Page 1

INSTRUCTION

PARTS

&

CATALOG

-

:

r

GIBBS

WILLCOX

500/I

&

&

500/Il

OVERLOCKS

WILLCOX

1040

AVENUE

OF

THE

8’

AMERICAS

—1

gIBrn!’!!°

YORK.

NEW

NEW

YORK

10018

(212)

565-7900

Page 2

TABLE

OF

CONTENTS

Introduction

How

to

Driving

Lubrication

Threading

Regulating

Pressure

Needles

Regulating

Replacing

Regulating

Setting

Setting

the

the

clean

motor,

your

thread

of

presser

seam

the

stitch

welt

edge

your

pulley

machine

width

upper

length

guide

guide

machine

and

tension

foot

and

belting

lower

OPERATORS

knives

INSTRUCTION

PAG

4

4

4-5

4-5

6-7

6-7

8-9

8-9

8-9

8-9

10-11

10-1

10-11

E

1

Alignment

Feed

Adjusting

Left

looper

Adjusting

Right

Presser

Presser

Presser

Timing

of

adjustment

needle

needle

looper

arm

alignment

foot

foot

gauges

Millimeter-inch

needle

arm

adjustment

guards

adjustment

adjustment

lift

adjustment

fraction

plate

height

&

to

feed

decimal

MECHANICS’

conversion

INSTRUCTION

chart

12-13

12-13

12-13

14-15

14-15

16-17

18-19

18-19

20

21

1

—2—

Page 3

Mdclii

iC

Ma

n

Irarne

Crankshalt

Needle

Right

Right

Left

Main

Upper

Presser

(1)

(2)

Plain

Attachments

Chain

Suction

Mounting

Accessories

Thread

drive

looper

looper

looper

and

and

foot

Pump

Pump

feed

cutter

stand

bed

[raine

and

niechanisrn

mechanism

drive

drive

drive

diflerential

lower

and

lubricating

lubricating

mechanism

models

device

accessories

miscellaneous

mechanism

mechanism

mechanism

feed

knife

mechanism

lifting

mechanism

mechanism

KSR-570,

model

VSA-200

covers

for

for

mechanism

mechanism

KSR-571

for

PARTS

500/I

500/Il

chain

and

cutter

LIST

KSR-572

SECTION

503/I&11-4,

503/I

PAGE

22-23

24-25

26-27

28-29

30-31

32-33

34-35

36-37

38-39

40-41

42-43

44-45

11-8

&

46-47

48-49

50-51

52-53

54-55

56-57

58-59

504/1-5.

504/1-47.

503/1-4.

504/I-i.

504/11-5.

504/11-47.

1-4.

503/I

Additional

Numerical

Numerical

504/1-45.

514/1-41.

503/1-8.

504/I-9-Z7.

504/11-45.

514/11-41.

503/11-8.

organization

index

of

index

of

new

old

504/1-43

514/1-42

503/1-25

504/1-10

504/11-43

514/11-42

503/11-25

chart

product

numbers

ORGANIZATION

NUMERICAL

code

numbers

with

new

product

INDEX

with

code

CHARTS

PARTS

old

numbers

numbers

60-61

62-63

64-65

66-67

68

69-73

74-78

—3—

Page 4

OPERATORS’

INTRODUCTION

You

are

aliou

t

designed

overlock.

features

easier

increase

smoothly,

quietly.

machines

OPERATOR’S

HOW

by

In

to

assist

handling

your

has

The

are

TO

the

this

production.

Willcox

FAVORITES”.

CLEAN

MACHINE

Clean

operation.

Merely

Swing

lint

the

lint

sewing

DRIVING

the

release

out

from

needle

brush.

position.

machine

It

is

the

around

plate.

Replace

riot

the

covers

MOTOR,

BELTING

It

must

be

used

with

following

1.

Driving

watts

2.

Motor

50

3.

Belting

4.

The

pulley

specifications

(1/2HP)

speed

Hz

or

used

relation

diameter

motor

is

3,500

should

between

LUBRICATION

CAUTION:

Oil

when

Refill

was

INSTRUCTION

to

opera

people

macli

you,

as

and

[aster

automatic

&

the

machines

is

necessary

foot

and

and

the

loopers,

Blow

out

covers

the

for

of

3

phases,

is

recommended

approximately

r.p.m.

shipped.

with

be

is

determined

drained

oil

for

type

machine

Ic

an

who

me

you

the

operator,

sewing

It

is

lubrication,

Gibbs

YOUR

simple

a

to

swing

remove

feed

any

and

PULLEY

motor

individual

60

M

Table

from

before

overlock

first

will

that

easy

class

known

remove

it

all

slots,

loose

return

and

2

poles

to

2,900

Hz.

of

V-belt.

speed

by

Table

2

operating.

introd

wi

to

thread,

but

out

the

lint

belting

use.

this

Fig.

the

ii

iced

[mt

to

enjoy

I

help

and

500/I

as

important

any

to

the

collected

and

or

foot

Table

arid

machine.

r.p.m.

and

motor

1.

1,

machine

ach

the

LuIthe

the

you

feeds

ru

&

‘‘TH

parts.

left.

under

use

to

the

AND

of

the

400

for

2,3

no

is

a

1

II

E

A

new

Lit

Li

At

drained

Operational

7,000

Operational

being

Life

For

Table

Use

Changing

1.

Remove

a

table.

2.

Remove

machine.

3.

Replace

its

4.

Remove

5.

Pour

using

reaches

6.

Replace

7.

Run

splash

8.

Oil

gauge

9.

Change

OIL

SCREEN

Filter

cation

frictional

lack

of

Check

necessary,

Oil

contained

Changing

1.

Drain

2.

Remove

3.

Remove

4.

Clean

pressure

5.

Replace

6.

Replace

7.

Fill

gauge

ii

ach

inc

speed

not

the

end

of

oLit

arid

speed

s.p.m.

speed

performed

time

of

machine

lubricant

2.

recommended

for

oil

the

drain

drain

stand.

filler

fresh

oil

funnel

upper

filler

machine

sight

window

level

should

0.

oil

entirely

FILTER

should

0

oil

is

filtered

surfaces,

lubrication

and

clean

replace

jet

in

window

foam

filter

oil

from

bolts

screws

filter

0

air.

filter

oil

pan

reservoir

with

9.

sl

iou

to

exceed

bLur

replaced.

and

500/I

type

machine

plug

plug

plug

into

supplied

line

plug

and

be

be

always

clogging

and

filter

with

or

the

machine.

and

0

and

0

with

and

0

and

0

oil

Id

weeks,

alter

is

depending

ability

depends

0

0.

reservoir

of

gauge

0.

check

0.

kept

every

by

accidental

0

a

is

0

debris.

oil

petrol

tighten

on

I

run

rn

5,000

four

&

II,

oil

only.

from

and

0

and

with

between

three

kept

this

of

every

new

filter

restricted

pan

filter

and

tighten

a

level

at

s.p.m.

original

weeks

of

operator.

on

quality

use

oil

its

stand

drain

return

(700cc

accessories,

9.

oil

circulation

months.

clean.

and

delivered

this

filter

seizure

three

when:

or

0.

0.

blow

screws

bolts

of

least

oil

run-

upon

as

and

oil

the

two

Since

months,

weak,

it

0.

0.

upper

[our

should

in

may

operation

oil

specified

set

from

machine

Capacity)

until

at

lines

lubri

to

may

cause

of

parts.

or

or

with

low

line

weeks

used.

it

on

the

to

oil

oil

on

all

if

oil

of

he

be

in

p.

The

500/1

&

II

with

a

pressurized

the

connections.

concealed

by

features

a

pump

forced

fully

air

to

automatic

cooling

the

internal

lubrication

system.

surfaces

Oil

is

of

—4—

Page 5

MACHINE

(S.P.M.)

4,600

5,000

5,300

5,500

5,800

6,000

6,300

6,700

7,000

MACHINE

P.M.)

(S.

4,600

5,000

5,300

5,500

5,800

6,000

6,300

6,700

7,000

SPEED

SPEED

MOTOR

MM

95

105

110

115

120

125

I

130

140

145

MOTOR

MM

80

85

90

95

100

105

110

115

120

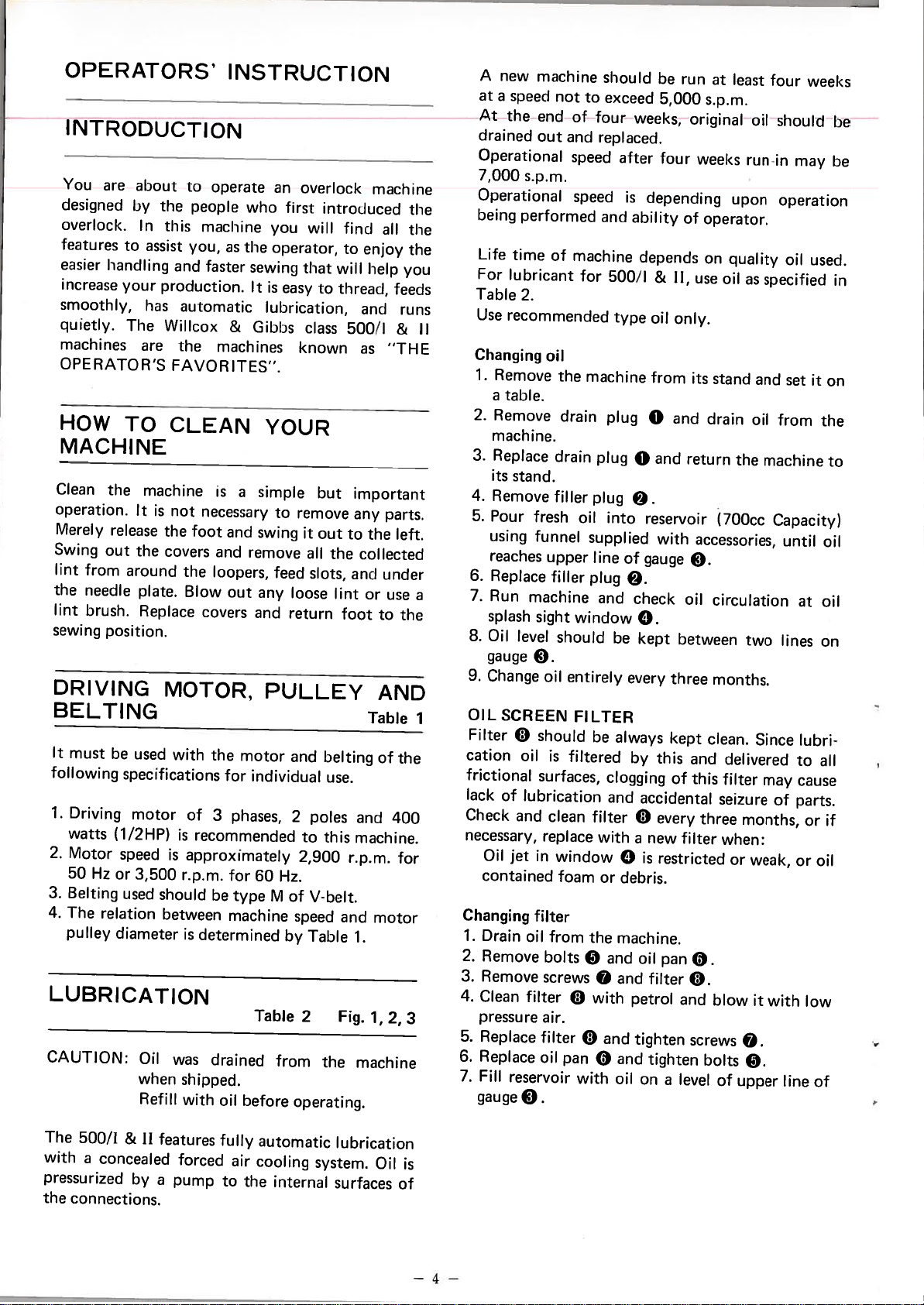

50

PULLEY

INCH

ES

3-3/4

4-1/8

4-3/8

4-1/2

4-3/4

4-7/8

5-1/8

5-1/2

5-3/4

PULLEY

INCHES

3-1/8

3-3/8

3-5/8

3-3/4

4

4-1/8

4-3/8

4-1/2

4-3/4

60

Hi

DIAMETER

PULLEY

in

Hz

DIAMETER

PULLEY

in

U.S.A.

