Page 1

PUREFIRE

®

REV

2

Boilers

PF-50 PF-80 PF-110 PF-140 PF-200 PF-210 PF-300 PF-399

Gas

Installation,

Operation &

Maintenance

Manual

As an ENERGY STAR®Partner, PB Heat, LLC has determined that

this product meets the ENERGY STAR guidelines for energy efficiency.

®

Page 2

USING THIS MANUAL 1

A. INSTALLATION SEQUENCE . . . . . . . . . . . . . .1

B. SPECIAL ATTENTION BOXES . . . . . . . . . . . . .1

1. PREINSTALLATION 2

A. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

B. CODES & REGULATIONS . . . . . . . . . . . . . . . .2

C. ACCESSIBILITY CLEARANCES . . . . . . . . . . . .3

D. COMBUSTION & VENTILATION AIR . . . . . . . .4

E. PLANNING THE LAYOUT . . . . . . . . . . . . . . . .6

2. BOILER SET-UP 8

A. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

B. WALL MOUNTING . . . . . . . . . . . . . . . . . . . . . .8

C. FLOOR STANDING INSTALLATION . . . . . . . . .8

3. VENTING & AIR INLET PIPING 9

A. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

B. APPROVED MATERIALS . . . . . . . . . . . . . . . . .9

C. EXHAUST VENT/AIR INTAKE

PIPE LOCATION . . . . . . . . . . . . . . . . . . . . . . . .9

D. EXHAUST VENT/AIR INTAKE PIPE SIZING . .14

E. EXHAUST VENT/AIR INTAKE PIPE

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . .14

F. EXHAUST TAPPING FOR VENT SAMPLE . .15

G. BOILER REMOVAL FROM COMMON

VENTING SYSTEM . . . . . . . . . . . . . . . . . . . .15

4. WATER PIPING AND CONTROLS 17

A. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

B. OPERATING PARAMETERS . . . . . . . . . . . . . .17

C. SYSTEM COMPONENTS . . . . . . . . . . . . . . . .17

D. SYSTEM PIPING . . . . . . . . . . . . . . . . . . . . . .21

E. FREEZE PROTECTION . . . . . . . . . . . . . . . . . .21

F. SPECIAL APPLICATIONS . . . . . . . . . . . . . . . .27

5. FUEL PIPING 28

A. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

B. FUEL LINE SIZING . . . . . . . . . . . . . . . . . . . . .28

C. GAS SUPPLY PIPING – INSTALLATION . . . .28

D. GAS SUPPLY PIPING – OPERATION . . . . . . .29

E. MAIN GAS VALVE – OPERATION . . . . . . . . .30

6. CONDENSATE DRAIN PIPING 31

A. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

B. CONDENSATE SYSTEM . . . . . . . . . . . . . . . .31

C. CONDENSATE DRAIN PIPE MATERIAL . . . .32

D. CONDENSATE DRAIN PIPE SIZING . . . . . . .32

E. CONDENSATE DRAIN PIPE

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . .32

7. ELECTRICAL CONNECTIONS 33

A. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . .33

B. CUSTOMER CONNECTIONS . . . . . . . . . . . . .33

C. ZONE CIRCULATOR WIRING . . . . . . . . . . . . .34

D. INTERNAL WIRING . . . . . . . . . . . . . . . . . . . .34

8. BOILER CONTROL: INTERNAL

WIRING & OPERATION 38

A. CONTROL OVERVIEW . . . . . . . . . . . . . . . . . .38

B. IGNITION SEQUENCE . . . . . . . . . . . . . . . . . .40

C. BOILER CONTROL . . . . . . . . . . . . . . . . . . . . .42

D. CENTRAL HEATING . . . . . . . . . . . . . . . . . . . .42

E. DOMESTIC HOT WATER (DHW) . . . . . . . . . .46

F. SERVICE NOTIFICATION . . . . . . . . . . . . . . . .47

G. SYSTEM TEST . . . . . . . . . . . . . . . . . . . . . . . .48

H. STATUS & FAULT HISTORY . . . . . . . . . . . . . .48

I. SENSOR RESISTANCE . . . . . . . . . . . . . . . . .49

J. MULTIPLE BOILERS . . . . . . . . . . . . . . . . . . . .49

9. START-UP PROCEDURE 55

A. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

B. CHECK WATER PIPING . . . . . . . . . . . . . . . . .55

C. CHECK GAS PIPING . . . . . . . . . . . . . . . . . . . .55

D. CHECK OPERATION . . . . . . . . . . . . . . . . . . . .55

E. LIGHTING & OPERATING PROCEDURES . . .57

10. TROUBLESHOOTING 58

A. BLOCKING ERRORS . . . . . . . . . . . . . . . . . . . .58

B. LOCKING ERRORS . . . . . . . . . . . . . . . . . . . . .58

C. ERROR MESSAGES IN A CASCADE

SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

D. WARNING ERRORS . . . . . . . . . . . . . . . . . . . .62

E. DELAYED IGNITION (HARD LIGHT-OFF) . . .64

F.

BOILER FAILS TO RESPOND TO A CH CALL

.64

11. MAINTENANCE 65

A. GENERAL (WITH BOILER IN USE) . . . . . . . .66

B. WEEKLY (WITH BOILER IN USE) . . . . . . . . .66

C. ANNUALLY (BEFORE START OF HEATING

SEASON) . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

D. CONDENSATE CLEANING

INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . .66

E. INSPECTION AND CLEANING OF

COMBUSTION CHAMBER COILS . . . . . . . . .67

12. BOILER DIMENSIONS & RATINGS 68

13. REPAIR PARTS 71

APPENDIX A. STATUS SCREENS 80

APPENDIX B. USER MENU 84

APPENDIX C. INSTALLER MENU 85

APPENDIX D. COMBUSTION TEST

RECORD 90

TABLE OF CONTENTS

TABLE OF CONTENTS

Page 3

A. INSTALLATION SEQUENCE

Follow the installation instructions provided in this manual

in the order shown. The order of these instructions has

been set in order to provide the installer with a logical

sequence of steps that will minimize potential

interferences and maximize safety during boiler

installation.

B. SPECIAL ATTENTION BOXES

Throughout this manual special attention boxes are

provided to supplement the instructions and make special

notice of potential hazards. The definition of each of

these categories, in the judgement of PB Heat, LLC

are as follows:

USING THIS MANUAL

1

USING THIS MANUAL

Compliance with the Energy Policy and Conservation Act:

DANGER

Indicates a condition or hazard which will cause

severe personal injury, death or major property

damage.

Indicates a condition or hazard which may cause

severe personal injury, death or major property

damage.

WARNING

Indicates a condition or hazard which will or can

cause minor personal injury or property damage.

CAUTION

Indicates special attention is needed, but not directly

related to potential personal injury or property

damage.

NOTICE

In accordance with Section 325 (f) (3) of the Energy Policy and Conservation Act, this boiler is equipped with a

feature that saves energy by reducing the boiler water temperature as the heating load decreases. This feature is

equipped with an override which is provided primarily to permit the use of an external energy management

system that serves the same function.

THIS OVERRIDE MUST NOT BE USED UNLESS AT LEAST ONE OF THE FOLLOWING CONDITIONS IS TRUE:

• An external energy management system is installed that reduces the boiler water temperature as the

heating load decreases.

• This boiler is not used for any space heating

• This boiler is part of a modular or multiple boiler system having a total input of 300,000

BTU/hr or greater.

• This boiler is equipped with a tankless coil.

IMPORTANT NOTICE

Page 4

A. GENERAL

1. PUREFIRE®boilers are supplied completely assembled

as packaged boilers. The package should be inspected

for damage upon receipt and any damage to the unit

should be reported to the shipping company and

wholesaler. This boiler should be stored in a clean, dry

area.

2. Carefully read these instructions and be sure to

understand the function of all connections prior to

beginning installation. Contact your PB Heat, LLC

Representative for help in answering questions.

3. This boiler must be installed by a qualified contractor.

The boiler warranty may be voided if the boiler is not

installed correctly.

4. A hot water boiler installed above radiation or as

required by the Authority having jurisdiction, must be

provided with a low water fuel cut-off device either as

part of the boiler or at the time of installation.

B. CODES & REGULATIONS

1. Installation and repairs are to be performed in strict

accordance with the requirements of state and local

regulating agencies and codes dealing with boiler and

gas appliance installation.

2. In the absence of local requirements the following

should be followed:

a. ASME Boiler and Pressure Vessel Code, Section

IV - “Heating Boilers”

b. ASME Boiler and Pressure Vessel Code, Section

VI - “Recommended Rules for the Care and

Operation of Heating Boilers”

c. ANSI Z223.1/NFPA 54 - “National Fuel Gas Code”

d. ANSI/NFPA 70 - “National Electrical Code”

e. ANSI/NFPA 211 - “Chimneys, Fireplaces, Vents

and Solid Fuel Burning Appliances”

3. Where required by the authority having jurisdiction,

the installation must conform to the Standard for

Controls and Safety Devices for Automatically Fired

Boilers, ANSI/ASME CSD-1.

**Please read if installing in Massachusetts**

Massachusetts requires manufacturers of Side Wall

Vented boilers to provide the following information

from the Massachusetts code:

·

A hard wired carbon monoxide detector with an

alarm and battery back-up must be installed on

the floor level where the gas equipment is to be

installed AND on each additional level of the

dwelling, building or structure served by the side

wall horizontal vented gas fueled equipment.

·

In the event that the side wall horizontally vented

gas fueled equipment is installed in a crawl space

or an attic, the hard wired carbon monoxide

detector with alarm and battery back-up may be

installed on the next adjacent floor level.

·

Detector(s) must be installed by qualified licensed

professionals.

·

APPROVED CARBON MONOXIDE

DETECTORS: Each carbon monoxide detector

shall comply with NFPA 720 and be ANSI/UL

2034 listed and IAS certified.

·

SIGNAGE: A metal or plastic identification plate

shall be permanently mounted to the exterior of

the building at a minimum height of eight (8) feet

above grade directly in line with the exhaust vent

terminal for the horizontally vented gas fueled

heating appliance or equipment. The sign shall

read, in print size no less than one-half (1/2) inch

in size, “GAS VENT DIRECTLY BELOW.

KEEP CLEAR OF ALL OBSTRUCTIONS”.

·

EXEMPTIONS to the requirements listed above:

°

The above requirements do not apply if the

exhaust vent termination is seven (7) feet or

more above finished grade in the area of the

venting, including but not limited to decks and

porches.

°

The above requirements do not apply to a

boiler installed in a room or structure separate

from the dwelling, building or structure used in

whole or in part for residential purposes.

·

This boiler installation manual shall remain with

the boiler at the completion of the installation.

See the latest edition of Massachusetts Code 248 CMR

for complete verbage and also for additional (non-vent

related) requirements (248 CMR is available online).

If your installation is NOT in Massachusetts, please

see your authority of jurisdiction for requirements that

may be in effect in your area. In the absence of such

requirements, follow the National Fuel Gas Code,

ANSI Z223.1/NFPA 54 and/or CAN/CSA B149.1,

Natural Gas and Propane Installation Code.

2

PREINSTALLATION

1. PREINSTALLATION

Liquefied Petroleum (LP) Gas or Propane is heavier

than air and, in the event of a leak, may collect in low

areas such as basements or floor drains. The gas

may then ignite resulting in a fire or explosion.

WARNING

Page 5

C. ACCESSIBILITY CLEARANCES

1. The PUREFIRE®boiler is certified for closet installations

with zero clearance to combustible construction. In

addition, it is design certified for use on combustible

floors. Do not install on carpeting.

2. Figure 1.1 shows the minimum recommended

clearances to allow reasonable access to the boiler

for Models PF-50, PF-80, PF-110 and PF-140.

For Models PF-200, PF-210, PF-300 and PF-399,

Figure 1.2 shows the minimum recommended

accessibility clearances. However, Local codes or

special conditions may require greater clearances.

PREINSTALLATION

Figure 1.1: Minimum Accessibility Clearances – PF-50, PF-80, PF-110 & PF-140

Figure 1.2: Minimum Accessibility Clearances – PF-200, PF-210, PF-300 & PF-399

3

DANGER

DO NOT INSTALL ON CARPETING.

