PeerlessBoilers ECT-03-120, ECT-04-125, ECT-04-150, ECT-04-175, ECT-05-175 Installation, Operation & Maintenance Manual

...Page 1

EC/ECT

Boilers

Installation,

Operation b

Maintenance

Manual

Pr=-r=-I_LESS"

CAST IRON BOILERS

Page 2

Packaged or Knockdown, Hot Water or Steam Boilers

11 Sizes 3-6 Sections .75 to 3.0 GPH Input 82.9% to 86.6% AFUE

Natural Draft (chimney) Venting

Factory Assembled Sections on Knockdown Boilers

• Reduces Installation Time

High Efficiency Flame Retention Burners

• Choice ofBeckett, Carlin or Riello

Full Plate Swing-Out Door

• Standard on All Boilers

• Provides Easy Access to Combustion Chamber AreaJor Cleaning and Servicing

Large Water Content, Wet Base Section Design

• Ideal for Steam and Large Volume Hot Water Applications

Steel Push Nipples

• Provide a Permanent Woter Tigh[ Seal Between Sections

• Unaffected by Petroleum and Other Contaminants

Easy to Clean

• Flueways carl be Cleaned from Either the Left Side or Top

Deluxe Insulated Enameled Steel Jacket

• Reduces Boiler Heat Loss

Safety Controls

• Probe or Float Type Low Water Cut OffApprovr_d on Steam Boilers

Tankless Coils

• For Domestic Hot Water Production on Hot Water Boilers

• Honeywell Operating Controls

• Barometric Draft Damper

• Taco 007 Circulalor on Packctged WcJler Boilers

• Float Type LWCO on Packagt'd Steam Boilers

\ Ix .,,p_o__ I

• "l_mkless Coils

• Gnlnc!lbs Circulalor on Pctckaged Water Boilers

.,,_ *Pcob<" Tt.ip_" LWCO olt Packaged Sly,am Boilers

P_'_I'It'ss Boilers is i)It'as_'_{ to QI]_'I oll(' QJ l]lt" IIl()sl co_lpr_.lll'llsit,t' iP(llT_lill_] i)fofjFQlll._ ill lh(' ill(_lisll_t]. All Pt,t'_l(_ss r(,sid_'tlti_ll

casl i!ott I)oilt'is irlt'ltt_l_" _t {illl oae ycat tP(llTTII!l{I. A [Jlllilt'tl. l([i'limt' tt,(¢lr(ull{I is ptY)l,i(]t'({ [or lilt" ('(isl iroii ._t'clioiIs o[ P_'('i[('_s

rz'sidt'llliQl ttot It'(lll'I t)oilt't,_. Pt't'rlt',_s also t)r_)t'itl_'s _l liIIlil+'_l I('ll []t'(ll II'(ll'l'Cllll!] Oll IIR" ('CISl il_)l] _;t'('liOIIS Q]'ilS r('_i(l('Illi(I/ slt'Cllfl

I)oilt'Is. l;'it,_" _llld ll'll !]('(l! <t','li'_Kl_'(I [t,(ll'l'(lll_it'_q ()It 131111.% (lli(l Itll)Ol CIl'(' IIolt, (IP_lil(l!)l_'. PI<'_i.';_' ('Oll.'_llll P('('tl('._.'_ [$oil('r.'_ li)r ('OllllIl('l('

{f!(ll'l'(lllll] it!Jorm(lliol£.

Peerless Boilers * 610-367-2153 • www.peerless-heater.eom

FAB EC R_{303 IM)

Prrn_l d _ll U S A

Page 3

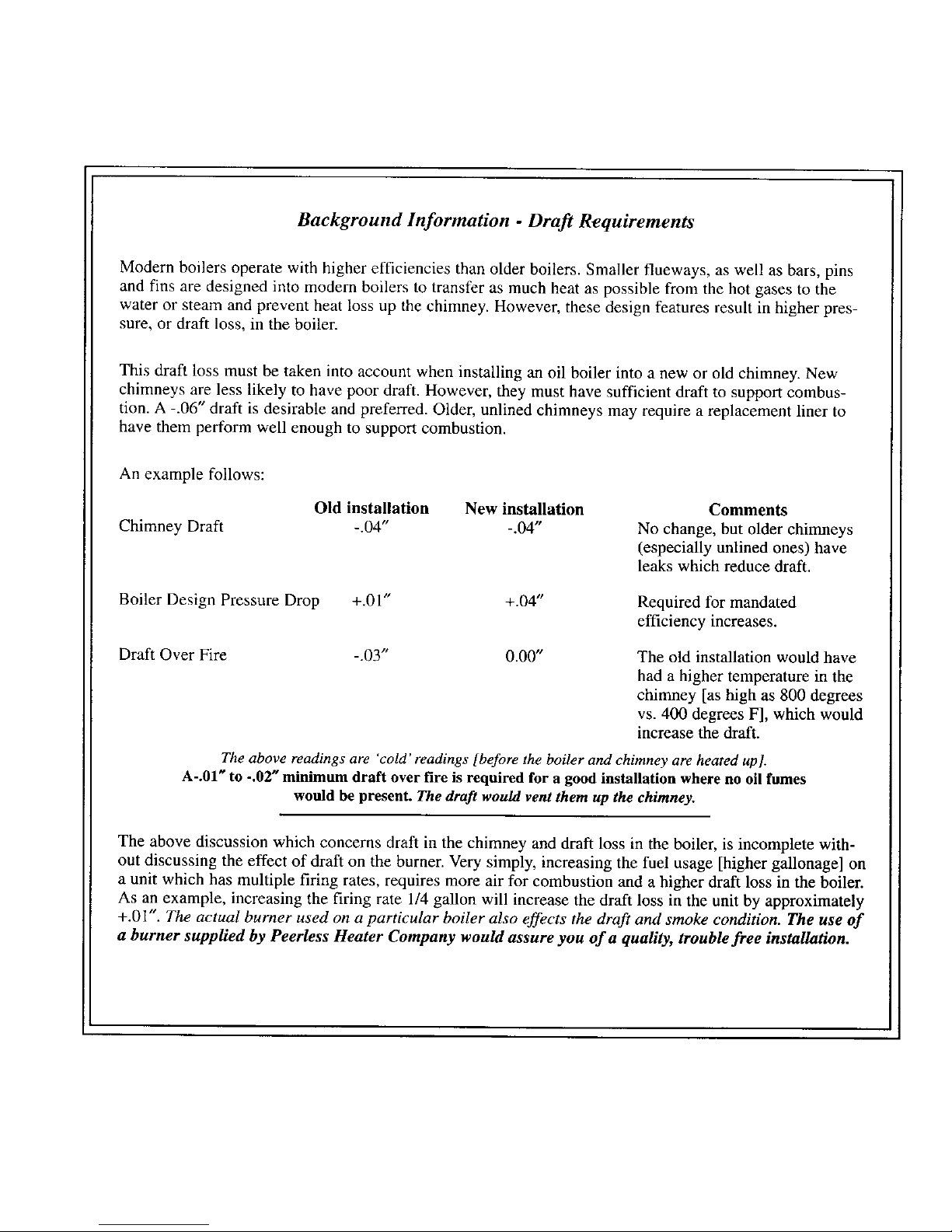

Background Information - Draft Requirements

Modern boilers operate with higher efficiencies than older boilers. Smaller flueways, as well as bars, pins

and fins are designed into modem boilers to transfer as much heat as possible from the hot gases to the

water or steam and prevent heat loss up the chimney. However, these design features result in higher pres-

sure, or draft loss, in the boiler.

