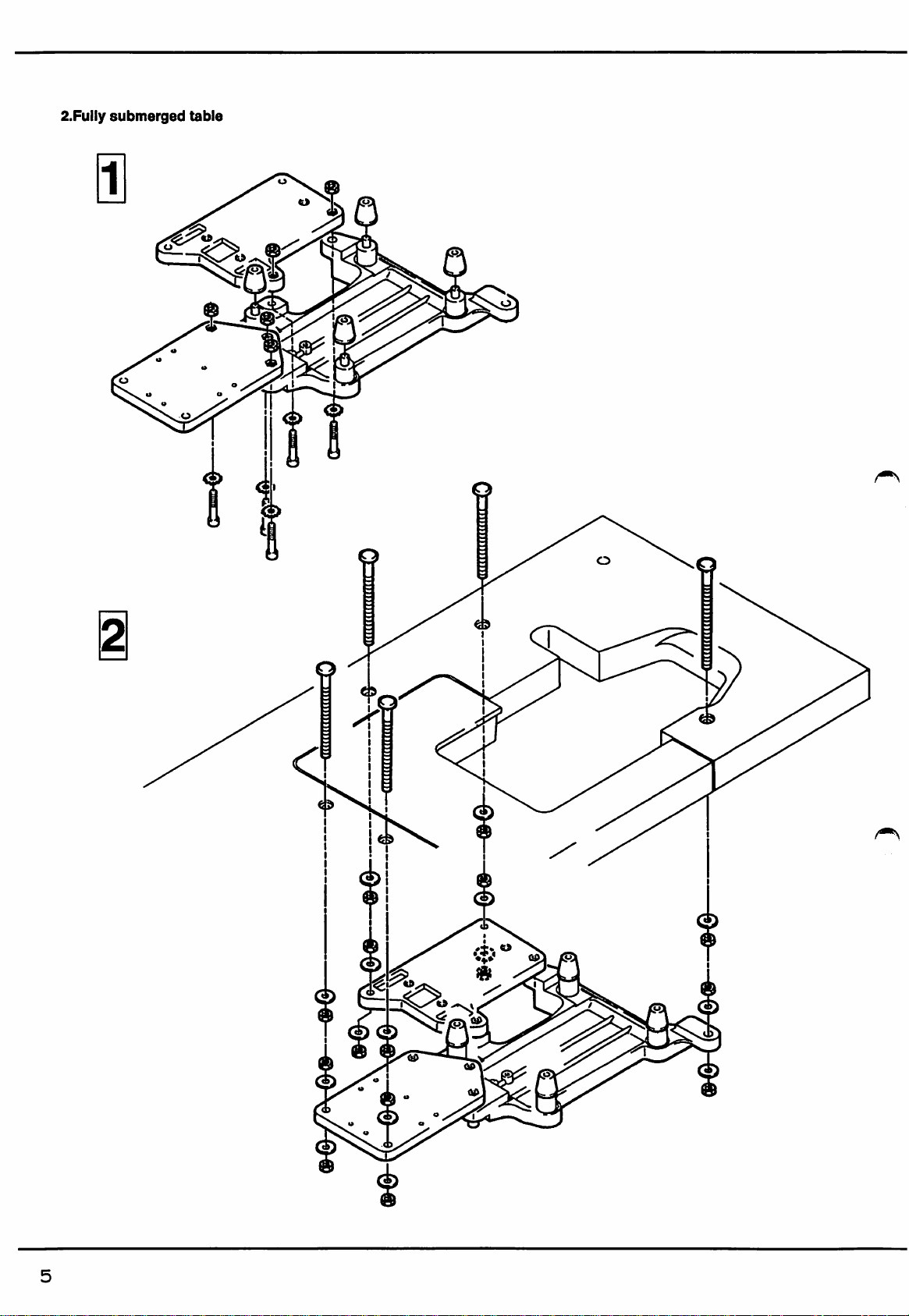

2.Fu[ly-submerged mounting 2

S.Detail drawings for the fullysubmerged table installation 3

INSTALLATION

1

.Semi-submerged

2.Fulty

[For

^

MOTOR

Relationship between machine

INSTALUNG

TURNING

HOOKING

CHARTOF THE TABLE

MOUNTING

table

submerged

table

Efka, Quick Mortoror othermotors] 7

PULLEY

AND

BELT

speed

and motor pully Table 1 8

THE

MACHINE

DIRECTION

THE

CHAIN

HEAD

OF THE

MACHINE

FORTHEPRESSER FOOTUFT

PULLEY

TREADLE.

