Operator’s Manual

Combination

Blanket/Fluid Warmer

P-2147

MN-39930

REV.01

3/19

EN

Manufacturer’s Information

Copyright © Copyright 3/19 by Pedigo Products, Inc.

All rights reserved.

This manual or any portion thereof may not be reproduced or used in any

manner whatsoever without the express written permission of Pedigo Products,

Inc.

Trademarks All trademarks referenced in this documentation are the property of their

respective owners.

Manufacturer Pedigo Products, Inc.

4000 S.E. Columbia Way

Vancouver, WA 98661, USA

1-800-822-3501

www.pedigo-usa.com

Original instructions The content in this manual is written in American English.

Combination Blanket/Fluid Warmer ▪ Operator’s Manual ▪ MN-39930 ▪ Rev 1 ▪ 3/19

2

FOREWORD

Thank you for your Purchase!

This warmer has been thoroughly tested and inspected to ensure only the

highest quality is provided. We supply the most durable, convenient, efficient

and safe warming equipment on the market. All warmers are manufactured and

fully inspected in the USA with a commitment to quality.

Pedigo Repair Service

Call Call 262-509-6517 to reach our service call center for immediate access to local

authorized service agencies. This service is provided exclusively for Pedigo

Product, Inc. equipment and is available throughout the United States.

Combination Blanket/Fluid Warmer ▪ Operator’s Manual ▪ MN-39930 ▪ Rev 1 ▪ 3/19

OREWORD

3

FOREWORD

This page intentionally left blank

Combination Blanket/Fluid Warmer ▪ Operator’s Manual ▪ MN-39930 ▪ Rev 1 ▪ 3/19

4

TABLE OF CONTENTS

Manufacturer’s Information . . . . . . . . . . . . . . . . . . . . . . . . 2

Foreword 3

Thank you for your Purchase! . . . . . . . . . . . . . . . . . . . . . . . 3

Pedigo Repair Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Table of Contents 5

Safety 7

The Meaning of Signal Words . . . . . . . . . . . . . . . . . . . . . . . 7

Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Labels 11

Label Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Specifications 13

Specification Information . . . . . . . . . . . . . . . . . . . . . . . . . 13

Dimension Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Installation 17

How to Unpack the Warmer . . . . . . . . . . . . . . . . . . . . . . . . 17

How to Install the Warmer . . . . . . . . . . . . . . . . . . . . . . . . . 18

Operation 21

Preparing the Warmer for First Use. . . . . . . . . . . . . . . . . . . . 21

How to Turn On and Turn Off the Warmer . . . . . . . . . . . . . . . . 22

How to Operate the Blanket Warmer (Bottom Cavity) . . . . . . . . . 23

How to Operate the Fluid Warmer (Top Cavity) . . . . . . . . . . . . . 24

How to Change the Temperature Scale. . . . . . . . . . . . . . . . . . 26

How to Change the Sound Settings . . . . . . . . . . . . . . . . . . . . 26

How to Lock and Unlock the Controller. . . . . . . . . . . . . . . . . . 27

How to Download Temperature Data from the Warmer . . . . . . . . 28

Maintenance 31

Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

How to Clean the Warmer . . . . . . . . . . . . . . . . . . . . . . . . . 32

Troubleshooting 35

What to do if a Power Interruption Occurs. . . . . . . . . . . . . . . . 35

What to do if the Alarm Indicator Light Flashes . . . . . . . . . . . . . 36

Error Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

How to Replace a Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

ONTENTS

C

OF

Electrical Information 43

Warranty 47

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Combination Blanket/Fluid Warmer ▪ Operator’s Manual ▪ MN-39930 ▪ Rev 1 ▪ 3/19

ABLE

T

5

TABLE OF CONTENTS

This page intentionally left blank

Combination Blanket/Fluid Warmer ▪ Operator’s Manual ▪ MN-39930 ▪ Rev 1 ▪ 3/19

6

The Meaning of Signal Words

This manual contains signal words where needed. These signal words must be

obeyed to reduce the risk of death, personal injury, or equipment damage. The

meaning of these signal words is explained below.

DANGER

Danger indicates a hazardous situation which, if not avoided,

will result in serious injury or death.

WARNING

Warning indicates a hazardous situation which, if not avoided,

could result in serious injury or death.

SAFETY

CAUTION

Caution indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

NOTICE

NOTE: Note indicates additional information that is important to a

concept or procedure.

Notice indicates a situation which, if not avoided, could result

in property damage.

Combination Blanket/Fluid Warmer ▪ Operator’s Manual ▪ MN-39930 ▪ Rev 1 ▪ 3/19

AFETY

7

SAFETY

Safety Precautions

Before you begin Read and understand all instructions in this manual.

Electrical precautions Obey these electrical precautions when using the warmer:

▪ Connect the warmer to a properly grounded outlet. Do not use the warmer if it is

not properly grounded. Consult an electrician if there is any doubt that the outlet

used is properly grounded.

▪ Keep the cord away from hot surfaces.

▪ Do not attempt to service the warmer or its cord and plug, when plugged in.

▪ Do not operate the warmer if it has a damaged cord or plug.

▪ Do not immerse the cord or plug in water.

▪ Do not let the cord hang over the edge of a table or counter.

▪ Do not use an extension cord.

Usage precautions Obey these usage precautions when using the warmer:

▪ Only use this warmer for its intended use of warming.

▪ Do not use this warmer for warming blood or blood products.

▪ Do not cover or block any of the openings of this warmer.

▪ Do not use this warmer in a wet location.

▪ Only clean the warmer when the power cord is unplugged.

▪ Do not use corrosive chemicals when cleaning the warmer.

▪ Do not use the warmer cavity for storage.

▪ Do not remove the top cover or exterior side panels. There are no user-

serviceable components inside.

Operator training All personnel using the warmer must have proper operator training. Before

using the warmer:

▪ Read and understand the operating instructions contained in all the

documentation delivered with the warmer.

▪ Know the location and proper use of all controls.

▪ Keep this manual and all supplied instructions, diagrams, schematics, parts lists,

notices, and labels with the warmer if the warmer is sold or moved to another

location.

Combination Blanket/Fluid Warmer ▪ Operator’s Manual ▪ MN-39930 ▪ Rev 1 ▪ 3/19

8

SAFETY

Operator

qualifications

Only trained personnel with the following operator qualifications are permitted

to use the warmer:

▪ Have received proper instruction on how to use the warmer.

▪ Are familiar with the purpose, limitations, and associated hazards of the warmer.

The warmer must not be used by:

▪ People impaired by drugs or alcohol.

Condition of warmer Only use the warmer when:

▪ All controls operate correctly.

▪ The warmer is installed correctly.

▪ The warmer is clean.

▪ The warmer labels are legible.

Servicing the warmer ▪ Obey precautions in the manual, on tags, and on labels attached to or shipped

with the warmer.

▪ Only trained personnel are permitted to service or repair the warmer. Repairs

that are not performed by a trained technician, or the use of non-factory parts,

will void the warranty and relieve all liability.

▪ Any troubleshooting guides and components views included with this manual

are for reference only and are intended for use by qualified and trained service

technicians.

▪ To prevent serious injury, death or property damage, have the warmer inspected

and serviced at least every twelve (12) months by a trained technician.

▪ Contact Pedigo for the authorized service partner in your area.

Combination Blanket/Fluid Warmer ▪ Operator’s Manual ▪ MN-39930 ▪ Rev 1 ▪ 3/19

9

SAFETY

This page intentionally left blank

10

Combination Blanket/Fluid Warmer ▪ Operator’s Manual ▪ MN-39930 ▪ Rev 1 ▪ 3/19

Label Locations

LABELS

a

b

c

d

EC-PHD-004613

Combination Blanket/Fluid Warmer ▪ Operator’s Manual ▪ MN-39930 ▪ Rev 1 ▪ 3/19

ABELS

11

LABELS

Security Seal

Security Seal

Security Seal

Security Seal

Security Seal

Security Seal

Security Seal

Security Seal

1

Security seal

Electrical warning label

2

Pedigo contact information

3

Quality inspected

4

12

Combination Blanket/Fluid Warmer ▪ Operator’s Manual ▪ MN-39930 ▪ Rev 1 ▪ 3/19

Specification Information

E471516

Protective Earth

Ground Symbol

SPECIFICATIONS

Transportation and

storage conditions

Weight

Storage cavity capacity

Temperature range

Clearance

requirements

▪ Ambient temperature range of -40°F to +159°F (-40°C to +70°C).

▪ Relative humidity range of 10% to 95%, non-condensing.

▪ Atmospheric pressure range of 7.25 psi to 15.37 psi (50kPa to 106kPa).

Net: 457 lb (207 kg)

Ship: 568 lb (258 kg)

Fluid cavity: 30 1-liter bottles or 24 1-liter bags

3

Blanket cavity: 30 blankets (13 ft

Irrigation fluids (IRR):

90°F to 150°F (32°C to 66°C)

Injection fluids (INJ):

90°F to 104°F (32°C to 40°C)

Blanket: 90°F to 160°F (32°C to 71°C)

4” (102mm) from rear

1” (25mm) from top

2” (51mm) from sides

1/2” (13mm) from bottom

)

Operating conditions ▪ The warmer must acclimate to the room temperature it will be placed—24 hours

is recommended.

▪ The recommended environmental temperature range is 60°F to 90°F

(15°C to 32°C).

▪ The recommended relative humidity is above 20%, non-condensing.

Standards for

electrical equipment

Combination Blanket/Fluid Warmer ▪ Operator’s Manual ▪ MN-39930 ▪ Rev 1 ▪ 3/19

▪ Medical equipment classified by Underwriters Laboratories with respect

to electrical shock, fire, and mechanical hazards only, in accordance with

UL 61010-1 and CAN/CSA C22.2 No. 61010-1.