This draft loss must be taken into account when installing an oil boiler into a new or old chimney. New

chimneys are less likely to have poor draft. However, they must have sufficient draft to support combus-

tion. A -.06" draft is desirable and preferred. Older, unlined chimneys may require a replacement liner to

have them perform well enough to support combustion.

An example follows:

Chimney Draft

Old installation New installation

-.04" -.04"

Comments

No change, but older chimneys

(especially unlined ones) have

leaks which reduce draft.

Boiler Design Pressure Drop +.01" +.04"

Required for mandated

efficiency increases.

Draft Over Fire -.03" 0.00"

The old installation would have

had a higher temperature in the

chimney [as high as 800 degrees

vs. 400 degrees F], which would

increase the draft.

The above readings are 'cold' readings [before the boiler and chimney are heated up].

A-.01 _ to -.02" minimum draft over fire is required for a good installation where no oil fumes

would be present. The draft would vent them up the chimney.

The above discussion which concerns draft in the chimney and draft loss in the boiler, is incomplete with-

out discussing the effect of draft on the burner. Very simply, increasing the fuel usage [higher gallonage] on

a unit which has multiple firing rates, requires more air for combustion and a higher draft loss in the boiler.

As an example, increasing the firing rate 1/4 gallon will increase the draft loss in the unit by approximately

+.01". The actual burner used on a particular boiler also effects the draft and smoke condition. The use of

a burner supplied by Peerless Heater Company wouM assure you of a quality, trouble free installation.

Page 4

INSTALLATIONINSTRUCTIONS- SERIESECand ECT

Readcarefullybeforebeginningwork.Itwillsavetime.Studythe includeddrawings.

This boilermust beinstalledbya qualifiedcontractor.

Theboilerwarrantycan bevoidedifthe boileris not installed,maintained,andservicedcorrectly.

Theequipmentshallbe installedinaccordancewiththoseinstallationregulationsinforce inthelocalareawheretheinstallationisto bemade,includingthe

currenteditionof NFPA-31.Theseshallbecarefullyfollowedin allcases.Authordieshavingjurisdictionshallbeconsultedbeforeinstallationsaremade.

A- ACCESSIBILITYCLEARANCES

1 - To provide for reasonableconditionsof accessibilityfor servicing,the following minimumclearancesare recommendedbetweenthe boiler and

adjacentwallsor otherappliances--atleast24" inthe front,rearandonboth sides.

B- AIRFORCOMBUSTIONANDVENTILATION

1- Becertainadequatefacilitiesareavailableto provideairfor satisfactorycombustionandventilation.

2- AppliancesLocatedinUnconfinedSpaces.

a. For installationsin unconfinedspaceswith conventionalconstructionandlargeareas suchas basements,the supplyof air for combustionand

ventilationcanusuallybe consideredadequate.

3- AppliancesLocatedinConfinedSpaces.

a. If all air for combustionandventilationis to comefromwithinthebuilding;twoopenings,onenearthe ceilingandone nearthe floorofthe boiler

roomshallbe providedwiththe minimumfreearea ofeachopeningequalto 140sq.in.pergallonofoil burned.

b. If all airfor combustionandventilationisto comefromoutsidethebuilding;twoopenings,one neartheceilingand one nearthefloorofthe boiler

roomshallbeprovidedwiththeminimumfreeareaof eachopeningequalto 35sq.in. pargallonofoil burned.Ifductsare usedto conveytheair,

areasof35 sq.in.pergallonofoil burnedfor verticalductsor 70 sq.in.per gallonofoil burnedfor horizontalductsareto beprovided.Ductsshall

havethesame areaasthefreeareaof theopeningstowhichthey areconnected.

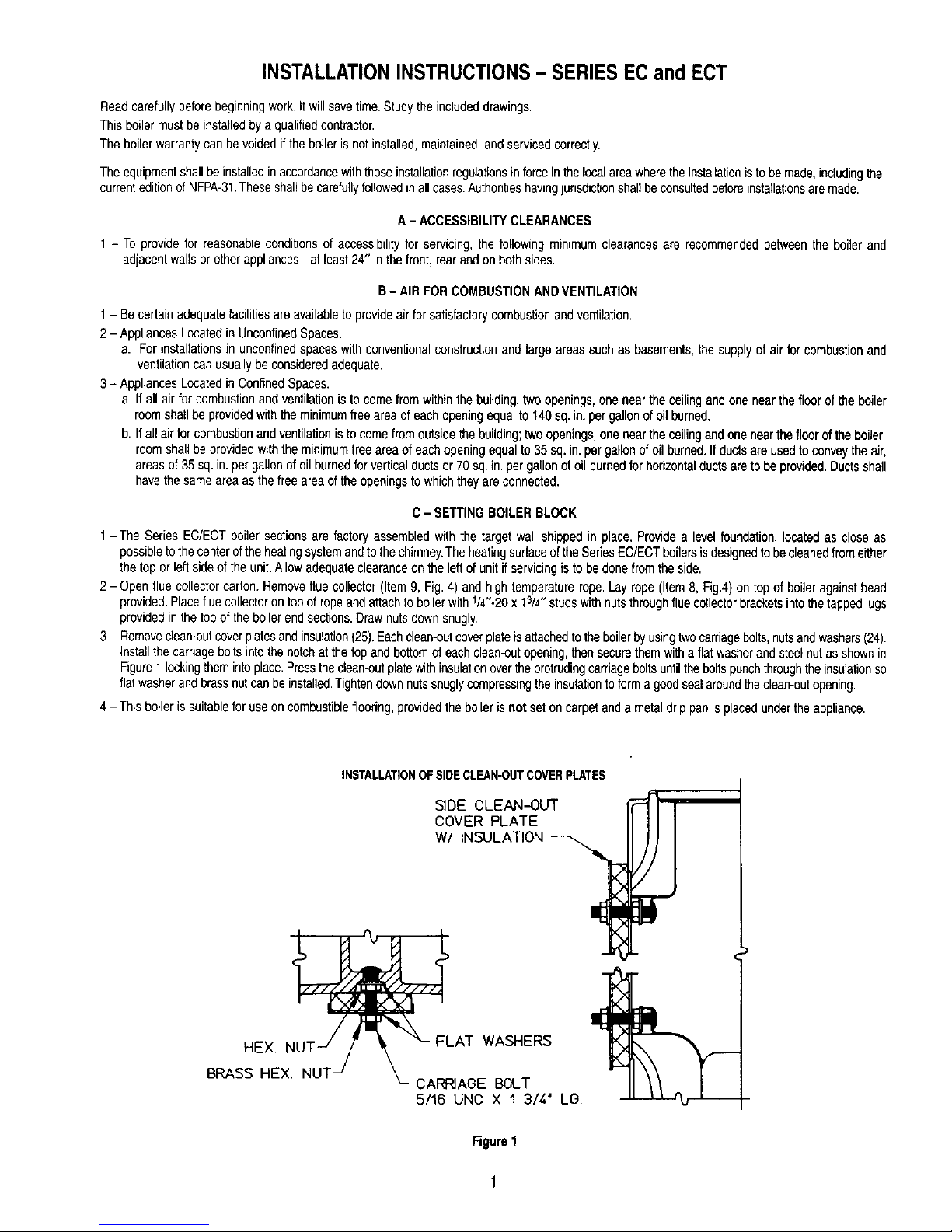

C- SETTINGBOILERBLOCK

1-The SeriesEC/ECT boilersectionsare factoryassembledwiththe target wallshippedin place. Providea levelfoundation,locatedas close as

possibletothecenteroftheheatingsystemandto thechimney.TheheatingsurfaceoftheSedesEC/ECTboilersisdesignedtobecleanedfromeither

thetopor left sideofthe unit.Allowadequateclearanceon the leftof unitif servicingisto bedonefromthe side.

