R

PROTECT

TEMP

SIG/CLIP

BRIDGE

CH D

0

-

CONTROLLED RADIATION

User’s Manual

TEMP

PROTECT

SIG/CLIP

BRIDGE

0

-

CH A

0

-

CH B

0

-

CH C

PS ampliers

PS amps

USER’S MANUAL

SOUND REINFORCEMENT CONTROLLED RADIATION ACOUSTIC RESEARCH

CONTROLLED RADIATION

1

AC

50Hz-60H

R

PROTECT

TEMP

SIG/CLIP

BRIDGE

CH D

0

-

User’s Manual

TEMP

PROTECT

SIG/CLIP

BRIDGE

0

-

CH A

0

-

CH B

0

-

CH C

PS ampliers

TABLE OF CONTENTS

1. IMPORTANT SAFETY INSTRUCTIONS pag. 3

2. DECLARATION OF CONFORMITY pag. 3

3. WARRANTY pag. 3

4. USER LIABILITY pag. 4

4.1 Damage to speakers

4.2 Dangerous output voltage

4.3 Radio interferences

5. INTRODUCTION pag. 4

5.1 Unpacking

5.2 Installation

5.3 Front panels

5.4 Rear panels

6. BRIEF DESCRIPTION OF THE SERIES pag. 7

7. OPERATING INSTRUCTIONS pag. 8

7.1 Connection to the AC mains supply and power absorption

7.2 Cooling

7.3 Connection cables

7.4 Configurations

8. PROTECTION SYSTEM FEATURES pag. 10

8.1 Limiter

8.2 Thermal protection

8.3 Load safety control

8.4 DC protection

8.5 Power on/off transients

9. TESTING PROCEDURE FOR ELECTRO-MECHANICAL OPERATION pag. 10

9.3 Electrical testing procedures

10. TECHNICAL SPECIFICATIONS pag. 12

SOUND REINFORCEMENT ACOUSTIC RESEARCHCONTROLLED RADIATION

2

9.1 Required equipment

9.2 Visual check

R

PROTECT

TEMP

SIG/CLIP

BRIDGE

CH D

0

-

User’s Manual

TEMP

PROTECT

SIG/CLIP

BRIDGE

0

-

CH A

0

-

CH B

0

-

CH C

PS ampliers

1. IMPORTANT SAFETY INSTRUCTIONS

This symbol indicates key operating instructions and

information requiring particular attention for correct use

of the product.

This symbol warns of dangerous voltage and the

consequent risk of electric shock. Take extra care and

proceed with caution.

1. Read carefully all the attached product documentation and keep for

further reference.

2. Heed the warnings.

3. Keep the packaging and check that all the material is in perfect

condition.

4. Do not use the product in the vicinity of water or pour water or any

other liquid on the amplier. Take care not to use it with wet hands or

with your feet in water.

5. Do not use near sources of heat such as radiators, stoves or other heatproducing appliances.

6. Check that the power cable is intact and undamaged. Do not tread on

the cable and take care not to put any pressure on the plug.

7. Connect the plug to a properly earthed electric socket. Do not tamper

with the plug. Should the plug supplied not t your socket, have an

electrician replace it with the correct one.

8. Connect to the mains supply having identical voltage as that indicated

on the back of the amplier.

9. Install the amplier in compliance with the instructions.

10. Do not obstruct the air ducts.

11. Disconnect the appliance in case of storms or when not in use.

12. Wire exclusively as shown in the instructions.

13. Do not remove the upper or lower covers as this would expose the

user to the risk of electric shock.

14. Do not attempt to repair the appliance yourself but always seek the

assistance of qualied technicians.

15. Do not connect an input signal higher than that indicated in the

manual.

16. Do not connect the amplier output to the input of another channel.

17. Do not connect the amplier output to any other power source such as

batteries, power supply unit or mains outlets, regardless of whether the

amplier is switched on or o.

18. Clean with a dry cloth only.

19. The product must be handled by qualied technicians when:

• the power cable or the plug is damaged

• the product has been exposed to rain or humidity

• liquid has got inside the unit

• an object has fallen on the unit

• the unit has fallen and is damaged

• the appliance seems to be malfunctioning or is showing a marked

change in performance

20. Careful supervision is required if the product is used in the presence of

children or by unskilled adults.

21. This appliance may produce sound pressure levels damaging to the

hearing. Take the utmost care and do not use the product for long

periods of time at high or uncomfortable volume levels. Should

you experience any hearing loss or buzzing in your ears, consult an

audiometric specialist.

2. DECLARATION OF CONFORMITY

This device complies with the requirements of the European Electromagnetic

Compatibility Directive 89/336/EEC and relevant 92/31/EEC amendment, as

well as the requirements of the Low Voltage Directive 72/23/EEC and relevant

93/68/EE amendment.

Regulations applied:

EN55103-1 (Emissions)

EN55103-2 (Immunity)

EN60065, Class I (Safety).

3. WARRANTY

Peecker Sound products are guaranteed against malfunction due to defective

materials or workmanship for a specied period of time, starting from the date

of original purchase. Should a malfunction occur during the warranty period,

the product will be repaired or replaced (at the manufacturer’s discretion) free

of charge. The shipping costs and related risks, and any loss during shipment

to authorized service centres are the responsibility of the customer. The

product will be returned to the customer with a carriage forward shipment.

