PEERLESS WV-DV, WV-DV Series, WV-DV-03-075, WV-DV-03-085, WV-DV-03-110 Installation, Operation & Maintenance Manual

...Page 1

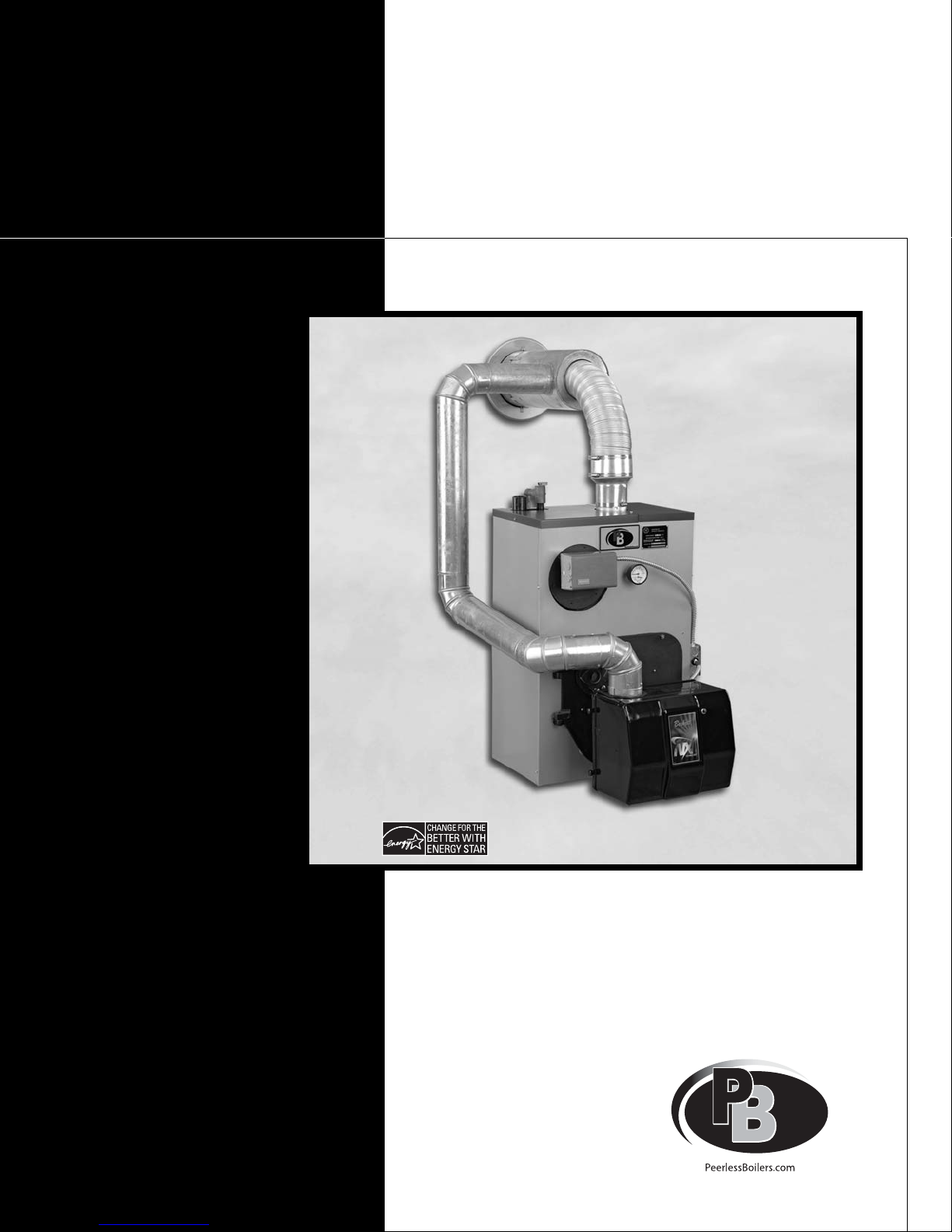

WV-DV

Boilers

Series

Oil

Installation,

Operation &

Maintenance

Manual

As an ENERGY STA R®Partner, PB Heat, LLC has determined that certain firing

rates of this product meet the

ENERGY STA R

®

guidelines for energy efficiency.

