Page 1

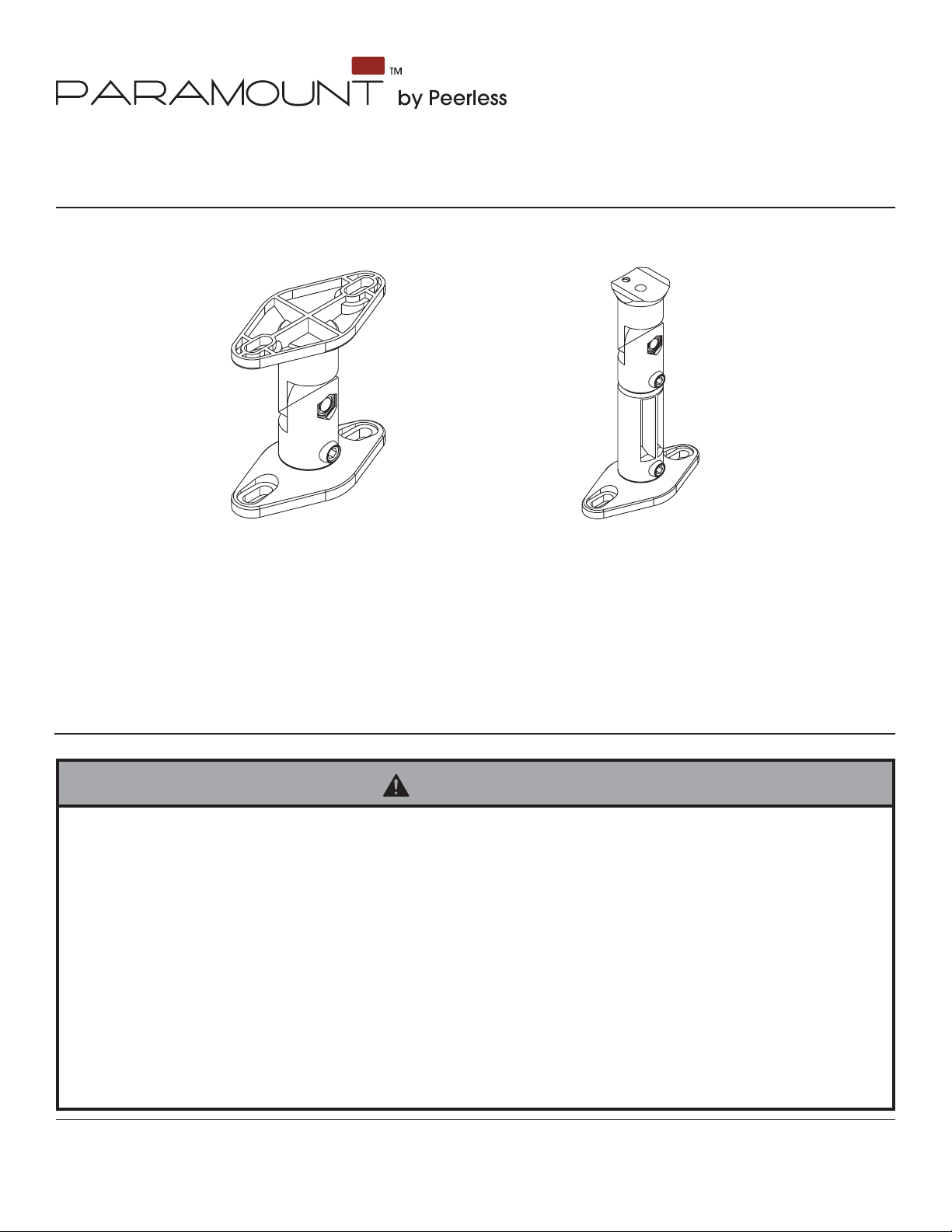

Installation and Assembly:

Universal Speaker Mounts

MODELS: PSP2, PSP2-W, PSP5, PSP5-W

Features:

• Colors: Black- PSP2 & PSP5 White- PSP2-W & PSP5-W

• Universal design fits most satellite speakers

• Easily mounts to wall or ceiling. Includes extensions for ceiling mounting

• Pivot and swivel capabilities make it easy to position speaker for optimal sound quality

• Maximum load capacity: 8 lb (3.62 kg)

• Available in packs of two (PSP2 & PSP2-W) or five (PSP5 & PSP5-W)

Maximum Load Capacity:

8 lb (3.62 kg)

Note: Read entire instruction sheet before you start installation and assembly .

WARNING

• Do not begin to install your Peerless product until you have read and understood the instructions and warnings

contained in this Installation Sheet. If you have any questions regarding any of the instructions or warnings, please

call Peerless customer care at 1-800-865-21 12.

• This product should only be installed by someone of good mechanical aptitude, has experience with basic building

construction, and fully understands these instructions.

• Make sure that the supporting surface will safely support the combined load of the equipment and all attached hardware and components.

• Never exceed the Maximum Load Capacity of 8 lb (3.62 kg).

• If mounting to wood wall studs, make sure that mounting screws are anchored into the center of the studs. Use of an

"edge to edge" stud finder is highly recommended.

• Always use an assistant or mechanical lifting equipment to safely lift and position equipment.

• Tighten screws firmly , but do not overtighten. Overtightening can damage the items, greatly reducing their holding

power.

3215 W. North Ave. • Melrose Park, IL 60160 • (800) 865-2112 or (708) 865-8870 • Fax: (708) 865-2941 • www.peerlessmounts.com

Page 2

Tools Needed for Assembly

• stud finder ("edge to edge" stud finder is recommended)

