Page 1

2-5CR 60-80-100

Multi-stage centrifugal pumps

Clean water

Domestic use

Civil use

PERFORMANCE RANGE

• Flow rate up to 130 l/min (7.8 m³/h)

• Head up to 67 m

APPLICATION LIMITS

• Manometric suction lift up to 7 m

• Liquid temperature between -10 °C and +40 °C

• Ambient temperature up to +40 °C

• Max. working pressure 7 bar

• Continuous service S1

CONSTRUCTION AND SAFETY STANDARDS

EN 60335-1

IE C 60 335-1

CE I 61-15 0

CERTIFICATIONS

Company with management system certied DNV

ISO 9001: QUALITY

EN 60034 -1

IE C 60 034 -1

CEI 2-3

INSTALLATION AND USE

Suitable for use with clean water and with liquids that are not

chemically aggressive towards the materials from which the pump

is made. As a result of their quietness these pumps are widely

used in domestic applications such as the distribution of water in

combination with small and medium sized pressure tanks, and for

the irrigation of gardens and orchards, etc.

The pump should be installed in an enclosed environment or

sheltered from inclement weather.

OPTIONS AVAILABLE ON REQUEST

• Pump body with NPT ANSI B 1.20.1 threaded ports

• Special mechanical seal

• Other voltages

GUARANTEE

2 years subject to terms and conditions

| 60 Hz |

86 | GENERAL CATALOGUE 60 Hz

Page 2

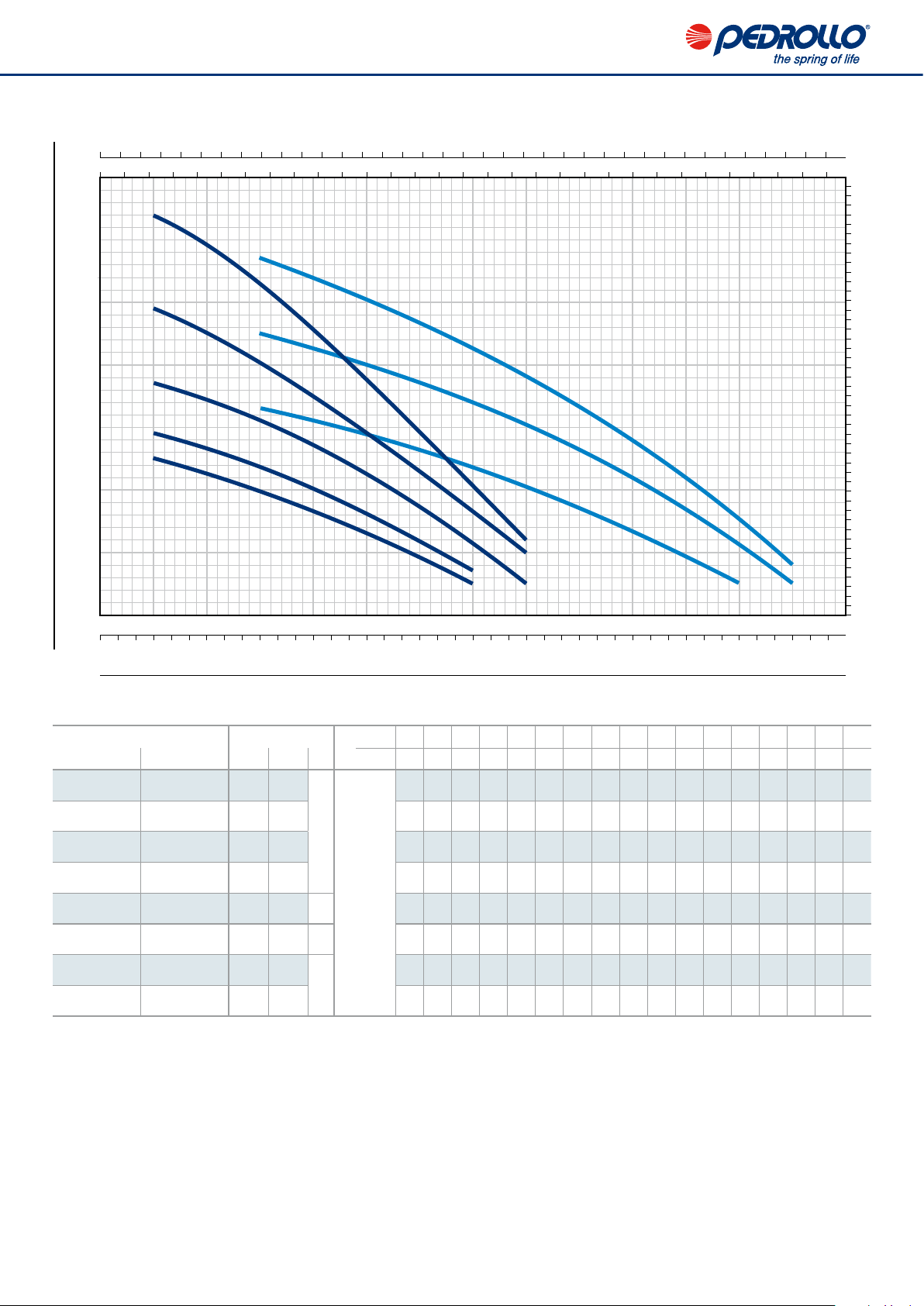

CHARACTERISTIC CURVES AND PERFORMANCE DATA 60 Hz n= 3450 min-1 HS= 0 m

0 5 10 15 20 25 30

0 5 10 15 20 25

70

5CR80

60

50

4CR80

5CR100

4CR100

4

40

30

Head H (metres)

3CR80

3CR100

3CR60

2CR80

20

10

US g.p.m.

Imp g.p.m.

feet

200

175

150

124

100

75

50

25

0

0 10 20 30 40 50 60 70 80 90 100 110 120 130

0 1 2 3 4 5 6 7 8

MODEL POWER (P)