Page 2

Sidewall Venting

The Peerless WV-DV is designed and built to be vented through a side wall of a building using a

stainless steel concentric vent terminal (4 inch diameter tube inside an 8 inch diameter tube).

Exhaust gases from combustion contain water vapor. During the cooler months of the year, this

water vapor will condense into a visible vapor plume. This water vapor may condense on any

surface near the vent terminal. Care must be taken not to locate the vent terminal where the exhaust

gas, vapor plume and condensation could cause a hazard or a nuisance. Do not locate terminal

under a deck, for instance, as it may create a coating of ice on the deck during the winter months,

as well as shorten the life of the deck materials. Refer to Chapter 4 in this manual for specific

terminal location requirements. Condensate from a side wall vent terminal may also cause paint on

surrounding surfaces to crack and peel. If the boiler is used to heat potable (tap) water, the boiler

will cycle year round.The effects of hot exhaust gases and odors must be taken into consideration

during summer months.

Side wall vented, oil fired appliances may cause soot staining on wall surfaces surrounding their

terminals. To reduce the potential for staining, the boiler must be serviced annually. Soot and scale

must be completely removed from the combustion chamber and cast iron heat exchanger flueways.

See Chapter 7 in this manual. The oil burner must be completely serviced and set up according to

the specifications shown in Chapter 5 of this manual.

NOTICE

Page 3

1

USING THIS MANUAL 2

A. INSTALLATION SEQUENCE . . . . . . . . . . . . .2

B. SPECIAL ATTENTION BOXES . . . . . . . . . . . .2

1. PREINSTALLATION 3

A. ACCESSIBILITY CLEARANCES . . . . . . . . . . .3

B. CLEARANCES FROM COMBUSTIBLE

CONSTRUCTION . . . . . . . . . . . . . . . . . . . . . .3

2. BOILER SET-UP 4

A. SETTING UP THE BOILER . . . . . . . . . . . . . . .4

3. PIPING AND CONTROLS 5

A. BOILER SUPPLY AND RETURN . . . . . . . . . . .5

B. TANKLESS WATER HEATER . . . . . . . . . . . . .6

C. INDIRECT-FIRED WATER HEATER . . . . . . . .6

D. SAFETY RELIEF VALVE . . . . . . . . . . . . . . . . .6

E. CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . .6

4. VENTING 7

A. VENT SYSTEM INSTALLATION . . . . . . . . . . .7

5. OIL BURNER 9

A. BURNER INSTALLATION . . . . . . . . . . . . . . . .9

6. ELECTRICAL 11

A. WIRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

B. ZONED SYSTEM WIRING . . . . . . . . . . . . . .11

7. MAINTENANCE 15

A. CLEANING HEATING SURFACES . . . . . . . .16

8. BOILER DIMENSIONS & RATINGS 17

9. REPAIR PARTS 18

TABLE OF CONTENTS

TABLE OF CONTENTS

Page 4

2

A. INSTALLATION SEQUENCE

Follow the installation instructions provided in this

manual in the order shown. The order of these

instructions has been set in order to provide the installer

with a logical sequence of steps that will minimize

potential interferences and maximize safety during

boiler installation.

B. SPECIAL ATTENTION BOXES

Throughout this manual you will see special attention

boxes intended to supplement the instructions and make

special notice of potential hazards. These categories

mean, in the judgment of PB Heat, LLC:

Indicates special attention is needed, but not directly

related to potential personal injury or property

damage.

NOTICE

Indicates a condition or hazard which will or can

cause minor personal injury or property damage.

CAUTION

DANGER

Indicates a condition or hazard which will cause

severe personal injury, death or major property

damage.

USING THIS MANUAL

USING THIS MANUAL

Indicates a condition or hazard which may cause

severe personal injury, death or major property

damage.

WARNING

Page 5

A. ACCESSIBILITY CLEARANCES

To provide for reasonable conditions of accessibility, the

following minimum clearances are recommended:

Alcove Installation.

