Page 1

Assembly Instructions - Universal Speaker Mounts

Models:

SPK 811, SPK 81 1W

IMPORTANT! Read entire instruction sheet before you start installation and assembly.

For customer service, call 1-800-729-0307 or 708-865-8870.

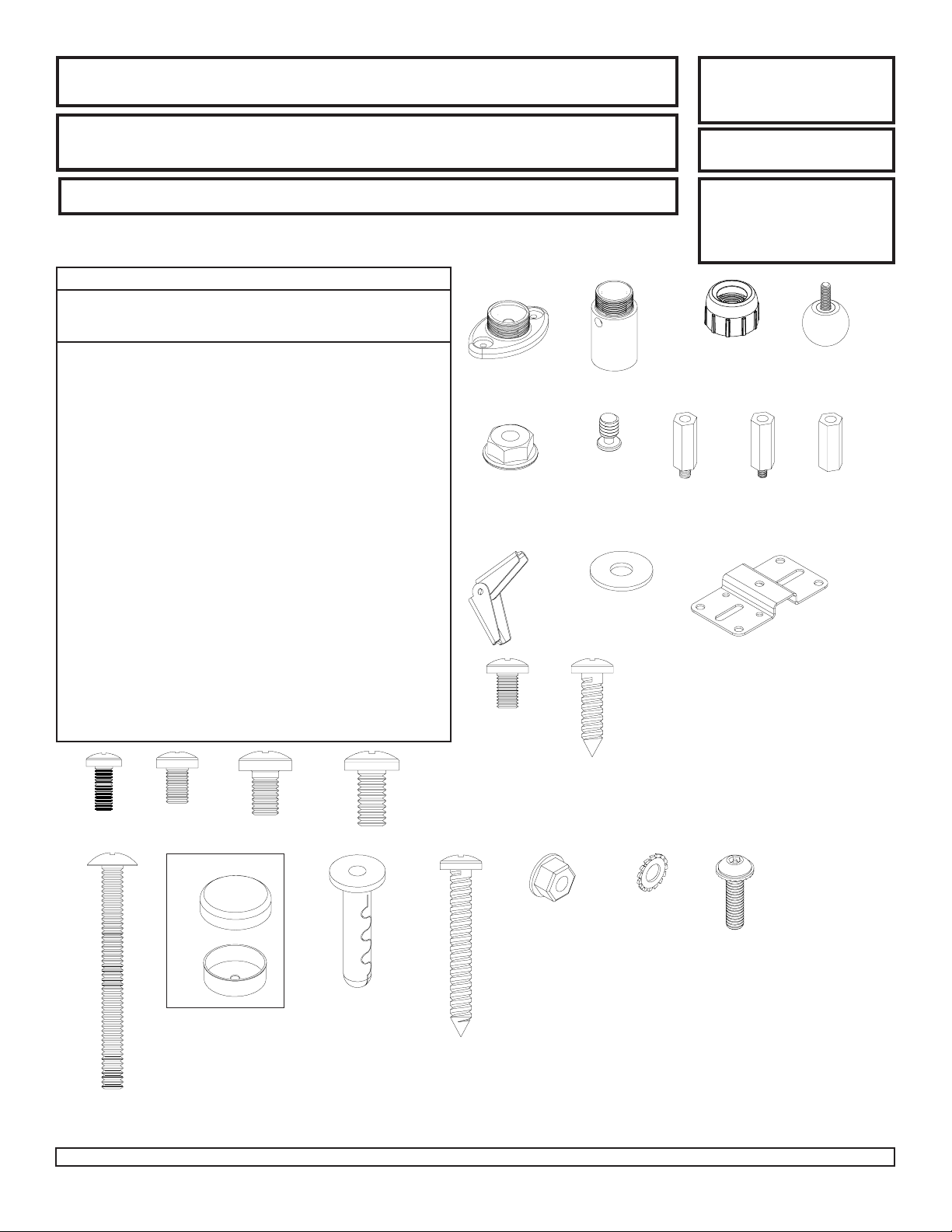

Description

A

mounting base

B

extension

C

cap

D

ball

E

M4 x .7 x 10 mm phillips screw

F

M5 x .8 x 8 mm phillips screw

G

M6 x 1 x 10 mm phillips screw

H

1/4-20 x 1/2 phillips screw

I

10-32 x .313 phillips screw

J

#10 x 3/4 phillips wood screw

K

1/4-20 serrated locknut

L

#10 flat washer

M

1/4-20 keyhole adapter

N

1/4-20 to M5 reducer

O

1/4-20 to M4 reducer

P

1/4-20 coupling

Q

mounting plate

R

toggler

S

#10-24 x 2" phillips screw

T

plastic #10 screw plug

U

concrete anchor

V

#10 x 1 1/2" wood screw

M4 KEPS hex nut

W

M4 serrated washer

X

M4 x 16 mm socket pin screw

Y

Parts List

Qty.

