Page 1

INSTRUCTIONS

Cat.

No.

9A2045

December,

1984

TOP

AND

BOTTOM,

SAFETY

ecember. 1 98

DIFFERENTIAL

STITCH

MACHINES

FEED

Page 2

INTRODUCTION

This

booklet

operation

machines.

before

derive

DAILY

Before

1.

Check

damaged.

2.

Check

3.

Check

4.

Check

formed.

5.

Check

lines

6.

Check

lubrication

7.

Check

while

After

1.

Clean

needle

2.

If

it

rapair.

3.

Place a dust

and

use

of

the

best

MAINTENANCE

starting

needle

needle

threading

thread

oil

of

oil

oil

oil

running

close

of

the

machine.

plate

any

trouble

to

the

plant

contains

maintenance

Careful

indicator

gauge.

is

parts.

monitor

work:

reading

the

machine

use

from

work:

is

in

sound

is

correctly

is

correct.

chain

of

not

color

the

machine.

tip

short

Especially,

and

looper.

or

irregularity

mechanic

cover

over

some

of

will

it.

condition

set.

about

is

between

for

is

changed

for

the

notes

the

of

10mm

ETS

this

help

length

on

booklet

you

and

the

the

manual

to

clean

around

is

found,

adjustment

machine.

the

series

to

not

is

two

green

report

or

FOR

SAFETY

1.

Make

sure

2.

Be

well

with

energizing.

3.

Turn

the

4.

Be

an

5.

Make

the

off

work

sure

to

electric

sure

checking

6.

Make

when

sure

the

replacing

NOTES

1.

Run

the

2.

In

after

drops

guide,

3.

Keep

level

lines

4.

Change

one

5.

If

even

ON

new

maximum

using

stop-page

of

needle

the

indicator

of

oil

oil

month

the

oil

when

immediately

6.

Thread

the

your

illustration.

Belt

Guard

careful

in

power

Motor

table.

and

Switch

turn

off

breakdown.

to

turn

cleaning

Motor

machine

Needles,

USE

machine

for

the

machine

for

oil

manually

holder

machine

is

gauge.

entirely

in

operation.

monitor

the

machine

and

check

machine

is

properly

connecting

source

whenever

Power

off

has

Switch

Power

the

machine.

completely

requires

etc.

at a 20%

the

first

one

for

the

some

time,

to

the

and

upper

oil

level

always

color

at

between

the

does

is

run,

the

filter.

correctly

fitted.

the

machine

and

checking

you

in

case

Switch

stopped

threading,

less

speed

month.

first

time

lubricate

needle

looper

so

that

the

end

of

the

not

turn

stop

operation

according

leave

of

before

than

and

2~3

holder

holder.

the

oil

two

first

green

to

Re:

Thread

Thread

skipping

chain

chain

of

stitch

is

always a thread

Be

sure

to

obtain

after

threading

and

necessary

at

the

start

chain

of

thread

chain

change

for

of

sewing.

about

before

of

needle.

preventing

Keep

10cm

length.

sewing,

Page 3

CONTENTS

Pattern

Assembling

Machine

Driving

Installation

Turning

Lubrication

Checking

Silicone

Needles

Replacing

Threading

Regulating

Presser

Presser

Stitch

Diffential

Top

Adjusting

Regulating

Needle

Looper

Chainstitch

Changing

Changing

Knives

Bottom

Auxiliary

Bottom

Needle

Lower

Upper

Chainstitch

Overlook

Chainstitch

Adjusting

Adjusting

Setting

Adjusting

Top

Adjusting

Adjusting

Adjusting

Adjusting

Height

Adjusting

Presser

Adjusting

Adjusting

Adjusting

paper

speed

motor

of

direction

and

oil

for

needles

thread

arm

foot

length

feed

feed

stroke

top

seam

thread

thread

looper

upper

lower

feed

feed

feed

height

looper

looper

looper

needle

needle

the

vertical

position

the

feed

stroke

the

the

top

presser

of

upper

sidewise

foot

edge

piping

shirring

for

the

machine

pulley

machine

replacing

H.R.

swinging-in

pressure

adjustment

adjustment

feed

guide

takeup

height

dog

leveling

setting

setting

setting

lengthwise

lengthwise

lengthwise

sidewise

feed

setting

guide

semi-submerged

rest

board

and

belting

of

machine

oil

filter

device

tension

and

-out

adjustment

pressure

width

setting

thread

position

and

looper

handling

knife

knife

height

position

adjustment

setting

guard

setting

guard

setting

position

stroke

of

and

top

diff.

of

top

feed

dog

position

feed

feed

ratio

position

position

dog

foot

and

knife

holder

position

height

of

top

feed

of

presser

binder

blade

installation

thread

of

guide

bottom

setting

feed

dog

of

top

feed

dog

of

top

feed

dog

top

feed

dog

dog

lift

arm

positions

dogs

^

2

3

4

4

4

4

6

7

7

8

8

8

8

13

13

14

14

15

15

15

16

16

18

18

19

19

20

20

20

22

22

24

26

27

28

29

30

30

30

32

34

34

36

38

40

42

42

42

43

43

-

1

Page 4

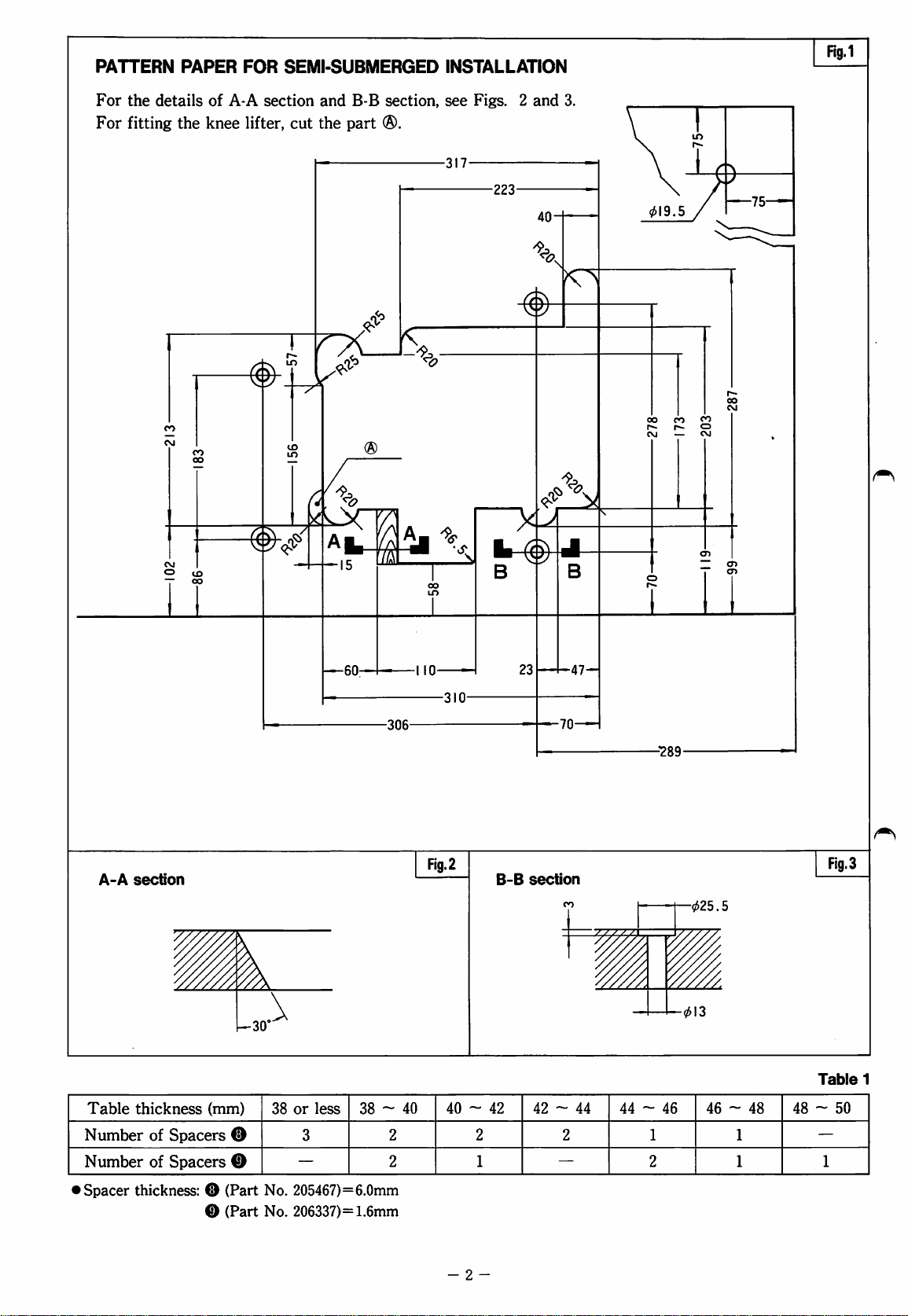

PATTERN

For

the

For

fitting

PAPER

details

the

CO

CM

of

knee

FOR

A-A

section

lifter,

SEMI-SUBMERGED

and

B-B

section,

cut

the

part

®.

rx

CO

3^

00

"7^

I

INSTALLATION

see

-317-

<7

o

Figs. 2 and

-223-

40-

3.

CO

r-

CM

CO CO

i>-

—

Rg.1

o

CM

A-A

section

CM

O I

B

B-B

23

section

J

B

-47-

-70-

-"289-

Fig.3

-025.5

kLX

a

rt

15

—60-

-306-

-■I

■I

'Si

10-

-310-

Flg.2

\

—30

Table

Number

Number

Spacer

thickness: O (Part

thickness

of

Spacers

of

Spacers

(mm)

0

0

0

(Part

38

or

less

3

—

No.

205467)=6.0mm

No.

206337)=1.6mm

40 ~ 42

2

2

2

1

- 2 -

42 - 44 44 ~ 46

2

—

-013

Table

1

46 ~ 48

1

2

1

1

48 ~ 50

—

1

Page 5

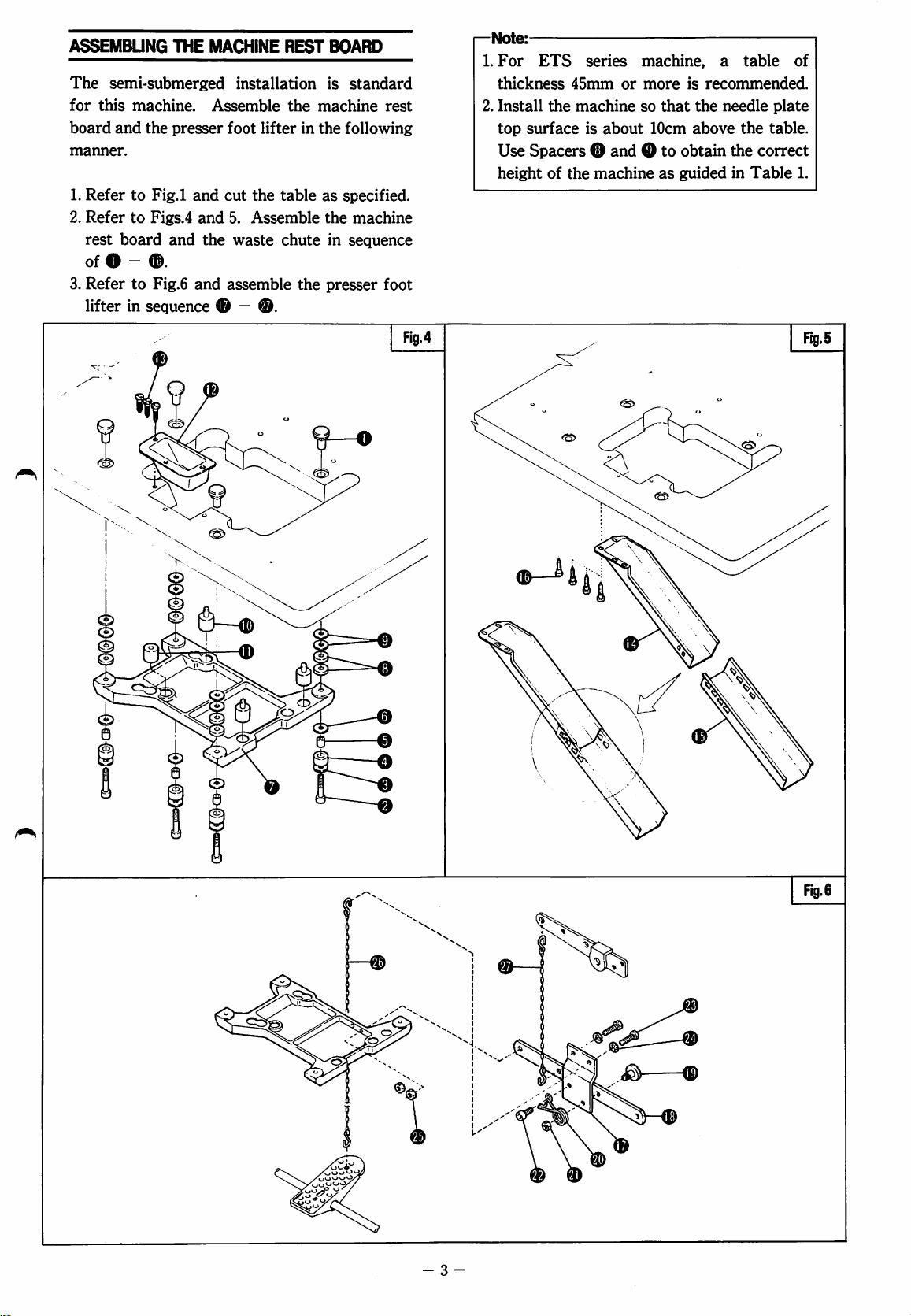

ASSEMBUNG

The

semi-submerged

for

this

machine.

board

and

the

manner.

