PeerlessBoilers 211A-07, 211A-04, 211A-05, 211A-06, 211A-08 Installation, Operation & Maintenance Manual

...Page 1

211A

Boilers - Steam

Installation,

Operation

Maintenance

Manual

PEEI_LESS _

CAST IRON BOILERS

Page 2

Factory Packaged, Hot Water or Steam

43 Sizes 4-46 Sections 630 to 9450 MBH Input 80% Combustion Efficiency

Natural or LP Gas

Natural Draft (chimney) Venting

Large Water Content

• Ideal for Steam and Large Volume Hot Water Jobs

Low Profile Design

• Horizontal to Vertical Draft Divel+ter

• Ideal.]br Installations with Low Ceilings

Individual Draw Rods

• For Ease of Assembly

Unique Fie_x-Sea! Flow Port Gaskets

• Injection Molded for SLq)eHor PerJ_)rmance and Flexibtlily

• Assures a Water Tight Seal Betweer_ Sections

• For Ease of Installation

Deluxe Insulated Enameled Steel Jacket

• Reduces Boiler Heat Loss

Tankless Coils

• For Domestic Hot Water Production on Hot Water Boilers

Safety Controls

• Low Water CubOJ]on

Steam Boilers • Honeywell Operating Controls

• Float and Probe Type LWCO on Steam Boilers

• Manual Reset High Limit Control

? • 5' ¸¸

• Tankless Coils.for Hot Water Boilers

• Modulating Firing Systems

• Electronk: Control Systems

• FM and IRI Control Systems

Ill IIll' lll(_ll>,II'l]. All [)('_'/[('_,:_ {'o/llnlt'Ill(ll ((I._/ II_Jll ])olhffN i/l('hld('_l ]Jill. oIIt" {l('(u IptlFI'(IIII{]. A

[[llllll'(_. /I'll ]]<'(11 IIl(lll'(lllll] 011 lilt' I tl:_l I1011 _,l "l /l(Jl[_ i.% _)lOl_itl('([ 101 (ll[ ('Ollllll('l('l(l[ lI{ll [p(I{('I CIII(I

%1('(1111 [)Oil['l_, [.'HI(, (llttl I('11 !]t't4l t'\llqltlt'(] II'(dll(llllit'_ Oil I)(l!'lF; (llJ(/ l(lt)(ll (ll_, llOlp (IlyUI(I[)I(,, CAST IRON BOILENS

1_1('(1_" ( I)IL'.,Illl /)('('l!(,.%N l [_'(lll'l ( (t?!lt)(l!l{ j [OI ( ll!l{[)_('!<" Ip(lll(l?lll] II!tOl'lll(l[[(lll

Peerless Heater Company • 231 North Walnut Street * Boyertown, PA 19512 1021 • 610-367-2153 • www.peerless-heater.com

FA[_ 211A (9/02 3MI

pnrlh (I ,fl U S A

Page 3

READ THESE INSTRUCTIONS CAREFULLY BEFORE BEGINNING THE INSTALLATION

[_ STUDY THE CONTROL FOLDER AND CONSULT DRAWINGS

The equipment shall be installed with those installation requirements of

the authority having jurisdiction or, in the absence of such requirements,

to the current edition of the Nationa/ Fue/ Gas Code, ANSI

Z223.1/NFPA54.

Where required by the authority having jurisdiction, the installation must

conform to American Society of Mechanical Engineers Safety Code for

Controls and Safety Devices for Automatically Fired Boi/ers, ANSI/ASME

CSD-1.

PEERLESS

CAST IRON BOILERS

PEERLESS HEATER COMPANY

231 NORTH WALNUT STREET • BOYERTOWN, PA 19512-1021 • PHONE 610-367-2153

www.peerless-heater.com

THE PREFERRED HEATING CHOICE

Page 4

TABLE OF CONTENTS

1. PREPARE THE BOILER LOCATION 3

ACCESSIBILITY CLEARANCES .................................. 3

COMBUSTIBLE CONSTRUCTION CLEARANCES..... 3

AIR FOR COMBUSTION AND VENTILATION ............. 3

CHIMNEY OR VENT .................................................... 4

BOILER SETTING ........................................................ 6

2. ASSEMBLE THE BASE 7

BASE ASSEMBLY ....................................................... 7

INSTALL THE PILOT BURNERS ................................. 8

3. PLACE THE BOILER SECTIONS 13

PREPARATION .......................................................... 13

PLACING THE SECTIONS ........................................ 13

HYDROSTATIC TEST THE BOILER ......................... 14

4. INSTALL THE FLUE COLLECTOR 15

5. PIPE THE BOILER 17

PREPARATION .......................................................... 17

SUPPLY PIPING ........................................................ 17

RETURN PIPING ........................................................ 17

MULTIPLE BOILER INSTALLATIONS ...................... 19

6. INSTALL THE JACKET _ DRAFT HOOD 21

PREPARE THE PARTS .............................................. 21

APPLY CLEANOUT COVER PLATES ....................... 21

APPLY JACKET END ASSEMBLIES ........................ 21

211A-B4 through 211A-08 ONLY ............................. 21

211A-09 8 LARGER ONLY ........................................ 21

APPLY JACKET TOP PANELS ................................. 22

APPLY LOWER END PANELS .................................. 22

APPLY PLATES AND LABELS ................................. 22

7. CONNECT GAS PIPING 27

INSTALL GAS TRAIN ............................................... 27

CONNECT PILOT GAS TUBING ............................... 27

INSTALL VENT AND BLEED PIPING ........................ 27

INSTALL GAS SUPPLY PIPING ................................ 28

TEST GAS SUPPLY PIPING ...................................... 28

8. INSTALL CONTROLS AND TRIM 30

INSTALL SAFETY VALVES ...................................... 30

INSTALL BLOWDOWN VALVES .............................. 30

INSTALL LOW WATER CUTOUT(S) ........................ 30

INSTALL PRESSURE CONTROLS ............................ 30

9. WIRE THE BOILER 35

CONNECT SUPPLY WIRING .................................... 35

PREPARE REMAINING CONTROLS ........................ 35

INSTALL CONTROL WIRING .................................... 35

10. STARTING THE BOILER 38

CHECK THE PIPING .................................................. 38

FILL THE BOILER ...................................................... 38

STUDY LIGHTING INSTRUCTIONS ......................... 38

RUN PILOT CHECK-OUT .......................................... 38

CHECK MAIN BURNER SYSTEM ............................. 38

CHECK BOILER CONTROLS .................................... 39

CLEAN THE BOILER ................................................. 39

11. LIGHTING INSTRUCTIONS - TYPICAL 40

TO LIGHT THE BOILER ............................................. 40

TO SHUT DOWN THE BOILER ................................. 40

PILOT FLAME FAILURE ............................................ 40

12. OPERATION _ MAINTENANCE

13.

14.

15.

41

PLACING BOILER IN OPERATION ........................... 41

TO SHUT DOWN THE BOILER ................................. 41

MAINTENANCE - ANNUAL ..................................... 42

MONTHLY MAINTENANCE ..................................... 42

WEEKLY MAINTENANCE ......................................... 42

DAILY MAINTENANCE ............................................. 42

TROUBLESHOOTING - SERVICE TIPS 43

BOILER RATINGS _ DIMENSIONS 45

REPAIR PARTS- SERIES 211A 48

Page 5

USING THIS MANUAL

1. This boiler must be installed by a qualified contractor•

E. The boiler warranty can be voided if the boiler is not

installed, maintained and serviced correctly.

1. For new and existing installations, a Steam Installation

Survey is available from Peerless Heater Company• The

survey will provide information on how a steam boiler

works with your specific system and will provide an

overview of steam system operation in general•

2. You can also use this survey to locate system problems

which will have to be corrected. To obtain copies of the

Steam Installation Survey, contact your Peerless

representative.

1. Check the system to make sure there are no leaks or

overfilling problems which might cause excessive

make-up water to be added. Make up water causes liming

in the boiler and brings in oxygen. Oxygen can cause

severe damage to the boiler through oxygen corrosion

pitting.

2. Clean the boiler as described in this manual Poor water

quality will cause foaming, priming and overfilling of the

system. Too much sediment in the water will cause

build-up in the boiler and could result in cracked sections

due to overheating.

3. If the condensate return time lag is too long, this boiler

may not work correctly with gravity return or with a

condensate return unit. Long time lags will cause

make+up water to be added to the boiler, resulting in

flooding of the boiler, carryover to the system, and

excessive make-up water addition. You will need to install

a boiler feed system to prevent problems in such cases.

4. Do not use chemicals or substances in the boiler

or system which contain petroleum or its

derivatives. This will damage the boiler seals.

i. We have provided suggested piping diagrams which will

cover most applications of this boiler.

2. Follow these guidelines to make sure the boiler will

operate correctly. Pay close attention to pipe sizing and

location of risers and returns.

]+This manual provides wlrmg diagrams and lighting

instructions for standard systems only.

2 Use the Lighting Instructions and Wiring Diagrams

provided with the boiler to make sure they represent fire

controls provided

I. Throughout this manual you will see special attention

boxes intended to supp]enrent the instructions and make

special notice of potential hazards. These categories

mean, in the judgment of Peerless Heater Company:

Indicates special attention is

needed, but not related to

potential personal injury or

property damage.

Indicates a condition or hazard

which will or can cause minor

personal injury or property

damage.

Indicates a condition or hazard

which could cause severe

personal injury, death or major

property damage.

Indicates a condition or hazard

which will cause severe personal

injury, death or major property

damage.

Page 6

1, PREPARE THE BOILER LOCATION

|

i

Vent,typcal _ 6j] 6',,

] P,p,ng,Typcal "-_ (3 if''_

II 1]

mm

(:-'--_ Front View C

Figure 1: Clearance Requirements

I The following recommendations allow for reasonable

access to the boiler Local codes or special conditions

may require greater clearances•

•

a) For servicing the boiler: provide 48" between tile

conh'ol manifold and adjacent wall or other appliance

b) For access to draft hood or passage to access the boiler 4

control manifold(s): provide 48" between the side of

the boiler and adjacent wall or other appliance.

c) See Figure 1, Clearances with an "S" are minimum

clearances for service accessibility. 5.

1. This boiler is design certified for the following clearances

to combustible construction.

a 24" between the front, sides and rear of the jacket

• 6" from steam and hot water pipes

• 6" from vent connector

a See Figure I. Clearances with a "C" indicate

minimum clearances from combustible construction•

1. The installation must provide adequate air for

combustion, ventilation and draft hood dilution•

2. Provide air openings as recommended below• The

lower opening provides combustion air and dilution

air. The upper opening provides proper air circulation

to control the boiler room temperature and air quality•

Without the upper opening, the boiler room

temperature will be too high, causing problems with

control operation and life

The boiler room must never be under negative pressure.

Ifexhaust fans or other equipment can cause a negative

pressure in the boiler room, the air openings and

equipment design must be engineered to assure a neutral

or slightly positive pressure in the boiler room at all times

of operation If the equipment design and air openings

cannot assure this, then the boiler must be located in an

isolated room.

