Page 1

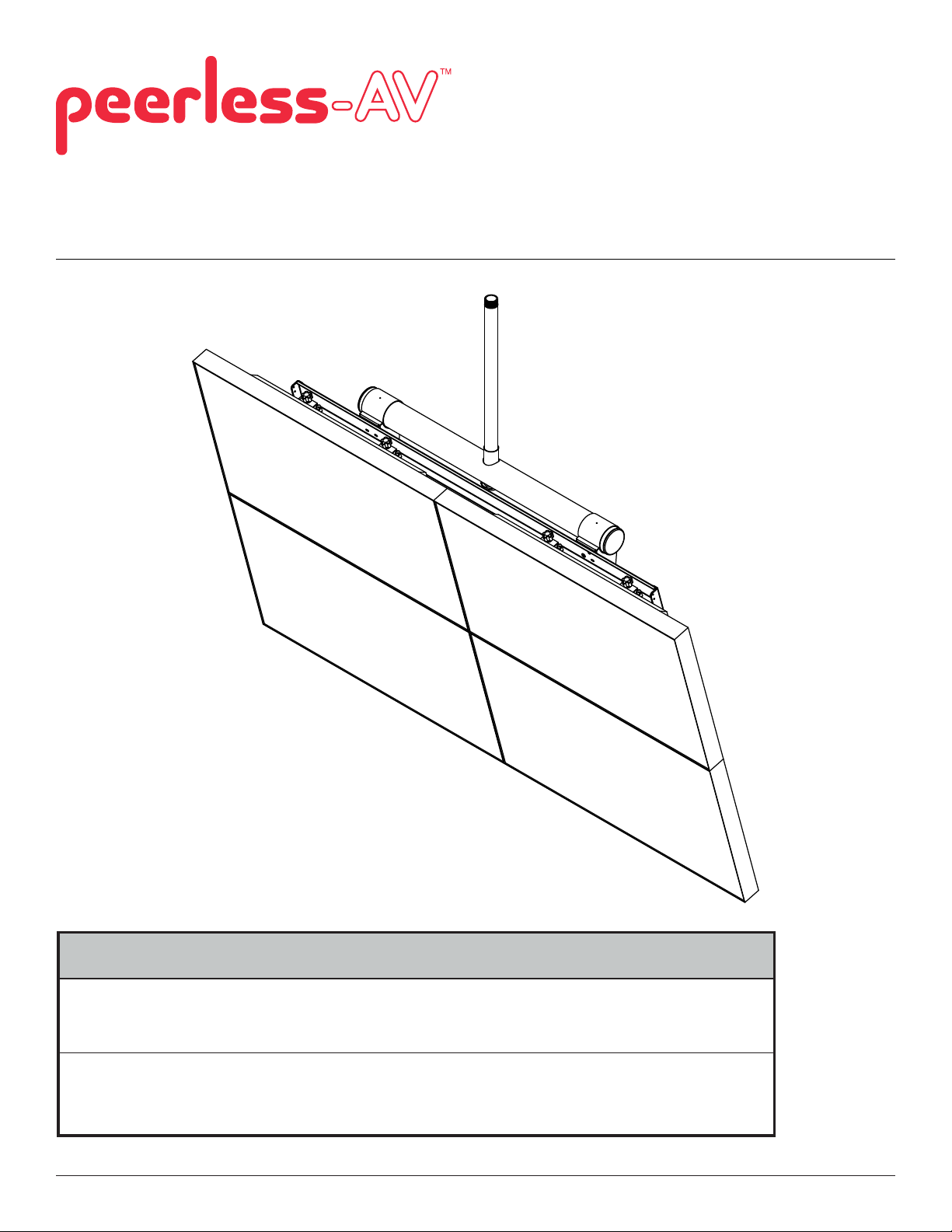

Installation and Assembly:

2 x 2 Video Wall Ceiling Mount for 40" - 55"

at Panel Displays

Model: DS-VWT955-2X2

EXTENSION COLUMN

(SOLD SEPARATELY)

COMPATIBILITY

Display width must be a minimum of 36"

Display height must be a minimum of 20.875"

Screen width + horizontal mounting hole pattern must be less than 1745mm

For 200 mm vertical mounting patterns, screen height + mounting hole pattern must be ≤ 890 mm

For 300 mm vertical mounting patterns, screen height + mounting hole pattern must be ≤ 990 mm