1.

Refer

to

Fig.l

2.

Refer

to

Figs.4

rest

board

of O -

3.

Refer

lifter

®.

to

Fig.6

in

sequence

THE

MACHINE

Assemble

presser

and

foot

cut

and

and

the

and

(D

REST

installation

the

machine

lifter

in

the

the

table

as

5.

Assemble

waste

assemble

the

chute

the

presser

—

BOARD

is

standard

rest

following

specified.

machine

in

sequence

foot

Fig.4

—Note:

1.

For

thickness

2.

Install

top

Use

height

ETS

surface

45mm

the

machine

series

or

is

about

machine, a table

more

so

that

10cm

Spacers ® and O to

of

the

machine

as

is

recommended.

the

needle

above

obtain

guided

the

in

plate

the

table.

correct

Table

of

1.

0

- 3 -

Page 6

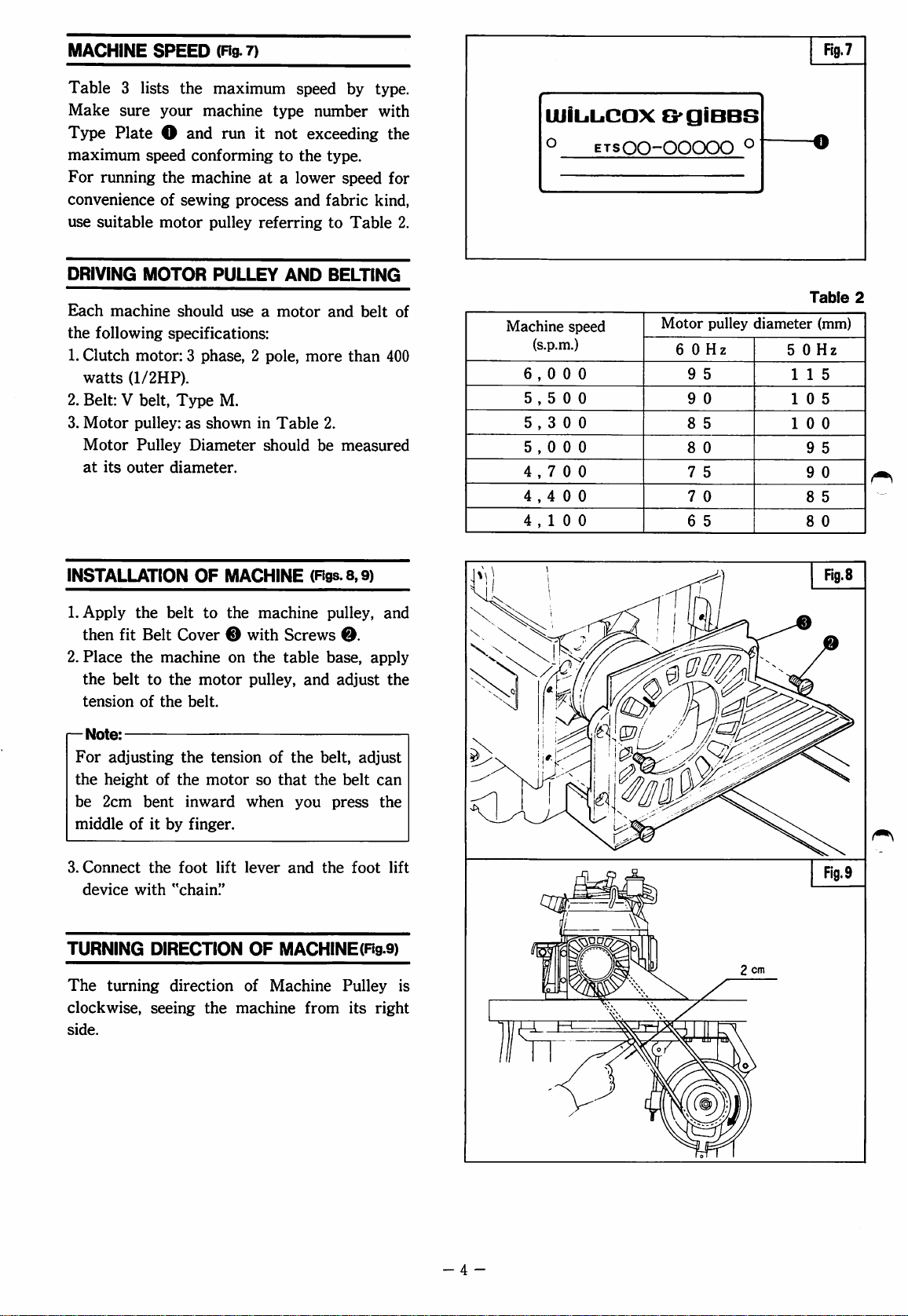

MACHINE

SPEED

(Fig.

7)

Fia.7

Table 3 lists

Make

Type

sure

Plate O and

maximum

For

running

convenience

use

suitable

DRIVING

Each

machine

the

following

1.

Clutch

watts

(1/2HP).

2.

Belt: V belt.

3.

Motor

Motor

at

its

outer

the

your

speed

the

of

sewing

motor

MOTOR

should

specifications:

motor: 3 phase, 2 pole,

Type

pulley:

Pulley

diameter.

maximum

machine

run

it

conforming

machine

at a lower

process

pulley

referring

PULLEY

use a motor

M.

as

shown

Diameter

in

should

speed

type

number

not

exceeding

to

the

type.

and

fabric

AND

more

Table

2.

be

by

type.

with

the

speed

for

kind,

to

Table

2.

BELTIN^

and

belt

of

than

400

measured

UJiL.L.CaX

o

Machine

speed

(s.p.m.)

6,000

5,500

5,300

5,000

4,700

4,4 0 0

4,100

B'giBBS

ETSOO-OOOOO

Motor

pulley

6 0 Hz

9

5

9

0

8

5

8

0

7

5

7

0

6

5

o

diameter

5 0 Hz

1 1 5

10

1

Table

(mm)

5

0 0

9

5

9

0

8

5

8

0

2

INSTALLATION

1.

Apply

then

2.

Place

the

tension

Note:

For

the

be

middle

3.

Connect

device

TURNING

The

clockwise,

side.

the

fit

Belt

the

machine

belt

to

of

the

adjusting

height

2cm

of

bent

of

it

by

the

with

DIRECTION

turning

seeing

OF

MACHINE

belt

to

the

machine

Cover 0 with

on

the

the

motor

belt.

the

the

inward

pulley,

tension

motor

so

when

finger.

foot

lift

lever

"chain."

OF

direction

the

of

machine

(Figs.

8,9)

pulley,

Screws

table

of

the

that

and

MACHINE(Fig.9)

Machine

and

belt,

the

you

the

from

0.

base,

adjust

adjust

belt

press

foot

Pulley

its

and

apply

the

can

the

lift

is

right

n

Fig.9

- 4 -

Page 7

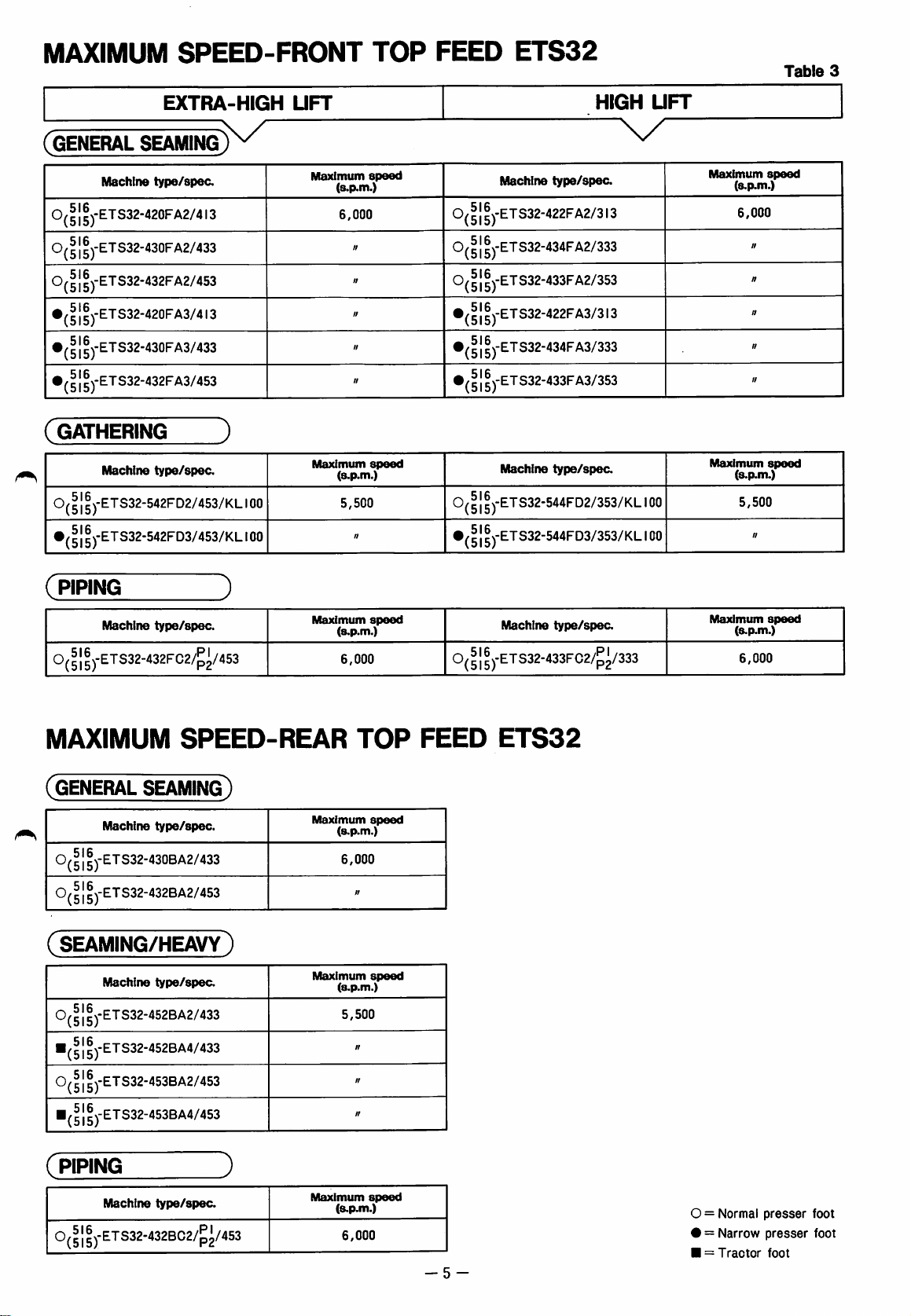

MAXIMUM

SPEED-FRONT

TOP

FEED

ETS32

Table

3

EXTRA-HIGH

(GENERAL

0( 1 ]

^)-ETS32-420FA2/413

0(

51

5)-ETS32-430F

SEAMING)

Machine

type/spec.

K/"

A2/433

IIJ-ETS32-432FA2/453

•(1IIJ-ETS32-420FA3/413

•(1

||)-ETS32-430FA3/433

•(II1J-ETS32-432F

(GATHERING

Machine

0(|

11J-ETS32-542FD2/453/KL100

•(II1J-ETS32-542FD3/453/KL

A3/453

)

type/spec.

i

00

UFT

Maximum

Maximum

speed

(s.p.m.)

6,000

//

//

//

//

n

speed

(s.p.m.)

5,500

ft

HIGH

Machine

type/spec.

