Page 1

Installation and Assembly:

Peerless Ultra-Thin Flat Mount for 37" - 65" (94 - 165 cm)*

Flat Panel Displays

Model: SUF661

*Display Compatibility Requirements

• The depth of this mount (0.19") may not provide

suffi cient space for proper ventilation on some displays.

Please refer to the manufacturer's requirements for

mounting your display before installation.

• The display must have a fl at mounting surface, or the

mounting holes need to be on the furthest back surface

of the display.

• Input/Output connection must be properly oriented to

accommodate mounting 0.19" from the wall.

2300 White Oak Circle • Aurora, Il 60502 • (800) 865-2112 • Fax: (800) 359-6500 • www.peerlessmounts.com

Max UL Load Capacity:

150 lb (68kg)

ISSUED: 04-01-11 SHEET #: 9029-2 07-27-11

Page 2

NOTE: Read entire instruction sheet before you start installation and assembly.

WARNING

• Do not begin to install your Peerless product until you have read and understood the instructions and warnings

contained in this Installation Sheet. If you have any questions regarding any of the instructions or warnings, for US

customers please call Peerless customer care at 1-800-865-2112, for all international customers, please contact

your local distributor.

• This mount is designed to attach the display 0.19" from the wall. Please refer to manufacturer's installation guide

recommendations for required distance from wall to avoid risk of injury or property damage.

• This product should only be installed by someone of good mechanical aptitude, has experience with basic building

construction, and fully understands these instructions.

• Make sure that the supporting surface will safely support the combined load of the equipment and all attached

hardware and components.

• Never exceed the Maximum UL Load Capacity. See page one.

• If mounting to wood wall studs, make sure that mounting screws are anchored into the center of the studs. Use of

an "edge to edge" stud fi nder is highly recommended.

• Always use an assistant or mechanical lifting equipment to safely lift and position equipment.

• Tighten screws fi rmly, but do not overtighten. Overtightening can damage the items, greatly reducing their holding

power.

• This product is intended for indoor use only. Use of this product outdoors could lead to product failure and personal

injury.

• This product was designed to be installed on the following wall construction only;

WALL CONSTRUCTION HARDWARE REQUIRED

• Wood Stud Included

• Wood Beam Included

• Solid Concrete Included

• Cinder Block Included

• Metal Stud Contact Qualifi ed Professional (not evaluated by UL)

• Brick Contact Qualifi ed Professional (not evaluated by UL)

• Other or unsure? Contact Qualifi ed Professional (not evaluated by UL)

Tools Needed for Assembly

• stud fi nder ("edge to edge" stud fi nder is recommended)

• drill

• 5/16" (8mm) bit for concrete and cinder block wall

• 5/32" (4mm) bit for wood stud wall

• level

Table of Contents

Parts List.................................................................................................................................................................................3

Installation to Wood Stud Wall ............................................................................................................................................ 4,5

Installation to Solid Concrete/Cinder Block walls ...................................................................................................................6

Installing Display Screws ........................................................................................................................................................7

Mounting Flat Panel Display ...................................................................................................................................................8

2 of 29

ISSUED: 04-01-11 SHEET #: 203-9029-2 07-27-11

Page 3

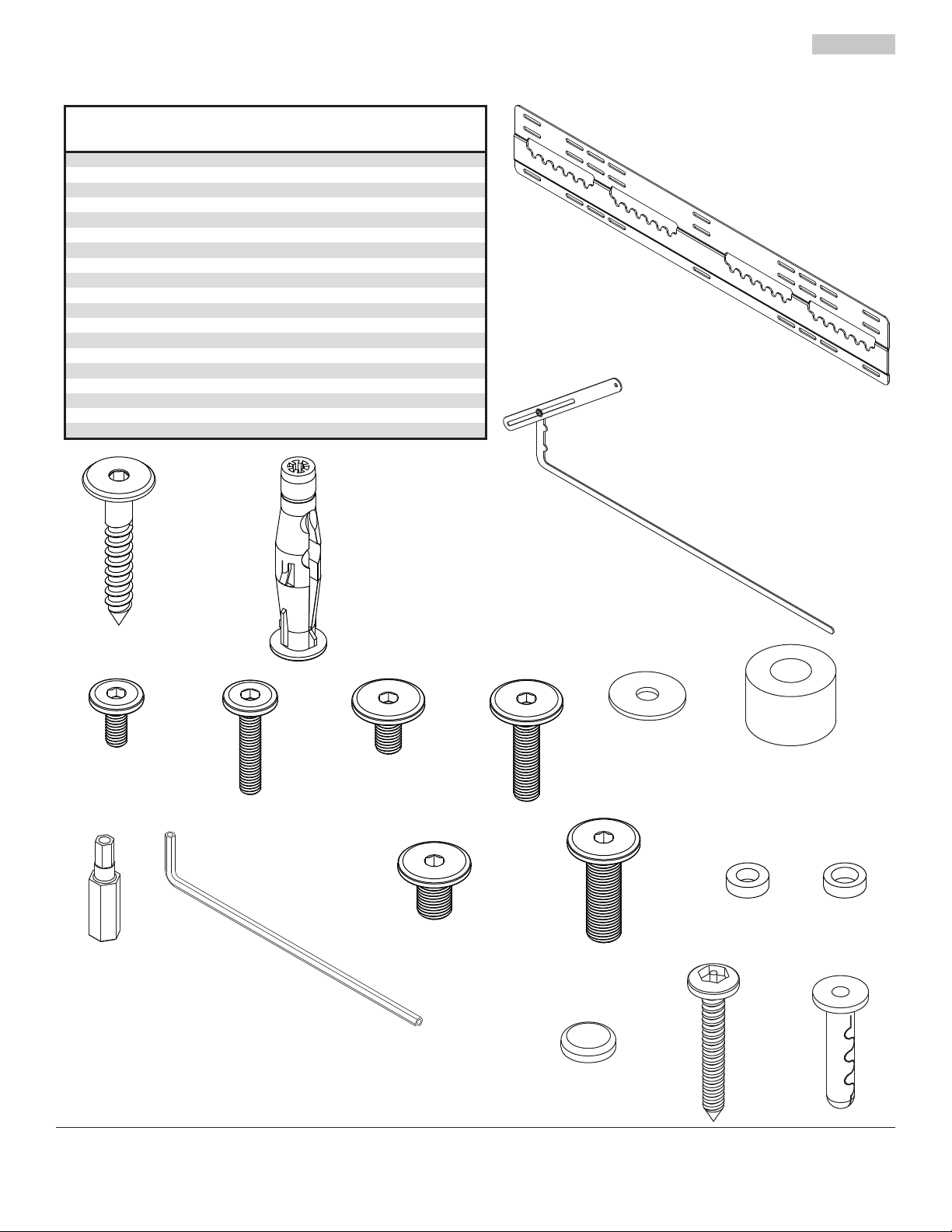

Before you begin, make sure all parts shown are included with your product.

A

r

Parts may appear slightly different than illustrated.