Page 6

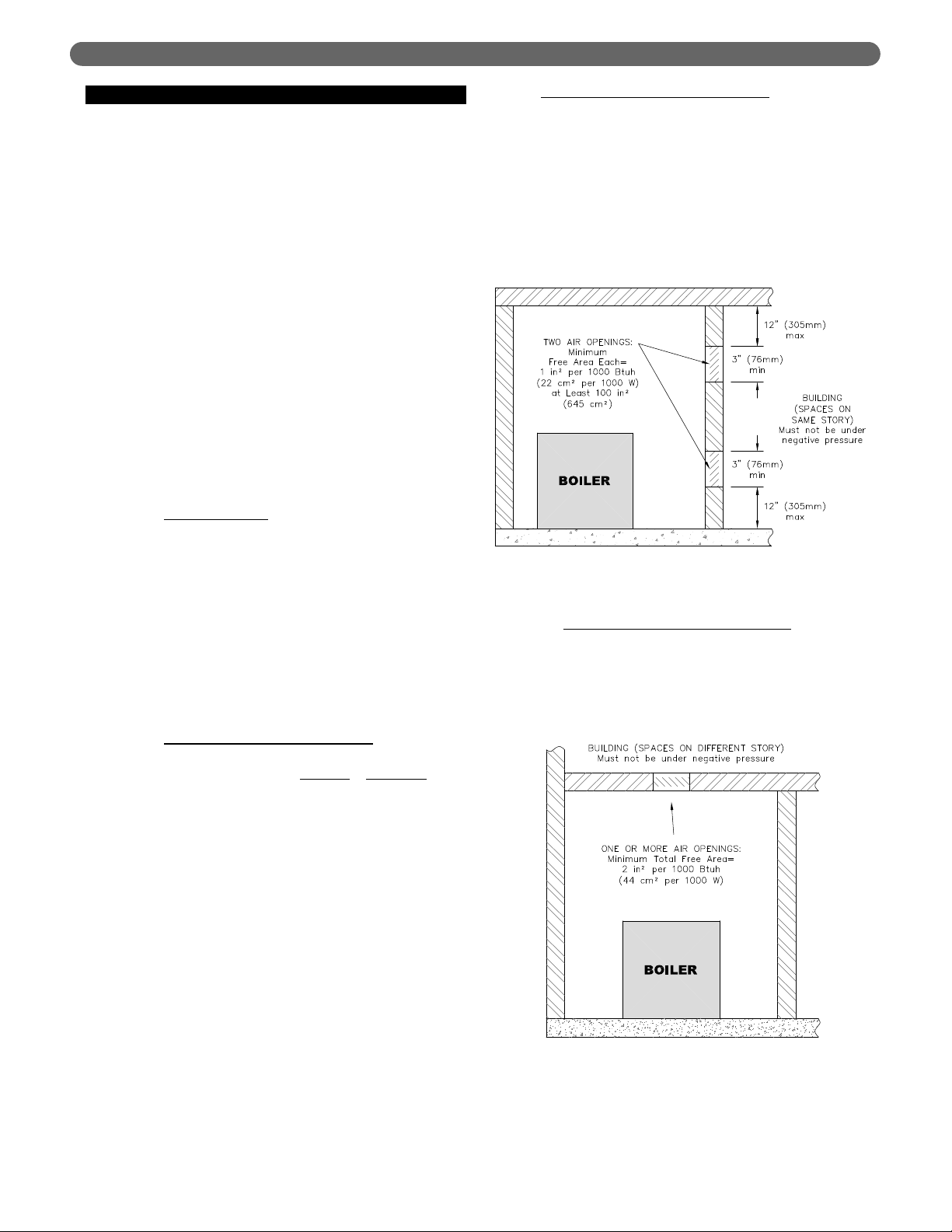

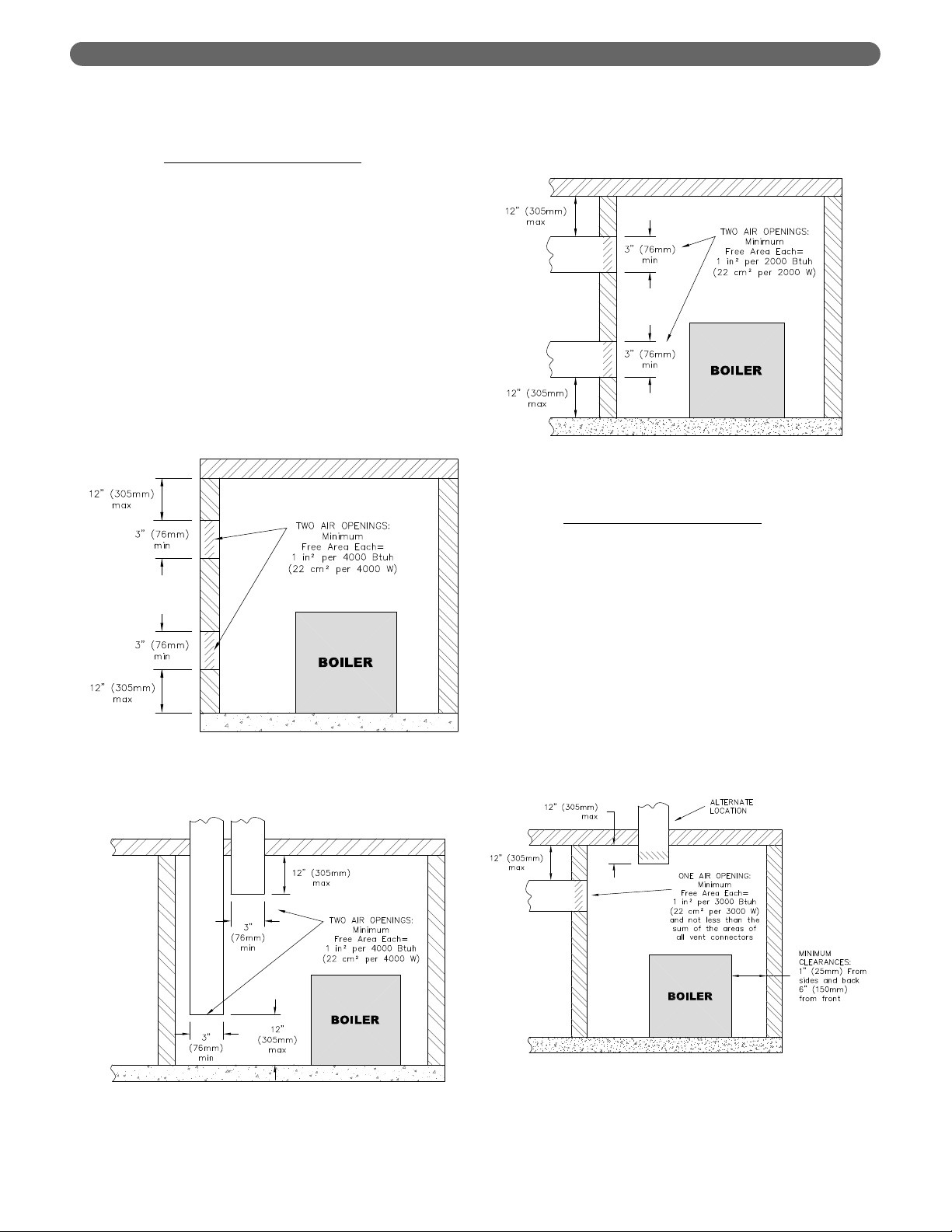

D. COMBUSTION AND VENTILATION AIR

1. The PUREFIRE®boiler is designed for operation with

combustion air piped directly to the boiler from

outside the building (sealed combustion). Combustion

air may be supplied from within the building only if

adequate combustion air and ventilation air is

provided in accordance with the National Fuel Gas

Code or applicable sections of the local building code.

Subsections 3 through 10 as follows are based on the

National Fuel Gas Code requirements.

2. If the combustion air is piped directly to the boiler

from outside the building, no additional combustion

or ventilation air is required. Otherwise, follow the

National Fuel Gas Code recommendations

summarized in subsections 3 through 10.

3. Required Combustion Air Volume: The total required

volume of indoor air is to be the sum of the required

volumes for all appliances located within the space.

Rooms communicating directly with the space in

which the appliances are installed and through

combustion air openings sized as indicated in

Subsection 3 are considered part of the required

volume. The required volume of indoor air is to be

determined by one of two methods.

a. Standard Method

: The minimum required volume

of indoor air (room volume) shall be 50 cubic feet

per 1000 BTU/Hr (4.8 m3/kW). This method is to

be used if the air infiltration rate is unknown or if

the rate of air infiltration is known to be greater

than 0.6 air changes per hour. As an option, this

method may be used if the air infiltration rate is

known to be between 0.6 and 0.4 air changes per

hour. If the air infiltration rate is known to be

below 0.4 then the Known Air Infiltration Rate

Method must be used. If the building in which this

appliance is to be installed is unusually tight, PB

Heat recommends that the air infiltration rate be

determined.

b. Known Air Infiltration Rate Method

:

where:

I

fan

= Input of the fan assisted appliances

in Btu/hr

ACH = air change per hour (percent of the

volume of the space exchanged per

hour, expressed as a decimal)

Note: These calculations are not to be used for

infiltration rates greater than 0.60 ACH.

4. Indoor Air Opening Size and Location: Openings

connecting indoor spaces shall be sized and located as

follows:

a. Combining Spaces on the Same Floor

: Provide two

permanent openings communicating with additional

spaces that have a minimum free area of 1 in

2

per

1000 Btu/hr (22 cm2per 1000 W) of the total input

rating of all gas fired equipment but not less than

100 in

2

(645 cm2). One opening is to begin within

12 inches (305 mm) from the top of the space and the

other is to begin within 12 inches (305 mm) from the

floor. The minimum dimension of either of these

openings shall be 3 inches (76 mm). See Figure 1.3

for an illustration of this arrangement.

b. Combining Spaces on Different Floors

: Provide

one or more permanent openings communicating

with additional spaces that have a total minimum

free area of 2 in

2

per 1000 Btu/hr (44 cm2per

1000 W) of total input rating of all equipment. See

Figure 1.4 for an illustration of this arrangement.

4

15 ft

3

I

fan

ACH 1000

Btu

/

hr

Required Volume

fan

=

⎛

⎜

⎝

⎛

⎜

⎝

Figure 1.3: Air Openings – All Air from Indoors

on the Same Floor

Figure 1.4: Air Openings – All Air from Indoors

on Different Floors

PREINSTALLATION

Page 7

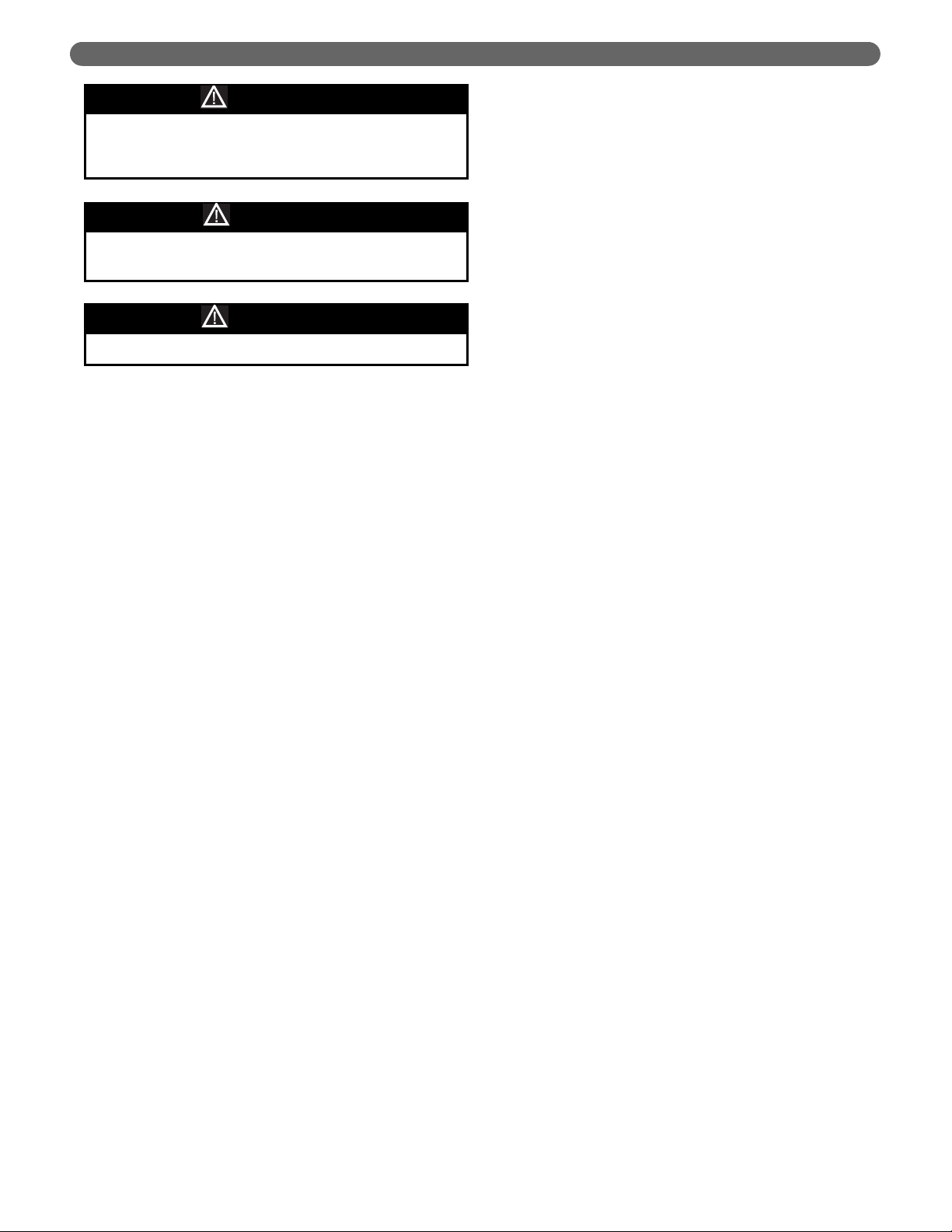

5. Outdoor Combustion Air: Outdoor combustion air is

to be provided through one or two permanent

openings. The minimum dimension of these air

openings is 3 inches (76 mm).

a. Two Permanent Opening Method

: Provide two

permanent openings. One opening is to begin

within 12 inches (305 mm) of the top of the space

and the other is to begin within 12 inches (305

mm) of the floor. The openings are to

communicate directly or by ducts with the

outdoors or with spaces that freely communicate

with the outdoors. The size of the openings shall

be determined as follows:

i. Where communicating directly or through

vertical ducts with the outdoors each opening

shall have a minimum free area of 1 in

2

per

4000 Btu/hr (22 cm

2

per 4000 W) of total

input rating for all equipment in the space. See

Figure 1.5 for openings directly

communicating with the outdoors or Figure

1.6 for openings connected by ducts to the

outdoors.

ii. Where communicating with the outdoors through

horizontal ducts, each opening shall have a

minimum free area of 1 in

2

per 2000 Btu/hr (22

cm2per 2000 W) of total rated input for all

appliances in the space. See Figure 1.7.

b. One Permanent Opening Method

: Provide one

permanent opening beginning within 12 inches

(305 mm) of the top of the space. The opening

shall communicate directly with the outdoors,

communicate through a vertical or horizontal duct,

or communicate with a space that freely

communicates with the outdoors. The opening

shall have a minimum free area of 1 in

2

per 3000

Btu/hr of total rated input for all appliances in the

space and not less than the sum of the crosssectional areas of all vent connectors in the space.

