Page 1

USER’S INFORMATION MANUAL

S

ERIES

63/64™G

AS

B

OILERS

TO THE INSTALLER:

This manual is the property of the owner and must be affixed near the boiler

for future reference.

TO THE OWNER:

This boiler should be inspected annually by a Qualified Service Agency.

TO BE COMPLETED BY THE INSTALLER

Service Agency Phone No.

Address

Boiler Model No. Serial No. Date of Installation:

If the information in this manual is not

followed exactly, a fire or explosion

may result causing property damage,

personal injury or loss of life.

– Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

– WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch;

do not use any phone in your

building.

• Immediately call your gas supplier

from a neighbor’s phone. Follow the

gas supplier’s instructions.

• If you cannot reach your gas supplier,

call the fire department.

– Installation and service must be

performed by a qualified installer,

service agency or the gas supplier.

– Ne pas ranger ou utiliser de la gazoline ou

d’autres liquides ou gaz inflammables à

proximité de cet appareil ou d’un autre du

même type.

– QUE FAIRE SI VOUS DÉTECTEZ UNE

ODEUR DE GAZ

• Ne pas tenter d’allumer l’appareil.

• Ne toucher à aucun interrupteur

électrique ; n’utiliser aucun appareil

téléphonique dans l’immeuble.

• Contacter immédiatement votre fournisseur

de gaz à partir du téléphone d’un voisin.

Suivre les instructions données par votre

fournisseur de gaz.

• S’il est impossible de rejoindre le

fournisseur de gaz, appeler le service

des incendies.

– L’installation et l’entretien doivent être

effectués par un installateur qualifié, une

société d’entretien ou le fournisseur de gaz.

PB HEAT, LLC

131 S. CHURCH ST • BALLY, PA 19503

TT8067 R3 (11/14-3M)

Printed in U.S.A.

©2014 PB Heat, LLC. All rights reserved.

WARNING

Négliger de suivre ces instructions à la

lettre pourrait provoquer un incendie ou

une explosion causant des dégâts

matériels, des blessures ou la mort.

MISE EN GARDE

Page 2

2

Basic Operation

Service on this boiler should be undertaken only by trained and skilled personnel from a

qualified service agency.

Should overheating occur or the gas supply fail to shut off, do not turn off or disconnect the

electrical supply to the pump. Instead, shut off the gas supply at a location external to the

appliance.

Do not use this boiler if any part has been under water. Immediately call a qualified service

agency to inspect the boiler and to replace any part of the control system and any gas control

which has been under water.

A. General. This water boiler is a natural draft appliance and is equipped with controls for proper

operation. All controls must be in proper working order. Contact a qualified service agency to provide

annual maintenance as specified in the Installation, Operation and Maintenance Manual.

