Page 1

msm,

TECHNICAL

MANUAL

PEGASUS

(8)

Page 2

1 .

Ply

shift

has

been

CONTENTS

completely

eliminated.

1

2 . There

3 . Five

4 . Presser

5 . ETS-32-FA(for

ETS-52-FA(for

ETS-52-FB(for

6 . ETS-52-FC(for

ETS

7 . Subclasses

8 . Subclasses

9 . Top

Shirring

are

two

features

Arm

types

of

Swinging-ln

plain

plain

heavy

piping)

Series

(rear

(Overedgers)

(Safety-stitch

feed

height

adjustments

ETS

top

adjustment

of

machines

Series

and

seaming)

seaming)

fabrics

such

feed)

machines)

(FD)

in

the

-out

as

sweaters)

ETS

series.

2

3

4

5

5

5

6

6

7

8

9

9

10.

Adjustment

11.

The

12.

STANDARD

13.

Adjustment

Differential

14.

Adjustment

feed

of

the

dog

lower

DIMENSIONS

of

top

ratio

alteration.

of

Top

top

feed

dead

feed

Feed

vertical

point

ON

ADJUSTMENTS

dog

and

Dog

stroke

adjustment.

presser

foot

10

11

12

13

13

14

Page 3

For

all

kinds

of

operation

on

all

kinds

of

material.