CONTBm

REPLACING

REPLACING

ADJUSTING

4

5-6

8

9

9

9

REPLACING

FEED

TILT

AUXIUARY

Feed dog height Table 3 19

NEEDLE

ADJUSTING

Needle height&Lowerloopersettingdistance Table4 21

THE

UPPER

THE

LOWER

OVEREDGE

THE

FEED

DOG

HEIGHT

ADJUSTMENT

FEED

DOG

HEIGHT

THE

LOWER

KNIFE

KNIFE

WIDTH

DOGS

HEIGHT

LOOPER

17

17

17

18

is

is

18

20

20

LUBRICATION

SlUCONEOILfbrKR.

OIL

REPLACEMENT

TO

DRAIN

THE OIL 11

REPLACING

REPLACING

ADJUSTING

OPENING/CLOSING THE PRESSERARM

ADJUSTINGPRESSER FOOT PRESSURE

ADJUSTING

^

Relationship

the

ADJUSTING

MAXIMUM/MINIMUM

ADJUSTINGTHE

1

feeding

.Needle

THE

STITCH

between

amounts

DIFFERENTIAL

DEVICE

THE OILFILTER 11

THE

NEEDLE

THREAD

TENSION

LENGTH

the

handwheel

ofthe

main

feeddog

FEED RATIO

DIFFERENTIAL

AMOUNT

thread

OF THREADTO BE FURNISHED

guides

2.Double chainstitch looperthread take-up

3.Looper

thread

take-up

thread

gauge

FEED

guides

settings

and

Table

2 14

RATIO

and

thread guides •••18

10

11

11

12

12

13

13

13

15

15

18

18

18

ADJUSTING

THE

UPPER

LOOPER

Positioningthe upper looper Table 5 23

ADJUSTING

THE

DOUBLE

CHAINSTITCH

LOOPER

FOR

EX320O

SERIES

Doublechainstitch looper setting distance Table 8 24

ADJUSTING

1.Adjusting

THE

NEEDLE

the

overlock

GUARD

needle

EX3200Series

guards

2.Adjustingthe double chainstitch needle guards 25

ADJUSTING

1.Adjusting

INSTALUNG

ADJUSTING

ADJUSTING

ADJUSTING

ADJUSTING

Presser

ADJUSTING

THE

NEEDLE

GUARD

EXS200Series

the

overlock

THE

PRESSER

THE

PRESSER

THEPRESSERFOOTUFT

THE

PRESSER

THEPRESSERFOOTSTOPPER

foot

lift

Table

THE

HEMMING

needle

FOOT

ARM

LEFTTORIGHT

FOOT

7

WIDTH

UFT

guards

LEVER

22

24

25

28

27

27

27

28

28

29

30

19.5

<p

hole

To

1

VI

( X 3)

Section

<l»9

•

B - B

,

A —ASection( x 4)

3

<1)13.

thick

40mm

than

more

table

a

for

line

Note) Cut parts C.D and E indicated by broken

E)

D.

(C.

asterisked ii( distances).

(see

n

e

o*

3

o

e

3

s.

5'

OQ

hole

To

10.5

<p

3 for

(1200)

20

Depth

4-016

page

detail drawings

See

\

cut

be

dewce

shirring

the

if

This part should

installed

is

-35-

1

25.51

4)

section

cross

A-A

(To hole 5 points)

section

cross

B

B-

N)

