Pearl VX141MS Owner's Manual

MODEL VX141MS™

MASONRY/BRICK SAW

Owner’s/OperatOr’s Manual

™

™

serial number -

You should record the Serial Number of your Saw on this

Owner’s/Operator’s Manual and on the Warranty Card. The Warranty

Card must be sent back with all the required pertinent information

for the warranty to take effect.

Caution!

REV. 2

Read Safety and General Instructions carefully before using saw for the first time.

Pearl Abrasive Co. 2.1 MASONRY SAW

TABLE OF CONTENTS

page

i. general saFetY rules FOr all pOwer tOOls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

ii. sYMBOls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

iii. Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

iv. speCiFiCatiOns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

v. unpaCKing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

vi. installatiOn and OperatiOn . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

vii. prOper Blade use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

viii. CarBOn BrusH replaCeMent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

ix. air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

x. Care and MaintenanCe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

xi. replaCeMent parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

xii. aCCessOries and parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

xiii. eleCtriCal MOtOr speCiFiCatiOns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

xiv. water HOse Kit installatiOn . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

xv. trOuBlesHOOting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

xvi. tHe rigHt Blades dOes tHe rigHt JOB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

xvii. HOw tO Order parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

i. GENERAL SAFETY RULES FOR ALL POWER TOOLS

WARNING!

operation and use of the machine. The following basic safety precautions should be followed at all times to

educe the risk of fire, electric shock and serious personal injury to you or others. Keep these important

r

operating instructions with this product.

1. Know your power tool - read owner’s/operator’s manual carefully. Learn its applications and limitations as

well as the specific potential hazards unique to this tool.

2. Keep guards in place - and in working order.

3. Ground all tools - if tools are equipped with three prong plug, it should be plugged into a three-hole electrical

receptacle. If an adapter is used to accommodate a two-prong receptacle, the adapter lug must be attached

to a known ground. Never remove the third prong.

4. Remove wrenches - Form a habit of checking to see that adjusting wrenches are removed from tool before

turning it “on”.

5. Keep work area clean. Cluttered areas and benches invite accidents.

6. Do not use in dangerous environment. Do not use power tools in damp or wet locations, or expose them

to rain. Keep work area well lighted. Do not use tool in the presence of flammable liquids or gasses.

7. Keep children and visitors away. All children and visitors should be kept at a safe distance from work area.

8. Make workshop childproof with padlocks, master switches or by removing starter keys.

9. Do not force tool. It will do the job better and be safer at the rate for which it was designed.

10. Use right tool. Do not force tool or attachment to do a job for which it was not designed.

Read all instructions. As with all machinery there are certain hazards involved with

11. Wear proper apparel. Do not wear loose clothing, gloves, neckties, rings, bracelets or other jewelry that

may get caught in moving parts. Non-slip footwear is recommended. Wear protective hair covering to contain

long hair.

12. Always use safety glasses. Wear safety glasses (must comply with ANSI Z87.1) at all times. Everyday

eyeglasses only have impact resistant lenses; they are not safety glasses. Use face or dust mask if cutting

operation is dusty, and ear protectors (plugs or muffs) during extended periods of operation.

13. Do not overreach. Keep proper footing and balance at all times.

14. Maintain tools in top condition. Keep tools sharp and clean for best and safest performance. Follow

instructions for lubricating and changing accessories. Inspect tool cords periodically and if damaged, have

repaired by authorized service facility.

15. Disconnect tools. When not in use, before servicing, and when changing accessories, such as blades, bits,

cutters.

16. Avoid accidental starting. Make sure switch is in “off” position before plugging in power cord.

17. Use recommended accessories only. Consult the owner’s manual for recommended accessories. The use

of improper accessories may cause risk of injury to persons.

18. Never stand on tool. Serious injury could occur if the tool is tipped or if the cutting tool is accidentally

contacted.

19. Check Damaged Parts. Before further use of the tool, a guard or other part that is damaged should be

carefully checked to ensure that it will operate properly and perform it’s intended function. Check for alignment

of moving parts, binding of moving parts, breakage of parts, mounting, and any other conditions that may

affect it’s operation. A guard or part that is damaged should be properly repaired or replaced.

20. Never leave tool running unattended. Turn power “off”. Do not leave tool until it comes to a complete stop.

– 3–

21. Extension cords. Make sure your extension cord is in good condition. When using an extension cord,

be sure to use one heavy enough to carry the current your product will draw. An undersized cord will cause

a drop in line voltage resulting in loss of power and overheating. Extension cord tables (refer to page 12)

how the correct size to use depending on cord length and nameplate ampere rating. If in doubt, use the

s

next heavier gauge. The smaller the gauge numbers the heavier the cord.

22. Do not abuse cord. Never carry tool by cord or pull it to disconnect from receptacle, Keep cord from

heat, oil, and sharp edges.

23. Guard against electric shock. Prevent body contact with grounded surfaces. For example, pipes,

radiators, ranges and refrigerator enclosures.

24.Outdoor use extension cords. When tool is used outdoors, use only extension cords intended for use

outdoors and so marked.