The gas-fired equipment shall have clearances of

at least 1 inch (25 mm) from the sides and back

and 6 inches (150 mm) from the front of the

appliance. See Figure 1.8 for this arrangement.

5

Figure 1.5: Air Openings – All Air Directly from

Outdoors

Figure 1.6: Air Openings – All Air from Outdoors

through Vertical Ducts

Figure 1.7: Air Openings – All Air from Outdoors

through Horizontal Ducts

Figure 1.8: Air Openings – All Air from Outdoors

through One Opening

PREINSTALLATION

Page 8

6. Combination Indoor and Outdoor Combustion Air: If

the required volume of indoor air exceeds the

available indoor air volume, outdoor air openings or

ducts may be used to supplement the available indoor

air provided:

a. The size and location of the indoor openings

comply with Subsection 3.

b. The outdoor openings are to be located in

accordance with Subsection 4.

c. The size of the outdoor openings are to be sized

as follows:

where:

A

req

= minimum area of outdoor openings.

A

full

= full size of outdoor openings calculated

in accordance with Subsection 4.

V

avail

= available indoor air volume

V

req

= required indoor air volume

7. Engineered Installations: Engineered combustion air

installations shall provide an adequate supply of

combustion, ventilation, and dilution air and shall be

approved by the authority having jurisdiction.

8. Mechanical Combustion Air Supply:

a. In installations where all combustion air is

provided by a mechanical air supply system, the

combustion air shall be supplied from the

outdoors at the minimum rate of 0.35 ft

3

/min per

1000 Btu/hr (0.034 m

3

/min per 1000 W) of the

total rated input of all appliances in the space.

b. In installations where exhaust fans are installed,

additional air shall be provided to replace the

exhaust air.

c. Each of the appliances served shall be interlocked

to the mechanical air supply to prevent main

burner operation when the mechanical air supply

system is not in operation.

d. In buildings where the combustion air is provided

by the mechanical ventilation system, the system

shall provide the specified combustion air rate in

addition to the required ventilation air.

9. Louvers & Grills:

a. The required size of openings for combustion,

ventilation, and dilution air shall be based on the

net free area of each opening.

i. Where the free area through a louver or grille

is known, it shall be used in calculating the

opening size required to provide the free area

specified.

ii. Where the free area through a louver or grille

is not known, it shall be assumed that wooden

louvers will have 25% free area and metal

louvers and grilles will have 75% free area.

iii. Non-motorized dampers shall be fixed in the

open position.

b. Motorized dampers shall be interlocked with the

equipment so that they are proven in the full open

position prior to ignition and during operation of

the main burner.

i. The interlock shall prevent the main burner

from igniting if the damper fails to open during

burner startup.

ii. The interlock shall shut down the burner if the

damper closes during burner operation.

10. Combustion Air Ducts:

a. Ducts shall be constructed of galvanized steel or

an equivalent corrosion- resistant material.

b. Ducts shall terminate in an unobstructed space,

allowing free movement of combustion air to the

appliances.

c. Ducts shall serve a single space.

d. Ducts shall not serve both upper and lower

combustion air openings where both such

openings are used. The separation between ducts

serving upper and lower combustion air openings

shall be maintained to the source of combustion

air.

e. Ducts shall not be screened where terminating in

an attic space.

f. Horizontal upper combustion air ducts shall not

slope downward toward the source of the

combustion air.

g. Combustion air intake openings located on the

exterior of buildings shall have the lowest side of

the combustion air intake opening at least 12

inches (305 mm) above grade.

11. Refer to Section 3 of this manual, Venting & Air Inlet

Piping, for specific instructions for piping the exhaust

and combustion air.

E. PLANNING THE LAYOUTS

1. Prepare sketches and notes showing the layout of the

boiler installation to minimize the possibility of

interferences with new or existing equipment, piping,

venting and wiring.

2. The following sections of this manual should be

reviewed for consideration of limitations with

respect to:

a. Venting and Air Inlet Piping: Section 3

b. Water Piping: Section 4

c. Fuel Piping: Section 5

d. Condensate Removal: Section 6

e. Electrical Connections: Section 7

f. Boiler Control: Section 8

g. Boiler Dimensions and Ratings: Section 12

6

PREINSTALLATION

A

req

= A

full

x 1 –

V

avail

V

req

⎛

⎜

⎝

⎛

⎜

⎝

Page 9

7

Do not install this boiler where gasoline or other

flammable liquids or vapors are stored or are in use.

WARNING

This boiler is certified as an indoor appliance. Do not

install this boiler outdoors or locate where it will be

exposed to freezing temperatures.

WARNING

Do not install this boiler in the attic.

WARNING

PREINSTALLATION

Page 10

8

A. GENERAL

1. PUREFIRE®boilers are intended for installation in an

area with a floor drain or in a suitable drain pan. Do

not install any boiler where leaks or relief valve

discharge will cause property damage.

2. The P

UREFIRE

®

boiler is not intended to support

external piping. All venting and other piping should

be supported independently of the boiler.

3. Install the boiler level to prevent condensate from

backing up inside the boiler.

4. P

UREFIRE

®

boilers can be wall mounted or floor

standing. The following instructions provide guidance

for both configurations.

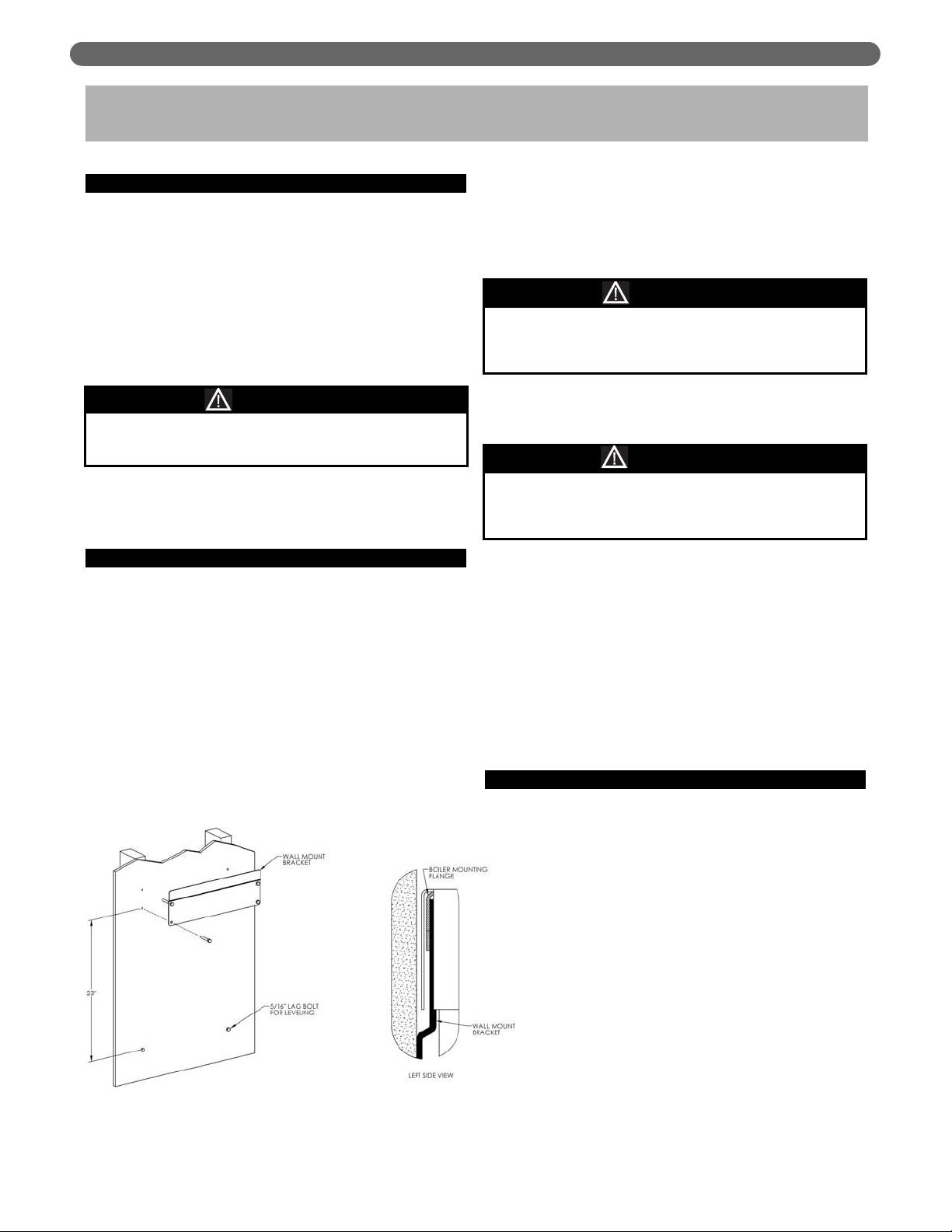

B. WALL MOUNTING

1. Models PF-50, PF-80, PF-110 and PF-140:

a. A wall mounting bracket kit (54171) is included

for wall mounting these boiler sizes.

b. Mount the bracket level on the wall using 5/16" lag

bolts. Be sure the lag bolts are fully supported by

wall studs or adequate wall structure.

c. The mounting bracket has (4) holes on 16" centers

as shown in Figure 2.1. This is intended to give

installers the ability to mount the bracket on two

wall studs spaced at this interval. If existing wall

studs are spaced differently or if the desired

location is not in line with the wall studs,

additional support is required.

d. Install the two additional lag bolts supplied with

the boiler into the wall structure approximately

23” below those used to attach the wall mounting

bracket to the wall as shown in Figure 2.1. The

depth that these are threaded into the wall can be

adjusted to assure level mounting of the boiler.

e. If the boiler is wall mounted using the optional

wall bracket, be sure that the wall provides

adequate support for the boiler.

f. Be sure to adequately support the boiler while

installing external piping or other connections.

g. Be sure that condensate piping is routed to a

suitable drain or condensate pump.

2. All Models can be wall mounted by using the optional

stand (91400).

a. Use the leveling feet provided with the boiler to

assure proper level.

b. Be sure to leave adequate provisions for

condensate piping and/or a pump (if required).

C. FLOOR STANDING INSTALLATION

1. For floor standing installations, use the leveling feet to

assure that the boiler is completely level. This will

prevent condensate from backing up in the boiler.

2. Be sure to leave adequate space for condensate

piping or a pump if required.

BOILER SET-UP

2. BOILER SET-UP

The wall mounting bracket is designed to support the

boiler. External piping for water, venting, air intake

and fuel supply is to be supported separately

WARNING

Figure 2.1: Optional Wall Mounting Bracket for PF-50,

PF-80, PF-110 and PF-140 Boilers

This boiler must be installed level to prevent

condensate from backing up inside the boiler.

CAUTION

Make sure the boiler wall bracket is adequately

supported. Do not install this bracket on dry wall

unless adequately supported by wall studs.

WARNING

Page 11

A. GENERAL

1. Install the PUREFIRE®boiler venting system in accordance

with these instructions and with the National Fuel Gas

Code, ANSI Z223.1/NFPA 54, CAN/CGA B149, and/or

applicable provisions of local building codes.

2. The P

UREFIRE

®

boiler is a direct vent appliance and is

ETL Listed as a Category IV appliance with Intertek

Testing Laboratories, Inc.

3. Sources of combustion air contaminated with chlorine,

ammonia or alkali agents must be avoided. Do not

install this boiler near a swimming pool, hot tubs or

laundry. Do not store chemicals near the boiler.

B. APPROVED MATERIALS

1. Table 3.1 lists approved materials for vent pipe (and

adhesives where applicable). Use only these materials

for exhaust vent piping.

2. PVC pipe and fittings are not to be used for venting in

confined spaces such as closet installations. Use only

CPVC or polypropylene (InnoFlue or PolyPro) vent

pipe under these conditions.

3. Cellular core piping is approved for inlet air piping only.

* PVC pipe/fittings are not to be used for venting within

confined spaces.

Notice: Installations in Canada require compliance with

ULC S636 - Standard for Type BH Gas Venting Systems.

C. EXHAUST VENT/AIR INTAKE PIPE

LOCATION

1. Install vent piping before installing water, fuel, or

condensate piping. Working from largest to smallest

diameter reduces the complexity of piping

interferences.

2. Vent and air intake piping is to be installed so that

there is sufficient access for routine inspection as

required in Section 11, of this manual.

3. The vent piping for this boiler is approved for zero

clearance to combustible construction. However, a fire

stop must be used where the vent pipe penetrates

walls or ceilings.

4. The Peerless

®

PUREFIRE®boiler, like all high efficiency,

gas-fired appliances, is likely to produce a vapor

plume due to condensation. Surfaces near the vent

termination will likely become coated with

condensation.

5. The maximum combined vent and air inlet vent length

for the Peerless

®

PUREFIRE®boiler is about 200

equivalent feet (60 m).Be sure that the boiler is located

such that the maximum vent length is not exceeded.

VENTING & AIR INLET PIPING

3. VENTING & AIR INLET PIPING

The venting system for this product is to be installed in

strict accordance with these venting instructions.

Failure to install the vent system properly may result in

severe personal injury, death or major property damage.

WARNING

This vent system operates under positive pressure.

Vent connectors serving appliances vented by

natural draft shall not be connected into any portion

of this venting system. Failure to comply may result

in serious injury, death or major property damage.

WARNING

Only the materials listed below are approved for use

with the

P

UREFIRE

®

boiler. Use only these components

in accordance with these instructions. Failure to use

the correct material may result in serious injury,

death, or major property damage.

