Page 1

Installation and Assembly -

Metal Stud Accessory Kit for

LCL, LCS, and LCA Models

Model: ACC 908

Read instruction sheet before you start installation and assembly.

Before you start check the parts list to insure all of the parts shown are included.

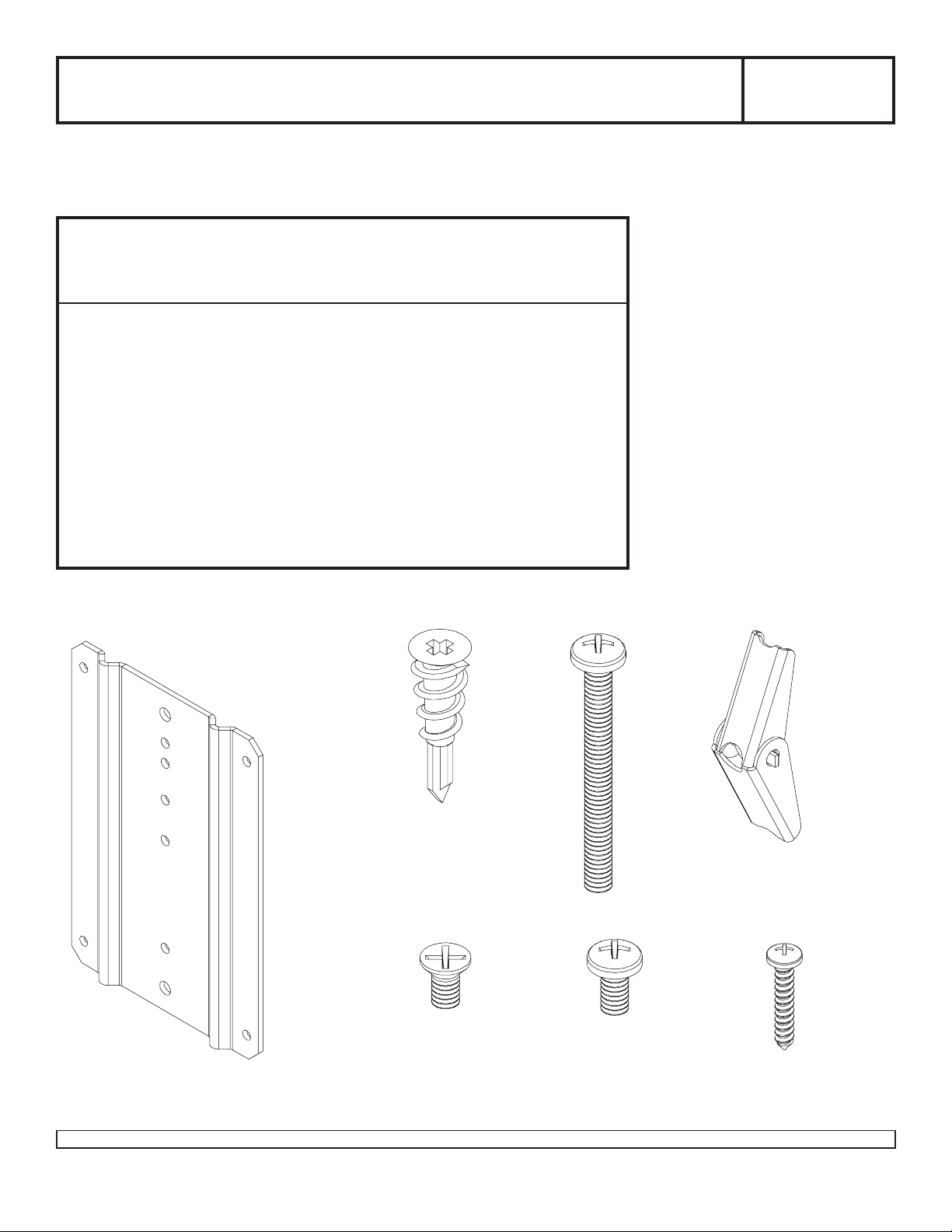

Parts List

Description Qty . Part Number

A metal stud wall plate 1 095-4173

B zip-it drywall anchor 4 590-2107

C 1/4-20 x 2.5" round head phillips screw 2 520-9522

D 1/4-20 toggler 2 590-1093

E 1/4-20 x 1/2" flat head phillips screw 2 520-2178

F 1/4-20 x 1/2" pan head phillips screw 2 520-951 1

G #8 x 1" pan head phillips sheet metal screw 4 520-2179

Note: Some parts may appear slightly different than illustrated.