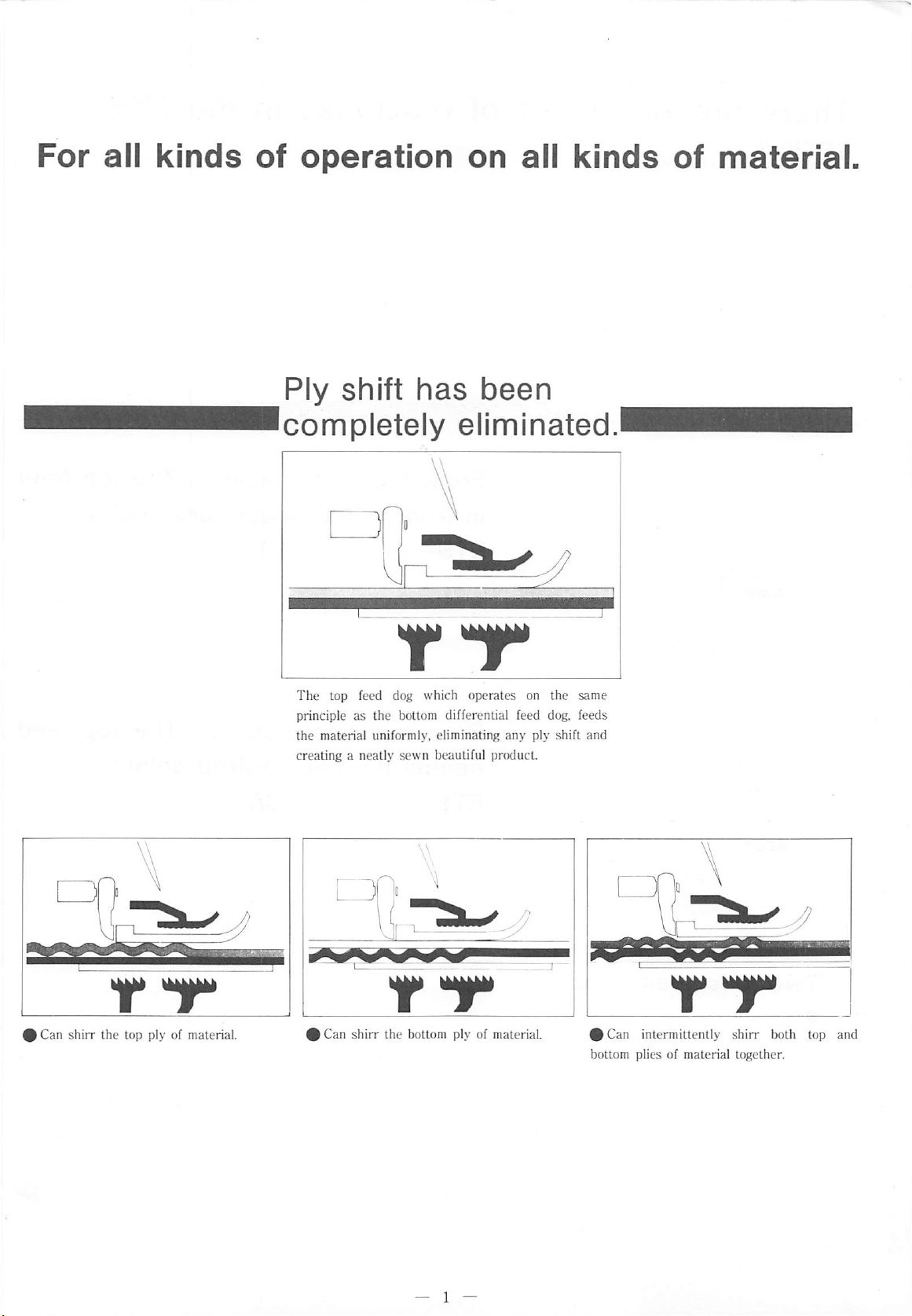

Ply

completely

shift

The

top

feed

dog

principle

the

creating a neatly

as

the

material

uniformly,

bottom

sewn

has

eliminated

which

differential

eliminating

beautiful

been

operates

feed

any

product.

on

ply

the

dog,

shift

same

feeds

and

I

Can

shirr

the

bottom

ply

of

I

Can

shirr

the

top

ply

of

material.

-

1

material.

-

0

Can

bottom

intermittently

plies

of

material

shirr

together.

both

top

and

Page 4

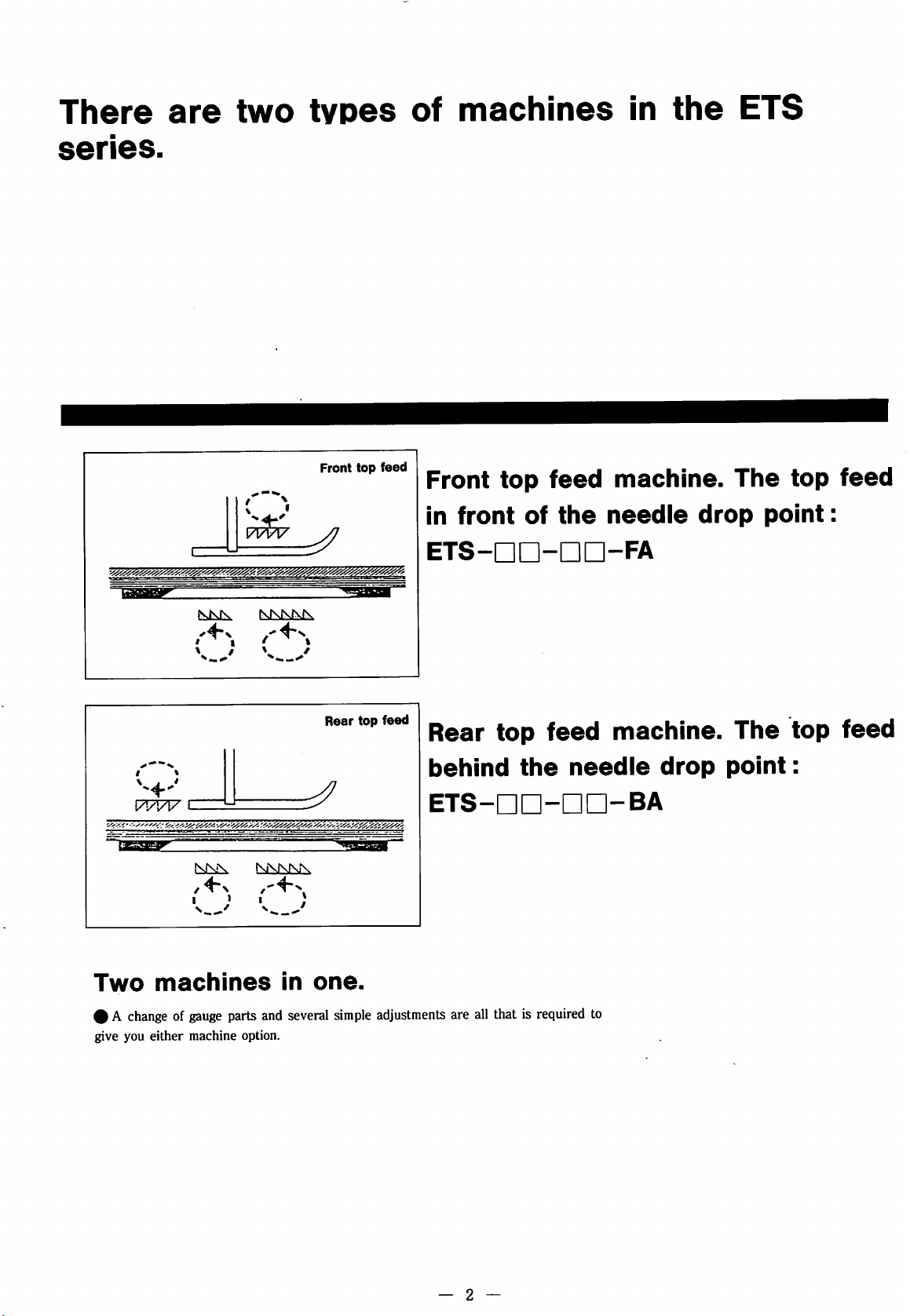

There

series.

