PEERLESS WBV SERIES, WV SERIES, WBV-03-08, WBV-03-110, WBV-04-095 Installation, Operation & Maintenance Manual

...Page 1

WBV/WV

Boilers

Installation,

Operation

Maintenance

Manual

PEERLESS"

CAST IRON BOILERS

Page 2

Packaged or Knockdo ,

8 Sizes 3-5 Sections .60 to 2.00 GPH Input 82% to 86% AFUE

Natural Draft (chimney) Venting

Factory Assembled Sections on Knockdown Boilers

• Reduces Installation Time

WBV in 3 and 4 Section for Hot Water or Steam

• Convertible from Rear to Top Flue for Venting Flexibility

WV in 5 Section for Hot Water

• Top Flue Only

High Efficiency Flame Retention Burners

• Choice ofBeckett, Carlin or Riello

Full Plate Swing-Out Door

• Standard on All Boilers

• Provides Easy Access to Combustion Chamber Area

jbr Cleaning and Servicing

Large Water Content, Wet Base Section Design

• Reduces On/O_'f'Cycling

Steel Push Nipples

• Provide a Permanent Water Tight Seal Between Sections

• Unaffected by Petroleum and Other Contaminants

Deluxe Insulated Enameled Steel Jacket

• Reduces Boiler Heat Loss

Safety Controls

• Prob_ or Floai Type Low Water

Cut-Qff Approved on Steam Boilers

Tankless Coils

• For Domestic Hot Water Production

on Hot Water Boilers

As an ENERGY STAR _ Partner Peerless Healer Comparl¥ Has delerr#med

that certain f_rin9 rales of this product mee_ Ihe ENERGY STAR" guidelines

for energy efficiency

• Honeywell Operating Controls

• Taco 007 Circulator on Packaged Water Boilers

• Probe Type LWCO on Packaged Steam Boilers

omp\e te J

• Tankless Coils

• Barometric Draft Damper

• Grundfos Circulator on Packaged Water Boilers

• Float Tltpe LWCO on Packaged Steam Boilers

/'_'<'rl(,._.s 1 lec_ttq Compony is p&_a.s_d lo q[]_'r otlt _ @the" most coml)reh_.t_siv¢" u,tu_c_ttty l)i-o()l(lms ill

the. hlHztstry. All P(x'rless tz!sidential cckst iron boilers i11chtde a.fidl orl(! !F.ar It,azTcUlty. A limiled.

li]_'litllt" It,(tt r(iNly is provided jbr Ihe cc_st iron sections q[ Pcerless rt_sidetltial hol [t,(llt_!t boilet_.

P_'_tl('._5 _tl._o i)tol,id<!s o linlit_'d. 11!11_](fOf [tl_UTO/l/t] Oil I_l(_ C€ISt irotl SeCtiotls Q[ il5 I'('si_lt,llllol sl(?at]l

boil_'t._. Fit,(, ariel !('n !j('cw _5\'l_!lld('d [t,olv_lltli('s oil parts €Old lclbor nre IIOIL! (Ip(lilflblt'. P[('_Is_' COllStll/

]_'('rl_'y;5 [ It'(tlt,r ('OmlXUl!lJbr compIt'lt" tt,(ltT_ttll[I il!fbrmation.

PEGRLESS _

CAST IRON BOILERS

Peerless Heater Company * 231 North Walnut Street • Boyertown, PA 19512-1021 * 610-367-2153 • www.peerless-heater.com

FAB WBV RI (5!02 5M)

