Page 1

Installation and Assembly - Support Column's

for Flat Panel Pedestal Mounts

IMPORT ANT! Read entire instruction sheet before you start installation and assembly .

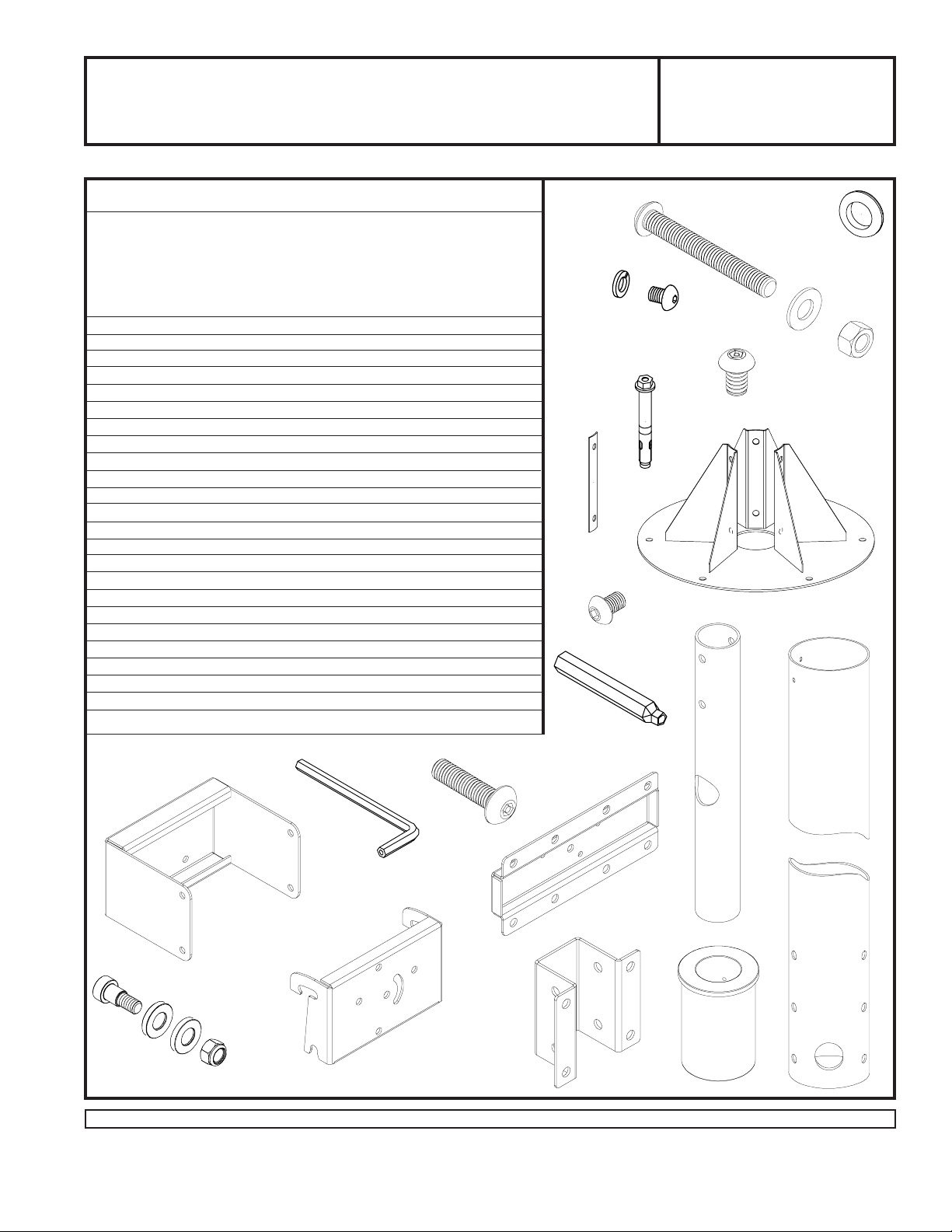

PARTS LIST

Parts List

PART # QTY. DESCRIPTION

A 200-1106 1 support column (model COL 510P only)

200-1107 (model COL 610P only)

200-1108 (model COL 710P only)

200-1109 (model COL 810P only)

