PEERLESS SERIES TC, TC-04, TC-05, TC-06, TC-07 Installation, Operation & Maintenance Manual

...Page 1

TC

Gas/Off Boilers

Installation,

Operation

Maintenance

Manual

pr=-r=-I_Lr=-SS®

CAST IRON BOILERS

Page 2

15 Sizes

Oil, Gas or Combination Gas]Oil Fired,

Hot Water or Steam Boilers

4-18 Sections 8.0 to 40.5 GPH Input 900 to 4,629 MBH Gross Output

Rugged Cast-Iron, Wet Base Sections

• Dzlrabl_ _ Corks m_ lOlLJot Loag L!fe and Optunllm I error mam:e

• CaT_ Be Asselrg)led al Job Siie

Forced Draft Venting

• Only RequirPs a Throe Foot Vent Above the Roo./

High Efficiency Power Burners

• Choice o.fBeckelt, Carlia, Power Flame, Webster. Gordon Piatt

• Provide the tf_hesi Possible E.{fi('iencies

Front and Rear Flame Observation Ports

• Aid Burner Selup

Oval-Shaped Upper Port

• Improves IT_teraal Circulation

• [-felps Creale Dr_j Sleam

Hi-Temperature, Flexible, Graphite Port Connectors

• Simplifij l_stallalion

• [Jl_q_2cled by Chemicals

Side Cleanout Access

• Assures Easy Cleaning oflqueways

Integral Cast Iron Flue Collector

• Adds Durability

• Reduces OperaliJ_g Noise

Tankless Coils

• For Domestic Hot Water on Sleam and Hot Waler Boilers

Insulated Enameled Steel Jacket

• Reduce_ Boiler Heat Loss

Short, Individual Draw Rods

• Simplify Assembly

• Reduce Slmss

• Burner Mortaring Plate with lllsulation Block

• 30 PSIASME Saj'e__ Relie]-Valve (Water Boilers)

• 15 PSI ASME Side Outlet Safe_. Valve (Steam Boilers)

• LWCO on Packaged Boilers

• Wide Variety of Tcmkless Heater Options

• Assembled Seclior'Ls

• Combixlation Low-Water CutoJ]aad Water F_'edel

P('i'l'lt_._;s Boils'Is is plc'ci_,_'(l Io _1]€'! olt(' _)] IIl_' nlo_;I ('olllplx,ll(,ltsit_<, w(u'roltty prof4rams ill Ih<" ill(lll._lUi. All P_'t_r[t!._;s col!lll!_'lx'i(ll

<'tlNl il'olt I)oil('15 ilte.'[tlcl(' _ ]illl, oil(' y<'ar It)(ll'l'(llll{]. A limit_,(l, lell yt'tu" ivanzulty oil Ill(" Ctl.g[ i!OII _('clioIl:q I.'q i_tovid_'d lbr _I1 corn

Ilr'l_'irl! I101 II_(ll('l (1!_(1 _;I¢'_llll t)oil_'t_. Fil_" (_ll(J I(!ll_!j('(lr (,xle_ded tValT(lltli_s oil pal_s (lilcJ I(lt)or (llx' llOII1 al,(lilable. PIt,(l.s_" ('(it_

s_l!l P_'_'l!_'s_; I$oil_'l% [})I _ olllplt'lt" II_(II_TUlI!I il!fi_llll(lliOII.

Peerless Boilers • www.peerless-heater.com

Page 3

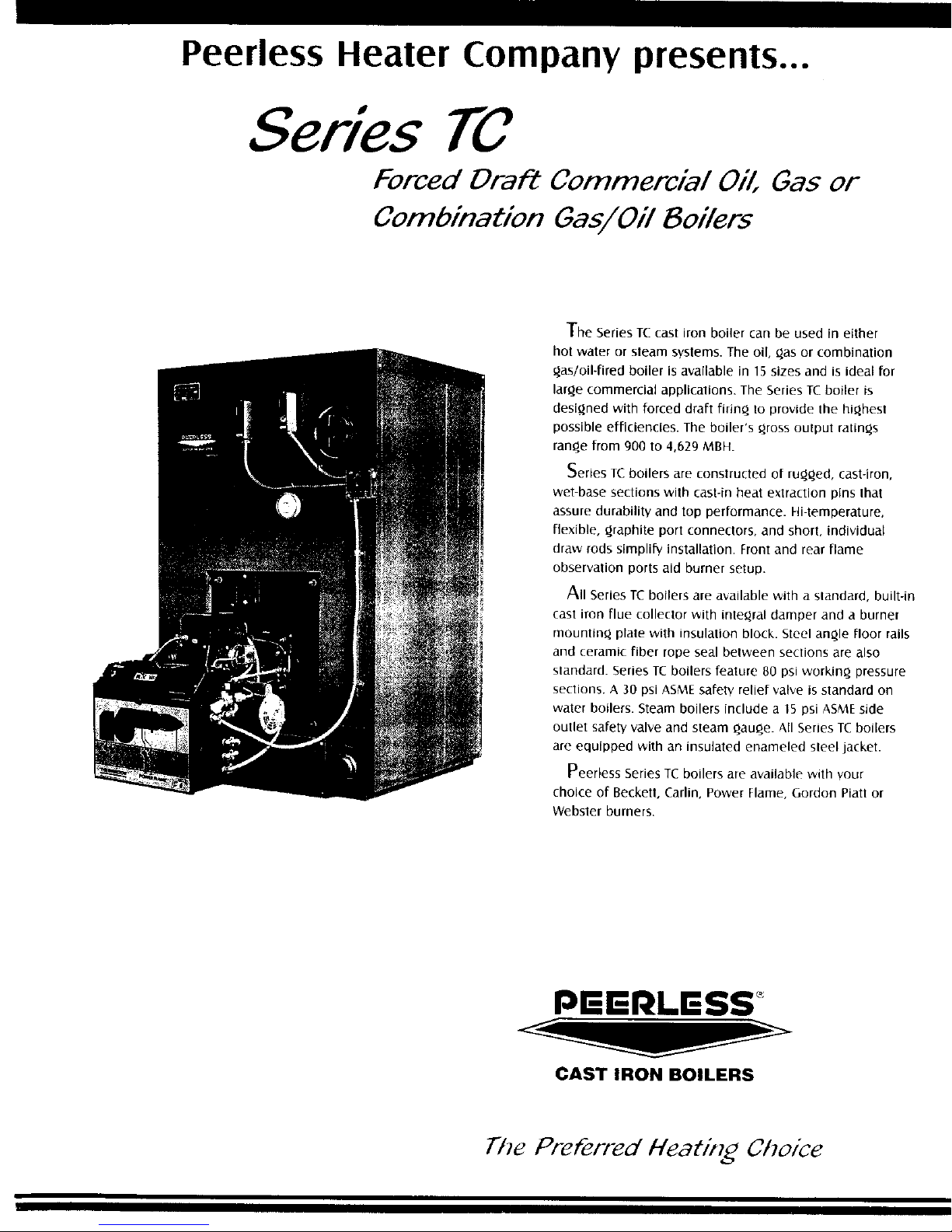

Peerless Heater Company presents...

Series TO

Forced Draft Commercial Oil, Gas or

Combination Gas/Oil Boilers

The Series TCcast iron boiler can be used in either

hol water or steam systems. The oii, _.asor combination

_.as/oil-fired boiler is available in 15sizes and is ideal for

lar_.ecommerclal applications. The Series TCboiler is

designed with forced draft firin_ to provide the highest

possible efficiencies. The boiler's _ross output ratings

range from 900 to 4,629 MBH.

Series TC boilers are constructed of ru_,ed, cast-iron,

wet-base sections with cast-in heat extraction pins that

assure durability and top performance. Hi-temperature,

flexible, _raphite port connectors, and short, individual

draw rods simpli_ installation. Front and rear flame

observation ports aid burner setup.

All Series TCboilers are available with a slandard, built-in

cast iron flue collector with integral damper and a burner

mountin_ plate with insulation block. Steel an_.le floor rails

and ceramic fiber rope seal between seclions are also

standard. Series TC boilers feature 80 psi workin_ pressure

sections. A 30 psi ASMEsafety relief valve is standard on

water boilers. Steam boilers include a t5 psi ASME side

outlet safety valve and steam _au_e All Series TCboilers

are equipped with an insulated enameled sleel jacket.

Peerless Series TC boilers are available with your

choice of Becketl, Carlin, Power Flame, Gordon Piatt or

Webster burners.

PEERLESS

CAST IRON BOILERS

The Preferred Heatiz_ Choice

Page 4

Series TO Features

• Power Burners - Oil. Gas, Gas/Oil

• Steam or Hot Water Boilers

• Ru_ed. Oast-lronConstruction

• Forced Draft Venting

• Wet-Base Sections

• Oast-in Heat ExtractionPins

• IntegralOast Iron Flue Oollector

• Hi-Temperature. Flexible,Graphite Port Connectors

Orderin_ Information:

Example:

O- TC- - W-ST - 30 PSI

| Series | 15 PSI Steam (STD)

| | 30 PSI Water (STD)

Blank = NO Burner 50 PSI Water

O = Oil li gO PSI Water

G - Gas WATER STEAM

GO - Gas/Oil W S = Less Burner

WL SL Less Burner & Controls

WU SU W/gurneT & Controls

WUP SUP = PkO.. w/Burner & Controls

WP SP Pkg. Less Burner

WLP SLP = PR#.. Less Burner & Controls

Series TC Standard Equipment

• Insulated Enameled Steel Jacket

• CastIron Flue Collector with Integral Damper

• Bumer Mounting Plate with Insulation Block

• Front and Rear Flame Observation Ports

• Steel Angle Floor Rails

• Ceramic Fiber Rope Seal Between Sections

• Manual Reset, Limit Control

• Operatin_ Control

Water

• 80 PSIWorking Pressure, CastIron Sections

• 30 PSIASMESafety Relief Valve

• Temperature Pressure Gauge

• Return Yoke with Flexible Seals

Steam

• 15 PSIASMESide Outlet Safety Valve

• Steam Gauge

• Gau_e Glasswith Gauge Cocks and Guards

Series TC Optional Equipment

• Combination Low Water Cutoffand Feeder

• Tankless Heater Sections

:. tankless Heaters

• Assembled Seaions

• Packaged Boilers

Inspection Tappin_s, 1-1/2". 3 per Section

Return Yoke (Steam)

Barometric Damper

Burner Specifications

Boiler

Model

Nuh,ber

re04

TC 05

TC-06

T( 07

rC 08

TC 09

TC I0

T( II

TC 12

r( I ]

IC 14

T( 15

T( Ib

l( 17

IL 18

Beckelt

Model

(:rl l0 T

O1 10_

LF2 )O 1

CF2 )O:

CF2 )0 _

(F2 )0 2

Cf2 )0 _

CH! OA:

CI3! 0A2|

i

Burners - Light Oii

Carlin

Model

NO. H.R

Gordon Plait Power Hame Webster

Mode_ Model Mode_

NO. H.P. NO H P. NO. H.P.