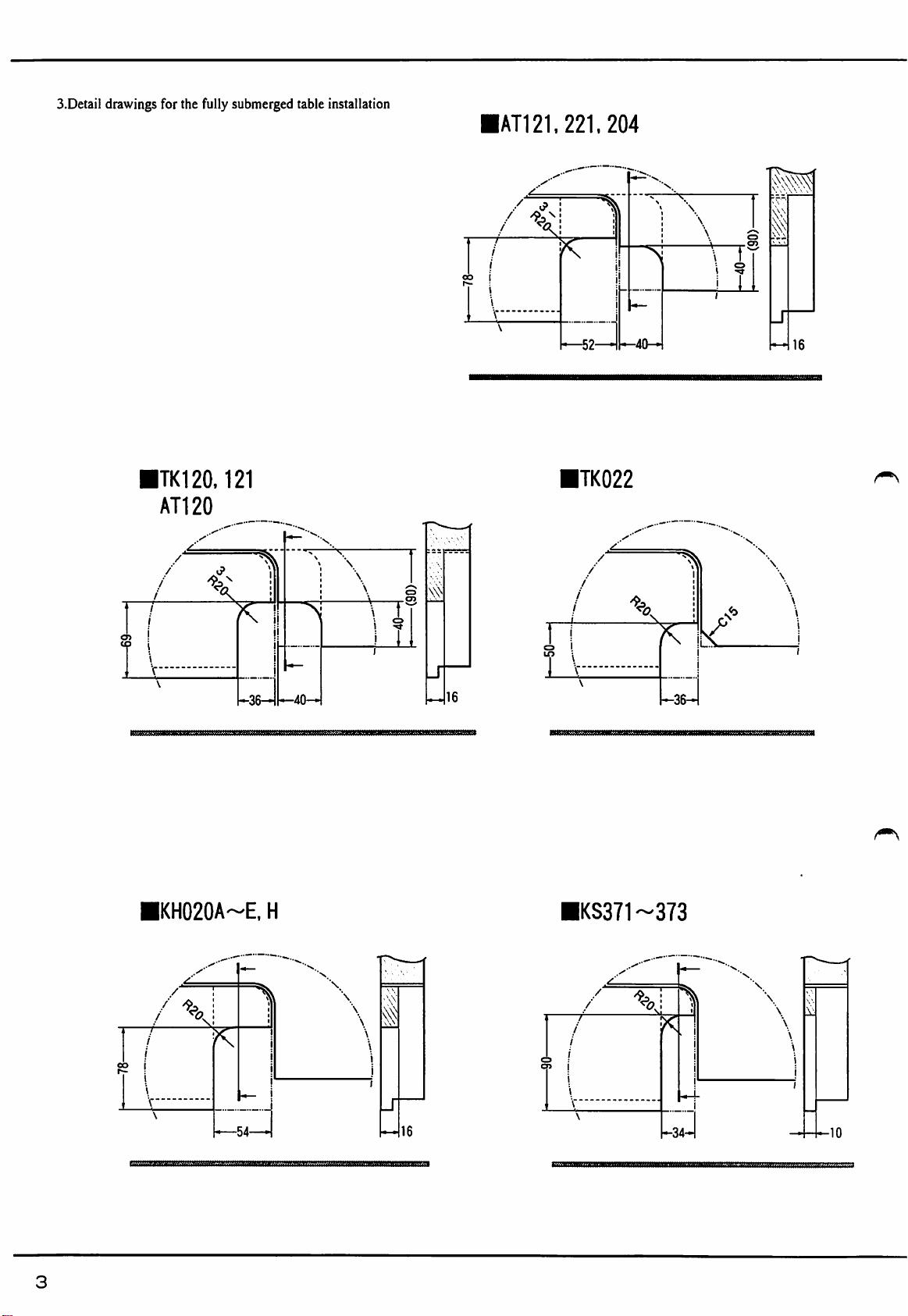

3.Detaildrawingsfor the fully submerged table installation

IAT121.221.204

ITK120.121

ATI20

%

FT

"i

F_L

1 /

S !

/ \

/

1

\

\*

\

./ A?

—1

f\

—52—1

—40—

\

\ o

\ t®

i 1

/

o

16

ITK022

\\>

5

K

|KH020A~E, H

/

/ %

/ F

/

/

f2 1

I

\

1-36-1

w8mmwawwiii«iw»Miiw«aiBi

y'

