Page 1

TAPE

CUTTER

FOR

THE

NEW

WILLCOX

&

GIBBS

TK

500

SERIES

SERIES

WILLCOX

GJII3E33JflC.

Page 2

Page 3

TABLE

C0NhihINlr5

OF

Page

I

ASSII’IC.NI

l?[IP.LAOENEN11OF

sis/iv,

505/IV,

500/V

PREPAEAq

1

I0N

515/IV,

503/TV,

soo/v with

INSTALLATION

515/TV,

503/TV,

500/v

INSTALLATTON

ECA—300/01 ECA—300/02

ACA—l00/10

PARTS

LTST

TKIJ—520

ECA—300/01

ACA—100/10

[ON

with

OP

with

OP

TK

MACHINE

510/TV

504/TV,

TKR—550

MACHINE

sio/iv

504/Tv,

TKR—550

TAPE

OF

510/TV

504/Tv,

TKR—530

OP

DRTVING

TKU—520

ECA—300/02

TAPE

PARTS

with

514/fl!

AND

with

514/Tv

CUTTER

with

514/Tv

UNIT

TKR—550

CUTTE

rp(1J_520

T}CU—520

TKU—520

ES

.

with

PARTS

with

with

TK1J—520

TKtJ—520

TICfJ—520

•

1

2

2

2

2

5

5

3

3

4—5

4

5

5

6—7

6

7

8—13

8—9

10—11

12—13

*

TK

Tape

on

fabrics

*

*

used

with

ACA—lOO/lO.

Your

operation

I

TK

Tape

Cutter

its

Cutter

sewn,

own

CLSTFICATI0N

Tape

model

surplus

cuts

perfect

driving

ECA—300/0l

ACA—l00/lO

choose:

may

(ECA—500/o2)

H

cutter

TKU—320

TKU—520

TKR—530

tape

cut

with

unit

(ECA—500/02)

ECA—soo/ol

Machine

515/Tv.

503/Tv.

All

as

model

OF

TK

500/v

well

slight

ECA—300/0l

I

1

TAPE

model

516/Tv

504/Tv.

as

touch

=

=

To

medium—heavy

as

CUTTERS

surplus

on

Electric

Pneumatic

surplus

cut

surplus

(ECA—300/02)

514/Tv

thread

switch.

Solenoid

Type

tape

thread

light

chain

as

chain.

left

or

Type

to

well

I

cut

TK

Tape

Cutter

ACA—lOO/lO

To

I

as

j

chain.

1

well

surplus

as

surplus

heavy

tape

thread

Page 4

I?l

PtA

CNN

lINt

kepi

ace

par

ic

ted

in

NodlIjed

or

reworked

515/IV,

5l/IV

New

pgrt.

number

303019

323—802—007

303130

323—550—025

303014

325—500—014

0.1’

MACI

to

jo

tiLe

the

cci

iunii

artu

can

no

opeciCied

with

Nxis

part

204215

ting

number

525—802—210

204l77B

323—550—016

204850

325—500—004

TiN

N

PACTS

maclime

ol

be

ordered

TXU—320

Foot

Machine

with

‘New

part

by

in

the

Description

c

th

0

pae

lift

those

number’

number

illustration.

1

t

lever

arm

/

tleft)

Fig.

no.

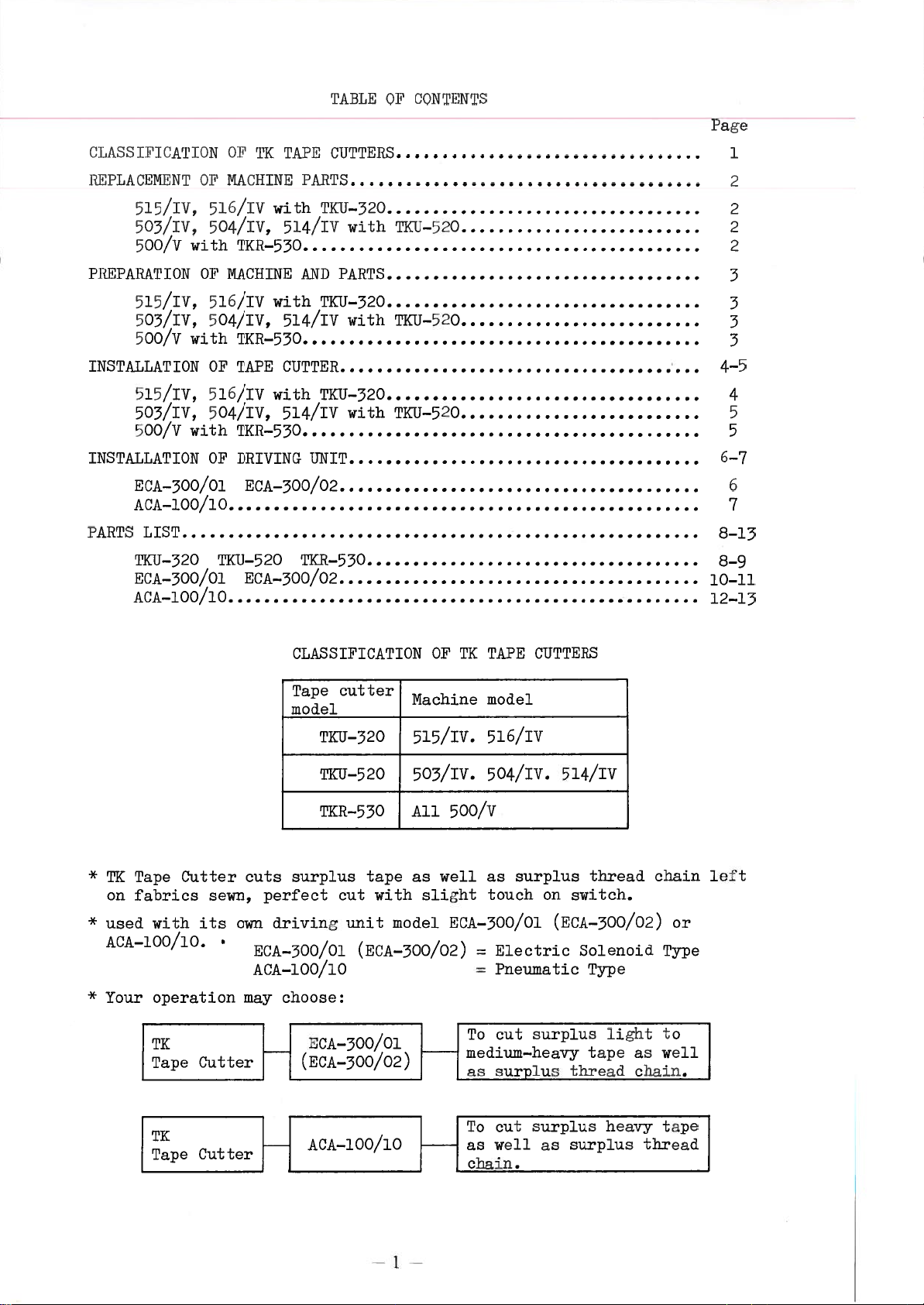

Cut

the

for

slashed

modification

portion

x

2

3

503/IV,

504/IV,

New

number

phrt

303066

325—802—008

303127

3

.Sr8O2—OO9

303014

323—500—014

303130

323—530—025

See

chart

500/V

with

New

part

number

300066

3?3—802—OlO

300014

323—500—015

300017

323—510—072

See

chart

Existing

part

204798

325—802—003

204740

323—802—002

204850

323—500—004

2041773

323—530—016

below

TKR—530

Existing

part

2011810

323—802—001

2026023

323—500—009

202934

323—510—017

below

514/IV

number

number

with

T}—520

Description

Cloth

Cloth

(narrow)

Machine

Foot

lift

Needle

Description

Cloth

Machine

Feed

mechanism

cover

Needle

plate

plate

plate

plate

Plate

arm

arm

lever

(left)

(wide)

(left)

Fig.

no.

