Page 1

lUiLiLiGOX

&niBBS

DISASSEMBLY

&

ASSEMBLY

INSTRUCTIONS

♦

•• •'

. •

A.•.•

"t • . *

3

M.

D [if^

to

Page 2

lUiL.L.COX

Page 3

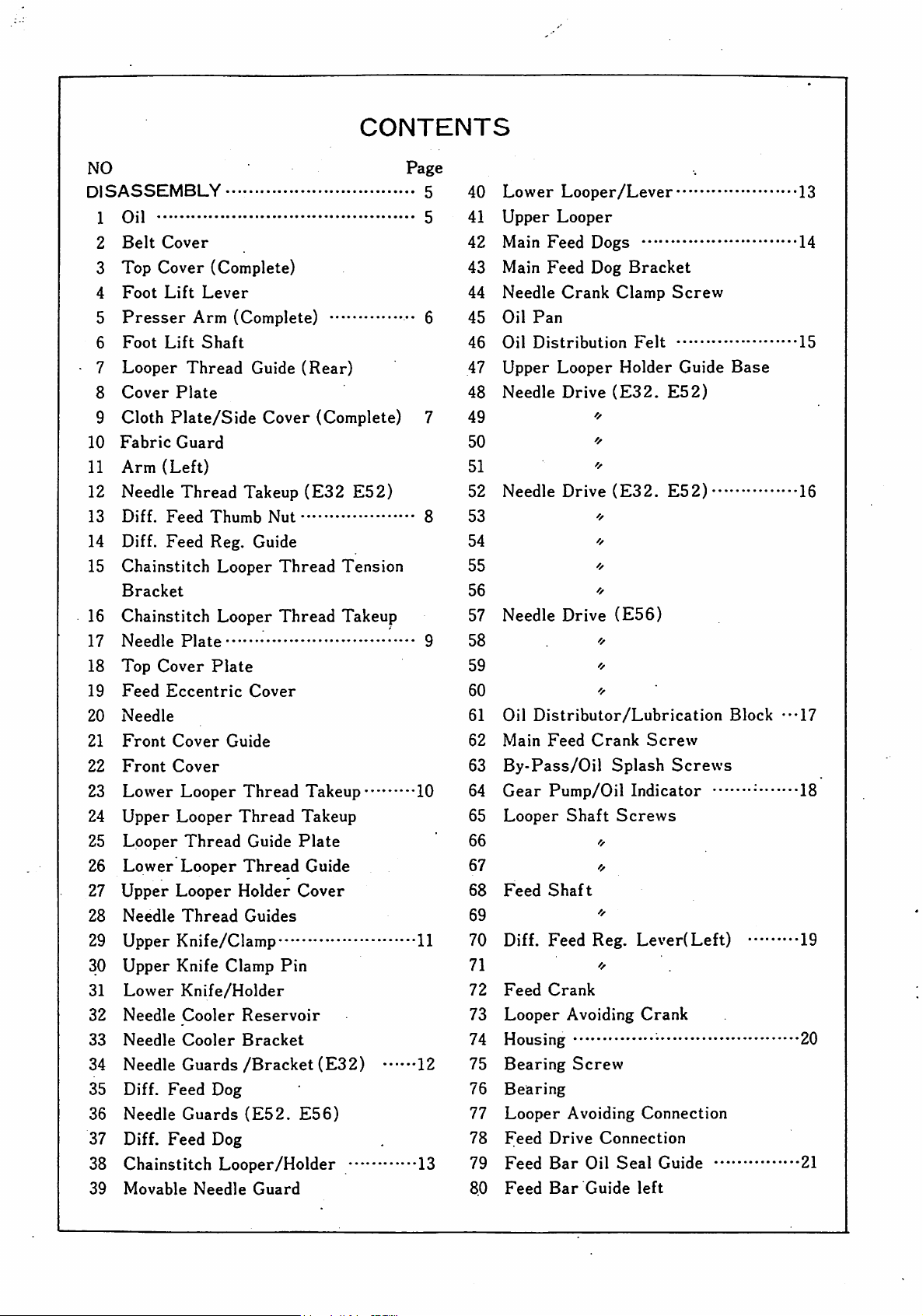

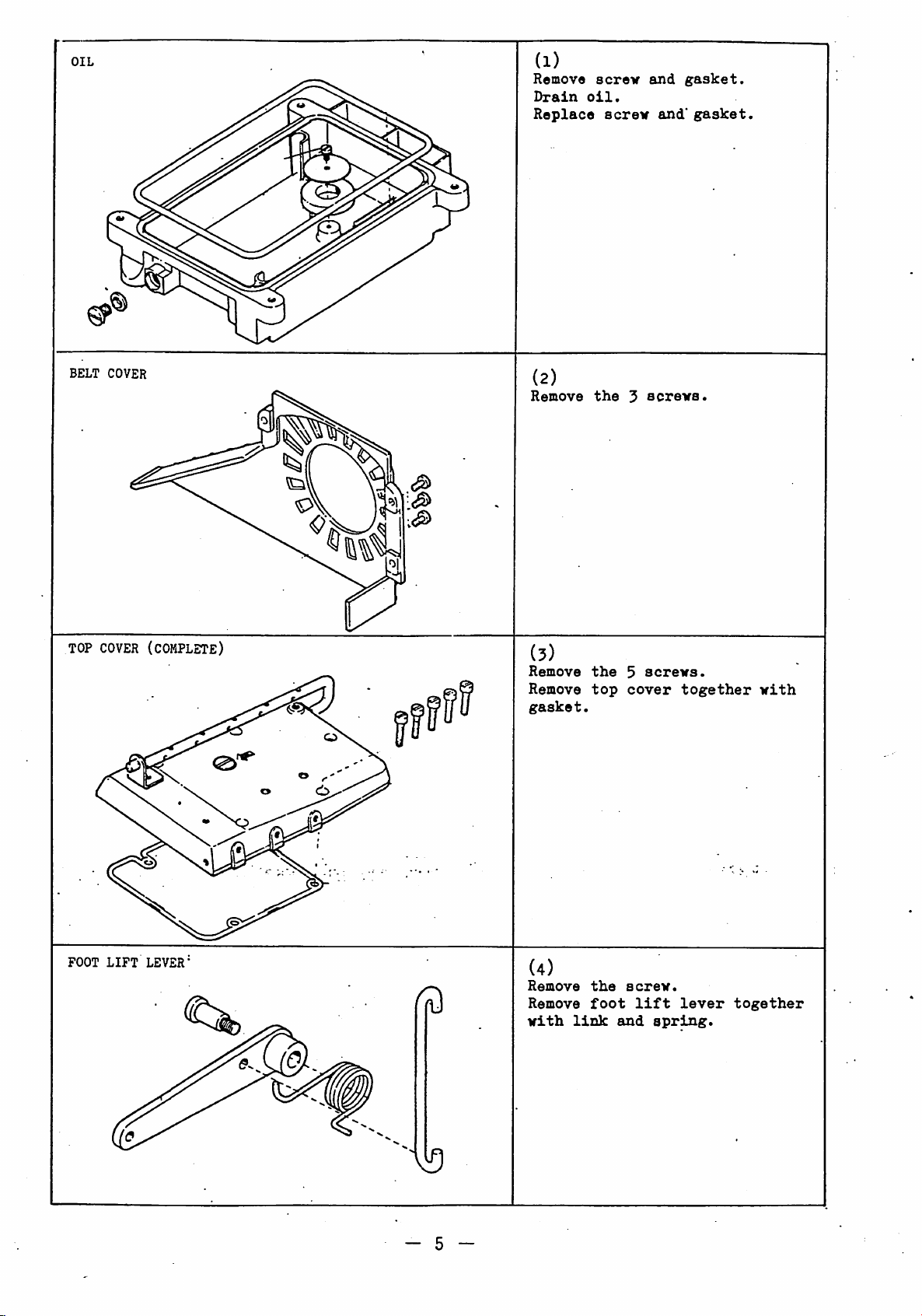

CONTENTS

NO

DISASSEMBLY

1

Oil

2

Belt

Cover

3 Top

4

5

6

7

8

9 Cloth

10

11

12 Needle

13

14 Diff.

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35 Diff.

36

37 Diff.

38

39

Cover

Foot

Lift

Presser

Foot

Lift

Looper

Cover

Plate

Plate/Side

Fabric

Arm

Guard

(Left)

Thread

Diff.

Feed

Feed

Chainstitch

Bracket

Chainstitch

Needle

Top

Feed

Needle

Front

Front

Lower

Upper

Looper

Lower

Upper

Needle

Upper

Upper

Lower

Needle

Needle

Needle

Plate

Cover

Eccentric

Cover

Cover

Looper

Looper

Thread

Looper

Looper

Thread

Knife/Clamp

Knife

Knife/Holder

Cooler

Cooler

Guards/Bracket

Feed

Needle

Guards

Feed

Chainstitch

Movable

Page

(Complete)

Lever

Arm (Complete) 6

Shaft

Thread

Thumb

Guide

Cover

Takeup

Nut

(Rear)

(Complete) 7

(E32

E52)

Reg. Guide

Looper

Looper

Thread

Thread

Tension

Takeup

Plate

Cover

Guide

Thread

Thread

Guide

Thread

Holder

Guides

Clamp

Reservoir

Bracket

Takeup

Plate

Cover

Pin

Takeup

Guide

(E3

2) 12

Dog

(E52.

E56)

Dog

Looper/Holder

Needle

Guard

10

11

13

5

5

8

9

40

Lower

41

Upper

42 Main

43 Main

44

Needle

45

Oil

46

Oil

47

Upper

48

Needle

49

50

51

52

Needle

53

54

55

56

57

Needle

58

59

60

61

Oil

62

Main

63

By-Pass/Oil

64

Gear

65

Looper

66

67

68

Feed

69

70 Diff.

71

72

Feed

73

Looper

74

Housing

75

Bearing

76

Bearing

77

Looper

78

Feed

79

Feed

80

Feed

Looper/Lever

Looper

Feed

Dogs

Feed

Dog

Bracket

Crank

Pan

Distribution

Looper

Drive

Drive

Drive

Distributor/Lubrication

Feed

Pump/Oil

Shaft

Shaft

Feed

Crank

Avoiding

Clamp

Holder

(E32.

(E32.

(E56)

Crank

Splash

Screws

Reg.

-c

Screw

Felt

Guide

E52)

E52)

Screw

Screws

Indicator

Lever(Left)

Crank

Screw

Avoiding

Drive

Bar

Bar

Oil

Guide

Connection

Connection

Seal

left

Guide

Base

Block

13

14

15

16

•••17

18

19

20

21

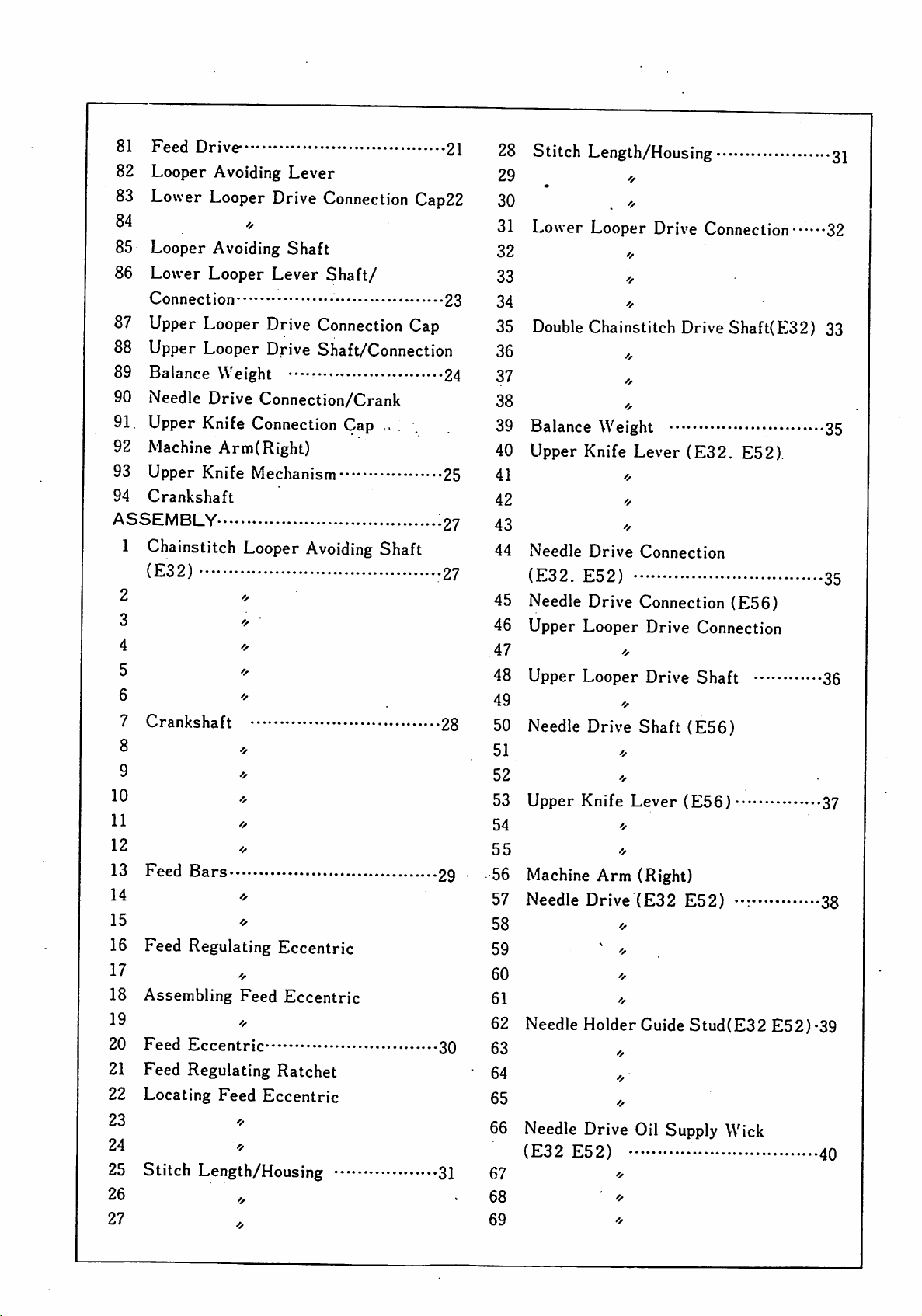

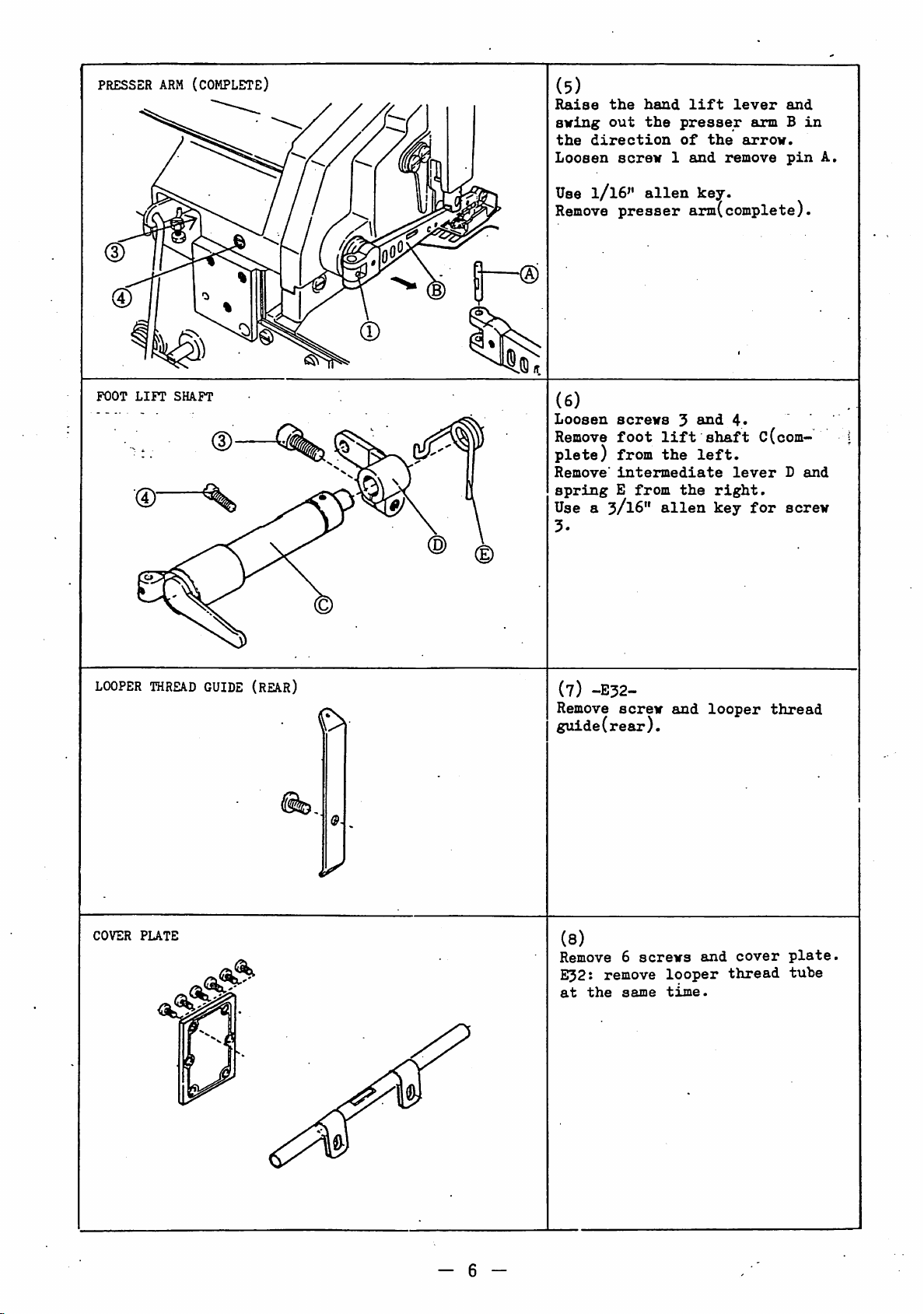

Page 4

81

Feed

Drive

82 Looper Avoiding

83 Lower Looper Drive

84

85 Looper Avoiding

86

Lower

Looper

Lever

Shaft

Lever

Connection

Shaft/

Cap22

Connection

87 Upper Looper Drive Connection Cap

88 Upper Looper Drive Shaft/Connection

89 Balance Weight 24

90 Needle Drive Connection/Crank

91. Upper Knife Connection Cap

92 Machine Arm(Right)

93 Upper Knife Mechanism 25

94

Crankshaft

ASSEMBLY

1 Chainstitch Looper

Avoiding

(E32)

2

3

4 o

5

6

7

Crankshaft

8

9

10

11

12

13 Feed

14

15

Bars

❖

16 Feed Regulating Eccentric

17

18

Assembling

19

20

Feed

Eccentric

21

Feed Regulating Ratchet

22

Locating

23

24

Feed

Feed

Eccentric

Eccentric

25 Stitch Length/Housing

26

27

...