636

641

643

644

646

647

651

654

666

U.S.A.

631

633

635

636

640

641

643

644

646

SIZE

SIZE

Fig.

L

Fig.2

0

Note

1:

2:

Note

(<inematic

Viscosity

(centistokes)

Viscosity

Index

Pour

Point

Carrying

Load

Capacity

Machine

Motor

its

outer

—

I

F)

(°

(kg/cm

2

)

pulley

diameter.

100°F

210°F

VI

(A)

VI

(B)

Table

pulley

[

1

diameter

diameter

Brand

19.01

4.04

130.0

123.5

—59.0

more

(170

than

should

“A”

psi.)

12

is

60mm

be

measured

Brand

147.5

142.5

—63.5

more

14.57

3.57

than

(170

(2.36”).

in

Fig.3

“B”

—0

/0

12

psi.)

Table

2

—5—

Page 6

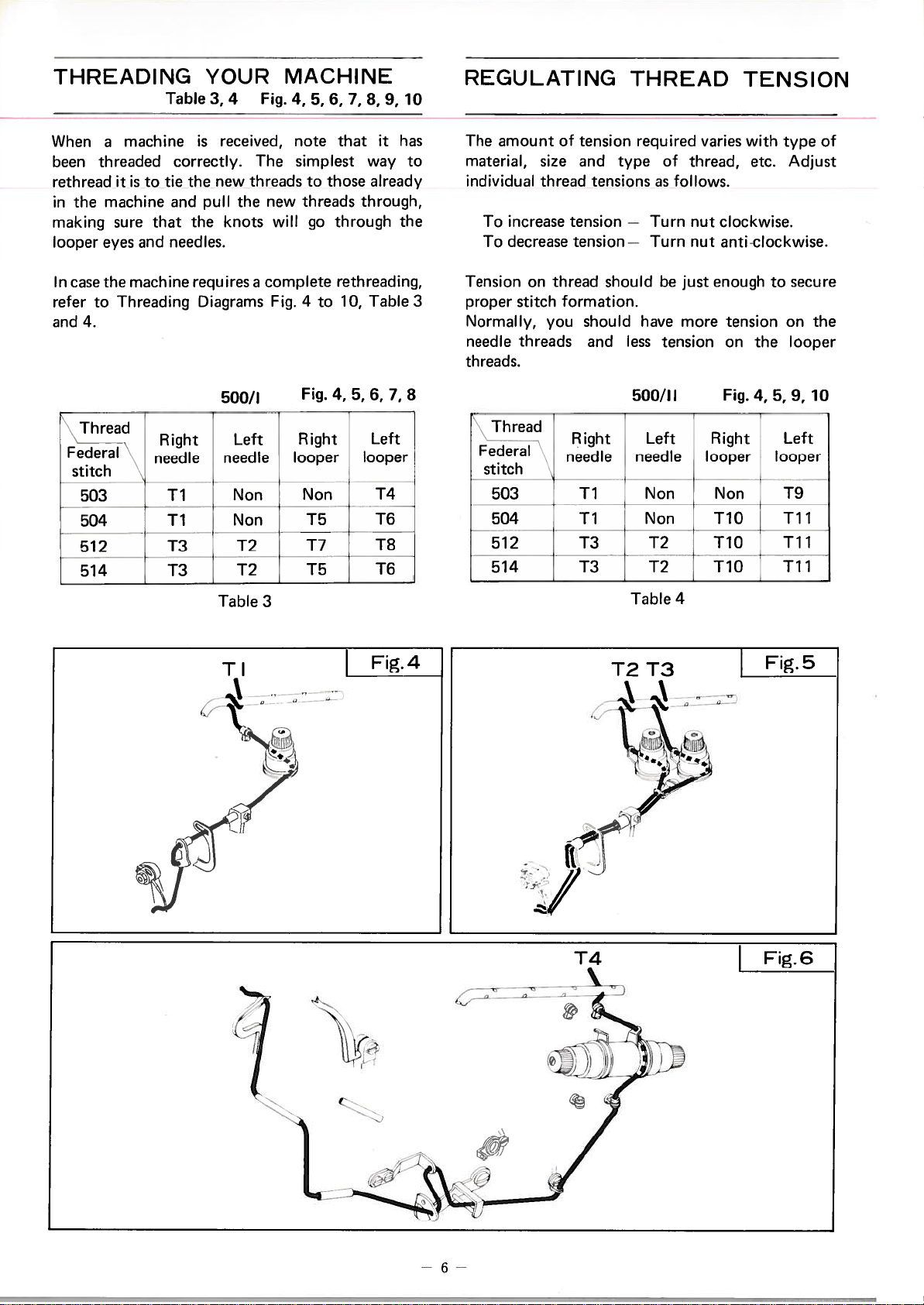

THREADING

Table

YOUR

3,

4

MACHINE

Fig.

4,

5,6,7,

REGULATING

8,

9,

10

THREAD

TENSION

When

been

rethreacl

in

the

making

looper

In

case

refer

and

4.

Thread

Federal

stitch

503

504

512

514

machine

a

threaded

it

is

machine

sure

eyes

the

machine

Threading

to

to

and

correctly.

tie

and

that

needles.

Right

needle

Ti

Ti

T3

T3

received,

is

the

flCW

pull

the

requires

Diagrams

500/I

needle

the

knots

Left

Non

Non

T2

T2

The

threads

new

will

complete

a

Fig.

note

simplest

those

to

threads

go

4

to

Fig.

Right

looper

Non

T5

T7

T5

that

it

way

already

through,

through

rethreading,

Table

10,

4,

5,6,7,

Left

looper

T4

T6

T8

T6

has

the

8

The

amount

to

material,

individual

To

increase

To

decrease

Tension

3

proper

Normally,

needle

size

thread

on

stitch

you

threads

of

tension

and

tensions

tension

tension—

thread

formation.

should

and

type

—

should

less

required

of

as

follows.

Turn

Turn

be

have

tension

varies

thread,

nut

clockwise.

nut

anti-clockwise.

just

enough

more

with

etc.

tension

on

the

to

type

Adjust

secure

on

looper

of

the

threads.

Thread

Federal

stitch

503

504

512

514

needle

.

Right

Ti

Ti

T3

T3

—.

500/Il

needle

V

Left

Non

Non

T2

T2

Fig.

Right

looper

Non

TiO

Ti0

TiC

4,5,9,

I

10

Left

looper

T9

Tli

Tii

Tii

Table

Table

3

Fig.4

T4

//V

/

4

Fig.5

Fig.6

C

—

6

—

Page 7

%-,-,

T5\

Fig.7

\T,

D

Fig.8

t

JJ

Fig.9

Fig.

10

—7—

Page 8

PRESSURE

Pressure

tilunhl)

just

stitch

material

little

stitches.

of

screw

enough

formation.

and

pressure

presser

0.

to

give

NEEDLES

Needles

organization

Generally

by

sewn.

Changing

Turn

1.

at

2.

Lift

left.

Loosen

3.

with

4.

Insert

until

Tighten

5.

Return

6.

Make

7.

needle

On

8.

at

the

its

two

the

for

the

size

of

needles

hahdwheel

highest

up

lever

nut

machine

the

new

needle

nut

arm

sure

hole

needle

right

500/I

charts

size

needle

rests

0

0

needle

in

REGULATING

Lift

1.

2.

3.

4.

5.

6.

7.

Turn

lowest

Loosen

far

as

Loosen

right

then

tighten

Loosen

position

Tighten

Return

up

lever

handwheel

position.

screw

asitwill

screw

or

left

screw

by

screw

arm

until

screw

spring

0

OF

loot

Pressure

lend

Too

it

more

may

&

as

of

thread

until

position.

and

0

using

0

and

against

securely.

the

to

descends

needle

machine,

position

and

0

until

Pull

0.

and

go

and move

D

the

then

0,

action.

0.

the

to

PRESSER

is

on

material

much

stretch

cause

II

shown

needle

weight

or

needle

swing

socket

remove

in

the

pin

sewing

plate.

be

or

SEAM

swing

upper

thumb

lightly

desired

di.

holder

sewing

requlated

presser

and

pressure

than

uneven

series

in

should

presser

wrench

old

groove

0.

position.

in

the

sure

between

WIDTH

arm

nut

tighten

holder

width

®

position.

are

pages

of

drive

needle.

to

0

knife

by

foot

should

obtain

may

it

needs.

feedings

Fig.

specified

60

be

determined

material

arm

arm

furnished

of

0

center

keep

two

Fig.

to

is

to

Ij

screw

®

is

obtained,

will

return

FOOT

Fig.

means

proper

Spoil

11,

to

to

0

to

0

clamp

of

shim

needles.

11,

left.

the

at

the

to

the

Too

68.

the

the

0

13

its

left

0.

to

be

or

12

be

11

of

in

is

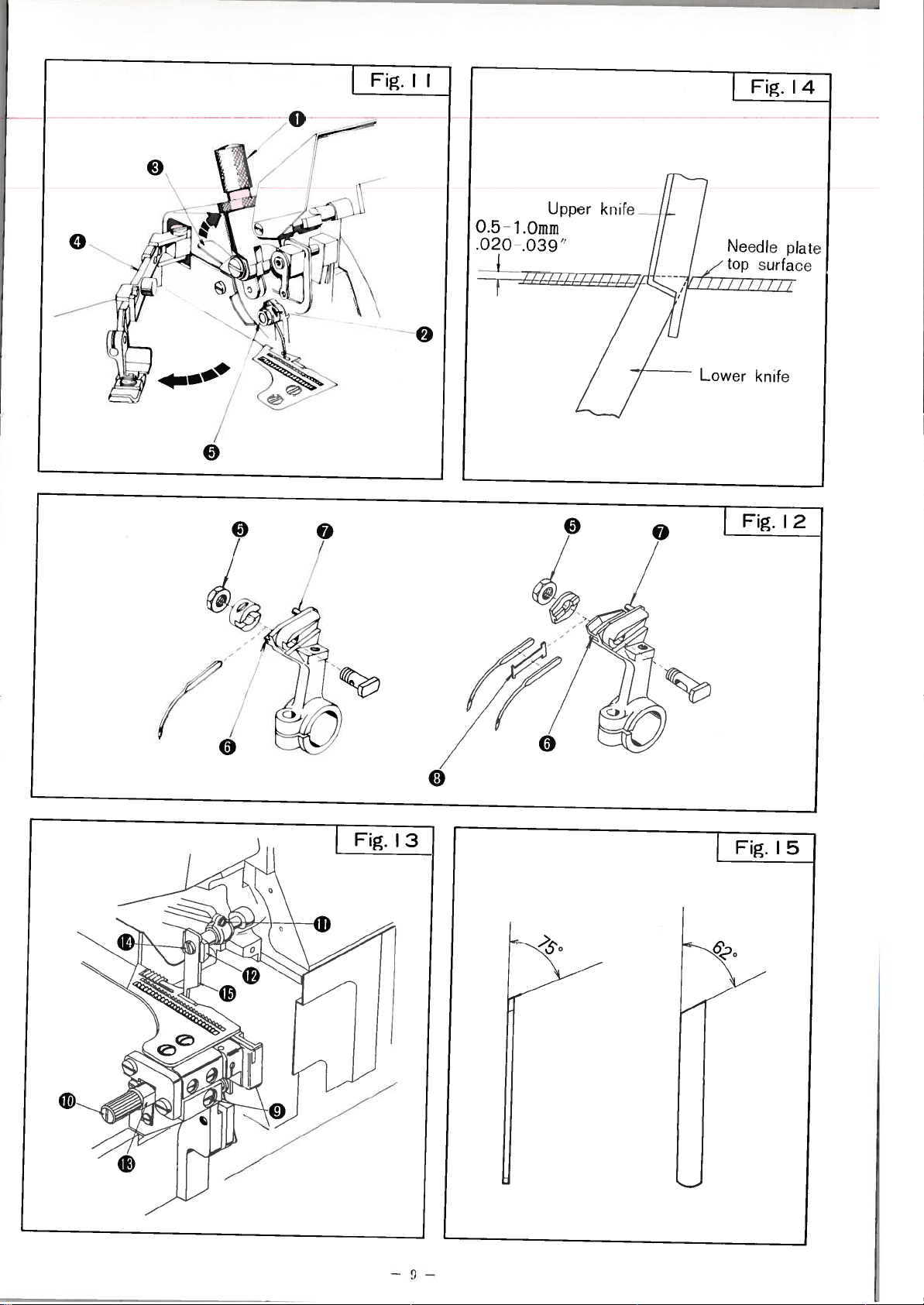

CAUTION:

REPLACING

LOWER

UPPER

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

LOWER

1.