Fig.

no.

Fig.2

x

X

3

2

1

x

x

x

1

7Q

New

J

part

number

300070

f

L323—sol—o92

300071

I

323—801—093

300072

2

—801—094

Existing

part

number

202499E

323—801—031

202542E

323—801—026

202546E

323—801—027

New

part

number

300073

323—801—095

300074

33—801—096

300075

323—801—097

I

Existing

part

number

202554E

323—801—030

202596E

323—801—028

202597E

323—801—029

more

—

INew

part

300076

323—801—098

300077

23—801—099

300078

323—801—100

continued

number

Existing

part

number

202616

323—801—038

202617

323—801—039

202618

323—801—222

to

page

3.

Page 5

PkI

ACA.PTON

0i

MACI

[[N

N

ANPPAi?’1

1

S

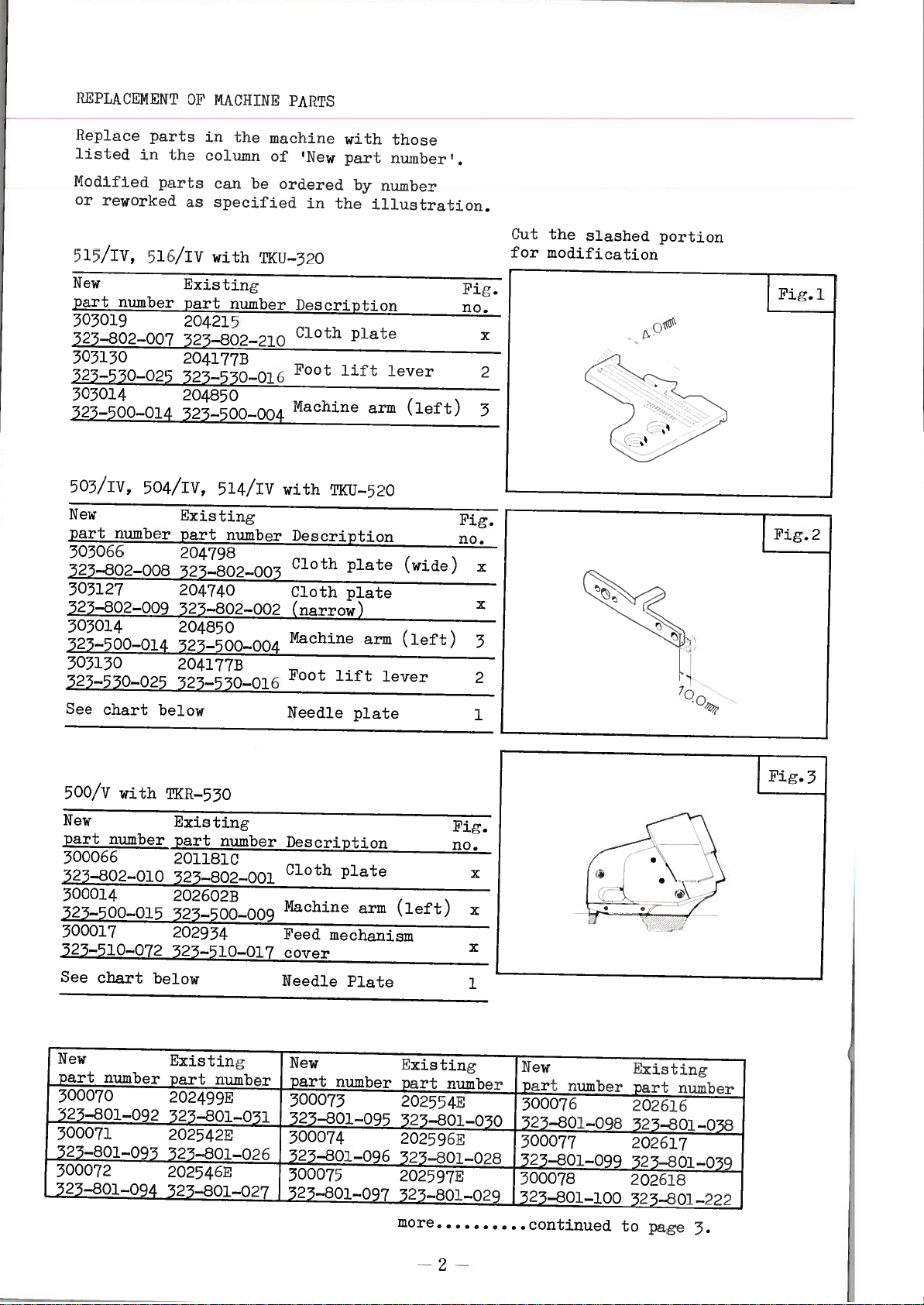

Remove

to

LI

OWi

515/TV,

Pro

1.

Cloth

2.

Needle

3.

Machine

4.

Poot

5.

*

replace

shown

500/V

1.

Presser

2.3.Cloth

Cloth

(no

Needle

4.

Machine

5.

6.

Feed

Foot

7.

*

replace

shown

par

I

51h/IV

sser

plate*

lift

with

in

with

plate*

plate

longer

plate*

mechanism

lift

with

in

from

hi

iiecf

UeIiCe.

with

arm

plate

(icyt)*

arm

lever

modified

pae

TKR—530

arm

fabric

used)

(left)*

arm

lever

modified

page

2.

2.

niacitine

TI1

X—320

cover*

parts

guard

parts

in

the

in

505/IV,

1.

Presser

2.

Cloth

Needle

5.

Cloth

4.

(no

Machine

5.

6.

Foot

*

replace

in

504/IV, 514/IV

arm

plateX

plate*

plate

longer

arm

lift

lever*

with

page

2.

fabric

used)

(left)X

modified

with

guard

parts

TKtJ—520

shown

Fig.4

0

Polish

Arm

surface

portion

(Right)

forattaching

Bracket.