▪ Grounding reliability can only be achieved when the appliance is

connected to an equivalent receptacle marked “Hospital Grade.”

▪ IEC 60601-1-2

▪ IP-XO ordinary

PECIFICATIONS

13

SPECIFICATIONS

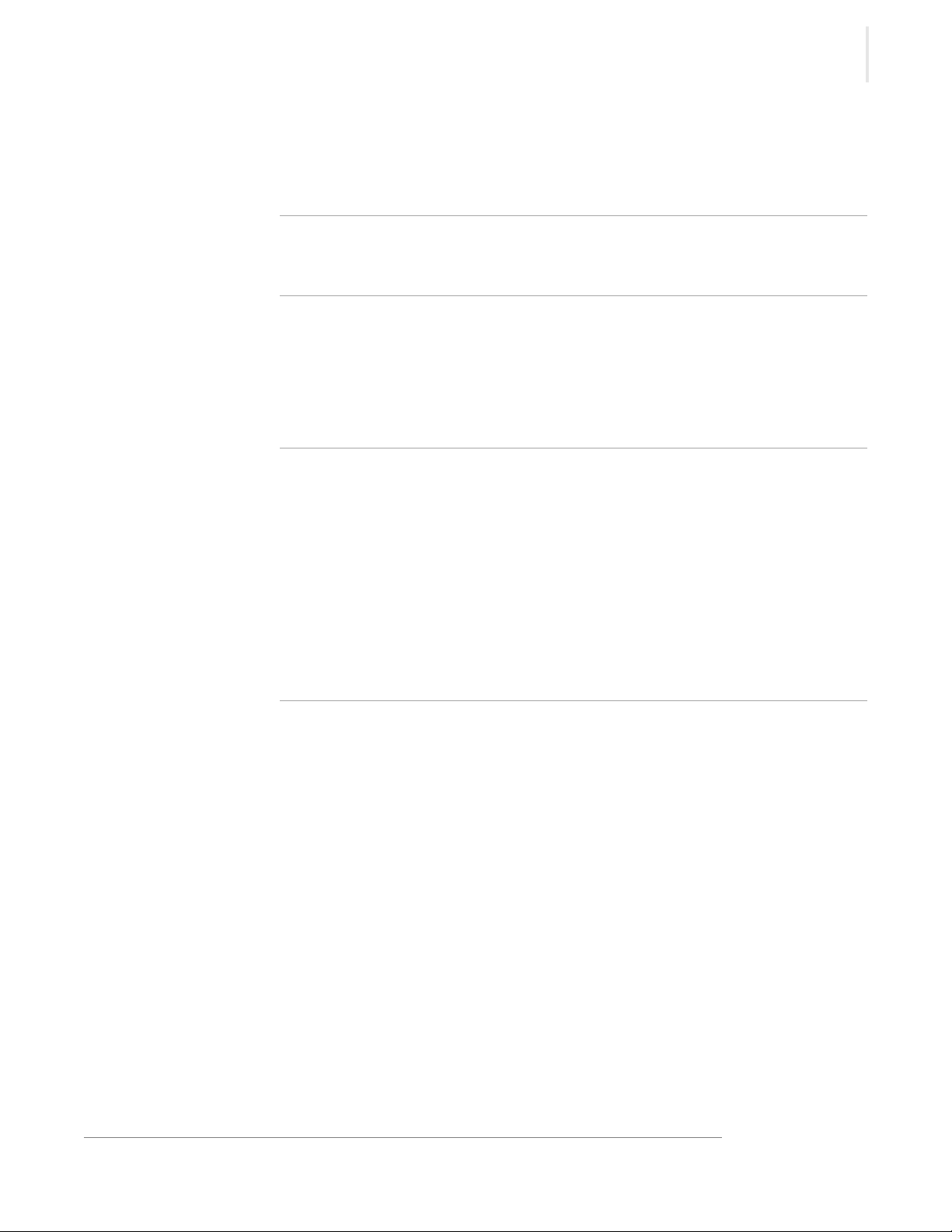

EC-DIM-004602

68.75

"

(1743mm)

68.10

"

(1729mm)

30" (763mm)

15

"

(381mm)

CAVITY & INSERT

26.5"

(673mm)

CAVITY

23.60" (598mm)

INSERT

36

"

(914mm)

CAVITY

35

"

(890mm)

INSERT

23.60" (598mm)

INSERT

58.75" (1492mm)

29.25

"

(743mm)

56

"

(1422mm)

26.5" (673mm)

28.25" (715mm)

43.30

"

(1100mm)

IEC Cord Inlet

23.75" (603mm)

CAVITY

23.75" (603mm)

CAVITY

Dimension Drawings

Warmer shown with feet

14

Combination Blanket/Fluid Warmer ▪ Operator’s Manual ▪ MN-39930 ▪ Rev 1 ▪ 3/19

Warmer shown with casters

(1422mm)

"

56

(743mm)

"

29.25

58.75"

(1492mm)

30" (763mm)

26.5" (673mm)

CAVITY

(381mm)

"

15

CAVITY & INSERT

"

(721mm)

28.5

26.5" (673mm)

23.75

"

(603mm)

CAVITY

SPECIFICATIONS

(1727mm)

(1901mm)

"

"

68

75

23.60" (598mm)

INSERT

23.60" (598mm)

INSERT

(890mm)

INSERT

"

35

(914mm)

CAVITY

"

36

23.75

" (603mm)

CAVITY

EC-DIM-004605

(1256mm)

"

IEC Cord Inlet

49.5

Combination Blanket/Fluid Warmer ▪ Operator’s Manual ▪ MN-39930 ▪ Rev 1 ▪ 3/19

15

SPECIFICATIONS

This page intentionally left blank

16

Combination Blanket/Fluid Warmer ▪ Operator’s Manual ▪ MN-39930 ▪ Rev 1 ▪ 3/19

How to Unpack the Warmer

Step Action

Before you begin Make sure you have:

▪ An appropriate lifting device and enough personnel to safely move and position

the weight of the warmer.

▪ Cutting tools to remove the packaging.

Unpack the warmer To unpack the warmer, do the following.

1. Remove the box or crate. Save all packing materials for inspection by the

carrier.

NOTE: Examine the warmer for damage. If the warmer has

been damaged, do not use the warmer until it has been

inspected by an authorized service provider. Contact your

carrier or customer service.

INSTALLATION

2. Cut and remove the retaining straps and plastic wrap.

3. Remove the warmer from the pallet using an appropriate lifting device.

4. Remove the paperwork from the cavity.

Result The warmer is now unpacked.

Combination Blanket/Fluid Warmer ▪ Operator’s Manual ▪ MN-39930 ▪ Rev 1 ▪ 3/19

NSTALLATION

17

INSTALLATION

How to Install the Warmer

Before you begin Make sure you have:

An appropriate lifting device and enough personnel to safely move and position

the weight of the warmer.

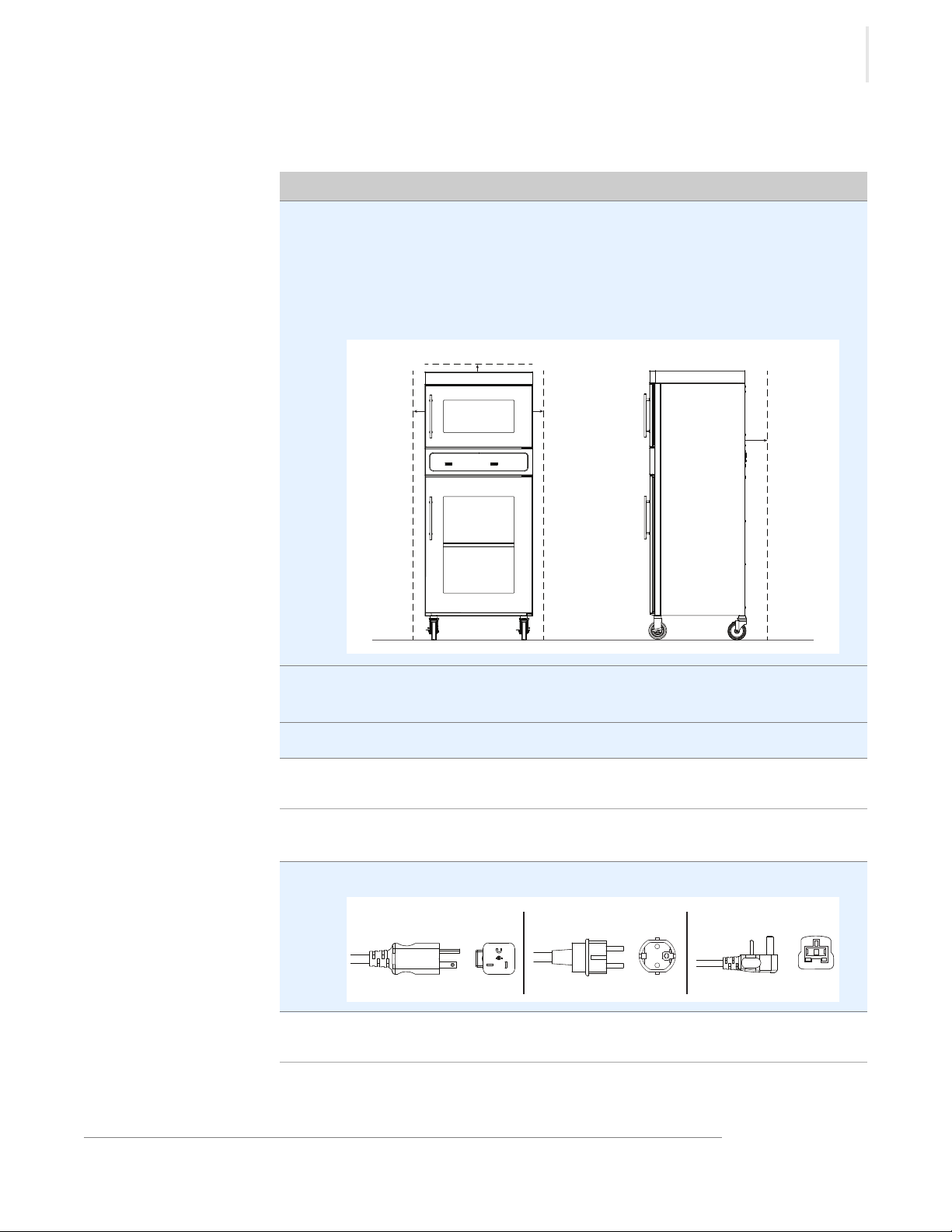

Requirements

Voltages

▪ The warmer must be installed on a level surface.

