Page 1

Installation and Assembly:

Peerless Ultra-Slim Articulating Mount for Samsung 46"

and 55" C9000 LED displays

Models: SUAC9000

Max UL Load Capacity: 75 lb (34 kg)

3215 W. North Ave. • Melrose Park, IL • (800) 865-2112 or (708) 865-8870 • Fax: (708) 865-2941 • www.peerlessmounts.com

ISSUED: 10-01-10 SHEET #: 095-9354-1

Page 2

NOTE: Read entire instruction sheet before you start installation and assembly.

WARNING

• Do not begin to install your Peerless product until you have read and understood the instructions and warnings

contained in this Installation Sheet. If you have any questions regarding any of the instructions or warnings, for US

customers please call Peerless customer care at 1-800-865-2112, for all international customers, please contact

your local distributor.

• This product should only be installed by someone of good mechanical aptitude, has experience with basic building

construction, and fully understands these instructions.

• Make sure that the supporting surface will safely support the combined load of the equipment and all attached

hardware and components.

• Never exceed the Maximum UL Load Capacity. See page one.

• If mounting to wood wall studs, make sure that mounting screws are anchored into the center of the studs. Use of

an "edge to edge" stud fi nder is highly recommended.

• Always use an assistant or mechanical lifting equipment to safely lift and position equipment.

• Tighten screws fi rmly, but do not overtighten. Overtightening can damage the items, greatly reducing their holding

power.

• This product is intended for indoor use only. Use of this product outdoors could lead to product failure and personal

injury.

• This product was designed to be installed on the following wall construction only;

WALL CONSTRUCTION HARDWARE REQUIRED

• Wood Stud Included

• Wood Beam Included

• Solid Concrete Included

• Cinder Block Included

• Brick Contact Qualifi ed Professional (Not evaluated by UL)

• Other or unsure? Contact Qualifi ed Professional (Not evaluated by UL)

Tools Needed for Assembly

• stud fi nder ("edge to edge" stud fi nder is recommended)

• phillips screwdriver

• drill

• 5/16" (8 mm) bit for concrete and cinder block wall

• 5/32" (4 mm) bit for wood stud wall

• level

Table of Contents

Parts List.................................................................................................................................................................................3

Wall installation ...................................................................................................................................................................4, 5

Installing Adapter plates to screen..........................................................................................................................................6

Mounting Flat Panel Screen ...................................................................................................................................................8