—

—

-54—j

1

—40—1

16

IKS371

"n

\

•\

\

\

\

\

i

i

1

j

16

/ ^

-36-1

-373

A

-34-^

-10

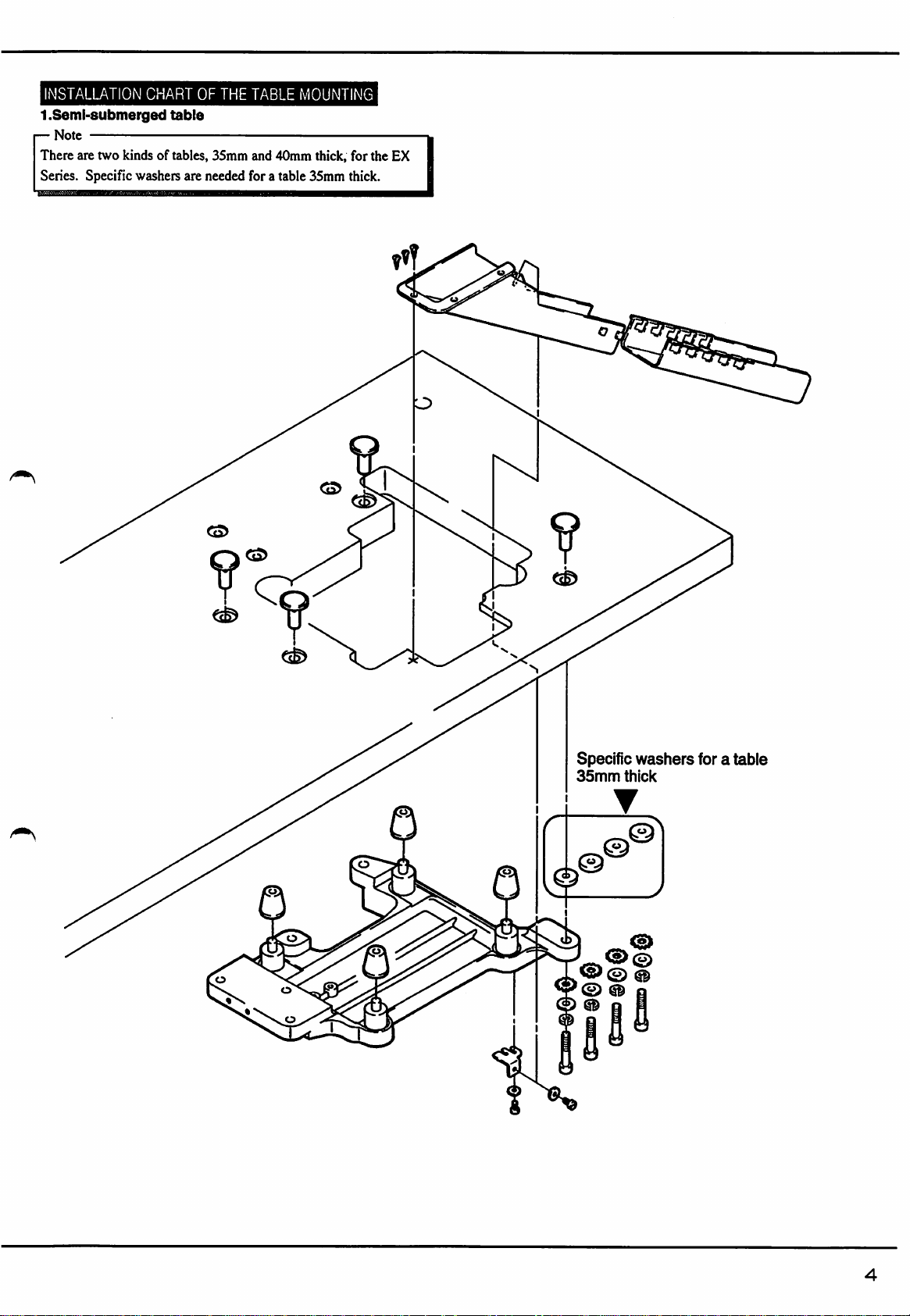

INSTALLATION CHART OF THE TABLE MOUNTING

1.Semi-submerged

—

Note

There are two kindsoftables, 35mm and

Series. Specific washers are needed for a table 35mm thick.

table

40mm

thick, for the EX

6©

Specific

35mm

washers

thick

for a table

II.