prlrlf(?(l _rl U S A

Page 3

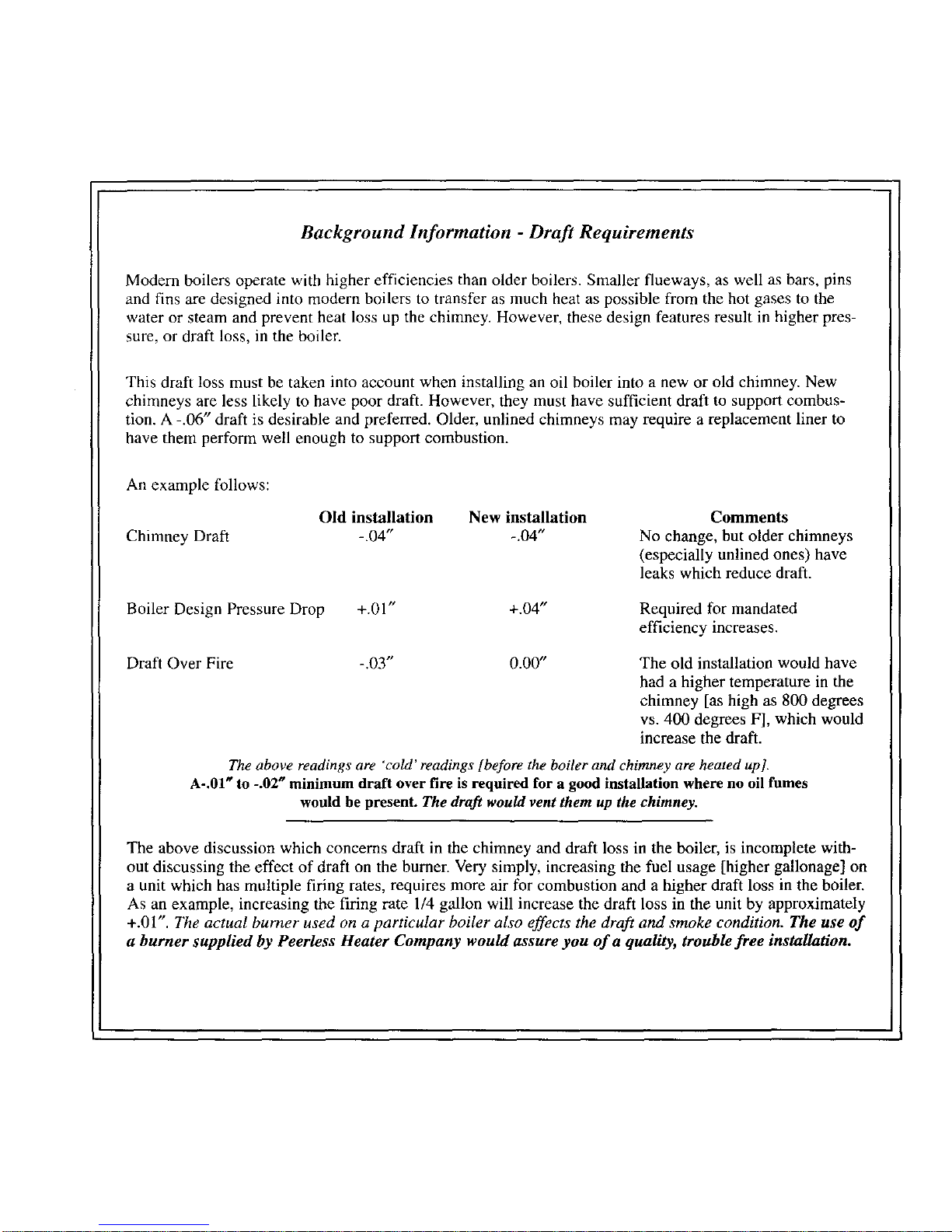

Background Information - Draft Requirements

Modern boilers operate with higher efficiencies than older boilers. Smaller flueways, as well as bars, pins

and fins are designed into modern boilers to transfer as much heat as possible from the hot gases to the

water or steam and prevent heat loss up the chimney. However, these design features result in higher pres-

sure, or draft loss, in the boiler.

This draft loss must be taken into account when installing an oil boiler into a new or old chimney. New

chimneys are less likely to have poor draft. However, they must have sufficient draft to support combus-

tion. A -.06" draft is desirable and preferred. Older, unlined chimneys may require a replacement liner to

have them perform well enough to support combustion.

An example follows:

Chimney Draft

Old installation New installation

-.04" -.04 °

Comments

No change, but older chimneys

(especially unlined ones) have

leaks which reduce draft.

Boiler Design Pressure Drop

+.01" +.04"

Required for mandated

efficiency increases.

Draft Over Fire -.03" 0.00"

The old installation would have

had a higher temperature in the

chimney [as high as 800 degrees

vs. 400 degrees F], which would

increase the draft.

The above readings are 'cold' readings [before the boiler and chimney are heated up].

A-.01 _ to -.02 _ minimum draft over fire is required for a good installation where no oil fumes

would be present. The draft would vent them up the chimney.

The above discussion which concerns draft in the chimney and draft loss in the boiler, is incomplete with-

out discussing the effect of draft on the burner. Very simply, increasing the fuel usage [higher gallonage] on

a unit which has multiple firing rates, requires more air for combustion and a higher draft loss in the boiler.

As an example, increasing the firing rate 1/4 gallon will increase the draft loss in the unit by approximately

+.01". The actual burner used on a particular boiler also effects the draft and smoke condition. The use of

a burner supplied by Peerless Heater Company would assure you of a quality, trouble free installation.

Page 4

INSTALLATIONINSTRUCTIONS- SERIESWBVandWV

Readcarefullybeforebeginningwork.It willsavetime.Studytheincludeddrawings.

Theequipmentshallbeinstalledinaccordancewiththoseinstallationregulationsin forceinthe localareawherethe installationisto be made,including

the currenteditionof NFPA-31.Theseshallbecarefullyfollowedinall cases.Authoritieshavingjurisdictionshall beconsultedbeforeinstallationsare

made.

Theboiler mustbe installedbya qualifiedcontractor.

Theboiler warrantycanbe voidedifthe boileris notinstalled,maintainedandservicedcorrectly.

A - ACCESSIBILITYCLEARANCES

1- Toprovidefor reasonableconditionsofaccessibility,thefollowingminimumclearancesarerecommended.

a. TopOutletFlue:At least24" in thefront,rear andon bothsides.

b. RearOutletFlue:At least24" infrontand bothsides;at least30" inthe rear.

B- AIRFORCOMBUSTIONANDVENTILATION

1- Be certainadequatefacilitiesareavailableto provideairforsatisfactorycombustionand ventilation.

2 -Appliances Locatedin UnconfinedSpaces.

a. Forinstallationsin unconfinedspaceswith conventionalconstructionand larger areassuchas basements,the supplyof airfor combustionand

ventilationcan usuallybe consideredadequate.

3 - AppliancesLocatedin ConfinedSpaces.

a. If all airfor combustionandventilationis to come fromwithinthe building:twoopenings,onenearthe ceilingand one nearthe floor of the boiler

roomshallbe providedwiththe minimumfree areaof eachopeningequalto 140sq. in. pergallonof oilburned.

b. If allairfor combustionandventilationisto comefromoutsidethe building:twoopenings,onenearthe ceilingandone nearthefloorofthe boiler

roomshallbeprovidedwiththe minimumfreeareaof eachopeningequalto 35 sq.in. pergallonof oil burned.

If ductsare usedto conveythe air,areasof 35 sq. in.pergallon ofoil burnedfor verticalductsor 70 sq.in.pergallonof oil burnedforhorizontal

ductsaretobe provided.Ductsshallhavethesameareaasthe freeareaof theopeningsto whichtheyare connected.

C- SETTINGTHE BOILER

1- TheWBV/WVBoilerSectionsare FactoryAssembledwiththeTargetWallShippedinplace.Providealevelfoundation,locatedas closeas possibleto

the center of the heatingsystemandtothe chimney.TheWBV/WVSeries is availableasa completepackage,or in a knockeddownform. Referto

page5 for explodedviewof boilerif on-the-jobassemblyisrequired.

2-This boileris suitableforuseon combustibleflooring,providedtheboiler is not setoncarpetand a metal drippan isplacedunderthe appliance.

3- TheWBV-03andWBV-04boilermodelsmaybe installedas a rearflueoutletunit ora topflue outletunit.This maybedonebymountingthe FlueCollar

Adapter(Item14)to eithertherear boilersectionfora rearflueapplication,orto the FlueCollectorCoverPlate(Item11)fora topflueapplication.The

RearOutletCoverPlate(Item13) isthenusedto closetheremainingopening.OnPackagedUnitsthe largeknockoutintheTopJacketPanelmustbe

removedtoconvertto a topflue application.NOTE:TheWV-05boilermodelisonlyavailableasa top flueoutletunit.