The following recommendations are in accordance with

the current edition of the National Fuel Gas Code, ANSI

Z223. I/NFPA54.

Ifall air for combustion and ventilation comes from inside

the building (Figure 2), the building must have adequate

A

TWO AIR OPENINGS:

Minimum

Free Area Each -

1 in _per 1000 Btu

at Least 100 in _

BOILER

3" rain

12"max

BUILDING

Aust communicate freely

with outdoors

Must not be under

negative pressure

3" min

[ ; 12" max

Figure 2: Air Openings - All Air from Inside

Building

3

Page 7

1 :::xll

,/

TWO AIR OPENINGS:

MhlinqLim

Free Area Eacl_

1 in* per 4000 Btu

12" max

I

Figure 3: Air Openings - All Air Directly

from Outside

provision for outside air to assure the air supply needed

for the boiler room. Provide openings as follows:

• Provide two openings:

--one starting no closer than 3 inches nor further than

12 inches from the ceiling

one starting no closer than 3 inches nor further than

12 inches from the floor

• The openings must be into areas which have

unrestricted access to outside air

• Each opening must have a free area (after deduction

for louvers) of at least One square inch per 1000

Btu/Hr of total boiler and other appliance input. The

openings must never be smaller than 100 square

inches each.

6. If all air for combustion and ventilation comes directly

from outside the building:

3" min

_, 12" max

TWO AIR OPENINGS:

Minimum

Free Area Each -

1 in 2per 4000 Btu

• Provide two openings:

one starting no closer than 3 inches nor further than

12 inches from the ceiling

.... one starting no closer than 3 inches nor frlrther than

12 inches horn the floor

• If air openings are directly in an outside wall (Figure

3), each opening must have a free opening (after

louver reduction) of at least One square inch per 4000

BtuiHr of total boiler and other appliance input.

• Ifairissuppliedthroughverticalducts(Figure4).each

opening must have a free opening (after louver

reduction) of at least One square inch per 4000 Btu!Hr

of total boiler and other appliance input The cross

sectional area of the ducts must be at least as much as

the free area of the openings to which they connect.

TWO AIR OPENINGS:

Minimum

Free Area Each -

1 inzper 2000 Btu

Figure 5: Air Openings- All Air from

Outdoors through Horizontal Ducts

• If air is supplied through horizontal ducts (Figure 5),

each opening must have a free opening (after louver

reduction) of at least One square inch per 2000 Btu/Hr

of total boiler and other appliance input. The cross

sectional area of the ducts must be at least as much as

the free area of the openings to which they connect.

7. Using combustion air dampers:

a) If motorized dampers are used on the combustion

and ventilation air openings, wire them such that

they must open when the boiler tries to operate.

They must include a switch which prevents the boiler

from operating if they do not open.

Figure 4: Air Openings - All Air from

Outdoors through Vertical Ducts

1.

2.

3.

Inspect the existing chimney or vent system. Make sure

it is in good condition. Inspect chimney liner and repair

or replace if necessary.

The vent system and installation must be in accordance

with Part 7, Venting of Equipment, of the current edition

of the National Fuel Gas Code, ANSI Z223.1/NFPA54,

or applicable provisions of the local building codes.

Chimney/Vent Operation: The vent system must be

sized and installed to provide the draft needed to remove

Page 8

0

0

all combustion products. If the vent system does not

provide enough draft, combustion products will spill into

the building from the draft hood relief opening. If spillage

of combustion products occurs, check the vent system,

the combustion and ventilation openings and make sure

the boiler room is never under negative pressure.

Failure to provide adequate

venting can result in severe

injury or death.

4. Exterior Vents

a) If the vent is outside, make sure it is insulated

sufficiently to ensure adequate draft.

5. Vent Sizing:

a) Individual vents: Use vent piping the same diameter

as the boiler vent connection. The minimum height

is I0 feet above the bottom of the draft hood (relief

opening). The vent must also extend above the roof

or any obstiructions as outlined in the current edition

of the National Fuel Gas Code, ANSI

Z223.1/NFPA54 or as required by local codes.

b) Combined vent- breeching:

• The recommended sizing in Section 14, "Boiler

Ratings and Dimensions", in this Manual is based

on a minimum chimney or vent height of 20 feet

and a maximum horizontal run of 6 feet to the

chimney with no more than one 90-degree

standard elbow.

• The minimum area of the chimney serving two or

more appliances must be at least the area of the

largest chimney connector plus 50% of the total

area of all other appliance connectors.

• The vent connector must be single wall steel or

Type B double wall vent pipe. The vent connector

must be Type B double wall if it is located in or

passes through cold areas. The vent connector

must extend into, but not beyond, the inside wall

of the chimney.

6. Vent Connection to Boiler (Figure 6):

a) Provide at least a three foot rise in the vent

connection on the boiler.

b) The vent system should provide a draft of at least

0.02" w.c. measured at the vent connections.

c) Support the weight of the vent system indepently of

the boiler draft hood. The draft hood is not designed

to carry structural loading.

d) Provide support ofthe vent connector (breeching] at

maximum 12 foot intervals to prevent sagging and

to provide a minimum upward slope of I/4" per foot.

e) Do not connect the vent for this boiler into any vent

system which operates with positive pressure.

f) Use Type B double-wall pipe for vents which run

through unheated spaces.

7.

Removing an existing boiler from a common vent: At the

time for removal of an existing boiler, the following steps

shall be followed with each appliance connected to the

common venting system placed in operation, while the

other appliances remaining connected to the common

venting system are not in operation.

Recommendedsizingfor chimneyand connectorsis

based on maximum 6 foot connectorlength and

maximumone 90 degree elbow.

Frovidesuppo_for I_lz_taJ secl_s to preventsagging•

Slopeve_tconnectorupw_d min 1/4 inch perfoot --

T

Connlz_tor must notprotrudeinlo chimney •

Boi)erven_c0nnect0r shCuldbeh_ghet

than 0tha:connectedapp_ances

I_Do not obs_ct draft.hood openfn_

Figure 6: Vent Connection

a) Seal any unused openings in the common venting

system.

b) Visually inspect the venting system for proper size

and horizontal pitch and determine there is no

blockage or restriction, leakage, corrosion and other

deficiencies which could cause an unsafe condition.

c) Insofar as is practical, close all building doors and

windows and all doors between the space in which

the appliances remaining connected to the common

venting system are located and other spaces of the

building. Turn on clothes dryers and any appliance

not connected to the common venting system. Turn

on any exhaust fans, such as range hoods and

bathroom exhausts, so they will operate at

maximum speed. Do not operate a summer exhaust

fan. Close fireplace dampers.

d) Place in operation the appliance being inspected.

Follow the lighting instructions. Adjust the

thermostat so appliance will operate continuously.

e) Test for spillage at the draft hood relief opening after 5

minutes of main burner operation. Use the flame of a

match or candle, or smoke from a cigarette, cigar orpipe.

f) After it has been determined that each appliance

remaining connected to the common venting system

propedy vents when tested as outlined above, return

doors, windows, exhaust fans, fireplace dampers

and any other gas-burning appliance to their

previous condition of use.

g) Any improper operation of the common venting

system should be corrected so the installation

conforms with the current edition of the National

Fuel Gas Code, ANSI Z223.1/NFPA54. When

resizing any portion of the common venting system,

the common venting system should be resized to

approach the minimum size as determined using the

appropriate tables located in the chapter "Sizing of

Category I Venting Systems" in the current edition

ofthe National Fuel Gas Code, ANSIZ223.1/NFPA54.

Page 9

1 Provid_ a good, levd foundation for the boi]el t_,.n mu

minimum dim_nsKJlm givun m Tahlf ] ThP fluulh _ ,--!

stlLwtura] SklI313olt _,t/stt,t3] RIU_t h( _ qUltdhlL' --

op_,_ating weif_ht o_ thu h_)dc, i dnd any conn_cIcc ....

2. Do not operate thin b()l}_ until the [ounoanon 11nett

concrete, has thoroughly cured• The high ternperuan_-

under the burners could cause major lamag_ ln_

concrete if it still contauled moisture.

Do not install this boiler on

carpeting or any combustible

flooring. A significant fire

hazard would result, with

potential for property damage,

personal injury or death.

3. If the boiler is installed in a penthouse or if wiring of any

sort is run undumeath the boiler foundation, construc_

the foundation with provision for air flow underneath

between the main floor and the' top of me boiisr

foundation.

a)

b)

Concrete block aligned with the openings connected

continuously would serve this purpose, for _'xampJe

If the foundation must be a concrete slab. use an air

cell high temperature insulating board, at least V_

inch thick, with aluminum backing, aiuminun slou

up One half inch Hi Temp millboard with aluminum

backing t_ould b_' acceptable as wall. PlaG, lnu

insulating board on thu slab inside tne 0ase

:z

l-

O uc

z I- :_

Lu {3 I-

z t_

z uJ 2

O -J LU

z < m

0

u.

Figure 7:

< BASE - 41" •

< JACKET - 45 _,' •

< FOUNDATION - 57 ,'

Foundation Layout

Table 1: Boiler Foundation Layout

Boiler Boiler Base Jackel Foundation

Model Length Length Length

2!1A 04 22 I 2 28 1 _ 40 1/8"

211A-05 28 1/8' 33 3/4 45 3/4

711A-06 33 3,4 39 3/_ 51 3 8'

211A-07 39 3/8 45' 57

211A 08 4[ 50 5/8' 62 5 8'

211A-09 50 5/8" 56 l/a, 68 1 4"

211A 10 56 1,,4 61 7/8' 73 7 8"

211A-11 61 7/8 67 1/2' 79 1/2"

211A-12 67 1/2 73 1/8' 85 1/8

211A-13 73 1/8 78 3/4" 90 3/4'

211A-14 78 3/4 84 3/8' 96 3/8'

211A-15 L 84318 90" 1 102

211A-' 6 90' 95 5/8" 107 5/8"

211A-17 955/8 101 1/4' •

1131/4

211A-18 101 1/4- 106 7/8' 118 7 8'

211A-19 1067/8" 1121/2" _ 1241/2"

211A-20 112 1/2 118 1/8' 130 !/8"

211A-21 1181/8 1233/4" [ 1353/4"

211A-22 123 3/4 129 3/8" 141 3 8

211A-23 129 3/8 135" 147

211A-24 135' 140 5/8 152 5 8

211A-25 140 5/8 146 1/a' 158 1/4"

211A-2( 146 1,4 151 7/8 163 7 8'

211A-27 151 7/8 157 1/2" 169 1/2'

211A-28 157 1/2 163 1/8" 175 1/8

211A-29 163 1/8 168 3/4" 180 7/8

211A-30 168 7/8 174 3/8 186 3/8

211A-31 174 3/8" 180' 192"

211A-32 180 185 5/8 197 5/8'

211A-33 1855/8" 191 1/4 203 1/z1'

211A-34 191 lm 196 7/8 208 7/8'

T

211A-35 l 196 7/8" 202 1/2" 214 1/2'

211A-36 202 1/2' 208 '/8 220 1/8'

211A-37 208 1/8" 213 3/4" ] 225 3/4"

211A 38 213 3 4" 219 3/8 231 3/8"

211A-39 219 3/8" 225" I 237"

211A-40 225 230 5/8 242 5/8

211A-41 2305/8' 2361/4" J 2481/4"

211A-42 236 1/4" 241 7/8" 253 7/8"

211A-43 241 7 8" 247 I/2" 259 1/2"

211A-44 247 1/2' 253 1/8" 265 1/8"

211A-45 253 1/8' 258 3/4" 270 3/4"

211A 46 258 3 ,_ 264 3 8' 276 3/8

Page 10

2. ASSEMBLE THE BASE

]. Co][_'cl the! cr_t_!s _onlaU/ing the 13as_Assemb[_; palts (able 2

shows the qu;_ntit'_ ¸¸at _ac]_ crate r_quired Th_ crates contain

the toi)owin9 pa_ts:

Crate i

Right End Panel Sub-Assembly

2 Left End Panel Sub-Assembl r 90339

Burner SUB[ _rt Channe[ 3s 121

Front Panel Sub-Assemo •

Back Panel Sub Assembl

Burner Support'C;nannelha_

2AA Anqle Tie Brace , _ 90340

Front Panel Support Bracket j

Section Assemb y Kit

Front Panel Sub Assemb .