Warranty terms

The warranty covers the appliance under its initial purchase in compliance

with the laws in force. The warranty is valid for 3 years, starting from the date

of receipt of the product. Peecker Sound reserves the right, in certain cases, to

decide to replace the appliance with another identical or similar product. The

warranty is not extended following a product failure. The warranty does not

cover any incidental or consequential damages, without limitation, caused to

persons or property during any period of inefficiency of the appliance.

Exclusions and limitations

The warranty does not apply to:

• any damage to exterior nishings or surfaces, aesthetic elements, or electric/

electronic parts resulting from negligent use of the product;

• malfunction resulting from incorrect or improper use of the product or from

transport without due care;

• malfunction resulting from repairs carried out by unauthorized persons or

service centres;

• malfunction due to circumstances that cannot be ascribed to manufacturing

defects of the appliance;

• plastic or glass parts, bulbs and the like, as well as all that can be regarded

as normal wear and tear. As regards circuit components (transistors, diodes,

etc.) the general terms set by the original manufacturers apply.

The following are also not covered by the warranty:

• damage caused by accidents, product modications, negligence or incorrect

connection

• damage that occurred during transport

• damage resulting from failure to comply with the instructions contained in

the user’s manual

• claims based on misrepresentations by the seller and any product whose

serial number has been rubbed o, modied or removed.

Receiving warranty service

To receive repair or replacement of the product under warranty, the customer

must deliver the product in its original packaging carriage paid to an

authorized Peecker Sound service centre together with the relevant proof of

purchase, i.e. bill of sale, receipt or invoice.

The warranty service and list of authorized service centres is available at the

address below:

Peecker Sound - “After Sales Service”

Via Monti Urali, 29 - 42100 Reggio Emilia (Italy)

Tel: +39 0522 557735 - Fax: +39 0522 391268

E-mail: info@peeckersound.com

SOUND REINFORCEMENT CONTROLLED RADIATION ACOUSTIC RESEARCH

CONTROLLED RADIATION

3

AC

50Hz-60H

R

PROTECT

TEMP

SIG/CLIP

BRIDGE

CH D

0

-

User’s Manual

TEMP

PROTECT

SIG/CLIP

BRIDGE

0

-

CH A

0

-

CH B

0

-

CH C

PS ampliers

Repair or replacement of the product and its return to the customer are the

only services provided to the customer. Peecker Sound shall not be held liable

to pay incidental or consequential damages including, without limitation,

injury to persons or property or loss of use.

Costs paid by Peecker Sound

Peecker Sound will pay for all labour and material expenses necessary for the

repairs covered by the warranty. Make sure you keep the original packaging;

otherwise, the cost of replacing will be charged to you if necessary. Produce

the original invoice to establish the date of purchase.

Do not send the product to the factory without prior authorization. Should

shipment of the product be a problem, please contact the service centre, who

will deal with it promptly. Otherwise, the customer is responsible for shipment

and handling of the product to be repaired and payment of all shipping costs.

Limitation of implicit warranties

All implicit warranties, including guarantee of merchantability and suitability

to specic purposes, are limited to the duration of the present warranty. With

the exception of certain types of damage, Peecker Sound liability is limited

to repairing or replacing, at its discretion, any defective products, with no

obligation of compensation for any kind of incidental or consequential

damages. In case of any controversy, the court of jurisdiction will be exclusively

the Court of Reggio Emilia (RE) – Italy.

4. USER LIABILITY

4.1 Damage to speakers

Check the peak power and continuous power of the

ampliers at all times.

These ampliers are extremely powerful and may be

potentially dangerous to both speakers and human beings.

Most loudspeaker systems may be easily damaged or broken, often if they are

driven by bridged ampliers. Although the gain may be attenuated by using

the controls on the front panel of the amplier, the maximum power output

can still be reached if the input signal is sufficiently high.

4.2 Dangerous output voltage

Ampliers can generate dangerous output voltage.

Do not touch any exposed speaker cables while the amplier

is operating.

5. INTRODUCTION

Congratulations on your choice of a Peecker Sound Professional Series

power amplier and thank you for your condence in us and our products.

Your amplier has been carefully engineered down to the smallest detail,

from component selection to nal assembly. All Peecker Sound products

aim for full customer satisfaction and you can rest assured that the product

you have chosen uses cutting-edge technology.

The ampliers have been designed in the Sound Corporation Design and

Research&Development (R&D) departments paying particular attention

to the choice of materials, safety devices and electronic design for the

manufacture of a safe, reliable and long-lasting product.

Since inappropriate use of the product can jeopardize its correct operating

performance, please ensure that you use it carefully and correctly.

Please read this manual carefully: all the information it contains is vitally

important for using your appliance safely.

5.1 Unpacking

Inspect the packaging and its contents immediately to check whether

there are any signs of damage. After unpacking, inspect the product

and any accessories. Should you notice any damage, inform your dealer

immediately.

Please keep all the packaging materials, which will be useful for returning

the product to Peecker Sound or sending it to one of our authorized

Service Centres if the product does not arrive in perfect condition. Use

exclusively the original packaging, as it is the best way to protect the

appliance from mishandling by the carrier.

Please take care of the environment.

Once the appliance has become obsolete, please

dispose of it in the appropriate recycling container.

5.2 Installation

All Peecker Sound Professional Series models can be installed in

standard 19” rack units as shown in Fig. 2. There are four installation holes

on the front panel for optimal securing of the appliance – an important

factor in mobile systems.

4.3 Radio interferences

A sample of this product has been tested and approved in compliance with

the limits set out by the Electromagnetic Compatibility Directive (EMC). These

limits have been determined in order to provide reasonable protection from

dangerous interferences caused by electrical appliances.