4- Open trim carton.RemoveFlueCollectorCoverPlateandBlanketSeal(Items10 and 11)and attachwith thefour (4)5/16" x 1_/2"studs,nutsand

washersprovided.Attacheitherthe FlueCollarAdapter(Item14)or the OutletCoverPlate(Item 13)to the FlueCollectorCoverPlatewiththe nuts

andwashersprovidedmakingsurethe ropeseal(Item12)is in place.Attachthe remainingFlueCollaror CoverPlatetothe rearsectionwithfour(4)

5/r6"bolts andwashers.

5- If a tanklesscoilisused,(Item9)installaspictured.WaterBoiler- frontsectionopening.SteamBoiler- rearsectionopening.Forsuggestedpipingof

tanklesswaterheatersreferto Figures4 and5.

6- Whena tanklesscoilis notemployed,covertheopeningwithcoverplate(Item 7 or 16).

D- JACKETASSEMBLY

1- If boiler is tobe installedwitharear flueoutlet,removethesquareknock-outinthe backpanelthenattachtobosseson middleof backsectionwith

two1/4" x 3/8"machinescrewsprovided.The backpanelhas two 5/16"dia.holesclosetothe centerofthe panel.

2 - Attach boththe left and rightsidepanelstothe backpanel andsecurewithsheetmetalscrews.

3 - RemoveBurnerMountingPlate (Item5) andmakecertainthe TargetWall(Item2) and CerafeltLineron floorofboilerin frontoftarget wall(Item3)

arefirmly in place.

4- Removethetwo(2)knockoutsinthefrontjacketpanelwhichwill allowclearanceforthe hinge.Placethefrontjacketpanelonthe blockandattachthe

leftand rightsidepanelsin the samemannerastheyareattachedto thebackpanel.Attachthe CombustionChamberCoverPlate.

5- ReinstallCombustionChamberCoverPlate.

6- If boiler is to be installedwitha top flueoutlet,removetheknock-outinthe topjacketpanelthensecurewith sheetmetalscrews.

Page 5

E - PIPING

DONOTPIPEBOILERBEFOREJACKET_SINSTALLED.

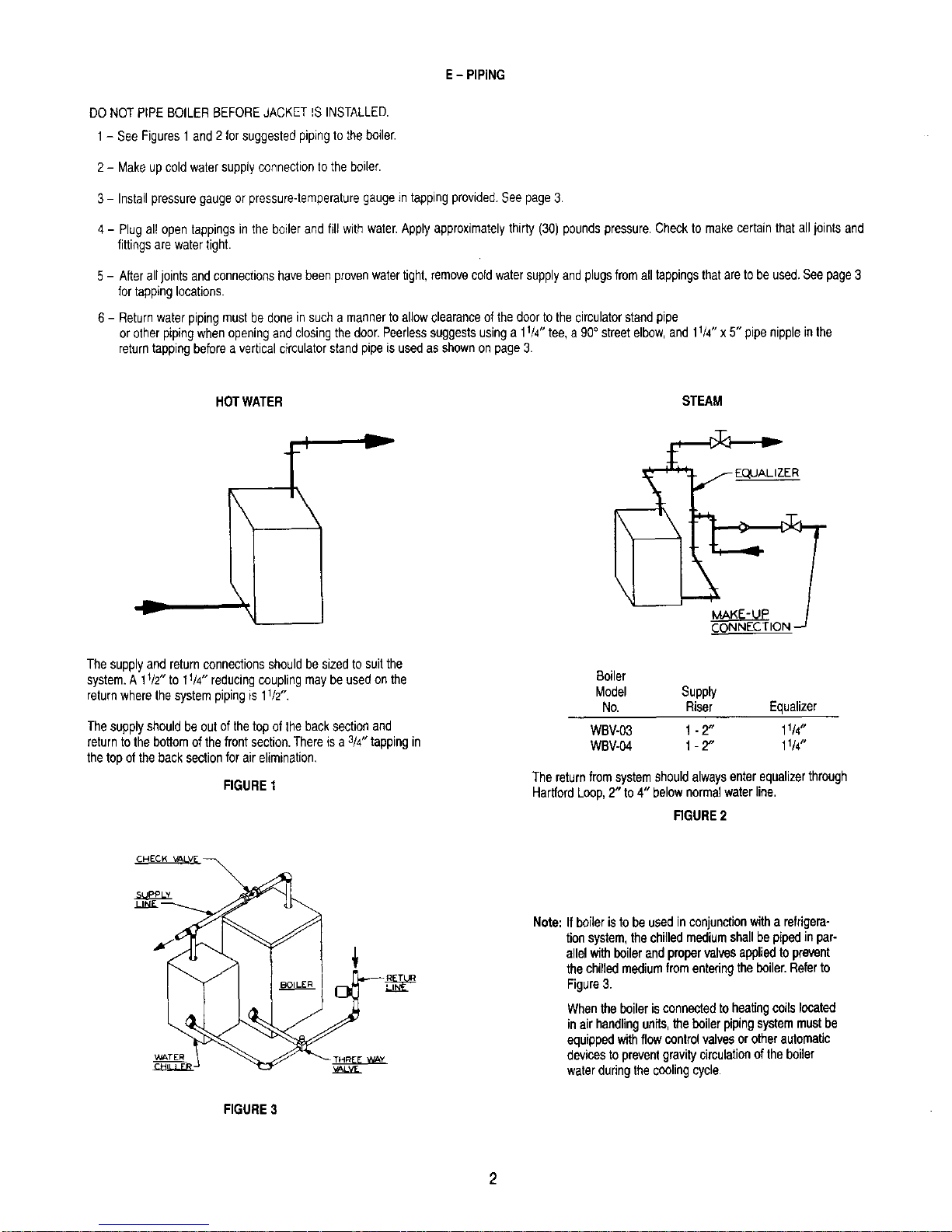

1- See Figures1 and2 forsuggestedpipingtothe boiler.