0(|||)-ETS32-422FA2/3i3

0(| 1 |)-ETS32-434FA2/333

0(

11

|)-ETS32-433FA2/353

•(|1|)-ETS32-422FA3/3I3

•(11

|)-ETS32-434F

A3/333

•(II1J-ETS32-433FA3/353

Machine

0(11

|)-ETS32-544FD2/353/KL

•(II

|)-ETS32-544FD3/353/KL

type/spec.

UFT

i

00

100

Maximum

(s.p.m.)

6,000

Maximum

(s.p.m.)

5,500

speed

ff

n

ft

ft

ft

speed

ft

(

PIPING

Machine

type/spec.

0(|||j-ETS32-432FC2/^^/453

MAXIMUM

(GENERAL

SEAMING)

Machine

type/spec.

0(| 1 |)-ETS32-430BA2/433

0(| 1 |)-ETS32-432BA2/453

3

SPEED-REAR

Maximum

(s.p.m.)

6,000

Maximum

(s.p.m.)

6,000

speed

TOP

speed

11

(seaming/heavy)

Machine

type/spec.

Maximum

0(|||j-ETS32-452BA2/433

■(II

|)-ETS32-452BA4/433

speed

(8.p.m.)

5,500

n

Machine

type/spec.

0(|||j-ETS32-433FC2/^^/333

FEED

ETS32

Maximum

(s.p.m.)

6,000

speed

Maximum

(s.p.m.)

6,000

tf

ft

speed

-5-

0(

11

|yETS32-453BA2/453

■(|||)-ETS32-453BA4/453

(

PIPING

Machine

type/spec.

0(|||j-ETS32-432BC2/p2/453

O = Normal

• = Narrow

■ = Tractor

presser

presser

foot

foot

foot

Page 8

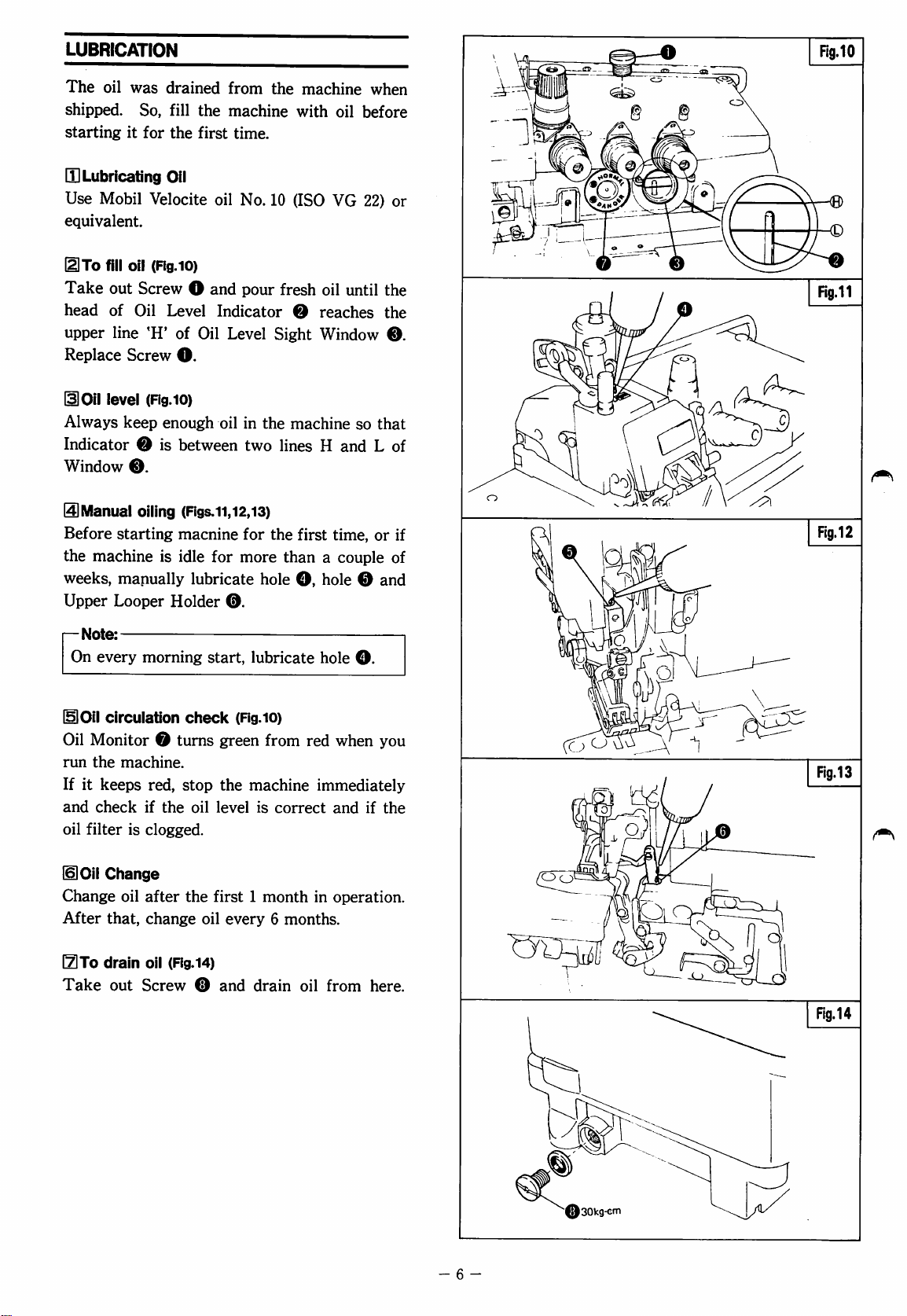

LUBRICATION

The

oil

was

drained

shipped.

starting

[H

Lubricating

Use

equivalent.

UTo

Take

head

upper

Replace

noil

Always

Indicator ® is

Window

So,

it

for

Mobil

Velocite

fill

oil

(Fig.

out

Screw O and

of

Oil

line

'H'

Screw

level

(Fig.iO)

keep

enough

®.

fill

the

Oil

Level

from

the

the

machine

first

time.

oil

No.

10

with

(ISO

10)

pour

fresh

Indicator O reaches

of

Oil

Level

O.

oil

between

Sight

in

the

machine

two

lines H and L of

machine

oil

before

VG

22)

oil

until

Window

so

when

or

the

the

®.

that

ID

Manual

Before

the

weeks,

Upper

r-

Note:

On

HlOII

Oil

run

If

it

and

oil

filter

moil

Change

After

I^To

Take

oiling

starting

machine

is

manually

Looper

every

morning

circulation

Monitor 0 turns

the

machine.

keeps

check

red,

if

the

is

clogged.

Change

oil

after

that,

change

drain

oil

(Rg.i4)

out

Screw 0 and

(Rgs.li,12,13)

macnine

idle

lubricate

Holder

check

stop

oil

the

for

the

for

more

than a couple

hole

0.

start,

lubricate

(Rg.iO)

green

from

the

machine

level

is

correct

first 1 month

oil

every 6 months.

drain

first

time,

O,

hole 0 and

hole

O.

red

when

immediately

and

if

in

operation.

oil

from

here.

or

you

the

if

of

- 6 -

Fig.14

30kg-Gfn

Page 9

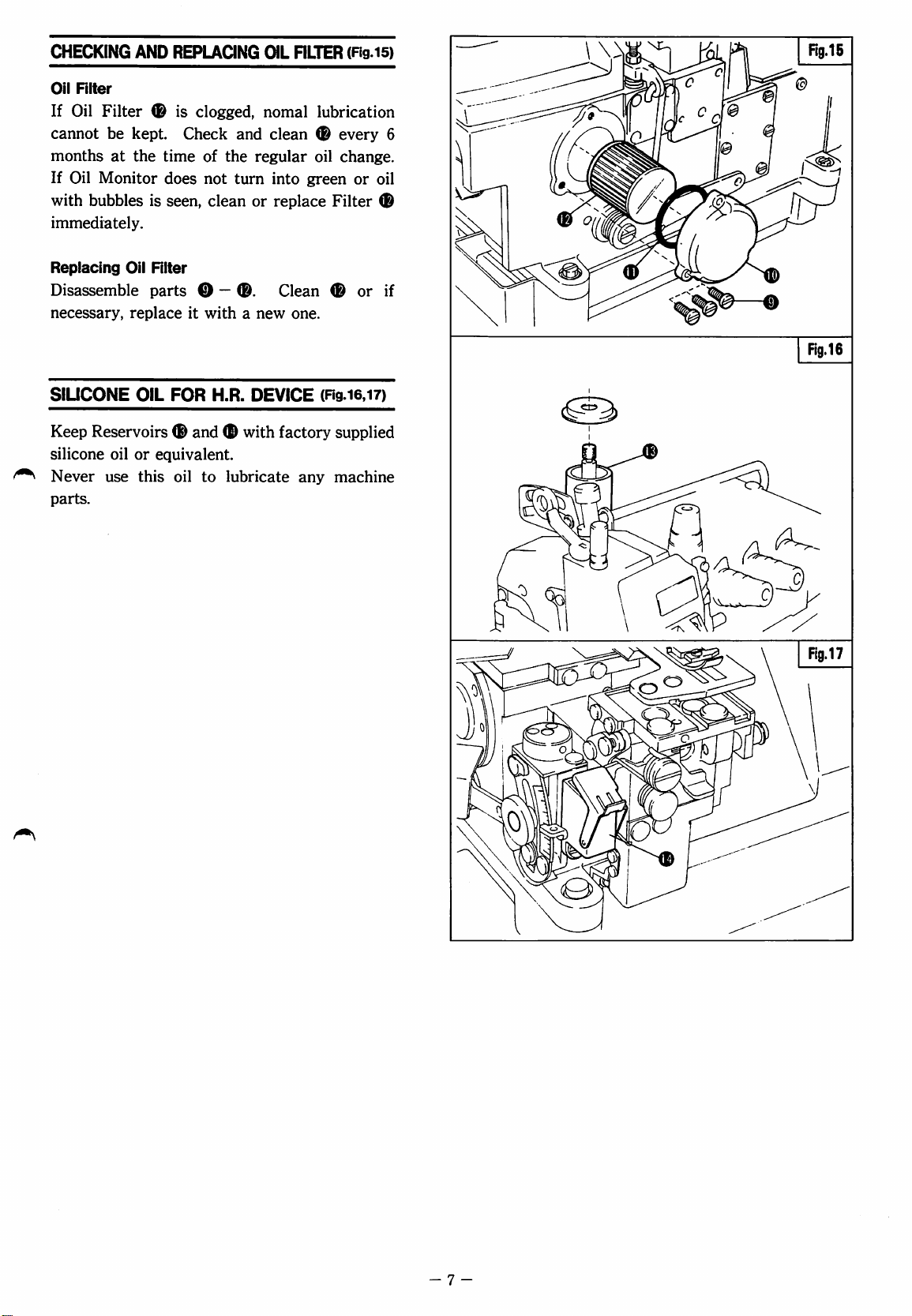

CHECKING

Oil

RIter

If

Oil

cannot

months

If

Oil

with

bubbles

immediately.

AND

Filter

be

kept.

at

the

Monitor

REPLAaNG

is

clogged,

Check

time

does

is

seen,

and

of

the

not

turn

clean

OIL

nLTER

nomal

(Fig.i5)

lubrication

clean ® every

regular

or

oil

into

green

replace

change.

Filter

or

6

oil

Replacing

Disassemble

necessary,

SlUCONE

Keep

silicone

^

Never

parts.

Oil

RIter

parts © —

replace

OIL

it

FOR

Reservoirs ® and © with

oil

or

equivalent.

use

this

oil

®.

with a new

H.R.

DEVICE

to

lubricate

Clean © or

factory

one.