R8"GO _ H C1 01 & JBI0-03 I

R8 2-GO _ !g C1 0' 5 ]B10-0] _ 91_

B8 2-GO L E2 DA z 4 )BIB-B71 Va

R8 2 GOI k_ C2-OA 1 'a JBI0 072 :_/_

R84 GO _ 2 C20B _ I JB10072 :_/_

R84GO I 2 20131: _, ]g20-1O 1

RIB.I GO z 2 L2"DBll / JB2_tB 2

RIOIGO l 3 (101 2 JB20-10 l

RIO I GO t 3 C] "O° 2 ]B20 202

RlO I-GO t ] (30 _ 2 1B20-20 _

RIB2GO _ 5 [3"0 _ 2 JB20213 _

R102GO/ 5 (_0B l ] ]B20 30l

RIO2GO: 5 (3.0B; ] JB20]O

RI0 -)(]O t 5 (40A 2 5 JB30-]0 t

RI_2(,D ! 5 (4{/A 3 I )_303Bl

I

Gordon Plait

Model

NO. HP.

R8G _ _

R82 O t _4

RB 2 G r %

R82 G 1 _4

R84(fl

R84 G 1

R_B 1 G_

R101 G _

RIO 1 Gl

RIO I-G z

R_B2 G_

R)02 {/

R102 G _

RIO 2 G'

RI_T 2 G"

Burners - Gas

Power Flame

Mode_

No H.P.

J30-X 12r

JSO_ 15_

)SO_,19

J5OA-15I

C2 G 20_,2

C2G 20B1;

C2-G 2{)gl

C3 G 20 _

L] G 25 _

C3-G 25

f3%2_:

C3.G.258 _

C] G 251{ !

(4 (, 25

£4 G 25 z

Webste_

Model

NO. H.P

IBIG O] _ V{

IBIG O] _ V_

)BIG O5t V_

IBIG-O5 _ ,/z

IB1G 05 _ Y_

]B2G-IO _ I

JB2G 10 _ 1

JB2G 10_ 1

]B2G 152 I12

JB2G.152 I]/

}B2G 15_ Ib'

JB2G-30 _ 3

JB2G 30 _ 3

JB2G 301 3

]B2G 3B _

Gordon Plait

Mod'_

NO. 4.P

R801 '/_

R8201 ¼

Rt_ 201 Y4

R8.2-O 1

Rfl4-O _

R84 O;

Rlr_I.O z

R101 O _

R10t O z

RI0 i.O _

R1B 2 O:

R102-O:

RIO 20 z

RI 02 O _

Rlg 2() ¸' %

Burners - Gas/Oil

Power Flame Webster

Model Model

NO. -l.P. NO. H,P.

C1-G0-12 _ [_z JBTC4)3 _ /a

C1 G0-I2 _ /2 JBICO3 _ /a

C2-GB-IS _ Y_ |BI£433 _ A

C2 GO 1S_ _/4 J81C_7 z _/_

C2_30 2OA _ l JBIC4)7 _ V_

Z2-GO-2OBI 1 9_z JB2C-101

24_B 2B_]12 % 1B2£ tO _

C3-GO-2O: 2 J82C-10 _

C3G025 _ 2 ]B2C 20 _

C3 GO 25_ 2 JB2C-20I

( 3-G($-251 2 IB2C 20_

(3G0258 _ 3 J82C-]0 _

C3-GO-25B _ 3 JB2(302

C4-GO 25: 5 JB3G301

C4 GO 252 5 IB3q 3B]

I [ttlln_ I opeldliorl: on-ol[

2 Burn(i opt'[alion: Io_-bre Marl, hi_h-bre run

Burn{'r ilpelaIiorl: full mildulalion

Nolu: IIl_ _. lliP.h II>_; or ModulaliOl] lilin_ (onsuk Pt'erle_,', H('dR'I Company

"ti>ur PeI'rlP'¢_ lh_aler Cl)mpanv represi'nlati_i' should b(' (onsullod before sele(tin_ boiB't', for inslallillion ha_ in_ unusudl pipin£_ and pick UD reQuiremenls, su(h d'_ in[ermiBenl

s\stem I)pefaIion, exlensive piDin _ svslems {'[{ I ol lorl ed hl)l _'.alcr healinQ s_slems where lhe boilel and all the pipinQ are within lhe area I(i b_' healed, the boiler may be

_,elot Iixl on [hi! basis ol ils Gross Oulpul

Page 5

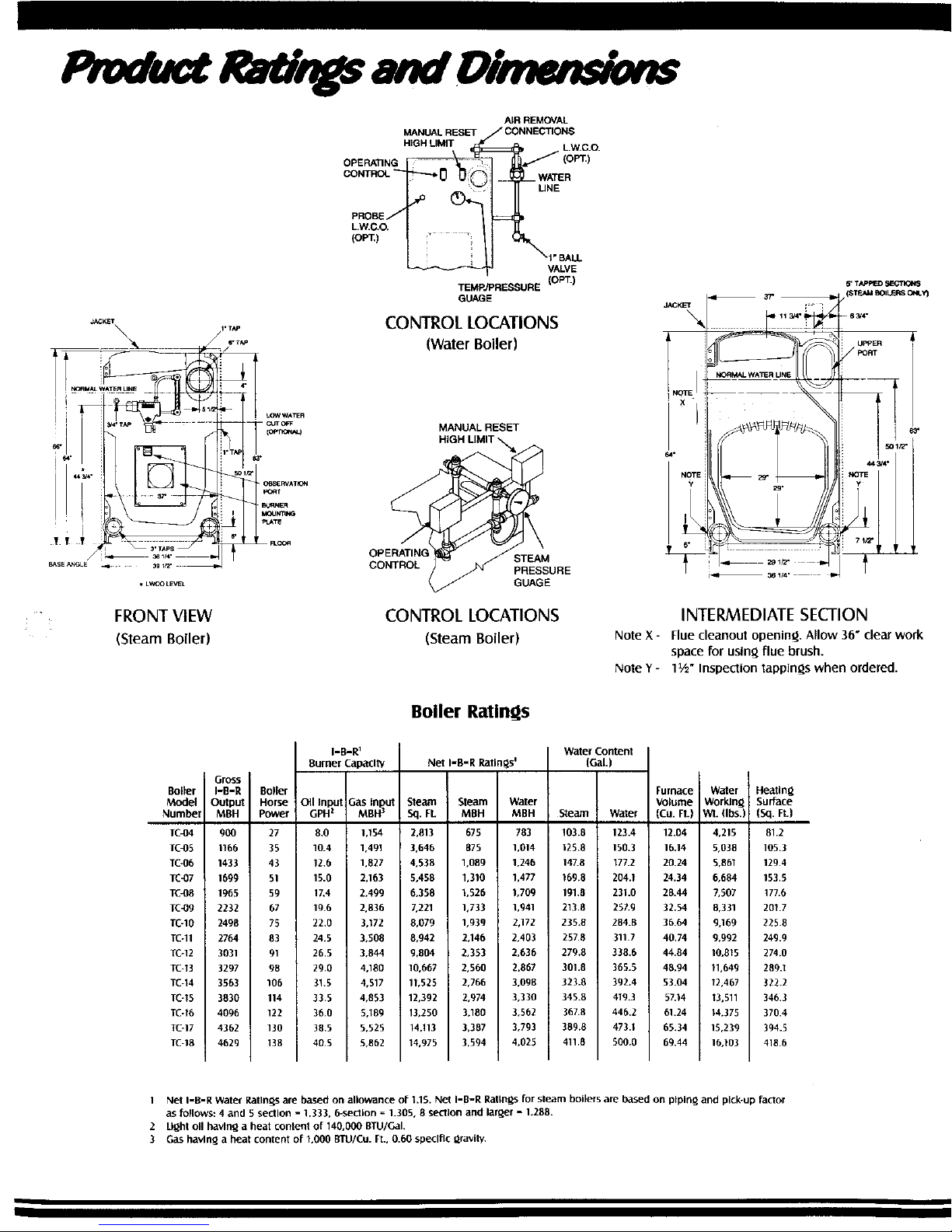

• FRONT VIEW

(Steam Boiler)

MANUALRESET

H]GH LIMIT

OPERATING

AIR REMOVAL

/CONNECTIONS

UNE

1"BALL

VALVE

TEMP./PRESSURE (OPT.)

GUAGE

CONTROL LOCATIONS

(Water Boiler)

MANUALRESET

OPERATING STEAM

CONTROL PRESSURE

GUAGE

CONTROL LOCATIONS

(Steam Boiler)

JAC_

\

5' TAPFEO_=CTIOI_

64"

NOTE

INTERMEDIATE SECTION

Note X- Flue cleanout opening. Allow 36" clearwork

spacefor using flue brush.

Note Y- 1½" Inspection tappings when ordered.

Boiler

Model

Number

TC_)4

TC-05

TC4)6

TC-07

TC_8

Tc_g

TC-10

TC-11

TC-12

TC-13

TC-14

TC-15

TC-16

TC-17

TC-18

Gross

I-B-R

Output

MBH

9O0

1166

1433

1699

1965

2232

2498

2764

3031

3297

3503

3830

4096

4362

4629

I-B-R 1

Burner Capadty

loller [

!orse OII Input Gas Input

'ower GPH z MBH 3

27 8.0 1,154

35 10.4 1,491

43 12.0 1,827

51 15.0 2,163

59 1L4 2,499

67 19.6 2,836

75 22.0 3,172

83 24.5 3,508

91 26.5 3,844

98 29.0 4,180

106 81.5 4,517

114 33.5 4,853

122 36.0 5,189

130 38.5 5,525

138 40.5 5,862

Boiler Ratings

Net I-B-R Ratln@s=

5teaxn Steam Water

Sq. Ft. MBH MBH

2,013 675 783

3,646 875 1,014

4,538 1,089 1,246

5,458 1,310 1,477

6,358 1,526 1.709

7,221 1,733 1,941

8,079 1,939 2,172

8,942 2,146 2,403

9,804 2,353 2,636

10,667 2,560 2,867

11,525 2,766 3.098

12,392 2,974 3,330

13,250 3,180 3,562

14.113 3,387 3,793

14,975 3,594 4,025

Water Content

(Gal.)

Ream Water

103.8 123.4

125.8 150.3

14L8 177.2

169.8 204.1

lgl.8 231.0

213.8 257.9

235.8 284.8

257.8 311.7

279,8 338.6

301.8 365.5

323.8 392.4

345.8 419.3

367.8 440,2

389,8 473.1

411.8 500.0

Furnace

Volume

(Cu. Ft.)

12.04

16.14

20.24

24.34

28.44

32,54

36.64

4074

44.84

48.94

53.04

57,14

61.24

65.34

69.44

Water !

Worldng

VlI. fibs.)

4,215

5,038

5,861

8,684

L507

8,331

9.169

9,992

10,815

11,649

12,467

13,511

14,375

15,239

16,103

Heatln_

Surface

(Sq. Ft.)

81.2

105.3

129.4

153.5

177.6

201.7

225.8

249.9

274.0

289.1

322.2

346.3

370.4

394.5

418.6

1 Net I=B-R Water Ratingsare based on allowance of 1.15. Net I=B=R Ratings for steam boilers are based on ptpJn_iand plcbup factor

as follows: 4 and 5 section = 1.333, 6-section = 1.305, 8 section and lar_er = 1.208.