2 of 11

ISSUED: 10-01-10 SHEET #: 095-9354-1

Page 3

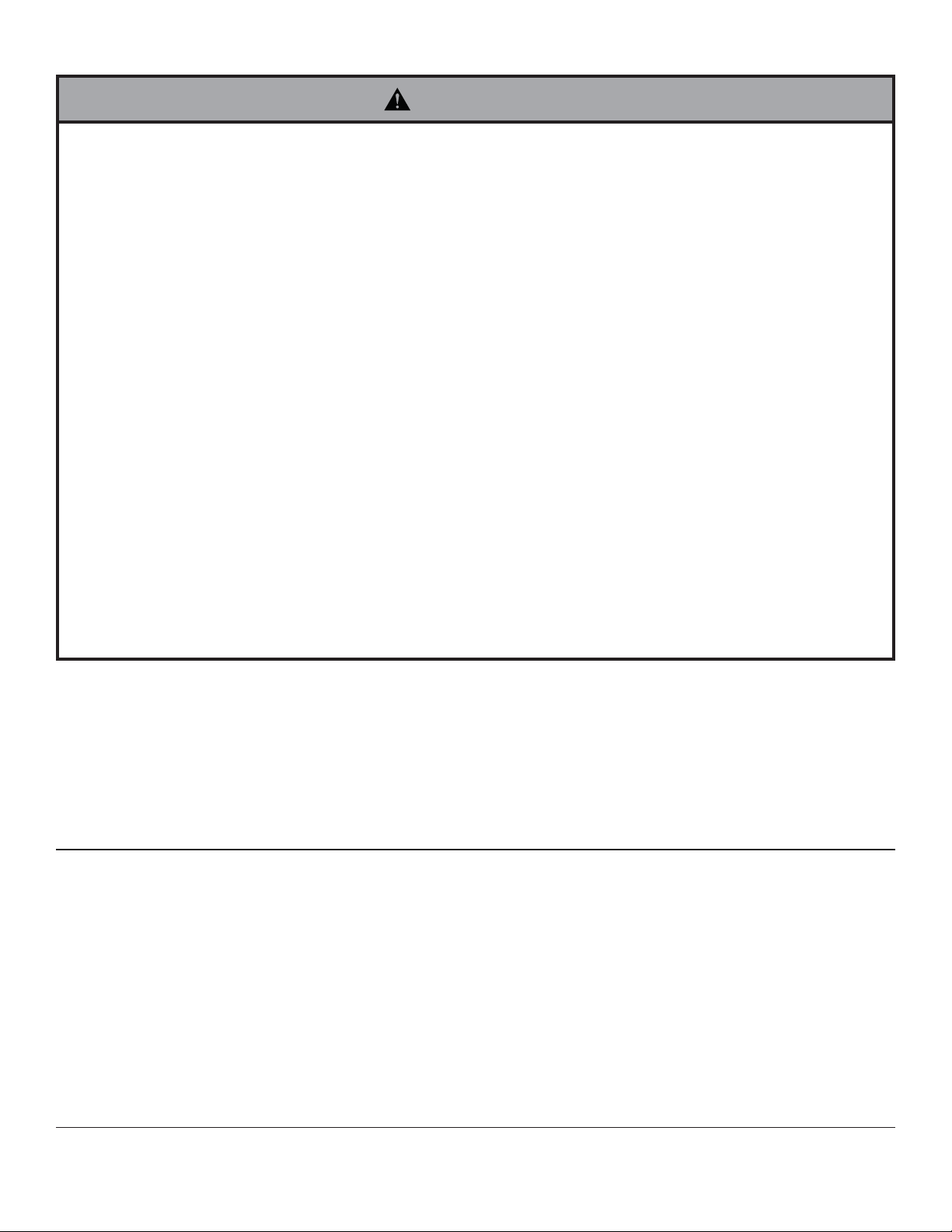

Before you begin, make sure all parts shown are included with your product.

A

Parts List

Description Qty. Part #

wall arm assembly 1 046-4176

B upper mounting plate 1 046-4177

C lower mounting plate 1 046-4178

D wood screw 4 500-1090

concrete anchor

E

security driver

F

G fastener cap 8 046-4096

H cable clip 1 046-4137

I short cable tie 3 560-2004

J snap caps 4 560-2029

8-32 x 1/4" flat head thread

K

forming screw

1/4-20 x 1/2" hex head

L

thread forming screw

M4 x 16 mm phillips screw

M

long cable tie

N

590-0320

4

560-1133

1

4 520-2622

4 520-2592

520-2088

4

590-2168

2

A

Parts may appear slightly different than illustrated.

C

B

D

EFG

N

LMK

I

JH

3 of 11

ISSUED: 10-01-10 SHEET #: 095-9354-1

Page 4

Installation to Wood Stud Wall

WARNING

• Installer must verify that the supporting surface will safely support the combined load of the equipment and all

attached hardware and components.

• Tighten wood screws so that wall plate is fi rmly attached, but do not overtighten. Overtightening can damage the

screws, greatly reducing their holding power.

• Never tighten in excess of 80 in. • lb (9 N.M.).

• Make sure that mounting screws are anchored into the center of the stud. The use of an "edge to edge" stud fi nder

is highly recommended.

• Hardware provided is for attachment of mount through standard thickness drywall or plaster into wood studs.

Installers are responsible to provide hardware for other types of mounting situations (not evaluated by UL).