(ng.i6.i7)

supplied

any

machine

if

- 7 -

Page 10

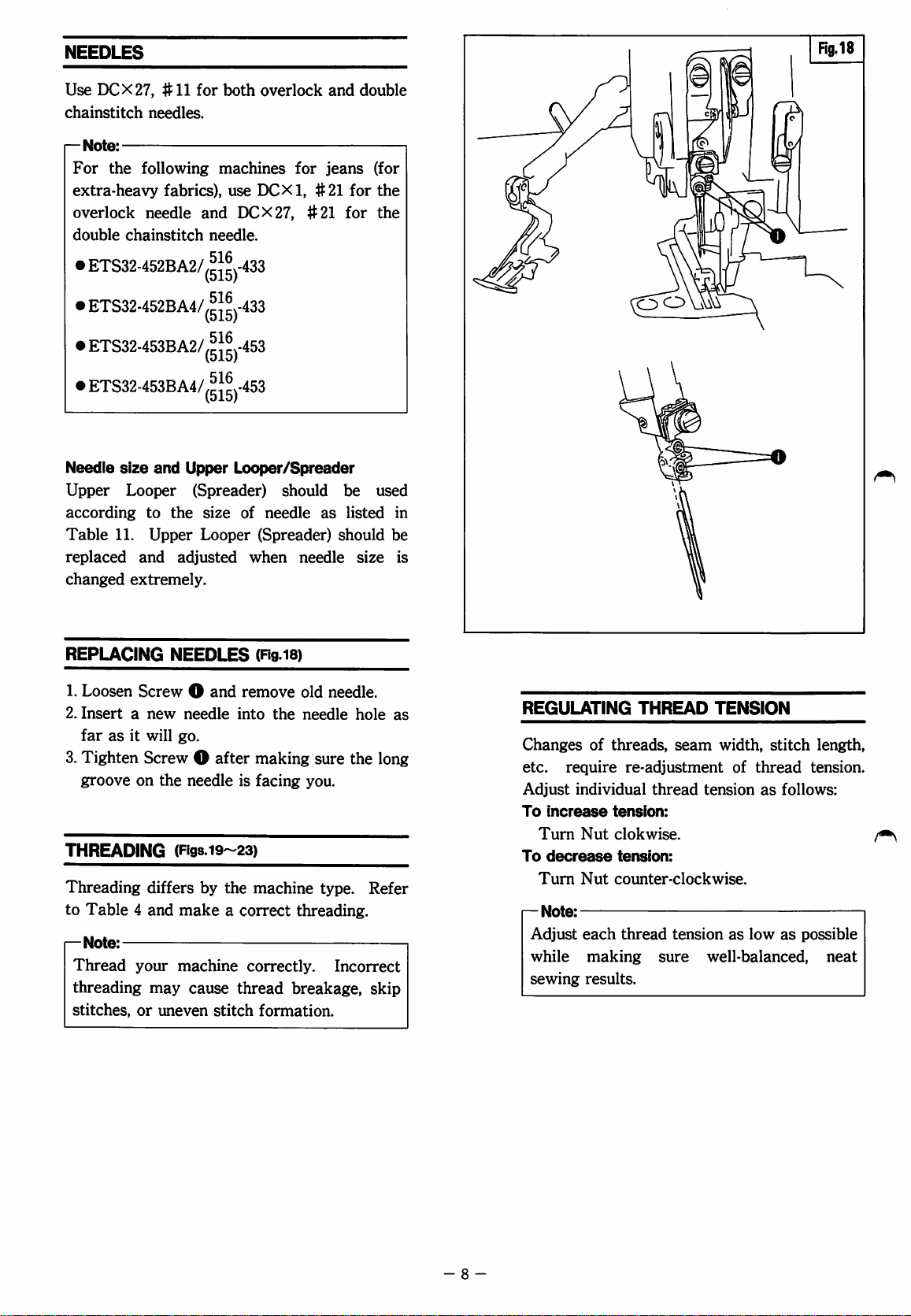

NEEDLES

Use

DCX27,

chainstitch

Note:

For

the

extra-heavy

overlock

double

•

ETS32-452BA2/,^}®-433

•

ETS32-452BA4/J

•

ETS32-453BA2/,cJ

•

ETS32-453BA4/|J5j-453

#11

for

needles.

following

fabrics),

needle

chainstitch

and

(OlD)

(515)

both

overlock

machines

use

DCX27,

needle.

DC

for

XI,

J|-433

rN-453

and

jeans

#21

#21

double

(for

for

for

the

the

Needle

Upper

according

Table

replaced

changed

REPLACING

1.

2.

3.

THREADING

Threading

to

^

size

and

Looper

to

11.

Upper

and

extremely.

Loosen

Insert a new

far

Tighten

groove

Screw O and

as

it

will

Screw O after

on

differs

Table 4 and

Note:

Thread

threading

stitches,

your

may

or

uneven

Upper

(Spreader)

the

adjusted

NEEDLES

needle

go.

the

needle

(Fig8.i9~23)

make a correct

machine

cause

Looper/Spreader

should

size

of

needle

Looper

(Spreader)

when

(Rg

is)

remove

into

the

making

is

facing

by

the

machine

correctly.

thread

stitch

formation.

be

used

as

listed

should

needle

old

needle

you.

threading.

breakage,

size

needle.

hole

sure

the

type.

Refer

Incorrect

long

skip

in

be

is

as

REGULATING

Changes

etc.

Adjust

To

Turn

To

Turn

r-

Note:

Adjust

while

sewing

of

require

individual

increase

Nut

decrease

Nut

each

making

results.

THREAD

threads,

re-adjustment

thread

tension:

clokwise.

tension:

counter-clockwise.

thread

sure

TENSION

seam

width,

of

thread

tension

tension

well-balanced,

as

as

low

stitch

length,

tension.

follows:

as

possible

neat

- 8 -

Page 11

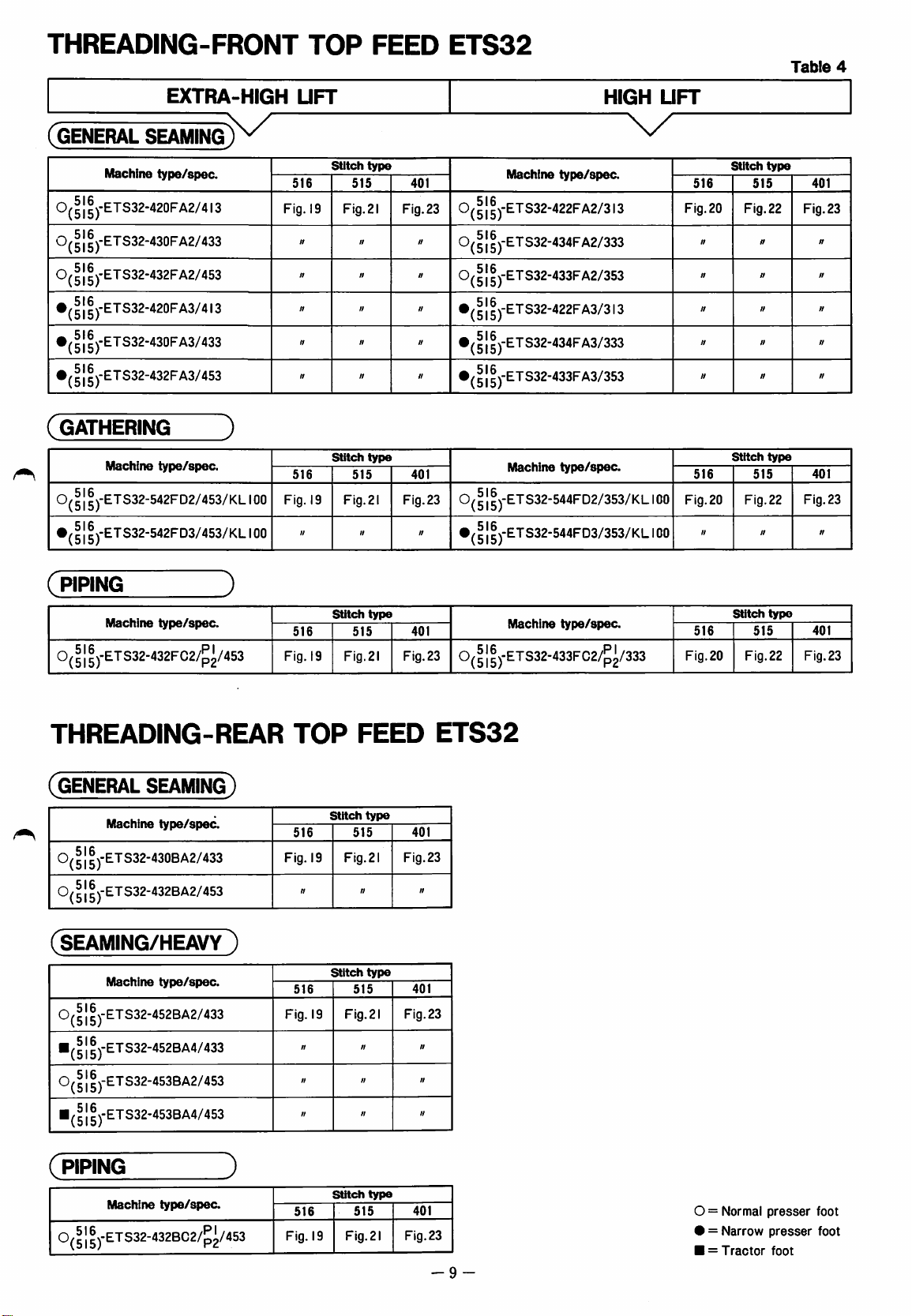

THREADING-FRONT

TOP

FEED

ETS32

Table

4

EXTRA-HIGH

(GENERAL

0(5 ] 5)-ETS32-420FA2/4

SEAMING

Machine

type/spec.

13

UFT

516

Fig.

19

Stitch

515

Fig.

0(5]5)"ETS32-430FA2/433

0(5]5)'ETS32-432FA2/453

516

'(515)"

^ ® J-ETS32-430FA3/433

•(5l5)-ETS32-432FA3/453

(gathering

Machine

0(

51 f )-ETS32-542FD2/453/KL

•(

51

5)-ETS32-542FD3/453/KL

type/spec.

)

100

100

516

Fig.

19

W

Stitch

515

Fig.

type

ft

21

type

21

401

Fig.

23

401

Fig.23

n

HIGH

Machine

O

(51

5)-ETS32-422F

516

O

0(|

ETS32-434FA2/333

(515)'

15

J-ETS32-433FA2/353

516

rETS32-422FA3/3l3

(515)"

type/spec.

A2/313

UFT

518

Fig.

20

Stitch

type

515

Fig. 22Fig.

•(5|5)-ETS32-434FA3/333

•(5]5)"ETS32-433FA3/353

Stitch

Machine

0(

51

5)-ETS32-544FD2/353/KL

•(51

5)-ETS32-544FD3/353/KL

type/spec.

516

Fig. 20Fig.22

100

100

ft

type

515

n

401

23

401

Fig.23

n

(

PIPING

Machine

0( ® 1

^)-ETS32-432FC2/^^/453

type/spec.

THREADING-REAR

(GENERAL

0(

51

5)-ETS32-430BA2/433

0(

51

5)-ETS32-432BA2/453

(SEAMING/HEAVY

SEAMING)

Machine

Machine

type/spec.

type/spec.

)

0(5l5)"ETS32-452BA2/433

■(

51

5)-ETS32-452BA4/433

0(51

5)-ETS32-453BA2/453

■JI5J-ETS32-453BA4/453

Stitch

516

Fig. 19Fig.2l

TOP

Stitch

516

Fig. 19Fig.21

ft

Stitch

516

Fig. 19Fig.

»

«

//

type

515

Fig.23

FEED

type

515

Fig.23

ft

type

515

Fig.23

2!

n

n

II

401

Machine

0(5l5)"ETS32-433FC2/p2/333

type/spec.

Fig.20

Stitch

516

ETS32

401

ft

401

ft

ft

ft

typo

515

Fig.22

401

Fig.23

(piping

Machine

1

®)-ETS32-432BC2/^^/453

type/spec.

J

516

Fig.

19

Stitch

Fig.2!