are

two

types

Front

top

feed

of

machines

Front

In

top

front

of

ETS-nn-nn-FA

feed

the

needle

in

the

machine.

ETS

The

drop

top

feed

point:

FPW

Two

0 A change

give

machines

of

you

either

C

tVNN

/4-x

\,J

gauge

parts

machine

NNNJSN

^ >

In

and

option.

Rear

one.

several

simple

top

feed

Rear

behind

ETS-nn-DD-BA

adjustments

are

all

top

the

that

is

required

feed

needle

to

machine.

drop

The

point:

top

feed

—

2

—

Page 5

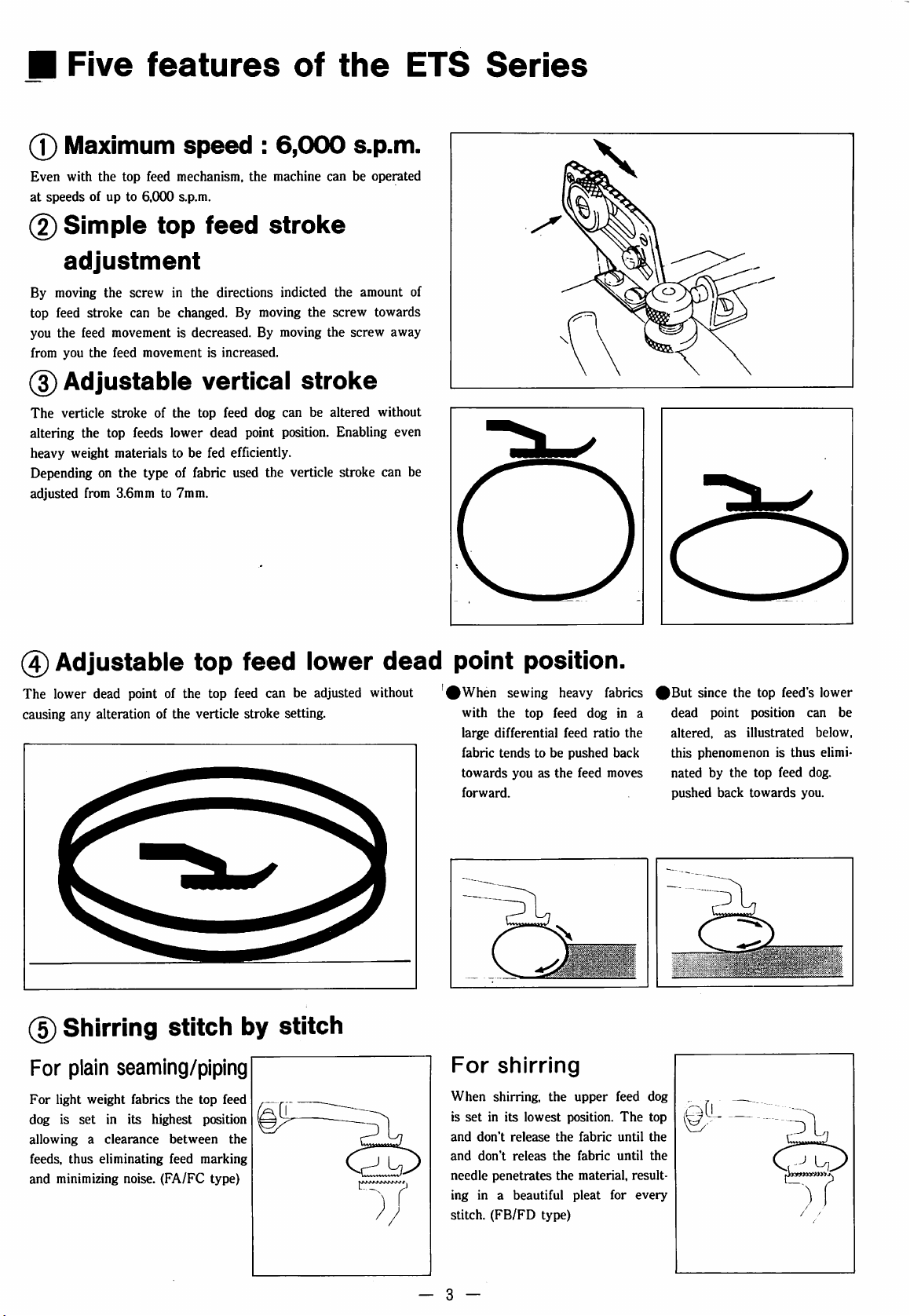

Five

0

Maximum

Even

with

the

top

at

speeds

of

up

to

(2)

