Page 1

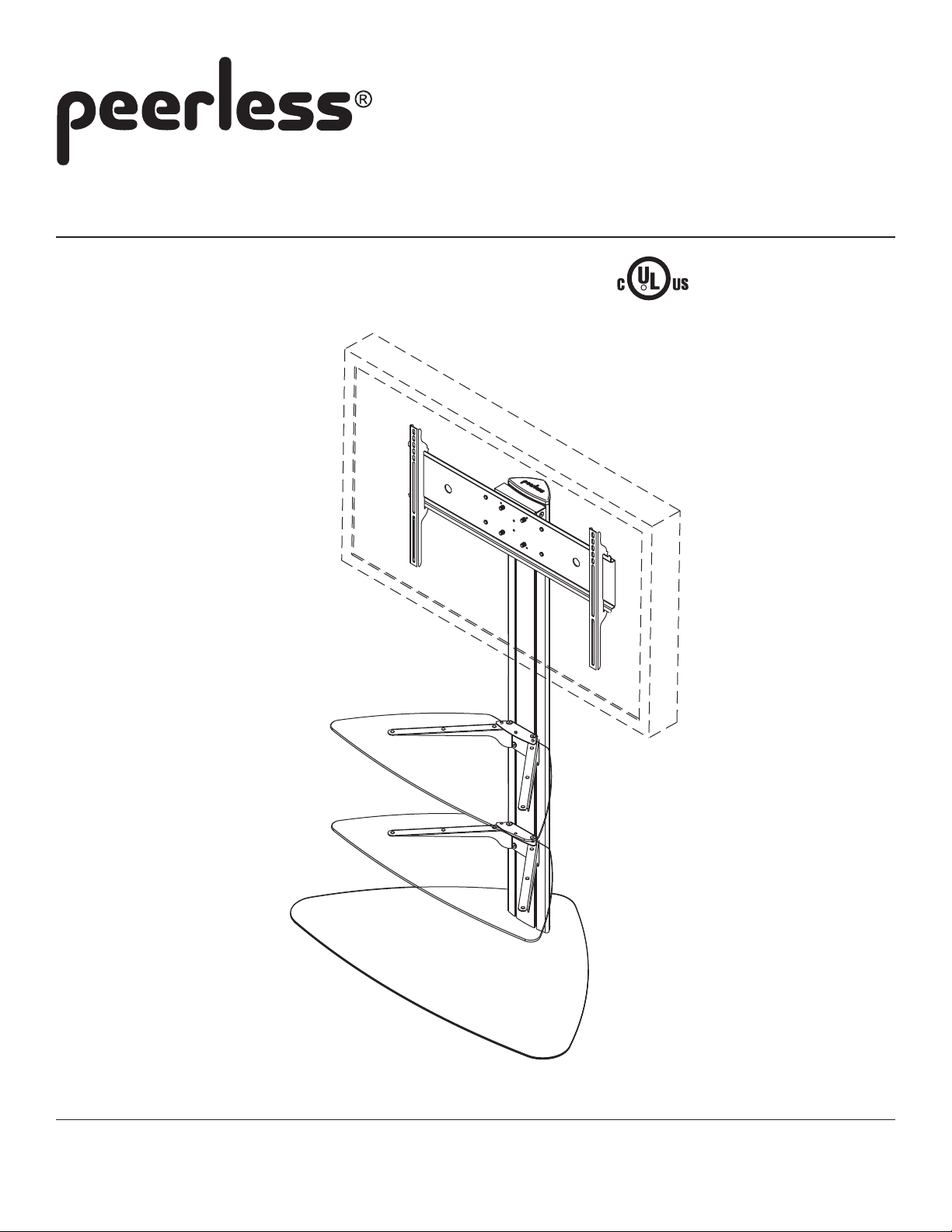

Installation and Assembly: 32" - 50" Flat Panel TV Stand

Models: SS550P, SS550P-S

This product is UL Listed. It must be

R

installed by a qualified professional

installer.

