Page 1

INSTRUCTION BOOK

WILLCOX

&

GIBBS

CLASS

500/1 &

500/1!

(overlook stitch) —

J

AaimJaa

r.A

onnai

UJILiLiCQX

111J

AVENUEOFTHE

&giBBSjnOJ

AMERICAS,

NEW

ujg

YORK.

NEW

YORK

10036 (2123869-1800

.

ijjii.iamx

oil

iHiJ.

IV

IIH3. L-y^,

k • r

tOIULiCOX

giBBs.

soo/n

T y

pf

504/n-45

B-

inc.

f

Page 2

TABLE

OF

CONTENTS

Introduction

Howtoclean

Driving

Lubrication

Threading

Regulating

Pressureofpresser

Needles

Regulating

Replacing

Regulating

Setting

Setting

motor,

your

thread

seam

the

stitch

the

welt

the

edge guide

your

pulley and belting 2-3

machine

width

upper

guide 8-9

machine

tension

foot

and

length

OPERATORS'

INSTRUCTION

PAGE

2

2

2-3

4-5

4-5

6-7

6-7

6-7

lower knives 6-7

8-9

8-9

Alignmentofneedle

Feed

adjustment

MECHANICS'

platetofeed 10-11

INSTRUCTION

10-11

Adjusting needle arm height 10-11

Left

looper

adjustment

12-13

Adjusting needle guards 12-13

Right looper

Presser

Presser

Presser

arm

foot

foot

adjustment

alignment

adjustment

lift

adjustment

14-15

16-17

16-17

16-17

Timing gauges 18

500/1 organization

500/11 organization

chart

chart

19

20

- 1 -

Page 3

OPERATORS'

INSTRUCTION

INTRODUCTION

You

are

about

designed

overlock.

by

featurestoassist

easier

handling

increase

smoothly,

quietly.

machines

OPERATOR'S

HOW

your

The

TO

to

the

In

this

and

production.

has

automatic

operate

people

machine

you,asthe

faster

an

overlook

who

first

introduced

you

will

operator,toenjoy

sewing

It is

that

easytothread,

lubrication,

find

will

Willcox & Gibbs class 500/1 &

are

the

machines

FAVORITES".

CLEAN

known

YOUR

machine

all

help

feeds

and

as

"THE

the

the

the

you

runs

MACHINE

Cleaning

It is

release

out

from

needle plate. Blow

brush. Replace covers and return

position.

DRIVING

BELTING

Each

following specifications:

1. Clutch motor: 3 phase; 2 pole;

is

2. Motor speed is approximately 2,900 r.p.m. for

50 Hz or

3. Beltingshould be V belt. Type

4. The relation between machine speed and

pulley diameter is determined by Table 1.

LUBRICATION

CAUTION:

the

machine is an

not

necessary

the

foot

the

covers

around

machine

recommended.

the

3,500

Oil

when

Refill with oil before operating.

important

to

remove

and

and

swing it

remove

outtothe

all

loopers, feed slots,

out

any

loose

MOTOR,

should

useamotor

r.p.m. for

was

drained

PULLEY

60

Table

shipped.

any

parts. Merely

the

collected

and

lintoruse a

foottothe

and

400

watts {112HP)

Hz.

M.

2 Fig.

from

the

operation.

left. Swing

lint

under

the

lint

sewing

AND

Table 1

beltofthe

motor

1,2,

machine

11

3

A

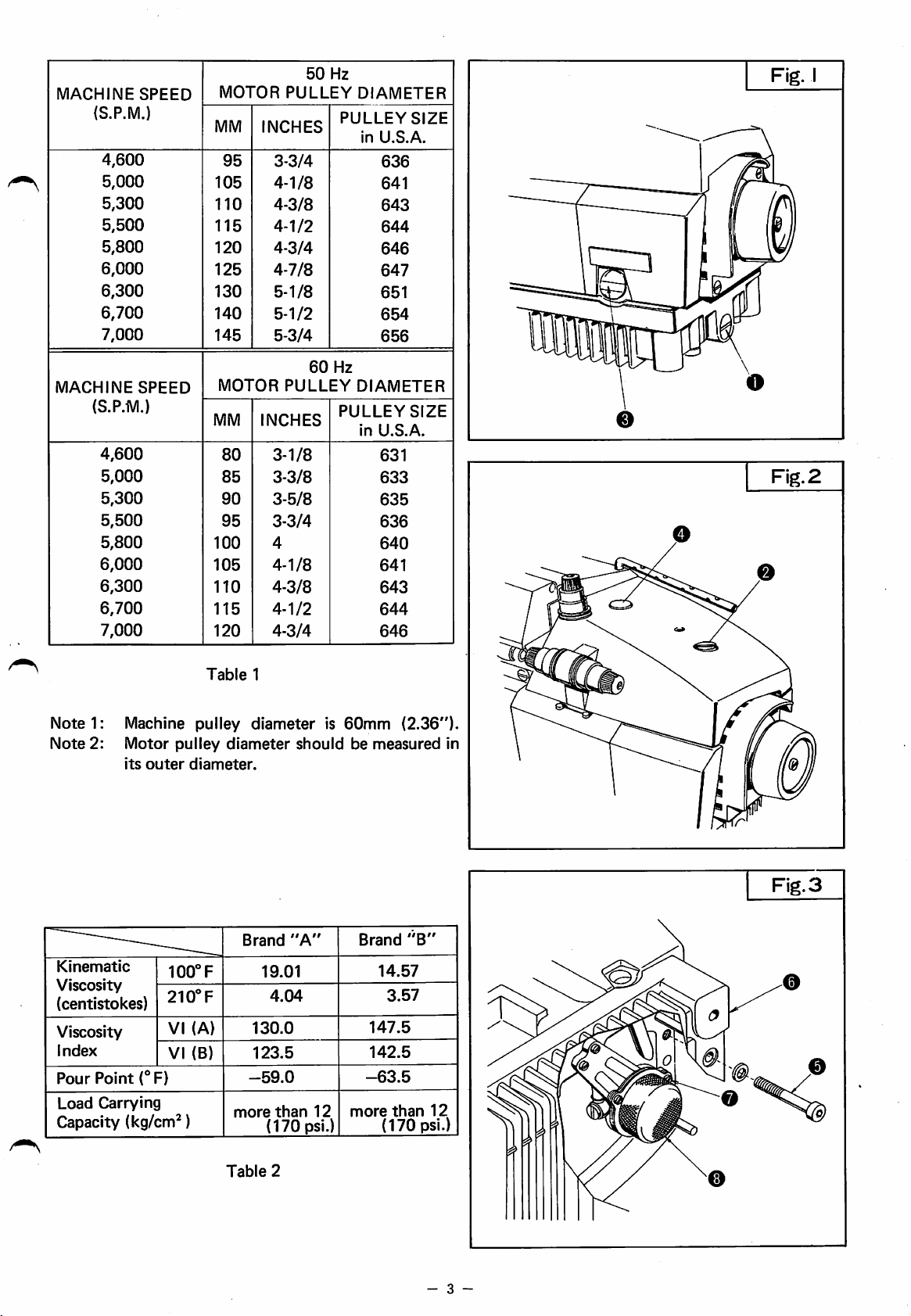

new

machine

ataspeed

At

the

drained

nottoexceed

end

out

Operational

7,000

s.p.m.

Operational

and

operation

Life

time

of

For

lubricant

Table

2.

Use

recommended

Changing

1.

Remove

a

oil

table.

2. Remove drain plug O and drain oil from

machine.

3. Replace

its

stand.

4. Remove filler plug

5.

Pour

fresh oil

using

funnel

reaches

upper

6. Replace filler plug

7.

Run

machine

splash sight

8. Oil level

gauge

©.

9. Change oil

OIL

SCREEN

of

and

speed

speed

being

machine

for

the

drain

window

should

entirely

FILTER

four

machine

supplied

should

be

5,000

weeks,

run

at

least

s.p.m.

original oil

four

should

weeks

replaced.

after

four

depends

weeks

upon

run-in

machine

may

model

performed.

depends

on

quality

oil

used.

500/1 & II, use oil as specified in

type

oil

only.

from

its

stand

and

setiton

plug O

and

return

the

machine

0.

into

reservoir

with

line of gauge

(700cc

accessories,

0.

Capacity)

until

0.

and

check

oil

circulation

at

O.

be

kept

every

between

three

two

months.

lines

be

be

the

to

oil

oil

on

Filter 0 should be kept clean. Lubrication oil is

filtered

Clogging

tion

clean

replace

Changing

1.

2. Remove bolts 0 and oil pan

3.

4. Clean filter 0 with petrol and blow it with low

5. Replace filter 0 and tighten screws

6. Replace oil pan 0 and tighten bolts

7. Fill reservoir

and

of

and

accidental

filter

withanew

Oil

jetinwindow

contains

filter

Drain

oil

Remove

pressure

gauge

0.

delivered

this

filter

seizure

0 every

three

filter

O is restrictedorweak,oroil

foam

or

debris.

from

the

machine.

screws0and

air.

with

oil on a levelofupper

to

all

frictional

may

cause lack

of

parts.

of

Check

months,orif necessary,

when:

©.

filter

0.

0.

