Page 1

PEGASUS

INSTRUCTION

FOR

MODEL

DCP-101

DCP-101W

HIGH

COMPLETELY

LUBRICATION

DIFFERENTIAL

SPEED

AUTOMATIC

FE|^„„„^^

DCP>t03

OVERLOOK^

STITCH

rTr

MACHINES

jCP

NO.

p

a

.

d

^

r.p

DCP-105

OATEf"^.

'

*'

DCP-109

F>

OBOEB

MIMA

SEWING

OSAKA

MACHINE

TOKYO

JAPAN

CO.,

Model

LTD

DCP-101

Page 2

ORGANIZATION

CHART:

DCP-101W

DCP-103

DCP-105

DCP-109

FEATURES:

4,500

stitches

Completely

Differential

Totally

enclosed

Independent

Single

main

Simplified

Uniform

Effortless,

(Suge?

1

per

minute

automatic

feeding

mechanism

drive

crankshaft

threading

stitches

at

quiet

operation

Number

of

1

lubrication

system

system

of

in

one

all

speeds

3

right

piece

Type

of

Presser

Hinged

Hinged

Solid

mechanism

and

left

loopers

Seam

Width

4-6

Attachment

8-18

8-18

9-16

Welting

guide

Edge

guide

Edge

guide

Edge

guide

Edge

guide

SPECIFICATIONS;

Continuous

Stitch

Seam

Lift

Needle

Type

Presser

Installation : Flush

Rating : 4,200

Range

Width

Clearance

of

under

Type & Size : DC x 1

~ "

Feed

Foot

Remarks

Plain

overedging,

hemming

General

Serging

Double

on

Double

on

stitches

:

8-18

stitches

by

wrench

:

2mm(0.08")-4mm(0.16")

presser

foot

:

4mm

(0.16")

(81 x 1)

#9

#13 & #14

:

Differential

:

Solid

or

Hinged

(Non-submerged)

plain

on

needle

knitted

needle

woven

per

per

available

and

woven

fabrics

fabrics

minute

inch

welting

overedging

fabrics

seaming

seaming

adjustable

CAUTION!