Max Load Capacity:

150 lb (68 kg) screen

50 lb (22.7 kg) per shelf

3215 W. North Ave. • Melrose Park, IL 60160 • (800) 729-0307 or (708) 865-8870 • Fax: (708) 865-2941 • www.peerlessmounts.com

ISSUED: 09-05-06 SHEET #: 202-9166-7 11-10-08

Page 2

Note: Read entire instruction sheet before you start installation and assembly.

WARNING

• Do not begin to install your Peerless product until you have read and understood the instructions and warnings

contained in this Installation Sheet. If you have any questions regarding any of the instructions or warnings, please

call Peerless customer care at 1-800-865-21 12.

• This product should only be installed by someone of good mechanical aptitude, has experience with basic building

construction, and fully understands these instructions.

• Make sure that the supporting surface will safely support the combined load of the equipment and all attached hardware and components.

• Never exceed the Maximum UL Load Capacity . See page one.

• If mounting to wood wall studs, make sure that mounting screws are anchored into the center of the studs. Use of an

"edge to edge" stud finder is highly recommended.

• Always use an assistant or mechanical lifting equipment to safely lift and position equipment.

• Tighten screws firmly , but do not overtighten. Overtightening can damage the items, greatly reducing their holding

power.

• This product was designed and intended to be mounted to the following supporting surfaces checked below with the

hardware included in this product as specified in the installation sheet. To mount this product to an alternative supporting surface, contact Peerless customer care at 1-800-865-21 12.

• This product was designed to be installed on the following wall construction only;

WALL CONSTRUCTION ADDITIONAL HARDWARE REQUIRED

x Wood Stud None

x Wood Beam None

x Solid Concrete None

x Cinder Block None

Metal Stud Do not attach except with Peerless accessory kit for metal studs;

Contact Customer Service for Peerless accessory kit for metal studs.

Brick Contact Customer Service

Other or unsure? Contact Customer Service

Tools Needed for Assembly

• level

• phillips screwdriver

Table of Contents

Parts List..........................................................................................................................................................................3, 4

Assembling Floor Stand........................................................................................................................................................4

Attaching Screen Using Universal Plate with Adapter Brackets ................................................................................................8

Attaching Screen with VESA 100 Mounting Pattern...............................................................................................................11

2 of 11

ISSUED: 09-05-06 SHEET #: 202-9166-7 11-10-08

Page 3

#

A

Before you begin, make sure all parts shown are included with your product.

Parts List

SS550P SS550P-S

Description Qty. Black Part

screen mount bracket 1 201-P1156 201-4156

B hook plate 1 201-P1157 201-4157

C shelf support 2 201-P1158 201-4158

D shelf clamp bracket 2 201-P1159 201-4159

E base 1 201-P1633 201-4633

F universal plate 1 201-P1109 201-4109

G adapter bracket 2 201-P1513 200-4513

H upright 1 580-P1180 580-4180

I glass shelf 2 590-1208 590-1208

J top cover 1 590-1210 590-4210

K button bumper 18 590-1209 590-1209

L 1/4-20 x 12mm decorative screw 18 520-2325 520-1325

M 1/4-20 x 20mm decorative screw 4 520-2326 520-1326

N 1/4-20mm nut 18 530-1022 530-2022

O 5/16" flat washer 14 540-9406 540-9446

P 3/8-16 x 2.5" socket screw 3 520-9550 520-9550

Q 7/32" allen wrench 1 560-9715 560-9715

R 4mm allen wrench 1 560-9646 560-9646

S adhesive felt 1 570-0043 570-0043

T M10 x15mm socket screw 4 520-9262 520-9262

U 6mm allen wrench 1 560-9716 560-9716

Silver Part#

A

C

D

E

F

B

H

G

P

I

J

QR

T

LK

NM

O

S

U

Some parts may appear slightly different than illustrated.