WARNING

Table 3.1: Approved Materials for Exhaust Vent Pipe

Use of cellular core PVC (ASTM F891), cellular core

CPVC, or Radel

®

(polyphenolsulphone) for exhaust

vent is prohibited. Use of these materials as exhaust

vent may result in severe personal injury, death, or

major property damage.

WARNING

If the maximum equivalent vent length is exceeded,

the maximum burner input rate may be reduced.

NOTICE

Description Material

Conforming to

Standard

Vent Piping

& Fittings

PVC (Sch 40 or 80)*

ANSI/ASTM D1785

CPVC (Sch 40 or 80) ANSI/ASTM F441

PVC-DWV*

ANSI/ASTM D2665

FasNSeal

®

UL1738 & ULC-S636

PolyPro

®

ULC-S636

InnoFlue

®

ULC-S636

Z-DENS

®

ULC S636

Pipe Cement

(PVC & CPVC Only)

PVC/CPVC Cement ANSI/ASTM D2564

9

Page 12

6. Air Intake Pipe Location – Sidewall Venting:

a. Provide a minimum 1 foot (30 cm) clearance from

the bottom of the air intake pipe above the

expected snow accumulation level. Snow removal

may be necessary to maintain clearances.

b. Do not locate air intake pipe in a parking area

where machinery may damage the pipe.

c. Maintain a minimum of 8" horizontal distance

between exhaust vent and the air intake.

Increasing this distance minimizes the potential for

contamination of the inlet air with exhaust.

d. For multiple boiler installations, the minimum

horizontal distance between the inlet of one boiler

to the exhaust of an adjacent boiler is 8" center-tocenter. In addition, the minimum vertical distance

between the exhaust and air inlet is 6". See Figure

3.1 for an illustration.

e. The exhaust outlet of the vent pipe should not be

angled any more than 5º from horizontal.

f. Precautions should be taken to prevent

recirculation of flue gases to the air inlet pipe of

the boiler or other adjacent appliances.

7. Sidewall Venting Configuration:

a. See Figure 3.2 for an illustration of clearances for

location of exit terminals of direct-vent venting

systems.

• This boiler vent system shall terminate at least

3 feet (0.9 m) above any forced air inlet

located within 10 ft (3 m). Note: This does not

apply to the combustion air intake of a directvent appliance.

• Provide a minimum of 1 foot (30 cm) distance

from any door, operable window, or gravity

intake into any building.

• Provide a minimum of 1 foot (30 cm) clearance

from the bottom of the exit terminal above the

expected snow accumulation level. Snow

removal may be required to maintain clearance.

• Provide a minimum of 4 feet (1.22 m)

horizontal clearance from electrical meters, gas

meters, gas regulators, and relief equipment. In

no case shall the exit terminal be above or

below the aforementioned equipment unless

the 4 foot horizontal distance is maintained.

• Do not locate the exhaust exit terminal over

public walkways where condensate could drip

and create a hazard or nuisance.

• When adjacent to public walkways, locate the

exit terminal at least 7 feet above grade.

• Do not locate the exhaust termination directly

under roof overhangs to prevent icicles from

forming or recirculation of exhaust gases from

occurring.

• Provide 3 feet clearance from the inside corner

of adjacent walls.

10

VENTING & AIR INLET PIPING

Figure 3.1: Vent Pipe Spacing for Multiple

P

UREFIRE

®

Boilers

Figure 3.2: Exit Terminal Location for Mechanical Draft and Direct-Vent Venting Systems

Condensing flue gases can freeze on exterior

building surfaces which may cause discoloration and

degradation of the surfaces.

CAUTION

Page 13

Figure 3.5: Exhaust and Air Inlet on Opposite Walls

b. Figures 3.3 through 3.6 show approved sidewall

venting configurations using the standard fittings

supplied.

c. Figure 3.4 is only approved for locations in which

the outdoor temperature is above -5°F (-21°C) in

accordance with ASHRAE 90A-1980

recommendations.

d. Figures 3.7 shows an approved sidewall vent

configuration using an optional concentric vent

termination kit. 3" (54498) or 4" (54499).

11

VENTING & AIR INLET PIPING

Figure 3.3: Standard Exhaust & Air Inlet Pipe

Terminations

Figure 3.4: Offset Exhaust and Air Inlet

Terminations

Page 14

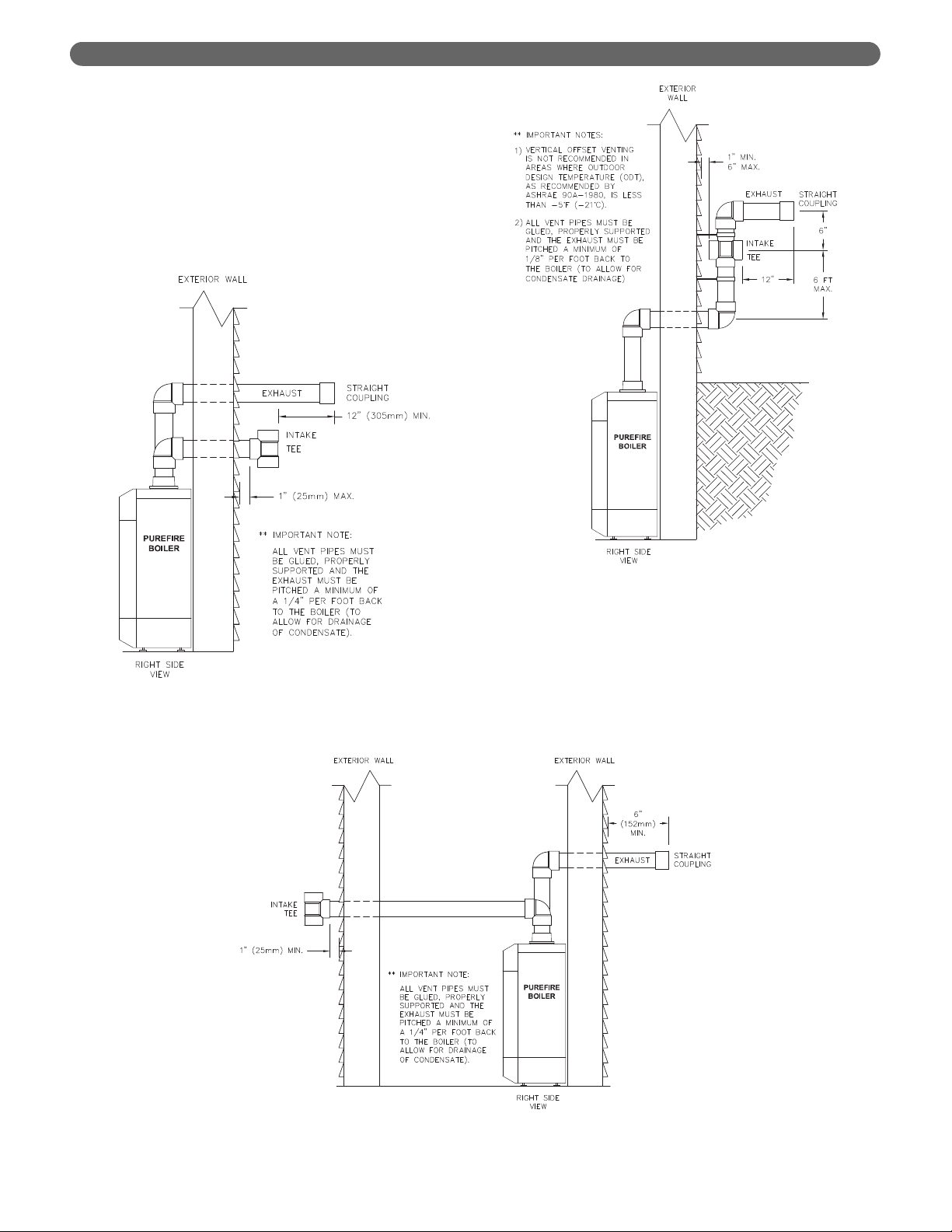

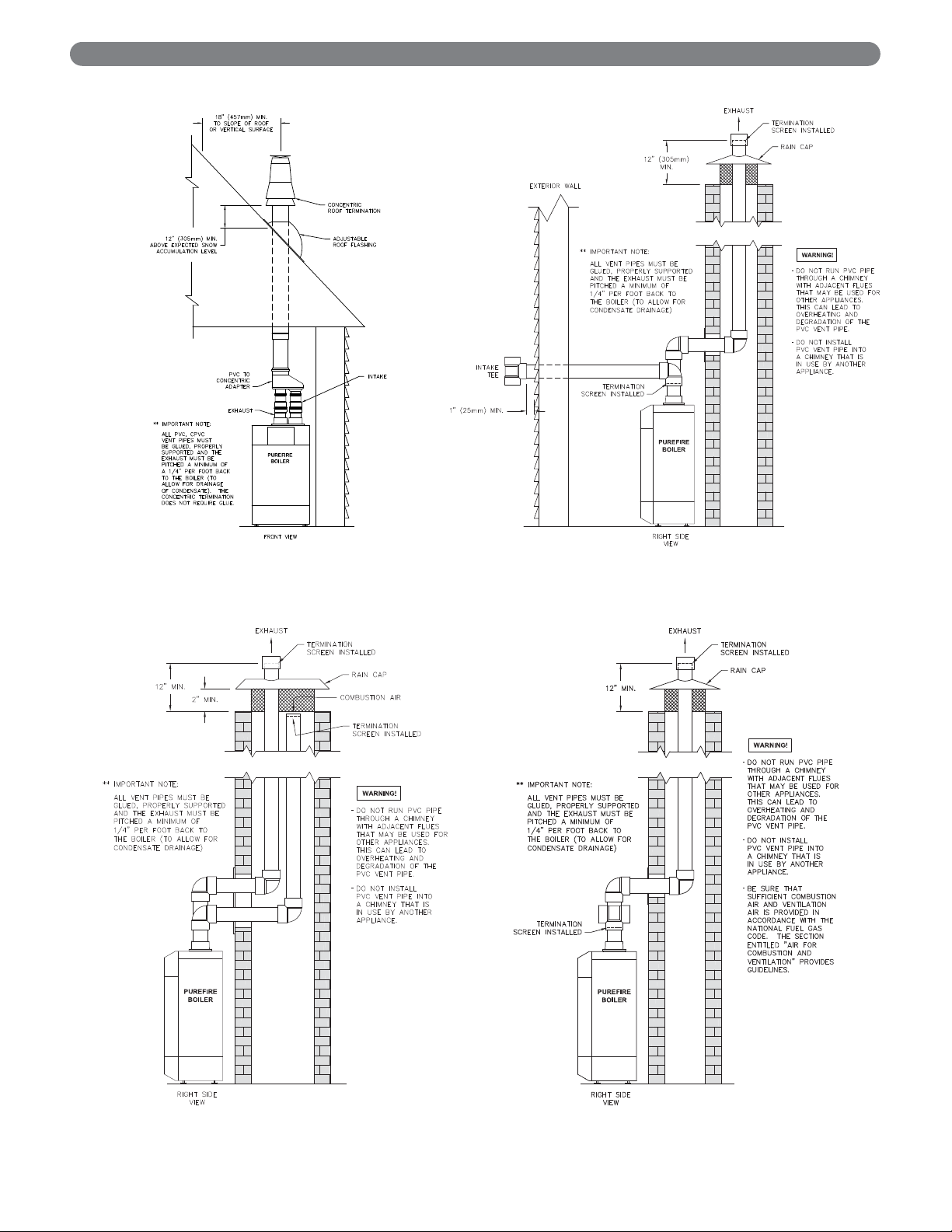

8. Vertical Venting Configuration:

a. Figure 3.8 shows the approved venting

configuration for vertical venting using the

standard fittings supplied.

b. Locate the air intake pipe inlet a minimum of 12"

above the expected snow accumulation on the

roof surface.

c. Locate the end of the exhaust vent pipe a minimum

of 12" above the inlet to the air intake pipe.

d. Figure 3.9 shows an approved vertical vent

configuration using the optional concentric vent

termination kit.

e. Figure 3.10 shows an option for routing the

exhaust and air inlet piping through an unused

chimney.

f. Figure 3.11 shows this option using inlet air from

a sidewall position.

g. Figure 3.12 shows an option for routing the

exhaust through an unused chimney with the

combustion air supplied from inside the building.

Be sure to note the requirements for combustion

air as listed under Section 1.D. "Combustion and

Ventilation Air". These requirements are in

accordance with the National Fuel Gas Code.

