PEERLESS SERIES 62, 61 Series, 61-03, 61-04, 61-05 Installation, Operation & Maintenance Manual

...Page 1

61/62

Boilers

Installation,

Operation Et

Maintenance

Manual

Page 2

3-8 90,0 Up to 81.7% AFUE

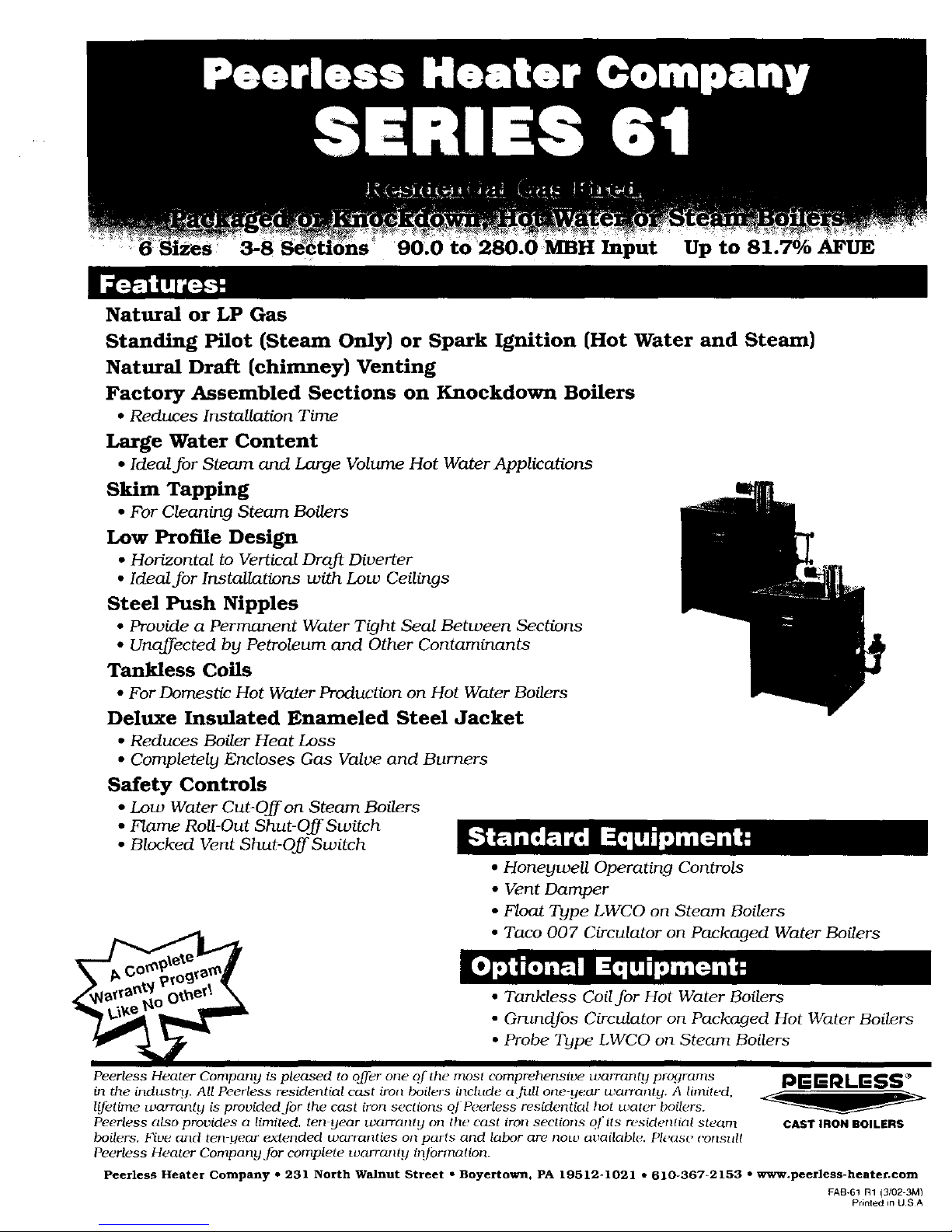

Natural or LP Gas

Standing Pilot (Steam Only) or Spark Ignition (Hot Water and Steam)

Natural Draft (chimney) Venting

Factory Assembled Sections on Knockdown Boilers

• Reduces Installation Time

Large Water Content

• Ideal for Steam and Large Volume Hot Water Applications

Skim Tapping

• For Cleaning Steam Boilers

Low Profile Design

• Horizontal to Vertical Draft Diverter

• Ideal for Installations with Low Ceilings

Steel Push Nipples

• Provide a Permanent Water Tight Seal Between Sections

• Unaffected by Petroleum and Other Contaminants

Tankless Coils

• For Domestic Hot Water Production on Hot Water Boilers

Deluxe Insulated Enameled Steel Jacket

• Reduces Boiler Heat Loss

• Completely Encloses Gas Valve and Burners

Safety Controls

• Low Water Cut-Offon Steam Boilers

• Flame Roll-Out Shut-OffSwitch

• Blocked Vent Shut-OffSwitch

• Honeywell Operating Controls

• Vent Damper

• Float Type LWCO on Steam Boilers

• Taco 007 Circulator on Packaged Water Boilers

• Tankless Coil for Hot Water Boilers

• Gnmdfos Circulator on Packaged Hot Water Boilers

• Probe Type LWCO on Steam Boilers

Peerless Heater Comparly is pleased to offer one of the most comprehensive warranty programs

icl tile indnstn 1, All Peerless residential cast troll _x_ilers include a fidl one-yea" warranty. A limited.

lifetone warranty is provided.for the cast iron sections ol Peerless residential hot water boilers.

Peerless also provides a limited, ten year warranty ot_ the cast iron sections of its residential steam

boilers. Five and ten year extended warratlties on parts and labor are now available. Pl_'asc consult

Peerl_,ss Heater Company for complete warranty inJbrmation.

PGGRLESS _

CAST IRON BOILERS

Peerless Heater Company * 231 North Walnut Street • Boyertown, PA 19512-1021 • 610-3S7-2153 * www.peerless-heater.eom

FAB-61 R1 (3/02 3M)

Printed in US A

Page 3

pr=-I RLESS o

CAST IRON BOILERS

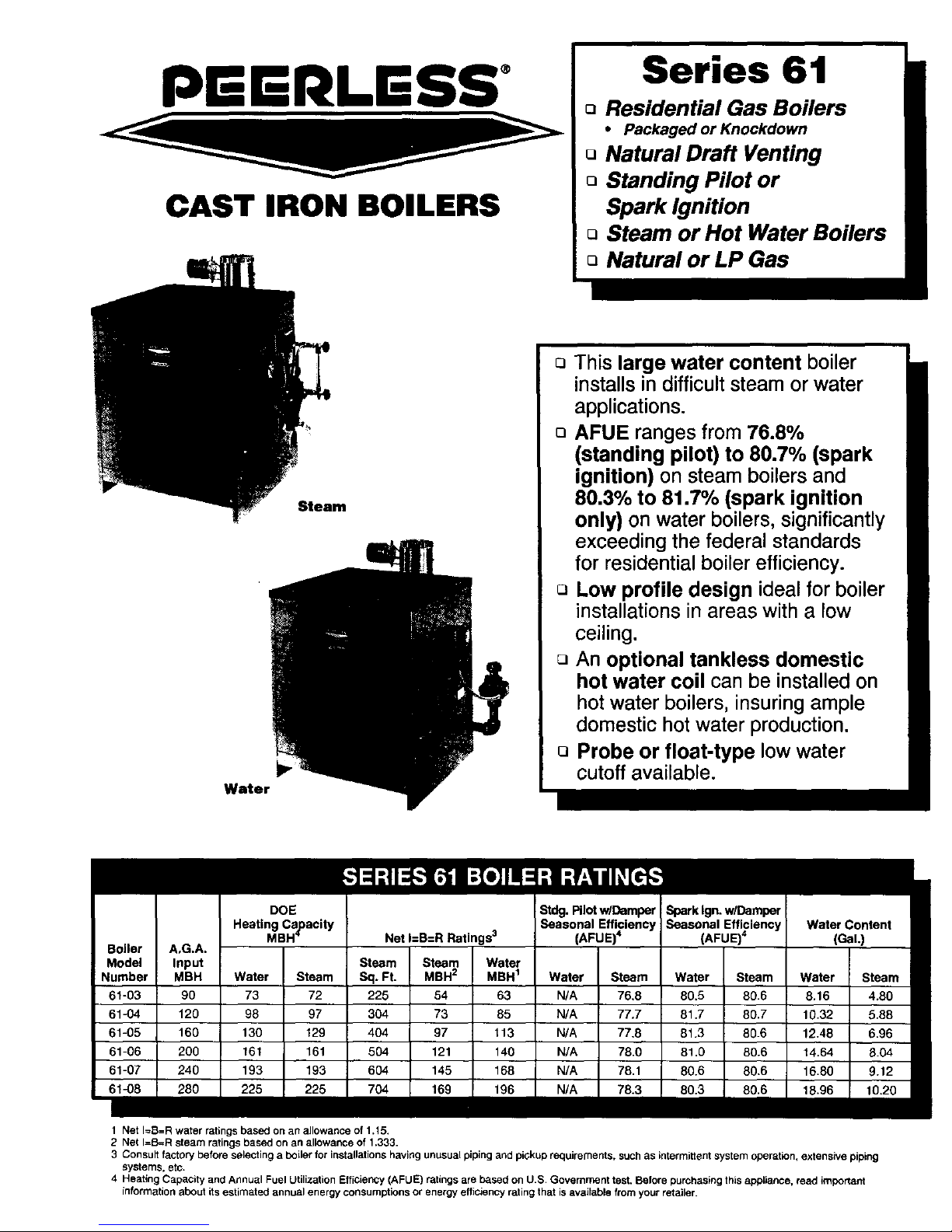

Series 61

o Residential Gas Boilers

• Packaged or Knockdown

o Natural Draft Venting

o Standing Pilot or

Spark Ignition

Q Steam or Hot Water Boilers

o Natural or LP Gas

Water

Steam

Q This large water content boiler

installsindifficultsteam or water

applications.

o AFUE ranges from 76.8%

(standing pilot) to 80.7% (spark

ignition) on steam boilers and

80,3% to 81.7% (spark ignition

only) on water boilers, significantly

exceeding the federal standards

for residential boiler efficiency.

o Low profile design ideal for boiler

installationsin areas with a low

ceiling.

An optional tankless domestic

hot water coil can be installed on

hotwater boilers, insuringample

domestichotwater production.

o Probe or float-type lowwater

cutoff available.

DOE

Heating Capacity

MBH--

Stdg.PilotwlDamper

Seasonal Efficiency

(AFUE)4

Net I=B=R Ratings 3

Steam Steam Water

Sq. Ft. MBH 2 MBH 1

225 54 63

304 73 85

4O4 97 113

504 121 140

604 145 168

704 169 196

Spark Ign. wlDamper

Seasonal Efficiency

(AFUE) 4

Water Content

(GaL)

I A,G.A.

I Input

N MBH Water Steam Water I Steam Water I Steam Water Steam

90 73 72 N/A I 76.8 80.5 I 80.6 8.16 4.80

120 98 97 N/A I 77.7 81.7 I 80.7 10.32 5.88

160 130 129 N/A I 77,8 81.3 I 80.6 12.48 6.96

200 I 161 161 N/A I 78.0 81.0 I 80.6 14.64 8.04

240 193 193 N/A I 78.1 80.6 I 80.6 16.80 9.12

280 225 225 N/A I 78.3 80.3 I 80.6 18.96 18.20

1 Net I=B=R water ratings based on an allowance of 1.15,

2 Net I=B=R steam ratings based on an allowance of 1.333.

3 Consult factory before selecting a boiler for installations having unusual piping and pickup requirements, such as intermittent system operation, extensive piping

systems, etc.

4 Heating Capacity and Annual Fuel Utilization Efficiency (AFUE) ratings are based on U.S. Government test. Before purchasing this appliance, read important

information about its estimated annual energy consumptions or energy efficiency rating that is available from your retailer.

Page 4

7 Sizes 9-15 Sections

320 to 560 MBH Input 80% Combustion Efficiency

Natural or LP Gas

Standing Pilot or Spark Ignition

Natural Draft (chimney) Venting

Factory Assembled Sp/it Block Sections on Knockdown Boilers

• For Ease of Handling

Large Water Content

• Ideal for Steam and Large Volume Hot Water Jobs

Skim Tapping

• For Cleaning Steam Boilers

Low Profile Design

• Horizontal to Vertical Draft Diverter

• Idealfor Installatiolis with Low Ceilings

Steel Push Nipples

• Provide a Permal_ent Water Tight Seal Between S_ctioris

• Unaffected by Petroleum arid Other Cor_tamiTlalltS

Tankless Coils

• For Domestic Hot Water Production o_ Hot Water Boilers

Deluxe Insulated Enameled Steel Jacket

• Reduces Boiler Heat Loss

• Completely Encloses Gas Valve and Burners

Safety Controls

• Low Water Ctlt Q[l'orl Steam Boil_'rs

• HoT_eywell Operating Co_ltrols

• Mar_ltal Reset High Limit Corltrol (12-15 Section)

• Float Type LWCO orl Steam Boilers

• Tcxl_lcless Coiljor Hol Watcr Boilers

• Moclultxtillg Fi1_rlg Systems (12 15 S<:cliorl}

• F_'I _rid IRI Colltrol S!]slerTls (12 15 Sectioll)

• Prot)t> "I_upe I.WCO o11Sle(lfll Boilers

_ll lilt" il_(lll._lr'!]. ./Ill I_'_'r'l( '.,_.s ('ollilll_'r('i(¢l _'cl.'q/ _rt)ll I)oih>l_ _ll_'h_(l_ >(I /illl. oil(' ! (>_'lr" tl,_ls't(_ll[ 1. A

lilliilt>(I. It'll !]('(1I II'_llltll_l[/ I)ll I]l(" _'tl._l il'oll ._('t'l_oll._ i.'_ [)l()l'l_ll'_ [i_t (ill ( Ollllll<'F('i_ll 11(>I I_ll('I _lll([

,'_l_>(llll I?l_il(>I'_. I+'il'( ' _lll_'l [I'll I I>tlr ('._l_'tl_l(>_l ll'_l_'ltlllll_'_ I)ll l_(It l_ (lll_l I_l!)ol (It't' /loll' ttl'(li[(l!)_('. CAST IRON BOILERS

!'lt>(_._;( ' €'otl.'_ll/I I>_'('t'l_ '.'q_ I h'_ll_'t ( "olllt)_lltt].[O_" _'Oml)lt'f_" it,t_r_t_i_l!] ir!]Oi rIl(llioll.

Peerless Heater Company • 231 North Walnut Street * Boyertown. PA 19512 1021 • 610 367-2153 - www.peerless-heater.com

FAB 6_7t9 02 :_,%

Page 5

pGr=-RLESS o

CAST IRON BOILERS

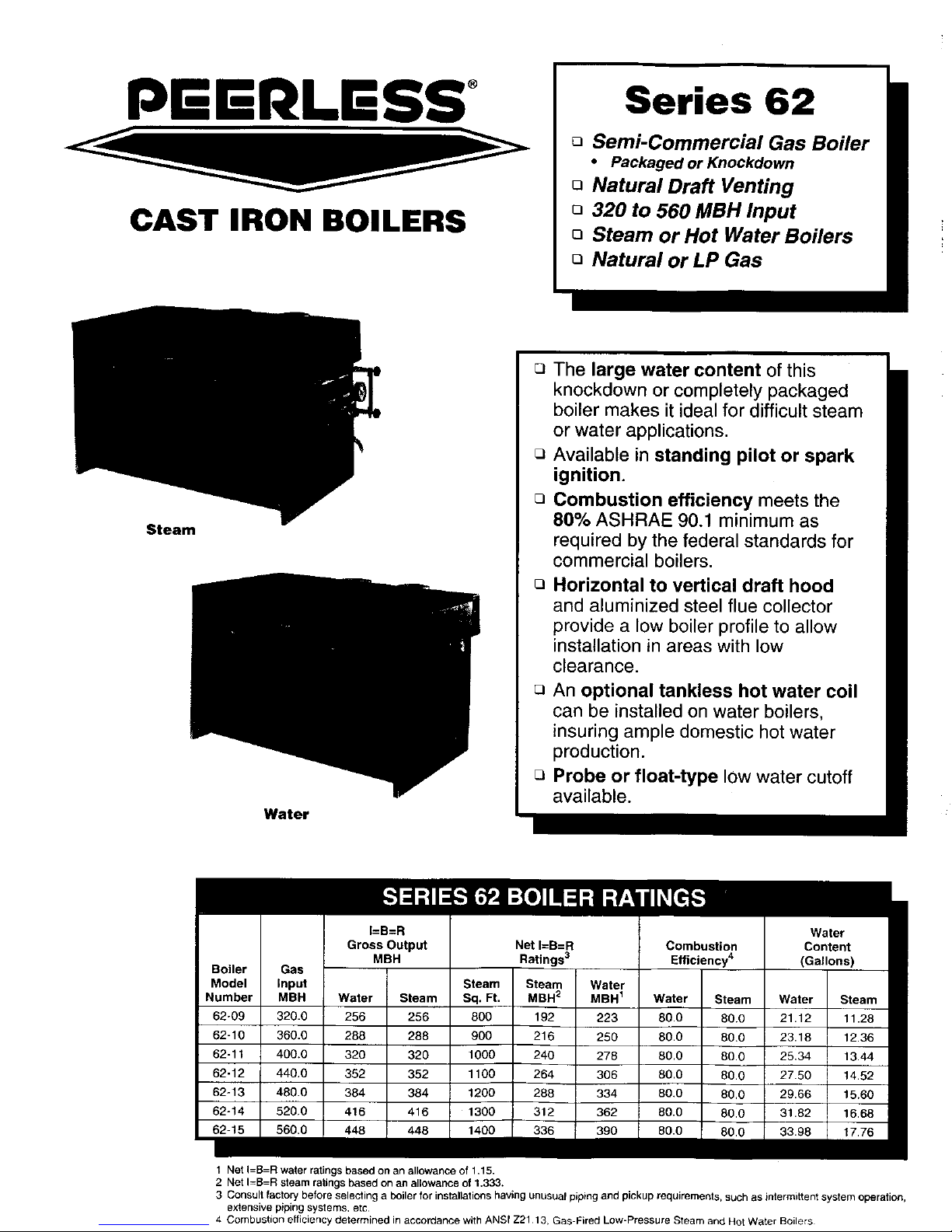

Series 62

o Semi-Commercial Gas Boiler

• Packaged or Knockdown

o Natural Draft Venting

o 320 to 560 MBH Input

o Steam or Hot Water Boilers

o Natural or LP Gas

Steam

Water

o The large water content of this

knockdown or completely packaged

boiler makes it ideal for difficult steam

or water applications.

o Available in standing pilot or spark

ignition.

o Combustion efficiency meets the

80% ASHRAE 90.1 minimum as

required by the federal standards for

commercial boilers.