• phillips screwdriver

• drill

• 1/8" bit for wood stud wall

• 5/16" bit for concrete and cinder block wall

• level

• tape measure

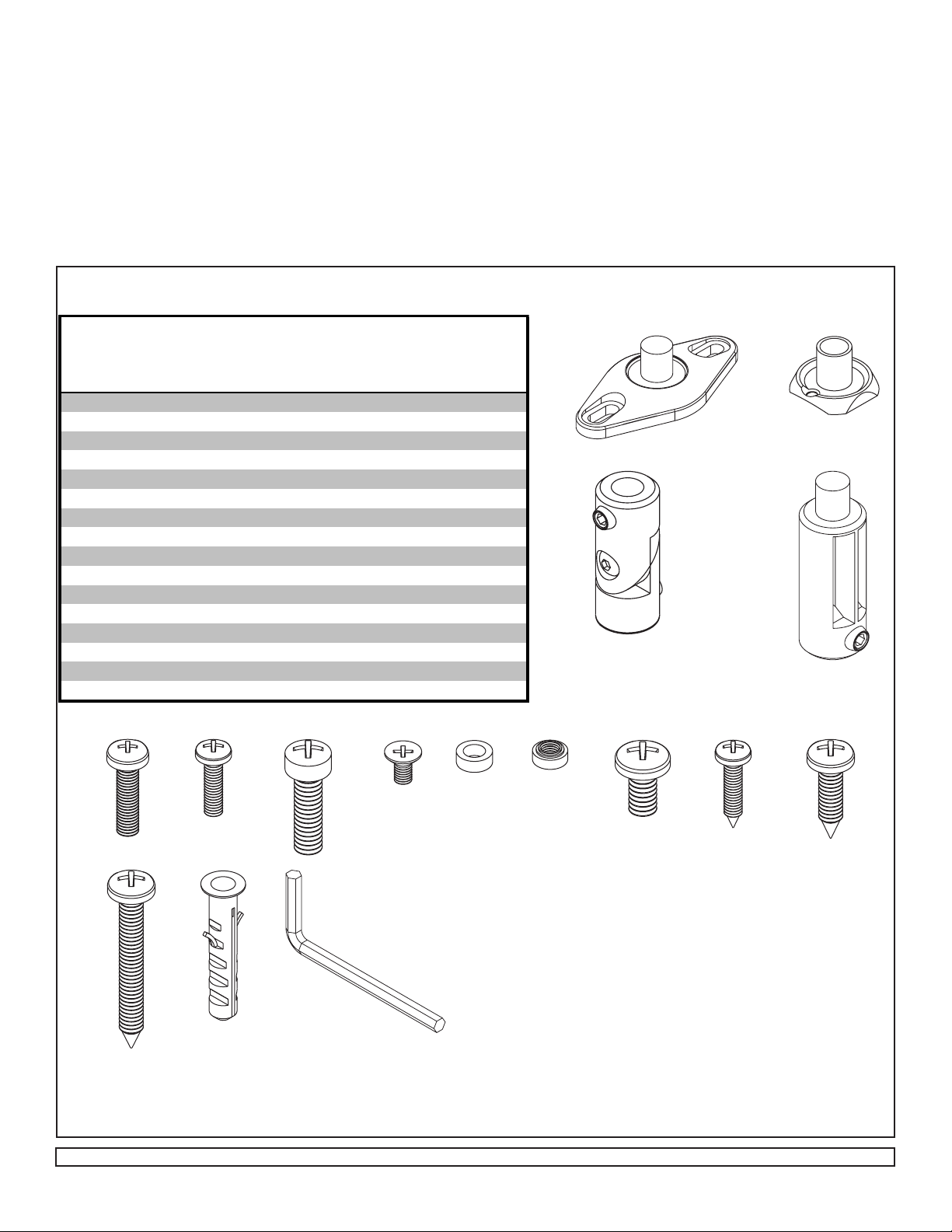

Before you begin, make sure all parts shown are included with your product.

Parts may appear slightly different than illustrated.

Parts List

Description Qty. Qty.

A double hole mounting plate 4 10

B single hole mounting plate 2 5

C arm 2 5

D arm extension 2 5

E M5 x 20 mm phillips screw 2 5

F 8-32 x 5/8" phillips screw 2 5

G 1/4"-20 x 7/8" phillips screw 2 5

H M4 x 8 mm flat head phillips screw 2 5

I M5 x 1/8" plastic washer 2 5

J 8-32 round key hole nut 2 5

K 1/4"-20 x 1/2" phillips screw 4 10

L #8 x 3/4" self tapping screw 2 5

M #12 x 3/4" self tapping screw 4 10

N #12 x 1-3/4" self tapping screw 4 10

O #12-14 Alligator concrete anchor 4 10

P allen wrench 1 1

PSPK2 PSPK5

PSPK2-W PSPK5-W

IEFGH JK LM

A B

CD

NOP

2 of 18

Visit the Peerless Web Site at www.peerlessmounts.com For customer care call 1-800-729-0307 or 708-865-8870.

ISSUED:10-23-07 SHEET #: 087-9016-1

Page 3

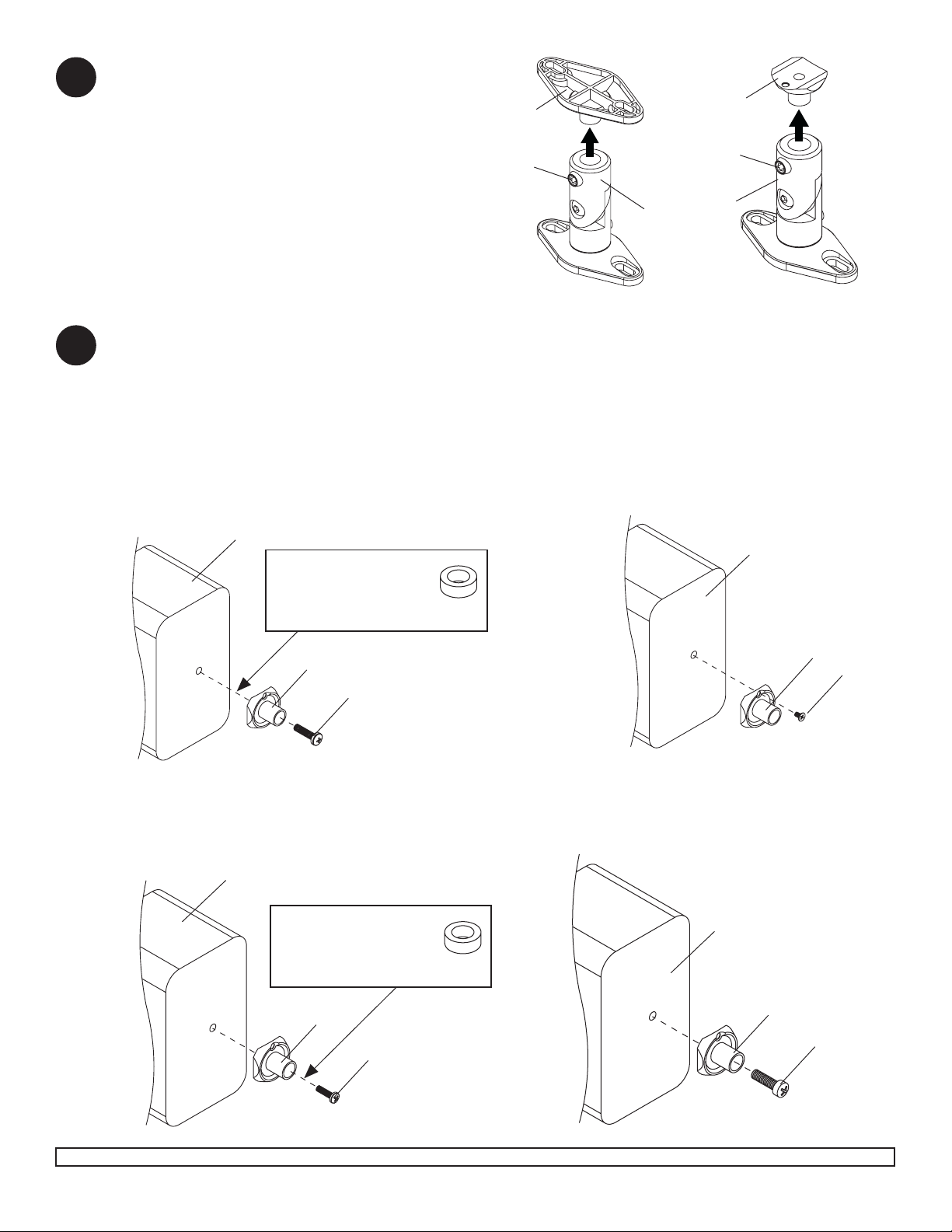

Remove Mounting Plate

Satellite speakers may require either the single

hole mounting plate (B) or the double hole

1

mounting plate (A). Remove mounting plates (if

attached) from arm (C or D) by disengaging the

hex set screws a few turns using the allen

wrench (P). Pull mounting plates (A or B) from

arm.

A

SET

SCREW

B

SET

SCREW

NOTE: Speaker mount s may come

preassembled in different configurations.

C or D

Installing Mounting Plate to Speaker

Single hole threaded insert mounting

2

Confirm the hole size on back of speaker can use either of the following screws: 8-32 x 5/8" screw (F), M5 x 20 mm phillips

screw (E), 1/4-20 x 7/8" phillips screw (G) or M4 x 8 mm flat head phillips screw (H).

For attachment to speakers with M5 threaded insert:

Attach single hole mounting plate (B) to back of speaker

using M5 x 20 mm screw (E) as shown.

SPEAKER

If M5 x 20 mm screw

does not fully secure

mounting plate to

speaker, spacer (I) can

be used.

For attachment to speakers with M4 threaded insert:

Attach single hole mounting plate (B) to back of speaker

using M4 x 8 mm flat head phillips screw (H) through the

off-center hole on mounting plate as shown.

