Page 1

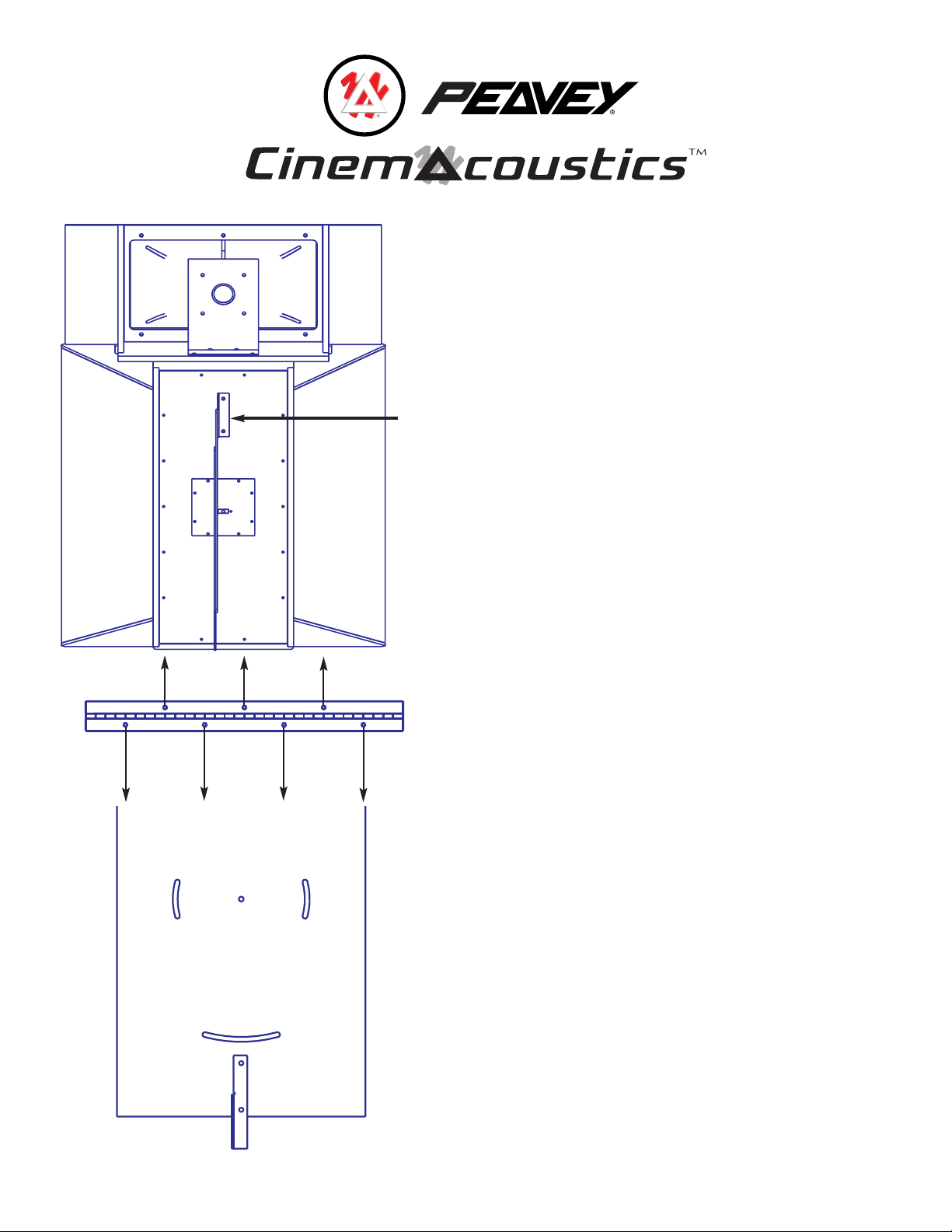

CA-S7330

™

Step 1. Install the upper bracket to the midrange horn as

shown with two 1/4" x 7/8" machine screws and

flatwashers. With the horn right side up, the

protruding flange with the center hole of the upper

bracket will be on the left when facing the cabinet

back.

Step 2. Position the separated plywood midrange horn

base with the t-nut side down. Install the lower

bracket to the separate plywood horn base as

shown with two 1/4" x 7/8" machine screws and

flatwashers.

Step 3. Position the midrange horn upside down on a flat

surface. Align the half of the hinge with the center

hole with the center hole of the midrange horn’s

front edge. Make sure that the hinge pivot pin is

toward the front. Install three #8 machine screws

into the three t-nuts in the horn.

Step 4. Align the front edge of the plywood midrange horn

base flush with the pivot of the remaining hinge

half. The bracket installed in S tep 2 above, needs

to be on the same side of the plywood base as the

hinge. Install four #8 x 3/4" wood screws through

the hinge into the plywood base.

Step 5. Position the midrange horn and plywood base

assembly right side up on top of the low frequency

speaker cabinet. Align the four pivot holes and slots

in the base with those in the speaker cabinet.

Loosely install four 1/4" x 1 1/4" machine bolts and

flatwashers through the base into the low frequency

cabinet.

Step 6. Loosely assemble the two extension arms by

inserting two 1/4" x 7/8" machine screws,

flatwasher, lockwasher, and nut.

Step 7. Loosely assemble the extension arm assembly to

the upper bracket with a 1/4" x 7/8" machine screw,

flatwasher, lockwasher, and nut.