▪ The warmer must not be installed in any area where it may be affected by

dripping water, high temperature, or any other severely adverse conditions.

Model V Ph Hz kW Plug Configuration

P-2147 120

220

230

*Other international plugs are available, contact the manufacturer for more

information.

1

1

1

50/60

50/60

50/60

1.3

1.2

1.3

NEMA 5-20P

CEE 7/7*

BS 1363 (UK only)

CEE 7/7*

Continued on next page

18

Combination Blanket/Fluid Warmer ▪ Operator’s Manual ▪ MN-39930 ▪ Rev 1 ▪ 3/19

Continued from previous page

Step Action

EC-DIM-004616

1.0"

25mm

2.0"

51mm

2.0"

51mm

4.0"

102mm

CEE 7/7NEMA 5-20P BS 1363

EC-TS-004622

Position the warmer To position the warmer, do the following.

1. Make sure that:

▪ The location where the warmer is being installed is rated to support the

weight of the warmer;

▪ The warmer is within five feet of the appropriate electrical outlet;

▪ You follow the warmer clearance guidelines shown below.

INSTALLATION

2. Move the warmer to the installation location and onto the final resting

surface.

3. Lock the casters, if equipped.

The warmer is now correctly positioned.

Connect power

To connect electric power to the warmer, do the following.

4. Connect the plug to the electrical outlet.

Result The warmer is now installed and ready to be used.

Combination Blanket/Fluid Warmer ▪ Operator’s Manual ▪ MN-39930 ▪ Rev 1 ▪ 3/19

19

INSTALLATION

This page intentionally left blank

20

Combination Blanket/Fluid Warmer ▪ Operator’s Manual ▪ MN-39930 ▪ Rev 1 ▪ 3/19

Preparing the Warmer for First Use

Step Action

Before you begin

CAUTION: Burn hazard.

Allow the warmer to cool before cleaning.

OPERATION

NOTICE

Procedure

Result The warmer is now ready for use.

To prepare the warmer for first use, do the following.

1. Make sure that the warmer is turned off and cool.

2. Wipe the outside of the warmer with a stainless steel cleaner.

3. Clean the interior of the warmer with a damp cloth.

4. Dry the interior and exterior of the warmer with a clean, lint-free cloth.

Leave the door open until the interior of the warmer completely dries.

5. Clean each side of the window pane with glass cleaner or distilled vinegar.

Do not use:

▪ abrasive cleaning compounds.

▪ chloride based cleaners.

▪ commercial or household cleaners containing ammonia.

▪ cleaners containing quaternary salts.

Combination Blanket/Fluid Warmer ▪ Operator’s Manual ▪ MN-39930 ▪ Rev 1 ▪ 3/19

PERATION

21

OPERATION

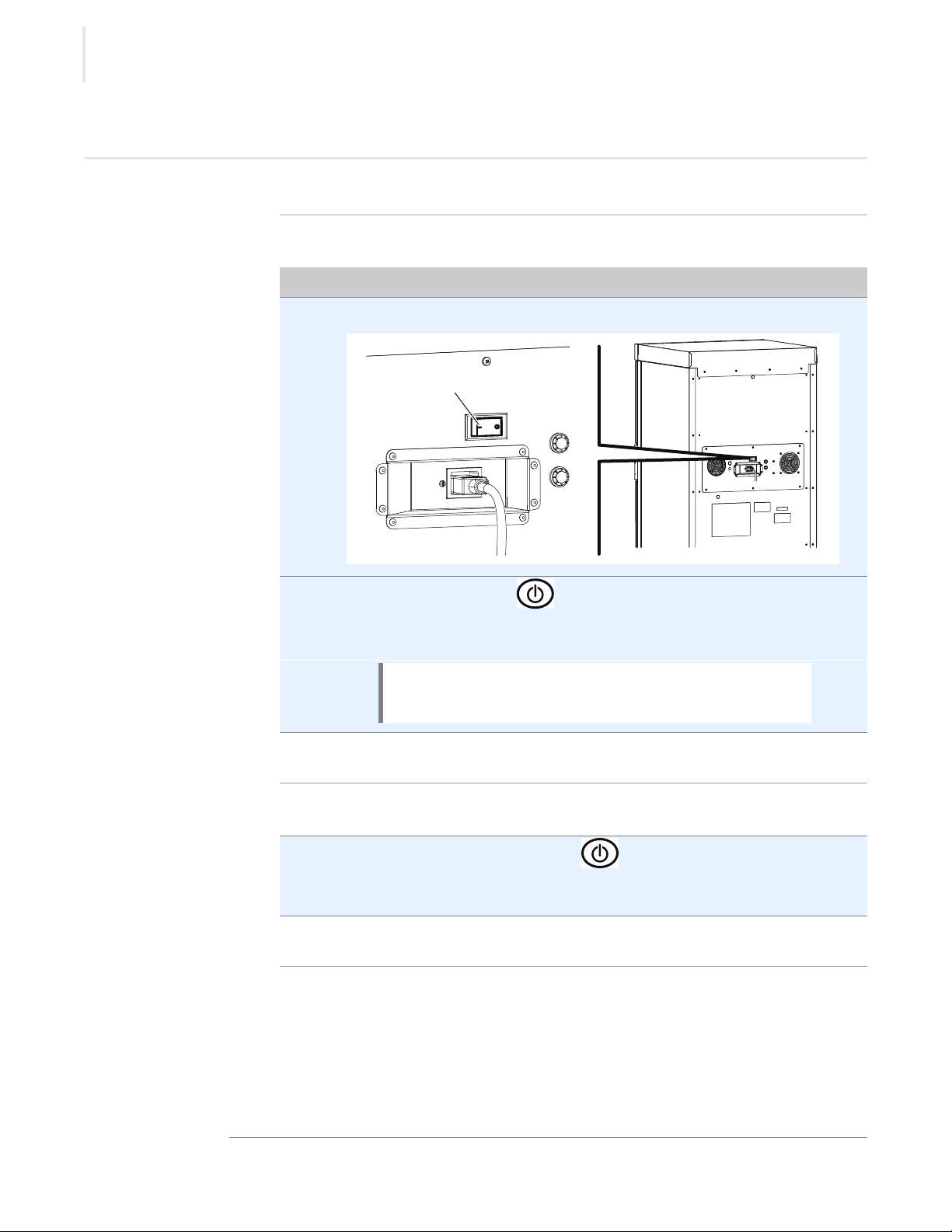

Step Action

EC-TS-004628

a

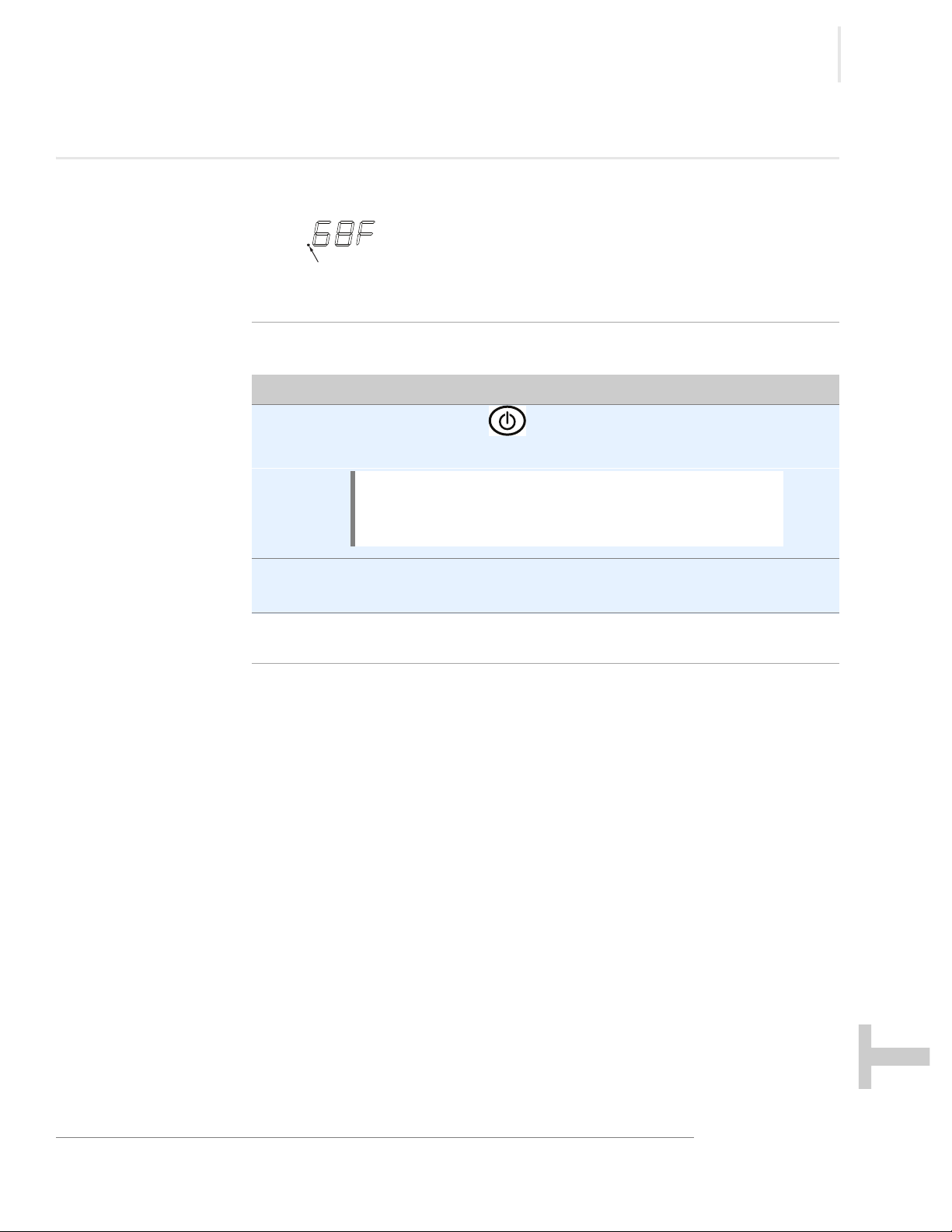

How to Turn On and Turn Off the Warmer

Before you begin The warmer must be connected to electric power.