2- Openfluecollectorcarton.Removefluecollector(Item9, Fig. 4) andhightemperaturerope.Lay rope(Item8, Fig.4) ontop of boileragainstbead

provided.Placefluecollectorontop of ropeand attachto boilerwith1/4"-20x13/4"studswithnutsthroughfluecollectorbracketsintothetappedlugs

providedin thetopof the boilerendsections.Drawnutsdownsnugly.

3- Removeclean-outcoverplatesandinsulation(25).Eachclean-outcoverplateisattachedtothe boilerbyusingtwocarriagebolts,nutsandwashers(24).

Installthe carriageboltsintothenotchatthe top andbottomof eachclean-outopening,thensecurethemwith a flatwasherandsteelnutasshownin

Figure1 lockingthemintoplace.Pressthe clean-outplatewithinsulationoverthe protrudingcarriageboltsuntiltheboltspunchthroughtheinsulationso

flatwasherandbrassnutcanbeinstalled,Tightendownnutssnuglycompressingthe insulationto forma goodsealaroundthecleen-outopening,

4- This boileris suitableforuseon combustibleflooring,providedthe boilerisnot seton carpetand a metaldrippanis placedundertheappliance.

INSTALLATIONOF SIDECLEAN-OUTCOVERPLATES

5/16 UNC X 1 3/4" L(3.

Figure1

Page 5

D- SWINGDOORANDOBSERVATIONCOVERASSEMBLY

1- Removeburnermountingplateincludingrightsidemountingstudsfor burnermountingplate(donot removeleftsidestuds)

2- CollecttheSwingDoorCarton(90924)containingthehingeassemblyandhardware.

3- InstallInternalHingeP/NEC1021(Item6, Fig,4)to frontsectionof boilerwith(2)5/16-18UNCx 3/4"hex headcapscrewsand5/16"flatwashers(do

netusethe11/4" longscrews).

4- InstallExternalHingeP/NEC10122(Item7, Fig.4) to theoutsideoftheburnermountingplatewith(2)5/16-18UNCx 11/4" hexheadcapscrews,flat

washers,andnuts.Thecapscrewsshouldbeinsertedthroughthe backoftheburnermountingplate,thenthroughthe hinge.Do NOTtightenExternal

Hingescrewsat thistime.Thiswillallowforalignmentofthe plateonceitis placedinposition.

5- Hangburnermounting plate in position,then close to alignthe remainingthree (3) studson leftside of section.Once alignmentis accomplished,

tightennutson ExternalHinge.DeNOTreinstallnuts!washerson left sidestudsuntilafterjacketinstallation.

6- Removeobservationdoor (Item4, Fig.4) frominsideburnermountingplate.Attachthe observationdoortothe outsideofthe mountingplate.

7- Theremainingswingdoorcartonpartswillbe usedinSectionH,Wiring.

E - JACKETASSEMBLY

1- Referto Page4,Fig,4forexplodedview.Attachthebackpanel(19)tobossesonmiddleofbacksectionwithtwo 1/4"x3/8"trussheadmachinescrews

(20) provided.Thebackpanelhastwo shG"diameterholesclosetothe centerof thepanel.

2- Liftoff theburnermountingplate.Placeeerafeltliner(28)on floorof boilerin frontoftargetwall.

3- Removethe (2)knock-outsinthefrontjacketpanel(23)whichallowclearanceforthehinge.Placethefrontjacketpanelonthe blockand replacethe

burnermountingplate.

4- Attachrightside jacketpanel(22)tothe frontandbackpanelswithsheetmetal screws,

NOTE:ON SERIESECTBOILERS,THEOPTIONALWATERHEATER(17) MUSTBEINSTALLEDINLARGEOPENINGIN BACKSECTION

BEFORETHE LEFTSIDE JACKETPANELSAREATTACHED.

5- Ifwater heaterisused, removeknockout piecesin upperleft side jacketpanel(21)and backjacketpanel(19) beforeinstalling.Attachleftsidejacket

panelsin thesamemanneras the rightsidepanel.

6- Attachthetop panel.Thetop ismadeintwopieces(26&27).Join thetwopiecestogetherwithsheetmetalscrews.Securetoppaneltofrontand back

panelwithsheetmetalscrews.