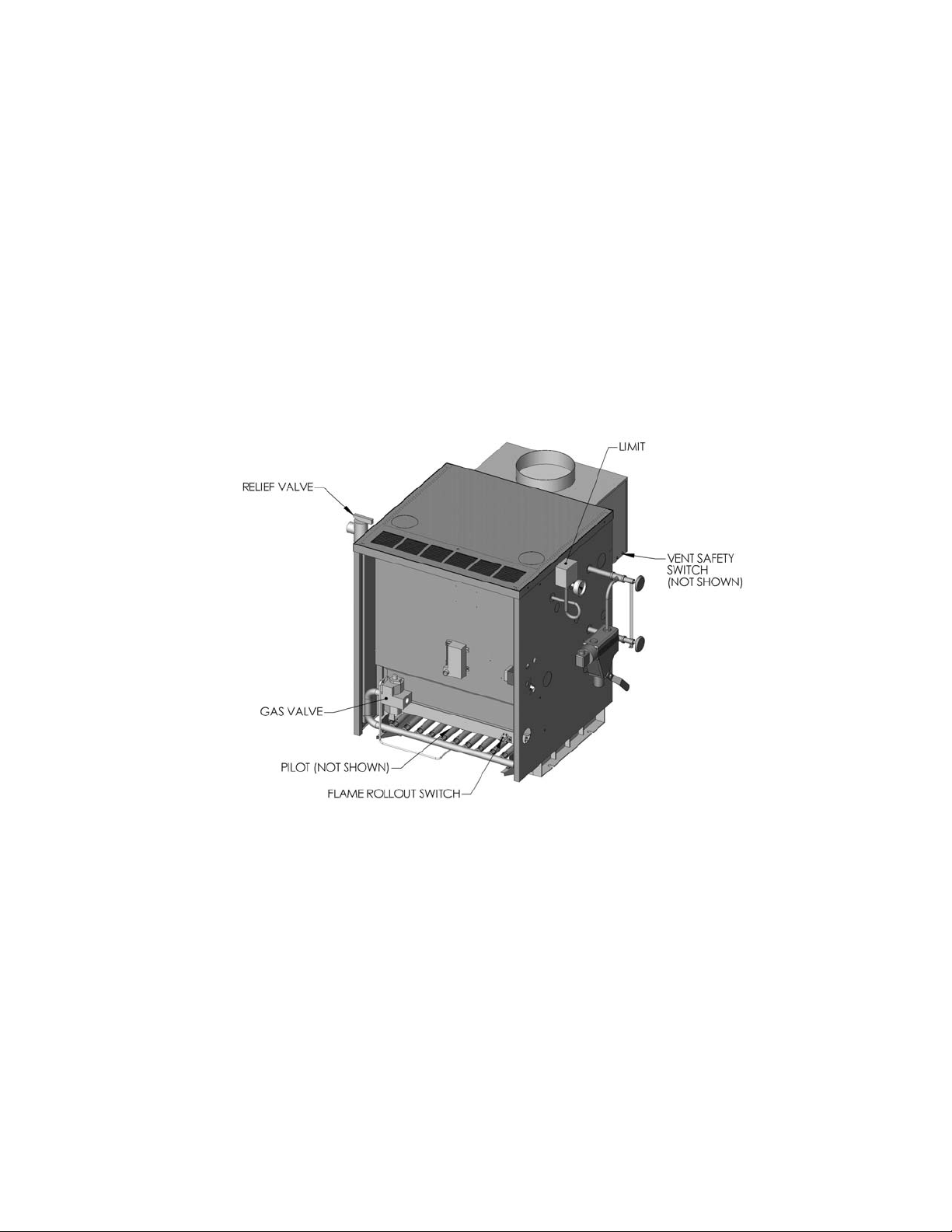

B. Control Locations. See Figure 1 for Control and Safety Device Locations.

1a. Limit (Steam Boiler). An electrical device that automatically interrupts the boiler operation when

the steam pressure exceeds the “CUT IN” pressure plus the differential (1 to 5 psi). Maximum

Pressure setting is 14 psig. The set point is usually less than 5 psig.

Original equipment with this boiler is a Honeywell PA404A1009. Boiler operation is interrupted

when the steam pressure exceeds the the “CUT IN” pressure plus the differential. Boiler operation

resumes automatically when the system pressure falls below the “CUT IN” pressure.

1b. Limit (Water Boiler). An electrical device that automatically interrupts the boiler operation when

the water temperature exceeds the set point. Maximum temperature setting is 220°F.

Boiler operation is interrupted when the water temperature exceeds the set point. Boiler operation

resumes automatically when the water temperature falls to approximately 15°F below the set point.

1c. Limit Control may incorporate a low water cut-off feature that will interrupt boiler operation upon

loss of water in the boiler. If the low water cut-off function is activated to interrupt boiler operation,

follow the instructions TO TURN OFF GAS TO THE APPLIANCE (see Figures 3-5) and contact a

qualified service agency.

2. Flame Rollout Switch (FRS). An electrical device that automatically interrupts the boiler operation

when excessive heat is present in the combustion area. The control is a thermal fuse device that

will require replacement if it is activated. If the control has been activated to interrupt the boiler

operation, do not attempt to restart the boiler. Contact a qualified service agency.

3. Blocked Vent Switch (BVS) An electrical device that automatically interrupts the boiler operation

when there is a blockage in the vent pipe or chimney. The control is located on the side of the draft

hood and is a manual reset device. If the control is activated to interrupt operation of the boiler, do

not attempt to restart the boiler. Contact a qualified service agency.