Back Panel Sub-Assemo

Burner SuDi]ort Channe

2BB 90341

Angle Tie Brace

Front Pa_el Suaoort Bracket

Section Assert 3_y r,l[

' Front Panel Sub-Assemb LBack Panel Sub-Assera[3]

BurnerS@port Channel

Front Panel Support Bracket

1 Fsentctl_onAssemb,y Kit

Front Pane SubAssernb .

Back Panel Sub Assemb

Burner SUI]D_/t Channe

2DD _0343

Angle Tie Brace

ronl Paue ._ _..o_ Bracket

Sect on Assertlo _ lYE

Front Panel Sub-Assembl,_

_ Back Panel Sub Assembl z

Items [ Sub-Assembly # Part #

2F E Burner Support Channel 90344

.. An£1e Tie Brace

Front Panel Support Bracket

Section Assemb t Ki{

GG 2105

GG 2106

3G 207(

GG-2080

GG-2081

GG-206{

N/A

GG-2069

GG-1030

GG-2080-"

GG-2081 -"

GG-2066-"

30 2065

GG 2069

GG-103(

GG-2080-2

GG-208]-2

GG-2066-2

GG-2065

GG-2069

GG-103O-'

GG-2080 3

GG 2081 3

GG 2066 3

GG 206._

GG 2069

GG 1030 2

GG-2080-4

GG-208!-4

GG-2066-4

GG-2065

GG-2069

_ GG-1B30-3

2. Op_zn cl_t_' numb*'l 2 t£_mov_, the End P_llc]_ ,,zd

IllOUI]t a _tippor_ ChL_lllle] C]ip toward t}t_ I_al o_ ,:_1_ n

panel as shown in Figure 9 using _"-20 x L,," round humid

machine screws and _' lock washers provided

Figure 9: Steel Base Assembly

Figure 8: Boiler Base Assembly

Base BackPanelSub-Assembly,GG-2081 BaseBightEnd PanelSub-Assembly,GG-2105

.... T .......... T== BACK = ='T ......... T ....... T: T

a.S,d0 TOP VIEW Burner Po,ition Number t

RightSide

BurnerSupport Channel,GG-2066 Burner Support Channel Clip, 06-2070

BaseLeft EndPanelSub-Assembly,GG-2106 BaseFrontPanelSub-Assembly,GG-20BO

FrontJacketSupportBracket,GG-2069 AngleTieBracew/Burner SupportChannel,GG-2065(whenrequired)

F.__ NT VI_V ! !1

• Assembly H Assembly b-• Assembly I=-• Assembly I_< Assembly •• Assembly I_• Assembly

A B C D E F G

• H(overaHlength) •

41"

Page 11

3. Attach the Front Panel and Back Panel (Figure 9) to the

Left Hand End Panel using 5/16" -18 x 1" cap screws

and hex head nuts provided.

4. For 211A-04 through 211A-08 Only:

a) Complete the base assembly by attaching the Right

End Panel and setting the Burner Support Channel

on the clips.

_ Front

Jacket •

Panel

Figure 11: Support Bracket Installation

5,

6,

7.

8,

9.

For 211 A-09 through 211 A-46 Only:

a) Attach a Front Panel Support Bracket to each Front

Panel as shown in Figure 11.

Attach an Angle Tie Brace at each panel joint to secure

the front and back panels as shown in Figure i0 using

5/16"48 x 1" cap screws and hex head nuts.

Bolt remaining Front and Back Panels together using

5/16"-18 x I" cap screws and hex head nuts. See Table

2 for panels required. Place the panels in the positions

shown in the table and Figure 8.

Complete the base assembly by attaching the Right Hand

End Panel using 5/16"-18 x i" cap screws and hex head

nuts.

Set the Burner Support Channels in place as shown in

Figure 8.

I,

,

3.

Check the location of the Burner Support Channels in

the Base Assembly. The dimensions should be:

a) Height above boiler foundation: 63/4"

b) Distance from back of Base: 33/4"

Remove the Gas Manifold and Pilot Line Assembly from

Box Number 7.

Place Manifold on front of Base. Bolt the hangers using

5/16"-18 x 1" long cap screws with 5/16" fiat washers.

See Figure 12.

Front Panel

Angle Tie Brace

3 3/4"

T

6 3/4"

Figure 10: Angle Tie Brace Installation

8

Page 12

Overall Length

_r......... 7-

• Assembly I_• Assembly I_• Assembly I_• Assembly I_• Assembly Ib• Assembly I_• Assembly ip

A B C D E F 6

Model Overall

A B C D E F G

Number Length

211A 04 2AA 2434

211A O5 2BB -- -- -- 30 3/8"

211A 06 2CC 36'

211A 07 2DD -- 41 5/8"

211A 1)_ 2EE -- 47 1 4'

- - i 27/8

211A-09 2BB 2BB

211A 1 2CC 2BB 58 1'2'

211A 11 2CC 2CC .... 64 1/8

211A 12 2DE 2CC 693,4

] -- 75 3/8"

211A-13 2DD 2DD

ZIIA 14 2EE 2D[ 81"

-- -- _ -- 86518"

211A-15 2EE 2EE

2 ! 1A ] _ ?CC 2CC 2CC 92 ! _4"

21IA 17 2DD 2CC 2CC -- 97 7/8

VllA 18 2EE 2CC 2CC 8 7 ]

EllA 19 2DD 2DD 2DD 9"-1 1,'8'

EllA d0 2EE ELL 2CC _) 634

211A-21 2EE 2EE 2DD -- -- 10L0 3/8 ''

211A 22 2EE 2LF 2EE I0' 6

211 A-23 2EE 2CC 2CC 2CC -- -- I0'-11 518

211A24 2DD 2DD 2DD 2CC -- 11 51'4

211A-25 2EE 2EE 2CC [ 2CC ] 1 -- 11' 107/8"

211A 26 2EE 2hE 2EE 2BB -- 12" 4 b2'

211A-27 2EE 2EE 2EE I 2CC ] -- _ 12'-10 1/8"

211A-28 2BE 2EE 2EE 2DD 13"-3 :_ 4 '

2EE 2EE 2EE

211A-29

21 IA ,J* 2DD 2DD 2DD 2DD 2CC 14"-3'

211A-31 2DD 2DD 2DD 2DD 2DD -- [ [

14'-85/8'

21 IA ," 2EE 2DD 2DD 2DD 2DD 15-2 1,4'

J 2BE 2EE 2BB 2EE 2EE

211A-33

211A-34 2EE 2EE 2BE 2EE 2CC -- 16" I U2'

21 IA-35 2EE 2EE 2EE 2EE 2DD 16'-7 1/8'

211A-36 2EE 2EE 2EE 2EE 2EL -- 17" 03/4

211A-37 2DD 2DD 2DD

21 IA-38 2EE 2DD 2DD 2DD 2DD 2DD 18' 0"

2EE 2EE 2DD 2DD -- I 18'-55/8'

211A-39 2DD

2DD

21 IA 41 2BB 2EE 2EE 2hE 2E£ 2EE 18' i i I/4

211A 41 2EE 2EE 2DD 2DD 2EE 2EE T -- J

19'4 7/8"

211A 42 2DD 2F[ 2hE 2EE 2EE 2EE 19'-10 1/2'

211A 43 2EE 2EE 2EE 2EE 2EE 2EE 20'4 1/8'

211A 44 2EF EBB 2EE Zhk 2hE 2BB 2EE )' 9 3/4'

21 IA-45 2CC 2BB 2EE 2EE 2EE 2EE 2EE 21'.3 3/8'

211A 41 2C( 2('C 2EL 2FL 2[-E 2EE 2EE 21 9

Table 2: Base Front and Back Panel Crates

Page 13

_ :1II:1/ill: I:f:T_'_

© ©

Mounting Clamp

GG-3052thru GG-3052-3

Manifold Weldment

GG-4084 thru GG-4084-46

Orifix_e4A0d3Pter\\ _

©

Imperial #68F

1/4" NPT x 3/8" O.D.

Tube Straight Connector

\

\

\

3/8" x 3/8" x 1/4" Tee

I 1/4" Street Elbow

3/8" Pipe Cap_

Pipe Cap _ 1/4" x 1/8" 1/4" X 1 1/2" Nipple

\\\ Hex Bushing

Ignition Control _ Relay _\

Mounting Box Assembly

(Standard System, HSP-X-3O 11-3) PB-H91 BG-2 or

(Other panels mounted on Imperial #69F Elbow H-V8046C

jacket front, left side) 1/8' NPT x 1/4"O.D.Tubing Pilot Gas Valve

3/8" Pilotstatls)

H17CA

J

3/8" x I/4" Elbow

/

/

(21 5/16"-18 x 3/4" Square

Head Set Screw

Figure 12: Typical Gas Manifold and Pilot Line Assembly

4. Place only the Burners with pilots mounted in the

locations give in Table 3. Install the Burners by slipping

the opening on the front of the burner over the orifice

adapter and slipping the pin on the end of the burner into

the hole in the Burner Support Channel directly opposite

the orifice.

5. Cut and fit the I/4"aluminum tubing provided from the

pilot gas shut-off device(s) to the pilot burners.

6. Do not install the remaining burners until the Boiler

Sections are installed.