0.

surfaces.

lubrica

and

line

of

The 500/1 & II features fully automatic lubrication

with a concealed forced air cooling system. Oil is

pressurized by a

the

connections.

pump

to

the

internal

surfaces

of

- 2 -

Page 4

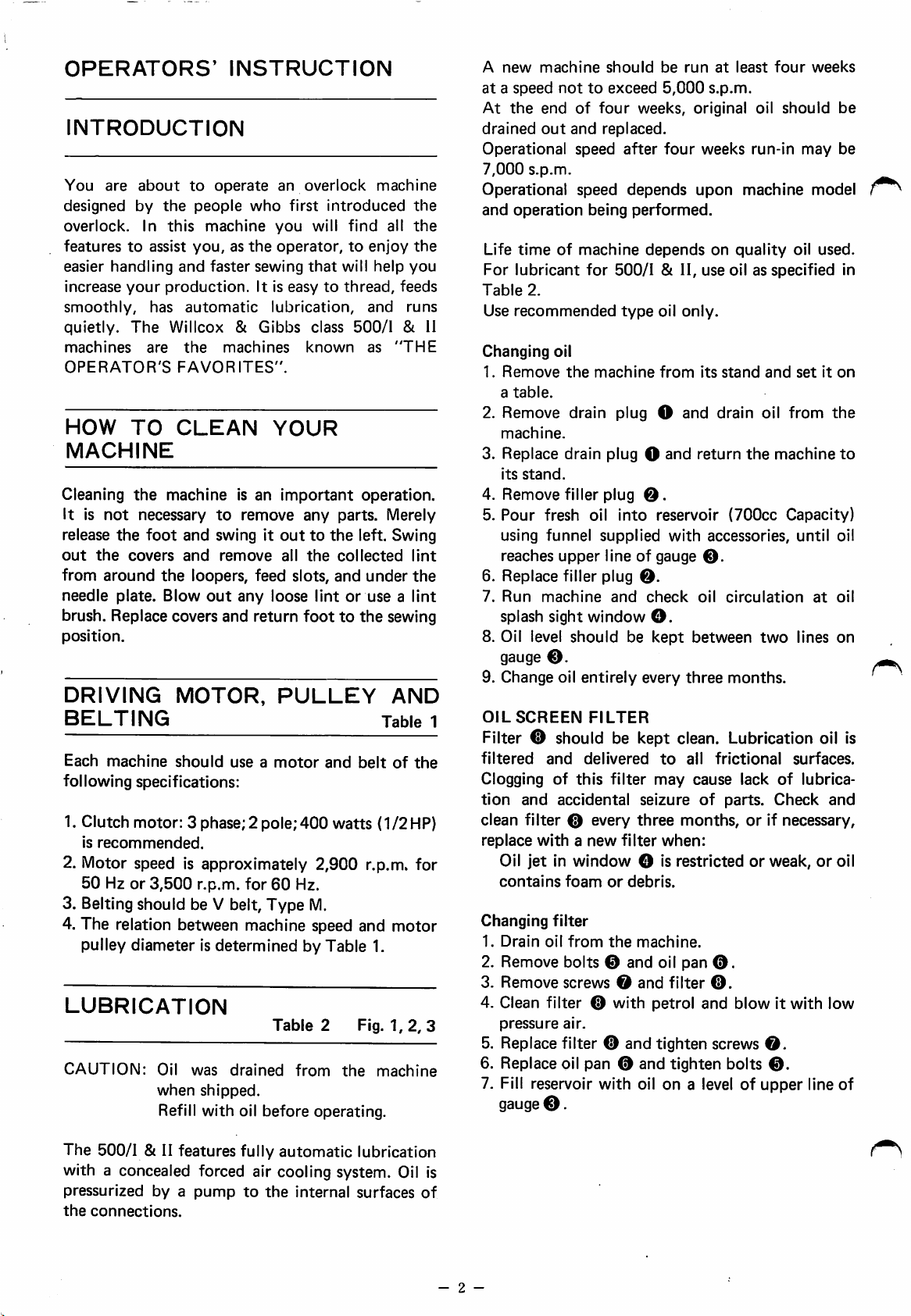

MACHINE

(S.P.M.)

4,600

5,000

5,300

5,500

5,800

6,000

6,300

6,700

7,000

MACHINE

(S.P.M.)

4,600

5,000

5,300

5,500

5,800

6,000

6,300

6,700

7,000

SPEED

SPEED

MOTOR

MM

95

105

110

115

120

125

130

140

145

MOTOR

MM

80

85

90

95

100

105

110

115

120

PULLEY

INCHES

3-3/4

4-1/8

4-3/8

4-1/2

4-3/4

4-7/8

5-1/8

5-1/2

5-3/4

PULLEY

INCHES

3-1/8

3-3/8

3-5/8

3-3/4

4

4-1/8

4-3/8

4-1/2

4-3/4

50

60

Hz

DIAMETER

PULLEY

in

Hz

DIAMETER

PULLEY

in

U.S.A.

636

641

643

644

646

647

651

654

656

U.S.A.

631

633

635

636

640

641

643

644

646

SIZE

SIZE

Fig.

Fig.

I

2

Notel:

Note

Kinematic

Machine pulley diameter is

2:

Motor

its

outer

Viscosity

(centistokes)

Viscosity

Index

Pour

Point

(®F)

Load

Carrying

Capacity (kg/cm^)

pulley

diameter.

lOO^F

210®F

VI

(A)

VI (B)

Table

diameter

more

1

Brand

19.01

130.0

123.5

-59.0

(170

4.04

than

should

"A"

12

psi.)

60mm

{2.36").

be measured in

Brand

more

14.57

147.5

142.5

-63.5

(170

3.57

than

"B"

12

psi.)

Fig.

3

Table

2

- 3 -

Page 5

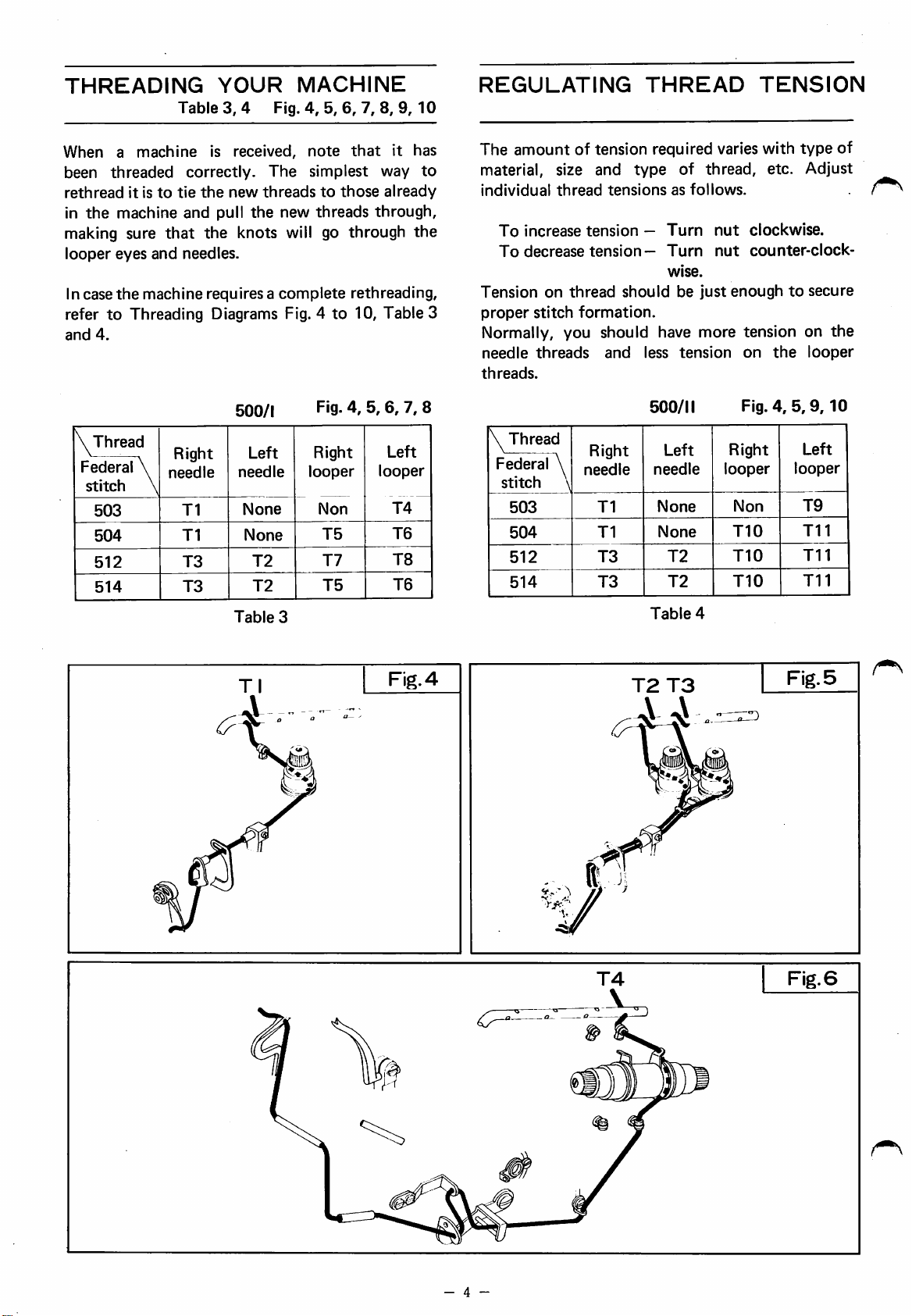

THREADING

When

been

rethread

in

making sure

looper

In case

refer

and

a

machine

threaded

it istotie

the

machine

eyes

and

the

machine

to

Threading Diagrams Fig. 4 to 10, Table 3

4.

YOUR

MACHINE

Table3,4 Fig.4,5,6,7,8,9,

is received,

correctly.

the

new

and

pull

the

that

the knots will go through

note

that

The

simplest

threadstothose

new

threads

needles.

requires a

complete

rethreading,

10

it

has

way

to

already

through,

the

REGULATING

The

amount

material, size and

individual

To

increase

To

decrease

Tension

proper

of tension required varies with

thread

tension

tension—

on

thread

stitch

formation.

type

tensions

—

should

THREAD

of

thread,

as

follows.

Turn

Turn

wise.

be

just

TENSION

type

etc. Adjust

nut

clockwise.

nut

counter-clock

enoughtosecure

Normally, you should have more tension on

needle

threads.

threads

and

less

tension

on

the

of

the

looper

Thread

Federal

stitch

503

504

512

514

Right

looper

4

Fig.4,5,9,10

Left

looper

Non

T10

T10

T10

T9

Til

Til

Til

500/1

Right

\

needle

Left

needle

Fig.4,6,6,7,

Right

looper

\

T1

T1

T3

T3

None

None

T2

T2

Table

Tl

Non

T5

T7

T5

3

Left

looper

T4

T6

T8

T6

Fig.

8

\

Thread

Federal \

stitch

503

504

512

514

Right

needle

\

T1

T1

T3

T3

4

T2

500/11

Left

needle

None

None

T2

T2

Table

T3

- 4 -

Fig.