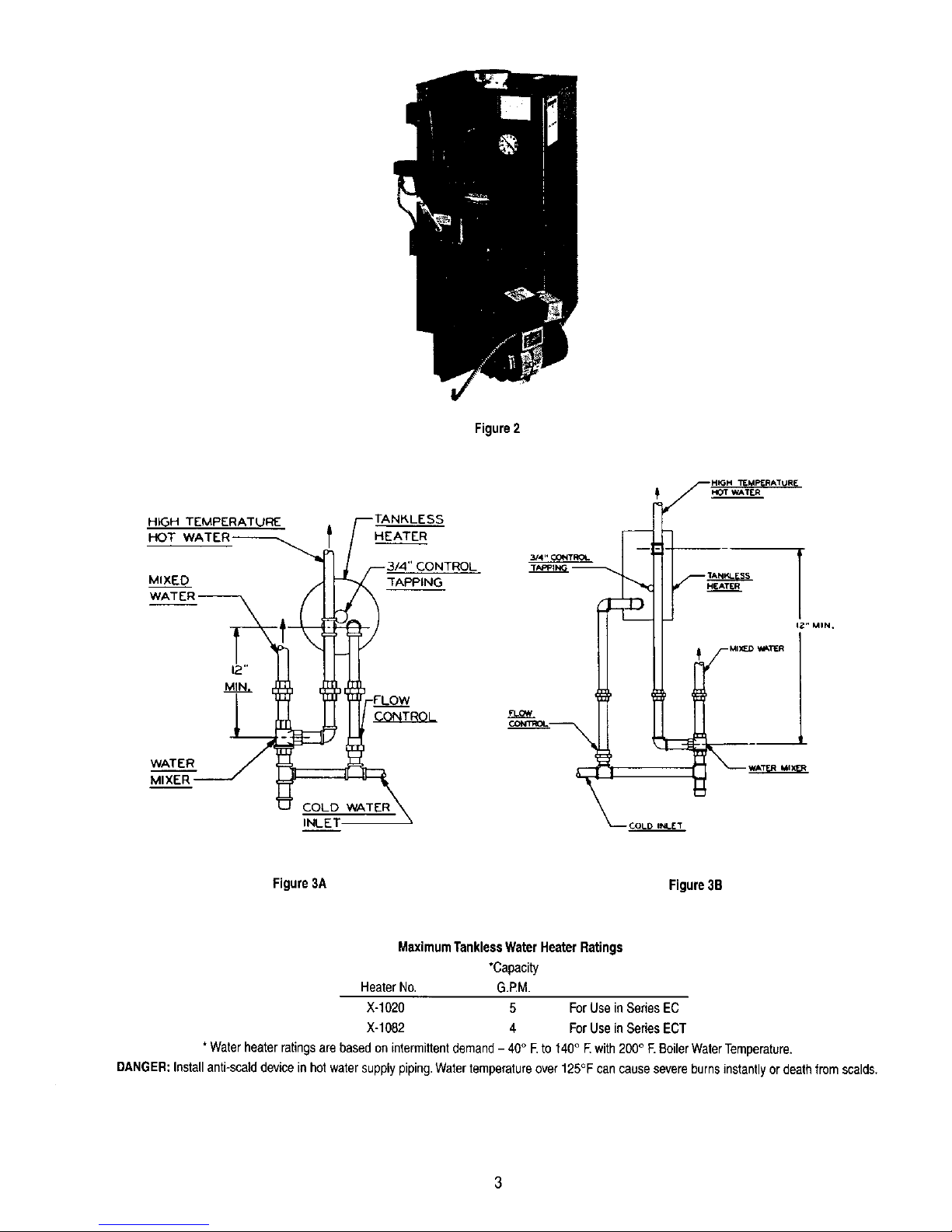

7- Install waterheater(13)whenrequired,inlargeopeninginfrontofboiler.SeeFigure3Aor3Bforsuggestedpiping.Whenwaterheaterisnotemployed,

coverthe heateropeningwithcoverplate(12)or (16).

BESURERUBBERGASKETISIN PLACEBETWEENCOVERPLATEORWATERHEATERPLATEANDBOILERSECTION.

Page 6

Figure2

HIGH TEMPERATUFE

HOT

MIXED

WATER

MIXER

COLD

INLET

HEATER

7lAPPING

CONTROL

3/4" OOfl'rROL -- I_" MIN.

Figure3A Figure3B

MaximumTanklessWaterHeaterRatings

*Capacity

HeaterNo. G.F_M.

X-1020 5 FurUse inSeriesEC

X-t082 4 ForUse inSeriesECT

*Waterheaterratingsarebasedon intermittentdemand- 40° F.to140° E with200° F.BoilerWaterTemperature.

DANGER:Installanti-scalddeviceinhotwatersupplypiping.Watertemperatureovert25°F cancausesevereburnsinstantlyordeathfromscalds.

Page 7

27

_26

-N

._h c

J_h

F4

Page 8

ItemNo.

1

SERIESECand ECT

Part No.

EC-1001

EC-1001-1

X-1096

X-!096-1

EC-10O2

EC-1OO2-1

X-1097

X-1097-1

X-3019

X-1060

X-1031

X-1061

EC-1021

EC-1022

Description

BlockAssembly- EC-03

BlockAssembly- EC-04

BlockAssembly- EC-05

BlockAssembly- EC-06

BlockAssembly- ECT-03

BlockAssembly- ECT-04

BlockAssembly- ECT-05

BlockAssembly- ECT-06

TargetWall

BurnerMountingPlate

ObservationDoor

5/16"-18x 2-1/4" Studsw/Nuts- 5 Req'd

SwingOutBurnerMountingPlateHinge- Internal

SwingOutBurnerMountingPlateHinge- External

HighTemp.Rope3/8" Diameter.48" Long

HighTemp.Rope3/8" Diameter.56" Long

HighTemp.Rope3/8" Diameter.64" Long

HighTemp.Rope3/8" Diameter.72" Long

FlueCollector

FlueCollector

FlueCollector

FlueCollector

1/4"-20x 1-3/4" Studsw/Nuts- 2 Req'd

RubberGasket

CoverPlate

TanklassCoil(OptionalWaterOnly)

3/8"-16x 3/4" HexHal.CapScrews- 6 Req'd

RubberGasket(ECTModels)

CoverPlate(OptionalECTModels)

TanklessHeater(OptionalECTModels)

3/8"-16x 3/4" Hex Hd.CapScrews- 8 Req'd

BackJacketPanel

1/4"-20x 3/8"Truss Hd,Mach.Screws- Cad,Plate- 2 Req'd

UpperLeftSideJacketPanel

UpperLeftSideJacketPanel

UpperLeftSideJacketPanel

UpperLeftSideJacketPanel

EC/ECT-03

X

x

X

X

2 X x

3 X X

4 X X

5 X X

6 X X

7 X X

8 X

X

9 EC-50O0 X

EC-5000-1

EC-5000-2

EC-5000-3 X

10 X-5000 X X

11 X-1023 X X

12 X-1034 X X

13 X-1020 X X

14 X X

15 X-1083 X X

16 X-t084 X X

17 X-t082 X X

18 X X

19 EC-6003 X X

20 X X

21 EC-6007 X

EC-6007-1

EC-6007-2

EC-6007-3 X

ModelNo.

EC/ECT-04 EC/ECT.O5

X

X

X

X

X X

X x

X X

X X

X X

X X

X

X

X

X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X

X

EC/ECT-06

Page 9

ItemNo.

21A

SERIESECand ECT

PartNo.

EC-6008

EC-6008-1

EC-6008-2

EC-6008-3

EC-6O02

EC-6002°1

EC-6002-2

EC-6002-3

EC-6000

Description

LowerLeftSideJacketPanel

LowerLeft SideJacketPanel

LowerLeft SideJacketPanel

LowerLeft SideJacketPanel

RightSideJacketPanel

RightSideJacketPenet

RightSideJacketPanel

RightSideJacketPanel

FrontJacketPanel

5/18"-18x 1-3/4" CarriageBoltw/Nuts

SideClean-OutCoverPlate

RightTopJacketPanel

RightTopJacketPanel

RightTopJacketPanel

RightTopJacketPanel

LeftTopJacketPanel

LeftTopJacketPanel

LeftTopJacketPanel

LeftTopJacketPanel

BaseLiner

BaseLiner

BaseLiner

BaseLiner

EC/ECT-03 EC/ECT-06

X

X

22 X

X

23 X X

24 X X

25 X-1085 X X

26 EC-6005 X

EC-6005-1

EC-6005-2

EC-6005-3 X

27 EC-6004 X

EC-6004-1

EC-6004-2

EC-6004-3 X

28 EC-3000 X

EC-3000-1

EC-3000-2

EC-30O0-3 X

ModelNo.

EC/ECTo04 EC/ECT-05

X

X

X

X

X X

X X

X X

X

X

X

X

X

X

E - PIPING

DONOTPIPEBOILERUNTILAFTERJACKETISINSTALLED.

1- See Figures5 and 6 forsuggestedpipingtothe boiler.Also,seeHydronicsInstituteResidentialHydronicHeatingGuide2000.

2- Makeupcold watersupplyconnectiontothe boiler.