Turning on the

warmer

To turn on the warmer, do the following.

1. Set the power switch a to the ON (l) position.

2. Press the ON/OFF button . The screen turns on.

The blanket warmer and fluid warmer screens must be turned ON

separately.

NOTE: A temporary odor may be noticeable upon initial

start-up of the warmer. Contact the manufacturer if the

odor persists after a day or more of continuous use.

Turning off the

warmer

22

The warmer is now on.

To turn off the warmer, do the following.

3. Press and hold the ON/OFF button until the screen turns off.

The blanket warmer and fluid warmer screens must be turned OFF

separately.

The warmer is now off.

Combination Blanket/Fluid Warmer ▪ Operator’s Manual ▪ MN-39930 ▪ Rev 1 ▪ 3/19

OPERATION

Step Action

How to Operate the Blanket Warmer (Bottom

Cavity)

Before you begin The warmer must be connected to electric power and turned on.

WARNING: Personal injury hazard.

Do not operate the warmer in the presence of flammable

anesthetic mixtures (with air or with oxygen or nitrous oxide).

WARNING: Personal injury hazard.

Make sure the blanket support assembly and shelves are

installed to prevent the blankets from being scorched or

discolored.

Procedure

During the warming

process

NOTICE

To operate the warmer, do the following.

1. Set the temperature using the arrow buttons .

2. Open the door and load the dry, cotton blankets into the warmer.

Close the door.

3. Press the temperature recall button to view the actual temperature.

The actual temperature will display for five seconds. Then, the set-point

temperature will display.

4. Rotate the blankets daily from the bottom to the top of the load to ensure

equal heating and to prevent discoloration.

Do not overload the cavity.

Allow 1” (25mm) between the blankets and the interior walls.

NOTE: The temperature set-point range is 90°F – 160°F

(32°C – 71°C).

NOTICE

Do not warm items containing plastic, rubber, metal

snaps, studs, hooks, etc.

Result The blankets are now warming.

Combination Blanket/Fluid Warmer ▪ Operator’s Manual ▪ MN-39930 ▪ Rev 1 ▪ 3/19

23

OPERATION

Step Action

How to Operate the Fluid Warmer (Top Cavity)

Before you begin The warmer must be connected to electric power and turned on.

WARNING: Personal injury hazard.

Do not operate the warmer in the presence of flammable

anesthetic mixtures (with air or with oxygen or nitrous oxide).

WARNING: Personal injury hazard.

Verify the fluid temperature prior to using the fluid. Refer to the

fluid manufacturer’s label for recommended warming

procedures.

Do not use any fluids that are warmed above the suggested

temperature.

Procedure

NOTICE

Do not overload the cavity.

Refer to topic Specification Information for the storage cavity

capacity.

To operate the warmer, do the following.

1. Select the operation mode.

▪ Press the irrigation button for irrigation mode.

▪ Press the injection button for injection mode.

The selected operation mode will illuminate .

NOTE: Open the door to cool the cavity before changing

from a higher temperature to a lower temperature.

2. Set the temperature using the arrow buttons .

NOTE: The irrigation temperature set-point range is

90°F – 150°F (32°C – 66°C).

The injection temperature set-point range is 90°F – 104°F

(32°C – 40°C).

24

Continued on next page

Combination Blanket/Fluid Warmer ▪ Operator’s Manual ▪ MN-39930 ▪ Rev 1 ▪ 3/19

Continued from previous page

3. Open the door and load the fluid into the warmer.

Close the door.

OPERATION

During the warming

process

4. Press the temperature recall button to view the actual temperature.

The actual temperature will display for five seconds. Then, the set-point

temperature will display.

Result The fluids are now warming.

Combination Blanket/Fluid Warmer ▪ Operator’s Manual ▪ MN-39930 ▪ Rev 1 ▪ 3/19

25

OPERATION

Step Action

Step Action

How to Change the Temperature Scale

Before you begin The warmer must be connected to electric power and the screen turned off.

Procedure

Result The temperature scale has now been changed.

To change the temperature scale from °F to °C and vice versa, do the following.

1. Press and hold the ON/OFF button until the screen turns off.

2. Press and hold the temperature recall button to display the current

temperature scale.

3. Press the up and down arrow buttons to toggle between the

temperature scales.

How to Change the Sound Settings

Before you begin The warmer must be connected to electric power and the screen turned off.

Procedure

Result The sound setting has now been changed.

26

To change the sound settings, do the following.

1. Press and hold the ON/OFF button until the screen turns off.

2. Press and hold the temperature recall button , then the down arrow

button .

The sound setting displays.

3. Press the up and down arrow buttons to adjust the volume.

The volume range is 0 (mute) to 12 (maximum).

Combination Blanket/Fluid Warmer ▪ Operator’s Manual ▪ MN-39930 ▪ Rev 1 ▪ 3/19

OPERATION

Step Action

How to Lock and Unlock the Controller

Before you begin The warmer must be turned on (screen is on).

Background The controller can be locked to prevent changes being made to the temperature

set-point.

Locking the

controller

Unlocking the

controller

Result The controller has now been locked or unlocked.

To lock the controller, do the following.

1. Press the ON/OFF button and the up arrow button at the same

time.

The lock indicator will illuminate.

To unlock the controller, do the following.

2. Press the ON/OFF button and the down arrow button at the

same time.

The lock indicator goes off.

Combination Blanket/Fluid Warmer ▪ Operator’s Manual ▪ MN-39930 ▪ Rev 1 ▪ 3/19

27

OPERATION

Step Action

How to Download Temperature Data from the Warmer

Before you begin ▪ The warmer must be turned on (screen is on).

▪ Do not remove the USB drive during the download process.

▪ You will need a SanDisk Cruzer Glide USB drive.

NOTICE

Background The warmer automatically downloads only the data that has not been previously

downloaded. The warmer will store multiple years of data. The download time

for one week of data should be under five seconds.

The warmer records various performance parameters:

▪ automatically every five minutes while the power switch is ON.

▪ each time the temperature set-point is changed.

▪ each time the fluid door is opened.

▪ each time the fluid operation mode is changed.

Procedure To download temperature data from the warmer, do the following.

1. Open the blanket warmer door.

Only use a SanDisk Cruzer Glide USB drive larger than 4 GB.

Using other USB drives may cause erratic operation or loss of

data.

Continued on next page

28

Combination Blanket/Fluid Warmer ▪ Operator’s Manual ▪ MN-39930 ▪ Rev 1 ▪ 3/19

OPERATION

EC-TS-005823

a

Continued from previous page

2. Plug the USB drive into the port a. The warmer downloads the temperature

data.

NOTICE

The warmer goes through the download process:

▪ The LED screen located above the USB port flashes for a few seconds to

show a data transfer is in progress.

▪ The LED screen stops flashing.

▪ The download is complete.

3. Remove the USB drive from the port.

4. Close the blanket warmer door.

Do not remove the USB drive during the download

process.

Result The data has now been downloaded.

Viewing the

To view the temperature data, do the following.

temperature data

5. Plug the USB drive into a computer.

6. Double-click on the file.

NOTE: Data is stored on the USB drive in a file named,

datalog_MMDDYY_HHMMSS.csv.

7. Sort the data as necessary.

Temperature data will be recorded in the same temperature units that are

displayed on the LED screen.

NOTE: Errors recorded by the warmer are intended for

use by service technicians only.

Combination Blanket/Fluid Warmer ▪ Operator’s Manual ▪ MN-39930 ▪ Rev 1 ▪ 3/19

Continued on next page

29

OPERATION

Continued from previous page

Viewing data in

The table below is an example of temperature data from the warmer.

Microsoft Excel

Time Stamp Chamber Mode Power Door Fan Temperature Set-point Errors

12/19/2018 14:48 bottom off closed off 71.7 130 Diagnostics.SensorSho

rtErrors=0x0c

12/19/2018 14:48 top off closed off 71.2 104 Diagnostics.SensorSho

rtErrors=0x0c

12/19/2018 14:53 bottom on closed on 71.7 130 Diagnostics.SensorSho

rtErrors=0x0c

12/19/2018 14:53 top INJ on closed on 70.4 104 Diagnostics.SensorSho

rtErrors=0x0c

12/19/2018 14:58 bottom on closed on 71.7 130 Diagnostics.SensorSho

rtErrors=0x0c

12/19/2018 14:58 top INJ on closed on 70.4 104 Diagnostics.SensorSho

rtErrors=0x0c

12/19/2018 15:03 bottom on closed on 71.7 130 Diagnostics.SensorSho

rtErrors=0x0c

12/19/2018 15:03 top INJ on closed on 70.3 104 Diagnostics.SensorSho

rtErrors=0x0c

Result The temperature data has now been viewed.