(continued

New

part

number

300079

323—801—101

300080

323—801—102

300081

523—801—103

300082

525—801—104

300085

325—801—105

300084

523—801—106

300085

525—801—107

500086

523—801—108

300087

323—801—109

on

A

to

flat

a

from

page

Existing

part

number

202674

523—801—040

202675

323—801—315

202702

•

323—801—070

202981

523—801—354

202983

523—801—355

202983

323—801—35

204731

323—801—041

205251

323—801—344

205232

523—801—345

the

Machine

smooth

Solenoid

2)

New

part

number

300088

523—801—110

300089

325—801—111

500090

325—801—112

500091

323—801—115

500092

325—801—114

300095

6

525—801—115 325—801—345

300094

325—801—116

500095

323—801—117

500096

325—801—118

205238

205239

325—801—560

205240

323—801—361

205241

323—801—562

Existing

part

number

205233

325—801—346

205234

323—801—547

205255

323—801—540

205236

New

part

numbe

300097

323—801—119

300098

525—801—120

300099

323—801—121

300100

323—801—341 525—801—122

205237

523—801—342

500101 205255

523—801—123 325—801—047

300102 205256

523—801—124

300105

323—801—125

Existing

number

part

205242

323—80l—3

205243

323—80l—4_

205244

525—801—)

65

205245

323—801—557

323—801—048

205257

323—801—049

Page 6

jN’lAllAl’

ON

Of

TAPf

(GJ’lt’lH?

ivszeni

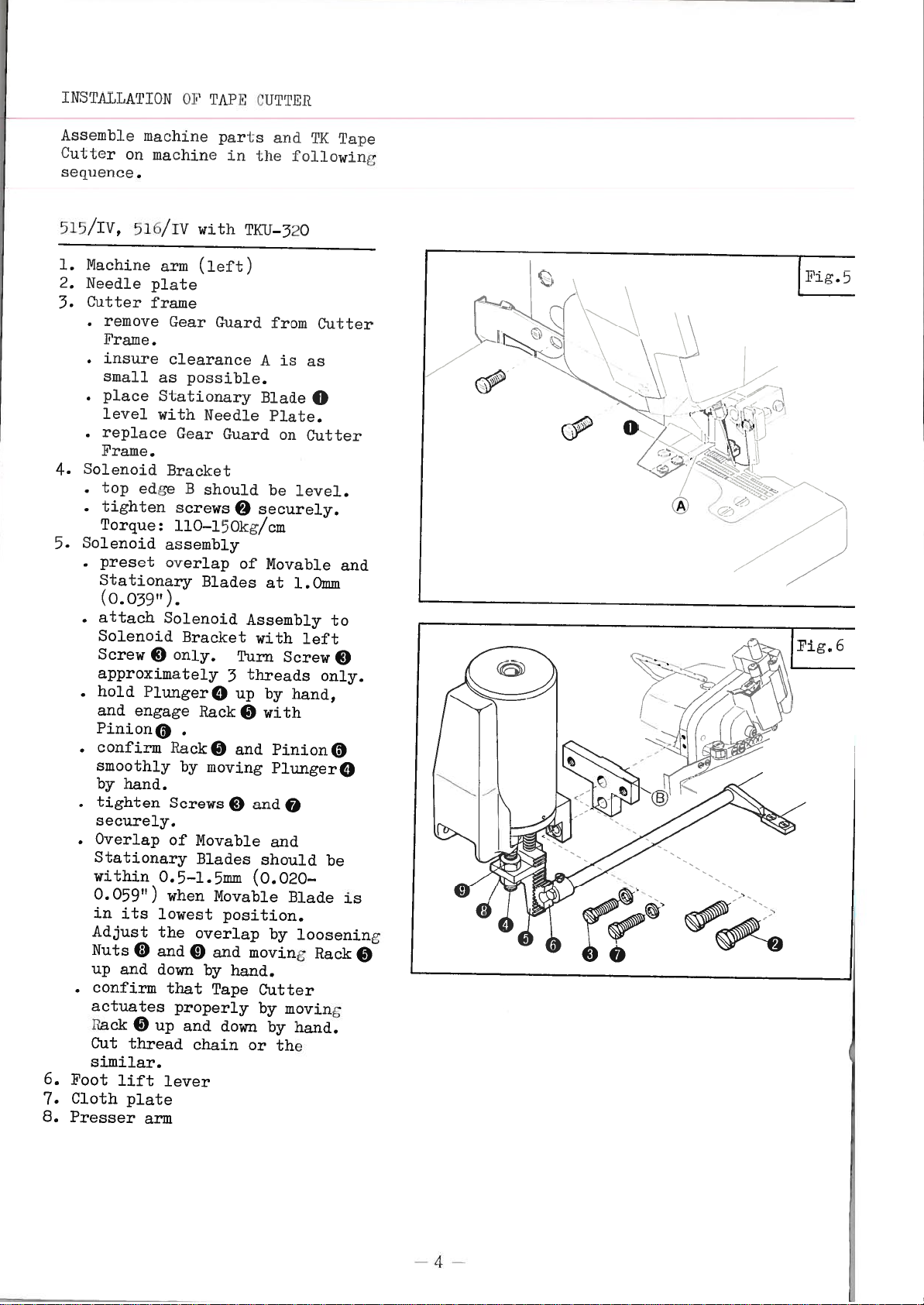

515/IV,

1.

2.

3.

4.

5.

6.

7.

B.

Pu

I

(H’

sequel

Nachurie

Needle

Cutter

•

•

•

Solenoid

•

•

Solenoid

•

•

attach

Solenoid

Screw

approximately

•

hold

and

PinionO

•

confirm

smoothly

by

•

tighten

securely.

•

Overlap

Stationary

within

0.059”)

in

Adjust

Nuts

up

•

confirm

actuates

kack

Cut

similar.

Foot

Cloth

Presser

b

I

e

lOLcI

00

Ce.

siu/iv

remove

‘rare.

insure

small

place

level

replace

Frame.

top

edge

tighten

Torque:

preset

Stationary

(0.039”).

Plunger

engage

hand.

its

0

and

0

thread

lift

plate

arm

Li

ie

IILCIIiIIe

with

arm

(lef

plate

frame

Kear

clearance

as

possible.

Stationary

with

Needle

Gear

Bracket

B

should

screws

110—150kg/cm

assembly

overlap

Blades

Solenoid

Bracket

only.

0

0

Rack

Rack

0

by

moving

Screws

of

Movable

Blades

0.5—1.5mm

when

lowest

the

overlap

and

dawn

up

lever

0

that

properly

and

chain

and

by

Tape

Li’

tO

in

TI<U—320

t)

Guard

Guard

0

of

Assembly

Turn

threads

3

up

0

and

and

0

(0.020—

Movable

position.

moving

hand.

dom

or

and

lie

lot

from

is

A

Blade

Plate.

on

be

securely.

Movable

at

1.0mm

with

Screw

by

hand,

with

Pinion

PlungerO

0

and

should

Blade

by

Cutter

by

moving

by

hand.

the

‘iK

I’a

lowing

Cutter

as

0

Cut

ter

level.

and

to

left

0

only.

0

be

loosening

Rack

pe

1”ig.5

0N;$

®

(>

6

is

oc

0

4

Page 7

‘)03/IV,

1.