1. 12" from left side

2. 24" from top

3. 24" from front

4. 9" from right side and rear

B. CLEARANCES FROM COMBUSTIBLE

CONSTRUCTION

The design of this boiler is certified for the following

clearances from combustible construction:

1. 0" from rear

2. 0" from right and left sides

3. 0" from top

4. 0" from vent pipe

5. 0" from vent connector

6. 0" from vent terminal

7. 24" from front

3

PREINSTALLATION

1. PREINSTALLATION

Read carefully, study these instructions before beginning work. It will save time. Study the included drawings. Save these

instructions for reference.

This boiler must be installed by a qualified contractor.

The boiler warranty can be voided if the boiler is not installed, maintained and serviced correctly.

The equipment shall be installed in accordance with those installation regulations in force in the local area

where the installation is to be made, including the current edition of NFPA-31. These shall be carefully followed

in all cases. Authorities having jurisdiction shall be consulted before installations are made.

NOTICE

Do not tamper with boiler or controls.

CAUTION

NEVER BURN GARBAGE OR PAPER IN THE UNIT,

AND NEVER LEAVE COMBUSTIBLE MATERIAL

AROUND IT.

CAUTION

Do not use this appliance if any part has been under

water. Improper or dangerous operation may result.

Immediately call a qualified service technician to

inspect the boiler and to replace any part of the

control system and any control which has been

under water.

WARNING

Page 6

4

BOILER SET-UP

A. SETTING THE BOILER

1. Prepare sketches and notes of the layout of the

installation. Include boiler location, venting system,

existing piping and wiring. Show existing equipment

that may interfere with installation of new

equipment. See Section 4-A. “Vent System

Installation,” Page 7, and Figure 4.1.

2. Provide a level foundation, located as close as

possible to the center of the heating system.

3. This boiler is suitable for use on combustible

flooring, provided the boiler is not set on carpet and

a metal drip pan is placed under the appliance.

4. See exploded view (Figure 9.1). After uncrating

boiler and setting it on foundation, open burner

mounting plate (Item 5) and make certain the target

wall (Item 2) is seated in the back of the combustion

chamber. (WV-DV-04) Ceramic fiber blanket base

liner (Item 3) should be lying flat on bottom of

combustion chamber between target wall and burner

mounting plate. Close burner mounting plate.