O

Horizontal to vertical draft hood

and aluminized steel flue collector

provide a low boiler profile to allow

installation in areas with low

clearance.

r_ An optional tankless hot water coil

can be installed on water boilers,

insuring ample domestic hot water

production.

o Probe or float-type low water cutoff

available.

I=B=R Water

Gross Output Net I=B=R Combustion Content

MBH Ratings 3 Efficiency 4 (Gallons)

Model Input Steam Steam Water

Number MBH Water Steam Sq. Ft. MBH2 MBH 1 Water Steam Water Steam

62-09 320.0 256 256 800 192 223 80.0 80.0 21.12 11.28

62-10 360.0 288 288 900 216 250 80.0 80.0 23.18 12.36

62-11 400.0 320 320 1000 240 278 80.0 80.0 25,34 13.44

62-12 440,0 352 352 1100 264 306 80.0 80.0 27.50 14.52

62-13 480.0 384 384 1200 288 334 80.0 80.0 29.66 15.60

62o14 520.0 416 416 1300 312 362 80.0 80.0 31.82 16.68

1 Net I=B=R water ratings based on an allowance 011.15.

2 Net I=B=R steam ratings based on an allowance of 1.333.

3 Consult factory before selecting a boiler for installations having unusual piping and pickup requirements, such as intermittent system operation,

extensive piping systems, etc

4 Combustion efficiency determined in accordance with ANSf Z21 13, Gas-Fired Low-Pressure Steam and Hot Water Boilers

Page 6

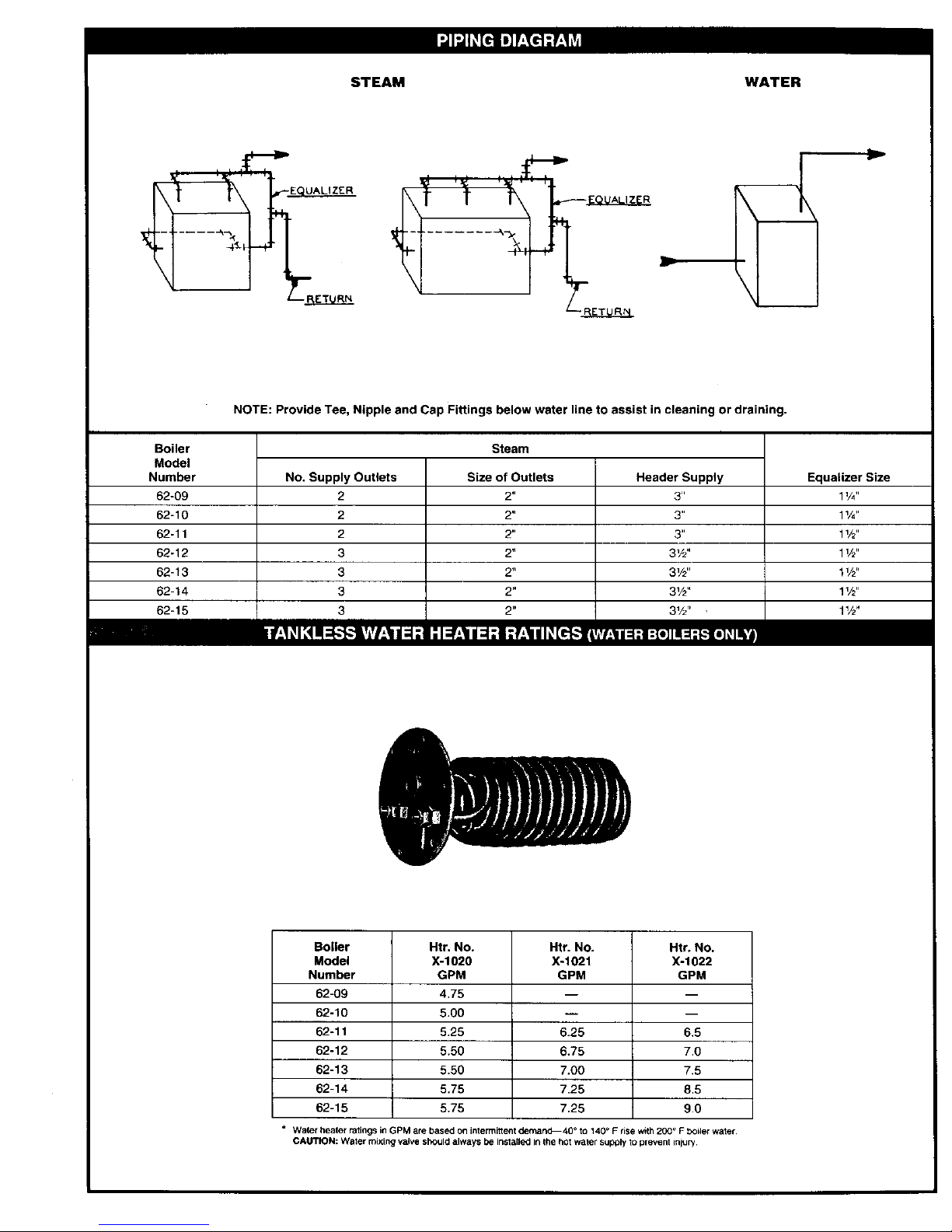

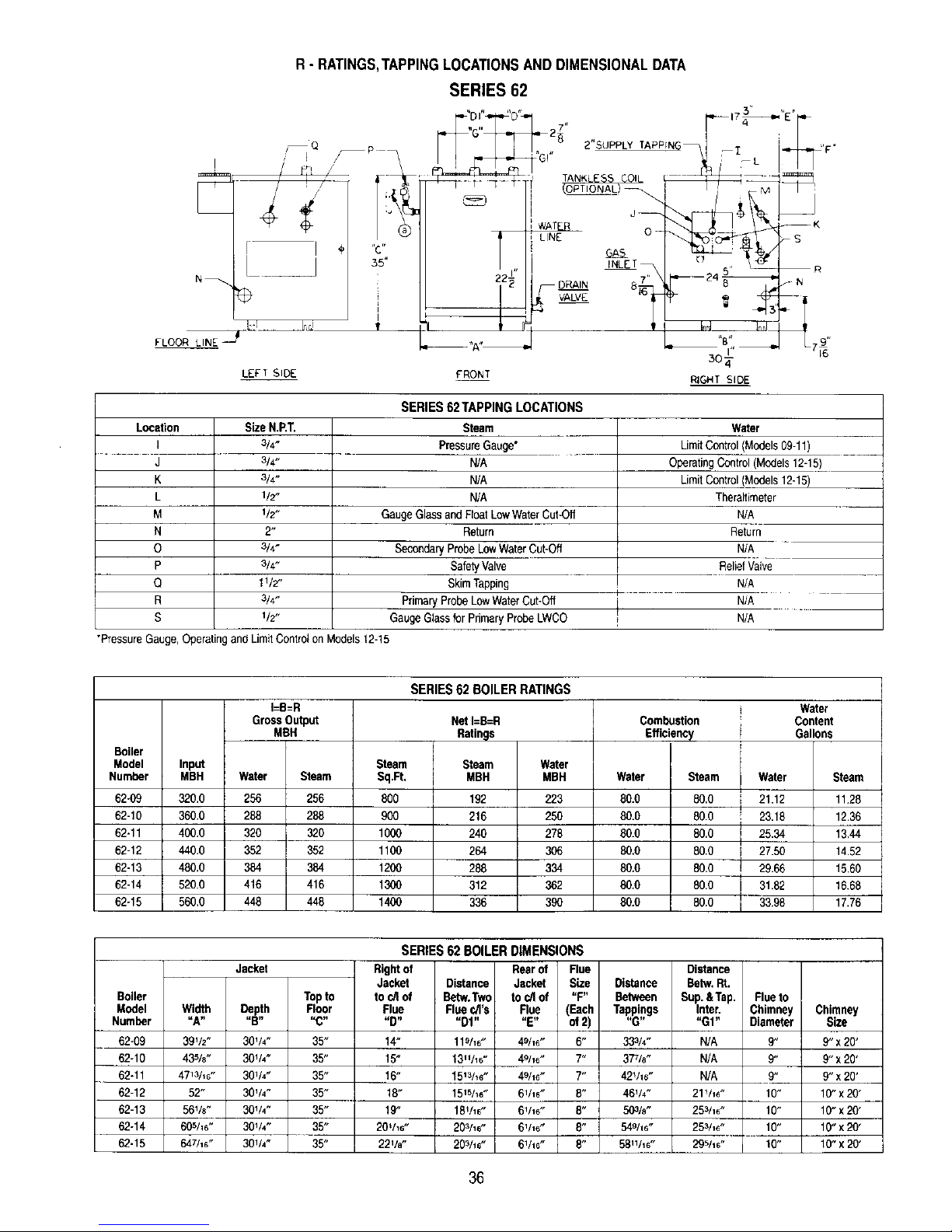

I

J

K

L

M

N

O

P

Q

R

m

Boiler

Model

Number

62-09

62-10

62-11

62-12

62-13

62-14

62-15

Steam Water

3/4" Pressure Gauge* Limit Control (Models 09-11)

3/4,, N/A Operating Control (Models 12-15)

3/4" N/A Limit Control (Models 12-15)

V2" N/A Temperature-Pressure Gauge

V2" Gauge Glass and Low Water Cutoff N/A

2" Return Return

3/4" Secondary Probe Low Water Cut-Off N/A

3/4" Safety Relief Valve Safety Relief Valve

1V2" Skim Tapping N/A

¾" Primary Probe Low Water Cut-Off N/A

3o4-

L£_'T SID_ £RON_ RIGH T SIDE

• Pressure gauge, operating control and I_mitcontrol on Models 62 12 to 62 15

Jacket Right of Distance Rear of Distance , . .

Jacketto Betw. Two Jacketto Flue Between !Rt. Sup.& C_uetOy

Width Depth Top to Fir. c/I of Flue Flue c/l's c/I of Flue Size Tappings Tap. Inter. Chimney

"A .... B.... C.... D.... D1 .... E.... F.... G.... GI"

39V2" 30V4" 35" 14" 11%#' 4%s" 2-6" 333/." N/A 9" 9" x 20'

43%" 30V4" 35" 15" 13_V_6" 4%8" 2-7" 37%" N/A 9" 9" x 20'

47_¾_' 30V4" 35" 16" 15_3/lS" 4%4' 2-7" 42V16" N/A 9" 9" x 20'

52" 30V4" 35" 18" 15_%#' 6_/_6" 2-8" 46V4" 21_/_6" 10" 10" x 20'

56Ys" 30V4" 35" 19" 18V_6" 6Vls" 2-8" 50%" 253/16" 10" 10" x 20'

60%6" 30_/4" 35" 20VI4' 20¾e" 6V_6" 2-8" 54%6" 25z/_6" 10" 10" x 20'

64W_6" 30V4" 35" 22W' 203Ae" 6%6" 2-8" 58"A_" 29s/_6" 10" 10" x 20'

Page 7

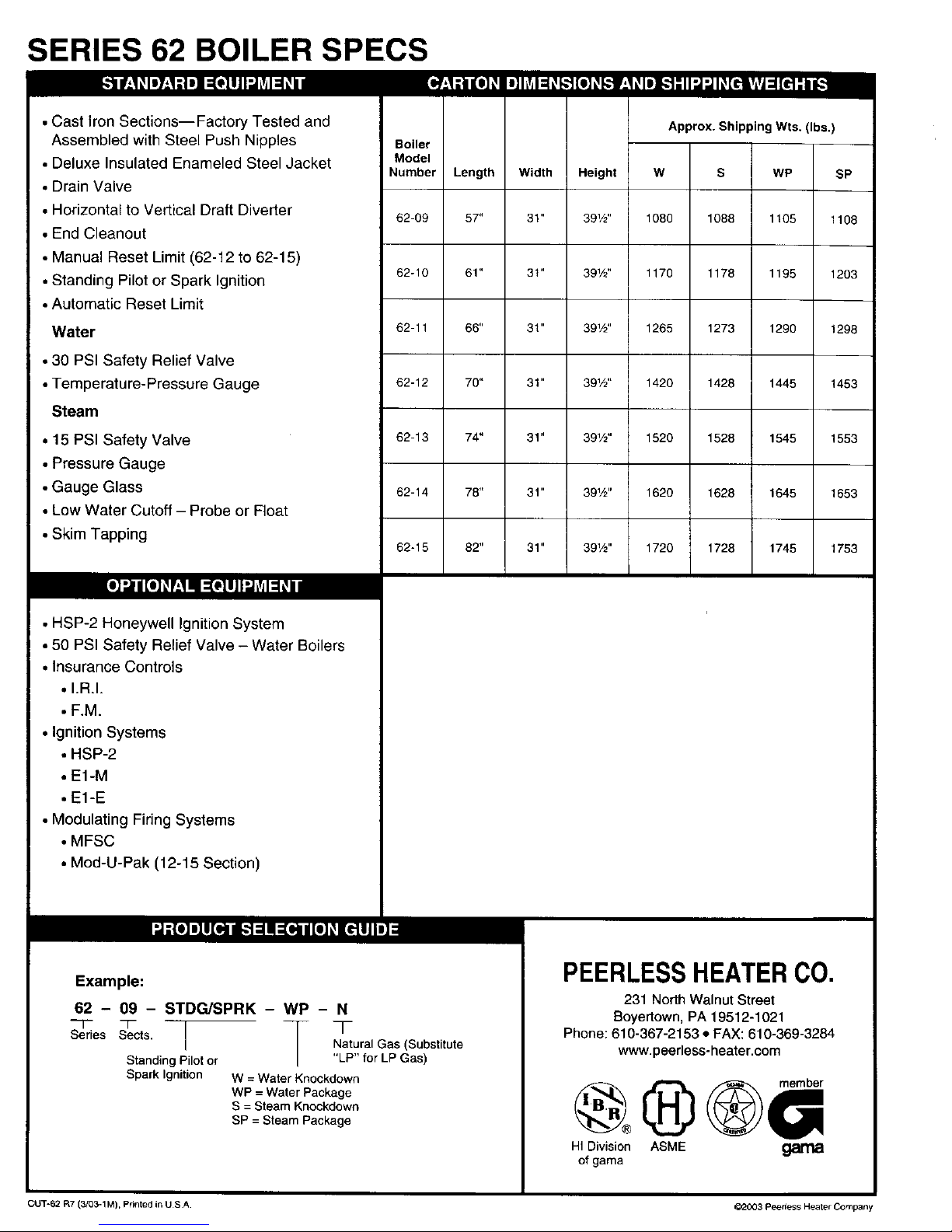

STEAM WATER

, , i

t t

"L

Boiler

Model

Number

62-09

62-10

62-11

62-12

62-13

62-14

62-15

NOTE: Provide Tee, Nipple and Cap Fittings below water line to assist in cleaning or draining.

Steam

No. Supply Outlets

2

2

2

3

3

3

3

Size of Outlets

2"

2"

2"

2"

2"

2"

Header Supply

3 _=

3"

3"

3V2"

31/2''

31/2'`

31/2" ,

Equalizer Size

1V4"

11/4"

1V2"

1V2"

1V2"

1W'

1V2"

Boiler

Model

Number

62-09

62-10

62-11

62-12

62-13

62-14

62-15

Htr. No.

X-1020

GPM

4,75

5.00

5.25

5.50

5.50

5.75

5.75

Htr. No. Htr. No.