SPEAKER

I

B

B

H

E

For attachment to speakers with 8-32 threaded insert:

Attach single hole mounting plate (B) to back of speaker

using 8-32 x 5/8" phillips screw (F) as shown.

SPEAKER

If 8-32 x 5/8" screw

does not fully secure

mounting plate to

speaker, spacer (I) can

be used.

B

For attachment to speakers with 1/4"-20 threaded

insert:

Attach single hole mounting plate (B) to back of speaker

using 1/4-20 x 7/8" phillips screw (G) as shown.

SPEAKER

I

B

G

F

3 of 18

Visit the Peerless Web Site at www.peerlessmounts.com For customer care call 1-800-729-0307 or 708-865-8870.

ISSUED:10-23-07 SHEET #: 087-9016-1

Page 4

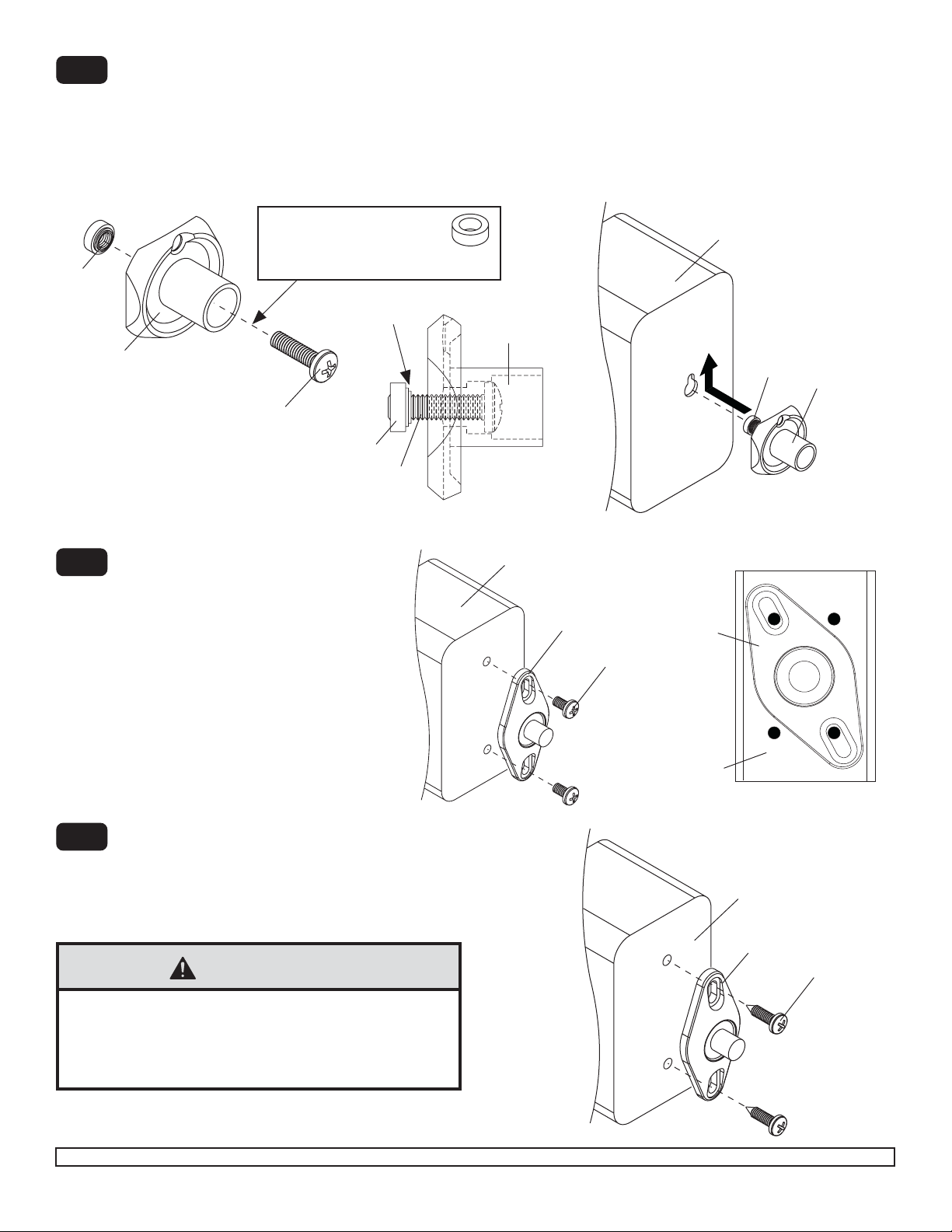

2-1

Insert 8-32 x 5/8" phillips screw (F) through the single hole mounting plate (B) and thread the 8-32 round key hole nut (J) a

few turns onto the 8-32 x 5/8" phillips screw as shown in figure 2.1 and figure 2.2. Be certain beveled edges of round key

hole nut face mounting plate. Do not fully secure 8-32 round key hole nut at this time. Insert 8-32 round key hole nut into

the key hole slot of speaker and slide upward into narrow end of key hole as shown in figure 2.3. Secure mounting plate to

speaker by gently pulling back on mounting plate and tighten 8-32 x 5/8" phillips screw .

Single Keyhole Mounting

If 8-32 x 5/8" screw does

not fully secure mounting

plate to speaker,

spacer (I) can be used.

J

B

fig. 2.1

BEVELED

EDGES

F

J

2-2

Attach double hole mounting plate (A) to speaker

using two 1/4-20 x 1/2" screws (K) as shown in

figure 2.4. Four-hole speaker mount patterns can

be accommodated by positioning the mounting

plate diagonally as shown in figure 2.5.

Two-hole or Four-hole Mounting

F

I

B

fig. 2.2

SPEAKER

A

K

SPEAKER

fig. 2.3

A

J

B

SPEAKER

fig. 2.4

fig. 2.5

2-3 Self-Tapped Mounting

Position double hole mounting plate (A) on back of speaker

in mounting location and use it as a template to mark

center of holes. Drill two pilot 1/8" (3 mm) dia. holes .5" (12

mm) deep. Do not drill deeper than .5".

SPEAKER

A

CAUTION

• Do not drill or screw into the speaker where you could

possibly damage the internal components. If unsure of

location of internal components, check specifications

with manufacturer of the speaker.

Secure mounting plate to speaker with two #12 x 3/4" self

tapping screws (M).

4 of 18

Visit the Peerless Web Site at www.peerlessmounts.com For customer care call 1-800-729-0307 or 708-865-8870.