Parts List

Description Qty. Part #

wall plate 1 046-P1202

locking arm 1 046-P1212

B

wood screws 6 500-1090

C

concrete anchors 6 590-0320

D

M5 x 12 mm hex screw

E

M5 x 25 mm hex screw

F

M6 x 12 mm hex screw

G

M6 x 25 mm hex screw

H

.725" washer

I

3/4" spacer

J

4 mm security driver

K

4 mm security allen wrench

L

M8 x 12 mm hex screw

M

M8 x 25 mm hex screw

N

M5 x 1/8" spacer

O

M6 x 1/8" spacer

P

cloth bumper

Q

security wood screw

R

S

C

alligator ancho

®

D

4

4

4

4

4

4

1

1

4

4

4

4

2

1

1

560-1732

560-1733

560-1734

560-1735

540-9478

540-1059

560-1133

560-9646

560-1736

560-1737

046-0223

046-0224

570-0051

520-1092

590-0097

A

B

E

K

L

F

G

M

H

3 of 29

I

J

OP

N

QRS

ISSUED: 04-01-11 SHEET #: 203-9029-2 07-27-11

Page 4

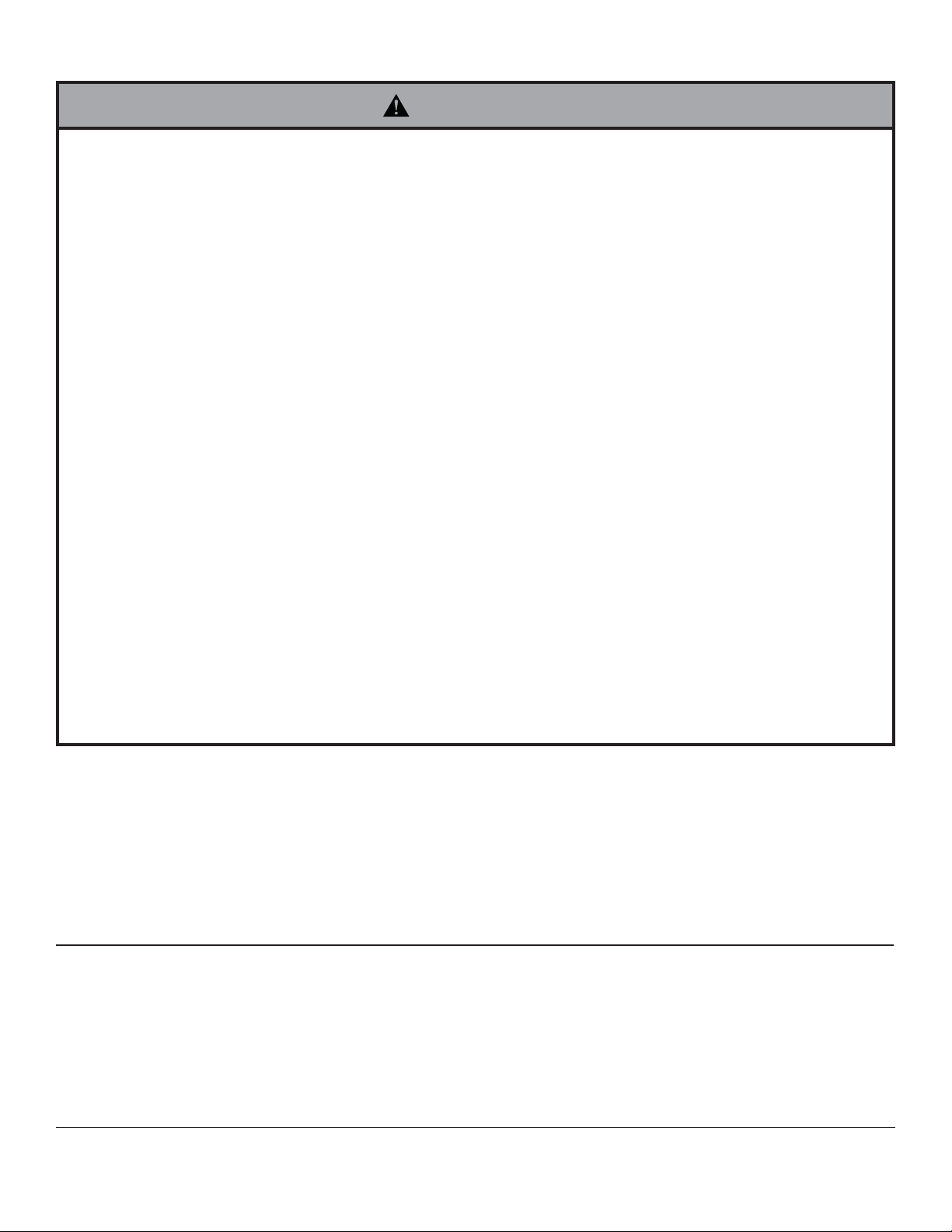

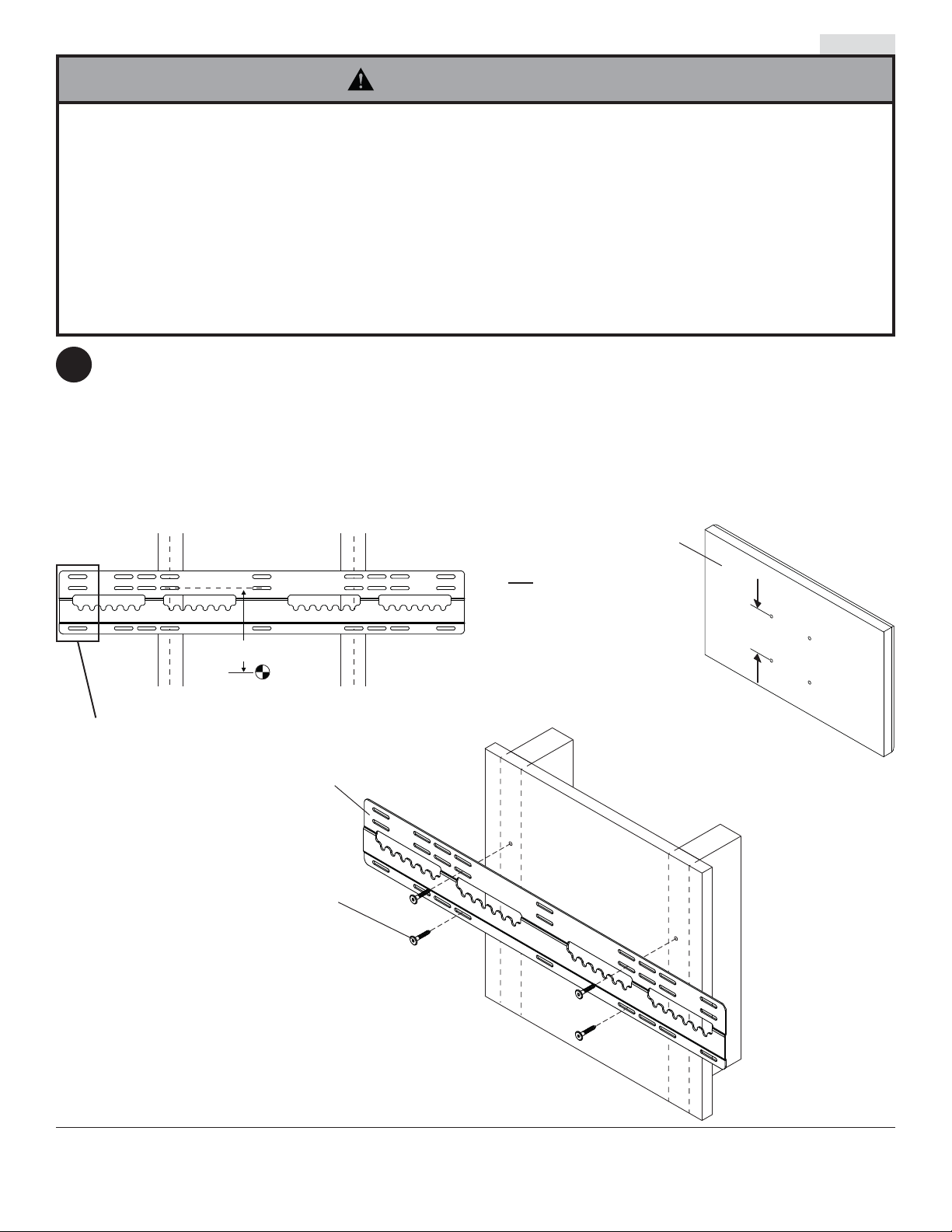

Installation to Double Wood Stud Wall

WARNING

• Installer must verify that the supporting surface will safely support the combined load of the equipment and all

attached hardware and components.

• Tighten wood screws so that wall plate is fi rmly attached, but do not overtighten. Overtightening can damage the

screws, greatly reducing their holding power.

• Never tighten in excess of 80 in. • lb (9 N.M.).

• Make sure that mounting screws are anchored into the center of the stud. The use of an "edge to edge" stud fi nder

is highly recommended.

• Hardware provided is for attachment of mount through standard thickness drywall or plaster into wood studs. Installers are responsible to provide hardware for other types of mounting situations (not evaluated by UL).

Wall plate (A) can be mounted to two studs that are 16", 20", or 24" apart. Use a stud fi nder to locate the edges

1

of the studs. Use of an edge-to-edge stud fi nder is highly recommended. Based on their edges, draw a vertical

line down each stud’s center. Place wall plate on wall as a template. The top mounting slots should be located

X" above the desired display center as shown in fi gure 1.1 and 1.2. Level plate, and mark the center of the four

mounting holes. Make sure that the mounting holes are on the stud centerlines. Drill four 5/32" (4mm) dia. holes

2" (51mm) deep. Make sure that the wall plate is level and secure it using four wood screws (C) as shown

in fi gure 1.3.

fi g. 1.1

XXX

XXX

XXX

Y

()

Y = distance between

display mounting holes

+ 1.75"X =

2

X"

NOTE: When mounting wall

plate (A) to two studs, do not

use center mounting holes or

outer mounting holes.

fi g. 1.3

A

C

DISPLAY

fi g. 1.2

Y"

4 of 29

ISSUED: 04-01-11 SHEET #: 203-9029-2 07-27-11

Page 5

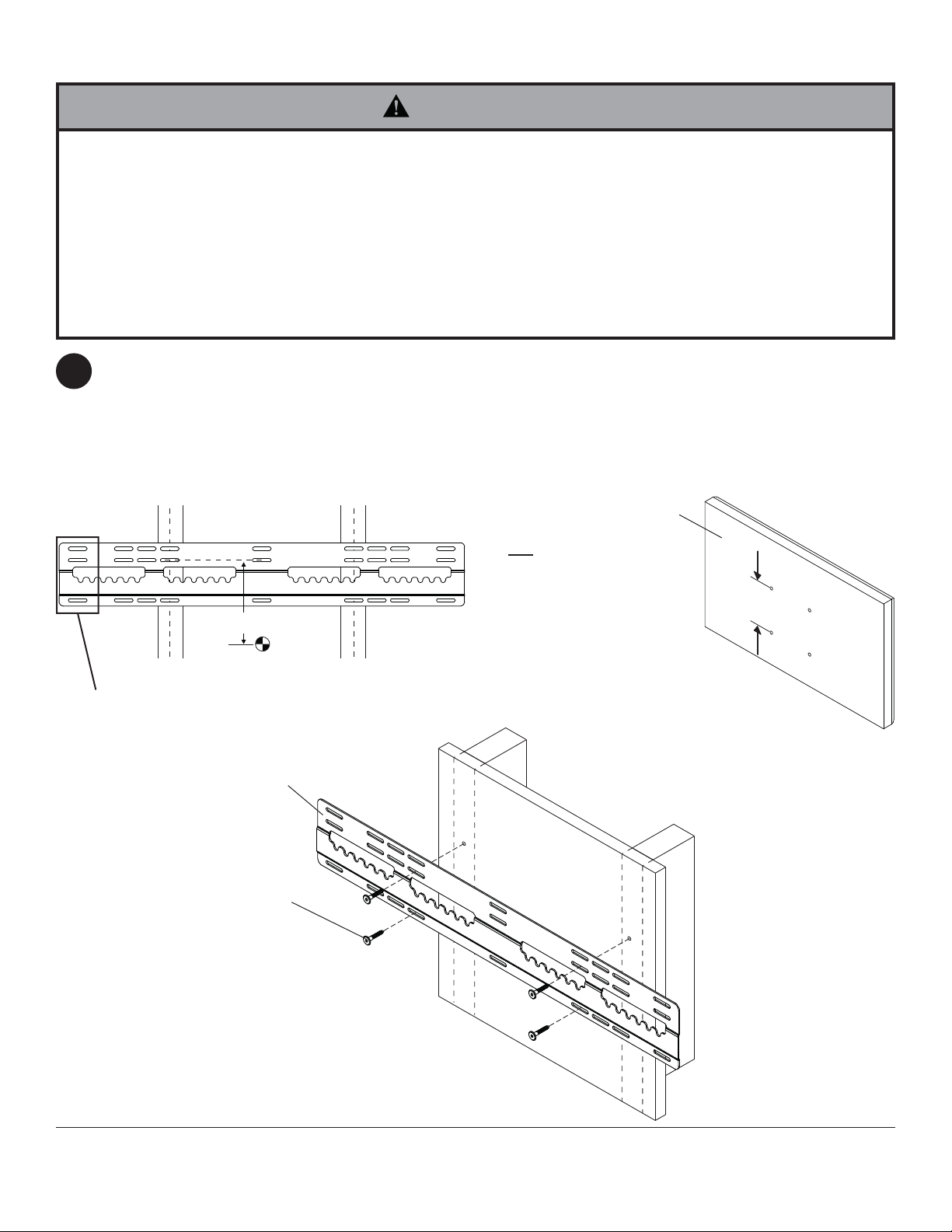

Installation to Triple Wood Stud Wall

WARNING

• Installer must verify that the supporting surface will safely support the combined load of the equipment and all

attached hardware and components.

• Tighten wood screws so that wall plate is fi rmly attached, but do not overtighten. Overtightening can damage the

screws, greatly reducing their holding power.

• Never tighten in excess of 80 in. • lb (9 N.M.).

• Make sure that mounting screws are anchored into the center of the stud. The use of an "edge to edge" stud fi nder

is highly recommended.

• Hardware provided is for attachment of mount through standard thickness drywall or plaster into wood studs.

Installers are responsible to provide hardware for other types of mounting situations (not evaluated by UL).

Wall plate (A) can be mounted to three studs that are 16" apart. Use a stud fi nder to locate the edges of the studs.