X-1021 X-1022

GPM GPM

6.25

6.75

7.00

7.25

7.25

m

6.5

7.0

7.5

8.5

9.0

* Water healer ratings in GPM are based on intermittent demand40 ° to 140 _ F rise with 200 ° F bOiler water

CAUTION: Water mixing valve should always be installed in the hot water supply to prevent injury,

Page 8

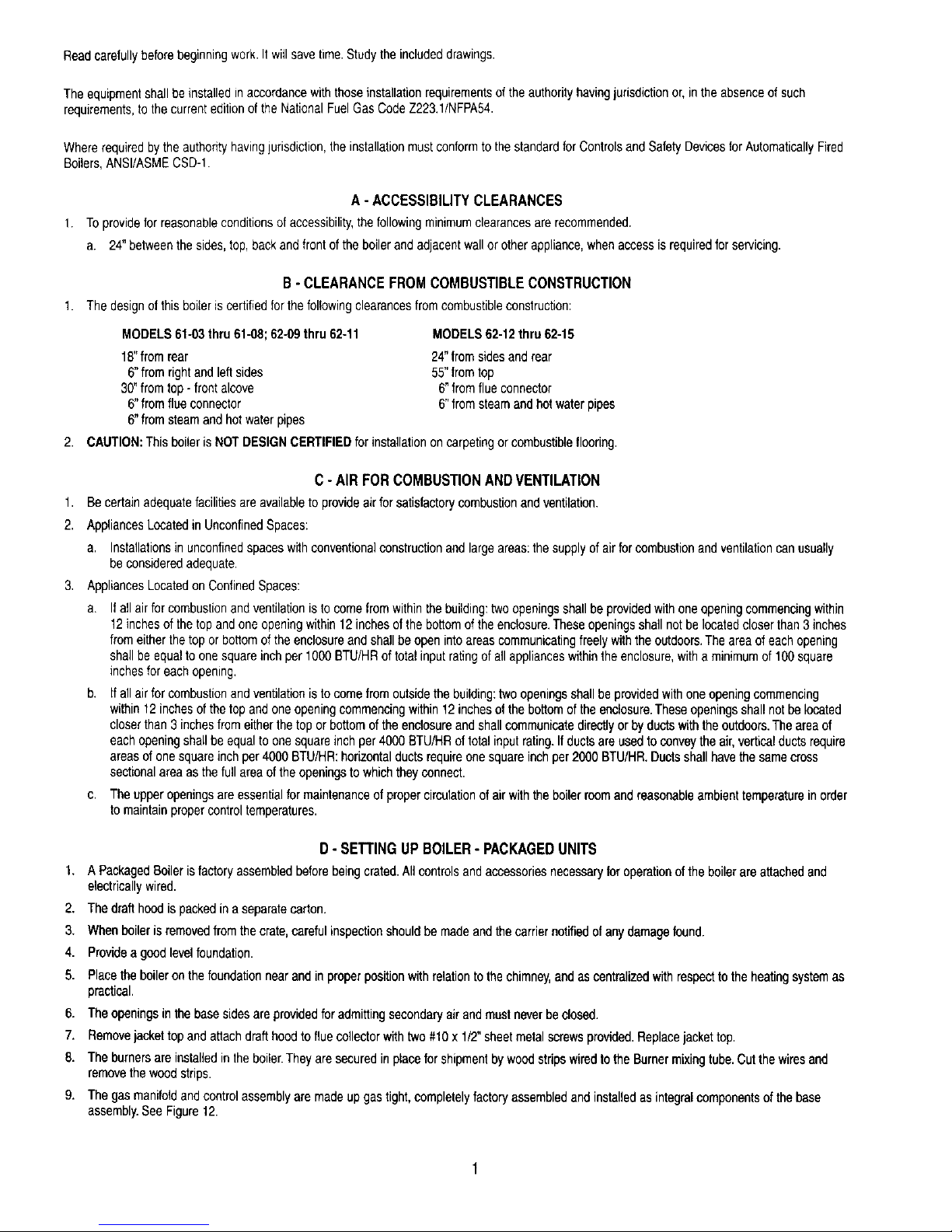

SERIES 62 BOILER SPECS

_-_-_ LlJl-J_vd_id

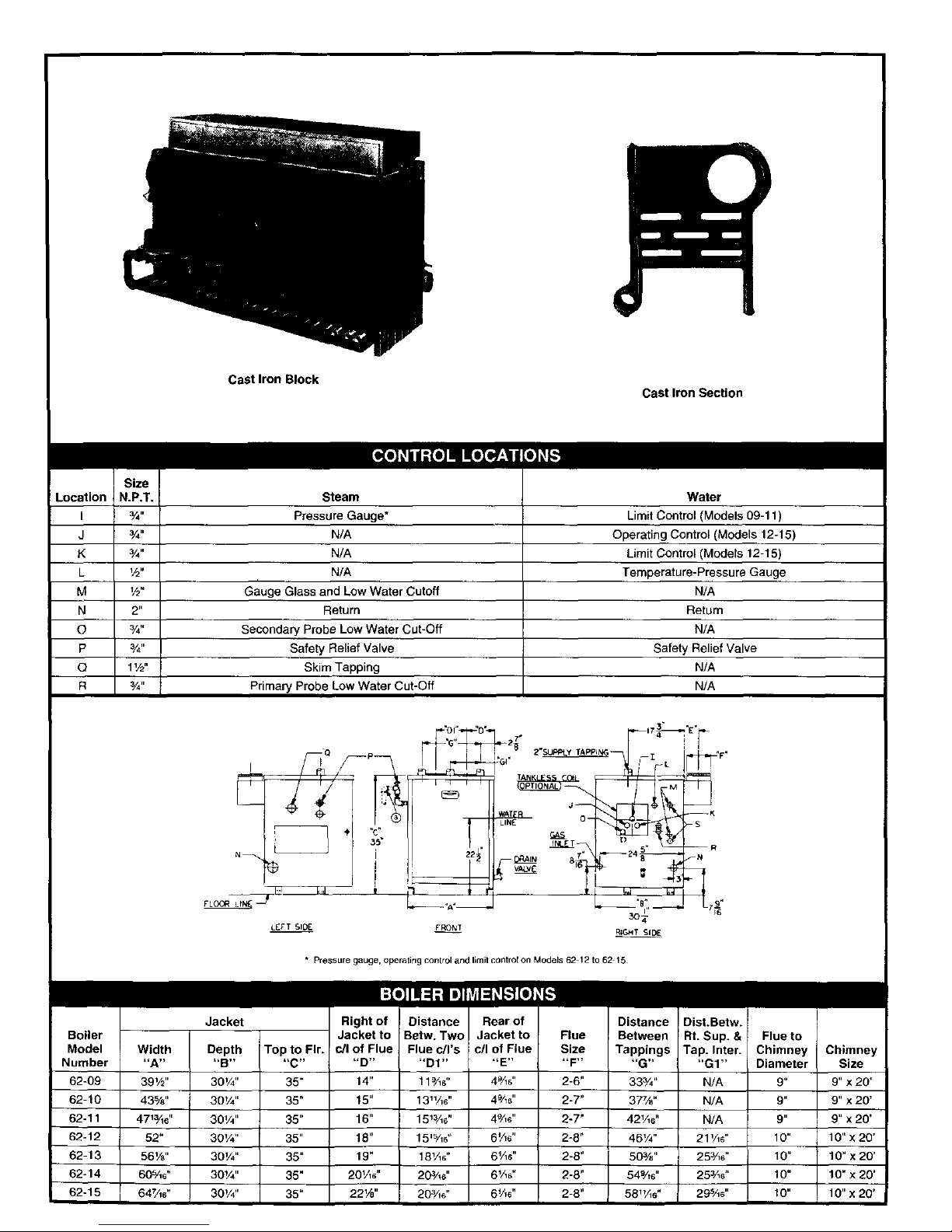

• Cast Iron Sections--Factory Tested and

Assembled with Steel Push Nipples

• Deluxe Insulated Enameled Steel Jacket

• Drain Valve

• Horizontal to Vertical Draft Diverter

• End Cleanout

• Manual Reset Limit (62-12 to 62-15)

• Standing Pilot or Spark Ignition

• Automatic Reset Limit

Water

• 30 PSI Safety Relief Valve

• Temperature-Pressure Gauge

Steam

• 15 PSI Safety Valve

• Pressure Gauge

• Gauge Glass

• Low Water Cutoff - Probe or Float

• Skim Tapping

• HSP-2 Honeywell ignitionSystem

• 50 PSI Safety Relief Valve - Water Boilers

• Insurance Controls

• I.R.I.

,F.M.

• Ignition Systems

• HSP-2

• E1-M

• E1-E

• Modulating Firing Systems

• MFSC

• Mod-U-Pak (12-15 Section)

Approx. Shipping Wts. (Ibs.)

Boiler

Model

Number I Length I Width ! Height I W S

I I I !

62-09 I 57" 31" I 391/2" I 1080 I 1088

I I I I

62-10 I 61" 3t" J 391/2" J 1170 I 1178

I I I I

62-11 I 66" 31" I 391/2`' ! 1265 I 1273

I I I ]

62-12 I 70" 31" I 391/2" ] 1420 I 1428

I I I !

62-13 I 74" 31" I 391/2" I 1520 I 1528

I I I J

62-14 I 78" 31" I 391/2'' ] 1620 I 1628

I I I I

62-15 I 82" 31" I 391/2" I 1720 1 1728

WP SP

1105 1108

1195 1203

1290 1298

1445 1453

1545 1553

1645 1653

1745 1753

nnam

Example:

62 - 09 - STDG/SPRK - WP - N

Series Sects. Natural Gas (Substitute

Standing Pilot or "LP" for LP Gas)

Spark Ignition W = Water Knockdown

WP = Water Package

S = Steam Knockdown

SP = Steam Package

PEERLESSHEATERCO.

231 North Walnut Street

Boyertown, PA 19512-1021

Phone: 610-367-2153 • FAX: 610-369-3284

www.peerless-heater.com

HI Division ASME garNa

of gama

CUT-62 F_7(3/03-1M), Printed in U SA. _003 Peedess Heater Company

Page 9

Readcarefullybeforebeginningwork.It witlsavetime.Studythe includeddrawings.

Theequipmentshallbe installedin accordancewith thoseinstallationrequirementsofthe authorityhavingjurisdictionor, in theabsenceof such

requirements,to thecurrenteditionof the NationalFuelGas CodeZ223.1/NFPA54.

Whererequiredbythe authorityhavingjurisdiction,theinstallationmustconformto the standardforControlsand SafetyDevicesforAutomaticallyFired

Boilers,ANSI/ASMECSD-I.

A - ACCESSIBILITY CLEARANCES

1. Toprovidefor reasonableconditionsofaccessibility,the followingminimumclearancesarerecommended.

a. 24" betweenthesides,top,backandfrontof theboilerand adjacentwallor otherappliance,whenaccessis requiredforservicing.

B- CLEARANCEFROMCOMBUSTIBLECONSTRUCTION

1. Thedesignofthisbelieriscertifiedforthefollowingclearancesfromcombustibleconstruction:

MODELS61-03thru61-08;62-09thru 62-11

18"fromrear

6"from rightand left sides

30"fromtop- frontalcove

6"fromflue connector

6"from steamandhot waterpipes

MODELS62-12thru62-15

24"fromsidesand rear

55"fromtop

6"fromflueconnector

6"fromsteamandhotwaterpipes

2. CAUTION:This boileris NOTDESIGNCERTIFIEDforinstallationon carpetingor combustibleflooring.

C-AIR FORCOMBUSTIONANDVENTILATION

1. Be certainadequatefacilitiesareavailableto provideairforsatisfactorycombustionandventilation.

2. AppliancesLocatedin UnconfinedSpaces:

a. Installationsin unconfinedspaceswithconventionalconstructionandlarge areas:thesupplyofairfor combustionandventilationcanusually

beconsideredadequate,

3, AppliancesLocatedonConfinedSpaces:

Ifallair for combustionand ventilationistocomefromwithinthebuilding:twoopeningsshallbe providedwithone openingcommencingwithin

12inchesof thetop andone openingwithin12inchesof the bottomof theenclosure.Theseopeningsshallnotbe locatedcloserthan 3inches

fromeitherthe topor bottomof the enclosureandshallbeopenintoareascommunicatingfreely withtheoutdoors,Theareaof eachopening

shallbe equaltoonesquareinchper 1000BTU/HRof totalinput ratingof all applianceswithinthe enclosure,witha minimumof100square

inchesforeachopemng,

Ifallair for combustionand ventilationistocomefrom outsidethebuilding:twoopeningsshallbe providedwithone openingcommencing

within12inchesofthetop and oneopeningcommencingwithin12inchesof the bottomof theenclosure.Theseopeningsshallnotbe located

closerthan3 inchesfromeitherthe top or bottomoftheenclosureandshallcomreunicatedirectlyor byductswiththeoutdoors.Theareaof

eachopeningshall beequalto onesquareinchper4000BTU/HRof totalinputrating.If ductsare usedto conveytheair,verticalductsrequire

areasofonesquareinch per4000 BTU/HR:horizontalductsrequireone squareinchper 2000BTU/HR,Ductsshallhavethe samecross

sectionalareaas thefull areaofthe openingsto whichtheyconnect.

c. Theupperopeningsareessentialformaintenanceof propercirculationofairwiththe boilerroomandreasonableambienttemperatureinorder

tomaintainpropercontroltemperatures.

D - SETTING UP BOILER - PACKAGED UNITS

1. A PackagedBoiler isfactoryassembledbeforebeingcrated.Allcontrolsandaccessoriesnecessaryforoperationof the boilerareattachedand

electricallywired.

2. The draft hoodis packedin a separatecarton.

3. When boileris removedfromthecrate,carefulinspectionshouldbe madeandthecarriernotifiedofanydamagefound.

4. Provideagood levelfoundation.

5. Placethe boileronthe foundationnearandinproperpositionwithrelationtothe chimney,andas centralizedwithrespecttothe heatingsystemas

practical,

6. The openingsin thebasesides areprovidedforadmittingsecondaryairand mustneverbeclosed.

7. Removeiackettop andattach drafthoodto flue collectorwithtwo #10x 1/2"sheetmetalscrewsprovided.Replacejackettop.

8. The burnersare installedinthe boiler.Theyaresecuredin placefor shipmentbywoodstripewiradto the Burnermixingtube.Cutthewiresand

removethewood strips.

9. The gasmanifoldandocntrolassemblyaremadeup gastight,completelyfactoryassembledandinstalledas integralcomponentsof thebase

assembly.SeeFigure12.

Page 10

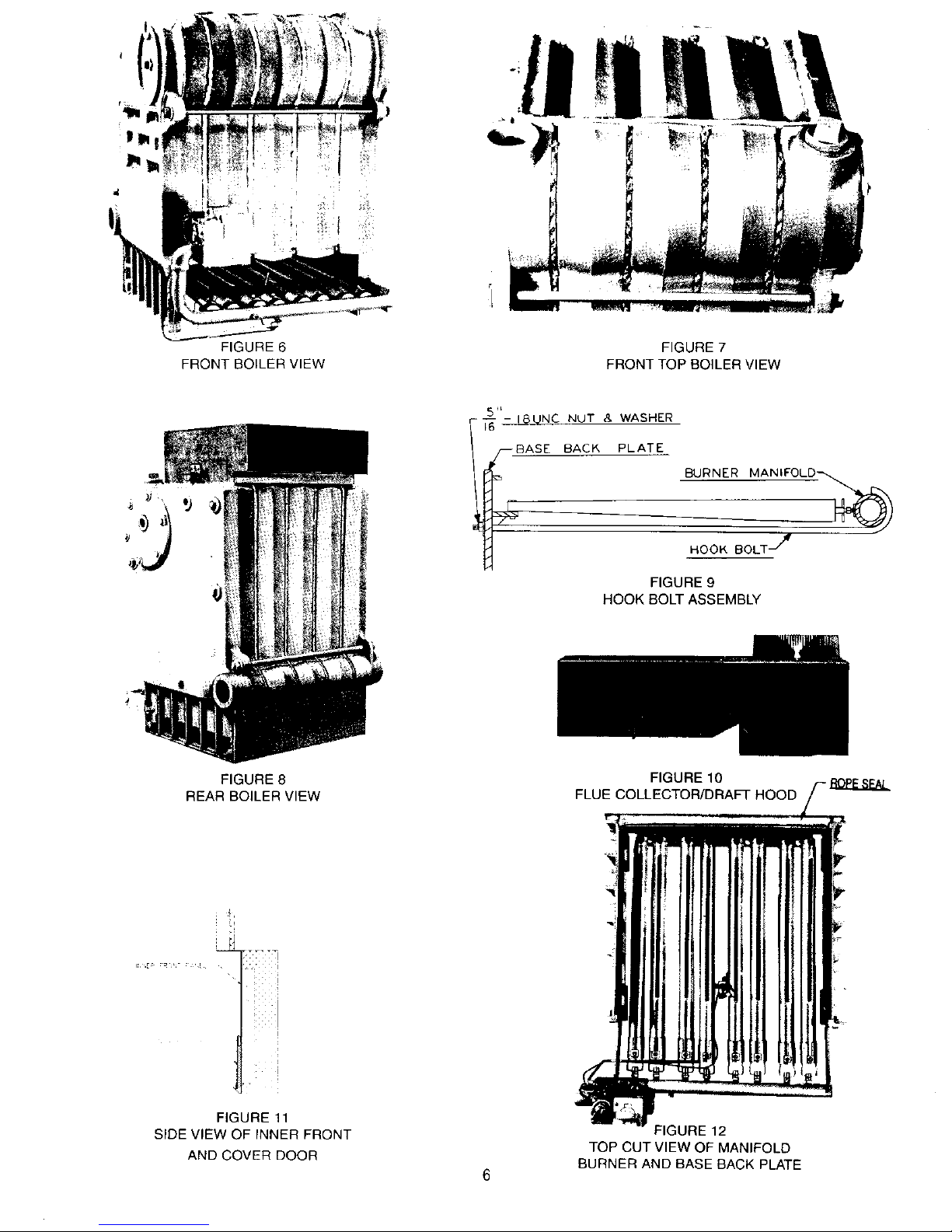

D - SE'I-rlNG UP BOILER - UNASSEMBLED UNITS

I-- ASSEMBLEDBLOCKS

1--The boilersectionsandbase,Models61-03thru61-07arefactoryassembled.Removeshippingskidfromtheboilerbase.Ifboilerisa61-08,

or62-09thru62-15beginassemblyasnotedin PartII"SplitBlockAssembly".

2--Provideagoodlevelfoundation,The Boilershouldbelocatedasneartothechimneyandcentralizedwithrespecttotheheatingsystemas

possible.

3--Open controlbox.Removecontrolandmanifoldassembly,Referto Figure6 andattachmanifoldto boilerwithfourV4-20x 1"machinescrews

andnutsprovided.Figures43thru45showthestandardcontrolassembliesusedon Models61-08thru 62-15.

4 Openfluecollectorcarton.RemovefluecollectorandHi Tempropeandlay ropeontop of boileragainstbeadprovided.SeeFigure7.

5--Place fluecollectoron topof ropeand attachto boilerwithtwo1/4"-20studs,washersandhex nutsprovided,throughfluecollectorbrackets

intothetappedlugs providedontopof theboilerend sections.Drawboltsdownsnugly.SeeFigure8,

6--Attach castironclean-outplate10clean-outopeningon leftside ofthe boiler.Thisplate, HiTempropeand mountinghardwaremaybe foundin

thecontrolboxreferred1opreviously.

7--Removetheburnersfromthecontrolboxandinstall.Installeachburnerby slippingtheopeninginthe venturioverthe orificespud.Insertthe

pinon thebottomof theburnerintothe holeprovidedintheflangeonthe basebackplate.SeeFigure9.TheBurnerswithpilotsattachedmust

be installedasfollows:Note:Hookbolt isprovidedon models62-11through62-15.

ModelNo. No.Pilots

61-03 1

61-04 1

61-05 1

61-06 1

61-07 1

61-08 2

62-09 2

62-10 2

62-11 2

62-12 2

62-13 2

62-14 2

62-15 2

Location of Pilot

Between2ndand3rdBurnerfromLeft

Between4th and5th BurnerfromLeft

Between4th and5th BurnerfromLeft

Between4th and 51hBurnerfromLeft

Between4th and 5thBurnerfromLeft

Between4th and5th Burnerfrom Leftand4th and5thfrom Right

Between4th and5th BurnerfromLeftand4th and5thfrom Right

Between4th and 5thBurnerfromLeftand4th and5thfrom Right

Between4th and5th Burnerfrom Leftand4th and 5thfrom Right

Between4th and 5thBurnerfromLeftand4th and 5thfrom Right

Between4th and 5thBurnerfromLeftand41hand5thfrom Right

Between41hand5th BurnerfromLeftand6th and7thfrom Right

Between6th and7th BurnerfromLeftand6th and7thfrom Right

8..-Removepilottubingfromcontrolboxand installbetweengas valveandpilot.Referto figures43 through45.