I0

Page 14

Table 3: Pilot Burner Locations-Numbered Right to Left (See Figure 8)

Model Number of

Number Pilots

2ilA-04

NATURAL GAS ONLY

Total

Number Pilot Burnei Locations

of Positions Numbered Right [o Left)

Burners Electronic Pilots Standing Pilots

(Spark Ignited) IThermocouple)

5

PROPANE GAS ONLY

Pilot Burner Locations

Positions Numbered Right to Left

Electronic Pilots Standing Pilots

Manually Lighted Whermocoupte

5

211A 05 1 8 5

211A-06 1 10 5 --

"_7 1 1 12 5 I

211A-08 i 14 5

l 211A-09 I 16 5 --

I211A-10 I 18 5 --

I

L

[ 211A-11 ,r 2 - 26 15 5

211A-12 2 22 15 5

211A 13 2 24 17 5 13

211A-14 i 2 _26 •. _.....17 5 t 9.19

211A-15 , 2 28 19 ] 5 ; 9.21

211A-16 3 30 25 5.15 5.15.23

211A-17 3 32 25 5. 15 5.15.25

211A-18

211A-19

211A-20

211A 21

211A-22

211A-23

211A-24

5

5

5

5

5

7

13 5

13 5

3

3

3

25 [ _ 15

34

36 29 5.17

38 35 5.21

5

I

]

9,19,27

1....... --

9.21.29 _ --

i

9 21.31

:3 40 {7 5.23 9.23.33

3

3

42

44

19 5.39 9.23.35

19 5.41 9.23.37

3

4_ 21 5.39 9 23.39

211A 25

211A-26

211A-27

211A-28

3 48 25

4 50 19

4 52 21

4 54 23

5.45 9.23.41

5.33.47 9.23.33.45

5.35.49 9.23.35.45

5.37.51 9.23.35.47

211A-29 4 56 27

211A-30 4 58 _ 29

211A-31 4 60 31

211A-32 4 62 33

211A 33 4 64 35

211A-34 [ 5 i 66 35

211A-35 5 68 37

211A-36 5 70 37

211A-37 5

2nA-38 [ 5

211A-39 ] 5

211A-40 5

211A 41 6

211A-43 ] 6

211A-44 6

211A-45 6

211A-46 6

72 37

74 25,55

76 I 23,49

78 25,55

80 19,45

82 ! 23,51

84 23,53

86 21,55

88 23,57

90 25,59

5.39.53 9.23.39.49

5.39.51 l 9.21,39,$1 1

/

5.41.53 9.23, 39, 53 J

9.25.41.55

9.25.41.57

9. 23.39.51.59

39.51.61 1

9. 23.

9.23.39.51.63

9.23.39.51.65

Models 21 IA-38 through 21 IA-46

Are Certified for Natural Gas Only

5.41.59

5.41.61

5.21.49.63

5.17.51.65

5 19.53.67

5.2347.65

5,43,67

5,35,69

5,33, 75

5,33,57,77

5,31,65,79

5,33,67,81

5, 33, 67, 83

5, 37.65.85

5, 39, 67, 87

11

Page 15

J

C

D

F

r_

_o

o3

r_ r-

Lo

r_

oo

,r-

_O

%.

_o

o3 O0

%-

LO

A 3/4" npt Tapping

B 1/2" npt Tapping, Upper

C 1" npt Tapping, Upper

D 1/2" npt Tapping, Lower

E 3/4" npt Tapping, Probe LWCO

F 1" npt Tapping, Lower

TAPPINGS, EACH END SECTION

G 1 1/2" nptTapping, Back, Blowdown

H 3" npt Tapping, Pop Safety Valve(s) and

Upper Equalizer for Special Float

Controls (157, etc)

J 6" npt Tapping, Steam Riser

K 6" npt Tapping, Return

Figure 13: Assembling Sections on Base

12

Page 16

3. PLACE THE BOILER SECTIONS

1 Check the level of the Boiler Base using a spirit level•

Make sure the base is level and that the base panels are

aligned within plus or minus I'16".

2 Check the area around the Flow Ports (Figure 14). Use

solvent and a clean cloth to thorougly clean the flat

surfaces and recesses• All foreign matter must be

removed to assure a proper seal when the sections are

drawn together•

Gaskets will be damaged by

petroleum or its derivatives.

Completely remove all solvent

residue before placing gaskets•

Do not use petroleum based

compounds in the boiler.

Flat Machined Recess Machined

Face Face

Flow Port

Gasket

Figure 14: Flow Port Machining b Gasket

I. Begin by placing the Left Hand End Section on the left

end of the base, The upper flow port goes toward the

front of the boiler as shown in Figure 15.

Figure 15: Placing the First Section on Base

2 Slide the section to the back of the base until the cast lug

on the bottom of the section under the lower flow port is

against the base back panel• Keep the section upright by

a supporting prop or other means•

The sections are heavy and

must be supported securely•

.

4.

S.

6.

Align the parting line of the section with the seam

between the Base End panel and the Base Front Panel

as shown in Figure 13.

Apply Hi-Temp rope seal by spreading a thin coat of

RopeAdhesive in the grooves on each end of the section•

Place the rope in the grooves. Do not stretch the rope.

The longer rope goes in the front groove•

NOTE: The ends of each rope must extend _/' beyond

the top and bottom.

Place the Flow Port Gaskets in the recesses provided (see

Figure 14). Do not use adhesive.

The following steps must be followed to insure that no

damage is done to the tie rod lugs. A 0 100 ft.-Ibs, torque

wrench is required•

a) Place an Intermediate Section on the base and slide

it carefully against the Left Hand End Section.

b) Align the flow ports from front to back, as close as

possible.

c) Insert a tie rod into each of the lugson each section

and app}y a nut and washer to each end of the tie

rod.

d) Before tightening, check the vertical alignment of the

sections using a spirit level (see Figure 16). Make

sure they are square with the Base

13

Page 17

Spirit

Level

Left Hand

- " Et_d Section

Base

/ Assembly

Figure 16: Align Sections Vertically

e)

f)

9)

Draw sections together evenly, alternating between

top lug and bottom lug in increments of 20 ft.-lbs.

Continu{, until both top and bottom lugs are

tightened to 60 It. lbs DO NOT EXCEED 60

FT -LBS

Check the level while tightening to make sure

alignment stays true Also make sure sections remain

square with the Base from front to back as the tie

rods are tightened and as additional sections are

installed.

If the sections tend to run out of plumb, this will

usually be at the bottom front. Loosen the upper nuts

slightly and tighten the lower ones to adjust•

7. Assemble the remaining sections in the same way for a

finished assembly as shown in Figure 13.

8. Some of the Intermediate Sections have tappings for

installing additional steam risers from the boiler. These

Tapped Intermediate Sections must be installed as shown

in Figure 17A. The placement order is left to right (Figure

17).

Left Hand End Section, Position Number 1

'!f!lf!!f'lI' lF'l'.... i=,

r;,1,,,,, - _ _ _ "

1 3 5 43 45

Figure 17: Section Positioning Numbering

Boiler Model Number

211A ]S

211A-19

211A 2{I

211A-21

211A _7

211A-23

211A 24

211A 25

211A 26

211A-27

211A 28

211A-29

211A 3(

211A-31

211A 32

Place Tapped Intermediate Sections

at Positions (Numbered Left to Right)

iU

10

H

11

& 16

9,17

7, 13, 19

7, 1:_ 20

7, 12, 17, 22

5 11,17 23

5. 10. 15.20.25

11. lb. 21.2b

6. 10. 14. 18.22. 26

o. 1] 15.19.23.27

11A- 3 " s.9.la.17Z-£TT-..... 1

211A 34

211A 35

211A 3(

211A-37

211A 38

5 9 13.17 22 26.30

5.9. 13. 18.23.27.31

5 9.13 17. 21 2[ 29.33

5.9. 13. 17.21.25.29.33 q

4 8 12 1722.27.31 35

211A-39 4 8. 12. 16.20.24.28.32:.36_ ]

ZllA4( 4 8 12 16.21 25.29.33.37

211A 41

211A-42

211A 43

211A-44

211A45

211A-46

4.8 12 16.19.23.26.30.34.38

a _ 12 16 2023 27 31 35.39

4.- 11.14.18.22.26.30.33.37.40

a - 12 16 19 23.26 29.33 37 41

4.- 11 14.18.21,25,28 32.35.39.42

4 11 14 18 22 25 29 33.36,40,43

Figure 17A: Section Positioning Numbering

1.

.

3.

4.

5.

6.

7.

The supply and return piping can be permanently

erected before applying the Boiler Jacket if the pipe

nipples applied to the boiler tappings are long enough to

clear the jacket.

Install a drain cock in the tapping provided at the bottom

rear of each section.

Provide a water supply line to the boiler.

Plug all open tappings in the boiler.

Provide a means to vent air as the boiler fills.

Fill the boiler with water, venting air as water level rises.

Pressurize boiler to 45 psig. Do not exceed this

plregsulre

a) Maintain pressure while checking all joints and

fittings for leaks

b) After inspection is complete, drain the boiler and

remove plugs from tappings that are to be used.

14

Page 18

4. INSTALL THE FLUE COLLECTOR

1. ColDct the l:lu_' Coikzctor cartons. The Flue Cdlactot

sections are ]abal_,d on tile part and on the carton See HiTempRope AngleBracket,

Table 4 for the items needed. GG-50O5

2. Install Hi Tamp Rope for each collector section asshown

in Figure 18. The rope provides the seat to prevent flue

gases from leaking from the collector. Make certain that

the rope is well under the bottom edges of each flue

collector section in order to obtain a tight sea].

3. Place the Flue Collector sections in the positions given in

Table 4. These positions are numbered from left to

right when facing the front of the boiler•

4. Fasten an angle bracket, part number GO-5005, to the

top of each Collector section with two #10- Vi' sheet

metal screws. See Figure 19.

5. Insert a Long Hook Bolt, part number 00-5003, through

the angle bracket Slip the hook end over the tie rod.

Apply a W'-20 hex nut on the end of the rod and snug

against the bracket. See Figure 19. Do not tighten yet.

6. Insert a Short Hook Bolt, part number GO-5004, through

the flange in the rear of the flue collector. Catch the hook

around the spacer pads at the top of the boiler sections.

Apply a V4"-20 hex nut on the Bolt and snug against the

flange. See Figure 19. Do not tighten yet.

7. Draw the Flue Collector sections tight against the sealing

rope by tightening the nuts on the Hook Bolts. Draw the

nuts evenly, alternating tightening.

ShortHookBolt,

6G-5004

Figure 19:

'\

\

\

\

\

\,

\

LongHookBolt,

6G-5003

,\ TieRod

\X •

\\

\\

\\

\\

\\

Installing Flue Collector Sections

Figure 18: Applying Flue Collector Hi Temp Rope Gasket

15

Page 19

Table 4: Flue Collector Section Location (From Left to Right Facing Front of Boiler) - Crates

Crate 14 = Part number GG-5000 Crate 14A = Part number GG-500O-1

Crate 14B = Part number GG-5000-2

Boiler

Model

Number

211A-04

F

Position ! Position

1 2

14

Position

3

i

Position ! Position Position

4 5 6

Position

7

Position Position

8 9

211A-05 14A

211A-06 , 14B --- -- [ -- ] -- ! ii

211A-08 14A 14 -- - i --

211A 09 14A t4A

i 211A-11 _/ 14B _/ 14B k -- 1| -- _ Z ,/ -- J/ ---'-- [ --

211A-12 14 : -- -- --

14A i2i1AL13

211A-14

211A-15

21]A-I6

211A I7

211A-18

211A-19

211A 20

14A ! 14A

14A 14A

14B ---14A I

14B 14A

14B 14B

14A 14A

14B 14A

14A 14B

14B 14B

2iiA-21 14B 14B

211A-26

211A-27

211A-28

211A-29

211A-30

14B -- I __

14A 14A

_4B E 4A L --

14B i 14A -- --

14B ! i4B

211A23 14B _ i4B 14A _ 14A _ 14A

211A24 14B 14B 14B 14A 14A

211A25 ! i4B 14B IqB 14B 14A

_4B | 14B _4A -_ 14 A [

211A-31

211A 32

, 211A 33

I 211A-34

_211A-35

211A-36 !