Shaft

.27

29

30

31

21

23

28 Stitch Length/Housing

29

30

'

31

Lower

32

33

34

35 Double

36

37

38

39

Balance

40

41

42

43

44

Upper

Needle

(E32.

Knife

E52)

45 Needle Drive Connection

28

46 Upper

47

48 Upper

49

50 Needle

51

52

53

Upper

54

55

Looper

Looper

Knife

•56 Machine Arm (Right)

57 Needle

58

59

60

61

Drive

62 Needle Holder Guide

63

64

65

66 Needle Drive Oil Supply Wick

(E32

67

68

69

E52)

Looper

Drive Connection••••••32

Chainstitch

Weight

Lever

Drive

Connection

Drive Connection

Drive

Drive

Shaft

Lever

(E32

^

Drive

Shaft(E32)

(E32.

{E56)

Shaft

(E56)

(E56)

E52)

Stud(E32

E52)

E52)

31

33

35

35

36

37

38

-39

40

Page 5

70

Needle

(E32

71

Needle

72 Oil

73

Drive

Oil

E52)

Arm

(E56) (E32 E52)

Distributors

Supply

Wick

114

40

115

41 116

117

Lower

Movable

Upper Looper

Looper

Needle

Setting

Guard

(E56)

(Rear)

50

51

74 Differential feed

75 // 119 Upper Looper Gauge

76

77

Feed Shaft 42

73

79 123

30

31

82 126

83

Gear

Pump/Oil

84

85

By-Pdss

86

87

Feed Bar

Guide

38

89

Differential

90 r, 131 Adjusting Needle Guard

91

92 Positioning Diff. Feed Crank

93 • '

94

Positioning

Lever

95 » 136

96

Upper

97

98 139

99 Main Feed Dog

100 Checking Needle

101

Needle

102

Needle

103

Needle

104 Needle Height

105 Needle Height

106

Needle

(E32

107

Needle

108

Lower Looper Lever (E32 E52)

109 Positioning Lower Looper

110 Lower Looper Setting

111

Positioning Lower Looper

112

Lower

113

Positioning

Looper

Alignment

(E56)

Plate

Thread

E52)

Plate 148 Upper & Lower Looper Thread Guides

Looper

Crank

'S'

❖

Indicator

-5-

Left/Oil Seal

❖

Feed

Regulating

❖

❖

Diff.

Feed Regulating

Guide

❖

Bracket

(E32

(E32 E52)

(E32

(E56)

Takeup

Setting (E32)

Lower

Base

E52)

E52)

(E52)

Looper

Guide

Guide

(E52)

•••••

(E32)

(E56)

118

120

121

Double

122

Positioning

Double

124

Needle Guard Bracket 53

125

Adjusting

43

127

Adjusting

(Front) (E32)

128

Adjusting

(£32)

129"

Needle

130

Adjusting

•••44

45 135 Positioning Main Feed Dogs

46 141

47 145

48

— 49 150

•••50

(E52 E56)

(Front) (E52

132

Feed

133 Needle Plate 55

134

Maximum

Feed

137

Oil

138 Needle Cooler Reservoir (Lower)

Lower

140 '''

142

Upper

143

144

146

147

Upper Looper Holder Cover

(E32

149 '''

151

152

Upper

(E56)

Chainstitch Looper

Double

Chainstitch Looper Setting

Needle

Needle

Chainstitch Looper

Guard

Guard

Chainstitch

Guard

Dogs

Dog Height

Pan

Knife

Knife

(E52 E56)

Needle

Stitch Length

Guard (Rear)

E56)

Holder

E52)

Looper

Holder

Holder

(Rear) (E32)

Needle

Guard

; -

Cover

••••52

54

56

57

58

39

Page 6

153 Upper &

Guides

154

155

156

157

158

Needle

159

Feed

160

Cover

161 Machine

162

Fabric

163

Needle

164

Lower

(E56)

Plate

Eccentric

Plate

Arm

Guard

Thread

Looper

Cover

(Left)

Guides

(E32

(E32

Thread

E52)

E52)

59

60

•••61

165 "

166

Needle

167

168

Chainstitch

Bracket

169

Stopper

170 Chainstitch Looper

Thread

Looper

(E32)

(E32)

Guides

Thread

Thread

(E56)

Guide

62

Takeup

(E32)

171

172

173

174

175

176

177

178

179

180

181

182

183

184

Chainstitch

(E32)

Chainstitch

Bracket

Presser

Foot

Lift

Chainstitch

(E32)

Cover

Cloth

Front

Belt

Plate

Cover

(E32)

Arm-

Plate.

Cover

Looper

Looper

Lever

Looper

Thread

Thread

Thread

Eyelets

Tension

63

64

Guide

65

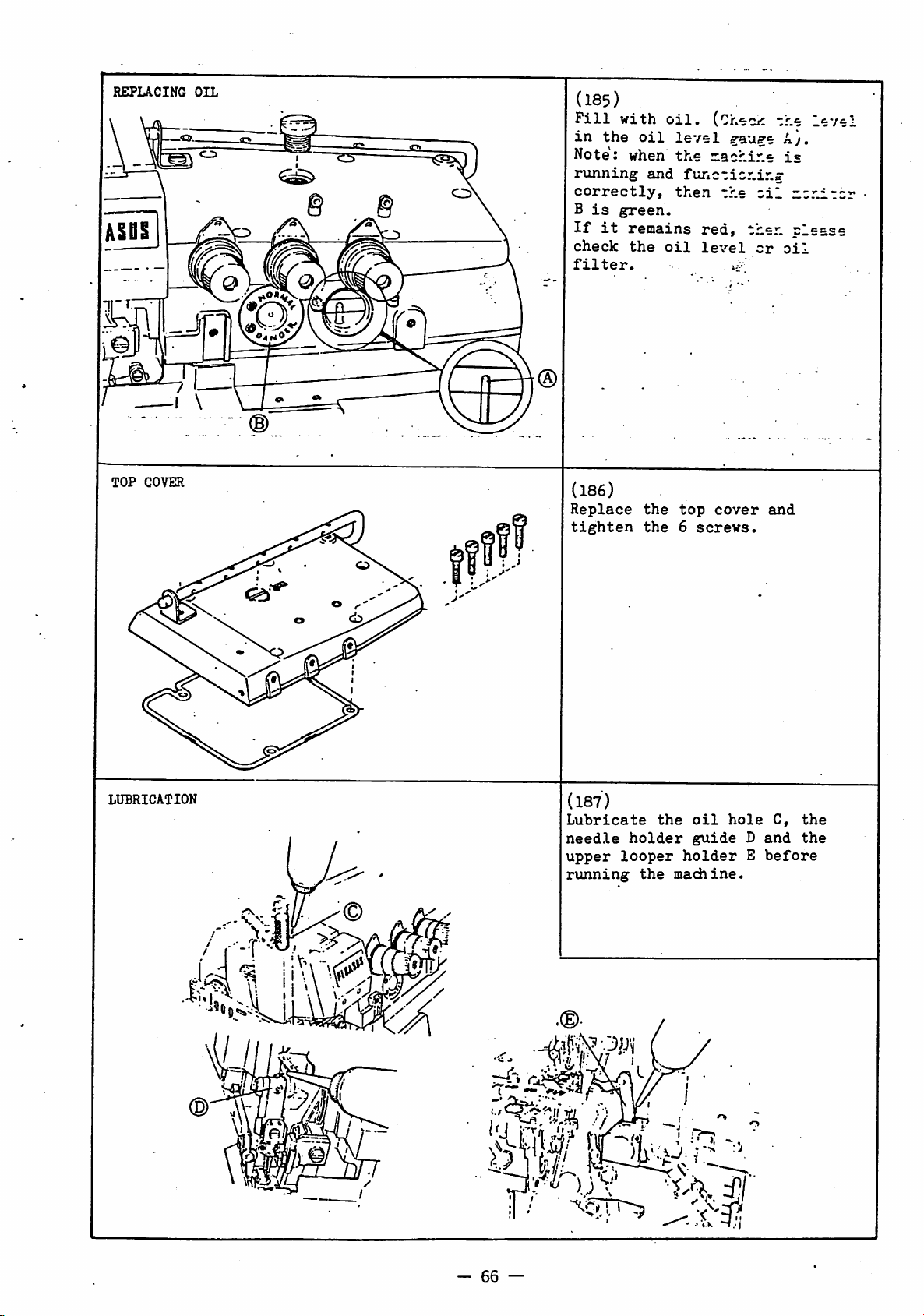

185 Replacing Oil •••• 66

186

Top

Cover

187

Lubrication

188

189

190

191

192

193

Threading

Threading

(E52)

(E5

6)

67

68

194

Threading

195

Threading

196

Threading

197

198 Needle

199

Looper

200

Needle

201

Looper

202

Needle

203

Looper

204

Chainstitch

Control

205

Stitch

206

Differential

207

Feed

208 Auxiliary

209

210

Presser

211

Presser

212 Needle

(E32

213

Sharpening

214 Oil

Filter

215 Changing

OLD

216

Standard

217 Needle Height

218

Lower

219 Upper Looper

220 Double Chainstitch

221

Threading (E52) 81

222

223 Threading

224 Threading

225

Threading

226

Threading

227

Needle

Looper

228

229

Needle

230

Looper

(E56)

(E32)

(E3

2) 70

ADJUSTMENTS

Thread

Thread

Thread

Thread

Thread

Thread

Control

Control

Control

Control

Control

Control

Looper

(E52)

(E52)

(ESS)

(ESS)

(E32)

(E32)

Thread

(E32)

Length Adjustment

Feed

Dog

Tilt

Feed

Ratio

Dog Height

Adjustment

(E32)

Foot

Lift

Adjustment

Foot

Alignment

Holder

E52)

Replacement

'•

Knives

Inspection

Differential

TYPE

MACHINES

Feed

Adjustments 79

(E32

Looper

(E32

(E32

E52)

ES2)

ES2)

Looper

(E5

2) 82

(E32)

(E32)

(E32)

Thread

Thread

Thread

Thread

Control

Control

Control

Control

(E52)

(ES2)

(E32)

(E32)

•.^•71

•^••72

(ES2

E56)

Capacity

(E32)

; 83

69

73

74

7S

76

77

78

80

84

85

Page 7

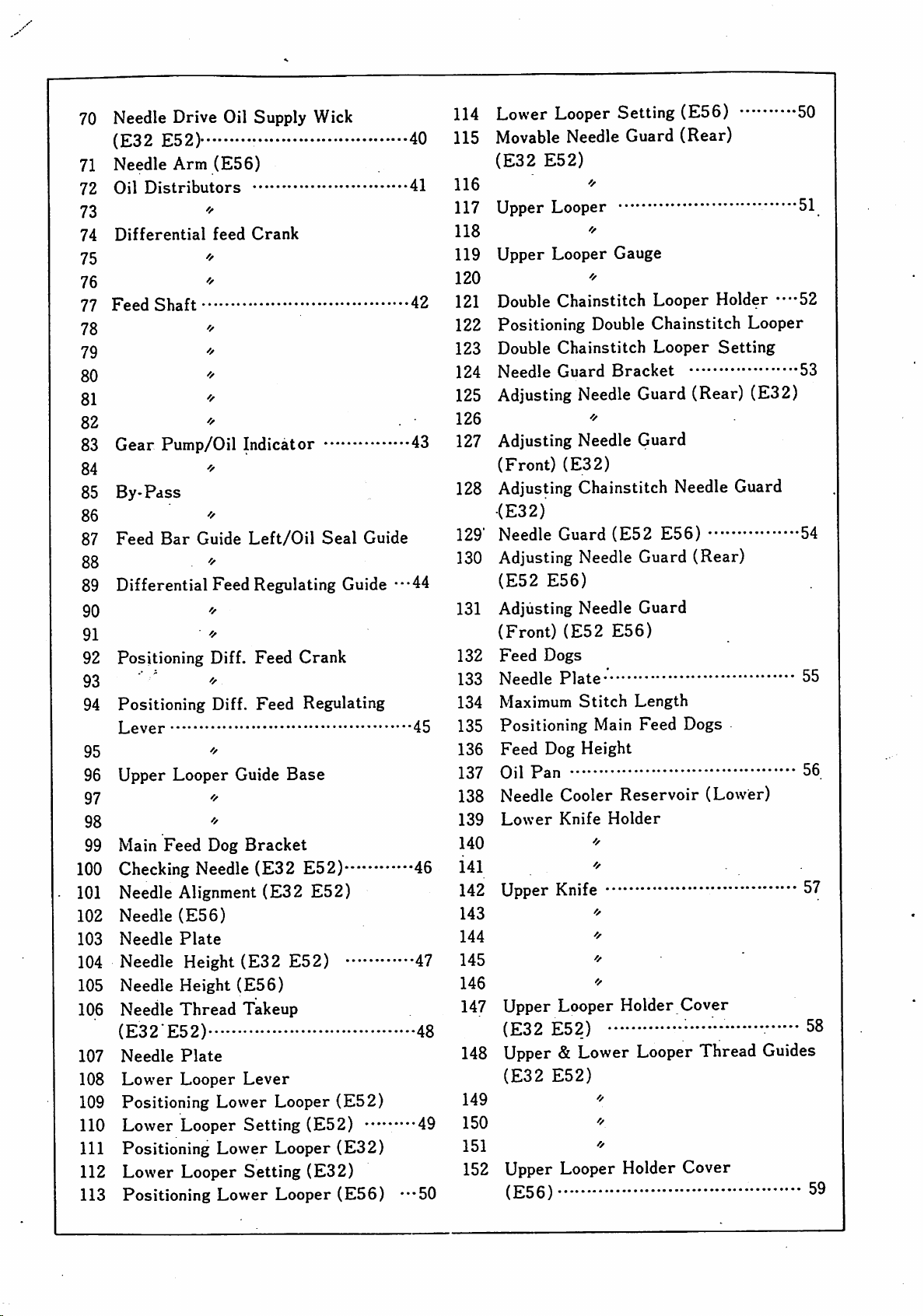

OIL

BELT

COVER

(i)

Remove

Drain

Replace

(2)

Remove

screv

oil.

the

screv

5

and

and'

screva.

gasket.

gasket.

TOP

FOOT

COVER

LIFT

(complete)

LEVER'

fd

(5)

Remove

Remove

gasket.