Machine,

cause

weeks

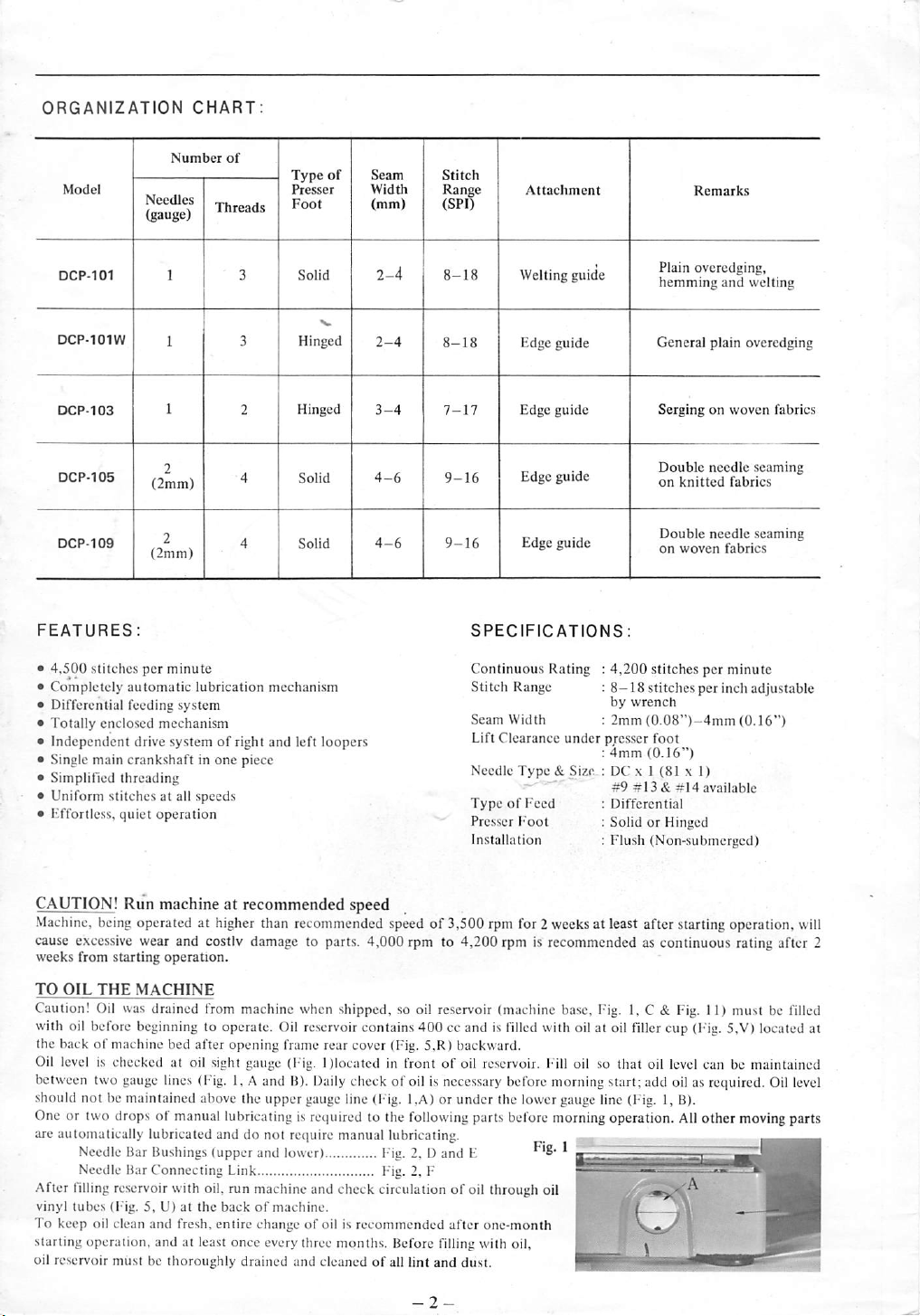

TO

OIL

Caution!

with

oil

the

back

Oil

level

between

should

One

or

are

automatically

After filling

vinyl

To

keep

starting

oil

re.servoir

Run

being

operated

excessive

from

not

two

wear

starting

THE

MACHINE

Oil

was

before

beginning

of

machine

is

checked

two

gauge

be

maintained

drops

drained

lubricated

Needle

Bar

Bushings

Needle

Bar

Connecting

reservoir

lubes

(Fig.

5,

oil

clean

and

operation,

must

be

machine

operation.

and

at

at

higher

costiv

from

to

operate.

bed

after

at

oil

sight

lines

(Fig.

above

of

manual

lubricating

and

(upper

with

oil.

U)

at

the

back

fresh,

entire

and

at

least

thoroughly

recommended

than

recommended

damage

machine

opening

gauge

1, A and

the

do

Link

run

once

drained

to

when

Oil

reservoir

frame

(Fig.

B).

Daily

upper

gauge

is

required

not

rctiuire

and

lower)

machine

of

change

and

machine.

of

oil

every

three

and

cleaned

speed

speed

parts.

4,000

rpm

shipped,

rear

Dlocatcd

manual

check

is

months.

so

contains

cover

check

line

oil

400

(Fig.

in

front

of

oil

(Fig. 1 ,A)

to

the

following

lubricating.

Fig.

2. D and

I-'ig.

2,

circulation

recommended

Before

of

all

lint

of

3,500

to

4,200

reservoir

cc

and

5.R)

backward.

of

oil

reservoir.

is

necessary

or

under

parts

E

F

of

oil

after

one-month

filling

with

and

dust.

rpm

for 2 weeks

rpm

is

recommended

(machine

is filled

with

Fill

before

the

lower

before

through

oil

oil,

at

least

base.