3 of 11

ISSUED: 09-05-06 SHEET #: 202-9166-7 11-10-08

Page 4

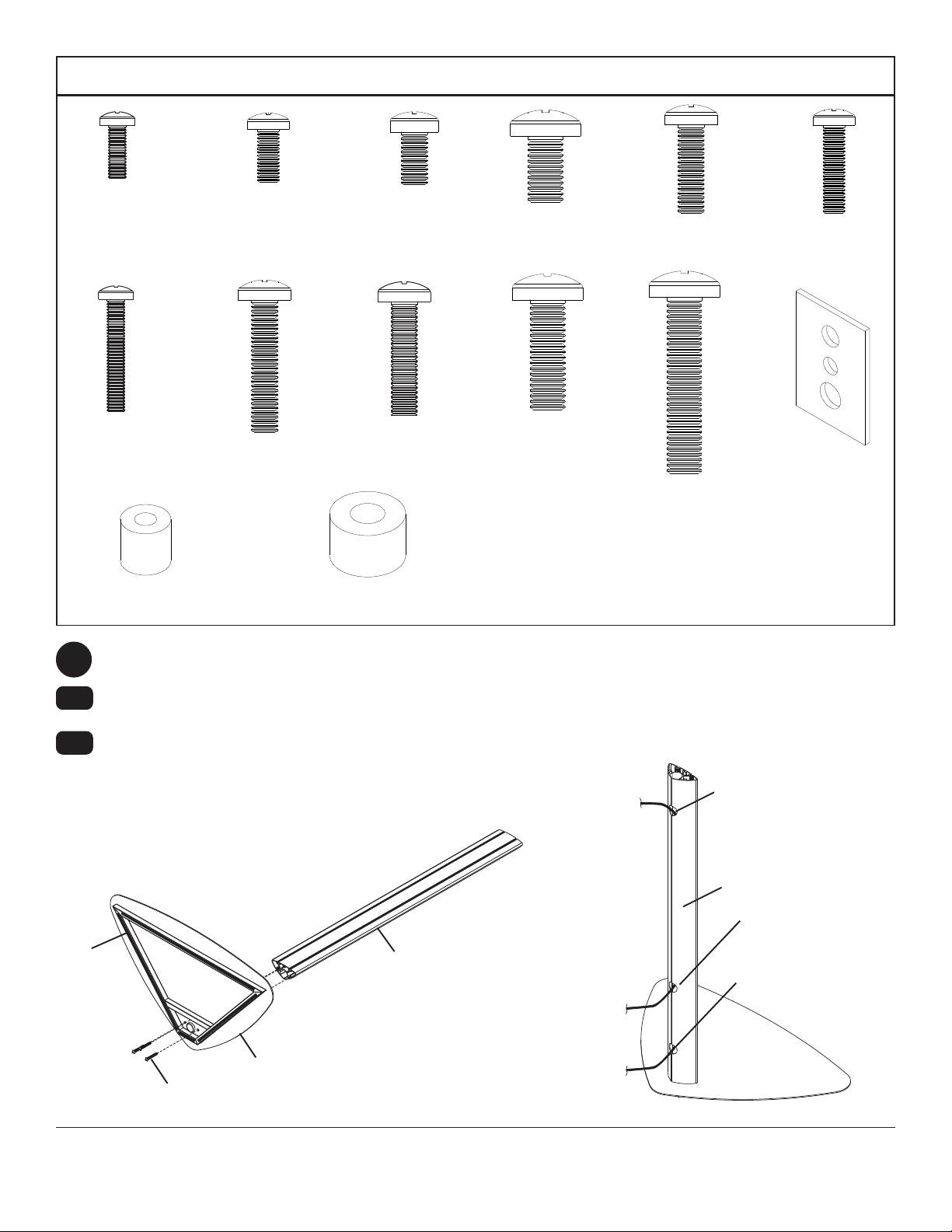

Phillips Adapter Bracket Fasteners

M4 x 12 mm (6)

504-9013

M4 x 25 mm (4)

504-1015

I.D. .22" (5.6 mm) (4)

540-1057

M5 x 12 mm (4)

520-1027

M6 x 30 mm (4)

510-9109

I.D. .34" (8.7 mm) (4)

M6 x 12 mm (4)

520-1 128

M6 x 25 mm (4)

520-1208

540-1059

M8 x 16 mm (6)

520-9257

M8 x 25 mm (4)

520-1031

M6 x 20 mm (4)

520-9402

M8 x 40 mm (4)

520-1 136

M5 x 25 mm (4)

520-9543

multi-washer (6)

580-1036

Cut adhesive felt (S) into four pieces as shown in figure 1.1 below and affix to bottom of base (E).