30

Combination Blanket/Fluid Warmer ▪ Operator’s Manual ▪ MN-39930 ▪ Rev 1 ▪ 3/19

Maintenance Schedule

Daily For daily maintenance, do the following.

Check:

▪ the air vents in the airflow insert panels are not obstructed (if applicable).

▪ all fan guards are clear and not obstructed (if applicable).

▪ the number of bottles, bags, or blankets do not exceed the maximum capacity

per shelf or basket.

Clean:

▪ any spills with a clean, lint free cloth.

Monthly For monthly maintenance, do the following.

Check:

▪ the door gasket for tears and holes. Make sure that it is firmly attached to the

door. Check the seal when the door is closed.

▪ the guards around the air temperature sensor are in place and fully secure to the

warmer.

▪ the hardware securing the warmer(s) to the wall, if applicable.

Clean:

MAINTENANCE

▪ the outside of the warmer with stainless steel cleaner.

▪ vacuum (if applicable):

□ fan openings

□ fan sail switch

□ vent openings

Yearly For yearly maintenance, do the following.

Check:

▪ the set-point temperature compared to the actual temperature displayed.

□ Check the cavity air temperature with a thermocouple placed 1” (25mm) from

the cavity sensor. Do not allow the thermocouple to touch any surface.

Monitor the temperature for approximately one hour in an empty cavity.

▪ the condition of the plug and cord and replace if damaged.

▪ the controller screen for excessive wear. Make sure the controller screen displays

and operates properly.

Clean:

▪ the shelves and interior of the warmer.

AINTENANCE

Combination Blanket/Fluid Warmer ▪ Operator’s Manual ▪ MN-39930 ▪ Rev 1 ▪ 3/19

31

MAINTENANCE

Step Action

How to Clean the Warmer

Before you begin

WARNING: Electric shock hazard.

Disconnect the warmer from electric power before cleaning.

CAUTION: Burn hazard.

Allow the warmer to cool before cleaning.

Monthly cleaning

procedure

NOTICE

Do not use:

▪ abrasive cleaning compounds.

▪ chloride based cleaners.

▪ commercial or household cleaners containing ammonia.

▪ cleaners containing quaternary salts.

To clean the warmer monthly, do the following.

1. Make sure that the warmer is disconnected from electric power and cool.

2. Wipe the outside of the warmer with a stainless steel cleaner.

3. Vacuum lint from fan openings, fan sail switch, and vent openings.

4. Clean the interior of the warmer with a damp cloth.

5. Dry the interior and exterior of the warmer with a clean, lint-free cloth.

Leave the door open until the interior of the warmer completely dries.

6. Clean each side of the window pane with glass cleaner or distilled vinegar.

32

Continued on next page

Combination Blanket/Fluid Warmer ▪ Operator’s Manual ▪ MN-39930 ▪ Rev 1 ▪ 3/19

Continued from previous page

Step Action

EC-TS-004655

a

a

EC-TS-004658

b

MAINTENANCE

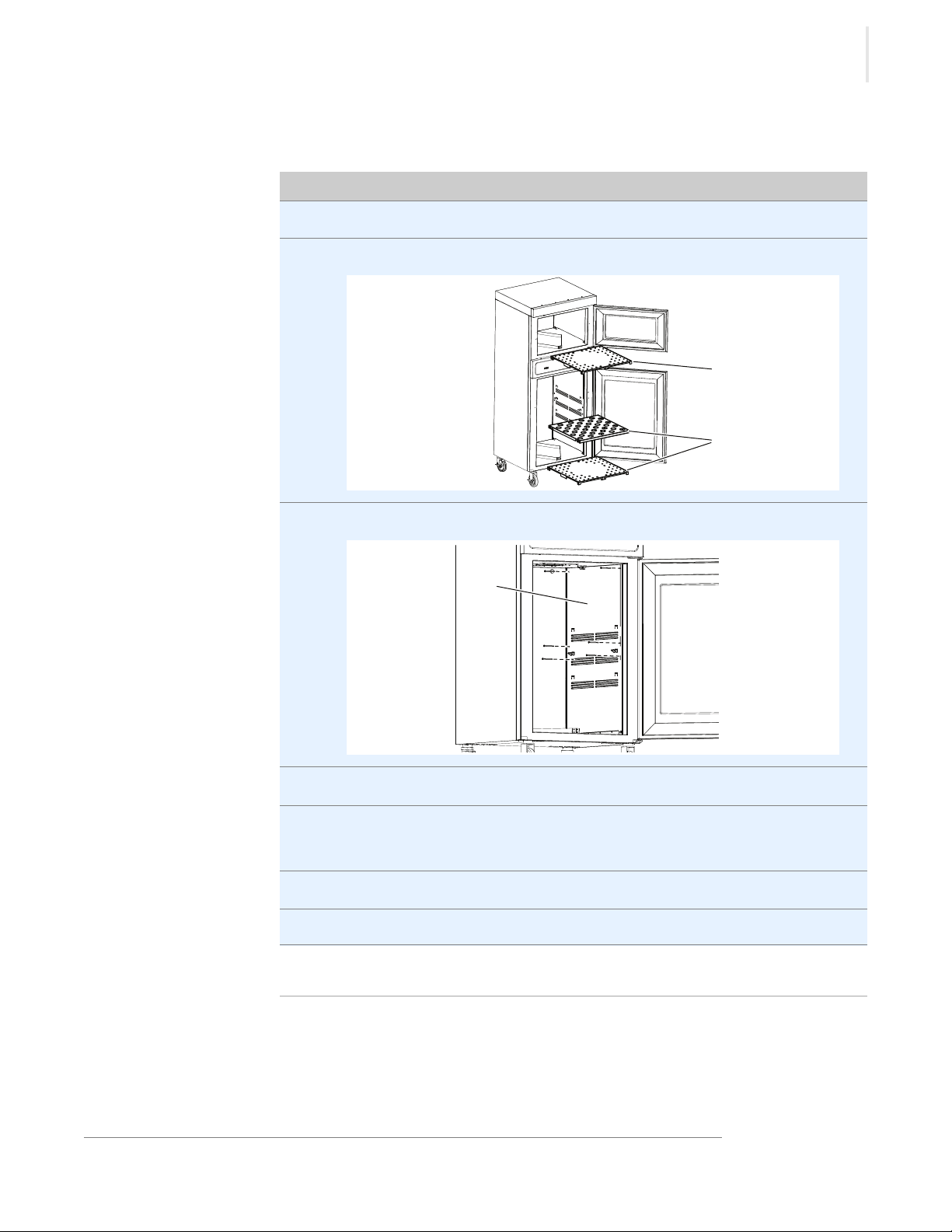

Yearly cleaning

procedure

To clean the warmer yearly, do the following.

1. Make sure that the warmer is disconnected from electric power and cool.

2. Remove the shelves a from the interior of the warmer.

3. Remove the side panels b from the interior of the blanket warmer cavity.

Result The warmer is now clean.

Combination Blanket/Fluid Warmer ▪ Operator’s Manual ▪ MN-39930 ▪ Rev 1 ▪ 3/19

4. Clean the shelves and interior with a damp cloth.

5. Dry the interior of the warmer with a clean, lint-free cloth.

Leave the door open until the interior of the warmer completely dries.