(4)

Remove

Remove

vith

link

the

top

the

foot

5

cover

screv.

and

screvs.

lift

together

lever

spring.

vith

together

- 5 -

Page 8

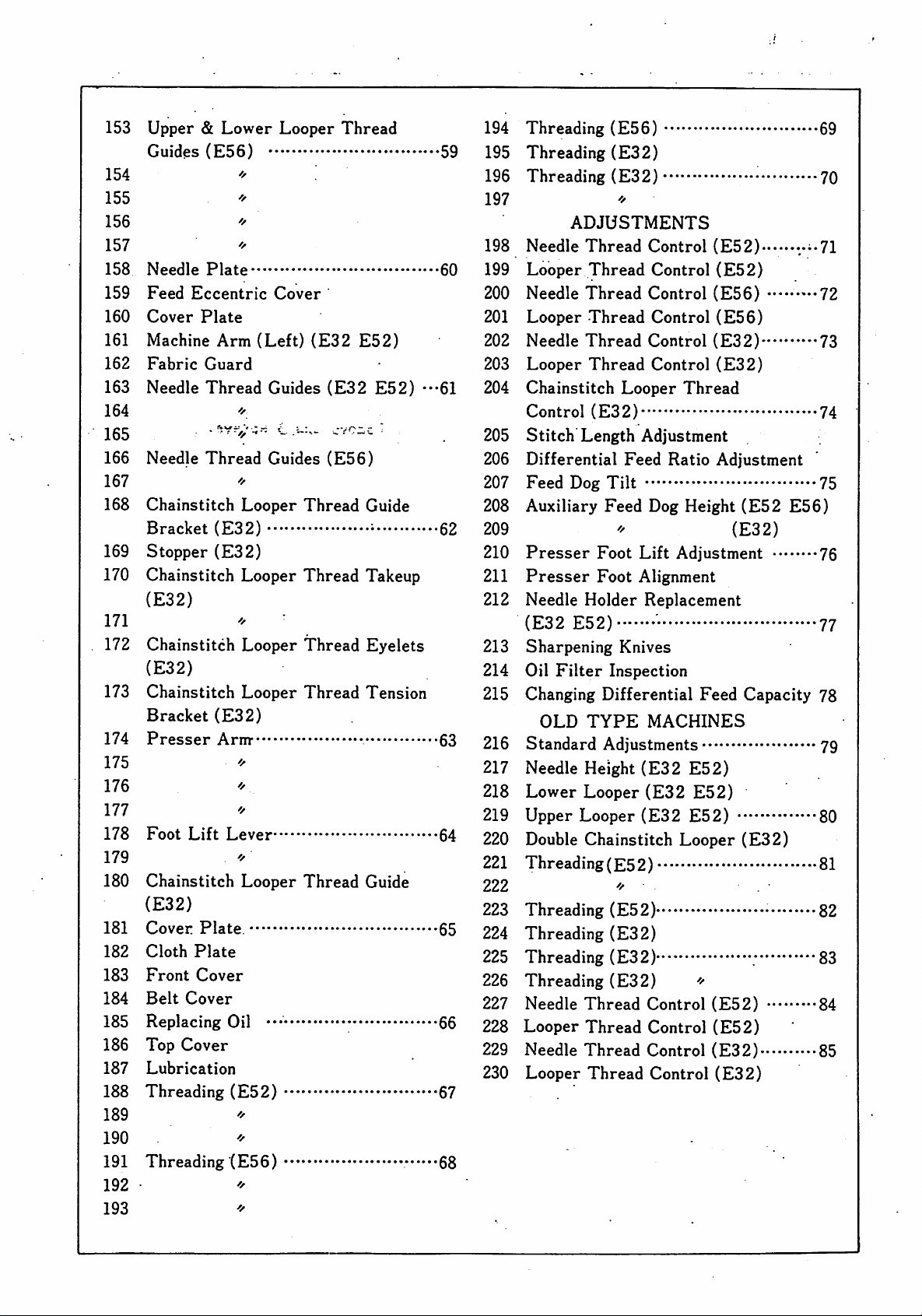

PRESSBR

(D

POOT

LIFT

•®

ARM

(COMPLETE)

SHAFT

(5)

Raise

aving

the

Loosen

Use

Remove

the

out

direction

screw

1/I6"

presser

hand

lift

the

presser

of

the

1

and

alien

key.

arm(complete).

lever

armBin

arrow.

remove

and

pin

A.

(6)

Loosen

Remove

plete)

Remove'

\

spring

Use

3.

screws

foot

from

intermediate

E

from

a 3/16"

3

lift

the

the

alien

and

shaft

left.

right.

key

4.

lever

c(com

for

B

and

screw

LOOPER

COVER

THREAD

PLATE

GUIDE

(REAR)

(7)

-E32-

Remove

screw

guide(rear).

(8)

Remove6screws

Ei32j

remove

at

the

same

and

looper

time.

looper

and

cover

thread

thread

plate.

tube

- 6 -

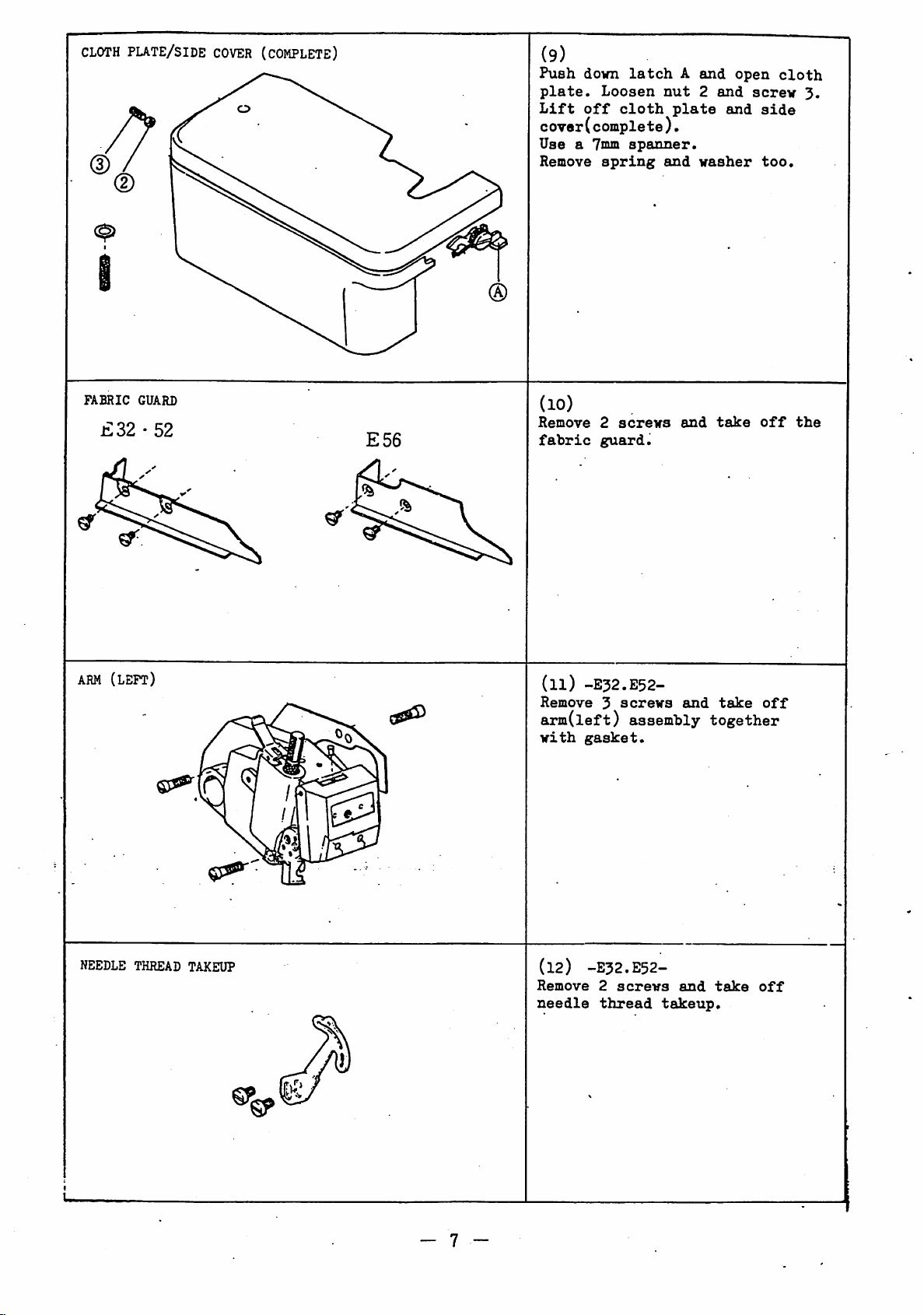

Page 9

CLOTH

plate/side

COVER

(COMPLETE)

(9)

Push

down

latch

plate.

Lift

Loosen

off

nut

cloth

cover(complete).

Usea7mm

Remove

spanner.

spring

and

A

plate

and

2

and

and

washer

open

screw

cloth

3.

side

too.

FABRIC

£32•52

ARM

(left)

GUARD

E56

(lO)

Remove

fabric

(ll)

Remove3screws

arm(left)

with

2

screws

guard.

-E32.E52-

assembly

gasket.

and

and

take

off

take

off

together

the

NEEDLE THREAD TAKEUP

- 7 -

(12) -E32.E52-

Remove

needle

2

screws

thread

and

takeup.

take

off

Page 10

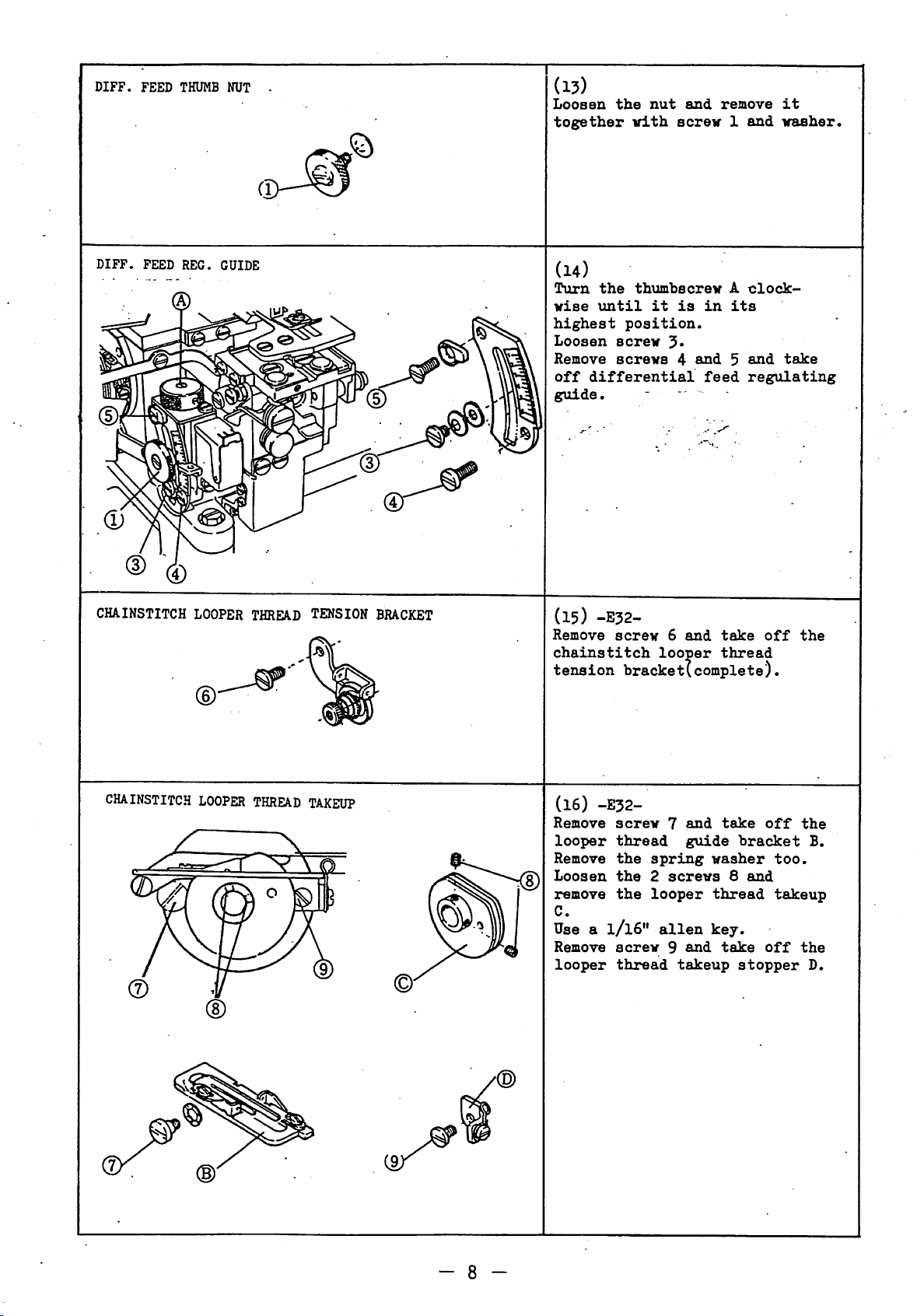

DIFF.

FEED

THUMB NUT -

Cl

©

(13)

Loosen

together

the

vith

nut

and

screw

remove

1

and

it

washer.

DIFF.

CHA.INSTITCH LOOPER

FEED

REG.

GUIDE

THREAD

TENSION

BRACKET

(14)

Turn

the

wise

\intil

highest

Loosen

Remove

off

differential

guide.

(15)

-E32-

Remove

chainstitch

tension

thimbscrew

it

is

A

clock

in

its

position.

screw

screws

screw

4

6

looper

and5and

feed

and

take

thread

regulating

hracket(complete).

off

take

the

CHAINSTITCH

LOOPER

THREAD

TAKEUP

(16)

-E32-

Remove

looper

Remove

Loosen

remove

C.

screw

thread

the

the

the

Use a 1/16"

Remove

looper

screw

thread

7

spring

2

screws

looper

alien

9

takeup

and

guide

and

take

"bracket

washer

8

thread

key.

take

stopper

and

off

too.

takeup

off

the

B.

the

D.

- 8 -

Page 11

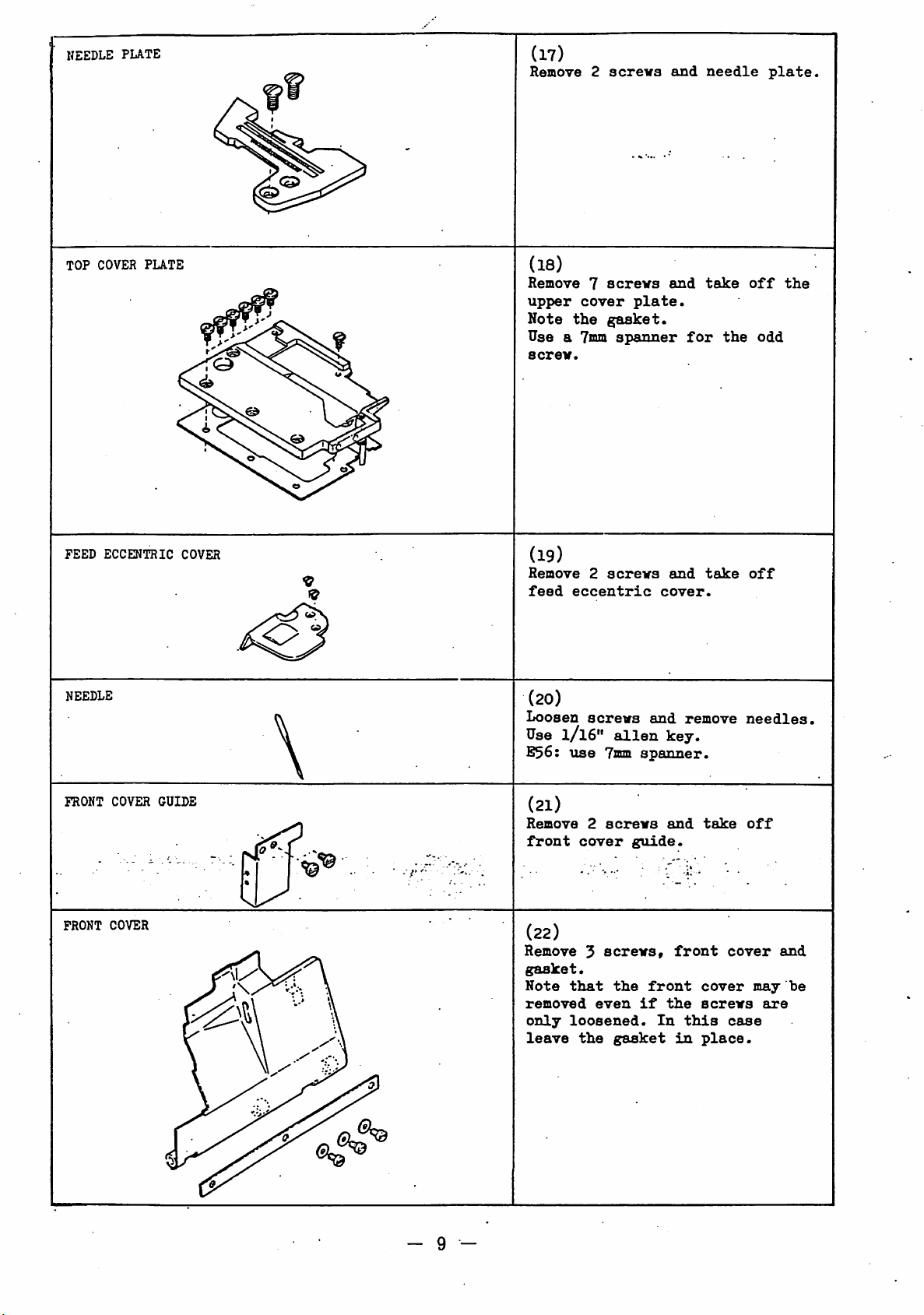

NEEDLE

TOP

COVER

PUTE

PLATE

(17)

Remove2screva

(18)

Remove7acrevs

upper

Note

Usea7mm

screv.

cover

the

plate.

gasket.

spanner

and

and

for

needle

take

the

off

plate.

the

odd

FEED

NEEDLE

FRONT

FRONT

ECCENTRIC

COVER

COVER

GUIDE

COVER

(19)

Remove

feed

2

acreva

eccentric

(20)

Loosen

Use

S36:

screws

1/I6"

use

alien

7mm

(21)

Remove

front

2

cover

screws

guide.

(22)

Remove5screws,

gasket.