Simple

adjustment

By

moving

top

feed

you

the

from

(3)

The

altering

heavy

Depending

adjusted

the

stroke

feed

movement

you

the

feed

Adjustable

verticle

stroke

the

top

weight

materials

on

from

3.6mm

the

features

speed

feed

mechanism,

6,000

s.p.m.

top

screw

can

movement

of

feeds

type

feed

in

the

directions

be

changed.

is

decreased.

is

increased.

vertical

the

top

feed

lower

dead

to

be

fed

efficiently.

of

fabric

to

7mm.

By

point

used

of

:

6,000

the

machine

stroke

indicted

moving

By

dog

the

moving

stroke

can

be

position.

the

verticle

the

s.p.m.

can

be

operated

the

amount

screw

towards

the

screw

altered

without

Enabling

stroke

can

ETS

of

away

even

be

Series

N

0

Adjustable

The

lower

dead

point

causing

any

alteration

Shirring

For

plain

seaming/piping

For

light

weight

fabrics

dog

is

set

in

its

allowing a clearance

feeds,

thus

eliminating

and

minimizing

noise.

top

of

the

top

of

the

verticle

stitch

the

top

feed

highest

between

feed

marking

(FA/FC

position

type)

feed

feed

can

stroke

setting.

by

stitch

the

lower

be

adjusted

dead

without

point

IWhen

with

large

fabric

towards

forward.

For

When

is

set

and

don't

and

needle

ing

stitch.

position.

sewing

the

top

differential

tends

to

you

shirring

shirring,

in

its

lowest

release

don't

releas

penetrates

in a beautiful

(FB/FD

heavy

feed

feed

be

as

the

the

position.

the

the

the

type)

fabrics

dog

in

ratio

pushed

back

feed

moves

upper

feed

The

fabric

until

fabric

until

material,

pleat

for

a

the

dog

top

the

the

result

every

>But

since

dead

point

altered,

this

phenomenon

nated

by

pushed

the

top

position

as

illustrated

the

top

back

towards

feed's

can

is

thus

feed

dog.

you.

lower

be

below,

elimi

3

-

Page 6

Presser

When

swinging

always

raise

1.

Pull

and

lift

2.

Press

and

the

Keeping

arm

out

When

reinserting

4

back

and

press

Keeping

back

to

the

the

into

this

this

the

the

needle

spring 4 in

the

lever

footlift

top

feed

dog 2 will

this

condition

to

the

left.

the

its

original

the

footlift

condition

original

Arm

presser

5.

treadle

presser

position.

arm

to

its

higest

the

arrowed

be

swing

arm

position.. Raise

treadle

swing

the

Swinging

in

or

out

position.

direction

or

lever

down

raised.

the

presser

push

spring

lever

5

or

lever

down.

presser

arm

-in

and

-out

(D

4

-

Page 7

-32-FA(for

plain

seaming)

These

basic

•

For

eliminating

Nylon

taffeta

coats

is

difficult

which

is

caused

ing

wear,

which

liable

to

uneven

However,

machines

•

Sleeve

such

clog

the

top

presser

problems.

•

In

or

patterns

little

can

thanks

which

perfect

there

will

For

cross

or

side

as

for

easily

in

variable

feed

dog

foot

For

matching

conventional

T-shirts,

by

at a time.

sew

the

to

eliminates

matching.

-52-FA(for

models

are

designed

ply

shift

as

used

in

jumpers

to

sew

due

to

by

slippery

has

feeding

is

no

eliminate

seaming

seam

layers

training

top

wear

front

of

feed

forces

these

effortlessly

patterns

pattern

the

operator

hand

and

Now,

garment

the

variable

ply

surfaces.

high

elasticity,

and

need

to

worry : these

all

such

problems.

of

heavy

or

bulky

the

presser

machine,

however,

layers

eliminating

matching

must

sew

the

however,

in

one

top

feed

shift

the

straight

and

for

general

or

rain

ply

shift

Train

is

also

ply

shift.

fabrics

sweaters

foot.