2- Makeupcold watersupplyconnectiontothe boiler.

3- Installpressuregaugeor pressure-temperaturegaugein tappingprovided.See page3.

4- Plugal_opentappingsin the boilerandfill with water.Applyapproximatelythirty (30) poundspressure.Checkto make certainthat all iointsand

fittingsarewatertight.

5- Afteralljoints andconnectionshavebeenprovenwatertight,removeooldwatersupplyandplugsfromalltappingsthataretobe used,Seepage3

fortappinglocations.

6- Returnwater pipingmustbe donein sucha mannertoallowelearaooeofthe doortothe circulatorstandpipe

orother pipingwhenopeningandclosingthedoor.Peerlesssuggestsusinga 11/4"tee,a90° streetelbow,and 11/4"x 5" pipenippleinthe

returntappingbeforea verticalcirculatorstandpipeis usedas shownon page3.

HOTWATER

v

Thesupplyand returnconnectionsshouldbe sizedto suitthe

system.A 1r/2" to 11/4" reducingcouplingmaybeusedon the

returnwherethe systempipingis 11/2".

Thesupplyshouldbe outof thetop ofthe backsectionand

returnto thebottomofthe frontsection.Thereisa 3/4"tappingin

the top oftheback sectionfor airelimination,

FIGURE1

STEAM

Boiler

Model Supply

No. Riser Equalizer

WBV-.03 1-2" 11/4"

WBV-04 1- 2" 11/4"

Thereturnfromsystemshouldalwaysenterequalizerthrough

HartfordLoop,2" to 4" belownormalwaterline,

RGURE2

_TER

FIGURE3

Note:If boileris to be usedinconjunctionwitha refrigera-

tionsystem,thechilledmediumshallbepipedin par-

allelwithboilerandpropervalvesappliedtoprevent

thechimedmediumfromenteringtheboiler.Referto

Figure3.

Whentheboilerisconnectedtoheatingcoilslocated

inairhandlingun_S,the boilerpipingsystemmustbe

equippedwithflowcontrolvalvesor otherautomatic

devicestopreventgravitycirculationof theboiler

waterduringthe coolingcycle.

Page 6

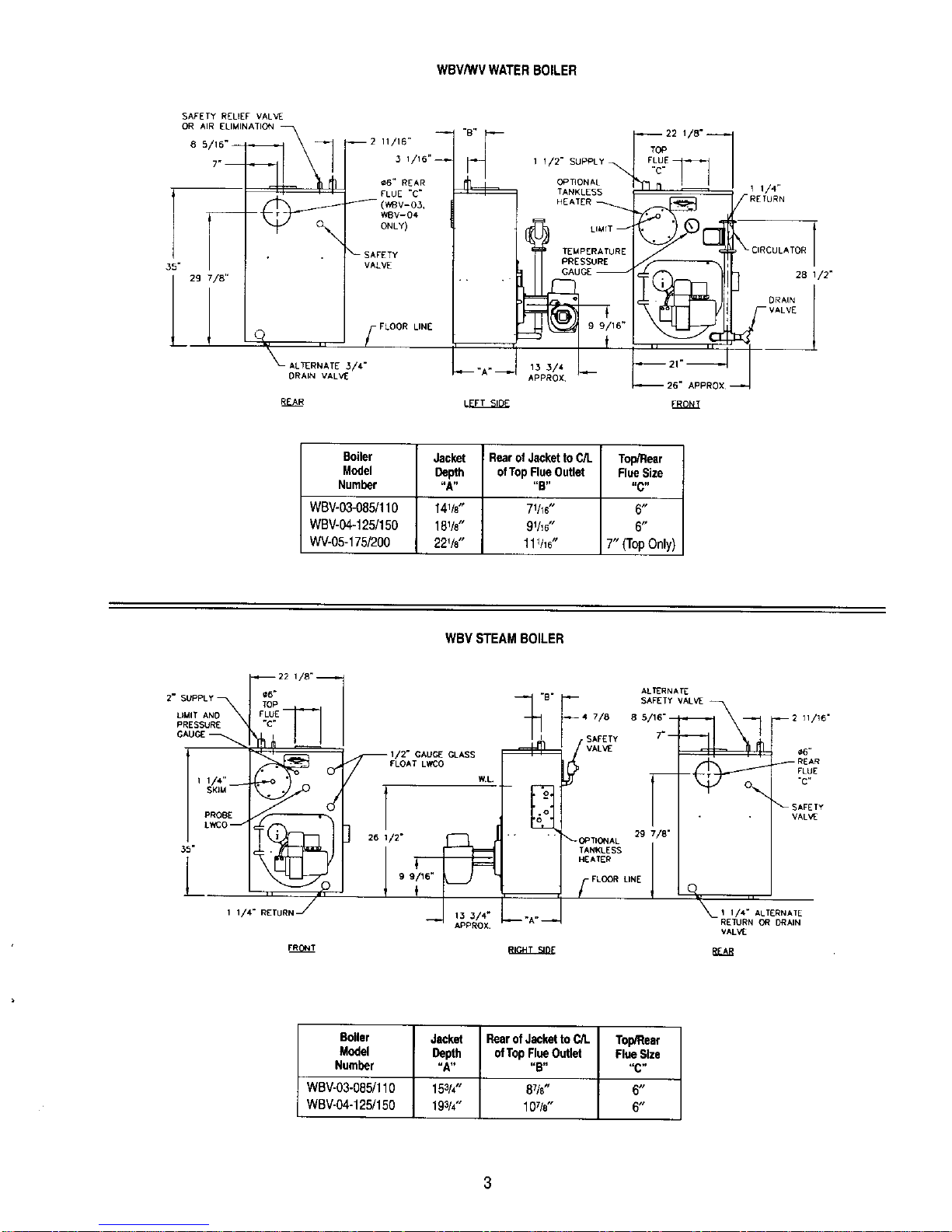

WBV/WVWATERBOILER

SAFETY RELIEF VALVE

.35" VALVE

DRAIN VALVe"

--2 11/16"

3 1/16" _

• 6" REAR

FLUE "C"

_(WBV-O3,

WBV-04

ONLY)