2. BOILER SET-UP

Page 7

5

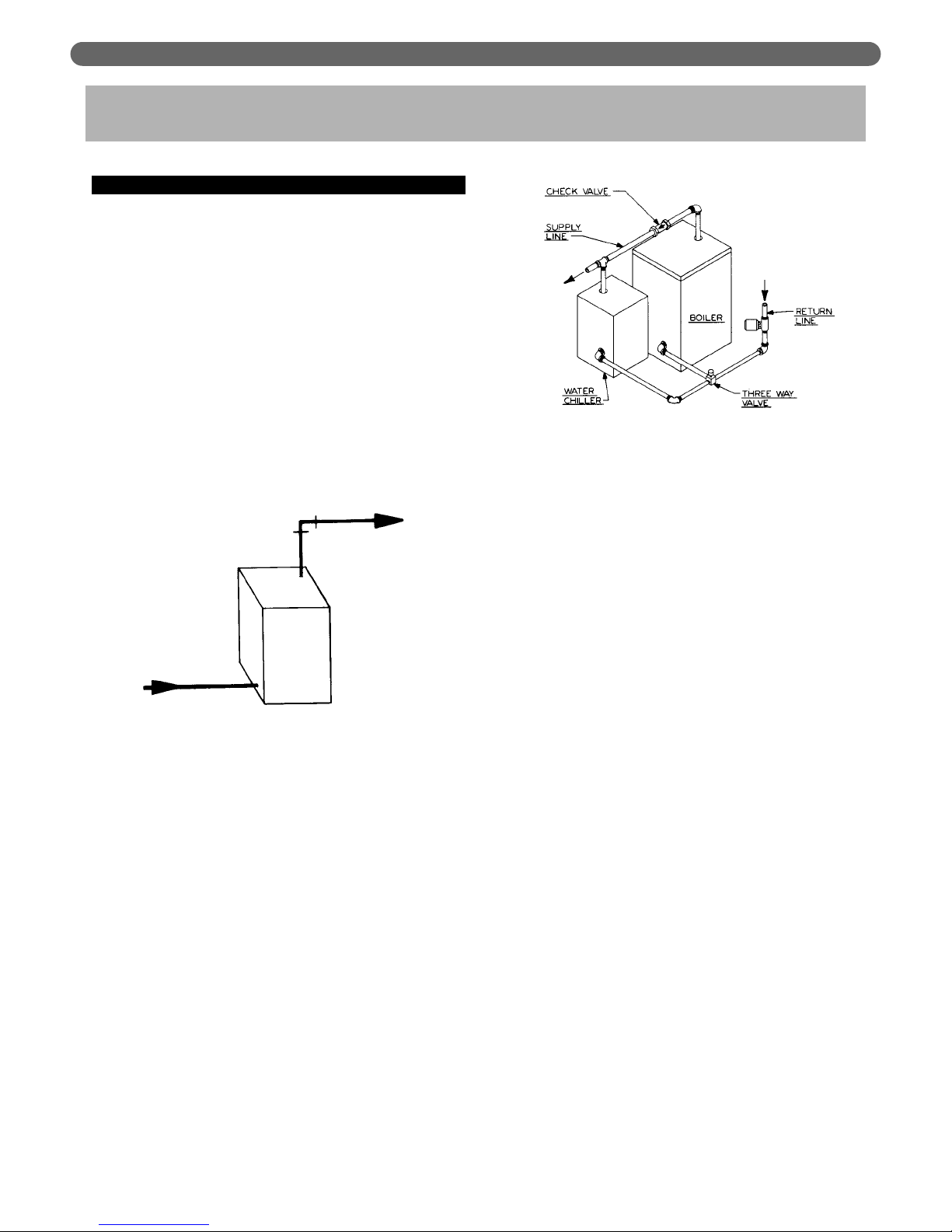

A. BOILER SUPPLY AND RETURN

1. See Figure 3.1 for suggested piping to the boiler.

2. Make up cold water supply connection to the boiler.

3. Plug all open tappings in the boiler and fill with

water. Apply approximately thirty (30) psi pressure.

Check to make certain that all joints and fittings are

water tight.

4. After all joints and connections have been proven

water tight, remove cold water supply and plugs

from all tappings that are to be used. See Figure 8.1

for tapping locations.

5. Return water piping must be done in such a manner

to allow clearance from the burner mounting plate to

other piping when opening and closing the burner

mounting plate.

3. PIPING AND CONTROLS

PIPING AND CONTROLS

6. The supply and return connections should be sized to

suit the system. A 1-1/2" to 1-1/4" reducing coupling

may be used on the return where the system piping is

1-1/2". The supply should be out of the top of the

back section and return to the bottom of the front

section. There is a 3/4" tapping in the top of the back

section for air elimination.

Figure 3.2

Note: If boiler is to be used in conjunction with a refrigeration

system, the chilled medium shall be piped in parallel with

boiler and proper valves applied to prevent the chilled

medium from entering the boiler. Refer to Figure 3.2.

When the boiler is connected to heating coils located in

air handling units, the boiler piping system must be

equipped with flow control valves or other automatic

devices to prevent gravity circulation of the boiler water

during the cooling cycle.

Figure 3.1

Page 8

6

B. TANKLESS WATER HEATER

C. INDIRECT-FIRED WATER HEATER

1. If a water boiler is to be used in conjunction with an

indirect-fired water heater refer to Figure 3.4 for

typical piping. Also refer to additional instructions

supplied with tank.

D. SAFETY RELIEF VALVE

1. Remove safety relief valve and 3/4" x 3" nipple from

parts bag. Install nipple and safety relief valve in top

or rear tapping. See Figure 8.1. If rear tapping is

used, installer must supply an elbow so that safety

relief valve is installed in vertical position.

E. CONTROLS

1. For complete information on servicing and

adjustment of controls, refer to the attached control

specification sheets.

Figure 3.3

Figure 3.4

Install mixing valve in hot water supply piping. Water

temperature above 125°F can cause severe burns

instantly or death from scalds.

DANGER

PIPING AND CONTROLS

Pipe the discharge of the safety relief valve to

prevent injury in the event of pressure relief. Pipe the

discharge to a drain. Provide piping that is the same

size as the relief valve.