Should this product not be installed or used in compliance with the instructions

as set out in this manual, it might interfere with other appliances such as radio

receivers, for example. There is no guarantee, however, that interferences will

not occur in a particular installation.

Should the device interfere with two-way radios (switching the

device on and off will allow you to check whether this is the

case), you should try to eliminate the interference by adopting

one of the following measures:

B) Connect the appliance to a socket positioned on a circuit

C) Re-position or move the aerial of the receiver.

Check that the unit complies with the EMC immunity limits (it must carry

the CE mark). All electrical appliances sold in the EU must be approved for

immunity to electromagnetic elds, high voltage and radio interferences.

Seek professional assistance.

A) Increase the distance between the appliance and the receiver.

different from which the receiver is connected to.

SOUND REINFORCEMENT ACOUSTIC RESEARCHCONTROLLED RADIATION

483 mm

Figure 1. PS amplifier dimensions

Figure 2. Flight case for pro amplifiers

4

R

PROTECT

TEMP

SIG/CLIP

BRIDGE

CH D

0

-

User’s Manual

AMPLIFICATORI PS

Owner’s manual

Owner’s manual

AMPLIFICATORI PS

Owner’s manual

Owner’s manual

5.3 Front panels

TEMP

PROTECT

SIG/CLIP

BRIDGE

0

-

CH A

Figure 3. PS1000 – PS1400 – PS2000 – PS2600 – PS3400 Front panel

0

-

CH B

0

-

CH C

PS ampliers

Figure 4. PS650-F front panel

1. CHA/CHB (CHC/CHD) - Precision input level controls that allows the amplification level of each channel to be adjusted.

Note: when using in bridged mode (only applicable to PS650-F, PS1000 and PS1400 amplifiers), the various

level attenuators must be in the same position. We recommend setting them on the 0 position.

2. TEMP - When the temperature LED lights up, the channel gets deactivated as a protection measure against

overheating. The fan will continue to operate so as to bring the temperature down as quickly as possible.

3. PROTECT - This protection LED lights up when the load connected is below 1 Ω or the amplifier output has been

short-circuited.

4.a) CLIP - LED indicator for input signal clip point.

4.b) SIGNAL - LED indicator for signal presence.

Note: this situation normally occurs when there is inadequate ventilation. Check the amplifier installation

carefully.

5.a) SIG/CLIP - Dual-mode LED indicator for both signal presence (green) and signal clip point (red).

5.b) BRIDGE - LED indicator for amplifier operating in bridged mode.

6. POWER - On/Off switch.

7. Ventilation grille for correct amplifier ventilation.

8. 19’’ rack installation holes.

SOUND REINFORCEMENT CONTROLLED RADIATION ACOUSTIC RESEARCH

CONTROLLED RADIATION

5

AC

50Hz-60H

R

PROTECT

TEMP

SIG/CLIP

BRIDGE

CH D

0

-

User’s Manual

Manuale d’uso

R

PROTECTPROTECT

TEMPTEMP

SIG/CLIPSIG/CLIP

BRIDGEBRIDGE

CH C

0

-

CH A

0

-

CH DCH B

0

-

0

-

POWER INPUT

SERIAL NO:

EARTH

D C

INPUTS

2

1

3

+

GND

BRIDGESTEREO

+

D C

BRIDGE MIN 8

C/D MIN 4

PIN1 2

PIN1 2

+

SPEAKER

IMPEDANCE

C-D A-B

OUTPUTS BRIDGE BRIDGE OUTPUTS

B A

BRIDGE MIN 8

A/B MIN 4

PIN1 2

PIN1 2

+

SPEAKER

IMPEDANCE

B A

2

1

3

+

GND

BRIDGESTEREO

INPUTS

AC 230V 10%

50Hz-60Hz

®

speakON per ogni canale

®

speakON bridge CHA-CHB, CHC-CHD

9 9

10 10

11

16

13

14 15

Figura 5: Pannello posteriore PS650-F

Manuale d’uso

R

PROTECTPROTECT

TEMPTEMP

SIG/CLIPSIG/CLIP

BRIDGEBRIDGE

CH C

0

-

CH A

0

-

CH DCH B

0

-

0

-

AMPLIFICATORI PS

R

PROTECT

TEMP

SIG/CLIP

BRIDGE

CH A

0

-¡

CH B

0

-¡

AMPLIFICATORI PS

10

9

13 14 15

11

Figura 7: Pannello posteriore PS1600

R

PROTECT

TEMP

SIG/CLIP

BRIDGE

CH A

0

-¡

CH B

0

-¡

CH-B IN

CH-A IN

LINK LINK

BALANCED

0dB

30KOHM

BALANCED

0dB

30KOHM

OUTPUT

IMPEDANCE

16 OHM

8 OHM

4 OHM

PIN1+ 2+

PIN1 2££

+

£

CH-B OUT

CH-A OUT

+

£

LINK

OUTPUT

IMPEDANCE

16 OHM

8 OHM

4 OHM

PIN1+ 2+

PIN1 2££

+

£

+

£

LINK

BRIDGE

£

+

SERIAL NO:

EARTH

POWER INPUT

!

BRIDGE

STEREO

MONO

AC 230V 10%

50Hz 60Hz¡£

R

TEMP

CH A

0

-¡

CH B

0

-¡

PROTECT

CLIP

SIGNAL

5.4 Rear panels

TEMP

PROTECT

SIG/CLIP

BRIDGE

0

-

CH A

0

-

CH B

0

-

CH C

PS ampliers

9 10

12 13 15 11 15

Figure 5. PS1000 rear panel

11

OUTPUT

IMPEDANCE

16 OHM

8 OHM

4 OHM

PIN1+ 2+

PIN1 2££

+

£

CH-B OUT

+

POWER INPUT

AC 230V 10%

!