Note

that

the

removed

only

leave

even

loosened.

the

gasket

and

cover.

and

remove

key.

spanner.

and

front

front

if

the

In

this

in

take

take

cover

screws

place.

off

needles,

off

cover

case

may

are

and

be

- 9 -

Page 12

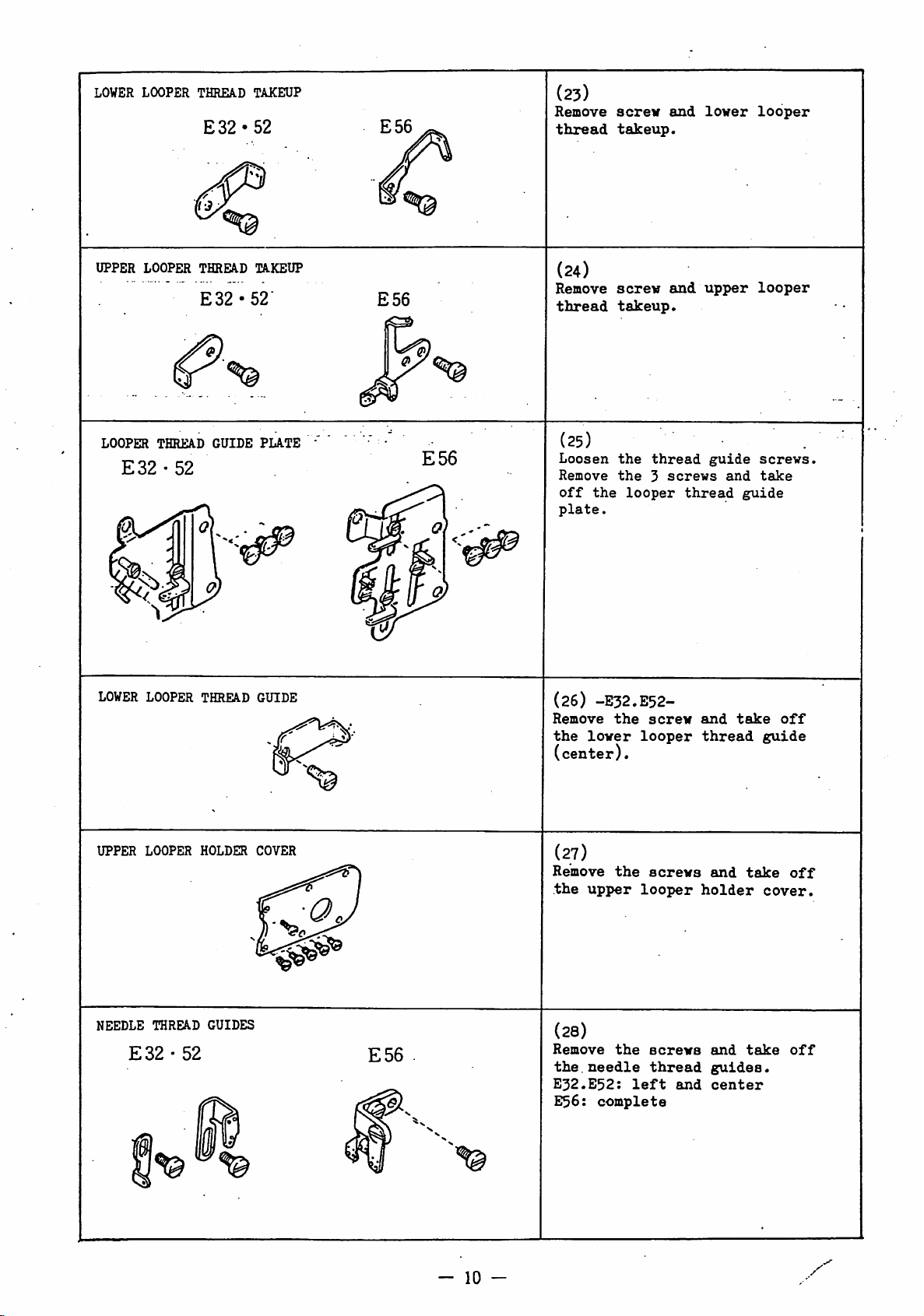

LOWER

LOOPER

THREAD

E32•52

TAKEUP

E56

(23)

Remove

thread

screw

takeup.

and

lower

looper

UPPER

LOOPER

E32-52

LOWER

LOOPER

THREAD

LOOPER

THREAD

TAKEUP

E32-52"

GUIDE

THREAD

GUIDE

PLATE

E56

E56

(24)

Remove

thread

(25)

Loosen

Remove

off

the

plate.

(26)

-E32.E52-

Remove

the

lower

(center).

screw

takeup.

the

the

looper

the

looper

and

thread

3

screws

screw

upper

guide

thread

and

thread

and

guide

take

looper

screws.

take

off

guide

UPPER

NEEDLE

LOOPER

THREAD

E32•52

HOLDER

GUIDES

COVER

E56

(27)

Remove

the

upper

the

looper

(28)

Remove

the.

E32.E52:

E56:

-

10

-

the

needle

left

complete

screws

screws

thread

and

and

holder

and

guides.

center

take

take

off

cover.

off

Page 13

UPPER

knife/clamp

1^

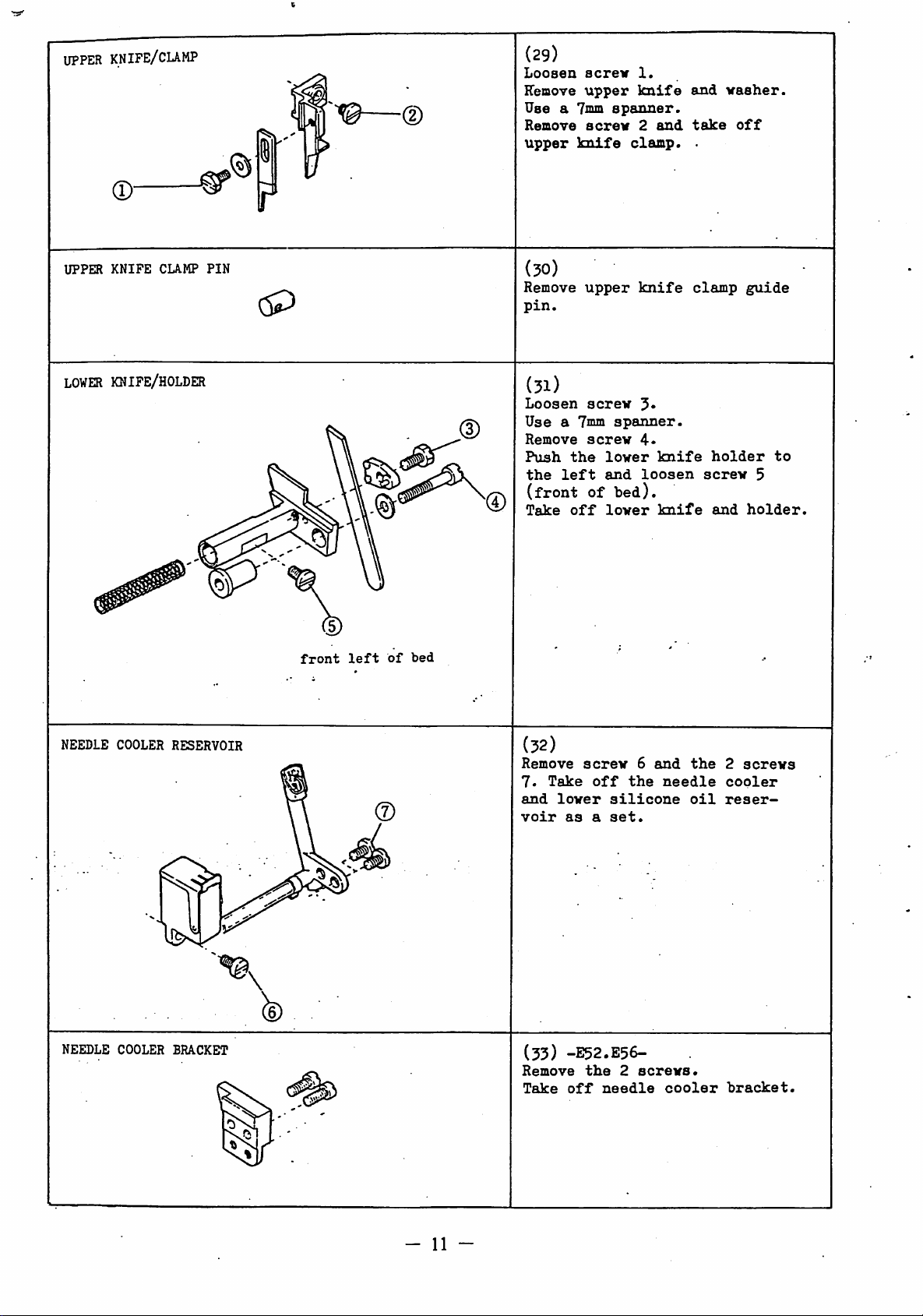

(29)

Loosen

Remove

Use

Remove

upper

acrev

upper

a 7mm

screw

knife

1.

knife

spanner.

2

clamp.

and

and

take

.

vasher.

off

r

UPPER

LOWER

KNIFE

CUMP

KNIFE/HOLDER

PIN

front

left

(30)

Remove

pin.

upper

knife

clamp

guide

(31)

Loosen

Use

Remove

Push

the

(front

Take

of

bed

screw

a 7mm

screw

the

left

of

off

spanner.

lower

and

bed).

lower

4.

knife

loosen

knife

holder

screw

and

to

5

holder.

NEEDLE COOLER

NEEDLE

COOLER

RESERVOIR

BRACKET

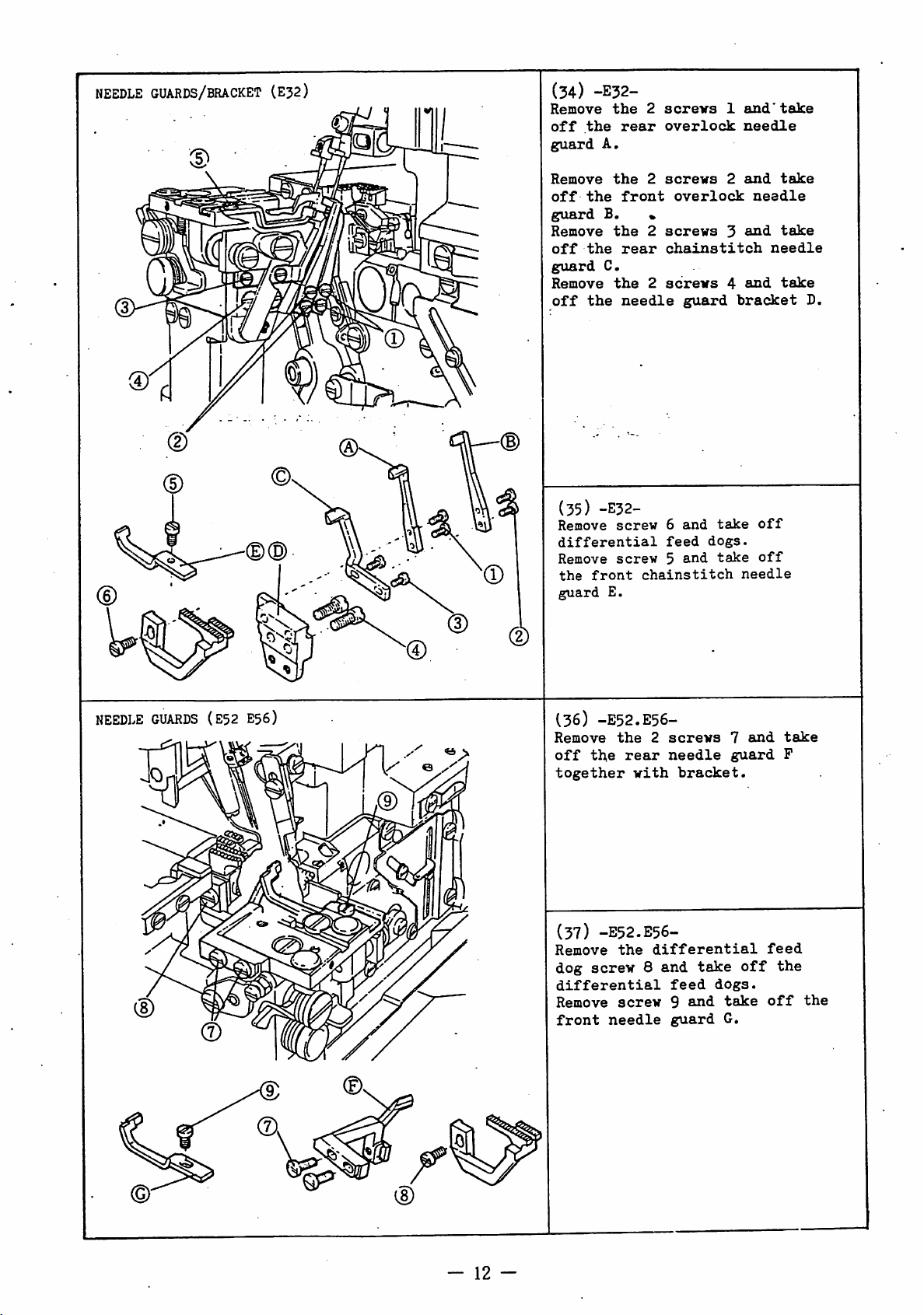

(32)

Remove

7.

Take

and

lower

voir

(33)

Remove

Take

screw

off

silicone

as

a

set.

-J52.E56-

the

2

off

needle

6

the

screws.

and

needle

cooler

the

oil

2

screws

copier

reser

bracket.

- 11 -

Page 14

NEEDLE

GUARDS/BBAOKET

(E32)

Q

(34)

Remove

off

guard

-E32-

the

A.

the

rear

2

screirs

overlook

1

and'take

needle

(D

d)®

n

Remove

off

the

guard

Remove

off

the

guard

Remove

off

the

(35)

Remove

differential

Remove

the

front

guard

the

2

front

B. »

the

2

rear

C.

the

2

needle

-E32-

screw6and

screw

chainstitch

E.

screws

overlook

screws

chainstitoh

screws

guard

feed

dogs.

5

and

2

3

4

take

take

and

needle

and

needle

and

bracket

off

off

needle

take

take

take

D.

NEEDLE

GUARDS

(E52 E56)

(36)

-E52.E56-

Remove

off

the

together

(37)

-E52.E56-

Remove

dog

screw8and

differential

Remove

front

the

rear

with

the

screw

needle

2

screws

needle

bracket.

differential

take

feed

9

and

guard

7

guard

dogs.

take

G.

and

off

feed

the

off

take

P

the

-

12

-

Page 15

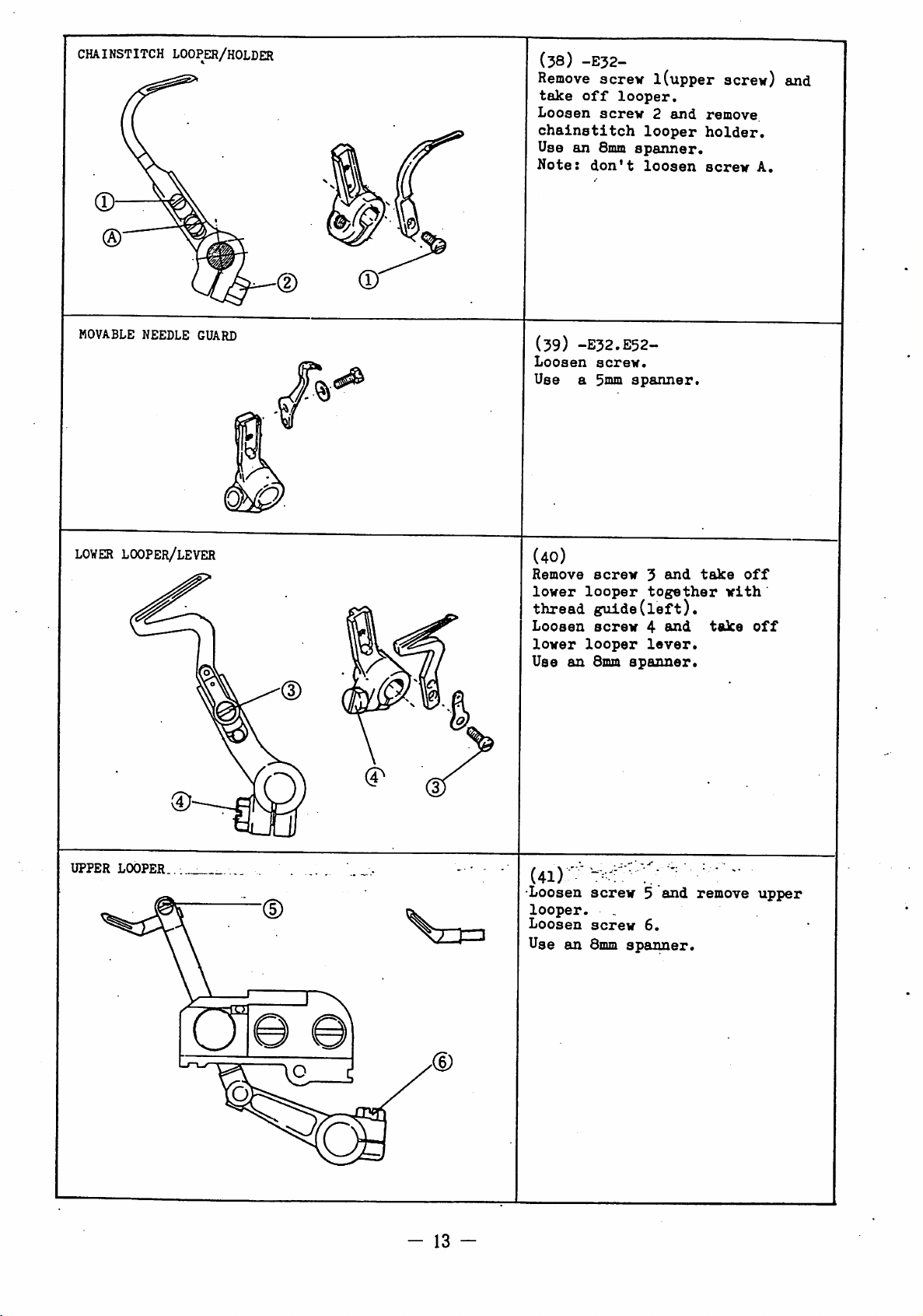

CHAINSTITCH

L00PE21/H0LDER

(58)

-E32-

Remove

take

off

Loosen

chainstitch

Use

an

Smm

Note:

don't

screw

1(upper

looper.

screw2and

looper

spanner.

loosen

screw) and

remove.

holder.

screw

A.