515

typo

401

Fig.23

-9

O = Normal

• = Narrow

■ = Tractor

presser

presser

foot

foot

foot

Page 12

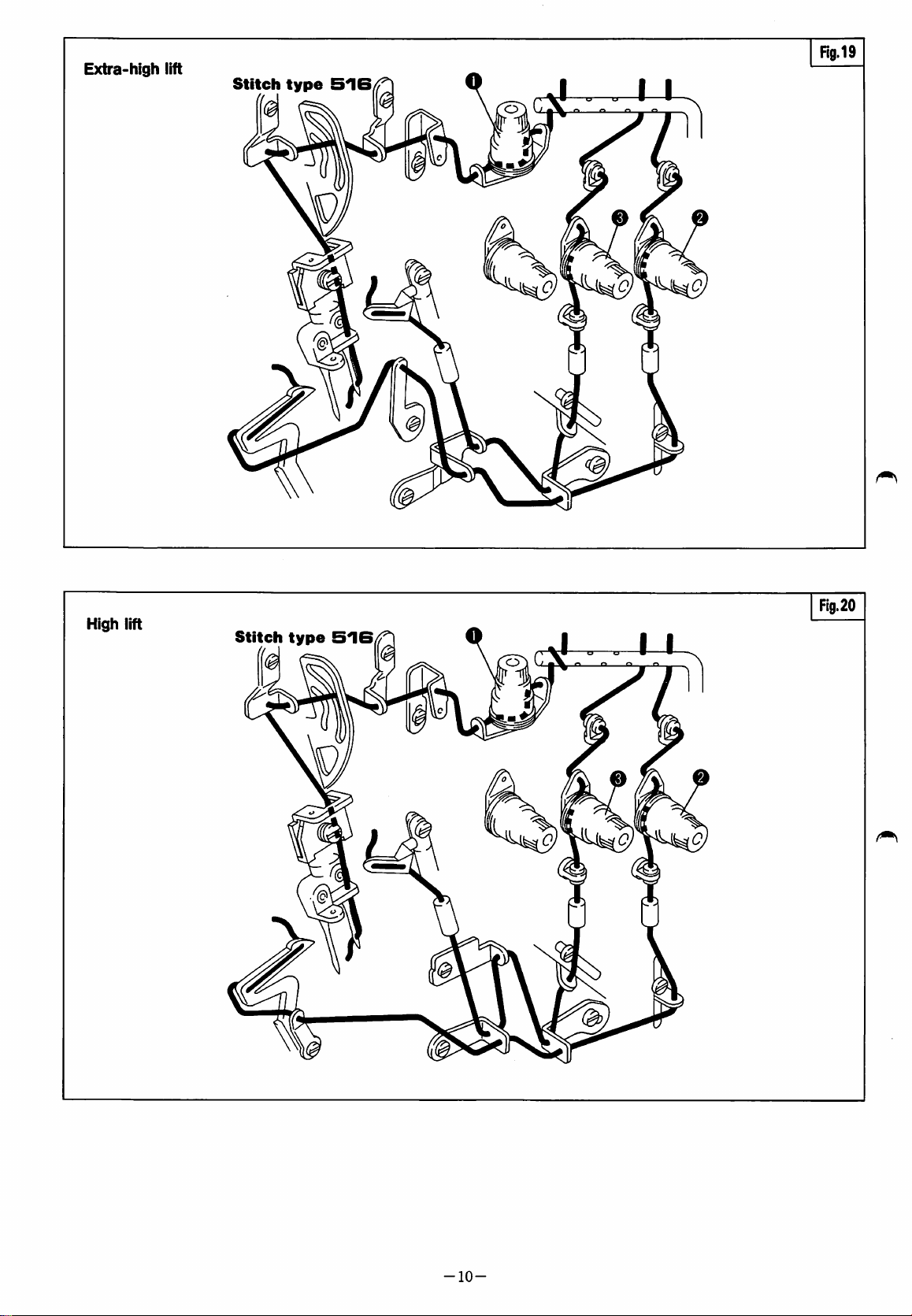

Extra-high

lift

Stitch

type

Rg.19

SIB

High

lift

Stitch

type

Fig.20

516

-10-

Page 13

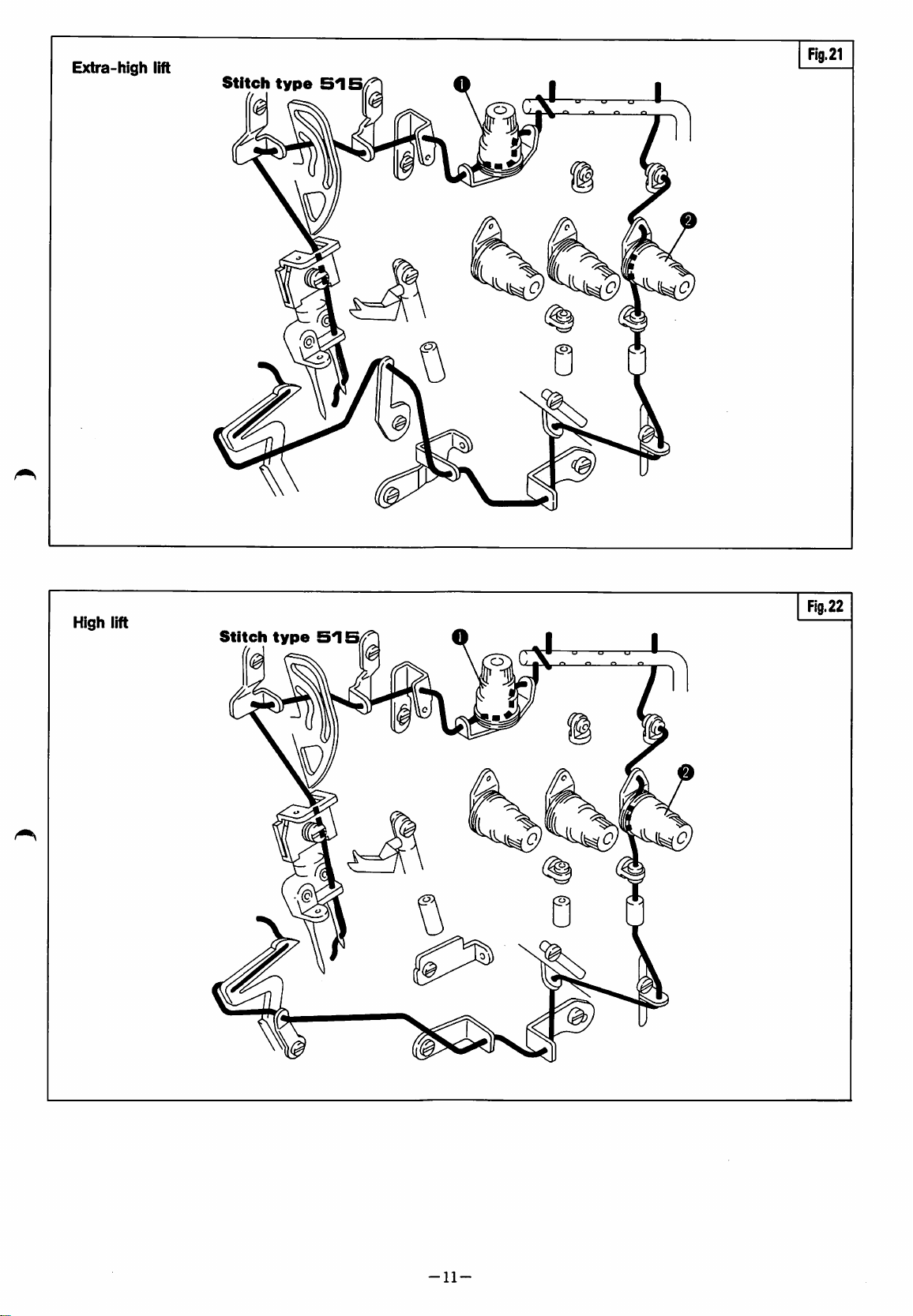

Extra-high

lift

Fig.21

Stitch

High

lift

Stitch

type

Fig.22

515

-11

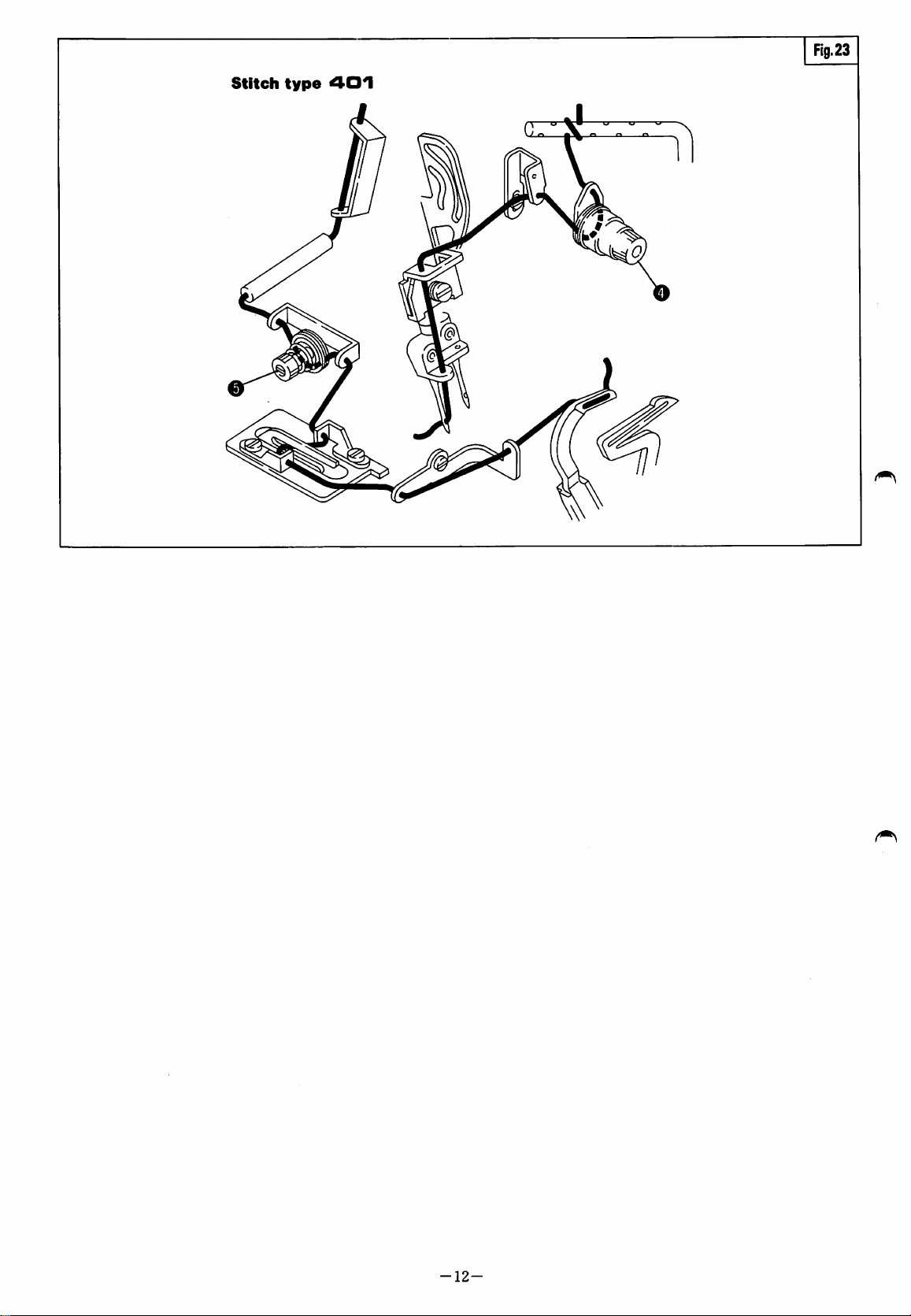

Page 14

Fig.23

Stitch

type

401

-12-

Page 15

PRESSER

ARM

SWINGING-IN

AND

-0UT(Rg.24)

When

arm,

Swingfng-out

Open

the

only

this

Presser

Swinging-in

Press

Swinging-in

first

raise

Spring O in

foot

lifting

the

top

feed

position,

Arm O to

the

foot

Lever 0 and

Keeping

return

i—

Note:

Rear

CBC23

Raise

you

Arm

this

Presser

Top

Feed

in

the

the

needle

can

swing-in

O.

or

swinging-out

the

needle

the

treadle

dog

pull

up

the

lifting

the

top

position,

Arm O to

Machines

last 3 figures

to

to

the

arrowed

or

lower

will

be

Lever O and

left.

treadle

feed

pull

or

dog

up

the

shown

of

the

highest

or

swing

the

presser

highest

direction,

position.

press

Lever 0 and

raised.

Keeping

swing-out

lower

Foot

will

be

raised.

Lever O and

original

Type

position.

as

CBA2]

Plate:

position

out

and

Presser

Lift

or

PRESSER

To

adjust

Presser

possible,

and

foot

while

obtain

FOOT

the

pressure,

pressure

still

proper

PRESSURE

turn

should

sufficient

stitch

formation.

(Rg

Screw

be

to

25)

0.

as

light

feed

Fig.25

as

fabric

-13-

Page 16

STITCH

LENGTH ADJUSTMENT

(ng8.26,27)

While

Q

Turn O further

Release

For a longer

direction.

For a shorter

direction.

^Note:

HANDWHEEL

pressing

until

Button O drops

O.

stitch

The

stitch

nominal.

length

Table 5 shows

scale

setting.

an

approximate

MAIN

FEED

STROKE

SCALE

Handwheel

scale

setting

Main

feed

stroke

Push

for a desired

stitch

this

It

may

stitch

1

1.0

Button

O,

turn

in.

length,

length,

is

stroke

(mm)

SETTING

2

1.5

turn 0 in

turn 0 in

the

main

by

the

be a reference

length.

BY

THE

3

4

2.0

2.5

Handwheel

stitch

feed

stroke

handwheel

to

5

3.0

length.

the

(+)

the

(—)

in

know

Table

6

7

3.5

3.8

5

a

DIFFENTIAL

Loosen

To

direction.

To

direction.

I—

Nut

gather

stretch

Note:

0.

the

the

Table 6 shows

the

lever

setting.

When

differential

•

Lever 0 is

If

set

feed

higher

differential

Maximum

•

If

set

lower

feed

is

applied.

Maximum

FEED

fabric,

ADJUSTMENT

turn

fabric,

the

differential

set

ratio

than

feed

is

applied.

up

to 1 ^

than

(2),

up

to

11

Screw O in

turn

Screw O in

to

the

is 1 :

1.