1

Attach upright (H) to base (E) using three 3/8-16 x 2.5" socket screws (P). Tighten screws using 7/32"

1-1

allen wrench (Q).

Run cords through upright (H) using cord management holes as shown in figure 1.2.

1-2

S

H

E

fig. 1.1

P

fig. 1.2

CORD MANAGEMENT HOLE

H

CORD MANAGEMENT HOLE

CORD MANAGEMENT HOLE

4 of 11

ISSUED: 09-05-06 SHEET #: 202-9166-7 11-10-08

Page 5

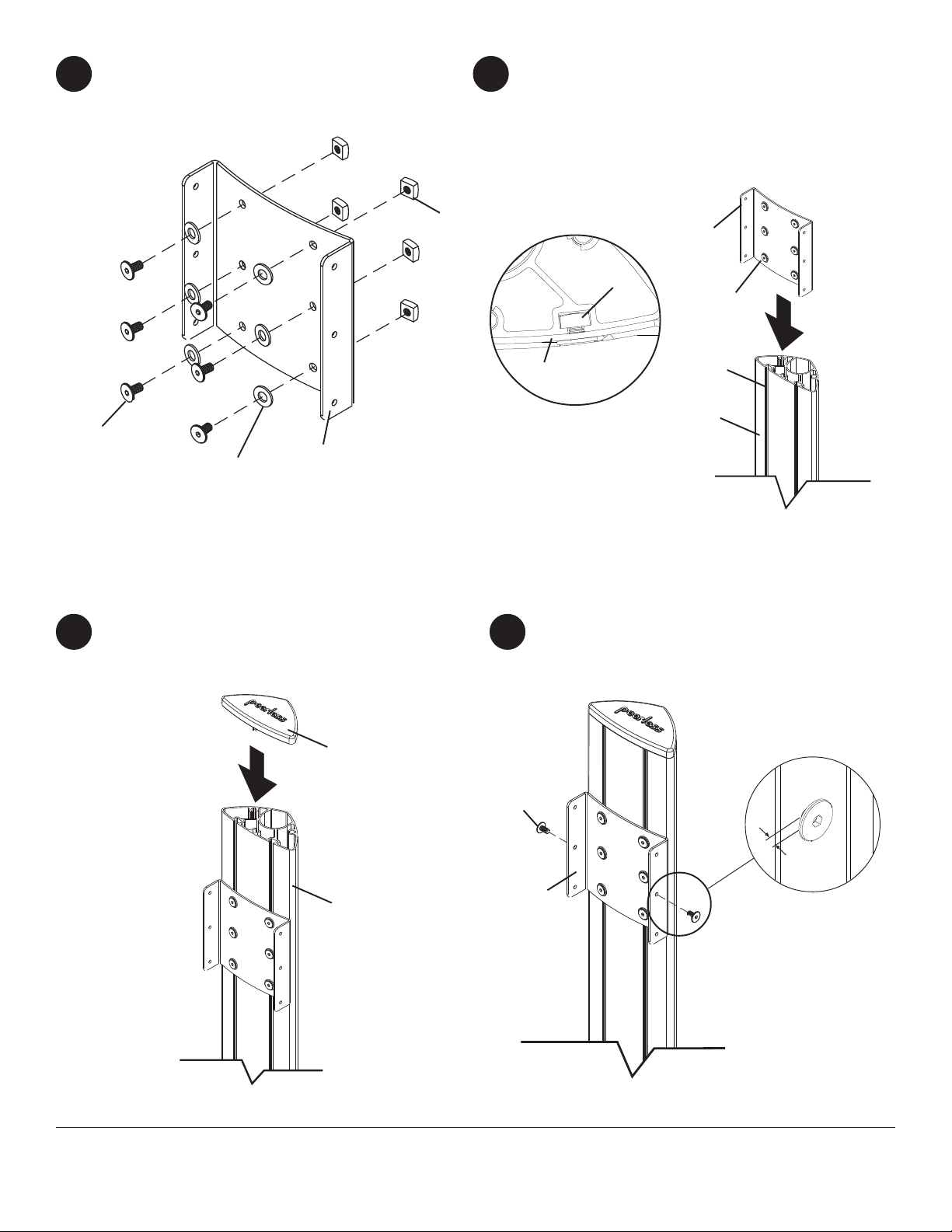

Loosely attach four 1/4-20 x 12 mm screws (L),

2

washers (O), and 1/4-20 nuts (N) to shelf

support (C).

N

Slide shelf support (C) onto upright (H) so that 1/4-20

3

nuts (N) slide into slots of upright (H) as shown in figure

3 and detail 1. Slide shelf support to desired position,

level, then tighten 1/4-20 x 12 mm screws (L) using

4 mm allen wrench (R).

NOTE: MAXIMUM OF TWO SHEL VES

3-1

Max height of top shelf is 34" from base.

Max height of second shelf is 28" from base.

L

O

C

Insert six button bumpers (K) into shelf support (C).

4

Place glass shelf (I) on shelf support.

I

C

L

N

SLOT

H

H

DETAIL 1

Insert three button bumpers (K) into bottom of shelf

5

clamp bracket (D).

Attach shelf clamp bracket (D) to shelf support (C)

5-1

using two 1/4-20 x 20 mm screws (M) and two

1/4-20 nuts (N).

For second shelf installation, repeat steps 2

5-2

through 5-1.