1

Use of an edge-to-edge stud fi nder is highly recommended. Based on their edges, draw a vertical line down each

stud’s center. Place wall plate on wall as a template. The top mounting slots should be located X" above the desired

display center as shown in fi gure 1.4 and 1.5. Level plate, and mark the center of the six mounting holes. Make

sure that the mounting holes are on the stud centerlines. Drill six 5/32" (4mm) dia. holes 2" (51mm) deep. Make

sure that the wall plate is level and secure it using six wood screws (C) as shown in fi gure 1.6.

fi g. 1.4

C

X"

A

DISPLAY

Y

()

Y = distance between

display mounting holes

+ 1.75"X =

2

fi g. 1.6

fi g. 1.5

Y"

5 of 29

ISSUED: 04-01-11 SHEET #: 203-9029-2 07-27-11

Page 6

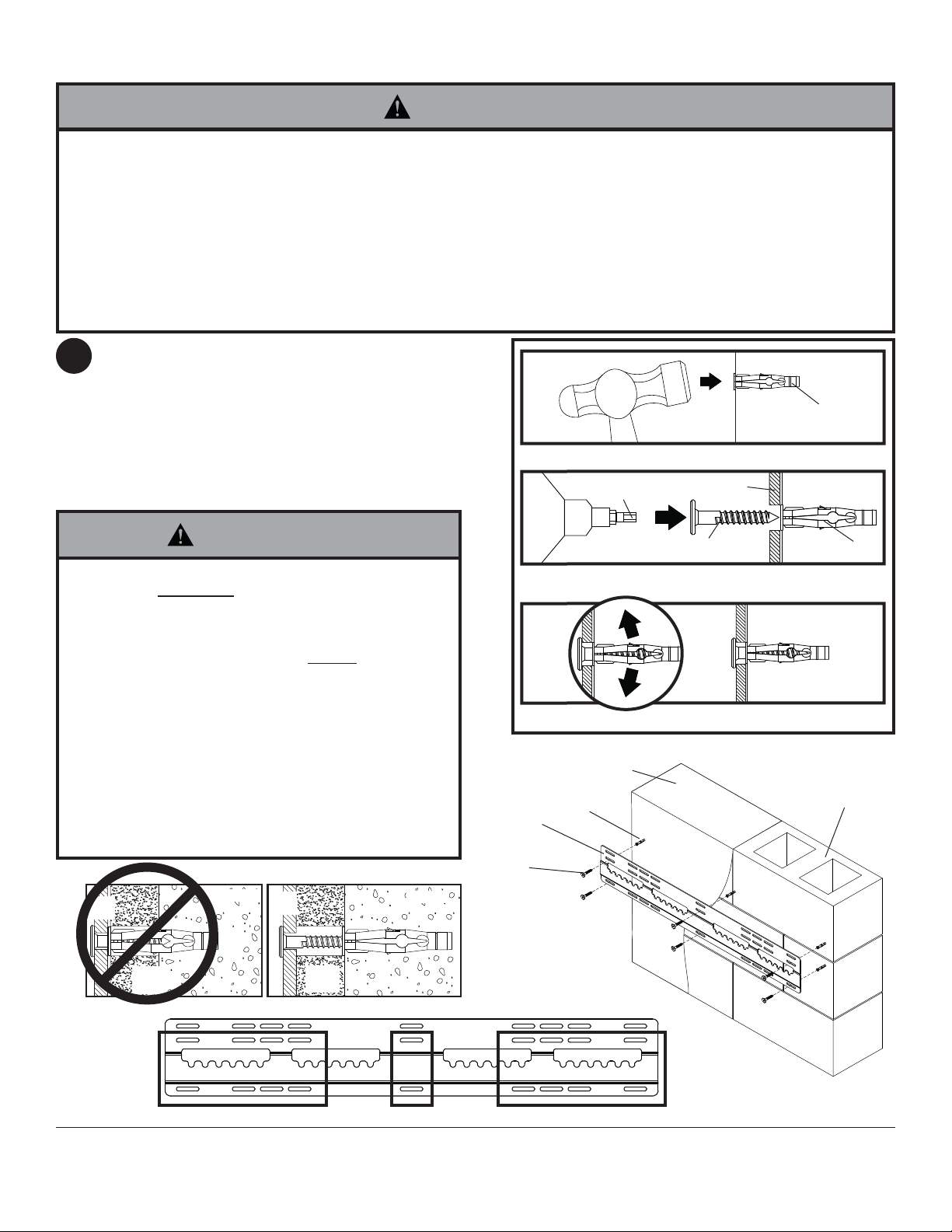

Installation to Solid Concrete or Cinder Block

WARNING

• When installing Peerless wall mounts on cinder block, verify that you have a minimum of 1-3/8" of actual concrete

thickness in the hole to be used for the concrete anchors. Do not drill into mortar joints! Be sure to mount in a

solid part of the block, generally 1" minimum from the side of the block. Cinder block must meet ASTM C-90

specifi cations. It is suggested that a standard electric drill on slow setting is used to drill the hole instead of a

hammer drill to avoid breaking out the back of the hole when entering a void or cavity.

• Two wood screws (C) must be installed into wall plate (A) in each segment as shown in detail 1, or product may fail.

• Concrete must be 2000 psi density minimum. Lighter density concrete may not hold concrete anchor.

• Installer must verify that the supporting surface will safely support the combined load of the equipment and all

attached hardware and components.

Make sure that wall plate (A) is level, use it as

1

a template to mark six mounting holes. The top

mounting slots should be located X" above the

desired display center as shown in fi gure 1.4 and

1.5 on page 5. Drill six 5/16" (8mm) dia. holes to a

minimum depth of 2.5" (64mm). Insert anchors (D) in

holes fl ush with wall as shown (right). Place wall plate

over anchors and secure with six wood screws (C).

Level, then tighten all fasteners.

1

Drill holes and insert anchors (D).

2

K

A

concrete

surface

D

WARNING

• Tighten screws so that wall plate is fi rmly attached,

but do not overtighten. Overtightening can damage

screws, greatly reducing their holding power.

• Never tighten in excess of 80 in. • lb (9 N.M.).

• Always attach concrete anchors directly to loadbearing concrete.

• Never attach concrete anchors to concrete covered

with plaster, drywall, or other fi nishing material.

If mounting to concrete surfaces covered with a

fi nishing surface is unavoidable (not evaluated by

UL), the fi nishing surface must be counterbored

as shown below. Be sure concrete anchors do not

pull away from concrete when tightening screws. If

plaster/drywall is thicker than 5/8", custom fasteners

must be supplied by installer (not evaluated by UL).

INCORRECT CORRECT

plate

CUTAWAY VIEW

wall

plaster/

dry wall

concrete

wall

plate

plaster/

dry wall

concrete

C

Place plate (A) over anchors (D) and secure with screws (C).

3

Tighten all fasteners.

SOLID CONCRETE

D

A

C

D

CINDER

BLOCK

DETAIL 1

SEGMENT 1 SEGMENT 2 SEGMENT 3

6 of 29

ISSUED: 04-01-11 SHEET #: 203-9029-2 07-27-11

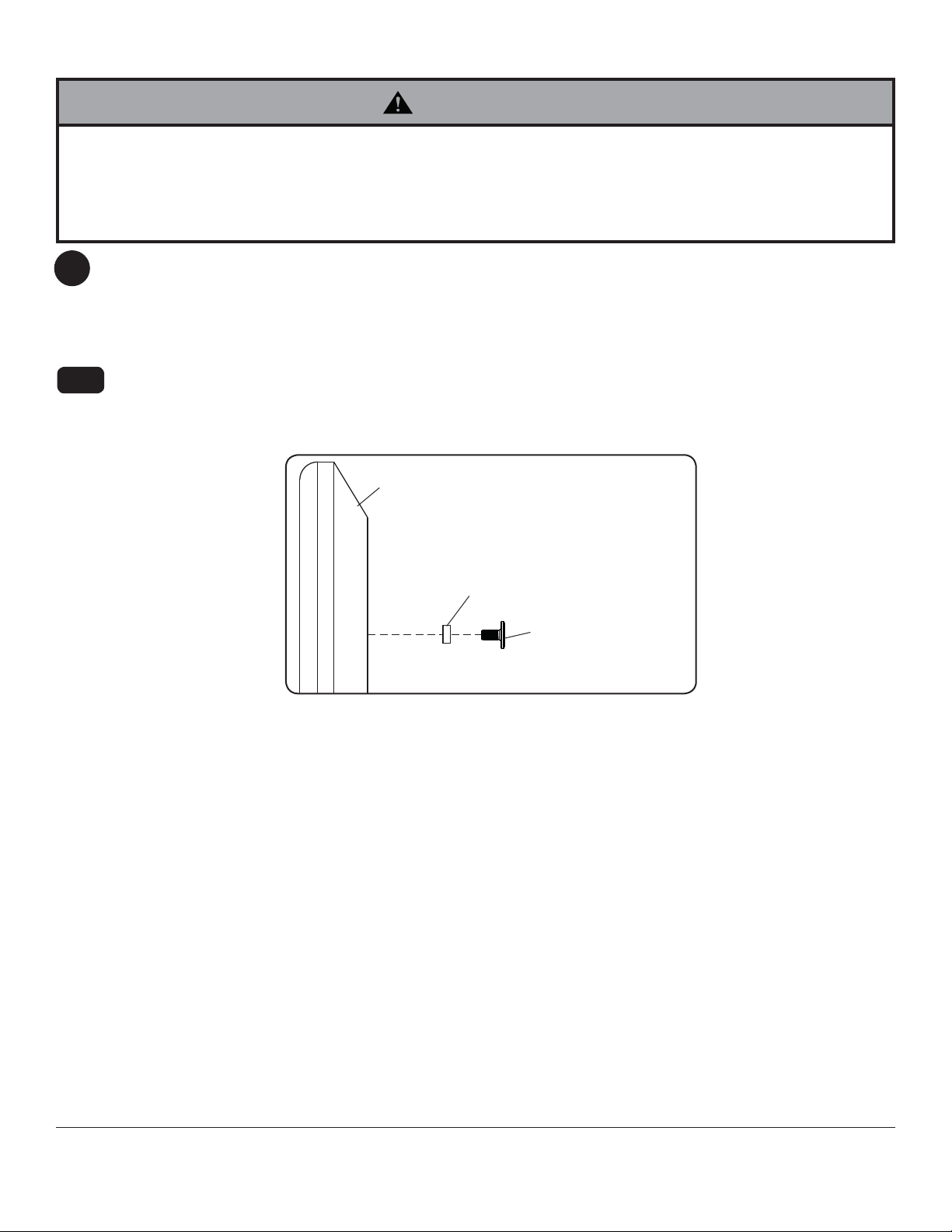

Page 7

Installing Display Screws

WARNING

• Tighten screws so they are fi rmly attached. Do not tighten with excessive force. Overtightening can cause stress

damage to screws, greatly reducing their holding power and possibly causing screw heads to become detached.