B 120-0041 1 base plate

C 1390-472 3 fastener plate

D 5S1-M10-A20 6 M10-1.5 x 20 mm socket head screw

E 540-9424 6 lock washer

F 540-9407 14 flat washer

G 530-9401 2 rubber grommet

H 5M9-381-H03 6 concrete expansion anchor

I 560-9646 1 4 mm security allen wrench

J 200-1096 1 tilt bracket

K 200-1095 1 tube support

L 200-1094 1 adapter mount

M 200-1093 1 swivel bracket

N 200-1517 1 neck tube

O 590-1111 1 column bushing

P 520-9263 16 M10 x 1.5 x 15 mm penta pin screw

Q 530-9310 2 3/8 x 16 nylock nut

R 520-1015 2 3/8 x 16 x 3" socket screw bolt

T 520-1065 2 M5 x .8 x 20 mm socket pin screw

U 520-9260 1 M10 penta pin tool

V 520-9525 3 M8 x 1.25 x 12 mm socket head screw

W 530-9306 1 5/16-18 nylock nut

X 500-1082 1 5/16-18 x 3/8 shoulder bolt screw

Y 540-9454 2 3/8 x 3/4 x 1/8 flat washer

Some parts may appear slightly different than illustrated.

E

C

V

U

Models:COL 510P, COL 610P,

COL 710P, COL 810P

R

G

D

P

H

B

F

Q

A

T

I

L

N

J

X

YW

Before you start make sure all parts listed are included with your product.

Visit the Peerless Web Site at www.peerlessindustries.com For customer service call 1-800-729-0307 or 708-865-8870.

M

1 of 6

K

ISSUED: 11-24-99 SHEET #: 200-9192-2 07-23-04

O

Page 2

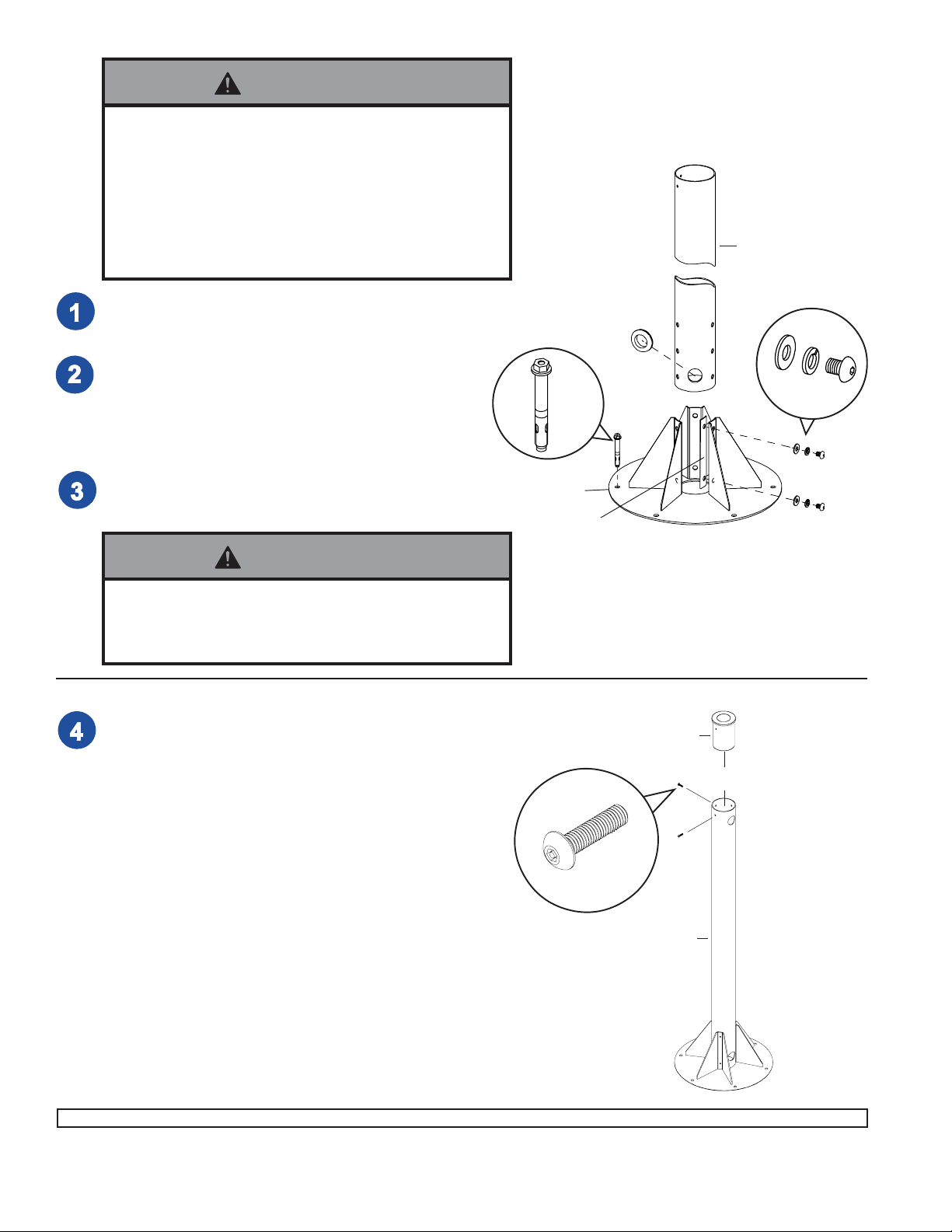

WARNING

• Flat panel weight is restricted to a maximum of 150 lb

(68 kg). Interfacing flat panel into electrical system at

installation site must conform to local electrical codes

governing such installations and be done by a qualified

electrician / electrical contractor.