2.

3.

4.

5.

6.

7.

8.

Knives

sharpened

that

Fig.

or

from

must

KNIFE

Lift

up

Loosen

far

as

Remove

screwdriver

Withdraw

Replace

screw

Turn

cutting

to

Tighten

Return

Lift

Loosen

far

Loosen

Insert

stud,

is

Fig.

Tighten

Loosen

to

Tighten

Return

15.

return

handwheel

lowest

(.020-.039”)

Retighten

Loosen

position

KNIFE

up

it

as

setting

level

14.

position

must

by

the

correct

Upper

to

a

special

sharpened

be

it

edge

arm

nut

new

with

nut

screw

screw

arm

When

extremely

needle

width

See

pages

KNIVES

lever

screw

will

screw

furnished

knife

with

completely.

position.

overlaps

as

screw

screw

by

screw

0

lever

screw

will

Ij

knife

the

the

ji’

by

0

be

kept

use

angle

knife

us

for

tungsten

seam

wide

plate

recommended.

is

organization

to

60

THE

and

0

Pull

0.

go

and

downward.

®

new

knife

until

Set

lower

shown

securely.

then

0,

spring

0.

0

0

go

0,

spring

0.

to

of

by

action.

to

the

and

swing

and

pull

and

and

withdraw

into

blade

top

of

securely.

then

action.

the

sewing

sharp.

grinder

a

is

may

be

resharpening

carbide

diamond

a

width

or

for

larger

charts

68.

UPPER

Fig.

swing

sewing

lightly

maintained

nut

lightly

with

with

upper

upper

in

Fig.

holder

nut

the

so

that

needle

holder

Lower

sent

arm

socket

the

but

knife

position.

arm

tighten

groove

position.

while

to

alloy

grinder.

is

narrow,

or

11,

0

to

tighten

machine.

do

knife

knife

by

14.

®

0

Iii

knife

the

plate

®

knife

our

since

material,

changed

replace

to

narrower

as

shown

AND

13,

14,

to

the

the

left

screw

wrench

not

tighten

is

at

so

that

0.5-1.0mm

will

return

to

the

to

the

left

screw

downward.

clamp

of

cutting

shown

as

will

return

may

making

shown

as

distributors

itismade

to

seam

in

15

left.

as

0.

or

its

its

left.

as

0.

edge

in

be

sure

in

and

Page 9

LLL

FigH4

0

Upper

0.5-

1.0mm

0

.020

.039”

knife

Needle

top

surfa(n

plak

0

Lower

/

0

0

/

0

/

0

/

knife

Fig.12

13

Fig.

15

Page 10

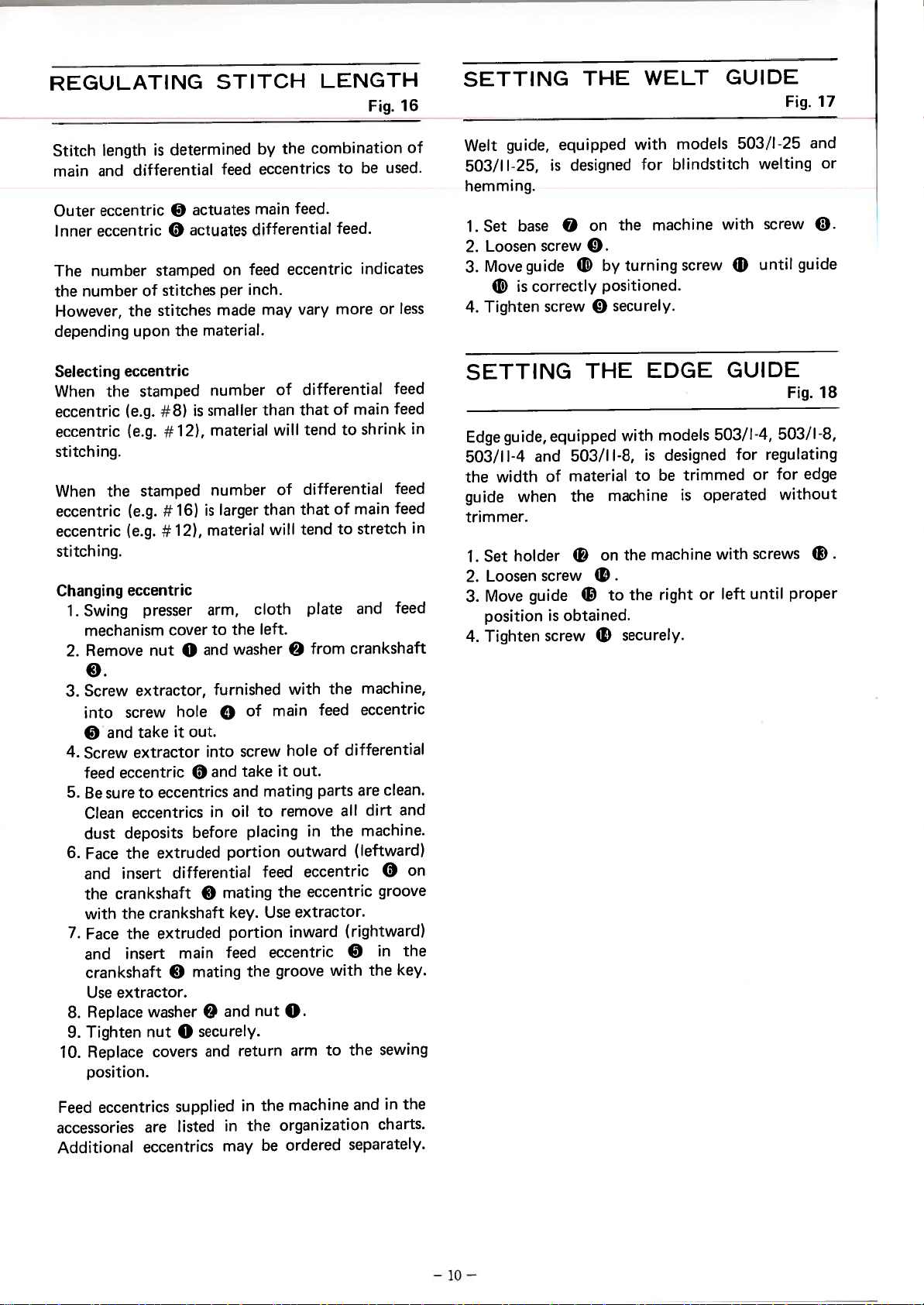

REGULATING

STITCH

LENGTH

Fig.

16

SETTING

THE

WELT

GUIDE

Fig.

17

eccentric

Tiller

number

number

Swing

1.

mechanism

Remove

2.

length

and

eccentric

the stamped

SUtch

main

Outer

The

the

However,

depending

Selecting

When

eccentric

eccentric

stitching.

When

eccentric

eccentric

stitching.

Changing

0.

Screw

3.

into

O

4.

Screw

feed

5.

sure

Be

Clean

dust

6.

Face

and

the

with

7.

Face

and

crankshaft

Use

Replace

8.

Tighten

9.

Replace

10.

position.

dillerential

of

the

upon

eccentric

(e.g.

(e.g.

the

stamped

(e.g.

(e.g.

eccentric

presser

nut

extractor,

screw

take

and

extractor

eccentric

to

eccentrics

deposits

the

insert

crankshaft

crankshaft

the

the

insert

extractor.

washer

nut

determined

is

feed

actuates

0

actuates

0

feed

is

0

hole

out.

0

before

main

mating

securely.

0

on

per

made

material.

number

smaller

material

number

is

larger

material

arm,

to

the

washer

and

furnished

0

screw

into

take

and

and

oil

in

mating

0

key.

portion

feed

and

0

return

and

Inch.

of

placing

the

stamped

stitches

stitches

the

=8)

12),

#16)

#12),

cover

it

eccentrics

extruded portion

differential

extruded

0

covers

the

feed.

eccentric

vary

differential

of

that

will

tend

differential

of

that

will

tend

plate

0

with

main

hole

it

out.

remove

outward

eccentric

eccentric

the

extractor.

Use

inward

eccentric

groove

0.

arm

combination

from

in

by

eccentrics

main

differential

may

than

than

cloth

left.

mating

to

feed

nut

to

feed.

more

of

to

of

to

the

feed

differential

of

parts

all

the

(rightward)

0

with

the

to

used.

be

indicates

or

less

feed

feed

main

shrink

feed

feed

main

stretch

feed

and

crankshaft

machine,

eccentric

clean.

are

dirt

and

machine.

(leftward)

0

groove

in

the

key.

the

sewing

of

on

in

in

guide,

Welt

503/11-25,

hemming.

base

Set

1.

Loosen

2.

guide

Move

3.

correctly

is

€i

4.

Tighten

SETTING

guide,

Edge

503/11-4

the

width

guide

trimmer.

1.

2.

3.

4.

when

holder

Set

Loosen

Move

position

Tighten

guide

equipped

is

0

screw

screw

equipped

and

of

screw

obtained.

is

screw

designed

on

0.

by

positioned.

securely.

0

THE

503/11-8,

material

machine

the

on

®

to

®

with

for

machine

the

turning

EDGE

models

with

is

to

be

machine

the

right

the

securely.

models

blindstitch

screw

designed

trimmed

operated

is

or

503/1-25

with

GUIDE

503/1-4,

for

or

screws

with

until

left

welting

screw

guide

until

Fig.

503/1-8,

regulating

for

without

proper

and

or

0.

18

edge

eccentrics

Feed

accessories

Additional

supplied

listed

are

eccentrics

in

may

in

the

the

be

machine

organization

ordered

and

charts.

separately.