D

K

fig. 3

M

K

C

5 of 11

C

ISSUED: 09-05-06 SHEET #: 202-9166-7 11-10-08

N

Page 6

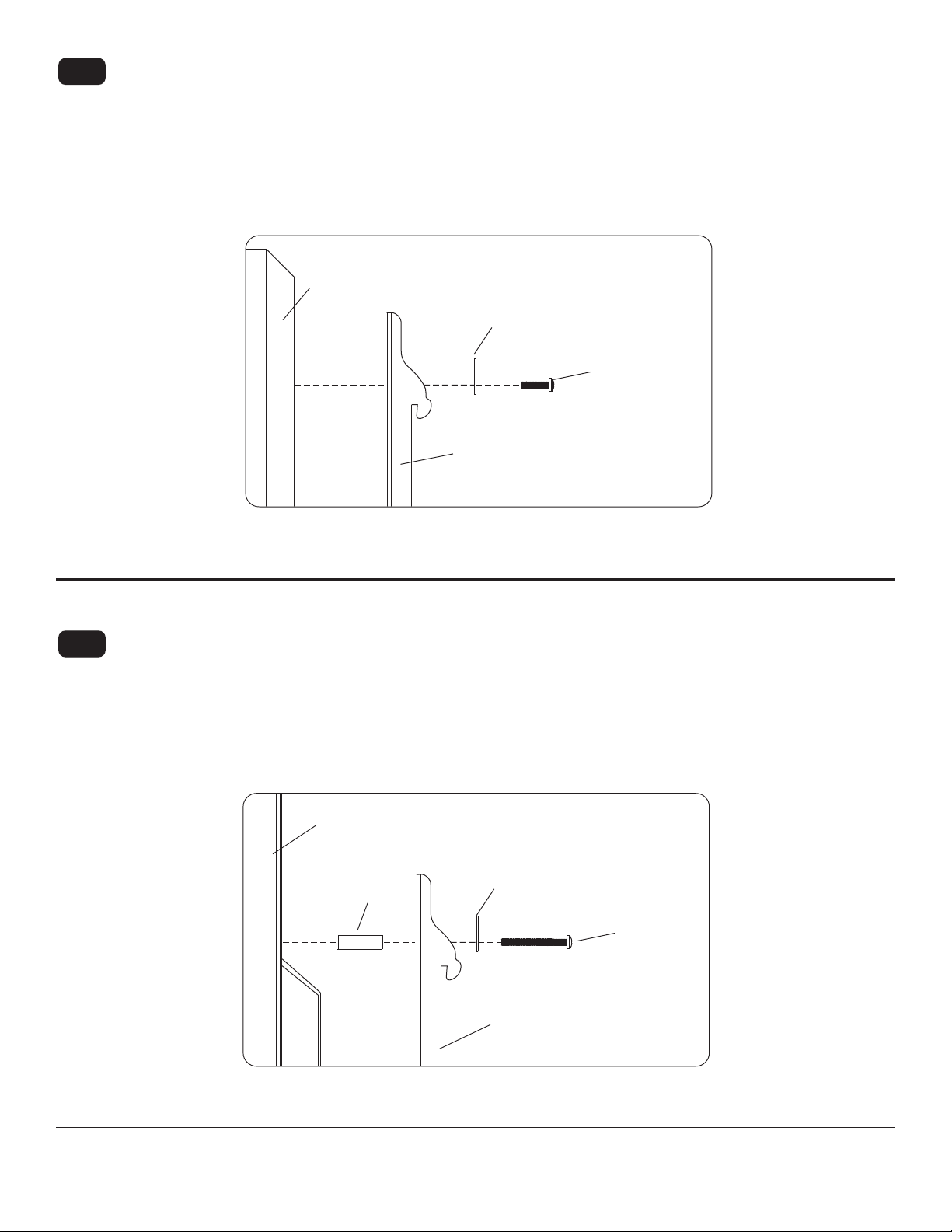

Loosely attach six 1/4-20 x 12 mm screws (L),

6

washers (O), and 1/4-20 nuts (N) to screen mount

bracket (A).

N

Slide screen mount bracket (A) onto upright (H) so that

7

1/4-20 nuts (N) slide into slots of upright (H) as shown

in figure 7 and detail 2. Slide screen mount bracket to

desired position, level, then tighten 1/4-20 x 12 mm

screws (L) using 4 mm allen wrench (R).

A

N

L

L

O

Snap top cover (J) onto upright (H).

8

A

J

H

DETAIL 2

Insert two 1/4-20 x 12 mm screws (L) into screen

9

mount bracket (A), leaving 1/8" of exposed thread as

shown in figure 9 and detail 3.

SLOT

H

L

1/8"

fig. 7

H

6 of 11

A

DETAIL 3

fig. 9

ISSUED: 09-05-06 SHEET #: 202-9166-7 11-10-08

Page 7

Attaching Screen Using Universal Plate with Adapter Brackets

For attaching screens with VESA 100 hole pattern, skip to page 10.