Maximum Load Capacity:

25 lb (11.4 kg)

A

Visit the Peerless Web Site at www.peerlessindustries.com

B

D

C

E

F

G

1 of 5 ISSUED: 04-28-03 SHEET #: 095-9161-3 08-16-04

For customer service call 1-800-729-0307 or 708-865-8870.

Page 2

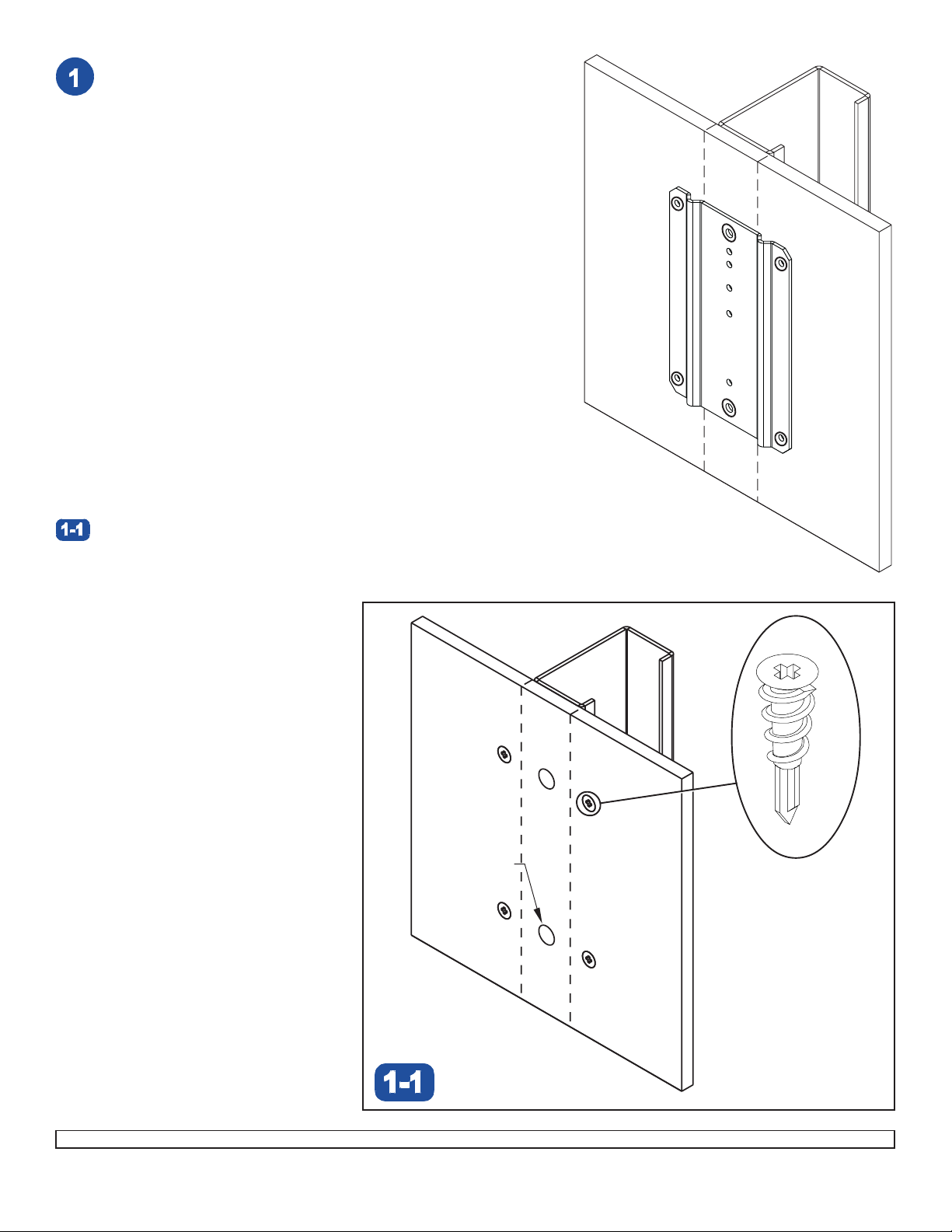

Use stud finder to locate center of metal stud. Place and level

metal stud wall plate (A) on wall and mark the centers of the

six circled holes on the wall as shown right.