LINE

R_

1

1 I/2" SUPPLY_

OPTIONAL

TANKLESS

HEATER x

LIMIT -

TEMPERATURE

PRESSURE

GAUGE _'

1_3/_ I_-

APPROX '

-_-_2,18"7

1 114"

' "C'"DOLATO"

28 I/2"

DRAIN

VALVE

FRONT

Boiler Jacket RearofJackettoC/L Top/Rear

Model Depth ofTopFlueOutlet FleaSize

Number "A.... B.... C"

WBV-03-085/110 141/8" 71h6" 6"

WBV-04-1251150 18%" 91h6" 6"

WV-05-175/200 22%" 111116" 7" (TopOnly)

WBVSTEAMBOILER

SKIM

PROBE

FLOAT LWCO

[

ALTERNATE

29 7/8"

_OP_ONAL

TANKLESS J

HEATER

-FLOOR LINE

_2 11/16"

_6"

_REAR

FLUE

-C-

'_SAFETY

VALVE

1 I/4" ALTERNATE

RETURN OR DRAIN

VAL'AE.

g_

Boiler

Model

Number

Jacket Rear of Jacketto C/L Top/Rear

Depth of Tap FleaOutlet Flue Size

"A.... B" "C"

WBV-03-085/110 153/4" 87/8" 6"

WBV-04-125/150 19314" 10%" 6"

3

Page 7

HIGH TEMPERATURE

HOT

MIXED

MIN.

WATER

MIXER

HEATER

V4" CONTROl_

"TAPPING

CONTROL

HIC.H TCMPCRATUR_"

HEATER

i2 _ MiN°

3/4" CONTROL

FLOW

INLET

COLD WATER

INLET

FIGURE4 FIGURE5

7-Tankless WaterHeater

Whenwaterheateris not employed,coverthe heateropeningwith coverplate(Item7or 16)

BESURERUBBERGASKETIS IN PLACEBETWEENCOVERPLATEORWATERHEATERPLATEANDBOILERSECTION.

8- StorageTankHeater- if awaterboileristo beusedin conjunctionwithastoragetankheaterreferto Figure6fortypicalpiping.Alsorefertoadditional

instructionssuppliedwith tank,

THREE WAY VALVE

DOMESTIC HOT

WATER SUPPLY

SYSTEM

RETURN

SYSTEM

BOILER

FIGURE6

INTERNAL

CO_L_

fCOLDWATER

SUPPLY

DOMESTIC HOT WATER

ST0f_AC-.,_:TANK

DANGER:INSTALLANTI-SCALDDEVICEINHOT WATERSUPPLYPIPING.WATERTEMPERATUREABOVE125°FCANCAUSESEVEREBURNS

INSTANTLYOR DEATHFROMSCALDS.

Page 8

FIGURE7:STEAMBOILERS

FIGURE8:WATERBOILERS

(Seepage 13for partsidentification)

Page 9

F-OILBURNERINSTALLATION

1-The oil burneris suppliedwitha mountingflangefixedin position.

2- Mounttheburnertothe combustionchambercoverplate(Item5) withfour(4)5/r6"studsand nutsprovided.

BESUREHITEMPGASKETISBETWEENTHE BURNERMOUNTINGFLANGEAND THECOMBUSTIONCHAMBERCOVERPLATE.

3- Caremustbe takenwhen routingtheoil lines so notto interferewith theopeningandclosingofthe door.Flexibleoillinesor flaredcopperdiscon-

nectswithvalves(whencopperlinesare used)maybeinstalledto assurefullopeningofthe doorwhenservicing.

4- Oil BurnerSpecifications:

Forinformationpertinenttothe oilburnersuchas nozzlesizing,fuelsupplypiping,adjustingor servicing,referto thechartsbelowand theinstalla-

tion manualaccompanyingthe burner.

BECKETTBURNERWITH140 PSI PUMPPRESSURE

Boiler Burner Burner Static Nozzle Start-UpSettings Head

ModelNo, ModelNo. Head Plate Size AirShutter AirBand Setting

WBV-03-085 AFG-F3* F3 33/8" 0.7580" B HAGO 6.0 1 N/A

WBV-03-110 AFG-F4 F4 33/8" 0.9080° BHAGO 6.0 0 N/A

WBV-04-095 AFG-F4 F4 33/8" 0.85800B DEL 6.0 0 N/A

WBV-04-125 AFG-F4 F4 33/8" 1.10800B HAGO 5.0 2 N/A

WBV-04-150 AFG-F6 F6 23/4" 1.25800B HAGO 8.0 1 N/A

WV-05-175 AFG-MV1 V-1 1.5060° BHAGO 10.0 3 3

WV-05-200 AFG-MV1 V-1 1.7560° BHAGO 10.0 9 3

*RequiresLowF_ringRateBaffle

WAYNEBURNERWITH100PSIPUMPPRESSURE

Boiler Burner AirCone Nozzle** Start-UpSettings

ModelNo, ModelNo, I,D. Size FlameLock Off-CycleDamp, AirShutter

WBV-03-085 HS 21/2" NoHoles 0.8580° B 1 t.0 0.50

WBV-03-110 HS 21/2"NoHoles 1.1080" B 1 2.0 1.50

WBV-04-125 HS 21/2"6 Holes 1.25 80°B 1 2.0 1.75

WBV-04-150 HS 21/2,,6 Holes 1.5080°B 1!/2 2.0 2.00

WV-05-175 HS 21/2"6 Holes 1.7580° 8 3 2.0 2,25

WV-05-200 HS 21/2"6 Holes 2.0080° B 5 2.0 2.50

** DelavanRecommended

CARLIN99FRDOILBURNERWITHMODEL98022PSCMOTOR

Boiler Burner Start-UpSettings

ModelNo. ModelNo. AirShutter NozzleSize PumpPressure HeadDim.A AirBand

WV-05-175 99FRD Open 1.50x600BHAGO 150PSi 5 10%open

WV-05-200 99FRD Open 1.65x 600B HAGO 150PSI 5 45%open

CARLINEZ-1HPOIL BURNERWITHMODEL98022PSCMOTOR

Boiler Burner Start-UpSettings

ModelNo. ModelNo. AirShutter NozzleSize PumpPressure AirBand HeadBar

WBV-03-085 EZ-IHP Blank 0.65x 70°ADEL 150PSI 0.60 0.60- 0.65

WBV-03-f10 EZ-1HP Blank 0.85x 700ADEL 150 PSI 0.65 0.85- 1.00

WBV-04-095 EZ-1HP Blank 0.75 x 70° A.DEL 150 PSI 0.60 0.75

WBV-04-125 EZ-1HP Blank 1.00x 700ADEL 150PSI 0.85 0.85- 1.00

WBV-04-150 EZ-1HP Blank 1.25x 60° B DEL 150PSI 1.00 1.10- 1.25

NOTE:Start-upandAdjustmentRecommendations...AdjustburnerforhighestCO2 (Maximum13%)whilemaintaininga0 Smokeand