9--If boileris toincorporateatanklessheaterfordomestichot water,installinopeningprovidedin the rightsideofthe boiler.Sixmountingbolts

3/8"16 x3/4 are rovldedBesurerubber asketi I

( - ) p " • g "sbetweencoverplateandtheboier, Ifboilerdoesnot incorporatea fanklessheater,a

blankcoverplateis providedwithrubbergasketand bolts.One3/4"pipeopeningisprovidedin the platefor the operatingand/orlimit control.

This 3/4"tappingis alsousedfor the pressuregaugeonthesteamboiler,

10--For suggestedpipingto fanklessheaterreferto Figure23.

DANGER:Installmixingvalveinhotwatersupplypiping.Watertemperatureover125°Fcancausesevereburnsinstantlyor deathfromscalds,

2

Page 11

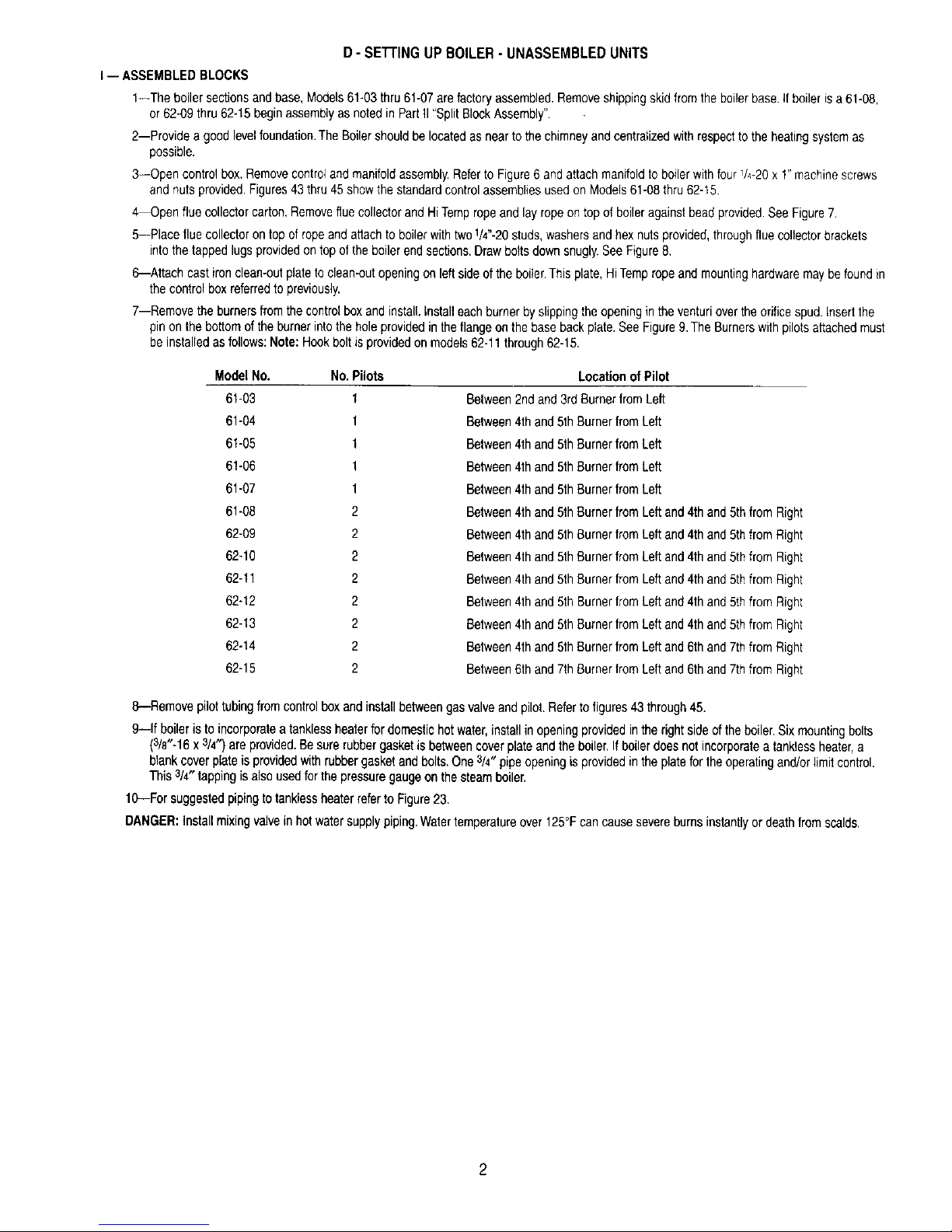

I:'ROC_"OUR lr FOR STACKING PALLtr'rq

II-- SPLITBLOCKASSEMBLY

1--Boiler sectionsfor Models61-08,62-09thru 62-15are shippedintwo parts.Removeskidfromeach blockofsections.

2--Place each blockofsectionson the stackedskids.See Fig.A. Becertainto removethesmall blocksonthetop skid.See Fig.B,

3--To clean nippleportsand removeprotectivecoating,usea wire brushandmineralspiritsor lacquerthinner.Makecertainthereareno burrs

aroundthe outsideedgeof the ports.

4--Spread athincoatof PeerlessNippleSealerinthe nippleports,NEVERON NIPPLES.

5--Insert the push nipples,withthe chamferededgeout. Makecertaintheyare cleanand freeofburrs.

6--Apply a thin coatof PeerlessNippleSealerto the ropegroove.Press5/8"Dia.ropeintothegroove.Thenipplesealeractsasan adhesiveto

holdthe ropeinplaceuntilthesecgonsare drawnup.

7--Arrange bothblocksso that protrudingnippleentersthe openport.Caremustbetakento keepnipplesstraightand blocksaligned.

8--Insert drawrodsthroughthe nippleports.Makecertainthatthe3/4"drawrod is usedonthelargenipple.Payparticularattentiontothe

placementof the drawwashers.SeeFig.A.

9--Before startingdraw,oil thethreadsand betweenthe nutsandwashers.

10--Tightenthe hexnutsanddraw boilerevenlyuntilthe smallpadson each sectionjusttouch.

11--After boilerisdrawn,removethedraw rodsand cut 5" fromthe 6V4" threadedend.Inserttherodthroughthe lugsoneachendsectionand

tightenthehex nutshandtight.

12--Attach3/8"Dia.ropeto baseback platebylayingropeacrosstopofbackplateflangeandinropegrooveon eachendofbackplate.Usenipple

sealerto hold ropein place.Referto figures9 & 12.Attachbase backplate bymeansof V4"-20x lr/2" machinescrewsandnutsfurnished.

Thebase backplateisattachedtobackof boiler.SeeFigure8.Becertainthatthe flange portionofplateistowardstheinsideof the boiler.

Note: hook boltisprovidedon models62-11through62-15only.

13--Install pressuregage,drainvalve,watersupplylinewith shutoffvalve,and meansto ventair.Plugunusedtappings.

14--Fill boilerwith water,ventingair aswaterlevelrises.Pressurizeboilerto75-85psig.Do notexceed85 psig.

15--Verifypressureis maintained.Checkalljointsand fittingsfor leaks.

16--Drainboiler.Removepressuregage,drainvalve,watersupplyandairvent.ContinuewithStep2 underD-1.

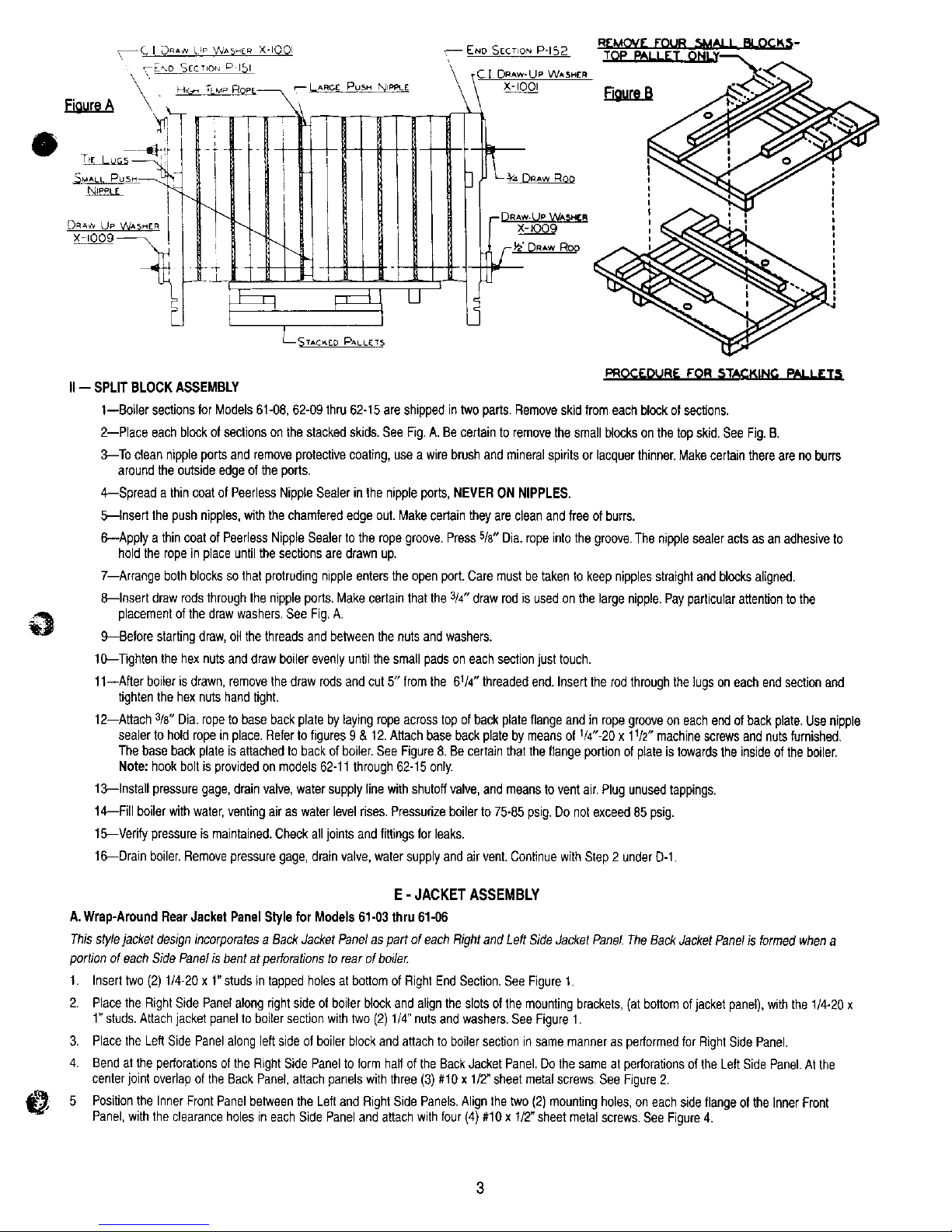

E - JACKET ASSEMBLY

A.Wrap-AroundRearJacket PanelStylefor Models61-03thru 61-06

Thisstylejacket designincorporatesa BackJacketPanelaspart of eachRightand Left SideJacketPanel.TheBack JacketPanelis formedwhena

portionofeach SidePanelis bentatperforationsto rearof boile_:

I, Inserttwo (2) 1/4-20x 1"studs intappedholesat bottomof RightEndSection.SeeFiguret.

2. Placethe RightSide Panelalongright sideof boiler blockandalignthe slotsof the mountingbrackets,(atbottomofjacketpanel),withthe 1/4-20x

1"studs.Attachjacketpanel toboilersectionwithtwo (2)1/4" nutsandwashers.SeeFigureI.

3. Placethe Left SidePanelalongleftsideof boilerblockand attachto boilersectionin samemannerasperformedforRightSidePanel.

4. Bendat theperforationsofthe RightSidePaneltoform halfof the BackJacketPanel.Dothe sameat perforationsofthe LeftSidePanel.Atthe

centerjointoverlapof the Back Panel,attachpanelswiththree (3) #10x 1/2"sheetmetalscrews.See Figure2.

PositiontheInnerFrontPanelbetweenthe Leftand RightSide Panels.Alignthe two(2)mountingholes,on eachsideflangeofthe InnerFront

Panel,with the clearanceholesin eachSide Panelandattachwith four(4) #10x 1/2"sheetmetalscrews.See Figure4.

Page 12

6. PlacetheSecondaryAirCoverDooratbottomofInnerFrontPanel.ThetopbendoftheCoverDoorslipsoverthetopreversebendatcutout

openingoftheinnerFrontPanel.RefertoFigure11.

7. AtlachDraftHoodtoFlueCollectorwithtwo(2)#10x1/2"sheetmetalscrews.RefertoFigure10.

8. AttachtheLowerFrontPaneltothebottomtrontoftheLeftandRightSidePanelswithtwo(2)#10x1"sheetmeta_screws.SeeFigure4.

9. PositionTopJacketPanelsotheflangesoverlapSideJacketPanelsandairlouversareatthefrontoftheboiler.Securewithsix(6)#10x1/2"sheet

metalscrews.SeeFigure4.

10.AttachtheCleanOutCoverPlatePaneloveropemnginLeftSideJacketPanet,withfour(4)#10x1/2"jacketscrews.SeeFigure4

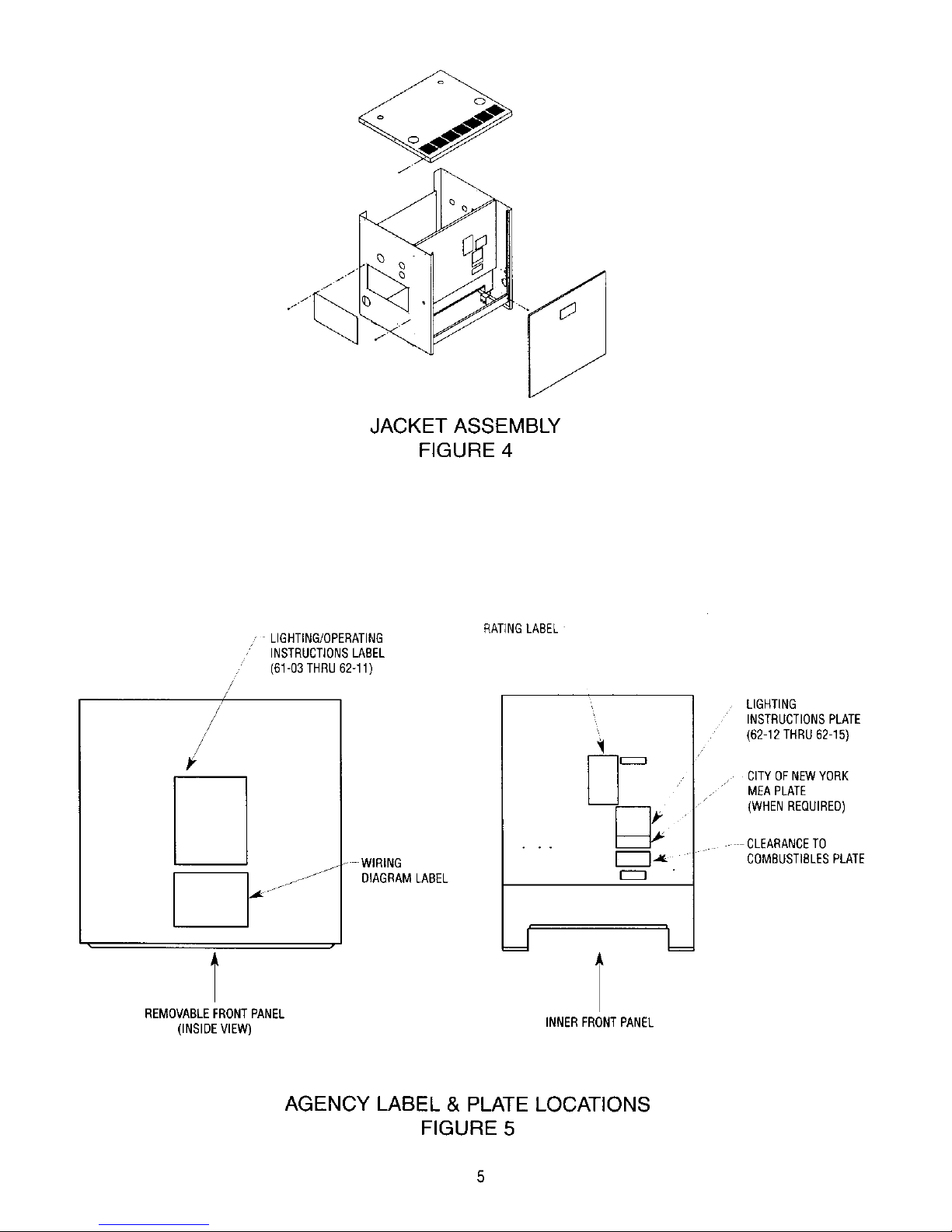

11.ThemanilaenvelopethatcontainstheInstallationManualalsocontainstheboilerratinglabel,clearancetocombustiblesplate,Lighting/Operating

instructionplateorlabelandwiringdiagramlabel.SeaFigure5forlocationofplatesandlabels.Attachplateswith#6x3/8"screwsprovided.

12.PositiontheRemovableFrontPanelinplacebyslidingthePanelunderthefrontflangeoftheTopPanelandthendownuntilitrestsonLowerFront

Panel.

B.IndividualBackJacket PanelStyle for Models61-07thru 62-t5

Thisjacketstyle hasaseparateBackJacketPanelthatis attachedtoindividualRightandLeftSidePanels.

1. AttachSide Panelsperinstructionsin #1thru3 above.SeeFigure1.

2. Positionthe BackJacketPanelonthe insideof theLeft and RightPanelflangesand attachwithsix(6) #10x !/2" sheetmetalscrews.SeeFigure3.