For 400 mm vertical mounting patterns, screen height + mounting hole pattern must be ≤ 1090 mm

Maximum Load Capacity: 300 lb (136 kg)

1 of 8

SHEET #: 125-9278-5 09-19-12

Page 2

A

r

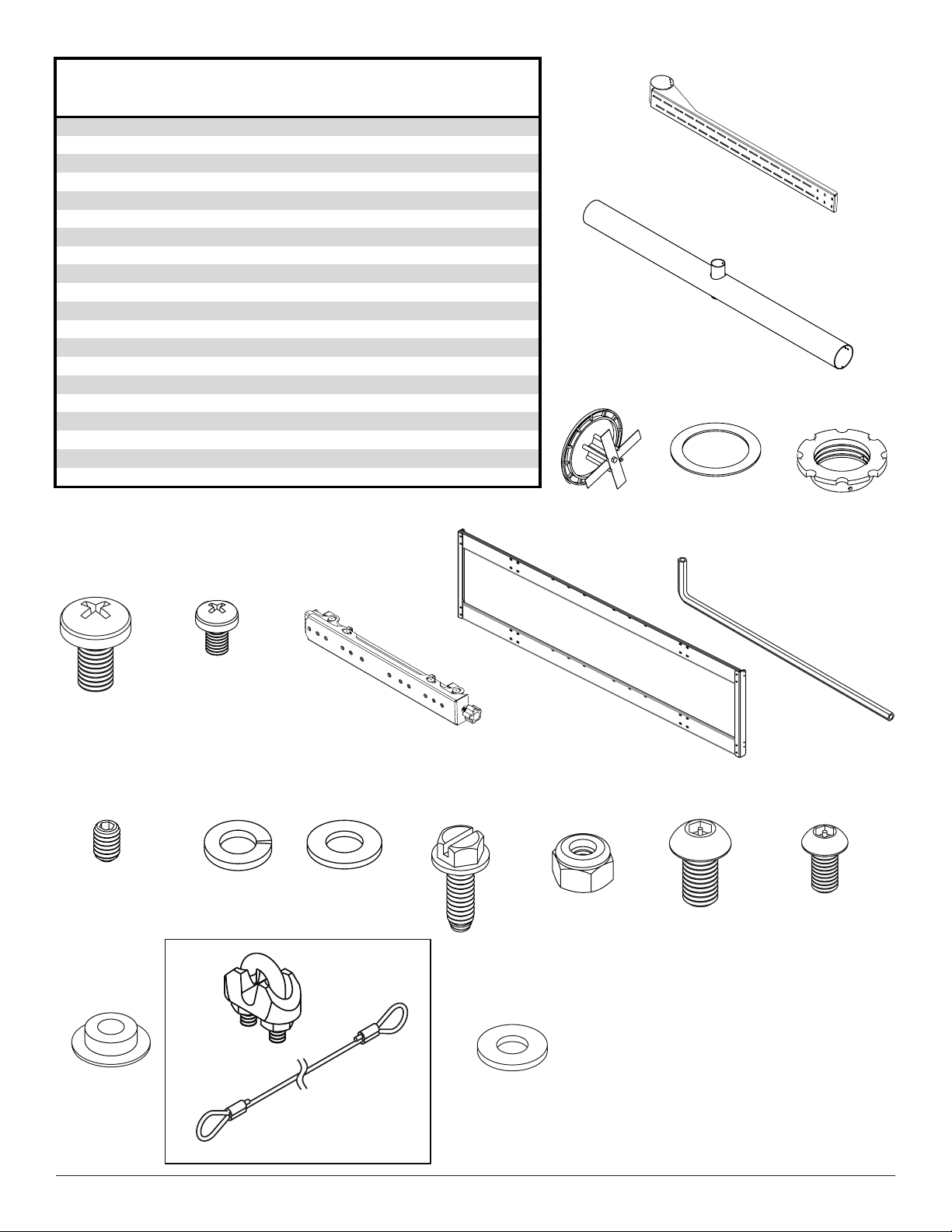

Parts List

Description Qty. Part #

tilt bracket 2 145-1710

cross support tube 1 145-1708

B

end cap 2 590-1333

C

fiber washer 1 540-9432

D

retaining collar 1 1800-375

E

M8 x 16 mm phillips screw 4 520-9257

F

M5 x 8 mm phillips screw 3 570-0005

G

adapter bracket 8 145-1711

H

adapter support 2 145-1238

I

4 mm allen wrench 1 560-9646

J

M6 x 6 mm set screw 2 510-9150

K

5/16 split washer 4 540-9405

L

5/16 flat washer 4 540-9406

M

1/4-20 x 3/4 hex head type-F screw

N

1/4-20 nylock nut

O

M8 x 15 mm socket pin screw 16 520-1068

P

M6 x 12 mm socket pin screw 16 520-1050

Q

shoulder washer 16 590-2233

R

safety cable assembly 1 130-8012

S

1/4" washe

T

Parts may appear slightly different than illustrated.