6

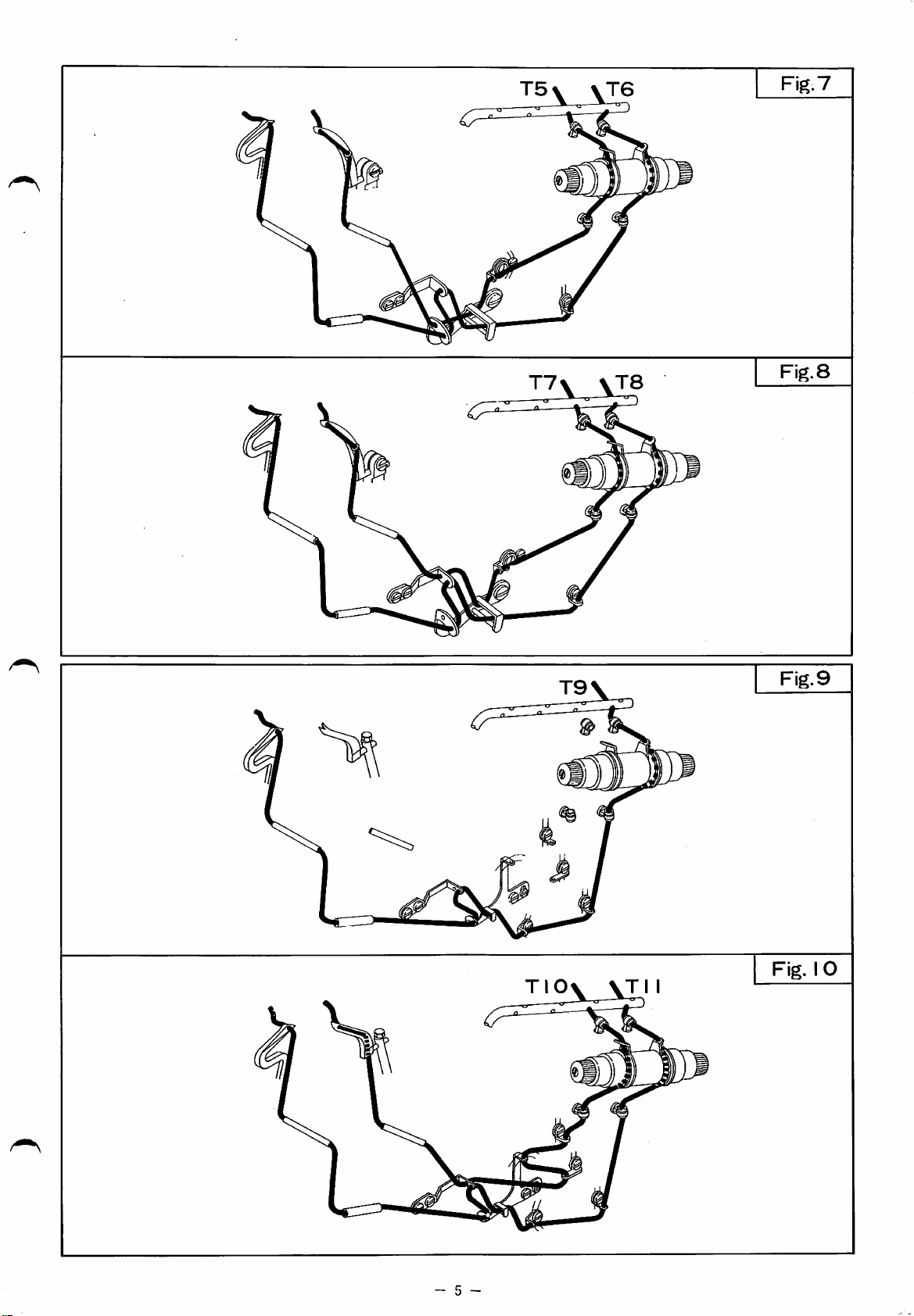

Page 6

T7\

\T8

Fig.

Fig.

7

8

TlOv

\TII

Fig.

Fig.

9

IO

- 5 -

Page 7

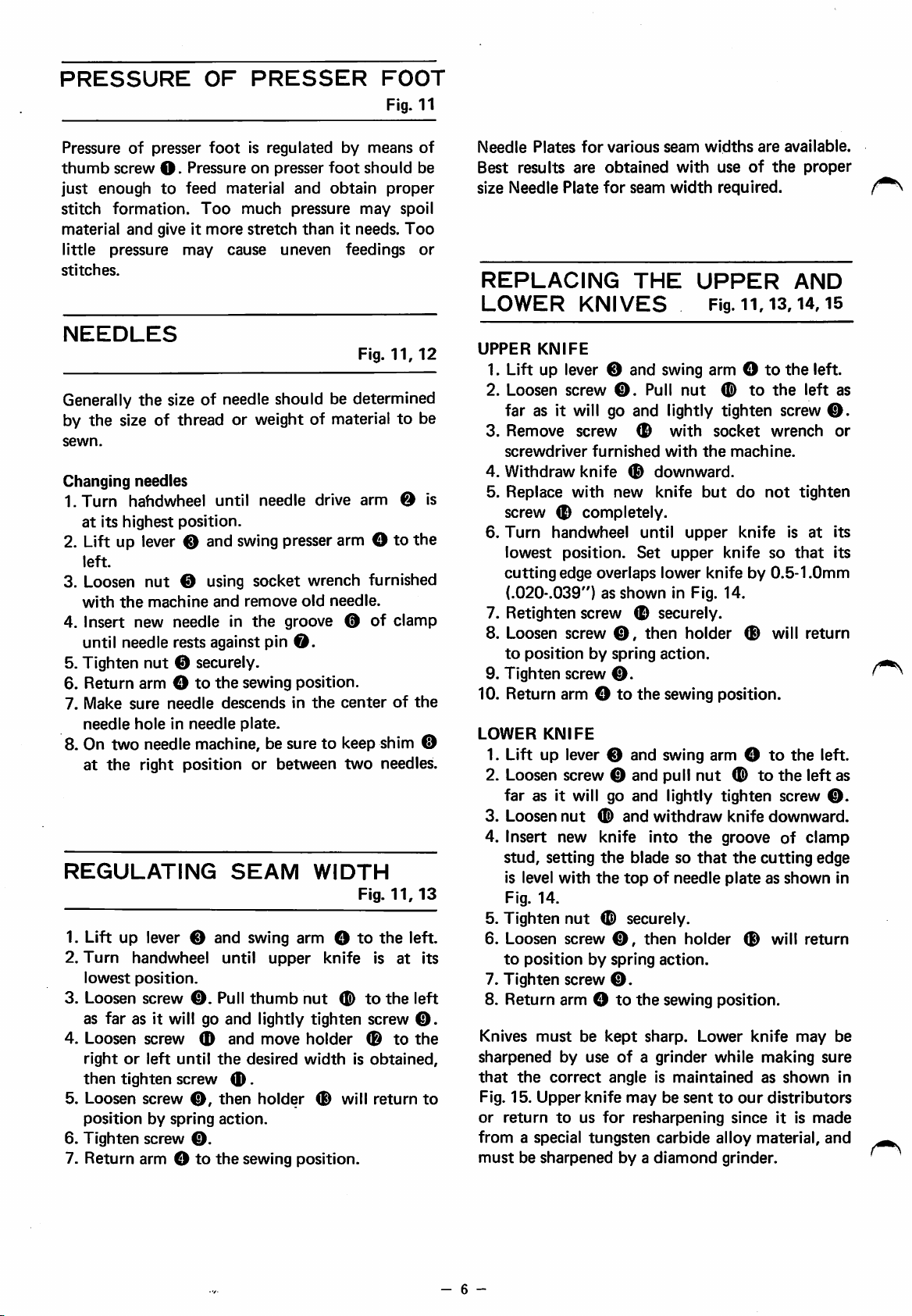

PRESSURE

OF

PRESSER

FOOT

Fig.

11

Pressure

thumb

just

stitch

material

little

stitches.

of

screw

enough

formation.

and

pressure

presser

Oto

give it

foot

Pressureonpresser

feed

material

Too

more

may

cause

is regulated by

foot

and

obtain

much

stretch

pressure

thanitneeds.

uneven

means

should

proper

may

feedings

spoil

Too

NEEDLES

Fig.

11,12

Generally

by

the

sewn.

Changing

1.Turn

at

2. Lift up

left.

3. Loosen

with

4. Insert new needle in

until needle rests against pin

5. Tighten

6.

Return

7.

Make

needle

the

size of needle should be determined

size of thread or weight of material

needles

hahdwheel

its

highest

the

lever

nut

machine

until

position.

0 and

0 using

and

needle

swing

socket

remove

the

drive

presserarm O to the

wrench furnished

old

needle.

groove 0

0.

nut

0 securely.

arm O

sure

holeinneedle

to

needle

the

sewing

descends

plate.

position.

in

the

arm

center

of

to

0 is

clamp

of

the

8. On two needle machine, be sure to keep shim ©

at

the

right position

REGULATING

1. Lift up lever 0 and swing arm O

2.

Turn

lowest

3. Loosen

as

4.

Loosen

rightorleft

then

5. Loosen

positionbyspring

6.

Tighten

handwheel

position.

screw

far

as it will go

screw

tighten

screw

screw

©.

0

until

screw

0,

0.

7. Return arm Otothe

or

between

SEAM

until

upper

Pull

thumb

and

lightly

and

move

the

desired

0.

then

holder

action.

sewing position.

two

needles.

WIDTH

Fig.

11,13

to

the

left.

knife

nut

tighten

holder

widthisobtained,

0 will

is

at

©

to

the

left

screw

©

to

0.

the

return

be

of

or

be

its

to

Needle

Best

size

REPLACING

LOWER

UPPER

Plates

results

Needle

KNIFE

for

various

are

obtained

Plate

for

KNIVES

seam

THE

seam

with

width

widths

use

required.

UPPER

Fig.

ii,

are

of

the

13,14,15

1. Lift up lever 0 and swing arm Otothe

2.

Loosen

screw

0.

Pull

nut

©

to

the

far as it will go and lightly tighten screw

3.

Remove

screwdriver

4.

Withdraw

5.

Replace

screw

6.

Turn

lowest

cutting

(.020-.039")asshown

screw

furnished

knife

with

0

completely.

handwheel

position.

edge

overlaps

0

©

new

Set

with

with

downward.

knife

until

upper

upper

lower

in Fig. 14.

socket

the

but

knifeby0.5-1.0mm

machine.

do

knife

knife

wrench

not

so

7. Retighten screw 0 securely.

8. Loosen

to

9.

Tighten

10. Return arm Otothe

LOWER

1. Lift up lever 0 and swing arm O

2. Loosen screw 0 and pull

far

3.

Loosen

4.

Insert

stud,

is level

Fig.

5. Tighten

6. Loosen

to

7.