6. Clean each side of the window pane with glass cleaner or distilled vinegar.

7. Re-install the side panels and shelves.

33

MAINTENANCE

This page intentionally left blank

34

Combination Blanket/Fluid Warmer ▪ Operator’s Manual ▪ MN-39930 ▪ Rev 1 ▪ 3/19

TROUBLESHOOTING

Step Action

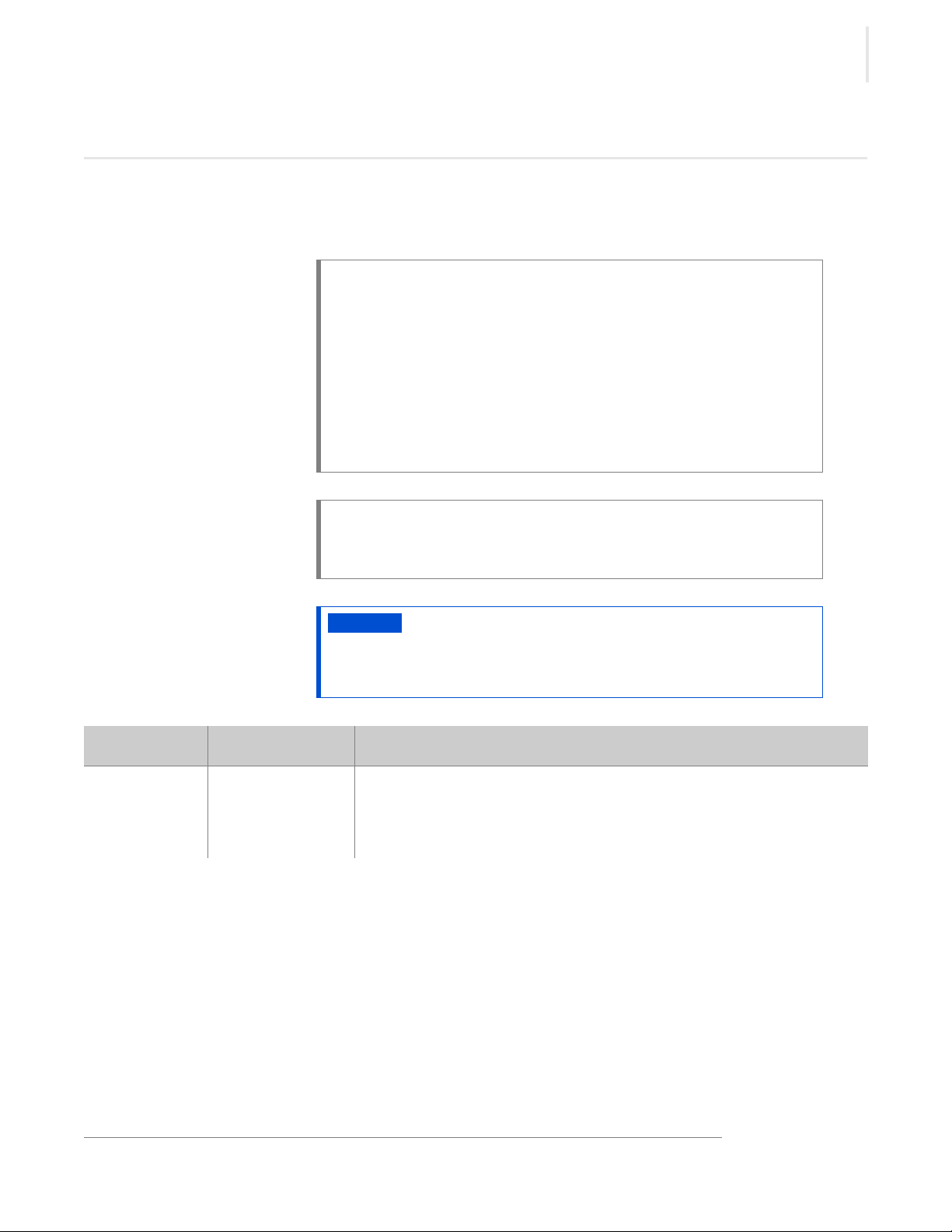

LED

What to do if a Power Interruption Occurs

Background You may need to reset the warmer in the case that a power interruption occurs.

When the power is restored, the ON/OFF status indicator LED decimal

flashes .

The controller stores all settings and continues operation using these settings in

the event of a power interruption.

Procedure

Result Resume operation of the warmer.

To continue operation of the warmer, do the following.

1. Press the ON/OFF button .

The LED goes out.

NOTE: The screen displays the length of time of the

power interruption in hours and minutes (hh:mm) for five

seconds. Then, the screen displays the set-point

temperature.

2. Make sure the fluids and blankets are at the correct temperature before

using.

Combination Blanket/Fluid Warmer ▪ Operator’s Manual ▪ MN-39930 ▪ Rev 1 ▪ 3/19

ROUBLESHOOTING

35

TROUBLESHOOTING

Step Action

What to do if the Alarm Indicator Light Flashes

Background The alarm indicator light flashes and the controller sounds an alarm when

the warmer malfunctions.

Procedure

Result Resume operation of the warmer.

If the alarm indicator light flashes, do the following.

1. Press the ON/OFF button to acknowledge the alarm.

Refer to the troubleshooting section for the error code.

2. Make sure the fluids and blankets are the correct temperature before using.

36

Combination Blanket/Fluid Warmer ▪ Operator’s Manual ▪ MN-39930 ▪ Rev 1 ▪ 3/19

TROUBLESHOOTING

Error Codes

Background This section is provided for the assistance of qualified and trained service

technicians only and is not intended for use by untrained or unauthorized service

personnel. Failure to observe this precaution may void the warranty.

NOTE: If the warmer is not operating properly, check the following

before calling an authorized service agent:

Verify that the power to the warmer is on.

If applicable, ensure the female end of plug is securely seated in the

warmer and that the male end of plug is in an appropriate,

functioning outlet.

If applicable, examine the fuses. Replace the fuses, refer to topic How

to Replace a Fuse.

If applicable, examine the high limit manual reset button. If the high

limit manual reset button is tripped, reset the warmer, refer to topic

How to Manually Reset the Warmer.

NOTE: All non-critical codes can be cleared using the ON/OFF button.

Critical errors (marked with a *) can only be cleared by setting the

power switch at the rear of the warmer to the off (O) position and

allowing the warmer to cool.