1

1

1

1

4

4

4

4

2

4

2

2

1

1

1

1

1

2

2

2

2

2

2

2

2

SPK 811

590-1144

590-1145

590-1146

590-1147

504-9012

570-0005

520-9401

510-9108

520-1173

500-9006

530-1021

540-9400

580-1026

580-1027

580-1028

580-1029

087-1037

560-9717

520-2078

590-1158

590-0097

510-9163

530-1041

540-1033

510-1087

SPK 811W

590-2144

590-2145

590-2146

590-2147

520-2027

520-9530

520-9524

520-9511

520-2173

500-2014

530-2021

540-9442

580-2026

580-2027

580-2028

580-2029

087-2037

560-9717

520-2078

590-2158

590-0097

500-2002

530-2041

540-2033

510-2087

A B C

K

R

I

MAXIMUM LOAD CAPACITY:

20 lb (9 kg) each mount.

Tools Required: Drill,

screwdriver, two 7/16"

open end wrenches,

channel locks, hammer,

pencil, tape measure, level.

MNO

L

Q

J

D

P

E

F

S

If you are missing a fastener, please contact our customer service department before returning the speaker mounts to store from which they

were purchased.

Visit the Peerless Web Site at www.peerlessmounts.com For customer care call 1-800-729-0307 or 708-865-8870.