-.01to -.02" W.C.OverfireDraft.Alladjustmentsmustbe madeusingsuitableinstrumentssuchasfoundin a8acharachCombustion

TestKit.

6

Page 10

F - OIL BURNERINSTALLATION(continued)

RIELLOSERIES40OIL BURNER

Boiler Burner Nozzle** Pump Turbulator AirDamper

ModelNo. ModelNO. Size Pressure Setting Setting

WBV-03-060 F3 0.50 90°B 145 0.0 2.9

WBV-03-085 F5 0.65 60" W 170 1.0 2.45

WBV-03-110 F5 0.85 60°W 165 2.5 2.8

WBV-04-125 F5 1.0060°W 155 25 3.4

WBV-04-140 F5 1.1060° W 160 4.0 4.2

WV-05-175 F10 1.3560"B 165 2.0 2.5

WV-05-200 F10 1.5060° B 170 2.5 2.8

** DelavanRecommended

NOTE:AboveTurbulatorandAir DamperSetlingsare start-upsettings only. Finaladjustmentsmustbe madewithcombustiontestinstruments.

ADVERSEFUELCONDITIONS

Ifanadversefuelconditionsuchascoldoilexists,itmaybeneces-

sarytoincreasethepumppressuretothenozzle.Coldoilis much

hardertoatomizeat 100psicomparedto roomtemperatureoil.Tothe

rightis a chartgivingflowrates ofstandardnozzlesizesat120 psi

and140psi pumppressure.

Note:If itwasnecessarytoincreasethepumppressureabovethe

standard100psi,toeliminateanyconfusionforthenextroutine

servicinga tagmustbeplacedontheburnerindicatingpump

pressureandnozzlesizeused.

Approx.NozzleRatesGPH

NozzleRating

At100 PSI 120PSI 140 PSI

0.50 0.55 0.59

0.65 0.71 0.77

0.75 0.82 0.89

0.85 0.93 1.00

0.90 0.99 1.07

1.00 1.10 1.18

1.10 1.21 1.30

1.20 1.31 1.41

1.25 1.37 1.48

1.35 1.48 1.60

1.50 1.64 1.78

1.65 1.81 1.95

1.75 1.92 2.07

G - CONTROLS

1- Applycontrolsas follows:

a. WaterBoilers:

Installthelimitoroperatingcontrol,pressure-temperaturegaugeandsafetyreliefvalve.Seepage3 for properlocation.

b. SteamBoilers:

Installlimit,pressuregauge,gaugeglasstrimandsafetyvalve.Seepage3.Forapplicationofprobelow-watercut-offsee

page3, andcontrolmanufacturersinstructionsheetshippedwiththecontrol.Whenprobe-typeLWCOisused,Peerlessrecommends

HydrofavelCG450.

2- Forcompleteinformationonservicingandadjustmentofcontrols,refertotheattachedcontrolspecificationsheets.

Caution:Pipethe dischargeofthe safetyvalveorreliefvalveto preventinjuryinthe eventofpressurerelief.Pipethedischargeto a drain.Provide

pipingthatis thesamesizeasthereliefvalve.

H-WIRING

1- All electricalwiringshallbe doneinaccordancewiththeNationalElectricalCodeand LocalRequirements.SinglePoleSwitchesincludingthoseof

SafetyControlsorProtectiveDevicesshallnotbewired ina groundedline.

2- Locatejunctionboxin thetrim carton.Mountjunctionboxto theholesin the rightside of jacketwith (2)#10 x 1"sheetmetalscrews.

3- Locatepolarizedharnessin thetrim carton.Connectharnessfromthejunctionboxto the limit (waterboilers)orlowwatercut-off(steamboilers).See

JunctionBoxdetail(Figure9),photos(Figure10& cover),and wiringdiagrams(Figures11-13).

7

Page 11

WARNING:Improperinstallationof burnerharnesscanallowburnerto energizewithswingdooropen,creatingasevereburnhazardtoboiler

maintenancepersonnel

4a - Locatethe polarizedburnerharnessin theburnercarton.Attachharnessbetweenburner andjunctionbox. SeeJunctionBoxdetail (Figure9),

photos(Figure10& cover),and wiringdiagrams(Figures11-13).

4b.- If using anon-Peerlesssuppliedburner,obtainappropriateburnerharnessfroma PeerlessDistributor,or hardwireburnersuchthat burnerswing

doorcannot beopenedwithoutdisconnectingpower.