—

10

—

the

in

Page 11

d

0

L!d

0

8

—

IT

—

Page 12

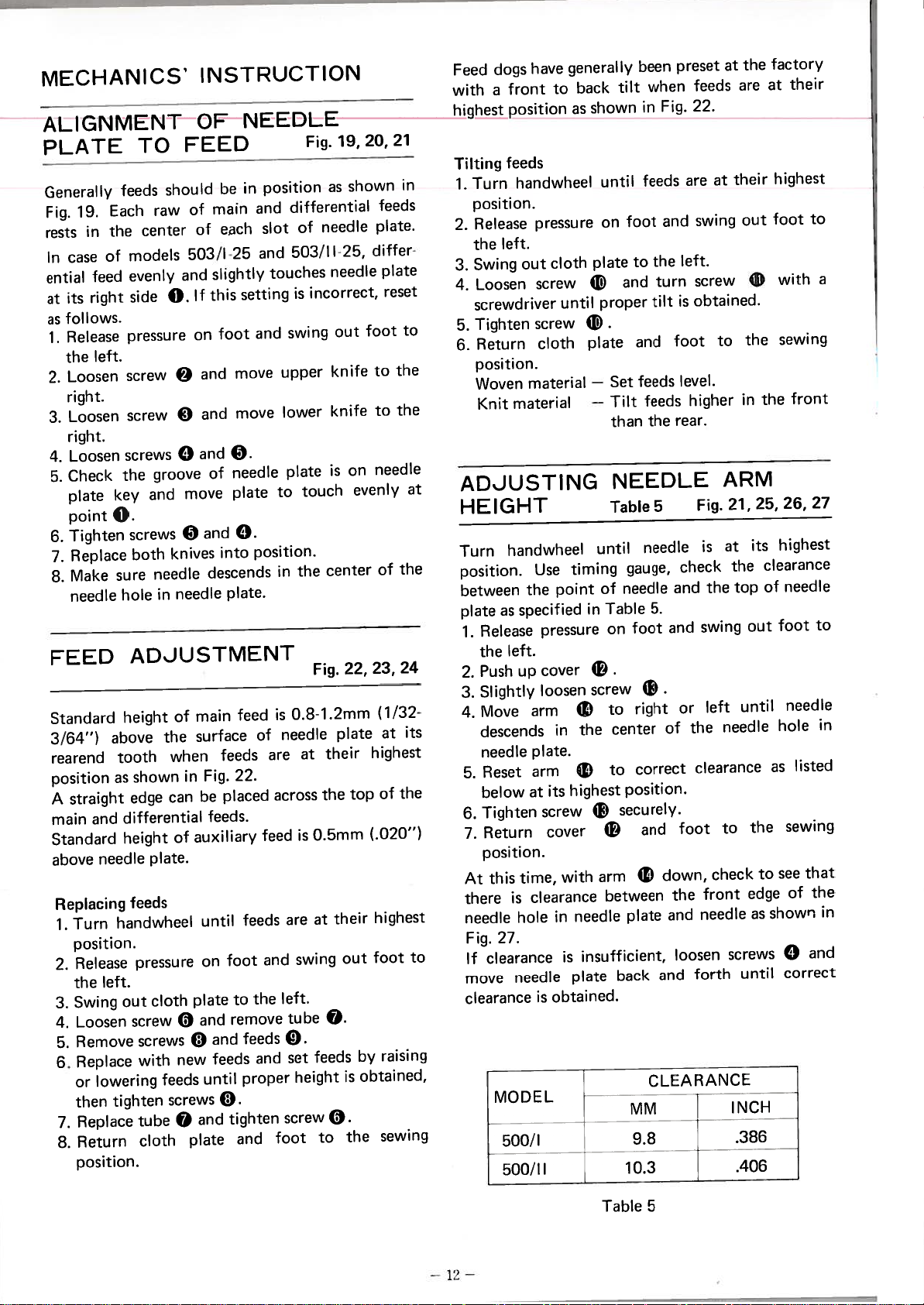

MECHANICS’

ALIGNMENT

PLATE

Generally

19.

Fig.

in

rests

case

In

[ial

en

right

its

at

follows.

as

Release

1.

the

Loosen

2.

right.

Loosen

3.

right.

Loosen

4.

Check

5.

plate

point

Tighten

6.

Replace

7.

Make

8.

needle

FEED

Standard

3/64”)

rearend

position

straight

A

main

Standard

above

Replacing

Turn

1.

position.

Release

2.

the

Swing

3.

Loosen

4.

Remove

5.

Replace

6.

or

then

Replace

7.

Return

8.

position.

TO

feeds

raw

Each

CCfl

the

models

of

evenly

feed

side

pressure

left.

screw

screw

screws

groove

the

and

key

0.

screws

both

needle

sure

in

hole

ADJUSTMENT

height

above

tooth

shown

as

edge

differential

and

height

feeds

handwheel

pressure

left.

out

screw

screws

with

tighten

tube

cloth

plate.

cloth

needle

lowering

INSTRUCTION

NEEDLE

OF

FEED

n

be

Id

sliou

main

of

each

of

[Cr

503/1-25

slightly

and

setting

this

II

0.

foot

on

move

and

move

and

@

and

of

move

and

0

descends

main

surface

Fig.

in

be

feeds.

auxiliary

until

on

plate

and

and

0

feeds

until

and

plate

0.

needle

plate

0.

into

plate.

feed

22.

placed

feeds

foot

to

remove

feeds

proper

0.

tighten

and

0

knives

needle

of

the

when feeds

can

of

0

new

feeds

screws

0

position

differential

and

slot

503/11-25,

and

touches

swing

and

upper

lower

plate

to

position.

in

0.8-1.2mm

is

needle

of

are

across

feed

are

and

left.

the

tube

0.

set

and

screw

foot

Fig.19,20,21

as

needle

of

needle

incorrect,

is

out

knife

knife

is

touch

center

the

22,

Fig.

plate

their

at

the

0.5mm

is

their

at

out

swing

0.

feeds

height

is

0.

to

shown

feeds

plate.

differ-

foot

to

to

needle

on

evenly

of

23,

(1/32-

highest

of

top

(.020”)

highest

foot

by

obtained,

sewing

the

—

in

plate

reset

to

the

the

at

the

24

its

at

the

to

raising

have

dogs

Feed

front

a

with

highest

Tilting

1.

2.

3.

4.

position

feeds

Turn

position.

Release

left.

the

Swing

Loosen

handwheel

pressure

out

screw

screwdriver

5.

6.

Tighten

Return

screw

cloth

position.

Woven

Knit

material

material

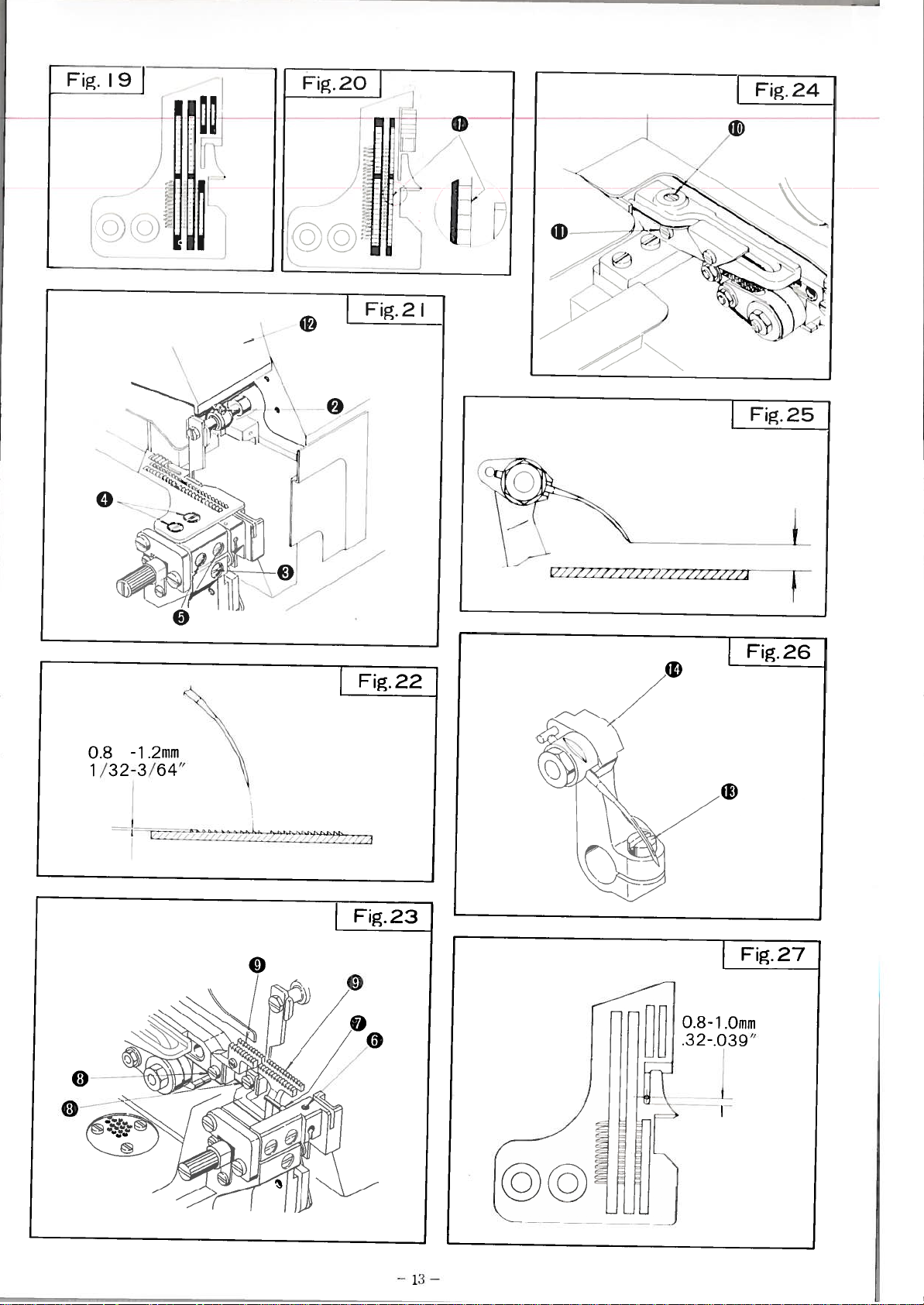

ADJUSTING

HEIGHT

between

as

plate

Release

1.

the

Push

2.

Slightly

3.

Move

4.

descends

needle

Reset

5.

below

Tighten

6.

Return

7.

position.

this

At

there

needle

27.

Fig.

clearance

If

move

clearance

MODEL

-

500/I

-

500/Il

handwheel

Use

the

specified

pressure

left.

cover

up

loosen

arm

plate.

arm

at

screw

cover

time,

clearance

is

hole

needle

is

Turn

position.

generally

back

to

shown

as

cloth

Ij

until

plate

timing

point

in

screw

the

in

highest

its

with

needle

in

insufficient,

is

plate

obtained.

been

tilt

until

foot

on

to

plate

and

proper

and

feeds

Set

—

Tilt

—

than

NEEDLE

Table

until

gauge,

needle

of

Table

foot

on

right

to

center

correct

to

position.

securely.

®

®

arm

between

plate

back

MM

9.8

10.3

preset

Fig.

and

[lie

turn

tilt

feeds

22.

are

swing

left.

screw

obtained.

is

at

when

in

feeds

foot

level.

higher

feeds

rear.

the

Fig.

5

needle

is

check

the

and

5.

swing

and

left

or

the

of

clearance

foot

and

the

and

check

front

needle

down,

loosen

forth

and

CLEARANCE

the

at

are

their

out

the

to

in

ARM

21,

at

the

top

out

until

needle

to

edge

screws

until

INCH

.386

--

factory

at

highest

foot

with

D

sewing

the

25,

highest

its

clearance

of

foot

hole

as

the

see

to

shown

as

-

their

to

front

27

26,

needle

needle

listed

sewing

that

of

the

and

0

correct

a

to

in

in

—

12

—

Table

5

Page 13

Fig.24

/

0.8

-1

1/32-3/64”