50Hz 60Hz¡£

LINK

£

£

BRIDGE

SERIAL NO:

+

CH-A OUT

LINK

OUTPUT

IMPEDANCE

16 OHM

8 OHM

4 OHM

+

PIN1+ 2+

£

PIN1 2££

+

£

EARTH

13 14 15

Figure 6. PS1400 rear panel

13

9

11

Figure 7. PS2000 - PS2600 - PS3400 rear panel

9

10

CH-B IN

LINK LINK

BALANCED

0dB

30KOHM

MONO

STEREO

BALANCED

0dB

30KOHM

BRIDGE

14 15

CH-A IN

9

9 9

10 10

INPUTS

1

2

GND

+

3

BRIDGESTEREO

D C

SPEAKER

IMPEDANCE

BRIDGE MIN 8

C/D MIN 4

+

PIN1 2

PIN1 2

9. Inputs (CHA IN/ CHB IN) – Cannon® XLR inputs for each channel.

10. Operating mode switch – Operating mode selection switch: mono, stereo, parallel or bridge.

11. Outputs (CHA OUT/ CHB OUT) – Neutrik® SpeakOn output connectors for each channel.

12. Limit - Limiter control switch. LIMIT ON: soft clip limiter enabled, LIMIT OFF: disabled.

13. Power Input – IEC 3-pin power supply connector.

14. Earth - Ground lift that allows connection-disconnection of electrical earth to/from mechanical earth.

15. Ventilation grille.

16. Bridge - CHA-CHB, CHC-CHD outputs with Neutrik® SpeakON connectors for bridge mode.

SOUND REINFORCEMENT ACOUSTIC RESEARCHCONTROLLED RADIATION

11

16

OUTPUTS BRIDGE BRIDGE OUTPUTS

+

D C

POWER INPUT

AC 230V 10%

C-D A-B

SERIAL NO:

50Hz-60Hz

13

Figure 8. PS650-F Rear panel

6

SPEAKER

IMPEDANCE

BRIDGE MIN 8

A/B MIN 4

+

PIN1 2

B A

PIN1 2

B A

EARTH

14 15

INPUTS

1

2

GND

+

3

BRIDGESTEREO

R

PROTECT

TEMP

TEMP

SIG/CLIP

BRIDGE

CH D

0

-

t.VMUJBQQMJDBUJPO

t)JHIUFDIOPMPHZ

t-JHIUOFTT

PROTECT

User’s Manual

-

CH A

SIG/CLIP

BRIDGE

0

-

CH B

6. BRIEF DESCRIPTION OF THE SERIES

Professional Series amplifiers are available in six models,

differentiated according to power ratings and number of channels.

PS1000, PS1400, PS2000, PS2600, and PS3400 models are twochannel amplifiers capable of delivering from 450 W up to 1700 W

per channel onto 4 Ω. PS650-F model, by contrast, has four 650 W

channels, also onto 4 Ω.

All Professional Series amplifiers have been designed to meet the

specific requirements of the world of professional audio based

on criteria of maximum reliability and ease of use. Power delivery

remains constant even at high loads, with low heat dissipation and

high performance thanks to low-leakage toroidal transformers, which

provide an extra margin above the stated nominal output. The power

supply unit is protected against possible overvoltages, overheating

and short circuiting.

Each of the power stage modules is fully independent in terms of both

electrical and thermal protections. Each channel, in fact, is equipped

with its own heat sink and independent temperature control which

acts directly on the cooling fan.

The signal is constantly monitored, with the LED light on the front

panel checking and indicating the level.

An internal limiter provides loudspeaker system protection against

signal distortion. The mechanical construction and subsequent circuit

engineering are such as to guarantee high production standards.

Thanks to its rigid steel chassis, the amplifier is able to withstand even

the toughest tours, guaranteeing maximum reliability in all operating

conditions.

PS ampliers

0

0

-

CH C

t.VMUJBQQMJDBUJPO

t)JHIUFDIOPMPHZ

• Durability

t)JHIQPXFSFGmDJFODZ

PS1000

Output Power @ 4 Ohm 2 x 450 W*

Output Power @ 8 Ohm 2 x 280 W*

PS2600

Output Power @ 4 Ohm 2 x 1300 W*

Output Power @ 8 Ohm 2 x 850 W*

* EIA 1 kHz - 1% THD, both ch.s driven @ 230 VAC

PS1400

Output Power @ 4 Ohm 2 x 700 W*

Output Power @ 8 Ohm 2 x 450 W*

PS3400

Output Power @ 4 Ohm 2 x 1700 W*

Output Power @ 8 Ohm 2 x 1000 W*

PS2000

Output Power @ 4 Ohm 2 x 1000 W*

Output Power @ 8 Ohm 2 x 650 W*

PS650-F

Output Power @ 4 Ohm 2 x 650 W*

Output Power @ 8 Ohm 2 x 300 W*

SOUND REINFORCEMENT CONTROLLED RADIATION ACOUSTIC RESEARCH

CONTROLLED RADIATION

7

AC

50Hz-60H

R

PROTECT

TEMP

SIG/CLIP

BRIDGE

CH D

0

-

User’s Manual

TEMP

PROTECT

SIG/CLIP

BRIDGE

0

-

CH A

0

-

CH B

0

-

CH C

PS ampliers

7. OPERATING INSTRUCTIONS

7 .1 Connection to the AC mains supply and power absorption

Check that your mains power supply is sufficient for the power requirement of

your amplier (consult the data at the end of this manual). Note that the voltage

of the electric mains should correspond to the voltage indicated on the back of

the amplier. Maximum current absorption is limited by internal fuses.