CAUTION

Note: X-1019R, X-1020R and PP-1011R Coils installed in

WV-DV boilers have internal flow controls installed.

Do not use external flow controls with

these coils.

Page 9

A. VENT SYSTEM INSTALLATION

1. Determine vent terminal location:

a. Vent length must be between 3' and 20' long.

See paragraph 3 and Figure 4.1 for air intake

requirements.

b. No clearance is required between vent terminal

and combustible construction.

c. Vent terminal extends 12" beyond outside wall

surface and at least 16" beyond inside wall

surface. See Figure 4.1.

d. Provide 3' clearance above any forced air inlet

within 10'.

e. Provide 4' clearance below, 4' beside, or 1' above

any door, window, or gravity air inlet into any

building.

f. On multiple boiler installations, provide 18"

clearance between vent terminals. Located

terminals on same horizontal plane.

g. Provide 1' clearance between bottom of vent

terminal and ground level or between bottom of

vent terminal and normal snow lines.

h. Provide 4' horizontal clearance from, and in no

case above or below, unless a 4' horizontal

clearance is maintained, from electric meters, gas

meters, gas regulators, and gas relief equipment.

i. Provide 5' clearance to the vent outlet of a fuel

oil supply tank.

j. Provide 1' clearance to the soffit of the roof and

3' clearance to an inside corner of an L-shaped

building.

k. Do not locate vent terminal over public walkways

where condensate could create a nuisance or

hazard.

l. When adjacent to a public walkway, locate vent

terminal at least 7' above grade.

7

4. VENTING

VENTING

Figure 4.1: Venting

This boiler is shipped with a Flex-L International Vent

Terminal carton, and a Flex-L International Venting

Components Kit. The following components from

these two cartons must be used in the installation of

this boiler:

·

CeraFlex Oil Vent Terminal

·

CeraFlex Vent Pipe

·

CeraFlex Appliance Adapter

·

CeraFlex Terminal Adapter

· CeraFlex Sealant

NOTICE

This Oil-Fired Unit Shall be Connected to a Direct Vent

System, to Assure Safe Proper Operation of the Unit.

CAUTION

Table 4.1

Page 10

8

2. Use Flex-L International Inc. 4" diameter CeraFlex

Vent Pipe.

3. For air intake, use 4" diameter galvanized smoke

pipe or 4" diameter flexible corrugated aluminum

pipe. Maximum equivalent length of galvanized

smoke pipe is 40'. Allow 5 equivalent feet for each

90° elbow used. (Example: No more than 20' straight

smoke pipe can be used with four 90° elbows.) To

connect air intake to Riello BF5 burner, use burner

air adapter from trim bag to connect 4" air intake to

3" opening on top of burner. See Figure 4.1.

4. For specific installation and maintenance instructions

for the Flex-L Vent Terminal, Appliance Adapter,

Terminal Adapter, Burner Air Adapter (Riello only),

and Sealant that are included with the boiler, as well

as instructions for installation of flexible vent pipe and

air intake pipe, refer to Flex-L Manual #Y4-CF12

included in vent kit.

PB Heat, LLC requires that the vent slopes down 1/4"

per foot towards the vent terminal.This takes

precedence over the requirements shown in the

Flex-L manual.

NOTICE

VENTING

Page 11

9

A. BURNER INSTALLATION

1 The oil burner is supplied with a mounting flange

fixed in position.

2. BE SURE HI TEMP GASKET IS BETWEEN THE

BURNER MOUNTING FLANGE AND THE

COMBUSTION CHAMBER COVER PLATE.

3. Care must be taken when routing the oil lines so not

to interfere with the opening and closing of the

burner mounting plate. Flexible oil lines or flared

copper disconnects with valves (when copper lines

are used) may be installed to assure full opening of

the burner mounting plate when servicing.

Note: Two-pipe oil supply for Riello burner requires a sep-

arate kit. Order part #C7001026 from Riello dealer.

4. Oil Burner Specifications:

For information pertinent to the oil burner such as

nozzle sizing, fuel supply piping, adjusting or

servicing, refer to the charts below and the burner

installation manual.