MOVABLE NEEDLE GUARD

LOWER

LOOPER/LEVER

(59)

Loosen

Use

(40)

Remove

lower

thread

Loosen

lower

Use

an

-E32.E52-.

screw.

a 3mm

spanner.

screw

looper

guide(left).

screw

looper

Smm

spanner.

3

and

together

4

and

lever.

take

take

off

with

off

UPPER

LOOPER.

-

13

-

(4i)

" " : ; • •

Loosen

looper.

Loosen

Use

screw5and

.

screw

an

Smm

6.

spanner.

•'

remove

upper

Page 16

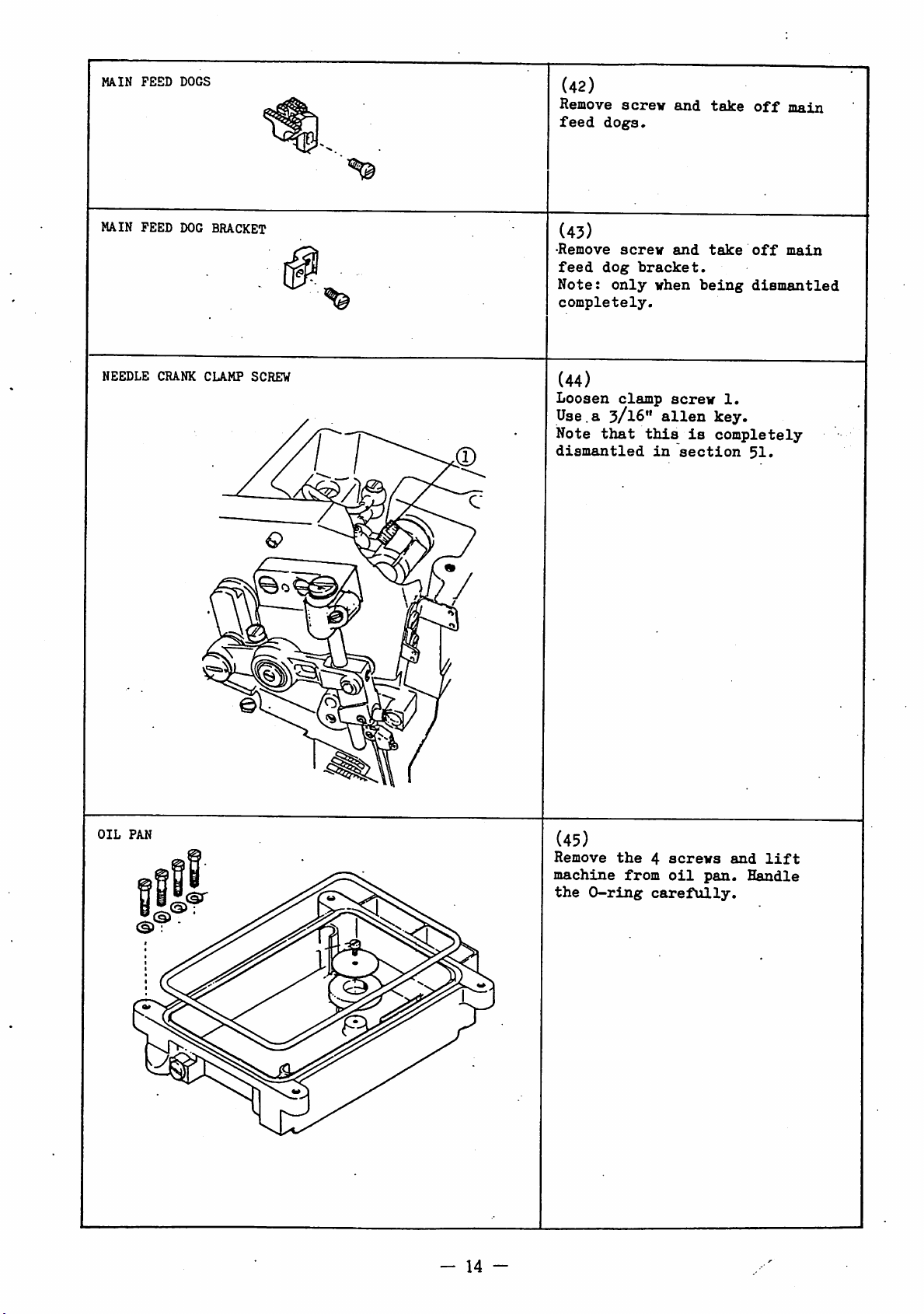

MAIN

FEED

DOGS

(42)

Remove

feed

screw

dog:s*

and

take

off

main

MAIN FEED

NEEDLE

CRANK

DOG

BRACKET

CLAMP

SCREW

€>

(43)

•Remove

feed

Note:

completely.

dog

only

screw

bracket.

(44)

Loosen

clamp

Use.a 3/16"

Note

that

dismantled

when

this

in

and

screw

alien

is

section

take

off

being

dismantled

1.

key.

completely

51.

main

OIL

PAN

(45)

Remove

machine

the

-

14

-

the

O-ring

from

4

screws

oil

carefully.

pan.

and

Handle

lift

Page 17

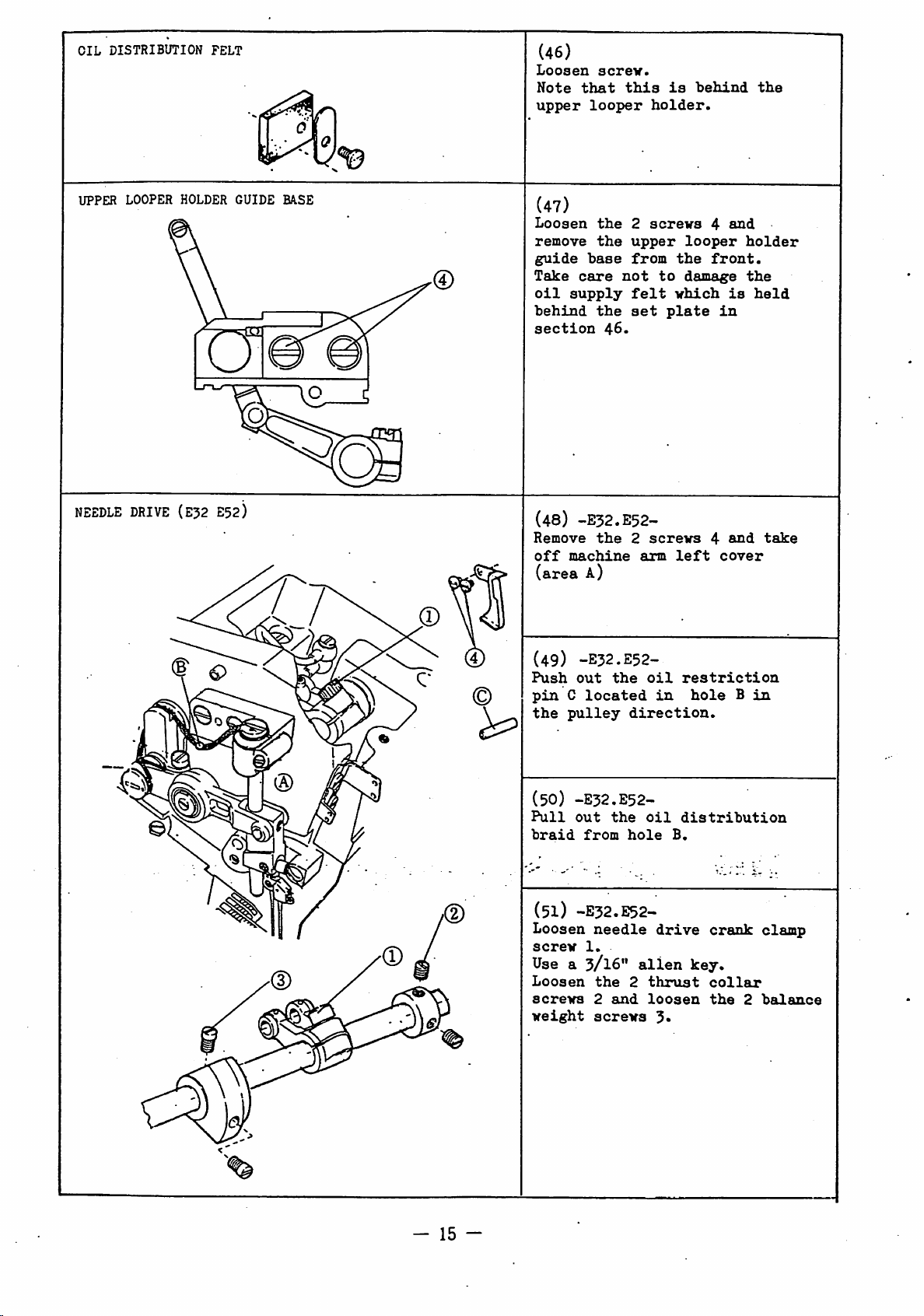

OIL

DISTRIBUTION

FELT

(46)

Loosen

Note

upper

screv.

that

looper

this

is

holder.

behind

the

UPPER

NEEDLE

LOOPER

DRIVE

HOLDER

(E32 E52)

GUIDE

BASE

(47)

Loosen

remove

guide

Take

oil

behind

section

(48)

Remove

off

(area

the

the

base

care

not

supply

the

46.

-E32.E52-

the

machine

A)

2

screws

upper

from

felt

set

2

screws

arm

to

plate

looper

the

damage

which

left

4

and

front.

is

in

4

and

cover

holder

the

held

take

(49)

-E32.E52-

Push

out

the

pin

C

located

the

(50)

Pull

braid

pulley

-E32.E52-

out

from

direction.

the

hole

(51) -E32.E52-

Loosen

screw

needle

1.

Usea3/I6"

Loosen

screws

weight

the

2

and

screws

2

oil

in

oil

drive

alien

thrust

loosen

3»

restriction

hole

distribution

B.

crank

key.

collar

the

B

in

2

clamp

balance

-

15

-

Page 18

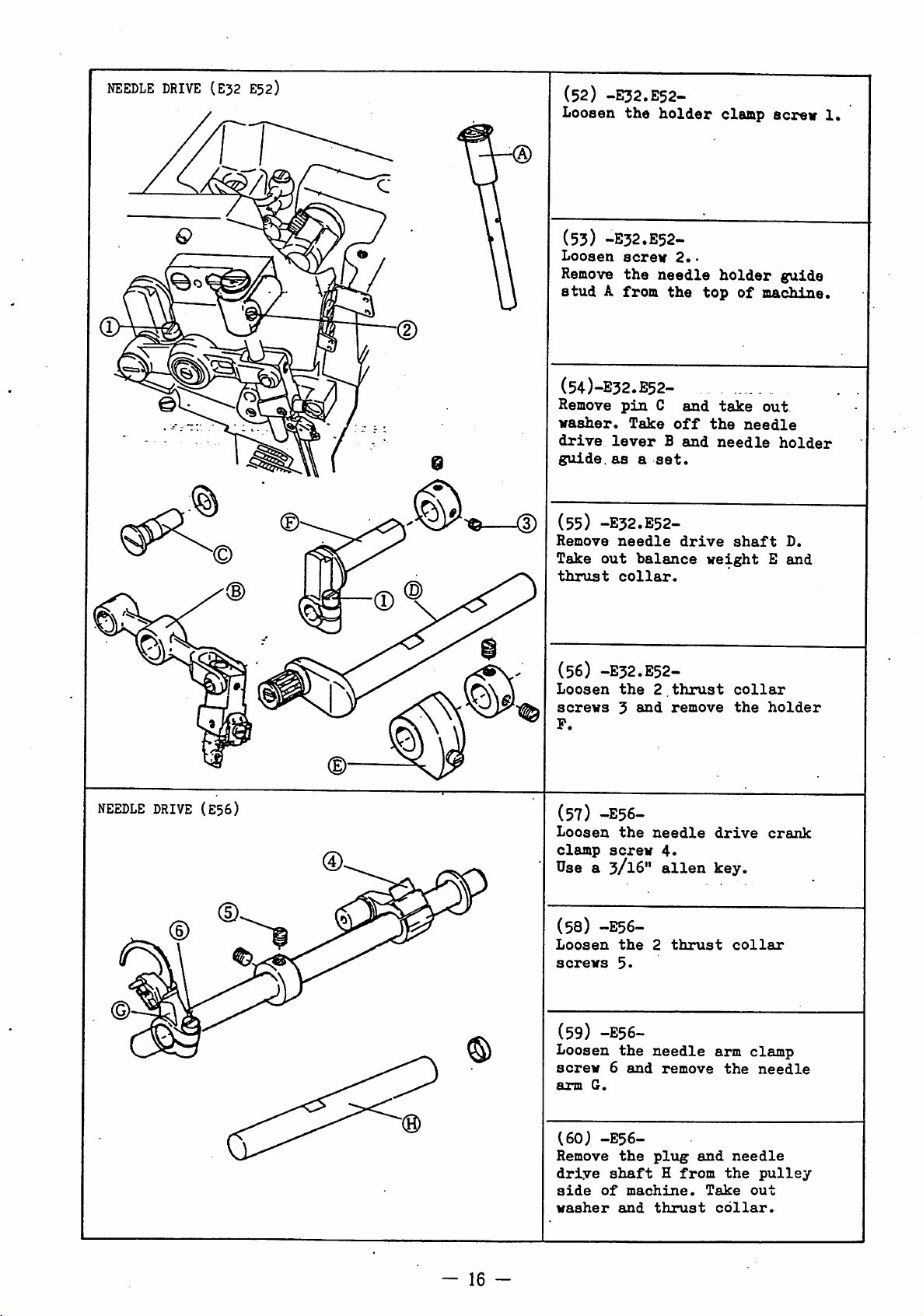

NEEDLE

DRIVE

(E32 E52)

(52) -E32.E52-

Loosen

the

holder

(53) -E32.E52-

Loosen

Remove

stud

A

screv

the

from

needle

(54)-E32.E52-

Remove

washer.

drive

guide,

pin

C

Take

lever

asaset.

(55) -E32.E52-

Remove

Take

thrust

out

needle

balance

collar.

the

B

2.•

and

off

and

drive

claap

holder

top

take

the

needle

weight

of

needle

shaft

screv

guide

machine.

out

holder

D.

E

and

1.

NEEDLE

DRIVE

(E56)

(56) -E32.E52-

Loosen

screws

P.

(57)

Loosen

clamp

Use

(58)

Loosen

screws

(59)

Loosen

screw

arm

the

3

and

-E56-

the

screw

a 3/16"

-E56-

the

5-

-E56-

the

6

and

G.

2

needle

4*

alien

2

needle

remove

thrust

remove

thrust

collar

drive

key.

collar

arm

the

the

clamp

holder

crank

needle

(60)

-E56-

Remove

drive

side

washer

-

16

-

shaft

of

the

machine.

euid

plug

H

thrust

from

and

Take

needle

the

collar.

pulley

out

Page 19

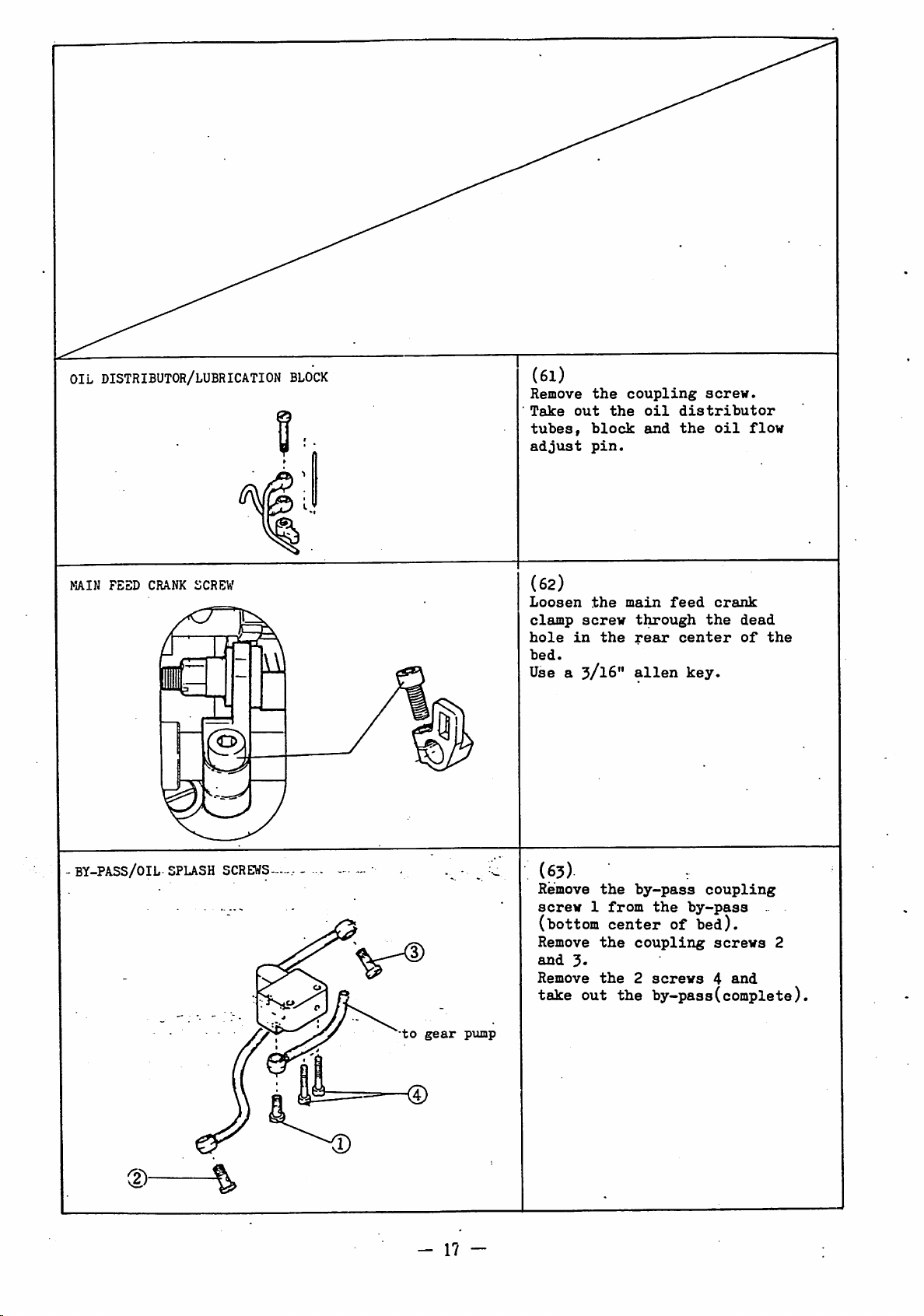

OIL

distributor/lubrication

MAIN

FEED

CRANK

SCREW

block

(61)

Remove

Take

tubes,

adjust

(62)

Loosen

clamp

hole

bed.