Note: Remember that before connecting any of the cables

it is always better to switch o and disconnect the amplier

from the power supply. When switching on the amplier, the

volume controls should always be set to the lowest level.

7 .2 Cooling

Pay particular attention to the ventilation/cooling conditions of the ampliers.

An internal system of forced airflow by means of a variable speed fan allows

the heat sinks to cool down from the heat generated by power parts. The air

ows from the front panel of the amplier to its rear panel, so that the air is

drawn in from the front opening and let out through the back opening.

Ensure that there is sufficient space in front of the appliance to allow

adequate inflow and outflow of air. With rack installation, make sure there

are sucient openings for air to ow freely through the amplier.

7 .3 Connection cables

• Using in stereo mode (standard)

When using in stereo mode, each channel operates independently and

the dedicated input attenuators control the respective channel level.

The recommended minimum load for using in stereo mode is 4 Ω per

channel for all Peecker Sound Professional Series models (see Technical

Specifications). To connect the input signal, use the Cannon XLR connectors

on the rear panel. The loudspeaker systems must be connected to the

Neutrik® SpeakOn output connectors.

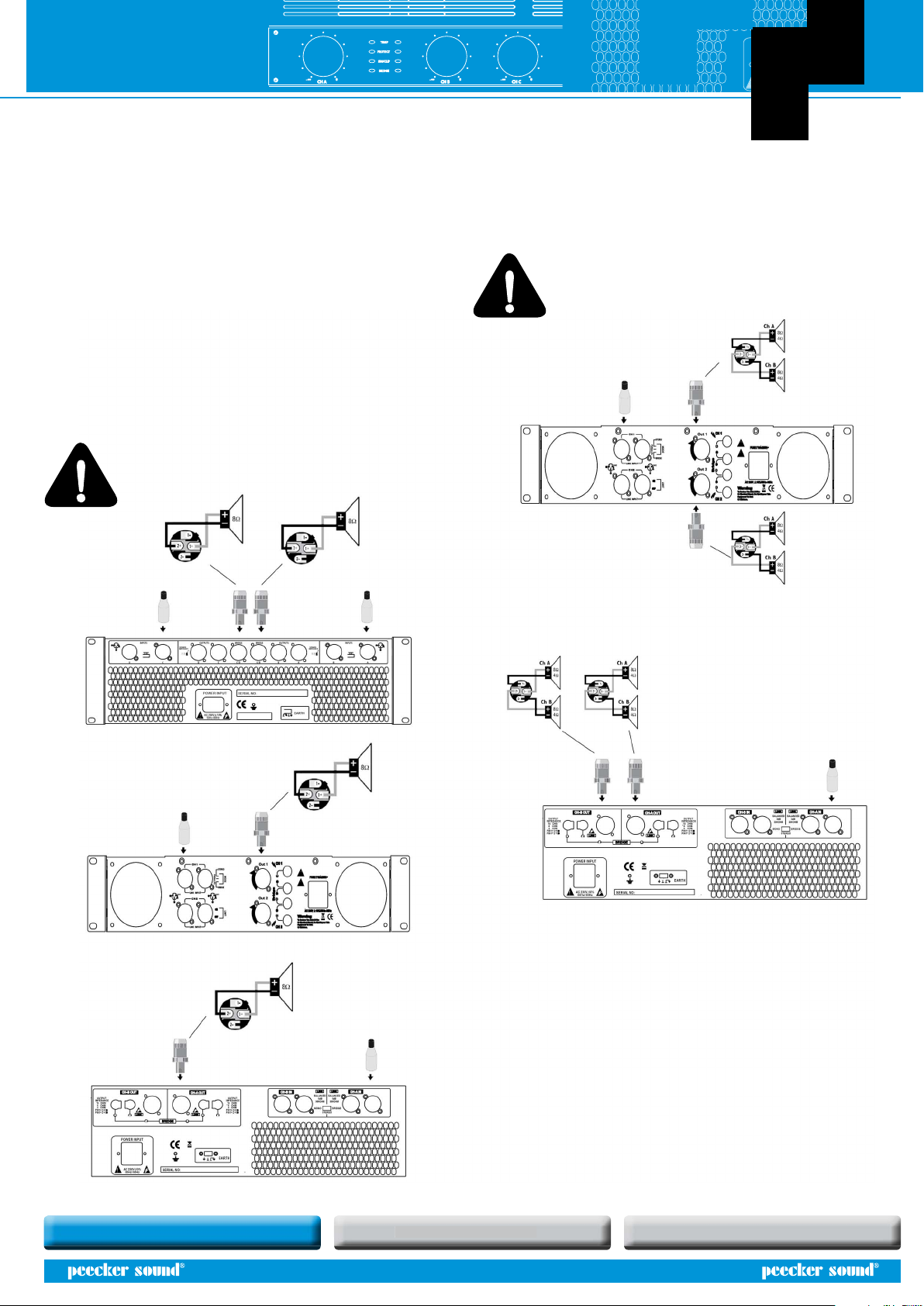

Figure 10. Stereo Mode PS650-F

To connect the amplier to the speakers, always use suitable cables to avoid

amplier power dispersion due to inadequate cable section.