2 Light oll havln_ a heat content of 140,000 BTU/GaI.

3 Gas havln_Jabeat content of 1,000 BTU/Cu. R., 0.60 specific _ravit_

Page 6

RE_URN

yOKE

BURNER _X. ,

o II I I II o

r-

rTA_m _U_

.... _ ...... ..,_. ....... _. _ X_ •

l ! "

i _2" i j

SIDE VIEW

Note X- Flue cleanout opening. Allow 36" clear work

space for usin_ flue brush.

Note Y - t½" Inspection tappin_s when ordered.

Note Z - Tankless heater sections when ordered. Allow 36" clear space for

heater withdrawal.

Optional Assembled Section and

Packa_led Base

*'Caution: Add 6" to all vertlcal measurements

on 4 - 14 section boilers and 8" on 15 - 18

sectlons.

(oPT.)

/

• VENT

CONNECTIONS

- SUDE DAMPER

(_SERVATION

PORT

WATER R_RN

CONNECTION 5'

RETURN YOKE

WATER BOILE/_ Opa_y

4" RETURN TAPFING

{BOTH SIDES)

REAR VIEW

Boiler Dimensions

Boiler

Model

Number

TC-04

TC4)5

TC-06

TG07

TC4)8

TC-09

TC-10

TC-11

TC-12

TC-13

TC-14

TC-15

TC-16

TC-17

TC-18

Overall LenRth - "A"_

Power

dl Be Flame Webster

¼ I 71%" 66"%"

,¼ : 83%" 74%"

,_ 81 91%" 82%"

1/_ 8; 99%" 90%"

% g' I07%" 98%"

1_ IC 115%" 110%"

i_/ 11 128" 118%"

;9 1_ 137%" 126%"

19 13 145%" 154%"

IZ/ 153%" 142%"

);/ 161%" 150%"

169%" 158%"

177%" 166%"

191%" 183%"

199%" 191%"

Optional

Package(

Base

Dimenslo

91sA_"

104%"

112_A_"

120%"

128%_"

136%"

144_A_"

157%"

165z%_"

173_/_"

181_¾_"

189%"

197z%_"

211"

219¼e"

Furnace

Len&_h

23_A_"

31%d'

39_Ae_

47%e_

55%_"

63%e"

71SAd"

79%_"

87%e"

95%6"

111_/1e"

119_ze"

127%e"

135_Ao"

Boiler

Ler_h

33"

41"

49"

57"

65"

73"

81"

8g"

97"

105"

113"

121"

129"

137"

145"

5reamUpla_eLocatlonS _

"D ° "E" "F"

12%"

20%"

12%" 16"

12%" 24"

12%" 32"

12V_" 40"

20%" 40"

20%" 24" 24"

20V2" 24" 32"

20%" 32" 32"

20%" 32" 40"

20%" 40" 40"

20%" 48" 40"

20_" 48" 48"

20%" 56" 48"

Draft

Loss Ins.

W.C.

.24

.25

.26

.27

.28

.29

.30

.31

.33

.34

.35

.36

.37

.38

39

Firebox

Press.

Ins.

W.C.*

.34

.35

.36

.37

.38

.39

.40

.41

.43

.44

.45

.46

.47

.48

.49

Dial

Vent

Conn.

"G"

10"

10"

10_

12"

12"

14"

14"

14"

14"

14"

16"

16"

16"

18"

18"

Height

Vent

Conn.

57%"

57%"

57%"

56%"

56%"

55%"

55%"

55%"

55%"

55%"

54%"

54%"

54%"

54%"

54%"

I When unit Isassembled or packaged, add 6" 1o hei_hls for 4 - 14 see., 8" to heights for 15 - 18 sect.

2 Add 2-3/4" to secllons 17 and 18 for flue oullet adapten

*Based on 0.10 Ins. W.C. pressure al boiler outlet. If venl slzin_ results in a back pressure Qreater than 0.10 ins. W.C., consult Peerless Heater Compan%

3 Tllese measLwemen?s are approximate.

Page 7

CONNECt GRAVI)_"

RETURN OR PUMP

RETURN BELOW

WATER LINE AND

ABOVE LOWEST

PERMISSIBLE

WATER LINE

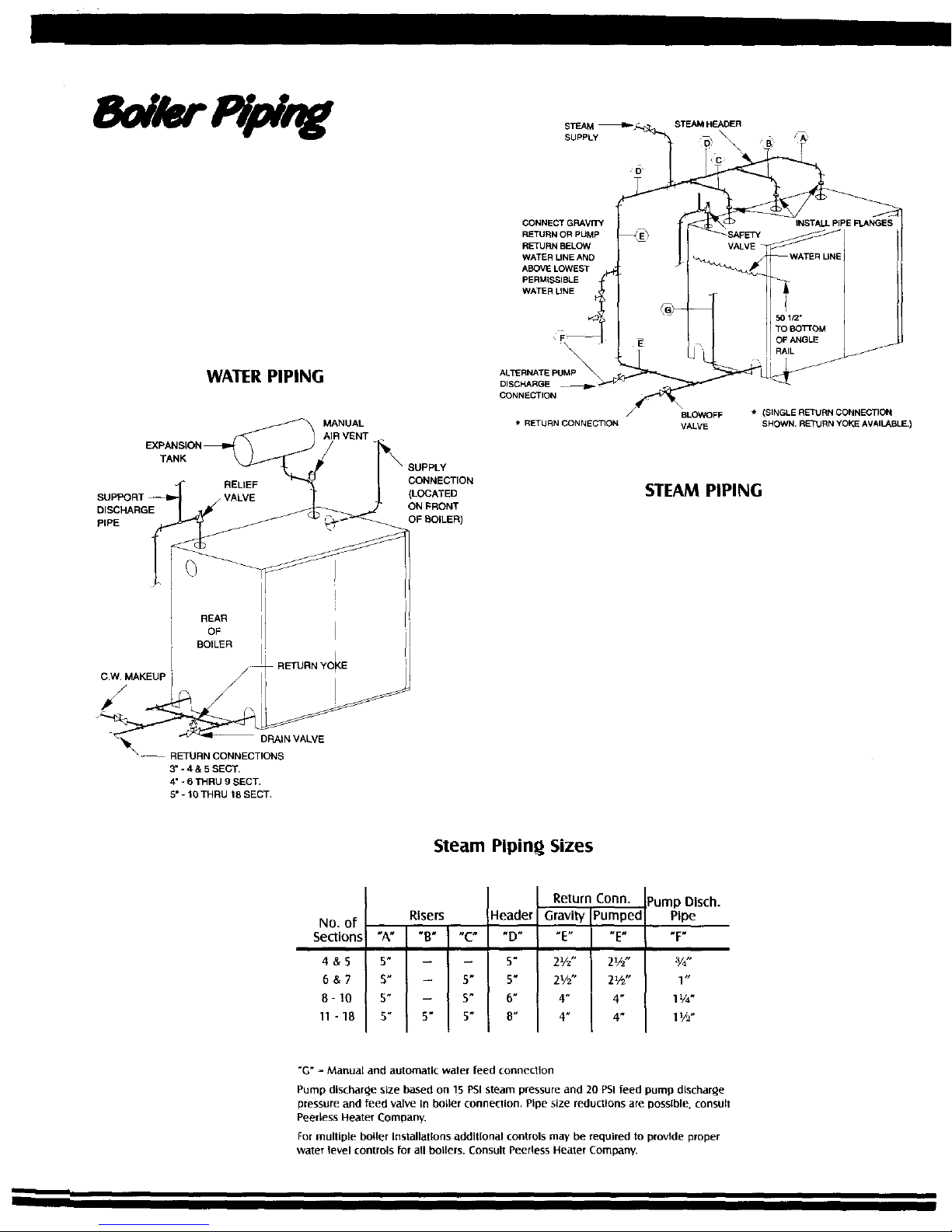

WATER PIPING

MANUAL

AIR VENT

EXPANSION _

TANK

RELIEF CONNECTION

SUPPORT _ VALVE (LOCATED

o,so ,RG ff ON RONT

PIPE OF ROLLER)

\

ALTERNATEPUMP_

DISCHARGE

CONNECTION

* RETURN CONNECTION

BLOWOFF * (SINGLE RETURN CONNECTION

VALVE SHOWN. RETURN YOKE AVAILABLE.)

STEAM PIPING

REAR

OF

BOILER

/

C.W. MAKEUP ' RETURN YO_E

vALVE

3" - 4 & 5 SECT.

4' - 6 THRU 9 SECT.

E" - t0 THRU 18 SECT,

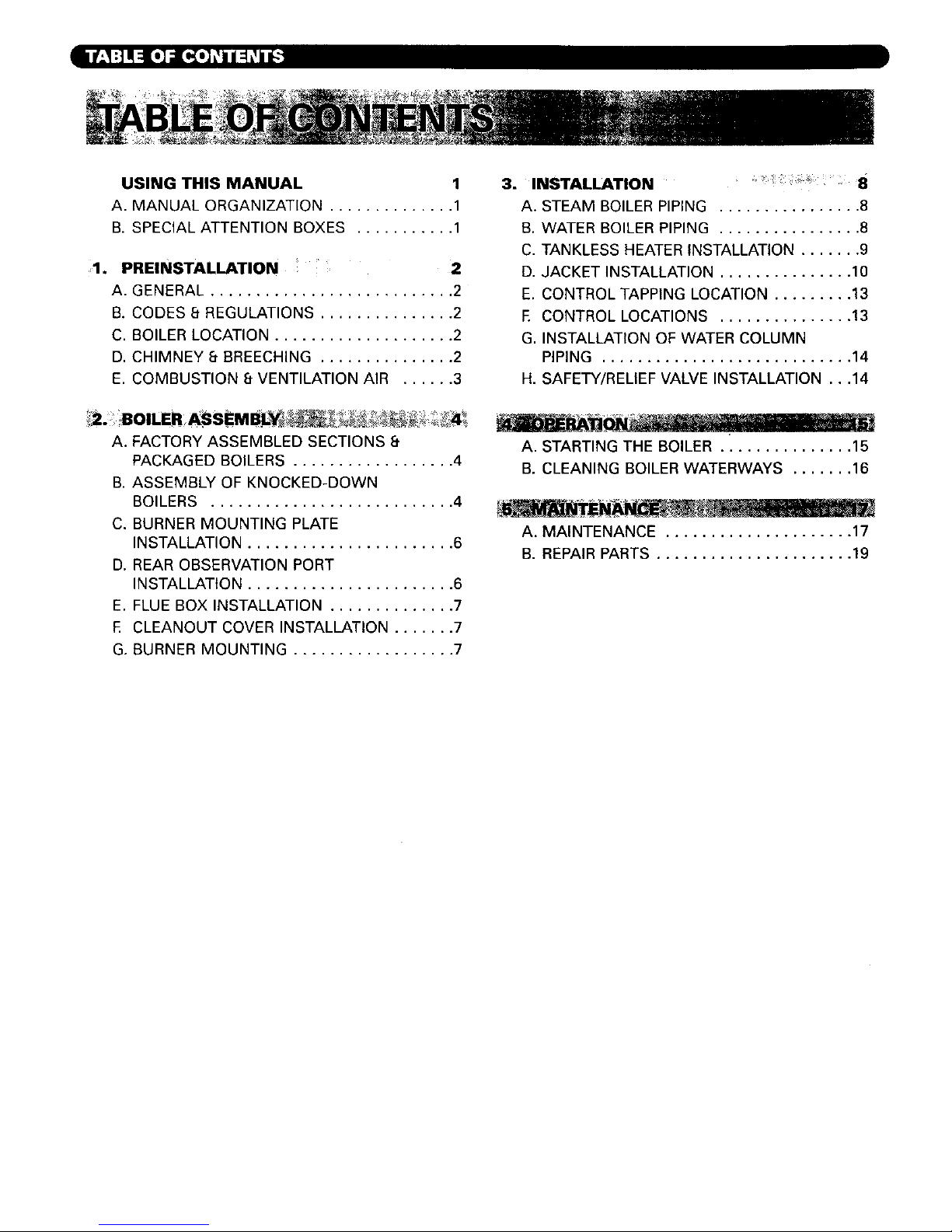

Steam Plpin_ Sizes

No. of

Sections

4&S

o&7

8- 10

11 -18

Risers

.A.I.8.l.c.