(2),

0.7.

the

positive

2.

(Rg.28)

the

(+)

the

(—)

feed

ratio

scale

(2),

the

the

negative

differential

by

DIFFERENTIAL

Scale

on

indication

Differential

feed

ratio

FEED

plate

i:

RATIO

1

0.7

1:1

©

Table

6

2

3

1:1.4

4

1:1.7

5

1:2

-14-

Page 17

TOP

FEED

STROKE

ADJUSTMENT

(Fig.29)

Loosen

stroke

Nut © shift

will

Shift O in

will

increase.

Shift O in

will

decrease.

•

When

will

•

When

depending

ADJUSTING

For

Loosen

top

i—

•

•

•

seaming,

not

occur.

standard

Nut

feed

pressure

Notes:

Too

much

on

the

fabric.

Too

little

the

top

abnormal

Adjust

while

positive

Lever © and

be

changed.

the

(+)

direction,

the

(—)

direction,

adjust

shirring/adding

on

the

TOP

pressure

®,

turn

on

pressure

pressure

feed

noise.

the

pressure

feeding

so

that

fullness,

nature

FEED

of

PRESSURE

set

gap

the

Screw © and

the

fabric.

may

cause

may

cause

dog,

uneven

as

weak

should

the

and

and

the

fabrics.

(a)

to

feed

jumping

feeding

as

be

top

the

stroke

the

stroke

ply

adjust

(Fig.30)

25mm.

adjust

marking

possible

kept.

feed

shift

Q

Fig.30

the

(a)25<™fl

of

or

REGULATING

1.

Loosen

©

2.

Loosen

Screw

to

the

Screw © and

Clamp © to

seam

width

Tighten

3.

Turn

Knife

Plate

will

4.

Make

Tighten

5.

Check

thread

check

-

Note:

Needle

available.

of

width

Screw

Handwheel

is

top.

return

sure

Screw

Knives

between

the

Plates

the

proper

required.

SEAM

©,

left

and

the

is

obtained.

®.

about

Loosen

to

position.

Knives

®.

cut

Knives,

cutting

for

Best

results

size

WIDTH

push

lightly

right

or

so

that

l.Omm

Screw

are

in a perfect

sharply;

of

knives.

various

are

Needle

(Rgs.3i.32)

Lower

tighten

move

above

Knife

Screw

Upper

left

until a desired

the

point

from

©,

then

Holder

alignment.

insert a piece

turn

Handwheel

seam

widths

obtained

Plate

for

Holder

©.

Knife

'b'

Needle

with

seam

and

are

use

of

©

of

Fig.

32

-15-

Page 18

NEEDLE

The

guides

Refer

positions

For

adjust

THREAD

standard

O,

to

Table 7 and

to

adjusting,

Guides

GUIDE

SETTING

setting

positions

©, ® are

your

machine.

loosen

O,

®.

as

shown

set

them

Screws

POSITION

of

to

O,

(Fig.

needle

in

Table

the

correct

©, ® and

33)

thread

7.

LOOPER

THREAD

Check

for

the

Extra-high

1.

2.

3.

•

•

your

the

extra-high

high

lift

Looper

Loosen

lowest

Upper

Lower

When

point,

Guides

position

Looper

For

loosen

© ©

For

Thread

as

Thread

position.

Looper

Looper

the

loosen

©, © up

Thread

the

Screws

to

the

Guides © ©

(516).

THREAD

GUIDE

machine

machines.

Lift

(Fig.

Screw o and

lower

TAKEUP

SETTING

with

lift

machines.

34)

Guide

Thread

Thread

looper

Screws

O

Takeup

Takeup

and

shown

the

machines

in

Fig.

Guides

machines

© ©

positions

of

34.

of

and

indicated

the

to

AND

POSITIONS

Table

See

set

Guide O to

O,

<£)

is

at

the

(D,

®,

down

and

© ©

the

stitch

set

Thread

stitch

the

positions

LOOPER

7.

See

Fig.35

right

shift

Thread

set

type

Guides

as

(515).

type

516,

indicated

Fig.

for

the

dead

to

the

515,

set

34

A = Highest

B = Center

C - Lowest

Extra-high

lift

515

516

High

Lift

(Fig.35)

High

1.

Looper

Loosen

between

Thread

2.

Upper

Lower

When

point,

Takeups

position

3.

Looper

•

For

loosen

© ©

•

For

loosen

© ©

Thread

Screw © and

Guide © is

Looper

Looper

the

loosen

Bed

surface

Thread

Thread

lower

Screws

Guide

©, © up

as

shown

Thread

the

Screws © ©

to

the

Screws © ©

to

the

Guides

machines

the

positions

machines

positions

©

set

(a)

39.0mm.

Takeup

Takeup

looper

is

©.

and

down,

in

Fig.

© ©

of

the

and

indicated

of

the

and

indicated

that

and

©,

©

at

the

©,

adjust

35.

stitch

set

Thread

stitch

set

Thread

the

the

and

as

as

distance

hole

right

dead

Thread

set

at

type

515,

Guides

(515).

type

516,

Guides

(516).

of

the

lift

Bed

surface

(a)

Page 19

NEEDLE

THREAD

GUIDE

SETTING

POSITION-FRONT

TOP

FEED

ETS32

Table

7

EXTRA-HIGH

(GENERAL

0(51

5)-ETS32-420FA2/4

0(

51

5)-ETS32-430FA2/433

0(

51

5)-ETS32-432FA2/453

,

516

(515)'

,

516

(515)'

^ I ®

(gathering

0(51

5)-ETS32-542FD2/453/KL

•(

51

5)-ETS32-542FD3/453/KL

SEAMING)

Machine

type/spec.

13

•ETS32-420FA3/4I3

ETS32-430FA3/433

J-ETS32-432FA3/453

)

Machine

type/spec.

100

100

LIFT

Stitch

type

o

e

Stitch

type

O

e e

B B B B

//

n

516

516

//

stitch

type

O

®

Stitch

type

O

e e

A

ti

W

515

0(51|)-etS32-

0(51

515

0(

A

n

•(51

Machine

1

5)-ETS32-422FA2/3

type/spec.

434FA2/333

5)-ETS32-433FA2/353

>

516

ETS32-422FA3/3I3

(515)'

,

516

rETS32-434FA3/333

(515)'

,

516

,-ETS32-433FA3/353

(515)'

Machine

type/spec.

515yETS32-544FD2/353/KL

5)-ETS32-544FD3/353/KL

HIGH

13

LIFT

100

100

Stitch

type

Stitch

type

O

e

B

c

tl

tl

516

516

0

C

It

Stitch

type

stitch

type

o

0

c c

B

It

If

515

515

0

tl

(

PIPING

Stitch

Machine

type/spec.

0(5l5)"ETS32-432FC2/p2/453

NEEDLE

(general

0(51

5)-ETS32-430BA2/433

0(

51

5)-ETS32-432BA2/453

(seaming/heavy

0(51

5)-ETS32-452BA2/433

,

516

'{515)'

0(

51

5)-ETS32-453BA2/453

THREAD

seaming)

Machine

Machine

ETS32-452BA4/433

type/spec.

type/spec.

GUIDE

)

type

O

0

B B

Stitch

type

0

0 0

B

B

tl

Stitch

type

e

ft

Stitch

516

O

0

B

B

SETTING

Stitch

516

0

B

B

tl

tt tt

stitch

516

type

515

0

0

A

A

0(5'

Machine

5)-ETS32-433FC2/^^/333

POSITION-REAR

type

515

0

0

A

A

tt

type

515

type/spec.

TOP

Stitch

type

0

0

C C

B

FEED

516

Stitch

0 0

0

B

ETS32

type

C

515

0

C

l(^|5j-ETS32-453BA4/453

(

PIPING

Machine

0( ^ 1

®)-ETS32-432BC2/^^/453

type/spec.

J

Stitch

type

0

0

B

B

516

0

B

Stitch

type

0

0

B

515

0

A

A

-17-

O = Normal

• = Narrow

■ = Tractor

presser

presser

foot

foot

foot

Page 20

CHAiNSTITCH

HANDLING

(ng8.36.37)

LOOPER

THREAD

dlLooper

Adjust

Thread

the

gap

Bracket 0 and

Takeup

Loosen

m

When

adjust

Guide O to

Screw 0 and

Looper

Thread

the

the

needle

gap

Bracket 0 and

dimension

Loosen

dlLooper

Adjust

Bracket

Loosen

^

Note:

•

For

the

•

For

the

c)

to

6.5mm.

Screws 0 and

Thread

the

eye

0.

Screw 0 and

more

thread

(+)

direction.

less

thread

(—)

direction.

Takeup

Guide

between

the

tip

6.0 — 6.5mm.

adjust.

Takeup

is

at

O

the

between

tip

(b)

of

adjust.

Eyelets

of

Eyelet

adjust.

in

the

in

the

O

the

top

surface

of

Looper

upper

the

top

Takeup O (Fig.

i

to

seam,

seam,

Thread

dead

point,

surface

36,

mark

(d)

shift

shift 0 in

m

of

of

of

Fig.

37

©

CHANGING

1.

Loosen

0

2.

Remove

to

Screw

the

Replace

Adjust 0 so

for

the

seam

Upper

when

3.

Turn

Knife

Plate

Loosen

to

Make

and

Upper

Handwheel

is

top.

Screw

position.

sure

Tighten

4.

Check

thread

check

Knives

between

the

UPPER

0,

left

and

Screw

0.

Upper

that

width

Lower

Knife 0 is

about

0,

Knives

Screw

0.

cut

cutting

KNIFE

push

lightly

(Figs.

Lower

tighten

Knife 0 with

it

is

in

the

correct

and

also,

the

Knives

is

lowest.

so

that

the

1.0mm

Knives,

above

then

Holder 0 will

are

in a perfect

sharp;

of

insert a piece

turn

Knives.

Handwheel

38.39,40)

Knife

Holder

Screw

the

0.

new

one.

position

overlap

0.5 — 1.0mm

point

'e'

from

Needle

return

alignment.

of

of

of

and

Upper

knife

0.5~ I .0™n

Needle

top

surface

plate

Fig.

39

-18-

Lower

knife

Page 21

CHANGING

1.

Loosen

0

2.

Loosen

Replace

•

Move

edge

Tighten

3.

Turn

Upper

Needle

Screw

to

the

left,

Screw

Lower

Knife

is

level

Screw

Handwheel

Knife

Plate

Holder 0 will

4.

Make

sure

Tighten

5.

Check

thread

check

Screw

Knives

between

the

cutting

LOWER

0,

push

and

lightly

®.

Knife 0 with

up

or

with

Needle

0.

so

is

about

top.

return

Knives

are

0.

cut

sharp;

Knives,

of

Knives.

KNIFE

(Fig8.40,4i)

Lower

Knife

tighten

the

down

Loosen

to

until

Plate

top.

that

the

point

l.Omm

above

Screw

position.

in a perfect

insert a piece

turn

Handwheel

Holder

Screw

new

its

0.

one.

cutting

'e'

of

from

0,

then

alignment.

of

and

Needle

top

surface

plate

KNIVES

Knives

If

the

sharpen

Sharpening

Sharpen

Upper

Upper

returned

special

(Fig.42)

must

be

machine

the

lower

Lower

the

lower

Knife

Knife

may

to

us

grinding.

kept

sharp.

does

not

trim

knife.

Knife

0

knife

as

be

sent

for

resharpening

the

fabric

specified

to

our

distributors

since

sharply,

in

Fig.

it

requires

42.

or

-19-

Page 22

BOTTOM

FEED

HEIGHT

(Rgs.43.44)

Fig.43

Bottom

Table

to

1.

2.

3.

feed

8.

Make

your

machine.

Turn

the

dog

to

the

Adjust

needle

of

the

For

Main

Set

gap

plate

the

main

type.

adjusting,

Feed

the

tooth

Dog ® to

(c)

of

the

For

adjusting,

dog

hand

highest

the

main

Differential

height

sure

that

wheel

(a)

to

feed

position.

from

the

tooth

dog

to

to

loosen

Dog O up

end

(b)

same

height

feed

dog.

loosen

Feed

Dog 0 up

by

type

is

as

shown

the

lift

the

end

the

setting

the

top

height

of

the

is

bottom

face

rear

correct

Screw O and

and

down.

of

Differential

as

the

tooth

Screw O and

and

down.

in

correct

feed

of

the

part

to

shift

Feed

end

shift

(a)

(c) (b)

AUXILIARY

Gap

(d)

dog

to

is

adjusted

Generally,

wider,

smaller.