01

n

3

3

•a

A

3

£»

0

o

E

SS

CM

Q

V..—^

immniiiinm\

Q

iiiiiiiiiitiiitii»V—

^

Q

iiiiiiiiniiiiii^^^

Q

iiiiiiiiiiimmu—/-^

^

0-®

/-

A A /

(

0

t w

ffi

in

N

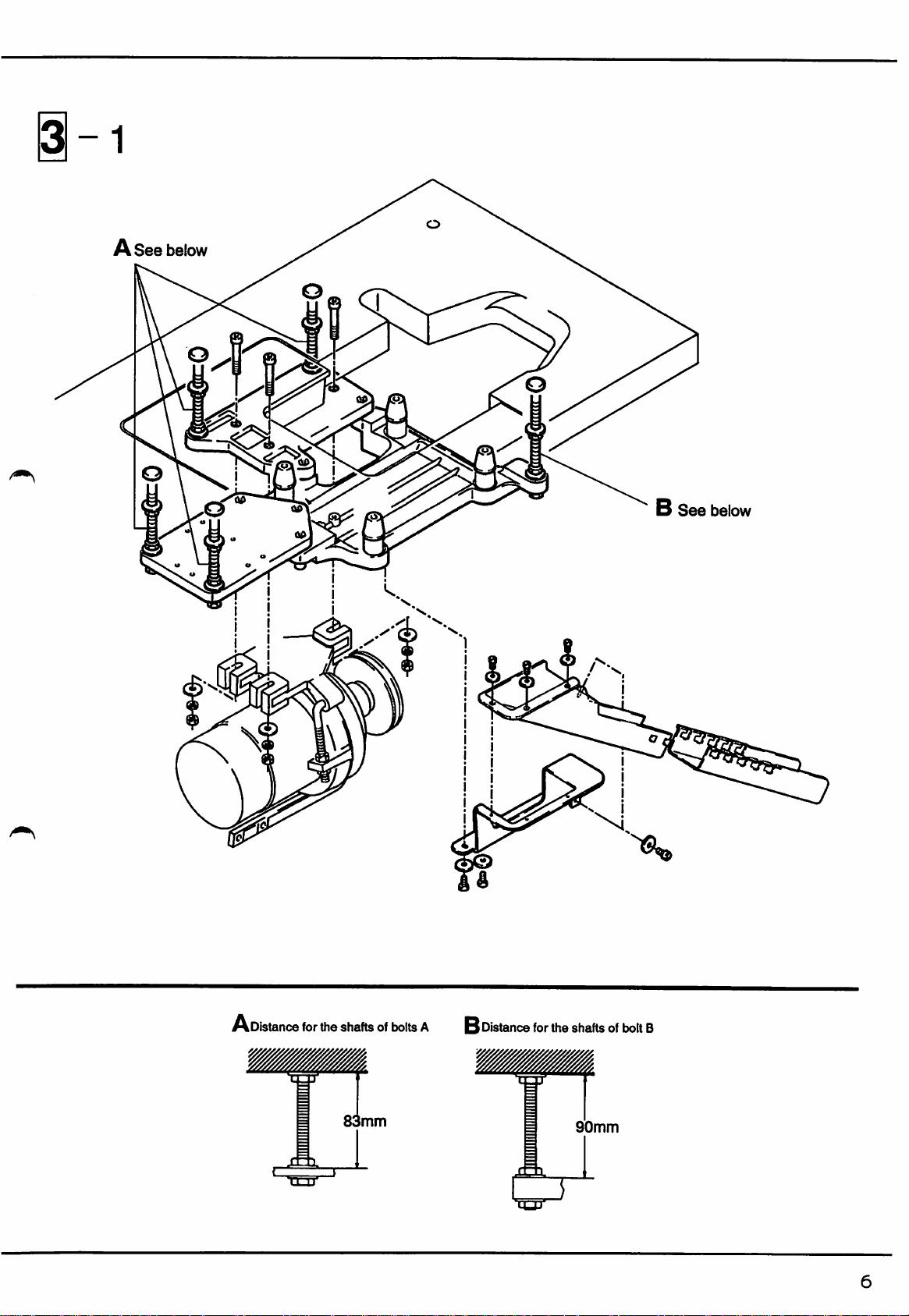

3-1

A

See

below

B

See

below