GH

T

U

V

1 of 4

W

X

ISSUED:03-26-03 SHEET #: 087-9012-4 06-14-07

Y

Page 2

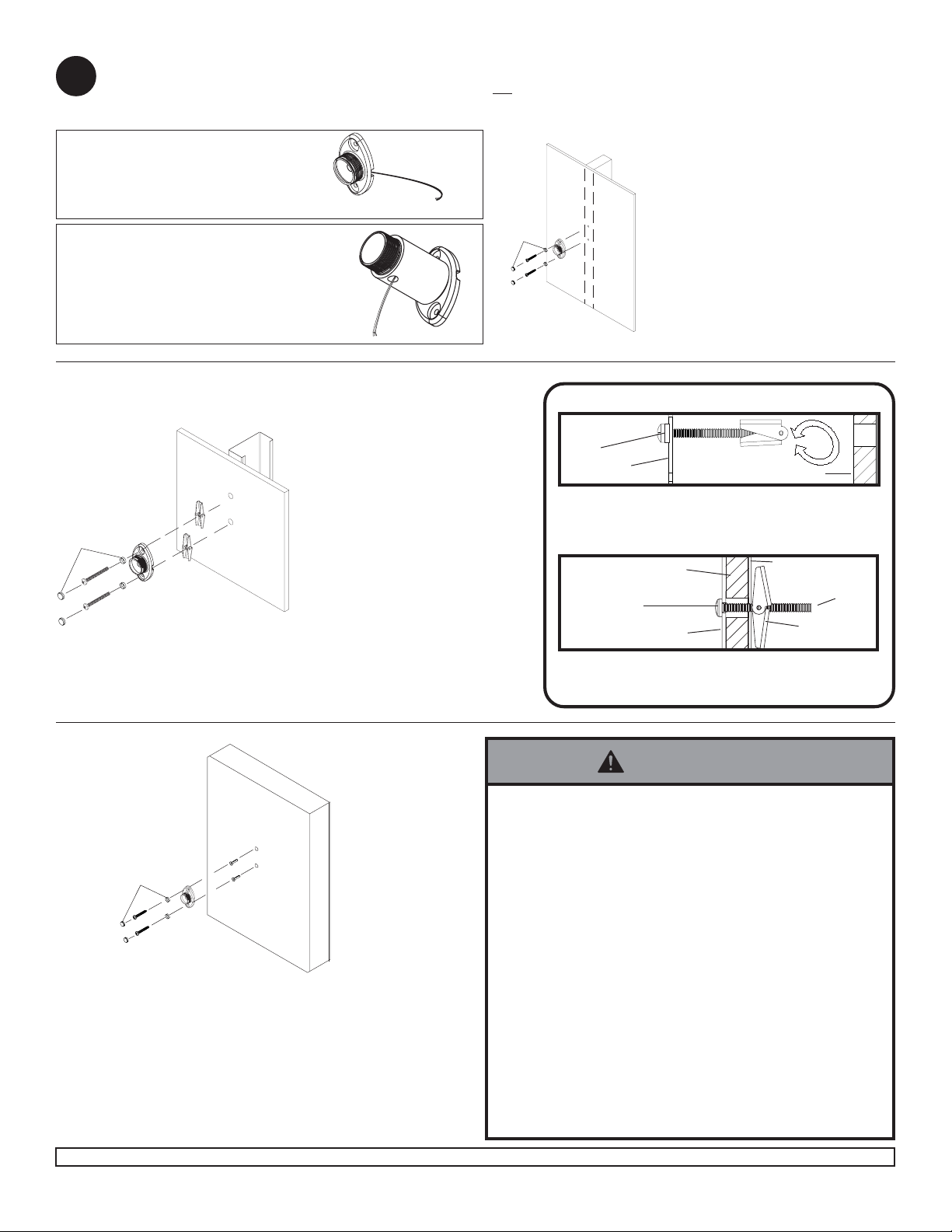

Attachment of Base Unit to Wall or Ceiling

1

Note: Ceiling applications must be mounted to a ceiling joist (NO Drywall Only).

Extension column will be used mostly with ceiling applications.

If bringing wire in from behind wall,

make sure that wires are run through

wire management slot* before mounting

base unit (A) to wall or ceiling.

*

A

When using extension column, be sure to mount

base unit (A) with wire management slot* facing

right so that wire management hole in extension

** is facing down. Remember to run wires

(B)

through wire management hole before mounting

base unit (A) to wall or ceiling.

**

B

*

A

For Attachment to Wood Stud Walls:

Use a stud finder to locate center of

stud. Drill two 3/16" (5 mm) dia. holes to

T

A

V

a minimum depth of 2" (51 mm). Attach

mounting base unit (A) to center of

wood stud using two wood screws (V)

and two plastic screw plugs (T) as

shown left.

IMPORTANT: Make sure wall bracket is

level on wall.

For Attachment to Metal Stud Walls

or Direct Attachment to Drywall for

Speakers Over 10 lb: Use a stud

finder to locate center of stud. Drill two

5/8" (16 mm) dia. holes through metal

stud. Attach mounting base unit (A) to

center of metal stud using two #10-24

T

R

A

S

phillips screws (S), two plastic screw

plugs (T) and two togglers (R) as

shown in DETAIL ONE.

IMPORTANT: Make sure mounting

base (A) is level on wall. Product must

be mounted through drywall that has a

minimum thickness of 1/2" and into

metal studs, 26 gauge or heavier.

Bottom of

plastic screw

plug (T)

A

Place screw (S) through bottom of plastic screw plug (T)

and mounting base (A). Partially fasten toggler (R) to

back of screw. Pivot toggler ends 90° and push through

hole in drywall.

Top of plastic

screw plug (T)

Pull screw back until toggler is flush with metal stud and

hold. Thread screw through with fingers and tighten

securely. Place top of plastic screw plug (T) over screw.

DETAIL ONE

S

Drywall

A

R

Metal Stud

Drywall

R

WARNING

• When installing Peerless wall mounts on cinder block,

verify that you have a minimum of 1 5/8" of actual

concrete surface in the 1/4" diameter hole to be used

T

U

A

V

For Attachment to Concrete or Direct Attachment to Drywall

for Speakers Under 10 lb: Drill one 1/4" (6 mm) dia. hole to a

minimum depth of 2" (51 mm). Insert one anchor (U) in hole flush with

wall. Place mounting base unit (A) over anchor (U) and secure with

one wood screw (V) and one plastic screw plug (T). Make sure wall

bracket is level, mark other hole and repeat steps with other

fasteners. Tighten all fasteners.

IMPORTANT: Make sure wall bracket is level on wall.

2 of 4

Visit the Peerless Web Site at www.peerlessmounts.com For customer care call 1-800-729-0307 or 708-865-8870.

for the concrete anchors. It is suggested that a

standard electric drill on slow setting is used to drill

the hole instead of a hammer drill to avoid breaking out

the back of the hole when entering a void or cavity . Do

not drill into mortar joints!

• Never attach concrete expansion anchors to concrete

covered with plaster, drywall or other finishing material.

If mounting to concrete surfaces covered with a

finishing surface is unavoidable, the finishing surface

must be counterbored.

• Tighten concrete anchor bolt firmly , but do not overtighten. Overtightening can damage the bolt, greatly

reducing its holding power.

• Never tighten in excess of 80 in • lb (9 N.M.).