2.

3.

4.

5.

6.

7.

8.

Nachinc

Needle

Cutter

•

insure

as

•

place

level

Solenoid

•

top

•

Lighten

Torque:

Solenoid

•

preset

Stationary

(0039”)

•

attach

Solenoid

Screw

approximately

•

hold

and

Pinion9

confirm

smoothly

by

hand.

•

tighten

securely.

•

Overlap

Stationary

within

when

lowest

Adjust

Nuts

up

and

•

confirm

properly

and

Cut

Foot

Presser

lift

Cloth

504./Iv,

arm

plate

frame

clearance

possible.

Stationary

with

Bracket

edge

Screws

110—150kg/cm

assembly

overlap

Solenoid

only.

9

Plunger

engage

Rack

Screws

of

0.5—1.5mm

Movable

position.

the

and9

9

down

Tape

by

down

by

thread

lever

plate

arm

514/Iv

(left)

Needle

should

B

Blades

Bracket

0

Rack

9

moving

by

Movable

Blades

overlap

by

moving

hand.

chain

A

BladeO

securely.

9

of

Assembly

with

Turn

threads

3

up

with

9

and

and

9

should

(0.020—0.059”)

Blade

and

moving

hand.

Cutter

or

h

wi

is

as

Plate.

be

level.

Movable

at

1.0mm

left

Screw

by

hand,

Pinion

Plunger

9

and

is

in

by

loosening

actuates

Rack

the

‘I1IQJ—520

small

and

to

9

only.

0

0

be

its

Rack

up

9

similar.

500/V

1.

2.

3.

4.

5.

6.

with

Cutter

mount

Base

Use

mouting.

insure

Machine

Needle

Cutter

insure

as

place

with

Solenoid

top

tighten

Torque:

Solenoid

preset

Stationary

rllI<i?_550

frame

Cutter

on

screws

no

arm

plate

frame

clearance

possible.

Stationary

Needle

bracket

edge

assembly

overlap

bracket

Prame

Peed

Screws

110—150kg/cm

play

(left)

B

Bar

for

Plate.

should

Blades

the

in

9

of

A

Blade

securely.

base

Bracket

Guide

Guide

Feed

is

be

level.

Movable

1.0mm

at

(Right).

Bars.

as

0

for

small

level

and

(0.039”).

attach

Solenoid

ScrewØ

approximately

•

hold

and

confirm

smoothly

by

•

tighten

securely.

•

Overlap

9

7.

8.

9.

Stationary

within

when

lowest

Adjust

Nuts

up

•

confirm

properly

and

Cut

Foot

Cloth

Presser

Plunger9

engage

hand.

Movable

0

and

down

thread

lift

plate

Solenoid

Bracket

only.

Rack

by

Screws

of

Movable

0.5—1.5mm

position.

the

overlap

and

0

down

Tape

by

by

chain

lever

arm

3

Rack

9

moving

Blades

Blade

and

by

Cutter

moving

hand.

Assembly

with

Turn

Screw

threads

up

by

hand,

with

9

Pinion9

and

Plunger

andO

9

and

should

(0.020—0.059”)

is

by

moving

hand.

actuates

Rack

or

the

to

left

9

only.

Pinion

0

be

its

in

loosening

Rack

up

9

similar.