WARNING

CAUTION

Page 3

3

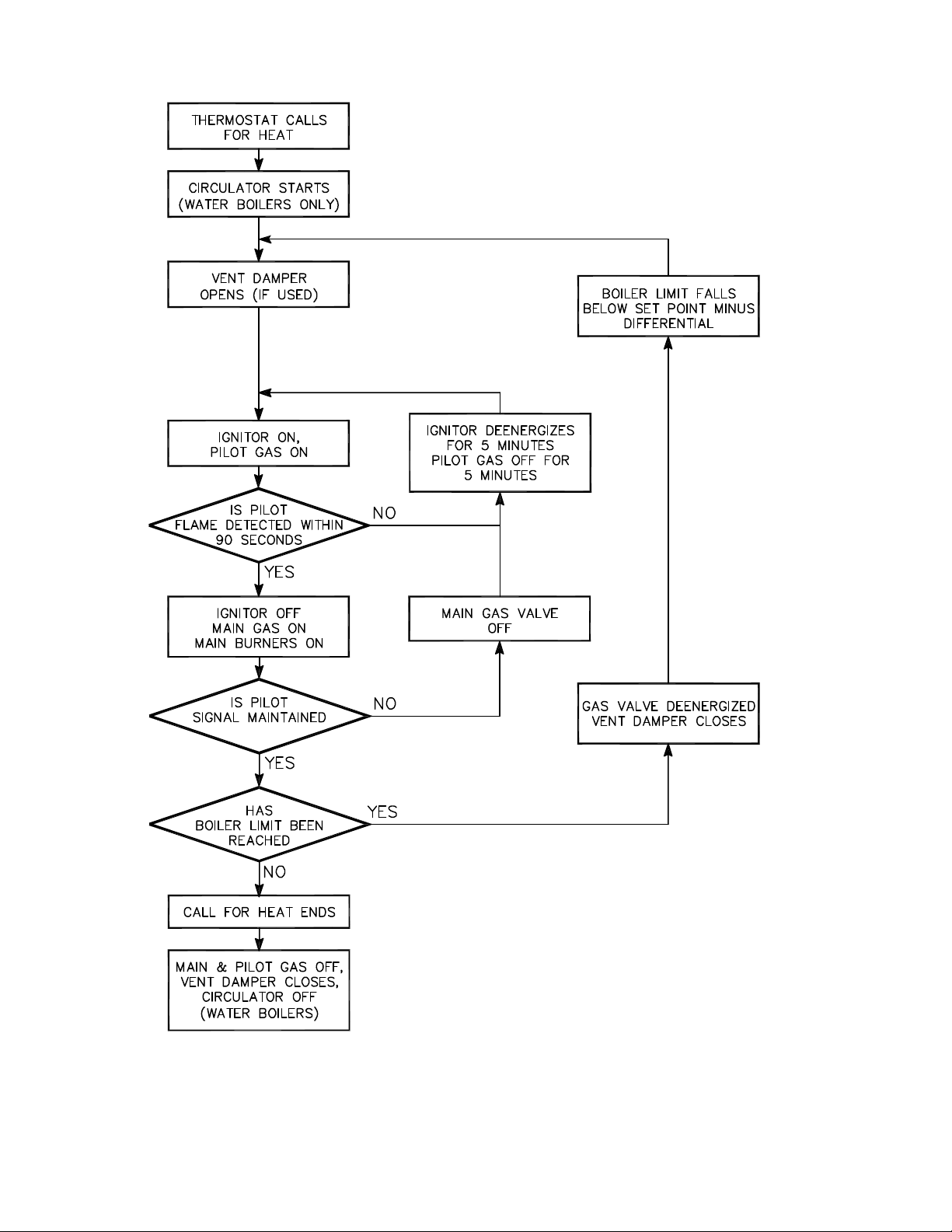

4. Pilot. The pilot provides an ignition source for the main burners. Your boiler has either a standing

(continuous) pilot or an intermittent (spark ignited) pilot. The standing pilot should always be lit

while the intermittent pilot ignites only when there is a call for heat and extinguishes when the call

for heat ends. See Figure 6.