When connecting the amplier to the mixer, only use shielded cables and

not electric power cables. The main inputs and outputs are connected using

Cannon® XLR and Neutrik® SpeakOn connectors.

7 .4 Congurations

XLR BAL INPUT/OUTPUT

Pin 1 GND

Pin 2 HOT +

Pin 3 COLD -

Neutrik® speakON

Pin 1 + POS (CH1 CH3)

Pin 1 - NEG (CH1 CH3)

Pin 2 + POS (CH2 CH4)

Pin 2 - NEG (CH2 CH4)

Figure 9. Cannon® XLR and Neutrik® SpeakOn connectors

Make sure the unit is switched o before conguring according to your

requirements. To turn on the unit, use the ON/OFF switch located on the

right of the front panel. To adjust the volume of individual channels turn the

corresponding knobs, i.e. ChA/ChB for PS1000, PS1400, PS2000, PS2600 and

PS3400 and ChA/ChB/ChC/ChD for PS650-F.

Figure 11. Stereo Mode PS1000

Figure 12. Stereo Mode PS1400

With audio systems it is always better to switch off the amplifier first. Remember

to switch o the amplier before connecting or disconnecting it to other units

and always switch on the mixer rst and then the amplier, in order to avoid

peaks that could cause disturbances and may damage the speakers.

SOUND REINFORCEMENT ACOUSTIC RESEARCHCONTROLLED RADIATION

Figure13. Stereo Mode PS2000 – PS2600 – PS3400

8

R

PROTECT

TEMP

SIG/CLIP

BRIDGE

CH D

0

-

User’s Manual

TEMP

PROTECT

SIG/CLIP

BRIDGE

0

-

CH A

0

-

CH B

0

-

CH C

PS ampliers

• Using in mono bridge mode

To activate the mono bridge mode, set the switches on the rear panel on

the Bridge position. This conguration is only available in PS650-F, PS1000

and PS1400 models. Using in mono bridge mode requires both amplier

channels (A and B, C and D) to operate with the same input signal

but with inverted phases. Power values can be found in the technical

specications table at the end of this manual.

To use the PS650-F model in mono bridge mode, the input signal

necessarily has to be connected to Ch A (for bridging between Ch

A and Ch B) and to Ch C (for bridging between Ch C and Ch D). The

corresponding volume is adjusted using the potentiometers of Ch A and

Ch C. Make sure that the level attenuators are in the same position.

In the case of PS1000, the input signal necessarily has to be connected

to Ch A and the corresponding volume is thus adjusted using the

potentiometer of Ch A.

The input signal for PS1400, on the other hand, must necessarily be

connected to Ch A and the corresponding volume is thus adjusted by

the potentiometer of Ch A. To connect the input signal, use the Cannon®

XLR connectors on the rear panel. The speakers must be connected to

the Neutrik® SpeakOn output connectors.

Note: when using in bridge mode do not connect loads

under 8 Ω.

• Parallel inputs

Parallel mode is activated using the dedicated switches on the rear panel.

When operating in parallel mode, the inputs of both channels are connected

and receive the same signal.

This function is only available in models PS1000 and PS1400. To connect the

input signal, use Cannon® XLR connectors.

The loudspeaker systems must be connected to the Neutrik® SpeakOn

output connectors.

Make sure that only the inputs are connected in parallel. Never

earth positive output terminals or connect them in parallel.

Figure 14. Bridge Mode PS650-F

Figure 15. Bridge Mode PS1000

Figure 17. Parallel Mode PS1000

Figure 18. Parallel Mode PS1400

Figure 16. Bridge Mode PS1400

SOUND REINFORCEMENT CONTROLLED RADIATION ACOUSTIC RESEARCH

CONTROLLED RADIATION

9

AC

50Hz-60H

R

PROTECT

TEMP

SIG/CLIP

BRIDGE

CH D

0

-

User’s Manual

TEMP

PROTECT

SIG/CLIP

BRIDGE

0

-

CH A

0

-

CH B

0

-

CH C

PS ampliers

8. PROTECTION SYSTEM FEATURES

All Peecker Sound Professional Series ampliers are equipped with

powerful systems to protect the amplier and its load.

Protection systems are designed to ensure that power ampliers have a long

operating life.

8.1 Limiter

When the CLIP LED lights up, the limiter is active. In this case the channel

gain will be reduced automatically to protect the load (acoustic speakers)

from damage caused by a distorted signal.

The limiter circuit cannot be deactivated, except for the PS1000 amplifier.

8.2 Thermal protection

The temperature level of the heat sink is constantly monitored, as indicated by

the TEMP LED. When the heat sink temperature goes above 60° C the cooling

fan switches on, while at 90° C (anomalous operating condition) the TEMP LED

lights up and the whole system goes into mute mode until the temperature

returns to normal levels.

8.3 Load safety control

The state of the input signal in Peecker Sound ampliers is constantly

monitored. Should the power load exceed the maximum allowable level,

the output voltage will be automatically readjusted so that the amplier

can operate safely. Should the connected load impedance be signicantly

below recommended levels, the amplier output phase will be inhibited.

9. TESTING PROCEDURE FOR ELECTRO-MECHANICAL OPERATION

The testing protocols for the various series of ampliers manufactured

by Sound Corporation (XTDT series by X-Treme and PSDSP and PS series

by Peecker Sound) have been designed according to the FMEA (Failure

Mode and Effect Analysis) method.