Figure 3.7: Optional Concentric Vent Kit

Installation

12

Figure 3.8: Standard Vertical Vent Installation

VENTING & AIR INLET PIPING

Figure 3.6: Sidewall Exhaust with Indoor Air

Page 15

13

VENTING & AIR INLET PIPING

Figure 3.9: Concentric Vertical Vent Installation

Figure 3.10: Venting Through a Chimney Using

Outside Air

Figure 3.11: Venting Through a Chimney Using

Sidewall Outside Air

Figure 3.12: Venting with a Chimney Using Inside Air

Page 16

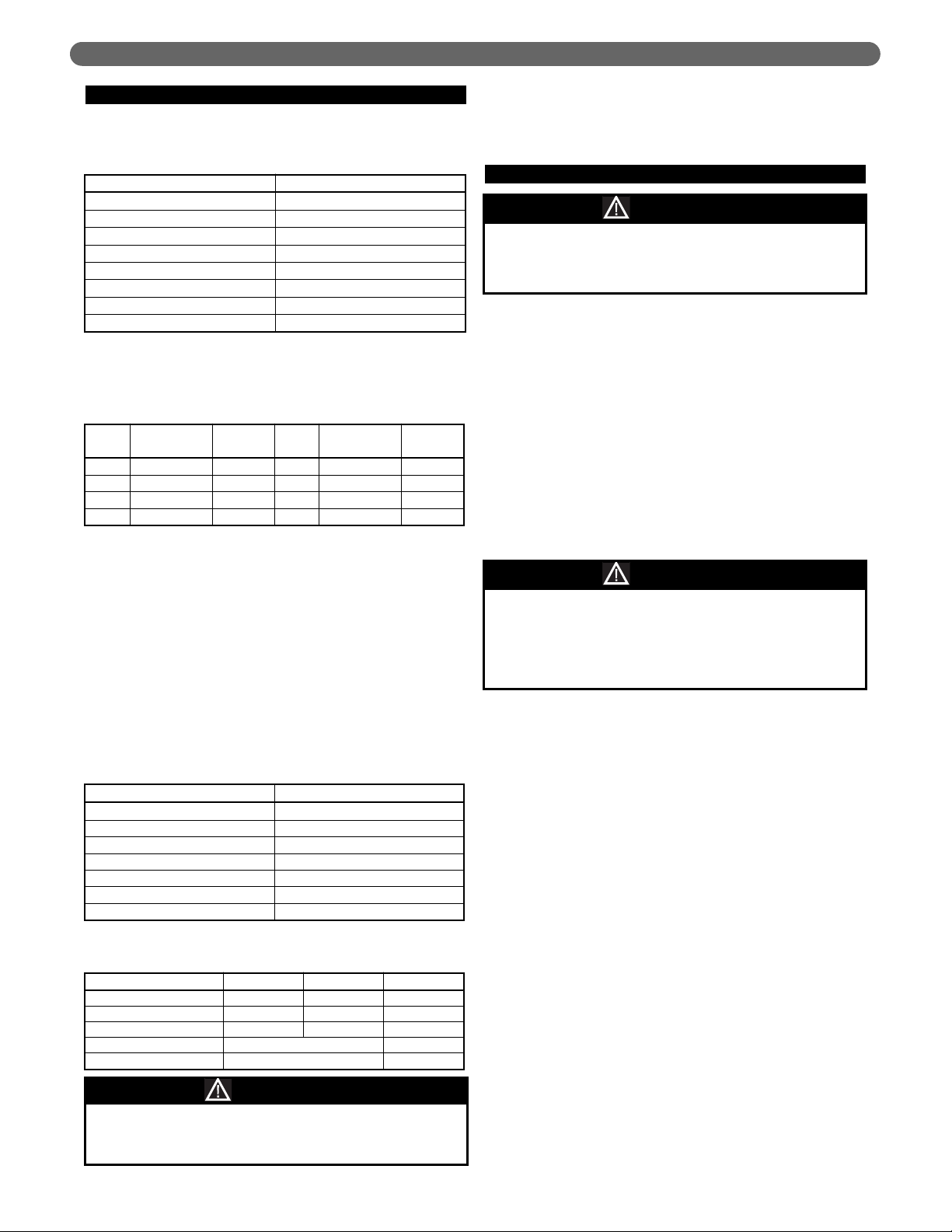

D. EXHAUST VENT/AIR INTAKE PIPE SIZING

1. Table 3.2 shows Exhaust Vent/Air Intake Sizes for

P

UREFIRE

®

boilers.

2. Polypropylene vent systems can be installed using

optional InnoFlue

®

or PolyPro®vent adapters. Table

3.3 shows the appropriate PB Heat stock codes.

Contact your PB Heat, LLC Representative for more

information on this option.

3. Combined systems using separate polypropylene

exhaust & air inlet pipes which transitions to concentric

can also be installed. Contact your Centrotherm or

DuraVent representative for more information.

4. The total combined length of exhaust vent and air

intake piping is 200 equivalent feet (60 m).

a. The equivalent length of elbows, tees and other

fittings are listed in Table 3.4.

b. The equivalent length can be calculated as follows.

This is well below the 200 feet maximum

equivalent length. If the total is above 200

equivalent feet, alternate boiler locations or

exhaust penetration location should be considered.

E. EXHAUST VENT/AIR INTAKE INSTALLATION

1. Figures 12.1 & 12.2 show the exhaust connection on

top of the boiler, near the rear in the center.

a. The exhaust connection for PF-50, PF-80, PF- 110 &

PF-140 boilers is a 3" CPVC Female Pipe Adapter.

b. The exhaust connections for the PF-200/210 (3”),

PF-300 (4”) and PF-399 (4”) are male CPVC

pipe.

c. These connections are to be joined with suitable

PVC/CPVC adhesives in accordance with

manufacturers’ instructions.

2. The Air Intake connection is to the right of the exhaust.

3. Both connections are clearly marked.

4. Remove all burrs and debris from the joints and fittings.

5. Horizontal lengths of exhaust vent must be installed with

a slope of not less than 1/4" per foot (21 mm per meter)

toward the boiler to allow condensate to drain from the

vent pipe. If the vent pipe must be piped around an

obstacle that causes a low point in the piping, a drain

with an appropriate trap must be installed.

6. All piping must be fully supported. Use pipe hangers

at a minimum of 4 foot (1.22 meter) intervals to

prevent sagging of the pipe.

7. Exhaust and air inlet piping is to be supported

separately and should not apply force to the boiler.

8. Penetration openings around the vent pipe and air

intake piping are to be fully sealed to prevent exhaust

gases from entering building structures.

9. PVC & CPVC Piping:

a. Use only solid PVC or CPVC Schedule 40 or 80

pipe for exhaust venting. Cellular core PVC or

CPVC is not approved for exhaust vent.

b. All joints in vent pipe, fittings, attachment to the

boiler stub, and all vent termination joints must be

properly cleaned, primed and cemented. Use only

cement and primer approved for use with PVC or

CPVC pipe that conforms to ANSI/ASTM D2564.

14

VENTING & AIR INLET PIPING

This appliance uses a positive pressure venting

system. All joints must be sealed completely to

prevent leakage of flue products into living spaces.

Failure to do this may result in severe personal injury,

death or major property damage.

WARNING

Exhaust Air Inlet Total

Straight Length of Pipe 50' 50' 100'

90° Elbows, SR 2 x 5'= 10' 1 x 5' = 5' 15'

45° Elbows, SR 2 x 3' = 6' 6'

Conc. Vent Termination 1 x 3' = 3' 3'

Total 124'

Table 3.5: Sample Equivalent Length Calculation

Boiler

Model

Centrotherm

InnoFlue

®

DuraVent

Pol yPro

®

Boiler

Model

Centrotherm

InnoFlue

®

DuraVent

Pol yPro

®

PF-50 54632 54630* PF-200 54632 54630*

PF-80 54632 54630* PF-210 54632 54630*

PF-110 54632 54630* PF-300 54633 54631*

PF-140 54632 54630* PF-399 54633 54631*

Table 3.3: Polypropylene Vent Adapter Stock Codes

Boiler Model Exhaust Vent/Air Intake Size

PF-50 3" (80 mm)

PF-80 3" (80 mm)

PF-110 3" (80 mm)

PF-140 3" (80 mm)

PF-200 3" (80 mm)

PF-210 3" (80 mm)

PF-300 4" (100 mm)

PF-399 4" (100 mm)

Table 3.2: Exhaust Vent/Air Intake Sizing

Fitting Description Equivalent Length

Elbow, 90° Short Radius 5 feet

Elbow, 90° Long Radius 4 feet

Elbow, 45° Short Radius 3 feet

Coupling 0 feet

Air Intake Tee 0 feet

Stainless Steel Vent Kit 1 foot

Concentric Vent Kit 3 feet

Table 3.4: Equivalent Length of Fittings

Exhaust Vent/Air Intake length in excess of 200

equivalent feet may result in reduced input due to

excessive pressure drop.

NOTICE

Covering non-metallic exhaust venting material is

prohibited and may result in severe personal injury,

death, or major property damage.

WARNING

*Use Duravent adapter connector, Part# PPS-PAC, with PB Heat Parts

54630 and 54631.

Page 17

c. A straight coupling is provided with the boiler to

be used as an outside vent termination. One of

the two screens is to be installed to prevent birds

or rodents from entering.

d. An air intake tee is provided with the boiler to be

used as an outside air intake termination. A screen

is to be installed to prevent birds or rodents from

entering.

e. The following are optional combination air

intake/exhaust terminations that are available

separately from your PB Heat, LLC distributor for

use with P

UREFIRE

®

boilers. A 3” CPVC/PVC

coupling is required for the PF-200/210 and a 4”

CPVC/PVC coupling is required for the

PF-300/399 models when using a concentric vent

termination.

f. Refer to Figures 3.3 through 3.7 for sidewall

venting options using PVC or CPVC pipe.

g. Refer to Figures 3.8 through 3.12 for vertical

venting options using PVC or CPVC pipe.

F. EXHAUST TAPPING FOR VENT SAMPLE

To properly install the PUREFIRE®boiler, carbon dioxide

(CO

2

) and carbon monoxide (CO) levels in the exhaust

vent must be determined from a sample of combustion

products. To do this in PVC or CPVC pipe, a hole must

be drilled in the exhaust vent pipe:

a. Drill a 21/64" diameter hole in the pipe in a position

that that the combustion analyzer probe can be

inserted between 6" and 12" from the boiler

connection.

b. Tap the hole with a 1/8" NPT pipe tap.

c. Use a 1/8" NPT PVC or Teflon Pipe Plug to seal the

hole.

InnoFlue

®

and PolyPro®vent systems offer test port

fittings for obtaining a sample of combustion products.

See your Centrotherm or DuraVent Representative for

recommendations.

See Section 9.D.7 for instructions on taking combustion

readings.

G. BOILER REMOVAL FROM COMMON

VENTING SYSTEM

At the time of removal of an existing boiler, follow these

steps with each appliance remaining connected to the

common venting system placed in operation, while the

other appliances remaining connected to the common

venting system are not in operation:

Retrait de la chaudière d’un système d’évacuation

commun. Au moment de retirer une chaudière existante,

il est important de suivre les étapes suivantes pour chaque

appareil raccordé au système d’évacuation commun qui

sont en service, alors que les autres appareils demeurant

raccordés au système d’évacuation commun ne sont pas

en service :

1. Seal any unused openings in the common venting

system.

Sceller toute ouverture du système d’évacuation

commun non utilisée.

2. Visually inspect the venting system for proper size and

horizontal pitch and determine there is no blockage or

restriction, leakage, corrosion and other deficiencies

which could cause an unsafe condition.

Effectuer un contrôle visuel du système d’évacuation

pour vérifier la taille et la pente horizontale et

s’assurer qu’il n’existe aucun blocage ou obstruction,

fuite, corrosion ni tout autre problème pouvant

menacer la sécurité.

3. Insofar as is practical, close all building doors and

windows and all doors between the space in which

the appliances remaining connected to the common

venting system are located and other spaces of the

building.

Dans la mesure du possible, fermer toutes les portes

et fenêtres de l’immeuble ainsi que toutes les portes

entre l’espace dans lequel les appareils qui demeurent

raccordés au système d’évacuation commun se

trouvent et le reste de l’immeuble.

4. Turn on any clothes dryers and any appliance not

connected to common venting system. Turn on any

exhaust fans, such as range hoods and bathroom

exhausts, so they will operate at maximum speed. Do

not operate a summer exhaust fan.

Mettre en marche les sécheuses et tout autre appareil

non raccordé au système d’évacuation commun.

Mettre en marche tous les ventilateurs aspirant, tels

que les hottes de cuisinière et les ventilateurs de salle

de bain, en les faisant fonctionner à vitesse maximum.

5. Close fireplace dampers.

Ne pas faire fonctionner les ventilateurs aspirant d’été.

Fermer les registres de foyers.

6. Place in operation the appliance being inspected.

Follow the lighting instructions. Adjust thermostat so

appliance will operate continuously.

Mettre en service l’appareil à inspecter. Suivre les

instructions concernant l’allumage. Régler le

thermostat afin que l’appareil fonctionne sans arrêt.

7. Test for spillage at the draft hood relief opening after 5

minutes of main burner operation. Use the flame of a

match or candle, or smoke from a cigarette, cigar, or

pipe.

Vérifier toute fuite à l’orifice de décharge du coupetirage après que le brûleur ait fonctionné pendant 5

minutes. Utiliser la flamme d’une allumette ou d’une

chandelle ou encore la fumée d’une cigarette, d’un

cigare ou d’une pipe.

15

VENTING & AIR INLET PIPING

Boiler

Model

Description

Stock

Code

PF-50,

PF-80,

PF-110,

PF-140,

PF-200,

PF-210

Sidewall Vent Termination Kit – PolyPro 3PPS-HK 54498

Vertical Vent Termination Kit – PolyPro 3PPS-VK 54500

PF-300

PF-399

Sidewall Vent Termination Kit – PolyPro 4PPS-HK 54499

Vertical Vent Termination Kit – PolyPro 4PPS-VK 54501

Table 3.6: Concentric Vent Termination Kits

Page 18

16

VENTING & AIR INLET PIPING

8. After it has been determined that each appliance

remaining connected to the common venting system

properly vents when tested as outlined above, return

doors, windows, exhaust fans, fireplace dampers and

any other gas-burning appliance to their previous

conditions of use.

Après avoir établi que les résidus de combustion de

chaque appareil qui demeure raccordé au système

commun sont adéquatement évacués lorsque soumis

au test décrit ci-dessus, remettre en place les portes,

fenêtres, portes intérieures, ventilateurs aspirants,

registres de foyer et appareils fonctionnant au gaz.

9. Any improper operation of the common venting system

should be corrected so that the installation conforms

with the National Fuel Gas Code, ANSI Z223.1/NFPA

54 or CAN/CGA B149 Installation Codes.

Tout fonctionnement inadéquat du système

d’évacuation commun doit être corrigé de manière à

respecter les normes du National Fuel Gas Code,

ANSI Z223.1/NFPA 54 et/ou des Codes d’installation

CAN/ACG B149.