0

.2mm

H

II:>

0

L

‘/V77ZZ7Z7?ZZ7772ZX7J

_Fig.25

Fig.26

Fg.22

N

/

®

Fg.23

L

0

—

Page 14

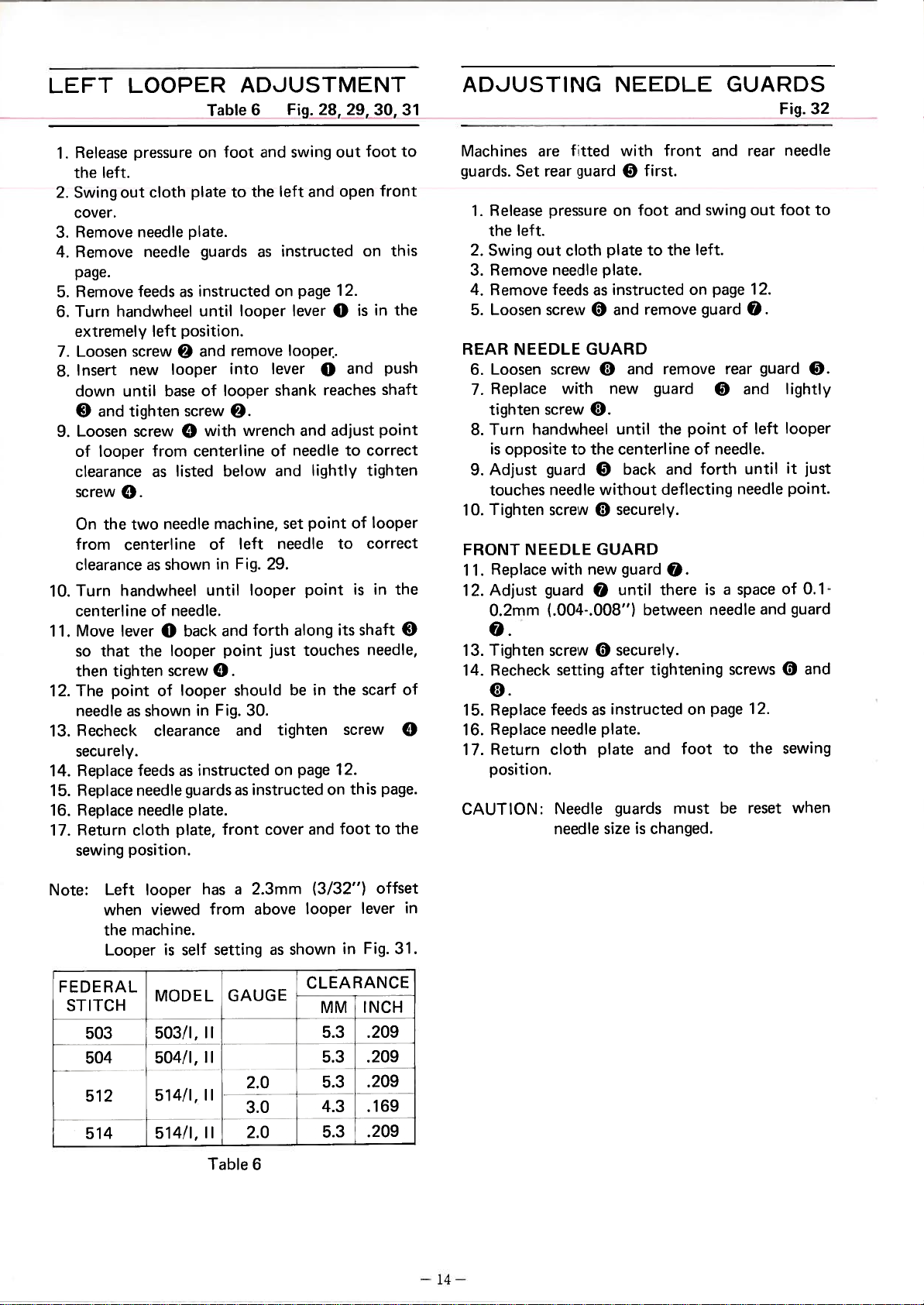

LEFT

LOOPER

ADJUSTMENT

Table

Fig.

6

28, 29,

30,

31

ADJUSTING

NEEDLE

GUARDS

Fig.

32

.

R

elease

1

the

2.

Swing

cover.

Remove

3.

4.

Remove

page.

Remove

5.

Turn

6.

extremely

Loosen screw

7.

Insert

8.

down

and

o

Loosen

9.

looper

of

clearance

screw

On

from

clearance

Turn

10.

centerline

Move

11.

so

that

then tighten

The

12.

needle

Recheck

13.

secu

Replace

14.

Replace

15.

Replace

16.

Return

17.

sewing

pressure

left.

out

cloth plate

needle

needle

feedsasinstructed

handwheel

left

position.

0

looper

new

until

base

tighten

screw

from

listed

as

0.

the two

point

rely.

needle

centerline

shown

as

handwheel

needle.

of

lever0back

the

looper

screw

of

looper

showninFig.

as

clearance

feedsasinstructed

needle

needle

cloth

plate,

position.

on

plate.

guards

until

and

of

screw

with

0

centerline

machine,

of

in

until

0.

guards

plate.

[001

to

looper

remove

into

looper

wrench

below

left

Fig.

looper

and

point

should

30.

and

as

front

and

swing

left

the

as

forth

instructed

and

instructed

on

page

lever

looper..

lever

shank

and

needletocorrect

of

lightly

and

point

set

needle

29.

point

along

touches

just

be

in

tighten

on

page

cover

and

out

open

12.

0

and

0

reaches

adjust

of

to

its

the

screw

12.

this

on

foot

loot

on

is

tighten

looper

correct

is

shaft

needle,

scarf

front

in

push

shaft

point

in

page.

to

to

this

the

the

0

0

the

of

Machines

guards.

4.

REAR

6.

10.

FRONT

11.

12.

Set

1.

Release

the

left.

Swing

2.

Remove

3.

Remove

Loosen screw

5.

NEEDLE

Loosen screw

Replace

7.

tighten

Turn

8.

opposite

is

Adjust

9.

touches

Tighten

NEEDLE

Replace

Adjust

0.2mm

0.

Tighten

13.

Recheck

14.

0.

Replace

15.

Replace

16.

17.

Return

position.

CAUTION:

guard

plate

plate.

as

0

GUARD

with

0

on

instructed

and

are

rear

pressure

out

cloth

needle

feeds

fitted

0

with

screw

handwheel

guard

needle

screw

with

guard

(.004-.008”)

screw

setting

feedsasinstructed

needle

cloth

Needle

needle

to

new

0.

until

the

centerline

0

without

securely.

0

GUARD

new

until

securely.

0

after

plate.

plate

guards

size

back and

guard

first.

foot

to

remove

and

guard

the

between

tightening

and

changed.

is

front

swing

and

the

left.

on

guard

remove

point

of

forth

deflecting

0.

is

there

on

foot

must

and

page

rear

0

of

needle.

needle

space

a

needle

screws

page

to

be

rear

out

12.

0.

and

left

until

12.

the

reset

foot

guard

of

and

0

sewing

needle

0.

lightly

looper

it

just

point.

0.1-

guard

and

when

to

in

offset

lever

Fig.

.209

.209

.209

.169

.209

31.

in

—

14—

Note: Left

when

the

Looper

FEDERAL

STITCH

503

504

512

514

looper

viewed

machine.

is

MODEL

503/1,11

504/I,

514/I

514/1,11

self

has

from

setting

II

II

Table

2.3mm

a

above

i

GAUGE

2.0

-

3.0

2.0

6

(3/32”)

looper

shown

as

CLEARANCE

[

MMIINCH

5.3

5.3

5.3

4.3

5.3

Page 15

Fig.

28

\\\

\\

Fig.

30

H

H

\\

\\

Fig.

\

29

\S—

Fig.31

2.3mm

3/32”

Fig.

32

\\

\\

0.1

-

.0O4-.OO8”

0.2mm

zz:

15—

—

Page 16

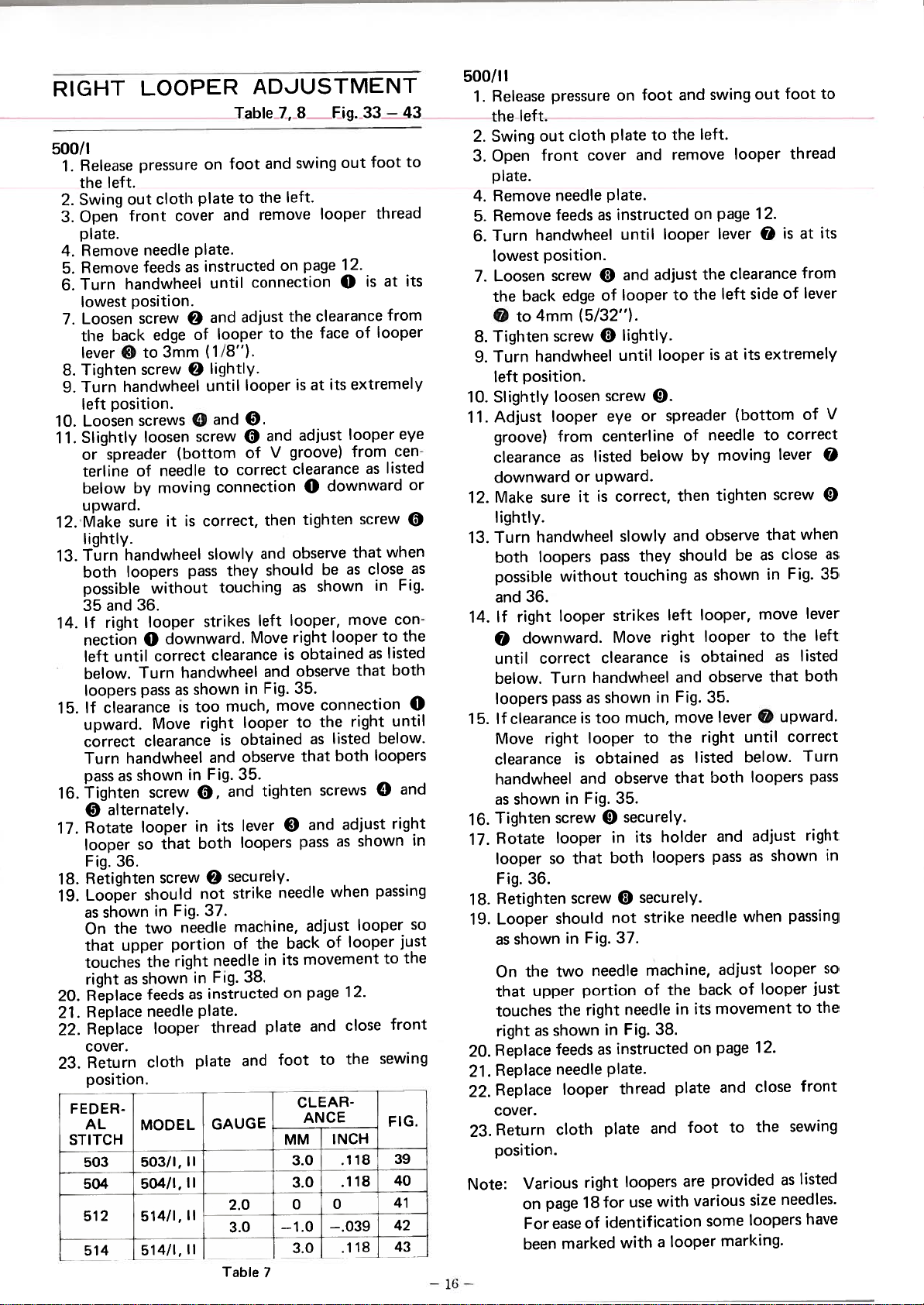

RIGHT

500/I

.

Release

1

[lii’

Svving

2.

Open

3.

I

i

Remove

4.

Remove

5.

Turn

6.

lowest

Loosen

7.

[lie

lever

Tigh

8.

Turn

9.

left

Loosen

10.

Slightly

11.

or

terline

below

upward.

Make

12.

lit

Ii

g

Turn

13.

both

possible

35

If

14.

nection

left

below.

loopers

If

15.

upward.

correct

Turn

pass

Tighten

16.

o

Rotate

17.

looper

Fig.

Retighten

18.

Looper

19.

as

On

that

touches

right

Replace

20.

Replace

21.

Replace

22.

cover.

Return

23.

position.

rERf

AL

STITCH

503

L504

LOOPER

essii

pi

left.

out

Iron

[C

needle

feeds

handwlioel

position.

screw

edge

hack

to

0

screw

ten

handwheel

position.

screws

loosen

spreader

of

by

sure

I

y.

handwheel

loopers

without

36.

and

looper

right

0

correct

until

Turn

pass

clearance

Move

clearance

handwheel

shown

as

screw

alternately.

looper

so

36.

should

the

upper

shown

as

MODEL

j5031l,

J50411,

in

two

the

feeds

needle

looper

cloth

shown

re

plate

cloth

cover

t

plate.

as

of

3mm

0

0

screw

(bottom

needle

moving

it

is

pass

downward.

hanclwheel

shown

as

too

is

right

in

0,

in

both

that

screw

not

Fig.

needle

portion

right

in

as

plate.

plate

II

II

on

inst

(1/8’’).

correct,

strikes

0

37.

ADJUSTMENT

Table

and

toot

to

the

remove

aiid

toil

mc

connection

until

adjust

and

tly.

looper

0.