This is a risk assessment system deriving from electro-mechanical

reliability studies used widely in industrial and non-industrial sectors to

evaluate the reliability of both products and processes. FMEA consists

of procedures for analysing potential failures; they are repeatable,

transparent and guarantee total control of the operating functions and

absolute reliability of the manufactured products.

FMEA results basically consist of the following two documents:

• The rst is an internal Sound Corporation tool designed for the Product

Development Department with an indication of the various critical areas

detected and suggested actions for improvement, such as increasing

MTTF (Mean Time to Failure) and/or the life cycle of the amplier under

investigation.

• The second arises from detailed knowledge of failure modes and is

used to determine precisely the amplier correct operating conditions

as well as the corresponding checking operations.

This procedure is also available to the nal customer in the form of

checking procedure for the amplifier correct electro-mechanical

operation, as provided below.

Note: Before removing any module or connector,

remember to disconnect the amplier from the mains and

take care when handling power supply capacitors as they

might be under load.

8.4 DC Protection

The presence of a DC voltage is monitored on both channels independently.

If a value equal to or above 7 Volts is detected, the amplier output stage will

be inhibited. This protects the speakers against DC voltage.

8.5 Power on/off transients

To eliminate power on/off transients, which can damage the loudspeaker

systems, a soft start circuit is enabled that connects the load with delay and

disconnects it immediately.

To prevent short-circuits during testing, the oscilloscope must be earth

insulated. Do not test the amplier while the speakers or cones are output

connected, use the appropriate dummy loads only. When increasing the

output voltage of the variable voltage transformer (Variac), never exceed

the amplier nominal output value plus its tolerance, since higher voltage

levels might seriously damage the amplier.

9 .1 Required equipment

List of testing equipment:

• Digital multimeter

• AC millivoltmeter

• Dual trace oscilloscope

• Audio signal generator

• 15A-250V Variac

• Two 4 Ω (1800W) dummy loads

• Two 8 Ω (1100W) dummy loads

• Audio Precision (AP) analyser

• Vibrating table for mechanical testing

• Withstanding voltage tester

9 .2 Visual check

Check that the product is correctly assembled and verify whether there

are any incorrectly mounted or damaged parts, open connections or

short circuits.

SOUND REINFORCEMENT ACOUSTIC RESEARCHCONTROLLED RADIATION

10

R

PROTECT

TEMP

TEMP

SIG/CLIP

BRIDGE

CH D

0

-

PROTECT

User’s Manual

-

CH A

SIG/CLIP

BRIDGE

0

-

CH B

9 .3 Electrical testing procedures

1. Use the withstanding voltage tester to test the amplier: turn o the

amplier, set the voltage testing level at 1500 V and the test time at 60

seconds. If the leakage current does not go above 5 mA the test has

been successful.

2. Check the whole unit thoroughly for any short circuits using the

multimeter. Verify that the voltage supply and earthing are correct

and that the power supply cable is undamaged. After the amplier has

been turned on once, make sure there are no short circuits.

3. Using the Variac, set the power supply in the primary coil of the

transformer at 230 V. This voltage value has to be monitored and

adjusted in order to be kept constant throughout the duration of

the test. Turn the amplier on and o six times to check whether the

power switch works correctly, the relays are activated (with a certain

amount of delay), and both protection LEDs are flashing.

4. Check that the voltages in the power supply module are as follows:

• PS650-F:

A) AC voltage values in the secondary coil should be:

65V---0---65V, 20V---0---20V, 17V---0---17V, 0---10V.

B) DC voltage on the amplier modules should be ±89 V.

(tolerance: ±1V).

C) Protection circuits power supply voltage: ±24 V.

(tolerance ±2 V).

D) Fans power supply voltage: -24V (tolerance ±2 V).

E) Power supply voltage in the pre-amplier module: ±12 V

(tolerance ≤ ±0.5V).

• PS1000:

A) AC voltage values in the secondary coil should be:

56V---0---56V (GRN---BLK---BLU).

B) DC voltage on the amplier module should be ±77 V.

C) Fans’ power supply voltage: +24 V.

• PS1400:

A) AC voltage values in the secondary coil should be:

65V---0---65V (GRN---BLK---GRN), 19V---0---19V (BLU---BLK---BLU),

17V---0---17V (YEL---BLK---YEL), 0---10V (WHI---WHI).

B) DC voltage on the amplier module should be ±88 V.

C) Fans’ power supply voltage: +24 V.

• PS2000-PS2600-PS3400

A) AC voltage values in the secondary coil should be:

56V---0---56V (PS3400), 50V---0---50V (PS2600), 45V---0-45V (PS2000).

All models must have the following AC output voltage values:

19V---0---19V, 17---0---17V, 0---10V.

B) DC voltage on the amplier modules should be:

±78 V (PS3400), ±68 V (PS2600), ±61 V (PS2000)

(tolerance: ±1 V).

C) Protection circuits power supply voltage: ±24V (tolerance ±2 V).

D) Fans power supply voltage: +24 V.

E) Power supply voltage in the pre-amplier module: ±12 V.

(tolerance ≤ ±0.5 V).

5. Check that the background noise in both channels is below 1 mV (-58

dBu) and that there is no signal after switching off the unit. Use the

oscilloscope to perform this test, connecting a speaker for a sound

check if necessary.

5.a. (Only applicable to PS2000 – PS2600 – PS3400)

Measure the voltage on collectors for Q104, Q103, Q204 and Q203 and

check that it is ±1.2 V. If necessary, adjust the 1 kΩ trimmer so that this

value has a tolerance level less than or equal to ±0.1 V (≤ ±0.1 V). The

output terminal DC voltage must be less than or equal to 10 mV (≤ 10

mV).