ISSUED:10-23-07 SHEET #: 087-9016-1

M

Page 5

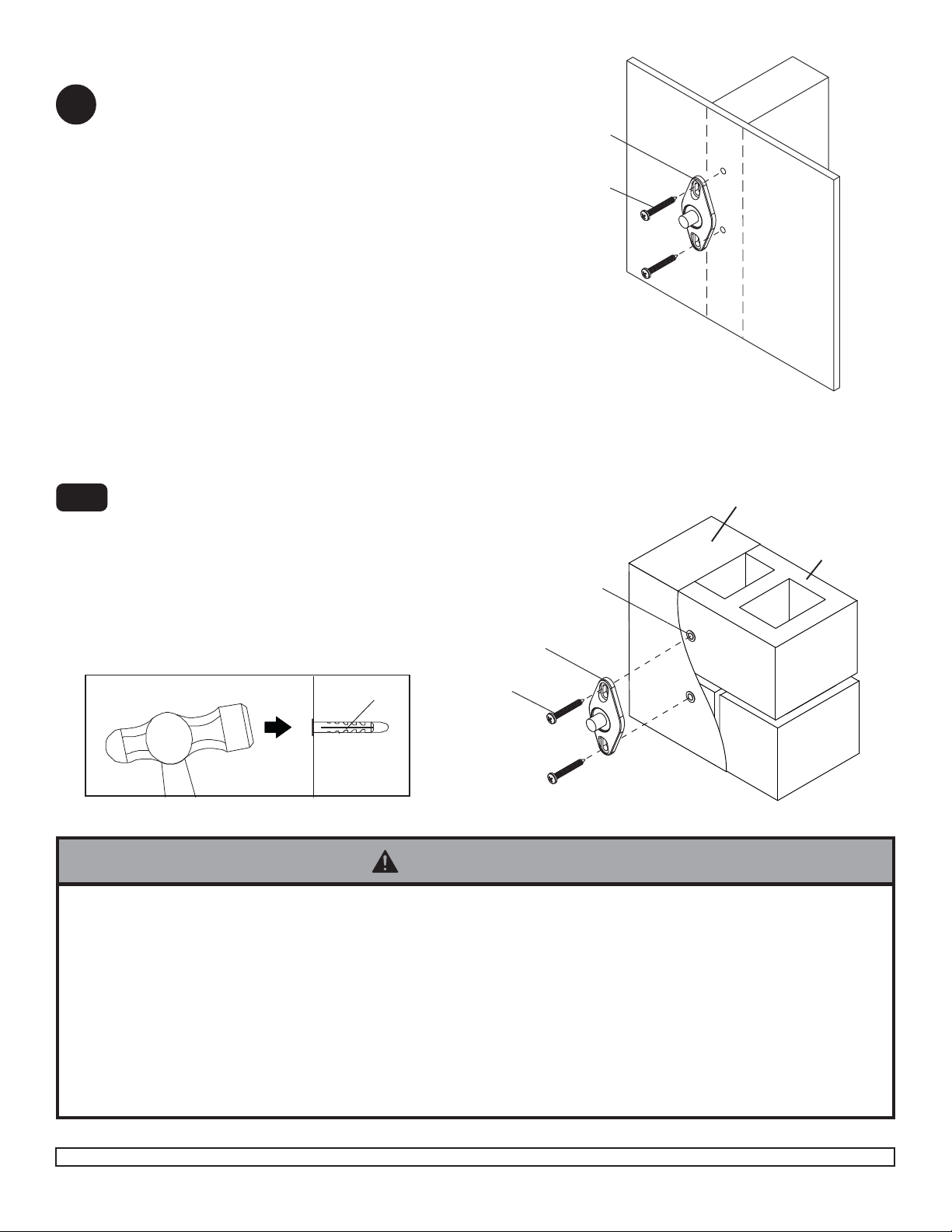

Installing Mounting Plate to Wall or Ceiling

For Attachment to Wood Studs or Wood Beams

3

Use a stud finder to locate the edges of the stud. Use of an

edge-to-edge stud finder is highly recommended. Based on

their edges, draw a vertical line down the stud’s center . Place

mounting plate (A) on wall as a template. Mark the center of

the two mounting holes. Make sure the mounting holes are on

the stud centerline. Drill four 1/8" (3 mm) dia. holes1-7/8" (48

mm) deep. Secure mounting plate using two #12 x 1-3/4" self

tapping screws (N).

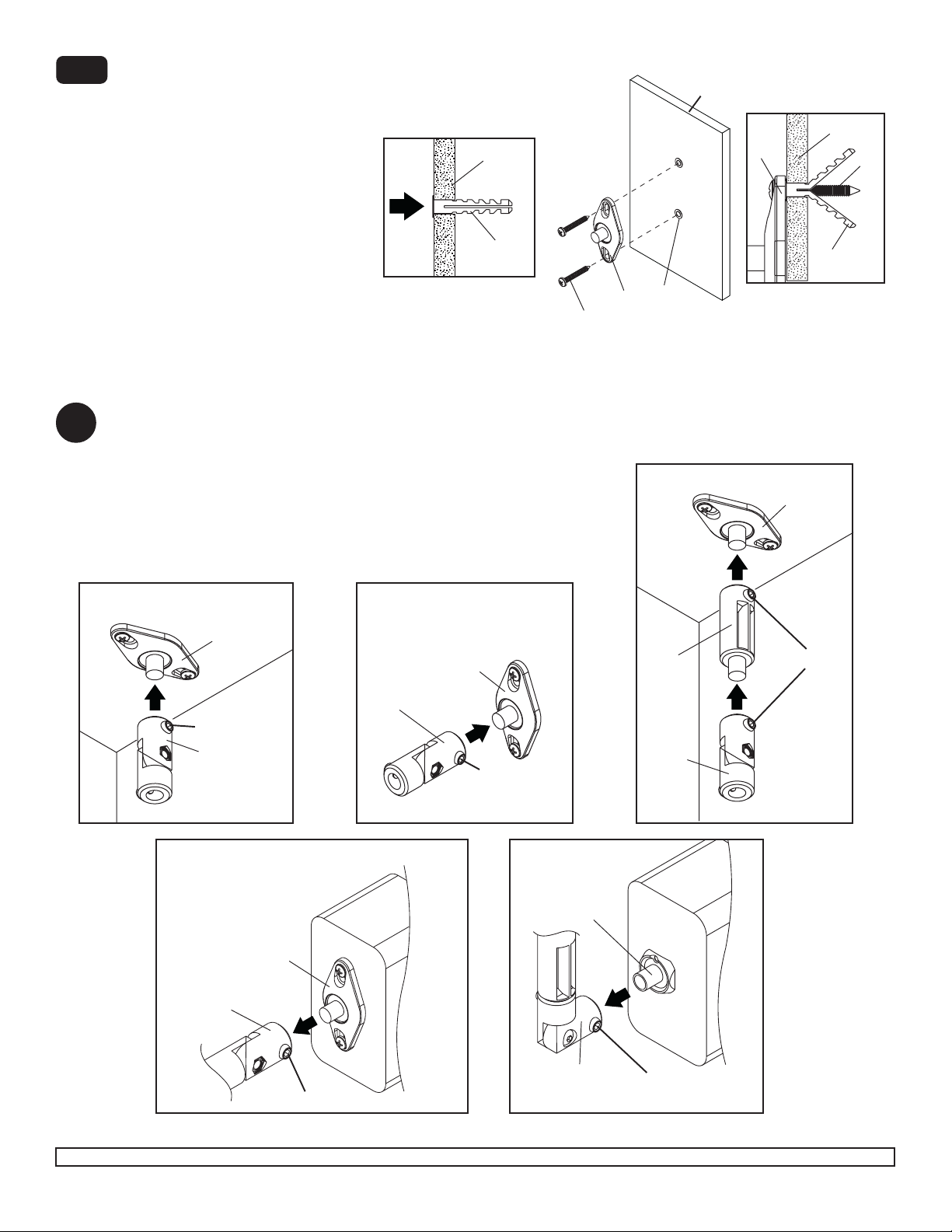

3-1

Use mounting plate as a template to mark the two

mounting holes. NOTE: For wall mounting applications,

position mounting holes in a vertical pattern. Drill two

5/16" (8 mm) dia. holes to a minimum depth of 1-7/8"

(48 mm). Insert anchors (O) in holes flush with surface

as shown in figure 3.2. Place mounting plate over

anchors and secure with two #12 x 1-3/4" self tapping

screws (N) as shown in figure 3.3.

For Att achment to Concrete or Cinder Block

A

N

fig. 3.1

SOLID

CONCRETE

CINDER

BLOCK

O

A

O

concrete

surface

N

fig. 3.3

fig. 3.2

WARNING

• When installing Peerless wall mounts on cinder block, verify that you have a minimum of 1-5/8" of actual concrete

surface in the 1/4" diameter hole to be used for the concrete anchors. It is suggested that a standard electric drill on

slow setting is used to drill the hole instead of a hammer drill to avoid breaking out the back of the hole when entering

a void or cavity . Do not drill into mortar joints!