5" -- J --

5" -- I 5"

S" -- S"

5" 5" 5"

Header

"D"

s"

5"

6"

8"

Return

Gravity

2V2"

2%"

4"

4"

Conn.

_umped

_E R

21/2"

2_"

4"

4"

•ump Dlsch.

Pipe

I"

1¼"

1½"

"G" = Manual and automatic water feed connection

Pump dischar_e size based on 15 PSI steam pressure and 20 PSI feed pump discharge

pressure and feed valve In boller connection. Pipe size reductions are DOSslble, consult

Peerless Heater Company.

For multiple boiler Installatlons additional controls may be required to provide proper

water level controls for all bo_lers. Consult Peerless Heater Compan_

Page 8

No. of

Sections

4 Section

5 Section

6 Section

7 Section

8 Section

9 Section

10 Section

II Section

12 Section

13 Section

14 Section

15 Section

16 Section

17 Section

18 Section

Arrangement of

Sections for Steam Boilers

F-T-H-B

F-H-T-H-B

F-T-H-T-H-B

F-T-H-P-T-H-B

F-T-H-P-H-T-H-B

F-T-H-P-H-P-T-H-B

F-H-T-H-P-H-P-T-H-B

F-H-T-H-P-ToH-P-T-H-B

F-H-T-H-P-T-H-P-H-T-H-B

F-H-T-H-P-H-T-H-P_H-T-H-B

F-H-T-H-P-H-T-H-P-H-P-T-H-B

F-H-T-H-P-H-P-T-H-P-H-P-T-H-B

F-H-T-H-P-H-P-H-T-H-P-H-P-T-H-B

F-H-T-H-P-H-P-H-T-H-P-H-P-H-T-H-B

F-H-T-H-P-H-P-H-PoT-H-P-H-P-H-T-H-B

F = Front Section

T = Intermediate Sectlon with 5" Tapping

H = Optlonal Intermediate Heater SeCtion

P = Plain Intermediate Sectlon

B = Back

Boiler

Model

Number

SM8-TC

SM12-TC

Capacity, Gals./Min.

200° Boiler Water -

8.0

12.0

Pressure

Drop - PSI

13.0

11.0

Inlet and Outlet

Tapplngs

%-

%-

t Intermlttent draw IO0°F average lemperature rise.

Peerless_ Partner_ Indirect-Fired

Water Heater Standard Equipment

• Hi, h-Grade 316L StainlessSteel Tank

• Enclosed Thermostat Well

• Malntenance-FreePlastlcJacket

• Adjustable Honeywell Control

• 2" Polyurethane Foam Insulation

• T&PRelief Valve

• Cupronickel, Fin-TubeHeat Exchanger

• Modern Ooil Design

• MinimalSS.t_l Temperatum Los

• Rapid RecoveO, Rate

• Easy Installation

• Long Lasting Stainless Steel Constzuct/bn

• No Separate Chimne F or Burner Needed

The Peerless® Partner_ indirect-fired water heater providesa true

advancement in hot water generation. By utilizing the Series TC

boiler as its heat source, the boiler fires only when necessary

and transfers heat energy from the boiler to the water heater

through a highly efficient cupronickel, fin-tube heat exchanger.

PEEI LESS

CAST IRON BOILERS

Peerless Heater Company

231 North Walnut Street • Boyertown,PA 19512-1021

Phone: 610-367-2153• www.peerless-heater.com

HI Division ASME

of _ama

c_ 21102 Peerle,_ Healel ("r_mr_,inv Prfnled in t) S A , OIT-T(- RI 110/02-_I

Page 9

USING THIS MANUAL 1

A. MANUAL ORGANIZATION .............. 1

B. SPECIAL ATTENTION BOXES ........... 1

1. PREINSTALLATION " 2

A. GENERAL ........................... 2

B. CODES 8-REGULATIONS ............... 2

C. BOILER LOCATION .................... 2

D, CHIMNEY 8" BREECHING ............... 2

E. COMBUSTION 8.VENTILATION AIR ...... 3

3. INSTALLATION 8

A. STEAM BOILER PIPING ................ 8

B. WATER BOILER PIPING ................ 8

C. TANKLESS HEATER INSTALLATION ....... 9

D. JACKET INSTALLATION ............... 10

E. CONTROL TAPPING LOCATION ......... 13

E CONTROL LOCATIONS ............... 13

G. INSTALLATION OF WATER COLUMN

PIPING ............................ 14

H. SAFETY/RELIEF VALVE INSTALLATION ...14

A. FACTORY ASSEMBLED SECTIONS 8"

PACKAGED BOILERS .................. 4

B. ASSEMBLY OF KNOCKED-DOWN

BOILERS ........................... 4

C. BURNER MOUNTING PLATE

INSTALLATION ....................... 6

D. REAR OBSERVATION PORT

INSTALLATION ....................... 6

E. FLUE BOX INSTALLATION .............. 7

E CLEANOUT COVER INSTALLATION ....... 7

G. BURNER MOUNTING .................. 7

A. STARTING THE BOILER ............... 15

B. CLEANING BOILER WATERWAYS ....... 16

A. MAINTENANCE ..................... 17

B. REPAIR PARTS ...................... 19

Page 10

7,_1111_vlF±IL_tIY'..! II [e] *'{€'7-'1b,'_lV.J'-_III[*] L_

The Series TC Installation, Operation & Maintenance

Manual is divided into five basic sections:

I. Preinstallation (Sections A through E)

2. Boiler Assembly (Sections A through F)

3. Installation (Sections A through J)

4. Operation (Section A through B)

5. Maintenance (Sections A through B)

=J _.'-]"]:_a,]7±IW_*_IInd:::1L_IIII[o]b._II:{o),_4_

Throughout this manual you wi]l see special attention

boxes intended to supplement the insh_uctions and make

special notice of potential hazards. These categories

mean, in the judgment of the Peerless Heater Company:

Indicates a condition or hazard which will cause

severe personal injury, death or major property

damage.

Indicates a condition or hazard which may potentially

cause severe personal injury, death or major property

damage.

Indicates a condition or hazard which will or can

cause moderate personal injury or property damage.

Indicates special attention is needed, but not directly

related to potential personal injury or property

damage.

Page 11

'-'1 [_ :lOl:l;_r.*1

Series TC boilers are supplied completely knocked down

for field assembly, completely assembled as packaged

boilers or as assembled blocks of sections. All items

should be inspected for damage upon receipt and any

damage reported to the wholesaler and trucker. All

components should be stored in a clean dry area.

Im]! [o,l:lllVd_'_l::li"dt:'1 I:]:t:d=(e,];llO[,€

Carefully read these instructions, burner and controls

manuals before beginning work. This boiler must be

installed by a qualified contractor. The boiler warranty

can be voided if the boiler is not installed correctly.

:N [I'[e] I] _L,"Jl-'JR;| :[L"[I JW-'_IHi[I] _I.:

1,

2,

All work shall be performed in strict accordance with

the requirements of state and local regulating

agencies and codes dealing with boiler installations.

In the absence of such local requirements the

following should govern:

A.S.M.E. Section IV - "Heating Boilers"

A.S.ME Section VI - "Care and Operation Boilers"

ANSIfNFPA 31 - "Installation of Oil Burning

Equipment"

ANSI!Z223.1 - "National Fuel Gas Code"

ANSI/NFPA 70 "National Electrical Code"

A.SM.E. CSD-1 "Controls and Safety Devices for

Automatically Fired Boilers"

ANSI/NFPA 211 - "Chimneys, Fireplaces, Vents,

and Solid Fuel Burning Appliances"

If this boiler is to installed on combustible flooring.

Consult local building authorities for proper

installation, or in the absence of regulations consult

ANSI/NFPA 31, Section 4-4. Failure to comply with

this warning can result in a fire, severe personal

injury or death!

[OglI:.[o]lll::l:] li[oIo,Y,__l/[O]_

1. The boiler should be installed on a concrete floor or

pad. If a pad is used, it should be at least 2" high

and strong enough to support the boiler's weight. Do

not install electrical conductors of any type under the

boiler or pad. The pad must be as level and fiat as

possible.

Locate the boiler close to the chimney to minimize

the breeching length, but allow adequate clearance

for piping, service, maintenance and tanldass coil

replacement. A clearance of 36" on the sides of the

boiler and 48" in front of the boiler is recommended

for serviceability. The minimum clearance to

combustible materials, based on ANSI!NFPA 31,

Table 4-4.11 Clearances to Combustible Materials, is

as follows:

2

I Sides: 6"

2. Rear of Jacket: 6"

3. Front of Boiler: 24"

4. Top of Jacket: 6"

5. Vent/Chimney/Flue Box: 18"

]. Vent System Inspection:

a) Inspect the existing chimney or vent system.

Make sure it is in good condition.

b) Inspect the chimney liner and repair or replace if

necessary.

2. Vent System Installation:

a) The vent system and installation must be in

accordance with the current edition of the

American National Standard ANSI!NFPA 211,

"Chimneys, Fireplaces, Vents, and Solid Fuel

Burning Appliances" or applicable provisions of

the local building codes.

b) Always extend vent terminations three feet above

the roof line.

c) The breeching connection between the boiler

and chimney should be as short as possible with

a minimum number of elbows. [t should be

pitched upwards 1/4" per foot. The breeching

must be the same diameter as the boiler outlet

up to 16 section boilers and 18" diameter for 17

and 18 section boilers.

d) If extreme length, excessive number of turns or a

reduction in diameter is necessary, consult your

Peerless Heater Company representative for

recommendations.

3. Vent System Operation:

a) The vent system must be sized and installed to

remove all combustion products. If the vent

system is not properly sized, the burner may not

operate properly. This can cause poor

combustion or sooting to occur.

b)

c)

If the vent system terminates in any area where

wind-generated down drafts are likely, install a

suitable vent cap which can control wind effects.

This boiler is designed to fire only with a positive

pressure firebox with no more than 0.1" water

column at the boiler outJet before the slide

damper. If venting conditions cause a greater

back pressure, burner capacity may be reduced.