16 520-1321

16 530-9413

16 540-9440

A

B

C D

E

F G H I J

K L M N O P Q

R

S

T

2 of 8

SHEET #: 125-9278-5 09-19-12

Page 3

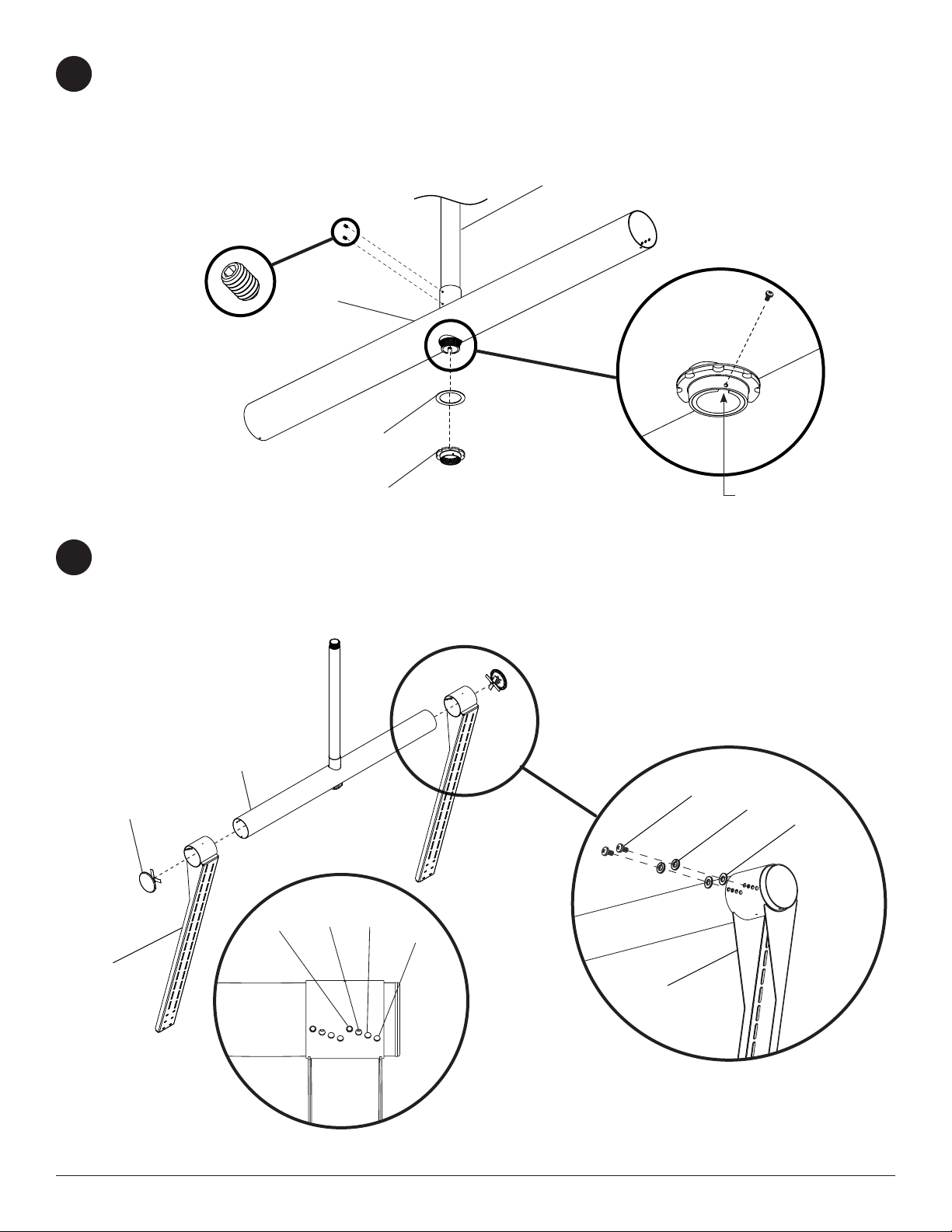

Secure extension column (sold separately) to cross support (B) using retaining collar (E), ber washer (D), and

1

one M5 x 8 mm phillips screw (G). Restrict swivel using two M6 x 6 mm set screws (K).