5. Gas Valve. The gas valve monitors pilot flame and regulates gas flow to the burners and pilot.

6. Safety Relief Valve. A mechanical device that protects the boiler against excessive pressure. The

safety relief valve can discharge a large amount of steam or hot water – the installer should

provide piping to discharge water near the floor close to a floor drain. If the safety relief valve

discharges water, follow the instructions TO TURN OFF GAS TO APPLIANCE on the Lighting

Instructions affixed to the inside of the removable front jacket panel (see Figures 3 through 5 for

typical lighting instructions), and contact a qualified service agency.

C. Lighting Instructions. Instructions to place the boiler in operation and to turn off the boiler are shown

on the Lighting Instructions Label posted on the inside of the front jacket panel of the boiler. Typical

lighting instructions are shown in Figures 3 through 5.

Figure 1: Control Location

Page 4

4

Figure 2: Sequence of Operation Intermittent Pilot

Page 5

5

Figure 3: Operating Instructions, Spark Ignition

63-03 thru 64-08 Natural Gas & LP Gas, 64-09 thru 64-12 LP Gas

Page 6

Figure 4: Operating Instructions, Spark Ignition

63-03 thru 64-08 Natural Gas & LP Gas, 64-09 thru 64-12 LP Gas

Page 7

7

SPRK 7000DERHC 9363R REV.0

FOR YOUR SAFETY READ BEFORE LIGHTING

WARNING: If you do not follow these instructions exactly, a fire or explosion may

result causing property damage, personal injury, or loss of life.

OPERATING INSTRUCTIONS

TO TURN OFF GAS TO APPLIANCE

1. Set the thermostat or operating control to lowest

setting.

2. Turn off all electric power to the appliance if service is

to be performed.

3. If the gas valve is not visible, remove the control

access panel.

4. Turn the gas control knob clockwise to "OFF".

5. Replace control access panel, if applicable.

1. STOP! Read the safety information above on this

label.

2. Set the thermostat or operating control to lowest

setting.

3. Turn off all electric power to the appliance.

4. This appliance is equipped with an ignition device

which automatically lights the pilot. Do not try to light

the pilot by hand.

5. If the gas valve is not visible, remove control access

panel.

6. If the gas control knob is not in the "OFF" postion,

turn the knob clockwise to "OFF".

7. Wait five (5) minutes to clear out any gas. Then smell

for gas, including near the floor. If you smell gas,

STOP! Follow "B" in the safety information above on

this label. If you don't smell gas, go to the next step.

8. Turn the gas control knob counterclockwise to

"ON".

9. Replace control access panel, if applicable.

10. Turn on all electrical power to the appliance.

11. Set thermostat or operating control to desired setting.

12. If the appliance will not operate, follow the

instructions "To Turn Off Gas To Appliance"

and call your service technician or gas supplier.

A. This appliance is equipped with an ignition device

which automatically lights the pilot. Do not try to

light the pilot by hand.

B. BEFORE OPERATING smell all around the appliance

area for gas. Be sure to smell next to the floor

because some gas is heavier than air and will settle

on the floor.

WHAT TO DO IF YOU SMELL GAS

Do not try to light any appliance

Do not touch any electric switch;

do not use any phone in your building.

Immediately call your gas supplier from a

neighbor's phone. Follow the gas supplier's

instructions.

If you cannot reach your gas supplier,

call the fire department.

C. Use only your hand to push in or turn the gas control

knob. Never use tools. If the knob will not push in or

turn by hand, don't try to repair it, call a qualified

service technician. Force or attempted repair may

result in a fire or explosion.

D. Do not use this appliance if any part has been under

water. Immediately call a qualified service technician

to inspect the appliance and to replace any part of the

control system and any gas control which has been

under water.

Gas Control Knob

(shown in "OFF"

position)

Figure 5: Operating Instructions, Spark Ignition

64-09 thru 64-12 Natural Gas

Page 8

8

Product Safety Information

Refractory Ceramic Fiber Product

This appliance contains materials made from refractory ceramic fibers (RCF). Airborne RCF

fibers, when inhaled, have been classified by the International Agency for Research on Cancer

(IARC), as a possible carcinogen to humans. After the RCF materials have been exposed to

temperatures above 1800°F, they can change into crystalline silica, which has been classified by

the IARC as carcinogenic to humans. If particles become airborne during service or repair,

inhalation of these particles may be hazardous to your health.