• Never attach concrete expansion anchors to concrete covered with plaster , drywall or other finishing material. If

mounting to concrete surfaces covered with a finishing surface is unavoidable, the finishing surface must be

counterbored.

• Tighten concrete anchor bolt firmly , but do not overtighten. Overtightening can damage the screw , greatly reducing its

holding power.

• Never tighten in excess of 80 in • lb (9 N.M.).

5 of 18

Visit the Peerless Web Site at www.peerlessmounts.com For customer care call 1-800-729-0307 or 708-865-8870.

ISSUED:10-23-07 SHEET #: 087-9016-1

Page 6

3-2

Use mounting plate (A) as a template to mark

the two mounting holes. NOTE: In wall

mounting applications position mounting holes

in a vertical pattern. Drill two 5/16" (8 mm) dia.

holes through drywall. Insert anchors (O) in

holes flush with drywall as shown in figure 3.4.

Place mounting plate over anchors and secure

with two #12 x 1-3/4" self tapping screws (N).

For Att achment to Drywall surface

fig. 3.4

DRYWALL

fig. 3.5

DRYW

ALL

DRYWALL

A

N

Installing Arms to Mounting Plate

Insert arm (C) or extension arm (D) onto mounting plate attached to

4

surface as shown in figure 4.1 or 4.2. Extension arm can be used with arm

as shown in figure 4.3. Tighten set screws with allen wrench (P).

NOTE: Extension arm is not recommended with wall mounted

applications.

Insert mounting plate (A or B) attached on speaker into arm (C). Tighten

set screw with allen wrench (P) as shown in figure 4.4 or 4.5.

fig. 4.1

fig. 4.2

A

C

SET SCREW

A

O

N

A

fig. 4.3

O

D

O

fig. 3.6

A

SET SCREW

C

fig. 4.4

SET SCREW

fig. 4.5

C

A or B

A or B

C

SET SCREW

6 of 18

Visit the Peerless Web Site at www.peerlessmounts.com For customer care call 1-800-729-0307 or 708-865-8870.

All other brand and product names are trademarks or registered trademarks of their respective owners.

C

SET SCREW

ISSUED:10-23-07 SHEET #: 087-9016-1

© 2007, Peerless Industries, Inc. All rights reserved.

Page 7

Instalación y ensamblaje:

Soportes universales para altavoces

Modelos: PSP2, PSP2-W, PSP5, PSP5-W

Español

Capacidad de carga

máxima: 8 lb (3.62 kg)

Características:

• Colores: Negro- PSP2 & PSP5 Blanco- PSP2-W & PSP5-W

• El diseño universal sostiene la mayoría de los altavoces satélite.

• Se instala fácilmente en paredes o techos. Incluye extensiones para instalación en techos.

• Las funciones de giro y rotación hacen que sea fácil colocar los altavoces para lograr una calidad óptima del sonido.

• Capacidad de carga máxima: 8 lb (3.62 kg)

• A la venta en paquetes de dos (PSP2 & PSP2-W) o cinco (PSP5 & PSP5-W)

Nota: Lea la hoja de instrucciones completa antes de comenzar la instalación y el ensamblaje.

ADVERTENCIA

• No comience a instalar su producto de Peerless hasta haber leído y entendido las instrucciones y las advertencias

contenidas en la Hoja de Instalación. Si tiene alguna pregunta acerca de cualquiera de las instrucciones o las

advertencias, por favor, llame a Servicio al Cliente de Peerless al 1-800-865-21 12.

• Este producto sólo debe ser instalado por una persona que tenga una buena aptitud mecánica, que tenga

experiencia en construcción básica de edificios y que entienda estas instrucciones en su totalidad.

• Asegúrese de que la superficie de apoyo sostendrá, con seguridad, la carga combinada del equipo y todos los

fijadores y componentes.

• Nunca exceda la Capacidad de Carga Máxima de 8 lb (3.62 kg).

• Si va a instalar el producto en una pared con montantes de madera, asegúrese de que los tornillos de montaje estén

anclados en el centro de los montantes. Se recomienda utilizar un localizador de montantes de “borde a borde”.

• Siempre cuente con la ayuda de un asistente o utilice un equipo mecánico de izar para levantar y colocar el equipo

con más seguridad.

• Apriete los tornillos con firmeza, pero no en exceso. Apret arlos en exceso puede dañar los artículos y puede

disminuir significativamente su fuerza de fijación.

3215 W. North Ave. • Melrose Park, IL 60160 • (800) 865-2112 or (708) 865-8870 • Fax: (708) 865-2941 • www.peerlessmounts.com

Page 8

Herramientas necesarias para el ensamblaje

• localizador de montantes (se recomienda uno de “borde a borde”)

• destornillador phillips

• taladro

• broca de 1/8" para paredes con montantes de madera

• broca de 5/16" para paredes de concreto y de bloque de hormigón de escorias

• nivel

• cinta métrica

Antes de comenzar, asegúrese de que su producto contiene todas las piezas que se muestran.

Las piezas pueden verse un poco distintas a la ilustración.

Español

Lista de piezas

Descripción Cantidad Cantidad

A placa de montaje de dos agujeros 4 10

B placa de montaje de un agujero 2 5

C brazo 2 5

D brazo de extensión 2 5

E tornillo phillips M5 x 20 mm 2 5

F tornillo phillips de 8-32 x 5/8" 2 5

G tornillo phillips de 1/4"-20 x 7/8" 2 5

H tornillo phillips de cabeza plana M4 x 8 mm 2 5

I arandela plástica M5 x 1/8" 2 5

J tuerca bocallave redonda de 8-32 2 5

K tornillo phillips de 1/4"-20 x 1/2" 4 10

L tornillo autorroscante N.o 8 x 3/4" 2 5

M tornillo autorroscante N.o 12 x 3/4" 4 10

N tornillo autorroscante N.o 12 x 1-3/4" 4 10

O anclaje alligator para concreto N.o 12-14 4 10

P llave allen 1 1

PSPK2 PSPK5

PSPK2-W PSPK5-W

IEFGH JK LM

A B

CD

NOP

Visite el sitio Web de Peerless en www.peerlessmounts.com

ISSUED:10-23-07 SHEET #: 087-9016-18 of 18

Para el Servicio al cliente llame al 1-800-729-0307 ó 708-865-8870

Page 9

Quite la placa de montaje

Necesitará utilizar la placa de montaje de un

agujero (B) o la placa de montaje de dos

1

agujeros (A) dependiendo de los altavoces satélite.

Quite las placas de montaje (si están fijadas) del

brazo (C o D) dándoles algunas vueltas a los

tornillos de fijación hexagonales con la llave

allen (P). Saque las placas de montaje (A o B) del

brazo.

A

TORNILLO DE

SUJECIÓN

B

TORNILLO DE

SUJECIÓN

Español

C o D

Nota: Los soportes para altavoces pueden venir

preensamblados en diferentes configuraciones.

Instalar la placa de montaje al altavoz

Instalación en un agujero con un inserto roscado

2

Cerciórese de que, dependiendo del tamaño del agujero en la parte trasera del altavoz, pueda usar uno de los siguientes

tornillos: tornillo de 8-32 x 5/8 (F), tornillo phillips M5 x 20 mm (E), tornillo phillips de 1/4-20 x 7/8" (G) o tornillo phillips de

cabeza plana M4 x 8 mm (H).

Para instalar la placa a altavoces con un inserto

roscado M5: Fije la placa de montaje de un

agujero (B) a la parte trasera del altavoz usando un

tornillo M5 x 20 mm (E), como se muestra.

ALTAVOZ

Para instalar la placa a altavoces con un inserto

roscado M4: Fije la placa de montaje de un agujero (B) a

la parte trasera del altavoz pasando un tornillo phillips de

cabeza plana M4 x 8 mm (H) por el agujero que no está en

el centro de la placa de montaje, como se muestra.