Step 8. Similarly, assembly the bottom end of the extension

arm assembly to the lower bracket with a 1/4" x

7/8" machine screw, flatwasher, lockwasher, and

nut.

Step 9. On a separate surface, install the CH-7 horn into

the front of the high frequency horn baffle with six

1/4" Phillips head screws and flatwashers.

Upper

Bracket

(Step 1)

(Step 3)

(Step 4)

Lower Bracket

(Step 2)

Page 2

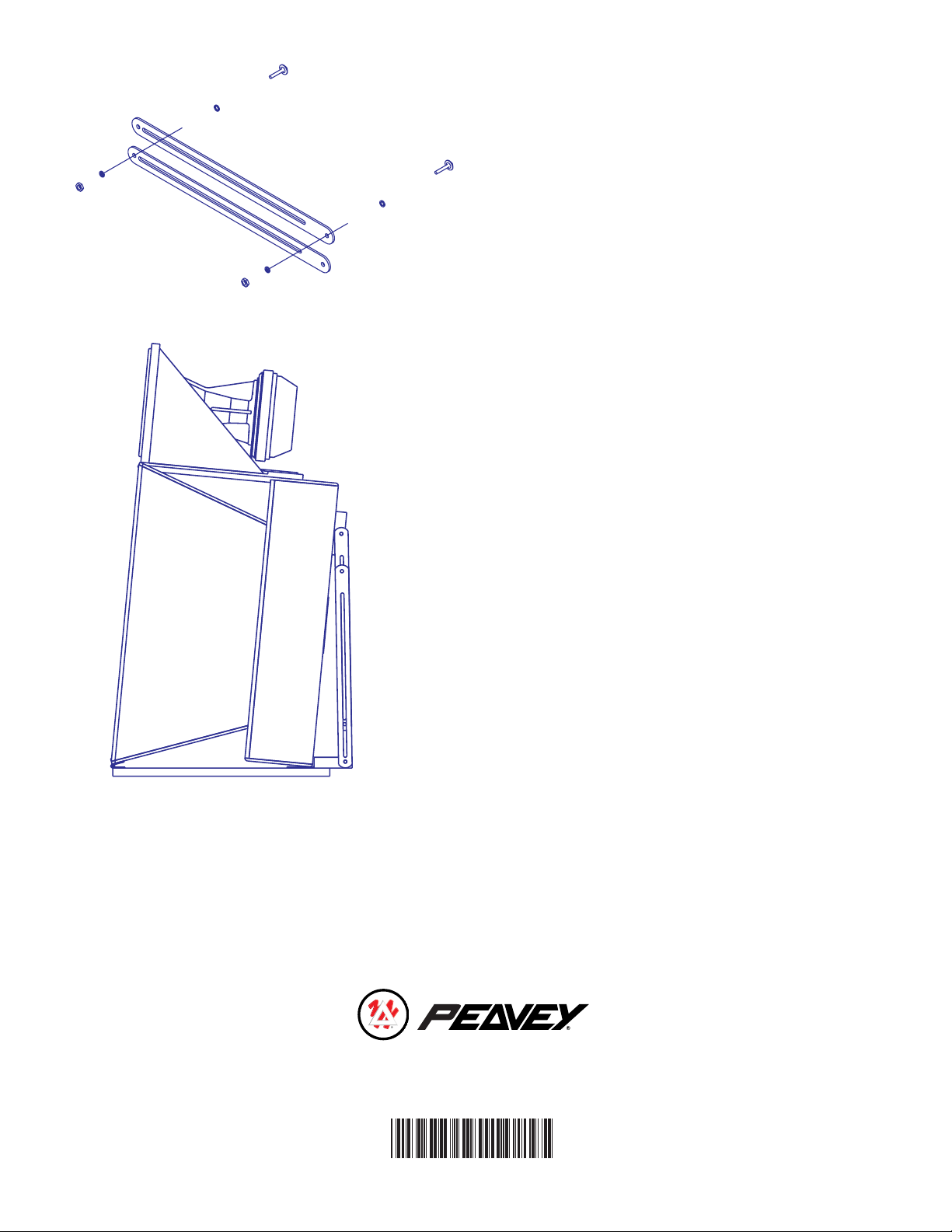

Step 10. Position the CH-7 horn bracket up against the

CH-7 horn throat with the bottom of the metal

flange facing toward the rear base edge. Two

holes in the metal bracket and in the base should

be in reasonable alignment. Install the 44XT

™

driver to the horn throat with four 1/4" x 3/4"

machine screws and flatwashers.

Step 11. Position the CH-7/44XT and bracket assembly

onto the top of the midrange horn. The horns

should align at the front edge. Install two 1/4" x

1 1/4" machine screws and flatwashers through

the 44XT bracket, wood base, and into two t-nut

holes provided in the midrange horn top. Do not

overtighten.

Step 12. T ilt and pivot the midrange horn assembly as

required by the room area coverage and tighten

all pivot and extension arm hardware.

Extension Arm Assembly

Scale .250

(Step 6)

(Step 10)

(Step 11)

(Step 7)

(Step 8)

Features and specifications subject to change without notice.

Peavey Electronics Corporation • 711 AStreet • Meridian • MS • 39301

(601) 483-5365 • FAX (601) 486-1278 • www.peavey.com

©1999 Printed in the U.S.A. 6/99

80304619

Loading...

Loading...