With

the

below

the

any

such

of

"blouses

match

the

materials

a

operator

run

machine

insures

plain

plain

seaming)

seaming

•

For

combining

When

fabrics

are

sewn

sweater

with

leather

the

top

and

individually

material,

properties

•

For

attaching

The

machine

operations

fabric

requires

while

sewing.

For

delicate

Feed

dogs

for

delicate

lawn,

and

marking.

•

Spin

tape

By

using

feed

dog

easily

be

•

For

ruffling

Attachment

permits

shirring.

operations.

different

of

different

together,

or

training

or

quilting,

bottom

feed

to

the

qualities

thus

allowing

to

be

sewn

sleeves

is

ideally

as

sleeve

extra

fabrics-

covered

other

the

even

sewn

with

materials

such

insertion

special

difficult

into

sweater

of a shirring

materials

elastic

for

example,

wear

is

partially

the

feed

dogs

can

be

of

each

fabrics

together

attachment,

fullness

rubber

such

materials

presser

to

of

uniformly.

suited

to

are

as

georgette,

liable

foot

sew

spin

seams.

attachment

properties

when

sewn

stroke

of

adjusted

ply

of

different

to

such

where

the

be

added

available

silk,

to

feed

and

top

tapes

can

alone

•

For

piping

A

This

type

Since

it

has a blade

only

on

the

Attaching

In

the

general

sewn.

If

the

body

and

the

the

hem

to

Because

feed

Up

of

machine

until

now

However,

First

the

bottom

The

operator

The

fabric

reguired,

with

expect

due

even

beautiful

-52-FB(for

is

used

for

adding

fullness

to

separate

upper

ply

but

also

the

bottom

hem

:

tuming-up

differential

bottom

be

folded

this,

ply-shift

is

recommended.

the

turning-up

now

by

hem

then

and

the

to

the

fullness.

sewn

method,

feed

stroke

hem

is

neatly

in

two, 3 plies

tends

method

using a variable

is

set

on

only

has

to

hem

plies

machines

The

operation

results

with

on

the

upper

on

the

lower

the

bottom

is

increased,

sewn

need

to

occur.

has

top

the

rollers

handle

the

are

sewn

variable

is

this

machine.

heavy

sweaters.

ply

from

ply.

hem

onto

the

(2

for

In

order

been

used

feed

machine,

and

guides,

body

fabric

together

top

and

so

simple

change

dog

the

is

then

body.

the

to

to

with

bottom

that

of

the

presser

permits

fabrics

overlapped

piping

lower,

adding

fullness

is

However,

hem

and 1 for

prevent

attach

the

and

while

exactly

even

such

circular

turning-down

the

performing

the

feeds.

The

an

—

(such

such

fullness

on

the

added

naturally

since

the

ply-shift a variable

hems

body

fabric

correct

finished

inexperianced

5

—

foot

and

as

double

piping).

as

sweaters)

is

available

fabric

body and

to

the

this

method

body)

to

be

to

the

fabric

method

the

is

is

placed

sewing

amount

garment

available.

operation.

of

operator

top

then,

fabric

requires

sewn.

body.

on

fullness

is

feed

not

top

top.

neat

can

Page 8

ETS-52-FC(for

This

model

is

•

For

decorative

Piping

is

frequently

polo

shirts,

and

colorful

T-shirts.

When

piping

to

slip

or

stretch

number

Especially

side

machine,

of

seams

however,

designed

sport

pipings

training

plies

sweatsuit

are

for

piping

accenting

used

as

shirts,

etc.

have

become

wear,

the

because

(including

prone

is

of

the

parts

to

equipped

Recently,

piping

where

ply

operations.

an

accent

on

pretty

popular

material

the

shift.

with a presser

on

tends

increased

tape).

the

long

This

piping)

foot

and

feed

performing

from

•

For

Attachment

dogs

training

piping

any

ply

double

of

permits

wear

shift.

dogs

specially

operations

piping

special

fashionable

etc.

presser

double

designed

perfectly,

foot

for

free

and

feed

piping

of

,_52-FD(For

ETS-32-FD

These

models

are

separate

materials.

bottom

The

a

Because

ing

can

worry

Intermittent

by

the

This

plies

can

ability

to

shirr

major

feature

the

operator

the

shirring

be

done

with

that

when

shirring

using a knee

upper

equiped

and

means

that

be

shirred

the

top

of

the

top

can

sew

process,

press

thus

more

confidence

shirring

is

also

operated

with a blade

lower

plies

the

top

independently.