Si el tornillo M5 x 20 mm

no fija la placa de

montaje al altavoz por

completo, puede utilizar

un espaciador (I).

B

E

Para instalar la placa a altavoces con un inserto

roscado de 8-32: Fije la placa de montaje de un

agujero (B) a la parte trasera del altavoz usando un

tornillo phillips de 8-32 x 5/8" (F), como se muestra.

ALTAVOZ

Si el tornillo de 8-32 x 5/8"

no fija la placa de montaje

al altavoz por completo,

puede utilizar un

espaciador (I).

ALTAVOZ

I

B

H

Para instalar la placa a altavoces con un inserto

roscado de 1/4"-20: Fije la placa de montaje de un

agujero (B) a la parte trasera del altavoz usando un

tornillo phillips de 1/4-20 x 7/8" (G), como se muestra.

ALTAVOZ

I

B

F

Visite el sitio Web de Peerless en www.peerlessmounts.com

B

G

ISSUED:10-23-07 SHEET #: 087-9016-19 of 18

Para el Servicio al cliente llame al 1-800-729-0307 ó 708-865-8870

Page 10

Español

2-1

Pase el tornillo phillips de 8-32 x 5/8" (F) por la placa de montaje de un agujero (B) y déle algunas vueltas a la tuerca

bocallave redonda de 8-32 (J) para enroscarla al tornillo philips de 8-32 x 5/8", como se muestra en las figuras 2.1 y 2.2.

Asegúrese de que los bordes biselados de la tuerca bocallave redonda queden hacia la placa de montaje. No fije la

tuerca bocallave redonda de 8-32 completamente en este momento. Inserte la tuerca bocallave redonda de 8-32 en la

ranura en forma de llave del altavoz y deslícela hacia arriba, hacia el extremo angosto de la bocallave, como se muestra

en la figura 2.3. Fije la placa de montaje al altavoz tirando la placa de montaje ligeramente hacia atrás y apriete el tornillo

phillips de 8-32 x 5/8".

Instalación en un agujero bocallave

Si el tornillo de 8-32 x 5/8" no

fija la placa de montaje al

altavoz por completo, puede

utilizar un espaciador (I).

J

B

fig. 2.1

BORDES

BISELADOS

F

J

2-2

Fije la placa de montaje de dos agujeros (A) al

altavoz usando dos tornillos de 1/4-20 x 1/2" (K),

como se muestra en la figura 2.4. Los patrones

de montaje de cuatro agujeros de los altavoces

se pueden acomodar colocando la placa de

montaje de forma diagonal, como se muestra en

la figura 2.5.

Instalación en dos agujeros o

cuatro agujeros

F

I

B

fig. 2.2

ALTAVOZ

A

K

A

ALTAVOZ

J

fig. 2.3

B

fig. 2.4

2-3 Instalación en agujeros autorroscados

Coloque la placa de instalación de dos agujeros (A) en la

parte trasera del altavoz en el lugar donde la fijará y

utilícela como una plantilla para marcar el centro de los

agujeros. T aladre dos agujeros piloto de 1/8" (3 mm) de

PRECAUCIÓN

• No taladre ni atornille hacia el interior del altavoz en

los puntos donde pueda dañar los componentes

internos. Si no está seguro de dónde se encuentran

los componentes internos, vea las especificaciones

del fabricante del altavoz.

Fije la placa de montaje al altavoz con dos tornillos

autorroscantes N.o 12 x 3/4" (M).

Visite el sitio Web de Peerless en www.peerlessmounts.com

ALTAVOZ

fig. 2.5

ALTAVOZ

A

M

ISSUED:10-23-07 SHEET #: 087-9016-110 of 18

Para el Servicio al cliente llame al 1-800-729-0307 ó 708-865-8870

Page 11

Instalar la placa de montaje a la pared o al techo

Fijación en montantes de madera o en

3

vigas de madera

Utilice un localizador de montantes para localizar los bordes

del montante. Se recomienda utilizar un localizador de

montantes de “borde a borde”. Tomando los bordes como

punto de referencia, trace una línea vertical por el centro del

montante. Coloque la placa de montaje (A) contra la pared

para utilizarla como plantilla. Marque el centro de los dos

agujeros de montaje. Asegúrese de que los agujeros de

montaje estén sobre las líneas que trazó por el centro del

montante. Taladre cuatro agujeros de 1/8" (3 mm) de diámetro

y 1-7/8" (48 mm) de profundidad. Fije la placa de montaje con

dos tornillos autorroscantes N.o 12 x 1-3/4" (N).

Español

A

N

fig. 3.1

3-1

Fijación en concreto macizo o en bloques de

hormigón de escorias

Utilice la placa de montaje como plantilla para marcar

los dos agujeros de montaje. Nota: Para instalar el

soporte en paredes, coloque los agujeros de montaje en

un patrón vertical. Taladre dos agujeros de 5/16" (8 mm)

de diámetro a una profundidad mínima de 1-7/8" (48

mm). Inserte los anclajes (O) en los agujeros a ras con

la superficie, como se muestra en la figura 3.2. Coloque

la placa de montaje sobre los anclajes y fíjela con dos

tornillos autorroscantes N.o 12 x 1-3/4" (N), como se

muestra en la figura 3.3.

O

superficie de

concreto

fig. 3.2

ADVERTENCIA

CONCRETO

MACIZO

BLOQUE DE

HORMIGÓN DE

ESCORIAS

O

A

N

fig. 3.3

• Cuando vaya a instalar soportes de pared de Peerless en bloques de hormigón de escorias, asegúrese de que

cuente con una superficie de concreto de un grosor mínimo de 1 5/8" en el agujero de 1/4" de diámetro, que pueda

usar para los anclajes para concreto. Se sugiere utilizar un taladro eléctrico convencional a baja velocidad para hacer

el agujero en vez de un taladro percutor para no perforar el fondo del agujero al entrar en un vacío o una cavidad. ¡No

taladre en juntas de argamasa!

• Nunca fije los anclajes de expansión para concreto a una pared de concreto recubierta con yeso, yeso-cartón u otro

material de acabado. Si es inevitable hacer la instalación en una superficie de concreto recubierta con una superficie

de acabado, la superficie de acabado tiene que ser escariada.

• Apriete los pernos del anclaje para concreto con firmeza, pero no en exceso. Apretarlos en exceso puede dañar los

tornillos y puede disminuir significativamente su fuerza de fijación.

• Nunca apriete a más de 80 pulg-lb (9 N•m).

ISSUED:10-23-07 SHEET #: 087-9016-111 of 18

Visite el sitio Web de Peerless en www.peerlessmounts.com

Para el Servicio al cliente llame al 1-800-729-0307 ó 708-865-8870

Page 12

3-2

Utilice la placa de montaje (A) como plantilla

para marcar los dos agujeros de montaje.

NOTA: Cuando instale para utilizar el equipo

en paredes, coloque los agujeros de montaje

en un patrón vertical. Taladre dos agujeros de

5/16" (8 mm) de diámetro que atraviesen el

yeso-cartón. Inserte los anclajes (O) en los

agujeros a ras con el yeso-cartón, como se

muestra en la figura 3.4. Coloque la placa de

montaje sobre los anclajes y fíjela con dos

tornillos autorroscantes N.o 12 x 1-3/4" (N).

Fijación en superficie de yeso-cartón

fig. 3.4

YESOCARTÓN

Instalar los brazos a la placa de montaje

Inserte el brazo (C) o el brazo de extensión (D) en la placa de montaje

4

fijada a una superficie, como se muestra en la figura 4.1 ó 4.2. El brazo

de extensión se puede utilizar con el brazo, como se muestra en la figura

4.3. Apriete los tornillos de fijación utilizando una llave allen ( P).

NOTA: No se recomienda utilizar el brazo de extensión con soportes

instalados en paredes.