Consult the Peerless Heater Company for

verification of burner capacity under these

conditions. The breeching and vent may be sized

for negative, neutral, or positive pressure as

desired. However, negative pressure overfire can

cause lifting of the flame and poor combustion or

overheating of the boiler crown sheet.

Page 12

d) Breechingusedwithforceddraftboilersmustbe

sealedandofheavygaugesteelconstruction.

Breechingmustcomplywithallapplicablecodes

ofconstruction.

I::m [_o]Lv_l:_lk'li[o]b,_l.'livdqLlilllr-'ll[o]L_l F-'II:

Configuration of breeching and chimney on some

installations may result in a positive breeching

pressure. In these cases, the breeching must be

constructed of pressure tight material, Consult local

building authorities for proper installation. Failure to

comply with this warning can result in carbon

monoxide poisoning or a fire resulting in severe

personal injury or death.

1.

2.

Provide adequate air for combustion and ventilation.

Unless boiler room construction and natural air

infiltration supply all necessary combustion air,

provide an outside air opening or duct. The free

cross sectional area of the opening or duct shall meet

or exceed i square inch per 4000 Btuh input for all

installed appliances. At altitudes above 2000 feet,

increase this requirement by 4% per each thousand

feet above sea level.

3.

If motorized dampers are used on the combustion

and ventilation air openings, wire them such that

they must open in order for the boiler to operate.

They must include a switch that prevents the boiler

from operating if they do not open.

Page 13

"I_.'_-"I-'] 5F'ul:]led

2.

3.

Careful inspection should be made of all assemblies

to detect possible damage during shipment. Factory

assembled blocks of sections and package boilers are

hydrostatically tested at the factory to insure pressure

tightness. Before piping connections are made to the

boiler, hydrostatically retest boiler sections to detect

leaks that may have developed from rough handling

during shipment.

All completed boilers shall satisfactorily pass the

hydrostatic tests as prescribed by ASME Code,

Section I'_

a) Steam boilers - the assembled boiler shall be

subjected to a hydrostatic test pressure of not less

than 45 PSIG.

b) Water boilers - the assembled boiler shall be

subject to a hydrostatic test pressure of not less

than 1-I/2 times the maximum allowable

working pressure.

c) The required test shall not exceed the pressures

prescribed above by more than I0 PSI.

Maintain the test pressure while carefully checking for

leaks. If a leak is found it must be eliminated. Once

the cast iron sections have proven to be water tight

drain them and remove the plugs from any tappings

that will be used in service.

HOLES FOR MOUNTING LOWER

__ JACKET CHANNELS _

" 36-1/2" '1

Figure 1: Shim b Grout Under Angles to Provide

Full Bearing

RETURN

CONNECTION

BOSS

Remove the shipping lugs bolted to the ends of the

base angles and the straps from the draw rods to

angle base after the boiler is in place. Leave the

boiler on the angle iron base.The lifting lugs on

assembled blocks of sections must be removed for

the boiler to accept its jacket,

4. Remove left side jacket panels and check that the

cleanout covers are secure and gas tight.

:tll,__..'&ff__,d:]I_[e] ;I [(OTeIdN=ID_]_DIol_'_,Tl?!:{o]1IF-J_

Section Assembly

1.

Drilled and tapped steel angles are furnished to

provide a level footing, facilitate section assembly

and provide a means of attaching the jacket. Set the

angles in parallel position measuring 36-I/2" outside

of the angles as shown in Figure I. Shim the angles

to make them level and grout after the sections are

assembled.

2.

Place the back section in position on the angles as

shown in Figure 2. The end of the floor angle must

extend beyond the boss for the return connection by

up to 3/8" or be flush with the return connection boss.

Figure 2

3.

MIN.- FLUSH

MAX. 3/8"

Inspect the graphite port connector recesses and

rope groove for dirt and obstructions. Clean the port

connector recesses with a stiff wire brush. Apply the

spray-on adhesive supplied with the boiler to the

rope groove to hold the rope gasket in place during

assembly. Apply a length of rope gasket while

avoiding bends and twists. Ensure that the ends of

the rope extend past the clean-out cover opening as

shown in Figure 4.

Install large port connector with steel inner ring

into the upper port making sure that the inner ring

stays inside the port.

Page 14

4,

5.

Install two smaller port connectors in the lower

recessed ports.

Note: If port connectors will not stay in place: Use

spray adhesive, supplied with the rope gasket, to

hold the graphite port connector (with steel ring) in

place. Alternatively, hold the port connector in place

with a putty knife or similar tool, making certain to

remove the tool before the sections mate. Failure to

remove the tool may dent the port connector,

causing a leak.

Select the correct intermediate section (refer to Table

I), and slide it in place against the back section.

Ensure that the sections are plumb and the port

connectors properly seated in the port recess as

indicated in Figure 3. Install the draw rods and

hardware and tighten them lightly.

It is essential to locate tapped intermediate and

optional tankless heater sections, as shown in Table

1, in order to maintain steam quality and jacket fit.

6. Inspect the rope gasket to ensure that it remains in its

groove. Check the section alignment and port

connector position by looking through the ports, if

necessary, reposition the port connector by loosening

the draw rods and then retighten them. Check the

floor angles and section for alignment.

GOOD BAD

SECTIONS READY SECTIONS

FOR DRAW UP DRAWN UP

Figure 3: Section Alignment

7. Gently draw the sections together until the port

connectors are in full contact with both mating

surfaces. Make sure the port connectors stay inside

the boiler ports.

8.

Torque the draw rods as described below. Do not

completely tighten one side. Gradually work each

side until the correct torque is reached.

Torque Specifications for Series TC

Boiler with Graphite Port Connectors

Step 1 Upper Right

Step 2 Lower Left .

Step 3 Lower Right

Step 4 Upper Left .

Step 5 Upper Right

Step 6 Lower Left .

.... 25 ft. Ibs.

.... 25 ft. Ibs.

.... 25 ft. lbs.

.... 10 ft. Ibs.

.... 50 ft. Ibs.

.... 50 ft. lbs.

Step 7 Lower Right .... 50 ft. Ibs.

Step 8 Upper Right .... 75 ft. Ibs.

Step 9 Lower Left ..... 75 ft. Ibs.

Step i0 Lower Right . . .75 ft. Ibs.

9.

Step 11 Upper Left ..... 30 ft Ibs.

Step 12 UpperRight . . .125 ft. Ibs.

Step 13 Lower Left . . .125 ft. Ibs.

Step 14 Lower Right . 125 ft. Ibs.

Step 15 Upper Right . .125 ft. Ibs.

Step 16 Upper Left .... 40 ft. Ibs.

The boiler sections may not attain metal-to-

metal contact. This is acceptable using the

graphite port connectors. The torque

specifications listed above are only a

guideline. If any ports develop leaks during

the hydrostatic test, the torque can be

increased up to 200 ft Ibs. on the upper right

and 150 ft. Ibs. on both of the lower ports or

until the sections make metal-to-metal

contact. Additional torque after the sections

are in contact will not improve the seal.

Prepare the rope groove and gasket recess on the

intermediate section as described for the back

section in section 2B2 of this manual.

I0. Select the next appropriate section and repeat the

assembly process.

Hydrostatic Testing

II. Plug all openings in the boiler waterways and fill the

boiler with cold water to hydrostatically test for leaks

as indicated in section 2A2 of this manual.

12. While filling the boiler for hydrotest, RECHECK the

torque on all ports and tighten the draw rods if

Aecessary.

If any port connector leaks, tighten the draw rods

until it stops leaking or until either metal-to-metal

contact is made or the 200 ft. Ibs. limit on upper

right and 150 ft. Ibs. on lower ports is reached as

described in Step 8. Check the torque on draw rods

for adjacent ports.

13. When the boiler is ready to be put into operation for

the first time, the temperature should be brought up

slowly (low fire when applicable).

FIT ROPE GASKET IN

GROOVE WITH 1/8"

SHOWING AT JOINT

CONTINUOUS

LENGTH

OF ROPE GASKET

Figure 4: Rope Gasket Installation

5

Page 15

Table 1: Arrangement of Sections for Steam Boilers

4Section-F T H B

5Section-F-H-T-H B

6Section-F T H-T-H-B

7Section-F-T-H-P-T H B

8Section-F-T H P H-T-H-B

9Section-F T-H-P-H P T H B

10 Section-F-H-T H P H-P-T-H-B

11 Section-F H-T-H-P-T-H P-T-H-B

12Section-F-H-T H P-T-H-P-H-T-H-B

13Section-F-H-T H P H-T-H-P-H T-H-B

14 Section- F- H-T H- P- H-T- H- P-H-P-T-H-B

15Section-F-H T H-P-H-P-T-H P-H-P-T-H-B

16Section-F-H-T-H-P-H P-H-T-H-P-P H-T-H-B

17 Section- F- H-T- H- P- H- P- H-T- H- P- H- P- H-T H-B

18 Section- F- H - T- H- P- H P-H-P-T- H-P-H-P-H-T-H-B

Note: Tapped intermediate (T) are furnished for supply on steam boiler only. For water

boilers use plain intermediate sections (P) in place of tapped intermediate sections (T).

F - Front Section

T - Intermediate Section with 5" Tapping

H - Optional Intermediate Heater Section

P - Plain Intermediate Section

B - Back Section

Do not exceed 200 ft.-Ibs, torque on the upper right

side draw rods, 150 ft. Ibs. on the lower draw rods and

40 ft.-tbs on the upper left side draw rods.Tighten the

rods in the sequence shown in section 2B8.

Overtightening draw rods does not improve the

sealability of the joint. Excessive torque may damage

castings.

1.

2.

Cement the 3/8" diameter rope gasket into the

groove of the burner mounting plate with spray-on

adhesive. Install the 7/16" x 2-1/2" studs in the screw

seats around the opening in the front section. Install

the burner mounting plate insulation block in the

hole in the front section with the small flame

observation port cutout on the top left side. Place

the burner mounting plate over the block and force

the block inward until the studs extend far enough

through holes in the burner mounting plate to accept

the nuts. Tighten the nuts.

Use a long drill, awl, or other such tool for form

holes through the insulation block for four 1/4"

machine screws. Install the i/4" x 5" machine screws

through the holes in burner mounting plate,

supporting the insulation block on the inside to

prevent tearing. Install the 2" x 1-1/2" stainless steel

washers and nuts over the insulation block and

tighten lightly, being careful not to crush the

insulation. At the time of burner installation the

burner hole may have to be enlarged and shaped.

This may be done with a hacksaw blade.

I. Assemble rear obsewation port as follows:

a) Locate steel "flapper door," Item 6 as shown in

Figure 5. Drive Item 7, "expansion pin," into

hole in Item 1 to secure Item 6 in position.

b) Lift Item 6 up and install Item 2, "hex bolt."

c) Slide Item 3, "compression spring" over the hex

bolt and screw Item 4 "hex nut" to hex bolt.

d) Screw Item 5, "ball knob" into position and lock

location using Item 4 as a "jam" nut.

e) Adhere I/8" x 3/4" x 24" long insulating tape, as

shown, to observation port frame, Item I.

2. Screw the 5/16" x 1-I/2" studs into the screw seats

around the op_ning for the rear observation port in

the back section. Apply a thin layer of furnace

cement over the mounting flap and install the port

assembly. Install the washers and nuts and tighten.