10. When resizing any portion of the common venting

system, the common venting system should be resized

to approach minimum size as determined using the

appropriate tables located in the chapter “Sizing of

Category I Venting Systems,” of the National Fuel Gas

Code, ANSI Z223.1/NFPA 54 or CAN/CGA B149

Installation codes.

Lorsqu’il est nécessaire de modifier les dimensions de

toute portion du système d’évacuation commun, ces

dernières doivent être modifiées de manière à

respecter les dimensions minimums indiquées dans les

tableaux du chapitre « Sizing of Category I Venting

Systems » du National Fuel Gas Code, ANSI

Z223.1/NFPA 54 ou des Codes d’installation

CAN/ACG B149.

Page 19

A. GENERAL

1. Size water supply and return piping in accordance

with system requirements rather than the boiler

connections.

2. If the P

UREFIRE

®

boiler is used to replace an existing

boiler, make sure the system piping is thoroughly

cleaned and free from debris before installing this

boiler. Sentinel Performance Solutions

(http://www.sentinel-solutions.net/us/) offers a full line

of cleaners (X300), sludge remover (X400), antifreeze

(X500) and corrosion inhibitors (X100/X500) for

hydronic applications.

3. In hydronic systems where sediment may exist, install

a strainer in the boiler return piping to prevent large

particles and pipe scale from entering the boiler heat

exchanger. Use a large mesh screen in the strainer.

4. Install this boiler so that the gas ignition system

components are protected from water (dripping, spraying,

etc.) during operation and service (circulator replacement,

condensate trap cleaning, sensor replacement, etc.).

5. The P

UREFIRE

®

heating boiler is intended for use in a

closed-loop hydronic system. Leaks in the piping

system may require constant make-up water which

may include oxygen, calcium and other substances

which may cause corrosion, calcium scale buildup, or

other attack on the hydronic system piping. The

system water should have a pH value of between 8.2

and 9.5. The water hardness is to be maintained

between 50 ppm CaCO

3

(3 gr/gal) and 150 ppm

CaCO

3

(9 gr/gal). Also, a minimum water pressure of

5 psi is required for proper performance.

B. OPERATING PARAMETERS

1. The PUREFIRE®boiler is designed to operate in a

closed loop hydronic system under forced circulation.

This requires the system to be completely filled with

water and requires a minimum water flow through the

boiler to operate effectively.

2. The minimum system pressure is 14.5 psig (100 kPa).

3. Table 4.1 lists the minimum flow rates for each P

UREFIRE

®

model. If a glycol solution is to be used, contact your PB

Heat, LLC representative for minimum flow rates.

Section 4.E provides detailed information about using

glycol for freeze protection.

Table 4.2 provides the water volume of the heat

exchanger including the supply and return pipes that

are attached at the factory.

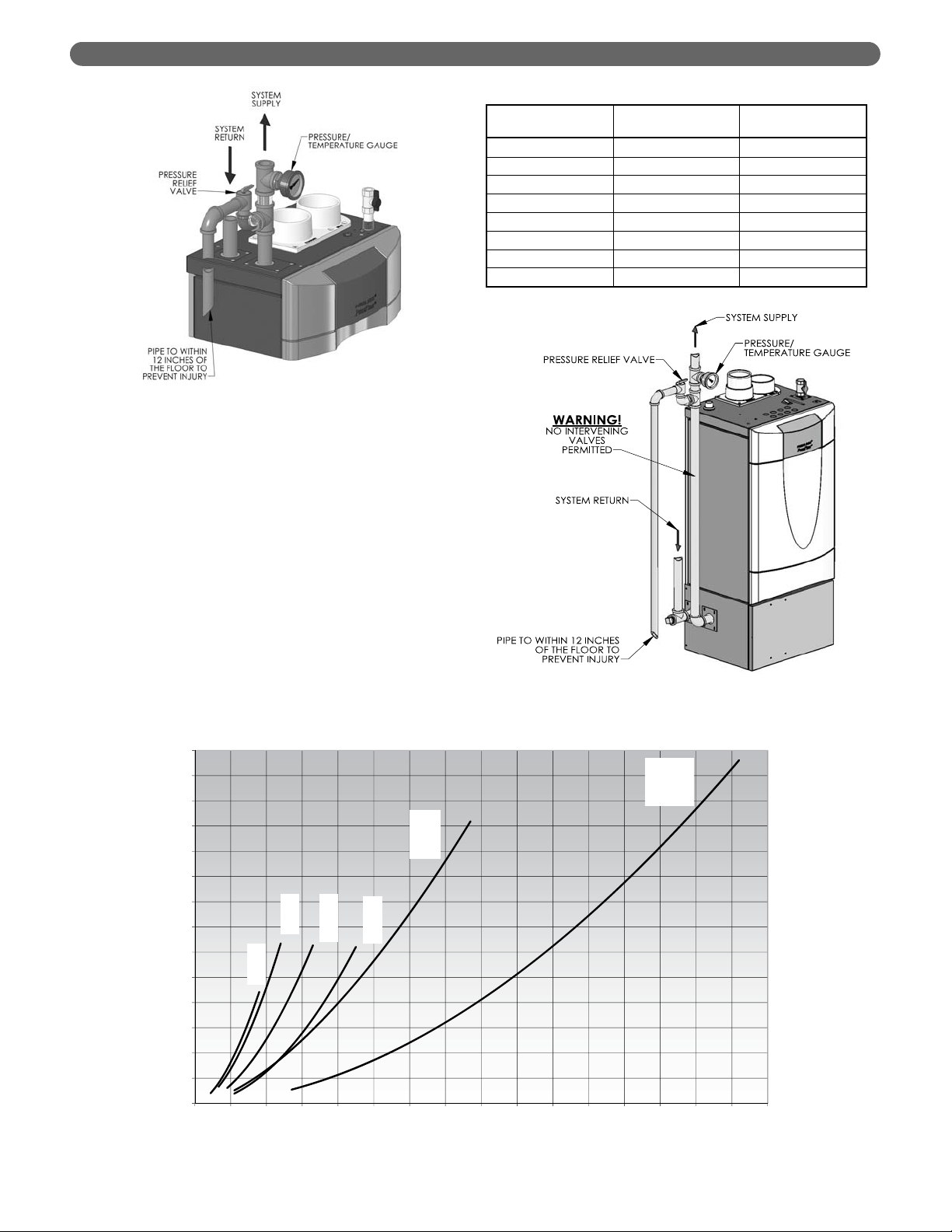

C. SYSTEM COMPONENTS

Figure 4.1 shows the symbol key for piping diagrams in

this section. The following are brief descriptions of system

components.

1. Pressure/Temperature Gauge: A combination

pressure/temperature gauge is provided with each

P

UREFIRE

®

boiler to be mounted in the piping from the

boiler supply to the system as shown in Figure 4.2 &

4.3. Most local codes require this gauge.

2. Air Elimination: Closed loop hydronic systems require

air elimination devices. As the system water is heated,

dissolved oxygen and other gases will separate from

the liquid. An air elimination device (such as a TACO

Vortech

®

Air Separator) is required to remove the

dissolved gases preventing corrosion in the piping

system and eliminating noise.

3. Expansion Tank: An expansion tank (such as a Bell &

Gossett Series HFT) is required to provide room for

expansion of the heating medium (water or glycol

solution). Consult the expansion tank manufacturer's

instructions for specific information regarding

installation. The expansion tank is to be sized for the

required system volume and capacity. In addition, be

sure that the expansion tank is sized based on the

proper heating medium. Glycol solutions may expand

more than water for a similar temperature rise.

WATER PIPING AND CONTROLS

4. WATER PIPING & CONTROLS

Use only inhibited propylene glycol solutions which

are specifically formulated for hydronic systems.

Unlike automotive antifreeze, solutions for hydronic

applications contain corrosion inhibitors that will

protect system components from premature failure

due to corrosion.

CAUTION

Use only inhibited propylene glycol solutions which

are specifically formulated for hydronic systems.

Ethylene glycol is toxic and may cause an

environmental hazard if a leak or spill occurs.

WARNING

PUREFIRE

®

Model

Minimum Flow Rate

Water

GPM (LPM)

50% Glycol Solution

GPM (LPM)

PF-50 2.2 (8.3) 2.8 (10.6)

PF-80 3.3 (12.5) 4.1 (15.5)

PF-110 4.4 (16.7) 5.5 (20.8)

PF-140 5.5 (20.8) 6.8 (25.7)

PF-200 5.5 (20.8) 6.8 (25.7)

PF-210 5.5 (20.8) 6.8 (25.7)

PF-300 13.2 (50.0) 16.5 (62.5)

PF-399 13.2 (50.0) 16.5 (62.5)

Table 4.1: Minimum Flow Rate

PUREFIRE

®

Model

Total Water Capacity

Gallons (Liters)

PF-50 0.62 (2.35)

PF-80 0.72 (2.73)

PF-110 0.89 (3.37)

PF-140 1.25 (4.73)

PF-200 1.19 (4.50)

PF-210 1.19 (4.50)

PF-300 2.60 (9.84)

PF-399 2.60 (9.84)

Table 4.2: Heat Exchanger Water Capacity

17

Page 20

18

4. Y-Type Strainer or Filter Ball®Valve: PB Heat

recommends the use of a strainer device in the system to

prevent dirt or sediment from clogging the heat

exchanger. A 20 mesh stainless steel screen is adequate to

protect the heat exchanger. The strainer should be

cleaned often in the first several months of operation. The

Filter Ball

®

Valve from Jomar International incorporates a

strainer into a ball valve which allows the technician to

isolate the water circuit while cleaning the strainer.

5. Flow Control Valve: Flow control valves such as the

TACO Flo-Chek or Bell & Gossett Flo-Control™ are

used to prevent gravity circulation by incorporating a

check valve with a weighted disc.

6. Pressure Reducing Valve: A pressure reducing valve,

such as the Bell & Gossett B-38 or a TACO #329, is

used in a hydronic system to automatically feed water

to the system whenever pressure in the system drops

below the pressure setting of the valve. These valves

should not be used on glycol systems unless close

supervision of the glycol solution is practiced.

7. Back Flow Preventer: A back flow preventer (check

valve) is required by some jurisdictions to prevent water

in the hydronic system from backing up into the city

water supply. This is especially important on systems in

which glycol solution is used as the heating medium.

8. Pressure Relief Valve: The boiler pressure relief valve

is shipped separately for field installation.

The valve is to be installed as shown in Figures 4.2 or

4.3. Pipe the discharge of the relief valve to within 12"

of the floor and close to a floor drain.

Provide piping that is the same size or larger than the

relief valve outlet.

9. Low Water Cut Off: When installing a probe type

LWCO, locate the LWCO in the boiler supply above

the top jacket panel. Refer to Section 7. Electrical

Connection in this manual for wiring details.

WATER PIPING AND CONTROLS

Figure 4.1: Piping Symbol Key

Do not operate this appliance without installing the

pressure relief valve supplied with the boiler or one

with sufficient relieving capacity in accordance with

the ASME Rating Plate on the boiler heat exchanger.

WARNING

Pipe the discharge of the relief valve as close as

possible to the floor and away from high traffic areas.

Pipe the discharge to a floor drain. Failure to do so

may result in personal injury and/or property

damage.

CAUTION

Page 21

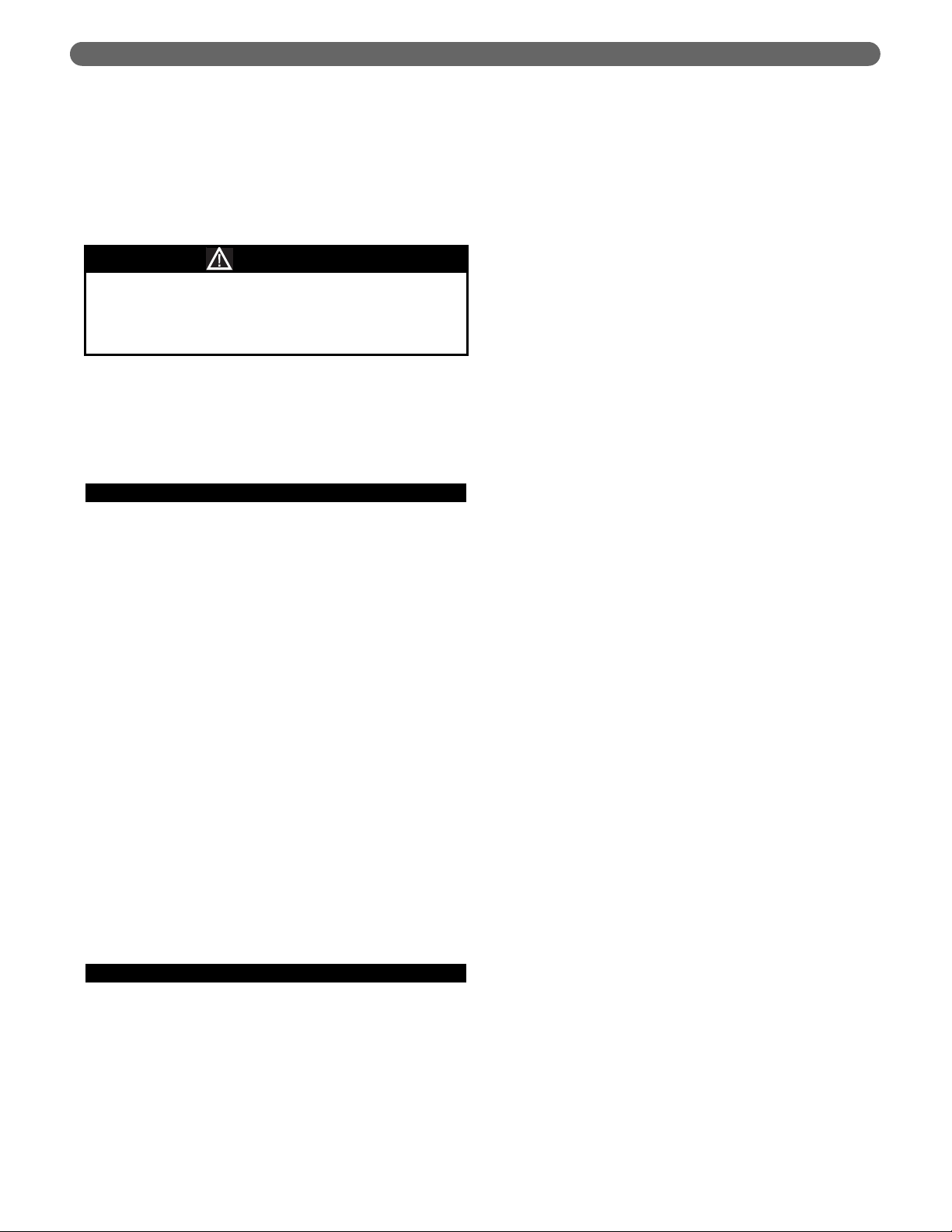

10. Circulator: The boiler circulator is to be sized to

overcome the pressure drop of the system while

providing the flow required by the boiler.

a. If the boiler is piped in a secondary loop of a

primary/secondary heating system, the circulator

will need only to overcome the resistance of the

boiler and any fittings in that loop.

b. The circulator should be sized based on gross

output of the boiler. Table 4.3 shows the Boiler

Output as reported to the Hydronics Institute

Section of AHRI.

c. The required flow is calculated based on the design

temperature difference from the return to the supply

of the boiler. For a PF-110 with a design temperature

difference of 20°F the calculation is as follows.