25. Stay alert. Watch what you are doing. Use common sense. Do not operate tool when you are tired.

26. Drugs, alcohol, medication. Do not operate tool while under the influence of drugs, alcohol or any

medication.

27. Store idle tool. When not in use, tool should be stored in a dry and locked place, out of reach of children.

WARNING!

particles may cause irritation to eyes, skin and respiratory tract. To avoid breathing impairment always employ

dust controls and protection suitable to the material being saw or drilled in accordance with OSHA (29 CFR Part

1910.1). Diamond blades improperly used are dangerous. Comply with ANSI Safety Code B7.1 and OSHA covering

speed, safety guards, flanges, mounting procedures, general operating rules, handling, storage and general

machine condition.

CALIFORNIA PROPOSITION 65: Sawing and drilling generates dust. Excessive airborne

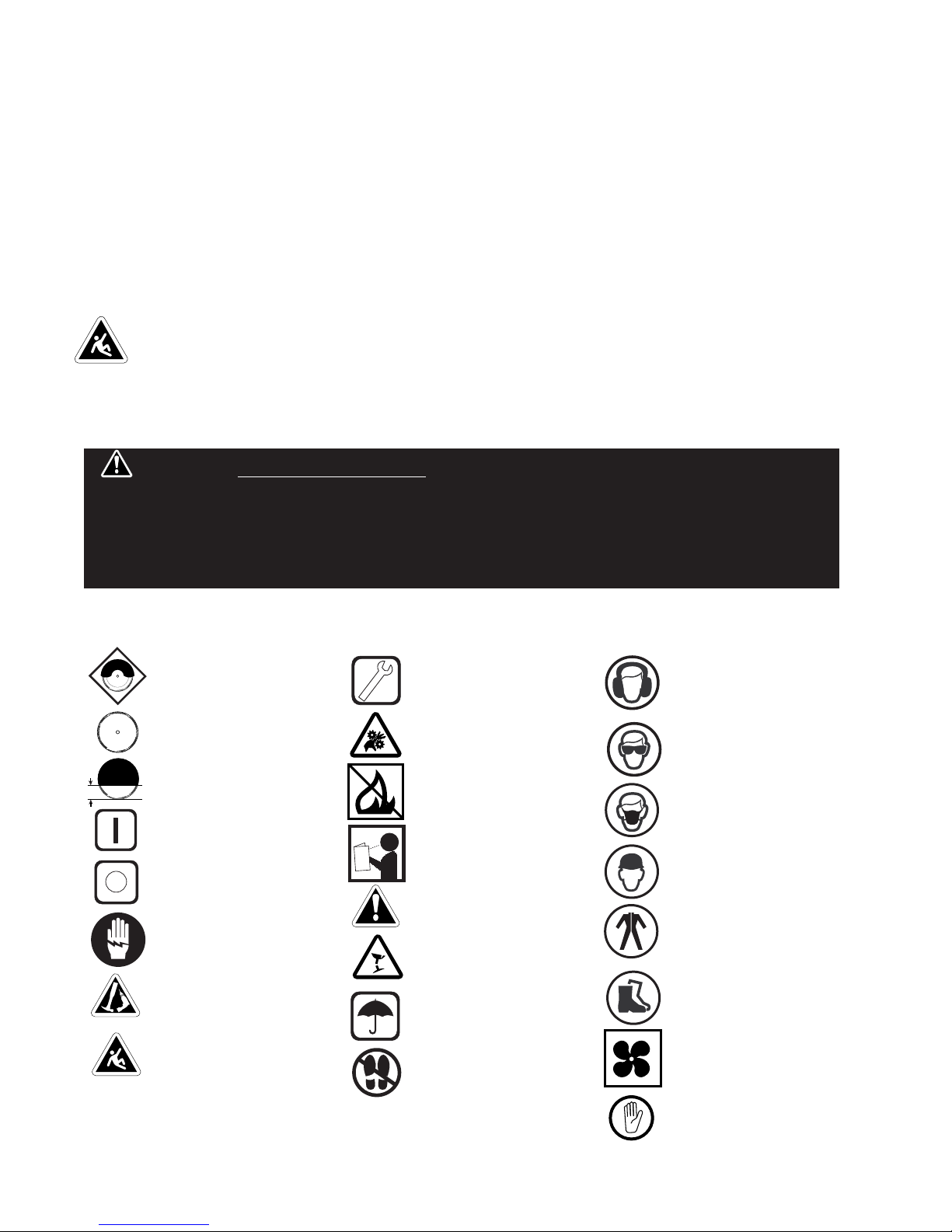

ii. SYMBOLS

KEEP GUARD IN PLACE

DIAMOND BLADE

BLADE CUTTING DEPTH

ELECTRIC SWITCH OFF

ELECTRIC SWITCH ON

ELECTRICAL HAZARD

REPAIRS TO BE DONE

MACHINE HAZARD

FLAMMABLE

READ INSTRUCTIONS

CAREFULLY

WARNING

FRAGILE

WEAR HEARING