Inserte la placa de montaje (A o B) fijada al altavoz en el brazo (C).

Apriete el tornillo de fijación utilizando una llave allen (P), como se

muestra en la figura 4.4 ó 4.5.

O

fig. 3.5

N

A

fig. 4.3

O

YESO-

CARTÓN

A

fig. 3.6

A

Español

YESOCARTÓN

N

O

fig. 4.1

A

TORNILLO DE

SUJECIÓN

C

fig. 4.4

A o B

C

fig. 4.2

C

A

TORNILLO DE

SUJECIÓN

fig. 4.5

A o B

D

C

TORNILLO DE

SUJECIÓN

TORNILLO DE

SUJECIÓN

Visite el sitio Web de Peerless en www.peerlessmounts.com

TORNILLO DE

C

SUJECIÓN

ISSUED:10-23-07 SHEET #: 087-9016-112 of 18

Para el Servicio al cliente llame al 1-800-729-0307 ó 708-865-8870

All other brand and product names are trademarks or registered trademarks of their respective owners.

© 2007, Peerless Industries, Inc. All rights reserved.

Page 13

Installation et assemblage :

Montures universelles pour haut-parleurs

Modèles PSP2, PSP2-W, PSP5, PSP5-W

Français

Capacité de charge

Caractéristiques :

• Couleurs : Noir - PSP2 et PSP5 Blanc - PSP2-W et PSP5-W

• Conception universelle s’adaptant à la plupart des haut-parleurs satellites

• Se monte facilement au mur ou au plafond. Comprend des rallonges pour le montage au plafond.

• Pivotement et rotation facilitant le positionnement du haut-parleur pour un son de qualité optimale.

• Capacité de charge maximale : 3,62 kg (8 lb)

• Proposé en paquets de deux (PSP2 et PSP2-W) ou de cinq (PSP5 et PSP5-W)

Remarque : lisez entièrement la fiche d’instructions avant de commencer l’installation et l’assemblage.

maximale: 8 lb (3.62 kg)

AVERTISSEMENT

• Ne commencez pas à installer votre produit Peerless avant d’avoir lu et assimilé les instructions et les mises en

garde contenues dans cette fiche d’installation. Pour toute question concernant les instructions ou les mises en

garde, appelez le service à la clientèle de Peerless au 1-800-865-21 12.

• Ce produit ne doit être installé que par une personne ayant de bonnes aptitudes en mécanique, expérimentée en

travaux de construction élémentaires, et démontrant une parfaite compréhension de ces instructions.

• Assurez-vous que la surface de support pourra soutenir sans danger la charge combinée de l’équipement, de toute

sa visserie et de tous ses composants.

• Ne dépassez jamais la capacité de charge maximale de 3,62 kg (8 lb).

• Si vous effectuez le montage sur un mur à montants en bois, assurez-vous que les vis de montage sont ancrées au

centre des montants. L ’usage d’un localisateur « bord à bord » est fortement conseillé.

• Pour lever et positionner l’équipement en toute sécurité, faites-vous toujours aider par une autre personne ou utilisez

un matériel de levage mécanique.

• Serrez fermement les vis, mais sans excès. Un serrage excessif peut endommager les éléments et en réduire

considérablement le pouvoir de maintien.

3215 W. North Ave. • Melrose Park, IL 60160 • (800) 865-2112 or (708) 865-8870 • Fax: (708) 865-2941 • www.peerlessmounts.com

Page 14

Outils nécessaires pour l’assemblage

• localisateur de montants (le localisateur de montants « bord à bord » est recommandé)

• tournevis cruciforme

• perceuse

• mèche de 1/8 po pour les murs à montants en bois

• mèche de 5/16 po pour les murs en béton et les blocs de béton de mâchefer

• niveau

• mètre ruban

Avant de commencer , assurez-vous que toutes les pièces indiquées sont incluses avec le produit.

Il est possible que les pièces semblent légèrement différentes de l’illustration.

Français

Liste des pièces

Description Quantité Quantité

A plaque de montage à deux trous 4 10

B plaque de montage à un trou 2 5

C bras 2 5

D extension de bras 2 5

E vis cruciforme M5 x 20 mm 2 5

F vis cruciforme 8-32 x 5/8 po 2 5

G vis cruciforme 1/4-20 X 7/8 po 2 5

H vis cruciforme à tête plate M4 x 8 mm 2 5

I rondelle plastique M5 x 1/8 po 2 5

J écrou rond de trou de serrure 8/32 po 2 5

K vis cruciforme 1/4-20 X 1/2 po 4 10

L vis autotaraudeuse nº 8 x 3/4 po 2 5

M vis autotaraudeuse nº 12 x 3/4 po 4 10

N vis autotaraudeuse nº 12 x 1 1/4 po 4 10

O ancrage de béton Alligator nº 12-14 4 10

P clé hexagonale 1 1

PSPK2 PSPK5

PSPK2-W PSPK5-W

IEFGH JK LM

A B

CD

NOP

Adresse de notre site internet : www.peerlessmounts.com

ISSUED:10-23-07 SHEET #: 087-9016-114 of 18

Service clientèle : 1-800-729-0307 ou 708-865-8870

Page 15

Retrait de la plaque de montage

Les haut-parleurs satellites peuvent nécessiter

soit la plaque de montage à un trou (B), soit la

1

plaque de montage à deux trous (A). Pour retirer

les plaques de montage (le cas échéant) du bras

(C ou D), desserrez les vis de pression

hexagonales de quelques tours à l’aide de la clé

hexagonale (P). Séparez les plaques de montage

(A ou B) du bras.

A

VIS DE

PRESSION

B

VIS DE

PRESSION

Français

C ou D

Remarque : Les montures de haut-parleur

peuvent être pré-assemblées en différentes

configurations.

Installation de la plaque de montage sur le haut-parleur

Montage de l’insert fileté à un trou

2

Vérifiez que la dimension du trou à l’arrière du haut-parleur correspond à celle de l’une des vis suivantes : Vis 8-32 x 5/8 po

(F), vis cruciforme M5 x 20 mm (E), vis cruciforme 1/4-20 x 7/8 po (G) ou vis cruciforme à tête plate M4 x 8 mm (H).

Fixation aux haut-parleurs à l’aide des inserts

filetés M5 : Fixez la plaque de montage à un trou (B) à

l’arrière du haut-parleur à l’aide de la vis M5 x 20 mm (E)

comme illustré.

HAUT-PARLEUR

Si la vis M5 x 20 mm ne

parvient pas à fixer la

plaque de montage au

haut-parleur, la pièce

d’écartement (I) peut

être utilisée.

B

E

Fixation aux haut-parleurs à l’aide des inserts

filetés 8-32 : Fixez la plaque de montage à un trou (B)

à l’arrière du haut-parleur à l’aide de la vis cruciforme

8-32 x 5/8 po (F) comme illustré.

HAUTPARLEUR

Si la vis 8-32 x 5/8 po ne

parvient pas à fixer la

plaque de montage au

haut-parleur, la pièce

d’écartement (I) peut

être utilisée.

Fixation aux haut-parleurs à l’aide des inserts

filetés M4 : Fixez la plaque de montage à un trou (B) à

l’arrière du haut-parleur en faisant passer la vis

cruciforme à tête plate M4 x 8 mm (H) dans le trou

central de la plaque de montage, comme illustré

HAUT-PARLEUR

I

B

H

Fixation aux haut-parleurs à l’aide des inserts filetés

1/4po-20 : Fixez la plaque de montage à un trou (B) à

l’arrière du haut-parleur à l’aide de la vis cruciforme

1/4-20 x 7/8 po (G) comme illustré.