Output 101,000

Required Flow =

________=_________

= 10.1 GPM

Δ

T x 500 20 x 500

19

WATER PIPING AND CONTROLS

PUREFIRE

®

Model

Boiler Input

Btu/hr (kW)

Gross Output

Btu/hr (kW)

PF-50 50,000 (14.7) 46,000 (13.5)

PF-80 80,000 (23.4) 74,000 (21.7)

PF-110 110,000 (34.2) 102,000 (29.9)

PF-140 140,000 (41.0) 131,000 (38.4)

PF-200 199,000 (58.3) 183,000 (53.6)

PF-210 210,000 (61.5) 193,000 (56.6)

PF-300 300,000 (87.9) 289,000 (84.9)

PF-399 399,000 (116.9) 373,000 (109.3)

Table 4.3: Boiler Inputs and Outputs

Figure 4.4: PUREFIRE®Circulator Sizing Graph (General Pump – Primary/Secondary)

Figure 4.2: Relief Valve Installation – PF-50, PF-80,

PF-110 & PF-140

Figure 4.3: Relief Valve Installation – PF-200, PF-210,

PF-300, PF-399 & PF-460

3UHVVXUH'URS)WRI:DWHU

PF-80

PF-110

PF-50

PF-200

PF-140

PF-210

PF-300

PF-399

)ORZ5DWH*30

PF-460

Page 22

20

d. The boiler pressure drop for various flow rates can

be determined using Figure 4.4, the P

UREFIRE

®

Boiler Circulator Sizing Graph.

e. Table 4.4 provides the flow rate and pressure drop

information that corresponds to various system

temperature rise values (ΔT). The pressure drop

shown is for the boiler only. If there is significant

pressure drop in the system, this should be

included when specifying circulators.

Table 4.4: Flow Rate and Pressure Drop for Various System Temperature Rise Values

ΔT

(°F)

Flow Rate & Pressure Drop

PF-50 PF-80 PF-110 PF-140 PF-200 PF-210 PF-300 PF-399

GPM FT GPM FT GPM FT GPM FT GPM FT GPM FT GPM FT GPM FT

40 2.3 2.17 3.7 3.92 5.1 3.74 6.5 2.70 9.2 5.77 9.6 6.23 14.5 3.11 18.7 4.97

35 2.6 2.72 4.2 4.95 5.8 4.75 7.4 3.51 10.5 7.13 11.0 7.69 16.6 3.99 21.3 6.38

30 3.1 3.54 4.9 6.49 6.7 6.27 8.7 4.75 12.2 9.10 12.8 9.81 19.3 5.32 24.9 8.50

25 3.7 4.83 5.8 8.95 8.1 8.70 10.4 6.80 14.6 12.14 15.4 13.09 23.2 7.47 29.8 11.93

20 4.6 7.06 7.3 13.25 10.1 12.99 13.0 10.55 18.3 17.27 19.2 18.63 29.0 11.32 37.3 18.08

15 6.1 11.52 9.7 21.97 13.5 21.78 17.3 18.58 24.4 27.21 25.6 29.35 38.7 19.34 49.7 30.90

10 9.2 22.97 14.6 44.81 20.2 45.11 26.0 41.26 36.6 51.64 38.4 55.71 58.0 41.14 74.6 65.74

Table 4.5: Circulator Selection Chart (General Pump – Primary Secondary)

Circulator

Manufacturer

Temp.

Difference PF-50 PF-80 PF-110 PF-140 PF-200 PF-210 PF-300 PF-399

Taco

20°F

005* 009 0014 0014 1400-20 1400-20 2400-60 1400-50

Grundfos

UPS15-58FC

Med Speed

UPS15-58FC

Hi Speed

UPS26-99FC

Med Speed

UPS26-99FC

Med Speed

UPS32-80F

Med Speed

UPS32-80F

Med Speed

UPS26-150 SF

Hi Speed

UPS32-160F

Med Speed

Bell & Gossett

NRF-22 NRF-22 NRF-36 NRF-25 NRF-36 NRF-36 NRF-45 Speed 3 PL-55

Wilo

Star S 21 FX

Med Speed

Star S 21 FX

Hi Speed

Star S 21 FX

Hi Speed

Star 30 F

Top S 1.25 x 25

Max

Top S 1.25 x 25

Max

Top-S 1.5 x 20 1

- 115V Min

Top S 1.25 x 35

Max

Armstrong

Astro 230CI

Speed 2

Astro 250CI

Speed 3

Astro 280CI

Speed 2

Astro 280CI

Speed 2

E9 E9 — E21

Taco

25°F

006F* 007 008 007 0014 0014 0011 1400-20

Grundfos

UPS15-58FC

Lo Speed

UPS15-58FC

Med Speed

UPS15-58FC

Hi Speed

UPS15-58FC

Hi Speed

UPS26-99FC

Med Speed

UPS26-99FC

Med Speed

UPS26-99 FC

Med Speed

UPS32-80F

Med Speed

Bell & Gossett

NRF-9F/LW NRF-22 NRF-22 NRF-22 NRF-45 NRF-45 NRF-36 Speed 2 PL-50

Wilo

Star S 21 FX

Low Speed

Star S 21 FX

Med Speed

Star S 21 FX

Hi Speed

Star S 21 FX

Hi Speed

Star 30 F Star 30 F Star 17 FX

Top S 1.25 x 35

Max

Armstrong

Astro 230CI

Speed 2

Astro 230CI

Speed 3

Astro 230CI

Speed 3

Astro 230CI

Speed 3

Astro 280CI

Speed 2

Astro 280CI

Speed 2

— E11

Taco

30°F

006F* 005* 005* 005* 0014 0014 0011 0013

Grundfos

UP15-10F

UPS15-58FC

Med Speed

UPS15-58FC

Med Speed

UPS15-58FC

Med Speed

UPS26-99FC

Med Speed

UPS26-99FC

Med Speed

UPS44-43

Med Speed

UPS26-99FC

Hi Speed

Bell & Gossett

NRF-9F/LW NRF-22 NRF-22 NRF-22 NRF-25 NRF-25 NRF-45 Speed 1 NRF-36

Wilo

Star S 21 FX

Min Speed

Star S 21 FX

Med Speed

Star S 21 FX

Med Speed

Star S 21 FX

Hi Speed

Star 30 F Star 30 F Star 30 F Star 17 FX

Armstrong

Astro 230CI

Speed 1

Astro 230CI

Speed 2

Astro 230CI

Speed 2

Astro 230CI

Speed 3

Astro 280CI

Speed 2

Astro 280CI

Speed 2

—

Astro 290CI

Speed 3

Taco

35°F

006F* 006F* 006F* 006F* 0010 0010 0011 0014

Grundfos

UP15-10F

UPS15-58FC

Lo Speed

UPS15-58FC

Med Speed

UPS15-58FC

Med Speed

UPS15-58FC

Hi Speed

UPS15-58FC

Hi Speed

UPS15-55 SFC

Hi Speed

UPS26-99FC

Hi Speed

Bell & Gossett

N/A NRF-9F/LW NRF-9F/LW NRF-9F/LW NRF-22 NRF-22 NRF-25 Speed 2 NRF-45

Wilo

Star S 21 FX

Min Speed

Star S 21 FX

Min Speed

Star S 21 FX

Med Speed

Star S 21 FX

Med Speed

Star S 21 FX Hi

Speed

Star S 21 FX

Hi Speed

Star S 33 RFC Star 30 F

Armstrong

Astro 230CI

Speed 1

Astro 230CI

Speed 2

Astro 230CI

Speed 2

Astro 230CI

Speed 2

Astro 250CI

Speed 3

Astro 250CI

Speed 3

—

Astro 290CI

Speed 2

Taco

40°F

006F* 006F* 006F* 006F*

007

007 0011 0010

Grundfos

UP15-10F

UPS15-58FC

Lo Speed

UPS15-58FC

Lo Speed

UPS15-58FC

Lo Speed

UPS15-58FC

Hi Speed

UPS15-58FC

Hi Speed

UPS15-58FC

Hi Speed

UPS26-99FC

Med Speed

Bell & Gossett

N/A NRF-9F/LW NRF-9F/LW NRF-9F/LW NRF-22 NRF-22 NRF-25 Speed 2 NRF-33

Wilo

Star S 21 FX

Min Speed

Star S 21 FX

Min Speed

Star S 21 FX

Min Speed

Star S 21 FX

Min Speed

Star S 21 FX

High Speed

Star S 21 FX

Hi Speed

Star S-21 F Star 30 F

Armstrong

Astro 230CI

Speed 1

Astro 230CI

Speed 1

Astro 230CI

Speed 2

Astro 230CI

Speed 2

Astro 250CI

Speed 3

Astro 250CI

Speed 3

—

Astro 290CI

Speed 2

* A model 007 circulator can be substituted for those marked with an asterisk based on availability.

WATER PIPING AND CONTROLS

Page 23

21

WATER PIPING AND CONTROLS

f. Table 4.5 provides a list of recommended

circulators for boilers on a secondary loop of a

primary/secondary system which uses water as a

heating medium.

g. Special consideration must be given if a glycol

based anti-freeze solution is used as a heating

medium. Propylene glycol has a higher viscosity

than water, therefore the system pressure drop will

be higher.

11. Indirect Water Heater: An indirect water heater should

be piped to a dedicated zone. The P

UREFIRE

®

boiler

provides electrical terminals for connecting a domestic

hot water (DHW) circulator. Examples of piping for

the indirect water heater are shown under subsection

“D”, System Piping of this section.

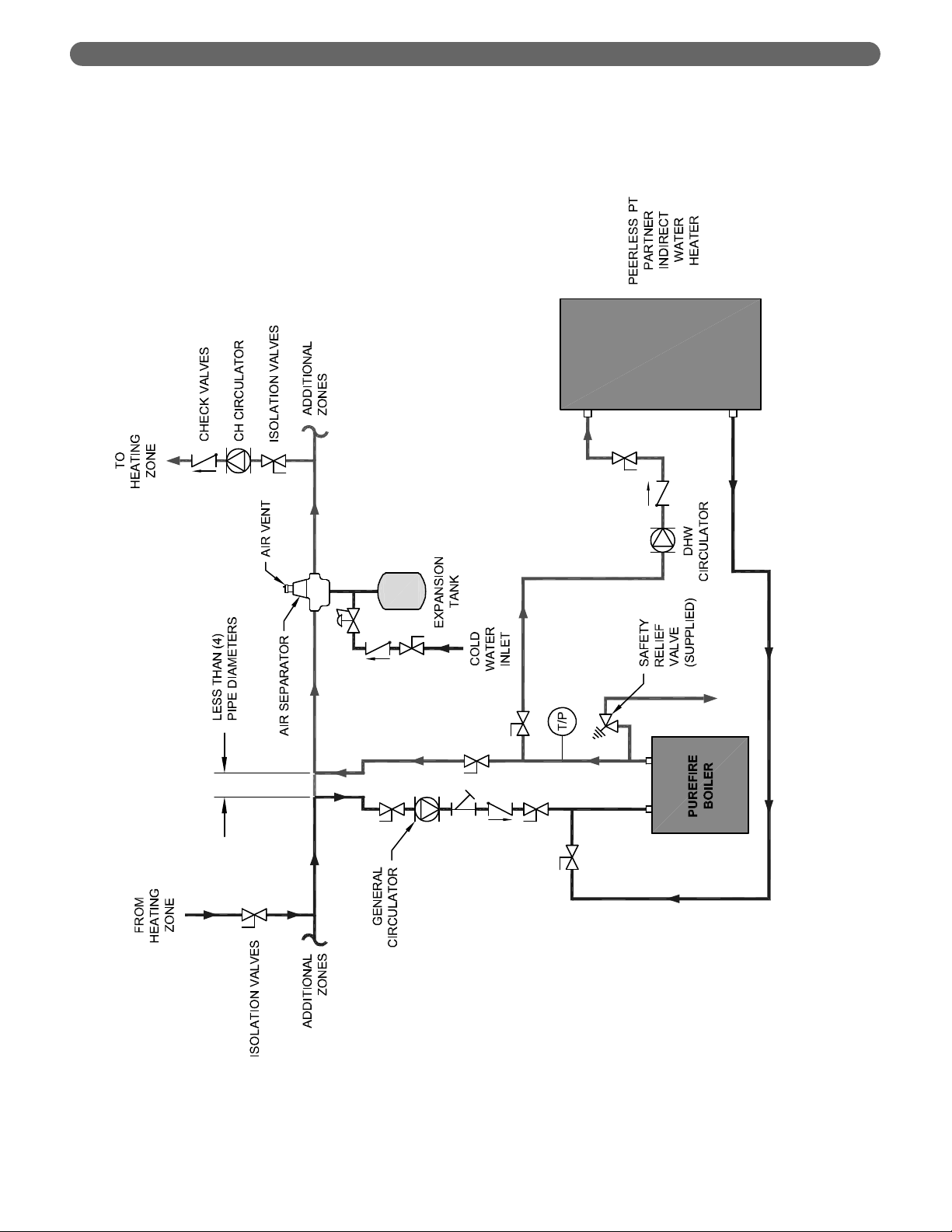

D. SYSTEM PIPING

1. Figure 4.5 shows a single boiler with multiple heating

zones. In this case, the DHW zone is piped in parallel

to the heating zones on the primary loop.