Single-phase Three-phase kW HP

2CRm 80 2CR 80 0.37 0.50

3CRm 60 3CR 60 0.37 0.50

Flow rate Q

m³/ h

Q

l/min 0 5 10 15 20 25 30 40 50 60 70 80 90 100 110 120 130

0 0.3 0.6 0.9 1.2 1.5 1.8 2.4 3.0 3.6 4.2 4.8 5.4 6.0 6.6 7.2 7. 8

27 26 25 24 22.5 21 20 16.5 13 9 5

31 30 29 28 26.5 25 23.5 20 16 11.5 7

4

l/min

m³/h

0

0

IE2

3CRm 80 3CR 80 0.45 0.60

4CRm 80 4CR 80 0.55 0.75

5CRm 80 5CR 80 0.75 1 IE3

3CRm 100 3CR 100 0.55 0.75 IE2

4CRm 100 4CR 100 0.75 1

H

metres

40 38 37 36 34.5 33 31 27 22.5 17 11 5

52 50 49 47 44.5 42 40 34 28.5 22.5 16 10

67 66 64 62 59 56 53 45.5 37. 5 29.5 20.5 12

38 37 36 35 34.5 33.5 33 31 28 26 23 20 17 13.5 10 5

50 50 49 48 47 46 45 42 39.5 37 34 30.5 26.5 22 17 11 5

IE3

62 61.5 60.5 59.5 58 57 53.5 50.5 46.5 42.5 38 33 28 22 15 8

5CRm 100 5CR 100 1.1 1.5

Q = Flow rate H = Total manometric head HS = Suction height Tolerance of characteristic cur ves in compliance with EN ISO 9906 Grade 3B.

Performance class of the three-phase motor (IE C 60 034 -30 -1)

63

GENERAL CATALOGUE 60 Hz | 87

| 60 Hz |

Page 3

2-5CR 60-80-100

POS. COMPONENT CONSTRUCTION CHARACTERISTICS

1 PUMP BODY Stainless steel AISI 304 complete with threaded ports in compliance with ISO 228/1

2 BODY BACKPLATE Stainless steel AISI 304

3 IMPELLERS Noryl FE1520PW

4 DIFFUSERS Noryl complete with anti-wear ring

5 MOTOR SHAFT Stainless steel EN 10088-3 - 1.4104 (AISI 431 for 4CR 100, 5CR)

6 MECHANICAL SEAL

7 BEARINGS

8 C APACITOR

9 ELECTRIC MOTOR 2-5CRm:

Seal Shaft Materials

Model Diameter

AR -13 Ø 13 mm Ceramic Graphite NBR

Pump Model

2CR 80

3CR 60

3CR 80

4CR 80

3CR 100

4CR 100

5CR 80

5CR 100

Pump Capacitance

Single-phase (220 V) (110 V or 127 V)