NOTICE

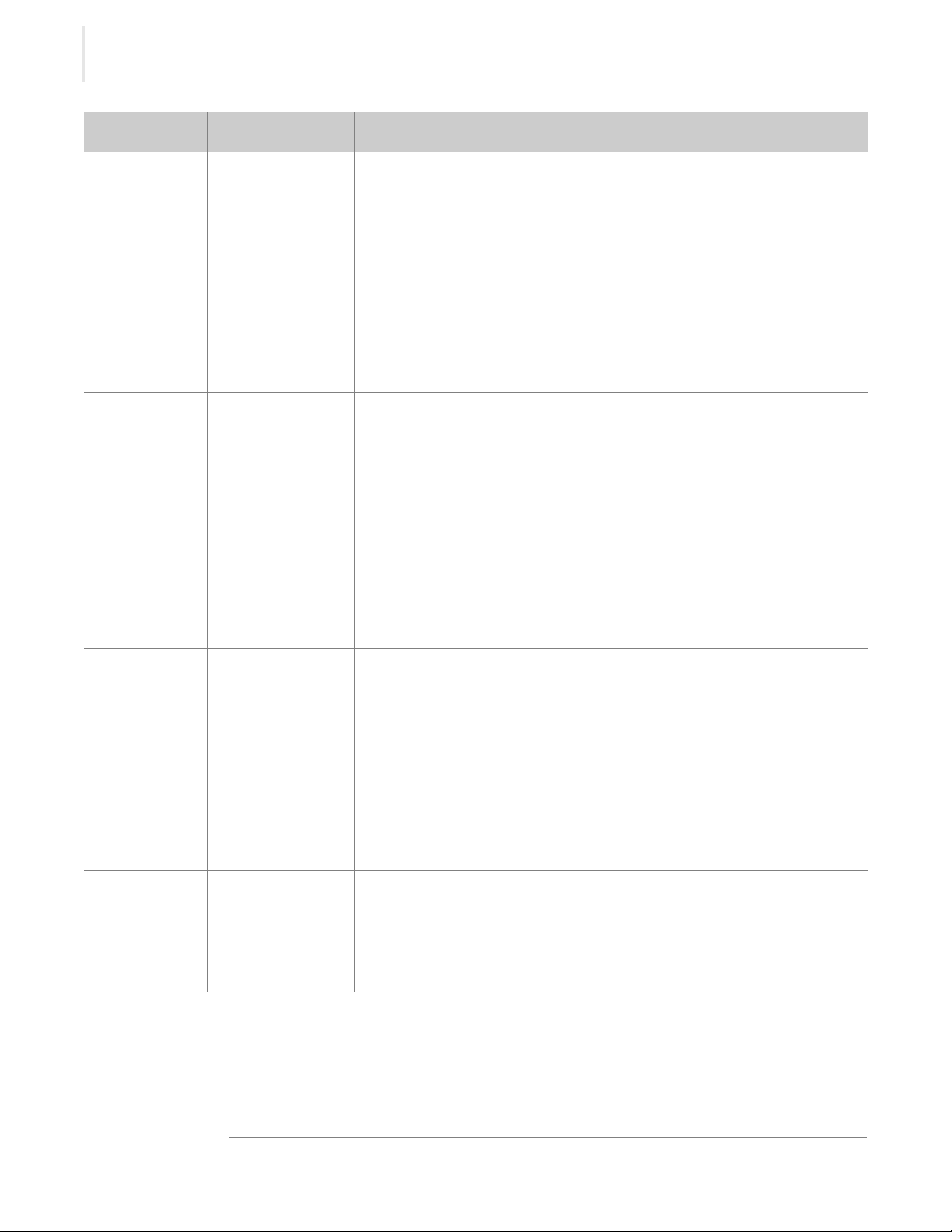

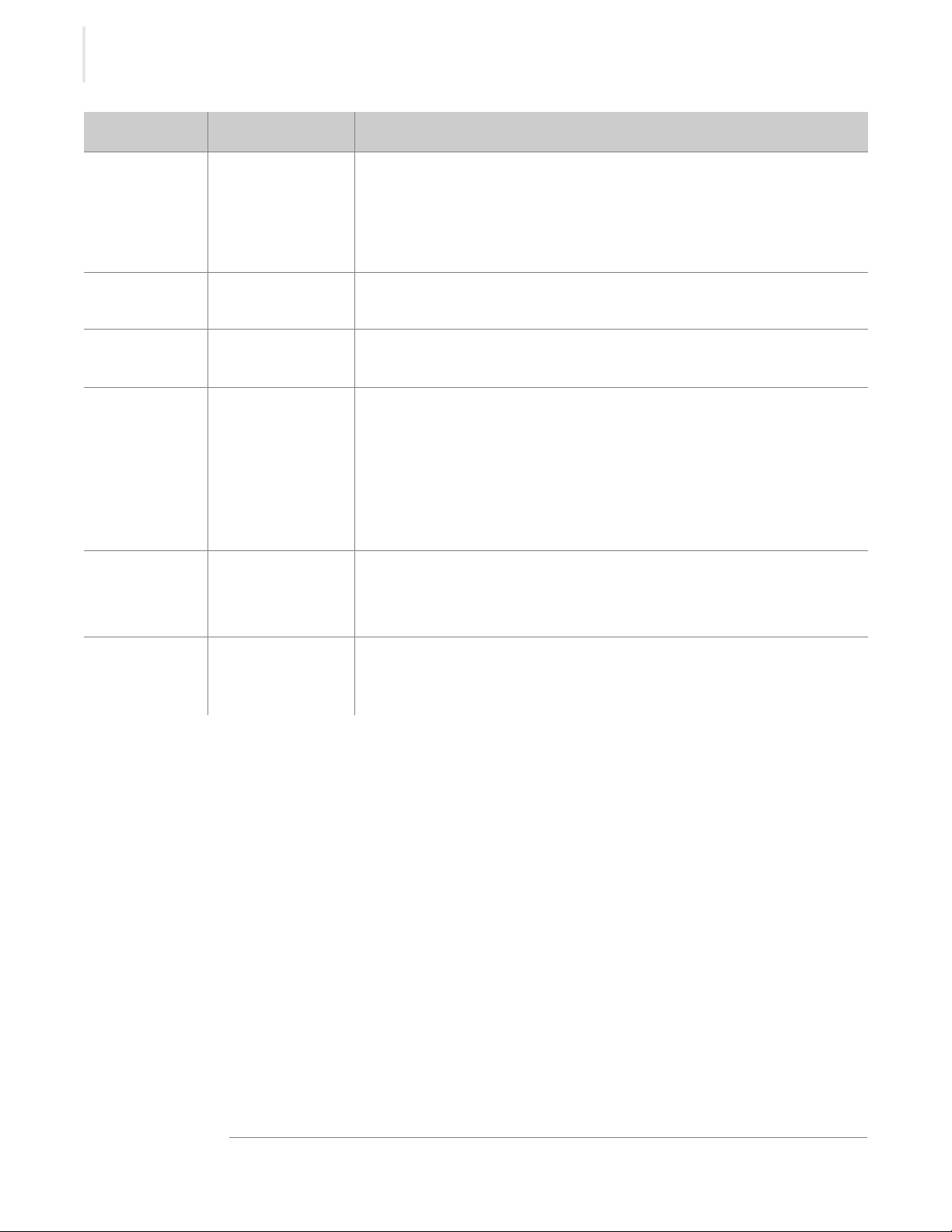

Code Refers to Action required

Display flashes

set point

Cavity

temperature

higher than set

point

Do not attempt to repair or service the warmer beyond this

point. Contact the manufacturer for the nearest authorized

service agent. Repairs made by any other service agent

without prior authorization by the manufacturer will void the

warranty.

Cavity temperature is higher than the set point temperature.

◾Allow cavity to cool to set point temperature.

Combination Blanket/Fluid Warmer ▪ Operator’s Manual ▪ MN-39930 ▪ Rev 1 ▪ 3/19

37

TROUBLESHOOTING

Code Refers to Action required

E-10

ES10

ES20

ES30

ES40

ES50

ES60

ES70

E-11

ES11

ES21

ES31

ES41

ES51

ES61

ES71

Cavity sensor

Sensor 1

Sensor 2

Sensor 3

Sensor 4

Sensor 5

Sensor 6

Sensor 7

Cavity sensor

Pad sensor 1

Pad sensor 2

Pad sensor 3

Pad sensor 4

Pad sensor 5

Pad sensor 6

Pad sensor 7

Sensor is shorted. Software disengages heating pads. Acknowledge error

by pressing the ON/OFF button. If error persists, a qualified service

technician should test the sensor.

◾Test the sensor. Detach the sensor from the warmer. Use an Ohm meter

to measure the resistance of the sensor. Check the sensor at 25°C (77°F).

If the reading is 10 KOhm ±1.5 KOhm, replace the display. If the reading

is ±2 KOhm, replace the sensor.

◾Check the wires for integrity. Inspect the connections at the control and

terminal block to ensure proper and secure connections. If necessary,

re-secure the faulty connections.

◾Contact service if error persists.

Sensor is open. Software disengages heating pads. Acknowledge error by

pressing the ON/OFF button. If error persists, a qualified service technician

should test the sensor.

◾Test the sensor. Disconnect the sensor from the warmer control PCB

and use an Ohm meter to measure the resistance of the sensor.

Sensor PR-37140 should measure 10 KOhm ± 1.5 KOhm at 25°C (77°F).

Sensor SN-33541 should measure 100 Ohm ± 10 Ohm at 25°C (77°F).

Replace sensor if measurement is outside of tolerance.

◾Check the wires for integrity. Check for proper and secure connections

at the control and terminal block. If necessary, re-secure the faulty

connections.

◾Contact service if error persists.

E-30 Under

temperature

*E-31 Cavity sensor

The blanket cavity temperature is lower than the set temperature for 90

minutes or longer.

◾Make sure the door is closed.

◾If the cavity is overloaded, redistribute the inventory. Do not exceed the

height of the insert.

◾Test the sensor. Disconnect the sensor from the warmer control PCB

and use an Ohm meter to measure the resistance of the sensor.

Sensor PR-37140 should measure 10 KOhm ± 1.5 KOhm at 25°C (77°F).

Sensor SN-33541 should measure 100 Ohm ± 10 Ohm at 25°C (77°F).

Replace sensor if measurement is outside of tolerance.

◾The sensor reading is above the temperature set-point. Blanket warmer

triggers at 15° over set-point. Fluid warmer triggers at 5° over set-point.

◾The difference between the room temperature and the fluid set-point

temperature must be greater than 11°C (20°F).

◾Contact service if error persists.

38

Combination Blanket/Fluid Warmer ▪ Operator’s Manual ▪ MN-39930 ▪ Rev 1 ▪ 3/19

Code Refers to Action required

TROUBLESHOOTING

P131

P231

P331

P431

P531

P631

P731

Pad sensor 1

Pad sensor 2

Pad sensor 3

Pad sensor 4

Pad sensor 5

Pad sensor 6

Pad sensor 7

*E-33 Cavity sensor

*E-50 Analog to Digital

Converter Error

E-60 Real Time Clock

Checksum Error

(Blanket warmers only)

*E-61 Real Time Clock

(Blanket warmers only)

Heater pad over-temp error.

◾Software disengages heating pads.

◾Acknowledge error by pressing the ON/OFF button.

◾Allow the warmer to cool.

◾Contact service if the error persists.

◾Sensor reading is above maximum allowable temperature set-point and

over temp value. Blanket warmers trigger at 82°C (180°F). Fluid warmers

trigger at 71°C (160°F).

◾Contact service if error persists.

◾Remove inventory, discard if necessary, and allow the warmer to cool

down.

◾If error persists after cool down and reset, the control assembly should

be replaced by a qualified service technician. Contact service.

Real time clock rechargeable battery backup has discharged.

◾Plug the warmer into the outlet for 30 minutes.

Real time clock not responding. Contact service if error persists.

E-62 Real Time Clock

(Blanket warmers only)

Timer overlay is present, but no real time clock is detected. Contact service.

*E-70 Pad Count Error More heater pads detected than set for. Hold the ON/OFF button for 12

seconds until display shows "PAd#” (# = number of pads selected [3-7]).

Press up or down arrow to adjust to correct number of pads. [Blanket

warmers: 1.5ft

Fluid warmers: 2.5ft

3

, 2.5ft3 = 3 pads, 3.5ft3, 4.0ft3, 7.5ft3 = 4 pads.

3

& 4.0ft3 = 3 pads].

*E-71 Personality Error Contact service.

E-80 EEPROM Error EEPROM not responding. Contact service if error persists.

*E-81 Calibration not

Contact service.

locked

*E-83 EEPROM Error Contact service for help resetting the control.

Combination Blanket/Fluid Warmer ▪ Operator’s Manual ▪ MN-39930 ▪ Rev 1 ▪ 3/19

39

TROUBLESHOOTING

Code Refers to Action required

E-87 EEPROM Error Stored off sets corrupted. Off sets reset to 0.

◾Control may need to be re-calibrated.

◾Possible bad EEPROM.

◾Contact service if error persists.

E-90 Button stuck A button has been held down for >60 seconds. Adjust control. Error will

reset when the problem has been resolved.

E-95 Factory Test pin

short detected.

*E-98 Temperature

Delta Error

E-99 Hardware Over

Temp

*EFAn Fan or Fan Sensor

Failure

*All non-critical codes can be cleared using the ON/OFF button. Critical errors (marked with a *) can

only be cleared by setting the power switch at the rear of the warmer to the OFF position and

allowing the warmer to cool.

Ensure that debris is not causing a short between the test pins. If the pins

are clean, replace the control.

Temperature of the cavity sensors 1 and 2 differ by more than 3.3ºC (6ºF).

◾Remove product and allow the warmer to cool down.

◾Verify that the product sensor is clean and operating correctly.

◾Set the power switch to the OFF position to clear the error code.

◾If error persists, the cavity sensor should be replaced by a qualified

service technician. Contact service.

◾Inspect the connections and condition of high limit bimetal thermostat.

◾If applicable, make sure that the compartment fan motor is operating.

◾Contact service if error persists.

◾Check to make sure the fan sensor wires did not disconnect from the fan

or the control board.

◾If the error persists after checking the wires, replace the fan.

40

Combination Blanket/Fluid Warmer ▪ Operator’s Manual ▪ MN-39930 ▪ Rev 1 ▪ 3/19

How to Replace a Fuse

Step Action

EC-TS-004628

a

EC-TS-004675

b

c

d

e

WARNING: Fire and electrical shock hazard.

Use only UL listed 20A, 250V fast acting fuses, 6.3mm x 32mm

(F1, F2). Access should be made by qualified service technicians

only.

Procedure To replace a fuse, do the following.

1. Press and hold the ON/OFF button until the screen turns off.

2. Set the power switch a to the OFF (0) position.

TROUBLESHOOTING

Combination Blanket/Fluid Warmer ▪ Operator’s Manual ▪ MN-39930 ▪ Rev 1 ▪ 3/19

3. Unplug the power cord b from the electric power source and the power

inlet

c on the warmer.

4. Unscrew the cap on the fuse holder d.

5. Remove the fuse e from the fuse holder.

Continued on next page

41

TROUBLESHOOTING

Continued from previous page

6. Replace the fuse with a new fuse.

7. Re-install the cap back onto the fuse holder.

Result The fuse has now been replaced.

42

Combination Blanket/Fluid Warmer ▪ Operator’s Manual ▪ MN-39930 ▪ Rev 1 ▪ 3/19

ELECTRICAL INFORMATION

Guidance and Manufacturer’s Declaration

The warmer requires special precautions regarding EMC (Electromagnetic

Compatibility) and needs to be installed and put into service according to the

EMC information provided in the accompanying documents.