3. Followinstructionsaboveper #5thru 12for assemblyof remainingjacketpanels.

SIDE PANEL ATFACHMENT

FIGURE 1

-,_ RIGHT SIDE PANEL

ONEPIECERIGHT

SIDEANDREAR

PANEL

1/4" WASHER

1/4" NUT

J

J

ONEPIECE LEFT

SIDEAND REAR

PANEL

REAR VIEW WRAPPER

STYLE JACKET

(61-03THRU 61-06)

FIGURE 2

LEFTSIDEPANEL

RIGHT

SIDE

PANEL

REAR VIEW OF BACK PANEL

(61-07 THRU 62-15)

FIGURE 3

BACKPANEL

4

Page 13

JACKET ASSEMBLY

FIGURE 4

/

/

#,

, LIGHTING/OPERATING

, INSTRUCTIONSLABEL

(61-63 THRU 62-11)

" WIRING

_J

/jJ DIAGRAMLABEL

RATINGLABEL

LIGHTING

INSTRUCTIONSPLATE

(62-12 THRU 62-15)

CITYOFNEWYORK

• MEAPLATE

(WHENREQUIRED)

CLEARANCETO

COMBUSTIBLESPLATE

REMOVABLEFRONTPANEL

(INSIDEVIEW)

INNERFRONT PANEL

AGENCY LABEL & PLATE LOCATIONS

FIGURE 5

Page 14

FIGURE 6

FRONT BOILER VIEW

FIGURE 7

FRONT TOP BOILER VIEW

T_6"- !_UNC NUT & WASHER

_BASE BACK_

-- PLATE

BURNER MANIFOLD-_

HOOK BOLT _'w

FIGURE 9

HOOK BOLT ASSEMBLY

FIGURE8

REAR BOILERVIEW

FIGURE 10

FLUE COLLECTOR/DRAFT HOOD

.f,

H

FIGURE 11

SIDE VIEW OF INNER FRONT

AND COVER DOOR

-"IGURE 12

TOP CUT VIEW OF MANIFOLD

BURNER AND BASE BACK PLATE

6

Page 15

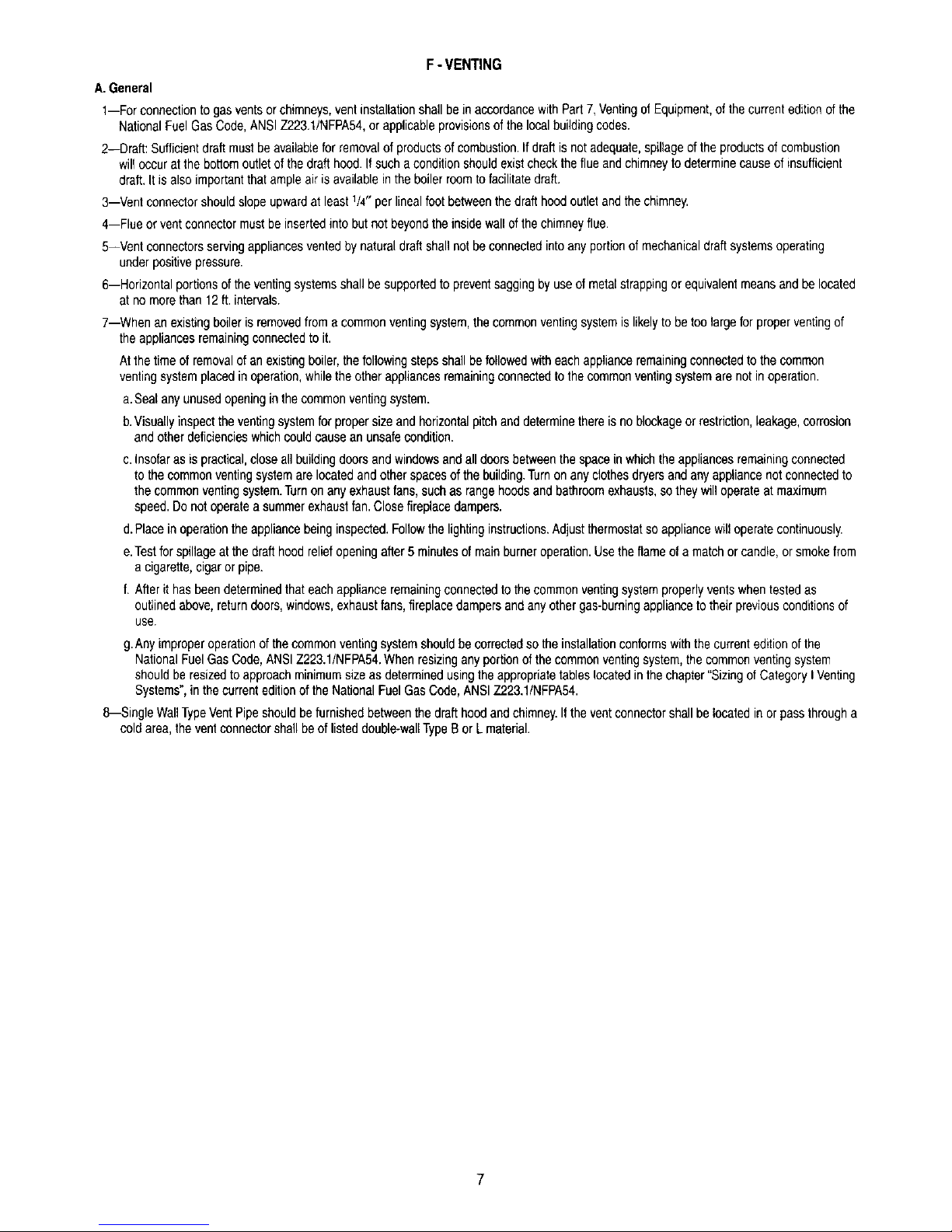

F-VENTING

A.General

1--For connectionto gasventsor chimneys,ventinstallationshallbein accordancewith Part7,VentingofEquipment,ofthecurrenteditionof the

NationalFuelGas Code,ANSIZ223.1/NFPA54,orapplicableprovisionsofthe localbuildingcodes.

2--Draft: Sufficientdraftmustbeavailableforremovalof productsof combustion.If draftis notadequate,spillageofthe productsof combustion

will occuratthebottomoutletofthe drafthood.Ifsucha conditionshouldexistchecktheflueand chimneytodeterminecauseof insufficient

draft.It isalsoimportantthat ampleairis availablein theboiler roomtofacilitatedraft.

3--Vent connectorshouldslopeupwardat least1/4"per lineal footbetweenthe drafthood outletandthechimney.

4--Flue orvent connectormustbe insertedinto butnot beyondtheinsidewallofthechimneyflue.

5--Vent connectorsservingappliancesventedbynaturaldraftshallnot beconnectedintoany portionof mechanicaldraftsystemsoperating

underpositivepressure.

6--Horizontalportionsof theventingsystemsshall besupportedtopreventsaggingbyuseof metalstrappingor equivalentmeansandbe located

atno morethan 12ft. intervals.

7--When anexistingboilerisremovedfrom acommonventingsystem,thecommonventingsystemis likelytobetoo largeforproperventingof

theappliancesremainingconnectedto it.

Atthetime of removalof an existingboiler,thefollowingstepsshall befollowedwith eachapplianceremainingconnectedtothe common

ventingsystemplacedin operation,whilethe otherappliancesremainingconnectedtothecommonventingsystemarenot inoperation.

a.Sealany unusedopeninginthecommonventingsystem.

b.Visuallyinspecttheventingsystemforpropersizeandhorizontalpitchand determinethereisno blockageorrestriction,leakage,corrosion

andotherdeficiencieswhichcouldcausean unsafecondition.

c.Insofaras is practical,closeall buildingdoorsand windowsandalldoorsbetweenthespacein whichtheappliancesremainingconnected

to thecommonventingsystemarelocatedandotherspacesofthe building.Turnon any clothesdryersandanyappliancenotconnectedto

the commonventingsystem.Turnon anyexhaustfans,suchasrangehoodsand bathroomexhausts,so theywilloperateatmaximum

speed.Donot operateasummerexhaustfan.Close fireplacedampers.

d.Placein operationtheappliancebeing inspected.Followthe lightinginstructions.Adjustthermostatso appliancewill operatecontinuously.

e.Testfor spillageatthedrafthoodreliefopeningafter5 minutesof mainburneroperation.Usethe flameofamatchorcandle, orsmokefrom

a cigarette,cigar orpipe.

f. Afterit hasbeendeterminedthat eachapplianceremainingconnectedtothecommonventingsystemproperlyventswhentestedas

outlinedabove,returndoors,windows,exhaustfans,fireplacedampersandanyothergas-burningappliancetotheir previousconditionsof

use.

g.Anyimproperoperationofthecommonventingsystemshouldbe correctedsotheinstallationconformswiththecurrenteditionof the

NationalFuelGasCode,ANSIZ223.1/NFPA54.When resizinganyportionof the commonventingsystem,thecommonventingsystem

shouldberesizedto approachminimumsizeas determinedusingtheappropriatetableslocatedin the chapter"SizingofCategoryI Venting

Systems",inthe currenteditionof theNationalFuelGasCode,ANSIZ223.1/NFPA54.

8--Single WallTypeVentPipeshouldbefurnishedbetweenthedrafthoodandchimney.Iftheventconnectorshallbelocatedin orpass througha

coldarea,the ventconnectorshallbeoflisteddouble-wallTypeB or L material.

Page 16

B,VentDamperInstallation

1 Ventdampersare providedonmodels61-03through61-08as standardequipment.

2--Unpack theventdamperandfollowthese instructionsandthe installationinstructionsin theventdampercarton.Observethecautionsand

warmngthataccompanyallinstructions.Do notmodifyventdamperor boilerdrafthood

3--The ventdampercanbe mounteddirectlyontothe drafthoodoutletcollar,or in theventpipingclose tothe boiler.Seefigures14and 15,Be

suredirectionofflow arrowlocatedondampercollar,ispointingawayfromdraft hoodcollarand damperpositionindicatorisvisibleafter

installation,Forinstallationwithdampermountedin the horizontalposition,mountthedamperasshowninfigure15to avoidexcessiveheat

andpossiblecondensationdripsonthe damperoperatingcontrol.

4--Do not useoneventdamperto controltwo or moreheatingappliances.Seefigure 13.

5 Makecertainthatthe minimumclearancesprovidedinthe ventdampermanufacturersinstructionsaremaintainedandthatadequatespaceis

providedfor damperaccessand service.

6--A wiringharnessis packedwiththe ventdamperwith pluginconnectionsat eachendof theharness.Connectsmallerendinto dampermotor

receptacleand connectotherendto boileraquastatrelay_imit(on waterboilermodelsequippedan L8148Eor L8124Elimitcontrol),orboiler

junctionbox (onsteamboilermodels),

7--Damper mustbe in theopenpositionwhenappliancemainburnersare operating.

OTHERHEATING

APPLIANCE

I[_ OTHER

HEATING

APPLIANCE

INCORRECT CORRECT

Figure13:VentingMultipleAppliances

8

Page 17

SLOPE UP

A MINIMUM

OF 1/4"

PER FOOT -m

VENT

DAMPER

AS REQUIRED

DRAFT HOOD

OUTLET

Figure14:VentingwithVentDamperinVerticalPosition

/- VENT TO

SLOPE UP VENT /CHIMNEY

A MINIMUM DAMPER

oF1/4" "7F" 1

PER FOOT_ 11 O'CLOCK

r_

1 O'CLOCK

POSITION

OPERATOR

-CONDENSATION

ZONE

7 O'CLOCK 5 O'CLOCK

POSITION POSITION

DO NOT MOUNT DAMPER

OPERATOR IN SHADED REGION

SECTION A-A

Figure15:VentingwithVentDamperinHorizontalPosition

Page 18

G - PIPING

1--Hot Water:

a.The recommendedpipinghook-upis showninFigure17.Alsoreferto PeerlessWaterSurvey.

2--Steam:

a.Therecommendedpipinghook-upis shownin Figure16.Pleasenotethat a Hartfordreturnloopis recommendedtobe usedonall steam

boilers.Also referto PeerlessSteamSurvey.

3--The reliefvalveand popsafetyvalveshallbe installedbyusingthe3/4"x 3"nippleand 3/4"elbowsuppliedwith theboiler.Refertoillustrations

locatedinSectionR-"Ratings,Tappingsand DimensionalData".LargeNPTsizevalvesmaybe installedinsupplypiping.

NOTE:IFTHIS BOILERANDDISTRIBUTIONSYSTEMISUSEDINCONJUNCTIONWITHA REFRIGERATIONSYSTEM.THECHILLED

MEDIUMSHALLBEPIPEDIN PARALLELWITHTHEBOILERANDTHEPROPERVALVEAPPLIEDTOPREVENTTHECHILLED

MEDIUMFROMENTERINGTHE BOILER.A DRAWINGILLUSTRATINGTHIS HOOK-UPIS PROWDEDINFIGURE18.

WHENTHEBOILERIS CONNECTEDTOHEATINGCOILSLOCATEDINAIRHANDLINGUNITWHERETHEYMAYBE EXPOSED

TO REFRIGERATEDAIR CIRCULATION,THE BOILERPIPINGSYSTEMMUSTBE EQUIPPEDWITHFLOWCONTROLVALVESOR

OTHERAUTOMATICMEANSTO PREVENTGRAVITYCIRCULATIONOFTHEBOILERWATERDURINGTHECOOLINGCYCLE.

CAUTION:PIPETHEDISCHARGEOFRELIEFVALVETO PREVENTINJURYINTHE EVENTOFPRESSURERELIEE SUGGEST

DISCHARGETOBE PIPEDTODRAIN.PIPEFULLSIZEOFOUTLET.

H - GAS PIPING

1--Gas supplypipingistobe sizedand installedproperlyinorder toprovidesupplyof gassufficienttomeetthemaximumdemandwithoutundue

lossofpressurebetweenthemeterandthe boiler.

2_onsult the followingtablefor propersizingofgas piping for variouslengthsand diameters.

CAPACITYOF PIPEOF DIFFERENTDIAMETERSANDLENGTHSINCU. FT PERHOURWITHPRESSUREDROPOF 0.3 IN.AND

SPECIFICGRAVITYOF0.60. NOALLOWANCEFORAN ORDINARYNUMBEROFFITTINGSIS REQUIRED,

PipeLength 3/4" 1" 11h" 11/2"

Feet Pipe Pipe Pipe Pipe

10 278 520 1,050 1,600

20 190 350 730 1,100

30 152 285 590 890

40 130 245 500 760

50 115 215 440 670

60 105 195 400 610

MULTIPLIERSTO BEUSEDWITHABOVETABLE,WHENTHESPECIFICGRAVITYOFTHEGASISOTHERTHAN 0.60

SpecificGravity 0.5 0.55 0.60 0.65 0.70

Multiplier 1.10 1.04 1.00 0.962 0.926

3.-Locate the droppipe adjacentto,butnotinfrontof theboiler.

4--Locate a tee in thedroppipeat sameelevationasthegasinletconnectiontothe boiler.Extendthedroppipetoa pipecapasshownin Figure

19to formasedimenttrap.

5--Install a groundjointunionaheadofthe gascontrolassemblyto permitservicingoftheequipment.See Figure19.Somelocalcodesrequirean

additionalshut-offvalve.Ifyourcoderequiressucha valve,a suggestedlocationis shownin Figure19.

6_OTE: Wheninstallingboilerbesureapipecompoundresistanttotheactionof liquefiedpetroleumis used.

7--Check pipingforleaks.Alwayscheckleakswitha waterandsoapsolutionor equal.DONOTUSE A FLAMEFORCHECKINGGASLEAKS,

8--The boilerandits individualshut-offvalvemustbedisconnectedfromthegassupplypipingsystemduringanypressuretestingofthatsystem

attest pressuresin excessof r/2psig (3.5kPa),

Theboiler mustbeisolatedfromthegassupplypipingsystembyclosingits individualmanualshut-offvalveduringany pressuretestingof the

gassupplypipingsystemat testpressureequalto or lessthanV2psig(3.5kPa).

10

Page 19

Table1:SteamHeader,Risersand EqualizerSizing

L---RETURN

SUGGESTEDPIPING

t t

ETURN

NOTE:Thereturnfrom systemshouldalwaysenterequalizer

throughHartfordLoop,approximately2"- 4" below

normalwaterline.

Steamheadershouldbe24" rain.aboveboilernormal

waterline.

Figure16:SteamSupplyand ReturnPiping

Model No.Supply Size of Header Equalizer

No. Outlets Outlets Supply Size

6t-03 1 2" -- 1114"

61-04 1 2" -- 11/4"

61-05 1 2" -- lr_"

61-06 2 2" 21_" 11_"

61-07 2 2" 2+/2" 11_"

61-08 2 2" 3" 11_"

62-09 2 2" 3" 11_"

62-10 2 2" 3" 1!_"

62-11 2 2" 3" 1_"

62-12 3 2" 31_" 11_"

62-13 3 2" 31_" 11_"

62-14 3 2" 31_" tl_"

62-15 3 2" 31_" 11_"

STEAM BOILER

SUGGESTEDPIPING

HOT WATERBOILER

_TOP • w_STt ¥_LV[ (Nomwl_eJrY O_J_W_

Cu_{D _to _ [xF_l_,_ TANK

_ S_T_II_ESS v,_Tl_ ;_'_1_ is _ _Fw°_ ;4(ATW4G<

Figure 17: Hot Water Supply and Return Piping

11

Page 20

Figure18:ParallelHook-UpwithWaterChiller

J

SERVICE

_JACKET

G.J. UNION

SEDIMENT TRAP

_./FLOOR LINE

Figure19:GasConnectiontoBoiler

Figure20:GravityHotWater

Figure22:SteamW/FloatLWCO

Figure21:ForcedHotWater

.HIGH TEMPERATURE

HOT WATER _.

MIXEO

WATER

MIXER

HEATER

"rAPPING

12 Figure23:SuggestedPipingForTanklessHeater

Page 21

A

c

©

o ©

F_

1/2 TAPPINGS

TO MOUNT

9 1/4 LONG

GAUGE GLASS

FROM PROBE

L.WC.O. CARTON

L_ I_

RIGHT SIDE PANEL

Figure24:Steam:PrimaryProbeLWCO,HydrolevelCG400P

THRU

i1_11 _.

I

I

Figure21A

IMPORTANT

1. InspectProbeElectrodeannuallyfor scaleandbuild-upand cleanif necessary.

2. Forpropermaintenance,recommendedwaterfeederapplicationsandoperation,refertotheHydrolevelProbeLWCOInstallationInstructions.