3- Installpressuregaugeortemperature-pressuregaugein tappingprovided.SeeFigure9.

4- Pluga!lopen tappingsin the boilerandfill withwater.Applyapproximatelythirty(30) poundspressure.Checktomakecertainthatalljoints

andfittingsare watertight,

5- Afteralljointsand connectionshavebeenprovenwatertight,removecoldwatersupplyandplugsfromall tappingsthat areto be used.See Figure

9for tappinglocations.

6- The returnpipingto the 1-1/4" NPT lowertappingonthe frontsectionmustbe installedin sucha mannerto assureproperclearanceof the oil

burnerandmountingplatewhenopeningandclosing the burnermountingplate.Peerlesssuggestsusinga 1-1/4"90 degreestreetelbowat this

lowertappingin orderto positionthereturnpipingawayfromthe mountingplateassembly.

NOTE:IFTHISBOILERANDDISTRIBUTINGSYSTEMIS USEDiNCONJUNCTIONWITHAREFRIGERATIONSYSTEM,THECHILLEDMEDIUM

SHALLBE PIPEDIN PARALLELWITHTHEBOILERANDTHE PROPERVALVESAPPLIEDTO PREVENTTHECHILLEDMEDIUMFROM

ENTERINGTHEBOILER.WHENTHEBOILERISCONNECTEDTOHEATINGCOILSLOCATEDINAIRHANDUNGUNITSWHERETHEY

MAYBEEXPOSEDTOREFRIGERATEDAIRCIRCULATION,THEBOILERPIPINGSYSTEMMUSTBEEQUIPPEDWITHFLOWCONTROL

VALVESOROTHERAUTOMATICMEANSTOPREVENTGRAVITYCIRCULATIONOFTHEBOILERWATERDURINGTHECOOLINGCYCLE.

Page 10

I

\ i i

ERON[

ID

_ EQUALIZER

X

REAR

FRONT REAR

Boiler

Model

No, Risers Header Equalizer

EC/ECT-03-075 1-2" 11/4"

EC/ECT-03-1O0 1-2" 1V4"

EC/ECT-03-120 1-2" 1V4"

EC/ECT-04-125 2-2" 21/2', 11/2"

EC/ECT-04-150 2-2" 21/2", 11/2"

EC/ECT-04-175 2-2" 21/2" 11/2"

EC/ECT-05-175 2-2" 3" 11/2"

EC/ECT-05-200 2-2" 3" 11/2"

EC/ECT-05-250 2-2" 3" 11/2"

EC/ECT-06-275 2-2" 3" 1112"

EC/ECT-06-300 2-2" 3" 11/2"

Thereturnfrom systemshouldalwaysenterequalizerthrough

HartfordLoop,2" to4" belownormalwaterline (seedimensional

drawingfornormalwaterline).

STEAM

Figure5

Sizethesupplyand returnconnectionsto suit thesystem.

Pipethe supplyandreturninoneoftwoways:

1) Pipethesupplyfromthetop ofthe rearsectionand

returntothe bottomof thefrontsection.Use the 3/4"

tappinginthe topof thebacksectionforairelimination.

2) As an acceptablealternative,pipethesupplyfromthe

topof thefrontsectionandreturntothe bottomofthe

rearsection.Providean aireliminationmeanswithinthe

supplypiping.

HOTWATER

ALTERNATE

SUPPLY

FRONT

r

ALTERNATE

RETURN

REAR

Figure6

F- OILBURNERINSTALLATION

1- Theoilburneris suppliedwitha mountingflangefixedinposition.

2- Mountthe burnerto theburnermountingplate(3)Figure4 withfour5/16"studsandnutsprovided.

BESUREHIGHTEMPGASKETISBETWEENTHEBURNERMOUNTINGFLANGEANDTHE BURNERMOUNTINGPLATE.

3- Routethe oillinesto avoidinterferencewhenopeningthe platefor boilerservicing.Useflexibleoillinesorcopper.Whenusingflexibleoillines,

providetubinglongenoughto allowthe plateto swingfreelyoveritsentirerange.Whenusingcopper,installflaredcopperdisconnectswithvalves.

4- See Figure7for OilBurnerSpecifications.If exceeding100PSIpumppressureon burnersshownat100PSI,seechartonpage13to determine

therequiredreductioninnozzlesize.