5. Sampling tapping in CeraFlex Appliance Adapter must

be used for CO², smoke and flue pressure readings.

6. Burner should start automatically when thermostat is

turned up and main boiler service switch is turned

on. If burner does not start, check to be sure there is

oil in the tank and push reset button on burner

control: (Beckett) square red button; (Carlin) round

red button; (Riello) round red button inside clear

flexible cover on back of burner cover. If burner still

does not start, contact serviceman.

7. Burner and boiler can be shut down by turning

down the thermostat and moving the main boiler

service switch to the “off” position.

8. Post-purge timing on Riello BF5 burner is controlled

by 3/8" diameter dial near top right corner of

AL1009 circuit board inside burner cover. Post-purge

duration must be a minimum of one minute. Adjust

dial so arrow is pointing directly to the right (toward

mounting screw for AL1009 bracket). Check postpurge timing to confirm it is at least one minute long.

5. OIL BURNER

OIL BURNER

BURN ONLY #2 FUEL OIL IN THIS APPLIANCE. DO

NOT USE GASOLINE, CRANKCASE DRAININGS OR

ANY OIL CONTAINING GASOLINE.

CAUTION

Do not attempt to start the burner when excess oil

has accumulated, when the unit is full of vapor, or

when the combustion chamber is very hot.

CAUTION

Always keep the manual fuel supply valve shut off

if the burner is shut down for an extended period

of time.

CAUTION

Page 12

10

Table 5.1

Beckett NX Burner Specifications

Boiler Model No. Burner Model Nozzle Manufacturer, Size Pump Pressure (psig) Head/Air Setting Low Fire Baffle

WV-DV-03-075 NX70LB Delavan 0.60 60° W¹ 175 2.25 Ye s

WV-DV-03-085 NX70LB Delavan 0.65 60° W 175 3.00 Ye s

WV-DV-03-110 NX70LB Hago 0.85 60° B¹ 175 3.75 No

WV-DV-04-115 NX70HB Hago 0.85 60° B 170 1.50 Ye s

WV-DV-04-130 NX70HB Hago 1.00 60° B¹ 170 1.50 No

Table 5.2

Table 5.3

Carlin EZ1-HP Burner Specifications

Boiler Model No. Delavan Nozzle Size Pump Pressure (psig) Air Boot Setting Head Bar

WV-DV-03-075 .60 70° A¹ 150 0.5 0.75

WV-DV-03-085 .65 70° A¹ 150 0.6 0.75

WV-DV-03-110 .85 70° A 150 0.85 1.10 - 1.25

WV-DV-04-115 Hago 1.00 60° B¹ 140 1.00 1.10 - 1.25

WV-DV-04-130 Hago 1.10 60° B 140 1.25 1.10 - 1.25

Riello BF5 Burner Specifications

Boiler Model No. Nozzle Size Pump Pressure (psig) Turbulator Setting Air Damper Setting

WV-DV-03-075 Delavan .60 80° B¹ 165 1 3.3

WV-DV-03-085 Delavan .65 80° B¹ 165 1 3.8

WV-DV-03-110 Delavan .90 80° B 165 2 5.0

WV-DV-04-115 Hago .85 60° B¹ 180 2 5.0

WV-DV-04-130 Hago 1.10 60° B 140 4 5.0

Start-up and adjustment recommendations: Above Turbulator, Pin, Air Damper, and Air Dial settings are start-up settings only. Adjust burner for highest

CO²(no more than 13%) while maintaining a 0 smoke spot. Pressure or draft over fire and in flue cannot be adjusted. However, draft and/or pressure

measurements must be taken in these two locations and recorded for reference. All adjustments and measurements must be made using suitable

instruments such as those found in a Bacharach Combustion Test Kit.

Factory Installed Nozzles are indicated in Boldface.

1. Shipped Loose

OIL BURNER

Page 13

11

ELECTRICAL

A. WIRING

1. All electrical wiring shall be done in accordance with

the National Electrical Code and Local

Requirements. Single Pole Switches including those

of Safety Controls or Protective Devices shall not be

wired in a grounded line.