• °

LEFT I';AhlD OPPOSITE

F3 TI

Figure 25: Steam: Gauge/Pressuretrols Piping Arrangement

t[[

Figure26:Steam:Gauge/PressuretrolsAlternatePipingArrangement

13

Page 22

Figure27:ProbeLWCOLocationfor HotWaterBoiler

I - CONTROLS

l--Steam:

a.Forproper}ocationofcontrolsandaccessoriesreferto SectionR"Ratings,TappingLocationsandDimensionalData".

b.TheMcDonnell& Miller#67PE-2LWCOisfurnishedasa standardwith all steamboilers.TheHydrolevelCG400-PPrimaryProbeLWCOis

optional.This controlprovidesa lg minuteon cyciefollowedby a 90secondoffcycle.Thisfeatureallowsthe waterlevelinboilerto settleso

thattheprobe cansensea true waterlevel.

c.TheHydrolevelCG550-P ProbeLWCOmaybeusedin combinationwitha PrimaryFloatLWCOandisto bemountedinthe secondary

probelocation.

1.TheCG550PLWCOincorporatesa 10minuteon cyclefollowedbya 90secondoff cycle.

d.Whena 67PE-2FloatLWCOissupplied,thepressuretroland brasssiphonare mountedontop ofthe 67PE-2.Thisisstandardformodels

61-03thru 62-1t. Refertofigure22.The67PE-2is providedwithfittingsto attachdirectlyto tappingsA and B,asshowninfigure24.The

20q05-10gaugeglassset isinstalledas partof the67PE-2quickhook upfittings.

e.WhenaHydrolevelCG400-PPrimaryProbeLWCOis supplied,the pressuretrol,brasssiphonand gaugearemountedasshowninfigure

24.Thefittingsrequiredformountingthesethreecomponentsarefoundinthe ProbeLWCOCartonand theSteamTrimCarton.

A longergaugeglassw/rods, (22-162-10carton),arerequiredforusewith the HydrolevelCG-400-Pprobe.Two1/2"x 3" nipples,two1/2"

couplers,longergaugeglassw/rodsand gaugevalvesare mountedintoTappingsA andC asshowninfigure24.ForPackagedBoilers,

theseparts are suppliesinthe Misc.PartsCarton,locatedin boilercrate.ForKnockdownBoilers,usethegaugevalvesfoundin20-105-10

WaterGaugeCarton,whichis packedinthe SteamTrimCarton.Thelongergaugeglassw/rodsandfittingsare in PrimaryProbeLWCO

Carton.

NOTE:REFERTO FIGURE25 AND26 FORMOUNTINGOFDUALPRESSURETROLS,FORMODELS62-12THRU62-15

CAUTION:Ifusingchemicaladditivesto preventfoamingandsurging,suchas "Squick",watchthegaugeglassandshutdownboilerif water

disappearsfrom glass.Thencyclethe boilera fewtimesuntil the waterstabilizes.

2--Hot Water:

a.Forproperlocationofcontrolsandaccessoriesreferto SectionR "Ratings,TappingLocationsandDimensionalData".

NOTE:A HOTWATERBOILERINSTALLEDABOVERADIATIONLEVELMUSTBE PROVIDEDWITHA LOWWATERCUTOFFDEVICE

EITHERAS A PARTOF THEBOILERORATTHETIMEOFBOILERINSTALLATION.

b.WhenaprobeLWCOis provided,installprobeLWCOin supplypiping.

Supply Piping (left or right).

Note:This mountingmethoddoesnot requirea probewitha timed on/offfeature.

1. Instal_a2" x 10" inch or longer nipple in the boiler supply tapping. Install a 2" x 2" x 3/4"

tee on the nipple. See figure 27.

TO SYSTEM

__ 2,,x

2 X 10 ] I,P" TEE

NIPPLE _

RO Eo'

2. Install theremainderof the boilersupplypiping.Pipesizemaybe reducedasrequired.Referto low

watercut off manufacturer'sinstructionsfor installationandmaintenanceprocedures.

Do not install a probe low water cut off in the boiler primary or secondary probe tapping unless the

low water cut off is equipped with a timed on and off feature. The cycled off time will allow the probe

low water cut off to sense the true water level in the boiler and eliminate a false reading caused from

sensing a foaming or surging water condition. Failure to use a timed low water cut off could result in

a failed heat exchanger.

14

Page 23

3--Specificdetailsregardingthe installationofthe variouscontrolsaregiveninthe controlsheetsattached.

4--In theeventofa controlfailurethe replacementshallbe identicalwiththeoriginalequipment.

5_n certainmodelsa separatepilot switchmustbe used.Theswitchshallbe mountedonthe leftsideoftheinnerfrontjacketpanel.Usethe

twoYs"holesprovided,if holesare not provided,drillaccordinglyasshowninFigure45.

6--For Models61-08,62-09thru62-16the sparkignitioncontrolboxwhensupplied,mustbe mountedon theouterleftsidejacketpanelasshown

in Figure43. Ifadditionalspark ignitioncontrolboxis supplied,this mustbemountedto the outerrightsidejacketpanel.

7--For Models61-03thru61-07thesparkignitioncontroland mountingbracket,whensupplied,canbe mountedto the rightor left outerjacket

panelas requiredfor easeof wiring.

8--This boilermaybesuppliedwithsafetylimitsinadditiontothe highlimitaquastatandpressuretrol.Thefollowingisa descriptionoftheselimits

andhowtheyworkin conjunctionwith thesafe operationof theboiler.

a.FLAMEROLL-OUTSAFETYSHUTOFFSWITCH--ForModels61-03thru61-08ONLY,this is athermallyactivatedswitchthat is located

onthe burneraccesscoverplate.The flameroll-outsafetyshutoft switchwill senseexcessivetemperaturecausedbycontinuedflameroll-

outand shutdownmainburnergas.This is a non-recyclingswitchthat mustbereplacedonceit hasbeenactivatedandthe causeof the

roll-outeliminated.

b.VENTSAFETYSHUTOFFSWITCH--ForModels61-03thru 61-08ONLY,this is a thermallyactivated,manuallyresetableswitch,located

inthe drafthoodreliefopening.Ifventingsystembecomespartiallyortotallyblocked,thevent safetyshutoff switchwill senseexcessive

temperaturecaused byflueproductsexitingthe drafthoodreliefopeningandshut downmainburnergas.

NOTE:REFERTOSECTIONQ FORINSTRUCTIONSWHENBOILERISSHUTDOWNBYTHEACTIVATIONOFEITHEROFTHEABOVE

SWITCHES.

9--Water & SteamModels62-12lhru 62-15are suppliedwith2 limitcontrols.Themanualresetlimitmustbe setfor a highercut out pointthanthe

operatinglimitcontrol.If aThermostatis usedas an operatingcontrol,itshouldbeusedin additiontoand not in lieuofthe operatinglimit

control.

NOTE:THISBOILERSHALLBEINSTALLEDSOTHATTHEGASIGNITIONSYSTEMCOMPONENTSAREPROTECTEDFROMWATER

(DRIPPING,SPRAYING,ETC.)DURINGAPPLIANCEOPERATIONANDSERVICE(CIRCULATORREPLACEMENT,CONDENSATE

TRAP,CONTROLREPLACEMENTS,ETC.).

J - WIRING

NOTE:]HISUNITWHENINSTALLEDMUSTBEELEC'rI_AU.YGROUNDEDINACCORDANCEWI]HTHEREQUIREMENTSOF]HEAU_ HAVING

JURISDIC'I]ONOR,INTHEABSENCEOFSUCHREQUIREMENTS,wm.ITHECURRENTEDmONOF]HENATIONALELECTRICALCODE,ANS_FPANO.70,

IFANEXTERNALELECTRICALSOURCEISUI1L_D.

1--All electricalwiringshallbe donein accordancewithTheNationalElectricCodeANSI/NFPA70andlocalrequirements.

2--For recommendedwiringof controls,referto Figures28 thru42.SeeFigures20,21,22 and 24forlocationof wiringand controls.

3--A lengthof 150° C lowvoltagewireis provided.

4--The boilershouldbeconnectedbya separate,permanentlyliveelectricalsupplylinewithafusedswitch.

5--ThermostatAnticipatorSettings:(note:settingsmayneedtobe adjustedupor downfromset pointsnotedbelow)

a.Setto .4ampwhena 8222A-1002IsolationRelayisapplied.

b.NI othersystems,matchanticipatorsettingtoamploadof24 voltcontrolcircuit.

NOTE:Singlepole switchesincludingthoseof safetycontrolsor protectivedevicesshall notbe wired ina groundedline.

CAUTION:LABELALLWIRESPRIORTO DISCONNECTIONWHENSERVICINGCONTROLS.WIRINGERRORSCANCAUSEIMPROPERAND

DANGEROUSOPERATION.VERIFYPROPEROPERATIONAFTERSERVICING.

K - STARTING BOILER

1--Referto INSTRUCTIONSFOROPERATIONandthe lighting/aperatinglabelwhichis mountedtojacketpanel.

2--The boilerand itsgas connectionmustbe leaktestedbeforeplacingtheboilerin operation.Checkgasconnectionswithsoap solution.

15

Page 24

L1 - ADJUSTMENT TO GAS PRESSURE REGULATOR

1--Set manifoldpressureasfo_lowsforvariousgases.

a.NaturalGas................ 31/2"WaterColumn b,LiquefiedPetroleumGas ................ 10"WaterColumn

2--To adjustgaspressure,turnadjustingscrewof gaspressureregulator,outto decreasepressure,turnintoincreasepressure,Refertocontrol

sheetssuppliedwith boilerfor locationofgas pressureregulator•

3--In no caseshouldthe finalmanifoldpressurevarymorethanplusor minus03 incheswatercolumnfromtheabovespecifiedpressures•Any

necessarymajorchangesintheflowshouldbemadeby changingthe sizeofthe burnerorifice.

MinimumPermissibleSupplyPressurefor Purposeof InputAdjustment.... 5.0" W.C.NaturalGas 11.0" W.CLiquefiedPetroleumGas

MaximumPermissibleSupplyPressuretothe Boiler .................. 13.5" W.C.NaturalGas 13.5" W.CLiquefiedPetroleumGas

NOTE:MINIMUMRATEAS SHOWNONTHE RATINGPLATE!S OBTAINEDBYA FIXEDORIFICELOCATEDINTHEGASTRAINANDISNOT

ADJUSTABLE•

L2-ADJUSTMENTOF PILOTGASFLOWWITHMR8200ANDMR8300COMBINATIONGASVALVES

Tomaximizethermocouplelife,particularlyonnaturalgasinstallationswithgassupplypressuresabove9" W,C.,reducethepilotgasflow.

WARNING:TURNOFFALL ELECTRICPOWERTOTHEAPPLIANCE.TURNGASCONTROLKNOBTO "PILOT'POSITION•

1--Locate and removethe pilotadjustmentcapscrew,whichisadjacenttothepilottubeconnectionontopof gasvalve.

2--Removepilotobservationcoverdoor.SeeFigure11.

3--Turn the pilot adjustmentscrewclockwiseuntilthe pilotflameextinguishes•Then increasethe pilotflow justtothepointthatthegasvalveholds

in whenrelightingthe pilotpersteps9 and 10of LightingInstructionsonpage25 (turnscrewno morethana 1/8turn).

NOTICE:THEFIRSTFEWTURNSOFTHEADJUSTMENTSCREWMAYNOTCAUSEANYCHANGEINTHEPILOTFLOW.SUBSEQUENT

PARTIALTURNSOFTHE ADJUSTMENTSCREWMAYHAVEA GREATIMPACTON PILOTFLOW.

4--Turn on electricpowertothe appliance.

5--Turn GasControlKnobto"On"positionperthe LightingInstructionsonpage25.

6--Verify pilotremainslitaftershutdownfroma boiler"ON"cycleof at leasttenminutes,If pilotextinguishes,followLightingInstructionsonpage25

andagainslightlyincreasepilotflow.

7--Make a fina_slightincreaseinthe sizeofthe pilottoensuresufficientpilotsignal underalloperatingconditions,justtothepointthat youobserve

a slightincreaseinthesizeof theflame (nomore thanan 1/8turn).

8--Replace adjustmentcapscrew andobservationcoverdoor•

M-BURNERINPUT

1--Referto ratinglabelmountedon thejacketinner-frontpanelto obtainthe requiredBTUper hourinput•Innocaseshallthe inputtotheboiler

exceedthat shownonthe ratinglabel.

2--Checkinputbyuseofthefollowingformula:Suggestreadingmeterfor2 Cu.Ft.

_Q0 x Fx H_ BTU/Hr.Input

T

3600 -- Secondsperhour

F -- Cu.Ft.GasRegisteredonMeter

H -- HeatValueofGas inBTU/Cu.Fb

T -- TimeinSecondsofMeterisRead

NUMBER OF ORIFICE SPUDS REQUIRED

MODELNUMBER-- 61-03 61-04 61-05 61-06 61-07 61-08 62-09 62-10 62-11 62-12 62-13 62-14 62-15

ORIFICESPUDS-- 4 6 8 10 12 14 16 18 20 22 24 26 28

• k

16

Page 25

HONEYWELL 24V STANDING PILOT - STEAM w/DAMPER, FLOAT LWCO AND ISOLATION RELAY

Models61-03thru61-08

2_v 7

I

TST_ _LA¥ COIL

I F

_ ml I

R _ RELAY II I

_ADC,CR LEr_ND

LINE VOLTAGE

LO_ VOLTAGE

_TUB _AP,NES$

X_ _X

H V88_

Figure28

HONEYWELL 24V STANDING PILOT- STEAM OR GRAVITY HOTWATER

Models62-09thru62-11

/ r_'f_

Figure29

17

Page 26

HONEYWELL SPARK IGNITION (HSP) - GRAVITY OR STEAM w/DAMPER, FLOATLWCO AND ISOLATION RELAY

Models61-03thru61-07

-- ?

TRANSFORME_

120V

_J_J_J

I

TSTAI F_ELA_"COIL

_R L I I SpARK

IAODER tECENO

:IN_ VOLTAGE

_OW VOL_SE

ilrl

Figure30

HONEYWELL SPARK IGNITION (HSP) - FORCED HOTWATER w/DAMPER

Models61-03thru61-07

4_OJTJL_

Z4_

' / ?v"

......... _ : _ -4,

_)_ ..........................._t _. _ ,, _l_._ _L,._J _...........

, i i i

_ _ ,

_ /_ , ,

• w

i i ii i 1_ !

Figure31

18

Page 27

HONEYWELL SPARK IGNITION (HSP) - FORCED HOTWATER w/COIL AND DAMPER

Models61-03thru61-07

_--_ ..... _-rr'ccc_..... _'-.... -

I

i....

L............ _w...... L I i _ I

....

_---= __=__-_2

-- L_IN__,rAG_ _tt 14 _ rY_ TW

........ IC_ _ SiZE 16 _ BO'C STA,*I,_O W,RI_

I@_ -* ..... , ............

* 1

@

L...... __'..iJ__J z-__.,qt_ •

, i

• _ x- __+J

Figure32

HONEYWELL SPARK IGNITION (HSP-2) - GRAVITY OR STEAM w/DAMPER, FLOATLWCO AND ISOLATIONRELAY

Model61-08only

OPERAnNGCO_IFtOL O_

120V_60HZ r_ERUOS_I ISOLAtiON_[tAY H-RB222A IC,0_

TRANSFORMER

.... <.o.<t!, ; • ....

I LOW WAEP,Cu_-Orr

_ L ME _3LtC_JT

I I I COt_TFIO_S

_'_ _ _ _lii ' 1

SmEi HARNESS_ Il I Z: i %\ flING HIN SS u i FILO:_RNER _, I C_BL_ _ I , , _BL_ A

_RC_ D roif i_ x 7039 _ i _ I I PILOT BURN[R

--.......... _ppkor GAS._ L _LO_ iigAIN LOW VI_IA_ "Z[ 15 A" " C 51R_D£D "R<.............. L_.,_,, R _-- _--1-- -- --J_'

-- LINE VOtTACE VAL',_

VAL , ,_,_5 V;*L_ H VRll_<14

¢OL .... LOW VOLT,_Gt"SIZE 16/'2 A_ POll UkilErl FIRE

pROIE_TI_ _I_JNALqN__II!_ULT¢_E IflS'C

_ROUND LEAEitI4N_IZ_ If Al_f__<1" C SIRAN_I] II_ll[

MORES ALL _4111N8HUST CC_4mty141H I_PLIOABLE _(:(YES 0RDINAN_[_ #*bid RECNLAllI:_t5

In ANY I Ill( ilCINAL _I4N[AS _PPU[I_ li4]H [HE _P_IANg[ MU_T

BE FIEPL#*CE_IT IdUSTI_ REPLACED1,41H11411[A_ _H_)l_ldt ITS EQUIVALENI

Figure33

19

Page 28

HONEYWELL SPARK IGNITION (HSP-1) - w/DUAL 24V MAIN GASVALVES

Models62-09thru62-15

_j m

1 [ ................

i i ;

i i

_,L W_ _ _,V___ _T_ _ICA_[ COOlS. C,_O_',_ES. A_ _1'_ A_IC,_S,

Figure34

HONEYWELL SPARKIGNITION (HSP-1) - w/DUAL 120V MAIN GAS VALVES

Models62-09Thru62-15

........"F

............ [ ' ! ....... "

_ _, _D ,_ ,¢_,_ ._=_.p_,x _L_._. *,.,_ _0_ T_pL_;T _

NOTES=

=

Figure35

2O

Page 29

WIRING APPLICATION OF HYDROLEVEL PROBE LOW WATERCUTOFFS

Models550P,650PandCG550P

RefertoSectionI - Controlsofthis manualformountinglocationandinstructions.