Tighten

8. Return arm O

Knives

sharpened

that

Fig. 15.

or

return

from

mustbesharpened

screw

0,

positionbyspring

screw

KNIFE

0.

as it will go

nut

©

and

new

knife

setting

14.

positionbyspring

with

nut

screw

screw

the

the

topofneedle

© securely.

©,

0.

to

must

be

kept

by

useofa

the

correct

Upper

to

a special

angleismaintained

knife

maybesenttoour

us

for

tungsten

byadiamond

then

holder

action.

sewing position.

nut

and

lightly

withdraw

into

the

blade so

then

the

sharp.

resharpening

that

holder

action.

sewing position.

Lower

grinder

carbide

© will

to

©

to

tighten

knife

downward.

groove

the

cutting

plateasshown

© will

knife

while

making

as

distributors

since

it is

alloy

material,

grinder.

available.

proper

AND

left.

left

tighten

is

at

that

return

the

the

left as

screw

of

clamp

edge

return

may

shown

made

as

0.

or

its

its

left.

0.

in

be

sure

in

and

- 6 -

Page 8

Fig.

I I

Upper knife

Fig.

14

.020-039"

1

Needle plate

top

mnni/

Lower

Fig.

surface

t<nife

I2

Fig.

I3

- 7 -

Fig.

I5

Page 9

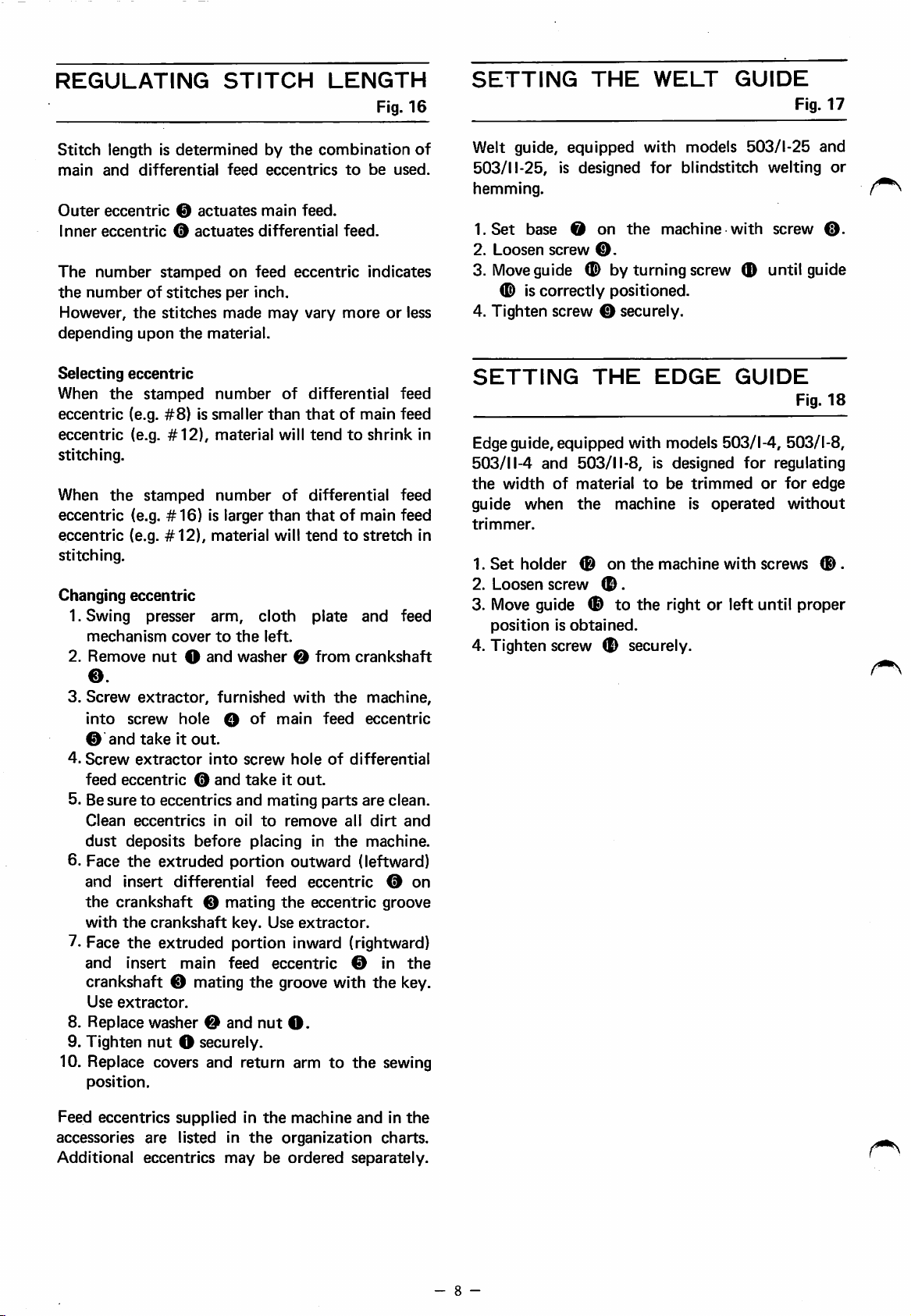

REGULATING

STITCH

LENGTH

Fig.

16

SETTING

THE

WELT

GUIDE

Fig.

17

Stitch

main

Outer

Inner

The

the

However,

depending

Selecting

When

eccentric

eccentric

stitching.

When

eccentric

eccentric

stitching.

Changing

lengthisdetermined

and

differential

eccentric

eccentric

number

0

0

stamped

numberofstitches

the

stitches

upon

eccentric

the

stamped

(e.g.

#8)

(e.g.

#12),

the

stamped

(e.g.

#16)

(e.g.

#12),

eccentric

1. Swing presser

mechanism

2.

Remove

0.

3.

Screw

into

0

4.

Screw

feed

and

eccentric

cover

nut

extractor,

screw

takeitout.

extractor

actuates

actuates

the

material.

number

is smaller

material

number

is larger

material will

arm,

to

O

and

furnished

hole

into

0

and

by

feed

eccentrics

main

differential

on

feed

per

inch.

made

cloth

the

left.

washer

O

of

screw

takeitout.

the

combination

feed.

feed.

eccentric

may

vary

moreorless

of

differential

than

thatofmain feed

will

tendtoshrink

of

differential

than

thatofmain feed

tendtostretch

plate

0

from

with

the

oiai"

feed

hole

of

to

be

indicates

and

crankshaft

machine,

eccentric

differential

5. Besuretoeccentrics and mating parts are clean.

Clean

dust

6. Face

and

the

with

7. Face

and

crankshaft 0 mating

8. Replace

9.

Tighten

10. Replace covers and return arm

deposits

the

insert

crankshaft

the

the

insert

Use

extractor.

position.

eccentrics

extruded

crankshaft

in

before

portion

differential

0

mating

key. Use

oil

placing

to

feed

remove

in

outward

eccentric

the

eccentric

extractor.

all

the

(leftward)

extruded portion inward (rightward)

main

washer0and

nut

O securely.

feed

eccentric

the

groove with

nut

O.

to

0 in

the

dirt

machine.

0

groove

the

sewing

used.

feed

feed

feed

and

the

key.

of

on

Welt guide, equipped with models 503/1-25 and

503/11-25, is

hemming.

I.Set

2.

3.

base

Loosen

Move

O

screw

designed

on

0.

the

for

machine

blindstitch

with

welting

screw

or

0.

guide 0 by turning screw (D until guide

/^^

0 is correctly positioned.

4. Tighten screw 0 securely.

trimmed

is

operated

with

GUIDE

for

regulating

or

screws

Fig.

for

edge

without

0 .

18

SETTING

in

in

Edgeguide, equipped with models 503/1-4, 503/1-8,

503/11-4

the

guide

trimmer.

1.

Set

2.

Loosen

3.

Move

positionisobtained.

and

width

when

holder

guide 0 to the right or left until proper

THE

EDGE

503/11-8, is designed

of

material

the

0

screw

machine

on

the

0.

to

machine

be

4. Tighten screw 0 securely.

Feed

eccentrics

accessories

Additional

supplied in

are

listed in

eccentrics

may

the

the

organization

be

ordered

machine

andinthe

charts.

separately.

- 8 -

Page 10

Fig.

Fig.

I 6

I7

- 9 -

Fig.

I8

Page 11

MECHANICS'

ALIGNMENT

PLATE

TO

INSTRUCTION

OF

NEEDLE

FEED

Rg.

19.20.21

Generally feeds should be in position as shown in

Fig. 19. Each row of main and differential feeds

rests

in

the

center

For

503/1-25

even and slightly touching needle plate

side

O.

If this setting is incorrect, reset as follows.

as

follows.

1. Release pressure on

the

left.

2. Loosen screw O and move

right.

3.

Loosen

right.

screw

4. Loosen screws O

5. Check

the

plate key and move plate

point

O-

6. Tighten screws 0 and

7. Replace

8.

Make

needle

FEED

Standard

3/64")

back

as

shown

A

straight

main

Standard

above

Replacing

1.

Turn

position.

2. Release

the

3.

Swing

4.

Loosen

5.

Remove

6.

Replace

or

then

7. Replace

8.

Return

position.

both

sure

holeinneedle

ADJUSTMENT

heightofmain feed is 0.8-1.2mm (1/32-

above

tooth

when feeds areattheir

in Fig.

edge

and

differential

heightofauxiliary

needle

left.

plate.

feeds

handwheel

pressure

out

cloth

screw0and

screws 0

with

lowering

tighten screws

tube

cloth

of

each

slot

of

and

0

503/11-25,

foot

and

move

and

0.

set

differential feed

and swing

upper

lower

needle

knifetothe

knife

out

at

foot

plate.

right

to

the

groove of needle plate is on needle

to

touch evenly at

O.

knives

needle

the

22.

canbeplaced

new

feeds

0 and tighten screw

into

descends

plate.

surface

feeds.

until

feeds

on

foot

platetothe

remove

and

feeds

feeds

until

proper

0.

plate

and

position.

in

the

center

Fig.

of

needle

highest position

across

the

feedis0.5mm

areattheir

and

swing

left.

tube

0.

0.

and

set

feeds

heightisobtained,

0.

foot

to

of

22,

23,

plate

at its

topofthe

(.020")

highest

out

foot

by

raising

the

sewing

the

24

to

to

Feed dogs have generally been preset at the factory

withafront

to

back

tilt

when

feeds

areattheir

highest position as shown in Fig. 22.

Tilting

1.