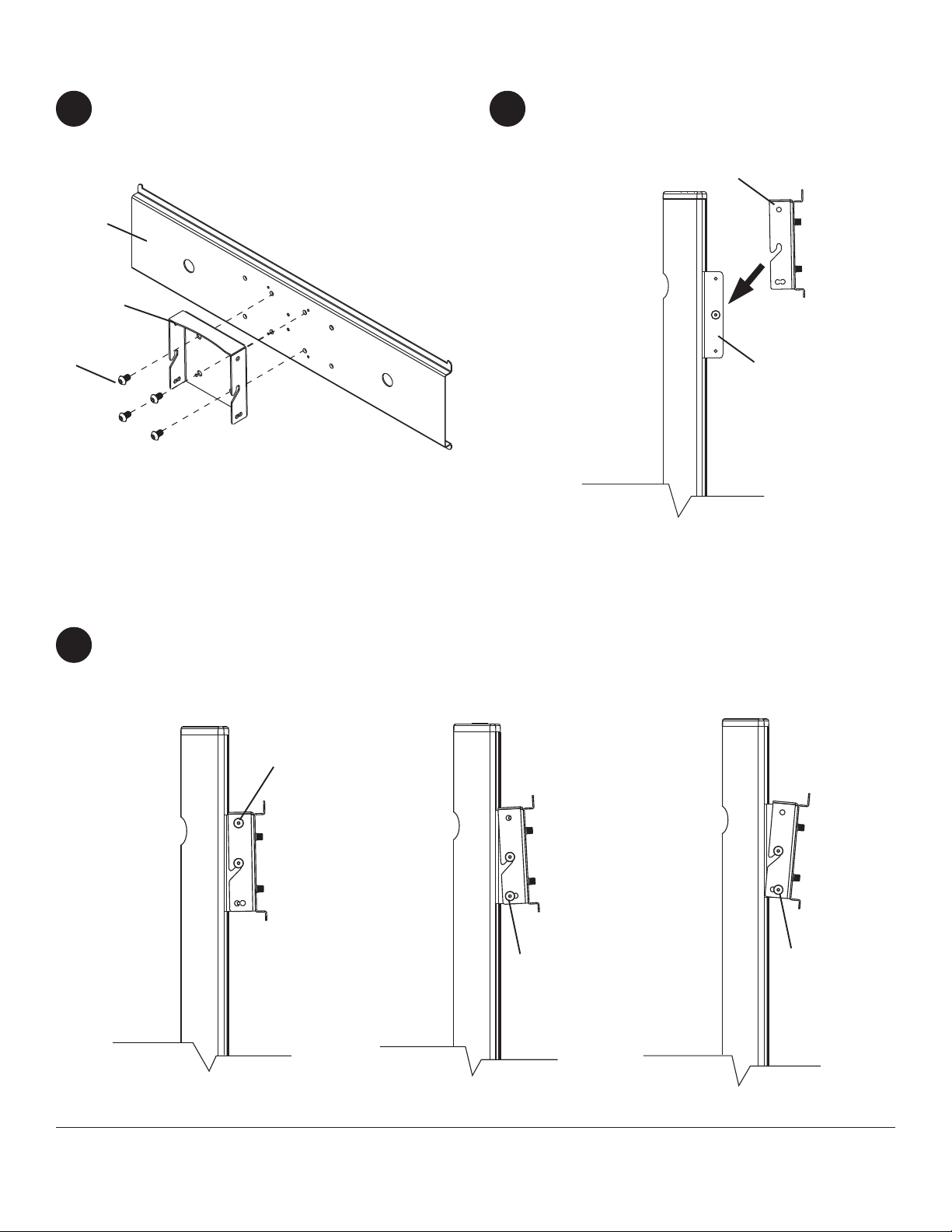

Attach universal plate (F) to hook plate (B) using four

10

M10 x 15 mm socket screws (T). Tighten screws

using 6 mm allen wrench (U).

Attach hook plate (B) to screen mount bracket (A).

11

B

F

B

T

Insert two 1/4-20 x 12 mm screws (L) into holes indicated below for desired screen orientation. Tighten all screws

12

using 4 mm allen wrench (R).

A

L

L

L

2° Backward Tilt 5° Forward TiltNo Tilt

7 of 11

ISSUED: 09-05-06 SHEET #: 202-9166-7 11-10-08

Page 8

Installing Adapter Brackets

WARNING

• Tighten screws so adapter brackets are firmly attached. Do not tighten with excessive force. Overtightening can cause

stress damage to screws, greatly reducing their holding power and possibly causing screw heads to become

detached. Tighten to 40 in. • lb (4.5 N.M.) maximum torque.

• If screws don't get three complete turns in the screen inserts or if screws bottom out and bracket is still not tightly

secured, damage may occur to screen or product may fail.

T o prevent scratching the screen, set a cloth on a flat, level surface that will support the weight of the screen. Place screen

13

face side down. Refer to screen manufacturers instructions or customer service, for removing any knobs, base, cover , or

screw(s) on the back of the screen to prepare mounting. These need to be removed to allow the adapter brackets to be

attached. Select the small, medium, large or extra large screws from the baffled fastener pack then attach tilt brackets to

screen following figure 13.1 or 13.2.

NOTE: T op and bottom mounting holes must be used for att aching brackets. Verify that all holes are properly aligned, and

then tighten screws using a phillips screwdriver.

X

G

Notes:

• The number of fasteners used will vary ,

depending upon the type of screen.

• Multi-washers and spacers may not be

used, depending upon the type of screen.