To

adjust

Auxiliary

BOTTOM

from

the

and

Feed

FEED

the

tooth

to

the

for

using

for

using

the

gap,

Dog 0 up

FEED

ADJUSTMENT

Adjust

the

appear.

For

Screw

so

that

all

needle

adjusting,

0,

plate

and

turn

remove

DOG

HEIGHT

tooth

end

of

the

end

of

Auxiliary

machine

type.

coarse

finer

loosen

and

LEVELING

thread,

thread,

Screw ® and

Feed

down.

POSITION

(Figs.46.47)

the

teeth

ends

are

top

surface

cover

Washer

when

plate

0

(Fig.45)

main

Dog

set

the

set

the

shift

flush

they

O,

loosen

feed

©

gap

gap

with

first

p

Needle

top

surface

Fig.45

Flg.46

plate

f—

Note:

1.

For

hold

so

2.

Be

after

tightening

the

as

to

avoid

sure

the

Screw 0 after

feed

bar

exactly

sidewise

to

adjust

adjustment.

with

shifting.

"bottom

adjustment,

Washer

feed

0

height"

-20-

Page 23

BOTTOM

FEED

HEIGHT-FRONT

TOP

FEED

ETS32

Table

8

EXTRA-HIGH

(GENERAL

SEAMING)

Machine

type/spec.

O(^|^)-ETS32-420FA2/4I3

0(11

5)-ETS32-430FA2/433

O

J15

J-ETS32-432F

A2/453

•(5l5)"ETS32-420FA3/4l3

51

5)-ETS32-430FA3/433

•(5 ] 5)-ETS32-432FA3/453

(gathering

Machine

0(11

^)-ETS32-542FD2/453/KL

type/spec.

)

i

•(5l5)"ETS32-542FD3/453/KLI00

00

UFT

Bottom

Bottom

feed

0.9-1

feed

0.9-l

height

.1

//

//

//

H

ft

height

.i

ft

HIGH

Machine

^(51

5)-ETS32-422FA2/3

type/spec.

i

0(^l®)-ETS32-434FA2/333

0( 5 ] 5 J-ETS32-433F

A2/353

•(5l5)'ETS32-422FA3/3l3

•(51

5)-ETS32-434FA3/333

•(5|5)-ETS32-433FA3/353

Machine

0(

51

5)-ETS32-544FD2/353/KL

•(51

5)-ETS32-544FD3/353/KL

type/spec.

3

UFT

100

100

o

Bottom

0.8~i

Bottom

0.8-1.0

I

00

feed

n

ft

u

ft

ft

feed

ft

O

height

.0

height

(PIPING

Machine

type/spec.

0(^]^)-ETS32-432FC2/^^/453

BOTTOM

(general

seaming)

Machine

type/spec.

0( ^ 1 ^ J-ETS32-430BA2/433

0(5l5)"ETS32-432BA2/453

(seaming/heavy

Machine

0(51

5)-ETS32-452BA2/433

■(

51

^)-ETS32-452BA4/433

type/spec.

)

FEED

)

Bottom

feed

height

0.9-1.1

HEIGHT-REAR

Bottom

feed

height

0.9-i.

Bottom

0.9-1.1

ft

feed

//

l

height

Bottom

feed

Machine

type/spec.

height

0(5|5)-ETS32-433FC2/p2/333

TOP

FEED

ETS32

0(5l5)"ETS32-453BA2/453

■(51

5)-ETS32-453BA4/453

(PIPING

Machine

type/spec.

)

Bottom

0(^ 1 ^)-ETS32-432BC2/^^/453

tf

tf

feed

0.9-i.l

height

-21-

O = Normal

• = Narrow

■ = Tractor

presser

presser

foot

foot

foot

Page 24

NEEDLE

HEIGHT

SETTING

(Fi98.48.49)

Fig.48

Table 9 shows

each

machine

Make

sure

machine.

To

adjust

1.

Turn

the

highest

2.

Measure

the

needle

and

adjust

dimension.

For

adjusting,

Needle

f—

Note:

Make

sure

the

center

plate.

If

necessary,

Needle

type.

that

the

hand

level.

gap

plate

the

Holder

that

of

Holder 0 and

the

correct

the

setting

wheel

(a)

between

top

needle

loosen

Guide

the

chainstitch

the

needle

loosen

needle

is

and

bring

the

surface

height

height

correct

the

needle

needle

point

perpendicularly

to

the

Screw O and

©.

needle

hole

of

the

Screw 0 and

adjust.

for

for

your

and

correct

adjust

passes

needle

turn

to

Flg.49

LOWER

LOOPER

Table 9 shows

for

each

machine

setting

To

1.With

is

correct

adjust:

the

needle

0 — 0.05mm

comes

For

Looper

2.

When

point,

and

dimension.

For

Looper

to

the

adjusting,

Holder O back

the

lower

adjust

the

needle

adjusting,

Holder O to

the

correct

type.

for

bent

center

loosen

gap

(b)

loosen

SETTING

by

(Rgs.50,51)

lower

Make

your

machine.

guard

the

of

the

idle,

looper

needle.

Screw 0 and

and

forth.

looper

is

at

between

centerline

Screw 0 and

the

right

looper

sure

set

point

the

the

looper

to

the

or

left.

that

the

when

left

setting

the

needle

it

shift

dead

point

correct

shift

0 ~ 0.05"""

Fig.

50

Rg.51

-22-

Page 25

NEEDLE

HEIGHT/LOWER

EXTRA-HIGH

UFT

LOOPER

SETTING-FRONT

HIGH

TOP

UFT

FEED

ETS32

Table

9

(GENERAL

0(^ 1 ^)-ETS32-420FA2/413

O(^|^)-ETS32-430FA2/433

0(^l^)-ETS32-432FA2/453

•(51

5)-E"''S32-420FA3/4

•(

51

5)-ETS32-430FA3/433

•(

51

5)-ETS32-432F

(GATHERING

0(5 ] 5)-ETS32-542FD2/453/KL

•(11

1)"ETS32-542FD3/453/KL

(

PIPING

SEAMING)

Machine

Machine

type/spec.

type/spec.

13

A3/453

)

100

100

Needle

(a)

11.7-11.9

//

tf

//

//

//

Needle

(a)

11.7-11

ff

Lower

Lower

.9

looper

(b)

3.6--3.9

//

//

n

n

//

looper

(b)

3.6-3.9

//

Machine

type/spec.

0(5|5)"ETS32-422FA2/3I3

0(®j®)-ETS32-434FA2/333

0( 5 ]

5)-ETS32-433F

•(51

5)-ETS32-422FA3/3

•(11

5)-ETS32-434FA3/333

•(11

5)-ETS32-433FA3/353

Machine

0(515

J-ETS32-544FD2/353/KL100

•(515

J-ETS32-544FD3/353/KLI00

A2/353

13

type/spec.

Needle

(a)

I0.4~i0.6

n

//

//

n

//

Needle

(a)

10.4-10.6

it

Lower

3.8-4.1

Lower

3.8-4.

loopor

(b)

ff

n

n

n

n

looper

(b)

ft

1

Machine

0(^1

5)-ETS32-432FC2/^^/453

NEEDLE

(GENERAL

Machine

0(51

5)-ETS32-430BA2/433

0(

51

5)-ETS32-432BA2/453

(SEAMING/HEAVY

Machine

type/spec.

HEIGHT/LOWER

SEAMING)

type/spec.

)

type/spec.

0(5l5)'ETS32-452BA2/433

■(1|5)-ETS32-452BA4/433

Needle

(a)

II.7-11.9

Needle

(a)

II.7-11.9

if

Needle

(a)

II.7-11.9

tt

LOOPER

Lower

3.6-3.9

Lower

3.6-3.9

Lower

3.6-3.9

looper

(b)

0( 1 ]

Machine

ETS32-433FC2/^2/333

SETTING-REAR

looper

(b)

it

looper

(b)

it

type/spec.

TOP

Needle

(a)

10.4-10.6

FEED

Lower

(b)

ETS32

CO

00

1

loopor

Lower

3.6-3.9

tt

tt

(b)

looper

-23-

0(|]5j-ETS32-453BA2/453

51 ® J-ETS32-453BA4/453

(

PIPING

Machine

type/spec.

J

0(5l5)"ETS32-432BC2/p2/453

if

a

Needle

(a)

II.7-11.9

0=

Normal

• = Narrow

■ = Traotor

presser

presser

foot

foot

foot

Page 26

UPPER

The

Make

machine.

1.

2.

3.

(c)

LOOPER

standard

sure

that

Tentatively

Screw

When

adjust

Loosen

and

When

check

0.5mm.

Tighten

0.

the

gap

(a)

Screw

adjust

the

that

Turn

to

approximately

Screws 0 and

SETTING

setting

set

looper

this.

upper

clearance

the

the

to

the

®,

the

move

looper

is

setting

is

and

(ng8.52-57)

as

shown

is

correct

looper

at

correct

in

the

left

dimension.

Crank O up

lower

(b)

is

and

adjust

0.2mm.

0.

in

Table

for

10.

your

Holder O by

dead

point,

or

down,

loopers

approximately

cross,

clearance

Extra-high

High

lift

lift

Rg.52

Fig.

53

Fig.

57

Extra-high

(a)4.5--5.0mm

High

lift

(a)4.5~5.Qmm

lift

(a)4.5~

(a)4.5~5.0mm

5.0mm

(c)

0.2mm

-24-

Rg.56

(b)0.5mm

Page 27

UPPER

LOOPER

SETTING-FRONT

TOP

FEED

TYPE

ETS32

Table

10

EXTRA-HIGH

(GENERAL

SEAMING)

Machine

type/spec.

O(^|^)-ETS32-420FA2/4I3

O(5l5)'ETS32-430FA2/433

0(^1

^)-ETS32-432FA2/453

•(5|5)-ETS32-420FA3/4I3

•

J1 ^ J-ETS32-430FA3/433

•

J15

J-ETS32-432F

(GATHERING

Machine

0(51

5)-ETS32-542FD2/453/KL

•(11

5)-ETS32-542FD3/453/KL

A3/453

)

type/spec.

100

100

UFT

Position

A

//

//

tf

ff

ff

Position

A

ff

Distance

Distance

(a)

4.5-5.0

ft

ft

ft

tt

tf

(a)

4.5-5.0

HIGH

Machine

type/spec.

0(5l5)-ETS32-422FA2/3i3

51

5)-ETS32-434F

A2/333

0(5l5)"ETS32-433FA2/353

•(5|5)-ETS32-422FA3/3I3

•(5l5)-ETS32-434FA3/333

•(5 j 5)-ETS32-433FA3/353

Machine

0(51

5)-ETS32-544FD2/353/KL

•(51

5)"ETS32-544FD3/353/KL

type/spec.

UFT

100

100

Position

B

//

tt

tt tt

tt

tf

Position

B

II

Distance

4.5-5.0

Distance

4.5-5.0

(a)

//

tt

tt

tt

(a)

//

(PIPING

Machine

0(

51

5)-ETS32-432FC2/^^/453

UPPER

(general

Machine

type/spec.

LOOPER

seaming)

type/spec.

0(515J-ETS32-430BA2/433

0(

51

5)"ETS32-432BA2/453

(SEAMING/HEAVY

Machine

515

J-ETS32-452BA2/433

type/spec.

■(5l5)'ETS32-452BA4/433

)

Position

A

SETTING-REAR

Position

A

ff

)

Position

A

tt

Distance

Distance

(a)

4.5-5.0

(a)

4.5-5.0

tt

Distance

(a)

4.5-5.0

ff

Machine

0(51

5)-ETS32-433FC2/^^/333

TOP

type/spec.

FEED

TYPE

Position

B

ETS32

Distance

(a)

4.5-5.0

0(5! 5 )-ET

(

PIPING

0(

S32-453B

5 ] 5

J-ETS32-453BA4/453

A2/453

J

Machine

type/spec.

515)-ETS32-432BC2/p2/453

ff

tf

Position

A

tf

tf

Distance

4.5-5.0

(a)

-25-

O = Normal

• = Narrow presser

■ = Tractor

presser

foot

foot

foot

Page 28

CHAINSTiTCH

1.

Set

the

looper

Fig.

58.

•

At

the

factory,

this

by

the

looper

Insert

regulator

2.

When

its

the

dimension:

•

(a)

•

(a)

Loosen

3.

Distance

When

distance

needle

Loosen

shank.

the

O.

the

point

needle,

is

0~

0.05mm

is

0~0.1mm

Screw o and

from

the

between

centerline

Screw O and

LOOPER

in

the

the

regulator

looper

comes

looper

until

looper

behind

adjust

for

for

needle

is

moves

at

the

should

SETTING

holder

looper

O,

located

its

shank

to

the

gap

(a)

needles

needles

adjust

the

Looper

left

looper

be

1:67-1.8mm.

adjust

Looper

(Fig8.58~6i)

as

shown

is

adjusted

below

touches

the

right

centerline

to

the

correct

#16

or

thinner.