Harnessfor Beckettor Cadinburner- 50232(polarized,21" longconduit)

Harnessfor Rielloburner- 50226(polarized,36" long conduit)

5 Wirezone circulatorsasshownin Figure14and zonevalvesas shownin Figure15

©©

FIGURE9 FIGURE10

p_,:,dr_ CONT_O. OI_,_R • {WJT)

J/oo_ _ • iis/qso/I

i ws_ FORCED HOT WATER

-- WtTH TANKLES_ HEATER

, - _ HONEYWELL L8124A OR L8124C

t'l_ *I, CO

WW_OUT TANKLESS HEATER

• _ HONEYWELL L8148A

cr_c_U_TO_

FIGURE11:WATERBOILERS

Page 12

w

Y

_GNITOR l

BURNER

LIMIT

CAD

F , , ,

OPERATING CONTROL

FOR STEAU W/

TANKLESS HEATI_R ONLy

BC4LER T GROUND

J/ BOX

_OUNO

SCREW _ J / _GROUNB

G O SCREW ADDITIONAL

<_ UMIT SAFETY S_ TCHES

i-1-,_=

LBURNER _ SER_C[ S_TCH

BI_NEBT _ (BY INSTAL_.[R)

STEAM WITH OR _ (HOT)

WITHOUTHEATERTANKLESS I _ L2L•_$5/60/I

FUSED DISCONNECT

(BY INSTALLER)

24v _HERMOSTAT

--LINE VOLTAGE

........... LOW VOLTACE

ALL VelRING MUST COMPLY "t_TH ApI_LIANCE COO_S, (_O_NANCE5 AND REGULATIONS

FIGURE12:STEAMWITHFLOATLOWWATERCUT-OFF

w

,{

OP_RATIN G CaN TROL

TANI_ESS _a_R I_ILy

R71_B OIJI_ER /

PRIMARY CONmOL BURNER

J/ BOX

IGNITOR 8_LER

_rED J/ BOX

H YDROtE',_ L

ROUND CG4_ O

BURNER SCREW pROB E LWC0

LI 8K K GROUND FUS/ED D4SCONNECT

LIM_T JUMPER _R_ lee S_TCH (HOT/

_ URN_ R CONTROL[] STEAM WITH OR

WITHOUT TANKLESS

t" / ", , SAFETY S_ITCPE5

: _ "_ ..... -_) 24v THERMOSTAT

__ LIN_ VOLTAG_

.......... LOW VOL T&GE

ALL _q_ING MUST [_OMPLY I_TH APPLIANC_ C(_S, (_NAN{_S ANO R_GU_AIIONS

FIGURE13: STEAMWITHPROBELOWWATERCUT-OFF

Page 13

LINE VOLTAGE

LOW VOLTAGE

CIRCULATOR

NOTE:

ALL WIPING MU_T COMPLY WITH APPLICABLE

CODES,ORDINANCES_AND REGULATIONS. ZONE #l ZONE _B ZONE _3

-.+ _

FIGURE14:ZONINGWITHCIRCULATORS

iBOV - 6OMZ

TO MAIN

DISCONNECT

12o/z4v SOHZ _

4OVA _LIL2 I I

I

BOX

©

II

i I

j I

I

I

I

I

I

I

J

ALL WIRING MUST COMPLY WITH APPLICAI__E

CODES I ORDINANCES t AND REGULATIONS .

FIGURE15:ZONINGWITHZONEVALVES

10

Page 14

L2 LI

TO PEERLESS

PARTNER C:RCULAiOR

_O ZONE ]

SPACE HE ATIN_

THERMOSTAT

TO MAIN ,r_-A _"

DISCONNECT

---(9

®

i LINE VOLTAGE

...... LOW VOLTAGE

BOILER LIMIT

HONEYWELL LB148A

TO BOILER TO BURNER

CIRCULATOR DISCONNECT

FIGURE16:PARTNERWITHCIRCULATOR(NON-PRIORITY)

I - CLEANINGTHESTEAMSIDE(SKIMMING)

Cleanthe boiler withinone week afterinitialstart-up.Cleaningwill be moreeffectiveif boileroperatesa dayor twoto loosensedimentandimpuritiesin

system.

Boilermustbecleanedto removeanyaccumulationofoil,grease,sludge,etc.insystem,Thesesubstancescan causefoamingandsurgingofboilerwater,

producingan unstablewaterline andwatercarryoverto system.

WARNING:CLEANINGTHEBOILERREQUIRESTHEUSEOFVERYHOTWATERANDCORROSIVECHEMICALS.USECAREWHENHANDLING

TOPREVENTINJURY.

1- Connecta skimvalveoffthe 11/,NPTskimtappingonfrontof boiler.SeeWBVsteamboilerfiguresonpage3 to locateskimtapping.Runa drain

lineoff skimvalveto a pointof safedischarge.

2- Providea meansof supplyingcontinuousfreshwatertothe boilerfor thecleaningprocess.

3- Openthe skim valve.Fillboileruntil waterbeginsto flow outofthe valve.

4- Usecommonwashingsoda,suchasArm andHammerSuperWashingSoda.Mix1/2 poundof sodawithwaterin a 10quart pail.Pourthemixture

intothe boilerthroughthe safetyreliefvalvetapping.

CAUTION:DONOTLEAVEBOILERUNATTENDEDWHILEFIRINGBURNER.OPERATINGBOILERWITHWATERBELOWMINIMUM

PERMISSIBLEWATERLEVELMAYFRACTURESECTIONS.

5- Turnon burner.Allowboilerwaterto heatup tojust belowsteaming(180- 200° F). Donot allowboilerto steam;steamingmixesupcontaminants

insteadoffloatingthematsurface.

6- Openmake-upwatervalvetocontinuouslyfeedwaterto boiler.Adjustflowto maintainwatertemperatureat 180- 200° E

CAUTION:DONOTALLOWMAKE-UPWATERTO FLOWTOOFAST.EXCESSIVEQUANTITIESOFCOLDWATERMAYFRACTURESECTIONS.

7- Continueskimmingboileruntilwaterflowingfromskimtappingflowsclear.This willtakesome time,possiblyseveralhoursforadirty system.

8- Turnoff burner,closemake-upwatervalve.

9- Drainboilercompletely.Refilland drainone or twotimestowashoutall washingsoda.

10- Removeskimvalveand piping.Install11/4NPTplugin skimtapping.

NOTE:IF GAUGEGLASSBECOMESDIRTYMORECONTAMINANTSHAVEWORKEDLOOSEIN SYSTEM.REPEATCLEANINGANDSKIMMING

PROCESSAS NEEDEDTO CLEANSYSTEM.

11

Page 15

J- CLEANINGHEATINGSURFACES

NOTE:BOILERISTO BECLEANEDATLEASTONCEA YEAR.TOTHOROUGHLYCLEANTHEBOILERITMUSTBEBRUSHEDDOWNFROMTHE

TOE ALTERNATELY,FOR LIMITEDSPACE OR MINIMUM CLEARANCETO COMBUSTIBLEINSTALLATIONS,CLEANINGTHE HEAT

EXCHANGERFROMTHE COMBUSTIONCHAMBERSIDEISACCEPTABLE.