14B

1413

14B

14B

14B

14B

14B

14B

211A-37 14B

14B 14B 14B |

14B i4B l 14B l

14B l 14B L 14B L

T

14A [ --

14A

m i

14B 14B 14A

14B 14B 14B 14A

14B 14B 14B 14B

14B 14B 14B 14B |I

14B 14B 14B 14B

14B 14B 14B 14A

14A 14A -- i --

-B i I - I -

14B ! 14B I - I - / -

14A 14A 14A !

!4A 14A

14A 14A --

14B !4A --

14 2 14B

14A 14A 14A

211A-38

211A-39

211A40 14A 14B 14B 14B 14B

i/ 211A-4i 14B i 14B , 14B 14B 14B

2_ii_::ia_;- i_X 1 i4A-I i_g 14B

; 211A_44 14A i4; 14B -- 54B IQB

211A-45 14A 14B 14B 14B 14B

i 2iiA_ i4B 14B

[ I 1

.A I.A 114B .B ].B I.B --

14A 14A 14B L 14B 14B 14B 14B 14B --

14B 14B 14B

.i

14B i4B 14B

14B 14B 1 1413 14B

14B 14B L 14B 14B

14B : 14B 14 2 14B

14B 14B 14B 14B

14B _i 14B i i4B I 14B • 14B ] 14B i 14B _i

16

Page 20

5. PIPE THE BOILER

1 The boiler must be pressure tested as outlined in

Chapter 3. "Place the Boiler Sections", of this manual

2 TheSupplyandReturnpipingcanbeinstalledbeforethe

jacket is applied. Use nipples long enough to be sure they

will extend through the jacket.

1 Install End Riser connections sized per Table 5. The 3"

tappings in the tops of the end sections are not used for

steam boilers.

a) Install a reducing tee on one end riser. Install a 2"

valve, nipple and cap for skimming the boiler in the

tee as shown in the piping drawings.

2. Models 211A-08 and larger require risers in both end

sections.

3. Models 211A-18 and larger require additional 3"

risers off of the tapped intermediate sections. See Table

5 for the number required.

4 Pipe the header at least 24 inches above the normal

boiler water line. This is required to prevent water from

carrying over into the header and then to the system.

5 Figure 21 shows the Supply and Return piping for

Parallel Fk_w Gravity systems and all Pumped Return

Systems.

6. Counterflow Gravity systems require the boiler steam line

to enter the top of the steam main. See Figure 22 for this

special case.

Steam

Supply

7.

8.

9.

10.

11.

The piping in [hese drawings is shown off the right hand

side of the boiler The boiler may also be piped toward

the left side as shown in Figure 23, typical.

Do not reduce the size or number of risers shown

These are required for reliable operation of the boiler. If

the risers are undersized or incorrectly placed, a sloped

water line can occur in the boiler, causing possible

overheating of some sections.

Pipe the Header with an offset as shown in the

drawings. This offset prevents the expansion and

contraction of the Header from damaging the boiler

sections.

Always locate the Steam Supply take-off between

the Equalizer and the last Boiler Riser. (See

Peerless Heater Company's "Steam installation Survey"

for discussion). Locating the Steam Supply between the

risers will cause water carryover to the system.

Do not use a bull head tee to provide steam supply and

equalizer connections. This will cause water level bounce

and carryover.

I.

.

We recommend the use of a Hartford loop in all

installations. The loop provides additional reliability for

the system. A check valve must still be installed on the

pump discharge of all pumped return systems.

On pumped return systems, install a boiler cock after the

pump to allow throttling of the pump discharge. The

pressure after the boiler cock should be no more than 5

psig above the boiler operating pressure. Pumping the

Steam Supply should always

be piped between last boiler

riser and equalizer.

BOILER HEADER -

Pipe with offset

to allow for header

expansion

\{

Water

ix

24"

Min.

" " ,.'Useclose YI" "

-- _ --,. nipple on y JJ "

Hartford ,

Loop _! _

" Hartford q-"_

' , Loop

i

Figure 20: Supply and Return Positions, Skim Piping, Hartford Loop

17

Page 21

Steam

Supply

Return

2" Skim

Connection

211A-04 TO 211A-07

SINGLE END RISER

Second Equalizer

1A-16 and Larger

i ] Steam

_ _Supply

2' Skim

Connection

Offset Header Required to Prevent Damage

to Boiler From Expansion of Header _, Return

E _ 211A-08 TO 211A-17

Second quaL:;ger _ND RISERS

Steam

Supply

211A-18 _ LARGER

TWO END RISERS

PLUS ONE OR MORE

3" INTERMEDIATE

RISERS

Offset Header Required to Prevent Damage

to Boiler From Expansion of Header

Return

Figure 21: Supply and Return Piping - Pumped Return and Parallel Flow Gravity Systems

18

Page 22

Boiler Riser Piping

enters TOP of main

on Counterflow

System -,_

Counterflow

Steam Main

Pitch

Equalizer

T

I Figure 24 shows typica{ piping for multiple boiler Gravity

Return systems. Figure 25 shows typical piping for

multiple boiler Pumped Return systems•

2. Provide separate feed lines for multiple boiler pumped

return systems• Use eithez separate feed pumps or

solenoid valves to isolate feeding of the boilers. This is

needed to provide reliable level control and avoid

nuisance performance problems.

3. Condensate return units are not effective for multiple

boiler installations since they do not respond to the needs

of the boilers• Always use Boiler feed units•

a) Install a Float and Thermostatic trap at the boiler

water level on each of the multiple boilers on a

pumped return system. This prevents flooding of idle

boilers due to condensation of steam•

2" Skim Connection

Figure 22: Supply and Return Piping -

Connterflow Gravity Systems

water into the boiler too fast will cause collapse of the

water level and level control problems

3. Size the equalizer per Table 5.

4, Pipe the Hadford loop tee so the inside top of the close

nipple is 2 to 4 inches below the boiler water line.

5. If the pump discharge is looped overhead• above the

boiler water line, install spring-loaded check valves at

both the pump discharge and the connection to the boiler

return.

%

Figure 23: Left Hand Piping Arrangement -

Typical

Table 5: Header, Risers 8" Equalizer Sizing

il Boiler Header [=--End i:h-sers- ]interm._ Equalizers

I 211A-04 4" . 1 4" - : _ 1 i 2 1/2" ;

:_211AL05 5" 1 5" - i - 1 12 1/2"

211A-06::_:5; ] 1 F 5': i :-[---_-[--1 121/2111

L211=_,-_- _" I 1 LEI - / - ! 1 /2t/z '

211A-08 6" 2 4" - - ' 1 2 1/2" I

211A-09 6 2 5 - , - 1 2 1/2

2t_A-lO[ 6" _ 2_:_ : I I 1 I aQ

211A-12 8" 2 5" - i - i 1 3"

211A-13 8" 2 5" _ - - ! I ] 3"

21iA:14 8;i V 2 V 5;', : "q : I " i - 3""

211A-15 8' I 2 1 6' _ -_ - [1 I 3" ]

211A:16 8" ' 2 6" " _ 2 [ 4" i

211A 17 . 8" _ 2 6" 2 4"

211A-19 8" I 2 6" L 3'_1 1 ____[_ I 4"

i 4. i

211A-20 8" _ 2 6" 3" 1 2 F J

211A-21 8" 2 6" 3" 1 2 4"

211A-22 8" I 2 I 6" I 3" 2 2 4"

21_A-2318" _ 2 I 6" I 3" 2 2 4,,

211A-24 t 10'; =: 2 -6" 3" 2 [ 2 4"

2iiA-25 10" 2 i 6" 3" 3 2 4"

21iA:;)61 10" ] 2 I 6;; [ 3" 3- ] 2 4"

L 211A-27

: 211A-28, 10" 2 6" 3" _ 4 i 2 5"

i_HA:29 !9" & i 6' _ 3" _ 2 5':..

! 211A-30 10" 2 6" 3" 5___ .__

211A-32 10 2 6 3" 6/ 2 5

, 211A-33 = 10" 2 : 6" 3" 7 i 2 5"

: 211A-34 10" 2 6" 3" 7 2 5';-

: 211A 36 10" 2 6" 3" 8 2 5"

211A-37 _ 10" 2 " 6" 3" 8 2 5"

j21'IA-391 10 L 2 A 6 ! 3 I 9 1 2_ 5'

211A-40 10" 2

21tA41 10" 2

211A-42 : 10" ! 2

i 211A-43 I 10" 2

211A 44 12" 2

211A-45 12" 2

L _

,1211A-461 12" 2

[

6" 3" 9 2 5" ,

6" 3" 10 2 5"

6" i 3;' I-3_- 2 [_

6" 3" 11 2 5"

o" 3" 12 2 _"

6. [ 3. I _2] 2 I-g! i

19

Page 23

Stop Steam

Valve Supply

Pipe All Headers Minimum

24" Above Boiler Water Line

Stop

Valve

Stop t

Valve

Return

Figure 24: Piping Multiple Boilers, Typical, Gravity Return Systems

Pipe All Headers Minimum

24" Above Boiler Water Line

Steam

stop Supply

Valve

":5

F/T Drip To recover

Trap

Valve

;olenoid or Motorized Valve

Boiler Cock for ThtotBing

Pump Pressure to Boilers

CheckValve TO Pump

Alternate Piping: Use two separate pumps, separate return lines and no solenoid valves

Figure 25: Piping Multiple Boilers, Typical, Pumped Return Systems

20

Page 24

6. INSTALL THE JACKET 8 DRAFT HOOD

1. Collect the Jacket cartons and Draft Hood cartons

(numbers 12 and 13).

2. See Figure 27 for the Jacket Assembly. Use these

drawings for part identification and location.

3. See Figure 28 for the quantity of each carton required

and placement of the jacket sections on the boiler.

4. See Table 6 for the contents of each Jacket Carton and

Draft Hood carton.

5. See Table 7 for the Draft Hood cartons required.

i. Remove Cleanout Cover Plates from carton 12.

2. Install one cover plate on each End Section. Use four

5/16"-18 x 2" studs, 5/16"-18 hex nuts and 5/16" fiat

washers.

3. Seal around the cleanout plates using the furnace cement

provided. Also apply between base and bottom of

sections.

I. Remove necessary knockouts from the Jacket End Panel

pieces in carton 12.