Tighten to 40 in. • lb (4.5 N.M.) maximum torque.

• If screws don't get three complete turns in the display inserts or if screws bottom out and bracket is still not tightly

secured, damage may occur to display or product may fail.

To prevent scratching the display, set a cloth on a fl at, level surface that will support the weight of the display.

2

For Flat Back Display

Place display face side down. If display has knobs on the back, remove them to allow the adapter brackets to be

attached.

NOTE: Top and bottom holes of display must always be used.

Begin with the shortest length screw (E,G, or M) and hand thread through 1/8" spacer (O,P) into display as shown

2-1

in fi gure 2.1. Screw must make at least three full turns into the mounting hole and fi t snug into place. Do not over

tighten. If screw cannot make three full turns into the display, select a longer length screw (F,H, or N) from the

baffl ed fastener pack. Repeat for remaining mounting holes and tighten screws.

DISPLAY

fi g. 2.1

SPACER (O,P)

SCREW (E,G, or M)

7 of 29

ISSUED: 04-01-11 SHEET #: 203-9029-2 07-27-11

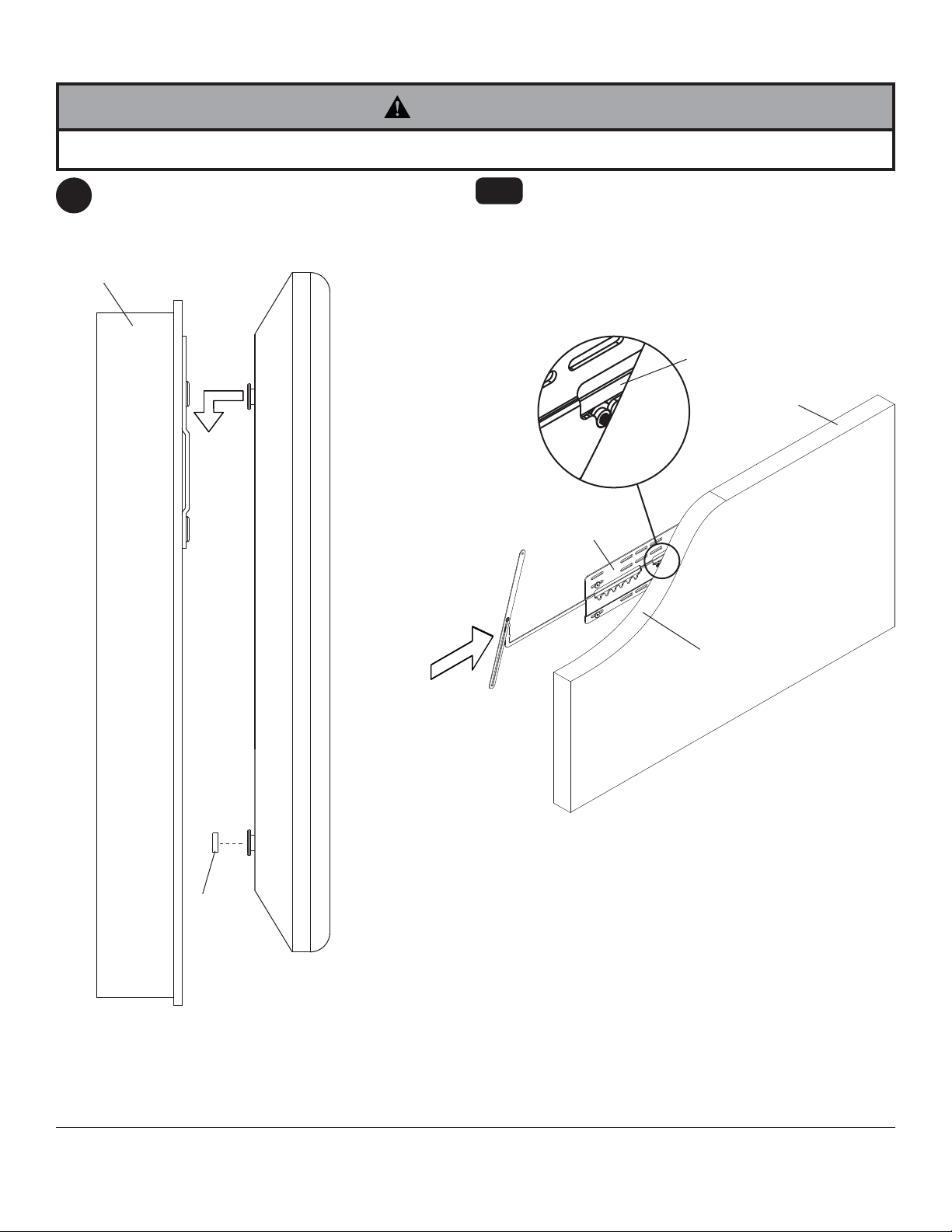

Page 8

Mounting Flat Panel Display

WARNING

• Always use an assistant or mechanical lifting equipment to safely lift and position the fl at panel displays.

Apply cloth bumpers (Q) to bottom mounting

3

screws as shown in fi gure 3.1.

Hook top mounting screws into wallplate grooves.

WOOD STUD

3-1

B

Secure display by inserting lock arm (B) into wall

plate (A) as shown in fi gure 3.2.

Lock arm must reside over top of display mounting

screws as shown in detail 2.

DETAIL 2

B

DISPLAY

A

Q

CUTAWAY

VIEW

fi g. 3.2

fi g. 3.1

8 of 29

ISSUED: 04-01-11 SHEET #: 203-9029-2 07-27-11

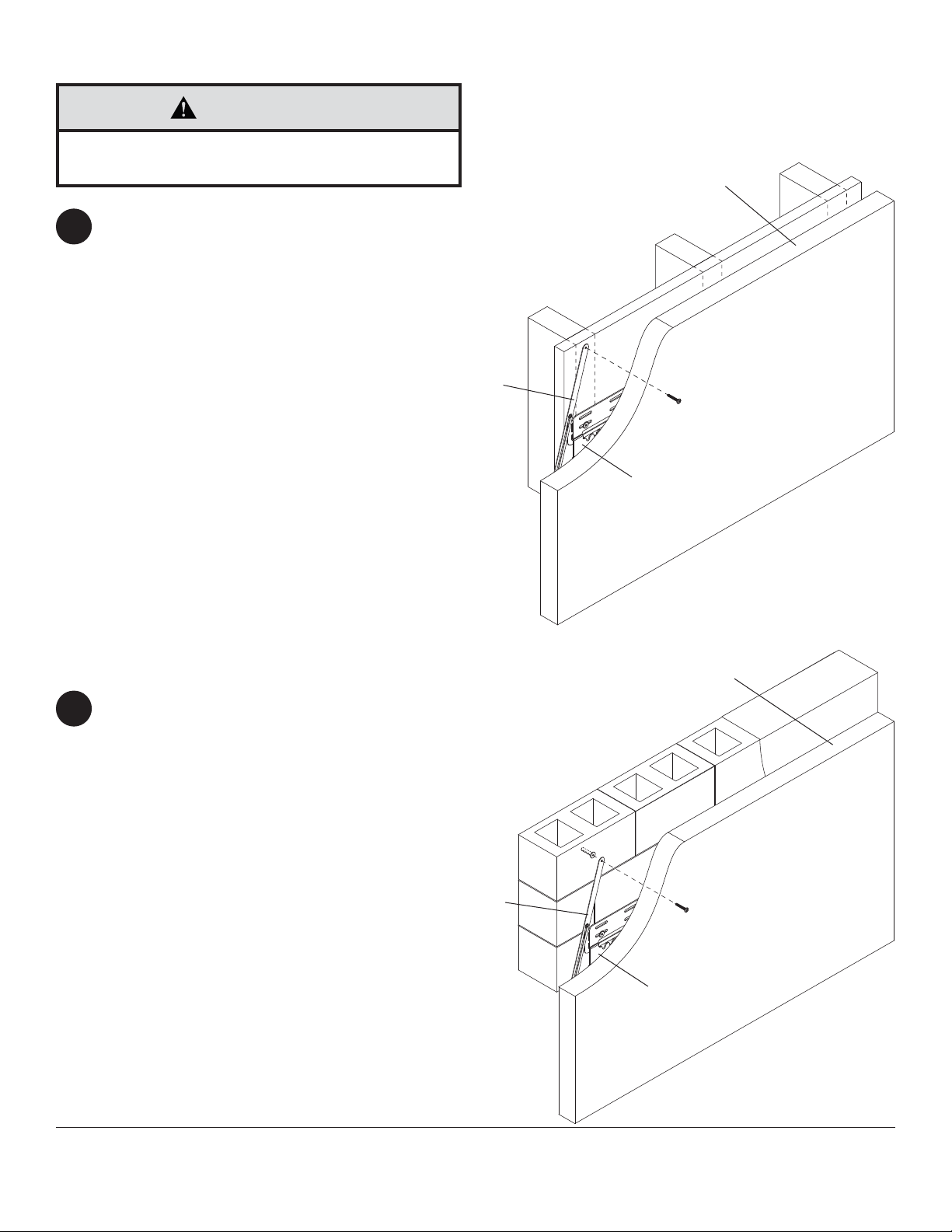

Page 9

OPTIONAL: Securing Locking Arm

CAUTION

• Be careful not to pinch fi ngers when adjusting

locking arm (B).

WOOD STUD: Adjust locking arm (B) until it aligns

4

to wood stud and secure using one #10 x 1-1/2"

security wood screw (R). If locking arm is diffi cult

to adjust, spin arm to loosen joint.

DISPLAY

B

R

A

CONCRETE/CINDER BLOCK: Adjust locking arm

4

(B) to desired position, mark center of mounting

hole, and drill one 1/4" (6mm) dia. hole to a

minimum depth of 2". Insert alligator anchor (S)

into hole and secure locking arm (B) with one #10

x 1-1/2" security wood screw (R). If locking arm is

diffi cult to adjust, spin arm to loosen joint.

B

DISPLAY

S

R

A

9 of 29

All other brand and product names are trademarks or registered trademarks of their respective owners.

ISSUED: 04-01-11 SHEET #: 203-9029-2 07-27-11

© 2011, Peerless Industries, Inc. All rights reserved.

Peerless Industries, Inc.

2300 White Oak Circle

Aurora, Il 60502

www.peerlessmounts.com

Page 10

Instalación y ensamblaje:

Soporte Plano Peerless Ultra-Delgado para Pantallas Planas de

37" - 65" (94 - 165 cm)*

Modelo: SUF661

*Requisitos para la compatibilidad de las pantallas

• Es posible que la profundidad del soporte (0.19") no

proporcione sufi ciente espacio para la ventilación

adecuada de algunas pantallas. Por favor, repase los

requisitos del fabricante en relación con la instalación

de la pantalla antes de proceder.