0

of

correct

then

and

they

left

Move

and

Fig.

in

much,

looper

obtained

observe

35.

tighten

and

lever

loopers

securely.

strike

machine,

the

of

in

38.

plate

and

JCLEAR

-

-

to

and

V

should

looper

ugh

until

and

to

connection

slowly

touching

clearance

is

and

Fig.

its

needle

Fig.

instructed

thread

-

GAUGE

7,

8

Svving

left.

page

on

the

the

is

adjust

groove)

clearance

0

tighten

observe

as

looper,

right

obtained

is

observe

35.

move

to

that

0

pass

needle

back

movement

its

on

foot

MM

3.0

3.0

Fig.

out

looper

12.

0

clearance

face

its

at

downward

be

shown

looper

connection

the

listed

as

both

screws

adjust

and

as

when

adjust

of

12.

page

close

and

the

to

TINCH

.118

.i18

33—

foot

thread

at

is

from

looper

of

extremely

looper

from

listed

as

screw

when

that

close

as

in

move

to

listed

as

that

right

below.

loopers

0

shown

passing

looper

looper

to

front

sewing

FIG.

43

to

its

eye

cen

or

0

as

Fig.

con

the

both

0

until

and

right

in

so

just

the

31

40

:

Table

7

500/Il

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.Ifclearance

16.

17.

18.

19.

20.

21.

22.

23.

Note:

--

—

Release

left.

the

Swing

Open

plate.

Remove

Turn

lowest

the

o

Tigh

Turn

Slightly

out

front

Remove

handwheel until

position.

Loosen

back

4mni

to

ten

handwheel

left

position.

Adjust

groove)

clearance

downward

sure

Make

lightly.

handwheel

Turn

loopers

both

possible

36.

and

right

If

downward.

o

correct

until

below.

loopers

shown

36.

shown

the

upper

as

Various

on

For

been

right

page

Move

clearance

handwheel

as

Tighten

Rotate

looper

Fig.

Retighten

Looper

as

On

that

touches

right

Replace

Replace

Replace

cover.

Return

position.

pressure

needle

feeds

screw

screw

loosen screw

looper

from

without

looper

Turn

pass

screw

looper

so

should

two

the

shown

feeds

needle

cloth

ease

cloth

cover

edge

(5/32”).

listed

as

upward.

or

it

handwheel

as

is

looper

is

and

Fig.

in

that

screw

Fig.

in

needle

portion

right

looper

right

18

of

marked

loot

on

to

plate

and

Plate.

instructed

as

and

0

of

0

adjust

looper

lightly.

until

0.

or

eye

centerline

below

correct,

is

slowly

they

pass

touching

strikes

Move

clearance

shown

much,

too

to

obtained

observe

35.

securely.

0

its

in

loopers

both

securely.

0

strike

not

37.

machine,

of

needle

38.

Fig.

in

instructed

as

plate.

thread

and

plate

loopers

use

for

identification

with

and

the

remove

looper

to

looper

spreader

of

then

and

should

left

right

is

and

Fig.

in

move

the

as

that

holder

the

in

plate

are

with

looper

a

swing

left.

on

the

the

isatits

needle

by

observe

shown

as

looper,

looper

obtained

observe

35.

right

listed

both

pass

needle

back

its

on

foot

provided

various

some

out

looper

12.

page

lever

0

clearance

side

left

extremely

(bottom

to

moving

tighten

that

as

be

in

move

to

lever

0

until

below.

loopers

adjust

and

as

when

adjust

looper

of

movement

12.

page

close

and

the

to

size

loopers

marking.

loot

thread

is

of

correct

lever

screw

close

Fig.

the

as

that

upward.

correct

shown

passing

looper

sewing

as

needles.

at

from

lever

of

when

lever

listed

both

Turn

pass

right

to

front

listed

have

to

its

V

0

0

as

35

left

in

so

just

the

Page 17

-Il

()

‘1

()

z

N.

-I,

(*)

r

Page 18

PRESSER

alignment

With

.

right

hole

to

arm

hack

foot

Pn;sei

and

and

needle

Front

1

0.

Adjust

2.

is

there

Tighten

3.

4.

Position

Tighten

5.

set

Once

left

to

Right

Loosen

1.

bracket

Shift

2.

until

left

in

hole

Check

3.

straight.

is

arm

Tighten

4.

PRESSER

Setting

1.

foot

Remove

anti-clockwise.

IIi’

niust

to

in

arm

no

screw

regulator

screw

do

screws

the

needle

bar

screws

pressure

ARM

he

to

left

the

of

needle

alignment

attached

back

in

bind

0.

0.

not

alignment

0

0

needle

plate

is

on

0

0

FOOT

square

aligned

insure

needle

plate.

to

and

bar

loosen

and

and

are

guide

and

and

from

ALIGNMENT

correctly

lilting

hole

loosen

arm,

while

forth

0.

against

0

screw

gLlide

hole

in

aligned.

properly

0

0

foot

0.

ADJUSTMENT

flat

by

foot

44,

Fig.

front

without

loot

in

screws

lilting

connection

the

to

and the

and

Fig.

turning

45,

to

a

with

to

right

46

hack

bind

the

and

0

insure

0.

needle

presser

46

45,

screw

or

handwheel

Turn

2.

Position.

ten

for

screw

plate.

screw

so

foot

screw

or

the

should

lower

Loosen

3.

needle

Tiqli

4.

screw

Pressure

5.

evenly

Adjusting

Loosen

1.

Raise

2.

tilt

Retighten

3.

PRESSER

ADJUSTMENT

1.

2.

3.

4.

5.

6.

7.

8.

Turn

Tighten

While

When

Loosen

lowest

Loosen

(15/64”)

for

500/I),

between

of

Tighten

®

bottom

—

2

Tighten

nut

position.

nut

screw

500/I)

nut

lifting

turn

screw

0.5mm

nut

presser

and

of

3mm

nut

clockwise.

proper

that

tilt

regulator

weight

screw

FOOT

1J.

D

when

U.

presser

screw

®

(.020”).

foot

adjust

screw

(5/64

®

until

and

he

just

of

and

until

presser

and

is

the

—1/8”)

feeds

and

reset

enoLigh

stitch

material

turn

lift

a

foot

foot

®

stopper

needle

on

play

to

posi

pressure

is

LIFT

screw

obtained

is

6.0mm

of

until

clearance

top

turning

by

are

Lion

to

formed.

give

to

being

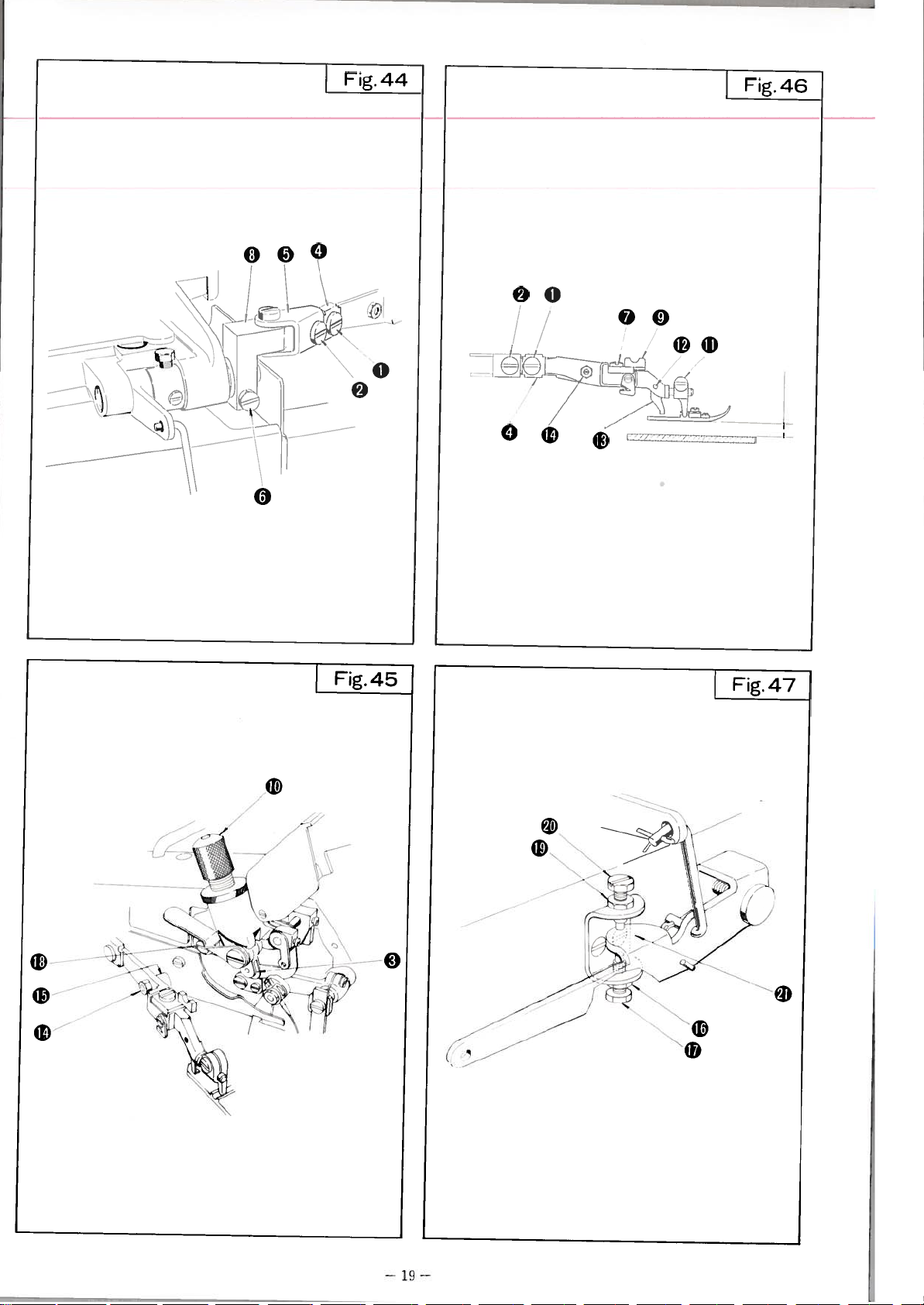

Fig.45,46,47

lifted.

is

the

®

plate,

of

at

loot

by

feed

the

sewn.

®

(4.5mm

is

loosen

lever

screw

lowest

its

flat

Lu

material

desired

until

6.0mm

of

(4.5mm

clearance

obtained

from

J

on

i

its

for

nut

the

to

MODEL

500/I

-1

500/Il

THREADS

2

3

4

4

2

3

3

4

4

RIGHT

FEDERAL

STITCH

LOOPERS

503

504

512

514

503

504

521

512

514

FOR

LOOPER

MARKING

2

1

4

2

3

7

1

USE

Table

WITH

SINGER

13-16

13-16

11-14

13-16

13-16

—

IDENTI

9-12

9-12

9-12

9-12

9-12

9-12

9-12

9-14

8

—

VARIOUS

NEEDLE

FICATION

25-32

34-40

25-32

34-40

30-36

25-32

25-32

25-32

-

34-40

25-32

25-32

34-40

25-36

SIZE

G

SIZE

METRIC

65-80

85-100

65-80

85-100

759Qi

65-80

65-80

65-80

85-100

65-80

65-80

85-100

65-90

NEEDLES

NEWNO.

323-810-003

323-810-013

323-810-001

323-810-004

323-810-001

323-810-004

323-810-213

323-810-211

.323-810-224

323-810-213

323-810-214

323-810-007

323-810-211

PART

NUMBER

QLDNO.