ply

of

material

feed

machines.

while

watch

the

operation

and

the

bottom

easily

performed

intermittent

shirring

to

of

and

is

less

ply.

shirring

These

ing

covers,

device.

machines

the

pyjamas

operation)

are

ideally

suited

yokes

of

blouses,

and

aprons

shirring

etc.

for

attach

pillow

•

lA'

1

1

i

•

t/i) Y \

\ \

I

ETS

The

variable

far

have

all

Also

available

series,

i.e.

the

drop

point.

thick

woven

seam

crowding

machine

behind

preventing

This

which

the

machine

Series

top

feed

been

front

is

the

top

feed

On

jeans,

fabrics,

to

occur.

sews

presser

foot

this

shrinkage.

is

also

machines

top

ETS

is

behind

working

there

is a tendancy

The

while

pulling

is

very

suitable

(rear

described

feed

machines.

rear

top

the

wear

and

rear

top

the

effective

for

so

feed

needle

other

for

feed

fabric

for

piping

top

feed)

operations.

As

you

can

see

the

machine

applications ; general

fullness,

materials.

A

you

described

shirring

variety

own

particular

of

—

and

models

operation.

6

ETS

variable

so

far

plain

piping

are

available

—

top

have

seaming,

on

all

types

feed

many

adding

of

to

suit

Page 9

INTRODUCTION

TO

SUBCLASSES

1-needle,

Operation

Seaming

Piping

\

Blind-

hemming

■

2-needle,

Seaming

front

Medium

Heavy

front

Medium

Heavy

top

Needle

gauge

top

feed

Seam

width

feed

2

3/4/5

ETS52

4/5

5

4

ETS52

Top

feed

2-row

3-row

2-row

3-row

2-row

3-row

2-row

3-row

2-row

type

Bottom

feed

3-row

3-row

3-row

3-row

type

top

feed

6

6.5

7

7

7

7

Lift

foot

5.5

7

6

5.5

5.5

7

Subclasses

ETS52-

ETS52-

ETS52-21

ETS52-

350FC2o'

in

Drdering

130FA3

141FA2

141FA3

/504-453W

Pa

0FE2/505-323N

133FA2

133FA3

142FA2

142FA3

/504-363N

/504-463W

/514-363N

514-463N

For

sweaters

\

Backiatching

Piping

Gathering

Gathering

/piping

Rear

top

Heavy

Heavy

Medium

Heavy

Medium

feed

\

ETS52

2

3/4/5

3

4/5

2

4/5

2

2

2

4

3/4/5

3/4/5

3-row

3-row

3-row

3-row

3-row

2-row

3-row

2-row

3-row

2-row

3-row

2-row

3-row

3-row

4-row

2-row

3-row

3-row

3-row

3-row

I42FB2I2

7

ETS52-

7

252FB4I2

184FB2/514-443N

7

6

5.5

7

5.5

7

ETS52-

ETS52-

ETS52-

ETS52-

184FB4/514-463N

351FC2gJ

351FC3^J

352FC2^J

352FC3^J

243FD2

243FD3

245FD2

245FD3

243FD4^!/514-463W

7

7

7

7

7

7

/514-463W

/514-493W

/514-453W

/514-353W

/514-463W

/514-363W

P2

ite

Piping

1

m

2

1

2 2

4/5

7.5

2

4/5

5

7.5

4/5

-

7

7

7

141BA2/504-463W

ETS52-

142BA2/514-463W

350BC2p2/504-465W

ETS52-

351BC2p2/514-453W

Page 10

Front

top

feed

ETS32

Operation

Seaming

Piping

Gathering

Heavy

Medium

Heavy

Medium

Heavy

Medium

Needle

gauge

3

3

5

3

3

5

3

5

3

5

Seam

width

3/4/5

3/4/5

5/6

3/4/5

3/4/5

5/6

4/6

5/6

3/4/5

5/6

Top

feed

3-row

2-row

3-row

2-row

3-row

2-row

3-row

2-row

3-row

2-row

3-row

2

3-row

2-row

3-row

2-row

3-row

2-row

3-row

2-row

type

50

Bottom

feed

2-row,

narrow

2-row,

wide

3-row,

narrow

2-row,

narrow

2-row,

wide

3-row,

narrow

3-row,

narrow

3-row,

narrow

type

Lift

top

feed

7 7

6.5

7

6

6.5

foot

5.5

6

5.5

6.5

5.5

Subclasses

when

ordering

!

i

420FA2

/516-413

420FA3

430FA2

/516-433

430FA3

432FA2

/516-453

432FA3

C1OOZ"