2. Attach a Corner Panel Support Bracket (GG 6029) to

each Corner Panel using two #10 x Vi' sheet metal

screws,

3.

4.

5.

6.

7.

8.

9.

3. Attach the four Corner Panels to the Base Ends using i.

I/4-20 x V/' machine screws and V4" fiat washers. The

locations are: 2.

• Right Front- GG-6015

• Left Front GG+6016

• Right Rear GG-6017 3

• Left Rear GG-6018 4.

4. Attach an End Panel Cover Plate (GG 6030) to the

opening on the Upper Left End Panel ifthe 6 inch tapping

on that end is not used.

5. Attach Upper Left End Panel (GG 6032) to the left end

corner panels with five #10 x V/' sheet metal screws

6. Place Top Left End Panel (GG-6020) over the Corner

Panels and Upper Panel with flange pointing downward.

Use four #i0 x _/2"sheet metal screws.

7. Repeat for the Right End.

I. Apply Front and Rear Panels as follows.

2. Open Jacket Intermediate Section carton. 12A, B, C, D

or E, per Table 6. Remove necessary knockouts from

panels.

Inselt Front Panel (GG 60231 flange (on light side of

panet) under the edge of the Right Front Corner Panel.

Place the left edge of the Front Panel over the offset

flange of the Left Front Corner Panel. Line up the screw

holes and secure with ten #10 x _,z'"sheet metal screws.

Insert the offset flange of the Upper Rear Panel under the

edge of the Left Rear Corner Panel. Place the left edge

of the panel over the Right Rear Corner Panel. Line up

the holes and secure with ten #10 x _'>" sheet metal

screws.

Apply the Lower Rear Panel using the same procedure

and secure with two #10 x !/_" sheet metal screws.

Install Rear Panel Support Leg (GG 6028) inside the Left

Rear Corner Panel. The flanges extend toward the boiler.

Line up the holes and secure with three #10 x _//' sheet

metal screws.

Attach the Lower Rear Panel Guide (GG-6031} to the

Rear Base Panel as shown in Figure 27.

Install the Draft Hood. Work from the left side (facing the

front) of the boiler to the right. Apply the Draft Hood

Sections in the sequence given in Table 7. Attach the

Hood sections to the Flue Collector with two #10 x _//'

sheet metal screws per collector section.

Insert the offset flange of the Jacket Top Panel under the

Top Left End Panel. Place the right flange on the Top

Right End Panel. The front edge flange goes over the

Jacket Front Panel. Line up the holes and secure with

#10 x 9/' sheet metal screws.

The boilers have multiple intermediate jacket panels.

Collect the jacket cartons listed in Table 6. When

installing the jacket panels, place them on boiler in the

order shown in Figure 28.

Open the cartons in the order listed in Figure 28.

Install the Jacket Front Panels:

• Make sure to slip the Front Panels into the Front Panel

Support Brackets (mounted on the base). See Figure 27.

Install the first Front Panel with the left edge over the

Left Front Corner Panel. Line up the holes and secure

with #10 x Vi' sheet metal screws.

Continue applying Front Panels this way.

Slip the right edge of the last Front Panel under the

Right Front Corner Panel. Line up the holes and

secure with #10 x V_"sheet metal screws.

5. Install the Jacket Rear Panels:

• Slip the offset flange of the first Upper Rear Panel

under the edge of the Left Rear Corner Panel. Secure

with #I0 x Vi' sheet metal screws

• Attach the first Lower Rear Panel inthe same way.

• Attach a Rear Panel Support Leg on the inside of the

Upper Rear Panel. The flanges point toward the

boiler. Attach with #10 x _ sheet metal screws.

21

Page 25

• InstallaPanelSupportAngleontheinsidetopofthe 5.

UpperRearPanel(SeeFigure27).Use#I0 x _/"

sheetmetalscrews.

6.

• Install the remaining Upper Rear and Lower Rear

Panels in the same way.

• Place the edge of the last rear panel ow, i the Right

Rear Corner Panel.

6. Install the Draft Hood Sections:

1.

• Start from the left of the boiler (facing the front) Apply

the Draft Hood sections from left to right in the order 2.

given in Table 7. 3

• Use two #i0 x Vi' sheet metal screws for each Flue

Collector section.

I. Apply the jacket top panels working from left to right

(facing front of boiler). Place the panels from the cartons

in the sequence given in Figure 28.

2. Mount a Panel Support Angle (GG-6027) on the back

bottom edge of each Top Panel with the long flange

pointed down. Peal the insulation slightly away from the

back edge of the panel for better contact. Secure with one

#I0 x _" sheet metal screw.

3. Slide the left hand offset flange of the first Top Panel

under the Top Left End Panel, Place the front flange of

the Top Panel over the Front Panel. Line up the holes

and secure with #10 x Vi' sheetmetal screws.

4. Slide the left hand edge of each additional panel under

the panel to its left. Secure with #I0 x _zi' sheet metal

screws.

Apply the last Top Panel in the same way. Place its right

hand edge over the Top Right End Panel. Secure with

#i0 x Vi' sheet metal screws.

Check for loose or missing screws as you complete the

jacket assembly

4.

THIS APPLIES TO ALL BOILER SIZES.

The parts are packed in carton # 12.

Attach an End Panel Cover Plate to the opening in the

Lower End Panel (GG-6022) if the tapping in the boiler

is not being used. Secure with two #10 x V/' sheet metal

screws.

Apply a Lower End Panel to each end of the boiler.

securing to the Corner Panels with eight #i0 x _/z"sheet

metal screws Attach to the Upper End Panels with two

#10 x V./' sheet metal screws.

I. Mount Boiler Rating Plates, Agency Plates and Caution

Labels on the Upper Right End Jacket Panel.

2. Plates to be field applied are packed in Box Number 7.

3. Place these plates as shown in Figure 26.

4. Secure metal plates with #6 x V4" sheet metal screws.

Apply all adhesive-backed labels.

Figure 26: Location of Rating, Agency and Instruction Plates on Upper Right End Panel

22

Page 26

Top Panel (GG-6024) Right End Panel

(GG-6019)

Top Left End Panel

(GG-6020)

Upper Left End

Panel (GG-6032

Lower End

Panel

(GG-6022)

i-

I_ Front Panel

(GG-6023)

E.

Right Front

Corner Panel

(GG-6015)

Corner Panel

Support Bracket

(GG-6029)

Cleanout Cover

Plate Assembly

(GG-60O4)

Draft Hood (GG-50Ol

Left End Corner

Panel (GG-6016)

-- Front Jacket Panel

Support Bracket

(GG-2069)

Top Panel (GG-6024)

Panel Support Angle

(GG-6027)

Right Rear

Corner Panel

(GG-6017)

Upper Rear Panel --

(GG-6025)

Lower Rear Panel Guida

(GG-6031)

Lower Rear Panel

(GG-6026)

Rear Panel Support Leg

(GG-6028)

End Panel Cover Plate

GG-6030

j-/

/- Left Rear

Corner Panel

(GG-6018)

Figure 27: Jacket Assembly

23

Page 27

• ' ,.::1 • '_._ oo_

Table 6: Jacket and Draft Hood Carton Contents - See Figure 27 for Placement of Jacket Sections

Ca_on No.

12

12A

Contents

' Cleanout Cover Plates

Jacket Corner Pane!, Right Front

Jack_'t Cumin Pan_'! Leit Front

Jacket Corner Panel. Right Rear

Jacket Corner Panel, Left Rear

Corn_i Pan_l Support Brackets

• Jacket Upper End Pane!. Left

Jacket Upper End Panel, Right

End Pane! Cover Plates

Jacket Lower End Pane!s

Sheet Mete! Screws

Machine Screws, Washers. Nuts

Jackefl l_ermediate Panel - Front 1

Jacket Intermediate Panel _

Jacket IntermP&ate Pane!- Upper Rear I

Jacket Intermediate Panel Lower Rear

Panel Suppor_ _Angle

Rear Panel Sup_o_ l_fl

Lower Rear Panel Guide

Sheet Metal Screws

Sub-Assembly No. Part Number Quantity

GG-6004 1_ I

GG-6015 I

G(J 6016 l

GG-6017 r 1

[ ....

GG-6018 _ 1 I

GG 6033 GG-6029 4

GG 603Z 1

_21 _ i -

GFG 6-6o3o 14-............z

, GG 6022 2

.... GG-6023GG_6024 A]il .......

GG 6025 1

GG-6034 GG-6026 I

GG-6027 [ 2

GG-6028 1 |

GG 6031 1

23

...... J_acket Intermediate Panel - Fron-( ...... 0G-6023-I [ -i ...........

Jacket Intermediate Panel-To_ _ _ 1

Jacket [ntermedlate Panel - Upper Rein GG-6025 I I _I-- ....

12B Jacket Intermediate Panel Lower Rear GG-6026-I 1

Panel Suppor_ Angle GG-6034-1 _ GG-6027 I 2

Rear Panel Support Leg G[GG-6028 _ I

Lower Rear Panel Guide _,o-6031 1

[ +

Sheet Metal Screws .... 23

Jacket Intermediate Panel - Front

Jacket Intermediate Panel - To_

Jacket Intermediate Panel - Upper Rear

Jacket Intermedmte Panel - Lower Rear

12C Panel Support Angle GG-6034-2

Lower Rear Panel Grade

Sheet Metal Screws

Jacket Intermediate Panel - Front

Jacket Intermediate Panel - Top

Jacket Intermediate Panel - Upper Rear

Jacket Intermediate Panel Lower Rear

12D GG 6034 3

Panel Support An_te

Rear Panel Support

Lower Rear Panel Guide

Sheet Metal Screws

Jacket Intermediate Panel- Front

Jacket Intermediate Panel- Top

Jacket Intermediate Panel - Upper Rear

Jacket Intermediate Panel Lower Rear

Lower Rear Panel Guide

Sheet Metal Screws

Draft Hood Section

13

Sheet Metal Screw_

Draft Hood Section

13A ...... j She_ Met_ Scre_ ......

Draft Hood Section

13B

Sheet Metal Screw_

I Sheet Metal Screws

GG-6023-2 _ I

_2 I_ ___

GG 6025-2 i

GG-6026 2

GG-6027

GG-6028

GG-6031

GG-6023-3

GG-6024-3

GG-6025 3

GG-6026-3

GG_027

GG-6028

GG-6031

GG-60234

I

2

, 1

23

1

1

1

' 1

23

GG 6025-4 1

' 1

GG-6028

GG-6031

GG-5001

GG 5001

I

23

I

GG-5001-1

GG-5_I-I

GG-5001-2 1

..... ....

24

Page 28

Boiler

Model

Number

of Ca_ons

_m

1 3 5 7 9 11 13 15 17 19

21 23 25 27

2iiA-O4 1 r ] F I A

211_ 1 L_ _ B

2! 1A 06 1 C

211A-07 1 D

211A-08 E

211A-09 B

211A-10 1 1 B

211A-1! 15

25

29 31 33

35 37 39 41 43 45

45

A I

A' !