3. Mount assembly to the back section of boiler.

4

3

6

INSULATINGTAPE

Figure 5: Rear Observation Port

Item 6 in Figure 5, must always be part of the assembly.

Check condition twice/year and replace as needed.

Page 16

l :N 3 KIJ :! :{o):| h'_F.'_IIt;1nn|;_1 i [o] _

Screw the 5/16" studs into the screw seats around the

flue box outlet on the back section. Place I/8" x 3/4" x

86" long, Type A, adhesive tape insulation over the

studs. Place the flue box in position and install the

washers and nuts, tightening the nuts uniformly. The

1/8" x 3/4" x 18" long, Type B, adhesive tape is installed

on the horizontal surface of the damper anchoring angle

on the bottom side of the flue box. Open the slide

damper all the way and leave ready for adjustment

during burner lightoff.

[€]l l:[lJ;|i_l:IH llVj[*llJ_,_illlL'_[€

Cleanout covers come insulated from the factory. Inspect

the insulation before installing. Prepare the rope in the

grooves at the top and bottom of the cleanout cover

openings between the sections to insure an air tight seal

when the covers are installed. Cleanout cover hex nuts

should be set at 15 Ibs. torque. Use Hi-Temp silicone

caulk around the cleanout covers to seal air tight.

Most large burners require support from the floor.

See Burner Manufacturer's Manual for such

specifications, if needed.

1.

2,

3.

4.

Remove the burner from its crate. Read the burner

instructions.

Insert (4) 3/8"-16 x 1 I/4" studs supplied with burner

mounting plate into the front plate holes.

Place the high temperature gasket on the burner

front plate and secure the burner to the front plate

with 3/8" fiat washers and hex nuts.

If the burner is supplied with a pedestal, install it to

the burner per the Burner Manufacturer's

Instructions. The pedestal provides additional

support and prevents the burner from sagging.

Page 17

_1 b._lll:!'_'W_ll:{o]lll_l:t I'_l'.lh_[_

1 Steam piping schedule is shown in Table 2. Pitch the

piping to allow condensate to t_ow in the same

direction as the steam. Refer to Figure 6 for an

acceptable steam piping arrangement. Swing joints

are recommended. For optimum circulation a return

yoke, as shown in Figure 8, should be used.

Table 2

Steam Boiler Piping

No. of 5"

Boiler Section Risers Header Equalizer

4 & 5 1 5" 2-112"

6 & 7 2 4 5" [ 2-1/2"

i6 2 I 6" €'

11 - 18 3 8" 4"

Spacing of steam risers must be checked for each

boiler installation.

STEAM HEADER SWING JOINTS

A

f /R_SER(S)

STEAM SUppLY

WHEN 3 RISERS

Table 3

Steam Boiler Feedwater Recommendations

I=B=R Minimum Condensate

Gross Evap Feedwater Receiver

Boiler Output Rate _ Pump Flow± Capacity 3

Model MBH GPM GPM Gallon

TC-04 [ 900 . 1.86 3.7 -- 37

TC-05 ] 1166 2.41 4.8 48

TC-06 1433 2.96 5.9 59

TC-07 [ 1699 3.56 _ 7.0 _ 70

TC-08 ! 1965 4.05 8.1 81

TC-09 . 523£ ' 4160 " 9.2 _ 92

TC-10 468 i ,15 lO.3 lO3

TC-1] 2764 _ .5.70 1i.4_ _114

TC-lg _o31 5.25 !a& _ !as

TC-13 _ 3297 ] 6.80 13.6 _ 136

--TC-14 T 335_ {. 7535_ 14/7 / 147

TC-15 + 3830 7.90 : 15.8 t 158

TC:16 ! _96 7 814,5 i6_. _69

TC17 V 4362 ! 9£10m 18d}_ 180 L

TC-18 4629 9,55 19.1 191

1 Evaporation rate based on heat of vaporization at 212 ° F,,970 BTU/Ibm

2. Minimum feedwater pump flow is based on 2 times evaporation rate

3. Condensate receiver capacities are based on 20 minute steam cycle. Chaa

shows actual capo¢ity and not gross receiver volume.

3. The front section has 3" tappings at the base for

installation of 3" close nipples and 3" caps. Removal

of caps allows flushing of sediment from boiler.

These recommendations are considered normal for

compact buildings, Where buildings are spread out,

additional receiver capacity may be necessary

because of the extended time required for

condensate to return to the receiver.

I:]! ih_l:_ll:l;t :{o]lll=l;tl'Jl'ZlL_[4

GRAVITY RE31JRN OR WATER FEED

CONNECTIONS AT OR ABOVE LOWEST

PERMISSASLE WATER LINE AND BELOW

NORMAL WATER LINE

Figure 6: Steam Piping

ALTERNATE PUMP

DISCHARGE

1. Piping for water boilers is shown in Figure 7. A

return yoke is provided as standard equipment for

each water boiler. Table 4 contains a pipe size

schedule for water boilers.

AIR REMOVAL

SUpPLy

CONNEC_DN

(LOCAllEDON

FRONTOF

BO_ER)

D/SCH/_GE PIPE

2. Feedwater requirements for steam boilers at full input

are shown in Table 3. Addition of water to the boiler

should be controlled by sensing the actual boiler

water level. One inch water column tappings are

provide on the front section to mount various low

and high water cutoffs and controllers.

CW. MAKEUp

RETURN

Figure 7: Water Piping

Page 18

Table 4

Water Boiler Piping

(Based on 20 ° A T System Temperature Drop)

Boiler Size Return Size Supply Size

TC-W-4 & 5 3 3

TC-W-6-9 4 4

TC-W-10 18 5 5

2. Series TC Return Yoke Assembly, Grooved Pipe (4 to

18 sections}

a) Cover edges and outer surface of the gasket with

a thin layer of petroleum-free silicone lubricant or

equivalent.

b) Install the gasket by placing the gasket over the

pipe and ensure that the gasket lip does not

overhang the pipe end.

Bring both pipe ends together, ensuring proper

alignment, and slide the gasket into position

properly centering it belween the grooved

portions of each pipe.

d) Place coupling housings over the gasket so that

the keys fully engage into grooves. Insert the

bolts into the couplings and tighten the nuts until

finger tight.

e) Tighten nuts alternately and evenly. Gasket

should not be visible after tightening•

Table 4A

Parts List

Item

•

Quantity Stock Code Description

I [ 6 __ 7656 Coupling 4"

2 . 1 7657 Coupling 5"

3 I 7658 Tee 4" x 4" x 5"

4 [ 2 - 7659 Tee 4"

8 i I 7663 Lube 4.5 oz.

Clean the heater flange to remove any dirt or rust. Install

the 7/16" x 1-1/2" studs in the screw seats around heater

opening. Place the heater gasket over the studs and

install the heater. Install the nuts and tighten them

evenly to ensure uniform gasket compression. Install the

operating control in one of the heater mounting plates.

This ensures quick burner response to hot water

demand. Figure Ii shows an acceptable piping

arrangement for multiple heaters.

GASKET_

OPERATING

CONTROL_

TAPPING

INTERMEDIATE

HEATER SECTION

Figure 8: Return Yoke Assembly

(4 to 18 Sections)

/

/

,(s)

OUTLET

Sm8HEATER

Figure 10: Tanklsss Heater

Before installing any controls or instrumentation on

the front panel, F1-F2, (refer to Figure 13) must be

installed.

Figure 9: Return Yoke Assembly - Individual Parts

Page 19

']_l_Jl_7i_[,]_l

HOT WATER SUPPLY

OPERATING

UNION

TEMPERATURE

TEMPERING

VALVE

GATE

VALVE

Figure 11: Tankless Piping

DJ nT'..Tq[q:llll Ildl,.'llf_,111'__ll[o]_

Boiler Assembly

The boiler must be completely assembled on base angles

supplied by Peerless Heater Company. These are drilled

and tapped to accommodate lower jacket channels.

Factory assembled blocks of sections are shipped on 6"

or 8" channel iron.

Control and Piping Installation

Any operating or limit controls to be located on the front

of the front section and the steam gauge glass must be

installed after front panel F2, refer to Fig. No. 13. All

other piping, burner and control connections may be

made before jacket installation.

Jacket Assembly (See Figure 12.)

1. Lower Channels: Locate lower channels and layout

on floor angles. Notches in channels are to

accommodate remaining stud from lifting lugs on

floor angles for factory assembled blocks of sections.

Ignore notches if boiler is not factory assembled.

Layout such that 5/16" hole on end of unnotched leg

of channels is at the front and rear of boiler, facing

upward. Boilers 15 through 18 sections have 3 piece

lower channels with center section only having hole-

to-mount channels to angles. Mount channels to

floor angles with 1/4" - 20 round head machine

screws and washers.

2.

Front Panels: Locate panel F2 over the front section

with the bottom corners supported by the lower

channels. Align holes and fasten with #I0 washer

bead sheet metal screws. Install panels FI and F2A

with #10 washer head sheet metal screws.

3.

Back Panels: Assemble right rear post to back panel

BI with #10 washer head sheet metal screws. Install

panel!post assembly on boiler. Assemble left rear

post to back panel. Align lower holes of right and left

posts with lower channel holes and join with #10

washer head sheet metal screws. Install panel B2

with sheet metal screws.

CHECK

VALVE

8" _r_R

UlaPLy

4,

5.

Upper Channels, 4 Through 7 Section Boilers:

Boilers from 4 through 7 sections have one piece

upper channels. These are installed and attached to

the top of front and back panels with 1/4" - 20 round

head screws, washers and nuts.

Upper Channels, 8 Through 18 Section Boilers:

These boiler sizes have two and three piece upper

channels supported at each splice by a bracket.

Assemble upper channels with splice pieces on the

floor with 1/4" - 20 round head screws, washers and

nuts. Assemble hardware hand tight. Install channel

assemblies on boiler to the top of the front and back

panels with 1/4" - 20 round head screws, washers

and nuts. Locate left support bracket and center over

splice and corresponding draw rods that allow

attachment of bracket to the boiler while overlapping

the splice in upper channels. Disassemble and install

splice hardware that align with slot in top of support

bracket. All holes will not align with slot.

Loosen nuts on draw rods to install brackets behind

washer, Level upper channel and re-tighten draw

rods nuts immediately to 40 ftJIbs, on left draw rods

and 125 ft./Ibs, on right draw rods, Install the right

support brackets in a similar manner. Check

alignment and tighten all hardware.

6. Side and Top Panels: Assemble knobs on left side

panels. Install panels by inserting the top first and

dropping the bottom into the groove made by the

lower channel.

Lay out top panels such that knockouts and

openings agree with the assembled boiler. After

layout has been checked, make necessary knockouts

and install panels.

Lay out and install right side panels similarly to top

panels. This completes the jacket assembly.