9

0

—

5

—

Page 8

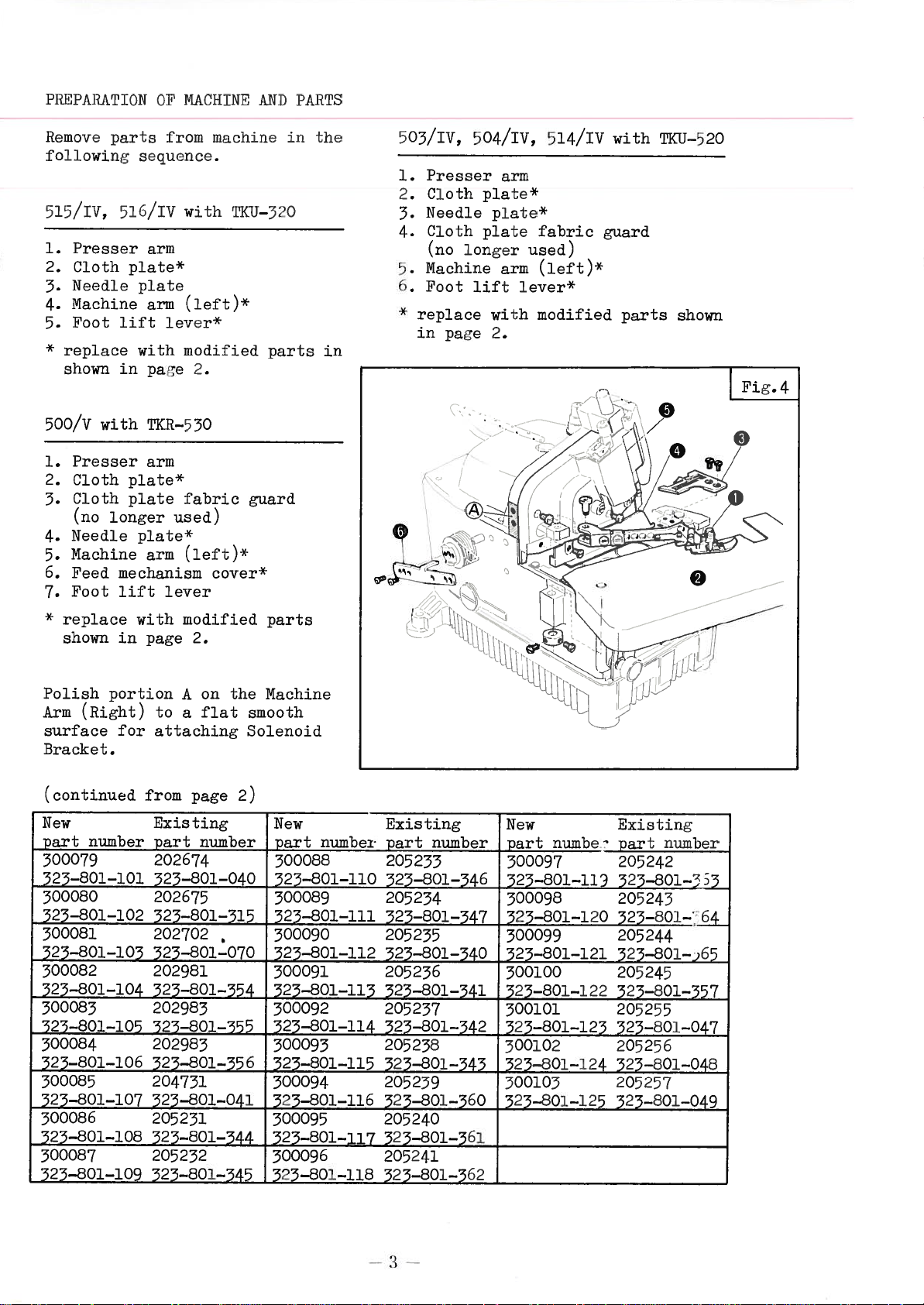

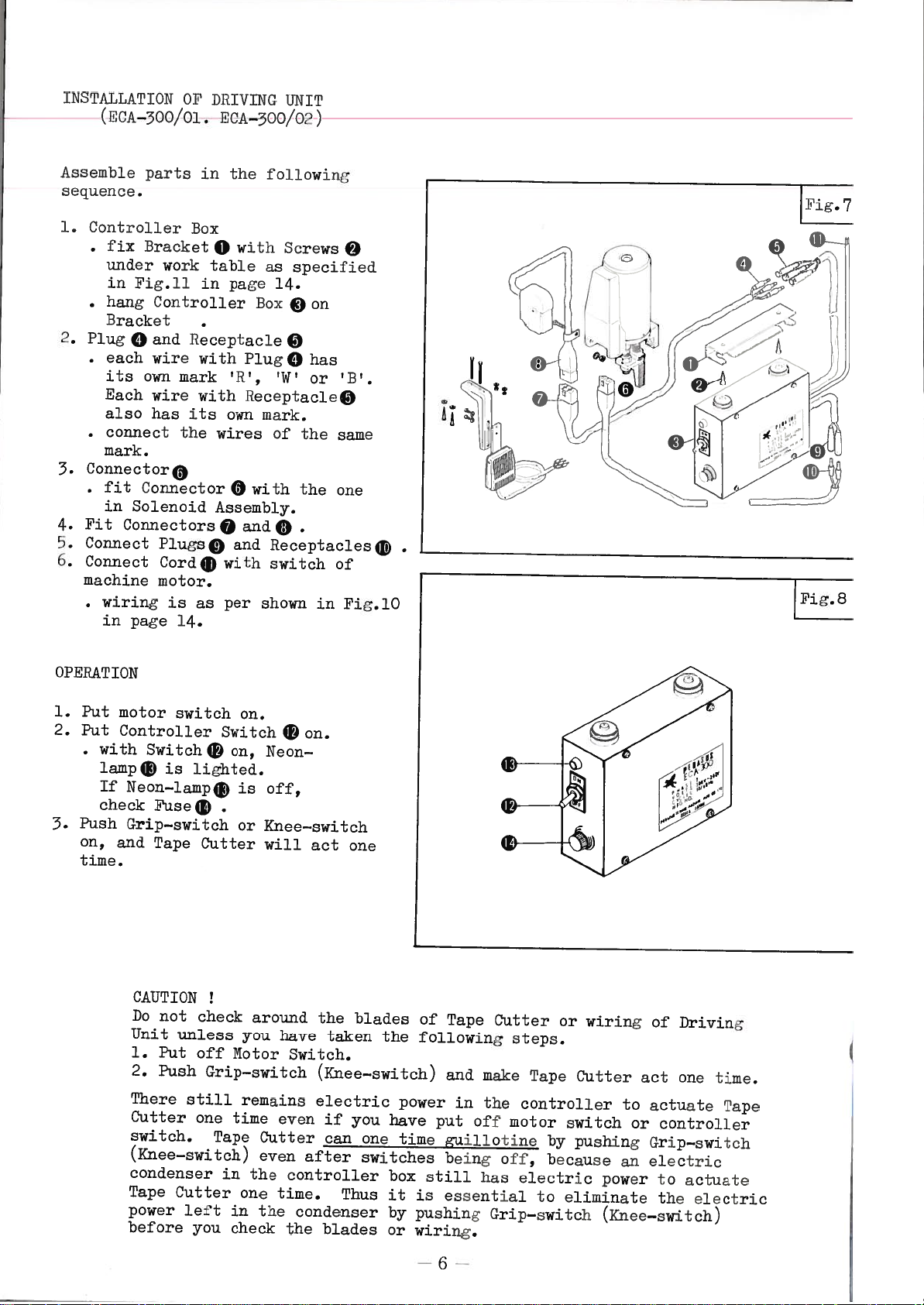

INPIAIIAnIhION

(

A—oo/o

UI

i)I?IVINC

U1TIT

Assombl

seq

none

1.

Controller

•

•

2.

PlugQand

•

•

3.

ConnectorO

•

Fit

4.

Connect

5.

6.

Connect

machine

o

0.

fiX

under

in

Fig.l1

hang

Bracket

each

its

Cach

also

connect

mark.

fit

in

Solenoid

Connectors

wiring

in

page

parts

Bracket

worktable

Controller

Receptacieø

wire

own

mark

wire

has

its

the

Connector

PlugsØ

Cord®

motor.

is

14.

in

Box

0

in

with

with

wires

Assembly.

0

with

as

per

the

toll

with

as

page

Box

Plug

‘R’,

ReccptacleØ

own

mark.

of

with

0

andØ

and

Receptacles

switch

shown

Screws

specified

14.

0

Q

?T.TI

owin

on

has

or

the

the

fig.

7

@

?

B?.

‘

L_)

/

I

(r4t

L

‘

0

o®i

A

i

H

@

same

one

of

in

Fig.lO

L

Fig.8

OPERATION

1.

Put

motor

2.

Put

Controller

•

with

lamp®

If

check

Push

3.

on,

and

time.

switch

Switch®

is

lighted.

Neon—lamp®

Puse®

Grip—switch

Tape

CAUTION

Do

Unit

1.

2.

There

Cutter

switch.

(Knee—switch)

condenser

Tape

power

before

not

Put

Push

Cutter

Cutter

check

unless

off

Grip—switch

still

one

left

you

Switch

on,

Motor

time

Tape

in

in

check

on.

®

Neon—

off,

is

or

Knee—switch

will

around

you

have

remains

even

Cutter

even

the

one

time.

the

the

on.

act

the

taken

Switch.

(Knee—switch)

electric

if

can

after

controller

Thus

condenser

blades

one

blades

you

one

switches

the

have

box

it

by

or

of

following

power

time

is

pushing

wiring.

Tape

and

put

uil1otine

being

still

essential

make

in

the

off

has

Cutter

steps.

motor

off,

Grip—switch

or

Tape

controller

by

because

electric

to

wiring

Cutter

switch

pushing

power

eliminate

(Knee—switch)

[/:

of

act

to

actuate

or

controller

Grip—switch

electric

an

to

the

Driving

one

actuate

electric

time.

Tape

—6

Page 9

LNSTALLATIUN

—

UI

Dd1V

(tWA—Iou/jo)

INC

UN

I

lease

Cultot

apu

shown

Lssernb]

3equeflce.

or

and

in

Fi.9.

-.

Ass

and

Mount

h

in

in

Mount

in

Fi;.

Solenoid

•

preset

and

(0039”)

•

push

then

0.

•

1ihtly

Machine

Screws

confirm

smoothly

by

•

tighten

Torque:

•

overlap

Stationary

within

when

lowest

overlap

and

down

confirm

properly

by

Cut

Connect

Compressor.

lix

and

position.

piucooC

in

IL

pu

e

asc(mb

coro

b

em

Knee

HiackotO

posi

pauc

BracketO

position

11.