A

Figure 28: Jacket Assembly Sequence - Carton Numbers and Locations

_J7

Page 29

Table 7: Draft Hood Section Placement (from Left to Right Facing Front of Boiler)

ModeIB°ilerli Position , Position2 Position3 Position4 Position5 Position6 Position7 Position8 Position9

211A 04 13

211A 05

=211A-06

[ 211A-07

! 2uA-os

L211A709 _ 13A

ii 211A-10 13C

!i 211A-!! 13C

i 211A-12 13A

, 211A 13 13A

211A-14 I 13C

211A-16 13C

13A

13A

I

; L

13

13A ,

13B "

13A 13

13A ! 13A

t

13B 13B l

13B 13C

13C 13C

211A-17 13B 13B 13B

211A-18

211A-19

211A-20 !

211A-211

211A-22

211A-23

13C

13B

13C

13C 13C

13C 13B

13C 13C

211A 24 13C 13C

211A-26 13C 13C

211A-27 13C 13C

211A-28 13C 13C

[

13B

i

13B 13B 13B

13C 13C 13B |

13C 13C 13B

13C 13C

13B 13B

13B 13B

13C 13B

13C 13C

13C 13C

13B 13B

13C 13B

i i

!-, i i

13B

13B

13B

13B

13C [

13B 13B I

13B 13B

211A-29

211A-30

211A-31

211A 32

211A-33

211A-34

211A45

13C 13C 13C

13C 13C 13C

13C 13C 13C

13C 13C 13C

13C 13C 13C

13C 13C 13C

13C 13C 13C

211A-38 I 13B

211A-39 13B

211A-40 13B

211A-41 13C

211A-42 13B

211A-43 13B

! 211A-44 13B

211A-45 13B

211A-36 : 13C 13C i

211A-37 13C i 13C

i

13B

13B

13C

13C

13B

13B

13B

13C

13C

13C

13B

13C

13C

13C

13B

13B

13C

13C

13C

13C

13C

13B 13B

13C 13C

13C 13C

13C 13C

13C i 13B

13B 13B

13c 13cL

13B 13B

13B

13B

13C

13C

13C 13C

13C 13C

13C 13C

13B

13B

13C

13B 13B

13C I 13C

13c j 13c

13C 13C

13B

lac

13C

13C 13C

13C 13C 13C

13B 13C 13C 13C 13C 13C

13C 13C 13C 13C 13C 13C

13C 13C 13C 13C13C 13C

13C 13C 13C 13C 13C 13C

I i3d i

i 211A46 I 13C 13C _ 13C [ 13C _ 13C I 13C _ 13C 7 13C

26

Page 30

7. CONNECT GAS PIPING

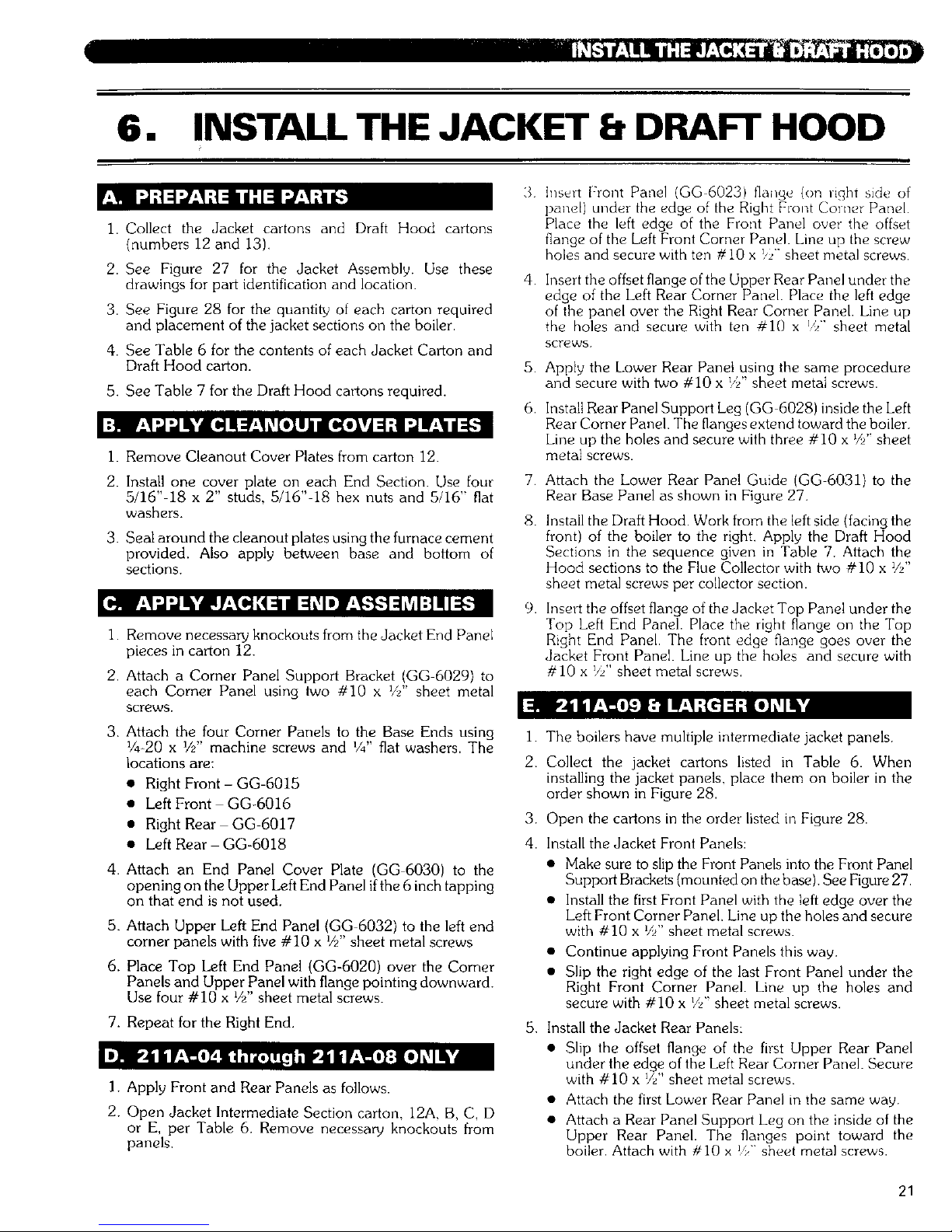

1 The Gas Control Train(s) supplied with this boiler:

s Has been factory assembled and tested for tightness

of joints,

• Mustbere-testedafterinstallationwithasoapsudstest

to assure it is still leak tight after assembly.

• Must be isolated from the gas supply piping during

testing of the supply piping.

2. Assemble the Gas Control Train(s) to the Manifold with

the ground joint union(s) provided. See Figure 29

Models 211A-04 through 211A 18 are supplied with a

single Gas Control Train. Models 211A-19 and larger are

supplied with two or more Gas Control Trains.

3. Support the Gas Control Train(s) with a permanent

brace.

I. Use 3/8" aluminum tubing or as required by local codes

2 Connect the Pilot Line to the, Pilot Cock Assembly

supplied with the Gas Control Train

3 Connect tubing to each pilot

a) Connect electronic pilots to the Pilot Gas Valves.

b) Connect standing pilots (when supplied see Table

3) to the Pilotstats.

c) Install thermocouples in the standing pilots and

connect to the Pilotstats

1. Gas Pressure Regulator

a) Connect regulator vent outlet to outside atmosphere

using V4"tubing or as required by local codes.

b) Terminate the tubing downward to prevent water

from entering the tubing and protect from any

obstruction.

c) Terminate the tubing above and well away from

normal breathing level or building air intakes.

Vent lines separately.

Connect Valve Bleed

line to bleed line to a

standing pilot (when

supplied) or outside

if required by local

codes

g

21 11 6 _---5

3 2 14

_1 15

1 _14

8

1 Pilot Gas Pressure Regulator

2 Pilot Cock

3 Line Gas Pressure Test Tapping

4 Pilotstat (One per Standing Pilot)

5 Red Pilotstat Indicator Button

6 PiiotGas Valve (One per Spark:ignited Piioti

7 Pilot Gas Line

8 Pilot Tubing, 3/8" OD Aluminum

9 Electronic Pilot (Spark Ignited), Typical

10. lgnit!gn/Sensing Cable to Pilot, Typical

11 i Electronic Pilot Ground Wire, Typical

12 Standing Pilot (Manually Lighted), Typical

13 Thermocouple to Standing Pilot, Typical

14 Manual Shut-Off Valve

15 Gas Pressure Regulator

16 Regulator Vent Line to Outside Atmosphere

17 Safety Gas Valve, Standard

18 Main Gas Valve, Standard

19 Gas Valve Bleed Line to Outside Atmosh #.

20 High Gas Pressure Switch (Over 2500 Btuh)

21 Ignition Control Panel

Figure 29: Gas Control Train and Burner Assembly, Single Natural Gas Control Train Shown

(Models 211A-19 and Larger Use Two or More Gas Control Trains)