2. For a single boiler with one heating zone and one

DHW zone which utilizes an indirect water heater like

the Peerless

®

Partner®, pipe the boiler as shown in

Figure 4.6. In systems like this, the DHW circulator

must be sized to provide the minimum flow rate

through the boiler.

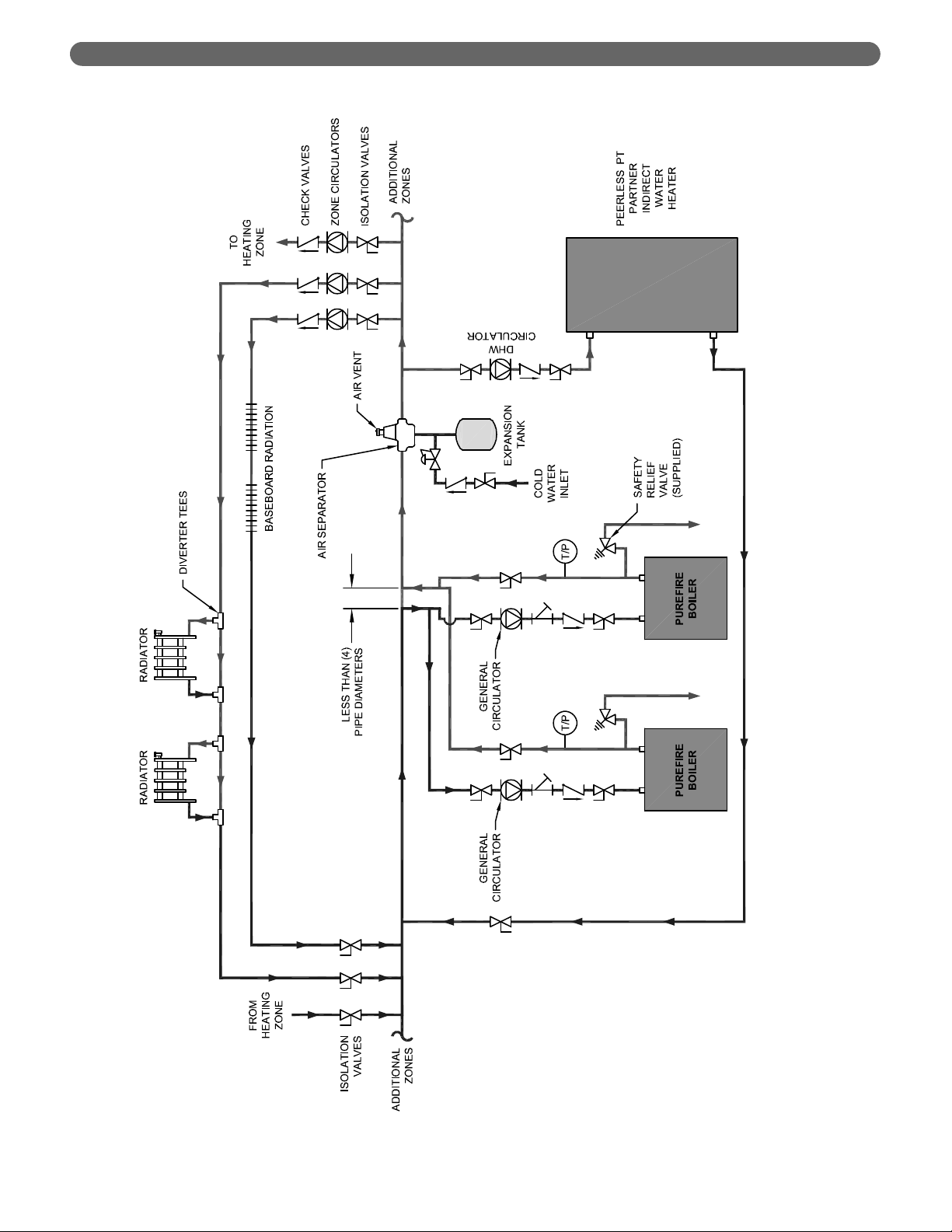

3. In Figure 4.7 an additional boiler is added and more

heating zones are shown. Notice that the two boilers

are piped in parallel on the secondary loop. This

maximizes the efficiency of the boilers since the lowest

temperature system water is returning to both boilers.

4. Figure 4.8 shows a multiple boiler system with several

different types of heat distribution units. This system

illustrates how different temperature zones can be

supplied from the same source by blending supply

and return water to the zone.

5. In Figure 4.9 zone valves are used instead of zone

circulators. Notice that the system is piped using

reverse return piping to help balance the flow through

the zones. If the zone lengths vary balancing valves

are required on each loop.

E. FREEZE PROTECTION

1. Glycol for hydronic applications is specially formulated

for heating systems. It includes inhibitors which prevent

the glycol from attacking metallic system components.

Make sure that the system fluid is checked for correct

glycol concentration and inhibitor level.

2. Use only inhibited polypropylene glycol solutions of

up to 50% by volume. Ethylene glycol is toxic and

can chemically attack gaskets and seals used in

hydronic system.

3. The anti-freeze solution should be tested at least once

per year and as recommended by the manufacturer of

the product.

4. Anti-freeze solutions expand more than water. For

example, a 50% by volume solution expands 4.8%

with a 148°F temperature rise while water expands

about 3% for the same temperature increase.

Allowance for this expansion must be considered in

sizing expansion tanks and related components.

5. The flow rate in systems utilizing glycol solutions

should be higher than in a water system to

compensate for decreased heating capacity of the fluid.

6. Due to increased flow rate and fluid viscosity, the

circulator head requirement will increase. Contact the

pump manufacturer to correctly size the circulator for

a particular application based on the glycol

concentration and heating requirements.

7. A strainer, sediment trap, or some other means for

cleaning the piping system must be provided. It

should be located in the return line upstream of the

boiler and must be cleaned frequently during the

initial operation of the system. Glycol is likely to

remove mill scale from new pipe in new installations.

8. Glycol solution is expensive and leaks should be

avoided. Weld or solder joints should be used where

possible and threaded joints should be avoided.

Make-up water should not be added to the system

automatically when glycol solution is used. Adding

make-up water will dilute the system and reduce the

ability of the solution to protect from freezing.

9. Check local regulations to see if systems containing

glycol solutions must include a back-flow preventer or

require that the glycol system be isolated from the

water supply.

10. Do not use galvanized pipe in glycol systems.

11. Use water that is low in mineral content and make

sure that there are no petroleum products in the

solution.

a. Less than 50 ppm of calcium

b. Less than 50 ppm of magnesium

c. Less than 100 ppm (5 grains/gallon) of total

hardness

d. Less than 25 ppm of chloride

e. Less than 25 ppm of sulfate

12. Check with the local water supplier for chemical

properties of the water.

13. The following test will determine if the water is of the

appropriate hardness. Collect a sample of 50% water

to 50% propylene glycol. Let the solution stand for 812 hours shaking it occasionally. If white sediment

forms, the water is too hard and should not be used

to dilute the glycol.

14. Mix the solution at room temperature.

15. Do not use a chromate treatment.

16. Refer to Technical Topics #2a published by the

Hydronics Institute for further glycol system

considerations.

The circulator sizing given is for primary/secondary

installations only. The system circulators must be

sized based on the flow and pressure drop

requirements of the system.

NOTICE

Page 24

22

WATER PIPING AND CONTROLS

Figure 4.5: Recommended Piping – One Boiler, Primary/Secondary with Two Zones (Zone Circulator)

Page 25

23

WATER PIPING AND CONTROLS

Figure 4.6: Alternate Piping – One Boiler, Primary/Secondary with a Peerless

®

Partner

®

(Zone Circulators).

Note: The DHW Circulator must be sized to provide minimum flow through the boiler

Page 26

24

WATER PIPING AND CONTROLS

Figure 4.7: Two Boilers, Primary/Secondary with Four Zones (Zone Circulator)

Page 27

25

Figure 4.8: Three Boilers, Primary/Secondary with Five Zones (Zone Circulator)

WATER PIPING AND CONTROLS

Page 28

26

WATER PIPING AND CONTROLS

Figure 4.9: Three Boilers, Primary/Secondary with Four Zones (Zone Valves)

Page 29

27

F. SPECIAL APPLICATIONS

1. If the PUREFIRE®boiler is used in conjunction with a

chilled medium system, pipe the chiller in a separate

secondary loop.

a. Assure that the boiler circulator is disabled during

chiller operation so that chilled water does not

enter the boiler.

b. Install a flow control valve (spring check valve) to

prevent gravity flow through the boiler.

c. See Figure 4.10 for recommended system piping

for chiller operation.

2. For boilers connected to heating coils in a forced air

system where they may be exposed to chilled air

circulation, install flow control valves or other

automatic means to prevent gravity circulation of the

boiler water during cooling cycles. See Figure 4.11 for

an illustration.

WATER PIPING AND CONTROLS

Figure 4.10: Boiler in conjunction with a Chilled Water System

Figure 4.11: Boiler Connected to a Heating Coil in a Forced Air System

Page 30

A. GENERAL

1. All fuel piping to the PUREFIRE®boiler is to be in

accordance with local codes. In the absence of local

regulations refer to the National Fuel Gas Code, ANSI

Z223.1/NFPA 54.

2. Size and install fuel piping to provide a supply of gas

sufficient to meet the maximum demand of all

appliances supplied by the piping.

3. P

UREFIRE

®

boilers are intended for operation with

Natural Gas or Propane with sulfur content of less than

105 ppm (150 mg/m

3

) peak with an annual average of

less than 20 ppm (30 mg/m

3

). Excessive sulfur content

in fuel input can result in black deposits resembling

coffee grounds in the combustion chamber of the boiler.

B. FUEL LINE SIZING

1. The required flow rate of gas fuel to the boiler can be

determined by the following.

The gas heating value can be supplied by the gas

supplier.

2. As an alternative, use Table 5.1 to determine the

required gas flow rate which uses typical heating values

for natural gas and liquefied petroleum (LP) gas.

3. Table 5.2 shows the maximum flow capacity of

several pipe sizes based on 0.3" of pressure drop.

a. The values shown are based on a gas specific

gravity of 0.60 (Typical for natural gas).

b. Multiply the capacities listed by the correction

factors listed for gas with a specific gravity other

than 0.60 to obtain the corrected capacity.

4. Size and install the fuel gas supply piping for no more

than 0.5 inches of water pressure drop between the

gas regulator and the boiler.

C. GAS SUPPLY PIPING - INSTALLATION

1. Do not install any piping directly in front of the boiler

or along either side. Always provide access to the

front cover and side panel openings.

2. Install a sediment trap as shown in Figure 5.1. Be sure

to allow clearance from the floor or other horizontal

surface for removal of the pipe cap.

* Natural gas input rates are based on 1,000 Btu/ft

3

, LP input

rates are based on 2,500 Btu/ft

3

.

FUEL PIPING

5. FUEL PIPING

Use a pipe joint sealing compound that is resistant to

liquefied petroleum gas. A non-resistant compound

may lose sealing ability in the presence of this gas,

resulting in a gas leak. Gas leaks may potentially

cause an explosion or fire.

WARNING

PUREFIRE

®

Model

Required Input Rate*

Natural Gas ft3/hr

(m3/hr)

LP Gas ft3/hr

(m3/hr)

PF-50 50 (1.4) 20 (0.6)

PF-80 80 (2.3) 32 (0.9)

PF-110 110 (3.1) 44 (1.2)

PF-140 140 (4.0) 56 (1.6)

PF-200 199 (5.6) 79 (2.2)

PF-210 210 (5.9) 84 (2.4)

PF-300 300 (8.5) 120 (3.4)

PF-399 399 (11.3) 166 (4.7)

Table 5.1: Required Fuel Input

Pipe

Length

ft (m)

1/2" NPT

Pipe

3/4" NPT

Pipe

1" NPT

Pipe

1-1/4"

NPT

Pipe

1-1/2"

NPT

Pipe

10

(3.0)

132

(3.7)

278

(7.9)

520

(14.7)

1,050

(29.7)

1,600

(45.3)

20

(6.1)

92

(2.6)

190

(5.4)

350

(9.9)

730

(20.7)

1,100

(31.1)

30

(9.1)

73

(2.1)

152

(4.3)

285

(8.1)

590

(16.7)

890

(25.2)

40

(12.2)

63

(1.8)

130

(3.7)

245

(6.9)

500

(14.2)

760

(21.5)

50

(15.2)

56

(1.6)

115

(3.3)

215

(6.1)

440

(12.5)

670

(19.0)

60

(18.3)

50

(1.4)

105

(3.0)

195

(5.5)