422FA2

/516-313

422FA3

434FA2

434FA3

433FA2

516-333

/516-353

433FA3

432FC2

432FC3

C 1 OwZ"*

433FC2

433FC3

542FD2

P1

P2

P1

P2

P1

P2

P1

P2

/516-453

/516-353

/516-453

542FD3

C 1 oOZ*

544FD2

/516-353

544FD3

Gathering

/piping

Rear

Seaming

For

top

jeans

Piping

feed

5

ETS32

5

3

5

3

3

5

3/4/5

3-row

5/6

5/6

3/4

5/6

3/4

3/4

5/6

3-row,

narrow

2-row,

wide

3-row,

narrow

2-row,

wide

3-row,

narrow

3-row,

narrow

8

6.5

7.5

7.5

7.5

-

6.5

7

7

7

3

ETS32-542FD4p2/516-453

430BA2/516-433

C1OOZ*

432BA2/51

452BA2/516-433

LL I OOZ-

453BA2/516-453

ETS32-432BCp2/51

6-453

6-453

Page 11

(1)

for

and

The

that

Top

machines

piping

(PC)

there

is a clearance

the

bottom

feed

for

plain

seaming

operations

feed

are

between

dogs.

height

(FA)

and

adjusted

the

so

top

adjustment

(4)

The

dog

maximum

and

throat

height

plate

is

between

4mm.

top

feed

(5)

The

adjusted

described.

feed

operation

this

the

machine.

height

of

the

by

repositioning

The

vertical

dog

is

set

according

and

the

adjustment

type

is

top

feed

the

stroke

to

of

material

easily

is

top

of

the

made

easily

feed

as

the

top

sewing

used,

inside

(2)

The

is

height

the

(3)

Loosen

feed

and

together

fullness.

vertical

adjusted

between

throat

plate

set

dog

in

bottom

for

stroke

of

the

to

4.5mm.

the

is

screw 1 and

the

feed

ruffling

top

6mm.

lowest

dogs,

(FD)

The

position ; the

top

maximum

feed

4.^111

place

should

or

for

feed

dog

and

6n,m

the

mesh

adding

dog

Adjustment

top

(For

stroke

(1)

top

top

Shirring

when

the

vertical

feed

dog

is

4.5mm

(standard).

the

adjustment

movement,

Loosen

dog

in

its'

screw 1 and

method

refer

lowest

position.

to

page

place

adjustments

(3)

stroke

of

the

10.)

the

of

the

vertical

top

feed

Turn

top

feed

(For

page

10.)

the

pulley

dog

the

adjustment

(FD)

and

7/?Y/////////////////)/A

(4)

Turn

pulley

and

bottom

feed

dogs

needle

point

reaches

If

the

top

feed

specified,

feed

top

dog

feed

check

and/or

dog

(3.5mm).

and

set

needle

check

are

the

dog

the

height

reduce

the

height

plate

to

method,

that

the

engaged

needle

rises

earlier

of

the

the

height

between

3.5mm.

refer

V

;)mm

top

and

until

the

plate.

than

bottom

of

the

to

(2)

Adjust

top

feed

dog

-

pressure

9

to

25mm.

—

Page 12

Adjustment

of

the

top

(5)

Position

needle

Set

according

required.

For

small

between

point : for

distance.

the

drop

the

blade

point.

to

the

pleats,

reduce

blade

and

large

pleats,

l-3mm

sewing

the

increase

from

conditions

the

distance

needle

drop

0

(iHr-1

the

the

-

LO

I

Front

CO

Dim.

®

OfTim

2

4

5.5

6.5

feed

OL

top

feed

Top

CD

feed

3.6mni

5.5

6.5

7

vertical

Loosen

screw 1 and

increase

A

If

using

(Example)

the

vertical

to

decrease.

distance A is

distance

When

2mm

for

ETS

top

B

is

adjusted

CD

feed

the

stroke

increase

stroke : reduce

difficult

B.

distance A is

OL

OL

OL

52,

the

dog

is

4.5mm ; when

to

6.5mm,

ETS52

■

lift

Dim.

8.5mni

6.5

3

2

d)

Standard

FA

FB

distance A to

to

measure,

adjusted

vertical

it

FC

is

4.5mm.

setting

FD

stroke

distance

adjust

to

of

distance

Remarks

(6)

and

the

Adjust

the

material.

the

pressures

torsion

of

spring

the

presser

2,

according

foot

to

■ETS32

0

1.5

5

6

■

Rear

0

2

4

5.5 5.2

top

8.5

3.8

5.5

6.5 3.5

7

feed

ETS32/ETS52

3

3.7

7

8.5

7

5

2.5

8.5

3

0

FA

All

FC

models

FA

—

10

Page 13

The

For

(FC)

plain

operations.