Portable and mobile RF communications equipment can affect medical electrical

equipment.

A risk of increased emissions or decreased immunity may result if the power

cord is altered or a manufacturer supplied power cord is not used.

The warmer should not be used adjacent to or stacked with other equipment.

The essential performance of the warmer is to not exceed an internal

temperature of 180ºF (82ºC) for blanket warmers or 150ºF (66ºC) for fluid

warmers.

Electromagnetic

emissions

The warmer is intended for use in the electromagnetic environment specified

below.

Emission test Compliance Electromagnetic environment - guidance

RF emissions;

CISPR 11

RF emissions;

CISPR 11

Harmonic

emissions; IEC

61000-3-2

Voltage

fluctuations/Flicker

emissions; IEC

61000-3-3

Group 1 The warmer uses RF energy only for internal

function. Therefore, its RF emissions are very

low and are not likely to cause any interference

in nearby electronic equipment.

Class B The warmer is suitable for use in all

establishments, including domestic

establishments and those directly connected to

N/A

N/A

the public low-voltage power supply network

that supplies buildings used for domestic

purposes.

NFORMATION

I

Combination Blanket/Fluid Warmer ▪ Operator’s Manual ▪ MN-39930 ▪ Rev 1 ▪ 3/19

Continued on next page

LECTRICAL

E

43

ELECTRICAL INFORMATION

Continued from previous page

Electromagnetic

immunity

Immunity test IEC 60601 test level Compliance level Electromagnetic environment - guidance

Electromagnetic

discharge (ESD)

IEC 61000-4-2

Electrical fast

transient/burst

IEC 61000-4-4

Surge

IEC 61000-4-5

Voltage dips, short

interruptions and

voltage variations

on power supply

input lines

IEC 61000-4-11

The warmer is intended for use in the electromagnetic environment specified

below.

±8 kV contact

±15 kV air

±2 kV for power

supply lines; ±1 kV for

input/output lines

±1 kV differential

mode; ±2 kV common

mode

<5% UT (>95% dip in

UT) for 0.5 cycle

40% UT (60% dip in

UT) for 1 cycle

70% UT (30% dip in

UT) for 25 cycles

±8 kV contact

±15 kV air

+2 kV for power

supply lines

±1 kV differential

mode; ±2 kV

common mode

<5% UT (>95% dip

in UT) for 0.5 cycle

40% UT (60% dip in

UT) for 1 cycle

70% UT (30% dip in

UT) for 25 cycles

Floors should be wood, concrete or ceramic

tile. If floors are covered with synthetic

material, the relative humidity should be at

least 30%.

Main power quality should be that of a

typical commercial or hospital environment.

The warmer does not have any input/output

lines.

Mains power quality should be that of a

typical commercial or hospital environment.

Mains power quality should be that of a

typical commercial or hospital environment.

If the user of the warmer requires continued

operation during power mains interruptions,

it is recommended that the warmer be

powered from an uninterrupted power

supply or a battery.

<5% UT (>95% dip in

UT) for 250 sec

Power frequency

(50/60 Hz)

magnetic field

IEC 61000-4-8

NOTE: UT is the a.c. mains voltage prior to application of the test level.

30 A/m 30 A/m Power frequency magnetic fields should be

<5% UT (>95% dip

in UT) for 250 sec

at levels characteristic of a typical location in

a typical commercial or hospital

environment.

Continued on next page

44

Combination Blanket/Fluid Warmer ▪ Operator’s Manual ▪ MN-39930 ▪ Rev 1 ▪ 3/19

Continued from previous page

ELECTRICAL INFORMATION

Electromagnetic

emissions

The warmer is intended for use in the electromagnetic environment specified

below.

Immunity test IEC 60601 test level Compliance level Electromagnetic environment - guidance

Conducted RF

IEC 61000-4-6

Radiated RF

IEC 61000-4-3

3 V/m

150 kHz to 80 MHz

3 V/m

80 MHz to 2.7 GHz

3 V/m Portable and mobile RF communications

equipment should be used no closer to any

part of the warmer, including cables, than

the recommended separation distance

calculated from the equation applicable to

the frequency of the transmitter.

Recommended separation distance

d = [3.5/3] √P

d = [3.5/3] √P 80 MHz to 800 MHz

d = [7/3] √P 800 MHz to 2.5 GHz

where P is the maximum output power

rating of the transmitter in watts (W)

according to the transmitter manufacturer

and d is the recommended separation

distance in meters (m).

Field strengths from fixed RF transmitters, as

determined by an electromagnetic site

1

survey

, should be less than the compliance

level in each frequency range2.

Interference may occur in the vicinity of

equipment marked with the following

symbol:

NOTE: At 80 MHz and 800 MHz, the higher frequency range applies. These guidelines may not apply in all situations.

Electromagnetic propagation is affected by absorption and reflection from structures, objects and people.

1. Field strengths from fixed transmitters, such as base stations for radio (cellular/cordless) telephones and land mobile radios, amateur radio, AM and

FM radio broadcast and TV broadcast cannot be predicted theoretically with accuracy. To assess the electromagnetic environment due to fixed RF

transmitters, an electromagnetic site survey should be considered. If the measured field strength in the location in which the warmer is used exceeds

the applicable RF compliance level above, the warmer shou ld be observed to verify normal operation. If abnormal performance is observed, additional

measures may be necessary, such as reorienting or relocating the warmer.

2. Over the frequency range 150 kHz to 80 MHz, field strengths should be less than [VI] V/m.

Continued on next page

Combination Blanket/Fluid Warmer ▪ Operator’s Manual ▪ MN-39930 ▪ Rev 1 ▪ 3/19

45

ELECTRICAL INFORMATION

d

3.5

3

-------

P=

d

3.5

3

-------

P=

d

7

3

---

P=

Continued from previous page

Electromagnetic

immunity distance

The warmer is intended for use in an electromagnetic environment in which

radiated RF disturbances are controlled. The user of the warmer can help

prevent electromagnetic interference by maintaining a minimum distance

between portable and mobile RF communications equipment (transmitters) and

the warmer as recommended below, according to the maximum output power

of the communications equipment.

Rated

maximum

output power of

transmitter

W

0.01 0.117 0.117 0.233

0.1 0.369 0.369 0.738

Separation distance according to frequency of transmitter

m

150 kHz to 80 MHz 80 MHz to 800 MHz 800 MHz to 2.5 GHz

1 1.167 1.167 2.333

10 3.689 3.389 7.379

100 11.667 11.667 23.333

For transmitters rated at a maximum output power not listed above, the recommended separation distance d in

meters (m) can be estimated using the equation applicable to the frequency of the transmitter, where P is the

maximum output rating of the transmitter in watts (W) according to the transmitter manufacturer.

NOTE: At 80 MHz and 800 MHz, the separation distance for the higher frequency range

applies. These guidelines may not apply in all situations. Electromagnetic propagation is

affected by absorption and reflection from structures, objects and people.

Combination Blanket/Fluid Warmer ▪ Operator’s Manual ▪ MN-39930 ▪ Rev 1 ▪ 3/19

46

WARRANTY

Warranty

Introduction Pedigo Products, Inc. warrants to the original purchaser that any original part

that is found to be defective in material or workmanship will, at our option,

subject to provisions hereinafter stated, be replaced with a new or rebuilt part.

Warranty Period The original parts warranty period is as follows:

▪ The labor warranty remains in effect one (1) year from installation or fifteen (15)

months from the shipping date, whichever occurs first.

▪ The original parts warranty for the cavity fan motor remains in effect one (1) year

from installation of appliance or fifteen (15) months from the shipping date,

whichever occurs first. The original parts warranty on all other parts remains in

effect three (3) years from installation of appliance or thirty-nine (39) months

from the shipping date, whichever occurs first.

Exclusions This warranty does not apply to:

▪ Calibration

▪ Equipment damage caused by accident, shipping, improper installation or

alteration.

▪ Equipment used under conditions of abuse, misuse, carelessness or abnormal

conditions including equipment subjected to harsh or inappropriate chemicals

including but not limited to compounds containing chloride or quaternary salts,

poor water quality, or equipment with missing or altered serial numbers.

▪ Any losses or damage resulting from malfunction, including loss of contents or

consequential or incidental damages of any kind.

▪ Equipment modified in any manner from original model, substitution of parts

other than factory authorized parts, removal of any parts including legs, or

addition of any parts.

▪ Collateral or incidental damage as a direct result of servicing equipment built

into a wall structure is not covered under warranty. It is the responsibility of the

owner to bear all expense related to structural repairs including, but not limited

to, external electrical connections and wiring, and the removal or replacement of

caulk, grout, tile, or wall covering of any kind. A service access panel for built-in

equipment installations is strongly recommended.

Conclusion This warranty is exclusive and is in lieu of all other warranties, expressed or

implied, including the implied warranties of merchantability and fitness for

purpose. In no event shall the company be liable for loss of use, loss of revenue,

or loss of contents or revenue, or for indirect or consequential damages. This

warranty is in lieu of all other warranties expressed or implied and Pedigo

Products, Inc. neither assumes or authorizes any persons to assume for it any

other obligation or liability in connection with Pedigo Products, Inc. equipment.

Combination Blanket/Fluid Warmer ▪ Operator’s Manual ▪ MN-39930 ▪ Rev 1 ▪ 3/19

ARRANTY

47

Pedigo Products, Inc.

4000 S.E. Columbia Way

Vancouver, WA 98661

Phone: 800.822.3501 | Fax: 360.696.1700

www.pedigo-usa.com

Made in the U.S.A

Printed in the U.S.A. Specifications are subject to change without notice.

Loading...

Loading...