2. Release pressure on

3. Swing

feeds

Turn

handwheel

position.

the

left.

out

cloth

until

feeds

foot

platetothe

areattheir

and swing

left.

out

highest

foot

to

4. Loosen screw 0 and turn screw 0 with a

screwdriver

until

proper

tiltisobtained.

5. Tighten screw 0 .

6. Return

position.

Woven

Knit material —

ADJUSTING

HEIGHT

Turn

position. Use timing gauge, check

between

plateasspecifiedinTable

1. Release pressure on

the

2. Push up cover

cloth

material

handwheel

the

pointofneedle

left.

plate

—

Set

Tilt

than

NEEDLE

Tables

until

0.

and

feeds

feeds

the

needle

5.

foot

foot

level.

higher in

rear.

Fig.

and

and

to

the

ARM

21,25,26,27

is

at

its

the

the

topofneedle

swing

out

sewing

the

front

highest

clearance

foot

to

3. Slightly loosen screw 0 .

4. Move arm

descends

needle

5.

Reset

belowatits

plate.

arm

in

the

0

highest

to

right

center

to

correct

position.

or

left until needle

of

the

needle

clearance

hole

in

as listed

6. Tighten screw 0 securely.

7. Return cover 0 and

position.

At this time, with arm 0 down, checktosee

there

needle

Fig.

27.

is clearance

holeinneedle

between

plate

foot

to

the

front

and

needleasshown

the

sewing

that

edgeofthe

in

If clearance is insufficient, loosen screws O and

move

clearance

needle

MODEL

500/1

500/11

is

obtained.

plate

back

CLEARANCE

MM

9.8

10.3

and

forth

until

INCH

.386

.406

correct

Table

-10-

5

Page 12

Fig.

I9

Fig.

20

Fig.

2 I

Fig.

Fig.

24

25

0.8

-1.2inni

1/32-3/64"

Fig.

Fig.

22

23

0.8-1

32-.039"

Fig.

Fig.

.Omm

26

27

-

11

-

Page 13

LEFT

LOOPER

ADJUSTMENT

Table

6 Fig.

28,

29,

30,

31

ADJUSTING

NEEDLE

GUARDS

Fig.

32

1. Release

the

left.

2.

Swing

cover.

3.

Remove

4.

Remove

page.

5.

Remove

6.

Turn

extreme

pressure

out

cloth

needle

needle

feedsasinstructed

handwheel until

left

on

platetothe

plate.

guards

position.

foot

looper

and

swing

left

as

instructed

on

page

lever O is in

and

out

open

12.

foot

on

to

front

this

the

7. Loosen screw o and remove looper..

8.

Insert

down

0 and tighten screw

9. Loosen

of

clearance

screw

On

from

clearanceasshown

10.

Turn

centerline

11. Move lever O back and forth along its

so

then

12.

The

needleasshown

13. Recheck clearance

securely.

14. Replace feeds as

new

until

screwOwith

looper

from

as listed

O-

the

two

centerline

handwheel

of

that

the

tighten

point

looper

baseoflooper

into

O.

centerline

below

needle

screw

of

machine,

of

in Fig.

until

needle.

looper

point

O.

looper

should

in Fig.

and

instructedonpage

lever O

shank

wrench

of

and

left

reaches

and

needletocorrect

lightly

set

pointoflooper

needle

29.

looper

just

point

touches

beinthe

30.

tighten screw O

and

adjust

to

is in

shaft

12.

push

shaft

point

tighten

correct

needle,

scarf

the

©

of

15. Replace needle guards as instructedon this page.

16.

17.

Replace

Return

sewing

needle

cloth

plate,

position.

plate.

front

cover

and

foottothe

Machines

guards.

1. Release

the

2.

Swing

3.

Remove

4.

Remove

5. Loosen screw 0 and remove guard

REAR

are

fitted

Set

rear guard 0 first.

pressure

left.

out

cloth

needle

feedsasinstructed

NEEDLE

GUARD

with

front

on

foot

platetothe

plate.

and

left.

on

and

swing

page

rear

out

12.

O.

needle

foot

6. Loosen screw 0 and remove rear guard

7. Replace with new guard 0 and lightly

tighten screw

8.

Turn

handwheel

is

oppositetothe

9. Adjust guard 0 back

touches

10.

Tighten

FRONT

NEEDLE

11. Replace

12.

Adjust

0.2mm

O.

13.

Tighten

14. Recheck setting

0.

15. Replace

16. Replace

17.

Return

position.

CAUTION:

0.

until

the

pointofleft

centerlineofneedle.

and

forth

needle

without

deflecting

screw 0 securely.

GUARD

with

new

guard

0.

guard 0 until

(.004

.008")

there

between

is a

needle

screw 0 securely.

after

tightening screws 0 and

feedsasinstructedonpage

needle

cloth

Needle

needle

plate.

plate

guards

size is

and

foot

must

changed.

to

be

looper

until it

needle

point.

spaceof0.1-

and

guard

12.

the

sewing

reset

when

to

0.

just

Note:

FEDERAL

when

the

STITCH

503

504

512

514

Left

machine.

Looper

looper

viewed

is self

MODEL

503/1,

504/1, II

514/1,

514/1,

has a

from

2.3mm

above

settingasshown

GAUGE

II

2.0

II

3.0

II

2.0

Table

6

(3/32")

looper

lever in

in Fig.

CLEARANCE

MM

INCH

5.3

.209

5.3

.209

5.3

.209

4.3

.169

5.3

.209

offset

31.

-12-

Page 14

Fig.

28

Fig.

30

Fig.

29

2.3niin

3/32"

t . .

0.1

- 0.2min

.004-.008"

Fig.

Fig.

31

32

-13-

Page 15

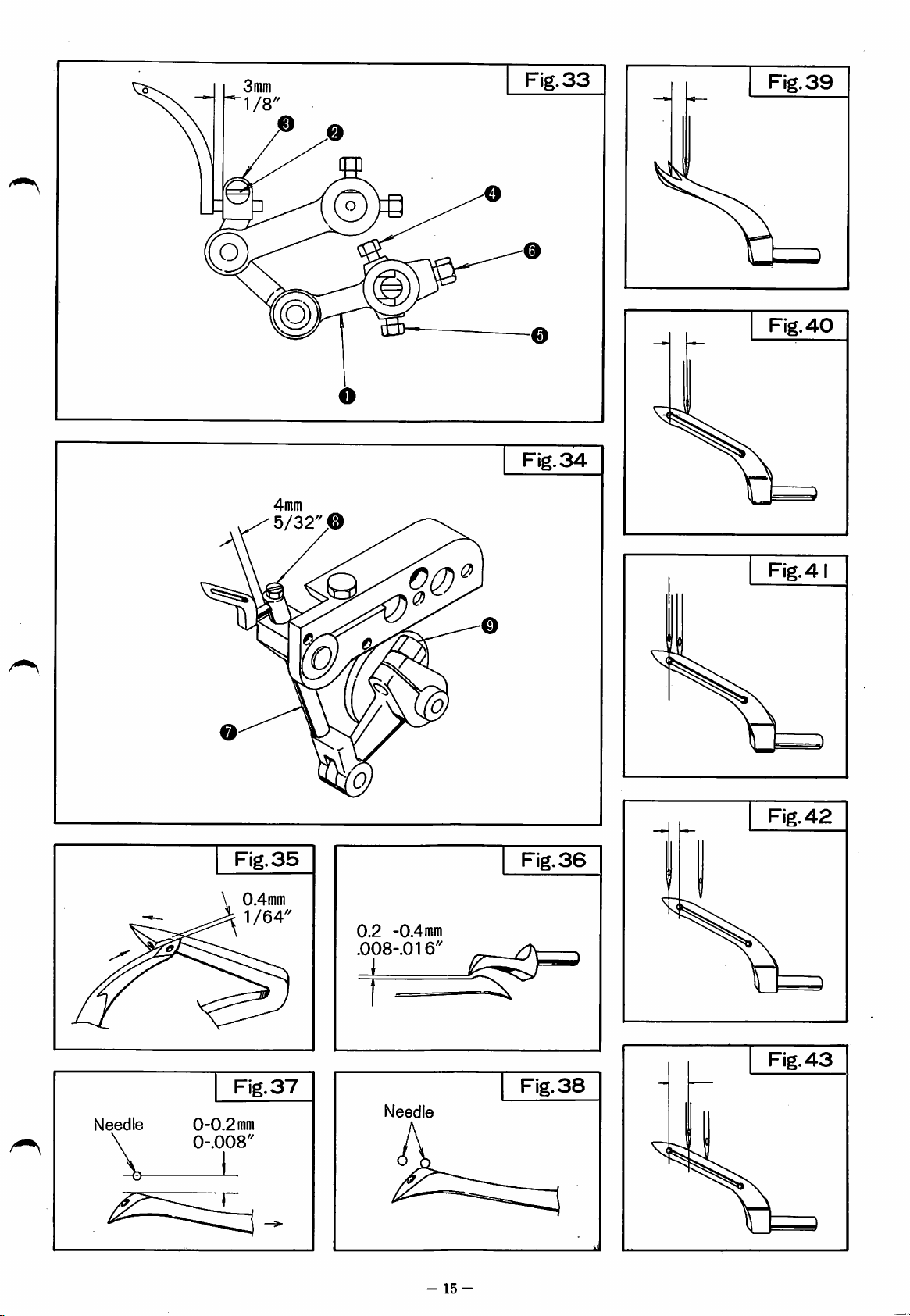

RIGHT

LOOPER

ADJUSTMENT

Table1.8 Fig.33-

500/1

1. Release pressureonfoot

the

left.

2. Swing

Open

3.

plate.

4.

5.

6.

Turn

lowest

7. Loosen

the

lever O

8.

Tighten

9.

Turn

left

10. Loosen screws O

Remove

Remove

back

handwheel

position.

out

cloth

platetothe

front

cover

needle

plate.

feedsasinstructed

handwheel

position.

screw

edge

to

3mm

until

and

of

loopertothe

(1/8").

screw 0 lightly.

until

and

11. Slightly loosen screw 0

or

spreader

terline

below

upward.

12. Make sure it is

(bottom

of

needle

by moving

to

connection

correct,

and

remove

connection

adjust

looperisat

0.

of

correct

then

and

and

V groove)

lightly.

13.