2CRm 80

3CRm 60

3CRm 80 12. 5 μF - 450 VL 25 μF - 250 VL

4CRm 80

3CRm 100

4CRm 100

5CRm 80

5CRm 100 25 μF - 450 VL –

2-5CR: three-phase 220/380 V - 60 Hz or 220/440 V - 60 Hz.

➠ The three-phase pumps are fitted with high performance motors up to

P=0.55 kW in class IE2 and from P=0.75 kW in class IE3 (IEC 60 03 4-30-1)

– Insulation: class F

– Protection: IP X4

Stationary ring Rotational ring Elastomer

6202 ZZ - C3 / 6201 ZZ

6203 ZZ / 6203 ZZ

10 μF - 450 VL 25 μF - 250 VL

14 μF - 450 VL 25 μF - 250 VL

20 μF - 450 VL 60 μF - 300 VL

single-phase 220 V - 60 Hz with thermal overload protector incorporated into the winding.

1 9

| 60 Hz |

88 | GENERAL CATALOGUE 60 Hz

4

3 52

6

7

8

7

Page 4

DIMENSIONS AND WEIGHT

f

a

DN2

h2

DN1

h3

h1

w

MODEL PORTS DIMENSIONS mm

Single-phase Three-phase DN1 DN2 a f h h1 h2 h3 n n1 w s

2CRm 80 2CR 80

3CRm 60 3CR 60 6.5 6.5

3CRm 80 3CR 80 7.3 7. 3

4CRm 80 4CR 80

5CRm 80 5CR 80 411

3CRm 100 3CR 100 113 367 182 9 7. 9 7. 3

4CRm 100 4CR 100

5CR m 100 5CR 100 11. 0 10.6

(*) h=221 mm for single phase versions at 110V

1” 1”

113 367

138

138 411

182

392 8.3 7.7

202

202

132 51 183 182 120 87

*

*

h

n

n1

s

kg

1~ 3~

6.5 6.5

9

10 10.7 10.7

10.6 10.6

10

ABSORPTION

MODEL VOLTAGE

Single-phase 220 V 110 V 127 V

2CRm 80 2.5 A 5.0 A 4.7 A

3CRm 60 2.5 A 5.0 A 4.7 A

3CRm 80 3.4 A 6.9 A 6.2 A

4CRm 80 4.5 A 9.0 A 8.3 A

5CRm 80 6.0 A 12.0 A 11.0 A

3CRm 100 5.0 A 10.0 A 9.5 A

4CRm 100 6.2 A 12.2 A 11. 6 A

5CR m 100 ??

PALLETIZATION

MODEL

Single-phase Three-phase n. pumps n. pumps

2CRm 80 2CR 80 84 108

3CRm 60 3CR 60 84 108

3CRm 80 3CR 80 84 108

4CRm 80 4CR 80 72 108

5CRm 80 5CR 80 72 108

3CRm 100 3CR 100 84 108

4CRm 100 4CR 100 72 108

5CR m 100 5CR 100 72 10 8

GROUPAGE CONTAINER

MODEL VO LTAGE

Three-phase 220 V 380 V 220 V 440 V

2CR 80 1.7 A 1.0 A 1.7 A 1.0 A

3CR 60 1.7 A 1.0 A 1.7 A 1.0 A

3CR 80 2.3 A 1.3 A 2.1 A 1. 3 A

4CR 80 3.0 A 1.7 A 2.6 A 1. 5 A

5CR 80 5.0 A 2.9 A 4 .1 A 2.3 A

3CR 100 3.0 A 1.7 A 2.6 A 1.5 A

4CR 100 5.0 A 2.9 A 4.1 A 2.3 A

5CR 100 ??

GENERAL CATALOGUE 60 Hz | 89

| 60 Hz |

Loading...

Loading...