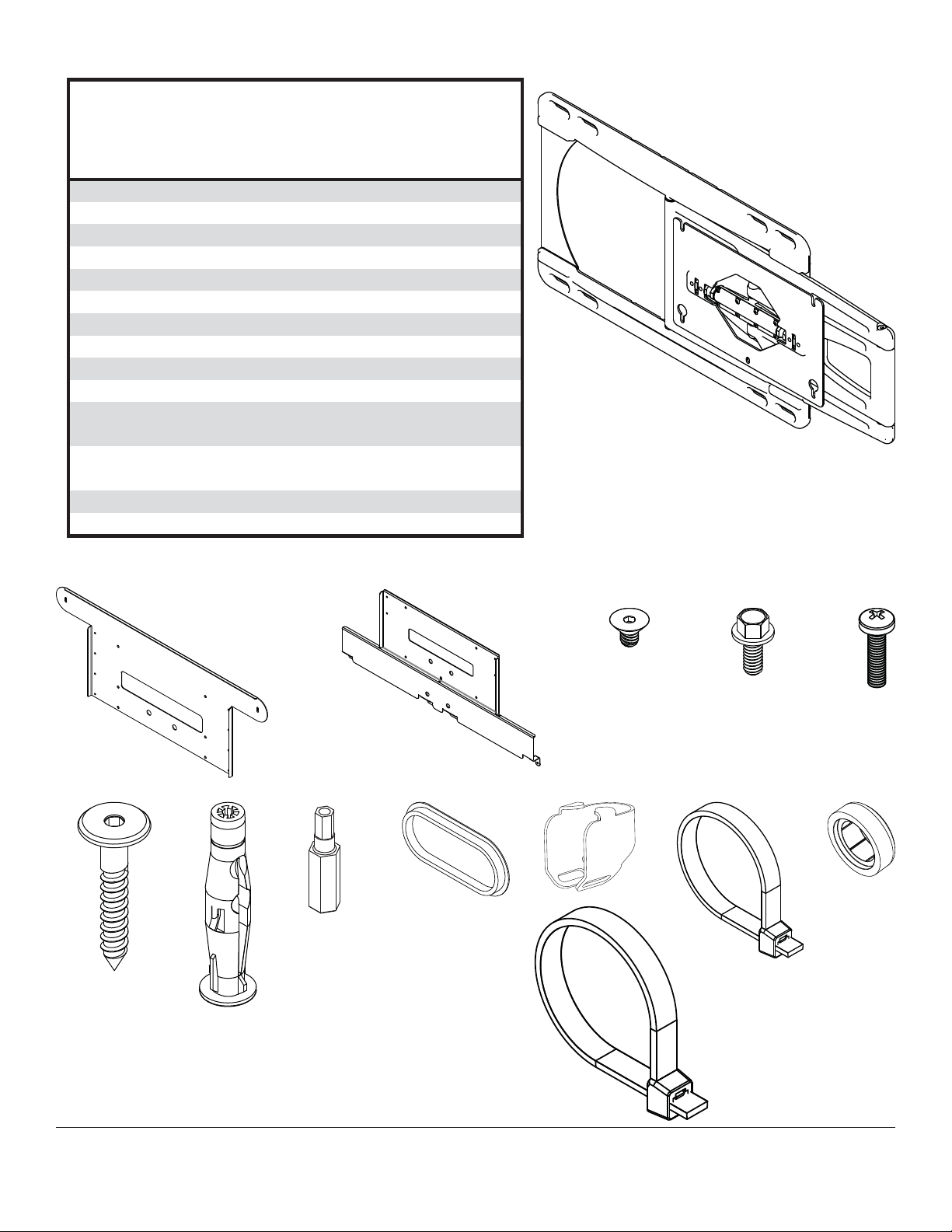

Use a stud fi nder to locate the edges of the studs. Use of an edge-to-edge stud fi nder is highly recommended.

1

Based on their edges, draw a vertical line down each stud’s center. Center of screen mounting plate will be

2.5" offset from center of outer mounting slot as shown in fi gure 1.1 or will be 0.19" offset from center of inner

mounting slot as shown in fi gure 1.2. Place wall arm (A) on wall as template, level, and mark the center of four

mounting holes. Top mounting slot will be X" above the screen center as shown in fi gure 1.1 and chart 1.

Drill four 5/32" dia. holes to a minimum depth of 2.5". Secure wall arm (A) to wall with four wood screws (D) as

shown in fi gure 1.2. NOTE: Be sure arrow is pointing up when mounting wall arm (A) to wall as shown in fi gure

1.1. Level, then tighten all fasteners.

Insert eight fastener caps (G) into wall plate mounting holes.

fi g. 1.1 fi g. 1.2

X"

2.5"

(64 mm)

ARROW

SCREEN

MOUNTING PLATE

Chart 1

for 46" display 10.7" (272mm)

for 55" display 9.1" (231mm)

= CENTER OF SCREEN

D

G

0.19"

(5 mm)

A

4 of 11

ISSUED: 10-01-10 SHEET #: 095-9354-1

Page 5

Installation to Solid Concrete or Cinder Block

WARNING

• When installing Peerless wall mounts on cinder block, verify that you have a minimum of 1-3/8" (35 mm) of actual

concrete thickness in the hole to be used for the concrete anchors. Do not drill into mortar joints! Be sure to mount

in a solid part of the block, generally 1" (25 mm) minimum from the side of the block. Cinder block must meet ASTM

C-90 specifi cations. It is suggested that a standard electric drill on slow setting is used to drill the hole instead of a

hammer drill to avoid breaking out the back of the hole when entering a void or cavity.