7

Page 11

WAYNE BURNER WITH 100 PSI PUMP PRESSURE

Boiler Burner Air Cone Nozzle Start-UpSettings

ModelNo, ModelNo, I,D, Size FlameLock Off-CycleDamp, AirShutter

EC/ECT-03-075 HS 21/2" NoHoles .7580°A DEL 1 1.0 .50

EC/ECT-03-100 HS 21/2" NoHoles 1.0080"B DEL 1 1.2 1.50

EC/ECT-03-120 HS 21/2"NoHoles 1.2080°B DEL 11/2 1.5 1.75

EC/ECT-04-125 HS 21/2" 6Holes 1.2580°B DEL 1 2.0 2.00

EC/ECT-04-150 HS 21/2" 6Holes 1.5080°B DEL 3 2,0 2.25

EC/ECT-04-175 HS 21/2" 6Holes 1.7580°B DEL 5 2,0 2.50

EC/ECT-05-175 HS 21/2" 6Holes 1.7580°B DEL 5 2.0 2.50

EC/ECT-05-200 HS 21/2" 6Holes 2.00 80° B DEL 5 2,0 3.50

EC/ECT-05-250 HS 21/2" 6Holes 2.50 80° S DEL 8 2.0 5.00

EC/ECT-06-275 HS 3-5/16" Str.Bore 2.7580°B DEL 2 2,0 4.00

EC/ECT-06-300 HS 3-5/16'` Str.Bore 3.00 80° B DEL 2 2.0 4.50

CARLIN BURNER

Boiler Burner Start-UpSettings

ModelNo. ModelNo. Air Shutter NozzleSize PumpPressure HeadDim.A Air Band

EC/ECT-04-125 *99FRD Blank 1.00x 70°B DEL 150 PSI 2 40%open

EC/ECT-04-150 *99FRD Blank 1.25x 60°B DEL 150 PSI 3 60%open

EC/ECT-04-175 *99FRD Blank 1,50x 60°B DEL 150 PSI 4 100%open

EC/ECT-05-175 *99FRD Open 1,50x 60° B HAGO 150 PSI 5 10%open

EC/ECT-05-200 *99FRD Open 1,65x 60° B HAGO 150 PSI 5 45%open

EC/ECT-05-250 *99FRD Open 2,00x 60° B HAGO 150 PSI 8 100%open

EC/ECT-06-275 102CRD Open 2,75x 60°B DEL 100 PSI 7 100%open

EC/ECT-06-300 102CRD Open 3,00x 60°B DEL 100 PSI 9 100%open

*Model99FRDBurnerEquippedwithModel 98022PSCMotor

CARLINEZ-IHP OILBURNERWITHMODEL98022PSC MOTOR

Boiler Burner Start-UpSettings

ModelNo, FiringRate ModelNo, AirShutter NozzleSize PumpPressure AirBand HeadBar

EC/ECT-03-075 .75 EZ-1HP Blank 0.60 x70° BDEL 150 PSI 0.55 0.60- 0.65

EC/ECT-03-100 1.00 EZ-1HP Blank 0.85x70° A DEL 150PSI 0.65 0.85- 1.00

EC/ECT-03-120 1.20 EZ-1HP Blank 1.00x70° A DEL 150PSI 0.80 0,85- 1.00

BECKETTBURNERWITH140 PSIPUMPPRESSURE

Boiler Burner Burner Static Nozzle Start-UpSettings Head

ModelNo. ModelNo. Head Plate Size AirShutter AirBand Setting

AFG-LI* LI* 33/8" .6560" BHAGO 9.0 2 N/A

AFG-L1 L1 33/8" .8560° BHAGO 10.0 1 N/A

AFG-L1 L1 ** 1.0060° B HAGO 9.0 2 N/A

AFG-F6 F6 23/4" 1.1080° A DEL 5.0 1 N/A

AFG-F6 F6 23/4" 1.2580° BHAGO 8.0 1 N/A

AFG-F6 F6 23/4" 1.5080° B HAGO 10,0 3 N/A

AFG-MV1 M-V1-3 -- 1.5060°B HAGO 10.0 3 3

AFG-MV1 M-V1-3 -- 1.7560° B HAGO 10,0 9 3

AFG-MV1 M-V1-5 -- 2.0045° BHAGO I0.0 5 5

CF-375 L1-S -- 2.25450P HAGO 10.0 6 2

CF-375 L1-S -- 2.5045° PHAGO 10.0 6 3

EC/ECT-03-075

EC/ECT-03-100

EC/ECT-03-120

EC/ECT-04-125

EC/ECT-04-150

EC/ECT..04-175

EC/ECT..05-175

EC/ECT,.05-200

EC/ECT..05-250

EC/ECT..06-275

EC/ECT-06-300

* RequiresLowFiringRateBaffle ** Removestaticplatefor 1.20GPHrate.

NOTE:Aboveair settingsare start-upsettingsonly-- finaladjustmentsare to bemadewithcombustiontest instruments.Adjustburnerfor

highestCO2 (Maximum13%)whilemaintaininga0 smokeand-.01to -.02ovediredraft.

Figure7 (continuedon nextpage)

8

Page 12

RIELLOSERIES40 OIL BURNER

Boiler Firing Burner Nozzle Pump Turbulator AirDamper

ModelNo. Rate ModelNo. Size Pressure Setting Setting

EC/ECT-03-075 .75 F5 .60600BDEL 155 .5 2.1

EC/ECT-03-100 1.00 F5 .8560° WDEL 145 2.0 2.6

EC/ECT-03-120 1.20 F5 1.00600WDEL 145 3.0 2.9

EC/ECT-04-125 1.25 F5 1.0O60°W DEL 155 2.5 3.4

EC/ECT-04-150 1.50 F10 1.2560° B DEL 145 1.5 3.1

EC/ECT-04-175 1.75 F10 1.3560° B DEL 165 2.0 2.5

EC/ECT-05-175 1.75 F10 1.3560° B DEL 165 2.0 2.5

EC/ECT-05-200 2.00 F10 1.5060oB DEL 170 2.5 2.8

EC/ECT-05-250 2.50 F10 2.00 60"B DEL 155 3.5 4.2

EC/ECT-06-275 2.75 F10 2.2560° BDEL 150 4.0 4.2

EC/ECT-06-300 3.00 F10 2.50 60° B DEL 145 4.5 4.2

NOTE:AboveTurbulatorand Air DamperSettingsarestart-upsettingsonly-- finaladjustmentsmustbemadewithcombustiontest instruments.

Figure7 (continued)

COVERPLATE 1 1/2_ 1

W/ WARNINGL

_2

BURNER

DISCONNECT BOX

BURNER

_LOWER LEFT

SIDE PANEL

Figure8

G-CONTROLS

1- Applycontrolsas follows:

a. Water Boilers:

installthe limitor operatingcontrol,temperature-pressuregaugeand safetyreliefvalve.See Figure9 for properlocation.

b. SteamBoilers,FloatLowWaterCut-Off:

installpressurelimitcontrol,pressuregauge,gaugeglasstrimand safetyvalve.See Figure9.Forapplicationoffloat lowwatercut-offsee

Figure9 andcontrolmanufacturersinstructionsheetshippedwiththe control.

c. SteamBoilers,PrimaryProbeLowWaterCut-off:

Caution: Donotinstalla probelowwatercut-offin the boilerprimaryprobetappingunlessthe lowwatercut-offis equippedwithatimedon and

off feature.Thecycledofftime willallowthe probelowwatercut-offto sensethe truewaterlevelinthe boilerandeliminatea false

readingcausedfromsensingafoamingorsurgingwatercondition.Failureto usea timedlowwatercut-offcouldresultin a failedheat

exchanger.

NOTE:Longergaugeglassandrodsarerequiredfor usewiththeoptionalCG450 PrimaryProbeLowWaterCut-off.Thegaugeglasscarton,22-

162-10,is providedwitha packagedboiler.Fora KDboilerthelongergaugeglasscartonislocatedin aspecialProbeLowWaterCut-Off

Carton,90759.

PackagedBoilers:TheCG450LWCO,andPA404Alimitareinstalledandwiredatthe factory.Theboilermiscellaneousparts carton,located

withintheboilercrate,containsthelongergaugeglasscarton22-162-10,GaugeValvesCarton20-105-03,fittingsandcomponents.

KDBoilers:A separatePrimaryProbeLowWaterCut-OffCarton,90759is required.ThiscartoncontainstheCG450LWCO,22-162-10longer

glass/rodscarton,3/4"x3" nipple,3/4"x3/4"x1/4"tee,(2) 1/2"x2" nipplesand(2) Vz"couplings.Usethesecomponentsalongwiththosefrom

theSteamTrimCartonandinstallfittingsandcontrolsperFigure11.

NOTE:ThePA404Alimitandsiphonarenot includedas part ofa standardKDboilerofferingfor ECTmodelboilers.

Caution:Pipethe dischargeof thesafetyvalveorsafetyreliefvalvetopreventinjuryin the eventofpressurerelief.Pipethedischargetoadrain.

Pipefull sizeof outlet.

Page 13

1,3

fRONT

3/4" AIR

P_

REAR

(2)

SUPPLY

TANKLESS-

COIL

LOCATION

STEAM

fN

FLOOR

LINE

SIDE F_

,,C,,

COIL 42"

LOCATION

WATER ONLY

Figure9

Boiler

Model

EC/ECT-03

EC/ECT-04

EC/ECT-05

EC/ECT-06

Width

-A-

221/2"

22112"

221/2"

221/2"

Jacket

Depth

"B"

153/4"

191_16"

24118"

288h6"

DIMENSIONS

Length

Height FireBox

"C.... D"

42" 10"

42" 143h8"

42" 183/8"

42" 229/18"

Rearof

Jacketto _LFlue

"E"

83/4"

10;/8"

13"

151/18"

FlueOutlet

Diameter.

-F-

6"

7"

8"

9"

*Dimensionsareapproximate.