•

La pantalla tiene que tener una superfi cie plana para la

instalación o tiene que tener los agujeros de montaje

en la superfi cie trasera más alejada de la pantalla.

•

La conexión de entrada / salida tiene que tener la

orientación adecuada para acomodar una instalación a

0.19" de la pared.

2300 White Oak Circle • Aurora, Il 60502 • (800) 865-2112 • Fax: (800) 359-6500 • www.peerlessmounts.com

Capacidad máxima de soportar carga por UL:

150 lb (68kg)

PUBLICADO: 04-01-11 HOJA #: 203-9029-2 07-27-11

Page 11

Lea la hoja de instrucciones completa antes de comenzar la instalación y el ensamblaje.

Nota:

Español

ADVERTENCIA

• No comience a instalar su producto de Peerless hasta haber leído y entendido las instrucciones y las advertencias

contenidas en la Hoja de Instalación. Si tiene alguna pregunta acerca de cualquiera de las instrucciones o las advertencias, por favor, llame a Servicio al Cliente de Peerless al 1-800-865-2112 si está en EE. UU. Si es un cliente

internacional, por favor, comuníquese con su distribuidor local.

• Este soporte está diseñado para sostener la pantalla a 0.33" de la pared. Por favor, repase las recomendaciones

del manual de instalación del fabricante con respecto a la distancia necesaria de la pared para evitar el riesgo de

sufrir lesiones o causar daños a la propiedad.

• Este producto sólo debe ser instalado por una persona que tenga una buena aptitud mecánica, que tenga experiencia en construcción básica de edifi cios y que entienda estas instrucciones en su totalidad.

• Asegúrese de que la superfi cie de apoyo sostendrá, con seguridad, la carga combinada del equipo y todos los

fi jadores y componentes.

• Nunca sobrepase la capacidad máxima de soportar carga aceptada por Underwriters Laboratories. Vea la página

10.

• Si va a instalar el producto en una pared con montantes de madera, asegúrese de que los tornillos de montaje

estén anclados en el centro de los montantes. Se recomienda utilizar un localizador de montantes de "borde a

borde".

• Siempre cuente con la ayuda de un asistente o utilice un equipo mecánico de izar para levantar y colocar el equipo

con más seguridad.

• Apriete los tornillos con fi rmeza, pero no en exceso. Apretarlos en exceso puede dañar los artículos y puede disminuir signifi cativamente su fuerza de fi jación.

• Este producto está diseñado para uso en interiores solamente. Utilizar este producto en exteriores podría causar

fallas del producto y lesiones a individuos.

• Este producto fue diseñado para ser instalado en paredes con la siguiente construcción solamente:

CONSTRUCCIÓN DE LA PARED ACCESORIOS NECESARIOS

• Montante de madera Incluido

• Viga de madera Incluido

• Concreto macizo Incluido

• Bloque de hormigón de escorias Incluido

• Montante de metal Comuníquese con un profesional califi cado

• Ladrillo Comuníquese con un profesional califi cado (no evaluados por UL)

• ¿Otra superfi cie o no está seguro? Comuníquese con un profesional califi cado (no evaluados por UL)

(no evaluados por UL)

Herramientas necesarias para el ensamblaje

• localizador de montantes (se recomienda uno de "borde a borde")

• taladro

• broca de 5/32" (4mm)para paredes con montantes de madera

• broca de 5/16" (8mm) y 1/4" (6mm) para

• nivel

concreto macizo o de bloques de hormigón de escorias

Tabla de centenido

Lista de piezas..................................................................................................................................................................... 12

Instalación en una pared con montantes de madera ..................................................................................................... 13,14

Instalación en una pared de concreto macizo o de bloques de hormigón de escorias ....................................................... 15

Instalar los tornillos de la pantalla ....................................................................................................................................... 16

Instalación de la pantalla plana ........................................................................................................................................... 17

11 de 29

PUBLICADO: 04-01-11 HOJA #: 203-9029-2 07-27-11

Page 12

A

r

Antes de comenzar, asegúrese de que su producto contiene todas las piezas que se muestran.

Las piezas pueden verse un poco distintas a la ilustración.

Español

Lista de piezas

Descripción Cant. Nº de pieza

placa de pared

bloqueo del brazo

B

tornillos para madera

C

anclajes para concreto

D

tornillos de cabeza hexagonal M5 x 12 mm

E

tornillos de cabeza hexagonal M5 x 25 mm

F

tornillos de cabeza hexagonal M6 x 12 mm

G

tornillos de cabeza hexagonal M6 x 25 mm

H

arandela de .725"

I

espaciador de 3/4

J

desarmador de seguridad de 4 mm

K

llave allen de seguridad de 4 mm

L

tornillos de cabeza hexagonal M8 x 12 mm

M

tornillos de cabeza hexagonal M8 x 25 mm

N

espaciador de M5 x 1/8"

O

espaciador de M6 x 1/8"

P

paño de parachoques

Q

tornillos para madera de seguridad

R

anclaje alligato

S

®

C

D

1 046-P1202

1 046-P1212

6 500-1090

6 590-0320

4

4

4

4

4

4

1

1

4

4

4

4

2

1

1

560-1732

560-1733

560-1734

560-1735

540-9478

540-1059

560-1133

560-9646

560-1736

560-1737

046-0223

046-0224

570-0051

520-1092

590-0097

A

B

E

K

L

F

G

M

H

12 de 29

I

J

OP

N

QRS

PUBLICADO: 04-01-11 HOJA #: 203-9029-2 07-27-11

Page 13

Instalación en una pared con montantes de madera

Español

ADVERTENCIA

• El instalador tiene que asegurarse de que la superfi cie de apoyo sostendrá, con seguridad, la carga combinada del

equipo y todos los fi jadores y componentes.

• Apriete los tornillos de madera de manera que la placa de pared se fi je fi rmemente, pero no en exceso. Apretarlos

en exceso puede dañar los tornillos y puede disminuir signifi cativamente su fuerza de fi jación.

• Nunca apriete a más de 80 pulg-lb (9 N•m).

• Asegúrese de que los tornillos de montaje estén anclados en el centro del montante. Se recomienda utilizar un

localizador de montantes de "borde a borde".

• Los accesorios para la instalación que se proveen son para fi jar el soporte a montantes de madera a través de

tabique de yeso-cartón o yeso de espesor estándar. Los instaladores son responsables de suministrar los accesorios necesarios para otros tipos de instalaciones (no evaluados por UL).

La placa de pared (A) sólo se debe instalar en dos montantes que tengan una separación de 16", 20" o 24".

1

Utilice un localizador de montantes para localizar los bordes de los montantes. Se recomienda utilizar un

localizador de montantes de "borde a borde". Tomando los bordes como punto de referencia, trace una línea

vertical por el centro de cada montante. Coloque la placa de pared contra la pared para utilizarla como plantilla.

Las ranuras de montaje superiores deben estar ubicados X" por encima del centro de la pantalla deseada

como se muestra en la fi gura 1.1 y 1.2. Nivele la placa y marque el centro de los cuatro agujeros de montaje.

Asegúrese de que los agujeros de montaje estén sobre las líneas que trazó por el centro de los montantes.

Taladre cuatro agujeros de 5/32" (4mm) de diámetro y 2" (51mm) de profundidad. Asegúrese de que la placa de

pared esté nivelada y fíjela utilizando cuatro tornillos para madera (C), como se muestra en la fi gura 1.3.

fi g. 1.1

XXX

XXX

XXX

Y

()

Y = distancia entre agujeros

de montaje de la pantalla

+ 1.75"X =

2

X"

NOTA: Cuando la placa de pared

(A) en dos montantes, no use los

agujeros de montaje central o

exterior agujeros de montaje.

A

C

PANTALLA

fi g. 1.3

fi g. 1.2

Y"

13 de 29

PUBLICADO: 04-01-11 HOJA #: 203-9029-2 07-27-11

Page 14

Instalación en una pared con montantes de madera triples

Español

ADVERTENCIA

• El instalador tiene que asegurarse de que la superfi cie de apoyo sostendrá, con seguridad, la carga combinada del

equipo y todos los fi jadores y componentes.

• Apriete los tornillos de madera de manera que la placa de pared se fi je fi rmemente, pero no en exceso. Apretarlos

en exceso puede dañar los tornillos y puede disminuir signifi cativamente su fuerza de fi jación.

• Nunca apriete a más de 80 pulg-lb (9 N•m).

• Asegúrese de que los tornillos de montaje estén anclados en el centro del montante. Se recomienda utilizar un

localizador de montantes de "borde a borde".

• Los accesorios para la instalación que se proveen son para fi jar el soporte a montantes de madera a través de

tabique de yeso-cartón o yeso de espesor estándar. Los instaladores son responsables de suministrar los accesorios necesarios para otros tipos de instalaciones (no evaluados por UL).

La placa de pared (A) se puede instalar en tres montantes que tengan una separación de 16". Utilice un

1

localizador de montantes para localizar los bordes de los montantes. Se recomienda utilizar un localizador de

montantes de "borde a borde". Tomando los bordes como punto de referencia, trace una línea vertical por el centro

de cada montante. Coloque la placa de pared contra la pared para utilizarla como plantilla. Las ranuras de montaje

superiores deben estar ubicados X" por encima del centro de la pantalla deseada como se muestra en la fi gura

1.4 y 1.5. Nivele la placa y marque el centro de los seis agujeros de montaje. Asegúrese de que los agujeros de

montaje estén sobre las líneas que trazó por el centro de los montantes. Taladre seis agujeros de 5/32" (4mm) de

diámetro y 2" (51mm) de profundidad. Asegúrese de que la placa de pared esté nivelada y fíjela utilizando seis

tornillos para madera (C), como se muestra en la fi gura 1.6.

fi g. 1.4

C

X"

A

PANTALLA

Y

()

Y = distancia entre agujeros

de montaje de la pantalla

+ 1.75"X =

2

fi g. 1.6

fi g. 1.5

Y"

14 de 29

PUBLICADO: 04-01-11 HOJA #: 203-9029-2 07-27-11

Page 15

Instalación en una pared de concreto macizo o

Español

de bloques de hormigón de escorias

ADVERTENCIA

• Cuando vaya a instalar soportes de pared de Peerless en bloques de hormigón de escorias, asegúrese de que cuente con una capa de concreto

de un grosor mínimo de 1-3/8" en el agujero, que pueda usar para los anclajes para concreto. ¡No taladre en juntas de argamasa! Asegúrese de

hacer la instalación en la parte sólida del bloque, por lo general, a un mínimo de 1" del extremo del bloque. Los bloques de hormigón de escorias tienen que cumplir las especifi caciones de la ASTM C-90. Se sugiere utilizar un taladro eléctrico convencional a baja velocidad para hacer el

agujero en vez de un taladro percutor para no perforar el fondo del agujero al entrar en un vacío o una cavidad.

• Dos tornillos para madera (C) debe estar instalado en la placa de pared (A) en cada segmento como se muestra en el detalle 1, o el producto

puede fallar.