Stationary

hand.

Movable

®

by

hand.

thread

Foot

Presser

the

up

to

e

4—5.

to

iII’,

I

prov

c

Bracket

Switch

tion

as

L4..

as

assembly

the

up

Plun;crØ

en;ae

attach

Arm

9

Rack9

by

Screws

llO—150kt,/cm

of

Movable

Blades

0.5—1.5mm

position.

by

1oosenin

and

moving

hand.

Tape

by

chain

Tube®

Lift

Arm

Luc

item

tOe

ace

jded,

0

9

unuer

specified

under

also

overlap

Rack

(Ritht)

movin

9

Blade

Cutter

movin

with

Lever,

on

t:tLLalion

‘Cut

tollowiriu

So

r

wo

ac

,

Ur

icke

in

one

work

work

specified

of

Movable

Blades

0

by

at

hand,

with

Bracket

with

and

Pinion

F1unerØ

securely.

and

should

(0.020—0.059”)

in

is

Adjust

Nuts®

Rack

0

actuates

Pluner

or

the

Air

Cloth

machine

Ler

,

per

unit.

in

Pinion

9

be

its

the

up

similar.

Plate

in

of

I

is

Nu

shown

9

table

ii

table

1.0mm

and

on

0

and

9

;u

¶Lino

¶

‘/

\

(same

Valve

be

hand.

Switoh

and

1

pushim

by

water

before

oil

in

of

from

lOk:;/cm

2

Nut®

one

adjust

cutting

of

adjust

accumulated.

is

it

to

Container®

Air

Air

or

and

by

turnin

Tape

and

time.

the

as

.

ID

_-/-

11

‘.

in

0

DAILY

1.

2.

Keep

half level.

7.

Loosen

8.

at

Facet®

Push

9.

will

10.

If

oil

per

Cutter.

Turn

,

-

I&

MAINTENANCE

Drain

finler

Drain

line

the

Open

water

when

water

A

oil

machine)

the

pressure

Air

should

Lock

3.5—5.0k;/cm

2

Knee

actuate

necessary,

in

Container®

times

5

Nut®

by

¶

Pin®

reaches

be

used

in

Compressor.

Compressor

below.

0aue

set

Cutter

drop

one

drop

of

Tape

this.

by

the

for

its

of

7

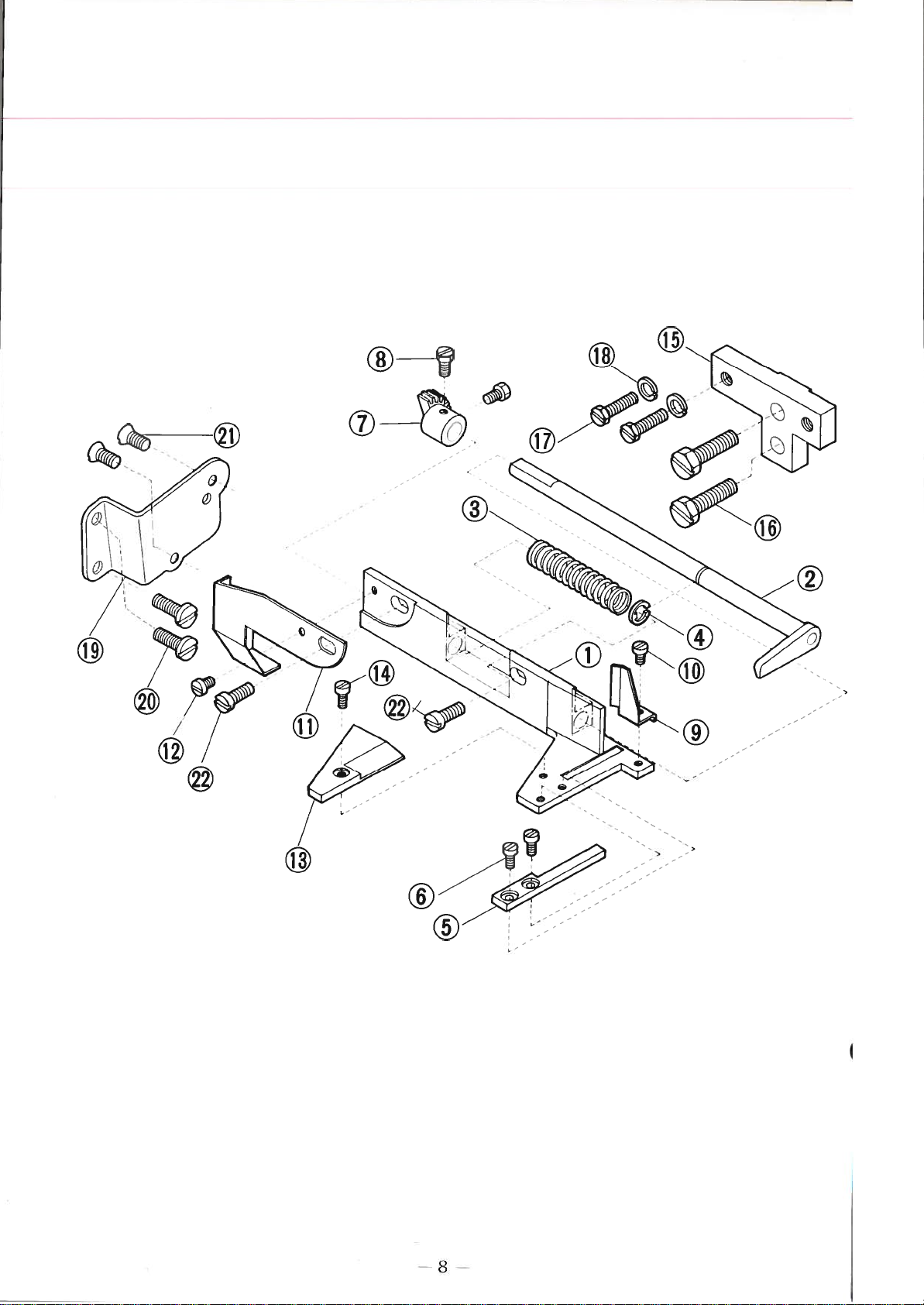

Page 10

©

//

—8--

Page 11

Ref.

No.