B. ZONED SYSTEM WIRING

1. Wire zone circulators as shown in Figures 6.4 and

6.5. Wire zone valves as shown in Figure 6.6.

6. ELECTRICAL

Do not connect power supply to Aquastat. To assure

service switch interrupts power to all boiler controls,

power supply must be connected to junction box as

shown below.

CAUTION

Figure 6.2: Beckett/Carlin Burner

Figure 6.1: Connecting Incoming Power

Page 14

12

ELECTRICAL

Figure 6.3: Riello Burner

Figure 6.4: Zoning With Circulators, Honeywell L8148 Aquastat

Page 15

13

ELECTRICAL

Figure 6.5: Zoning With Circulators, Honeywell L8124A, C Aquastat

Figure 6.6: Zoning With Zone Valves

Page 16

14

Figure 6.7: Partner with Circulator (Non-priority)

ELECTRICAL

Page 17

15

MAINTENANCE

7. MAINTENANCE

WARNING

Product Safety Information

Refractory Ceramic Fiber Product

This appliance contains materials made from refractory ceramic fibers (RCF). Airborne RCF

fibers, when inhaled, have been classified by the International Agency for Research on

Cancer (IARC), as a possible carcinogen to humans. After the RCF materials have been

exposed to temperatures above 1800°F, they can change into crystalline silica, which has

been classified by the IARC as carcinogenic to humans. If particles become airborne during

service or repair, inhalation of these particles may be hazardous to your health.

Avoid Breathing Fiber Particulates and Dust

Suppliers of RCF recommend the following precautions be taken when handling these materials:

Precautionar

y Measures:

Provide adequate ventilation.

Wear a NIOSH/MSHA approved respirator.

Wear long sleeved, loose fitting clothing and gloves to prevent skin contact.

Wear eye goggles.

Minimize airborne dust prior to handling and removal by water misting the material and

avoiding unnecessary disturbance of materials.

Wash work clothes separately from others. Rinse washer thoroughly after use.

Discard RCF materials by sealing in an airtight plastic bag.

Fir

st Aid Procedures:

Inhalation: If breathing difficulty or irritation occurs, move to a location with fresh clean air.

Seek immediate medical attention if symptoms persist.

Skin Contact: Wash affected area gently with a mild soap and warm water. Seek immediate

medical attention if irritation persists.

Eye Contact: Flush eyes with water for 15 minutes while holding eyelids apart. Do not rub

eyes. Seek immediate medical attention if irritation persists.

Ingestion: Drink 1 to 2 glasses of water. Do not induce vomiting. Seek immediate medical

attention.

Page 18

16

MAINTENANCE

A. CLEANING HEATING SURFACES

TO CLEAN:

1. Turn off all electrical power to the boiler before

beginning cleaning operation.

2. Remove top jacket panel and flue collector cover

plate, Item 11.

3. Brush the flue passages thoroughly from the top with

a wire brush. If unit is extremely dirty, brushing up

from the combustion chamber area also may be

necessary. The target wall is made of a soft ceramic

fiber. Care must be taken not to damage this

material during cleaning.

4. Remove any scale or soot from the combustion

chamber area by vacuum cleaning or any other

available means.

5. Replace oil burner and flue collector cover plate

making sure all gaskets are in place.

6. Replace jacket top panel.

7. Inspect venting system.

Entire heating system, including boiler, burner and

venting system, must be inspected at least once a

year by a qualified heating professional. Boiler is to

be cleaned at least once a year. To thoroughly clean

the boiler it must be brushed down from the top.

Alternately, for limited space or minimum clearance

to combustible installations, cleaning the heat

exchanger from the combustion chamber side is

acceptable.

NOTICE

Combustion chamber cover plate must be opened

to facilitate this operation.

NOTICE

Combustion chamber and flue collector may be

under pressure when burner is running. Flue

collector cover plate and combustion chamber

must be completely sealed before boiler is returned

to operation.

CAUTION

All Cover Plates, Enclosures, and Guards must be

maintained in place at all times, except during

maintenance and servicing.

NOTICE

Page 19

17

BOILER DIMENSIONS & RATINGS

8. BOILER DIMENSIONS & RATINGS

Table 8.1: WV-DV Ratings

1. Boiler Model No. may have the following suffix letters:

a. W–Water, b. P–Packaged, c. C–Circulator, d. T–Tankless Coil

2. Heating Capacity ratings are based on U.S. Government standard tests, with

13.0% CO².