Fig,

oil

at

oil filler

oil

so

morning

morning

gauge

line

start;

operation.

p'-

after

as

1, C &

that

oil

add

(Fig.

|

starting

operation,

continuous

Fig.

cup

level

oil

1,

B).

Ail

rating

11)

must

(F'ig.

5,V)

can

be

as

required.

other

moving

-jV

will

after

2

be filled

located

at

maintained

Oil

level

parts

Page 3

thread

needle

thread

for

left

looper

(DCP-IOIW,

105.

109)

TWO-NEEDLE

for

right

needle

bar

103

THREADING

•.uroad

for

for

Model

DCP-105 & 10 9 only

tension

needle

thread

(DCP-101.

bar

THREADING

for

needle

103,

only)

DIAGRAM

thread

(DCP-101.

for

right

105.

109

looper

only)

tension

right

looper

needle

spreader

(DCP-lW)

I thread

tension

eyelet

DCP-109

for

DCP-109

extension

only

only

holder

tension

left

looper

-6-

take-up

07723T15

Page 4

NEEDLE

Needles

type

Each

size

should

weight

Generally

weight

heavy

example

'TOO

Thread

eyes.

difficulty,

thread

TO

Turn

its

loosen

withdraw

Insert

the

nut

The

with

loosening

TO

LOOPERS

Threadings

DIAGRAM

to

the

unpacked

comes

Caution!

needle

TO

(Sec

The

by

threads

In

obtained

loosening

TO

FOOT

Pressure

thumb

clockwise

(W)

may

TO

Loosen

plate

proper

and

simultaneously

upper

screw

left

when

(K)

&

THREAD

for

DCP-lOO

DC X 1

(81 x 1),

needle

has

number

CHANGE

highest

front.

(G).

needle

THREAD

is

be

determined

of

material.

speaking

material,

weight

will

be

Needles

to

be

To

use

rough

will

breakage.

balance

wheel

position.

needle

needle.

needle

in

Holding

for

screw.

Inserting

or

tightening

stamped

material.

an

Type

used

interfere

THE

clamp

needle

DCP-105

(Sec

for

DCP-lOO

in

and

out

through

Draw

and

looper

2, 3 &

of

tension

should

for

by

page

thread

immediately

mounted,

about

tension

nut

be

DCP-lOO

tightening

tie a fresh

machine

REGULATE

1-ig.

amount

each

general

looper

REGULATE

(Sec

Fig.

of

presser

nut

(Fig.

or

downward.

anticlockwise

spoil

material.

REGULATE

thumb

(L)

to

left.

scam

width

left

slightly

as

is

and

of

knife

cover

with

required

move

knife

(M)

edge

upper

securely.

series

are

and

available

both a type

on

by

the

needle

size

of a size

#11

for

When

intelligible

DC x 1

Size

must

pass

or

uneven

with

NEEDLE

in

operating

With

nut

(Fig. 2 or

bar

as

it

THE

Page

6.

needle

eyes,

THE

4)

(Fig.

only

thread

3)

3.

W).

or

THE

screw

Loosen

is

screw

extension

is

far

in

position,

and

or

withdrawing

screw

NEEDLE.

6)

series

However,

with

the

and

and

two

inches

with

which

THREAD

on

needle

2,

H,

enougn

series

needle

tension

THE

PRESSURE

foot

on

To

increase

To

upward.

SEAM

(Fig.

screw

obtained.

(N)

lower

knife,

when

cover

extension

at

its

lowest

of

chrome

sizes

number

and a size

needle

shank.

size

of

thread

#9

is

No.

11"

through

or

stitch

recommended

and

needles,

thread

medium

ordering

order.

freely

thread,

proper

(Sec I ig. 2 or

direction

wrench,

as

3,

it

will

furnished

G)

go,

securely

109,

2-needle

needles

with

screw

driver.

RIGHT & LEFT

are

shown

the

simplest

end

of a thread

after

the

delivered

draw a thread

looper

eye.

(50mm)

to

start

TENSION

and

looper

Fig.

3,1

secure

proper

and

proper

stitch

to

tension

nuts

(Fig.