• El concreto tiene que tener una densidad mínima de 2,000 psi. Es posible que un concreto de menos densidad no sostenga el anclaje para

concreto.

• Asegúrese de que la superfi cie de apoyo sostendrá, con seguridad, la carga combinada del equipo y todos los fi jadores y componentes.

Asegúrese de que la placa de pared (A) esté nivelada y

1

utilícela como plantilla para marcar cuatro agujeros de

montaje. Las ranuras de montaje superiores deben estar

ubicados X" por encima del centro de la pantalla deseada

como se muestra en la fi gura 1.4 y 1.5 de la pagina 14.

Taladre seis agujeros de 5/16" (8mm) de diámetro a una

profundidad mínima de 2.5" (64mm). Inserte los anclajes

(D) en los agujeros a ras con la pared, como se muestra (a

la derecha). Coloque la placa de pared sobre los anclajes y

fíjela con seis tornillos para madera (C). Nivele y apriete todos

los sujetadores.

ADVERTENCIA

• Apriete los tornillos de manera que la placa de pared se fi je fi rmemente, pero no en exceso. Apretarlos en exceso puede dañar los

tornillos y puede disminuir signifi cativamente su fuerza de fi jación.

• Nunca apriete a más de 80 pulg-lb (9 N•m).

• Siempre fi je los anclajes para concreto directamente en la pared

que sostiene la carga.

• Nunca fi je los anclajes para concreto a una pared de concreto

recubierta con yeso, tabique de yeso-cartón u otro material de

acabado. Si es inevitable hacer la instalación en una superfi cie de

concreto recubierta con una superfi cie de acabado

por UL), la superfi cie de acabado tiene que ser escariada, como se

muestra abajo. Asegúrese de que los anclajes para concreto no se

separen del concreto cuando apriete los tornillos. Si el grosor de la

capa de yeso o tabique de yeso-cartón tiene un grosor mayor de

5/8", el instalador tiene que suministrar las fi jaciones especiales

evaluados por UL).

(no evaluados

1

Taladre los agujeros e inserte los anclajes (D).

2

Coloque la placa (A) sobre los anclajes (D) y fíjela con los

tornillos (C).

3

Apriete todas las fi jaciones.

CONCRETO MACIZO

(no

A

D

K

C

techno de

concreto

D

A

D

BLOQUE DE

HORMIGÓN DE

ESCORIAS

INCORRECTO

placa de

pared

VISTA EN CORTE

yeso / tabique de yeso-cartón

C

concreto

CORRECTO

placa de

pared

yeso / tabique de yeso-cartón

concreto

SEGMENTO 1 SEGMENTO 2 SEGMENTO 3

15 de 29

PUBLICADO: 04-01-11 HOJA #: 203-9029-2 07-27-11

Page 16

Español

Instalar los tornillos de la pantalla

ADVERTENCIA

• Apriete los tornillos de manera que los soportes adaptadores se fi jen con fi rmeza. No los apriete con fuerza

excesiva. Apretar los tornillos en exceso puede causarles daño por forzarlos y puede disminuir signifi cativamente

su fuerza de fi jación y podría causar el desprendimiento de las cabezas de los tornillos. Apriete los tornillos a un

máximo de 40 pulg-lb (4.5 N•m) de par torsor.

• Si no se les da tres vueltas completas a los tornillos en los insertos de la pantalla o si los tornillos topan fondo y el

soporte todavía no está fi rme, se podría dañar la pantalla o el producto podría no funcionar bien.

Para no rayar la pantalla, coloque un trapo sobre una superfi cie plana y nivelada que sostenga el peso de la pan-

2

talla. Coloque la pantalla boca abajo. Si la pantalla tiene perillas en la parte trasera, quíteselas para poder fi jar los

soportes adaptadores.

NOTA: Siempre se tienen que usar los agujeros superiores e inferiores de la pantalla.

Instalación de un televisor que tiene la parte posterior plana

Comience con uno de los tornillos más cortos (E, G o M), enrósquelo, con la mano, a través del espaciador de

2-1

1/8" (O, P) en la pantalla, como se muestra en la fi gura 2.1. El tornillo tiene que dar, por lo menos, tres vueltas

completas dentro del agujero de montaje y debe quedar ajustado en su lugar. No apriete los tornillos en exceso.

Si el tornillo no puede dar tres vueltas completas al entrar en la parte trasera de la pantalla, seleccione uno de

los tornillos más largos (F, H o N) de los sujetadores identifi cados y clasifi cados en las divisiones del empaque

plástico. Siga el mismo procedimiento con los agujeros de montaje restantes y apriete los tornillos.

PANTALLA

fi g. 2.1

ESPACIADOR (O,P)

TORNILLO (E,G, o M)

16 de 29

PUBLICADO: 04-01-11 HOJA #: 203-9029-2 07-27-11

Page 17

Español

Instalación de la pantalla plana

ADVERTENCIA

• Siempre cuente con un asistente o con un equipo mecánico de izar para levantar y colocar el televisor de plasma

con más seguridad.

Coloque los paragolpes de tela (Q) en los tornillos

3

de montaje inferiores, como se muestra en la fi gura

3.1.

Enganche los tornillos de montaje superiores en las

hendiduras de la placa de pared.

MONTANTE

Para fi jar la pantalla una vez la haya colgado en

su lugar, inserte el brazo fi jador (B) en el lado de la

placa de pared, como se muestra en la fi gura 3.2.

Cerciórese de que el brazo fi jador descanse sobre

los tornillos de montaje, como se muestra en el

detalle 2.

DETALLE 2

B

PANTALLA

A

B

Q

fi g. 3.1

17 de 29

VISTA EN

CORTE

fi g. 3.2

PUBLICADO: 04-01-11 HOJA #: 203-9029-2 07-27-11

Page 18

OPCIONAL: Fijar el brazo fi jador

PRECAUCIÓN

• Tenga cuidado de no pincharse los dedos cuando

fi jar el brazo fi jador (B).

MONTANTE DE MADERA: Ajuste el brazo fi jador

4

(B) hasta que se alinee con el montante de

madera y fíjelo con un tornillo de seguridad para

madera de 10 x 1-1/2" (R). Si el el brazo fi jador

es difícil de ajustar, girar el brazo para afl ojar las

articulaciones.

Español

PANTALLA

B

R

A

CONCRETO O BLOQUE DE HORMIGÓN DE

4

ESCORIAS: Ajuste el brazo fi jador (B) en la

posición deseada, marque el centro del agujero

de montaje y taladre un agujero de 1/4" (6mm)

de diámetro a una profundidad mínima de 2".

Inserte el anclaje alligator (S) en el agujero y fi je el

brazo fi jador (B) con un tornillo de seguridad para

madera de 10 x 1-1/2" (R). Si el el brazo fi jador

es difícil de ajustar, girar el brazo para afl ojar las

articulaciones.

B

PANTALLA

S

R

A

18 de 29

Cualesquiera otras marcas y nombres de productos son marcas comerciales o registradas de sus respectivos dueños.

PUBLICADO: 04-01-11 HOJA #: 203-9029-2 07-27-11

© 2011, Peerless Industries, Inc. Todos los derechos reservados.

Peerless Industries, Inc.

2300 White Oak Circle

Aurora, Il 60502

www.peerlessmounts.com

Page 19

Installation et montage:

Support Plat Ultra-Mince Peerless pour Écrans plats

37" - 65" (94 - 165 cm)*

Modèle: SUF661

*Exigences de compatibilité avec l'écran

• La profondeur de ce support (0,19 po) pourrait ne pas

laisser suffi samment d'espace pour permettre une

ventilation adéquate pour certains écrans. Veuillez vous

reporter aux exigences de montage du fabricant avant

d'installer votre écran.

•

L'écran doit avoir une surface de montage plate

ou alors les trous de montage doivent se trouver à

l'extrémité de la surface arrière de l'écran.

•

La connexion entrée/sortie doit être orientée de

manière à permettre l'installation du support à 0,19 po

du mur.

2300 White Oak Circle • Aurora, Il 60502 • (800) 865-2112 • Fax: (800) 359-6500 • www.peerlessmounts.com

Capacité de charge maximale établie par l’UL:

150 lb (68kg)

PUBLIÉ LE : 04-01-11 FEUILLE no : 203-9029-2 07-27-11

Page 20

Français

Remarque : lisez entièrement la fi che d’instructions avant de commencer l’installation et l’assemblage.

AVERTISSEMENT

• Ne commencez pas à installer votre produit Peerless avant d’avoir lu et assimilé les instructions et les

avertissements contenus dans cette fi che d’installation. Pour toute question concernant les instructions ou

les avertissements, veuillez appeler le service à la clientèle de Peerless au 1-800-865-2112; tous les clients

internationaux sont priés de contacter leur distributeur local.

• Ce support est conçu pour fi xer l’écran à 0,33 po du mur. Veuillez vous reporter aux recommandations du guide

d’installation du fabricant pour établir la distance au mur requise afi n d’éviter les risques de blessures ou de

dommages matériels.

• Ce produit doit être installé uniquement par quelqu’un possédant une bonne aptitude à la mécanique, une

expérience de la construction immobilière et ayant bien compris ces instructions.

• Assurez-vous que la surface de support puisse soutenir sans danger la charge totale de l’équipement ainsi que des

pièces et composants qui y sont attachés.

• Ne dépassez jamais la capacité de charge maximum établie par l’UL. Reportez-vous à la page 19.

• Lors d’une installation sur un mur à montants en bois, assurez-vous que les vis de montage sont ancrées au centre

des montants. L’utilisation d’un localisateur de montants « bord à bord » est fortement recommandée.

• Pour lever et positionner l’équipement en toute sécurité, faites-vous toujours aider par une autre personne ou

utilisez un dispositif de levage mécanique.

• Serrez fermement les vis, mais sans excès. Un serrage excessif peut endommager les composants et en réduire

considérablement la capacité de support.

• Ce produit est conçu uniquement pour un usage intérieur. L’utilisation de ce produit à l’extérieur peut causer une

défaillance du produit et des blessures corporelles.

• Ce produit a été conçu uniquement pour une installation sur les types de murs ci-dessous :

TYPE DE MUR PIÈCES DE FIXATION REQUISES

• Montant en bois Incluses

• Poutre en bois Incluses

• Béton plein Incluses

• Bloc de béton de mâchefer Incluses

• Montant métallique Contacter un professionnel qualifi é (non évalué UL)

• Brique Contacter un professionnel qualifi é (non évalué UL)

• Autre, ou vous n’êtes pas sûr ? Contacter un professionnel qualifi é

Outils nécessaires au montage

• localisateur de montants (un localisateur de montants « bord à bord » est recommandé)

• perceuse

• foret de 5/32 po (4mm) pour les murs à montants en bois

• foret de 5/16 po (8mm) et 1/4 po (6mm) pour les murs à block de béton

• niveau

Table des matières

Liste des pièces ................................................................................................................................................................... 21

Installation sur des murs à en bois ................................................................................................................................. 22,23

Installation sur du béton plein/block de béton ..................................................................................................................... 24

Montage des vis de l'écran .................................................................................................................................................. 25

Montage et demontage d'un écran plat ............................................................................................................................... 26

20 sur 29

PUBLIÉ LE : 04-01-11 FEUILLE no : 203-9029-2 07-27-11

Page 21

A

r

Avant de commencer, assurez-vous que toutes les pièces indiquées sont incluses avec le produit.