• Use the corresponding hole in the multiwasher that matches your screw size as

shown.

CENTER BRACKETS VERTICALLY

ON

BACK OF SCREEN

X

Note: "X" dimensions should be equal.

MULTI-WASHER

MEDIUM HOLE FOR M5 SCREWS

SMALL HOLE FOR M4 SCREWS

LARGE HOLE FOR M6 SCREWS

NOTE: For flat back screens proceed to step 13-1. For bump-out or recessed back screen skip to step 13-2.

8 of 11

ISSUED: 09-05-06 SHEET #: 202-9166-7 11-10-08

Page 9

For Flat Back Screen

13- 1

Refer to Screen Compatibility Chart to determine the proper fastener to use. Visit www.peerlessmounts.com/2

for a full screen compatibility chart for this mount.

Begin with the shortest length screw, hand thread through multi-washer and adapter bracket into screen as shown

below. Screw must make at least three full turns into the mounting hole and fit snug into place. Do not over tighten.

If screw cannot make three full turns into the screen, select a longer length screw from the baffled fastener pack.

Repeat for remaining mounting holes, level brackets and tighten screws.

NOTE: Spacers may not be used, depending upon the type of screen.

fig. 13.1

SCREEN

MULTI-WASHER

SCREW

ADAPTER

BRACKET (G)

If you have any questions, please call Peerless customer care at 1-800-865-2112.

For Bump-out or Recessed Back Screen

13- 2

Refer to Screen Compatibility Chart to determine the proper fastener to use. Visit www.peerlessmounts.com/2

for a full screen compatibility chart for this mount.

Begin with longer length screw, hand thread through multi-washer , adapter bracket and spacer in that order into

screen as shown below. Screw must make at least three full turns into the mounting hole and fit snug into place.

Do not over tighten. If screw cannot make three full turns into the screen, select a longer length screw from the

baffled fastener pack. Repeat for remaining mounting holes, level brackets and tighten screws.

SCREEN

SP ACER

fig. 13.2

MULTI-WASHER

SCREW

ADAPTER

BRACKET (G)

If you have any questions, please call Peerless customer care at 1-800-865-2112.

9 of 11

ISSUED: 09-05-06 SHEET #: 202-9166-7 11-10-08

Page 10

Mounting and Removing Flat Panel Screen

WARNING

• Always use an assistant or mechanical lifting equipment to safely lift and position the plasma television.

Hook adapter brackets (G) onto universal plate (F), then slowly swing screen in as shown. Turn screws clockwise at

14

least six times to prevent screen from being removed as shown in detail 4.

Note: Tighten using 4 mm allen wrench (R).

Screen can be adjusted horizontally if desired.

Note: It is important to lock screen down! To lock the screen down, tighten screws to adapter bracket as shown in

detail 4.

T o remove screen from mount, loosen screws, swing screen away from mount, and lift screen off of mount.

F

SCREWS

G

DETAIL 4

F

G

10 of 11

ISSUED: 09-05-06 SHEET #: 202-9166-7 11-10-08

Page 11

Attaching Screen with VESA 100 Mounting Pattern

WARNING

• If screws don't get three complete turns in the screen inserts or if screws bottom out and hook plate is still not tightly

secured, damage may occur to screen or product may fail.

Choose hole pattern as shown in figure 10. Attach

10

hook plate (B) to back of screen using four M4 x 12

mm screws. Tighten screws using a phillips screwdriver.

fig 10

M4 X 12 MM SCREWS

B

Attach hook plate (B) to screen mount bracket (A).

11

B

A

Insert two 1/4-20 x 12 mm screws (L) into holes indicated below for desired screen orientation. Tighten all screws

12

using 4 mm allen wrench (R).

L

L

L

2° Backward Tilt 5° Forward TiltNo Tilt

11 of 11

All other brand and product names are trademarks or registered trademarks of their respective owners.

ISSUED: 09-05-06 SHEET #: 202-9166-7 11-10-08

© 2007, Peerless Industries, Inc. All rights reserved.

Loading...

Loading...