3. The water ratings are based on piping pick-up allowance of 1.15. Consult factory

before selecting a boiler for gravity hot water installations and installations

having unusual piping and pick-up requirements, such as intermittent system

operation, extensive piping systems, etc.

4. Firing rate is based on a fuel oil with a heating value of 140,000 BTU per gallon.

Burner input based on maximum altitude of 2,000 ft. – for other altitudes

consult factory.

(1)

Boiler

Model

Number

(2)

Heating

Capacity

BTU/Hr.

(3)

Net I=B=R Ratings

BTU/Hr.

Water

(4)

I=B=R

Firing

Rate G.P.H.

WV-DV-03-075 92,000 80,000 0.75

WV-DV-03-085 103,000 90,000 0.85

WV-DV-03-110 131,000 114,000 1.10

WV-DV-04-115 141,000 122,000 1.15

WV-DV-04-130 158,000 137,000 1.30

Model A B

WV-DV-03

14¹⁄₈" 7¹⁄₁₆"

WV-DV-04

18¹⁄₈" 9¹⁄₁₆"

Figure 8.1: WV-DV Boiler Views

Page 20

18

REPAIR PARTS

9. REPAIR PARTS

Figure 9.1: Repair Parts

Repair parts are available from your installer or by contacting PB Heat, LLC, P.O. Box

447, New Berlinville, PA 19545-0447.

Note: Remember to include boiler model number and serial number when ordering parts.

5a

5b

5c

5d

5e

Page 21

19

Table 9.1: Repair Parts**

**See Figure 9.1

REPAIR PARTS

Item

No.

Description

Additional

Information

Stock Code

WV-DV-03

Stock Code

WV-DV-04

1

Block Assembly Water WPCT

— 90183 90184

Block Assembly Water WPC

— 90186 90187

2

Target Wall

— 50795 50795

3

Base Liner

— — 50857

4

Swing Door Hinge

— 3903 3903

5

Burner Mounting Plate Assembly

— PP1051 PP1051

Burner Mounting Plate Insulation

— 50794 50794

Flame Observation Assembly

— 90754 90754

5a

Flame Observation Cover Plate

— SC1007P SC1007P

5b

Face Gasket

— 50230 50230

5c

Pyrex Observation Window

— 51681 51681

5d

Ring Gasket

— 50229 50229

5e

Observation Glass Holder

— X1138P X1138P

6

Burner Mounting Plate Rope Seal — 51210 51210

7

Steel Cover Plate (Front) Water — 99812 99812

8

Rubber Gasket (Front Plate) — 51800

51800

9

Tankless Coil — 90637

90534

10

Flue Collector Plate Blanket Seal — 90999

90999

11

Flue Collector Cover Plate — 50245

50253

12

Rope Seal — 51209

51209

13

Rear Outlet Cover Plate — 90563

90563

15

Jacket Assembly — 90098

90418

Oil Burner

Specify Brand Name

and Boiler Size

—

—

Temperature-Pressure Gauge

— — —

Aquastat

— — —

Drain Valve

— — —

Relief Valve

— — —

Boiler Vent Adapter

CFAA44P 7612 7612

Flexible Pipe Termination Adapter

CFAT44 7613 7613

Riello Burner Adapter

CFBA34-RL 7615 7615

Tube of Sealant

XMMSC5 7616 7616

Concentric Vent Termination Kit

CFT4 91776 91776

Page 22

20

NOTES

Page 23

21

NOTES

Page 24

HI Division

of gama

ASME

PP8076 R5 (2/06-3M)

Printed in U.S.A.

©2006

WV-DV

Boilers

Series

Oil

Installation,

Operation &

Maintenance

Manual

TO THE INSTALLER:

This manual is the property of the owner and must

be affixed near the boiler for future reference.

TO THE OWNER:

This boiler should be inspected annually by a

Qualified Service Agency.

Service Information

PB HEAT, LLC

P.O. BOX 447 • NEW BERLINVILLE, PA 19545-0447

Name:

Address:

Phone:

Loading...

Loading...