201234A

202475

201067A

201287A

201067A

201287A

202842

202874

202828

202842

202872

202989

202874

Page 19

1

0

0

0

8

N

-

-

0

8

0

-n

01

1

a

\

\

Page 20

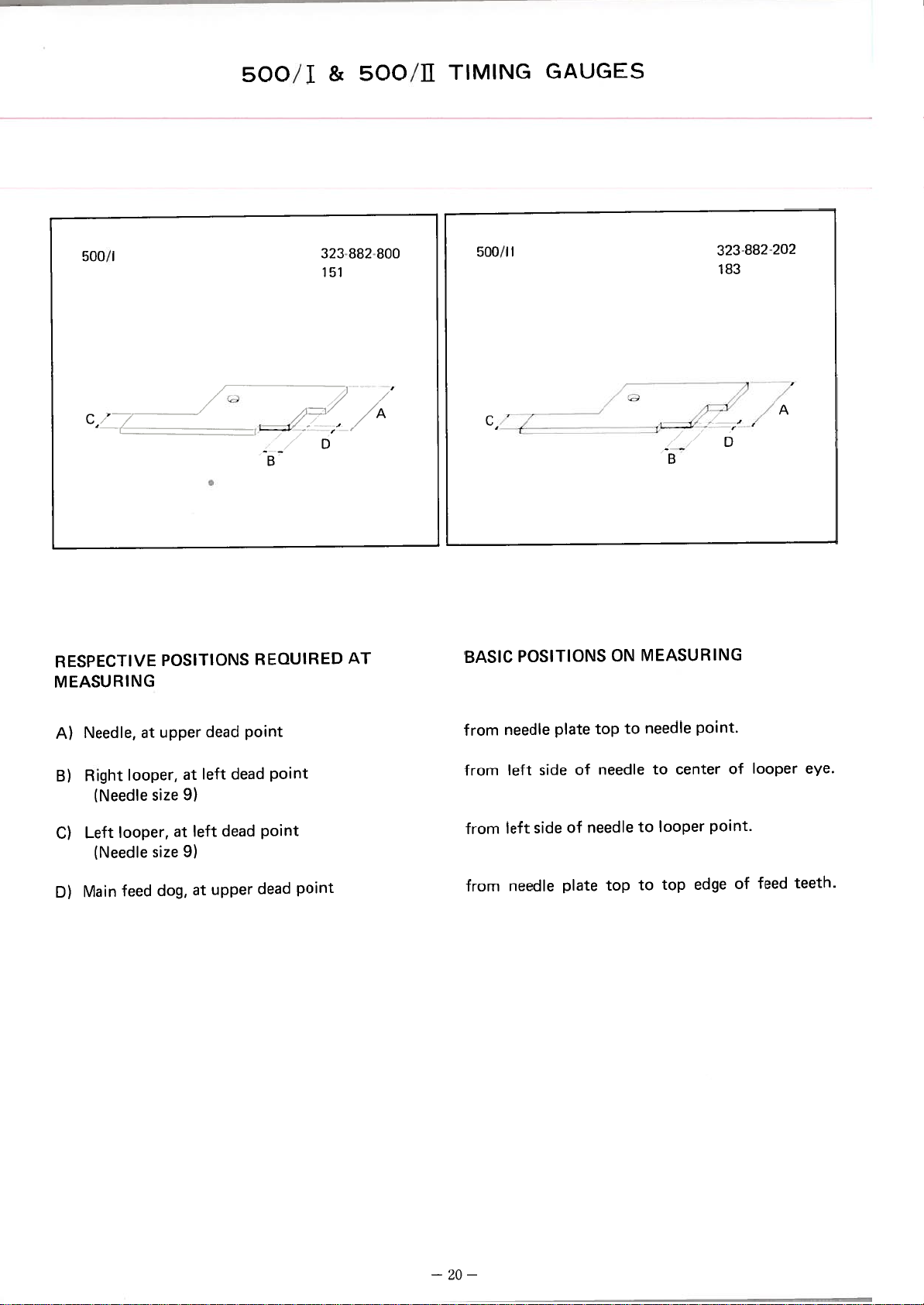

500/I

&

500/11

TIMING

GAUGES

500/I

C’

RESPECTIVE

MEASURING

.

POSITIONS

323

151

D

B

REQUIRED

882

AT

800

A

500/I

C’

BASIC

I

POSITIONS

MEASURING

ON

323-882202

183

A

D

B

A)

B)

C)

D)

Needle,

Right

(Needle

Left

(Needle

Main

at

looper,

looper,

feed

upper

size

size

dog,

to

point.

center

of

looper

eye.

needle

to

top

side

plate

of

needle

needle

point

dead

point

dead

left

at

from

from

left

9)

to

point

dead

left

at

from

needle

of

side

left

looper

point.

9)

teeth.

feed

of

at

upper

dead

point

from

needle

plate

top

to

top

edge

—

20

—

Page 21

MILLIMETER-INCH

DECIMAL

CONVERSION

FRACTION

CHART

&

MM

1.6

1

1.8

1

2.0

2.1

2.2

2.3

2.4

2.5

2.6

2.7

2.8

2.9

3.0

3.1

3.2

3.3

20.0

30.0

40.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

1.1

1

1

1

1.5

.7

.9

.0

.2

.3

.4

!

I

APPROX.

INCH

FRACTION

1/64

1/64

1/32

3/64

3/64

1/1

6

5/64

3/32

7/64

1/8

25/32

1

1

-37/64

-3/1

6

DECIMAL

.004

.008

.01

2

.01

6

.020

.024

.028

.032

.035

.039

.043

.047

.051

.055

.059

.063

.067

.071

.075

.079

.083

.087

.091

.094

.098

.1

02

.1

06

.11

0

.114

.11

8

.1

22

.125

.1

30

.787

.1

81

1

1

.575

+

50.0

60.0

70.0

MM

3.4

3.5

3.6

3.7

3.8

3.9

4.0

4.1

4.2

4.3

4.4

4.5

4.6

4.7

4.8

4.9

5.0

5.1

5.2

5.3

5.4

5.5

5.6

5.7

5.8

5.9

6.0

6.1

6.2

6.3

6.4

6.5

6.6

APPROX.

INCH

FRACTION

9/64

5/32

11/64

3/1

1

3/64

7/32

1

5/64

-31

1

/32

I

2-23/64

2-3/4

1/4

6

j

DECIMAL

34

.1

.1

38

.1

42

46

.1

.1

50

.1

54

.1

57

.1

61

.1

65

.1

69

.1

73

.1

77

.1

81

.1

85

.1

89

.1

93

.1

97

.201

.205

.209

.21

3

.21

7

.220

.224

.228

.232

.236

.240

.244

.248

.252

.256

.260

1.968

2.362

2.756

I

10.0

1

MM

6.7

6.8

6.9

7.0

7.1

7.2

7.3

7.4

7.5

7.6

7.7

7.8

7.9

8.0

8.1

8.2

8.3

8.4

8.5

8.6

8.7

8.8

8.9

9.0

9.1

9.2

9.3

9.4

9.5

9.6

9.7

9.8

9.9

80.0

90.0

00.0

APPROX.

INCH

FRACTION

1

7/64

9/32

1

9/64

5/1

+

21/64

11/32

23/64

3/8

25/64

3-5/32

3-35/64

5/1

3-1

6

6

DECIMAL

.264

.268

.272

.276

.280

.283

.287

.291

.295

.299

i

.303

.307

.31

.31

.31

.323

.327

.330

.335

.339

.343

.346

.350

.354

.358

.362

.366

.370

.374

.378

.382

.386

.390

.394

3.1

50

3.543

3.937

1

5

9

—

21

—

Page 22

29

29

29

28

)

14)

2

19

U)

()

4

8

11

21

60

13

‘25)

26

)23

16:

:

-

0

—

22:

12

12

Page 23

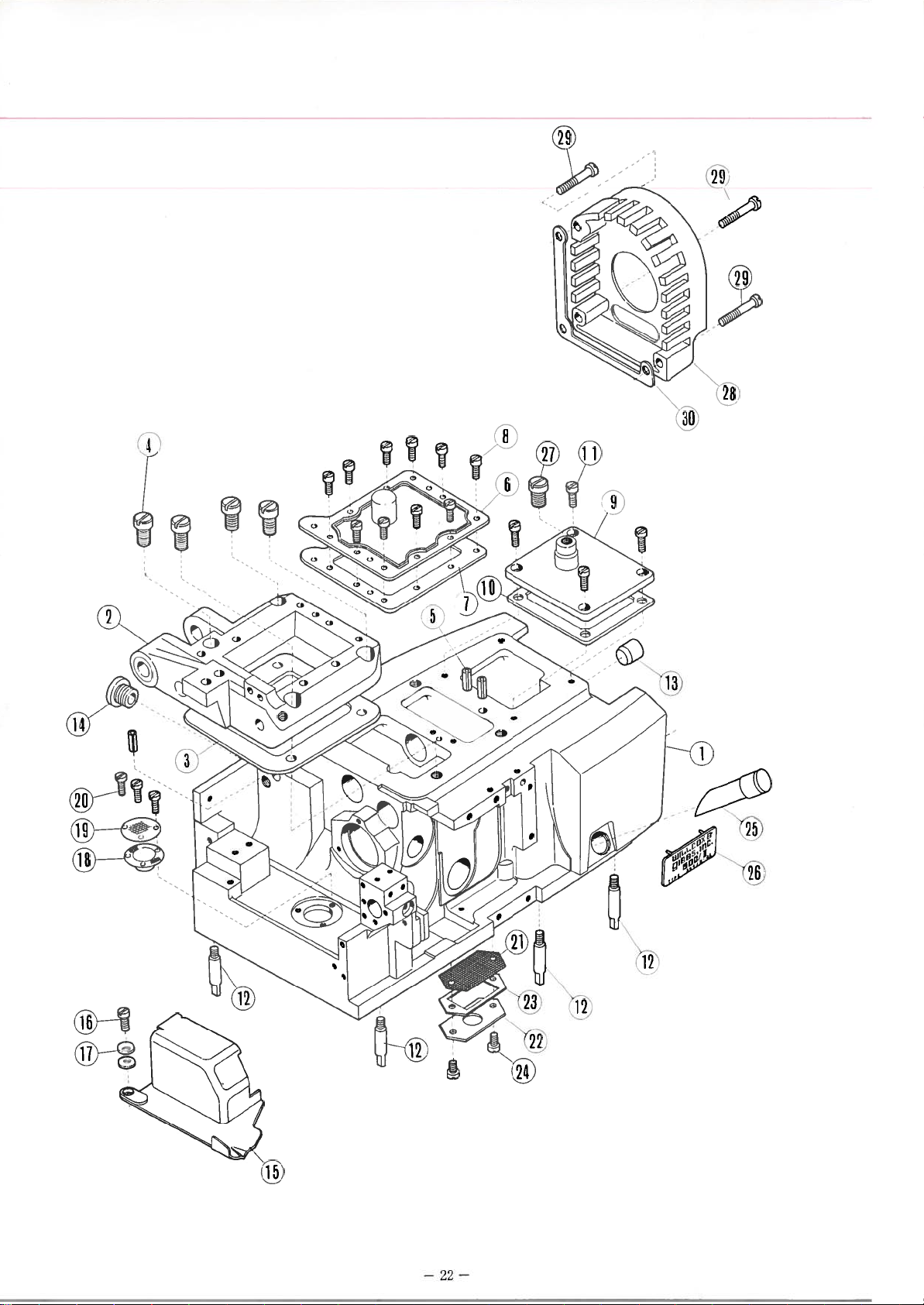

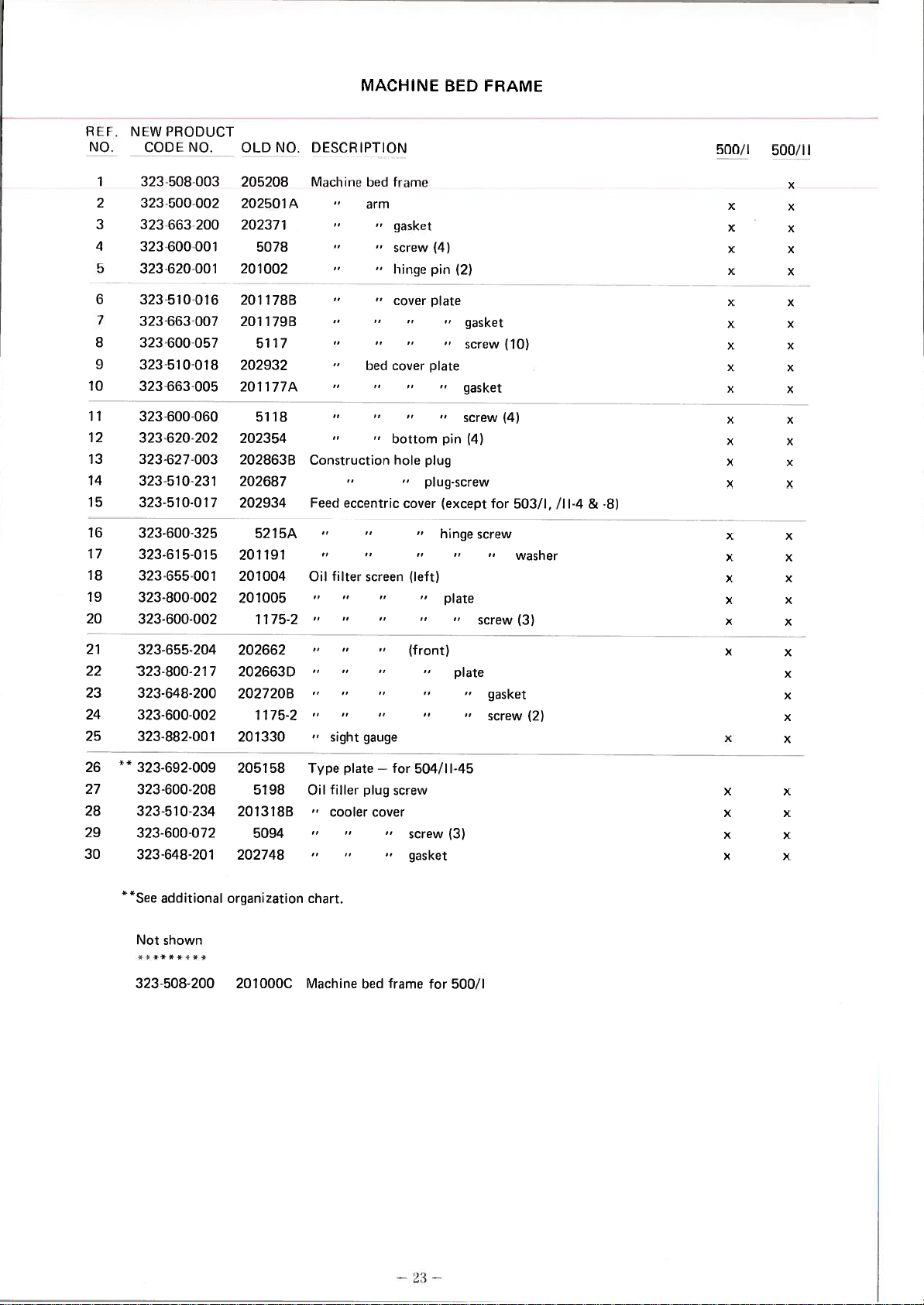

MACHINE

BED

FRAME

lEE.

ND.

10

11

12

13

14

15

16

17

18

19

20

I

2

3

‘1

5

6

1

3

0

IRODUCT

NEW

CODE

:123

503

323

500-002

323

663-200

373

600

323620001

323510-016

323-663-007

323-600-057

323-510-018

323663-005

323-600-060

323-620-202

323-627-003

323-510-231

323-510-017

323-600-325

323-615-015

323-655-001

323-800-002

323-600-002

NO.

003

001

OLD

205208

202501A

202371

5078

201002

201178B

201179B

5117

202932

201177A

5118

202354

202863B

202687

202934

5215A

201191

201004

201005

1175-2

NO.

DESCRIPTION

i(

)i(

arm

bed

Construction

Feed

eccentric

Ill

ter

screen

Oil

iI11f

gasket

screw

hinge

cover

cover

bottom

hole

cover

(left)

(4

pin

(2)

plate

gasket

screw

plate

gasket

screw

pin

(4)

pILIg

plug-screw

(except

hinge

plate

for

screw

screw

(10)

(4)

503/I,

washer

(3)

/11-4

500/I

500/Il

x

x

x

x

x

x

x

x

x

x

x

x

x

x

&

-8)

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

27

28

29

30

21

22

23

24

25

26

323-655-204

323-800-217

323-648-200

323-600-002

323-882-001

323-692-009

323-600-208

323-510-234

323-600-072

323-648-201

See

additional

shown

Not

**+

*

*

*

202662

2026630

202720B

1

1

201330

205158

5198

2013

5094

202748

organization

323-508-200 201000C

75-2

18B

“

sight

Type

Oil

filler

cooler

chart.

Machine

plate

“

gauge

—

plug

cover

bed

for

screw

frame

(front)

504/11-45

screw

gasket

for

plate

)3)

500/I

gasket

screw

(2)

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

Page 24

30

24

1

29

(11)-

25

21

II

26

16

20

56)

c

28

c13

2)

33)

\4

U

1

)

5’

3

8)

j

—

24—

Page 25

REF

NO.

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

1

2

3

4

5

6

7

8

9

.

NEW

CODE

323-900-003

323-802-00

323-802-212

323-7/10-006

323-600-068

323-600-032

323-61

323-728-208

323-600-038

323-618-007

323-620-207

323-630-009

323-615-013

323-625-200

323-600-357

323-643-003

323-600-068

323-615-014

323-734-206

323-600-069

323-600-069

323-630-001

323-560-024

323-560-025

323-600-068

323-620-203

323-600-012

323-634-200

323-510-009

323-600-072

323-600-038

323-627-011

323-510-206

323-728-200

323-600-073

323-620-204

323-641-200

323-600-057

323-692-200

323-560-203

323-600-068

323-600-074

323-560-201

323-600-026

323-510-006

323-728-003

323-600-068

323-620-01

323-643-005

323-600-068

323-510-020

323-600-068

323-800-025

-

323-800-202

323-600-068

323-734-002

323-600-068

*See

•x•See

PRODUC1

NO.

5-012

1

organization

additional

MAIN

OLD

NO.

202466

201181

202467

201184

1216

1202

201185

200159A

5095

200183

201221A

5099

200821

202865

5293

201186

1216

200162

200163A

1435

1436

3044

202513B

202795A

1216

202521

1457

202522

202514A

5094

5095

201755

202515A

202516

2918

202579

202517

5117

202524

202843

1216

2905

202660

2921

201200

201201

1216

201202

201203

1216

202937

1216

202938

201

204B

1216

202936

1216

chart.

organization

FRAME

DESCRIPTION

plate,

Cloth

1216x4,201185x4&

plate

Cloth

C

“

“

“

“

“ “ “

“ “

“ “

“ “

“

“

“ “

“

‘

“

“

“ “

“

“

“

“

“

Machine

“ “ “

“

“ “

Upper

knife cover

“ “

“

“

“ “

“ “ “ “

“

“

guard

Chip

“

“

“ “ “

Front

cover

“

“

“

cover

“

“

“

“

“ “

“

“

“

looper

“ “

“

“

eccentric

“

“ “ “

thread

-

Right

Looper

Feed

chart.

AND

MISCELLANEOUS

complete

Irame

‘

joint

(4)

“

‘

hinge

“

screw

screw

“

“

‘

thrust

“

pin

“

“

“““

“

“

“

‘““

lock

spring

“ “ “

“““

“““

“““

stop

screw

“““

“

fabric

“

“

cover

guard

guard

(for

“

“ “

“ “ “

top

screw

“

“ “

“

plug

(see

“

hinge

“

“ “

“

“ “

“

lock

“

name

screw

(upper)

(lower)

extension

“

hinge

“

screw

“

pin

lock

spring

cover

“

screw

plate

“

plate

“

“

cover latch

“ “ “

“

nut

retainer

“

“

“

screw

screw

with

1202x4

(upper)

(lower)

“

(2)

washer

washer

“

screw

“

stud

“

nut

(for

screw

pin

“

“

503,

(long)

(short)

page

screw

pin

spring

“

plate

(2)

screw

(2)

(3)

screw

201

screw

(2)

washer

screw

/1,

screw

stop

504/I

49

(2)

screw

(2)

181C,

(4)

(4)

washer

11-41,

(2)

ring

(2)

for

(2)

(2)

&

new

/11)

-________________

COVERS

202467,

(4)

-42,

-43,

cover with

-

201

-45

&

eye guard)

184x4,

-47)

500/I

500/Il

x

x

x

x

x

x

x

x

x x

x

x

x

x

x

x

x x

x

x

x

x

x x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x x

x

x

x

x

x

x

x

x

x x

X X

x

x

x x

x

x

x x

x

x

x x

x

X X

x

x x

x x

-

x x

x

x

x x

x

x

x

x

x

x

x

-

-

x x

-

--

---

x

x

x

x

x

x

x

x

x

x

x

-

x

x

x

x

x

x

Page 26

7-

0

C’D

CD

Page 27

REF-.

NO.

I

2

3

ii

5

NEW

IRODUC

CODE

323

5/10

323-5/10-010

323-6’19-00i

323-653-010

323-627-208

NO.

01/1

F

OLD

205259

205260

201009

202990

202903

NO.

CRANKSHAFT

DESCRIPTION

CrwikshaIt

Criikliift

key

oil

wick

stopper

MECHANISM

500/I

x

x

x

x

500/Il

x

x

X

x

13

14

15

16

19

20

21

22

23

24

25

10

11

12

17

18

6

7

8

9

323-672-001

323-634-003

323-686-005

323-686-008

323-600-002

323-634-002

323-686-004

323-676-037

323-618-201

323-600-007

323-579-001

323-600-004

323-765-001

323-600-004

323-672-001

323-634-003

323-800-021

323-663-008

323-600-002

323-680-005

202902

202907

202906

202943

1175-2

202908

202901

201212C

202722A

2022-3

201010A

5060

201298

5060

202902

202907

202904

202905

1175-2

202909

hewing

“ “

bushing

(left)

(center)

counterweight

worm

screw

hearing

(right)

“

“

“

“

oil seal

retainer

retainer

oil seal

retaining

thrust

screw

screw

(2)

oil seal

retaining

oil

seal

ring

-

screw

ring

ring

(2)

ring

collar

503/I,

washer

bracket

(3)

/11-4

(2)

gasket

screw

x x

x

x

&

-8

x

x

x

x

x

x

x

x

x x

x x

x

x

x

x

x

x

x

x

x

x

x

(3)

x

x

x

x

x

x

x

x

x

x

x

26

27

28

29

30

31

32

33

34

35

36

37

323-568-003

323-600-066

323-600-037

323-546-001

323-600-008

323-600-009

323-780-201

323-600-010

323-800-200

323-600-209

323-632-001

323-653-003

205149

5149A

1458

201017A

5080

5081

201018B

5010

202523

5214

201022

202081

Oil

Pulley

“

“

Feed

cooling

“

“

position

screw

cap

“““

‘0’

eccentric

fan

screw

name

ring

“

position

screw

screw

(3)

plate

(2)

oil

wick

screw

screw

(2)

x

x

x

x

x

x

X X

x x

x

x

x

x x

x

x

X

x

X

x

x

x

X

27

—

—

Page 28

44

41

.42

31

.38

(4O

(12)

I

17

15

(3)

14N

30

31

32

-

4

—

iN

33

34’

35

23:

24

—

—

2U

Page 29

REF.

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

NO.

1

2

3

‘1

5

6

7

3

9

10

11

12

13

14

15

16

17

18

19

NEW

CODE

323-525-001

323-600-056

323-620-237

323-600-012

323-576-001

323-600-013

323-540-011

323-676-020

323-618-008

323-626-001

323-618-002

323-600-013

323-502-xxx

*

323-600-0

323-683-xxx

*

323-604-001

*323630001

323-801-xxx

323-600-014

323-649-002

323-600-015

323-800-022

323-600-019

323-561-xxx

323-561-xxx

323-600-105

323-685-226

323-685-227

323-600-019

323-900-200

323-630-200

323-676-202

323-642-001

323-780-002