115V-60HZ

L2 L1 (HOT)

£

L

TO L2 ON

WIRING DIAGRAM _,

--I1_- 115V-60HZ

ALARM CIRCUIT

(WHEN REQ'D)

sTO L1 ON WIRING DIAGRAM

NOTES:

ALL WIRING MUST COMPLY W!TH APPLIANCE CCDE3,

ORDINANCES, AND REGULATIONS

(_) PLACE JUMPER

Figure36:WiringofProbeLWCO

21

Page 30

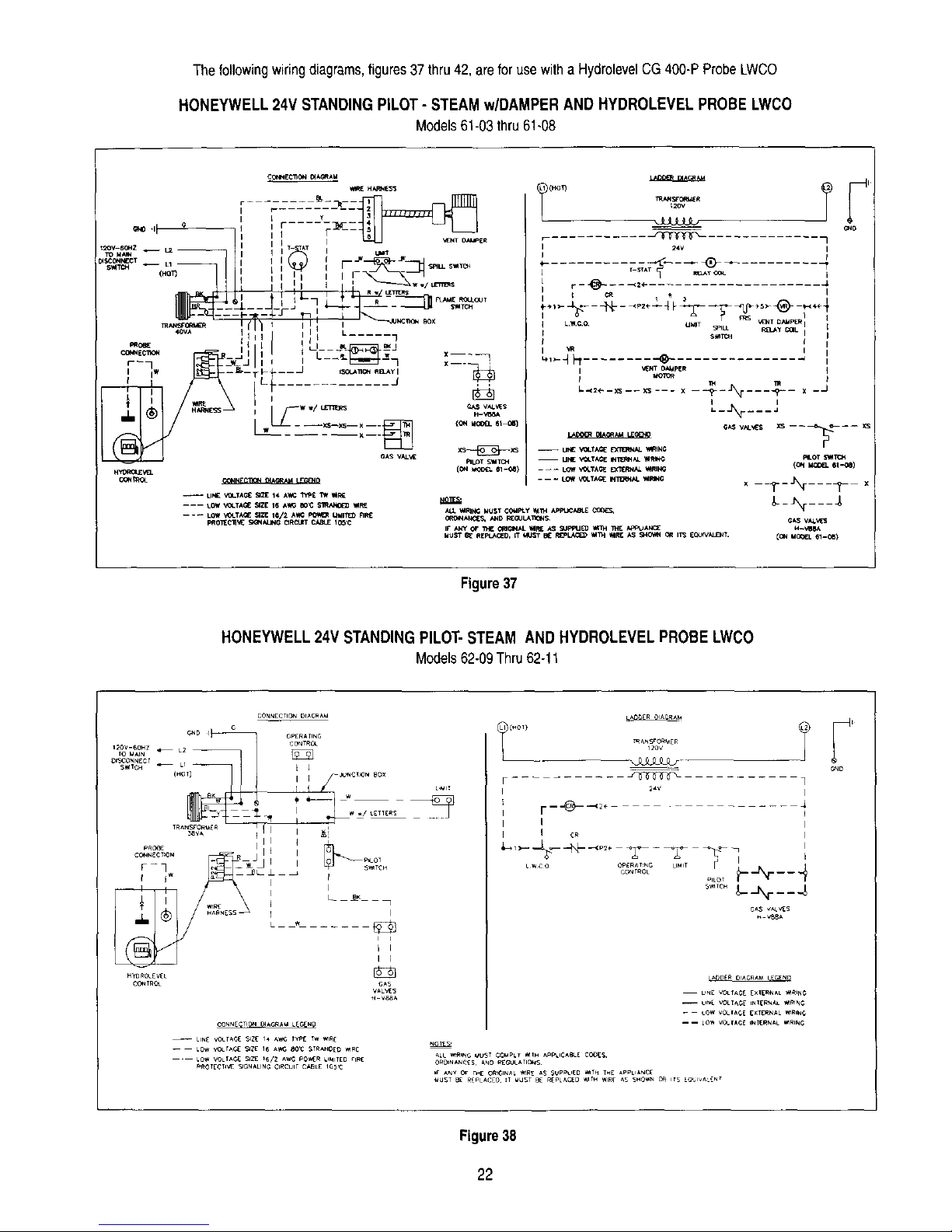

Thefollowingwiringdiagrams,figures37thru42,areforusewitha HydrolevelCG400-PProbeLWCO

HONEYWELL 24V STANDING PILOT - STEAM w/DAMPER AND HYDROLEVEL PROBE LWCO

Models61-03thru61-08

_SCON_J_T

S_TC _ -- L1

(HO

mANSF_

4OVA

PROBE

_E C_I_t -- -

r],

-- UN£ ",_.TA_ Sa21E14 AW_ _ TW tF, E

-- __ LOw t@-T_ NIl 1_/2 A_4_ _ UMI11_ RF_

C_,INEC_ _A_AU

_ H_ESS

r F

R

I : F _¢ _ _kL S_

I

I I I I r--

I x---_

I

L / _, ,

i___w w/ _ _ vat.s

- ---,=-_-- _<Zz_r_ 1 ion._o___ =1

CAS VAL_ _S---_-_XS

(ol+ii_ 61-0_)

ALL I_IRING MUST COMPly _n_ APP',JOm_

IF" ANy OF _ O_dG_NALI_R_ AS _JPPU_ _ _ P4_PI_AN_E

MUST _ REPtJ_C_O, IT 141JST BE R_PLl_ll_ _l113t llIRE AS SitO_I_4OR I/'3 _CAJIVALD_T.

/

RLOT metC_

-_---%---_- x

_-_N____

Figure37

HONEYWELL 24V STANDING PILOT-STEAM AND HYDROLEVEL PROBE LWCO

Models62-09Thru62-11

HYO_OLEV_L

CO_TRC_

CONNECTION DIAGRAU LEC,_NO

-- UN£ vo_r,_c_ _Z_ i,, _,wc WP[ _w ,_

LOW VO_IAC_ _zt _/2 ,_w_; pO_R UMIT[D rIFle

_OTE¢_V_ _ON_.LING ¢l_tCulr CABLE IO_:

I I

I I

V88_

I I

I I cR

L_co OP_R,_T_G LIMIT

CONTROL

L

F ....... J_ ]

I r--'@-_+ ....

I

I

.....

..... __N___ 4

G_S VALES

V88A

LADDEROAGIIAW G NB

U_E V0LrAG£ EXI[R_AL '_I_ING

GND

Figure38

22

Page 31

HONEYWELL SPARK IGNITION (HSP) - STEAM w/DAMPER AND HYDROLEVEL PROBELWCO

Models61-03thru61-07

CO_EClrO_ I_AGRAM

MRE HARNESS

! i i]ilZSS]

............ _1 . T,E,.O_,,T L....... I_,%

TRAN_C_M( R "l _

*,OVA

HY'OROLEVEL

CONNECTION =ACRa_ LEGE_ ! )WBK _ P_LOT BURN[r

m I¢_IIlON k _,_N_NG CABLE

LOWVOLI'_CE _ZE _6 _,WG aO_ STRa_C_D V4RE

---- LOW VOLIACE _ZE 16/2 AWG pO_'_ERLIM_TEOnRE G*_S vaU_

PROECnVE SIgnALING CIK'CUIt CABLE 105_3

O I_1_O N COnTr.. lgR_IN;*L

_) CROdND LE^0_E SIZE t6 AWC _00',3 _TRAND_D 'MI_E

T_N_FORME _

24V

/

•_,,---,_---.1_........ ;g Fo _ ,_ "p....... @.......

<_ _ rRS

LW¢O u_m_ _LL

,m

......_F: ......... ® ....................................

: VEN] _AMpE_? IGNIIE R

-- UN_ VOL;ACE INERNAL _IRING

UV

..... LOW _IDL_CE INT_RNA L _4RING : O=..=J_t _ .V/F=V

ALL _NG MUST COMPLY _ APPUCA_E CODEg G_ V_LVE

ORDNANCES AND _[_UL_T_OnS

rr AN_ OF THE oN6mNAL _E AS _PPLIED _'_TH THE A_IANCE

_USJ 8( r_EpLA¢£D tT _lUgT _ RfPL_Cf_ _TH WIRE AS SHO_IN OR FTS [oUWAI_NT

Figure39

HONEYWELL SPARK IGNITION (HSP-2) - STEAM w/DAMPER AND HYDROLEVEL PROBE LWCO

Model61-08only

PROT_CTNES_ O_O_t C_t£ I_

-fir

,,

I i*-nm"_ m_ __

I[' "%

e_s v,_u_

r..--- ¢[

i

v_v_

_o_

Figure40

23

Page 32

HONEYWELL SPARK IGNITION (HSP-1) - w/DUAL 24V MAIN GAS VALVESAND HYDROLEVEL PROBE LWCO

Models62-09thru62-15

............Ti(HOt)

IRANsrO_E_

_OV

_J3LLLt_

o,o

_'Iv i

I I

....

VAL_

-- LING VOtT;_C[EXT_F_N_L _e,NG

Figure41

HONEYWELL SPARK IGNITION (HSP-1) - w/DUAL 120V MAIN GASVALVES AND HYDROLEVEL PROBE LWCO

Models62-09thru62-15

CONNCC_ON DIACP,_U

rIIIC0_NECT _ i I I I

v • _ f I

.+,1 /_ \\ m ; j

- ' _ iiP _ -- G_S VALVES

HYr)NOLfV[L I t _

,,,..<,.,°%,,.,,y,,,,_,:,.,?,,,o,< ,..... W _-_ ]

ION'T'ON CONISOL I_P,'_INAL

_) GRoUNO LEAOIRE _ll{ 16 J_ 200C STRANDED IRE

(H°T) IRI 2RI 2_

T_AN_'0l_ ER

_V I

r_ ___.,._ .......

i IC'WITER I

; t :.- _ --_ - .<p2e

-- pr_A _ '_T _V _V/PV PV icN_o_

_wco OG _G LMIT _C (

I I I

,,

| |

-- LINGVOLTAGE E_IERNAL ,_RINe _I-- _

_C2_5

Figure42

24

Page 33

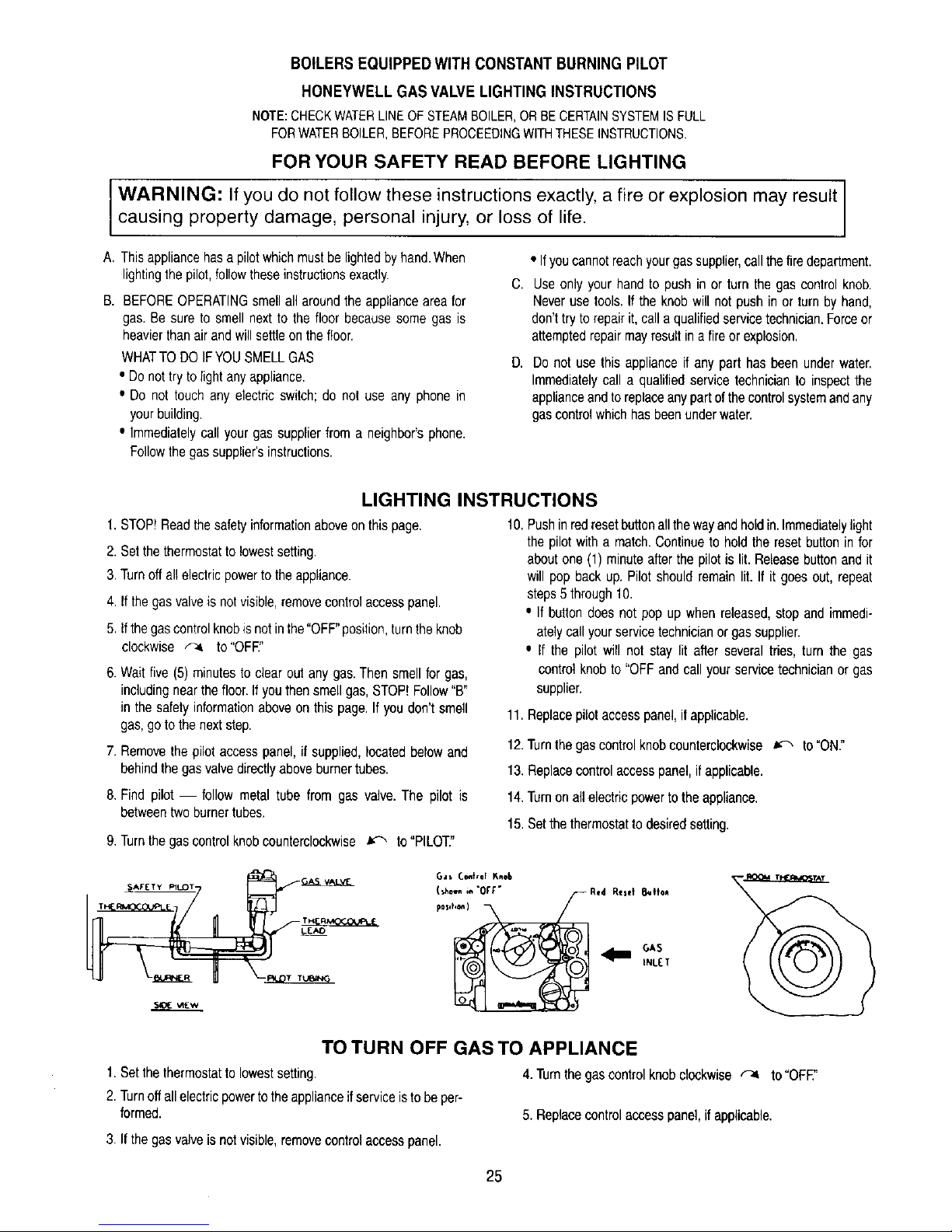

BOILERSEQUIPPEDWITHCONSTANTBURNINGPILOT

HONEYWELL GAS VALVELIGHTINGINSTRUCTIONS

NOTE:CHECKWATERLINEOFSTEAMBOILER,ORBECERTAINSYSTEMISFULL

FORWATERBOILER,BEFOREPROCEEDINGWITHTHESEINSTRUCTIONS.

FOR YOUR SAFETY READ BEFORE LIGHTING

WARNING: If you do not follow these instructions exactly, a fire or explosion may result

causing property damage, personal injury, or loss of life.

A, This appliance has a pilotwhichmust be lightedby hand.When

lightingthepilot, follow theseinstructionsexactly.

B. BEFORE OPERATINGsmell all around theappliance area for

gas. Be sure to smell next to the floor because some gas is

heavier thanair and will settleon the floor.

WHATTO DO IFYOUSMELL GAS

• Do not try to light any appliance.

e Do not touch any electric switch; do not use any phone in

your building.

• Immediately call your gas supplier from a neighbor'sphone.

Followthe gas supplier's instructions.

C,

D,

• Ifyou cannot reachyourgas supplier,callthe fire department.

Use only your hand to push in or turn the gas control knob.

Neveruse tools. If the knob will not push in or turn by hand,

don't try to repair it, call a qualifiedservicetechnician.Forceor

attemptedrepair mayresult in a fireor explosion,

Donot usethis applianceif anyparthasbeenunderwater.

Immediatelycall a qualifiedservicetechnicianto inspectthe

applianceandtoreplaceanypartofthecontrolsystemandany

gascontrolwhichhasbeenunderwater.

LIGHTING INSTRUCTIONS

1.STOP!Read the safety information aboveon this page.

2. Set the thermostatto lowest setting.

3. Turnoff all electric powerto the appliance.

4. If the gas valve is not visible, removecontrol access panel.

5. If the gascontrol knobis not inthe "OFF"position,turnthe knob

clockwise _ to"OFF."

6. Wait five (5) minutesto clear out any gas. Then smell for gas,

includingnear the floor.Ifyou then smell gas, STOP! Follow"B*

in the safety informationabove on this page. If you don't smell

gas, go to the nextstep.

7. Removethe pilotaccess panel, if supplied, located below and

behind the gas valve directly above burner tubes.

10.Pushinredresetbuttonallthewayandholdin.Immediatelylight

thepilotwitha match.Continueto holdthe resetbuttoninfor

aboutone(1) minuteafterthepilotis lit.Releasebuttonandit

will popbackup,Pilotshouldremainlit. If it goesout,repeat

steps5through10.

• If buttondoesnotpop upwhenreleased,stopand immedi-

atelycallyourservicetechnicianorgassupplier.

• If the pilotwill notstay lit after severaltries,turn the gas

controlknobto "OFFandcallyourservicetechnicianor gas

supplier.

11.Replacepilotaccesspanel,ifapplicable.

12.Turnthegascontrolknobcounterclockwise_ to=ON."

13.Replacecontrolaccesspanel,ifapplicable.

8. Findpilot followmetaltube from gas valve.The pilot is

betweentwoburnertubes.

9.Turnthegascontrolknobcounterclockwise_ to"PILOT"

14.Turnonallelectricpowertotheappliance.

15.Setthethermostattodesiredsetting.

S_E _Ew

Ga* Cont,_l Knob

(-_n ,,_"OFF" Rtd Reset 8ulto*

P°""') _ S

tNL[T

TO TURN OFF GAS TO APPLIANCE

1.Setthe thermostat to lowestsetting. 4. Turnthe gas control knob clockwise _ to "OFE"

2. Turnoff all electric powerto the applianceif service istobe per-

formed. 5. Replacecontrol access panel,if applicable.

3. If the gas valve isnot visible, removecontrol access panel.

25

Page 34

BOILERS EQUIPPEDWITH ELECTRIC IGNITION AND A COMBINATIONGAS VALVE

OPERATING INSTRUCTIONS

NOTE:CHECKWATERLINEOFSTEAMBOILER,OR BE CERTAINSYSTEMISFULL

FORWATERBOILER,BEFOREPROCEEDINGWITHTHESEINSTRUCTIONS.

FOR YOUR SAFETY READ BEFORE OPERATING

WARNING: If you do not follow these instructions exactly, a fire or explosion may result

causing property damage, personal injury, or loss of life.

A. This appliance isequipped with an ignitiondevice which auto-

matically lightsthe pilot.Do not try to lightthe pilot by hand.

B. BEFORE OPERATINGsmell all around the appliance area for

gas. Be sure to smell next to the floor because some gas is

heavier thanair and will settle on the floor.

WHATTO DO IFYOU SMELL GAS

• Do not try to light anyappliance.

• Do not touchany electric switch; do not use any phone in

yourbuilding.

• Immediately call your gas supplier from a neighbor's phone.

Followthe gas supplier's instructions.

C.

D,

• If youcannotreachyour gassupplier,call thefire department.

Useonlyyourhandto pushin or turn thegascontrolknob.

Neverusetools.Ifthe knobwillnotpushin orturn by hand,

don'ttryto repairit,callaqualifiedservicetechnician.Forceor

attemptedrepairmayresultinafireor explosion.

Donotusethis applianceif anypart hasbeenunderwater.

Immediatelycall a qualifiedservicetechnicianto inspectthe

applianceandtoreplaceanypartofthecontrolsystemandany

gascontrolwhichhasbeenunderwater.