DRYWALL

A

MET AL

STUD

Drill two 11/16" (17 mm) dia. holes through

stud. Screw four zip-it drywall anchors (B) in the four marked

corner holes as shown below .

center of metal

11/16" dia. hole

(2 plcs.)

B

Visit the Peerless Web Site at www.peerlessindustries.com

2 of 5 ISSUED: 04-28-03 SHEET #: 095-9161-3 08-16-04

For customer service call 1-800-729-0307 or 708-865-8870.

Page 3

Attach metal stud wall plate (A) to center of metal

stud using two 1/4-20 x 2.5" phillips screws (C) and

two 1/4-20 togglers (D) as shown below and in

Illustration A, but do not tighten until after the metal

stud wall plate (A) is securely fastened in step 3.

WARNING

• Product must be mounted through drywall that has a

minimum thickness of 1/2" and into metal studs, 26

gauge or heavier.

ILLUSTRATION A

C

A

Place screw (C) through

Partially fasten toggler (D) to back of screw. Pivot

toggler ends 90° and push through hole in drywall.

DRYWALL

D

DRYWALL

metal stud wall plate (A).

METAL STUD

C

D

C

Fasten metal stud wall plate (A) using four #8 x 1"

phillips sheet metal screws (G) as shown. Securely

tighten two 1/4-20 x 2.5" phillips screws (C).

A

Pull screw (C) back until toggler (D) is flush with

metal stud and hold. Thread screw through with

fingers and loosely tighten.

D

Visit the Peerless Web Site at www.peerlessindustries.com

C

A

G

3 of 5 ISSUED: 04-28-03 SHEET #: 095-9161-3 08-16-04

For customer service call 1-800-729-0307 or 708-865-8870.

Page 4

Instructions for mounting a Peerless® LCD screen mount model

LCS or LCL (articulating wall ar m) with a 5 1/2" wall plate

Attach wall plate to metal stud wall plate (A) using two 1/4-20 x 1/2" flat

head phillips screws (E) where indicated right and marked in detail 1.

TOP OF WALL PLATE

WALL

PLATE

A

A

CUTAWAY

OF LCL/LCS

MODEL

E

DETAIL 1

(FRONT VIEW)

Instructions for mounting a Peerless® LCD screen mount model

LCS or LCL (articulating wall ar m) with a 4 1/4" wall plate

Attach wall plate to metal stud wall plate (A) using two 1/4-20 x 1/2” flat

head phillips screws (E) where indicated right and marked in detail 2.

TOP OF WALL PLATE

WALL

PLATE

CUTAWAY

A

OF LCL/LCS

MODEL

A

DETAIL 2

(FRONT VIEW)

Visit the Peerless Web Site at www.peerlessindustries.com

E

4 of 5 ISSUED: 04-28-03 SHEET #: 095-9161-3 08-16-04

For customer service call 1-800-729-0307 or 708-865-8870.

Page 5

Instructions for mounting a Peerless LCD

screen mount model LCA Large (swing ar m)

Attach wall plate to metal stud wall plate (A) using two 1/4-20 x 1/2" pan head

phillips screws (F) where indicated right and marked in detail 3.

TOP OF WALL PLATE

WALL

PLATE

CUTAWAY OF LCA

LARGE MODEL

A

F

DETAIL 3

(FRONT VIEW)

Instructions for mounting a Peerless LCD screen

mount model LCA Small or Medium (swing arm)

Attach wall plate to metal stud wall plate (A) using two 1/4-20 x 1/2" pan head

phillips screws (F) where indicated right and marked in detail 4.

TOP OF WALL PLATE

A

A

CUTAWAY OF LCA

SMALL MODEL

DETAIL 4

(FRONT VIEW)

5 of 5 ISSUED: 04-28-03 SHEET #: 095-9161-3 08-16-04

Visit the Peerless Web Site at www.peerlessindustries.com

© 2004 Peerless Industries, Inc. All rights reserved.

Peerless is a registered trademarks of Peerless Industries, Inc.

All other brand and product names are trademarks or registered trademarks of their respective owners.

WALL

PLATE

A

F

For customer service call 1-800-729-0307 or 708-865-8870.

Loading...

Loading...