Turn

handwheel

both

loopers

possible

35

14.Ifright

and

without

36.

looper

nectionOdownward.

left

until

correct

below.

loopers

Turn

pass as

15. If clearance is

upward.

correct

Turn

Move

clearance

handwheel

passasshown

16. Tighten screw

slowly

pass

they

and

should

touching

strikes

left

Move right

clearance

handwheel

shown

too

right

and

in Fig.

0,

and

in Fig.

much,

looper

is

obtained

observe

35.

and tighten screws O and

0 alternately.

17.

Rotate

looper

Fig.

looper in its lever © and adjust right

so

that

both

loopers

36.

18. Retighten screw 0 securely.

19.

Looper

as

On

that

touches

rightasshown

20.

Replace feeds as

21.

Replace

22.

Replace

cover.

23.

Return

position.

FEDER

AL

STITCH

503

504

512

514

shown

the

upper

should

in Fig.

two

the

needle

looper

cloth

MODEL

503/1,

504/1,

514/1,

514/1,

not

strike

37.

needle

portion

right

machine,

of

needleinits

in Fig.

38.

instructedonpage

plate.

thread

plate

and

GAUGE

II

II

2.0

II

3.0

II

Table

the

plate

7

swing

out

left.

looper

on

page

12.

O isatits

the

clearance

faceoflooper

its

adjust

looper

from

clearance

O

downward

tighten

observe

screw 0

that

be as close as

as

shown

looper,

move

loopertothe

is

obtained

observe

that

35.

move

connection

to

the

right

as

listed

that

both

pass as

needle

adjust

shown

when

looper

backoflooper

movementtothe

12.

and

close

foot

to

the

CLEAR

ANCE

MM

-1.0

3.0

3.0

0 0

3.0

INCH

.118

.118

-.039

.118

43

foot

to

thread

from

extreme

eye

cen-

as

listed

or

when

in Fig.

con

as

listed

both

O

until

below.

loopers

passing

so

just

front

sewing

FIG.

39

40

41

42

43

in

500/11

1. Release pressure on

the

left,

2. Swing

3. Open

4.

5.

6.

7. Loosen screw 0

out

cloth

platetothe

front

cover and remove looper

plate.

Remove

Remove

Turn

lowest

needle

plate.

feedsasinstructed

handwheel until

position.

and

the

back edgeofloopertothe

0

to

4mm

(5/32").

8. Tighten screw © lightly.

9.

Turn

left

handwheel

position.

until

10. Slightly loosen screw

11. Adjust looper eye or spreader

groove)

from

centerline

clearance as listed below by moving lever 0

downwardorupward.

12. Make sure it is correct, then tighten screw 0

lightly.

13.

Turn

handwheel

both

possible

and

36.

loopers

without

slowly

pass

touching as shown in Fig.

14. If right looper strikes left looper, move lever

0

downward.

until

correct

below.

loopers

Turn

pass as

15. If clearance is

Move

clearance

right

handwheel

as

shown

in Fig.

clearance

handwheel

too

looper

is

obtained

and

Move

shown

much,

observe

35.

16. Tighten screw 0 securely.

17.

Rotate

looper

Fig.

36.

looper

so

that

in its

both

18. Retighten screw 0 securely.

19.

Looper

as

On

that

touches

rightasshown

20.

Replace

21.

Replace

22.

Replace

cover.

23.

Return

position.

Note:

shown

the

upper

should

in Fig.

two

the

not

37.

needle

portion

right

needle in

in Fig.

feedsasinstructedonpage

needle

cloth

looper

plate.

thread

plate

Various right loopers are provided as listed

on page 18 for use with various size needles.

For

easeofidentification

been

marked

-14-

withalooper

foot

and

looper

adjust

looperisat

©.

and

they

should

right

is

and

in Fig.

move

to

the

as

that

holder

loopers

strike

machine,

of

the

38.

plate

and

swing

out

left.

on

page

12.

lever 0 isatits

the

clearance

left sideoflever

its

(bottom

of

needle

observe

be as close as

looper

obtained

observe

to

35.

lever 0

right

until

listed

both

and

below.

loopers

adjust

pass as

needle

when

adjust

back

of

looper

its

movementtothe

12.

and

close

foot

to

the

some

loopers

marking.

foot

thread

extreme

to

correct

that

the

as

that

upward.

correct

shown

passing

looper

sewing

to

from

of V

when

35

left

listed

both

Turn

pass

right

in

so

just

front

have

Page 16

4inin

Fig.

Fig.

33

34

Fig.

Fig.

39

40

Fig.

35

\

0.4mm

A 1/64"

0

0.2

-0.4inm

.008-.016''

Fig.

36

Fig.4

Fig.

42

Fig.

38

Needle

0-0.2

0-.008"

Fig.

mm

37

Needle

_L

-

15

-

Fig.

43

Page 17

PRESSER

Presser arm

must

ARM

be aligned

ALIGNMENT

correctly

and righttoleft to insure lifting

and

alignmentofthe

needle

holeinneedle

needle

plate.

holeinfoot

Fig.

44, 45,

fronttoback

without

a bind

with

46

the

2.

Turn

handwheel

until

feeds

are

at

its

lowest

position.

3. Loosen screw

needle

plate.

and

position

foot

flat on

4. Tighten screw 0 and reset pressure by turning

screw

0

clockwise.

5. Pressure should be just enoughtofeed material

evenly so

that

proper

stitch

is formed.

Fronttoback

1. With

alignment

foot

attachedtoarm,

loosen screws O

o.

2.

Adjust

thereisno

3.

Tighten

arm

back

bindinbar

screw

©.

and

forth

while liftingtoinsure

©.

4. Position regulator O against connection

5.

Tighten

Once

Righttoleft

1.

Loosen

2.

Shift

left

holeinneedle

3.

Check

armisstraight.

,4. Tighten screws © and

PRESSER

Setting

1.

Remove

©

screw

O -

setdonot

loosen

alignment

screws©and

bracket

until

the

© and

needle

plate

bar

© is on guide ©

FOOT

foot

square

pressure

anti-clockwise.

and

hole

are

flat

from

screw

©.

guide

©.

©

in

foot

aligned.

properly

©.

ADJUSTMENT

foot

by

to

the

and

turning

right

the

and

Fig.

and

©.

or

needle

presser

45,

46

screw

Adjusting

1.

Loosen

foot

screw

tilt

0

2. Raise or lower regulator ®

tilt

for

the

weightofmaterial being sewn.

3. Retighten screw

PRESSER

0.

FOOT

ADJUSTMENT

1.

Loosen

lowest

2.

Loosen

3.

Turn

(15/64")

for

4. Tighten

5. While lifting presser

500/1),

between

of

position.

screw

500/1)

0.5mm

nut

nut

when

nut

turn

screw

(.020").

0

and

turn

0.

0

untilaliftisobtainedof6.0mm

presser

foot

0 .

footof6.0mm

screw

0

0 until

and

stopper

6. Tighten nut 0 .

7. With presser

0 and adjust

bottom

2 —

3mm

8.

Tighten

foot

the

of

screw

(5/64—1/8")

nut

0

on

needle

play clearance from

0

to

by

to

LIFT

screw

top

turning

give

Fig.

0

is lifted.

(4.5mm

the

0 is

plate,

of

lever ©

screw

the

desired

45,

46,

until

(4.5mm

clearance

obtained

loosen

47

its

for

nut

the

to

0.

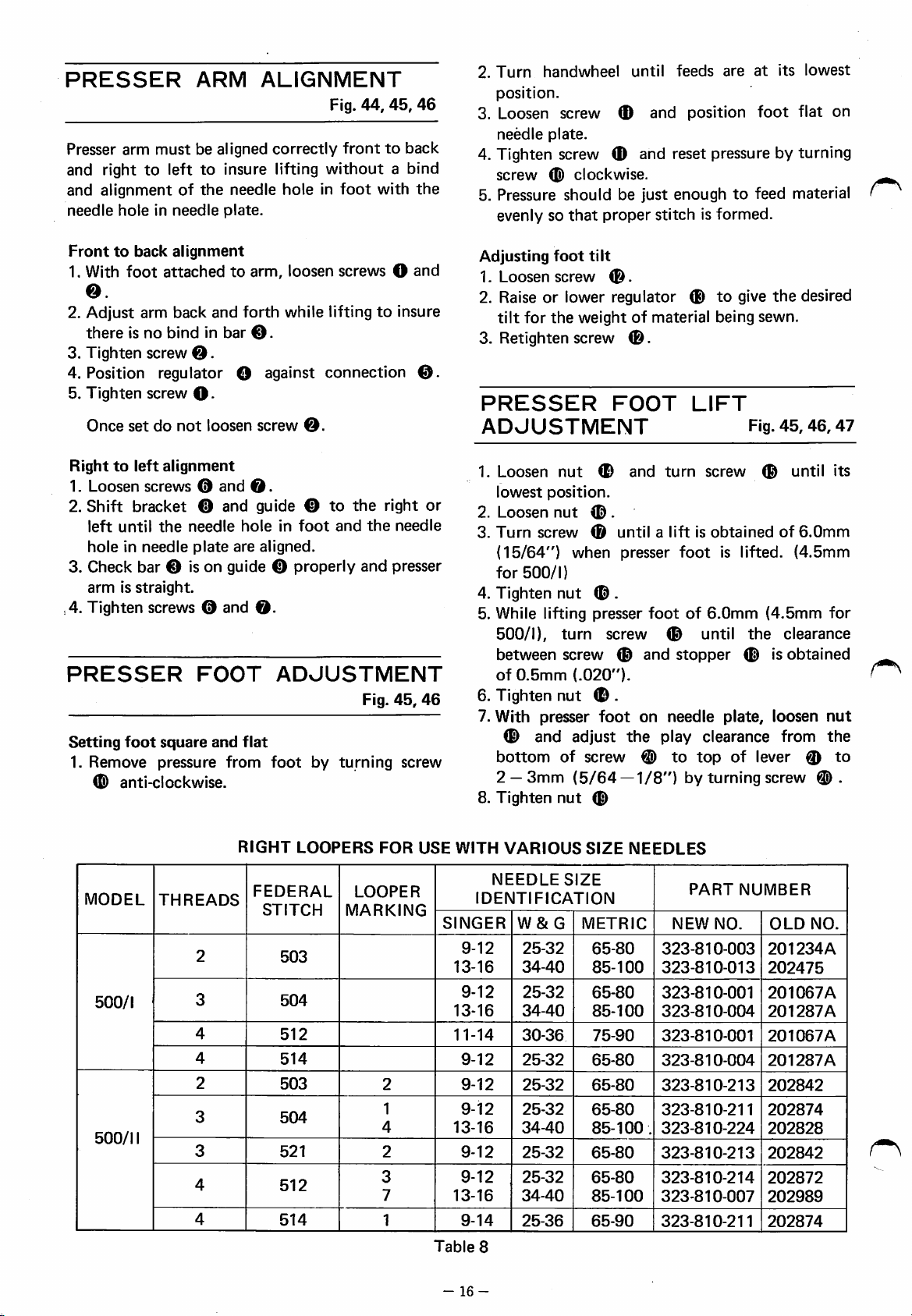

MODEL

500/1

500/11

RIGHT

THREADS

2

3

4

4

2

3

3

4

4

LOOPERS

FEDERAL

STITCH

503

504

512

514

503

504

521

512

514

FOR

LOOPER

MARKING

2

1

4

2

3

7

1

USE

Table

WITH

SINGER

13-16

13-16

11-14

13-16

13-16

-16-

VARIOUS

NEEDLE

IDENTIFICATION

9-12

9-12

9-12

9-12

9-12

9-12

9-12

9-14

8

W&G

25-32

34-40

25-32

34-40

30-36

25-32

25-32

25-32

34-40

25-32

25-32

34-40

25-36

SIZE

METRIC

SIZE

65-80

85-100

65-80

85-100

75-90

65-80

65-80

65-80

85-100

65-80

65-80

85-100

65-90

NEEDLES

.