I0

Page 20

LEFT

REAR

POST

LH1

LH3

LH4

SUPPORT

BRACKETS

RIGHT

REAR

POST

B2

CHANNELS,

T3

T4

T5

T6

T7

3E

\UPPER

RH3

T1

RH4

RH5

F1

BASE ANGLES

(NOT INCLUDED

WITH JACKET)

Figure 12: Jacket Assembly

11

Page 21

FI_-"]_ ! mE_i['L r

Table 5: Jacket Schedule

Jacket Channel Carton

Upper

Channels

_ Lower Channels

oo

2

2 2 2 2

2 2

2 2 2 2 I i 2 I 4

1 1 2 1 4

10, ,21

lli 1 1 2 1 4

12 1 1 2 1 4

1318 1 1 1 1 l I 1 2 1 4 2 2 2 2

14 2 2 I i 2 i 4

15 2 2 2 2 2 4 2 4

16 2 2 2 2 2 4 2 4

17 2 2 2 2 2 4 2 4

2 2 2 2 J2 4 2 4

Channel Carton Hardware

{17) 1/4" - 20 x 3/4" Slot, RD, Head Machine, Screws, Zinc Plated

(17} 1/4" ID Washe_, Zinc Plated

(17) 1/4" - 20 H_ Nuts, Zinc Plated

(4) 5/8" [E Std. Washer

Table 5A: Jacket Schedule

Top & Side Cartons

Jacket Front & Back Carton *_

Left Side

Front Panels Back Panels "_ Top Panels Panels Right Side Panels

< _ _ C3 Chrome Knob

The front and back carton, which

consists of one (1) each of the above

listed items, is the same for all size

boilers¸

Hardware Bag:

(23) #10 x 1/2" Slot. Hex. Washer Head

8M Screws, Zinc Plated

(21) 1/4" - 20 x 1/2" Slot Rd. Head

Machine Screvss,Zinc Plated

{9) I14" - 20 Hex Nuts, Zinc Plated

(21) 1/4" I.D. Washer, Zinc Plated

8-32 x 1/4"

Machine Screw

Q_.

A I I I 1 I I 3 3

B 1 I 2 I I I 4 4

C I I I I

D I I I I 1 I 2 2

E I 2 I 4 4

F I I I 2 2

G 1 I 1 2 3 3

H 1 2 I I 4 4

l I 2

1 1 1 2 2

12

Page 22

:Ill .D] L_i II;To)nil If_,1:J:JI_[€"I I(o0D.Y±_l| [o] L_

Figure 13 shows the location of tappings for controls and

piping for both water and steam boiler.

3\! _

I

Tappi.g Tapping Steam Water

No. Size Boiler Boi]eT

i 3/4" Probe LWCO

2 I" Water Column Top Air Removal

3 3/4" Manual Reset Hi Limit.

Operating Control &

Steam Gauge

4 314" -- Operating Control

5 3/4" Water Glass (2) Manual Reset Hi Limit (Top)

Temp/Press Gauge (Bottom)

6 114" Overflre Pressure Tap Overflre Pressure Tap

7 i" Water Column Bottom Water Column Bottom

1-1/2 'r Inspection Tapping - Top

8 3/4" Tankless Heater O]_ra_ng Tankless Heater Operating

Control (Located in Heater Control (Located in Heater

Mounting Plate) Mounting Plate)

Figure 13: Tapping Locations

I_ [e(0]t_/l:Te]g [0I#;_IID]L_[,

Figure 14 shows the suggested location of limit and

operating controls.

MANUAL RESET

HIGH

OPERATING

CONTROL

STEAM

PRESSURE

GUAGE

Steam Boiler Control Locations

AIR REMOVAL

MANUAL RESET /CONNECTIONS

HIGH LIMIT _ _ L.W.C,O.

OPERAT'N ,.........

CONTROL _'---_[_ 0"_ ___1_ WATER

PROBE/ =_

L.W.C.O.

II

......... _L_

(OPT.) ' -. k:2_ 1,,

BALL

VALVE

(OPT.)

TEMP/PRESSURE

GUAGE

Water Boiler Conll"ol Locations

Figure 14: Control Locations

13

Page 23

L.W.C.O.

1"PIPING

__A?E OPT')

L.W.C.O.

(OPT.)

R

NE

GUAGE

GLASS

I" BALL

VALVE

(OPT.)

Series TC Series boilers are available with a variety of

water level control devices. Figure 14A shows a typical

water column piping arrangement. For all installations,

the 1"x 7-I/2" hydronic nipple is installed in the lower

water column tapping. The remaining hydronic nipple is

installed above the control device.

Figure 14A: Typical Water Column

Piping Arrangement

i-'ll _r_,l_l_llL'J I:t:llll:llV/_,lliVJ=l [IL_I.1F:IlI:_I/[0]L'

The safety relief valve is located in the 3" tapping at the

top of the rear section for both steam and water boilers.

Water and steam b-irn cartons contain relief valves and

fittings.

Relief valve discharge piping must be piped to avoid

exposure of persons to hot liquid or vapor, see

Figure 15. Never install any type of valve between the

boiler and the relief valve,

SUPPORT DISCHARGE PIPING SO AS

TO AVOID STRAIN ON VALVE BODY

RELIEF OR SAFETY VALVE.

DO NOT REMOVE RATING

OR WARNING TAGS.

MOUNT AS SHOWN.

DISCHARGE PIPE SIZE TO

EQUAL VALVE OUTLET,

DO NOT RESTRICT FLOW.

DISCHARGE SO AS TO

AVOID EXPOSURE OF

PERSONS TO HOT

LIQUID OR VAPOR.

LEAVE OPEN END

VISIBLE FOR PERIODIC

INSPECTION FOR SLOW

LEAKAGE OR DRIPS.

Figure 15: Safety Relief Valve Installation

14

Page 24

r:! t-'_if:1;t/h_[Cli|:l= I:{e]lq:l"

1. Check the piping.

a) Water/Steam Piping

i. The Boiler must have been hydrostatically

tested.

2. Check the attached piping for joint tightness.

3. Continue monitoring as you proceed through

start up.

b) Gas Piping

1. Make sure the gas system piping and the

connections to the boiler Gas Control Train(s)

have been leak tested.

2. After the boiler is in operation, check the

tightness of all joints in the boiler gas piping

with a soap suds solution.

3. Purge the gas piping of all air up to the boiler

Gas Control Train.

c) Oil Piping

1. Check the oil piping visually. Make sure all

joints are tight.

2. When the burner is firing, check the suction

line and return line pressures.

3. If the pressure exceeds the allowable pressure

in the Burner Manual or if the suction line

vacuum is higher than allowable, correct the

piping as needed to bring the suction line and

return line pressures within acceptable range.

4. Excess pressure can causepump seal failures.

Excess vacuum will cause fuel flow problems

with the burner oil pump.

2. Fill the boiler.

a) Steam: Fill the boiler to the normal water line.

I. Gravity Systems and Pumped Return with

Condensate Units - Fill to the normal water

level mark on front jacket panel.

2. Pumped Return with Boiler Feed Unit - Fill

the boiler using the boiler feed unit. Fill level

will depend on the control being used, but

should be at the normal water level mark on

front jacket panel.

3. Fill the boiler.

a) Water: Fill the boiler and system.

1. Fill the system with fresh water only. If the

water hardness is high, use water treatment

to reduce the deposition of minerals in the

boiler.

Check the system for leaks and make sure the

automatic fill valve (if used) and the expansion tank

are oprating correctly. Leakage or weeping of the

relief valve will cause make-up water to be added to

the system. Excessive make-up water will damage

the boiler and system components due to liming and

oxygen corrosion.

2. If the system requires antifreeze, use only

antifreeze designed for hydronic systems.

These contain inhibitors to prevent corrosion

of the boiler and system components. Do not

use ethylene glycol or automotive antifreezes.

• Make sure the antifreeze supplier can

provide periodic inhibitor check service.

• If automatic fill is used, the system will

have to be checked periodically to make

sure the antifreeze concentration has not

been diluted below design level.

• Local codes may require the use of a

backflow preventer or manual fill only

with separation from the cii_ supply.

• Consider the minimum temperature of

potential exposure for the system when

deciding on the antifreeze concentration.

A concentration of 50% generally

provides protection from freezing down to

-30°E

3. Purge the air from the system.

4. Run burner check-out.

a) Before firing the burner, slide the Slide Gate

Damper on the rear flue box all the way down

(full open).

b) Follow the instructions in the Burner Manual for

starting the burner, adjusting air openings and

fuel rates. Perform ignition system and flame

supervisory control test and checkout as

described in the manual.

c)

After burner is set at rate, close the damper until

the pressure reading at the test opening in the

rear flue box is between 0.0" wc and 0.1" wc

positive.

d)

Wl_en a barometric draft regulator is installed in

the venting system, adjust the boiler damper for

0.0" wc pressure reading at the damper. Adjust

the draft regulator for -0.05" wc draft between

the boiler damper and the draft regulator.

On installations with high draft, do not leave the

boiler with a negative draft reading at the rear flue

box or draft damper. High negative draft can pull the

flame up into the boiler crown steet and overheat the

iron.This can result in cracked sections or shortened

boiler life.

e) Adjust the burner as needed for a CO 2

reading of:

I. Oil burners: 12% to 12.5% or 1% less than

the level at which the smoke reading goes

above a trace on the Bacharach scale.

2. Natural gas burners: 9% to 10% with CO less

than 50 ppm.

15

Page 25

5. Check boiler controls.

a) Limit and Operating Controls

1. Lower the setting of each control until the

burner shuts down.

b)

Low Water Cutoffs

I. Test probe type controls by using the Push-

to-Test Button.

2. Test float type controls. ASME CSD-1 requires

the control to be piped with Test-n-Check

valves in order to allow isolation for test.

c) Follow additional instructions in the Burner

Manual for proving the burner component

operation.

d) Check all controls to make sure they function

correctly.

e) After all controls have been proven, set the

Operating and High Limit Controls to the set

point desired.

Steam Boilers

1,

The boiler must be completely assembled before

cleaning. The burner must be installed and made

operational with the operating, limit and safety

controls functional. Combustion should be adjusted

to prevent sooting of the boiler flues.

2. Final burner adjustment is to be made after cleaning.

Plug any unused boiler tappings and install gauge

glass and safety valve.

3. Install a 2" skim valve and fittings in the 6" N.PT.

tapping of the front section.

4, Clean the boiler as described below no later than

one week after the initial start-up. Cleaning will be

more effective if the boiler operates a day or two to

loosen sediment and impurities in the system.

Cleaning the boiler requires the use of very hot water

and corrosive chemicals. Use care when handling to

prevent injury.

5. The boiler must be cleaned to remove any

accumulation of oii, grease, sludge, etc. that may be

in the system. These substances can cause foaming

and surging of the boiler water, producing unstable

water line and water carryover to the system.

6. Connect a 2 inch drain line off of the skim valve, run

to a point of safe discharge.

7.

8.

Close all valves to the system. Provide a means of

continuous fresh water to the boiler for the cleaning

process.

Open the skim valve. Fill the boiler until water begins

to flow out of the valve.

9.

Use common washing soda (such as Arm and

Hammer Super Washing Soda). Mix the soda with

water in a 10 quart pail and pour into the boiler

through the safety valve tapping. Use a proportion of

one (I) pound of washing soda for each 800 square

feet EDR net boiler rating.

10. Turn burner on and allow the boiler water to heat up

to just below steaming (180 ° to 200°F). Cycle the

burner to maintain temperature during skimming. Do

not allow the boiler to steam. Steaming mixes up the

contaminants in the water instead of floating them at

the surface.