NOTE: Make sure that M5 x 8 mm phillips screw is positioned inside of notch of extension column as shown in

detail 2.

EXTENSION COLUMN

Detail 1

Detail 2

B

G

K

D

E

Secure tilt brackets (A) to cross support tube (B) using four M8 x 16 mm phillips screws (F), four 5/16’’ split washers

2

(L), and four 5/16’’ at washers (M) in desired tilt position as shown in Detail 3 and 4. Once tilt is established secure

two end caps (C) to cross support tube (B).

EXTENSION

COLUMN NOTCH

A

C

B

5°

10° 15°

Detail 3

20°

3 of 8

A

F

L

M

Detail 4

SHEET #: 125-9278-5 09-19-12

Page 4

Secure two M5 x 8 mm phillips screws (G) to ends of cross support tubes (B) as shown in detail 5.

3

B

G

Detail 5

Attaching Adapter Brackets to Display

NOTE: Make sure to use largest hole pattern on back of display.

4

Attach adapter brackets (H) to back of display using four M6 x 12 mm socket pin screws (Q) or four M8 x 15 mm

socket pin screws (P). The M6 x 12 mm socket pin screws (Q) require nylon shoulder washers (R) as shown

below.

200 mm MIN

600 mm MAX

P or Q

R

USED WITH

M6 (Q)

200 mm

DISPLAY

PLP PLATE

400 mm

300 mm

H

FIGURE 4.1 FIGURE 4.2

4 of 8

SHEET #: 125-9278-5 09-19-12

Page 5

Determine position of horizontal rails (I) using the formula below.

5

1. Locate the position of the lower horizontal rail (I) and attach to tilt brackets (A).

2. Use display height to determine location of upper horizontal rail (I),

NOTE: Lowest horizontal rail (D) position shown below.

NOTE: Horizontal rails (D) must be secured using sixteen 1/4-20 hex head type-F screws (N, step 6).

UPPER HORIZONTAL RAIL

x

DISTANCE

EQUALS

DISPLAY

HEIGHT

LOWER HORIZONTAL RAIL

Attach adapter supports (I) to tilt brackets (A) using sixteen 1/4-20 hex head type-F screws (N) with sixteen

6

1/4’’ washers (T), and sixteen 1/4-20 nylock nuts (O) in a diagonal pattern as shown below.

DISPLAY

HEIGHT

FRONT

5 of 8

O

U

N

Detail 6

Detail 7

SHEET #: 125-9278-5 09-19-12

Page 6

Feed safety cable through extension column (sold separately). Run cable out of the bottom of the

7

extension column (sold separately) and through openings in adapter supports (I) as shown below.

Pull safety cable taught and secure using u-bolt to fasten the looped end to the cable as shown in detail 7.

Wrap excess cable around the extension column (sold separately).

SAFETY CABLE

CLAMP

U-BOLT

SAFETY CABLE

CLAMP NUT

Detail 8

I

6 of 8

SHEET #: 125-9278-5 09-19-12

Page 7

Hook adapter brackets (H) with displays onto adapter supports (I) as shown.

8

Loosely fasten in place using security screw as shown in detail 10.

DISPLAY NOT SHOWN

FOR CLARITY

I

Detail 9

I

H

H

SECURITY SCREW

Detail 10

Adapter Bracket Adjustment

Adapter brackets (H) can be adjusted horizontally as shown. Once adapter brackets (H) are in desired position

9

secure using 4mm allen wrench (K) to lock in place.

7 of 8

SHEET #: 125-9278-5 09-19-12

Page 8

Adapter Bracket Adjustment

Use legend below to determine position of display.

10

NOTE: Each knob can be adjusted independently for ne tuning angle adjustments.

Turn knobs CLOCKWISE to raise display height. Turn knobs CLOCKWISE to push out display.

Turn knobs COUNTER-CLOCKWISE to lower display height. Turn knob COUNTER-CLOCKWISE to pull in display.

UP DOWN IN OUT

KNOB

KNOB

8 of 8

SHEET #: 125-9278-5 09-19-12

Loading...

Loading...