• Concrete must be 2000 psi density minimum. Lighter density concrete may not hold concrete anchor.

• Installer must verify that the supporting surface will safely support the combined load of the equipment and all attached hardware and components.

NOTE: Wall arm assembly (A) must be mounted to

1

wall using inner mounting holes.

Make sure that wall arm assembly is level and use

wall plate as a template to mark four mounting holes.

Top mounting slot will be X" above the screen center

as shown in fi gure 1.1 and chart 1 on page 4. Drill four

5/16" (8 mm) dia. holes to a minimum depth of 2.5"

(64 mm). Insert anchors (E) in holes fl ush with wall as

shown. Place wall arm assembly over anchors and

secure with wood screws (D). Level, then tighten all

fasteners. Insert eight fastener caps (G) into mounting

holes.

NOTE: Be sure arrow of label is pointing up when

mounting wall arm assembly (A) to wall as shown in

fi gure 1.1.

1

E

Drill holes and insert anchors (E).

2

F

A

D

Place plate (A) over anchors (E) and secure with screws (D).

3

concrete

surface

E

WARNING

• Tighten screws so that wall plate is fi rmly attached,

but do not overtighten. Overtightening can damage

screws, greatly reducing their holding power.

• Never tighten in excess of 80 in. • lb (9 N.M.).

• Always attach concrete anchors directly to loadbearing concrete.

• Never attach concrete anchors to concrete covered

with plaster, drywall, or other fi nishing material.

If mounting to concrete surfaces covered with a

fi nishing surface is unavoidable (not evaluated by

UL), the fi nishing surface must be counterbored

as shown below. Be sure concrete anchors do not

pull away from concrete when tightening screws. If

plaster/drywall is thicker than 5/8" (16 mm), custom

fasteners must be supplied by installer (not evaluated

by UL).

INCORRECT CORRECT

wall

plate

concrete

wall

plate

concrete

Tighten all fasteners.

SOLID CONCRETE

CINDER BLOCK

E

D

G

A

CUTAWAY VIEW

plaster/

dry wall

plaster/

dry wall

5 of 11

ISSUED: 10-01-10 SHEET #: 095-9354-1

Page 6

WARNING

• Be sure to carry display upright, from the top and bottom edges, or damage to display may occur.

Follow instruction manual included with display to remove display from stand.

2

Set display on a fl at, level surface. Refer to display manufacturer's installation guide for recommended careful

handling. Remove two M4 chrome plated screws from Ultra-Slim wall mount bar. Save all screws. Install eight

standoff screws (included with display) into eight mounting holes on bottom of display.

M5 CHROME SCREWS

DISPLAY

STANDOFFS

WARNING

• Do not assemble mounting plates (B,C) on top of display or damage to display may occur.

Assemble upper mounting plate (B) to lower mounting plate (C) using four 8-32 x 1/4" fl at head thread forming

3

screws (K). Use confi guration as shown in fi gures 3.1 and 3.2.

B

C

K

B

C

FIG. 3.1

FOR 46" DISPLAYS

6 of 11

K

FIG. 3.2

FOR 55" DISPLAYS

ISSUED: 10-01-10 SHEET #: 095-9354-1

Page 7

Install two 1/4-20 x 1/2" thread forming screws (L) into lower mounting plate (C) leaving 1/8" exposed thread as

4

shown below.

C

L

Set control box into lower mount plate (C) and place assembly onto back of display.

5

Secure assembly to back of display by reinstalling two M4 chrome plated screws (included with display) into ultraslim wall mount bar, four M4 black phillips screws (included with display) into lower mounting holes of control box,

and four M4 x 16 mm phillips screws (M) into upper mounting holes of control box.