#17

or

thicker.

Holder

dead

point,

point

and

Holder

in

like

the

the

and

of

©.

the

the

®.

Rg.58

59.5"™

Hg.59

4.

Looper

Adjust

to

Loosen

•

For a thinner

•

For a thicker

avoiding

the

the

needle

Nut O and

looper

motion

avoiding

size.

move

needle,

needle,

move

motion

according

Pin 0 up

move

Pin 0 upward.

Pin 0 downward.

or

down.

1

.6— I .Bntm

Fig.

60

-26-

€

Page 29

OVERLOCK

SETTING

(Rgs.62--66)

NEEDLE

GUARD

Overlook

•

Movable

When

needle

the

the

Loosen

Overlook

When

needle

Needle

0.1 ~ 0.2mm.

Loosen

the

centerline,

needle

looper

Screw 0 and

Needle

the

centerline,

Guard O and

Screw o and

Needle

Guard

type

lower

so

that

point

and

Guard

lower

(rear)

looper

Needle

Guard O should

the

clearance

the

needle

adjust.

(front)

looper

the

clearance

the

adjust.

setting

point

is

is

setting

point

is

needle

O

behind

(b)

between

0mm,

O

behind

(c)

between

should

the

push

the

be

Overlook

•

Solid

When

needle

the

the

Loosen

Overlook

When

needle

Needle

0.1 ~ 0.2mm.

Loosen

Needle

type

the

centerline,

needle

looper

Screw 0 and

Needle

the

centerline,

Guard

Screw O and

lower

so

that

point

and

lower

Guard

(rear)

looper

Needle

the

the

adjust.

Guard

(front)

looper

the

and

adjust.

setting

point

is

Guard

clearance

needle

<D

is

(d)

0mm.

setting

point

is

clearance

the

(e)

needle

(D

behind

should

push

between

O

behind

between

should

the

the

be

(b)Onim

WO

0.2nmi

(d)Omm

-27-

(e)0.

1~0.2mm

Page 30

CHAINSTITCH

SETTING

(ng8.67,68)

NEEDLE

GUARD

Chainstitch

When

clearance

the

needle

Loosen

I—

Note:

If

Needle

heavy

chainstitch

wide

may

Chainstitch

When

clearance

needle

Loosen

Needle

the

needle

(a)

between

should

Screw O and

Guard O pushes

and

needle

(more

be

than

caused.

Needle

the

needle

between

should

be

Screw O and

Guard

(rear)

is

in

the

lowest

Needle

be

Omm.

adjust.

the

clearance

and

looper

0.05mm), a skip

Guard

(front)

is

in

the

lowest

Needle

0.05—0.1mm.

adjust.

setting

O

position,

Guard O and

the

needle

between

becomes

stitching

setting

0

position,

Guard 0 and

the

too

the

too

the

the

(a)

Omm

(b)0.05~0.

Fig.

68

Imm

NEEDLE

Stitch

515

516

SIZE

type

AND

UPPER

Needle

size

9-12

13-16

17-21

9-12

13-16

17-21

LOOPER/SPREADER

High

lift

Part

No.

210515

210514

210513

210366

210367

210365

(#27)

(#25)

(#23)

(#26)

(#28)

(#24)

Table

Extra-high

Part

211845

211719

lift

No.

(#29)

H

n

(#38)

//

it

11

-28-

Page 31

ADJUSTING

OF

BOTTOM

Set

Pin 0 and

Be

careful

To

adjust,

W

Limit

by

Stoppers 0 and

To

adjust,

THE

FEED

to

loosen

the

shifting

loosen

LENGTHWISE

DOGS

Washer © as

their

(Rg8.69-73)

direction

Nut

O-

range

of

0.

Screws 0 and

POSITION

shown.

and

position.

Lever ® to 1 —

0.

Fig.

5

70

Raise

Lever 0 and

Feed

Dog 0 to

setting = 1.

To

adjust,

When

Main

0

are

at

to

0.5mm.

To

adjust,

loosen

Feed

the

front

loosen

adjust

the

Nut

Dog 0 and

dead

the

stroke

minimum.

0.

Diff.

point,

Screw 0 and

of

The

Feed

adjust

move

gap

Crank

Diff.

lever

Dog

(c)

Fig.

73

(c)0.5'nfn

w

Set

the

stitch

Feed

Dog ® to

The

handwheel

w

When

search a position

Feed

Lever 0 up

To

the

Dog 0 does

adjust,

length

the

scale = 7.

feed

dogs

or

down.

loosen

or

the

stroke

maximum.

are

at

the

of

Crank 0 where

not

move

even

Screw

0.

end

if

of

of

stroke,

Diff.

you

Main

move

OOOl

\

W

-29-

Page 32

ADJUSTING

TOP

FEED

Table

feed

and

Make

machine.

For

Pin

SETTING

12

shows

dog

and

Crank

sure

adjusting,

O.

POSITIGN

VEffTTICAL

DOG

(Fig.74)

the

standard

the

gap

Pin 0 for

that

the

setting

loosen

OF

STROKE

stroke

(a)

between

each

machine

is

correct

Screw O and

TOP

FEED

DOG

OF

of

the

Crank

type.

for

shift

Crank

(ng.75)

top

O

your

a\(

a

Fig.

75

Table

feed

Make

machine.

ADJUSTING

OF

To

dog.

1.

2.

3.

12

shows

dog

for

sure

TOP

FEED

adjust

Pressing

and

set

Release

turn

the

dog

to

the

Make

sure

by

shifting

back

and

the

standard

each

machine

that

the

THE

LENGTHWISE

DOG

the

lengthwise

Push

Button

the

scale

to

your

hand

handwheel

rear

dead

that

the

Top

forth.

setting

type.

setting

is

correct

(ng8.76-78)

position

O,

turn

the

4.

from

the

bush

and

bring

the

point.

feed

dog

stands

Feed

Adjusting

of

the

for

your

POSITION

of

top

hand

wheel

button,

top

feed

still

even

Lever

top

A = Highest

B = Center

C = Lowest

feed

0

-30-

Page 33

TOP

FEED

FRONT

VERTICAL

TOP

FEED

STROTE

ETS32

AND

SET

POSITION-

Table

12

EXTRA-HIGH

(GENERAL

0(515

SEAMING

Machine

type/spec.

J-ETS32-420FA2/413

O(5l5)"ETS32-430FA2/433

0(^j®)-ETS32-432FA2/453

•(5|5)-ETS32-420FA3/4I3

•(5

l|)-ETS32-430FA3/433

•(5l5)'ETS32-432FA3/453

(GATHERING

Machine

0(

51

5)-ETS32-542FD2/453/KL

type/spec.

^ 1 ®)-ETS32-542FD3/453/KL

)

100

100

UFT

Stroke

4.5

//

//

//

n

n

Stroke

4.5

tl

Gap

1

Gap

1

(a)

.5

n

H

n

n

tt

(a)

.5

II

Position

A

//

W

U

n

If

Position

B

tt

HIGH

Machine

O

(515

J-ETS32-422F

0(5

||)-ETS32-434FA2/333

type/spec.

A2/313

0(^l®)-ETS32-433FA2/353

•(^]®j-ETS32-422FA3/3l3

•(51

5)-ETS32-434FA3/333

•(51

5)-ETS32-433F

Machine

A3/353

type/spec.

0(5]5)-ETS32-544FD2/353/KLIOO

•(51

5)-ETS32-544FD3/353/KL

UFT

100

Stroke

4.5

n

tt tt

tt tt

ft

tt

Stroke

4.5

tt

Gap

1

Gap

1

.5

tt

tt

tt

.5

tt

(a)

(a)

Position

A

If

If

tt

tt

Position

B

tt

C

PIPING

Machine

type/spec.

0(®|®j-ETS32-432FC2/^^/453

TOP

REAR

(GENERAL

FEED

TOP

SEAMING)

Machine

type/spec.

O(5|5)-ETS32-430BA2/433

O

(11

^)-ETS32-432BA2/453

(SEAMING/HEAVY

Machine

0(

515

J-ETS32-452BA2/433

type/spec.

■(5l5)"ETS32-452BA4/433

J

Stroke

VERTICAL

FEED

ETS32

Stroke

)

Stroke

4.5

STROKE

4.5

It

7.0

tt

Gap

1.5

Gap

4.0

Gap

8.0

(a)

(a)

11

(a)

tt

Position

Position

Position

Machine

A

0(515j-ETS32-433FC2/p2/333

AND

C

//

C

tt

SET

type/spec.

POSITION-

Stroke

4.5

Gap

1

(a)

.5

Position

A

0(

515

■

(515

(

PIPING

0(515

tt

Stroke

4.5

ft

Gap

J-ETS32-453BA2/453

)-ETS32-453BA4/453

Machine

type/spec.

j-ETS32-432BC2/p2/453

It

It

(a)

4.0

tt

tt

Position

C

-31-

O = Normal

# = Narrow

■ = Traotor

presser

presser

foot

foot

foot

Page 34

TOP

FEED

FEED

The

Make

machine.

Using

shifting

Loosen

RATIO

standard

sure

Stopper

range.

Screw

STROKE

(Fig.79)

setting

that

the

®,

set

o.

move

AND

DIFF.

is

as

shown

setting

is

correct

Lever O in

Stopper ® and

in

Table

the

13.

for

your

correct

adjust.

Rg.79

-=i

Q

-32-

Page 35

TOP

FEED

STROKE

AND

TOP

FEED

RATIO-FRONT

TOP

FEED

ETS32

Table

13

EXTRA-HIGH

(GENERAL

SEAMING

Machine

type/spec.

0(5 ] 5J-ETS32-420FA2/413

]

5)-ETS32-430FA2/433

0(51

5)-ETS32-432FA2/453

UFT

Sroke

2.8-5.8

•(5l5)'ETS32-420FA3/4l3

•(5l5)"ETS32-430FA3/433

,

516

ETS32-432FA3/453

^515)'

(GATHERING

Machine

0(51

5)"ETS32-542FD2/453/KL

•(51

5)-ETS32-542FD3/453/KL

type/spec.

)

100

100

Stroke

2.8-7.4

/;

Feed

ratio

1

:0.75

~i:

Feed

ratio

i:o.75

-i;

i.5

Setting

l~6

HIGH

Machine

type/spec.

■0(5|5)-ETS32-422FA2/3I3

^(51

5)-ETS32-434FA2/333

UFT

Stroke

2.8-5.8

Food

ratio

1:0.75

~i:i.5

Setting

1-6

0(m)-ETS32-433FA2/353

•(51

5)-ETS32-422FA3/3

.

516

ETS32-434FA3/333

(515)"

•(51

5)-ETS32-433FA3/353

Setting

1-9

i.95

H

11

Machine

type/spec.

O(^l^)-ETS32-544FD2/353/KLI00

•(^l^)-ETS32-544FD3/353/KLI00

13

Stroke

2.8-1

Feed

ratio

i:0.75

A

-i:

n

Setting

1-9

i.95

n

t!

Cpiping

Machine

0( ^ ]

^)-ETS32-432FC2/^^/453

TOP

FEED

(general

Machine

type/spec.

SEAMING)

type/spec.

O(5l5)"ETS32-430BA2/433

0(5l5)-ETS32-432BA2/453

(SEAMING/HEAVY

Machine

type/spec.

)

STROKE

)

00

ni

1

00

Stroke

CS

J

2.8-5.8

AND

Stroke

2.8-5.8

//

Stroke

0(5l5)'ETS32-452BA2/433

■(5l5)'ETS32-452BA4/433

II

Feed

ratio

1:

0.75

-i:

1.5

TOP

Food

ratio

i:0.75

-i:

i.95

n

Feed

ratio

1

:0.75

-i:i.95

;/

Setting

1-6

FEED

Setting

1-6

ft

Setting

1-6

//

Machine

0(®|®j-ETS32-433FC2/^^/333

RATIO-REAR

type/spec.

TOP

Stroke

2.8-5.8

FEED

Feed

ratio

i

:o.75

-i:i.5

ETS32

Setting

1-6

0( 5 j

®)-ETS32-453BA2/453

■

(11 ® J-ETS32-453BA4/453

(

PIPING

Machine

type/spec.

1 ® j-ETS32-432BC2/^^/453

J

2.8-5.8

II

Stroke

n

Feed

ratio

i:o.75

-i:

ft

1.95

II

ft

tt

Setting

1-6

-33-

O = Normal

• = Narrow

■ = Traotor

presser

presser

foot

foot

foot

Page 36

ADJUSTING

OF

TOP

FEED

The

standard

Make

sure

machine.

To

adjust

1.

Pressing

and

set

2.

Shift