Use a

the

out

block

pin.

the

screw

in

3/16"

the

the

coupling

oil

and

main

through

rear

alien

screw.

distributor

the

feed

the

center

key.

oil

crank

flow

dead

of

the

BY-PASS/OIL

SPLASH

SCREWS

-

to

gear

pump

-

1?

-

(63)

Remove

screw

(bottom

Remove

and

3«

Remove

take

out

the

1

from

center

the

the

by-pass

coupling

2

the

coupling

the

of

screws

by-pass

bed).

screws

4

.

2

and

by-pass(complete)

Page 20

GEAR

PUMP/OIL

0-ring

INDICATOR

%==KD

(64)

Remove

out

the

Note

the

Remove

indicator

indicator.

the2screws

gear

pump.

0-ring,

the2screws

support

and

1

2,

and

the

the

take

oil

oil

LOOPER

SHAFT

SCREWS

(65)

Remove

screw

the

3

together

washers. (The

right,

on

Use a

the

angles

pulley

7mm

spanner.

(66)

Remove

screw

washers.

center

(67)

Loosen

the

(The

the

the

4

together

(The

of

the

-E32-

the

nut

chainstitch

shaft

bed).

is

upper

shaft

to

side.)

lower

shaft

bed.)

on the

looper

with

the

looper

with

5 on

looper

shaft

the

2

is

at

crankshaft

-

shaft

the

2

is

in

the

the

end

shaft.

left

of

of

FEED

SHAFT

(68)

Loosen

clamp

drive

(The

machine

the

screw

crank

shaft

and

crankshaft)..

Usea3/I6"

(69)

Loosen

screws

shaft

from

-

18

-

the

8

A

the

and

together

left

diff.

6

clamp

at

parallel

alien

2

thrust

remove

the

of

and

feed

screw

rear

key.

with

the

crank

the

to

collar

the

cap

machine.

feed

7.

of

the

feed

the

Page 21

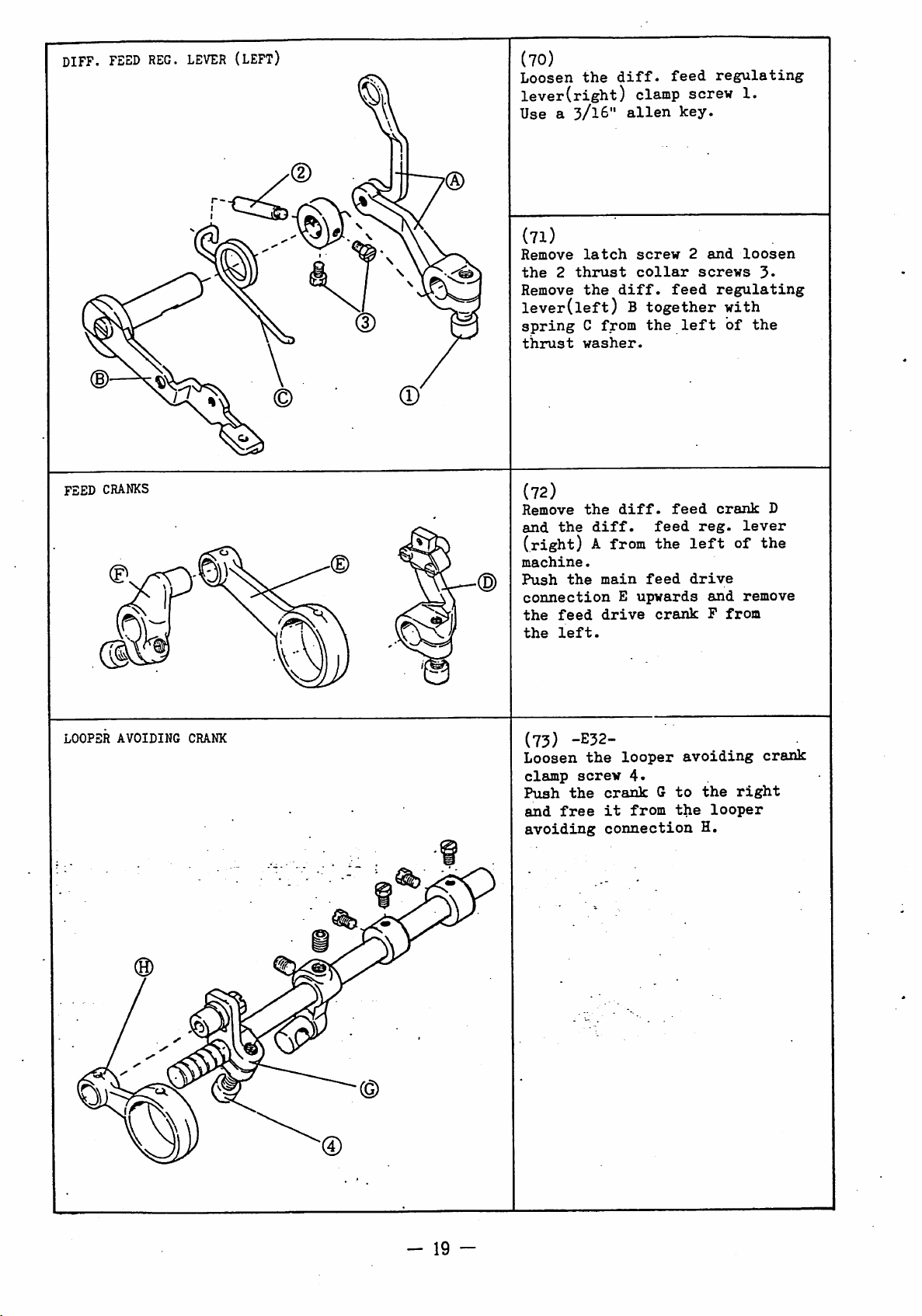

DIFF.

feed

feed

cranks

REG.

LEVER

(LEFT)

©

©

(70)

Loosen

the

lever(right)

Use a

(71)

Remove

the

Remove

2

3/16"

latch

thrust

the

lever(left)

spring

thrust

C

from

washer.

(72)

Remove

and

(right)

machine.

Push

connection

the

the

the

the

feed

left.

the

diff.

A from

main

drive

diff.

feed

clamp screw 1.

alien

diff.

B

diff.

E

screw

collar

feed

together

the

feed

feed

the

feed

upwards

crank

key.

2

screws

left

reg.

left

drive

regulating

and

loosen

regulating

with

of

crank

lever

of

and

remove

P

from

3«

the

D

the

loopsr

avoiding

crank

(73)

Loosen

clamp

Push

the

and

free

avoiding

-E32-

the

screw

looper

4.

crank

it

G

from

connection

avoiding

to

the

the

looper

H.

crank

right

-

19

Page 22

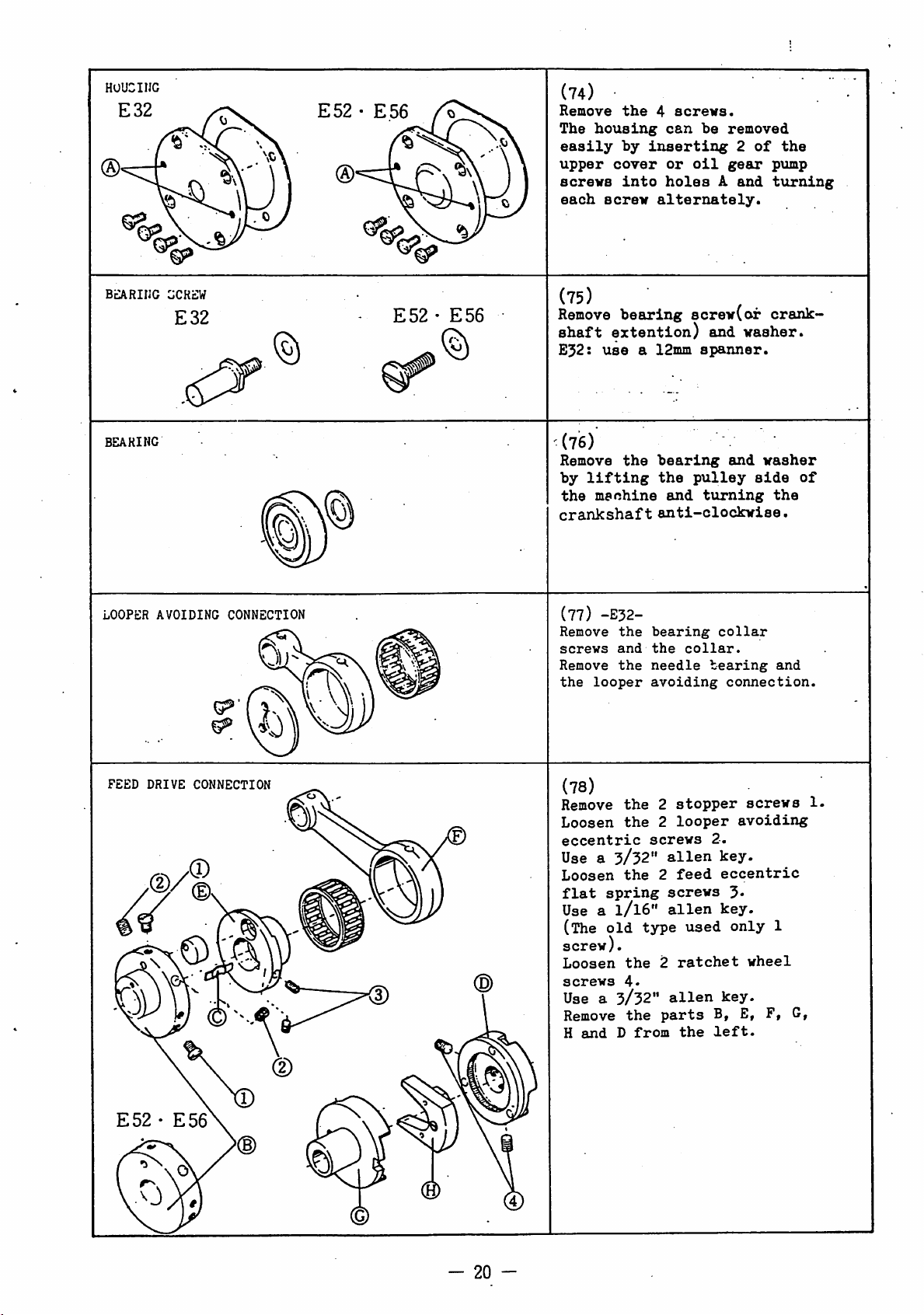

HOUCIIIC

E32

E52•E56

(74)

Remove

The

easily

upper

screws

each

the

housing

by

cover

into

screw

4

screws.

can

inserting

or

oil

holes

alternately.

be

removed

2

gear

A

and

of

pump

t\irning

the

BlARIIJC

BEARING

LOOPER

gcrsw

E32

AVOIDING

CONNECTION

E52•E56

(75)

Remove

shaft

E32:

extention)

use

(76)

Remove

by

lifting

the

machine

crankshaft

(77)

-E32-

Remove

screws

Remove

the

looper

bearing

a 12inm

the

bearing

the

anti-clockwise.

the

bearing

and

the

the

needle

avoiding

screw(or

pulley

and

collar.

and

spanner.

and

tiirning

collar

bearing

connection.

crank

washer.

washer

side

the

and

of

FEED

DRIVE

E52-E56

CONNECTION

(D

(78)

Remove

Loosen

eccentric

Use a

Loosen

flat

Use a

(The

screw).

Loosen

screws

Use a

Remove

H

and

the2stopper

the

2

looper

screws

3/52"

spring

1/I6"

old

3/32"

D

the

the

4.

the

type

from

alien

2

feed

screws

alien

2

ratchet

alien

parts

the

used

avoiding

2.

key.

eccentric

3-

key.

only

key.

B, E,

left.

screws

1

wheel

F,

1.

G,

20

Page 23

FEED BAR

FEED

BAR

FEED

DRIVE

OIL

SEA,L GUIDE

GUIDE

LEFT

® ^

(79)

Remove

Move

position

seal

the

feed

guide.

(80)

Remove

feed

the

base

(81)

Loosen

the

and remove

plete)

Remove

feed

D

the

and

.

main

bar

main

left

4

screws.

bars

to

and

take

2

screws

guide(left).

feed

bar

feed

bar

feed

C,

feed

feed

crank

of

the

machine.

bar

bar

their

off

and

pin

pin

the

B,

lift

E

highest

oil

take

screw

A (com

diff.

block

from

off

1

LOOPER

AVOIDING

LEVER

©

(82)-E32^-

Loosen

shaft

Loosen

lev^r

the2iboper

thrust

the2looper

screws

Use a 1/8"

collar

4-

alien

key.

-

avoiding

screws

avoiding

3.

-

21

-

Page 24

LOWER

LOOPER

DRIVE

CONNECTION

CAP

(85)

Remove

cap

from

Note:

together

-E52.E56-

the2cap

the

keep

the

asaset.

top

cap

screvs

center

and

and

of

bed.

connection

LOWER

CHAINSTITCH LOOPER

LOOPER DRIVE CONNECTION CAP

©

DRIVE

SHAFT

(84)

Remove

the

top

bed.

Prom

machine

avoiding

Remove

collar

Loosen

screw

shaft

Take

Use a

-E32-

the

center

the

bed

the

A.

looper

4

and

D.

out

3/16"

2

bottom

loosen

block

nut

remove

washer

alien

cap

drive

acrews

of

rear

collar

5

together

C.

the

the

crank

looper

key.

1

machine

of

the

lobper

screw

from

2.

with

clamp

drive

LOOPER

AVOIDING

SHAFT

22

(85)

-E32-

Loosen

screws

Remove

together

avoiding

avoiding

'the

-

2

the

1.

the

the

lever

crank

thrust

2

shaft

thrust

plug,

E,

P,

collars.

from

looper

looper

shaft

collar

the

left

U

and

Page 25

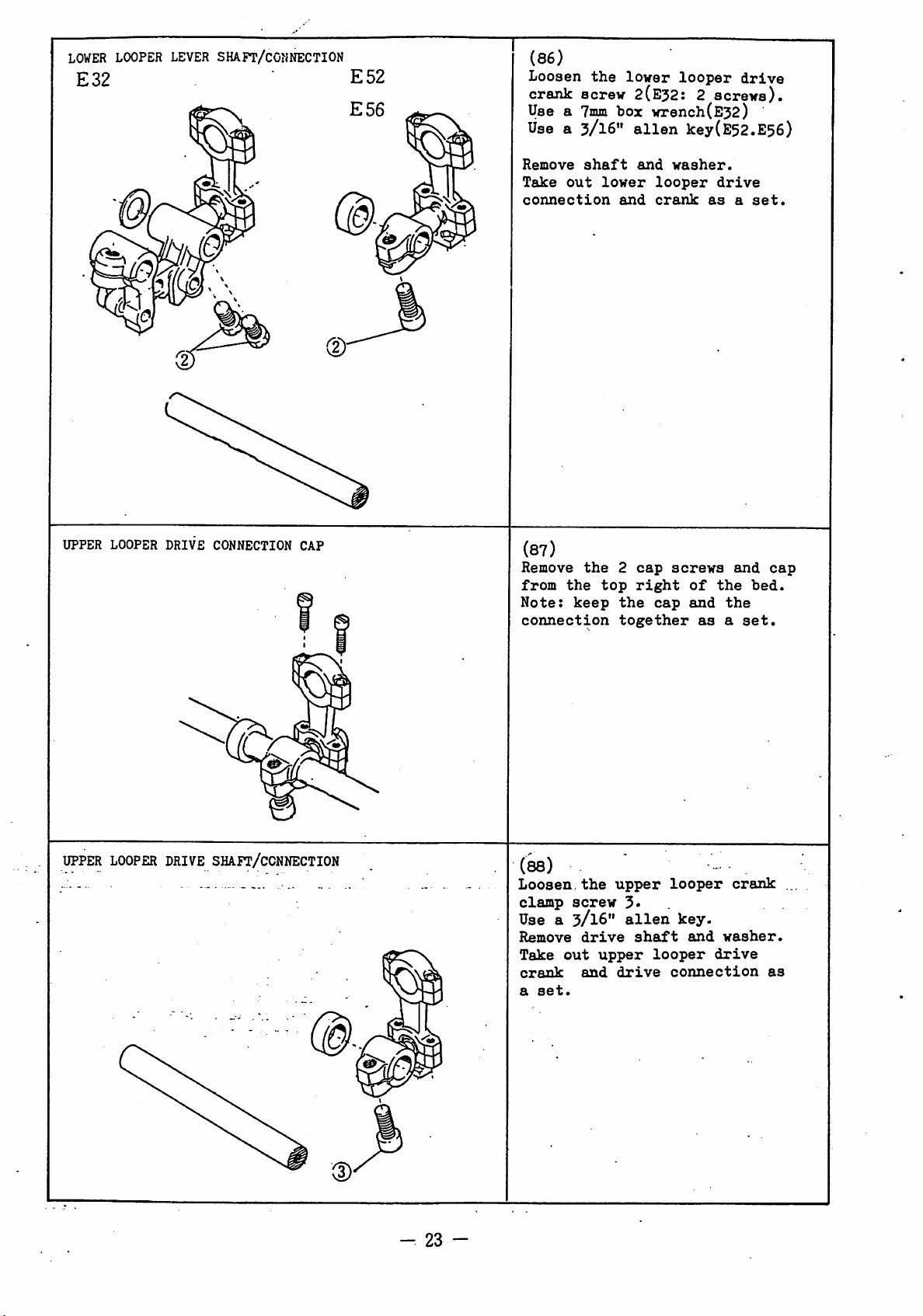

LOWER

E32

LOOPER

LEVER

SHAPT/CONNECTION

(86)

Loosen

the

lower

looper

crank screw 2(E52: 2

Use a

Use

Trnin

a 3/16"

box wrench(E32)

alien

key(E52.E56)

drive

screws).