Il est possible que les pièces semblent légèrement différentes de l’illustration.

Français

Lista de piezas

Descripción Cant. Nº de pieza

placa de pared

bloqueo del brazo

B

tornillos para madera

C

anclajes para concreto

D

tornillos de cabeza hexagonal M5 x 12 mm

E

tornillos de cabeza hexagonal M5 x 25 mm

F

tornillos de cabeza hexagonal M6 x 12 mm

G

tornillos de cabeza hexagonal M6 x 25 mm

H

arandela de .725"

I

espaciador de 3/4

J

desarmador de seguridad de 4 mm

K

llave allen de seguridad de 4 mm

L

tornillos de cabeza hexagonal M8 x 12 mm

M

tornillos de cabeza hexagonal M8 x 25 mm

N

espaciador de M5 x 1/8"

O

espaciador de M6 x 1/8"

P

paño de parachoques

Q

tornillos para madera de seguridad

R

anclaje alligato

S

®

C

D

1 046-P1202

1 046-P1212

6 500-1090

6 590-0320

4

4

4

4

4

4

1

1

4

4

4

4

2

1

1

560-1732

560-1733

560-1734

560-1735

540-9478

540-1059

560-1133

560-9646

560-1736

560-1737

046-0223

046-0224

570-0051

520-1092

590-0097

A

B

E

K

L

F

G

M

H

21 sur 29

I

J

OP

N

QRS

PUBLIÉ LE : 04-01-11 FEUILLE no : 203-9029-2 07-27-11

Page 22

Français

Installation to Double Wood Stud Wall

AVERTISSEMENT

• L’installateur doit s’assurer que la surface de support pourra soutenir sans danger la charge combinée de

l’équipement, de toute sa visserie et de tous ses composants.

• Serrez les vis à bois de manière que la plaque murale soit fermement fi xée, mais sans excès. Un serrage excessif

peut endommager les vis et en réduire considérablement le pouvoir de maintien.

• Ne serrez jamais à plus de 9 Nm (80 po-lb).

• Assurez-vous que les vis de montage sont ancrées au centre des montants. L’usage d’un localisateur de montants

« bord à bord » est fortement conseillé.

• La visserie est fournie pour fi xer la monture à travers une cloison sèche ou du plâtre d’épaisseur standard et

dans des montants en bois. Il appartient aux installateurs de fournir la visserie nécessaire pour d’autres types de

situations (non évalué UL).

La plaque murale (A) doit être installée uniquement à deux montants espacés de 16 po, 20 po ou 24 po. Repérez

1

le bord des montants à l’aide d’un localisateur de montants. L’utilisation d’un localisateur de montants « bord à

bord » est fortement recommandée. Après avoir repéré les bords, tracez une ligne verticale le long du centre

de chaque montant. Posez la plaque murale sur le mur et utilisez-la comme gabarit. Les fentes de montage

supérieures doivent être situées X po au-dessus du centre d'exposition, comme illustré à la fi gure 1.1 et 1.2.

Mettez la plaque à niveau et marquez le centre des quatre trous de fi xation. Veillez à ce que les trous de fi xation

soient sur la ligne médiane du montant. Percez quatre trous de 5/32 po (4 mm) de dia. et de 2 po (51mm) de

profondeur. Veillez à ce que la plaque murale soit de niveau et fi xez-la à l’aide de quatre vis à bois (C) comme

illustré à la fi gure 1.3.

fi g. 1.1

XXX

XXX

XXX

Y

()

Y = écart entre l'affi chage

des trous de montage

+ 1.75"X =

2

X"

ÉCRAN

fi g. 1.2

Y"

REMARQUE: Lorsque la

plaque de montage mural

(A) à deux montants,

ne pas utiliser le centre

des trous de montage

ou de trous de montage

extérieurs.

A

C

22 sur 29

fi g. 1.3

PUBLIÉ LE : 04-01-11 FEUILLE no : 203-9029-2 07-27-11

Page 23

Français

Installation sur un mur à triples montants en bois

AVERTISSEMENT

• L’installateur doit s’assurer que la surface de support pourra soutenir sans danger la charge combinée de

l’équipement, de toute sa visserie et de tous ses composants.

• Serrez les vis à bois de manière que la plaque murale soit fermement fi xée, mais sans excès. Un serrage excessif

peut endommager les vis et en réduire considérablement le pouvoir de maintien.

• Ne serrez jamais à plus de 9 Nm (80 po-lb).

• Assurez-vous que les vis de montage sont ancrées au centre des montants. L’usage d’un localisateur de montants

« bord à bord » est fortement conseillé.

• La visserie est fournie pour fi xer la monture à travers une cloison sèche ou du plâtre d’épaisseur standard et

dans des montants en bois. Il appartient aux installateurs de fournir la visserie nécessaire pour d’autres types de

situations (non évalué UL).

La plaque murale (A) peut être installée sur trois montants espacés de 16 po. Repérez le bord des montants

1

à l’aide d’un localisateur de montants. L’utilisation d’un localisateur de montants « bord à bord » est fortement

recommandée. Après avoir repéré les bords, tracez une ligne verticale le long du centre de chaque montant. Posez

la plaque murale sur le mur et utilisez-la comme gabarit. Les fentes de montage supérieures doivent être situées X

po au-dessus du centre d'exposition, comme illustré à la fi gure 1.4 et 1.5. Mettez la plaque à niveau et marquez le

centre des six trous de fi xation. Veillez à ce que les trous de fi xation soient sur la ligne médiane du montant. Percez

six trous de 5/32 po (4mm) de dia. et de 2 po (51mm) de profondeur. Veillez à ce que la plaque murale soit de

niveau et fi xez-la à l’aide de six vis à bois (C) comme illustré à la fi gure 1.6.

fi g. 1.4

C

X"

A

ÉCRAN

Y

()

Y = écart entre l'affi chage

des trous de montage

+ 1.75"X =

2

fi g. 1.6

fi g. 1.5

Y"

23 sur 29

PUBLIÉ LE : 04-01-11 FEUILLE no : 203-9029-2 07-27-11

Page 24

Installation sur du béton plein/block de béton

Français

AVERTISSEMENT

• Si vous installez des montures murales Peerless sur un bloc de béton de mâchefer, vérifi ez que vous disposez d’une épaisseur de béton d’au

moins 0,34 cm (1 3/8 po) dans le trou destiné aux ancrages de béton. Ne percez pas dans les joints de mortier ! Veillez à effectuer le montage

dans une partie pleine du bloc, généralement à au moins 2,5 cm (1 po) du côté du bloc. Le bloc de béton de mâchefer doit être conforme aux

spécifi cations de l’ASTM C-90. Pour percer le trou, il est conseillé d’utiliser une perceuse électrique standard sur un réglage bas au lieu d’un

marteau perforateur, afi n d’éviter de briser la partie arrière du trou lorsque vous pénétrez un vide ou une cavité.

• Vis à bois deux (C) doit être installé dans la plaque murale (A) dans chaque segment tel que montré dans le détail 1, ou le produit détérioré.

• Le béton doit avoir une densité minimale de 2000 psi. Un béton de densité moindre risquerait de ne pas retenir un ancrage de béton.

• Assurez-vous que la surface de support pourra soutenir sans danger la charge combinée de l’équipement, de toute sa visserie et de tous ses

composants.

Assurez-vous que la plaque murale (A) est de

1

niveau et utilisez-la comme gabarit pour marquer

l’emplacement des six trous de fi xation. Les fentes

de montage supérieures doivent être situées X po

au-dessus du centre d'exposition, comme illustré à la

fi gure 1.4 et 1.5 en page 23. Percez six trous de 5/16

po (8mm) de dia. à une profondeur minimale de 2,5

po (64mm). Insérez les chevilles d’ancrage (D) dans

les trous au ras du mur comme illustré (à droite).

Posez la plaque murale sur les chevilles d’ancrage

et fi xez-la à l’aide de six vis à bois (C). Assurez-vous

qu'elle est de niveau, puis serrez toutes les fi xations.

AVERTISSEMENT

• Serrez les vis de manière que la plaque murale soit fermement

fi xée, mais sans excès. Un serrage excessif peut endommager

les vis et en réduire considérablement le pouvoir de maintien.

• Ne serrez jamais à plus de 9 Nm (80 po-lb).

• Fixez toujours des ancrages de béton directement sur du béton

porteur.

• Ne fi xez jamais d’ancrages sur du béton recouvert de plâtre, une

cloison sèche ou autre matériau de fi nition. Si vous ne pouvez

pas éviter d’effectuer le montage sur du béton recouvert d’une

surface de fi nition (non évalué UL), celle-ci doit être chambrée,

comme indiqué ci-dessous. Assurez-vous que les ancrages de

béton ne se séparent pas du béton lorsque vous serrez les vis.

Si l’épaisseur du plâtre / de la cloison sèche dépasse 1,5 cm (5/8

po), des fi xations adaptées devront être fournies par l’installateur

(non évalué UL).

1

Percez des trous et insérez les ancrages (D).

2

K

A

surface en béton

C

Placez la plaque (A) sur les ancrages (D) et fi xez avec

des vis (C).

3

Serrez toutes les fi xations.

BÉTON PLEIN

BLOC DE BÉTON

DE MÂCHEFER

D

A

D

D

INCORRECT

plaque

murale

VUE EN COUPE

DÉTAIL 1

plâtre / cloison sèche

SEGMENT 1 SEGMENT 2 SEGMENT 3

béton

plaque

murale

CORRECT

plâtre / cloison sèche

béton

24 sur 29

C

PUBLIÉ LE : 04-01-11 FEUILLE no : 203-9029-2 07-27-11

Page 25

Français

Montage des vis de l'écran

AVERTISSEMENT

• Serrez les vis de manière à fi xer solidement les supports adaptateurs. N’employez pas une force excessive pour ce

faire. Un serrage excessif peut causer des contraintes risquant d’endommager les vis, de réduire considérablement

leur pouvoir de maintien et d’en détacher les têtes. Serrez les vis à un couple maximum de 4,5 Nm (40 po-lb).

• Si les vis ne sont pas enfoncées de trois tours complets dans les inserts ou si elles sont serrées au maximum sans

parvenir à maintenir solidement le support, l’écran peut être abîmé ou le produit détérioré.