PS ampliers

0

6. Dynamic testing:

• Set a sinusoidal signal at 1 kHz (set the signal level at a value close to clip

• Connect a 4 Ω load (of suitable power) in one channel only. The output

• Check that the output waveform is regular. Shake the input/output

7. Signal LED test: check that the LED lights up when there is an input signal

8. Make sure that the crosstalk is greater than or equal to 50 dB (≤ 50 dB).

9. Check that the CMRR (@ 1kHz) is greater than or equal to 60 dB (≤ 60 dB).

10. Check the phase between output and input.

11. Connect the 8 Ω loads on both channels, set the volume to maximum

12. Test the frequency response: 20 Hz-20 kHz ±0.5 dB.

13. Bring the heat sink temperature to 50° C (PS650-F, PS1400, PS2000, PS2600,

14. Check that, at maximum output power, the current is:

• PS650-F: 6 A with an 8 Ω load; 10 A with a 4 Ω load

• PS1000: 6 A with an 8 Ω load; 10 A with a 4 Ω load

• PS1400: 7 A with an 8 Ω load; 13 A with a 4 Ω load

• PS2000: 9 A with an 8 Ω load; 15 A with a 4 Ω load

• PS2600: 10 A with an 8 Ω load; 18 A with a 4 Ω load

• PS3400: 11 A with an 8 Ω load; 20.5 A with a 4 Ω load

15. Output protection test: short-circuit the output with 0 Ω and check that the

16. Adjust the mains power supply voltage (using the Variac) from 205 V to 255V

17. Check that the THD (@ 1kHz) is less than or equal to 0.08% with an 8Ω load.

18. Test for vibrations and correct amplier operation using the vibrating table

• Vibration frequency: 5-60 Hz

• Direction: vertical, horizontal

• Test duration: 180 seconds

• Check that there is no output signal after the vibration test has been

19. Burn-in test

• Using a Pink Noise generator, set the input signal so as to obtain 1/8 of

• Check that the Clip LEDs light up occasionally though not too repeatedly.

• After 4 hours of testing, check general operating functions.

0

-

CH C

LED activating signal).

signal voltage should be: 57 V (PS650-F), 47 V (PS1000), 56 V (PS1400), 72 V

(PS2000), 82 V (PS2600), 92 V (PS3600).

connectors to check that they are reliable and there are no faulty contacts.

(set the Gain of each channel at maximum level).

level and check that there is no background noise due to the power supply

transformer.

PS3400) or 70° C (PS1000) and check that the fans are operating (and

noiseless).

protection system activates (the relays should disconnect the load).

and check that the amplier is operating correctly.

for mechanical tests:

performed.

nominal output power @ 4Ω.

SOUND REINFORCEMENT CONTROLLED RADIATION ACOUSTIC RESEARCH

CONTROLLED RADIATION

11

AC

50Hz-60H

R

PROTECT

TEMP

TEMP

SIG/CLIP

BRIDGE

CH D

0

-

PROTECT

User’s Manual

-

CH A

SIG/CLIP

BRIDGE

0

0

-

CH B

0

-

CH C

PS ampliers

10. TECHNICAL SPECIFICATIONS

MODEL PS1000 PS1400 PS2000 PS2600 PS3400 PS650-F

Power Output (per channel)

8 Ω 280 W* 450 W* 650 W* 850 W* 1000 W* 300 W*

4 Ω 450 W* 700 W* 1000 W* 1300 W* 1700 W* 650 W*

Bridged Mono Power

8 Ω 880 W* 1300 W* / / / 1200 W*

* EIA 1 kHz - 1% THD, both ch.s driven @ 230 VAC

Net Weight 14 kg 22 kg 32 kg 32 kg 33 kg 30 kg

Frequency Response 20 Hz ÷20 kHz (± 0.5 dB)

SNR > 100 dB

Distortion (THD+N) < 0.1% (@ 1 kHz)

Level adjustment (per channel) -∞ ÷ 0 dB

Input Impedance 30 kΩ, electronically balanced

Input Sensitivity 0 dBu

Crosstalk > 50 dB

Phase Response -18° (@ 20 Hz), +25° (@ 20 kHz)

Damping Factor > 200 (@ 8 Ω, 1 kHz)

Input Connectors (per channel) 3-pin Cannon® XLR

Output Connectors (per channel) Neutrik® speakON, screw terminals (except for PS650-F)

Controls

Front: power switch, ChA/ChB (PS650-F: ChC/ChD) gain potentiometers

Rear: mode, limit or ground lift switches

Led Indicators Temperature, Protect, Clip, Signal, (PS1400, PS650-F: Bridge)

Amplifier Protections

overload, full short circuit, thermal, ultrasonic and radio frequency immunity

Load Protections soft start, soft clip limiter, DC-fault

Circuitry class AB

Cooling front to rear air flow, fan speed in function of temperature

Power Requirements 230 VAC (± 10%) , 50/60 Hz

Dimensions (W×H×D) 483 (19”) × 132 (3 RU) × 487 mm (PS100: 483 (19”) × 88 (2RU) × 388 mm)

Approvals CE EN55103-1 (Emissions), CE EN55103-2 (Immunity), CE EN6065, Class I (Safety)

SOUND REINFORCEMENT ACOUSTIC RESEARCHCONTROLLED RADIATION

12

Loading...

Loading...