DistanceBetween

¢t.Tappings*

"G"

91116"

131k"

17;/18"

215/e"

LOCATION

H

I

L

M

N

O

P

Q

R

S

T

TAPPINGLOCATIONS

SIZENPT

8/4"

3/4"

I/4"

1/2"

2"

8/4"

314"

11/4"

8/4"

11/2"

314-

WATER

N/A

LimitControl

Temperature-PressureGauge

WA

OptionalReturn

SecondaryProbeLowWaterCut-off

SafetyReliefValve

Return

DrainValve

OptionalHighLimit

N/A

STEAM

LowLimitControl

PressureGauge

LimitControl

GaugeGlassandLowWaterCut-off

Return

SecondaryprobeLowWaterCut-off

SafetyValve

N/A

DrainValve

Skim

PrimaryProbeLowWaterCut-off

10

Page 14

McD& M#67PE-2

LOWWATERCUT-OFF

__;OPT'ONAL LCK_TI(]N)

13"

Figure10

LIMIT

USE TAPPINGS A & C

FOR PRIMARY

APPLICATION

,3 NIPPLE

GAUGE

w/ 3/4 x 1/4

BUSHING

CG450 PROBE

GAUGE GLASS

1/2 x 1/2

w/ 1/2 COUPLING

Figure11

11

Page 15

H-WIRING

1- AllelectricalwiringshallbedoneinaccordancewiththeNationalElectricalCodeandLocalRequirements,

2- Locatejunctionboxin the swingdoorcarton.Mountjunctionboxto theholeson the left sideofjacketwith(2)#10 x 1" sheetmetalscrews.

3- Locatethe polarizedharness(es)in the swingdoorcarton. Ifyour cartonhas two polarizedharnesses,selectthe harnesswith malepins.Connect

harnessfromthejunction boxtothelimit(waterboilers)or lowwatercutoff(steamboilers)usingfield-suppliedconduit.Seewiringdiagrams(Fig.12,

13& 14),junctionbox detail(Fig.8), and photos(Fig.2 & cover).Theadditionalharnessisa duplicateofthe harnessnowlocatedin the burnercar-

ton andmaybediscardedifusinga Peerlesssuppliedburner(harnessin burnercartonincludesconduit),

Warning:Improperinstallationofburnerharnesscanallowburnertoenergizewithswingdooropen,creatinga severeburnhazardtoboilermaintenance

personnel

4a- Locatethepolarizedburnerharnessinthe burnercarton.Attachharnessbetweenburnerandjunctionboxasshownin Figure8.

4b- Ifusinganon-Peerlesssuppliedburner,obtainappropriateburnerharnessfroma PeerlessDistributor,or hardwireburnersuchthatburnerswingdoor

cannotbe openedwithoutdisconnectingpower.

*Harnessfor Beckettor Carlinburner- 50233(polarized,21" longconduit)

*Harnessfor Rielloburner- 50234(polarized,28" longconduit)

5_ Forcompleteinformationonservicingandadjustmentofcontrols,refertotheattachedcontrolspecificationsheets.

NOTE:Single PoleSwitchesincludingthoseof SafetyControlsor ProtectiveDevicesshallnotbe wiredin a groundedline.

=

Y

OPERATING CON TROt

FOR STEAM W/

TANKLZSS HZATI_R (3NLY

RT184B BURNER

PRIMARy CON]_ BURNER

J/ BOX

IGNITOR I

INTERRUP'ilED

r--GROUNO

BUI_CR SCREW

A BK _1 BK

MOTOR G

L2 W W

UMIT

STEAM WITH OR

I wo.o T =.ESS

i i "", "------_ 24 V mfZRMOSTAT

-- LINE V(_.TAG/Z

............... LOW V04_TAG_

ALL Y_IRING MUST COMPLY WI1_ APPLIANCE C00ES, (_OINANC[S AN{) R[GULAT]0NS.

GROUND

BK

ADDITIONAL

LIMIT SAFETy S_ TC,HES

CONTROL (WHEN REQUIRED)

_ _BK BK r¸--:_

67 FLOAT TYPE

LWCO

SER_ICE SV_ITCH

(BY INSTALLER)

x <_OT)

--x--x L2 _15/60/I

FUSED DISCONNECT

(BY INSTALLER)

HYOROLIEVEL 650-p/550-p

PROBE TYPE LWC0

(_EN REQU}RED)

Figure12

12

Page 16

ALL I_RING MUST CCMPLy I_TH APPLIANC_ C0(_S, 0JROINANCES AND REGULATION S

Figure13

J_P_ x

H_0LE_L 6_O-P/5_-P

p,R_ ,_o E t.w¢. 0

LS_A __C_ S_eTC_

(BY "VSt;_£_)

• R71S_g g_l_(R LeI_ c

_ ,, _ _,_

L I J ] J J _--_-._I _ FORCED HOT WATER

I[I _ e_< _i_ ij__: \ eK y_ ='-----,_-.... _ WITH TANKLESS HEATER

_j • (_._ HONEYWELL L812AA OR L8124C

] Le_ (ROT)

u_[ _.t_ -- r--- _ FORCED HOT WATER

LO_ "_.t_ .......... v_ _ WITHOUT TANKL ESS HEATER

Figure14

13

Page 17

I - CLEANINGHEATINGSURFACES

NOTE:CLEANBOILERATLEASTONCEPERYEAR.CLEANBOILERFROMTHELEFTSIDEORFROMTHETOE

TO CLEAN:

1 - Turnoffall electricalpowertothe boiler.Disconnectoilburnerwiringharness.

2a- If cleaningfrom theside,removeleftjacketpaneland sidecleanoutcoverplates.

2b- If cleaningfrom thetop, removefluepipe,lefftopjacketpane_andfluecollector.

3 - Brushthe fluepassageswithawirebrushto removeallscaleor soot.

4 - Removescaleandsootfromcombustionchamberbyvacuumcleaningoranyother means.

NOTE:BURNERMOUNTINGPLATEMUSTBEREMOVEDOR SWUNGOPENTOFACILITATETHISOPERATION.TARGETWALLISMADEOF

SOFTCERAMICFIBER.DO NOTDAMAGETHIS MATERIALDURINGBRUSHINGANDVACUUMCLEANING.

5 - Installclean-outcover platesorflue collector.Inspectclean-outcoverplate insulation,flue collectorgasket,or rope seal Replaceanypiecesnot

forminga gastightseal.

6 - Installjacketpanelsandfluepipeas required.

J - CLEANINGTHESERIESECSTEAMBOILERWITH SKIMTAPPING

Thefollowingcleaning procedureshaftbeperformedbya qualifiedserviceperson.Referto Figure9for locationofskimtapping.

1 - Cleanthe boilerasdescribedbelownolaterthanone weekafterthe initialstartup.Cleaningwillbemoreeffectiveifthe boileroperatesa dayor

twoto loosensedimentandimpuritiesin thesystem.

2 -The boilermust becleanedto removeanyaccumulationof oil,grease,sludge,etc.thatmaybe inthe system.Thesesubstancescancause

foamingandsurgingofthe boilerwater,producinganunstablewaterlineandwatercarryovertothe system.

WARNING:CLEANINGTHEBOILERREQUIRESTHEUSEOFVERY HOTWATERAND CORROSIVECHEMICALS.USECAREWHEN

HANDLINGTO PREVENTINJURY,

3 - Connecta 11/2"pipe nippleand shutoffvalveto skimtapping.