Aoistance

for

the

shaftsofbolts

83mm

A B

Distance

for

the

shaftsofbolt

90mm

B

3-2

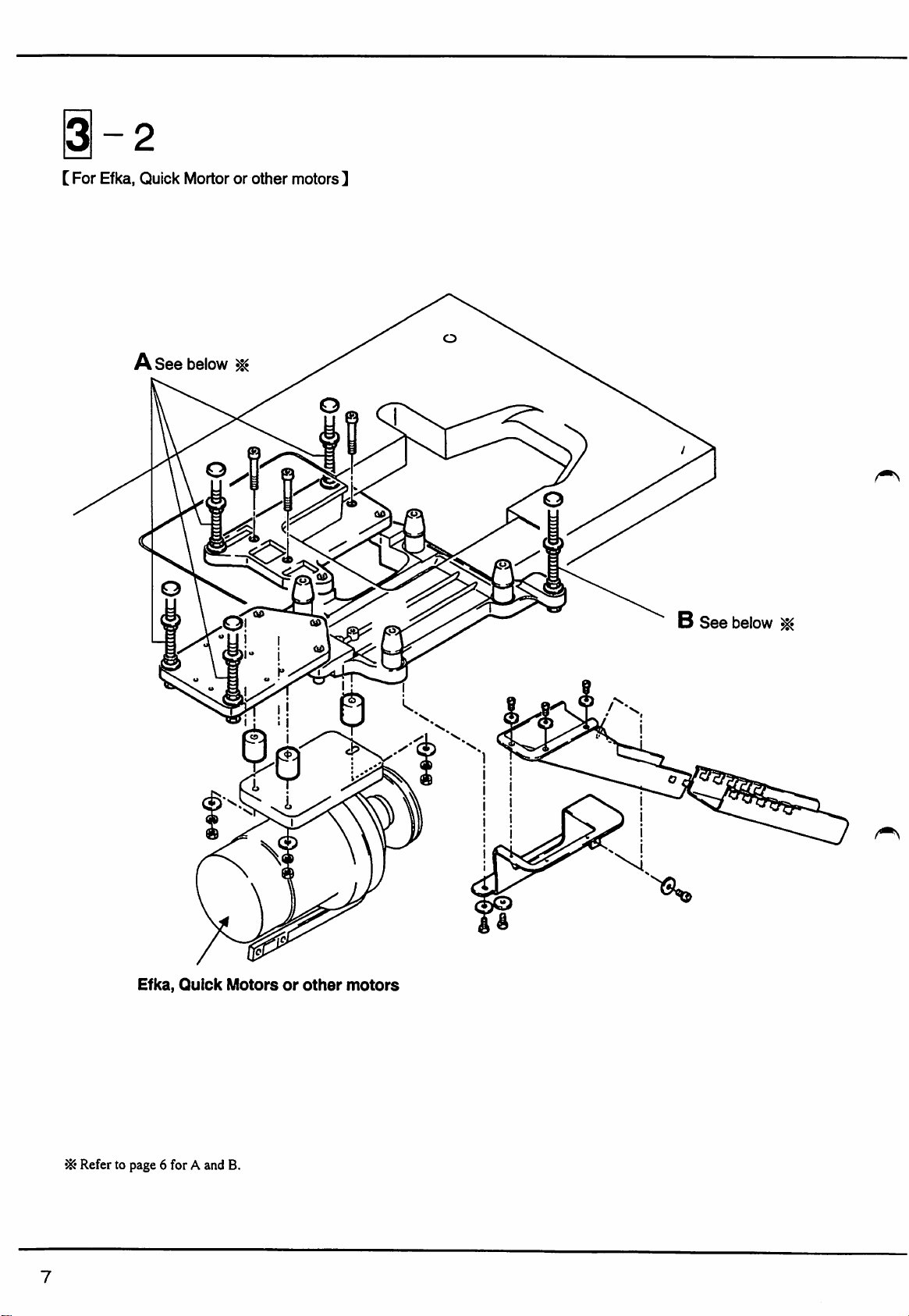

[ For Efka, Quick Mortor or

A See

below

^

other

motors]

B See

below

^

Efka,

Quick

Refer to page 6 for A and B.