10

12

14

15

16

17

18

19

20

21

22

PARTS

TKIJ—520

305169

523—900—038

505007

1

523—.508-.0l2

303002

2

523—873—015

305096

323—640—020

305097

323—633—005

500006

523—875—018

1186 1186

6

525—600—246

500007

523—765—001

5220

323—600—291

503005

525—560-037

1186

323—600—246

503065

523—560—040

1186

TKU—320

303135 500141

525—900—039

305020

525—508—015

305151 300003

323—873—016 325—873—017

303096 303096

325—640—020

303097 303097

323—655—005

303021 300006

525—875—019

525—600—246 525—600—246

300007

323—765—001 323—763—001

5220

523—600—291 523—600—291

505022

523—560-058

1186

323—600—246

305063

525—560—040

1186

525—600—246 523—600—246

503011

523—800—046

1186

523—600—246

303013

523—740—050

5266

323—600—265

5276

525—600—088

503067

523—616—002

305128

523—740—052

5113

323—600—039

5001

323—600—059

503011

523—800—046

1186

323—600—246

503013

523—740—050

5266 5266

523—600—265

5276 5276

323—600—088 323—600—088

305067

525—616—002

303128

525—740—052

5113

323—600—059 523—600—039

5001

523—600—059 523—600—059

5345

325—600—096

*

for

ECA—300/01

325—600—096

LIST

only

FOR

TKU—520,

TKR—530

523—900—040

50000lA

523—508—014

323—740—049

323—640—020

323—655—005

525—875—018

1186

500007

5220

500008

325—560—039

1186

323—600—246

505065

525—560—040

2921

525—600—026

300011

323—800—047

1186

525—600—246

300150

323—740—051

323—600—265

303067

325—616—002

500140

323—740—055

5115

5001

2902

325—600—259

(2)

(2)

(

TKU—520

=

)

AND

Description

Tape

cutter

“

Movable

U

U

Stationary

Pinion

Fabric

Gear

Tape

guard

guard

I?

U

guide

U

Solenoid

I?

Grip—switch

Tape

cutter

quantity

I?

blade

screw

U

bracket

screw

TKR550

head

frame

spring

blade

U

(2)

screw

screw

plate

U

washer

bracket

screw

frame

screw

screw

(2)

complete

bracket

stop

screw

(2)

(2)

*

screw

*

(2)

screw

ring

(2)

(2)

*

(2)

—9

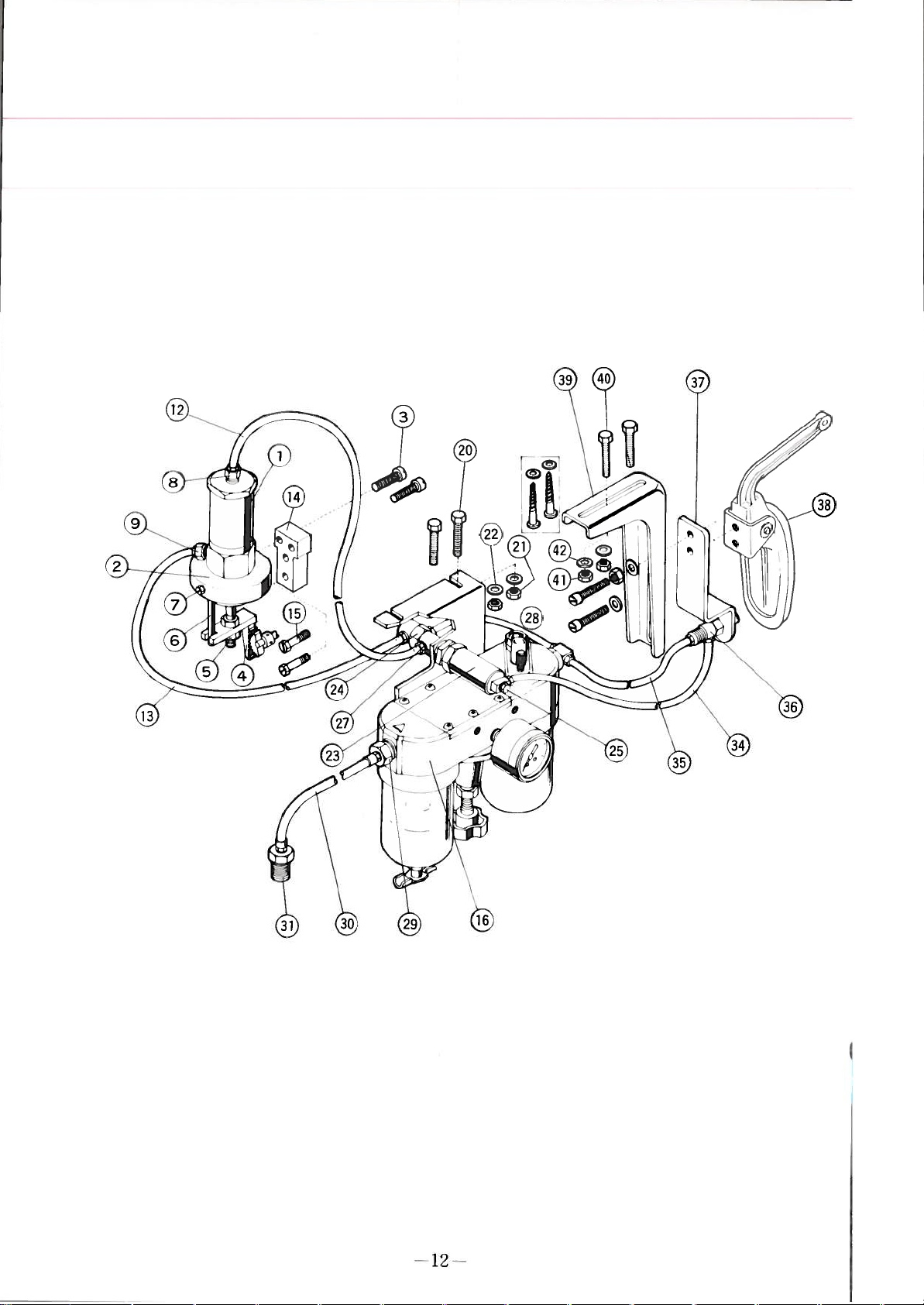

Page 12

r.