3,1

material

decrea.sc

Too

is

regulated

pressure,

pressure,

much

pressure

WIDTH

4,

K),

and

(M)

and

Lower

knife

is

turned,

and

so

no

seam

(P)

lateral

width

holder

slightly

position.

plated,

straight

are

9,

11,

number,

The

size

and

thickness

#14

for

the

or

'TOO

DC x 1

needle

which

formation

3)

until

needle

with

about

1/4

with

long

tighten

needle

machine,

is

simply

in

the

THREADING

way

of

originally

machine

until a fresh

of

thread

sewing.

threads

Fig.

4,

J).

stitch

formation

nut

(Fig.

and

Fig.

OF

PRESSER

by

turn

thumb

turn

on

presser

(Sec I ig

turn

Tighten

4)

swing

screw

will

move

upper

knife

adjustment

is

changed.

(O)

to

touches

upper

thumb

blade,

14

and

16.

and

a

of

needle

or

for

light

medium

following

#11"

and

looper

passes

with

or

cause

bar

is

at

machine,

turn

and

groove

to

clamp

is

clamped

made

by

threading

is

Tension

is

passed

in

is

thread

through

regulated

on

tormation.

will

be

2,

H)

and

4,

J).

means

of

nut

(W)

thumb

nut

foot

out

cloth

(N)

until

to right

will

move

on

Tighten

left

so

that

knife

screw

Q—-

I-"

H

%

V

Page 5

TO

REGULATE

In

general

produced

degree

and

To

regulate

(back)

is

out

frame

with

wrench,

upward

downward

main

changed.

To

To

move

amount

feeding

TO

In

move

plate

withdrawn

Cutting

surface

after

flush

avoided.

will

feeding

regulate

move

screw

of

ratio

CHANGE

preparation

cover

to

left.

edge

as

lower

of

lower

THE

main

feeding

and

differential

direction

main

positioned

rear

will

screw

downward.

shown

knife

of

stretch

feeding,

as

cover

(Fig.

furnished

increase

decrease

will

change

differential

(T)

upward

(T)

downward

main

feeding

is

changed.

THE

LOWER

for

removing

extension

Loosen

thumb

flush

of

lower

in

Fig.

is

set

knife

above

STITCH

determines

feeding

turn

close

with

stitch

stitch

slightly

feeding,

of

material

balance

to

5,

R)

machine.

length

length.

loosen

will

shrink

will

stretch

will

change

LENGTH

ratio

the

backward.

as

KNIFE

lower

knife,

holder

(0)

to

screw

(Q)

knife

must

7.

Be

sure

correctly.

or

Caution!

below

to

needle

(See

number

is

selected

to

wheel

front

To

and

to

Note

differential

screw

material

material.

slightly

(See

loosen

right

and

and

be

set

tighten

plate

Fig.

of

stitches

in

be

sewn.

until

main

as

possible.

Loosen

move

move

that

the

feeding

(T)

with

to

be

Note

as

Fig. 4 &

screw

swing

lower

knife

with

needle

thumb

To

set

cutting

surface

relation

amount

differential

5)

to

feed

Swing

screw

screw

screw

ratio

wrench.

sown.To

that

7)

(K)

and

out

cloth

will

plate

screw

(Q)

edge

must

be

to

dog

(S)

(S)

(S)

of

is

the

be

be

m-r-mm'

TO

CHANGE

To

remove

knife

upward.

knife

holder

cutting

edge

upper

knife

extend,

below

Tighten

TO

at

front

screw

SHARPEN

Dull

knives

grinder

sharp

is

shown

edge

rounded

in

in

THE

UPPER

upper

knife,

Upper

knife

(X)

with fingers

is

positioned

correctly,

its

cutting

(W)

should

front

bottom

edge

securely.