D

feed

dog

seaming(FA)

lower

and

piping

dead

(1)

(2)

O.Smm

(3)

point

Adjust

the

vertical

specified

(For

Tum

position.

vertical

set

C,

any

Note:

After

piping(FC)

lowest

Set

approximately

or

desired

adjustment,

pulley

and

Then,

stroke

screw

1.

Firmly

and

tighten

free

play

in

The

height

than

the

be

reduced

making

this

machines,

position.

the

clearance

dimension

screw 1 securely.

vertical

0.3mm.

adjustment

stroke

of

the

top

feed

dimension.

refer

page

10)

move

the

top

feed

dog

to

insert a gauge

move

the

top

must

stroke

by

spring

adjustment

when

between

1.5mm

between

latch A in

feed

shaft

be

set

approx.

dimension,

pressure

on

the

top

the

top

larger

feed

dogs

directions B and

Check

that

D.

1.5mm

because

after

plain

seaming(FA)

feed

and

bottom

dog

to

the

its

highest

than

the

and

loosen

there

isn't

greater

it

will

adjustment.

or

dog

is

in

its

feeds

to

For

shirring

operations.

(4)

For

shirring(FD

smaller

the

top

described

be

fully

needle

than

the

and

bottom

in

(1).

engaged

plate.

(Refer

type)

vertical

feeds

The

top

until

to

(4)

machines

the

stroke

and

complete

and

bottom

needle

on

page

insert a gauge

dimension

the

feed

dogs

point

reaches

9.)

1mm

between

operations

should

the

—

11

—

Page 14

STANDARD

DIMENSIONS

ON

ADJUSTMENTS

Top

Model

feed.

ETS32-FA

ETS52-FA

Vertical

Adjusting

manner

f?

Setting

dimension

1.5i

2.0

stroke-Top

Needle

Vertical

stroke

4.5i

Needle

feed

plate

Top

(upper

plate

height'Vertical

feed

height

dead

position)

position

Vertical

top

Needle

relationship

feed

plate

—

+1.5mm

and

4.5inm

between

needle

plate

ESS52-FB

ETS32-FC

ETS52-FC

ETS32-FD

ETS52-FD

1.5

2.0

1.5

2.0

5.5

4.5

4.5

Needle

Needle

Needle

plate

plate

plate

5.5mm

3.5mm

y////////A

Needle

Needle

plate

-

+

1.;1

Needle'

plate

-

1mm

5.5mm

4.5mm

4.5mra

ETS32

ETS52-

BA

BO

BA

BO

8.5

7.0

Needle

12

plate

7.0mm

7.0mm

Needle

plate

0

Page 15

Adjustment

of

top

feed

;k

dog

and

qn

presser

foot

(1(

Engage

back

horizontal

(2)

Insert

3.

(3)

Adjust

and

(4)

Adjust

0mm

the

feeds

and

forth

stroke.

l-l,5mm

the

gap

tighten

screw 7 securely.

the

gap

and

tighten

together

set

them

gauge

between

between

between

screw

10

and

turning

to

the

foot

lever 4 and

lever 8 and

securely.

the

pulley

center

lever 2 and

of

plate 5 to

flat

spring 9 to

0mm

their

pin

Differential

ratio

1 :

1 :

o

0

_

c

lo

o

alteration.

0.7—1 : 2

Q

@

1.1—1 ; 3.8

(5)

Remove

Loosen

position

(6)

Loosen

position,

washer,

rear

nut

3.

and

tighten

nut

while

and

tighten

bed

cover

set

eccentric

nut 3 securely.

3,

set

eccentric

paying

nut 3 securely.

plate.

pin

1,

pin 1 to

attention

to

to

the

the

direction

extreme

the

lowest

of

top

the

Ql

—

13

—

Page 16

Top

Feed

Dog

(1)Remove

(2)Set

Set

the

the

the

cover A from

stitch

length

top

feed

maximum(rearmost

(3)

Set

the

position

it

does

not

touch

the

presser

turned,

foot

loosen

screw 4 to

the

rear

to

maximum.

differential

lever 2 to

position)

of

the

top

feed

the

front

or

the

slots

when

the

adjust.

of

the

dog

so

rear

pulley

is

bed.

that

or

SQi

Pd

Catalog

No.

102280

Printed

Oct.

1989

030K.

Loading...

Loading...