PROTECTION

WEAR EYE PROTECTION

WEAR BREATHING

PROTECTION

WEAR HARD HAT

WEAR PROTECTIVE

CLOTHING

REMOVE TOOLS

PAY EXTREME

ATTENTION

WEAR SAFETY SHOES

KEEP DRY

WELL VENTILATED

DO NOT STEP ON

NO NON-WORKING

PERSONNEL

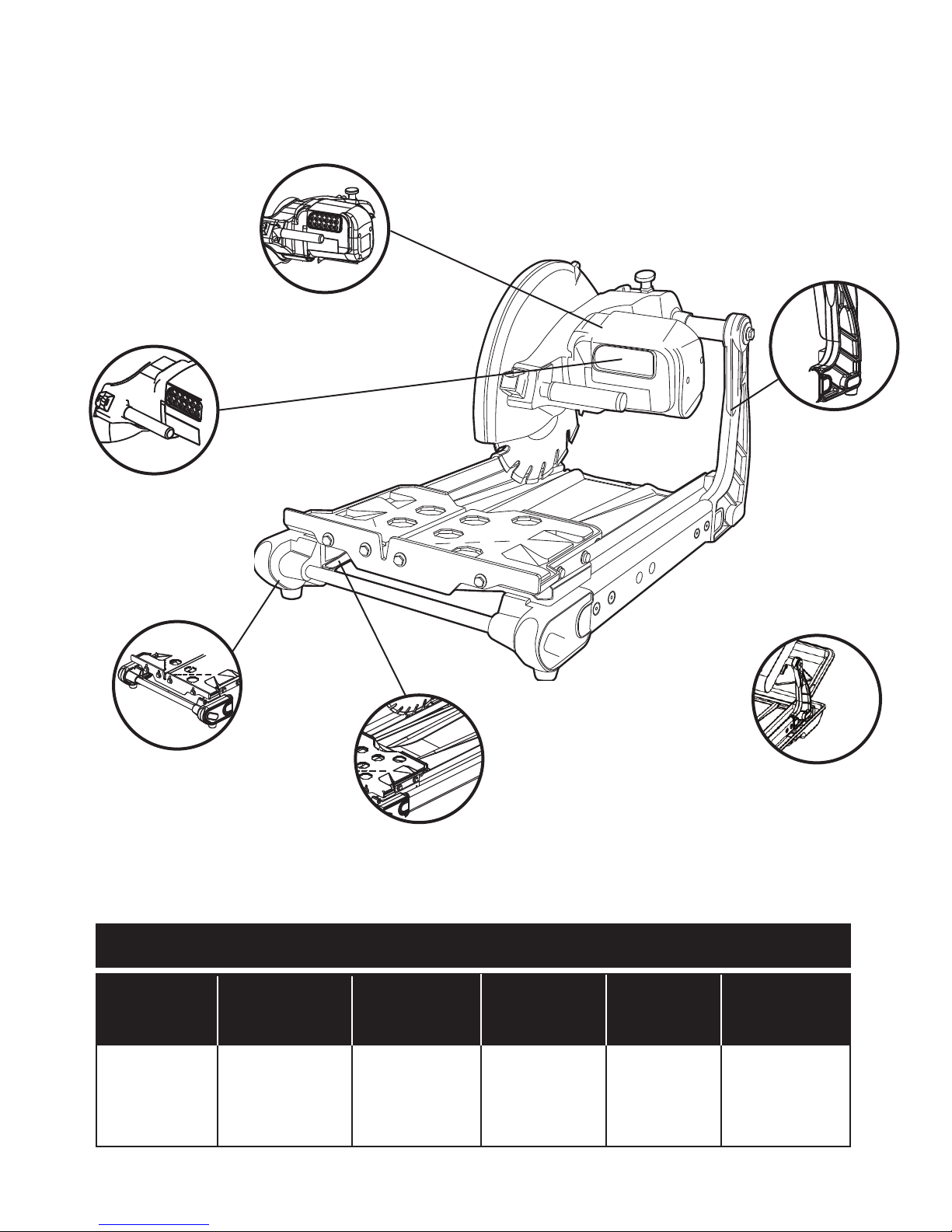

iii. FEATURES

The VX141MS Masonry saw is designed for the professional contractor in mind. I enhances performance with a

multitude of features facilitating operation.

REINFORCED

RIGID FRAME

contruction

provides steady

precision cutting

POWERFUL 3 HP (AT PEAK)

Carbon Brush motor cuts large

material in a single pass

CLEAR VIEW AIR FILTER

is easily maintained and

protects the motor

providing a longer life

for the motor

STURDY HANDLES

for easy transport

MOTOR

TABLE LOCKING MECHANISM

facilitates the saw’s chopping

operation

iv. SPECIFICATIONS

VX141MS MASONRY/BRICK SAW

MAX. BLADE

CAPACITY

CUTTING

LENGTH

CUTTING

DEPTH

OPTIONAL OUTER TRAY

for wet application

WEIGHT SIZE

3 HP Peak

115 v, 60 Hz,

3,600 rpm

14" blade with

1" (25.4mm)

arbor

16"

Max material

size 8 x 8 x16"

5" 75 lbs.

uncrated

31.5 x 18.5

x 19"

– 5––

Loading...

Loading...