HAUT-PARLEUR

I

B

F

Adresse de notre site internet : www.peerlessmounts.com

B

G

ISSUED:10-23-07 SHEET #: 087-9016-115 of 18

Service clientèle : 1-800-729-0307 ou 708-865-8870

Page 16

Français

2-1

Insérez la vis cruciforme 8-32 x 5/8 po (F) dans la plaque de montage à un trou (B) et vissez l’écrou pour trou de serrure

rond de 8-32 (J) de quelques tours sur la vis cruciforme 8-32 x 5/8 po comme illustré figures 2.1 et 2.2, Assurez-vous que

les bords biseautés de l’écrou de trou de serrure rond sont placés face à la plaque de montage. N’immobilisez pas

complètement l’écrou 8-32 pour le moment. Insérez l’écrou rond dans l’ouverture correspondante du haut-parleur et glissezle vers le haut dans la partie étroite du trou de serrure, comme illustré figure 2.3 Fixez la plaque de montage sur le hautparleur en tirant doucement la plaque en arrière, puis serrez la vis cruciforme 8-32 x 5/8 po.

J

Montage à un trou de serrure

Si la vis 8-32 x 5/8 po ne

parvient pas à fixer la plaque

de montage au haut-parleur,

la pièce d’écartement (I)

peut être utilisée.

HAUT-PARLEUR

I

BORD

BISEAUTÉ

B

B

fig. 2.1

J

B

F

J

2-2

Fixez la plaque de montage à deux trous (A)

sur le haut-parleur à l’aide de deux vis

1/4-20 x 1/2 po (K), comme illustré figure 2.4.

Les configurations à quatre trous peuvent être

utilisées en positionnant la plaque de montage

en diagonale, comme illustré figure 2.5.

Montage à deux ou quatre trous

F

fig. 2.2

HAUT-PARLEUR

fig. 2.4

2-3 Montage à l’aide de fixations autotarauseuses

Positionnez la plaque de montage à deux trous (A) à l’arrière du haut-parleur

à l’emplacement du montage et utilisez-la comme gabarit pour marquer le

centre des trous. Percez deux avant-trous de 3 mm (1/8 po) de diamètre et

de 12 mm (0,5 po) de profondeur. Ne percez pas à plus de 0,5 po.

A

fig. 2.3

A

K

HAUTPARLEUR

fig. 2.5

HAUT-PARLEUR

ATTENTION

• Ne percez pas et ne vissez pas dans le haut-parleur ,

car vous pourriez endommager les composants

internes. Si vous n’êtes pas sûr de l’emplacement

des composants internes, le fabricant du haut-parleur

peut vous le préciser.

Fixez la plaque de montage sur le haut-parleur à l’aide de deux vis

autotaraudeuses nº 12 x 3/4 po (M)

Adresse de notre site internet : www.peerlessmounts.com

A

M

ISSUED:10-23-07 SHEET #: 087-9016-116 of 18

Service clientèle : 1-800-729-0307 ou 708-865-8870

Page 17

Installation de la plaque de montage au mur ou au plafond

Fixation sur des montants ou des poutres en bois

3

Utilisez un localisateur de montants pour repérer les bords du

montant. L’usage d’un localisateur bord à bord est fortement

conseillé. En fonction de leurs bords, tracez une ligne verticale

le long des centres des montants. Utilisez la plaque de

montage (A) comme gabarit et placez-la sur le mur . Marquez

le centre des deux trous de montage. Assurez-vous que les

trous de montage se trouvent sur les axes des montants.

Percez quatre trous de 3 mm (1/8 po) de diamètre et de 48 m

(1 7/8 po) de profondeur. Fixez la plaque de mont age à l’aide

de deux vis autotaraudeuses nº 12 x 1 3/4 po (N)

A

N

fig. 3.1

Français

3-1

Fixation sur du béton ou des blocs de béton

de mâchefer

Utilisez la plaque de montage comme gabarit pour

marquer l’emplacement de deux trous de montage.

Remarque : Pour le montage sur un mur , positionnez

les trous de montage à la verticale. Percez deux trous

de 8 mm (5/16 po) de diamètre à une profondeur

minimum de 48 mm (1 7/8 po). Insérez les ancrages (O)

dans les trous au ras du mur comme illustré figure 3.2.

Placez la plaque de montage sur les ancrages et fixez

à l‘aide de deux vis autotaraudeuses nº12 x 1 3/4 po (N)

comme illustré figure 3.3.

O

surface en

béton

fig. 3.2

AVERTISSEMENT

N

A

O

fig. 3.3

BÉTON

PLEIN

BLOC DE

BÉTON DE

M

ÂCHEFER

• Si vous installez des montures murales Peerless sur un bloc de béton de mâchefer, vérifiez que vous disposez d’une

épaisseur de béton d’au moins 0,31 cm (1 5/8 po) dans le trou de 1/4 po de diamètre destiné aux ancrages de béton.

Pour percer le trou, il est conseillé d’utiliser une perceuse électrique standard sur un réglage bas au lieu d’un

marteau perforateur, afin d’éviter de briser la partie arrière du trou lorsque vous pénétrez un vide ou une cavité. Ne

percez pas dans les joints de mortier !

• Ne fixez jamais de coquilles d’expansion sur du béton recouvert de plâtre, cloison sèche ou autre matériau de

finition. Si vous ne pouvez pas éviter d’effectuer le montage sur du béton recouvert d’une surface de finition, celle-ci

doit être chambrée.

• Serrez fermement les boulons d’ancrage de béton, mais sans excès. Un serrage excessif peut endommager les

boulons et en réduire considérablement le pouvoir de maintien.

• Ne serrez jamais à plus de 9 Nm (80 po-lb).

ISSUED:10-23-07 SHEET #: 087-9016-117 of 18

Adresse de notre site internet : www.peerlessmounts.com

Service clientèle : 1-800-729-0307 ou 708-865-8870

Page 18

3-2

Utilisez la plaque de montage (A) comme

gabarit pour marquer l’emplacement des deux

trous de montage. REMARQUE : Pour le

montage sur un mur , positionnez les trous de

montage à la verticale. Percez deux trous de

8 mm (5/16 po) de diamètre dans la cloison

sèche. Insérez les ancrages (O) dans les

trous au ras de la cloison sèche comme

illustré figure 3.4. Placez la plaque de

montage sur les ancrages et fixez à l‘aide de

deux vis autotaraudeuses nº12 x 1 3/4 po (N).

Fixation sur une cloison sèche

fig. 3.4

CLOISON

SÈCHE

O

Installation des bras sur la plaque de montage

Insérez le bras (C) ou l’extension (D) sur la plaque de montage fixée à la

4

surface comme illustré figure 4.1 ou 4.2. L’extension peut être utilisée

avec le bras comme illustré figure 4.3. Serrez les vis de pression à l’aide

de la clé hexagonale (P).

REMARQUE : L’usage d’une extension de bras est déconseillé pour le

montage mural.

fig. 3.5

N

A

fig. 4.3

CLOISON

SÈCHE

O

Français

CLOISON

SÈCHE

A

N

O

fig. 3.6

A

Insérez la plaque de montage (A ou B) fixée sur le haut-parleur dans le

bras (C). Serrez la vis de pression à l’aide de la clé hexagonale (P)

comme illustré figure 4.4 ou 4.5.

fig. 4.1

fig. 4.2

A

A

VIS DE

PRESSION

C

fig. 4.4

C

VIS DE

PRESSION

fig. 4.5

A ou B

A ou B

D

C

VIS DE

PRESSION

C

VIS DE

PRESSION

Adresse de notre site internet : www.peerlessmounts.com

C

All other brand and product names are trademarks or registered trademarks of their respective owners.

VIS DE

PRESSION

ISSUED:10-23-07 SHEET #: 087-9016-118 of 18

Service clientèle : 1-800-729-0307 ou 708-865-8870

© 2007, Peerless Industries, Inc. All rights reserved.

Loading...

Loading...