UPPER

LOOPER

DRIVE

CONNECTION

CAP

Remove

Take

out

connection

(87)

Remove

from

the

Note:

connection

keep

shaft

the

lower

and

2

top

the

together

and

cap

right

washer.

looper

crank

screws

cap

drive

as

of

the

and

the

asaset.

a

and

set.

cap

bed.

UPPER

LOOPER

DRIVE

SHAFT/CCNNECTION

(88)

Loosen.the

clamp

Use a

Remove

Take

out

crank

a

set.

-

23

-

screw

3/16"

drive

upper

and

upper

3« .

alien

shaft

drive

looper

key.

looper

connection

and

crank

washer.

drive

as

Page 26

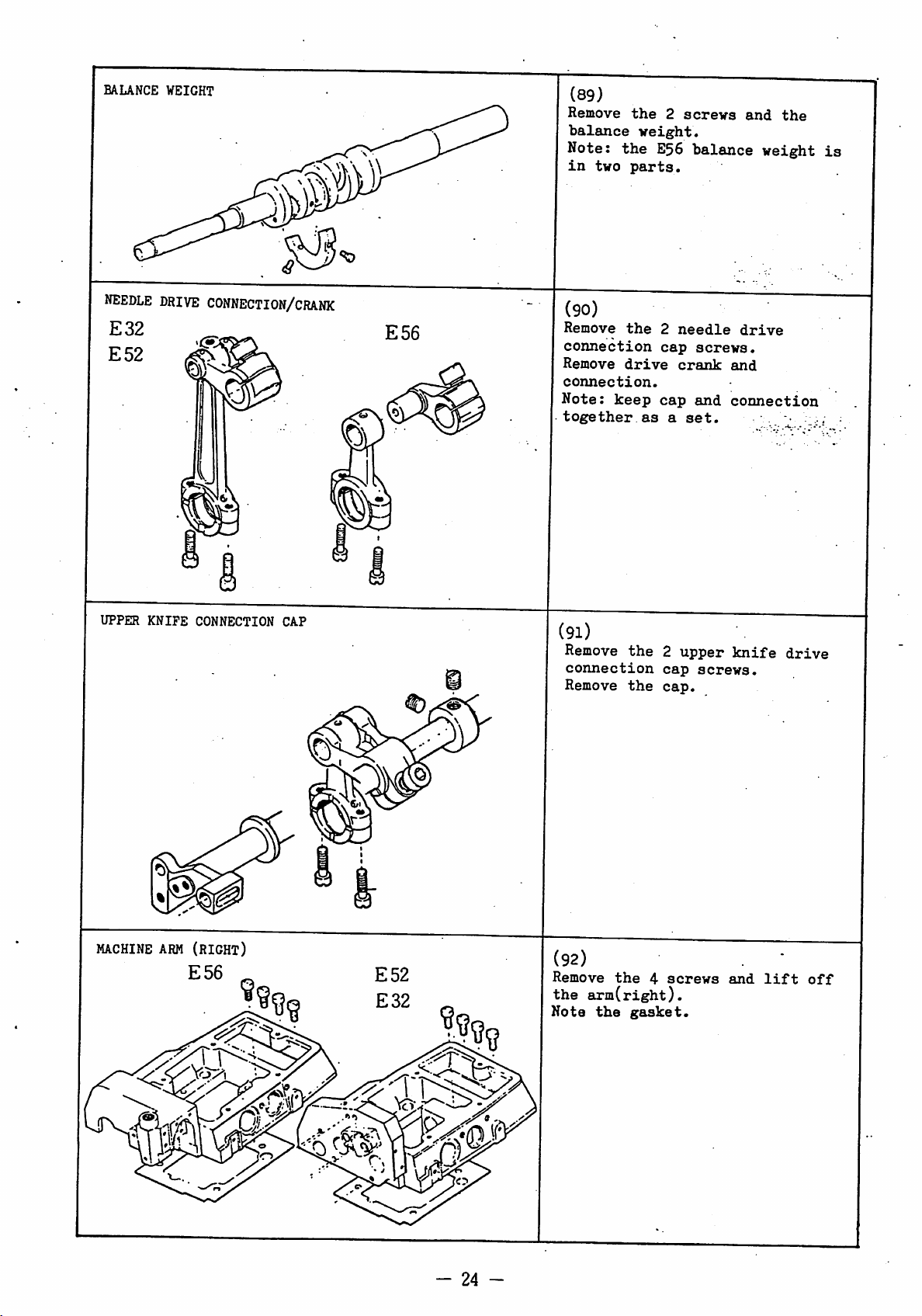

BALANCE WEIGHT

(89)

Remove

balance

Note:

in

two

the

weight.

the

parts.

2

E56

screws

balance

and

weight

the

is

NEEDLE

E32

E52

UPPER

KNIFE

DRIVE

CONNECTION/CRANK

CONNECTION CAP

E56

(90)

Remove

connection

Remove

connection.

Note:

together

(91)

Remove

connection

Remove

the

2

needle

cap

drive

keep

as

crank

cap

a

the2upper

cap

the

cap.

screws.

and

set.

screws.

drive

and

connection

•

knife

drive

MACHINE

ARM

(RIGHT)

E56

(92)

Remove

the

Note

-

24

-

the

arm(right).

the

gasket.

4

screws

and

lift

off

Page 27

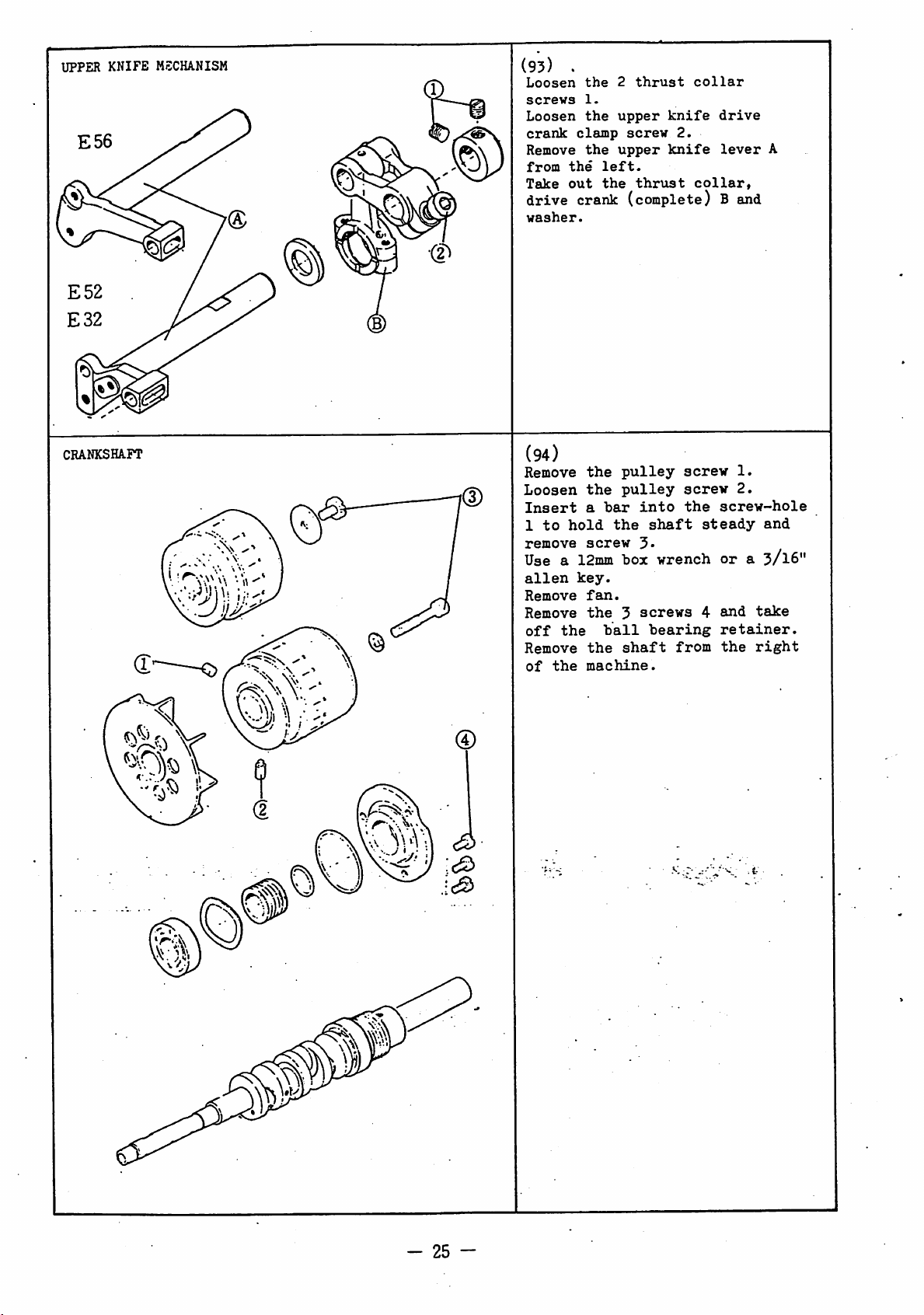

UPPER

KNIFE

MECHANISM

(93)

Loosen

screws

Loosen

crank

Remove

from

Take

drive

washer.

.

the

2

clamp

the

out

1.

the

the

left.

the

thrust

upper

screw

upper

thrust

knife

2.

knife

collar

drive

lever

collar,

crank (complete) B and

A

CRANKSHAFT

(94)

Remove

Loosen

Insert

1

to

remove

Use a

alien

Remove

Remove

off

Remove

of

the

hold

the

the

the

a

bar

screw

12mm

key.

fan.

the

ball

the

machine.

pulley

pulley

into

the

shaft

5*

box wrench

3

screws

bearing

shaft

from

screw

screw

the

screw-hole

steady

ora3/I6"

4

and

retainer.

the

1.

2.

and

take

right

-

25

-

Page 28

ASSEMBLY

—

26

-

Page 29

CHAINSTITCH

LOOPER

AVOIDING SHAFT

(l)

- E32 -

Insert

A

into

Replace

looper

collar

the

the

the

avoiding

E

right)

looper

bed

looper

(polished

and

avoiding

through

avoiding

lever

surface

thrust

(polished surface to the

on

the

shaft.

hole

crank

D,

thrust

collar

left)

shaft

B.

C,

to

P

1

i.' j.. ,

0pot

Bcr^v

(2)

- E52 -

Replace

(3)

- E32 -

Maintaining

cap

G,

push

left.

collar

the

screw

(4) -

Push

to

P

in

screws

first.

so

2

the

the

Lightly

F

screws

first.

E32

the

right,

that

2.

cap

to

thrust

shaft

G

in

a

small

the

push

the

1.

-

hold

there

and

Tighten

the

gap

shaft

the

left

Tighten

collar

thrust

i s

no

tighten

the

bushing.

with

to

the

thrust

and

tighten

the

E

lightly

free

spot

the

spot

collar

play

the

screw

2

(5)

-E32-

©

Insert

into

avoiding

Tighten

Tighten

(6)

Remove

-

27

the

the

center

block

the

the

- E52 -

the

looper

2

spot

looper

drive

of

onDas

screws

screw

the

drive

5*

shaft

looper

shown.

first.

shaft

H

H.

Page 30

CRANKSHAFT

(7)

Insert

bed

from

(8)

Replace

spring

C-ring

retainer

on

the

(9;

Carefully

1.

Check

can

move

the

the

the

washer

D

and

E

shaft.

tighten

that

smoothly.

crankshaft

right.

ball.bearing

B,

oil

ball

bearing

(together

the

the

crankshaft

into

seal

with

3

the

A,

C,

0-ring)

screws

-A'

(4)

>

'10;

Replace

on

crarikshaft.

Ali;^.

shaft.

groove.

Lightly

pulley

(11;

Insert

screwhole

shaft

screw

from

4.

(12)

Tighten

Tighten

the

screw

tighten

can

a

screw

screw

move.

short

3

moving

fan

2

to

F

with

screw

bar

prevent

2.

3-

and

the

into

and

pulley

crank

2

so

the

the

tighten

G

the

-

28

-

Page 31

FEED

BARS

(13)

Locate

the

main

replace

crankshaft

differential

(14)

Replace

Note

should

that

(15)

Replace

E

and

be

the

the

them

the

the

main

feed

together

feed

the

at

feed

needle

feed

bar

on

the

feed

polished

the

crank

link

left

with

bar

bar

pin

top.

bar

lift

bearing.

A

of

the

C.

D

surface

B

and

the

block

in

PEED REGULATING ECCENTRIC

ASSEMBLING FEED ECCENTRIC

allsninx

urk

(16)

Replace

the

crankshaft

Push

tighten

Tighten

(17)

Replace

on

the

G.

Note

at

the

(le)

Replace

the

feed

right.

it

that

the

lightly

the

the

feed

feed

top.

the

•

ratchet

2

spot

drive

regulating

the

needle

eccentric

from

to

screws

oil

wheel

the

the

1.

screw

connection

hole

bearing

K

from

F

left.

right

first.

eccentric

should

L on

the

on

and

H

be

(19)

flat

aprla<

ollcoMat

adjuatla*

screv

Replace

M

in

Replace

eccentric

eccentric

Align

touching

erankdhoft

J'

-

29

-

Replace

feed

the

the

the

the

the

the

eccentric

right.

feed

feed

looper

P (E52; E56

retainer).

aligning

spring

eccentric

eccentric

K

groove

K.

avoiding

feed

marks.

N

in

from

guide

the

Page 32

PEED

FEED

ECCENTRIC

REGULATING

RATCHET

(20)

Replace

eccentric

crankshaft

groove

Turn

the

needle

the

feed

the

feed

(21)

With

the

eccentric

replace

While

the

right

ratchet

pushing.the

crankshaft,

and

the

assembly

with

at

the

pulley

bearing

drive

regulating

feed

groove

the

locate

wheel

complete

the

bottom."

and

part

connection

regulating

6

ratchet

push

E.

A

at

ratchet

it

feed

on

the

spring

locate

between

eccentric

the

D.

it

to

in

the

the

B

top,

D

the

and

C.

onto

LOCATING

spot

FEED

ECCENTRIC

(22)

I'ush

ccconlric

ri/:ht

I.

Note

same

the

Lho

looper

and

Ti/^hton

that

position

ratchet

1'^

li,':hLly

ti,':}itcn

the

the

wheel

avoidin;j

spot

flat

as

the

tlio

E.

to

is

the

2

screws

screw

in

flat

firsl^

the

for

(23)

Check

ratchet

that

the

feed

regulating

D

can

move

smoothly.

§

(24)

i • ©

Press

it

so

when

Tighten

in

there

the

groove

the

screw

pushbutton

G.

is

a

slight

handwheel

3-

Tighten

is

and

locate

screw

pressure

turned.

2

-

30

-

Page 33

STITCH

LE3iCTH

RANOg/llOUsiNC

©

(25)

Replace

Press

stopper

Turn

it

pulley

touches

(26)

Release

Turn

clockwise

Note

check

is

only

2/3

pulley

the

pressed

move

turn.

and

in

pushbutton

in

stop

pushbutton.

and

position

that

when

in

1/3

tighten

eccentric

anti-clockwise

screw

about

replace

the

the

handwheel

turn

I/3

of

and

stop

screw

and

locate

groove

1.

turn

screw

the

screw:

pushbutton

not

1.