TOCLEAN:

1 Turnoffall electricalpowertothe boiler beforebeginningcleaningoperation.

2- Removetopjacket paneland fluecollectorcoverplate,item 11.

3- Brushthe fluepassagesthoroughlyfromthetop witha wirebrush.Ifunitis extremelydirty,brushingupfromthe combustionchamberareaalsomay

be necessaryThetarget wall is madeofa softceramicfiber,caremustbe takennotto injurethis materialduringcleaning.

4- Removeanyscaleor sootfromthe combustionchamberareaby vacuumcleaningoranyotheravailablemeans.

NOTE:THEOILBURNERMUSTBE REMOVEDTOFACILITATETHISOPERATION.

5- Replaceoil burnerandflue collectorcoverplatemakingsureall gasketsarein place.

6- Replacejackettoppanel.

HI Division of Gama

(1)

Boiler

Model

Number

WBV-03-60+*

WBV-03-085

WBV-03-110

WBV-04-095+

WBV-04-125

WBV-04-150

WV-05-175

! WV-05-200

(2)

Heating

Capacity

BTU/I-In

74,000

!02,000

129,000

116,000

150,000

178,000

209,000

237,000

SERIESWBV/WVRATINGS

(3)

NetI=B=RRatings

BTU/Hr, Steam BTU/Hr.

Steam Sq.R. Water

N/A N/A 64,000

76,000 317 89,000

97,000 404 112,000

N/A N/A 101,000

112,000 467 130,000

133,000 554 155,000

N/A N/A 182,000

N/A N/A 206,000

(4)

1=8=R

Firing

RateG.P.H.

0.60+*

0.85

1.10

0.95+

1.25

1.50

1.75

2.00

Chimney

Size Height

Inches Feet

6x8 !5

8x8 15

8x8 15

6x8 15

8x8 15

8x8 15

8x8 15

8x8 15

Minimum

Draft

Required

inStack

-.03"

-.04"

-.05"

-.03"

-,04"

-,05"

-,05"

-.06"

(1) BoilerModelNo.mayhavethefollowingsuffixletters:

W-Water P-Packaged

S-Steam C-Circulator

Uq_oiler-BurnerUnit(Unassembled) T-TanklessCoil

(2) HeatingCapacityratingsare basedonU.S.Governmentstandardtests,with13.0%CO2and-0.02"watercolumndraftoverfire.

(3) Thewaterratingsarebasedona pipingpick-upallowanceof 1.15;steamratingsarebasedonanallowanceof1.333.

Consultfactorybeforeselectinga boilerfor gravityhotwaterinstallationsandinstallationshavingunusualpipingandpick-uprequirements,suchas

intermittentsystemoperation,extensivepipingsystems,etc.

(4) Firingrateis basedon a fueloilwith a heatingvalueof 140,000BTU pergallon.Burnerinputbasedonmaximumaltitudeof2,000ft. - for other

altitudesconsultfactory.

+ Nozzlesforthesefiringratesnot providedasstandardequipment.Consultfactoryforprice andavailability.

* Thisfiringrate canonly be achievedwitha RielloF-3burner.ConsultPeerlessfor details.

12

Page 16

REPAIR PARTS

SERIES WBV/WV OIL BOILERS

REPAIR PARTSARE AVAILABLEFROMYOUR INSTALLER OR BY CONTACTING

PEERLESSHEATERCOMPANY,BOYERTOWN,PA 19512-1021

NOTE: REMEMBERTO INCLUDE BOILER MODEL NUMBER AND SERIAL NUMBER WHEN ORDERING PARTS

ItemNo.** StockCode

1

2

3

4

5

10

11

11A

12

13

14

15

16

17

50795

90538

90158

PP1004

51210

99812

X1078

51800

90532

90534

90530

90999

90562

51209

90563

90141

51673

Description

BlockAssemblyWater(Open)

BlockAssemblyWater(Closed)

BlockAssemblySteam(Open)

BlockAssemblySteam(Closed)

TargetWall

BaseLiner

SwingDoorHinge

BurnerMountingPlateAssembly

BurnerMountingPlateInsulation

BurnerMountingPlateRopeSeal

SteelCoverPlate(Front)Water

SteelCoverPlate(Front)Steam

RubberGasket(FrontPlate)

TanklessCoil

RueCollectorPlateBlanketSeal

FlueCollectorCoverPlate

TopOutletFlueCollectorPlate

RopeSeal

RearOutletCoverPlate

FlueCollarAdapter

JacketAssembly(Water)

JacketAssembly(Steam)

SteelCoverPlate(Rear)

RubberGasket(RearSectionPlate)

OilBurner

Temperature-PressureGauge

SteamGauge

Aquaatat

Pressuretrol

DrainValve

ReliefValve(Water)

PopSafetyValve(Steam)

Additional Information

SpecifySize

SpecifySize

SpecifySize

SpecifySize

SpecifySize

3Section-WaterOnly

4 & 5 Section-WaterOnly

3& 4 Section-Steam

SpecifySize

SpecifySize

5SectionOnly

SpecifySteamorWater

SpecifySize

SpecifySize

SpecifyBrandName

**SeeFigures7& 8 on page5

13

Page 17

Series WBV/WV

OH Boilers

Installation,

Operation b

Maintenance

Manual

TO THE INSTALLER:

This manual is the property of the owner and must

be affixed near the boiler for future reference.

TO THE OWNER:

This boiler should be inspected annually by a

Qualified Service Agency.

HI Division ASME

of gama

pr=-r=-RLESS *

CAST IRON BOILERS

PEERLESS HEATER COMPANY

231 NORTH WALNUT STREET • BOYERTOWN, PA 19512-1021 • PHONE 610-367-2153

www.peerless-heater, com

THE PREFERRED HEATING CHOICE

©2002 Peerless Heater Company PP8046 R14 (10/02-10M)

Printed in U.S,A.

Loading...

Loading...