Afi n d’éviter de rayer l’écran, posez un morceau de tissu sur une surface plane et de niveau qui peut supporter le

2

poids de l’écran. Posez l’écran à plat, tourné vers le bas. Si l’écran possède des boutons à l’arrière, enlevez-les

pour pouvoir fi xer les supports adaptateurs.

REMARQUE : Les trous supérieurs et inférieurs de l’écran doivent toujours être utilisés.

Pour les écrans à dos plat

Commencez par la vis la plus courte (E, G ou M) et vissez-la à la main dans l’entretoise de 1/8 po (O, P) puis

2-1

dans l’écran, comme illustré à la fi gure 2.1. La vis doit effectuer au moins trois tours complets dans le trou de

fi xation et tenir solidement en place. Ne pas trop serrer. S’il est impossible d’effectuer trois tours de vis complets,

choisissez une vis plus longue (F, H ou N) dans le jeu de fi xations à compartiments. Répétez pour le reste des

trous de fi xation et resserrez les vis.

ÉCRAN

fi g. 2.1

ENTRETOISE (O,P)

VIS (E,G, ou M)

25 sur 29

PUBLIÉ LE : 04-01-11 FEUILLE no : 203-9029-2 07-27-11

Page 26

Montage d'un écran plat

AVERTISSEMENT

• Pour lever et positionner l’écran plasma en toute sécurité, faites-vous toujours aider par une autre personne ou

utilisez un matériel de levage mécanique.

Français

Posez les protecteurs en tissu (Q) sur les vis de

3

montage inférieures comme illustré à la fi gure 3.1.

Accrochez les vis de montage supérieures aux

rainures de la plaque murale.

MONTANTS

Afi n de faire tenir l’écran en place une fois accroché,

insérez le bras de verrouillage (B) dans le côté de

la plaque murale comme illustré à la fi gure 3.2.

Veillez à ce que le bras de verrouillage repose sur le

dessus des vis de montage comme illustré dans le

dessin de détail 2.

DÉTAIL 2

B

ÉCRAN

A

B

Q

fi g. 3.1

26 sur 29

VUE EN

COUPE

fi g. 3.2

PUBLIÉ LE : 04-01-11 FEUILLE no : 203-9029-2 07-27-11

Page 27

FACULTATIF : Fixation du bras de verrouillage

ATTENTION

• Prenez garde à ne pas vous pincer les doigts en le

fi xation du bras de verrouillage (B).

MONTANT EN BOIS : Réglez le bras de

4

verrouillage (B) jusqu’à ce qu’il soit aligné avec

le montant en bois et fi xez-le à l’aide d'une vis à

bois de sécurité no 10 x 1-1/2 po (R). Si le bras

de verrouillage est diffi cile à régler, le spin du bras

pour desserrer commune.

B

Français

ÉCRAN

R

A

BÉTON/BLOC DE BÉTON : Réglez le bras

4

de verrouillage (B) dans la position souhaitée,

marquez le centre du trou de fi xation et percez

un trou de 1/4 po (6mm) de dia. à une profondeur

minimale de 2 po. Insérez l’ancrage alligator (S)

dans le trou et fi xez le bras de verrouillage (B) à

l’aide d'une vis à bois de sécurité no 10 x 1-1/2 po

(R). Si le bras de verrouillage est diffi cile à régler,

le spin du bras pour desserrer commune.

B

ÉCRAN

S

R

A

27 sur 29

Tous les autres noms de marques et de produits sont des marques de commerce ou déposées de leurs propriétaires respectifs.

PUBLIÉ LE : 04-01-11 FEUILLE no : 203-9029-2 07-27-11

© 2011, Peerless Industries, Inc. Tous droits réservés.

Peerless Industries, Inc.

2300 White Oak Circle

Aurora, Il 60502

www.peerlessmounts.com

Page 28

LIMITED FIVE-YEAR WARRANTY

Peerless Industries, Inc. (“Peerless”) warrants to original end-users of Peerless® products will be free from defects in material and workmanship, under normal

use, for a period of fi ve years from the date of purchase by the original end-user (but in no case longer than six years after the date of the product’s manufacture).

In no event shall the duration of any implied warranty of merchantability or fi tness for a particular purpose be longer than the period of the applicable

express warranty set forth above. Some states do not allow limitations on how long an implied warranty lasts, so the above limitation may not apply to you.

This warranty does not cover damage caused by (a) service or repairs by the customer or a person who is not authorized for such service or repairs by Peerless,

(b) the failure to utilize proper packing when returning the product, (c) incorrect installation or the failure to follow Peerless’ instructions or warnings when installing,

In no event shall Peerless be liable for incidental or consequential damages or damages arising from the theft of any product, whether or not secured

by a security device which may be included with the Peerless® product. Some states do not allow the exclusion or limitation of incidental or consequential

This warranty is in lieu of all other warranties, expressed or implied, and is the sole remedy with respect to product defects. No dealer, distributor, installer or other

person is authorized to modify or extend this Limited Warranty or impose any obligation on Peerless in connection with the sale of any Peerless® product.

At its option, Peerless will repair or replace, or refund the purchase price of, any product which fails to conform with this warranty.

using or storing the product, or (d) misuse or accident, in transit or otherwise, including in cases of third party actions and force majeure.

damages, so the above limitation or exclusion may not apply to you.

This warranty gives specifi c legal rights, and you may also have other rights which vary from state to state.

www.peerlessmounts.com

© 2011 Peerless Industries, Inc.

Español

GARANTÍA LIMITADA DE CINCO AÑOS

Peerless Industries, Inc. (Peerless) les garantiza a los usuarios fi nales originales de los productos Peerless® que los productos Peerless® estarán libres de

defectos de materiales o de manufactura, en condiciones de uso normal, durante un periodo de cinco (5) años a partir de la fecha en la que el usuario fi nal

original compre cualquier producto (pero, en ningún caso, durante un periodo mayor de 6 años después de la fecha de manufactura del producto). Queda a la

La duración de toda garantía implícita de comerciabilidad o de idoneidad para un propósito en particular no sobrepasará en caso alguno el periodo

de vigencia de la garantía explícita correspondiente indica en lo anterior. Algunos Estados no permiten que se establezcan limitaciones en relación con el

Esta garantía no cubre daños causados por (a) trabajos de mantenimiento o de reparación hechos por el cliente o alguna persona que no esté autorizada por

Peerless para realizar dichos trabajos de mantenimiento o de reparación, (b) no empacar el producto como es debido si lo devuelve, (c) hacer una instalación

incorrecta o no seguir las instrucciones o las advertencias de Peerless al instalar, utilizar o guardar el producto o (d) el mal uso o los accidentes, en tránsito o en

Peerless no tendrá responsabilidad en ningún caso de daños y perjuicios incidentales o indirectos o de daños y perjuicios que surjan por el robo de

cualquier producto, ya sea que el mismo esté o no esté asegurado con un dispositivo de seguridad que se haya incluido con el producto de Peerless®.

Algunos Estados no permiten que se excluyan o se establezcan limitaciones en relación con los daños y perjuicios incidentales o indirectos, de manera que es

Esta garantía remplaza toda otra garantía, expresa o implícita, y es el único recurso en lo que respecta a los defectos del producto. Ningún concesionario,

distribuidor, instalador ni ninguna otra persona está autorizada a modifi car o extender esta Garantía Limitada ni a imponer obligación alguna a Peerless en

Esta garantía concede derechos específi cos creados por ley y es posible que usted, además, tenga otros derechos que varían de acuerdo con el Estado donde

discreción de Peerless, reparar, reemplazar o rembolsar el precio de compra de cualquier producto que no cumpla esta garantía.

periodo de duración de una garantía implícita, de manera que es posible que la limitación expuesta en lo anterior no sea pertinente a usted.

otras circunstancias, incluidos los casos relacionados con las acciones de terceros o una fuerza mayor.

posible que la limitación o la exclusión expuesta en lo anterior no sea pertinente a usted.

relación con la venta de cualquier producto de Peerless®.

se encuentre.

www.peerlessmounts.com

28 of 29

© 2011 Peerless Industries, Inc.

ISSUED: 04-01-11 SHEET #: 203-9029-2 07-27-11

Page 29

Français

GARANTIE DE CINQ ANS

Peerless Industries, Inc. (« Peerless ») garantit aux utilisateurs fi naux d’origine des produits PeerlessMD que lesdits produits ne présenteront aucun défaut de

matériau ou de main-d’œuvre, dans la mesure où ils sont utilisés normalement, pendant une période de cinq ans à compter de la date d’achat par l’utilisateur fi nal

d’origine (mais en aucun cas plus de six ans après la date de fabrication du produit). Peerless, à sa discrétion, réparera ou remplacera tout produit non conforme

La durée de toute garantie implicite de qualité commerciale ou d’application à un usage particulier n’excédera en aucun cas la durée de la garantie

applicable expressément stipulée plus haut. Certains états ou provinces n’autorisent pas la limitation de la durée d’une garantie implicite, et la limitation ci-

Cette garantie ne couvre pas les dommages causés par (a) un entretien ou des réparations effectués par l’acheteur ou une personne non autorisée par Peerless

à effectuer un tel entretien ou de telles réparations, (b) un emballage inadéquat lors de l’expédition d’un produit retourné, (c) une installation incorrecte ou le non-

respect des instructions ou mises en garde de Peerless lors de l’installation, l’utilisation ou le rangement du produit, ou (d) une mauvaise utilisation ou un accident

survenu lors d’un transport ou autrement, y compris l’intervention de tiers et les cas de force majeure.

Peerless ne peut en aucun cas être tenu responsable de quelque dommage accessoire ou indirect que ce soit ni de dommages résultant du vol

d’un quelconque produit, que celui-ci ait été ou non protégé par un dispositif de sécurité intégré à un produit Peerless

n’autorisent pas l’exclusion ou la restriction des dommages accessoires ou indirects, et il est possible que les restrictions ou exclusions ci-dessus ne s’appliquent

Les dispositions de cette garantie remplacent toute autre garantie expresse ou implicite et constituent le seul recours possible en cas de défectuosité d’un

produit. Aucun marchand, distributeur, installateur ou autre personne n’est autorisé à modifi er ou étendre la portée de cette garantie limitée, ni à imposer quelque

obligation ce que soit à Peerless en ce qui concerne la vente de tout produit Peerless

Cette garantie offre des droits juridiques particuliers auxquels peuvent s’ajouter d’autres droits, susceptibles de varier d’une province ou d’un état à l’autre.

aux termes de cette garantie, ou en remboursera le prix d’achat.

dessus peut donc ne pas vous être applicable.

pas à votre cas.

MD

. Certains états ou provinces

MD

.

www.peerlessmounts.com

© 2011 Peerless Industries, Inc.

29 of 29

ISSUED: 04-01-11 SHEET #: 203-9029-2 07-27-11

Loading...

Loading...