PART

NEW

NO.

323-810-003

323-810-013

323-810-001

323-810-004

323-810-001

323-810-004

323-810-213

323-810-211

323-810-224

323-810-213

323-810-214

323-810-007

323-810-211

NUMBER

OLD

201234A

202475

201067A

201287A

201067A

201287A

202842

202874

202828

202842

202872

202989

202874

NO.

Page 18

© & P

Fig.

44

© O

Fig.

46

Fig.

45

Fig.

47

®.x

\o®

/V

{:

-17-

Page 19

500/1

&

500/11

TIMING

GAUGES

500/1

RESPECTIVE

MEASURING

POSITIONS

REQUIRED

323-882-800

151

AT

500/11

cz:^

BASIC

POSITIONS

©

ON

MEASURING

323-882-202

183

A) Needle, at upper dead

point

B) Right looper,atleft dead

(Needle

sizp 9)

C) Left looper,atleft dead

(Needle

size

9)

D) Main feed dog,atupper

point

point

dead

point

from

needle

plate

toptoneedle

from left side of needle

from

left

sideofneedletolooper

from

needle

plate

top

to

to

center

top

edgeoffeed

point.

point.

of

looper eye.

teeth.

-18-

Page 20

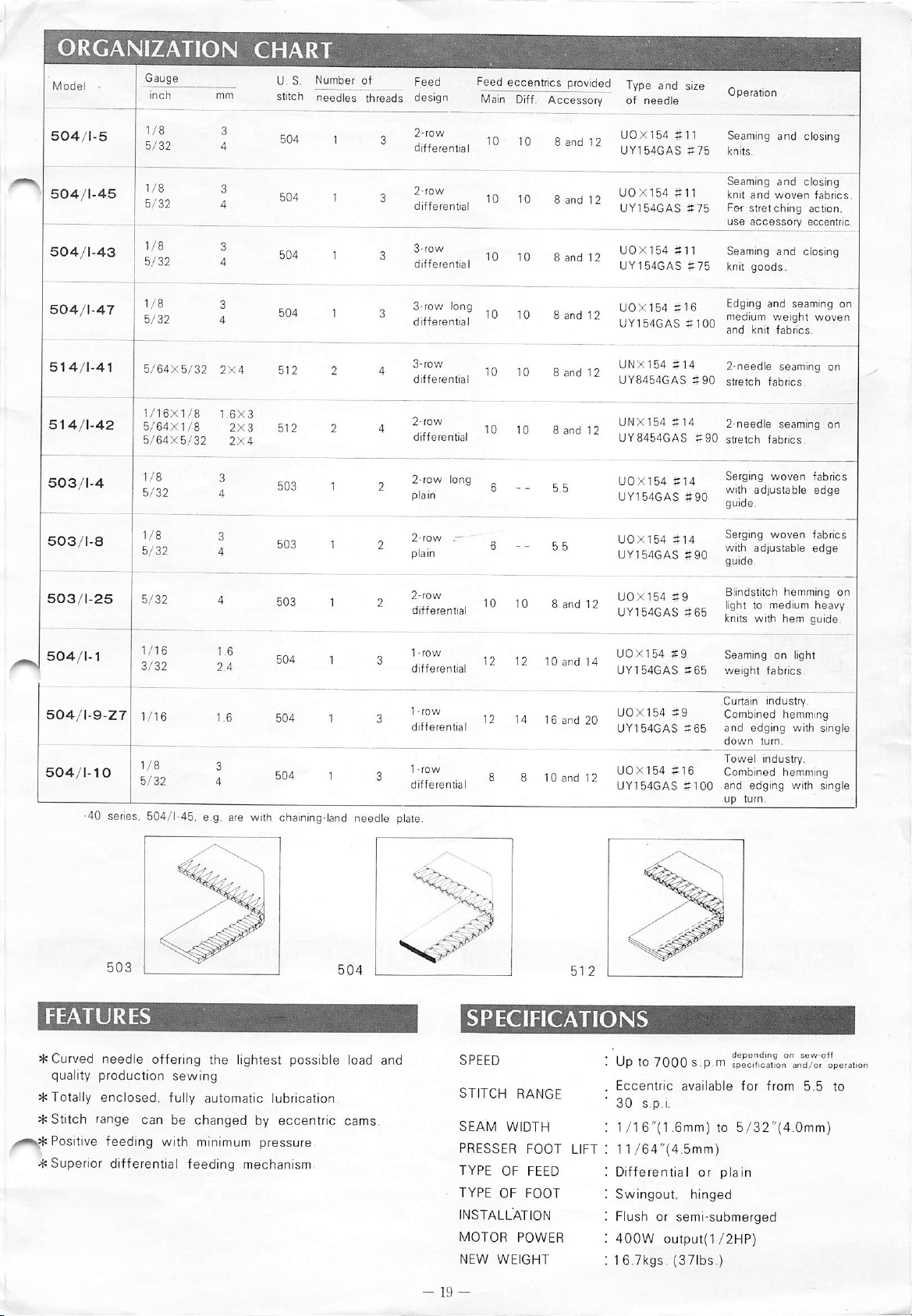

ORGANIZATION

CHART

504/1-5

i

504/1-45

504/1-43

504/1-47

514/1-41

5 1

4/1-42

503/1-4

5/64X5/32

1/16X1/8

5/64X1/8

5/64X5/32

2X4

1.6X3

2X3 512

2X4

U.S.Number

stitch

needles

504

504

504

504

512

503

1

1

1

1

1

of

threads

4

Feed

design

differential

2-row

differential

3-row

differential

3-row

differential

3-row

differential UY8454GAS

2-row

differential UY8454GAS

2-row

long

long

Feed

Main

in in

10

eccentrics

Diff.

Accessorv

10 8

B

Sanriio

provided

b ^ n UOX154 #11

and

Type

of

UY154GAS#75

12

UOX154

UY154GAS

and

needle

UGX154

UY154GAS#75

UOX154

uy154GAS#100

anH19ONX154

'-'NX154

UOX154

UY154GAS#90

#11

#11

#16

#14

#14

#14

size

#75

#90

#90

Operation

Seaming

knits.

Seaming

knit

Fsf

use

Seaming

knit

Edging

^^edium

and

2-needle

stretch fabrics.

2-needle

stretch fabrics

Serging

^^^h

and closing

and

and

woven

stretching

accessory

and

goods.

and

weight

knit

fabrics.

seaming

seaming

woven

ad|ustable

closing

fabrics.

action.

eccentric.

closing

seaming

woven

fabrics

edge

on

on

on

503/1-8

503/1-25

504/1-1

504/1-9-271

504/1-10

5/32

1/16

-40 series. 504/1-45, e.g. are

2-row

503

503

504

1

1

1

504 1 3 12 14 16

504

with

chaining-land

1 3

needle

plate.

-•

pla in

differential

differential

differential UY154GAS

1-fow

differential UY154GAS

10

12

g g

10

12 10

10

8

and

and

and

and

12

14

20

12

U0X154 #14

UY154GAS

UOX154

UY154GAS

'-'0X154

UY154GAS

'-'0X1S4

#9

#9

#16

Serging

#90

Blindstitch

#66

knits with hem guide.

Seamingonlight

#65

weight

.Curtain industry.

Combined

#65

and

edging with single

down turn.

Towel

Combined

#100

and edging with single

up

turn.

woven

hemming

fabrics.

hemming

industry.

hemming

fabrics

on

I

* Curved

quality production

*Totally

needle

enclosed,

offering the lightest possible load and

sewing

fully automatic lubrication.

* Stitch range can be changed by eccentric cams.

Positive

•4;

Superior differential feeding mechanism

feeding

with minimum

pressure

SPEED

STITCH

SEAM

PRESSER

TYPE

TYPE

INSTALLATION

MOTOR

NEW

RANGE

WIDTH

FOOT

OF

FEED

OF

FOOT

POWER

WEIGHT

LIFT

l^^f-ir\r\r\

Upto/UUUS.p.m

Eccentric

30

s.p.i.