27

Page 31

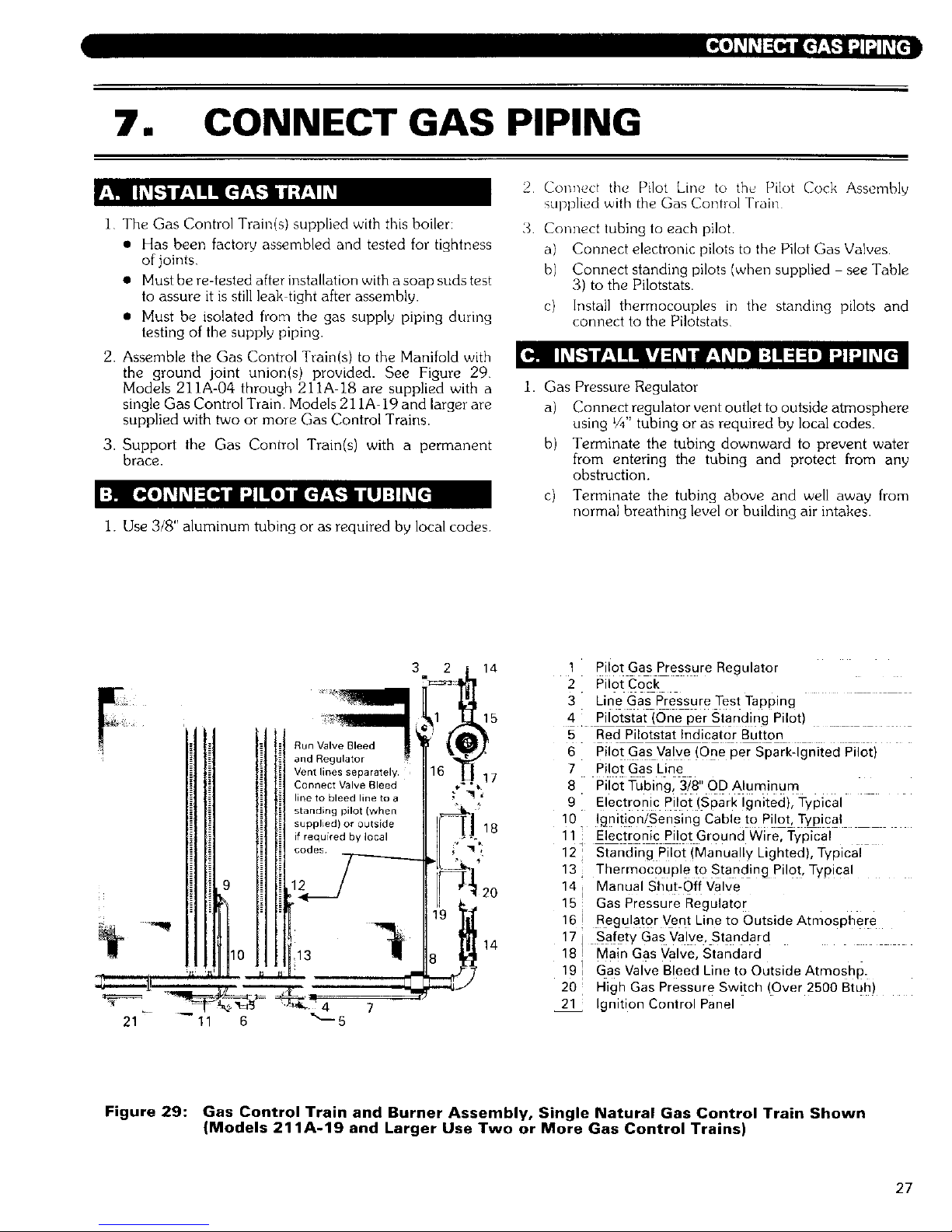

2 Diaphragm Gas Valves

a) Pipe diaphragm gas valve bleed lines to outside

atmosphere unless the boiler is equipped with a

standing pilot. On standing pilot boilers, pipe the

valve bleed lines to the bleed piping pre-installed to

the pilot burner

b) Use _'F tubing or as required by local codes Always

pipe the bleed lines separate from the regulator vent

lines

c)

When piping bleed lines to outside, terminate the

tubing downward to prevent water from entering the

tubing, and protect the tubing teimination from any

obstruction. Terminate the tubing above and wel}

away from normal breathing level or building air

intakes

To Gas Supply -_

Service Valve -_

Ground Joint Uni_i_

J

To Boiler Gas Control Train "n_

Sediment Trap _'_JT; !

Figure 30: Gas Supply Connection to Boiler

1,

2.

3.

4,

.

Size the piping as required by the National Fuel Gas

Code. ANSI Z223 1,_FPA54 or as required by local

codes

a) Use Table {4 for sizing of natural gas for a system

pressure drop of 0 3 inch water column

The standard gas train is designed for a Maximum

pressure of _/2psig (14 inches water column) Make sure

the system regulator will not allow a higher pressure to

the Gas Control Train under any conditions

The Minimum gas supply pressure is listed on the Boiler

Rating Plate. Make sure the system regulator and the

piping are sized and adjusted properly to provide this

pressure under all conditions.

Install a Service Valve. Sediment Trap and Ground Joint

Union at the supply connection to the Gas Control Train

as shown in Figure 30. These are not supplied with the

boiler. Install them in accordance with local codes.

Use only pipe joint compounds rated for use with

Liquefied Petroleum Gases.

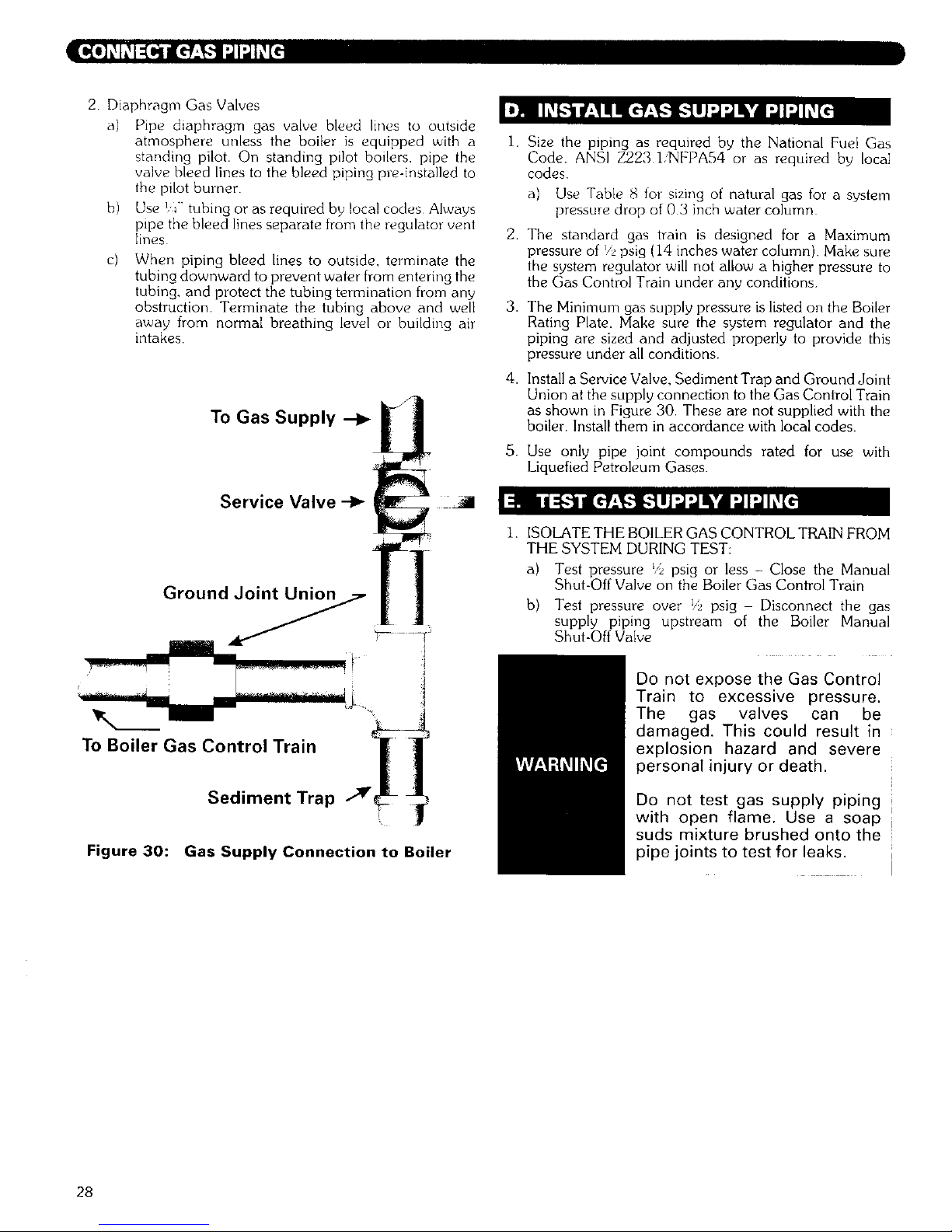

1. ISOLATE THE BOILER GAS CONTROL TRAIN FROM

THE SYSTEM DURING TEST:

a) Test pressure _/bpsig or less - Close the Manual

Shut-Off Valve on the Boiler Gas Control Train

b) Test pressure over _/5psig Disconnect the gas

supply piping upstream of the Boiler Manual

Shut-Off Valve

Do not expose the Gas Control

Train to excessive pressure.

The gas valves can be

damaged. This could result in

explosion hazard and severe

personal injury or death.

Do not test gas supply piping

with open flame. Use a soap

suds mixture brushed onto the

pipe joints to test for leaks.

28

Page 32

Table 8: Capacity of Gas Supply Pipe in Cubic Feet Per Hour of Natural Gas for 0.3 inch Drop

Pipe Length 1 V4"

(Feet) Pipe

1 1/2"

Pipe

2_9

Pipe

21/2" 3" 4" 6"

Pipe Pipe Pipe Pipe

J 1

1(} 1050 1600 3050 4800 8500 17500 44000

_o _o ' ,,oo _!00 _3o0 5oo_I i_oooi[3,o0o

l

30 590 890 1650 2700 4700 9700 I

25000

4o 500 ! 145o1 I 4,0o 22oo0

50 440 670 1270 2000 3600 __1 7400 / 20000

T ........... t- [ --

60 , 4;0 ;]; _ 1150 _ 1850 J. 32;0 + 6800

1050 1700 3000 i 6200

[

490 930 1500 2600 5400

460 ' 870 1400 2500 i 5100

i

380 710 1130 2000 4i00

70 350 560

90 I 320

100 305

150 250

18000

17000

15000

14000 "

11500 ,:

............... J

Above ratings based on natural gas with specific gravity of 0.60 allowing pressure drop of 0.3 inches. No allowance is

needed for pipe fittings. Use the following multipliers on above capacities for specific gravity other than 0.60:

--==SpecificGra;iU=_ 0.50 i_:55 i ] ;:6; ] 0.65

Multiply Capacity by: 110 1.04

....... i =

1.00 .962

0.70

.926

I

29

Page 33

8. INSTALL CONTROLS AND TRIM

1 Pipe the Pop Salety Valve(s) in the 3"" tappings located 1

on the right or left end sections Make sure the relief valve

sizing meets local code requirements• 2.

Pipe the discharge of the Safety

Valve away from any traffic area,

preferably to a floor drain. This

ts necessary to prevent injury

should the valve discharge.

Pipe the discharge full size of

valve outlet.

1. [nstall a I V2" full port ball valve in each of the tappings

provided at the lower back of the end sections. See Figure

31

2. Pipe the valve discharge to a floor drain if available or

apply a nipple and cap to close off when not in use.

Install Boiler Pop Safety Relief

Valve(s) in 3" End Section Tapping(s)

Pipe Safety Valve Discharge

to safe location, preferably to

a floor drain

2" Skim

Connection

12) 1 W' Blowdown Valves

ip off

Figure 31: Blowdown Valve Piping

.

4.

5.

6.

7.

Mount the float type Low Water Cutout and Gauge Glass

in the tappings provided in the front of either end section.

Do not apply piping which would raise or lower the

location of the cutout relative to the tappmgs in the boiler.

Raising the water level over the design height will cause

water carryover to the system.

For correct location of typical low water cutout!feeder or

low water cutout/pump control, see Figures 33 through

36.

Mount the probe type low water cutout supplied with the

boiler. The end sections have %" tappings in the front

for mounting the probe low water cutout auxiliary

control. See Figure 13.

a) The standard probe control is either the Hydrolevel

Model 650P or McDonnell & Miller Model PS850.

These controls are automatic reset type.

b) When a manual reset control is required, the boiler

can be supplied with either the Hydrolevel Model

550P or the McDonnell & Miller Model PS850M.

Provide each float low water cutout with a blowdown

valve. Pipe the blowdown away from traffic to a floor

drain if available• The blowdown valve is required for

proper maintenance of the control.

Maintain a height of 40 Vi' from boiler foundation to the

normal water level.

When using Multiple Float Type Controls: Always pipe