ULTRA-SLIM WALL

MOUNT BAR

M4 CHROME SCREWS

DISPLAY

CONTROL

BOX

M

M4 BLACK SCREWS

7 of 11

ISSUED: 10-01-10 SHEET #: 095-9354-1

Page 8

Mounting Flat Panel Screen

WARNING

• Tighten screws so screen brackets are fi rmly attached to screen. Do not tighten with excessive force. Overtightening

can cause stress damage to screws, greatly reducing their holding power and possibly causing screw heads to

become detached. Tighten to 40 in. • lb (4.5 N.M.) maximum torque.

Hook two 1/4-20 x 1/2" thread forming screws (L) onto top slots of front plate as shown in fi gure 6.1.

6

Fasten two 1/4-20 x 1/2" thread forming screws (L) into bottom mounting holes as shown in fi gure 6.2.

Tighten all screws.

FRONT PLATE

fi g. 6.1

8 of 11

L

fi g. 6.2

ISSUED: 10-01-10 SHEET #: 095-9354-1

Page 9

Cable Management

Cables may be routed using short cable ties (I).

7

Use holes on bottom of lower mounting plate (C) with cable ties (I) to secure cables as shown below.

CABLES

I

Cables may be routed using cable clip (H).

Slip cable clip (H) onto bottom of center joint as shown in fi gure 7.1 and secure cables to cable clip using long cable tie

(N) as shown in fi gure 7.2.

Secure cables to bottom of wall plate using cable tie (N) as shown below.

WALL PLATE

SLOTS

N

fi g. 7.1

CENTER

JOINT

H

CABLES

N

fi g. 7.2

CABLES

9 of 11

All other brand and product names are trademarks or registered trademarks of their respective owners.

ISSUED: 10-01-10 SHEET #: 095-9354-1

© 2009, Peerless Industries, Inc. All rights reserved.

Page 10

Roll Adjustment

Adapter plate may be rolled +/- 5°.

8

Loosen four M6 nylock nuts half a turn, grasp edges of display and roll screen to desired position as shown.

Retighten four M6 nylock nuts and place four snap caps (J) onto M6 nylock nuts.

CAUTION

• Do not tighten joint screws. Doing so may cause

damage to screws, greatly reducing its holding

power.

JOINT SCREWS

M6 NYLOCK NUTS

10 of 11

All other brand and product names are trademarks or registered trademarks of their respective owners.

ISSUED: 10-01-10 SHEET #: 095-9354-1

© 2009, Peerless Industries, Inc. All rights reserved.

Page 11

LIMITED FIVE-YEAR WARRANTY

Peerless Industries, Inc. establishes a warranty period of fi ve years for products manufactured or supplied by Peerless. This period commences from the date of

sale of the product to the original consumer, but will in no case last for more than six years after the date of the product’s manufacture. During the warranty period

such products will be free from defects in material and workmanship, provided they are installed and used in compliance with the instructions established by

Peerless Industries, Inc. Subject to applicable legal requirements, during the warranty period Peerless will repair or replace, or refund the purchase price of, any

Any other warranties prescribed by the law which may apply with respect to such products also are limited in duration to the warranty period specifi ed in this

This warranty does not cover damage caused by (a) service or repairs by the customer or a person who is not authorized for such service or repairs by Peerless

Industries, Inc., (b) the failure to utilize proper packing when returning the product, (c) incorrect installation or the failure to follow Peerless’ instructions or warnings

when installing, using or storing the product, or (d) misuse or accident, in transit or otherwise, including in cases of third party actions and force majeure.

In no event shall Peerless be liable for incidental or consequential damages or damages arising from the theft of any product, whether or not secured by a security

This Limited Five-Year Warranty is in lieu of all other warranties, expressed or implied, and is the sole remedy with respect to product defects. No retailer, dealer,

distributor, installer or other person is authorized to modify or extend this warranty or impose any obligation on Peerless in connection with the sale of any product

This warranty gives specifi c legal rights, and you may also have other rights provided by the national legislation of the country in which you purchased such

such product which fails to conform with this warranty.

Limited Five-Year Warranty.

device which may be included with the product.

manufactured or supplied by Peerless.

product.

www.peerlessmounts.com

© 2008 Peerless Industries, Inc.

11 of 11

ISSUED: 10-01-10 SHEET #: 095-9354-1

Loading...

Loading...