10

Page 13

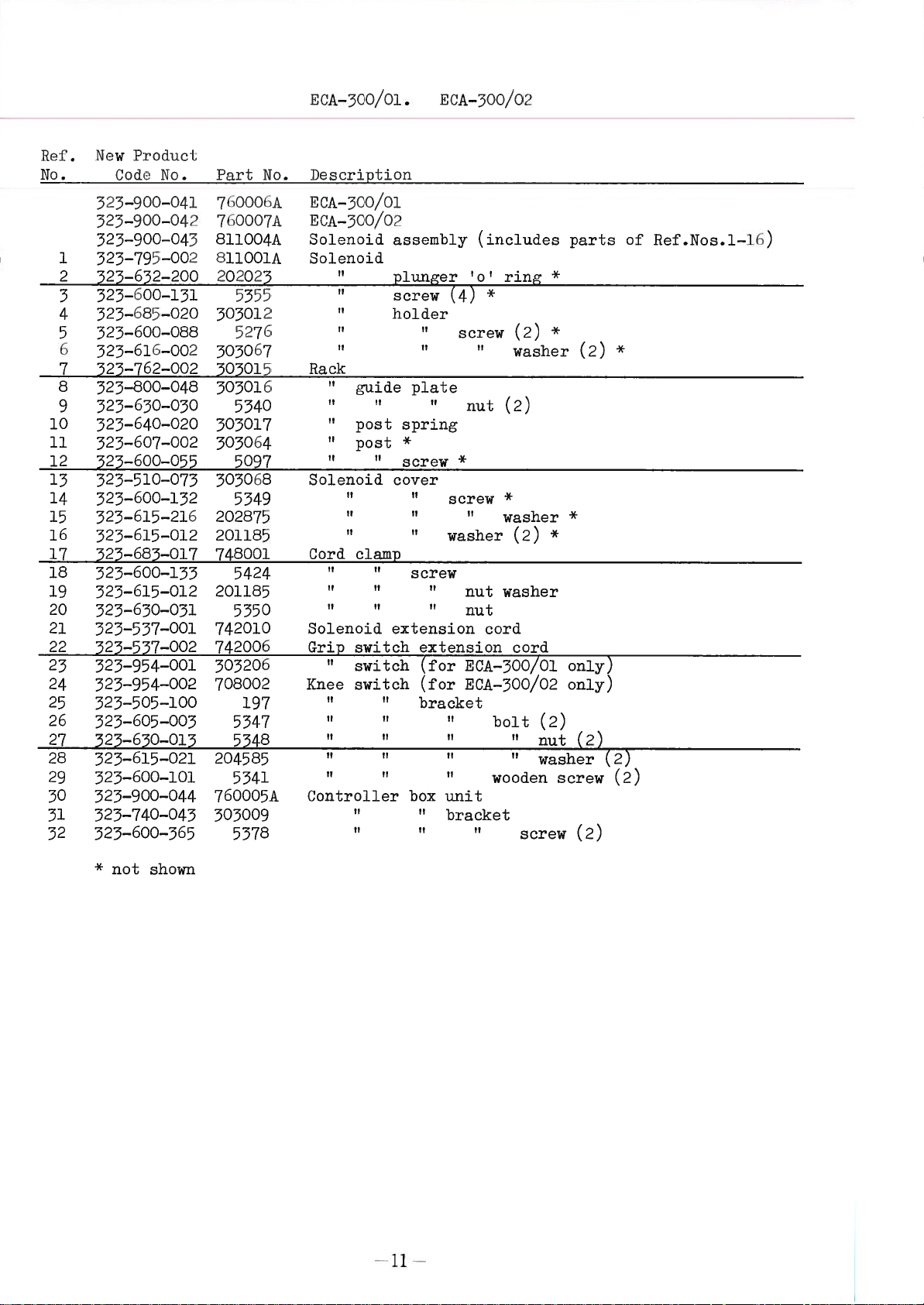

NUA—5oo/ol.

E0A—500/02

Ret’.

No.

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

51

32

owP[‘edo

N

Cod

525—500—041

525—500—0’1.2

525—500—04

525—755—002

1

2

323—u52—200

323—00—l5l

3

525—(&35—020

4

525—u00—01313

5

6

525—u1D—002

525—7D2—002

7

8

525—800—048

325—650—050

9

325—040—020

323—607—002

525—600—055

525—510—073

323—600—152

323—615—216

323—615—012

525—683.--017

323—600—133

523—615—012

523—630—031

323—537—001

525—557—002

323—954—001

525—954—002

325—505—100

325—605—005

525—650—015

323—615—021

525—600—101

525—900—044

523—740—045

525—600—565

No.

0

PurL

No.

000oA

7

7o000/IL

01100411

131100111

202025

5555

505012

527D

505067

505015

505016

5340

503017

503064

5097

303068

5349

202875

201185

748001

5424

201185

5350

742010

742006

303206

708002

197

5347

5348

204585

5541

76000511

303009

5578

Description

ECA—500/0l

ECA—500/02

Solenoid

Solenoid

Rack

guide

U

I

U

post

post

U U

Solenoid

U

U

Cord

clamp

H

U

U U

U

Solenoid

Grip

switch

switch

Knee

switch

U

U

U U

U

Controller

U

assembly

plunger

screw

holder

plate

spring

*

screw

cover

U

U

screw

extension

bracket

U

box

U

(4)

screw

*

screw

washer

nut

extension

(for

ECA—500/01

(for

ECA—300/02

U

U

unit

bracket

(includes

‘o’

*

nut

U

nut

cord

bolt

wooden

ring

(2)

washer

(2)

*

washer

(2)

washer

cord

U

screw

*

*

*

(2)

nut

washer

screw

parts

(2)

*

only)

only)

(2)

(2)

(2)

of

*

(2)

Ref.Nos.l—16)

*

not

shown

—11

Page 14

©

—12

-

Page 15

—ioo/io

A

hef.

No.

10

11

12

15

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

50

51

32

35

34

55

56

37

58

59

40

41

42

523—’

1

325—u05—OJ

2

523—.uOO—29i

3

4

5

6

7

8

9

—72—001

525—(50—050

525—75—OO’

5_i

3;

525—1

)2)—i)t—014.

525—027—Ol(

525—655—004

523—i59—02/

525—u59—028

325—740—054.

525—600—2u5

325—716—010

523—600—130

323—615—012

523—740—055

523—605—005

325—650—013

323—615—021

323—716—009

323—736—006

323—636—015

525—636—016

325—656—017

523—659—029

525—656—007

523—659—025

525—636—008

323—635—005

325—636—011

323—639—050

325—639—031

323—736—005

323—740—056

325—900—224

523—505—100

523—605—003

523—630—015

525—615—021

l’iodii

odL

0

3

I:

No.

—002

9

)—C:H

—01

1aiI.

513004

2040)4

52)3

20’l

‘0)40

20410

5040

01017

01005

Ol0O(

(01004

600015

(00014

204.615

5266

595002

5425

201185

300215

5547

5548

204585

555001

552001

601020

601026

601002

600012

601011

600005

601014

601012

601013

600015

600016

531001

300216

192

197

5547

5348

204585

Oh

No.

)ocrinLio

Air

1

‘

NIbow

Nipple

P1u

Sleeve

Tubo

rpube

Air

H

II

7

7

H

Elbow

Joint

Valve

Tube

Elbow

Tube

Nipple

Sleeve

P1u

Tube

Tube

Air

Il

Knee

7!

H

H H

H

indor

cy

nuL

support

(2)

(2)

cylinder

reu1ator

actuator

valve

joint

(2)

(2)

valve

H

pad

7

7

holder

2)

screw

‘

bracket

unit

H

H H

H

*

*

bracket

(switch)

bracket

7

7

H

H

I

H

H

screw

screw

screw

screw

1

bracket

H

H

71

H

(2)

nut

I

(2)

(2)

(2)

washer

bolt

(2)

washer

*

*

(2)

(2)

nut

H

(2)

washer

(2)

(2)

*

shown

not

Page 16

I

To

iiac)Lino

1iA1r1’

[cL

To

CCA—00/0j

(SuA—oo/o)

No

La

i

in

b

A5oo/o

flirccLLflc

motor

(IuA—5oo/o;

wi1;ch

)

Prom

Power

Source

Ij.

10

Knee

Bracket

Switch

tO

2

IvIouiiL

for

portion

ECA—500/01(/02)

I

oao

in

work

table

and

ACA—100/lO

Fi.11

30.0

Controller

Box

Bracket

—

Ii

Page 17

Page 18

Loading...

Loading...