4 - Connecta 11/2"drainlineoffofthe skimvalve,runto apointof safedischarge.

5- Closeallvalvesto thesystem.Providea meansof continuousfreshwatertothe boilerforthecleaningprocess.

6- Openthe skimvalve.Fiflthe boileruntilwaterbeginsto flowout of the valve.Shutofffill valve.

7- Usecommonwashingsoda(suchas Armand HammerSuperWashingSoda).Mixthesodawithwaterin a 10quart pailandpourintotheboiler

throughthesafetyvalvetapping.Mixa proportionofone (1)poundofwashingsodaforeach800 squarefeetEDRnetboiterrating.

CAUTION:DONOTLEAVETHEBOILERUNATTENDEDWHILEFIRING.TAKEGREATCARENOTTOALLOWTHEWATERLEVELTODROP

BELOWTHE BOTTOMOFTHEGAUGEGLASSORTOALLOWFRESHWATERMAKEUPTOFLOWINTOO FAST.THISWILL

AVOIDTHE POSSIBILITYOFCAUSINGTHE BOILERSECTIONSTOFRACTURE.

8-Turn burneronand allowtheboilerwatertoheat uptojust belowsteaming(180to 200degreesF).Cycletheburnerto maintaintemperature

duringskimming.Donotallowthe boilerto steam.Steamingmixesupthecontaminantsinthewaterinsteadoffloatingthemat the surface.

9- Openthe make-upwatervalvetocontinuouslyfeed waterto theboiler.Allowwatertoflow outof theskimtapping.

10- Continueskimmingtheboiler untilthewaterflowingfromtheskim tappingflowsclear.Thiswilltakesometime,possiblyseveralhoursfora dirty

system.

11- Afterskimmingiscomplete,closetheskim valveandturn offthe boiler.

12- Closethemake-upwatervalveand openthe boilerdrain valve.

13- Drainthe boilercompletely.Refilland drainagainoneor two timesto makesure allofthe sodahasbeenwashedout.

14- Restorepipingtonormal.Pipea nippleandcap inthe skimvalve.

15- NOTE:Ifthegaugeglassbecomesdirtyagain,thisindicatesmorecontaminantshaveworkedlooseinthe system.Repeatthecleaningand

skimmingprocessas neededtocleanthe system.

14

Page 18

(1)

Boiler

ModelNo,

EC/ECT-03-075

EC/ECT-03-100

EC/ECT-03-120

EC/ECT-04-125

EC/ECT-04-150

EC/ECT-04-175

EC/ECT-05-175

EC/ECT-05-200

EC/ECT-05-250

EC/ECT-06-275

EC/ECT-06-300

(2)

a)HeatingCapacityBTU/Hr.

b)GrossOutput

Water Steam

a 92,000 a 91,000

a 121,000 a 120,000

a 144,008 a 142,000

a 152,000 a 151,000

a 181,000 a 180,000

a 209,000 a208,000

a 214,000 a 212,000

a 241,000 a 240,000

b 286,000 b 286,000

b 321,000 b 321,000

b 347,000 b 347,000

SERIESECAND ECTRATINGS

(3)

NetI-8-RRatings

BTU/H_ Steam BTU/Hr.

Steam Sq.Ft. Water

68,000 283 80,000

90,000 375 105,000

107,000 446 125,000

113,000 471 132,000

135,000 563 157,000

156,000 650 182,000

159,000 663 186,000

180,000 750 210,000

215,000 896 249,000

241,000 1004 279,000

261,000 1083 302,000

(4)

I-B-R

Firing

RateG.P.H.

.75

1.00

1.20

1.25

1.50

1.75

1.75

2.00

2.50

2.75

3.00

Chimney

Size Height

inches Feet

8x8 20

8x8 20

8x8 20

8x8 20

8x8 20

8x8 20

8x8 20

8x8 20

8x12 20

8x12 20

8x12 20

Minimum

Draft

Required

inStack

,03"

,04"

.05"

.03"

,04 "t

,05"

,03"

.04 _r

,05"

.04 _

.05"

(1) BoilerModelNo.mayhavethe followingsuffixletters:

W-Water P-Packaged

S-Steam C-Circulator

Uq3oiler-BurnerUnit (Unassembled) T-TanklessCoil

(2a)HeatingCapacityBTU/Hr.basedon D.O.E.testingprocedureat t3.0% CO_,and -.02" watercolumndraftin firebox.

(2b)GrossOutputBTU/Hr.basedon12.5%CO=,and-.02" watercolumndraft infirebox.

(3) Net I=B=RRatingsbasedontheTestingandRatingStandardforCast IronandSteelHeatingBoilersofThe HydronicsInstituteDivisionof GAMA.

The Net I=B=RRatingsshownincludeallowancefornormalpipingandpick-upload.

Thewaterratingsare basedona pipingandpick-upaltowancefactorof 1.15,steamratingsarebasedona!lowanceof 1.333.

The PeerlessHeaterCompanyshouldbe consultedbeforeselectinga boilerforgravityhot waterinstallationsandinstallationshavingunusualpiping

andpick-uprequirementssuchasexposedpiping,nightshut-down,etc.

(4) Firing rateis basedon a fuel oil with a heatingvalueof 140,000BTUper gallon.Burnerinput basedon maximumaltitudeof 2,000ft.- for other

altitudesconsultfactory.

ADVERSEFUELCONDITIONS

Ifan adversefuelconditionsuchas cold oilexists,it maybe

necessaryto increasethepumppressureto the nozzle.Coldoilis much

hardertoatomizeat 100psicomparedto roomtemperatureoil.Tothe

rightis a chartgivingflowratesofstandardnozzlesizesat 120psiand

140psi pumppressure.

NOTE:Ifit wasnecessarytoincreasethepumppressureabovethe

standard100psi, toeliminateanyconfusionforthe nextrou-

tine servicinga tag mustbeplacedon theburnerindicating

pumppressureandnozzlesize used.

NozzleRating Approx.NozzleRatesGPH

At 100 PSI 120PSI 140 PSI

.50 .55 .59

.65 .71 .77

.75 .82 .89

.85 .93 1.00

.90 .99 1.07

1.00 1.10 1.18

1.10 1.21 1.30

1.20 1.31 1.41

1.25 1.37 1.48

1.35 1.48 1.60

1.50 1.64 1.78

1.65 1.81 1.95

1.75 1.92 2.07

2.00 2.19 2.37

2.25 2.47 2.66

2.50 2.74 2.96

2.75 3.00 3.24

15

Page 19

Series EC/ECT

OH Boilers

Installation,

Operation b

Maintenance

Manual

TO THE INSTALLER:

This manual is the property of the owner and must

be affixed near the boiler for future reference.

TO THE OWNER:

This boiler should be inspected annually by a

Qualified Service Agency.

HI Division ASME

of 9area

PEERLESS ®

CAST IRON BOILERS

PEERLESS HEATER COMPANY

231 NORTH WALNUT STREET • BOYERTOWN, PA 19512-1021 • PHONE 610-367-2153

www.peerless-heater.com

THE PREFERRED HEATING CHOICE

©2002 Peerless Heater Company ECS00O R15 (11/02÷5M)

Printed in U,S,A,

Loading...

Loading...