Avoid Breathing Fiber Particulates and Dust

Suppliers of RCF recommend the following precautions be taken when handling these

materials:

Precautionary Measures:

Provide adequate ventilation.

Wear a NIOSH/MSHA approved respirator.

Wear long sleeved, loose fitting clothing and gloves to prevent skin contact.

Wear eye goggles.

Minimize airborne dust prior to handling and removal by water misting the material and avoiding

unnecessary disturbance of materials.

Wash work clothes separately from others. Rinse washer thoroughly after use.

Discard RCF materials by sealing in an airtight plastic bag.

First Aid Procedures:

Inhalation: If breathing difficulty or irritation occurs, move to a location with fresh clean air.

Seek immediate medical attention if symptoms persist.

Skin Contact: Wash affected area gently with a mild soap and warm water. Seek immediate

medical attention if irritation persists.

Eye Contact: Flush eyes with water for 15 minutes while holding eyelids apart. Do not rub eyes.

Seek immediate medical attention if irritation persists.

Ingestion: Drink 1 to 2 glasses of water. Do not induce vomiting. Seek immediate medical

attention.

User Maintenance

WARNING

Page 9

9

Service on this boiler should be undertaken only by trained and skilled personnel from a

qualified service agency. Inspections should be performed at intervals specified in the

Installation, Operation and Maintenance Manual and this User’s Information Manual. Maintain

manuals in a legible condition.

Keep boiler area clear and free of combustible materials, gasoline and other flammable vapors

and liquids.

Do not place any obstructions in boiler room that will hinder flow of combustion and

ventilation air.

A. General Housekeeping (Continuous).

1. Keep boiler area clear and free of combustible materials and obstructions to the free flow of

combustion and ventilation air to the boiler.

2. Do not store or use gasoline or other flammable vapors or liquids in the vicinity of the boiler or any

other appliance.

3. Do not store or use sources of hydrocarbons in the vicinity of the boiler. Sources of hydrocarbons

include bleaches, cleaners, chemicals, sprays, paint removers, fabric softeners and refrigerants.

4. Check safety relief valve for water leakage. If leakage exists, contact a qualified service agency.

B. Inspect Vent System (Monthly).

1. The vent pipe must be continuous to chimney with no separations, obstructions, or sags. Vent pipe

must be supported at minimum 4 foot intervals and secured with sheet metal screws.

2. The vent system must not have signs of continuous wetness. If signs of continuous wetness are

observed, contact a qualified service agency.

3. The vent system must not have signs of deterioration from corrosion or other sources. If there is

evidence of deterioration contact a qualified service agency.

C. Inspect Pilot and Main Burner Flames (Monthly).

1. Remove front jacket panel by lifting and pulling out.

2. Adjust thermostat to highest setting. Verify operation follows Sequence of Operation (see page 3).

3. View flames through observation port. See Figure 1.

4. Check pilot flame. See Figure 6. The pilot flame should be medium blue covering approximately

3/8" to 1/2" of the thermocouple. If the flame is yellow and lazy, follow instructions TO TURN OFF

GAS TO APPLIANCE (see Figures 3-5), and contact a qualified service agency.

5. Check main burner flames. See Figure 6. The flames should have clearly defined inner cones

approximately 1-1/2" high and should have a very sharp blue color characteristic. If the flame is

yellow and lazy, follow instructions TO TURN OFF GAS TO APPLIANCE (see Figures 3-5), and

contact a qualified service agency.

6. Adjust thermostats to normal setting.

7. Install front jacket panel.

WARNING

Page 10

10

D. Controls (as required by control manufacturer)¹.

1. Safety Relief Valve. Conduct try lever test as outlined in manufacturer’s instruction tag on the

safety relief valve.

2. Low Water Cut-off (if used). Follow instructions provided by control manufacturer.

E. General Inspection and Maintenance (Annual). For continued safe operation a qualified service

agency must provide a more detailed inspection of burners, heat exchanger and vent system, and

provide maintenance as specified in the Installation, Operation and Maintenance Manual.

Figure 6: Pilot and Main Burner Flames

1

Controls maintenance may be part of annual inspection and maintenance by a qualified service agency if annual frequency is

specified by controls manufacturer.

Loading...

Loading...