Motorsorother

motors

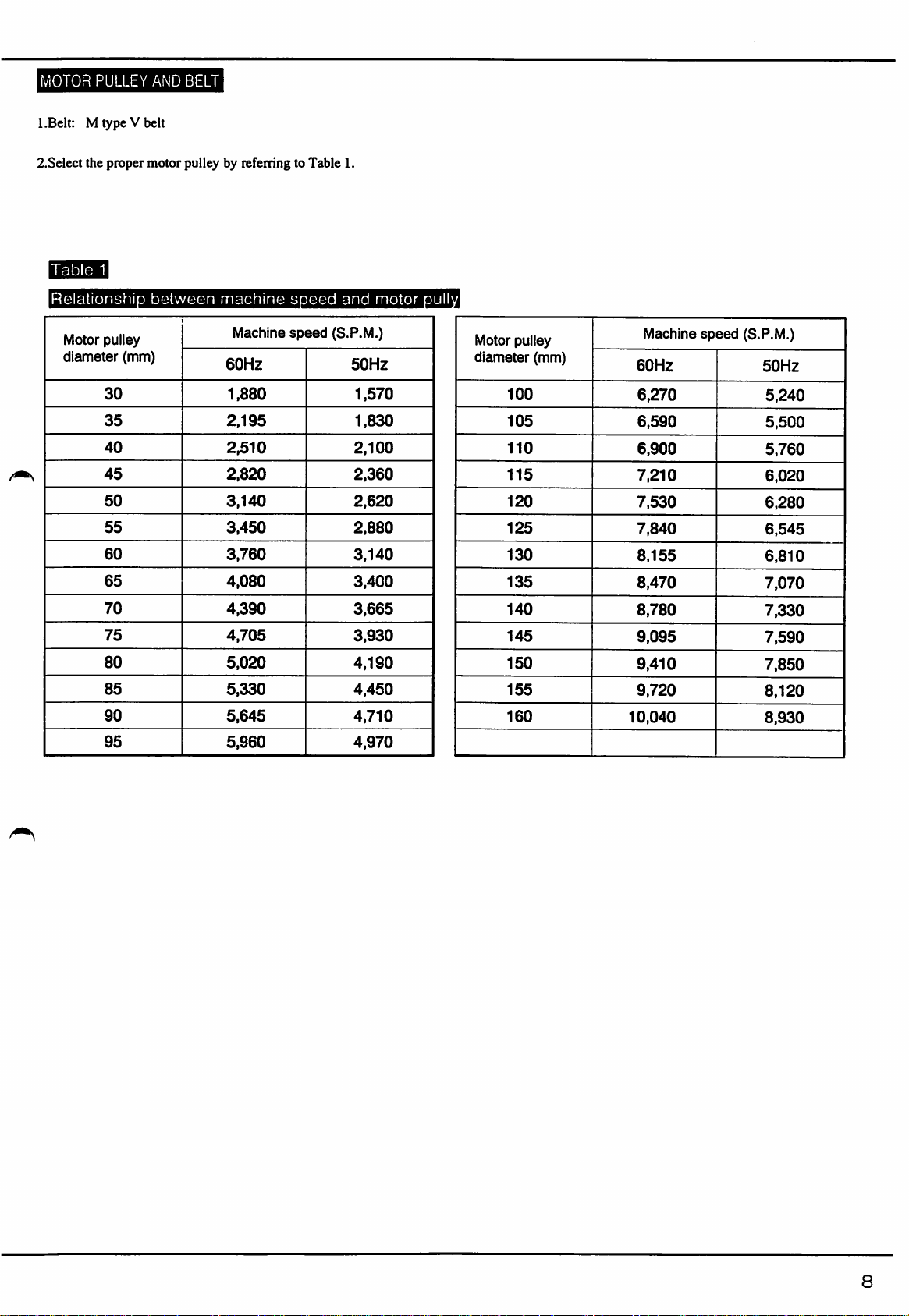

MOTOR PULLEY AND BELT

l.Belt: M type V belt

2.Select the proper motor pulley by referring to Table 1.

Table

1

Relationship

Motor pulley

diameter (mm)

30

35

40

45

50

55

60

65

70

75

80

85

90

95

between

machine

Machine

60Hz

1.880

2,195

speed

speed

and

(S.P.M.)

50Hz

1,570

1,830

2,510 2,100

2,820

3,140

3,450

3,760

4,080

4,390

4,705

5,020

5,330

5,645

5,960

2,360

2,620

2,880

3,140

3,400

3,665

3,930

4,190

4,450

4,710

4,970

motor

pull

Motor pulley

diameter (mm)

100

105

110

115

120

125

130

135

140

145

150

155

160

Machine

60Hz

6,270

6,590

6,900

7,210

7,530

7,840

8,155

8,470

8,780

9,095

9,410

9,720

10,040

speed

(S.P.M.)

50Hz

5,240

5,500

5,760

6,020

6,280

6,545

6,810

7,070

7,330

7,590

7,850

8,120

8,930

8

Loading...

Loading...