• Installer must verify that mounting surface will safely

support the combined weight of all attached equipment

and hardware.

Insert rubber grommet (G) into hole in bottom of support

column (A).

At all three support legs attach support column (A) to base

plate (B) using fastener plates (C), M10-1.5 x 20 mm

socket head screws (D), lock washers (E), and flat

washers (F). Note: Leave screws slightly loose until all are

attached, then tighten all screws securely.

Attach base plate (B) to concrete floor. Use six Rawl-Bolt

concrete expansion anchors (H). Drill 3/8" dia. holes to a

minimum depth of 2".

H

B

C

G

A

F

E

D

WARNING

• For attachment to concrete floor only! All six concrete

expansion anchors must be used.

• Tighten to 420 IN • LB (47.6 N.M.) torque.

Attach column bushing (O) to support column (A) using two

screws (T). The screws control swivel action, so do not

tighten until product is fully assembled and flat panel is in

viewing position.

O

T

A

2 of 6

Visit the Peerless Web Site at www.peerlessindustries.com For customer service call 1-800-729-0307 or 708-865-8870.

ISSUED: 11-24-99 SHEET #: 200-9192-2 07-23-04

Page 3

Attach tilt bracket (J) to tube support (K)

with four screws (P) using penta pin

tool (U).

Insert four screws and washers (P & F)

into tilt bracket (J). Do not fully tighten.

Leave 1/4" of exposed thread between

tilt bracket (J) and washers (F).

K

P

J

1/4" EXPOSED

THREAD

F

P

Attach tube support (K) to neck

tube (N) using two screw bolts

(R), nuts (Q), and washers (F)

as shown. Insert rubber

grommet (G) into neck tube (N).

R

F

K

F

Q

N

G

3 of 6

Visit the Peerless Web Site at www.peerlessindustries.com For customer service call 1-800-729-0307 or 708-865-8870.

ISSUED: 11-24-99 SHEET #: 200-9192-2 07-23-04

Page 4

Attach adapter mount (L) to adapter bracket (purchased separately and may

appear different than illustrated) with eight screws (P) shown right. Attach

swivel bracket (M) to adapter mount (L) using shoulder bolt (X), washers (Y),

and nut (W) as shown below.

FOR HORIZONTAL MOUNT: secure with three screws (V) shown below left.

FOR VERTICAL MOUNT: secure with three screws (V) shown below right.

W

Y

ADAPTER

BRACKET

L

P

Y

L

M

X

SLOT

V

V

4 of 6

Visit the Peerless Web Site at www.peerlessindustries.com For customer service call 1-800-729-0307 or 708-865-8870.

ISSUED: 11-24-99 SHEET #: 200-9192-2 07-23-04

Page 5

Hook swivel bracket (M) onto tilt bracket (J). Adjust tilt

(0° to 15°) and tighten screws (P) using penta pin

tool (U).

Adjust swivel and tighten two screws (T) securing

neck tube (N).

360° SWIVEL

ADAPTER BRACKET AND FLAT

PANEL MAY APPEAR SLIGHTLY

DIFFERENT THAN ILLUSTRATED.

M

P

J

N

T

5 of 6

Visit the Peerless Web Site at www.peerlessindustries.com For customer service call 1-800-729-0307 or 708-865-8870.

ISSUED: 11-24-99 SHEET #: 200-9192-2 07-23-04

Page 6

OPTIONAL: To rotate flat panel 90° without detaching

swivel bracket (M), follow detail one through detail three.

REMOVE TWO

SCREWS (V).

LOOSEN

SCREW (V).

DETAIL 1

ROTATE MONITOR

90° AND TIGHTEN

SCREW (V).

M

DETAIL 2

DETAIL 3

INSERT AND

TIGHTEN TWO

SCREWS (V).

6 of 6

Visit the Peerless Web Site at www.peerlessindustries.com For customer service call 1-800-729-0307 or 708-865-8870.

© 2004 Peerless Industries, Inc. All rights reserved.

Peerless is a registered trademark of Peerless Industries, Inc.

All other brand and product names are trademarks or registered trademarks of their respective owners.

ISSUED: 11-24-99 SHEET #: 200-9192-2 07-23-04

Loading...

Loading...