OPERATING INSTRUCTIONS

1.STOP!Readthesafetyinformationaboveonthispage.

2.Setthethermostatto lowestsetting.

3.Turnoffallelectricpowertotheappliance.

7.Waitfive (5)minutesto clearoutany gas.Thensmellforgas,

includingnearthe floor.If yousmellgas,STOP!Follow=B"in

thesafetyinformationaboveonthispage.Ifyoudon'tsmellgas,

gotothenextstep,

4. This appliance is equippedwith an ignitiondevice which auto-

matically lights the pilot.De not try to lightthe pilotby hand.

5. Ifthe gas valve is not visible, removecontrol access panel.

6. Ifthe gas control knobis not inthe "OFF position,turn the knob

dcokwise f-4 to "OFF"

8.Turnthegascontrolknobcounterclockwise_ to"ON."

9.Replacecontrolaccesspanel,ifapplicable,

10.Turnonallelectricpowerto the appliance.

11.Setthethermostattodesiredsetting.

12.If theappliancewillnotoperate,followtheinstructions"ToTurn

Off GasToAppliance"andcallyourservicetechnicianor gas

supplier.

H_H VOLTAC,_

Gas Conlrol Knob

position)_

6A5

INLIT

TO TURN OFF GAS TO APPLIANCE

1. Set the thermostatto lowestsetting. 4. Turnthe gascontrolknobclockwise F-4 to"OFF:'

2.Turnoff all electricpowertothe appliance ifserviceis to be per-

formed. 5. Replacecontrol access panel,if applicable.

3. Ifthe gas valveis not visible, removecontrol accesspanel.

26

Page 35

RefertoFigure43withthefollowinginstructions

BOILERS EQUIPPED WITH ELECTRIC IGNITION AND DUAL GAS VALVE

LIGHTING INSTRUCTIONS

NOTE:CHECKWATERLINEOF STEAMBOILER,ORBECERTAINSYSTEMISFULL

FORWATERBOILER,BEFOREPROCEEDINGWITHTHESEINSTRUCTIONS.

FOR YOUR SAFETY READ BEFORE LIGHTING

WARNING: If you do not follow these instructions exactly, a fire or explosion may result

causing property damage, personal injury, or loss of life.

A. This appliance is equipped with both a secondary pilot which

mustbe lighted by hand, and an ignition devicewhich automat-

ically lights the main pilot. Light only the secondary pilot by

handfollowingthese instructionsexactly.

B. BEFORE OPERATINGsmell all around the appliance area for

gas. Be sure to smell next to the floor because some gas is

heavierthan air andwill settle on the floor.

WHATTO DO IFYOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do not use any phone in

yourbuilding.

C.

B.

• Immediatelycall your gas supplier from a neighbor's phone,

Followthe gas supplier'sinstructions.

• If youcannot reachyour gas supplier,call thefire department,

Useonlyyourhandto pushin orturn the gas controlknob.

Neverusetools.If theknobwill notpushin or turnbyhand,

don'ttrytorepairit,calla qualifiedservicetechnician.Forceor

attemptedrepairmayresultinafire orexplosion.

Donotusethis applianceif anyparthasbeenunderwater.

Immediatelycalla qualifiedservicetechnicianto inspectthe

applianceandtoreplaceanypartofthecontrolsystemandany

gascontrolwhichhasbeenunderwater.

LIGHTING INSTRUCTIONS

1.STOP!Readthesafetyinformationaboveonthispage.

2.Setthethermostatto lowestsetting.

3.Turnoffallelectricpowerto theappliance.

4.Ifthegascontrolassemblyisnotvisible,removecontrolaccess

panel.Refertocontrolassemblyonfollowingpage.

5.Ifthemanualshut-offleverandpilotcockarenotinthe"OFF"

position,turnbothclockwise_-4 to"OFF."

Pil©_ Cock

{ 5how_in "ofF*

Man_al S_tu_- 0ll _osd_on)

Lever (s_o,n ;, -o[r-

6. Wait five (5) minutesto clear out any gas. If you smell gas,

STOP! Follow"B"inthe safetyinformationabove on this page.

Ifyoudon'tsmell gas, goto the nextstep.

7.Removethepilotaccesspanel,if supplied,locatedbelowand

behindthegasvalvedirectlyaboveburnertubes.

8.Findsecondarypilot-- followmetaltubefromgasvalve.Pilotis

betweentwoburnertubes.

R**d Rese+

Svff_,

9.Turnthepilotcockhandlecounterclockwise_ to"ON."

10.Pushin redresetbuttonon pilotvalveallthewayandholdin.

Immediatelylightthepilotwitha match.Continueto holdthe

resetbuttonin for aboutone (1) minuteafterthe pilotis lit.

Releasebuttonanditwillpopbackup.Pilotshouldremainlit.If

itgoesout,repeatsteps5through10.

• If resetbuttondoesnotpopupwhenreleased,stopandimme-

diatelycallyourservicetechnicianorgassupplier.

• Ifthepilotwillnotstaylitafterseveraltries,turnthepilotcock

handleto"OFF"andcallyourservicetechnicianorgas

supplier.

11.Replacepilotaccesspanel,ifapplicable.

12.Turnrnanualshut-offlevercountercleckwise_ to"ON."

13.Replacecontrolaccesspanel,ifapplicable.

14.Turnonallelectricpowertotheappliance.

15.Setthermostattodesiredsetting.

16.Iftheappliancewi[Inotoperate,followtheinstructions"ToTurn

Off GasToAppliance"andcall yourservicetechnicianor gas

supplier.

TO TURN OFF GAS TO APPLIANCE

1.Setthe thermostat to lowestsetting.

2. Turnoff all electric powerto the applianceif service isto be per-

formed.

3.Ifthegascontrolassemblyisnotvisible,removecontrolaccess

panel.

4. Turnthe pilotcock and the manual shut-off lever clockwise

to "OFF

5.Replacecontrolaccesspanel,ifapplicable.

27

Page 36

SIAqK IGNITED pILOT _STO. PILOT

IGNITI

BLEED TUBING

--VENT TO 118*qBLEED TU6E OR TO OUTSIDE

ATMOSPHERE WELL /M3OVE NORMAL _REATHING

LEVEL AS APPLICABLE

PILOT GAS VALVE

I/4" TEST

PILOT

pILOT COCK

MANUAL S:_UT -OFF

VALVE

E_ _ THERMOCOUPLE

LEAD

IGNITION CONTROL

BO_

LEFT SIOC JACKET PANEL

Figure43:HSPControlSystemandIgnitionControlBoxLocation

Models62-09thru62-15

28

Page 37

RefertoFigure44withthefollowinginstructions

BOILERS EQUIPPEDWITH ELECTRIC IGNITION AND A COMBINATION GAS VALVE

OPERATING INSTRUCTIONS

NOTE:CHECKWATERLINEOF STEAMBOILER,ORBE CERTAINSYSTEMIS FULL

FORWATERBOILER,BEFOREPROCEEDINGWITHTHESEINSTRUCTIONS.

FOR YOUR SAFETY READ BEFORE OPERATING

WARNING: If you do not follow these instructions exactly, a fire or explosion may result

causing property damage, personal injury, or loss of life.

A. Thisapplianceisequippedwithanignitiondevicewhichauto-

maticallylightsthepilots.Donotfryto lightthepilotsbyhand.

B. BEFOREOPERATINGsmellallaroundtheapplianceareafor

gas.Be sureto smellnextto the floorbecausesomegas is

heavierthanairandwillsettleonthefloor.

WHATTODOIFYOUSMELLGAS

• Donottrytolightanyappliance.

• Donottouchanyelectricswitch;donotuseanyphonein

yourbuilding.

• Immediatelycallyourgassupplierfroma neighbor'sphone.

Followthegassupplier'sinstructions.

• Ifyoucannotreachyourgassupplier,callthefiredepartment.

C.

D,

Use only your hand to push in or turn the gas control knob.

Neveruse tools. If the knob will not push in or turn by hand,

don't try to repair it, call a qualified service technician.Force or

attempted repairmay result in a fire or explosion.

Donotusethisapplianceif any part hasbeenunderwater.

Immediatelycalla qualifiedservicetechnicianto inspectthe

applianceandtoreplaceanypartofthecontrolsystemandany

gascontrolwhichhasbeenunderwater.

OPERATING INSTRUCTIONS

1. STOP! Readthe safety informationaboveon this page. 7. Wait five (5) minutes to clear out any gas. Then smell for gas,

2.Setthethermostatto lowestsetting.

3.Turnoffallelectricpowerto theappliance.

4.Thisapplianceisequippedwithanignitiondevicewhichauto-

maticallylightsthepilots.Donot trytolightthepilotsbyhand.

5.If the gasvalveis not visible,removecontrolaccesspanel.

Refertocontrolassemblyonfollowingpage.

6.Ifthegascontrolknobandpilotcockarenotinthe"OFF"

position,turnbothclockwise_ to"OFF."

includingnear the floor.Ifyou smellgas, STOP!Follow"B" inthe

safetyinformationaboveon this page. If you don't smell gas,go

tothe nextstep.

8. Turnthe gas control knob and pitotcock counterclockwise

to"ON."

9. Replacecontrolaccess panel, if applicable.

10.Turn on all electric power to the appliance.

11. Set the thermostatto desired setting.

,,,,,c,,, 12. If the appliance willnot operate, follow lhe instructions "ToTurn

"""'°'" Off Gas To Appliance" and call your service technician or gas

Gas Control Knob ............ o.- supplier.

(shownin "OFF....... --_

TO TURN OFF GAS TO APPLIANCE

t. Setthethermostattolowestsetting. 4.Turnthegascontrolknobandpilotcockclockwise_-4

2.Turnoffallelectricpowertotheapplianceifserviceistobeper- to"OFF."

formed.

3.Ifthegasvalveisnotvisible,removecontrolaccesspanel. 5.Replacecontrolaccesspanel,ifapplicable.

29

Page 38

SpAR_ IGNkTEO PLLOT

_N GAS VALVE

\

\

\

\

\

\

_ lLO__T _ VALVE

PILOT COCK

Figure44:HSP-2ControlSystem

Model61-08

30

Page 39

RefertoFigure45withthefollowinginstructions

BOILERS EQUIPPED WITH CONSTANT BURNING PILOT(S)

LIGHTING INSTRUCTIONS

NOTE:CHECKWATERLINEOFSTEAMBOILER,ORBECERTAINSYSTEMISFULL

FORWATERBOILER,BEFOREPROCEEDINGWITHTHESEINSTRUCTIONS.

FOR YOUR SAFETY READ BEFORE LIGHTING

WARNING: If you do not follow these instructions exactly, a fire or explosion may result

causing property damage, personal injury, or loss of life.

A. This appliance has pilotswhich must be lightedby hand.When

lightingthe pilots, followtheseinstructionsexactly.

B. BEFORE OPERATINGsmel_all around the appliance area for

gas. Be sure to smell next to the floor because some gas is

heavierthan air and will settleon the floor.

WHATTO DO IFYOUSMELL GAS

• Do not try to lightany appliance.

• Do not touch any electric switch; do not use any phone in

your building.

• Immediately call your gas supplier from a neighbor'sphone.

Followthe gas supplier's instructions.

C.

D,

• Ifyoucannotreachyourgassupplier,callthefiredepartment.

Use only your hand to push in or turn the gas control knob.

Neveruse tools. If the knob will not push in or turn by hand,

don't try to repairit, call a qualifiedservice technician. Forceor

attemptedrepairmayresultina fire or explosion.

Donotusethisapplianceif anyparthasbeenunderwater.

Immediatelycalla qualifiedservicetechnicianto inspectthe

applianceandtoreplaceanypartofthecontrolsystemandany

gascontrolwhichhasbeenunderwater.

LIGHTING INSTRUCTIONS

1. STOP!Read the safety informationaboveon thispage.

2. Setthe thermostatto lowest setting.

3.Turnoff all electric powerto the appliance.

4. Ifthe gascontrol assemblyis not visible, removecontrolaccess

panel,

5. gthe manualshut-off lever and pilot cock are not in the "OFF"

position,turnbothe,ockwiseto"OFF" ,o'o

posi_ion)_

6.Wait five (5) minutes to clear out any gas. If Nu smell gas,

includingnear the floor.Ifyousmell gas, STOP!Follow"B"in the

safety informationaboveon this page.If you don't smell gas, go

to the next step.

Vah_

9. Turnthe pilotcockhandlecounterclockwise _ to "ON."

10. Push inred reset buttonon righthand pilot valveall thewayand

hold in. Immediately light the right hand pilot with a match.

Continueto holdthe resetbutton in forabout one (1)minuteafter

the pilot is lit. Release button and it will pop back up, Pilot

shouldremainlit. If it goesout, repeat steps 5 through10.

11.

Repeatabovelightingprocedurewithlefthandpilotvalveand

lefthandpilot.

• Ifeitherbuttondoesnotpopupwhenreleased,stopand

immediatelycallyourservicetechnicianorgassupplier.

• Ifthepilotswillnotstaylitafterseveraltries,turnthepilot

cockhandleto"OFF"andcallyourservicetechnicianor

gassupplier.

12. Replace pilotaccess panel,if applicable.

7.Removethepilotaccesspanel,if supplied,locatedbelowand

behindthegasvalvedirectlyaboveburnertubes.

8.Findpilots-- followmetaltubefromeachpilotvalve.Eachpilot

isbetweentwoburnertubes.

13.

14.

15.

16.

Turnmanual shut-offlevercountercloekwise _ to"ON."

Replacecontrolaccess panel,if applicable.

Turnon all electric powerto the appliance.

Set thermostatto desired setting.

TO TURN OFF GAS TO APPLIANCE

1,Setthe thermostat to lowestsetting.

2. Turnoff all electric powerto the appliance ifservice is tobe per-

formed.

3. Ifthegascontrolassemblyisnotvisible,removecontrolaccess

panel.

4. Turnthe pilot cockandthe manual shut-offleverclockwise

to"OFF."

5. Replacecontrol accesspanel, ifapplicable.

31

Page 40

I/8"BLEED

GAS PI_ESSURE REGULATOR

_/_INNER FRONT J,t*CKET PANEL

16_"

i,, 7,,

_2 2 _8 F_LOT

- THERMC_ILOT

I/4" TEST

TAP

MAIN SAFETY _ ]'F_- P_

T PERMOCOUPLE

FLOO R LINE

Figure45:24 VoltControlSystemw/DualValves

Models61-08,62-09thru62-11

32

Page 41

0 - INSTRUCTIONS FOR OPERATION

1--The installationisnot completeuntilRatingand LightingPlatesareon the boilerandthe"UsersInformationManual"and "Installation

Instructions"arehungneartheboiler

2--System shouldbe maintainedingoodrepair.Radiators,baseboardunitsand/orconvectorsmustbekeptclean.

:_lf a radiatordoes notheatallover.air has probablyaccumulatedandshouldbevented.

P- CHECKOUTPROCEDURE

1--Afterstartingboiler,becertainall controlsareworkingproperlybeforeleavingit unattended,Checkto besure thatthe temperaturelimitcontrol

will shutoffthe boilerin theeventof excessivetemperature,by loweringlimitsetpointuntil mainburnersshutdown,Returnlimitto desiredset

point.

2_heck gastightnessof maingasvalvewhenclosedtobe certainthereis noleakageto theburners.Checkalljointsperiodicallyforgas

teakage.Usesoapsolutionto checkleakage.

3_heck theoperationofthe ignitionsystemsafetyshut-offdeviceusingthefollowingmethod:

a.ConstantBurningPilot:Withthegascockknobin the pilotposition,extinguishpilotflameand makecertainthe gasvalveshutsoffgasflow

to thepilotwithintwo (2)minutes,Torelight follow"LightingInstructions".

b.SparkIgnitionSystems:Withtheunitoperating,turnoff thegasat the inletshut-offvalveupstreamfromtheboiler.Theunitwill spark

attemptto relight.If pilotlock-outisprovided,thesparkwillstopwithinninety(90)seconds,Torelightfollow"OperatingInstructions".

Q - SHUT-DOWN CAUSED BY PILOT OUTAGE, VENT SAFETY SHUT OFF SWITCH OR FLAME ROLL-OUT SAFETY SHUT OFF

SWITCH

1--1nthe eventof ashut-downcausedby a pilotoutage,actionof the ventsafetyshutoffswitchorflameroll-outsafetyshut-offswitcheffectinga

shut-downof themain burners:

a.Turnoffall electricpowertothe boiler.

b.Referto"Lightingor OperatingInstructions"andturngascockknobto"off"position.

c. Callaqualifiedheatingserviceorganizationorlocalgascompanyandhavethe causeof the shut-downinvestigatedand corrected.

d. Referto "Lightingor OperatingInstructions"to re-startboiler.

- NOTE:-

SHOULDOVERHEATINGOCCURORTHEGASSUPPLYFAILTO SHUTOFF,DONOTTURNOFFORDISCONNECTTHE ELECTRICAL

SUPPLYTOTHEPUMP,INSTEAD,SHUTOFFTHEGASSUPPLYATA LOCATIONEXTERNALTOTHEAPPLIANCE.

DO NOTUSETHISAPPLIANCEIFANY PARTHASBEENUNDERWATER,IMMEDIATELYCALLA QUALIFIEDSERVICETECHNICIANTO

INSPECTTHEBOILERANDTOREPLACEANY PARTOFTHECONTROLSYSTEMANDANYGASCONTROLWHICHAS BEENUNDER

WATER.

33

Page 42

Cleaning the Series 61162Steam Boiler with Skim Tapping

Thefollowingcleaningprocedureshallbe performedbya qualifiedserviceperson.

1. Cleantheboileras describedbelowno laterthanoneweekaftertheinitialstart up,Cleaningwillbe moreeffectiveiftheboileroperatesa day

ortwoto loosensedimentand impuritiesinthesystem.

2, Theboiler mustbe cleanedto removeanyaccumulatior_ofoil, grease,sludge,etc.thatmaybeinthesystem,Thesesubstancescancause

foamingand surgingofthe boilerwater,producingan unstablewaterlineandwatercarryoverto thesystem,

WARNING:CLEANINGTHEBOILERREQUIRESTHEUSEOFVERY HOTWATERANDCORROSIVECHEMICALS.USECAREWHEN

HANDLINGTO PREVENTiNJURY.