THE

UPPER & LOWER

immediately

accordance

Fig. 8 Note

is

required.

off

or

Upper

without

loosen

is

to

cutting

of

stroke,

of

with

the

sharp

KNIFE

screw

spring

pressed,

to

right,

in.scrt

the

right

edge

not

lower

knife,

be

replaced.

the

dimensional

part

of a double

or

lower

edge

should

(See

(W)

and

of

of

less

knife

Fig. 6 &

withdraw

so

pushing

upper

knife

lower

knife.

upper

knife

than

0.5mm-lmm

as

shown

KNIVES

Sharpen

knives

requirement

circle

whose

cutting

not

be

used.

7)

upper

upper

until

To

should

in

Fig.

(See

Fig.

where

edge

its

set

7.

8)

with

as

upper

knife

i

needle

surface

plate

Page 6

TO

SET

THE

Welt

guide

blindstitch

To

bottom

the

of

plate.

left.

securely.

Fig. 4 (Z)

needle

shown

welting

install

welt

of

welt

same

time,

needle

plate,

Turn

screw

After

welt

shows

plate.

WELT

GUIDE

in

Fig. 9 enables

operation

guide,

set

guide

holder

setting

groove

loosely

(d),

and

guide

is

the

Welt

(See

only

for

tubular

the

projected

into

groove

(b)

of

tighten

welt

correctly

screw

screw

guide

positioned,

Guide

completely

will

Fig. 4 &

model

work.

part

of

to

(c)

move

9)

DCP-101

(Fig.

9,

needle

plate

engage

with

from

under

slightly

tighten

installed

to

a)

at

the

and

groove

needle

right

and

screw

(c)

on

the

do

at

TO

SET

THE

Edge

guide

material

machine

This

model

of

needle

and

to

be

determined.

TO

(See

The

four

furnished

fi

xed.

groove

base

wood

Fig.

unwinder,

top

are

MOTOR

200W

clutch

rpm

DCP-lOO

When

PULLEY

following

shown

to

be

is

operated

edge

guide

DCP-101.

plate

move

edge

trimmed

Tighten

INSTALL

Fig.

11 & 12)

machine

(base-oil

machine

with

Be

sure

of

cushion

before

setting

screw.

12

shows

furnished

and

pressed

non-submcrgedly

PULLEY

output

motor,

on

50

cycles,

series

only a machine

must

List.

EDGE

GUIDE

in

Fig.

10,

trimmed

without

is

furnished

To

install

and

tighten

guide

(g)

or

seam

screw

THE

is

or

designed

trimmer.

edge

screw

right

and

width

when

(0

securely.

MACHINE

reservoir,

base

set

hooks

machine,

to

the

steel

(1/4

approximately

machines.

be

after

set

correctly a machine

rubber

installed

the

other

typical

installation

with

machine,

stand.

Note

installed

HP)

or

250W

(direct

3,400

is

recommended

head

prepared

is

by

(See

Fig.

10)

designed

with

(Fig.

the

side

to

regulate

for

edge

all

DCP-lOO

guide,

set

screw

(e)

securely.

left

until

operated

ON

iMg.

11)

11,

location

on

(Fig.

and

that

mounting

(1/3

rpm on

for

bought, a clutch

you

Loosen

the

width

without

THE

TABLE

must

Y)

and

on

base

set

the

bottom

11,

Y)

of

machine

clutch

motor

in

general

on

HP), 2 pole,

60

efficient

in

accordance

the

width

guide

when

series

(e)

into

screw

of

material

trimmer,

be

installed

wood

the

table

hook

with

of

machine

of

hook

head,

with

DCP-lOO

table

top).

individual

cycles

or

operation

motor

with

of

the

except

groove

(0

is

TOP

with

screws,

top

is

the

with

thread

table

series

2,850

of

and

its

the

C

d b

^

- -

—

-

J

H

Fig.

12

Gutch

Motor

Machine

3,500

3,500

4,200

4,200

Speed

rpm

rpm

rpm

rpm

Motor

Pulley

(Effective

dia.)

Motor

3,400

2,850

3,400

2,850

Speed

rpm

rpm

rpm

rpm

Loading...

Loading...