H,

until

2.

can

©

(27)

- E32 -

Replace

connection

and

Tighten

Note

top.

collar

that

looper

A,

C

the

oil

2

(28)

Replace washer

and

washer

F

(29)

Replace

and

tighten

screw4(E52;

extension

5.

avoiding

needle

on

screws

holes

D,

on

E56)

bearing

crankshaft.

3»

should

ball

the

crankshaft.

bearing

or

B

be

bearing

crankshaft

at

E

(30)

31

Replace

Do

riot

Tighten

-

housing

omit

the

gasket.

4

G.

screws

6.

Page 34

LOWER

LOOPER

DRIVE

CONMECTIOH

(31)

Replace

connection

crankshaft

the

Align

replace

the

Tighten

Check

move

the

bed.

the

the

machine.

screws

that

smoothly.

lower

(complete) A on

B

from

aligning

cap

the

(32) - E52, E56 -

Replace

C

from

Insert

crank

Tighten

the

from

-

E32

Insert

flat

Lightly

D

shaft

the

-

lines

lower

the

it

through

and

the

protruding

rear

the

tighten

front

washer

clamp

shaft

up

looper

with

looper

the

marks

from

1

connection

the

carefully.

lever

of

the

the

E,

screw2with

slightly

bushing

0

so

the

screws

bottom

bed.

drive

vJ

F.

that

screws

3-

drive

the

and

top

can

shaft

the

of

of

•

3»

(33)

Tighten

washer

shaft

(34)

Loosen

Lightly

right

the

left.

Tighten

screws

is

no

the

onto

C

with

screw2or

push

and

the

the

clamp

3

sec\irely

free

play

washer

the

screw

screw

drive

in

and

end

of

4.

screw

screw2or

so

4

crank

the

to

that

shaft.

3 (E32)

the

spring

the

D

to

there

32

-

Page 35

double

chaikstitch

drive

©

shaft

(35)

- E32 -

Push

A

the

B.

to

(36)

the

the

looper

- E32 -

Insert

through

washer

front

Lightly

the

narrow

protruding

rear

bushing

the

E

of

looper

left

avoiding

looper

the

and

the

tighten

slightly

avoiding

and

locate

drive

drivecrank

block

bed.

screw

part

of

G.

crank

it

connection

shaft

D,

F

from

1

with

the

shaft

from

the

in

C

the

(37)

-E32-

Replace

the

so

between

Loosen

the

Tighten

(38) -

Loosen

With

connection

position

fully

M

to

looper

•'

securely.

Set

then

screw

collar

drive

that

there

collar

screw

shaft

nut

E32

screw

the

forwards)

0.8mm

avoiding

clearance

tighten

1

shaft

is

1

C

can

K.

-

1.

looper

B

(looper

and

securely.

H on

C.

H

and

move

in

then

N

the

the

Tighten

no

free

and

block

check

smoothly.

avoiding

its

drive

set

crank

to

0.5nim

driv.e

end

of

screw

play

F.

that

rearmost

shaft

clearance

tighten

A

screw

and

crank

3

the.

2

D

-

33

-

Page 36

BALANCE

WEIGHT

(39)

Replace

the

crankshaft,

Note

that

is

in

two

the

the

parts.

balance

E56

balance

weight

on

weight

UPPER

r"

KNIFE

LEVER

(E32 E52)

ipot

0cr«v

(40) - E32,

Replace

connection

crankshaft

the

bed.

Align

replace

of

Tighten

Check

smoothly.

(41;

Insert

into

Insert

drive

(42) - E32,

Set

surface

G

shown.

Push

the

screws

Tighten

the

the

the

bed.

the

that

- E32, E52 -

the

the

bed

it

crank

the

clearance

the

ri^t

of

the

collar

2.

the

and

E52

the

upper

assembly

B

from

aligning

cap

2

screws

the

upper

from

through

E

and

E52

the

upper

bedHto

and

tighten

spot

-

knife

the

marks

from

connection

knife

the

1;he

collar

-

between

knife

l.Oma

P

lightly

the

screw

A

the

1

left.

washer

as

first.

on

top

V .

drive

the

of

and

bottom

carefully

moves

lever

P.

the

lever

to

2

0

D,

(43)

- E32, E52 -

s*tn

Lightly

upper

lowest

Set

vertical.

E

lightly

tighten

is

no

Check

froa

vlov

abev*

34

top

smoothly.

the

tighten

knife

position.

surface

screw

free

that

Push

to

play

the

lever

the

3

screw

K

the

so

in

shaft

C

so

left

to

drive

that

the

that

can

3

its

and

shaft.

and

it

crank

there

move

move

is

Page 37

NEEDLE DRIVE

CONNECTION

(44)

- E32.

Replace

connection

from

the

Align

replace-the

Tighten

Check

smoothly.

(45)

- E56 -

.Locate

in

the

and

replace

B

from

Align

replace

Tighten

Check

move

smoothly.

the

the

the

that

the

needle

the

the

the

the

that

E52

needle

A

on

top

of

aligning

cap

2

connection

needle

it

top

aligning

cap

2

the

-

drive

the

the

marks

from

screws

drive

drive

on

the

of

the

marks

from

screws

connection

crankshaft

bed.

and

the

bottom.

1

carefully,

A

can

crank

connection

crankshaft

bed.

and

the

bottom.

2

carefully

C

B

move

D

0

can

UPPES

LOOPER

DRIVE

CONNECTION

(46)

Replace

connection

from

set.

the

Align

replace

Tighten

Check

move

smoothly.

(47)

Insert

shaft

crank

front

With

protruding

bushing

4.

the

the

that

the

G

through

H

and

of

M,

the

E

bottom

aligning

the

the

upper

the

end

slightly

lightly

upper

on

cap

2

the

washer

bed.

of

the

of

from

screws

connection

looper

the

the

looper

crankshaft

the

marks

the

3

upper

K

from

shaft

from

tighten

drive

bed

as

and

top.

carefully.

E

can

drive

looper

the

the

screw

F

a

rear

-

35

-

Page 38

UPPER

LOOPER

DRIVE

SHA-PT

(48)

Replace

washer

drive

1.

washer

on

shaft

the

A.

and

end

and

spring

of

the

tighten

looper

screw

NEEDLE

DRIVE

SHAFT

(E56)

(49)

Loosen

lightly

upper

the

left.

that

there

the

shaft

Check

smoothly.

(50)

- E56 -

Insert

through

drive

from

(51)

With

protruding

of

to

screws

Tighten

the

- E56 -

the

the

the

screw

xo

looper

that

the

the

crank

right

needle

bed,

left

3.

the

.

2.

the

crank

Tighten

is

A.

the

needle

washer

E

and

12.5nim

push

and

spot

Push

right

no

shaft

of

drive

collar

tighten

screw

screw

free

drive

the

the

from

B

screw

and

lightly

play

A

can

2

1

push

so

in

move

' '

shaft

D,

the

needle

collar

bed.

shaft

the

left

F

lightly

the

first.

to

C

F

C

2

(52)-E56-

Push

left,

crank

the

so

the

Check

smoothly.

Replace

-

36

-

right

that

shaft

the

push

E

that

and

there

cap

collar

the

washer

and

0.

the

G.

F

needle

tighten

is

no

shaft

lightly

D

lightly

free

C

drive

screw

can

to

play

move

the

to

4

in

Page 39

UPPES

KNIFE

LEVER

(E56)

(53)

Insert

through

knife

D

from

- E56 -

the

the

drive

the

upper

washer

crank

left

knife

B,

C

of

and

the

lever

the

the

bed.

A

upper

collar

(54)

Push

against

guide

the

right

screws

Tighten

(55)

Lightly

the

lowest

so

that

Push

C

lightly

t)ie

free

Check

smoothly.

- E56 -

the

surface

the

P,

push

1.

the

-

E56

tighten

upper

position.

it

the

screw

play

that

upper

and

spot

-

knife

is

upper

to

so

in

the

E

collar

tighten

screw

screw

lever

vertical.

knife

the

that

the

shaft

lightly

knife

Set

left

there

shaft

lever

D

lightly

the

first.

2

and

A

to

surface

drive

and

is

A.

can

to

2

move

its

G

crank

tighten

no

move

MACHINE

ARM

(RIGHT)

(56)

Replace

securely.

the

4

screws

^d

tighten

-

37

-

Page 40

NEEDLE

DRIVE

( E32 E52)

spot

aer«v

apot

©

aerav

(57) - E32,

Insert

hole

and

Tighten

there

holder

screw

Check

move

(58)

Insert

into

balance

crank

the

B

in

into

the

is

A.

first.

that

smoothly.

- E32, 252 -

the

the

arm

weight

G

and

(59) - E32,

Push

right

so

•0.5mm

left

Tighten

that

the

and

there

between

of

the

the

E52

holder

the

the

2

no

free

Tighten

the

needle

through

collar

E52

collar

tighten

arm.

spot

-

A

through

left

of

thrust

screws

collar

1

play

the

holder

. ' _

F,

drive

needle

shaft

the

H.

-

H

lightly

the

is

a

clearance

surface

screw

the

so

in

spot

A

hole

drive

2

K

first.

arm

C,

that

the

can

D

E,

to

screws

and

the

the

the

2

of

•

(60) - E32, E52 -

Push

lightly

the

the

3

in

Check

smoothly.

(61)

Replace

(complete) on

of

the

needle

to

balance

left.

so

that

the

shaft

that

- E32, E52 -

the

shaft

D.

the

weight

Tighten

there

D.

the.

needle

the

drive

right

is

shaft

shaft"

and

F

lightly

the

2

no

free

can

drive

needle

D

push

screws

play

move

lever

bearing

to

M

-

38

Page 41

NEEDLE

HOLDER

GUIDE

STUD

(E52 E52)

Fig.

(62)

- E32, E52 -

Insert

drive

holder

mark

centerline

lever

Hold

screwdriver

1

screw 1. (See

pin

lever

F.

Align

(circle)

D.

pin

C

A

C

through

D,

washer

on

of

in

position

and

Fig.

needle

E

and

the

aligning

pinCalong

the

needle

with

lightly

tighten

l).

into

the

drive

a

acctntrie

pin

align

caotarlinaAand

thia

eirclt

5)

Fig.

(63)

- E32, E52 -

Insert

the

front.

Turn

to

push

(64)

Turn

drive

up

2

side

and

Tighten

stud

upper

oil

(See

the

stud

side

as

shown

it

into

- E32, E52 -

stud

and

B

lever

of

cross

G

down

the

screw

G

into

holes

Figs.

slightly

place.

so

H

can

about

point

at

2.

in

that

right

the

H

2, 3)

Fig.

the

move

1cm

where

angles.

hole

facing

from

3

needle

smoothly

either

lines

with

the

side

and

A

Fig.

(65) - E32,

Turn

direction

and

holder

in

4

1

Push

screw

Note:

is

then

If

its

anti-clockwise.

-

39

—

set

the

tight

it

stroke

the

guide

range

holder

1.

if

turn

is

E52

eccentric

shown

it

so

F

the

at

eccentric

tight

then

that

M

shown.

lightly

needle

the

can

at

by

top

turn

pin

the

the

move

holder

of

clockwise.

the

0

arrow

needle

and

its

bottom

eccentric

in

the

smoothly

tighten

guide

stroke

of

Page 42

NEEDLE

DRIVE

OIL

SUPPLY

WICK

(E32 E52)'

(66) - E52,

Move

A

Set

holder

the

C

to

and

the

its

upper

guide

bottom

lightly

E52

needle

highest

surface

surface

B

about

tighten

-

drive

position.

of

of

connection

the

needle

6.0min

bracket

screw

from

1.

Fig.

(67)

Locate

groove

drive

together as

Drape

and

P

in

E32,

the

of

lever

the

insert

the''^arm

'E52

- ,

oil

wick

the

back

of

D

and

twist

shown

wick

it

.'' ;A ' -

(Fig.

over

through

in

the

the

the

the.

needle

the

l).

pin

hole

wick

E

1

(68) - E32,

Insert

the

top

the

hole

it

together

from

drive

the

lever

(69) - E32,

Insert

into

the

the

arm.

the

of

the

hole

P

back

E52

oil

the

in

with

D

E52

oil

-

wick

stud

the

arm

the

of

the

(step

-

restricting

P

from

which

G

through

and

oil

needle

67).

the

is

twist

wick

left

at

pinH

of

(70) - E32,

NEEDLE

ARM

(E56)

Replace

cover

the

Check

needle

2

the

K

on

screws

that

holder

(71) - E56 -

®

Replace

needle

left.

Lightly

-

40

-

the

drive

tighten

E52

machine

the

2.

it

does

guide

needle

shaft

-

arm

armMand

not

B.

armNon

P

from

screw

3»

left

tighten

touch

the

the

the

Page 43

OIL

DISTRIBUTORS

Fig.

Fig.

Dil >houl4 apl&sh

1

2

here

(72)

Insert

into

by

Locate

the

by

the

the

the

hole

the

hole

arrow.

the

B

arrow.

oil

flow

in

lubrication

on

the

the

adjust

bed

bed

block

as

pin

shown

shown

A

in

E56

E52•32

(73)

large

facing

dlaBctera

oil

Qonitor.'

inlet

oil

Bonitor

o

• •]

Replace

with

facing

Tighten

-

E32,

Position

distributor

lubricates

drive

Insert

into

-

E56

The

distributors

the

the

large

each

junction

E52

the

connection

the

the

oil

-

positions

two

other

-

upper

so

the

lower

monitor

are

oil

internal

that

top

of

screw

(see

oil

the

reversed.

distributors

bores

(see Fig.

D.

oil

it

of

needle

Pig.

distributor

hole

two

oil

l).

2).

E.

DIFFERENTIAL

FEED

CRANK

oil

Bonitor

(74)

Replace

regulating

differential

the

link

differential

F

on

feed

link

feed

the

G.

(75)

Replace

crank

differential

the

differential

(complete)

feed

H

in

link

feed

the

G.'

(76)

Lift

and

crank

the

locate

M

feed

from

drive

it

on

the

the

right.

connection

feed

K

drive

-

41

- .

Page 44

FEED

SHAFT

yj

(77)

Insert

hole

Insert

crank

crank

collar

the

feed

B

in

the

it

throu/;h

C,

the

D,

main

F.

shaft

left

of

the

differential

feed

crank

A.

the

feed

into

feed

13

bed.

drive

Mie

.

and

©

© ®

•pot

acrev

Push

the

the

right

lightly

Tighten

Tighten

(79)

Tighten

screw

2.

Replace

the

left

(81)

Insert

regulating

K

in

the

it

through

thrust

differential

lever

P.

feed

to

the

the

the

the

of

the

left

collar

shaft

and

the

2

screws

spot

feed

cap

the

differential

shaft

the

feed

push

'left.

G

bed.

of

spring

N

and

A

the

1.

screw

drive

in

the

H

into

the

bed.

the

regulating

lightly

collar

first.

crank

hole

feed

the

M,

the

to

F

•

on

hole

Insert

(82)

saen

Replace

the

©

fros

balow

-

42

-

Replace

Lift

T

(see

Push

latch

the

-ighten

spring

bushing

the

arrow)

collar

screw

2

screws

the

diff.

the

R.

latch

S

3-

spot

M

feed

to

down

on

screw

the

and

screw

the

reg.

left.

end

S.

lever

tighten

first.

/

of

Push

Page 45

GEAR

PUKP/OIL

0-rIn«

INDICATOR

C2)—

;6

(83)

Replace

bottom,

Tighten

Do

not

(84)

Replace

the

bottom,

of

the

Fasten

with

the

the

pulley

the

omit

the

bed.

the

oil

2

the

oil

front

indicator

2

screws

pump A on

side

screws

0-ring.

indicator

pulley

2.

of

the

1.

support

the

B

side

bed.

in

C

BY-PASS

bed

FEED

BAR

GUIDE

LEPT/OIL

SEAL

GUIDE

bed

pump

(85)

Replace

bottom,

Tighten

(86)

Fasten

bed.

Fasten

(from the

by-pass.

(87)

Loosen

4.

Replace

feed

bar

lightly

Tighten

the

feed

with

nc

Push

ri^ht

:he

the

and

grccve

the

the

to

the

free

the

center

the

2

gear

feed

the

guide

the

2

bars

feed

tighten

?

by-pass

of

2

screws.

oil

the-pass

pump)

eccentric

0-ring

F

and

front

screws

X

can

play.

bar

facing

D

the

tubes

pipe

to

G

push

and

5

move

;

pin

H

screw

backwards.

in

the

bed.

E.to

the

screw

in

it

right.

so

that

smoothly

-n;--l

to

4

with

the

R

the

"

the

(88)

Move

highest

the

Tighten

-

43

-

•

the

feed

position

feed

bar

the4screws

bars

oil

and

seal

K

to

their

replace

guide

6.

M.

Page 46

DIFFERENTIAL FEED

REGULATING

GUIDE

(89)

Fasten

regulating

•

the

guide

differential

A

with

feed

screw

1

©

Spring

vuh«r

.©

Lightly

(90)

Fasten

washer

regulating

so

that

Note

(91)

Turn

Check

regulating

be

differential

lever

screw

position

thumb

that

lifted

right

4.

tighten

thumb

to

differential

lever

nut

B

nutDfully

the

lever

to

mark

feed

F down

screw

nut

B and

C

can

of

spring

differential

surface

'1*.

regulating

and

2.

with

turn

clockwise.

E

Pull

tighten

spring

feed

screw

smoothly.

washer.

feed

can

3

POSITIONING

DIFF.

FEED

CRANK

(92)

Push

the

in

pulley

(93)

Lightly

the

differential

can

be

feed

drive

rearmost