ISSUED:03-26-03 SHEET #: 087-9012-4 06-14-07

S

Page 3

Note: If you are unable to attach your speaker to the Universal Speaker Mount please contact our customer service department for assistance prior

to returning this product to the store from which it was purchased.

Attachment of Ball and Cap to Speaker

2

For Attachment to Speakers with a Keyhole on Back: Thread

keyhole adapter (M) into coupling (P) a few turns. Insert assembly into

keyhole on back of speaker as shown in DETAIL TWO. Hand tighten

coupling (P) until it fits tightly against back of speaker. Use 7/16” open

end wrench to tighten coupling (P) until it is secured to speaker. Insert

ball (D) through cap (C) and thread into coupling (P). Hand tighten ball (D)

until it is secured to coupling (P).

DETAIL TWO

For Attachment to Speakers with a Single Threaded

Insert: For 1/4-20 size threaded inserts, thread one locknut

(K) halfway onto ball (D). Insert ball (D) through cap (C) and

thread directly into threaded insert on back of speaker.

Tighten locknut (K) until it is securely against back of

speaker. For M5 and M4 size threaded inserts, use reducer

(N) or (O) to thread ball (D) into threaded insert. Note:

Locknut (K) is not used with reducer (N) or (O).

Use reducer

(N) for M5

inserts

Use reducer

(O) for M4

inserts

M

P

C

P

D

Speaker

K

C

D

For Attachment to Speakers with More Than One Threaded Insert: Insert ball (D) through cap (C) and attach mounting plate (Q) using two

serrated locknuts (K) as shown in DETAIL THREE. Attach mounting plate (Q) to speaker using two or four screws (E),(F),(G),(H) or (I) as needed

for speaker threaded insert pattern.

DETAIL THREE

K

K

D

C

Q

Use two 7/16” open end wrenches to

tighten locknuts (K).

DETA IL FOUR

SPEAKER

L

W

Q

For Speakers with Four Threaded Inserts For Speakers with Two Threaded Inserts

M4 screws (E) and 10-32

screws (I) will require

washers (L) when used in

two threaded insert

applications.

Q

E, F, G or H

For Attachment to Speakers with Two Keyholes: Insert ball (D) through cap (C) and attach mounting plate (Q)

using two serrated locknuts (K) as shown in DETAIL THREE. For each keyhole, slide a M4 serrated washer (X) onto

a M4 x 16 mm socket pin screw (Y). Tilt and drop both M4 serrated washer (X) and M4 x 16 mm socket pin screw (Y)

into slot on speaker back and slide into locking position. Place bracket mounting plate (Q) onto M4 x 16 mm socket pin

screws (Y). Fasten #10 flat washer (L) then M4 KEPS hex nut (W) onto each M4 x 16 mm socket pin screws (Y) as

shown in DETAIL FOUR.

For Speakers with Two Keyholes

Q

E, F, G, H or I

W

Q

Y

Y

X

X

L

3 of 4

Visit the Peerless Web Site at www.peerlessmounts.com For customer care call 1-800-729-0307 or 708-865-8870.

ISSUED:03-26-03 SHEET #: 087-9012-4 06-14-07

Page 4

DETAIL FOUR

Q

J

Back of Speaker

Attachment of Ball/Cap and Speaker to Mounting Base or Extension

3

For Attachment to Speakers with

No Threaded Inserts: Insert ball (D)

through cap (C) and attach mounting

plate (Q) using two serrated locknuts

(K) as shown in DETAIL THREE. Use

mounting plate (Q) as a template to

mark four hole centers onto back of

speaker as indicated in DETAIL FOUR.

Using a 5/32" drill bit, drill four pilot

holes into back of speaker. Attach

mounting plate (Q) to speaker using

four #10-3/4" wood screws (J).

Thread ball/cap assembly

onto mounting base (A) or

extension (B) by hand.

For heavier speakers, it

OR

may be necessary to

tighten cap (C) with

channel locks. If so, wrap

a cloth around cap (C) to

prevent damage.

CA CB

WARNING

• In order to adjust speaker, cap must be loosen and re-tightened af ter adjustment. The speaker cannot be adjusted

after the cap has been tightened down. This will cause damage to the mount and speaker .

4 of 4

Visit the Peerless Web Site at www.peerlessmounts.com For customer care call 1-800-729-0307 or 708-865-8870.

All other brand and product names are trademarks or registered trademarks of their respective owners.

ISSUED:03-26-03 SHEET #: 087-9012-4 06-14-07

© 2007, Peerless Industries, Inc. All rights reserved.

Loading...

Loading...