1/16"(1.6mm)to5/32"(4.0mm)

II

/64"(4.5mm)

Differential

Swingout,

Flush or

400W

16.7kgs.

depending on sew-off

specification and/or operation

available

for

or

plain

hinged

semi-submerged

output{1/2HP)

(37lbs.)

from

5.5

to

Page 21

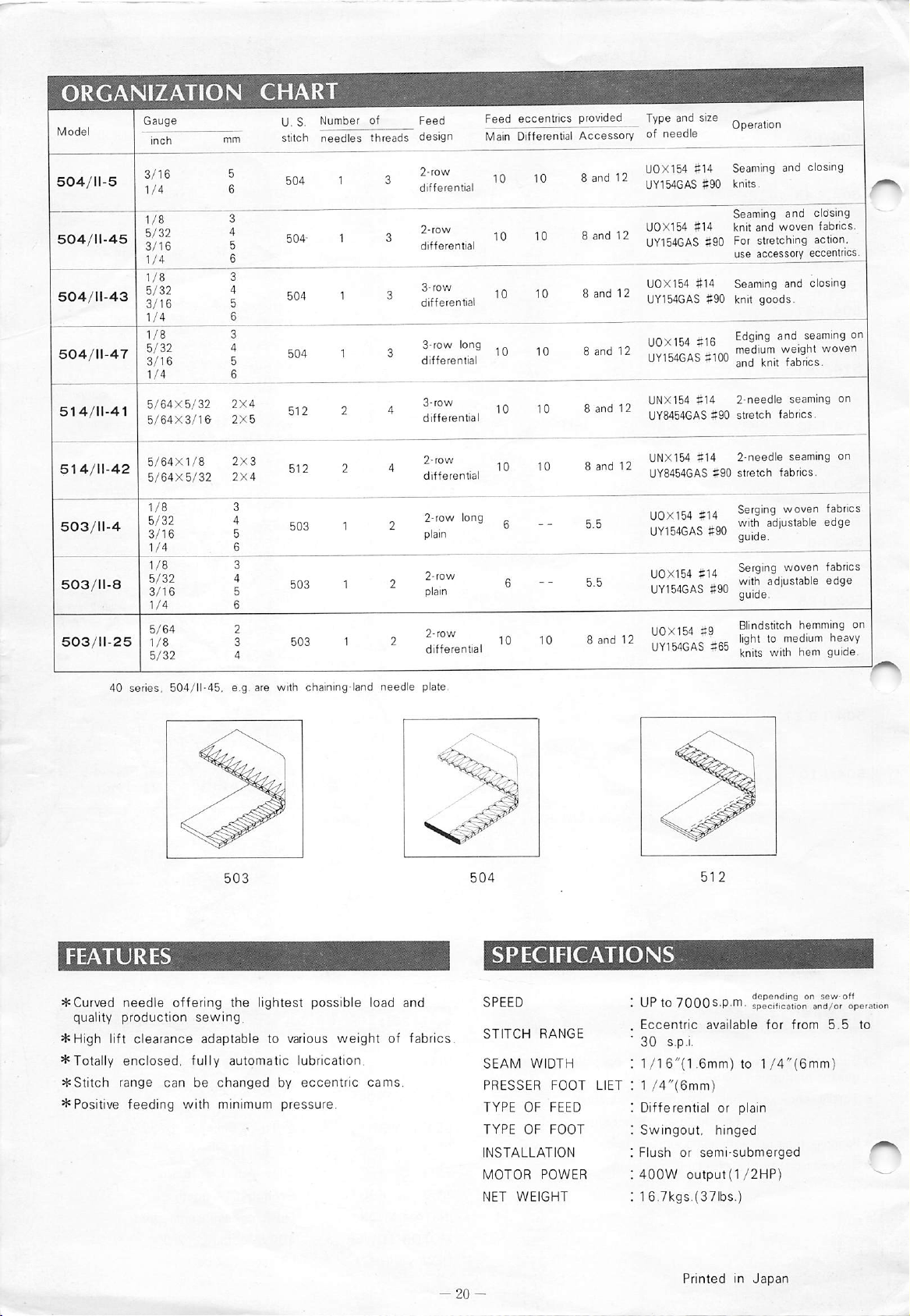

ORGANIZATION

CHART

U.S.

stitch

Number

needles

of Feed Feed eccentrics

threads

design

Main Differential

provided

Accessory

Type and size

of

needle

Operation

504/11-43

504/11-47

514/11-41

514/11-42

503/11-4

503/11-8

504

1/4

5/64X5/32

5/64X3/16

5/64X1/8

5/64X5/32

1/8

5/32

3/16

1/4

1/8

5/32

3/16

1/4

5/64

1/8

5/32

40 series. 504/11-45, e.g. are with chaining-Iand

2X4

2X5

2X3

2X4

3

4

5

6

3

4

5

6

2

3

4

503

1

1

needle

2-row

differential

2-row

differential

3-row

differential

3-row

differential

3-row

differential

2-row

differential

2-row

plain

2-row

differential

plate.

long

long

10

10 10

10 10

8

10

and

UOX154 fi14 Seaming and closing

12

UY154GAS

#90

knits.

Seaming and closing

UOX154

#14

knit

and

woven

seaming

fabrics.

seaming

fabrics.

seaming

fabrics.

-Tm"

hemming

medium

fabrics.

on

on

*!?""

heavy

guide.

on|

on

8

and

12

UY154GAS

8

and

8

and

8

and

8

and

UOX154 #14 Seaming and closing

12

UY154GAS

UOX154

12

IIV164rAS

UY154GAS#100

UNX154

12

UY8454GAS

UNX154

1 2

UY8454GAS

UOX154

u?r5iGAS

UOX154

UY154GAS

8

and

iiovit^d iQ

12

iiYirtdTA^

UY154GAS

#90 For stretching action.

use accessory eccentrics.

#90 knit

goods.

#16

ttlOO

#14

2-needle

#90

stretch

#14

2-needle

#90

stretch

#14

MO

S14

S90

Blindstitch

itfil

#65

I

.

^Curved

quality

*High

^Totally

*Stitch

* Positive

needle

production

lift

clearance

enclosed,

range

feeding

offering

sewing,

adaptable

fully

can

be

changed

with minimum

the

lightest

to various

automatic

possible

lubrication.

by

eccentric

pressure.

weight

load

of

cams.

and

fabrics.

-20-

SPEED

STITCH

SEAM

PRESSER

TYPE

TYPE

INSTALLATION

MOTOR

NET

RANGE

WIDTH

OF

FEED

OF

FOOT

POWER

WEIGHT

FOOT

iin.

. UP to

.

Eccentric

30

:

1/I

LIET

: 1

!

Differential

Swingout,

;

: Flush or

:

400W

:

16.7kgs.{37lbs.)

-t

n f. ^ -

7000s.p.m.

available

s.p.i.

6"{1.6mm) to

/4"(6mm)

semi-submerged

output(1/2HP)

PrintedinJapan

or plain

hinged

de

Bendingonsew-off

specification

for

and/or

from

1/4"(6mm)

5.5

operation

to

Page 22

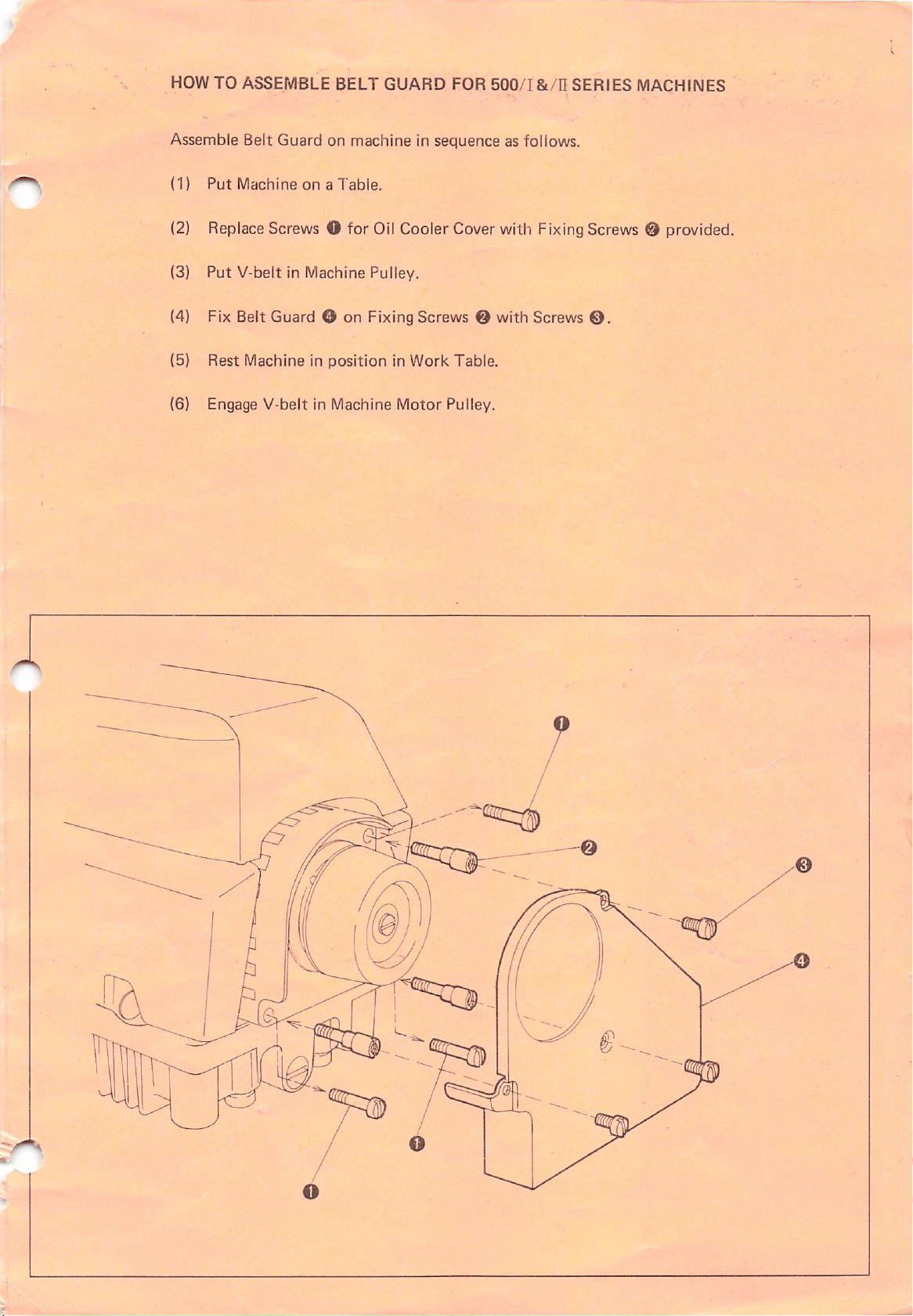

HOW TO ASSEMBLE BELT GUARD FOR

Assemble Belt Guard on machine in sequence as follows.

(1)

Put

Machineona

Table.

500/1

&/n

SERIES

MACHINES

(2) Replace Screws O for Oil Cooler Cover with FixingScrews 0 provided.

(3) Put V-belt in Machine Pulley.

(4) Fix Belt Guard O on Fixing Screws O with Screws

(5)

Rest

Machine in

(6) Engage V-belt in Machine Motor Pulley.

positioninWork

Table.

©.

Page 23

o

Cat.

No,

8082(023-410-026)

Printed in

Japan(0n781Tn5)

Loading...

Loading...