11. Open the make-up water valve to continuously feed

water to the boiler. Allow water to flow out the skim

tapping.

12. Continue skimming the boiler until the water flowing

from the skim tapping flows clear. This will take

some time, possibly several hours for a dirty system.

13. After skimming is complete, close the skim valve and

turn off the boiler.

14. Close the make-up water valve and open the boiler

blowdown valves.

15. Drain the boiler completely then refill and drain

again one or two times to make sure all of the soda

has been washed out.

16. Restore piping to normal. Pipe a nipple and cap in

the skim valve.

17.

Note: Ifthe gauge glass becomes dirty again, this

indicates more contaminants have worked loose in

the system. Repeat the cleaning and skimming

process as needed to clean the system.

Do not leave the boiler unattended while firing during

the cleaning cycle,

Take great care not to allow the water level to drop

below the bottom of the gauge glass or to allow fresh

water make-up to flow in too fast.This will avoid the

possibility of causing the boiler sections to fracture.

16

Page 26

Do not store or allow combustible or flammable

materials near the boiler. Substantial fire or explosion

hazard could result, causing risk of personal injury,

death or property damage.

Do not use this boiler if any part of it has been under

water. Immediately call a qualified service technician

to inspect the boiler. Any part of the control system,

any gas control or any burner or gas component

which has been under water must be replaced.

Should overheating occur or the fuel supply fail to

shut off: Shut off the fuel supply at a location

external to the boiler. Do not turn off or disconnect

the electrical supply to the pump. Immediately call a

qualified service technician to inspect the boiler for

damage and defective components.

1. Placing boiler in operation.

a) Start up the Burner/Boiler per the Burner Manual

and the insh'uctions in this manual on starting

the boiler.

b) Prove the correct operation of all controls on the

boiler and burner as outlined below.

c) Check the operation of the ignition and flame

proving controls as described in the Burner

Manual.

d) Test the limit and operating controls to assure

they are operating correctly.

e) Inspect and test all low water cutoffs.

f) Test the safety relief valve(s) using the procedure

given by the valve manufacturer on the valve tag.

g) Visually inspect the burner and pilot flames (if

applicable).

2. To shut down the boiler.

a) Turn off Burner.

b) Open main line power disconnect switch to

boiler/burner.

c) Close fuel shut-off valves.

d)

To take boiler out of service if the boiler and

system are not to be used when temperatures are

below freezing:

I. Shut off make-up water supply and drain the

boiler and system completely.

2. Open main line power disconnect switch to

boiler/burner. Remove the fuses or secure the

switch so that the power cannot be turned on

accidentally.

3. Do not use ethylene glycol antifreeze in a

boiler system.

4. Be certain that the boiler and system are

refilled before returning to service Follow the

instructions in this manual and the burner

instructions to operate.

Before servicing the boiler:

• Turn off all electrical power to the boiler.

• Close the Gas Service Valve and Oil Shut-Off Valve.

• Allow the boiler to cool if it has been operating.

• Label all wires prior to disconnection when

servicing controls. Wiring errors can cause

improper and dangerous operation. Verify proper

operation after servicing.

3. Maintenance - Annual

a) Before the start of each heating season,

inspect and make all necessary adjustments to

insure proper boiler and burner operation. Use

the maintenance and inspection procedures

following.

b) Inspect the Venting System

1. Check the chimney or vent to make sure it is

clean and free from cracks or potential leaks.

2. All joints must be tight and sealed.

3. The vent connector must extend into, but

not beyond the inside edge of the chimney

or vent.

c) Inspect the Boiler Area

1. The boiler area must be clean and free from

combustible materials, gasoline or any other

flammable liquids or vapors.

2. The combustion air openings and the area

around the boiler must be unobstructed.

d) Inspect boiler flueways and burner for

cleanliness. If cleaning is required, use the

following procedure.

I. Turn off all electrical power to the boiler.

2. Remove left jacket panels. Remove deanout

cover plates on each flueway.

3. Brush the boiler flue areas through cleanout

openings.

4. Remove the burner and burner mounting

plate. Remove any scale or soot from the

combustion chamber by means of vacuum

cleaning or other available means.

5. Reinstall the burner mounting plate, burner

and all cleanout cover plates. Make sure all

sealing rope and seals are in good condition.

Replace sealing rope if necessary.

6. Reinstall all jacket panels.

e) Inspect the boiler and piping for signs of leaks.

Check to see if there are signs of heavy make-up

water addition to the system.

17

Page 27

f) When placing boiler into operation, follow

burner manual, all instructions supplied with the

boiler and the instructions in this chapter.

g) Test the operation of all limit controls, float

controls and ignition components.

4. Monthly Maintenance

a) Inspect the burner and pilot flames.

b) Inspect the boiler and system for any signs of

leakage or excessive make-up water usage.

c) Inspect and check the operation of the venting

system.

5. Daily Maintenance

a) Inspect the boiler area to make sure the area is

free from combustible or flammable materials

and that there are not obstructions to the flow of

air to the boiler or combustion air openings to

the room.

b) Make sure there are no signs of abnormal

operation, such as overfilling or leakage.

Be vary careful when adding water to a hot boiler.

Add very slowly or, if possible, allow the boiler to

cool nautrally before adding water.

If an excessive loss of water occurs, check for a leak

in the piping and correct th problem. Excessive

make-up water will cause corrosion and damage to

the boiler.

STEAM BOILERS: Do not place cold boilers in

service on a hot steam line or severe damage may

occur to boiler and piping. Keep cold boilers valved

off line, fire until boiler reaches line pressure and

then open steam main isolation valve. Steam entering

a cold boiler cools quickly causing severe steam

hammer. Boilers not valved Off the system should

have an overflow installed to prevent idle boilers

from flooding. If this is not done, cold boilers must

be heated to near steaming conditions (210°F) and

then drop water level to normal.

WATER BOILERS: Avoid thermal shock of water

boilers. Establish water circulation through the boiler

before starting burner. Where hot standby is required,

special piping and operation procedures are

required. Consult your Peerless Heater Company

representative.

18

Page 28

Co

_'J!

t:

3

D"

11

19_

17

36 34....-..-.-_

35

9

15

35

39

34

5 4

29

1

28

2

27

21

13B

41

40 37 _/

I I

1

38

24

25

20

o_

_oe

_.._ __.

_ • _

5' _.._

_o _cr

c_ _3

- _

CJ"_

,.-._t.,Q

m m

g ,,D_

g_

_.t_

Page 29

Table 7: Series TC Repair Parts

1 !Front Section 76000

Intermediate Section 76002

2 lnlermediate Section w,Heater Connection 76004

4 Intermediate Section w, Supply Connection 76003

5 Back Section 76001

Flue Collector Assembly includes: Flue Collector, Slide Damper and Angle Bracket

76060

76061

i 76062

i 76063

7664

7679

7680

76064

76075

!

I 74019

i 76073

i 76074

I 7631

7622

51556

86

55521

Flue Collector Assembly (4-6 Section)

9 Flue Collector Assembly (7 8 Section)

Flue Collector Assembl_, (9 13 Section)

Flue Collector Assembly (14 18 Section)

Slide Damper Only {4-8 Section)

i0 Slide Damper Only (9-13 Section}

i Slide Damper Only (14-18 Section)

11 i 16" to 18" Increaser (17 18 Section)

12 Tankless Coil Cover Plate Assembly

13 Tankless Coil Cover Plate Gasket

13A TanMess Coil (8 GPM)

13B i Tankless Coil (12 GPM)

Cleanout Cover Plate Assembly Includes:

Cleanout Plate, Insulation, Rope and Hardware

15 Cleanout Cover Plate Assembly

16 Cleanout Cover Plate Bolts

17 Cleanout Cover Plate Nut

18 Cleanout Cover Plate Washer

19 !Rope Sea[ (3/8" Dia x 3 3/4 ft. Long)

Burner Mounting Plate Assembly Includes:

Burner Mounting Plate Observation Port Glass, and Cover

Burner Mounting Plate Assembly 7G/4"

76028

Burner Mounting Plate Assembly 8" 76023

Burner Mounting Plate Assembly - 9" 76027

20 Burner Mounting Plate Assembly - i0-i/4" (Web-JB2) 76026

Burner Mounting Plate Assembly I0 i/4" (GPR10.1) 76025

Burner Mounting Plate Assembly - 10-i/4" (STD) 76024

Burner Mounting Plate Assembly - 12-1/2" 76022

Burner Mountinq Plate Hardware I 7653

21 !Burner Insulating B}oek ! 76029

Burner Insulating Block Hardware 7720

22 Observation Glass Only 7648

23 Observation Glass Gasket 7650

24 Observation Glass Gaskel 7649

25 i Observation Glass Retainer 7651

26 Observation Cover Plate 7677

27 Rope Seal (3/8" x 7 ft Long) 55521

28 Upper Graphite Port Connector 7655

29 Lower Graphite Port Connector

51211

!

7621

51567

7289

55485

7632

7722

334 Rope Seal (1/2" x 7 ft Long) Between Sections

5/8" x 11" Draw Rod

5/8" Hex Nuts

35 ] 5/8 I' Washer

i Spray Adhesive

36 Rear Observation Port Assembly

- I Rear Observation Port Hardware

Steam Trim and Controls

_ 3-1/2" Steam Gauge w/Internal Syphon

Gauge Glass Set

1-1/4" Safely Relief Valve 15 PSI (4-5 Section)

1-1/2" Safety Relief Valve 15 PSI (6-7 Section)

I 2" Safely Relief Valve 15 PSI (8-10 Section)

39 2-1/2" Safely Relief Valve 15 PSi (11-13 Sedion

3" Safely Relief Valve 15 PSI (14-16 Section)

2-1/2" Safety Relief Valve 18 PSI (17 18 Section

40 PA404A Operating Contro

41 L404C Limit Control

51769

50521

50508

505O9

50503

50504

5O5O5

50511

50549

5O538

Water Trim and Controls

42 Pressure_emperature Gauge 55736

3/4" - 30 PSI Water Relief Valve (4 Section) : 51300

l" - 30 PSI Water Reie Vave 4-6Saction i 51301

39 1-1/4" 30 PSI Water Relief Valve (7 10 Section) 51302

1-1/2" - 30 PSI Water Relief Valve (11-13 Section) 51303

ve (15 18 Section) 51304

51702

45 LgOO6E Limit Control 51570

2O

Page 30

Series TC

Oil, Gas

Gas/Oil Boilers

Installation,

Operation

Maintenance

Manual

TO THE INSTALLER:

This manual is the property of the owner and must

be affixed near the boiler for future reference,

TO THE OWNER:

This boiler should be inspected annually by a

Qualified Service Agency.

member

HI Division ASME

of gama

PEERLESS"

CAST IRON BOILERS

PEERLESS HEATER COMPANY

231 NORTH WALNUT STREET- BOYERTOWN, PA 19512-1021 . PHONE 610-367-2153

www.peerless-heate_com

THE PREFERRED HEATING CHOICE

@2002 Peerless Heater Company TC8001 R1 (10/02-1M)

Printed in U,S.A,

Loading...

Loading...